Large-tonnage beam erection and transportation system in tunnel and beam erection span change procedure thereof

A large-tonnage, tunnel-inside technology, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve problems such as difficulties in erecting beams at the entrance and exit of tunnels, erection of box girders in tunnels with difficult bridge machines, etc., and increase equipment stability , High construction efficiency, reduce the effect of side bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0071] The specific implementation of the beam erection process of the present invention is as follows:

[0072] The basic beam erection operation method is as follows:

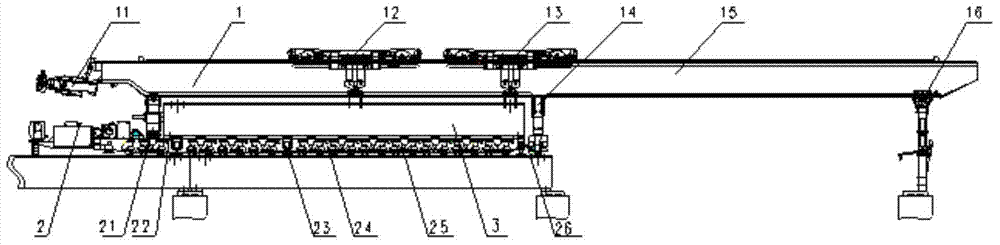

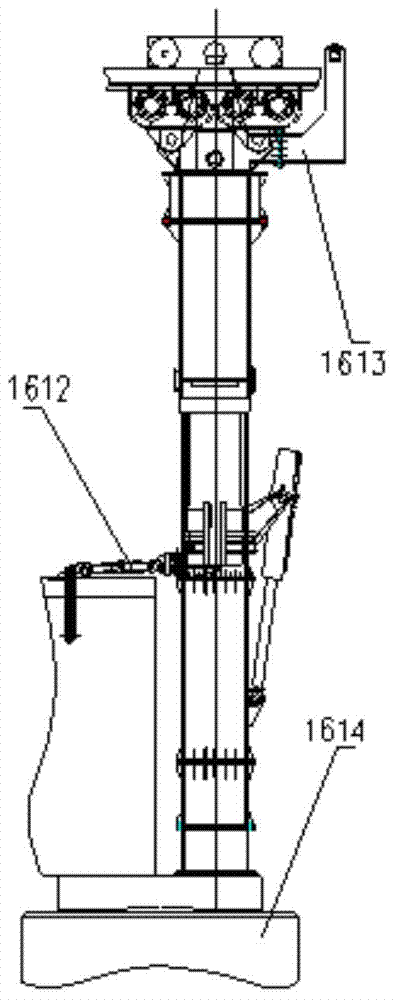

[0073] Step S101, such as Figure 6A As shown, when the beam transport vehicle 2 carries the girder piece 3 to feed the beam, the rear outrigger 11 of the bridge erecting machine is turned over to allow the beam feeding channel. At this time, the bridge erecting machine adopts the front outrigger 16 and the middle outrigger 14;

[0074] Step S102, such as Figure 6B As shown, when the feeding beam is in place, the telescopic legs 21 of the beam transport vehicle are supported on the lower cover plate of the main girder 15 of the bridge erecting machine, and are connected by bolts to form the rear support of the bridge erecting machine. The two trolleys 12 and 13 walk to the position of taking the beam;

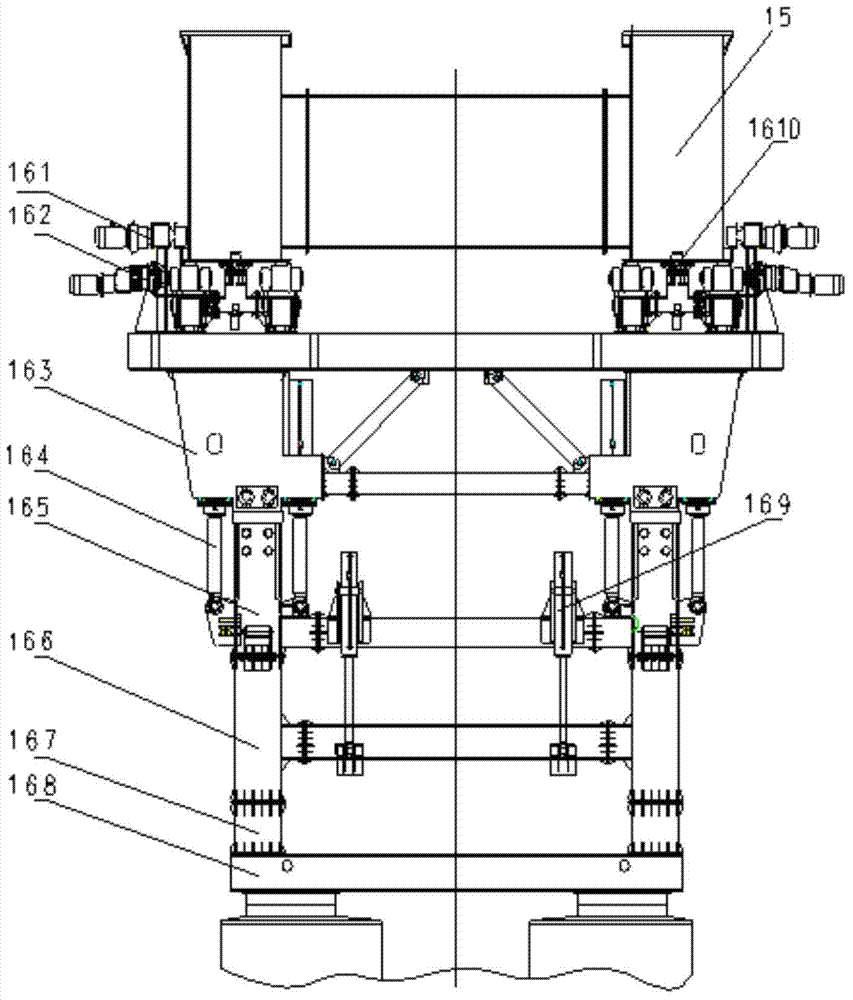

[0075] Step S103, such as Figure 6C As shown, the two-stage telescopic columns 146 and 148 on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com