Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

322results about How to "Meet working conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

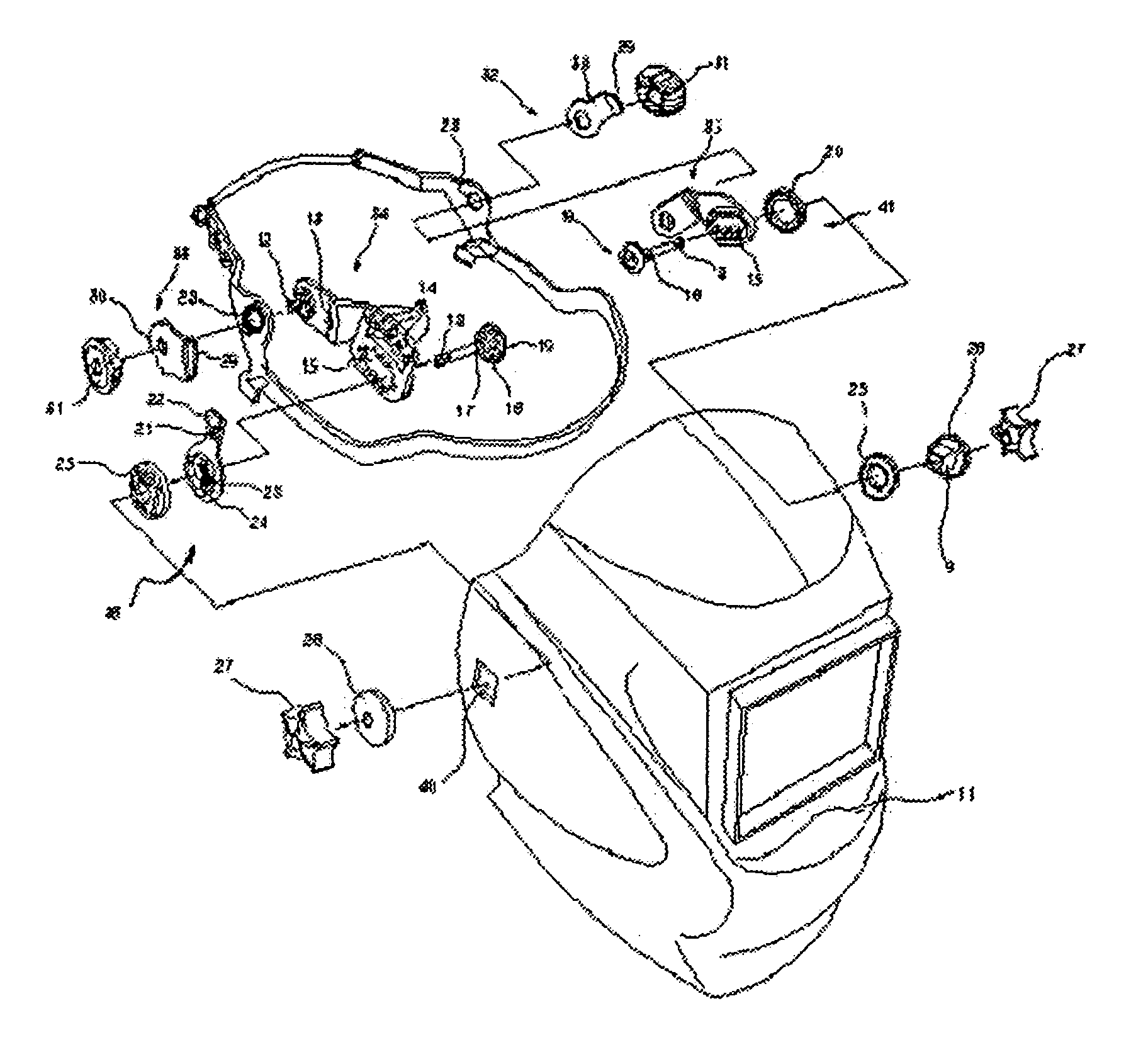

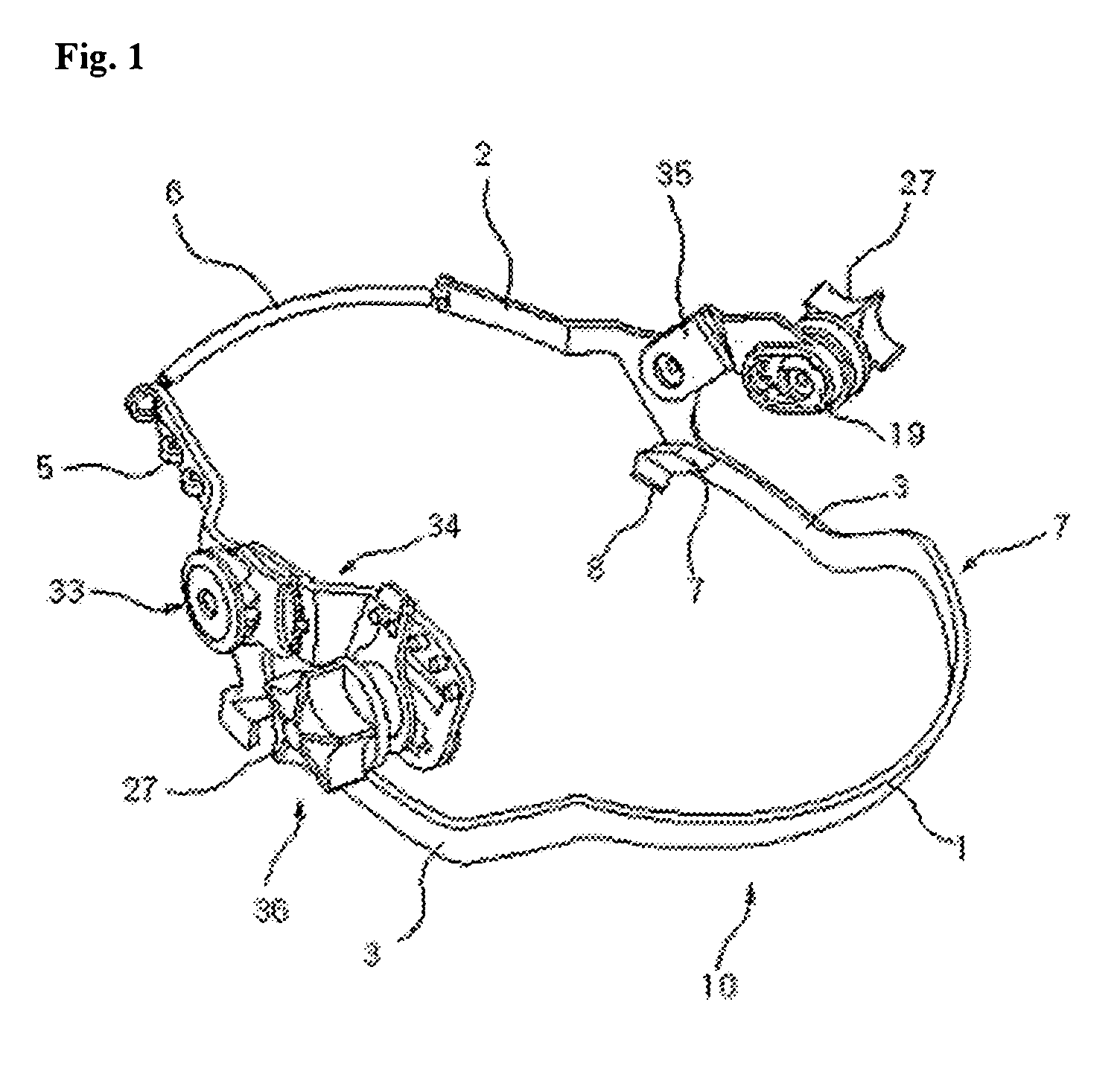

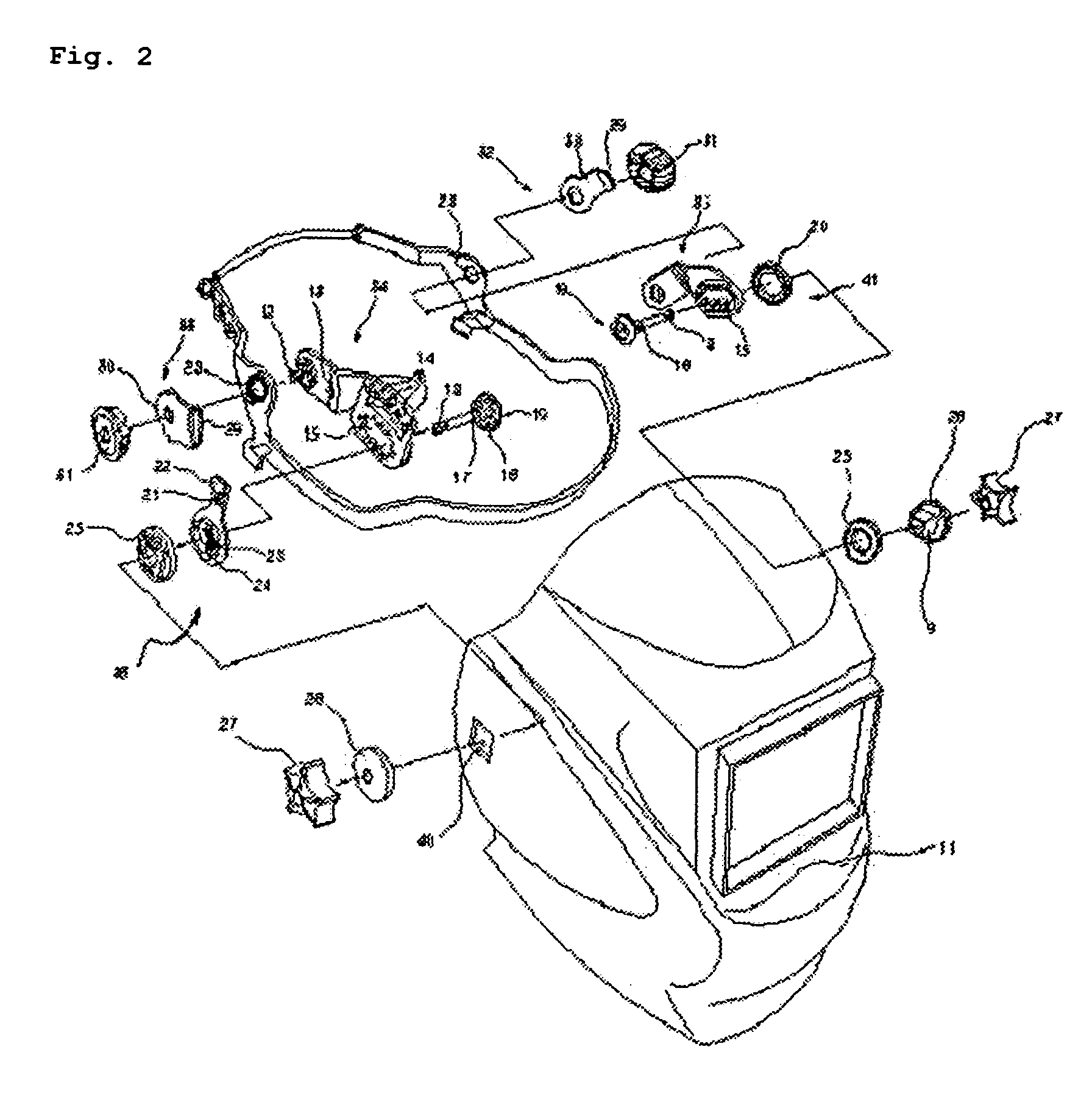

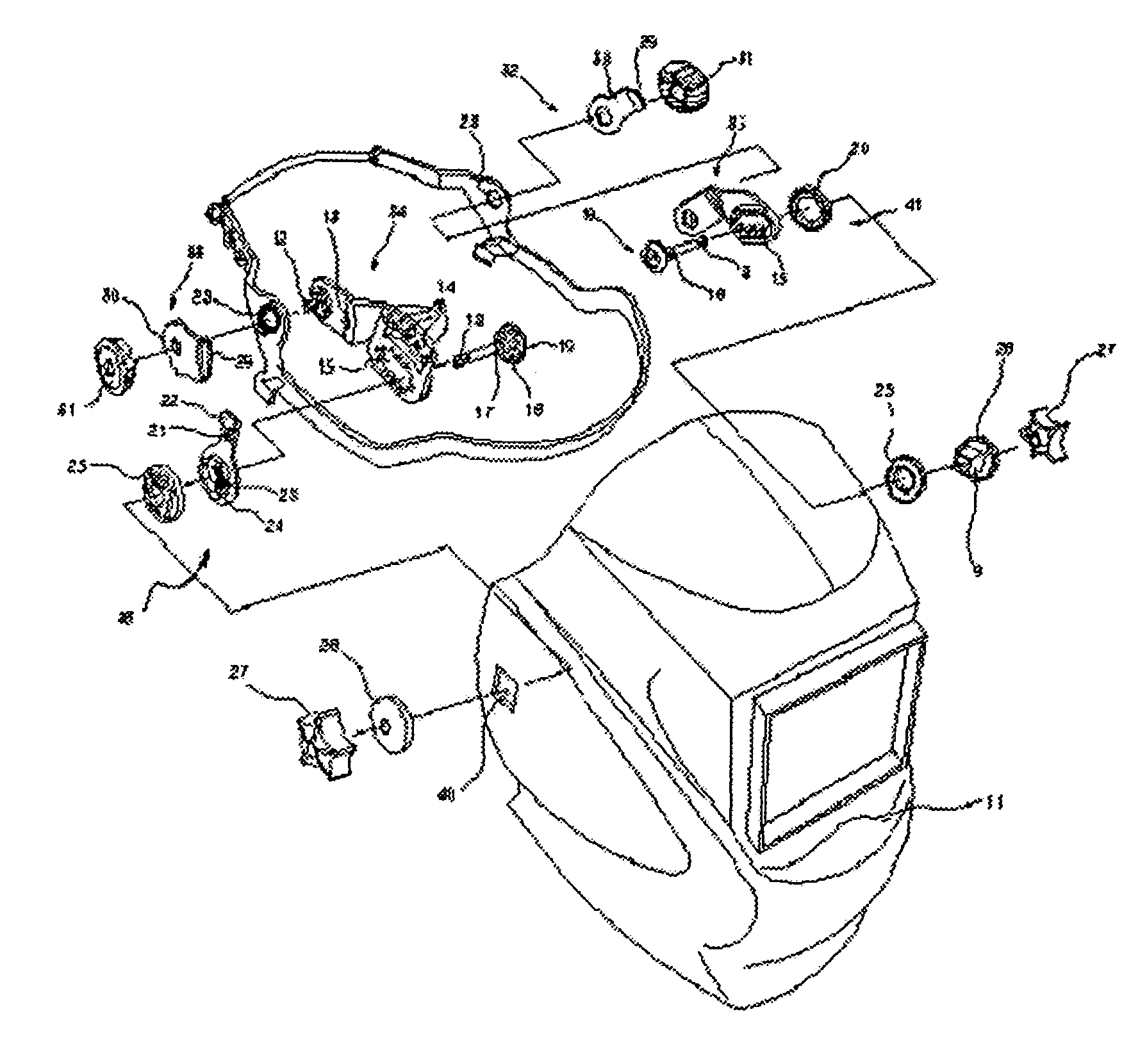

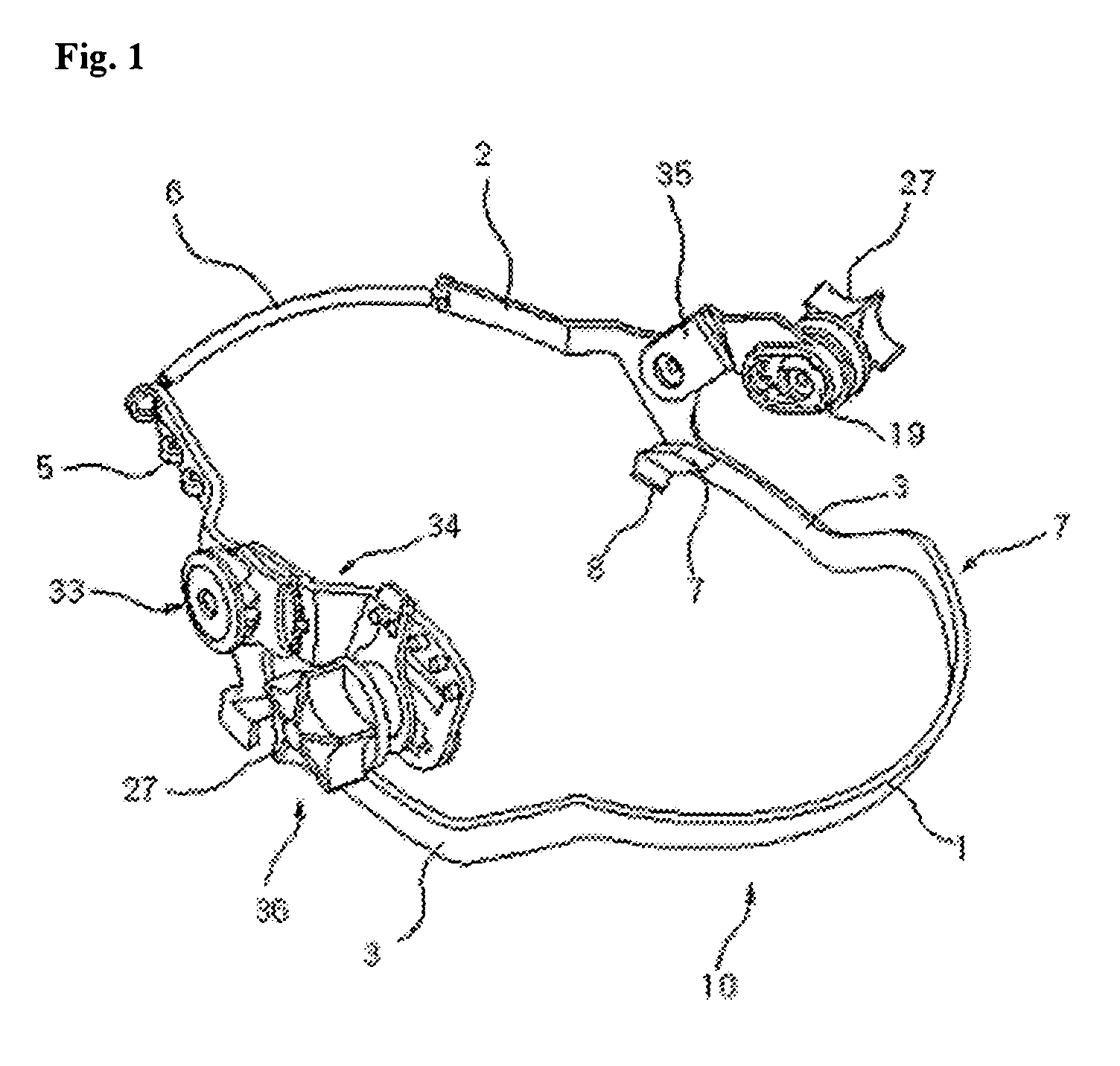

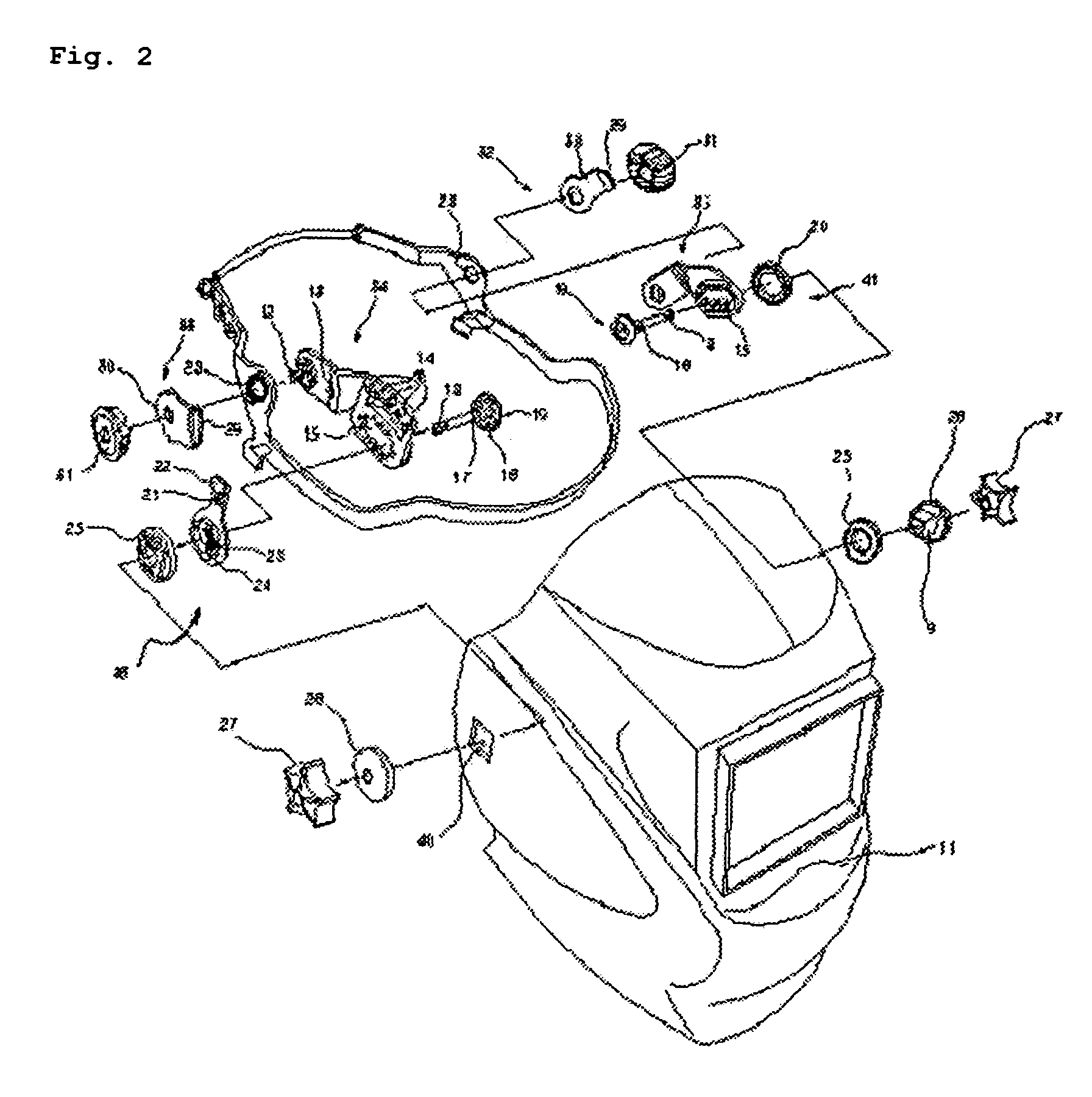

Multifunctional protection rack for safety helmet

InactiveUS20060080761A1Increase stickinessWork process safetyEye-masksHatsEngineeringForeign substance

A multifunctional protection rack for a safety helmet having interchangeability, which is connected to the safety helmet to install a welding mask for performing a welding operation, a shade for preventing a direct ray of light from passing therethrough, or a protective shield for preventing foreign substances from being introduced thereinto. The multifunctional protection rack includes a support frame bent into front and rear frames and side support frames, and made of an elastic member formed along the outer surface of a visor of the safety helmet so that the width of the support frame can be adjusted; a first connecting support member, one side of which is connected to the outer surface of the support frame by a rotational angle adjusting portion for adjusting a rotational angle of a protective equipment attached to the protection rack, and the other portion of which is connected to the outer of the support frame by an interval adjusting portion for adjusting an interval between the protective equipment and the face of a worker wearing the safety helmet; and a second connecting support member additionally installed between the support frame and the protective equipment, thereby being installed on the safety helmet such that the protection rack can be opened and closed.

Owner:OTOS TECH

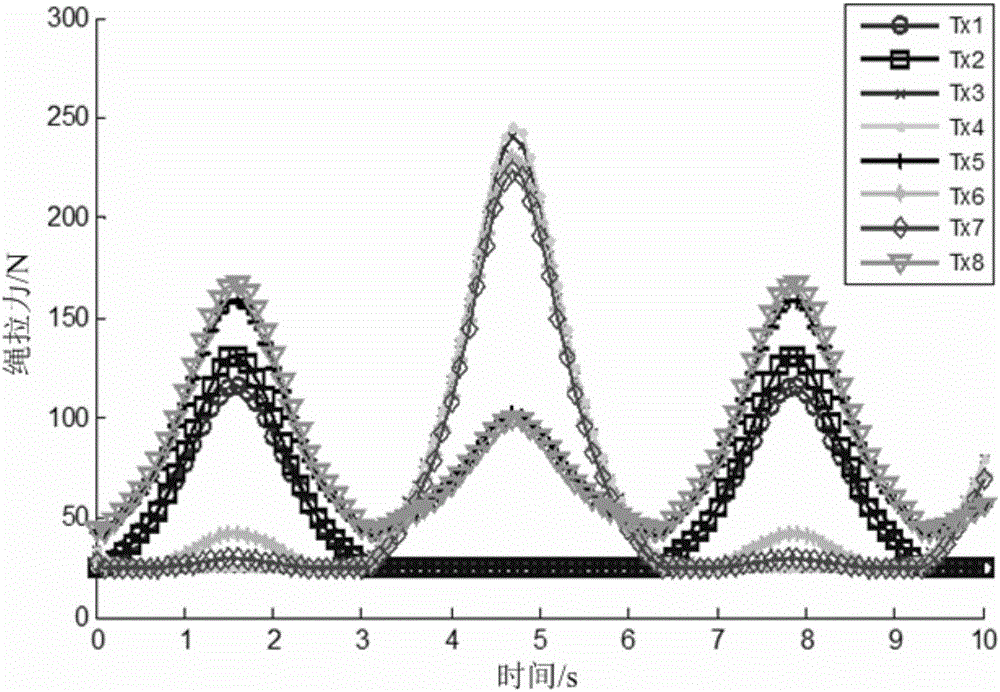

Rope-driven parallel robot motion control method in consideration of elasticity effect and compensation

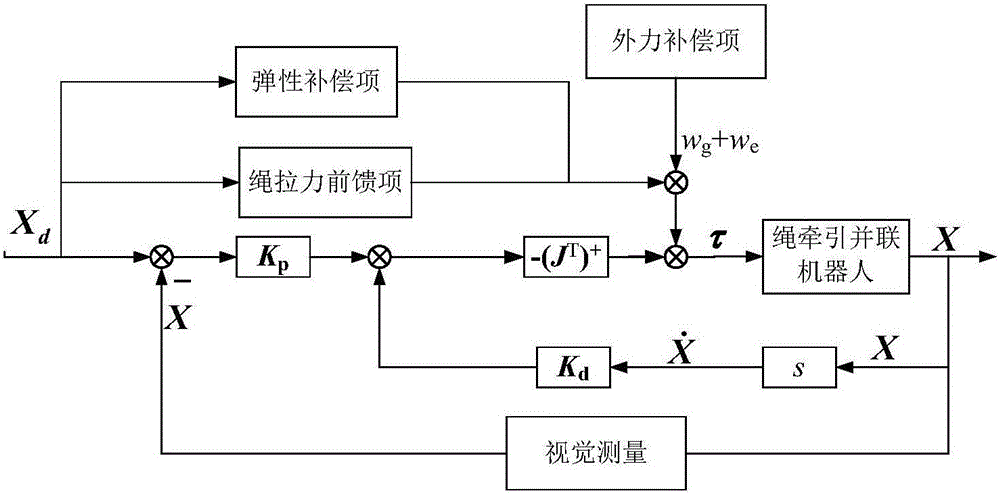

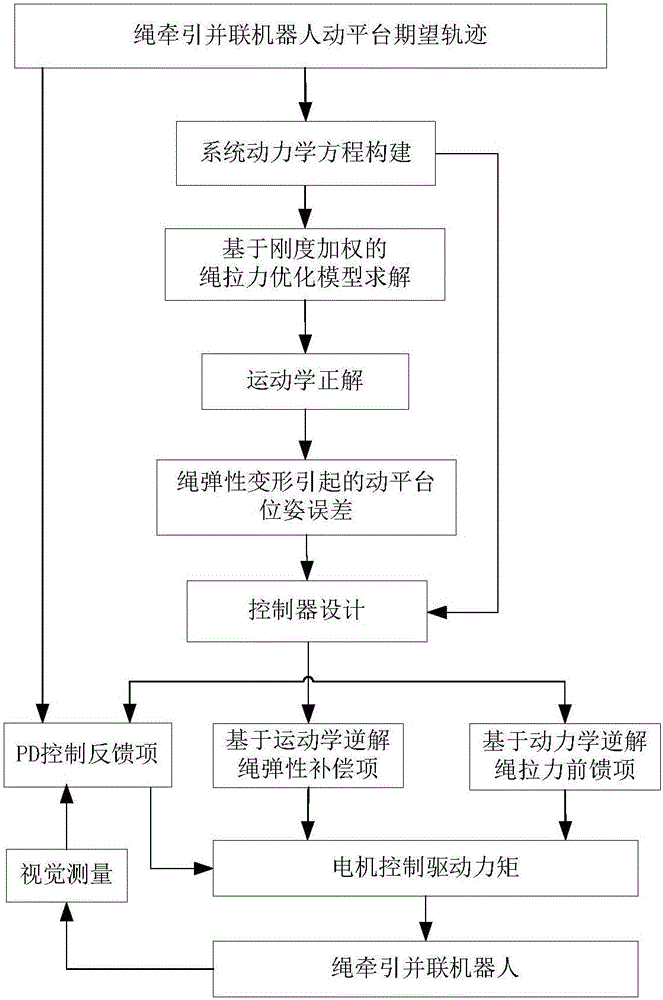

InactiveCN105974797AMeet working conditionsAchieve high precision controlAdaptive controlKinematicsPull force

The invention discloses a rope-driven parallel robot motion control method in consideration of elasticity effect and compensation, and relates to a robot. The method comprises the steps of constructing a system dynamic equation for rope pull optimization and controller design; optimizing rope pull distribution according to an expected moving platform motion track based on the system dynamic equation and a constraint condition by adopting a rope pull dynamic optimization model taking maximum rigidity weight as a target function, and calculating the deformation; analyzing a moving platform pose error caused by elastic deformation of a pull rope via kinematic forward analysis according to the actual rope length and the deformation; acquiring the actual motion state of a visual measurement moving platform, and taking the deviation between the actual motion state and the expected motion state as a control quantity; designing a controller; and calculating a control drive torque instruction according to the designed controller, and finally controlling the motion track of the moving platform and the pull of the rope, thereby meeting the requirement of the working condition.

Owner:XIAMEN UNIV

Electric power generator, steam turbine rotor spindle repaired by laser and repairing method thereof

InactiveCN1674408AMeet working conditionsHigh creep limitMagnetic circuit rotating partsPump componentsOptoelectronicsCobalt

The present invention provides a laser repaired power generator and turbine rotor shaft, on its matrix surface on alloy covering layer which can be mutually merged with matrix surface and is different from matrix completely in components is formed, and on the surface where the matrix and alloy layer are connected a micromolten layer whose thickness is 0.05-0.1 mm is formed, and said alloy covering layer is nickel base, cobalt base or iron base alloy. Said invention also provides a laser repairing method of the described power generator and turbine rotor shaft. It adopts a pre-set laser melt-covering mode, and its technological parameters are: laser power 1200-2000 W, spot diameter 2-6 mm and spot moving speed 2-20 mm / s.

Owner:SHENYANG DALU LASER TECH

Attitude-adjustable moon soft lander

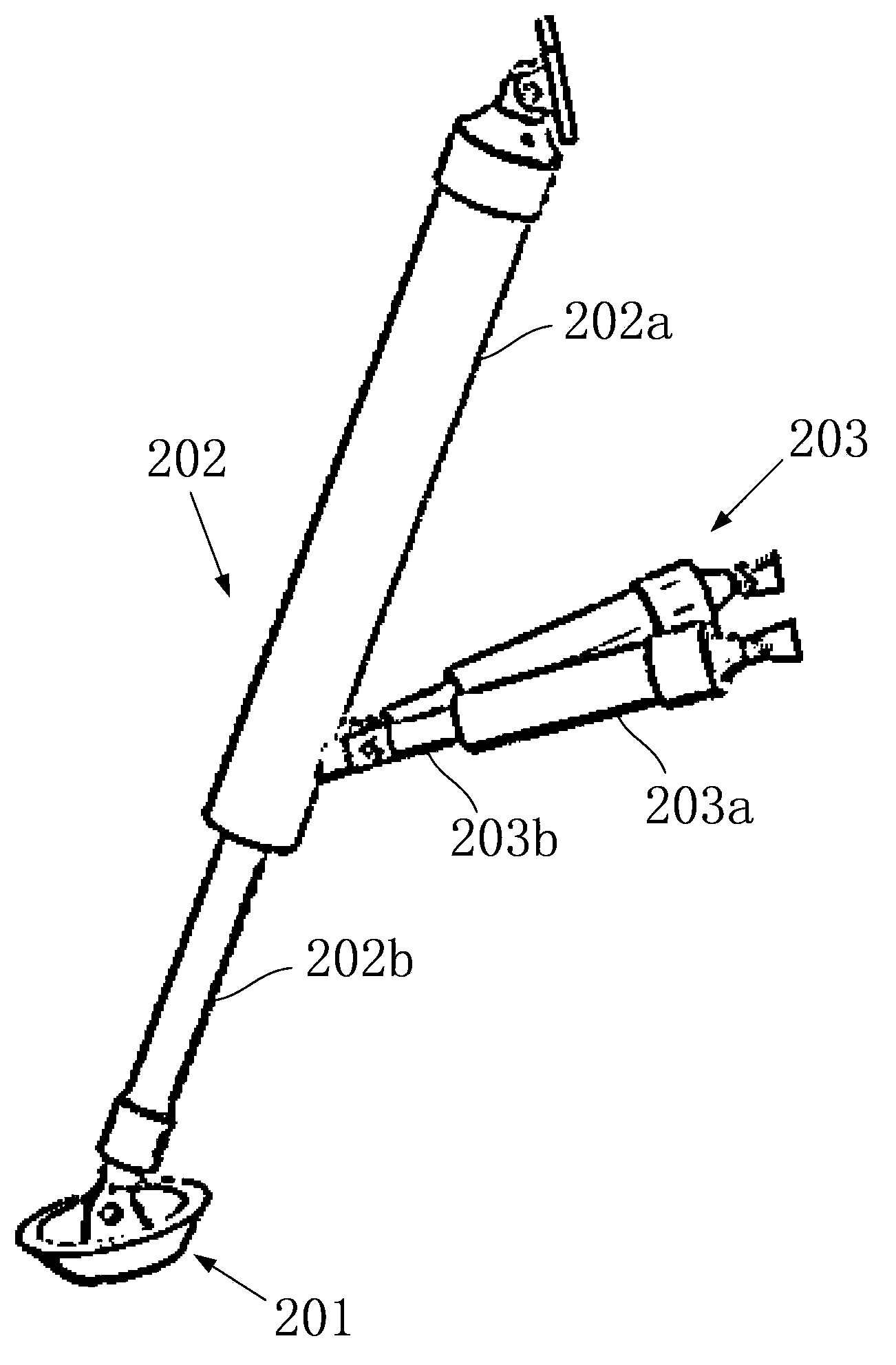

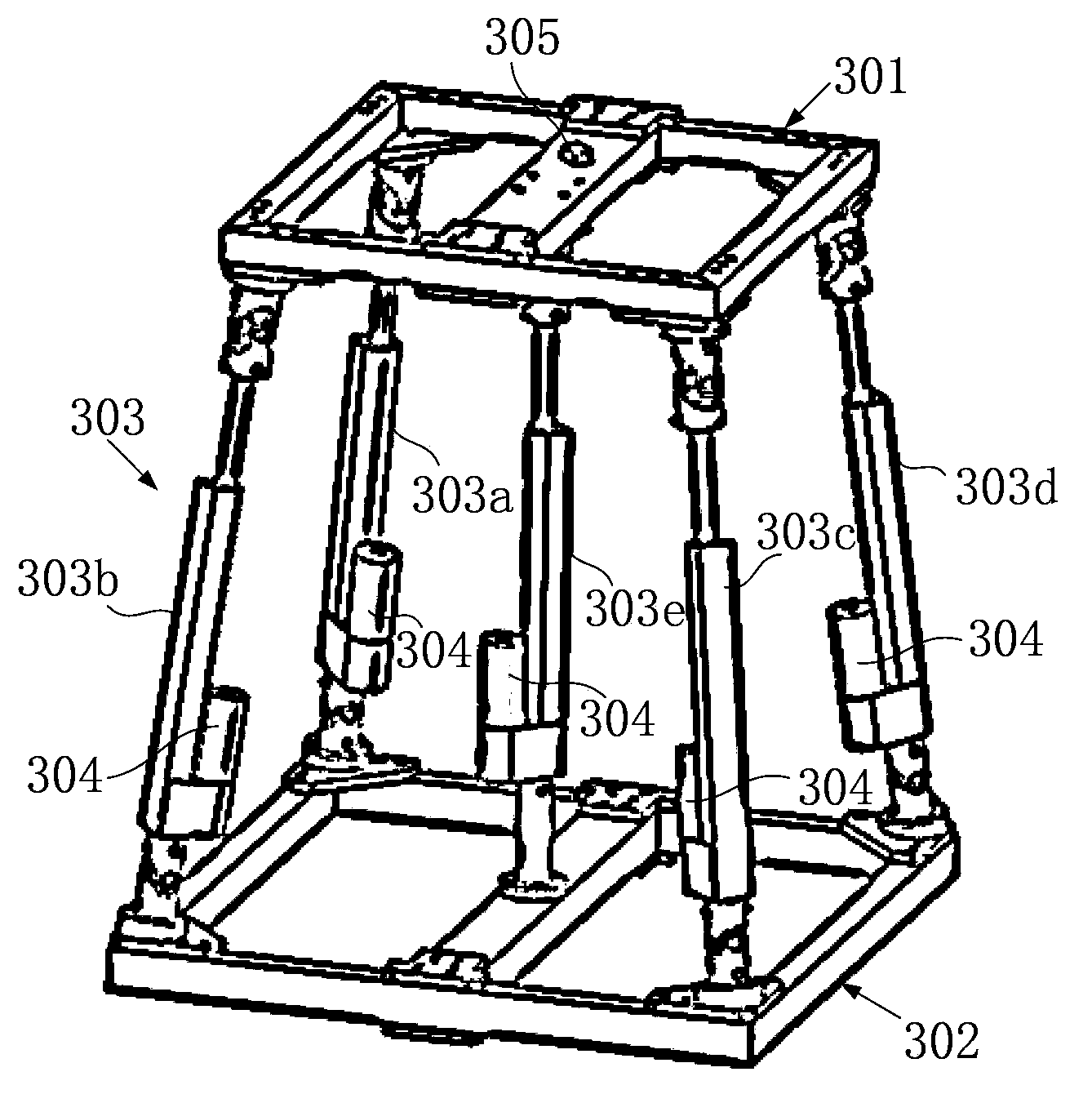

ActiveCN103350758AMeet the working conditions of the payloadMeet working conditionsSystems for re-entry to earthCosmonautic landing devicesEngineeringDegrees of freedom

The invention discloses an attitude-adjustable moon soft lander which comprises a lander body and buffering leg components, wherein the buffering leg components are uniformly mounted on the circumferential side wall of the lander body and can realize stable landing. An attitude-adjustable effective load carrying platform is mounted inside the lander body and adopts a four-degree-of-freedom parallel connection platform which comprises an upper platform, a lower platform and five electric push rods connected with the upper platform and the lower platform, wherein displacement sensors which are used for acquiring a distance between the electric push rods and the upper and lower platforms in real time are mounted at body ends of the five electric push rods; a double-shaft tilt angle sensor used for acquiring attitude information of the upper platform is mounted on the upper platform; and the five electric push rods are controlled to realize attitude adjustment of the moon soft lander. Solar panels used for charging the soft lander are mounted on the side walls of the soft lander body through torsional springs, and the torsional springs and electromagnets mounted on the side walls of the soft lander body are used for unfolding and folding the solar panels. The attitude-adjustable moon soft lander has the benefits as follows: soft landing can be stably realized, and the attitude can be adjusted.

Owner:BEIHANG UNIV

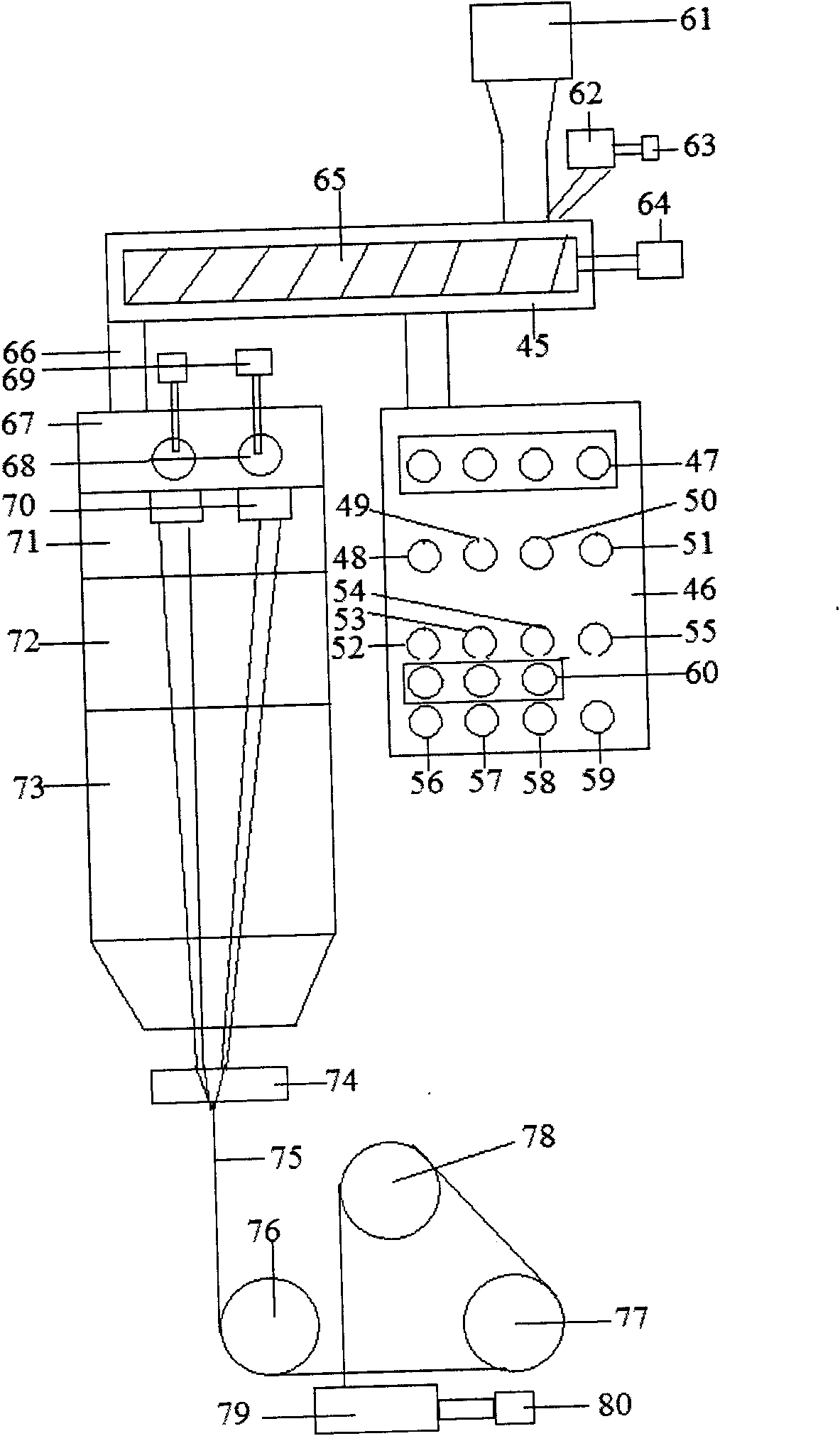

Preparation method of heat-resistant polyphenylene sulfide fiber

InactiveCN102220659AReasonable workmanshipAccurate and detailed dataFilament forming substance formingFibre typesCorrosionFineness

The invention relates to a preparation method of heat-resistant polyphenylene sulfide fiber, comprising the following steps: aiming at the demand on high-performance industrial fabric, adding silica to a polyphenylene sulfide material, preparing masterbatch, extruding by double screws to form strips, dicing, drying in vacuum, extruding and spinning by a single screw, cooling, applying oil to an oil roller, thermally sizing, and winding to form a wire barrel to finally obtain heat-resistant silica and polyphenylene sulfide fiber, namely, SiO2 / PPS fiber, wherein the fiber is white long silk, the fineness is 400dtex, the breaking strength is 3.75 cN / dtex, the heat resistance temperature is 230 DEG C, and the silk has stable chemical and physical performances; the fiber can be used for manufacturing heat-resistant, corrosion-resisting dedusting filter bags and the like, which has high demand on the breaking strength; the preparation method has advanced and remarkable technology and accurate and detailed quantity parameters, and is capable of performing large-scale industrial production; and the preparation method is a very ideal preparation method of the heat-resistant polyphenylene sulfide fiber.

Owner:TAIYUAN UNIV OF TECH

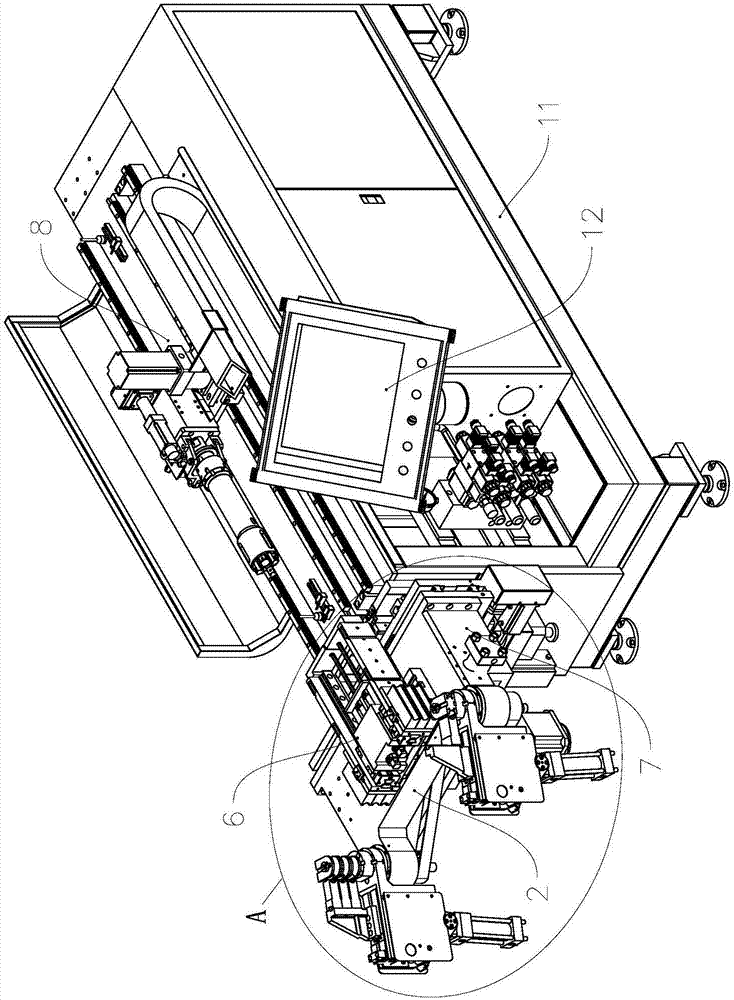

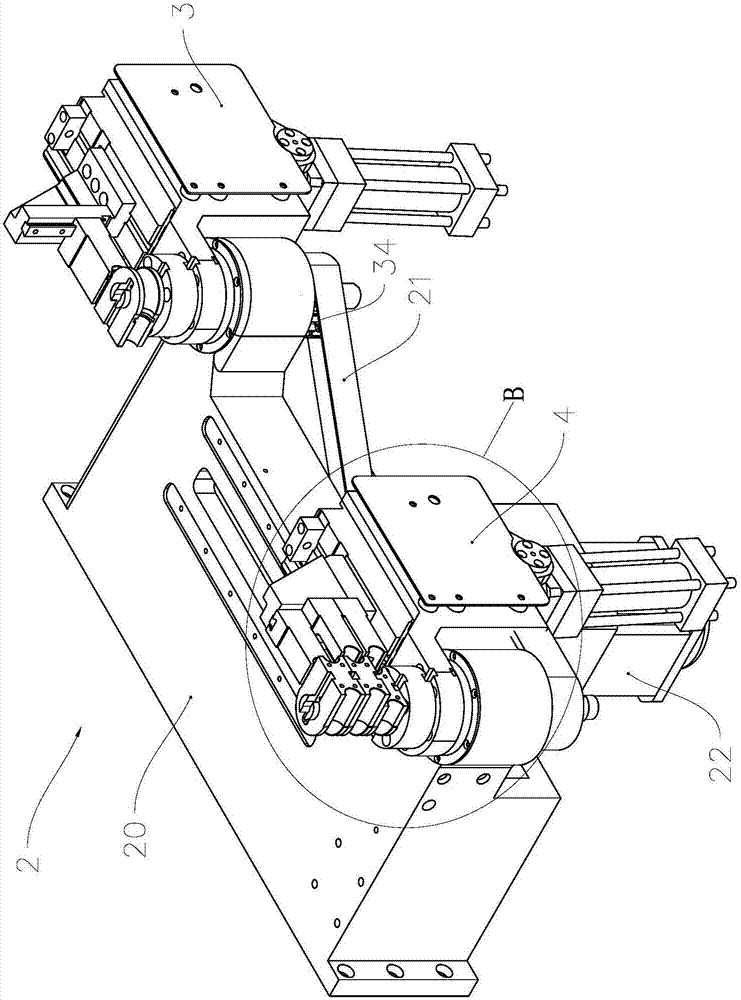

Leftward and rightward double-bending type numerical-controlled pipe bending machine

ActiveCN107282720AAvoid shakingQuality improvementMetal-working feeding devicesPositioning devicesAviationPipe fitting

The invention relates to a leftward and rightward double-bending type numerical-controlled pipe bending machine, and belongs to the technical field of pipe processing. The leftward and rightward double-bending type numerical-controlled pipe bending machine comprises a rack, a control unit, a pipe bending device and a feeding vehicle which are mounted on the rack and controlled by the control unit, wherein the pipe bending device comprises a machine head, a die guide unit and a die changing unit; the machine head comprises a mounting seat, a leftward pipe bending unit and a rightward pipe bending unit which are mounted on the mounting seat and driven by a same pipe bending motor; each of the leftward and rightward pipe bending units comprises a circular die, a swing arm and a clamping die mounted on the swing arm; the die changing unit is controlled by the control unit to drive the machine head to move in transverse and vertical directions being perpendicular to the axial direction of a pipe to be bent relative to the rack, so that the numerical-controlled pipe bending machine can switch between a leftward bending working mode and a rightward bending working mode. According to the leftward and rightward double-bending type numerical-controlled pipe bending machine, the same pipe bending motor drives the leftward pipe bending unit and the rightward pipe bending unit simultaneously, at the same time the switching between the leftward pipe bending unit and the rightward pipe bending unit is realized through the die changing unit, not only is the pipe bending quality effectively improved, but also the compactness of the integrated layout is improved, and therefore the leftward and rightward double-bending type numerical-controlled pipe bending machine can be extensively applied to fields such as air conditioning and aviation.

Owner:浙江和良智能装备有限公司

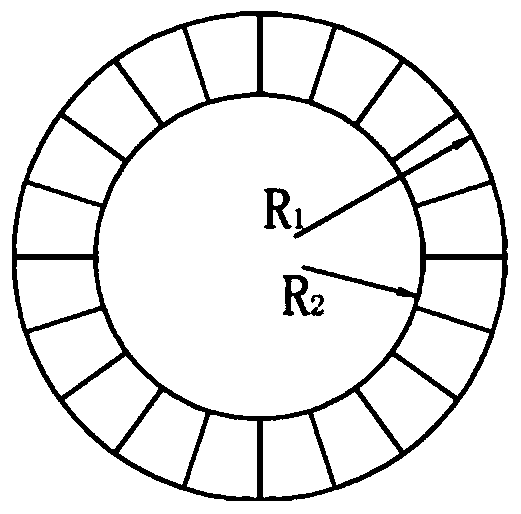

Natural gas engine powder metallurgy valve seat ring material

The invention discloses a natural gas engine powder metallurgy valve seat ring material. The natural gas engine powder metallurgy valve seat ring material contains the following element raw materials in percentage by weight: 0.6-1.5% of C, 0.3-1.5% of S, 3-10% of Cr, 4-12% of Mo, 0.5-5% of Ni, 3-10% of Co, 10-20% of Cu, 1-2.5% of Mn, 1-4% of V, 2-7% of W and the balance of Fe. The natural gas engine powder metallurgy valve seat ring material disclosed by the invention can effectively improve the abrasion resistance of the powder metallurgy seat ring and meet the working conditions and the requirements of a natural gas fuel engine.

Owner:安庆帝伯粉末冶金有限公司

Novel self-lubricating polymer composite material and its prepn process

The present invention relates to novel self-lubricating polymer composite material and its preparation process. The novel self-lubricating polymer composite material is prepared with calcium carbonate whisker in 10-25 weight portions, PTFE in 10 weight portions and polyether ether ketone in 65-80 weight portions; and the preparation process includes the following steps: drying the said materials at 130-150 deg.c and mixing through high speed stirring in a stirrer; melting the mixture in a hot pressing mold pressurizing at 20 MPa to form, maintaining for 8-10 min, cooling inside the die to 100 deg.c, demolding, cooling to room temperature, and maintaining at 250 deg.c of 1 hr. The present invention has calcium carbonate whisker to strengthen polyether ether ketone, PTFE as antifriction agent, and the cooperation of polyether ether ketone, PTFE and calcium carbonate whisker to result in self lubricating, reduced friction and raised wear resistance.

Owner:FUZHOU UNIV

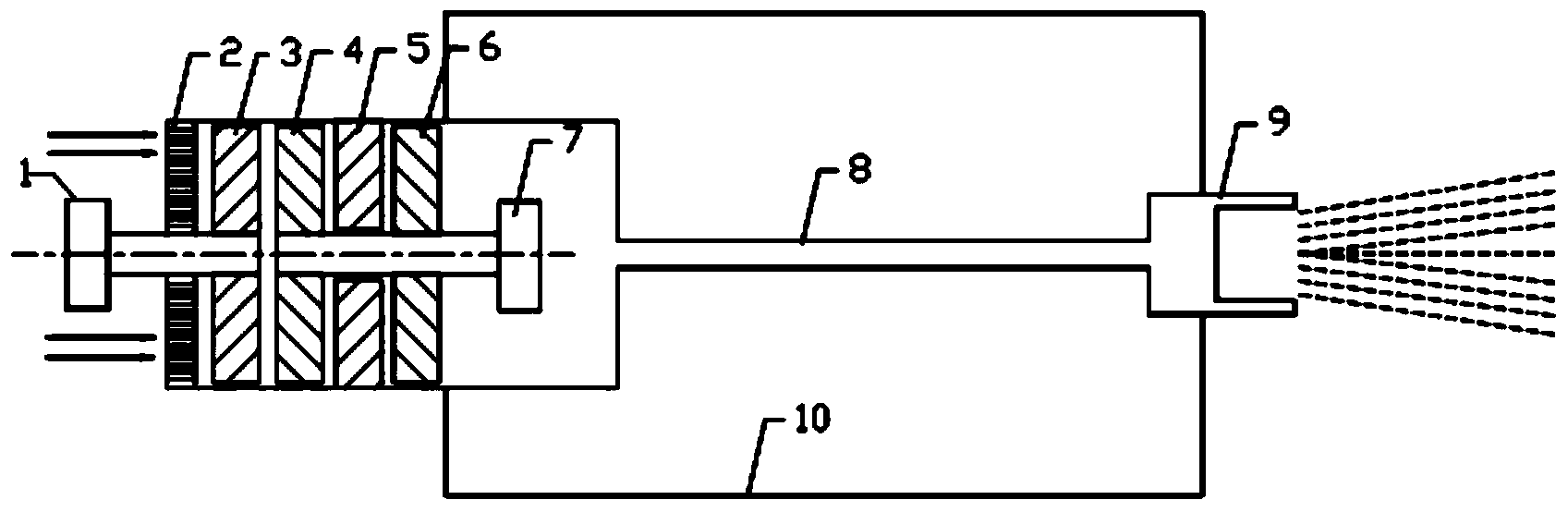

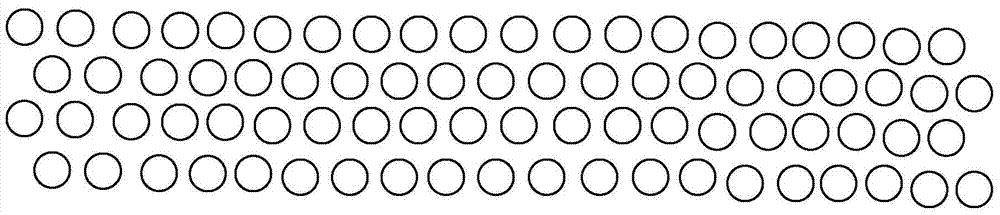

Air-breathing electric rocket for low-orbit spacecraft

InactiveCN103453805AIncrease the number ofMeet working conditionsSelf-propelled projectilesAir breathingTurbomolecular pump

The invention discloses an air-breathing electric rocket for a low-orbit spacecraft, which belongs to the field of space technology and vacuum technology. The electric rocket comprises a porous array plate, a turbo molecular pump, a compressed gas conveying pipeline, an electric thruster and a spacecraft body, wherein the turbo molecular pump is arranged on the front end of the spacecraft body; the electric thruster is arranged on the rear end of the spacecraft; one end of the compressed gas conveying pipeline is connected with the turbo molecular pump; the other end of the compressed gas conveying pipeline is connected with the electric thruster; the porous array plate is fixedly connected to a front end of the turbo molecular pump. The electric rocket can collect dilute gas of a spacecraft orbit environment as working medium of the electric thruster, the rigidity limitation on the service life of the spacecraft caused by the using up of fuel can be completely avoided, and the quantity of effective loads carried by the spacecraft and the capability of completing more complex tasks of the spacecraft are improved.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

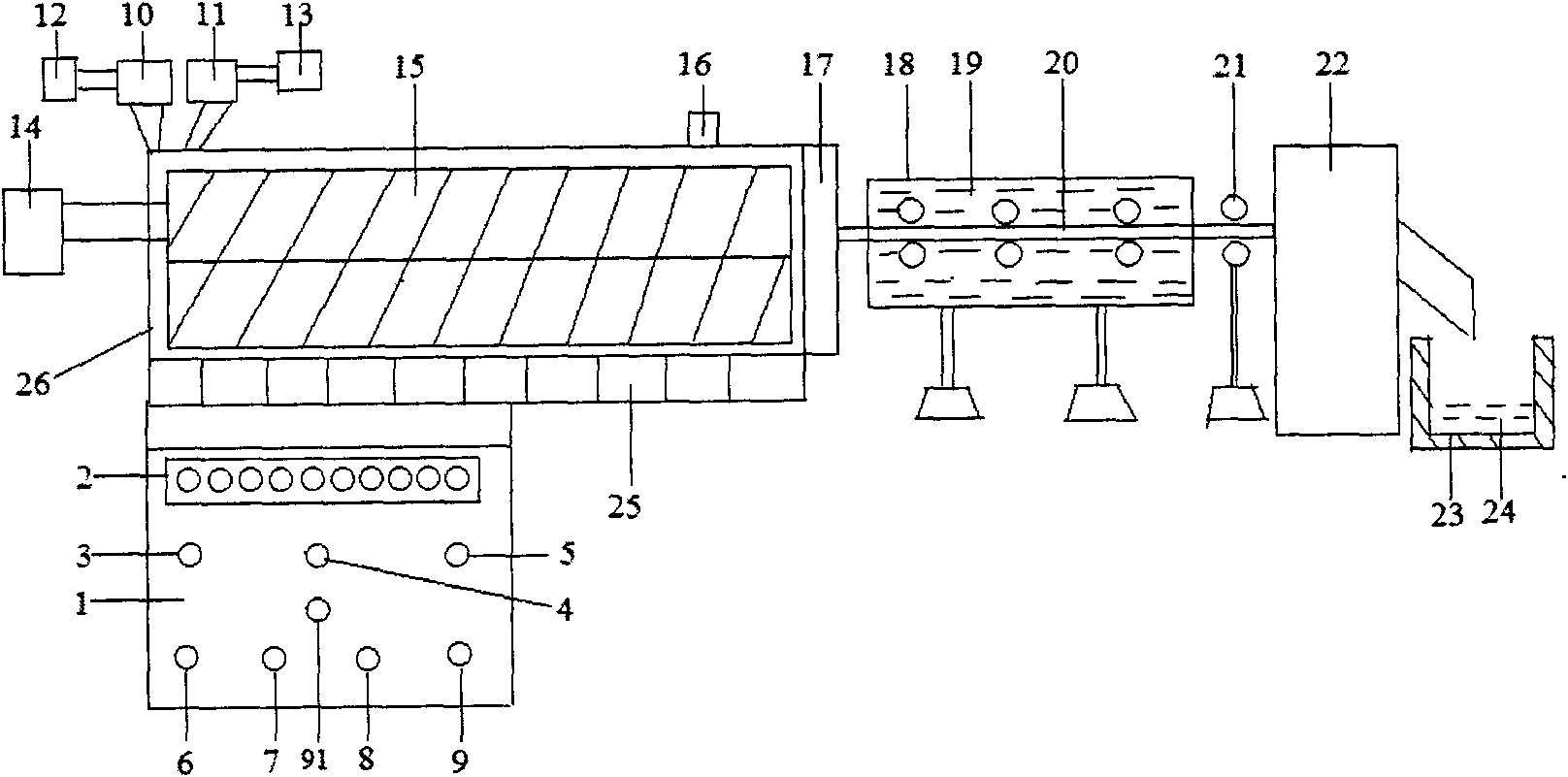

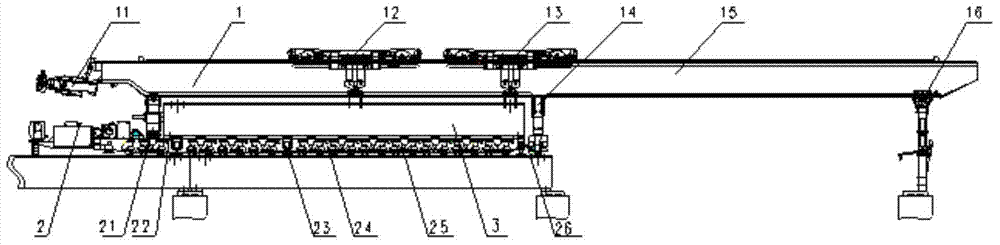

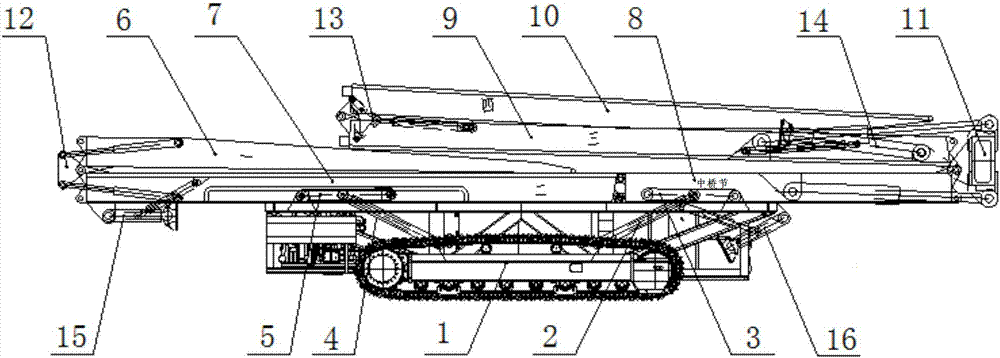

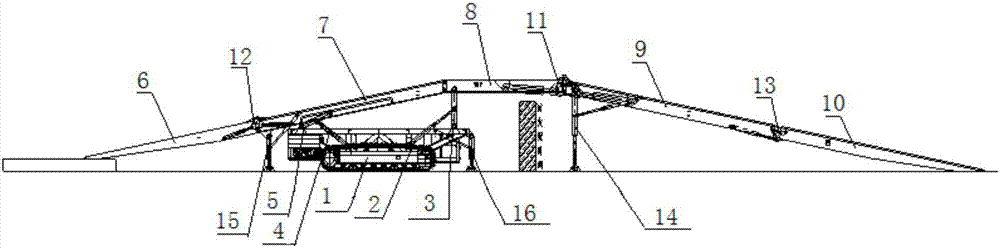

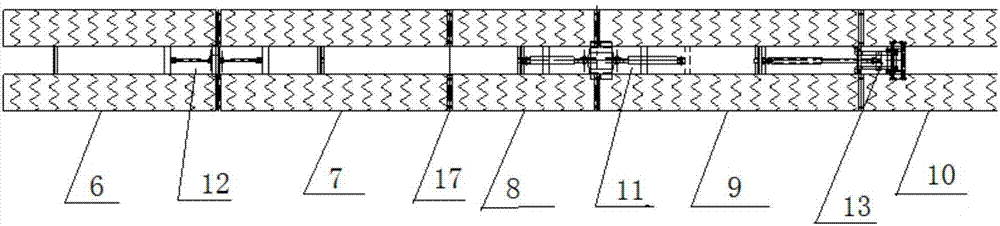

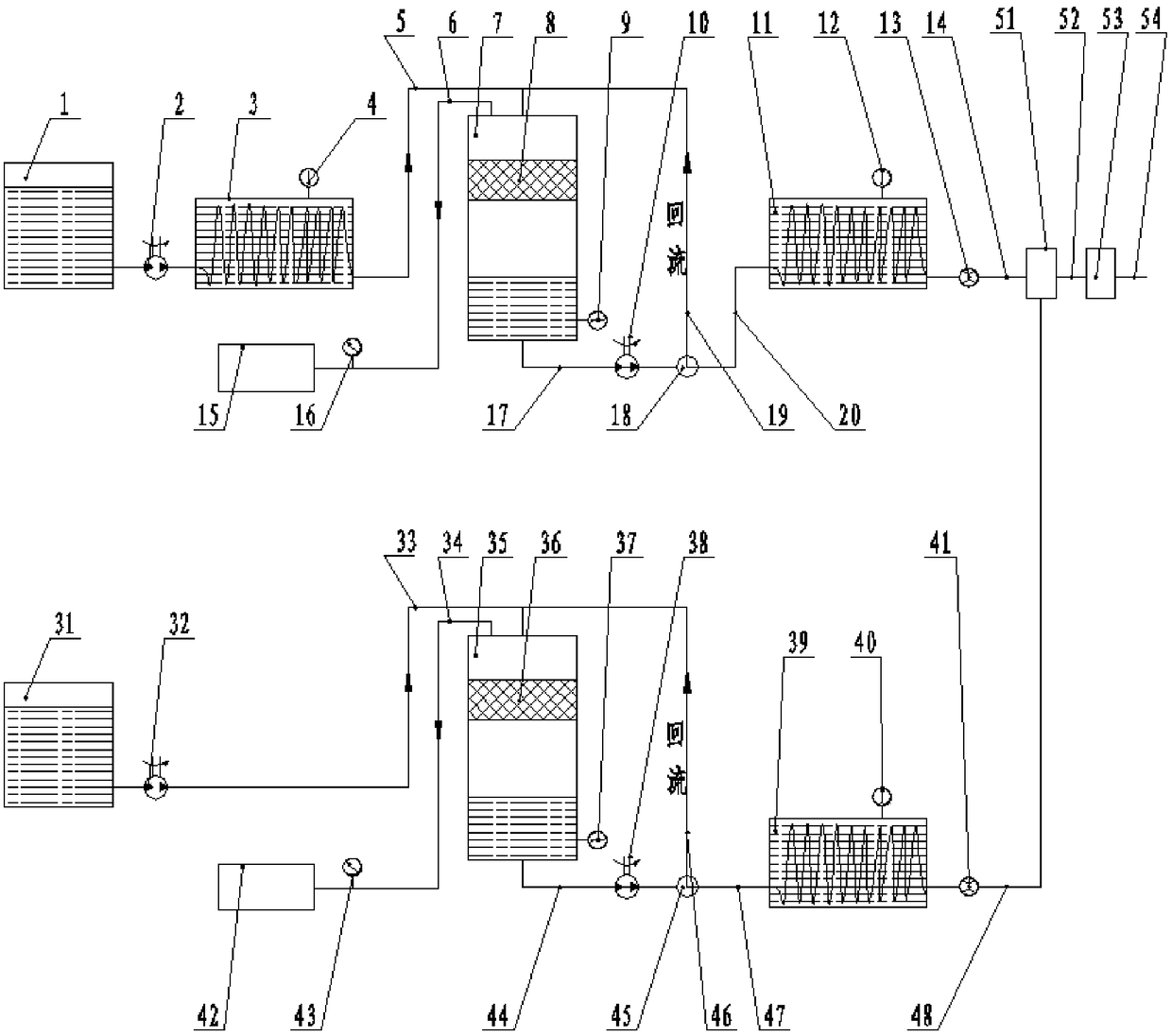

Large-tonnage beam erection and transportation system in tunnel and beam erection span change procedure thereof

ActiveCN104762885ALow costSimplify the beam erection processBridge erection/assemblyRoller chainBack support

The invention discloses a large-tonnage beam erection and transportation system in a tunnel and a beam erection span change procedure thereof, is used for transporting and erecting large prefabricated box beams in high-speed railway and passenger railway lines, and in particular, is suitable for transporting and erecting the box beams in the tunnel. A bridge erection machine comprises main beams, wherein back support legs are arranged at the bottoms of the back ends of the main beams; a downwards recessed front lifting trolley and a back lifting trolley are driven through driving devices by fixed roller chains, are rolled to walk by sliding devices, and are stridden over double main beams; extensible middle support legs are arranged at the bottoms of the middles of the main beams; front support legs capable of moving and extending are arranged at the bottoms of the front ends of the main beams; a beam transporting vehicle comprises a vehicle body; and extension legs, a movable beam support trolley, at least two sets of oil cylinder support legs in the beam support place, multiple wheel sets and front anchor pull rods mounted at the front ends are arranged above the tail end of the vehicle body. The system can satisfy the erection of multiple specifications of passenger railway lines, satisfies the beam erection conditions in tunnel entrances and exits and in the tunnel, simplifies the beam erection procedures, improves the equipment stability, is high in construction efficiency and reasonable and innovative in structural design, and improves the construction efficiency.

Owner:CHINA RAILWAY ENG MASCH RES & DESIGN INST CO LTD

Multifunctional protection rack for safety helmet

A multifunctional protection rack for a safety helmet having interchangeability, which is connected to the safety helmet to install a welding mask for performing a welding operation, a shade for preventing a direct ray of light from passing therethrough, or a protective shield for preventing foreign substances from being introduced thereinto. The multifunctional protection rack includes a support frame bent into front and rear frames and side support frames, and made of an elastic member formed along the outer surface of a visor of the safety helmet so that the width of the support frame can be adjusted; a first connecting support member, one side of which is connected to the outer surface of the support frame by a rotational angle adjusting portion for adjusting a rotational angle of a protective equipment attached to the protection rack, and the other portion of which is connected to the outer of the support frame by an interval adjusting portion for adjusting an interval between the protective equipment and the face of a worker wearing the safety helmet; and a second connecting support member additionally installed between the support frame and the protective equipment, thereby being installed on the safety helmet such that the protection rack can be opened and closed.

Owner:OTOS TECH

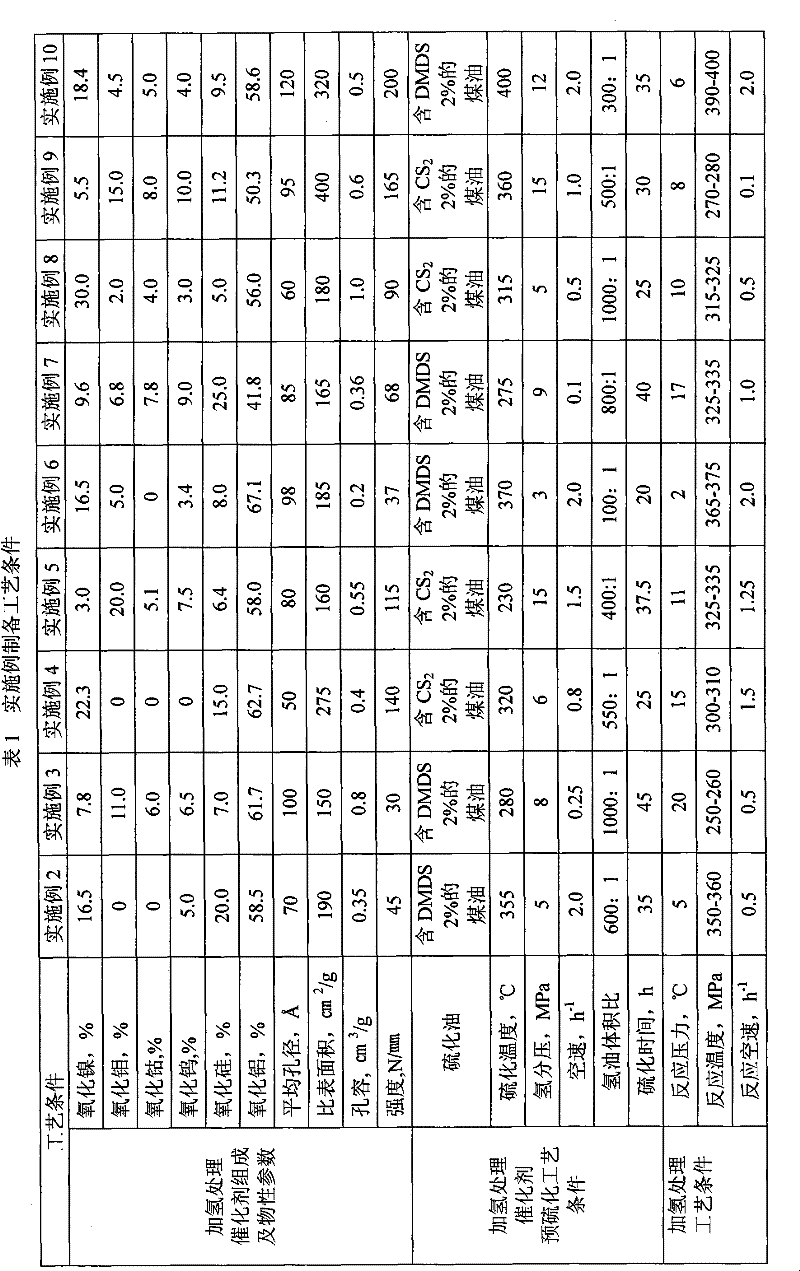

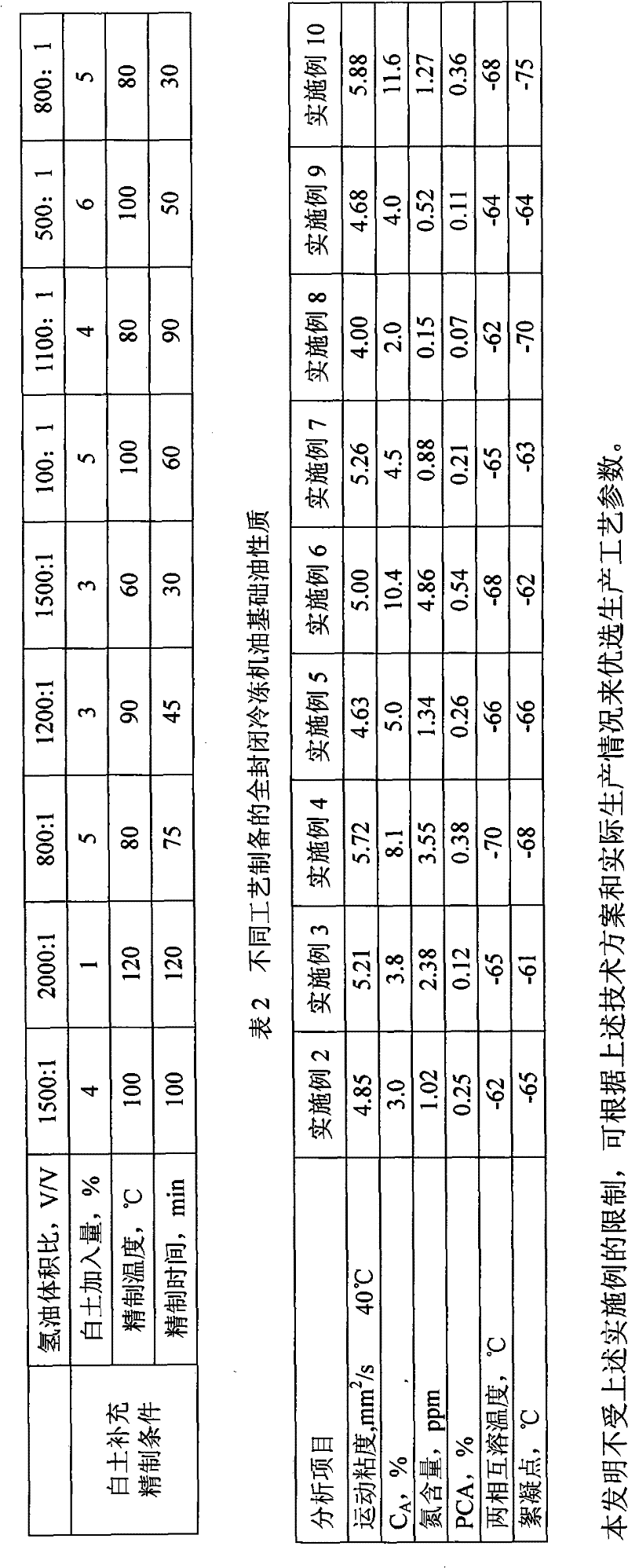

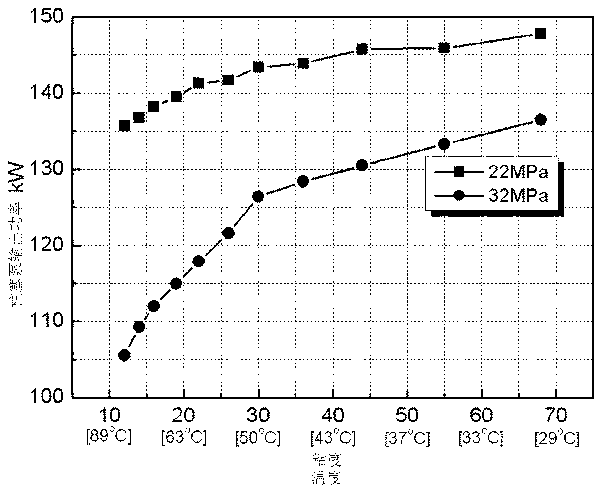

A kind of preparation method of refrigerating machine oil base oil

ActiveCN102295956AProcess environmental protectionEasy to prepareTreatment with hydrotreatment processesBase-materialsRefrigeration compressorPetroleum

The invention relates to a preparation method of refrigerator oil base oil. The method comprises the following steps of performing hydrotreatment on 300-500 DEG C naphthene petroleum fractions used as a raw material at a pressure of 2.0-20.0 MPa, a temperature between 250 and 400 DEG C, an air speed of 0.1-2.0 h-1, and a hydrogen-oil volume ratio of 100:1-2000:1; and cutting the hydrogenated oil into 270-320 DEG C fractions, and replenishing with white clay and refining, wherein the addition weight of the white clay is 1-6% of the weight of the distillate oil, the temperature is 60-120 DEG C and the time is 30-120 min, the catalyst active component in the hydrogenation reaction is one, two or more than three of Ni, W, Mo and Co, and the carrier is aluminum oxide. The coefficient of kinematic viscosity at 40 DEG C of the refrigerator oil base oil is 4-6 mm<2> / s, the flocculation point is less than -60 DEG C, the CA value is 2-12%, and the contents of nitrides and polycyclic aromatic hydrocarbons are low; and the base oil is suitable for a refrigerating compressor system of hydrocarbon coolant with 3 or 4 carbon atoms.

Owner:PETROCHINA CO LTD +1

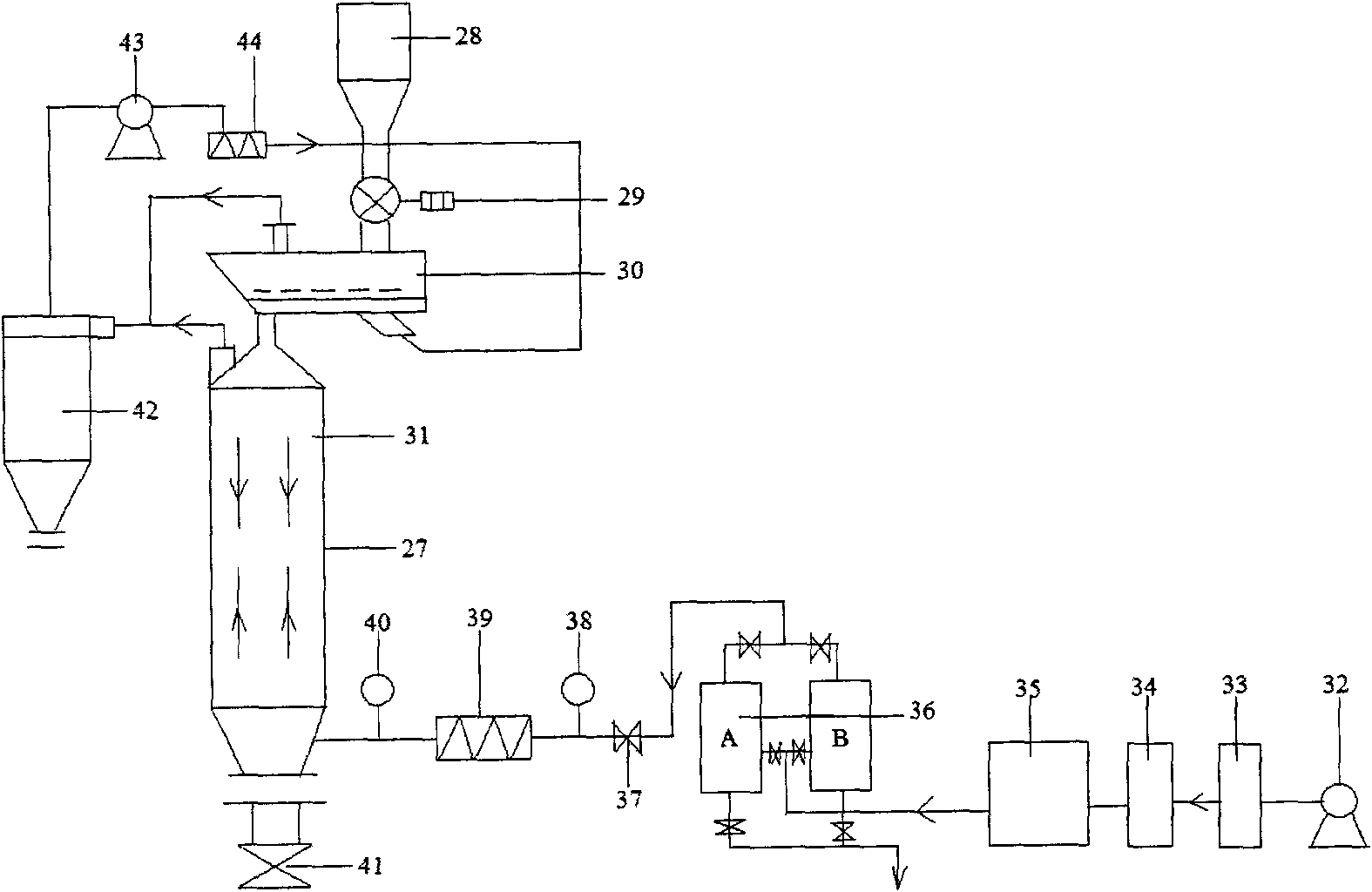

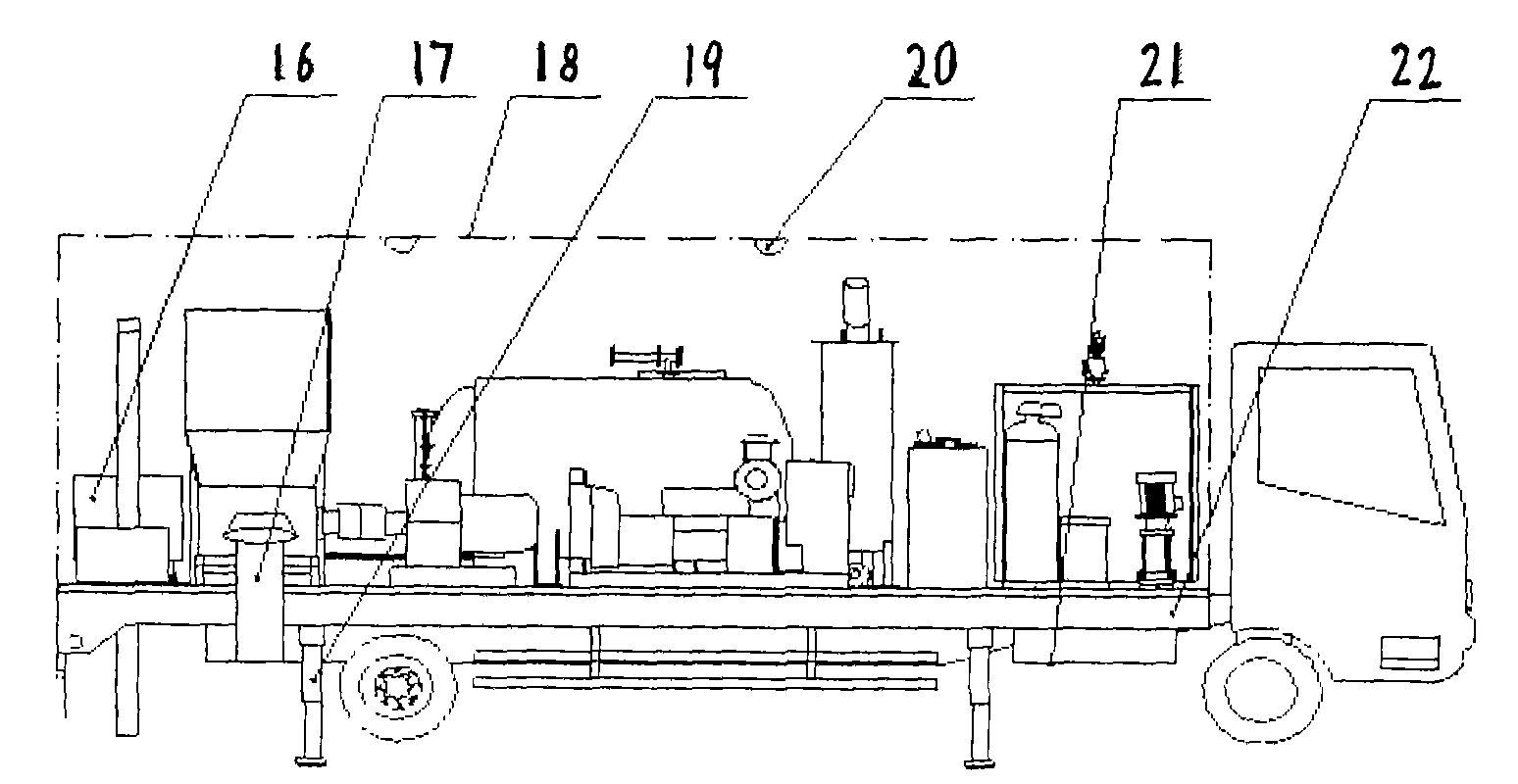

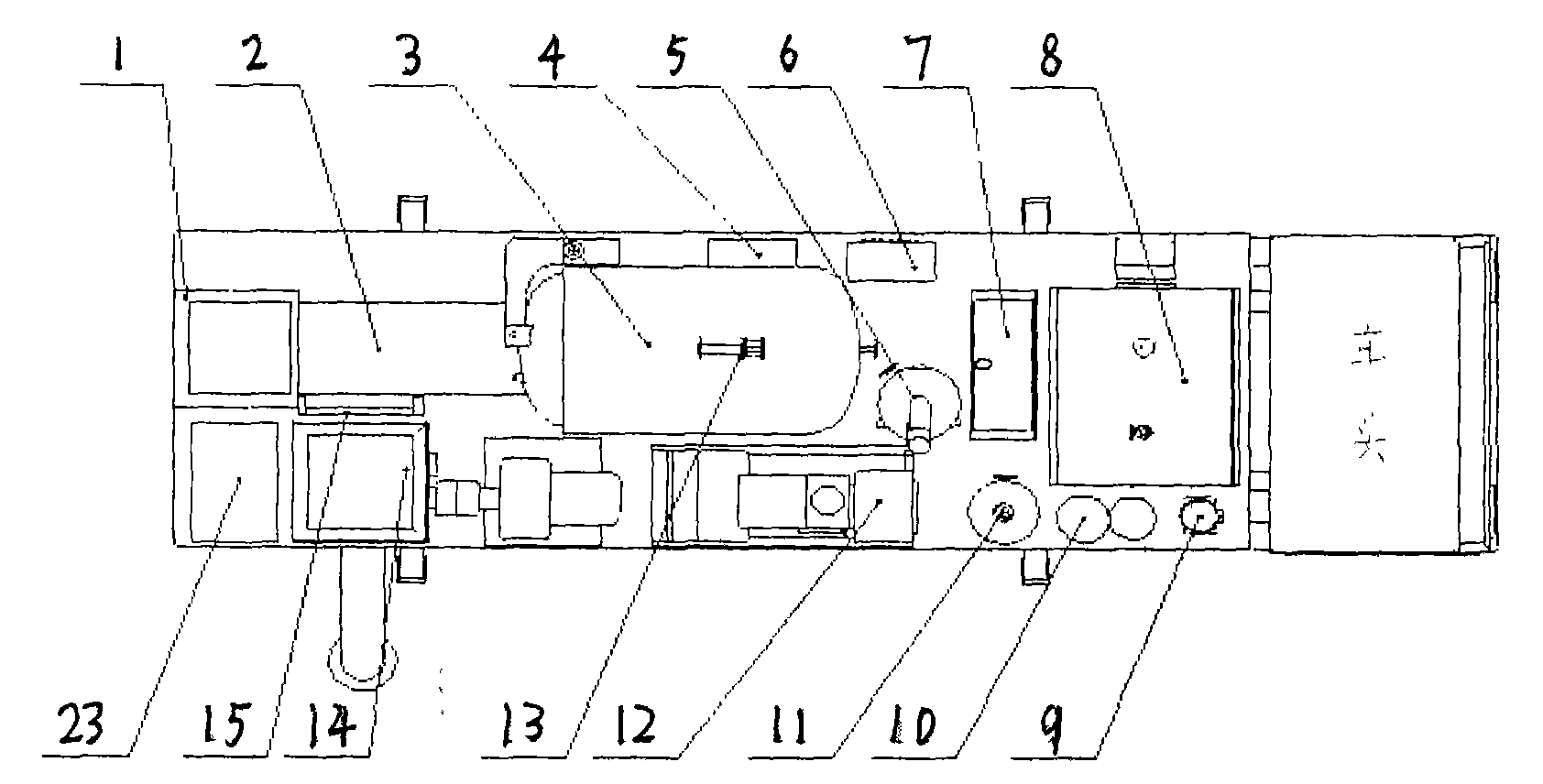

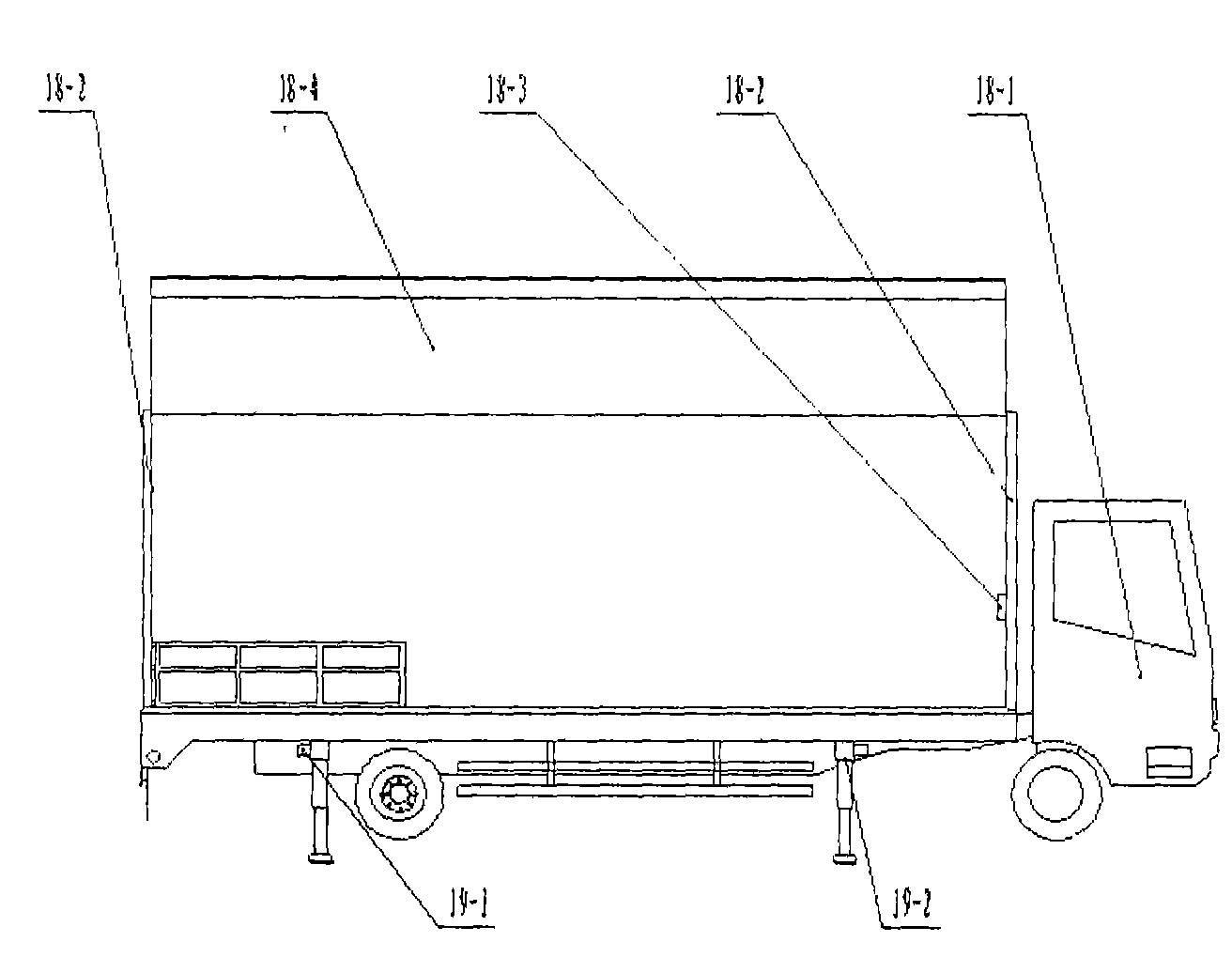

Vehicular mobile medical waste high temperature steam treatment device

ActiveCN101653775AEnable mobilityMeet working conditionsSolid waste disposalVehicle fittings for liftingVehicle frameTransit system

The invention relates to a vehicular mobile medical waste high temperature steam treatment device, comprising six subsystems of a half-wing open compartment / wing open compartment and car outrigger system, a medical waste transportation system, a steam supply system, a power supply and distribution and control system, a high temperature steam treatment system and a broken discharging system. Each system is uniformly and fixedly installed on the same car frame or is fixedly installed on a running strip or an engine base (frame), and then each system is assembled on the car frame through the running strip or the engine base (frame), thus realizing the mobility of the system. The treatment device has perfect functions, starts from the treatment effect of the medical waste generated in burst pollution incidents, thus giving consideration to the economy of treatment cost when ensuring motility and flexibility.

Owner:CHONGQING GIENT HEATING IND

Restoring method of last-stage blade of steam turbine

ActiveCN102031513ASmall heat affected zoneSave heatMetallic material coating processesEngineeringHeat treated

The invention relates to a restoring method of a last-stage blade of a steam turbine, which is characterized by comprising the following steps of: 1, detecting the last-stage blade of the steam turbine before restoring; 2, manufacturing a shape line sample plate of the last-stage blade of the steam turbine; 3, cleaning a fatigue layer of the last-stage blade of the steam turbine; 4, copying and cladding injured parts by lasers; 5, modifying by pliers; and 6, detecting after restoring. In the invention, the restored last-stage blade of the steam turbine does not need heat treatment and heat calibration, the blade is modified by only using the shape line template after cladding, and therefore, the last-stage blade of steam turbine has complete shape lines and higher service life at the same time.

Owner:SHENYANG DALU LASER TECH

Aluminum-silicon gradient material and selective laser melting forming method thereof

ActiveCN109706353ALow densityImprove controllabilityAdditive manufacturing apparatusSelective laser meltingSilicon alloy

The invention relates to a selective laser melting forming method of an aluminum-silicon gradient material. The selective laser melting forming method comprises the following steps of S1, designing the components and shape of the aluminum-silicon gradient material, and preparing raw materials with different silicon contents according to the weight percentage, wherein the raw materials comprise 22%-70% of silicon and the balance aluminum by weight; S2, smelting the raw materials to obtain aluminum-silicon alloy melts with different silicon contents; S3, preparing aluminum-silicon alloy powder with different silicon contents with the aluminum-silicon alloy melts obtained in the S2 through gas atomization separately; S4, preparing the aluminum-silicon gradient material in the design shape with the aluminum-silicon alloy powder with different silicon contents obtained in the S3 through a selective laser melting technology; and S5, performing heat treatment to the aluminum-silicon gradientmaterial obtained in the S4. The invention further relates to the aluminum-silicon gradient material prepared with the method. The method stated in the invention has the advantages of high designability, simplification of working procedures, high utilization rate of the material, high processing accuracy and the like; and the gradient material stated in the invention is high in designability, andapplicable for electronic packaging shells.

Owner:CENT SOUTH UNIV

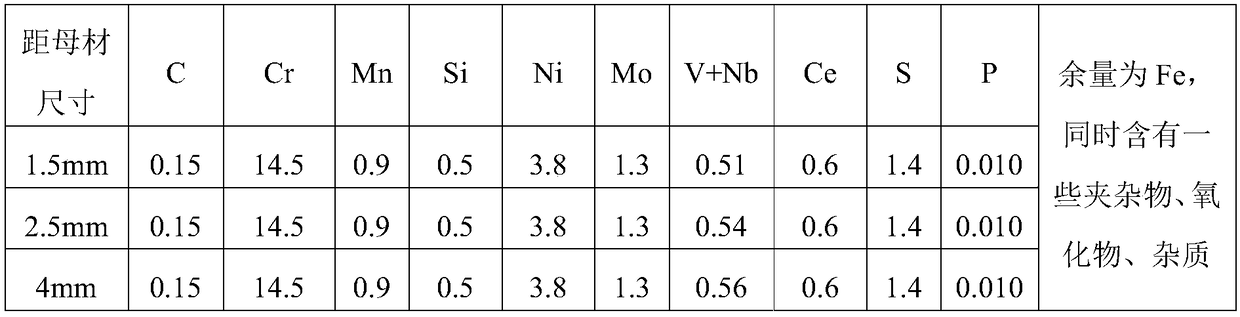

Cosmetic overlaying material for composite overlaying remanufacturing of support roller and preparation method for cosmetic overlaying material

InactiveCN104209663AMeet working conditionsImprove plastic toughnessWelding/cutting media/materialsSoldering mediaPipeSteel belt

The invention provides a cosmetic overlaying material for the composite overlaying remanufacturing of a support roller and a preparation method for the cosmetic overlaying material. The deposited metal of the cosmetic overlaying material comprises the following components in percentage by weight: 0.1 to 0.3 percent of C, 1.0 to 2.8 percent of Mn, 0.3 to 1.8 percent of Si, 5.0 to 8.0 percent of Cr, 0.01 to 1.0 percent of Ti, 3.0 to 10 percent of V, 0 to 1.0 percent of W, 1.0 to 6.0 percent of Mo, 0.2 to 2.0 percent of Co, 0 to 0.4 percent of Ca and Ba, 0 to 0.3 percent of rare earth oxide and the balance of Fe. The preparation method comprises the following steps of (1) selecting corresponding compounds or alloy powder according to the proportion of the components in the deposited metal of the cosmetic overlaying material, and uniformly mixing the compounds or alloy powder to obtain cosmetic material powder according to the proportion; (2) rolling a steel strip on a wire rolling mill until the section of the steel strip is U-shaped, filling the cosmetic material powder into a U-shaped groove of the steel strip, rolling the steel strip into a welding wire pipe billet with an O-shaped section, and drawing the welding wire pipe billet into a finished product welding wire. According to the cosmetic overlaying material and the preparation method for the same, the working condition of a Cr5 large-sized support roller can be met, and the roller rolling cost is greatly lowered.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

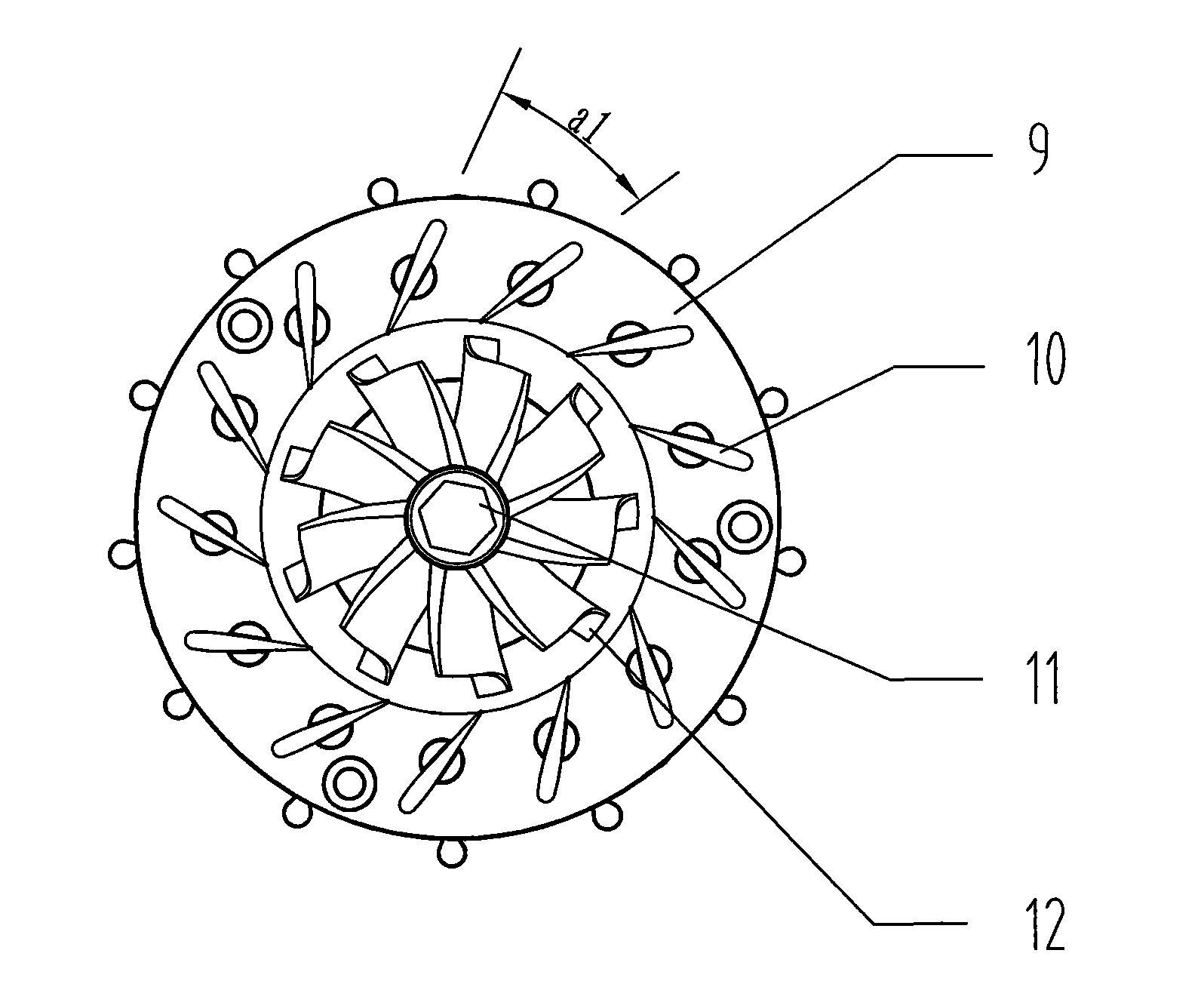

Asymmetric split turbine of turbocharger

ActiveCN101634244AAddressing High Discharge Pressure RequirementsReduce control difficultyNon-fuel substance addition to fuelInternal combustion piston enginesTurbochargerEngineering

The invention discloses an asymmetric split turbine of a turbocharger, comprising an engine. The engine is provided with an exhaust tube of the engine, a turbine casing and a turbine rotor, wherein, the turbine casing is provided with a casing high pressure flow channel and a casing low pressure flow channel, the exhaust tube of the engine is provided with a high pressure exhaust manifold and a low pressure exhaust manifold, the high pressure exhaust manifold is connected with the casing high pressure flow channel, the low pressure exhaust manifold is connected with the casing low pressure flow channel, and the A / R value of the casing high pressure flow channel is less than that of the casing low pressure flow channel. By adopting the asymmetric split structure, the two flow channels of the turbine casing have different A / R values and are respectively connected with different exhaust pipelines of the engine, thus effectively lowering the exhaust back pressure of part of engine cylinders and reducing the influence of EGR operation process on the pressurizing unit. The asymmetric split turbine has good succession, simple structure, easy upgrade and switch of products, low cost and easy and fast realization of engineering.

Owner:康跃科技(山东)有限公司

Integrated transport track type multipurpose mechanized fast obstacle-surmounting bridge

InactiveCN107542033AQuick erectionMeet shipping requirementsConstructionsEngineeringStructural engineering

The invention relates to an integrated transport track type multipurpose mechanized fast obstacle-surmounting bridge, and belongs to the field of mechanized bridges. In the obstacle-surmounting bridge, a first bridge section, a second bridge section, a third bridge section and a fourth bridge section are rotatably connected with a middle bridge section, unfolding and overturning are realized by anunfolding and overturning erection mechanism between the bridge sections, locking is realized by a transverse hydraulic inserting pin, and supporting is realized by a supporting mechanism at the bottom of the bridge sections; when the obstacle-surmounting bridge is not erected, the second bridge section and the middle bridge section are locked and arranged on a track frame bridge vehicle, and theremaining bridge sections are overlapped on the second bridge section and the middle bridge section; during erecting, the first bridge section, the third bridge section and the fourth bridge sectionrotate around all connecting points under pushing of the unfolding and overturning erection mechanism and are locked through the transverse hydraulic inserting pin after been unfolded to place; in theerection process, the supporting mechanism is extended to make contact with the ground for supporting; and after erection, the bridge sections and the track frame bridge vehicle are unlocked and separated, and the obstacle-surmounting bridge is formed. The obstacle-surmounting bridge adopts mechanized operation, a bridge for surmounting an obstacle can be erected quickly, road transporting requirements are met by integrated assembly, railway transporting requirements are met by split assembly, and supporting by the track frame bridge vehicle is not required after erection is completed.

Owner:CHINA HARZONE IND CORP

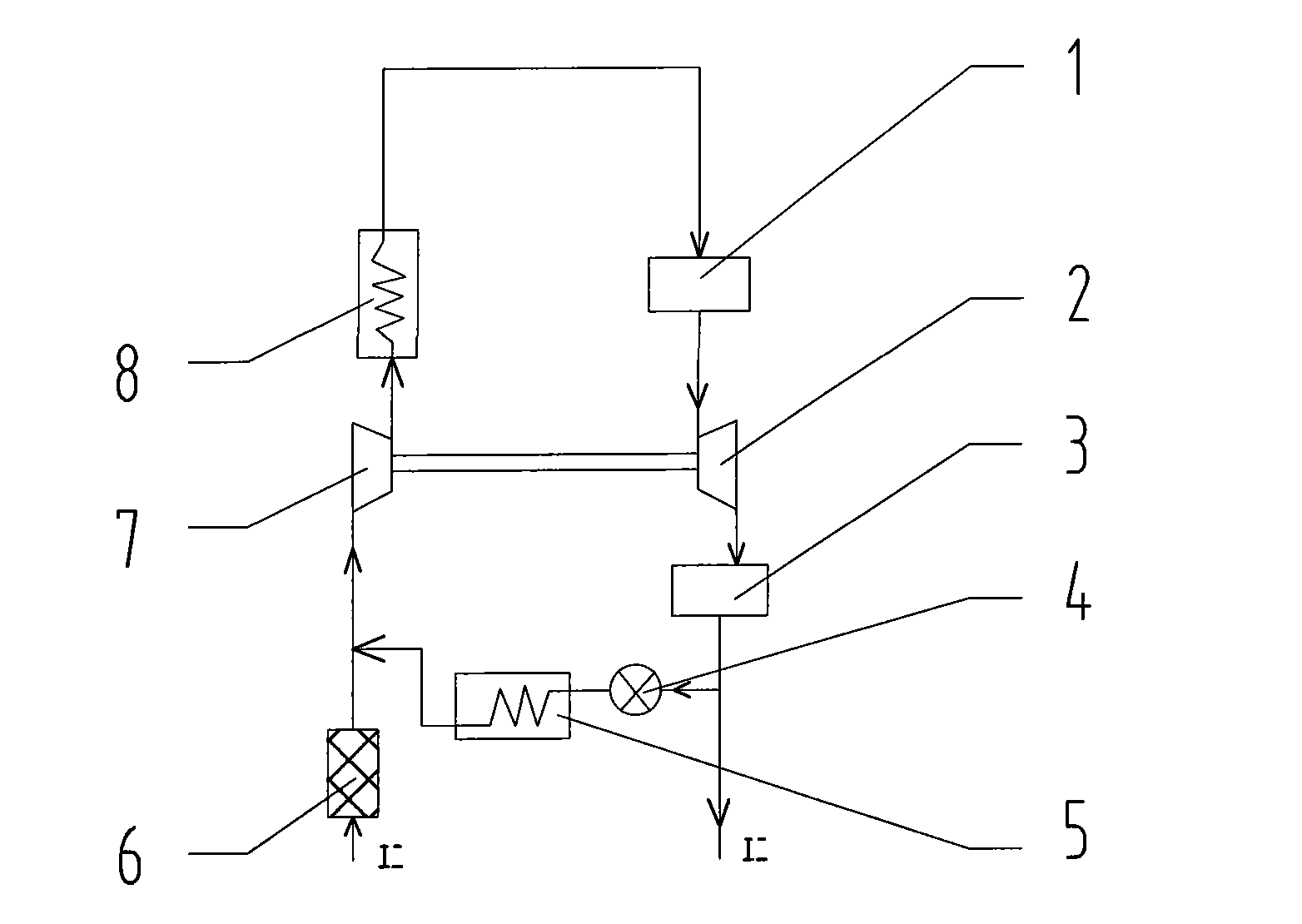

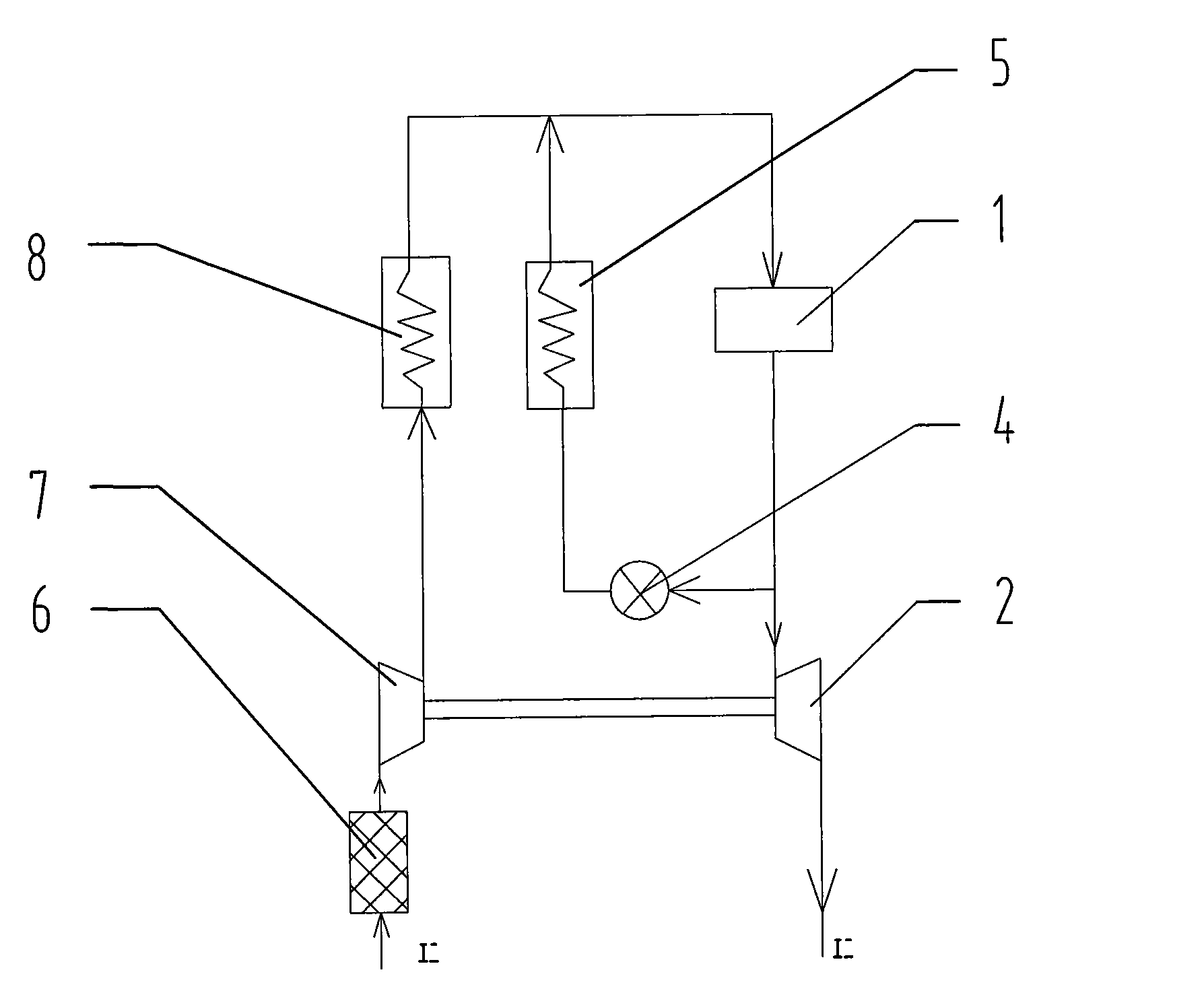

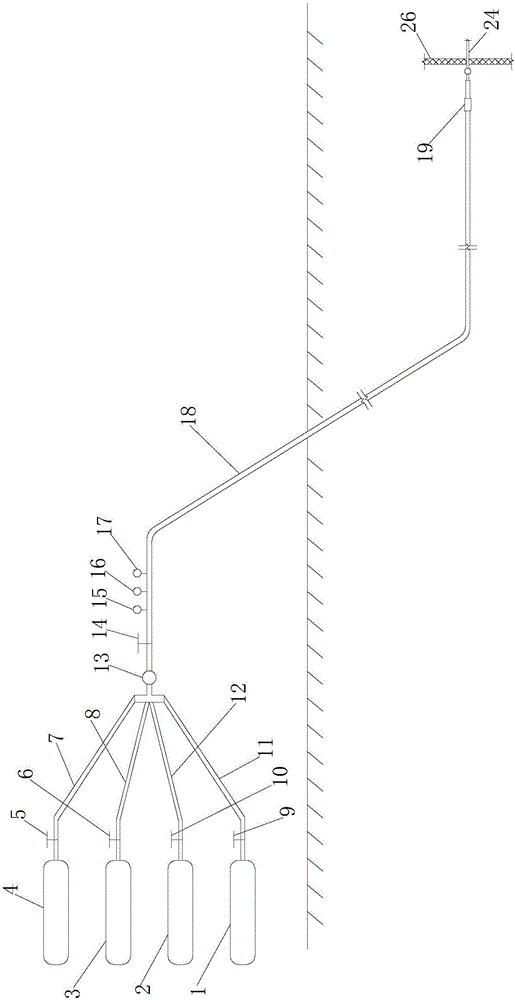

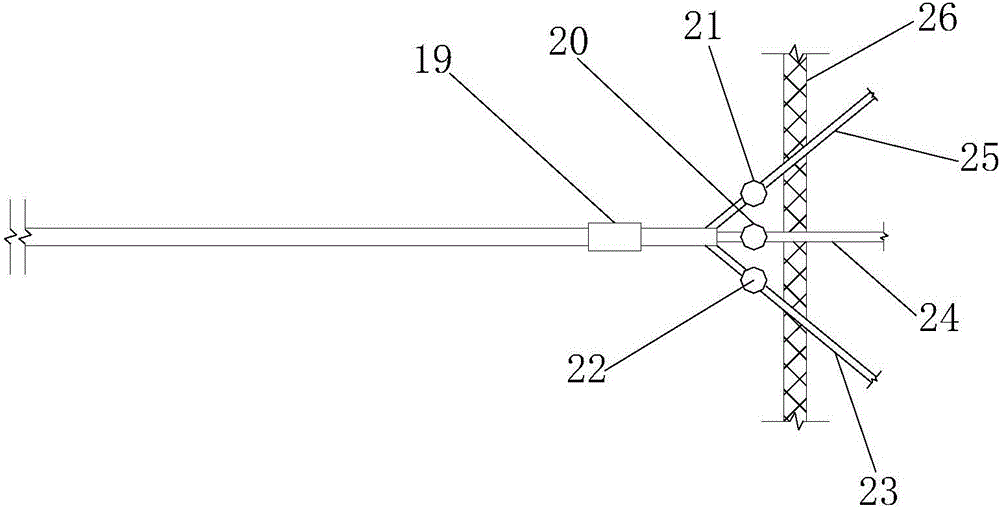

Mining liquid carbon dioxide pipeline conveying device and conveying method

InactiveCN106247169ASimple structureNovel and reasonable designDust removalFire preventionPressure riseLiquid state

The invention discloses a mining fire extinguishment liquid carbon dioxide long-distance pipeline conveying device. The device comprises a gas-state carbon dioxide storage tank , a liquid-state carbon dioxide storage tank and a conveying pipeline; a pressure stabilizing valve and a pressure meter are arranged at the end, located outside a mine body, of the conveying pipeline, the end, outside the mine body, of the conveying pipeline is communicated with the gas-state carbon dioxide storage tank, the upper end of the conveying pipeline is communicated with the liquid-state carbon dioxide storage tank, the end, located in the mine body, of the conveying pipeline is provided with a pressure control valve, and the end, located in the mine body, of the conveying pipeline is connected with a fire extinguishment pipe. Through the conveying device, the liquid-state carbon dioxide can be directly conveyed. The invention further discloses a conveying method. The method comprises the steps of arranging the conveying pipeline, arranging a fire extinguishment pipe, connecting the conveying pipeline with the gas-state carbon dioxide storage tank and the liquid-state carbon dioxide storage tank, injecting the gas-state carbon dioxide into the conveying pipeline for pressure rising, injecting the liquid-state carbon dioxide into the conveying pipeline for fire extinguishment and the like. Long-distance conveying of the liquid-state carbon dioxide can be simply, effectively and rapidly achieved.

Owner:CHINA ENERGY GRP NINGXIA COAL IND CO LTD +1

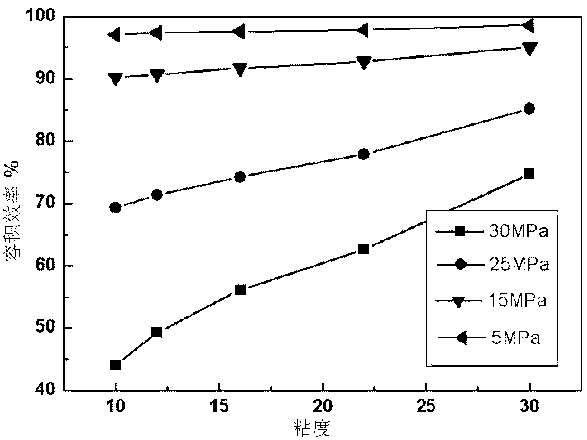

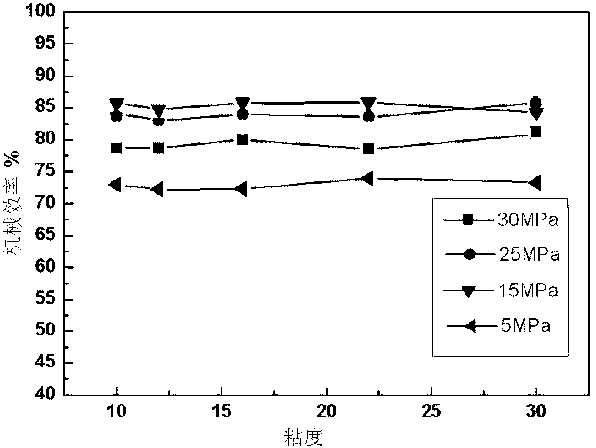

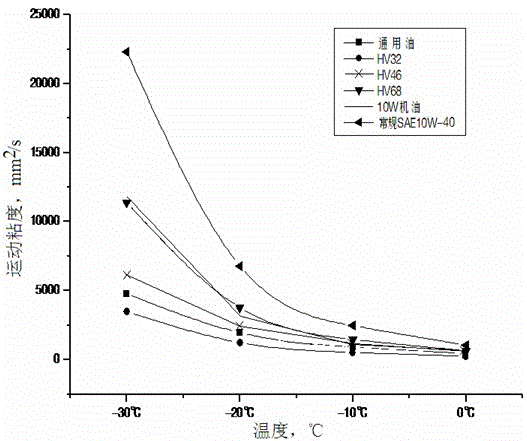

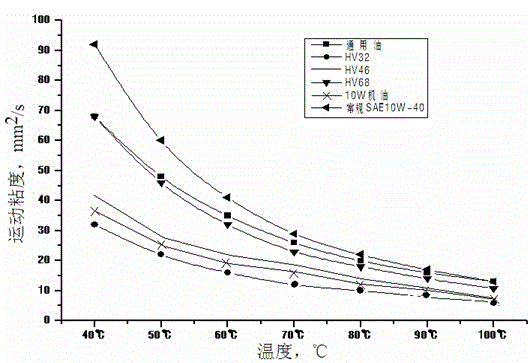

Efficient hydraulic oil with high viscosity indexes

The invention provides an efficient hydraulic oil with high viscosity indexes, belonging to the technical field of mechanical oil product. The efficient hydraulic oil comprises 75-85 wt% of base oil, 15-25 wt% of viscosity-index modifier and 0.5-2wt% of functional additive, wherein the kinematic viscosity of the hydraulic oil is 58 plus or minus 4mm<2> / s at the temperature of less than 40 DEG C, and the kinematic viscosity is 12 plus or minus 1mm<2> / s at the temperature of less than 100 DEG C, and the starting viscosity is less than or equal to 2156 mm <2> / s at the temperature of minus 20 DEG C, the viscosity index is 200 plus or minus 5, and the high-temperature high-shearing viscosity is more than or equal to 3.5 mm <2> / s. According to the efficient hydraulic oil with the high viscosity indexes disclosed by the invention, through improving the viscosity indexes, the usage temperature range is expanded, the shearing stability of the oil product is improved and the viscosity temperature stability of the oil product is guaranteed.

Owner:SHANGHAI SANY HEAVY IND

High temperature fireproof brick and preparation method thereof

The invention discloses a high-temperature refractory brick, which comprises the following components in weight portion: 10 to 12 portions of corundum powder, 6 to 8 portions of kaolin, 50 to 56 portions of Zircon sand, 13 to 16 portions of chromium dioxide, 8 to 10 portions of zirconium dioxide and 3 to 5 portions of water. The invention also discloses a technology for preparing the high-temperature refractory brick. The high-temperature refractory brick can tolerate the high temperature up to 2,100 DEG C and fully meet the working conditions of a high-temperature furnace, and has the advantages of stronger scouring and wearing resistance, good corrosion resistance and thermal shock resistance, and long service life. The preparation method adopts a unique twice baking technology to allow the ultra-temperature condition of the high-temperature refractory brick to fulfill super-high temperature conditions, and is simple and easy to realize.

Owner:宜兴市张泽工业炉材料厂有限公司

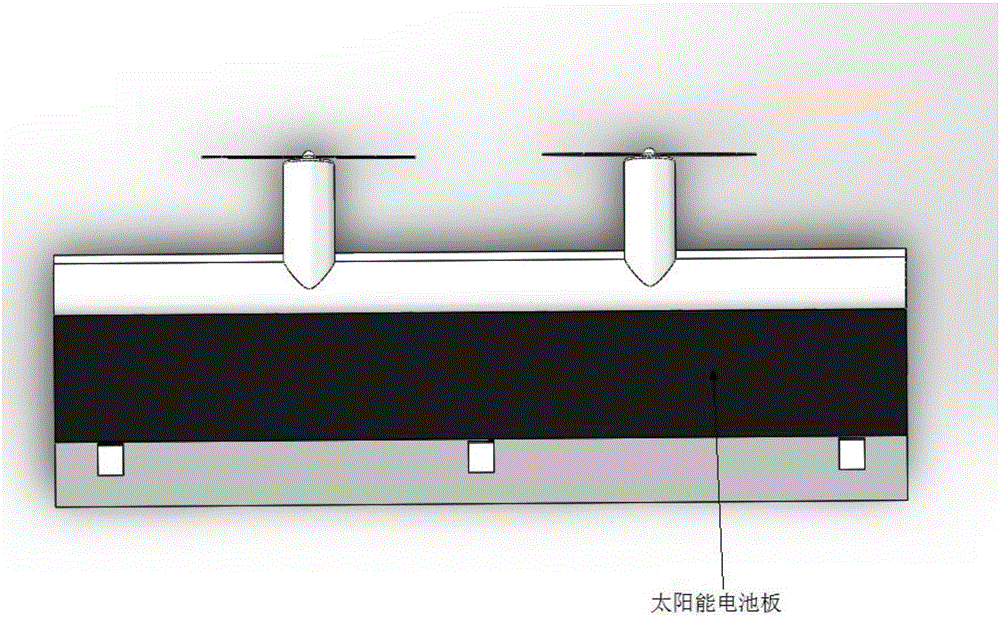

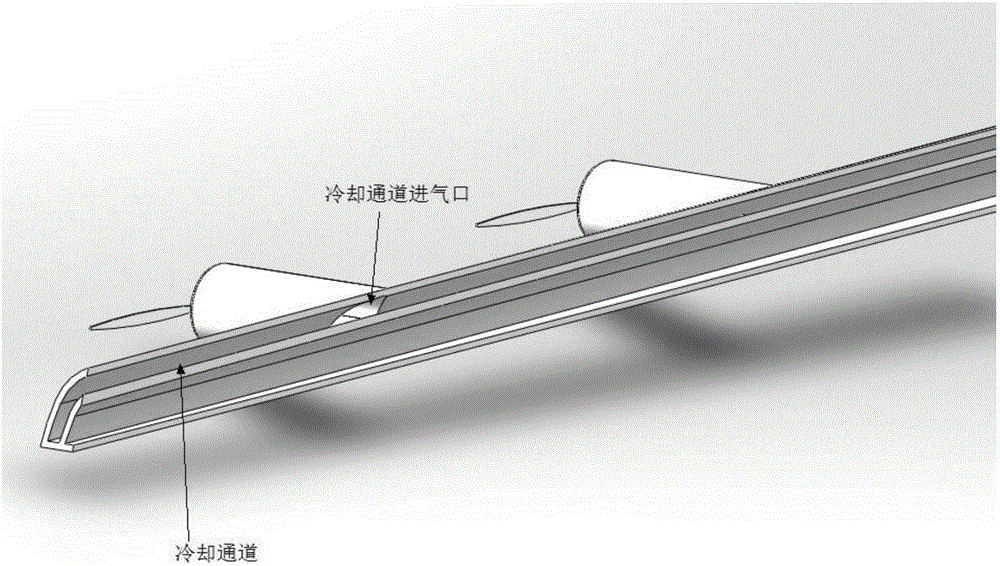

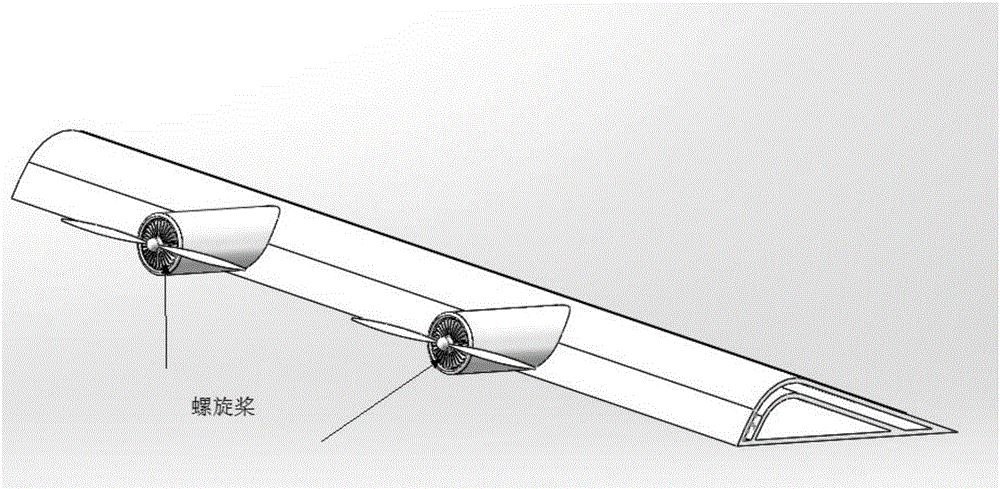

Joint heat radiation device for solar cell panel and propeller motor of high-altitude air vehicle

InactiveCN106828947AImprove aerodynamic efficiencyMeet working conditionsPower plant cooling arrangmentsEnergy efficient board measuresPropellerCells panel

The invention designs a device for the joint heat radiation of a solar cell panel and a propeller rear motor of a high-altitude air vehicle by utilizing a tail low-temperature high-speed airflow of a propeller of the air vehicle. According to the device, the heat exchange efficiency of a system can be improved by using a measure similar to forced convection heat radiation; the solar cell panel is enabled to meet a temperature needed by work; meanwhile, the heat radiation is also carried out through a fin to decrease the temperature of a centralized heat source propeller motor. In a sun irradiation condition, the temperature of the upper surface of the solar cell panel can reach 100 DEG C or above; the heat radiation efficiency is greatly reduced by low-density air at a 30,000-meter high altitude; therefore, in the severe working condition, the heat radiation design of a cell panel becomes very important. Through the way of carrying out convection heat radiation by using a wake flow of the propeller, the structural weight of a forced convection heat radiation fan can be omitted. Meanwhile, the inlet air drainage of the tail airflow of the propeller is carried out through a structure similar to an engine nacelle; the aerodynamic performance of the propeller can be also promoted to a certain extent; two things are achieved at one stroke.

Owner:BEIHANG UNIV

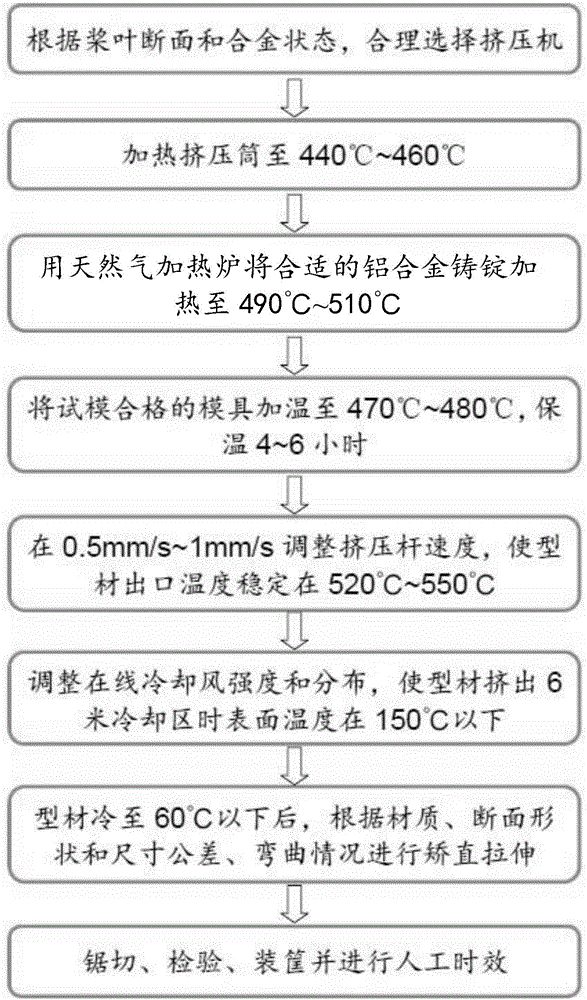

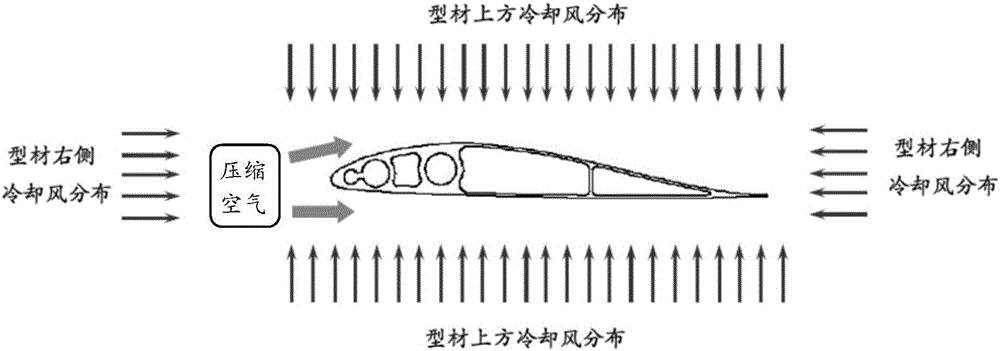

Aluminum alloy paddle profile and manufacturing process thereof

ActiveCN106391741AMeet working conditionsRealize mass productionExtrusion control devicesRotocraftHigh volume manufacturingIngot

The invention provides a manufacturing process of an aluminum alloy paddle profile. Hot extrusion forming is adopted, wherein an aluminum alloy cast ingot at the temperature of 490-510 DEG C is extruded through an extrusion barrel at the temperature of 440-460 DEG C to form a die at the temperature of 470-480 DEG C. The invention further provides an aluminum alloy paddle manufactured through the method. The manufacturing process is convenient to operate, simple and stable; and the aluminum alloy paddle profile manufactured through the method has excellent mechanical performance, meets various indexes of rotorcraft paddles, and can achieve mass production of the rotorcraft paddles.

Owner:SHANDONG NANSHAN ALUMINUM +1

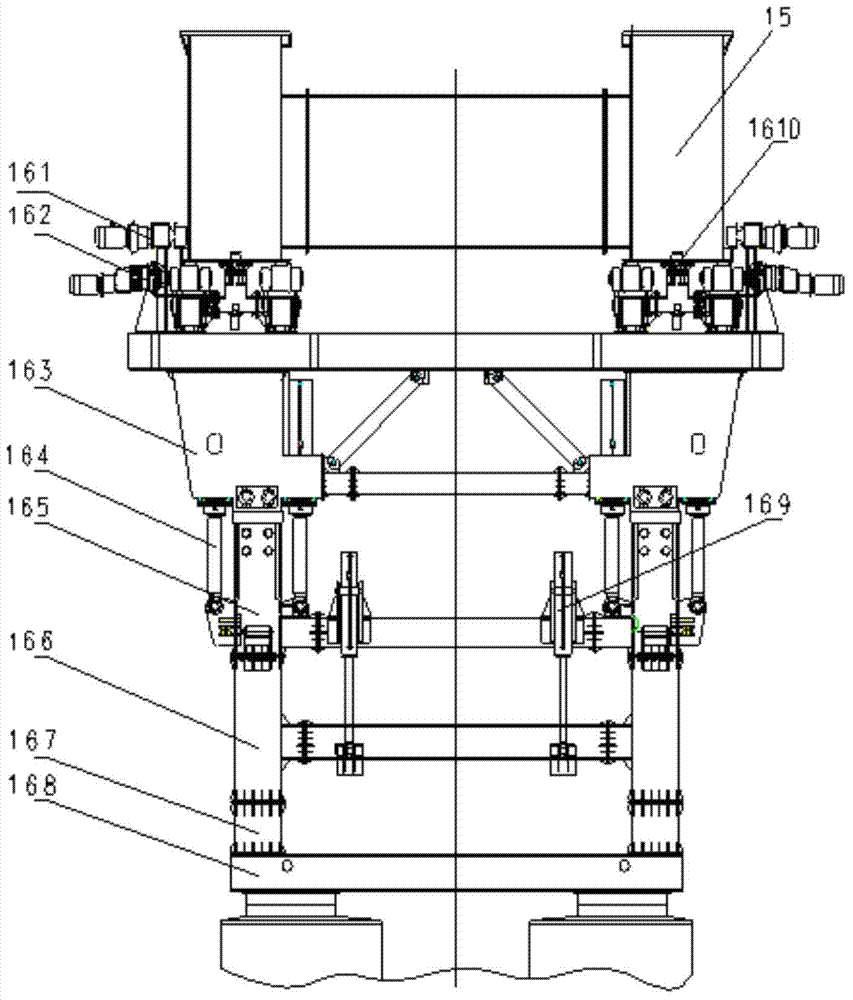

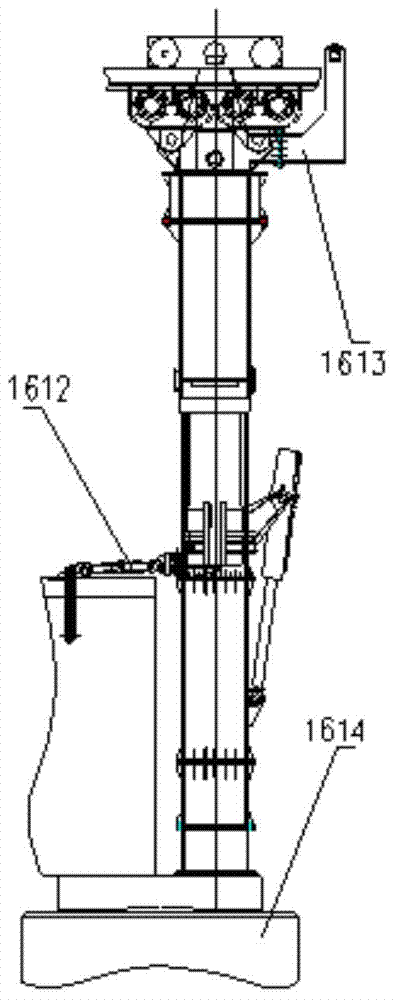

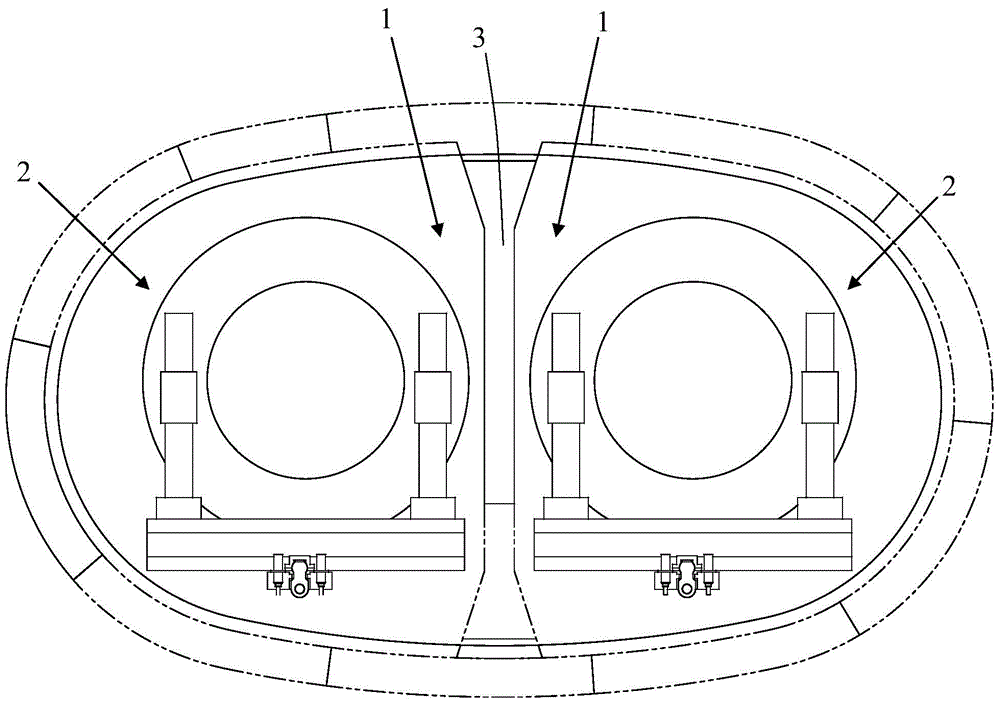

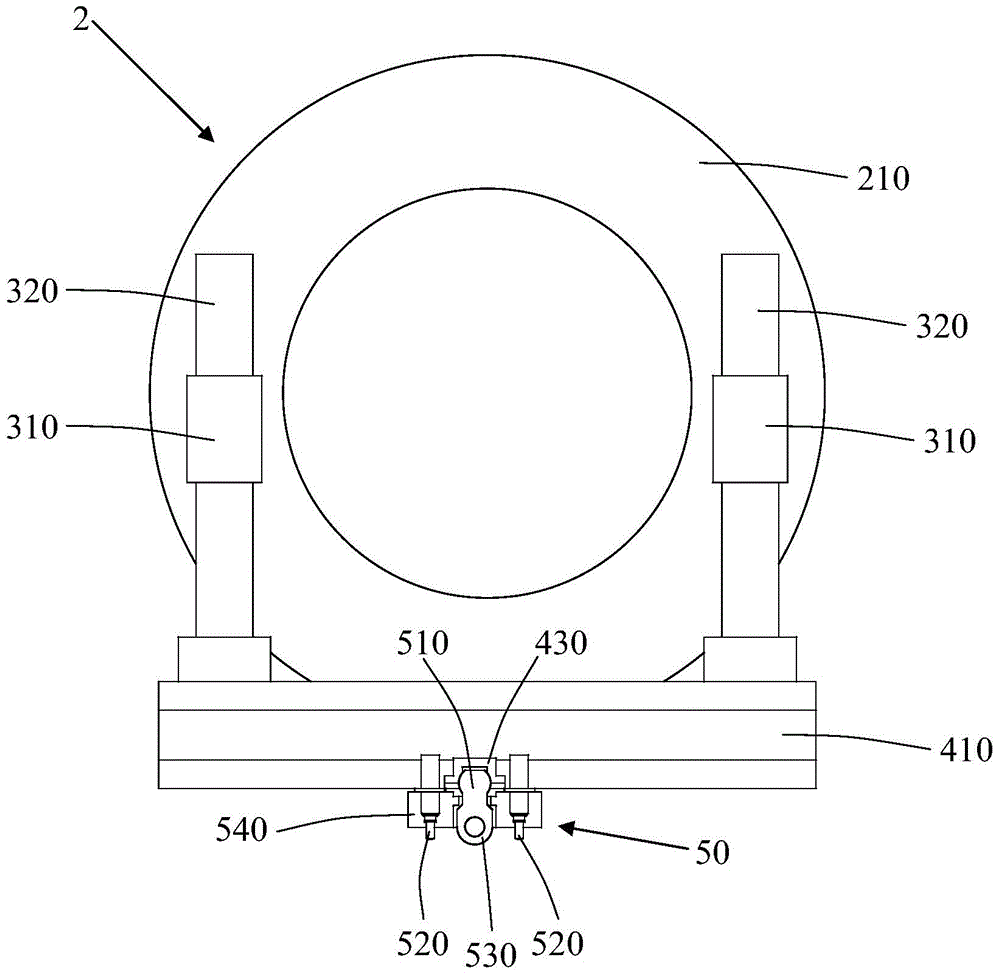

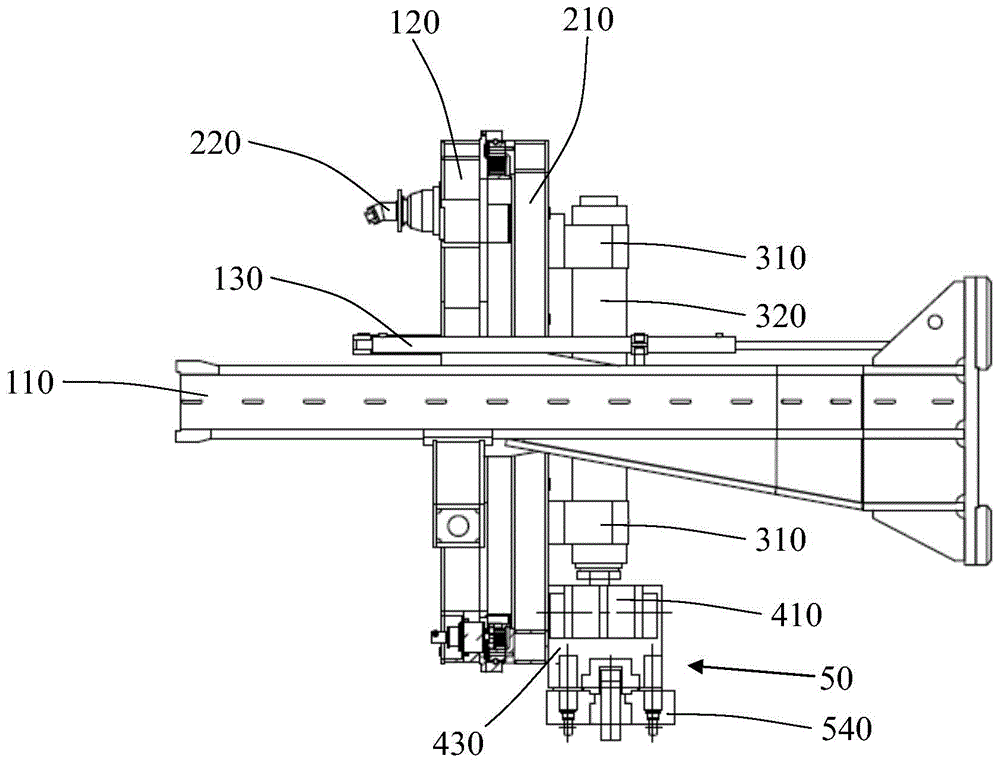

Segment assembling system for rectangular shield

ActiveCN104695975AEasy to solveSolve complexityUnderground chambersTunnel liningHorizontal translationHinge angle

The invention discloses a segment assembling system for a rectangular shield. The segment assembling system comprises two assembling machines, wherein a rectangular tunnel comprises two assembling space parts, and the two assembling machines are arranged in the two assembling space parts respectively; each assembling machine comprises an axial translation mechanism, a swing mechanism, a lifting mechanism, a horizontal translation mechanism and a fine adjusting mechanism, the axial translation mechanism comprises two axial guide rails arranged in an axis direction of the shield as well as fixed disks which are arranged on the two axial guide rails and can move along the axial guide rails, the swing mechanism comprises rotary disks which are arranged on the fixed disks and can rotate around the fixed disks in the axis direction of the shield, the lifting mechanism comprises two guide seats symmetrically arranged on the rotary disks as well as lifting columns which are arranged in the guide seats and can move in axis directions of the guide seats, the horizontal translation mechanism comprises racks fixed on the two lifting columns in the direction perpendicular to the axis directions of the guide seats, two horizontal guide rails arranged in the racks and lifting frames which are arranged on the two horizontal guide rails and can move along the horizontal guide rails, the fine adjusting mechanism comprises spherical hinge oil cylinders retractably arranged at bottoms of the lifting frames as well as a plurality of deviation adjusting oil cylinders, lifting appliances are arranged on the spherical hinge oil cylinders, and cushion blocks are arranged on the deviation adjusting oil cylinders.

Owner:SHANGHAI TUNNEL ENG CO LTD +2

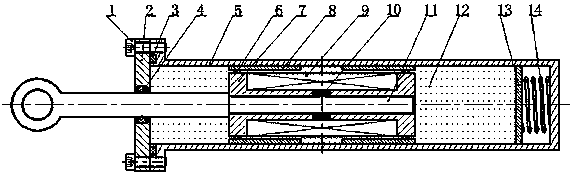

Novel anti-settling magnetorheological fluid damper

InactiveCN108561486AExtended service lifeImprove stabilitySpringsNon-rotating vibration suppressionSemi activePower flow

The invention provides a novel anti-settling magnetorheological fluid damper. The novel anti-setting magnetorheological fluid damper comprises a shell and a piston arranged in the shell. The shell isfilled with magnetorheological fluid. Annular excitation coils are embedded into the inner and outer surfaces of the piston. An annular permanent magnet embedded into the piston is arranged on the inner side of each excitation coil. The periphery of the piston is sleeved with a magnetic conducting ring. The magnetic conducting ring is connected with the piston through a connecting rod. The magnetic conducting ring is in clearance fit with the inner wall of the shell. The damper not only can realize variable-damping semi-active control to meet the working condition application, but also can fully utilize the maximum magnetic field area originally acting in the piston shell, a traditional magnetic conductive closed-loop magnetic circuit is changed so that the damper can act on the magnetorheological fluid, the anti-settling property of the magnetorheological fluid is enhanced, and the magnetic energy heating of a cylinder barrel is reduced. By the adoption of the embedded permanent magnet design, it is ensured that the damper also has the magnetic field output under the non-current condition, the anti-settling purpose is realized through the action of a magnetic field, the service life of the damper is prolonged, and longer stability performance is maintained; and meanwhile, the embedding of permanent magnets can also make the damper perform bidirectional adjustment of magnetization and demagnetization.

Owner:FUZHOU UNIV

Special working roller for tin-plating finishing machine and manufacturing method thereof

ActiveCN110656294AEfficient crushingIncreased effectiveness of high temperature homogenizationRevolution surface grinding machinesIncreasing energy efficiencyIngotImpurity

The invention discloses a special working roller for a tin-plating finishing machine and a manufacturing method thereof. The working roller is prepared from the following chemical components in percentage by weight: 0.70-0.90% of carbon, 0.40-0.80% of silicon, 0.20-0.50% of manganese, less than or equal to 0.020% of phosphor, less than or equal to 0.008% of sulfur, 4.00-4.90% of chromium, 0.20-0.60% of nickel, 0.10-0.50% of molybdenum, 0.05-0.30% of vanadium and the balance iron and inevitable impurities. The manufacturing method for the working roller comprises the following steps of smeltingelectroslag ingot blank, forging roller blank, preparing for thermal treatment, performing final thermal treatment, and finish-machining. Problems such as component segregation, carbide segregation and the like are effectively controlled by optimizing the components and optimizing the manufacturing links, so that abnormal grains caused by follow-up chromium-plating or roughening due to componentsegregation or carbide segregation are avoided, and therefore, working condition requirements of the tin-plating finishing machine are met.

Owner:BAOSTEEL ROLL SCI & TECH

Lubricating oil

The invention provides lubricating oil, which belongs to the technical field of oil products for machines, and comprises 75-85 wt % of base oil and 10-20 wt % of a viscosity index improver. According to the invention, the used oil type is reduced, thereby facilitating the unified management and the effective application of resources; the viscosity index is greatly increased, an effect of low-temperature low viscosity and high-temperature and high viscosity is achieved, the working conditions of a diesel engine and a hydraulic oil system are satisfied, and the problem of difficult starting at low temperature and low efficiency at high temperature is reduced. When the lubricating oil is used as hydraulic oil, the operating efficiency and the economy of fuel oil can be improved, and various performances are greatly improved and the service life is prolonged greatly.

Owner:SHANGHAI SANY HEAVY IND

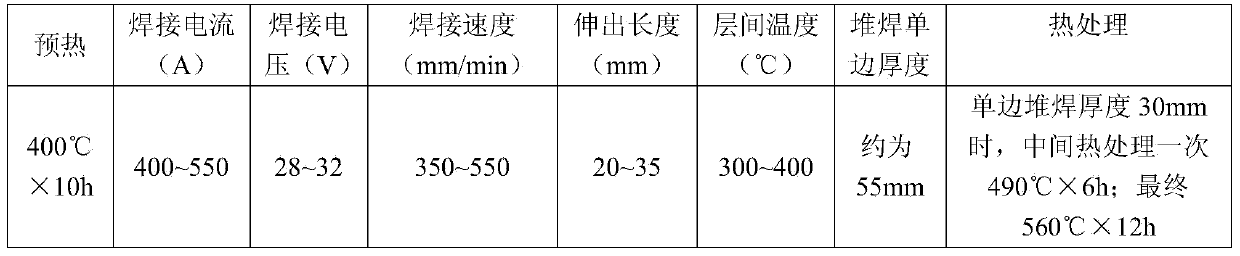

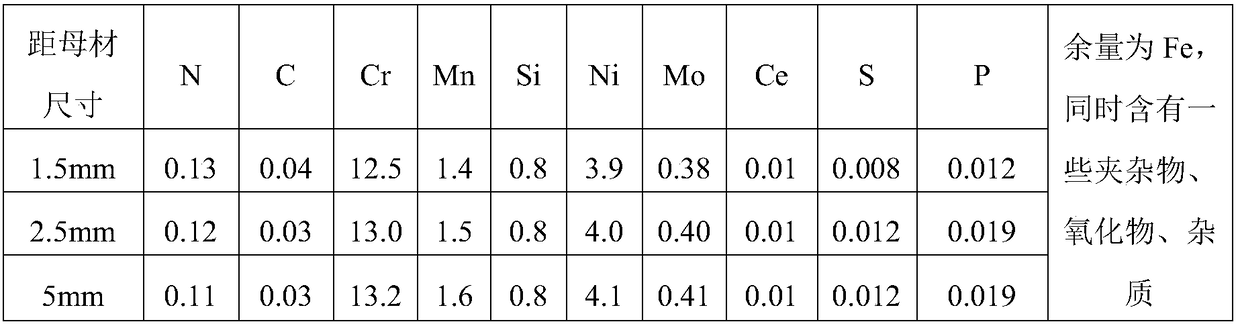

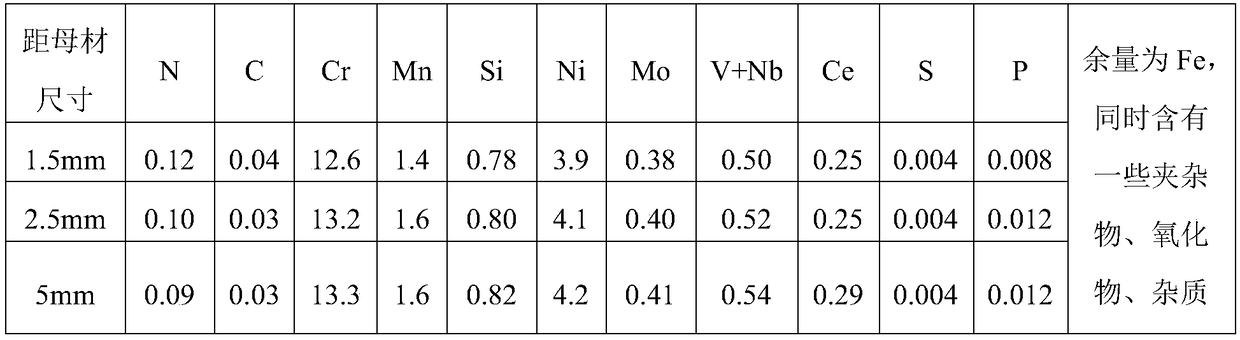

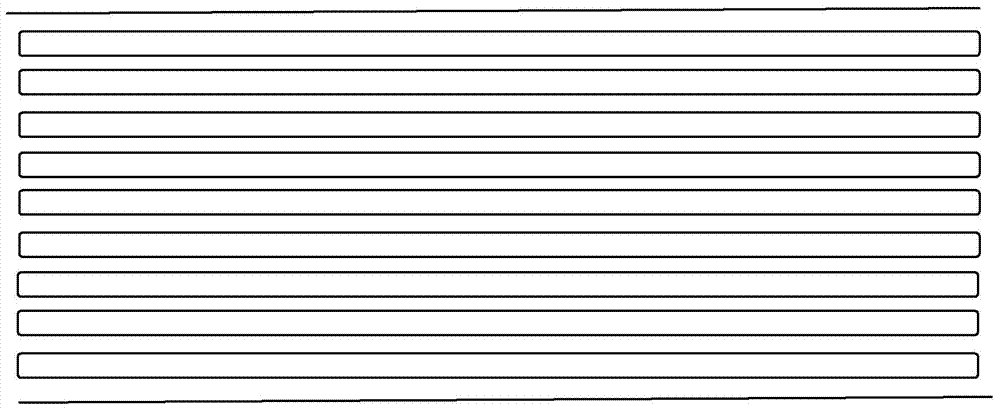

Submerged-arc surfacing flux-cored wire and technology for composite production and reproduction of continuous casting rollers

ActiveCN109014654ASolve the lack of hardnessAvoid the pitfalls of insufficient ingredientsArc welding apparatusWelding/cutting media/materialsRare-earth elementHardness

The invention discloses a submerged-arc surfacing flux-cored wire and a technology for composite production and reproduction of continuous casting rollers. The deposited metals of the flux-cored wirecomprises components in percentage by weight as follows: 0.02%-0.3% of C, 0.8%-2.8% of Mn, 0.1%-1.0% of Si, 12.0%-15.0% of Cr, 0.3%-2.0% of Mo, 1.5%-5.0% of Ni, 0.01%-1.5% of rare-earth elements, 0-1.2% of V and Nb, 0-0.16% of N, less than 0.03% of S, less than 0.03% of P and the balance of Fe. The technology comprises steps as follows: (1) rollers are turned into the size before surfacing; (2) the rollers are detected before surfacing; (3) the surfacing technology is determined, and technological parameters are determined according to the surfacing technology; (4) single-layer surfacing forming is performed; (5) components, hardness and structures of different positions after surfacing are detected. The technology is good in technological property and has the high cost performance.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

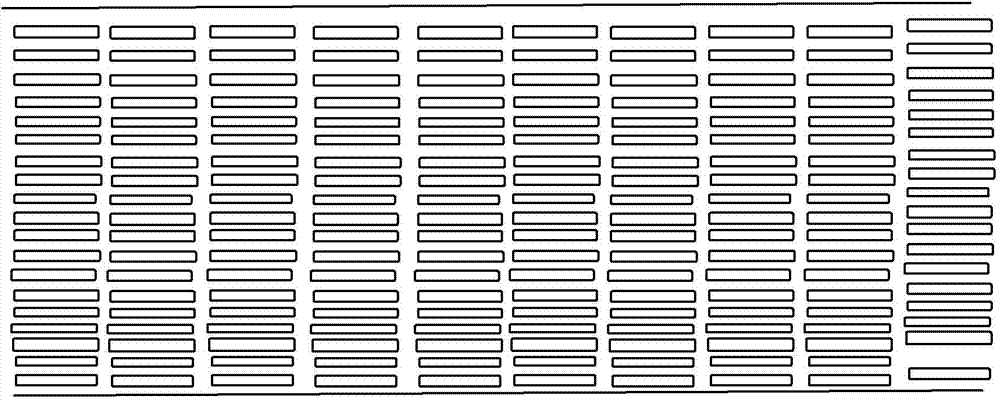

Novel on-line defoaming perfusion equipment

PendingCN108247925AAchieve vacuum filtration and defoaming effectNo external air interventionColloidPerfusion

The invention discloses novel on-line defoaming perfusion equipment which comprises a defoaming cooling device for a material A, a defoaming cooling device for a material B, a mixing unit and a bufferunit. The material A is defoamed and cooled at vacuum by the defoaming cooling device for the material A and then is sent to the mixing unit, and the material B is defoamed and cooled at vacuum by the defoaming cooling device for the material B and then is also sent to the mixing unit. After being mixed in the mixing unit, the material A and the material B are sent to the buffer device and then are sent out to a perfusion port by the buffer device for perfusing. The novel on-line defoaming perfusion equipment has the characteristics that a colloid and a curing agent are filtered, foamed, cooled and mixed at vacuum, and no external air is intervened in the whole process; all links have pressure, temperature and flow monitoring, and a system can conduct automatic blending and meets the demand of working condition; the heating and cooling response speed is high, and the fast rising and falling of the colloid problem is fully ensured; and the colloid and the curing agent can be defoamed on line, so that continuous pouring is realized.

Owner:SINPA INDAL AUTOMATION

High-strength high-toughness metal prefabricated material and preparation method thereof

InactiveCN105441777AHigh strengthReduce thicknessMetallic material coating processesHigh power lasersToughening

The invention discloses a high-strength high-toughness metal prefabricated material and a preparation method thereof. Metal or alloy serves as a substrate of the material. Heterogeneous isomerous reinforced phases obtained through selected area strengthening and toughening treatment are distributed on the substrate. Under the circumstance that the weight of the substrate of the material is essentially unchanged, the malleability and weldability of a metal equilibrium-state structure are achieved, and the strength and abrasion resistance of a metal metastable-state structure are also achieved. According to the preparation method, energy beams / fields which comprise high-power laser beams or electron beams, ion beams and an induction heat source are adopted, and the energy beams / fields conduct the selected area strengthening and toughening treatment on the metal or the alloy to obtain the heterogeneous isomerous reinforced phases on the substrate. On the premise that properties of components are not degraded, the thickness or the dead weight of the components is greatly reduced, and thus the high-strength high-toughness metal prefabricated material can be widely applied to industrial fields such as automobiles, aircrafts, ships and trains hopefully.

Owner:武汉飞能达激光技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com