Wet separation method for valuable metals in purified liquid cobalt slags of wet zinc smelting system

A technology of wet separation and zinc smelting, which is applied in the field of comprehensive waste slag separation, can solve problems such as the environmental impact of cobalt slag piles, and achieve the effects of low comprehensive utilization efficiency, reduced environmental pollution, and reasonable processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

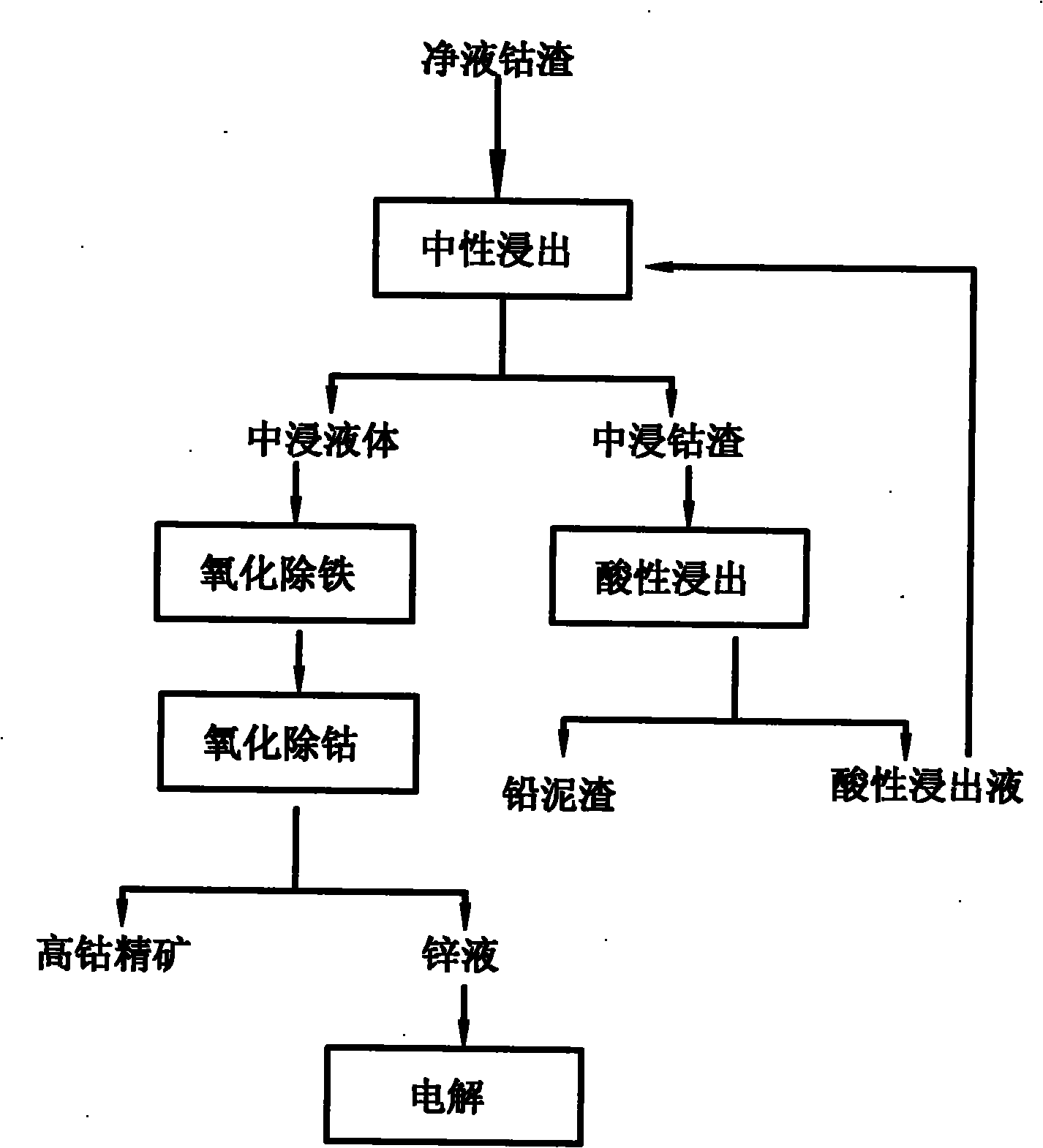

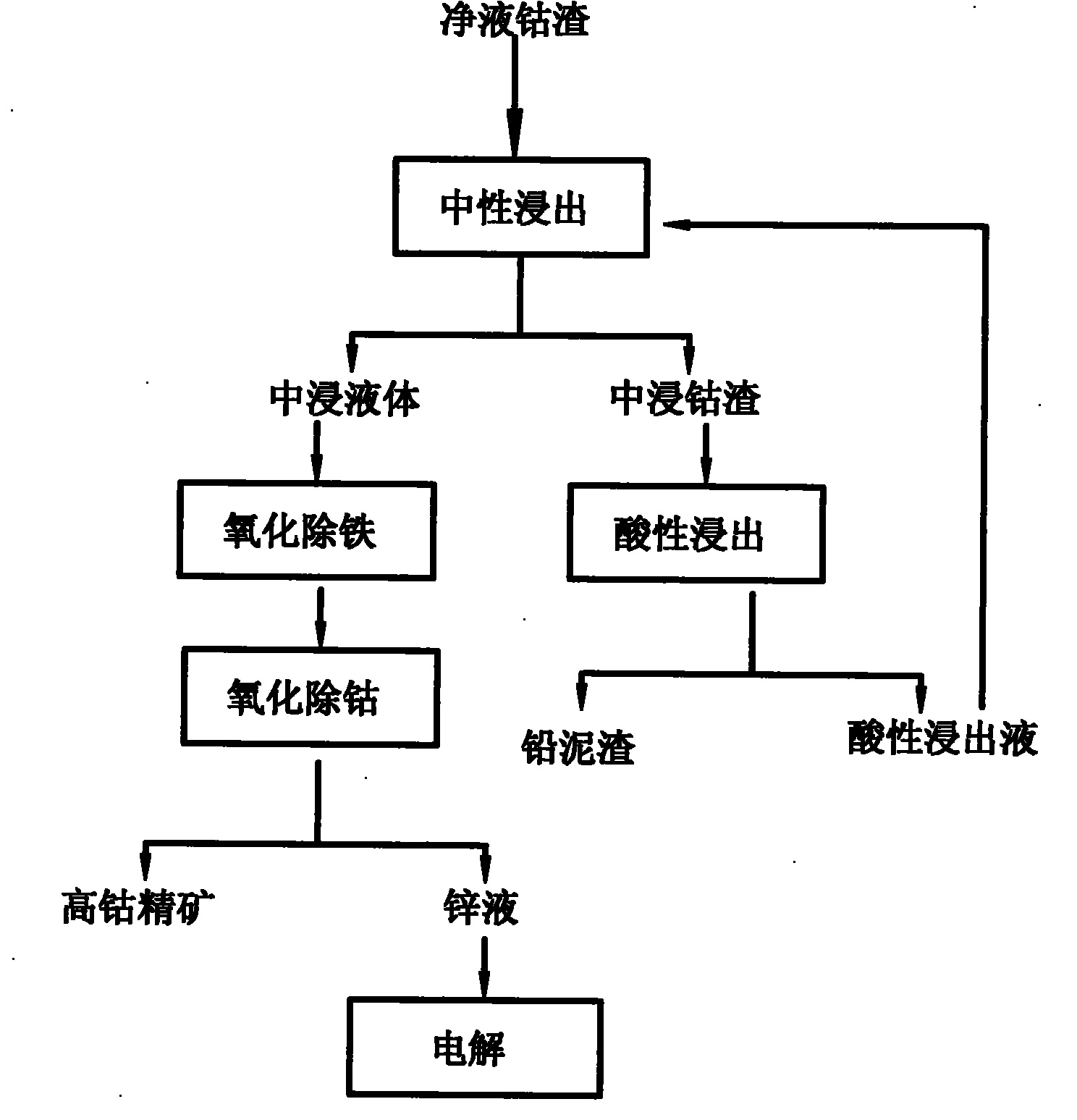

[0028] Embodiment 1: see figure 1 , the specific steps of the wet separation method of valuable metals in the net liquid cobalt slag of the wet electro-zinc system are as follows:

[0029] (1) Neutral leaching of cobalt slag

[0030] 1. Raw materials: net liquid cobalt slag, sulfuric acid, water

[0031] 2. The purpose of the process: leaching the cobalt slag of the net liquid with high metal content such as zinc and cobalt with dilute sulfuric acid, and the metal zinc, cobalt and their oxides are all dissolved in dilute sulfuric acid, while the lead in the slag is insoluble in dilute acid and enters The leaching slag forms lead sludge, and the obtained solution is a neutral leachate, so as to achieve the purpose of separating zinc, cobalt and lead sludge.

[0032] 3. Process conditions: (1) Control the liquid-solid ratio of 4-5:1 (2) The initial concentration of dilute sulfuric acid is 100-120g / l (3) The leaching temperature is 80-85°C (4) The leaching time is 4-5h (5) Reac...

Embodiment 2

[0062] Embodiment 2: The wet separation method of valuable metals in the net liquid cobalt slag of the wet-process electric zinc system is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that:

[0063] (1) Neutral leaching of cobalt slag

[0064] (1) Control the liquid-solid ratio to 4-5:1 (2) The initial concentration of dilute sulfuric acid is 115g / l (3) The leaching temperature is 82-83°C (4) The leaching time is 4-5h (5) The pH value of the solution at the end of the reaction is 5.0-5.2 .

[0065] Zn: 140g / l, Co: 2g / l in the obtained immersion liquid; Zn: 26.5%, Co: 0.2% in the immersion cobalt slag.

[0066] (2) Cobalt slag acid leaching

[0067] (1) Control the liquid-solid ratio to 5-6:1 (2) The leaching temperature is 80-85°C (3) The leaching time is 4-5 hours

[0068] (4) Initial acidity 140g / l (5) Final acidity 70g / l

[0069] The contents of Zn, Co and Pb in the obtained acid leaching lead sludge (Zn: 7.5%,...

Embodiment 3

[0076] Embodiment 3: The wet separation method of valuable metals in the net liquid cobalt slag of the wet-process electric zinc system is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that:

[0077] (1) Neutral leaching of cobalt slag

[0078] (1) Control the liquid-solid ratio of 4-5:1 (2) The initial concentration of dilute sulfuric acid is 110g / l (3) The leaching temperature is 82-83°C (4) The leaching time is 4-5h (5) The pH value of the solution at the end of the reaction is 5.0-5.2 .

[0079] Zn: 128g / l, Co: 1.7g / l in the obtained immersion liquid; Zn, Co content in the immersion cobalt slag (Zn: 22.8%, Co: 0.35%.

[0080] (2) Cobalt slag acid leaching

[0081] (1) Control the liquid-solid ratio to 5-6:1 (2) The leaching temperature is 80-85°C (3) The leaching time is 4-5 hours

[0082] (4) Initial acidity 125g / l (5) Terminal acidity 65g / l

[0083] Zn: 5.5%, Co: 0.03%, Pb: 27% in the obtained acid leaching l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com