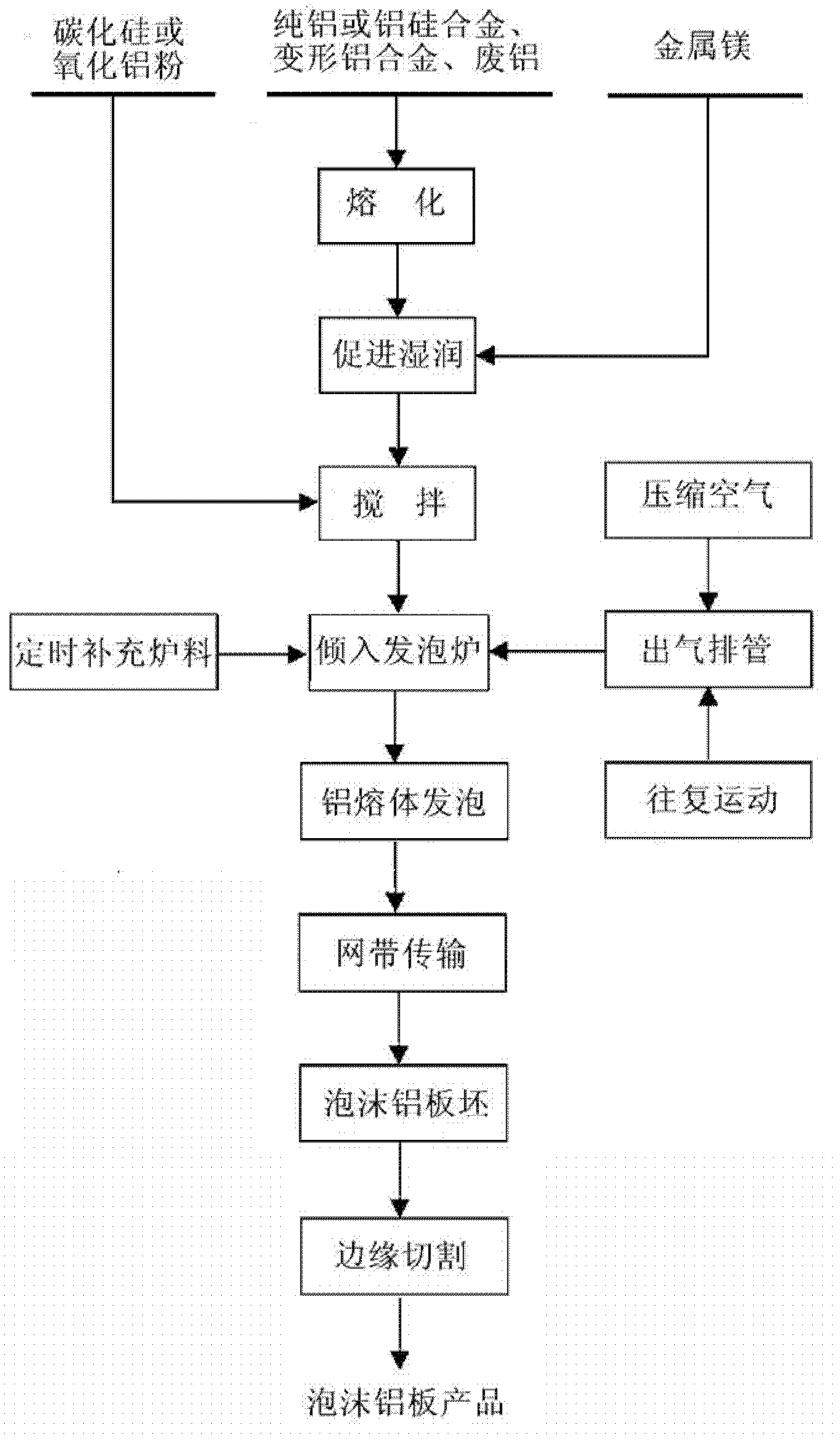

Process and apparatus for continuous production of closed-cell aluminum foam with blowing foaming

A technology of closed-cell aluminum foam and blown foam, which is applied in the field of metal material processing, can solve the problems of poor density uniformity of closed-cell aluminum foam, low production efficiency of high-density foam aluminum, and performance differences of aluminum foam with the same density. Accurate and reliable, uniform pore size and controllable density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

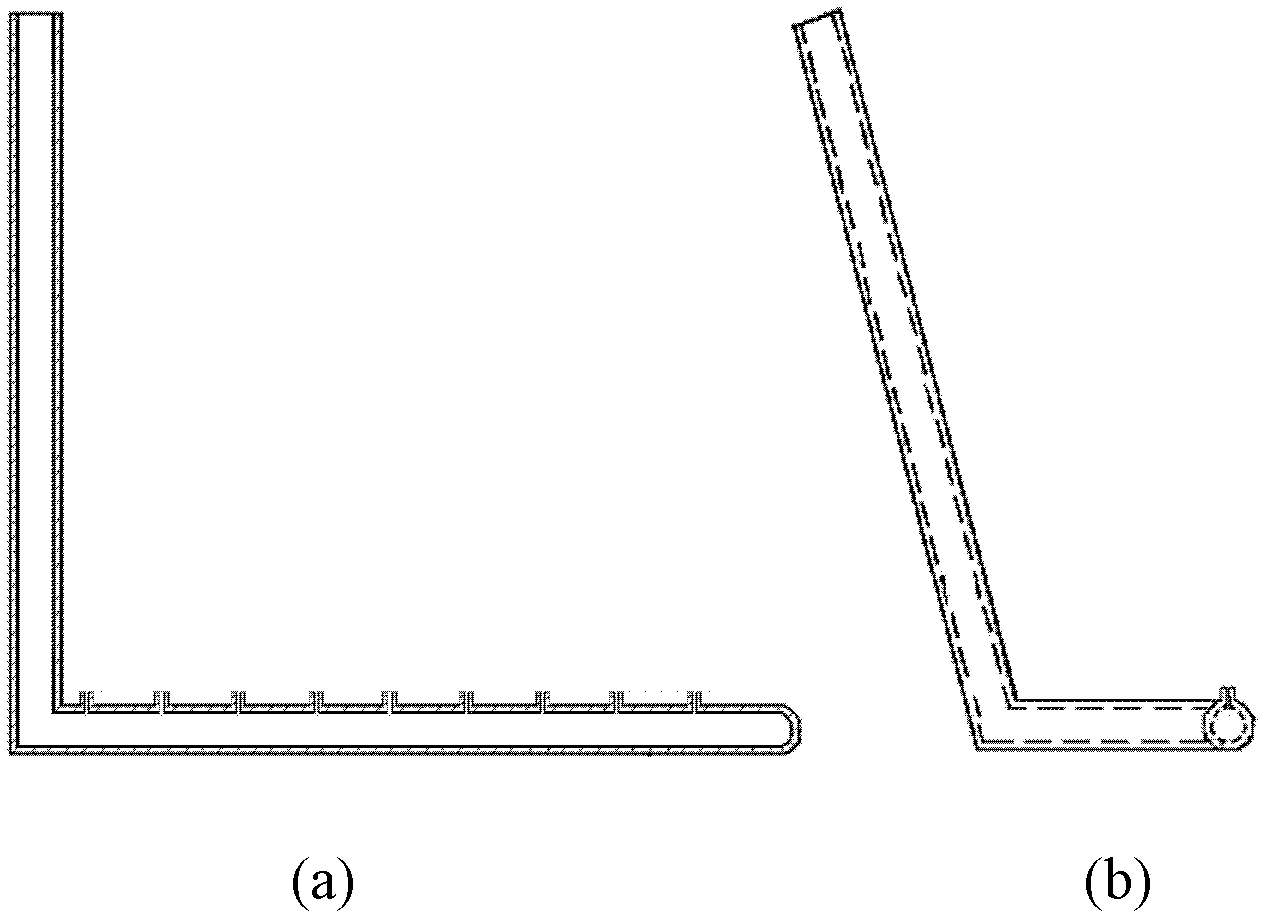

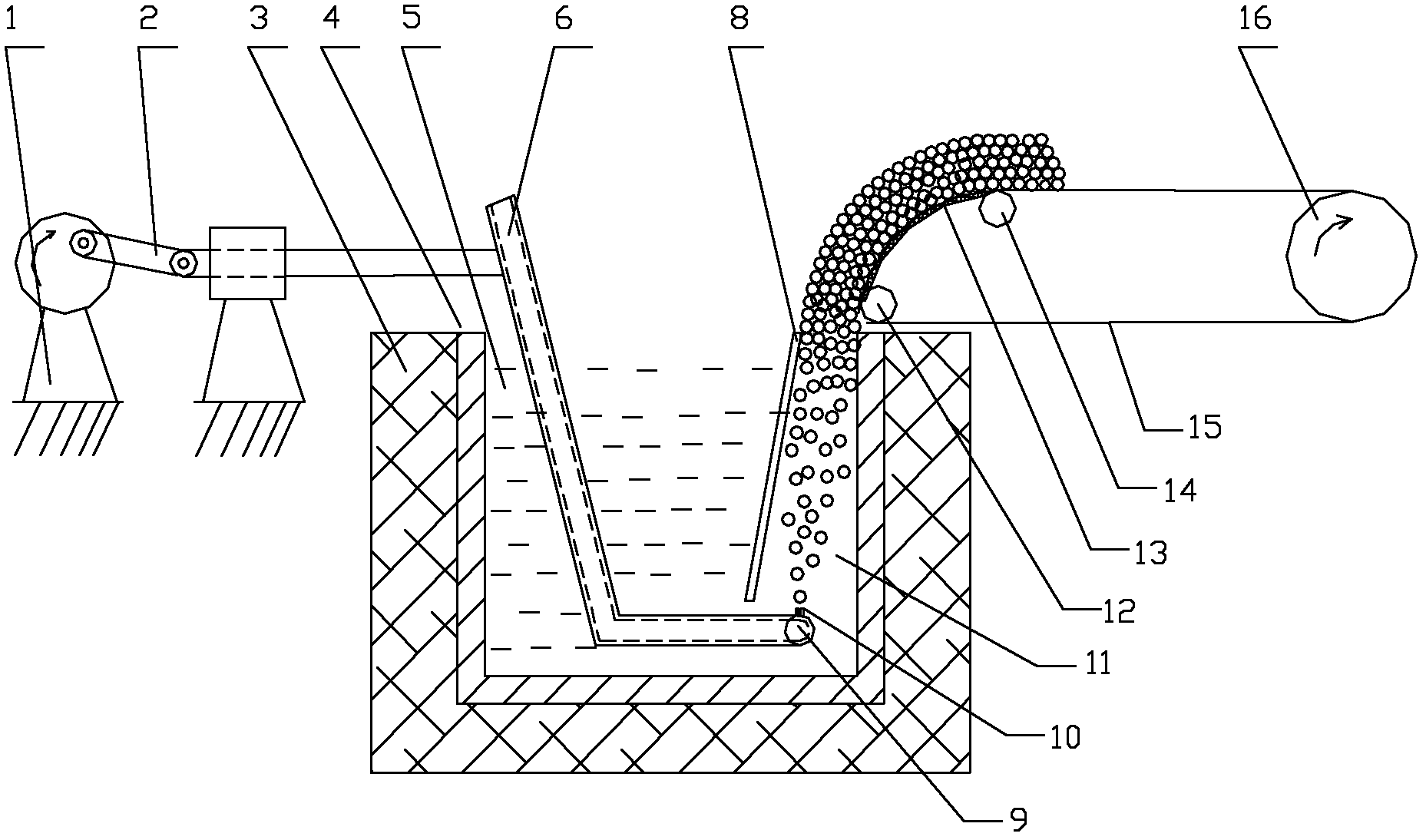

Embodiment 1

[0052] The aluminum and the aluminum-silicon alloy are melted above 800 DEG C, and when the melting temperature drops to the range of 680-750 DEG C, 0.8-3.5% metal magnesium by mass of the raw material is added and stirred. After the magnesium is completely melted, add 10Vol.% silicon carbide powder, stir well, and then move it into a foaming furnace kept at 600-660°C for foaming. Under the condition that the pressure and flow rate of compressed air are 0.2MPa and 1.5L / min respectively, a single row of horizontal outlet pipes, the diameter of air outlet microholes is 0.25mm and the reciprocating frequency of air outlet microholes is 400rpm, the width and thickness are respectively 1000mm And the density of 18mm closed-cell foam aluminum plate is 0.18g / cm 3 , The continuous production speed is 220mm / min.

Embodiment 2

[0054] The addition of metal magnesium is 1.0~3.0% of the raw material quality, the addition of silicon carbide powder is 12Vol.%, the flow rate of changing the compressed air is 3.0L / min, and the double row of horizontal air outlet pipes, other conditions are the same as in Example 1, and the width and The density of closed-cell foamed aluminum plates with thicknesses of 1000mm and 18mm is 0.18g / cm 3 , The continuous production speed is 450mm / min.

Embodiment 3

[0056] The addition of metal magnesium is 1.0 to 2.5% of the raw material quality, the addition of silicon carbide powder is 15Vol.%, and the pressure of the compressed air is changed to 0.3MPa. Other conditions are the same as in Example 2, and the width and thickness are respectively 1000mm and 18mm. The density of the porous aluminum foam board is 0.17g / cm 3 , The continuous production speed is 550mm / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com