Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

235 results about "Natural gas fuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natural gas, a fossil fuel composed of mostly methane, is one of the cleanest burning alternative fuels. It can be used in the form of compressed natural gas (CNG) or liquefied natural gas (LNG) to fuel cars and trucks.

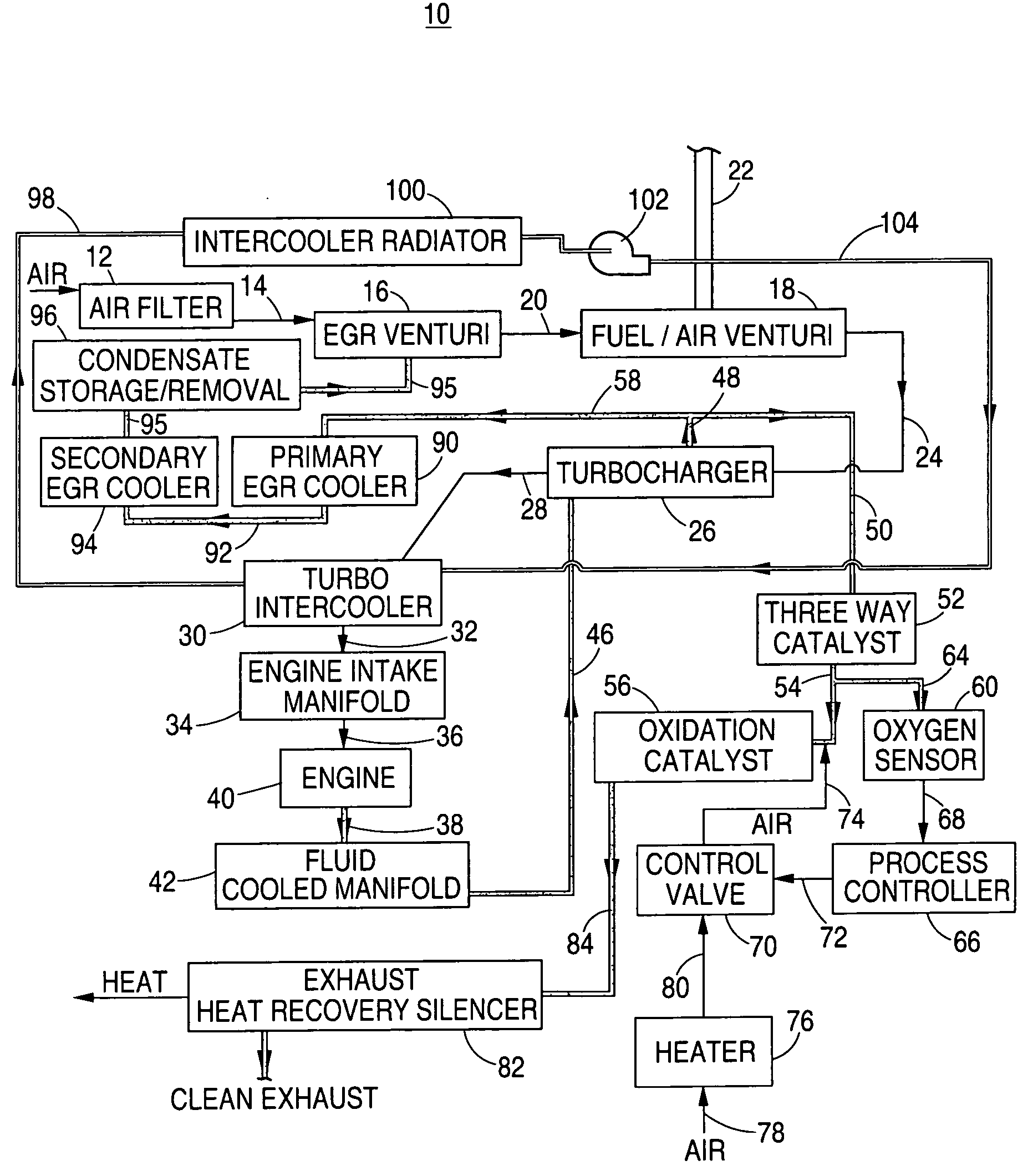

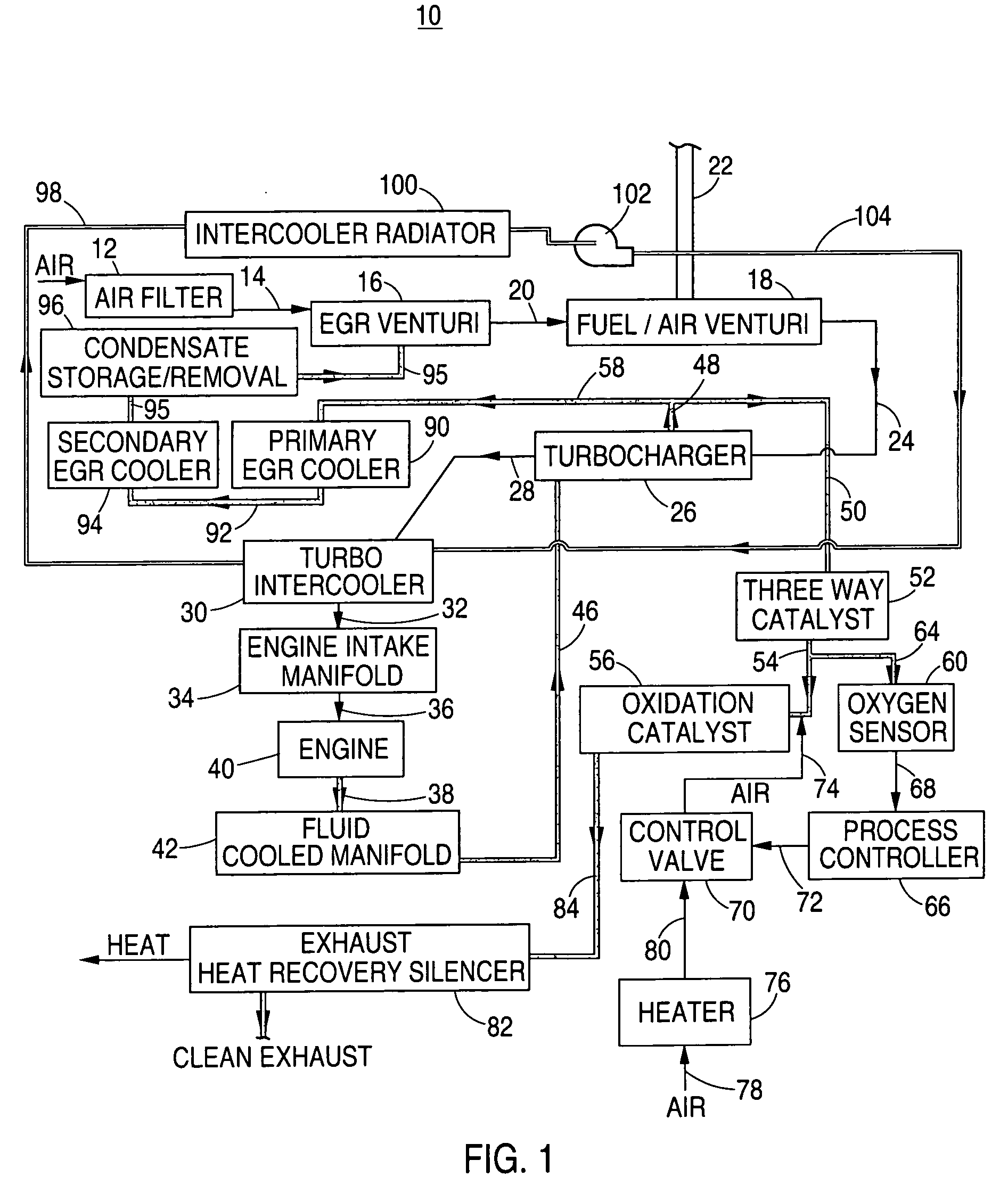

Air flow regulation system for exhaust stream oxidation catalyst

InactiveUS20060179824A1Improve oxidation capacityMinimize degradationNon-fuel substance addition to fuelInternal combustion piston enginesStream flowCogeneration

An air flow regulation system for enhancing the performance of oxidation catalyst in the exhaust stream of an internal combustion engine is provided wherein air flow into the exhaust upstream of an oxidation catalyst is dynamically controlled via a controlled feedback loop to ensure sufficient oxygen availability to induce enhanced oxidation catalyst performance while simultaneously limiting the exhaust cooling effect of the incoming air stream and the associated loss of catalytic conversion performance. The modulation of air temperature and flow into the exhaust gas stream of a reciprocating internal combustion natural gas fuel engine upstream of an oxidation catalyst is regulated such that oxidation of carbon monoxide, hydrocarbons, and ammonia is achieved to a level beyond the levels attainable and maintainable with a catalyst strategy that relies only upon pre-combustion air / fuel ratio management. In one aspect, the modulation of air flow into the exhaust is via an electronically controlled feedback loop. In another aspect, the induced air is heated to assure catalyst performance and retard the loss of recoverable heat from the exhaust stream for combined heat and power applications.

Owner:CHAPEAU

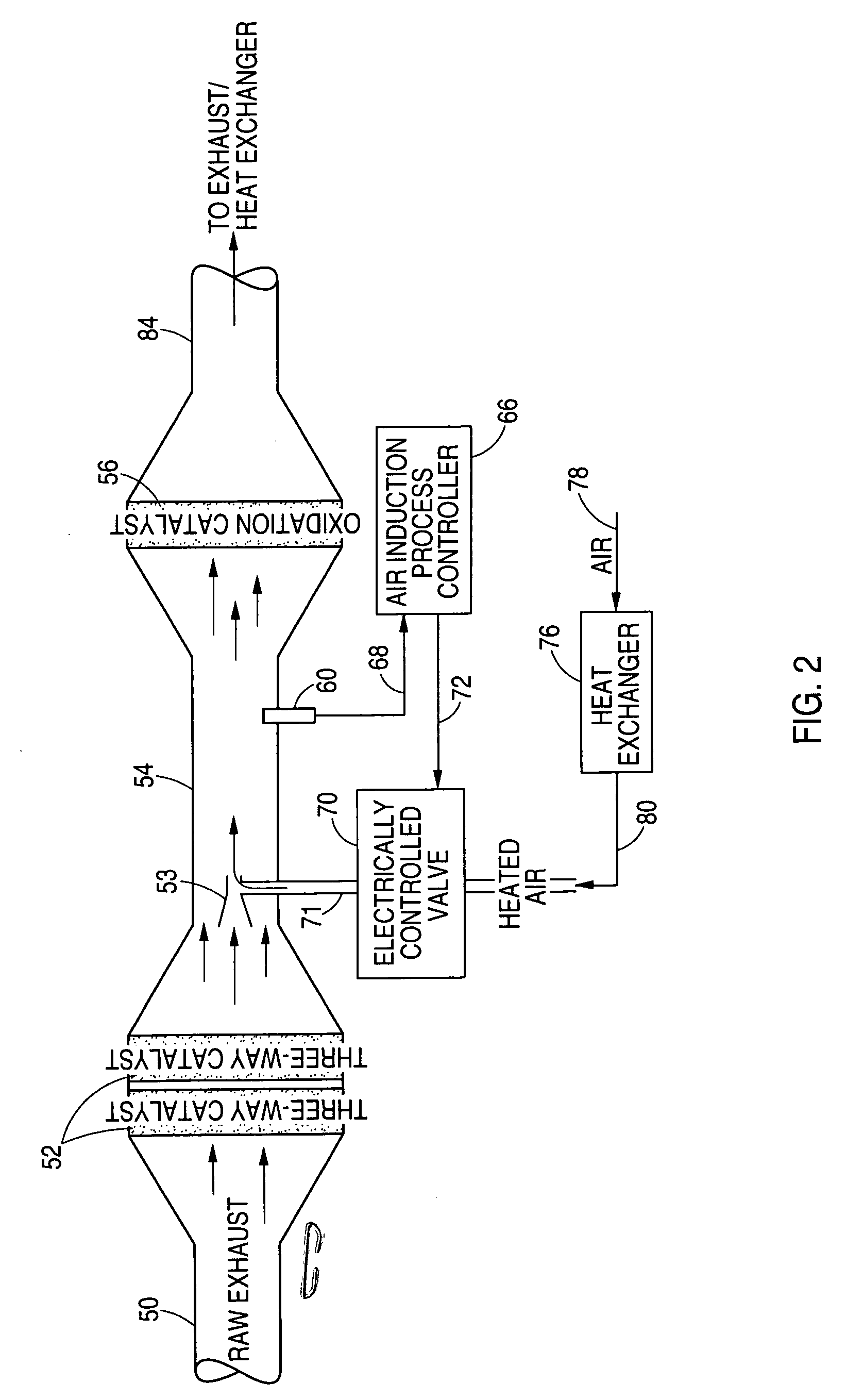

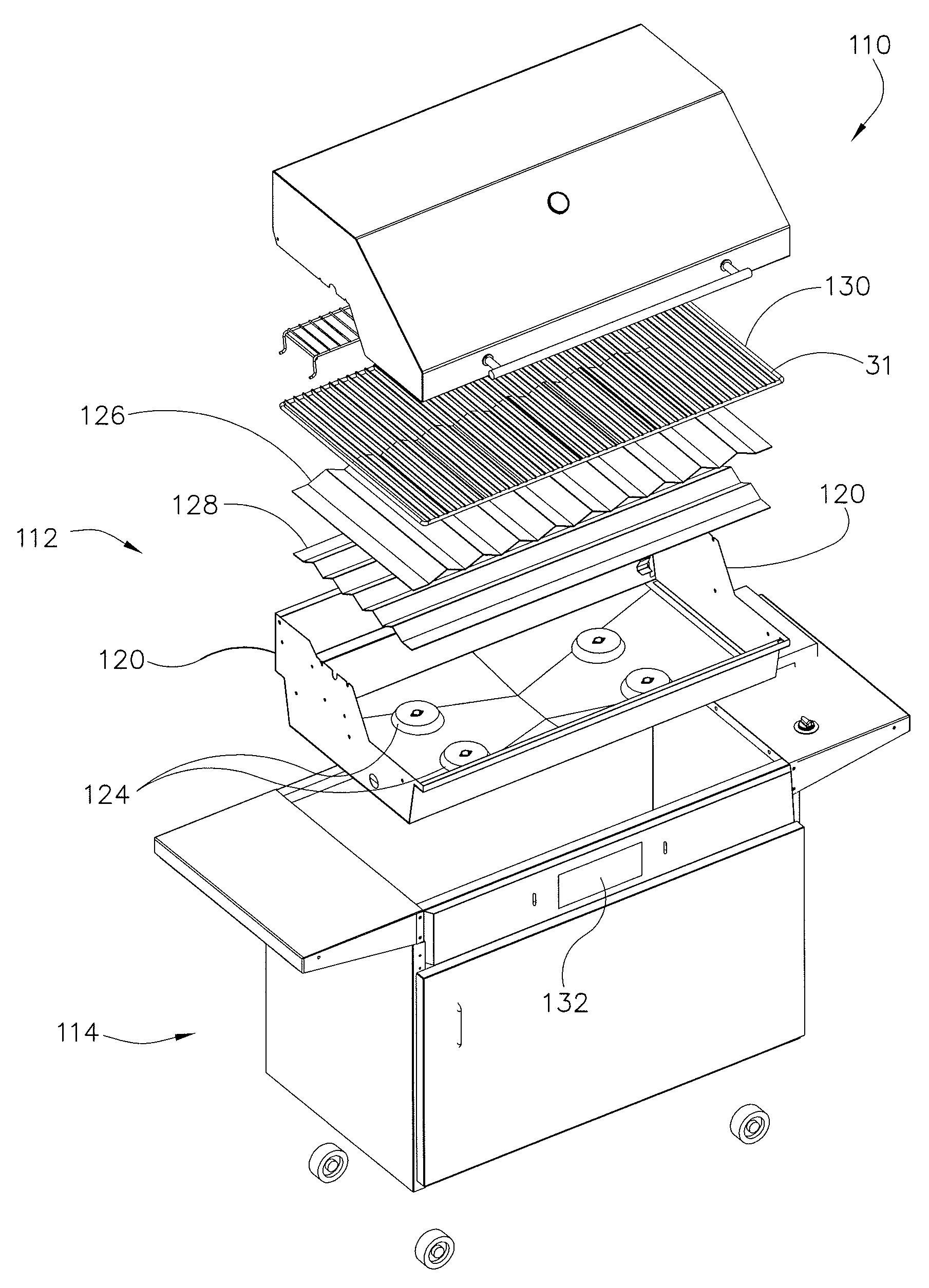

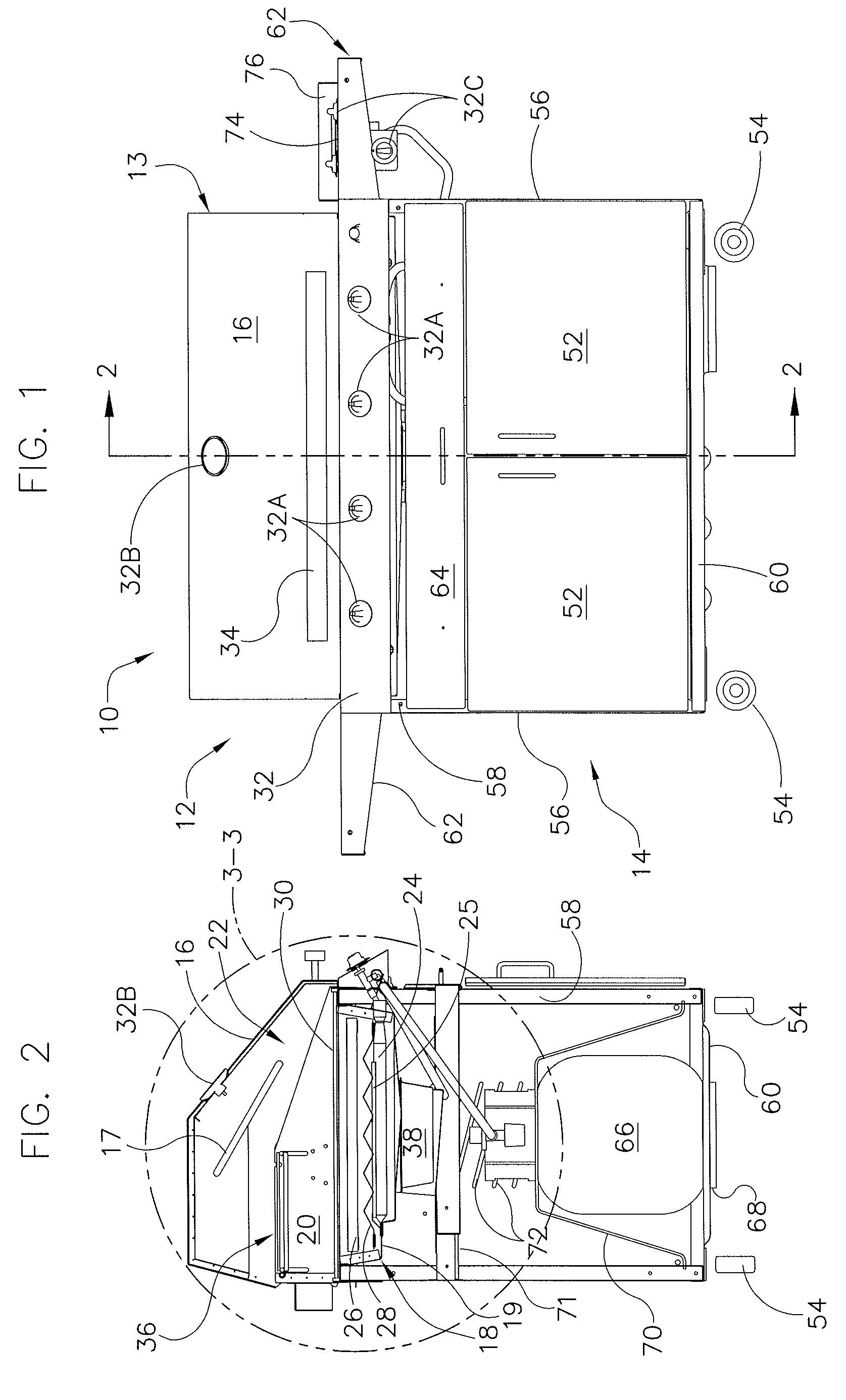

Modular portable grill

InactiveUS7798139B2Easy to controlImprove protectionStoves/ranges foundationsCombustion-air/flue-gas circulation for stovesTemperature controlCombustor

A modular portable gas grill including an energy management system for even temperature control, enhanced flavor devices, and electronic, electro-mechanical, or mechanical controls is provided. The grill includes a touch control system including sliders or knobs providing efficient, precise and accurate control. Heat and flame deflecting shields provide an improved air draft, heat, and flavoring system and can be removed for cleaning. Modular design construction and a quick-connect gas manifold permit the addition of additional components at a later date such as a rotisserie, and a smoke chute for flavoring. Burner shields protect the burner and flame from greases and liquids. The grill also features the ability to easily convert between propane and natural gas fuel and an electronic reigniting system providing individualized control to the burners. The grill also features a dual fuel mode giving a user the ability to use propane or natural gas along with charcoal or other solid fuel.

Owner:HAIER US APPLIANCE SOLUTIONS INC D B A GE APPLIANCES

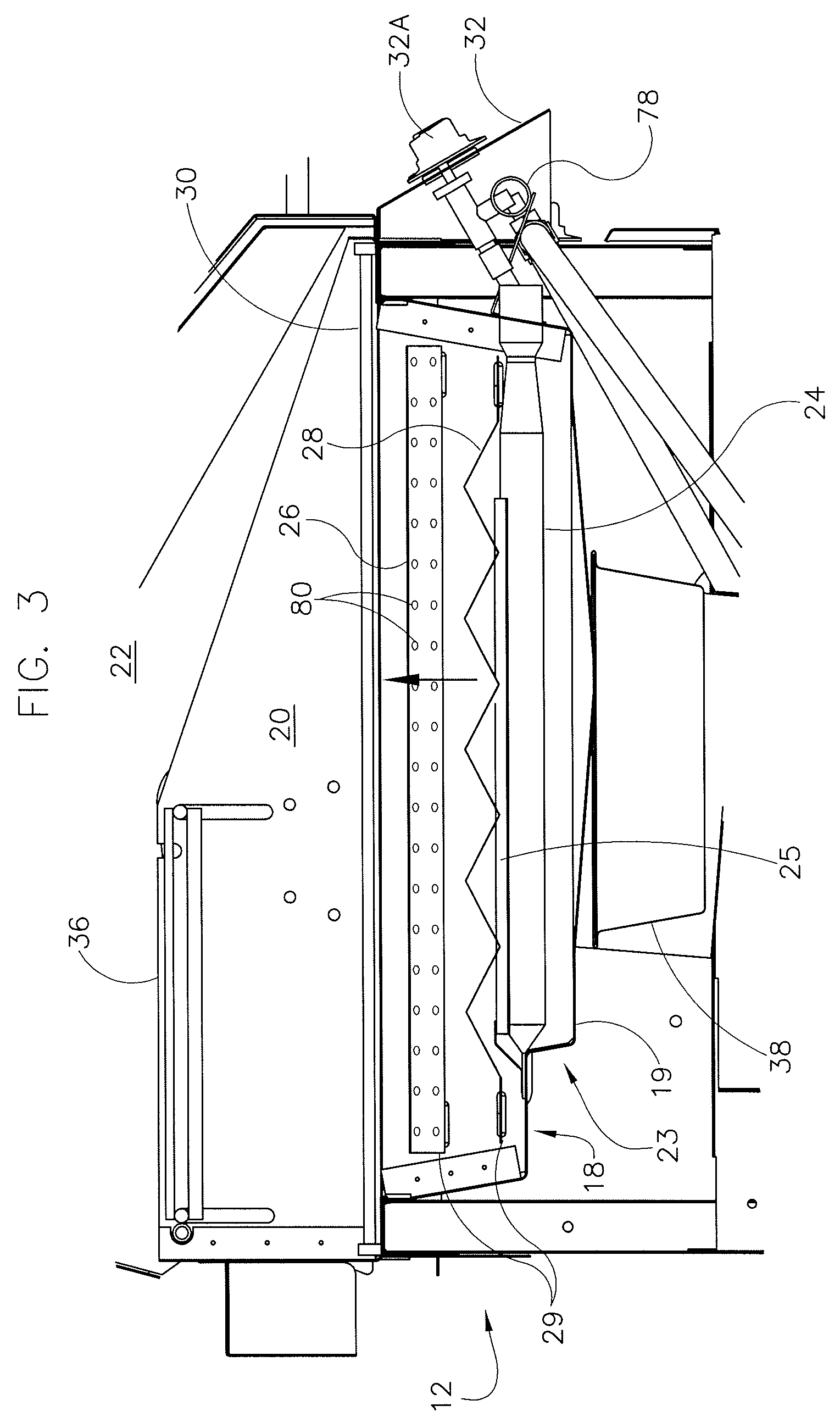

Separation of hydrogen sulfide from natural gas

A process for increasing the selectivity of an alkanolamine absorption process for selectively removing hydrogen sulfide (H2S) from a gas mixture which also contains carbon dioxide (CO2) and possibly other acidic gases such as COS, HCN, CS2 and sulfur derivatives of C1 to C4 hydrocarbons, comprises contacting the gas mixture with a liquid absorbent which is a severely sterically hindered capped alkanolamine or more basic sterically hindered secondary and tertiary amine. The improvement in selectivity is achieved at the high(er) pressures, typically least about 10 bara at conditions nearing the H2S / CO2 equilibrium at which CO2 begins to displace absorbed hydrosulfide species from the absorbent solution.

Owner:EXXON RES & ENG CO

Modular Portable Grill

InactiveUS20070028912A1Fast circulationFaster cooking timeDomestic stoves or rangesWater heatersPersonalizationEngineering

A modular portable gas grill including an energy management system for even temperature control, enhanced flavor devices, and electronic, electromechanical, or mechanical controls is provided. The grill includes a touch control system including sliders or knobs providing efficient, precise and accurate control. Heat and flame deflecting shields provide an improved air draft, heat, and flavoring system and can be removed for cleaning. Modular design construction and a quick-connect gas manifold permit the addition of additional components at a later date such as a rotisserie, and a smoke chute for flavoring. Burner shields protect the burner and flame from greases and liquids. The grill also features the ability to easily convert between propane and natural gas fuel and an electronic reigniting system providing individualized control to the burners. The grill also features a dual fuel mode giving a user the ability to use propane or natural gas along with charcoal or other solid fuel.

Owner:HAIER US APPLIANCE SOLUTIONS INC D B A GE APPLIANCES

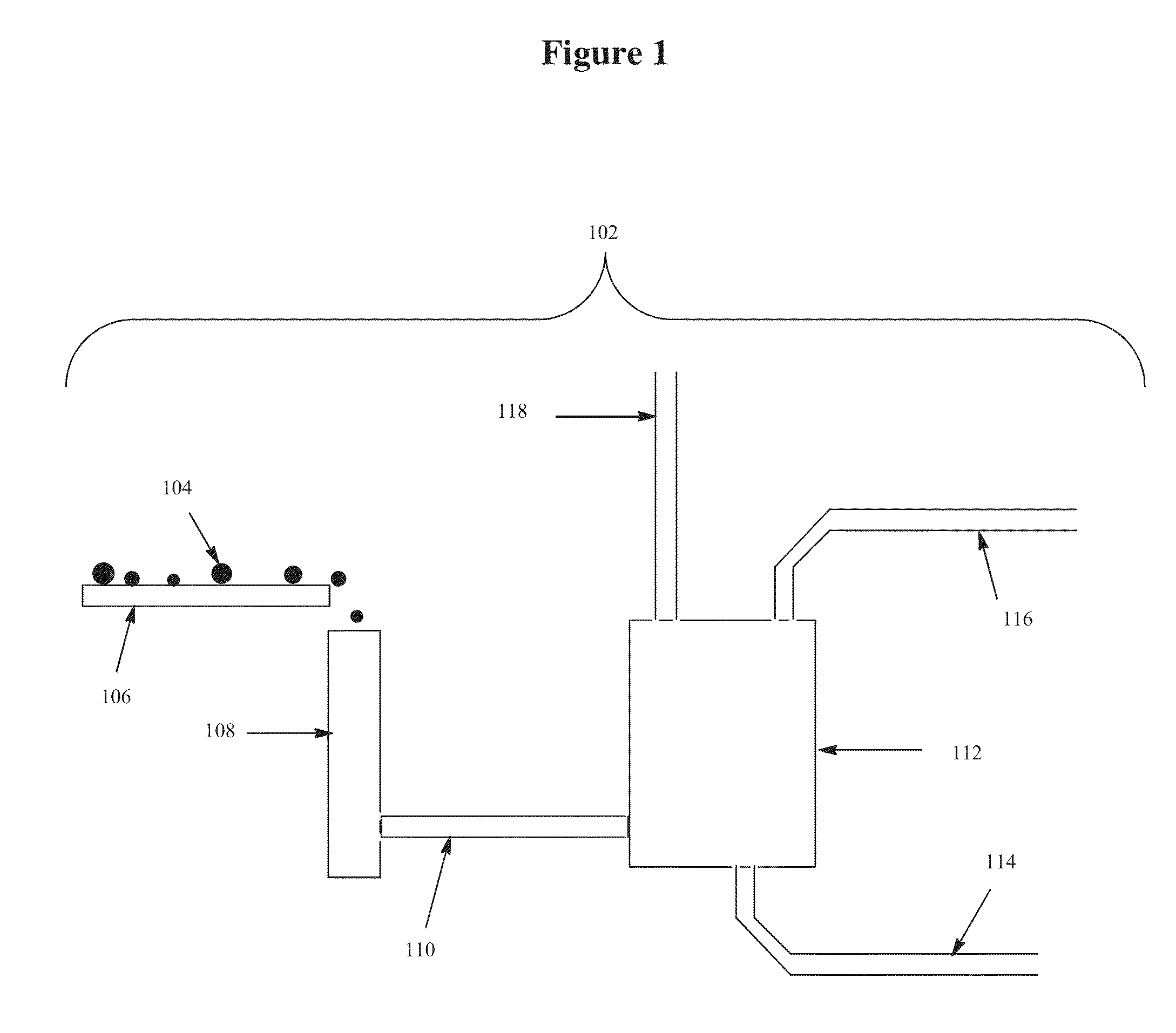

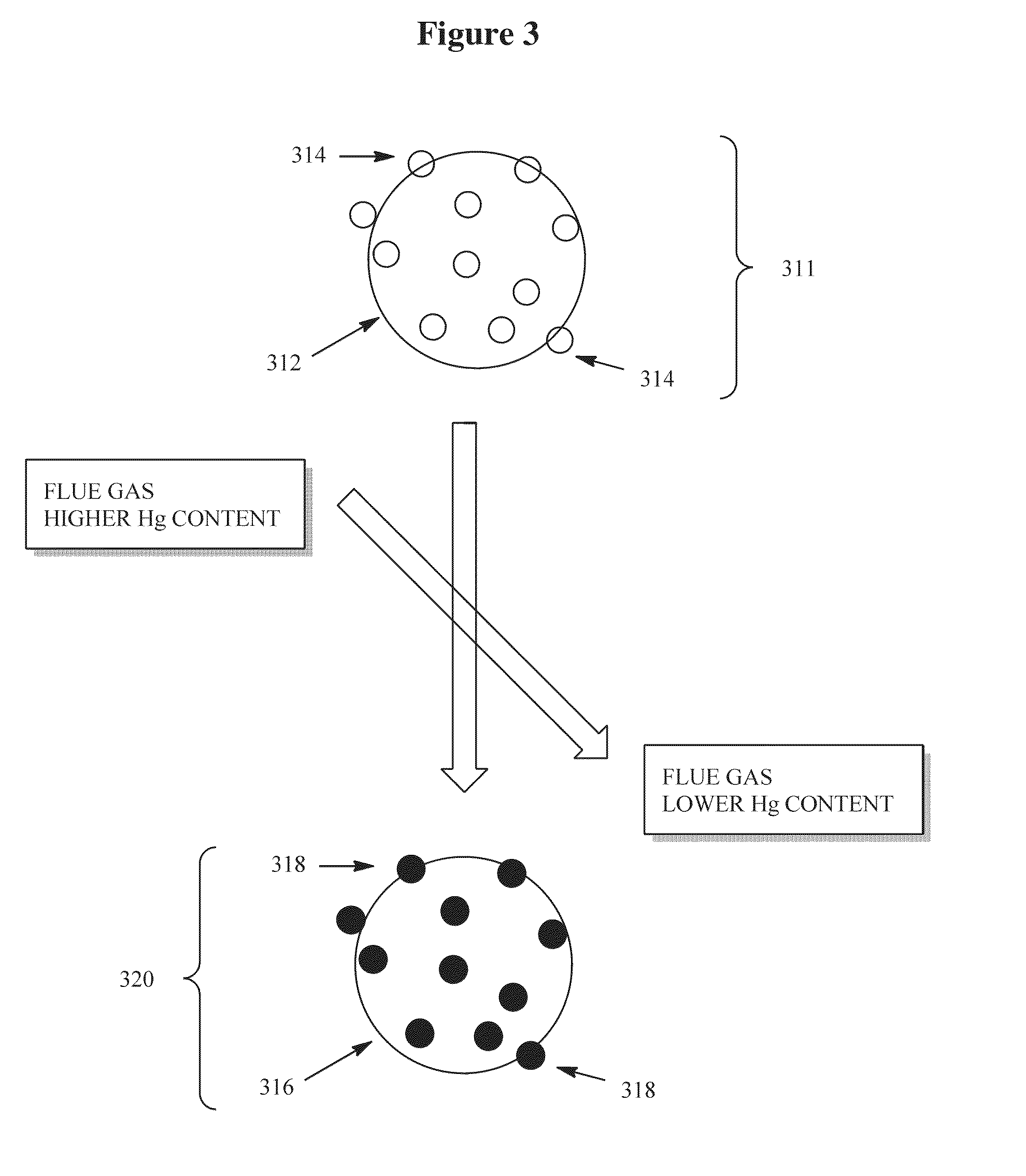

Particle-based systems for removal of pollutants from gases and liquids

InactiveUS20140252270A1Reduce total mercury contentReduce contentCombination devicesGas treatmentPetrochemicalRefinery

Systems, compositions, and methods for removing a substance or substances from a material, such as a gas or liquid material, are described. The compositions can comprise composite removal particles. In some embodiments, the composite removal particles can be comprised of support particles made from an inexpensive carrier material, and a reactive particle borne on the support particle. The reactive particle reacts with the substance or substances in the material. The reacted composite removal particles can then be removed from the material, which reduces the amount of the substance or substances present in the material. The composite removal particles are useful for removing pollutants, such as mercury, from exhaust gases, such as flue gas from a power plant combustion unit, and from other materials such as natural gas, liquefied natural gas, fuels, hydrocarbons, petrochemicals, and refinery streams.

Owner:SDC MATERIALS

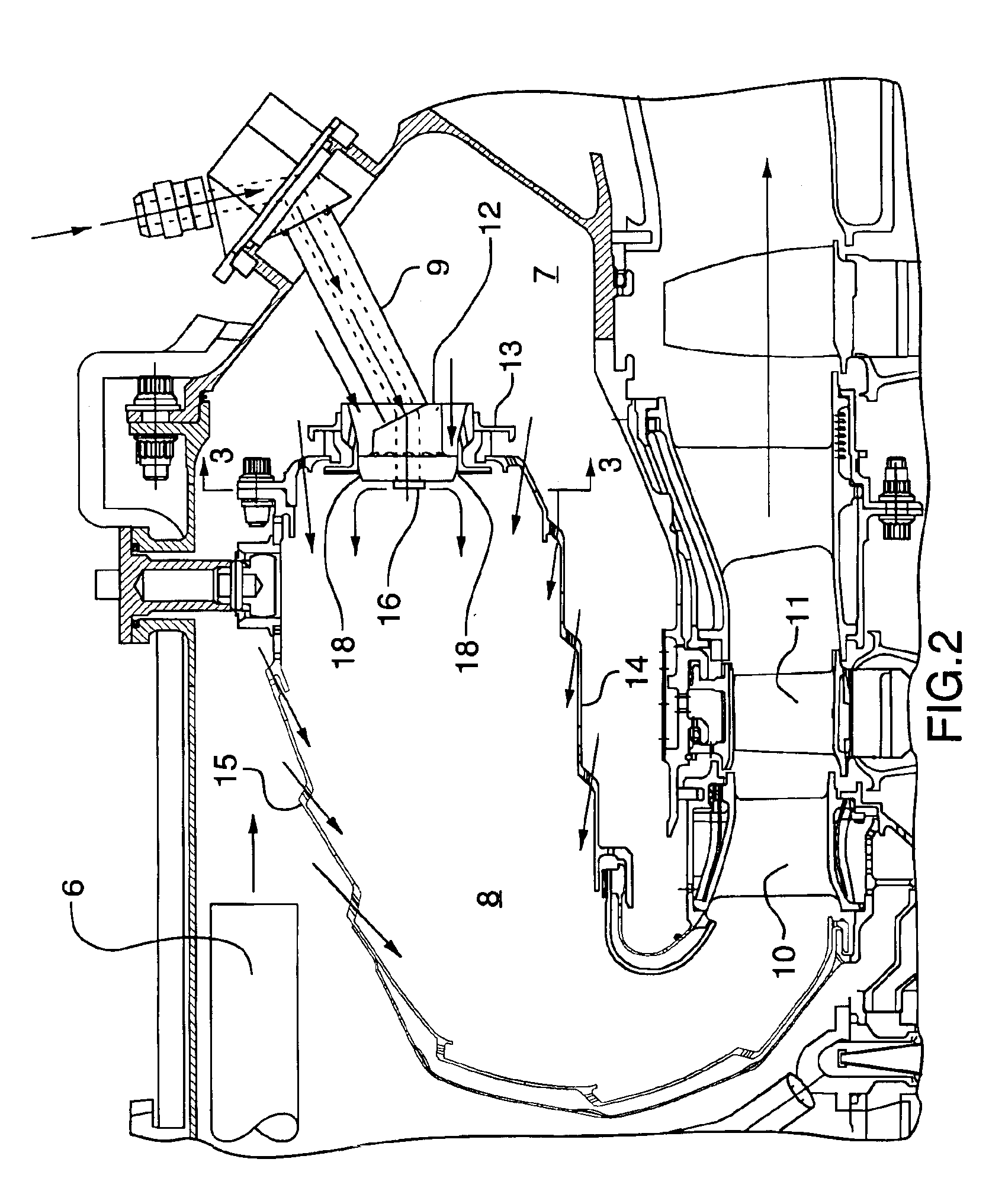

Natural gas fuel nozzle for gas turbine engine

InactiveUS6871488B2Turbine/propulsion fuel supply systemsContinuous combustion chamberCombustorNatural gas fuel

A gas fuel nozzle for mounting in a combustor wall of a gas turbine engine, with an at least partially radially-directed array of gas fuel outlets extending beyond an air flow head having an array of compressed air jet apertures around the gas fuel outlets. The air flow head also has a deflector for creating an axial flow of air for deflecting in an axial direction the radially-injected gas fuel.

Owner:PRATT & WHITNEY CANADA CORP

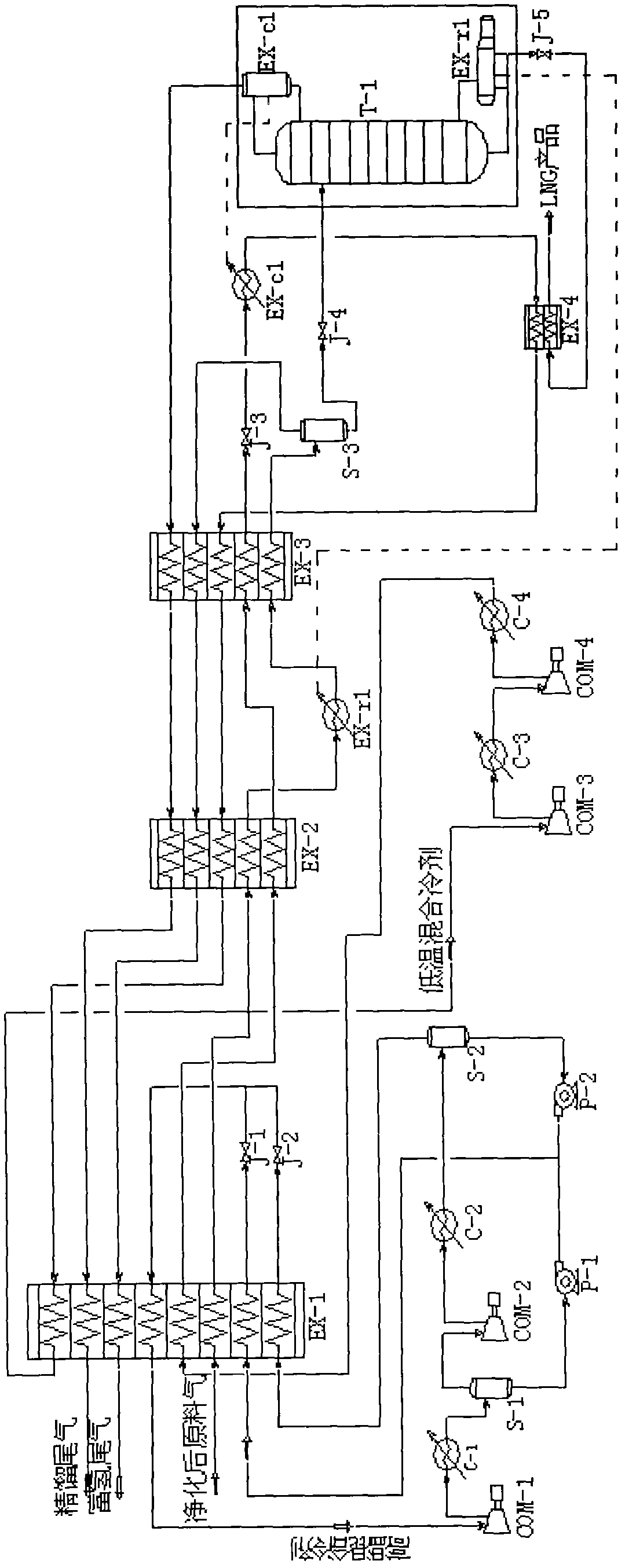

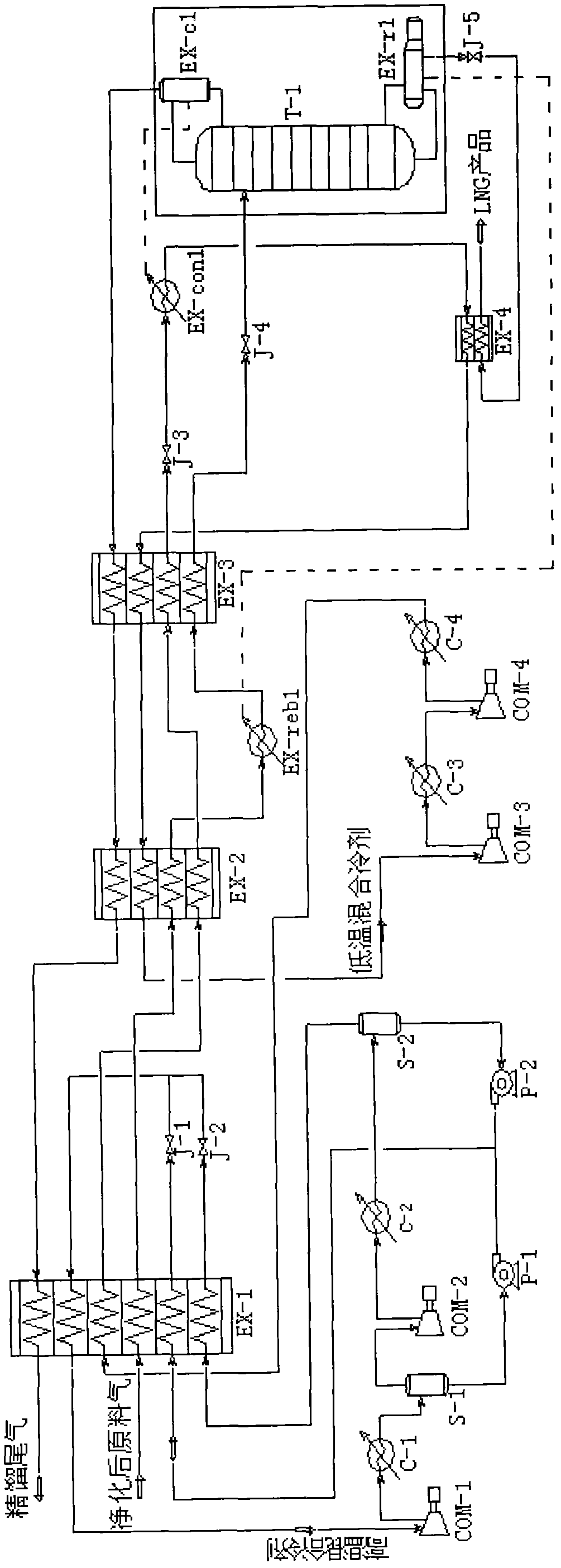

Method for producing liquefied natural gas by using coke oven gas

The invention provides a method for producing liquefied natural gas by using coke oven gas. The method comprises the following steps: (1) the coke oven gas is pretreated to remove benzene, naphthalene, tar and HCN (hydrogen cyanide); (2) sulfur is removed; (3) carbon is removed and the coke oven gas is dried; (4) the coke oven gas is led to a first heat exchanger and pre-cooled; (5) the pre-cooled coke oven gas passes through a second heat exchanger, a reboiler at the bottom of a low-temperature rectifying tower and a third heat exchanger in sequence, so that the temperature is lowered step by step; (6) gaseous liquid coming out of the third heat exchanger is led to a gas-liquid separator for gas-liquid separation, then the liquid coming out of the gas-liquid separator enters the low-temperature rectifying tower, and a liquefied natural gas product is acquired at the bottom of the low-temperature rectifying tower; and otherwise, the gaseous liquid coming out of the third heat exchanger is directly led to the low-temperature rectifying tower, and the liquefied natural gas product is acquired at the bottom of the low-temperature rectifying tower. The method for producing the liquefied natural gas by using the coke oven gas as raw material has the advantages of high output as well as low energy consumption and cost, and is easy to operate.

Owner:BEIJING ZHONGKE RUIAO ENERGY TECH CO LTD

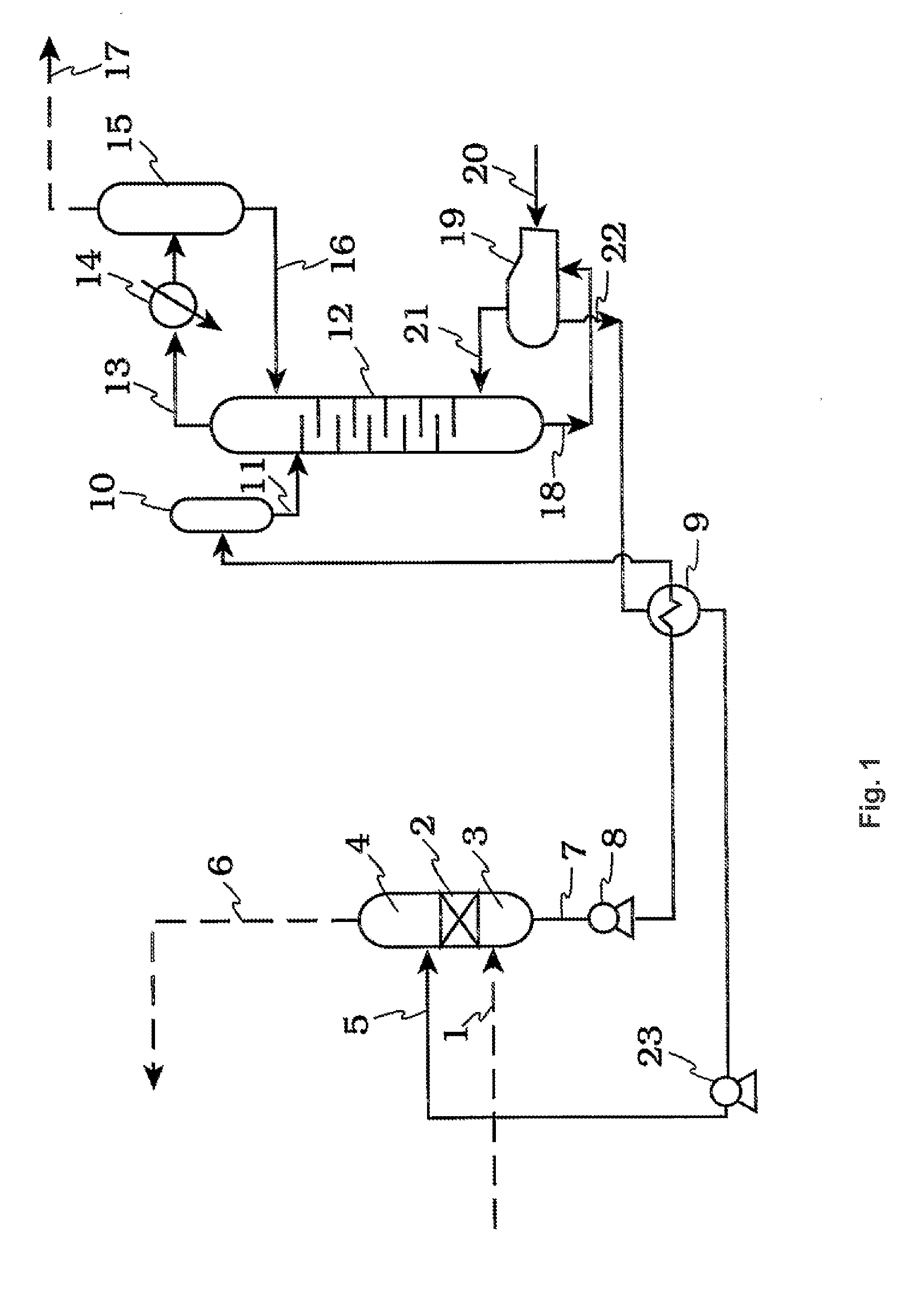

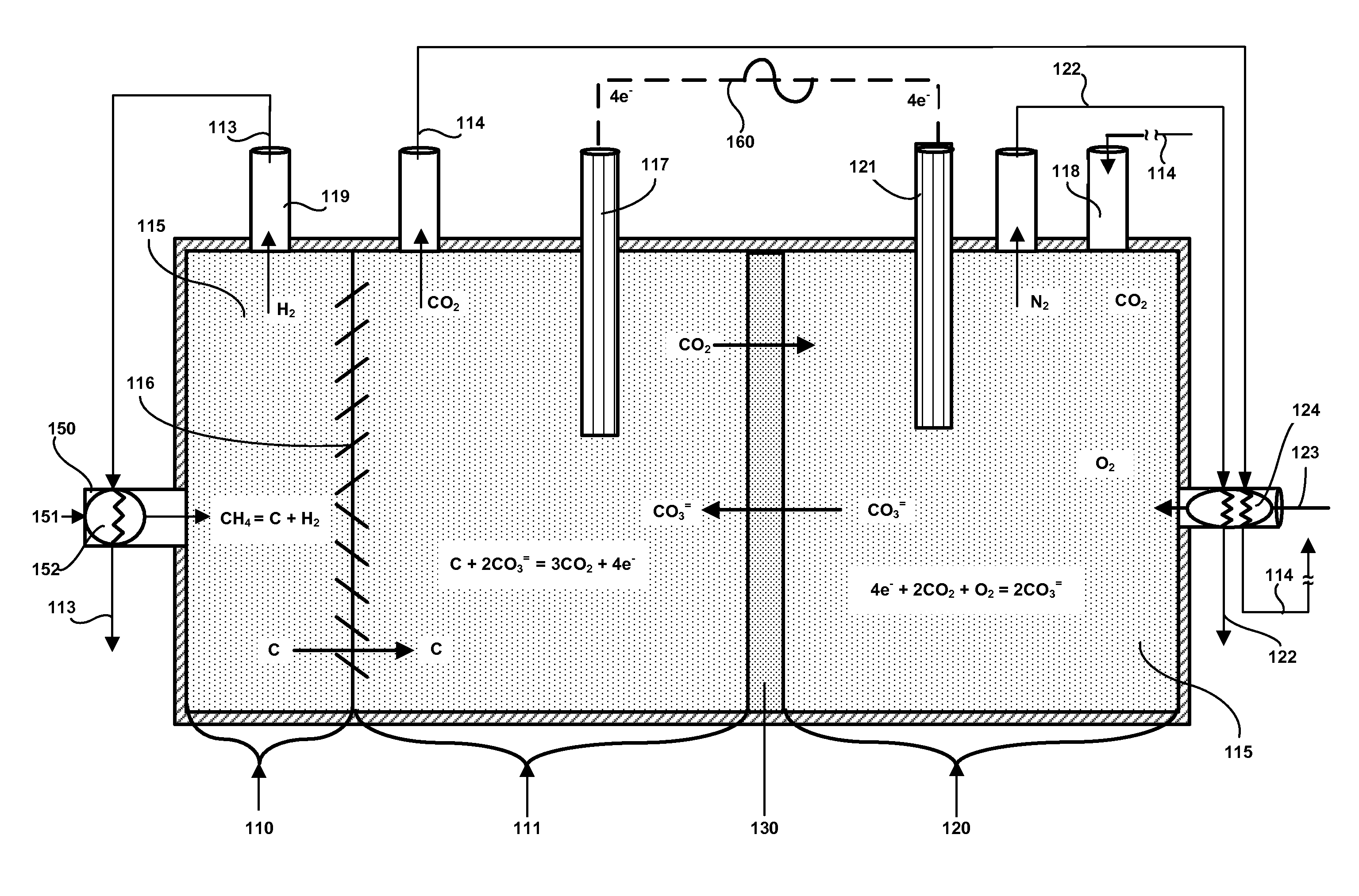

Natural gas direct carbon fuel cell

InactiveUS20090258278A1Improve hydrogen production efficiencyImprove power generation efficiencyFuel cell auxillariesFused electrolyte fuel cellsOxygenDirect carbon fuel cell

A natural gas fueled, direct carbon fuel cell produces electricity and hydrogen. It adds to an existing direct carbon fuel cell a carbon dioxide injection port to the cathode compartment; a natural gas feed port to the anode compartment, a hydrogen extraction port from the anode compartment, and a carbon dioxide extraction port from the anode compartment. To improve hydrogen generation efficiency, the anode compartment may have a louvered baffle dividing the anode compartment into an ante-chamber and a main chamber. The louvered baffle preferably has an upper section with slats angled from bottom to top and a lower section with slats angled from top to bottom. A heat exchanger is preferably included to pre-heat natural gas feed from hot hydrogen effluent. A second heat exchanger is preferably included to pre-heat oxygen-containing gas with hot nitrogen and carbon dioxide effluents.

Owner:HCE

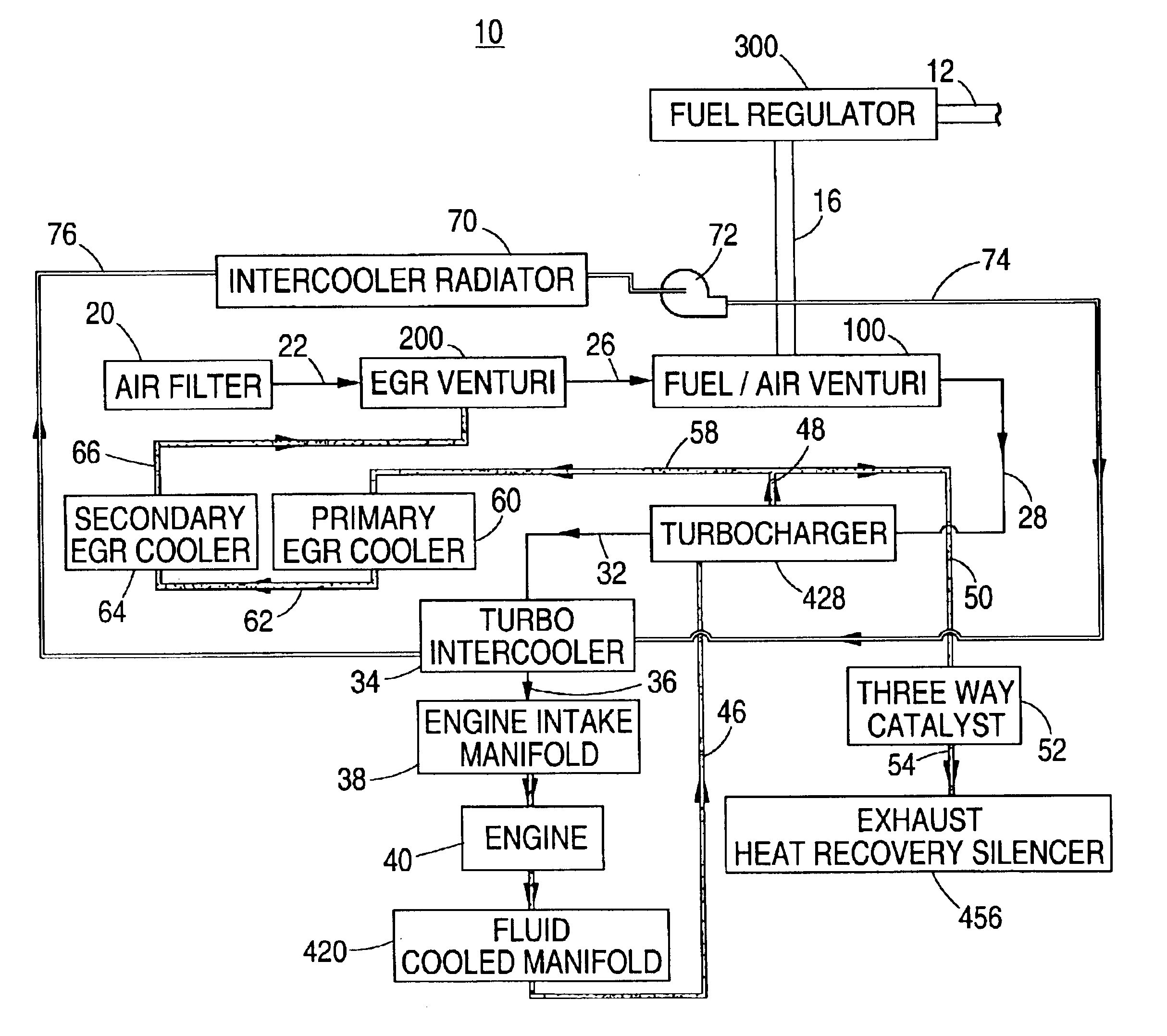

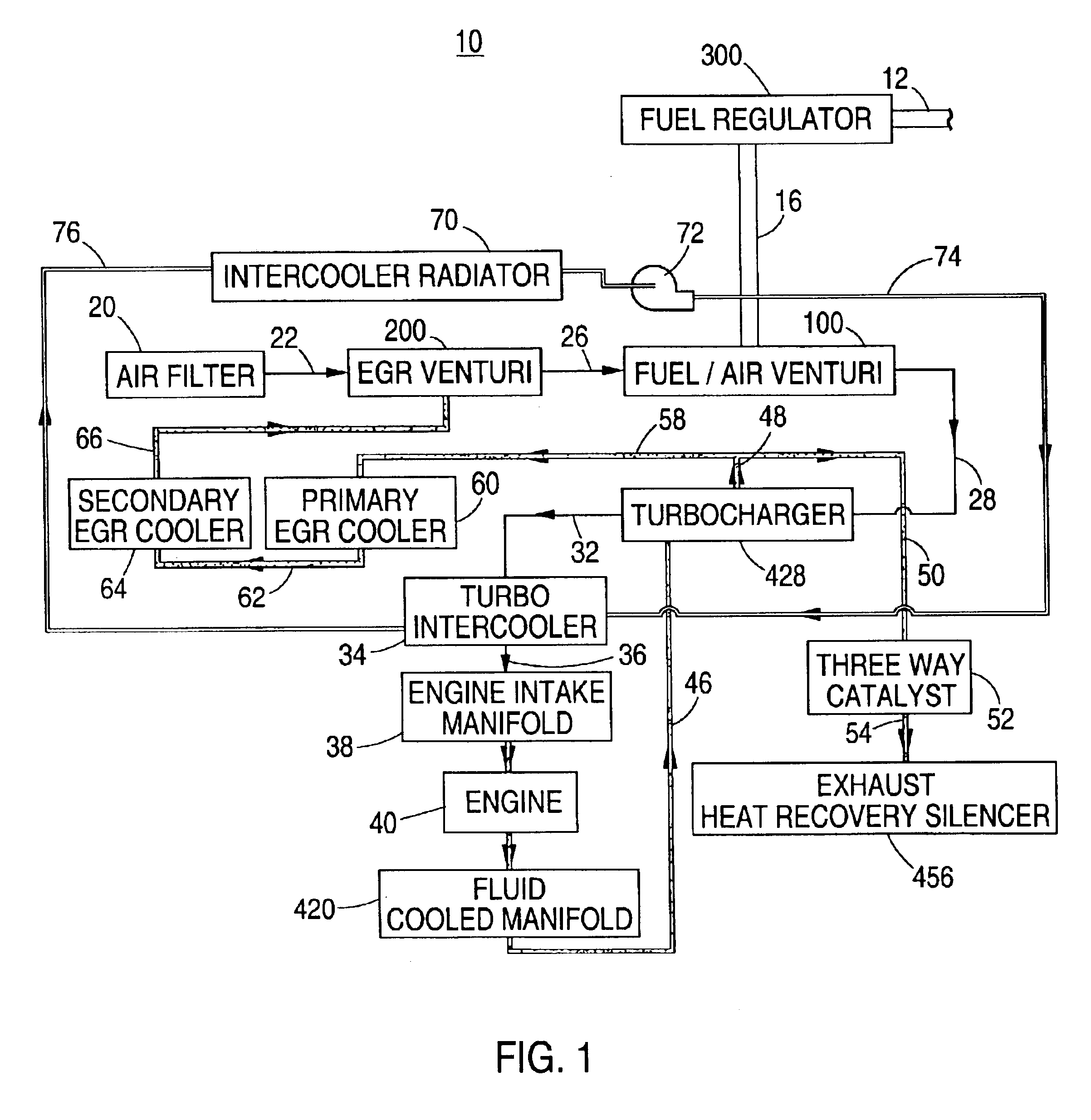

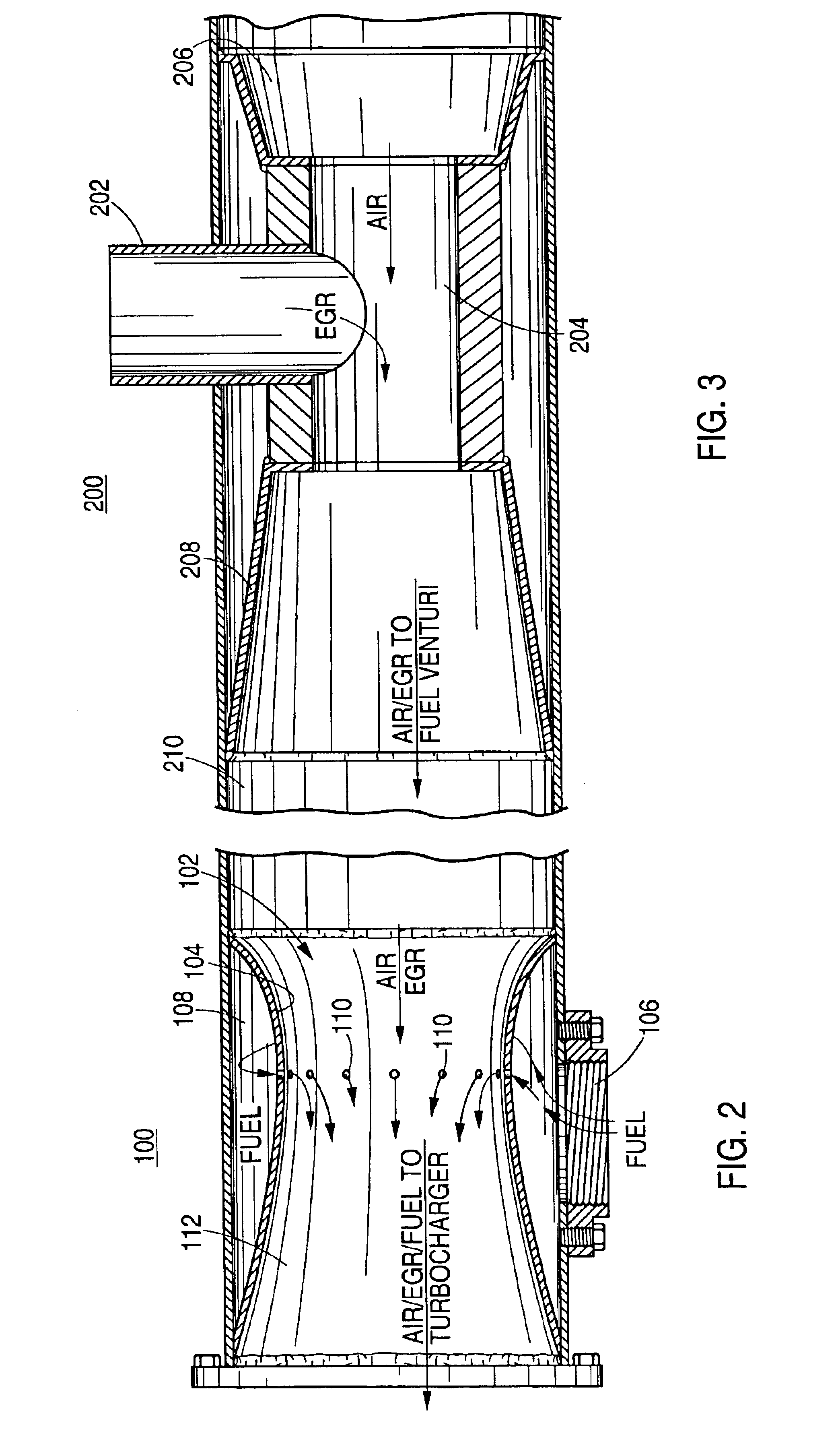

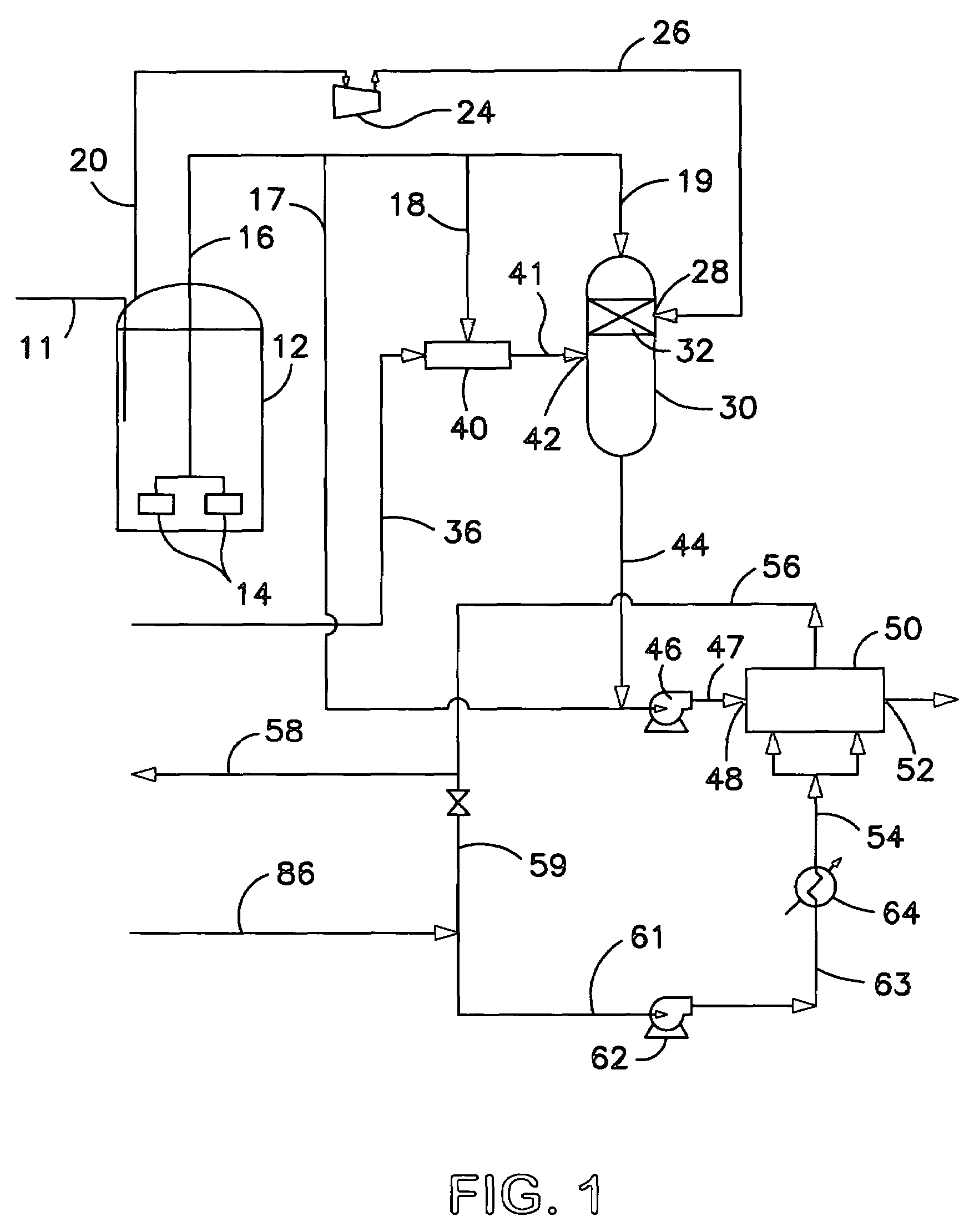

Carburetion for natural gas fueled internal combustion engine using recycled exhaust gas

InactiveUS6880535B2Efficient stable engine performanceLower head temperatureInternal combustion piston enginesNon-fuel substance addition to fuelTurbochargerExternal combustion engine

A carburetion system, without complicated control systems, functions uniformly throughout the range of engine load and incremental increases of power demand to provide efficient stable engine performance for a natural gas fired, internal combustion engine using EGR. A cogeneration system for supplying distributed generation of electricity and process / utility heat, employs a system for engine cooling and effective heat transfer to a cogeneration client, reduces engine head temperature, thereby reducing fuel consumption and reducing pollutants, as well as delivering substantially increased heat to a cogeneration process / utility heat facility by use of a carburetion system which employs at least a pair of spaced apart venturi positioned in series proximate one to another such that a first exhaust recycled gas venturi is upstream of a fuel venturi where fuel and air / exhaust gas are admixed prior to the resultant gas being introduced into a turbocharger. The distance between the exhaust venturi and fuel venturi is affective to provide a given amount of exhaust gas to air ratio prior to entering the fuel venturi inlet. Unexpectedly the spatial relationship between the two venturi, one to the other, affectively regulates exhaust gas air mixture, as well as the air / fuel / exhaust gas mixture to the engine by means solely of pressure increase and decrease (vacuum) of the engine intake system.

Owner:CHAPEAU

Natural gas fueled internal combustion engine

InactiveUS20140373531A1Emission minimizationFuel consumption is minimizedInternal combustion piston enginesFuel supply apparatusLoop controlTurbocharger

An internal combustion engine that can operate with 100% liquid fuel, 100% gaseous fuel and any combination in between includes a pressure expansion device used to reduce gaseous fuel pressure from the storage tank pressure to gaseous fuel injection pressure, and to extract energy from the expansion process. In one embodiment, the pressure expansion device is an air compressor that compresses intake air to an elevated pressure. In another embodiment, the pressure expansion device is a turbine, connecting to an alternator by a coupling, to generate electricity to charge the battery. The temperature of the pressure expansion device is controlled by a circuit of engine coolant or ambient air to avoid excessive deviation from room temperature. The cooled ambient air is used to cool the cabin temperature. In a further embodiment, the pressure expansion device is a turbocharger that comprises of a turbine and a compression fan.

Owner:WONG JIM

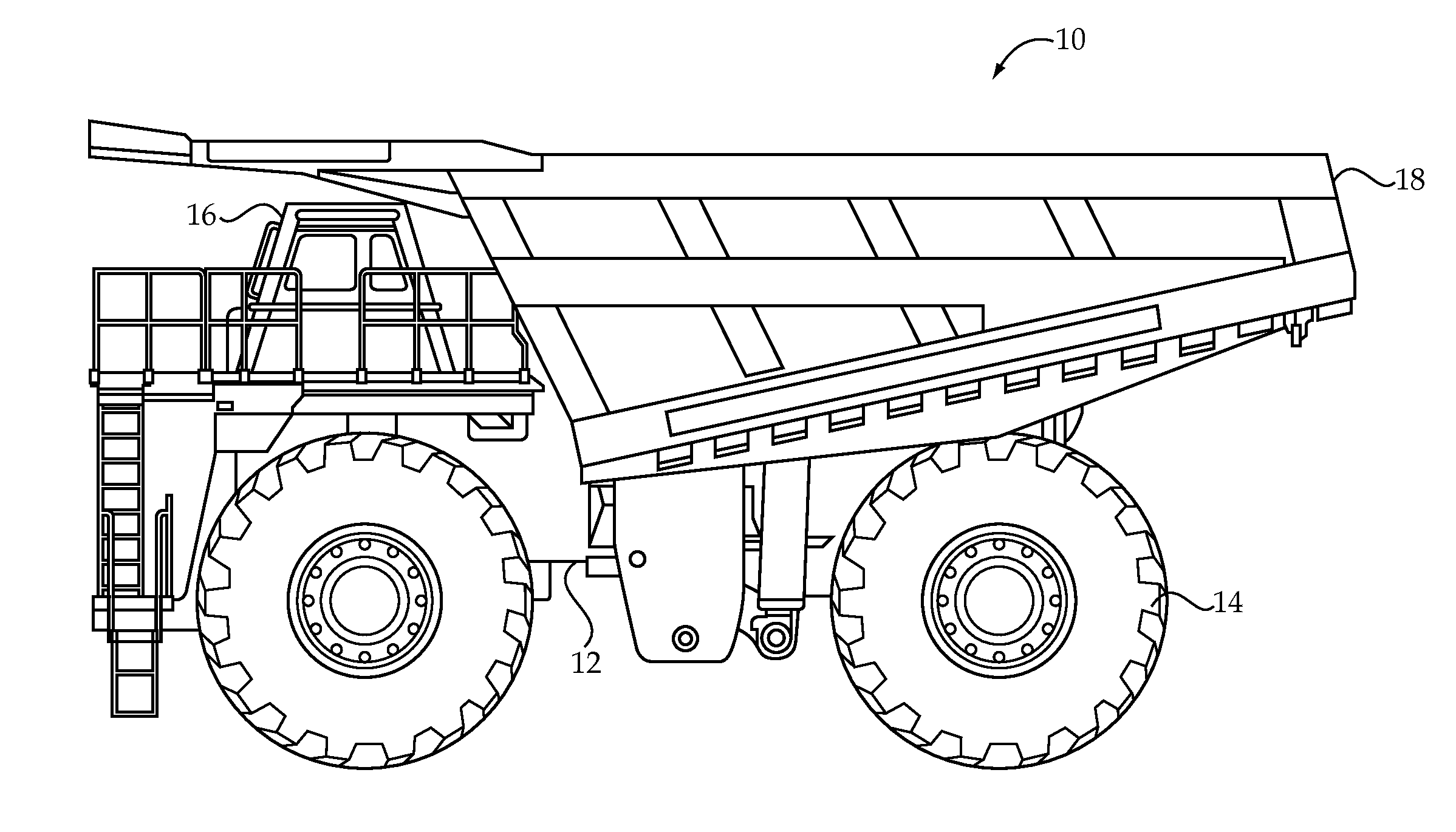

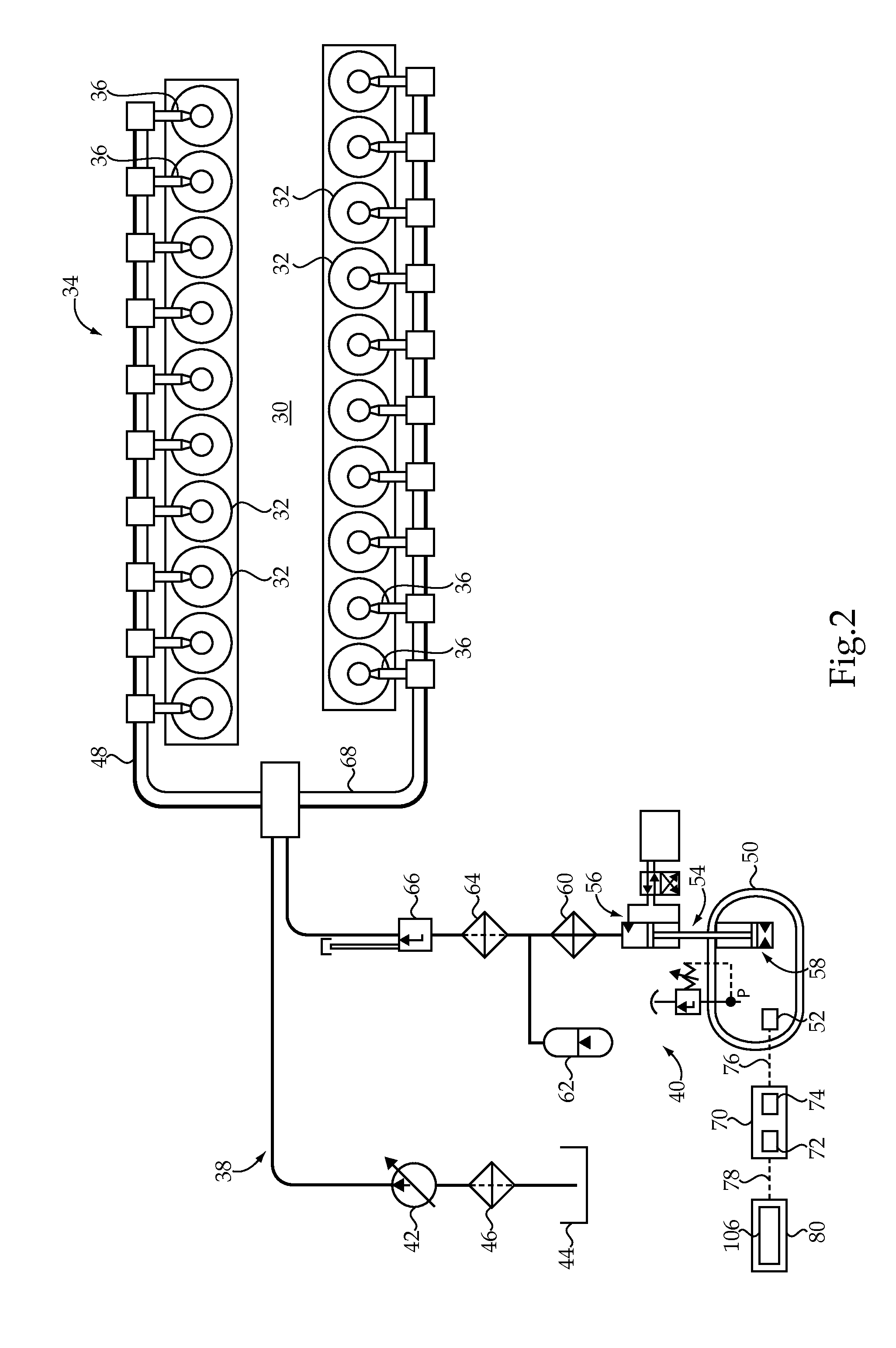

Dual Fuel System Diagnostics For Dual Fuel Engine And Machine Using Same

ActiveUS20140053800A1Electrical controlInternal combustion piston enginesElectronic controllerNatural gas fuel

A machine includes a machine body and a dual fuel compression ignition engine attached to the machine body. A dual fuel system is operably coupled to supply the engine with liquid diesel fuel and natural gas fuel directly into respective cylinders of the engine. The fuel system includes an insulated tank for storing the natural gas fuel, a pressure sensor positioned to measure fluid pressure within the tank, and a pump for drawing the natural gas fuel from the tank. An electronic controller is in communication with the pressure sensor and has a cryogenic system diagnostics algorithm executable thereon that is configured to receive a pressure signal from the pressure sensor, detect a cryogenic system fault based on the signal, and generate a notification signal based on the fault.

Owner:CATERPILLAR INC

Natural gas engine powder metallurgy valve seat ring material

The invention discloses a natural gas engine powder metallurgy valve seat ring material. The natural gas engine powder metallurgy valve seat ring material contains the following element raw materials in percentage by weight: 0.6-1.5% of C, 0.3-1.5% of S, 3-10% of Cr, 4-12% of Mo, 0.5-5% of Ni, 3-10% of Co, 10-20% of Cu, 1-2.5% of Mn, 1-4% of V, 2-7% of W and the balance of Fe. The natural gas engine powder metallurgy valve seat ring material disclosed by the invention can effectively improve the abrasion resistance of the powder metallurgy seat ring and meet the working conditions and the requirements of a natural gas fuel engine.

Owner:安庆帝伯粉末冶金有限公司

Method containing carbon dioxide replacement for absorbing methane in condensed coal bed gas through pressure varying mode

InactiveCN101549240AIncrease concentrationHigh yieldProductsMethane captureOperation modeNatural gas fuel

The present invention relates to a method which contains carbon dioxide replacement and is used for absorbing methane in condensed coal bed gas through pressure varying mode. The method mainly comprises the following steps: absorbing the feed gas, replacing the working substance gas, regenerating the bed layer, charging the secondary product gas, recovering the working substance gas, etc., wherein, the replacing of working substance gas adopts an operation mode of pressurized replacing or normal-pressure replacing, namely the carbon dioxide is used for replacing and absorbing the methane under the absorption pressure, or under the normal pressure. The invention causes that the methane becomes the tower top product thereby increasing the concentration and yield of methane of product gas. The product gas obtained from the coal bed gas with 20% of methane concentration. The recovery rate obtains 90%. The method of the invention is suitable for the coal bed gases with different methane contents. The coal bed gas with low methane concentration can be changed into the high-quality natural gas fuel with a low cost. The product gas can be conveyed through pipe and can be stored with pot.

Owner:TIANJIN UNIV

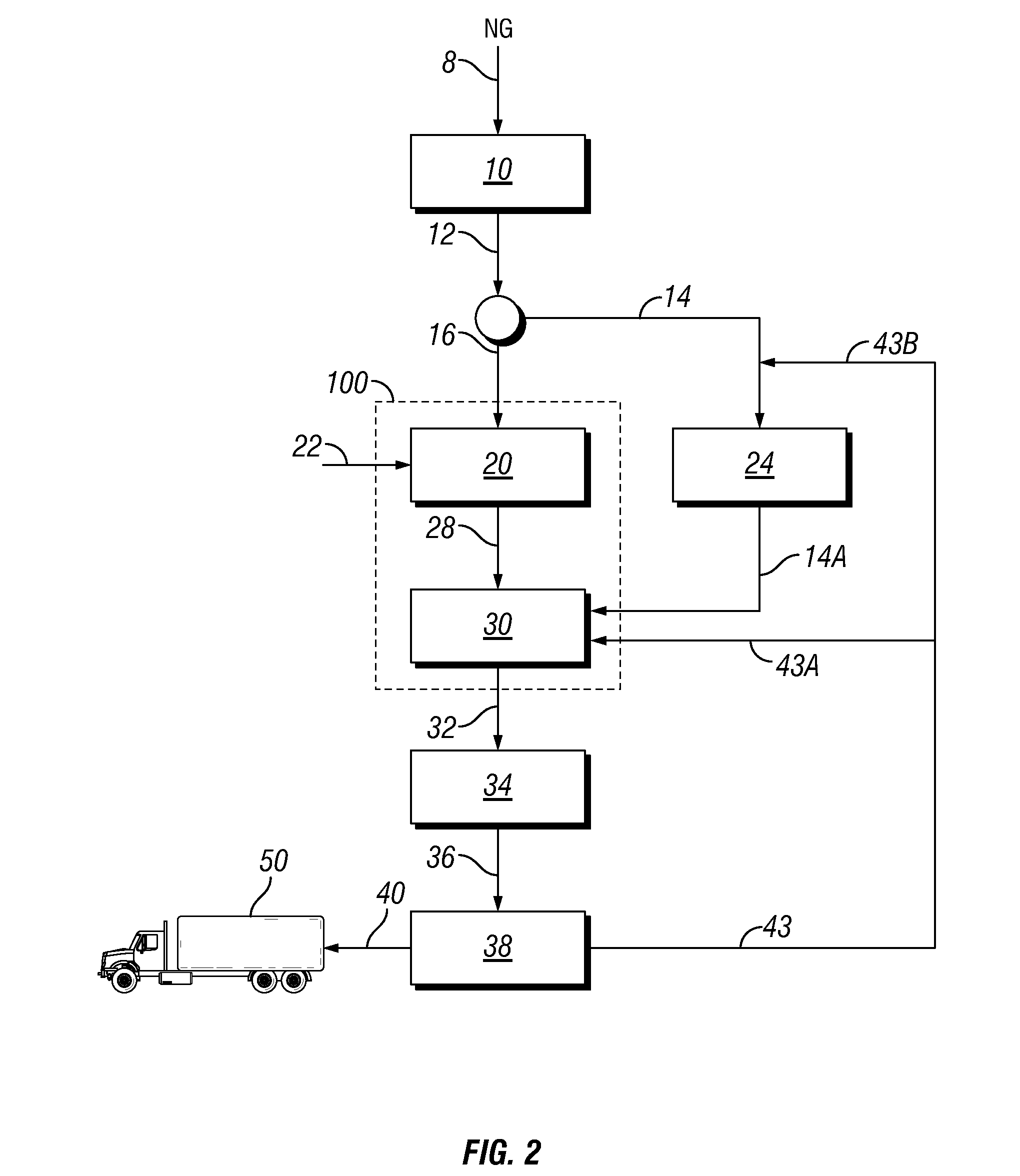

System and method for transferring natural gas for utilization as a fuel

InactiveUS20130199616A1Eliminate needInhibition releaseAuxillariesPipe couplingsNatural gas fuelEngineering

Natural gas is produced when LNG that is contained in an insulated LNG cargo tank(s) of a non-self-propelled LNG carrier (i.e., a barge) evaporates as a result of heat leakage through the walls of the insulated cargo tank(s). The natural gas is transferred from the barge to a tugboat or a towboat that is equipped with natural gas burning engines through a flexible gas transfer assembly so that the tugboat is powered by the natural gas fuel. The pressure in the cargo tank(s) on the barge is, therefore, effectively managed to prevent or substantially reduce the buildup of pressure within the LNG cargo tank(s). The LNG can then be contained within the LNG cargo tank(s) for an appropriate period of time and can be delivered at an appropriate and acceptable equilibrium pressure and temperature.

Owner:ARGENT MARINE MANAGEMENT

Laser spark distribution and ignition system

InactiveUS7421166B1High energyHigh energy sparkSparking plugsElectric ignition installationCombustion chamberLaser-induced breakdown spectroscopy

A laser spark distribution and ignition system that reduces the high power optical requirements for use in a laser ignition and distribution system allowing for the use of optical fibers for delivering the low peak energy pumping pulses to a laser amplifier or laser oscillator. An optical distributor distributes and delivers optical pumping energy from an optical pumping source to multiple combustion chambers incorporating laser oscillators or laser amplifiers for inducing a laser spark within a combustion chamber. The optical distributor preferably includes a single rotating mirror or lens which deflects the optical pumping energy from the axis of rotation and into a plurality of distinct optical fibers each connected to a respective laser media or amplifier coupled to an associated combustion chamber. The laser spark generators preferably produce a high peak power laser spark, from a single low power pulse. The laser spark distribution and ignition system has application in natural gas fueled reciprocating engines, turbine combustors, explosives and laser induced breakdown spectroscopy diagnostic sensors.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

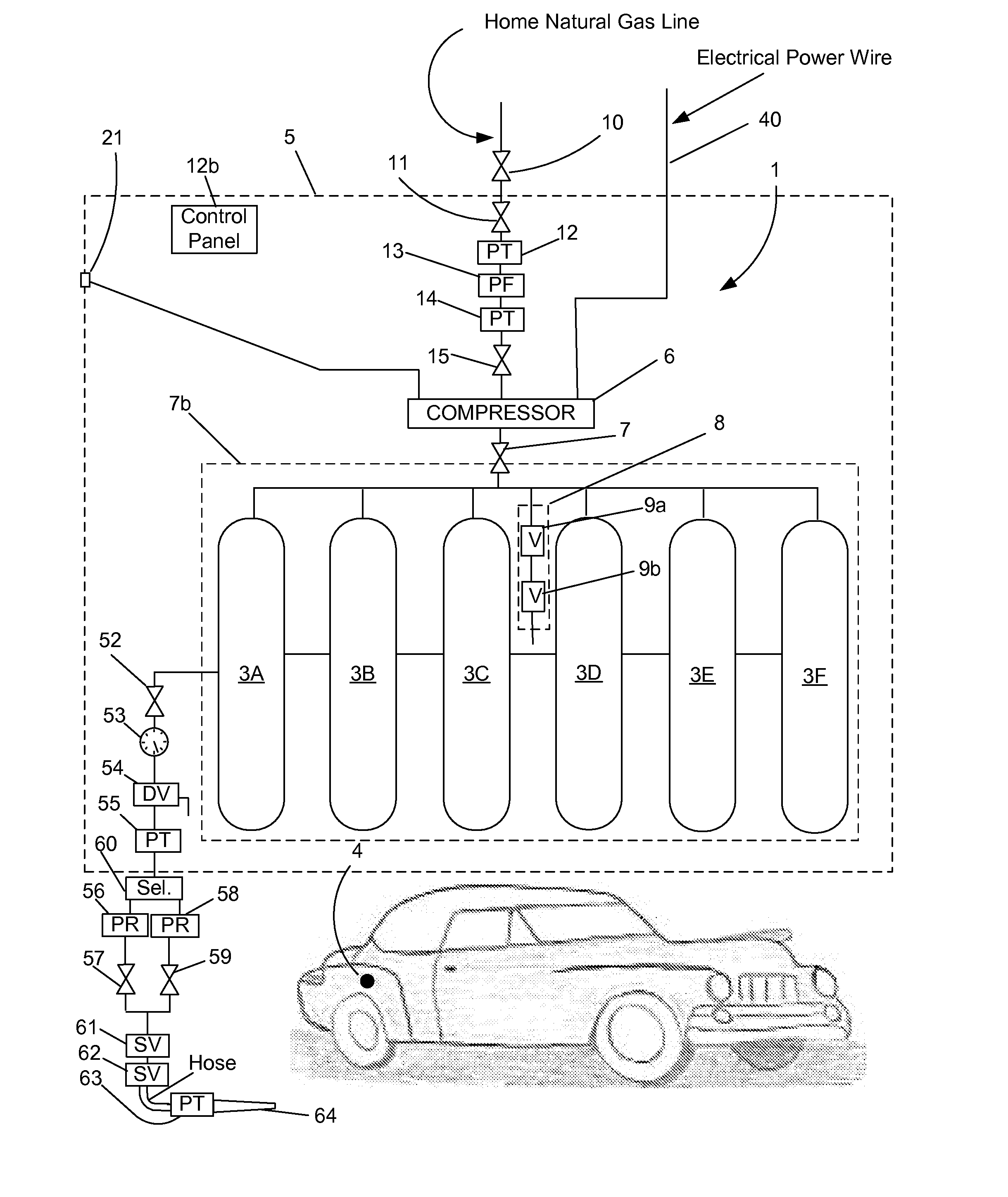

Natural gas home fast fill refueling station

InactiveUS20140130938A1Quick refuelingVessel mounting detailsVessel geometry/arrangement/sizeNatural gas storageProcess engineering

A home based fast-fill natural gas refueling station for providing natural gas fuel to a vehicle. A compressor is attached to the natural gas fill line. The compressor functions to pressurize a natural gas storage tank array. The storage tank array includes a plurality of natural gas storage tanks. A pressurized natural gas storage tank exit line is connected to a frontmost storage tank and a fill nozzle is connected to the storage tank exit line. During the refueling process the compressor is turned off. Also, during the refueling process as the pressure is depleted in the frontmost storage tank the frontmost storage tank is simultaneously and rapidly repressurized by other storage tanks in the storage tank array allowing for fast refueling of the vehicle.

Owner:LUPARELLO MICHAEL J

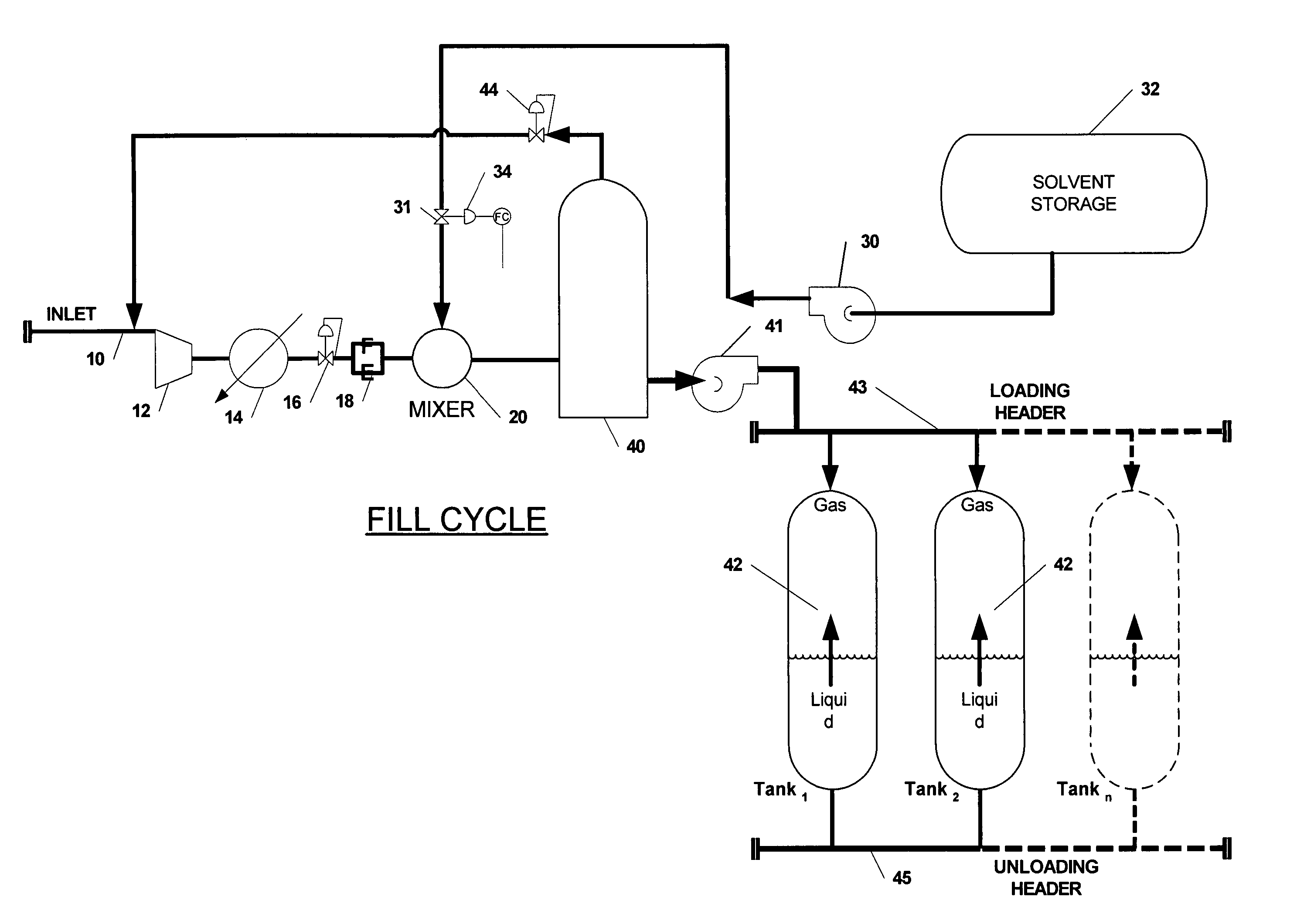

Storage of natural gas in liquid solvents and methods to absorb and segregate natural gas into and out of liquid solvents

ActiveUS7607310B2Efficient combinationIncrease speedSolidificationLiquefactionProduct gasNatural gas fuel

Systems and processes that facilitate the absorption of natural gas or methane through the interaction of moderate pressure and low temperature into a liquid or liquid vapor medium for storage and transport, and back into a gas for delivery to market. In a preferred embodiment, the absorptive properties of ethane, propane and butane under moderate conditions of temperature and pressure (associated with a novel mixing process) are utilized to store natural gas or methane at more efficient levels of compressed volume ratio than are attainable with natural gas alone under similar holding conditions. The preferred mixing process efficiently combines natural gas or methane with a solvent medium such as liquid ethane, propane, butane, or other suitable fluid, to form a concentrated liquid or liquid vapor mixture suited for storage and transport. The solvent medium is preferably recycled in the conveyance vessel on unloading of the natural gas.

Owner:SEAONE HLDG

Natural gas engine and operation method for natural gas engine

ActiveUS20150315986A1Minimize resultIncrease temperatureElectrical controlInternal combustion piston enginesMulti injectionNatural gas fuel

A natural gas engine equipped with a mechanism that introduces exhaust gas into a cylinder during an intake stroke, and in which an amount of diesel fuel injected into a cylinder is set to a diesel fuel amount for idling condition across an entire operating region of an engine, engine output is increased or decreased by increasing or decreasing an amount of a natural gas fuel, and fuel injection of the diesel fuel into a cylinder is performed using multi-injection in a high load region in which the accelerator opening degree is greater than a preset first opening degree.

Owner:ISUZU MOTORS LTD

Burner apparatus

InactiveUS7479008B2Harmful emissionDomestic stoves or rangesLiquid heating fuelCombustorControl system

A burner apparatus for an indoor or outdoor fireplace, fire pit, stove or oven is shown. The burner apparatus operates to produce natural gas fueled or liquid petroleum fueled amber flames among artificial logs, coals or a combination of artificial logs and coals, simulating a natural fire. One embodiment of the burner apparatus comprises a burner tube loop for the distribution of fuel, a fuel / air mixing valve for mixing the fuel and air before ignition of the resulting fuel / air mixture, metal cups for the dissipation of the fuel / air mixture and flames, an ignition system for igniting the fuel / air mixture, a control system for monitoring and controlling the ignition of the fuel and for regulating the flow of fuel, and artificial logs, coals or a combination of logs and coals placed around the burner tube loop to provide for an aesthetically pleasing and natural looking display.

Owner:THOMAS PAUL DAVID

Process for producing ammonia from urea used for denitration of boiler smoke and system thereof

ActiveCN101928014AStable temperature conditionsSave energyChemical industryDispersed particle separationBoiler furnaceDecomposition

The invention discloses a process for producing ammonia from urea used for denitration of boiler smoke and a system thereof. The process has the following flow: feeding a urea solution into a decomposition chamber by a urea solution feeding system; and heating and decomposing the urea solution into ammonia in the decomposition chamber, wherein a heat source for heating the urea solution in the decomposition chamber is air heated by heat in a boiler. The invention adopts the heat in the boiler as the heat source instead of traditional diesel and gas fuel, thus saving the energy resources, greatly lowering the operation cost and improving the system economy, and the process in the invention has safer and more reliable operation compared with the process utilizing fuels such as diesel, gas and the like as the heat source.

Owner:北京洛卡环保技术有限公司

Systems and methods for vaporization of liquefied natural gas

Owner:BP CORP NORTH AMERICA INC

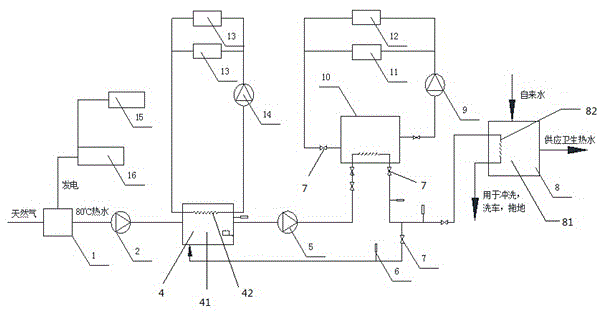

Cooling, heating and generation and hot-water supply combined system driven by proton film fuel cell

InactiveCN104567100ARealize cascade utilizationHigh total power generation effectFuel cell auxillariesHeating and refrigeration combinationsSolar water heating systemFossil fuel

The invention relates to a cooling, heating and generation and hot-water supply combined system driven by a proton film fuel cell. The cooling, heating and generation and hot-water supply combined system comprises the fuel cell, a first water pump, an auxiliary heating device, a second water pump, a third water pump, a storage heat exchange device, an absorptive cold and hot water unit, a fan coiler and air-conditioner end equipment, which are communicated through pipelines. The waste heat of the fuel cell is utilized, and solar renewable energy sources are introduced, so that the problems of generation of living buildings, heating in winter, cooling in summer and daily water usage of buildings are solved. Combining waste heat of the natural gas fuel cell with the solar hot water system, high-temperature hot water is generated, the absorptive cold and hot water unit can be started for cooling and heating of an air conditioner, hot water flowing out of the absorptive cold and hot water unit can be used for daily life after treated through a heat exchanger, gradient utilization of the energy sources is realized and utilization rate of fossil fuel is increased.

Owner:合肥万豪环境科技有限责任公司

Process for the conversion of natural gas to acetylene and liquid fuels with externally derived hydrogen

ActiveUS20110054231A1Hydrocarbon by dehydrogenationHydrocarbon by hydrogenationHydrogenLiquid hydrocarbons

A process for converting natural gas from which contaminants have been sufficiently removed to acetylene includes heating the purified gas through a selected range of temperature for adequate time or combustion of the purified gas at adequate temperature within a suitable environment during an adequate reaction time to convert a fraction of the gas stream to acetylene, wherein the acetylene is directed for other processes, reactions, and uses. A process for converting natural gas to liquid hydrocarbons by combusting externally derived hydrogen for heating natural gas to a selected range of temperature. A process for converting natural gas to liquid hydrocarbons by reacting conversion products with externally derived hydrogen to form olefins comprising ethylene, and catalytically forming liquid hydrocarbons from the olefins comprising ethylene.

Owner:SYNFUELS INT

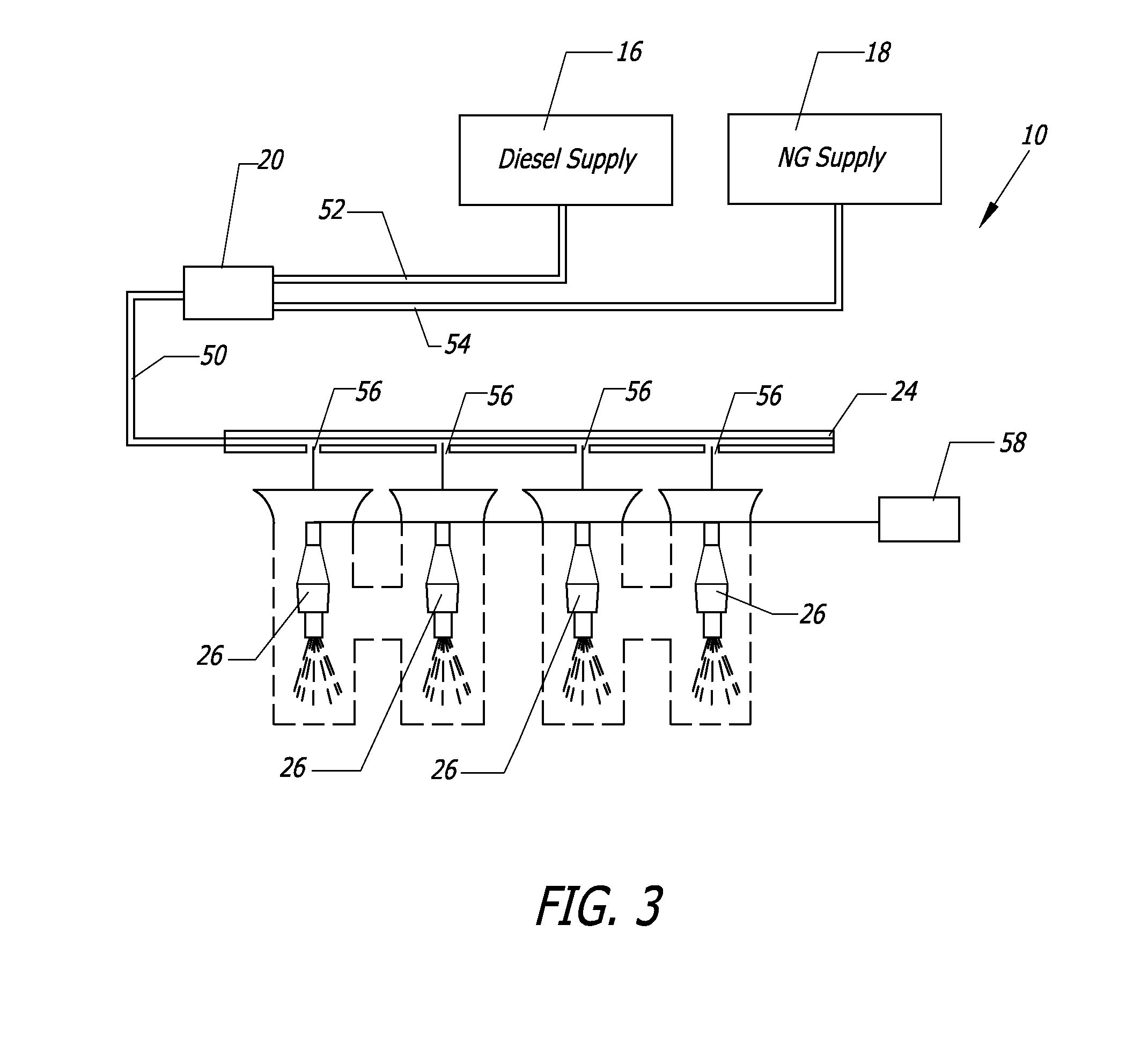

Multi-fuel system for internal combustion engines

ActiveUS20150000638A1Electrical controlInternal combustion piston enginesCombustion chamberNatural gas fuel

In a multi-fuel system for diesel engines, natural gas is mixed with diesel fuel and conditioned in a mixing chamber before being injected into the mixing chamber of the engine. Filtered blow-by gas may also be introduced into the combustion chamber. A computerized controller is used to determine and control the proportion of diesel fuel, natural gas fuel, the mixing and conditioning of these fuels, and the supply of filtered blow-by gas.

Owner:SVMTECH

Natural gas direct carbon fuel cell

InactiveUS7910258B2Improve power generation efficiencyFuel cell auxillariesFused electrolyte fuel cellsOxygenDirect carbon fuel cell

A natural gas fueled, direct carbon fuel cell produces electricity and hydrogen. It adds to an existing direct carbon fuel cell a carbon dioxide injection port to the cathode compartment; a natural gas feed port to the anode compartment, a hydrogen extraction port from the anode compartment, and a carbon dioxide extraction port from the anode compartment. To improve hydrogen generation efficiency, the anode compartment may have a louvered baffle dividing the anode compartment into an ante-chamber and a main chamber. The louvered baffle preferably has an upper section with slats angled from bottom to top and a lower section with slats angled from top to bottom. A heat exchanger is preferably included to pre-heat natural gas feed from hot hydrogen effluent. A second heat exchanger is preferably included to pre-heat oxygen-containing gas with hot nitrogen and carbon dioxide effluents.

Owner:HCE

Methods for storage and transportation of natural gas in liquid solvents

ActiveUS20120180502A1Increase the volume ratioImprove storage densityVessel mounting detailsLoad accommodationMass ratioNatural gas fuel

Systems and methods to create and store a liquid phase mix of natural gas absorbed in light-hydrocarbon solvents under temperatures and pressures that facilitate improved volumetric ratios of the stored natural gas as compared to CNG and PLNG at the same temperatures and pressures of less than −80° to about −120° F. and about 300 psig to about 900 psig. Preferred solvents include ethane, propane and butane, and natural gas liquid (NGL) and liquid pressurized gas (LPG) solvents. Systems and methods for receiving raw production or semi-conditioned natural gas, conditioning the gas, producing a liquid phase mix of natural gas absorbed in a light-hydrocarbon solvent, and transporting the mix to a market where pipeline quality gas or fractionated products are delivered in a manner utilizing less energy than CNG, PLNG or LNG systems with better cargo-mass to containment-mass ratio for the natural gas component than CNG systems.

Owner:SEAONE HLDG

Vehicular saturation flow control device of natural gas fuel

ActiveCN102562365ASteady heating and boostingUniform movementInternal combustion piston enginesFuel supply apparatusPressure riseWater baths

The invention discloses a vehicular saturation flow control device of natural gas fuel. The vehicular saturation flow control device comprises vehicular natural gas storing equipment which is internally provided with a temperature sensing device, and is characterized in that the vehicular natural gas storing equipment is connected with a water-bath type carburetor, a pressure adjusting valve and a buffer tank in sequence and in series by pipelines; the buffer tank is connected with a coil pipe component in the vehicular natural gas storing equipment by a gas return coil pipe which is provided with a stop valve; the coil pipe component is arranged on a liquid-phase part of the vehicular natural gas storing equipment by a fixed bracket; and normal-temperature gas in the gas return coil pipe is transferred to the coil pipe component and carries out heat convection with low-temperature liquid in the vehicular natural gas storing equipment, so that the temperature and the pressure in the vehicular natural gas storing equipment can rise stably. The vehicular saturation flow control device has the advantages of quick pressure rising, stable pressure in a control cylinder, good effect and low cost.

Owner:NINGBO MINGXIN CHEM MACHINERY +1

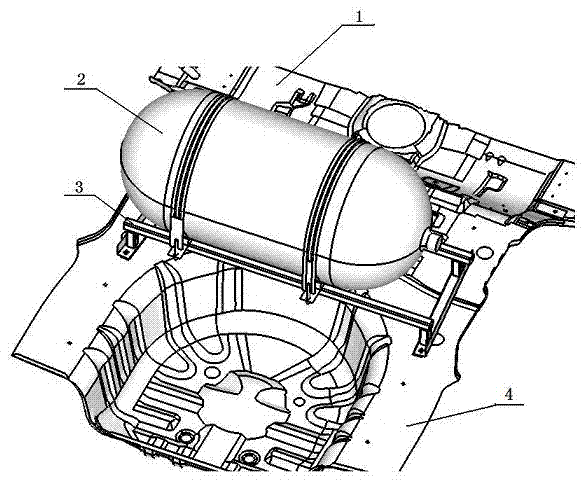

Novel CNG (compressed natural gas) steel cylinder fixing support

ActiveCN102381185ASolve the problem of slidingAvoid damageFuel supplyCompressed natural gasNatural gas fuel

The invention relates to a novel CNG (compressed natural gas) steel cylinder fixing support, which is characterized by comprising a steel cylinder fixing support assembly (3) fixedly mounted on a rear floor (4), the steel cylinder fixing support assembly (3) comprises a plurality of upper metal strap assemblies (31), a plurality of lower metal strap assemblies (32) and a base frame, the lower metal strap assemblies (32) are fixedly arranged on the base frame, and the upper metal strap assemblies (31) and the lower metal strap assemblies (32) clamp a steel cylinder (2) in a one-to-one correspondence fastening manner, so that the steel cylinder (2) cannot slip under the action of inertial force. The novel CNG steel cylinder fixing support is simple in structure and light in weight, and the steel cylinder can be easily mounted and detached.

Owner:CHERY AUTOMOBILE CO LTD

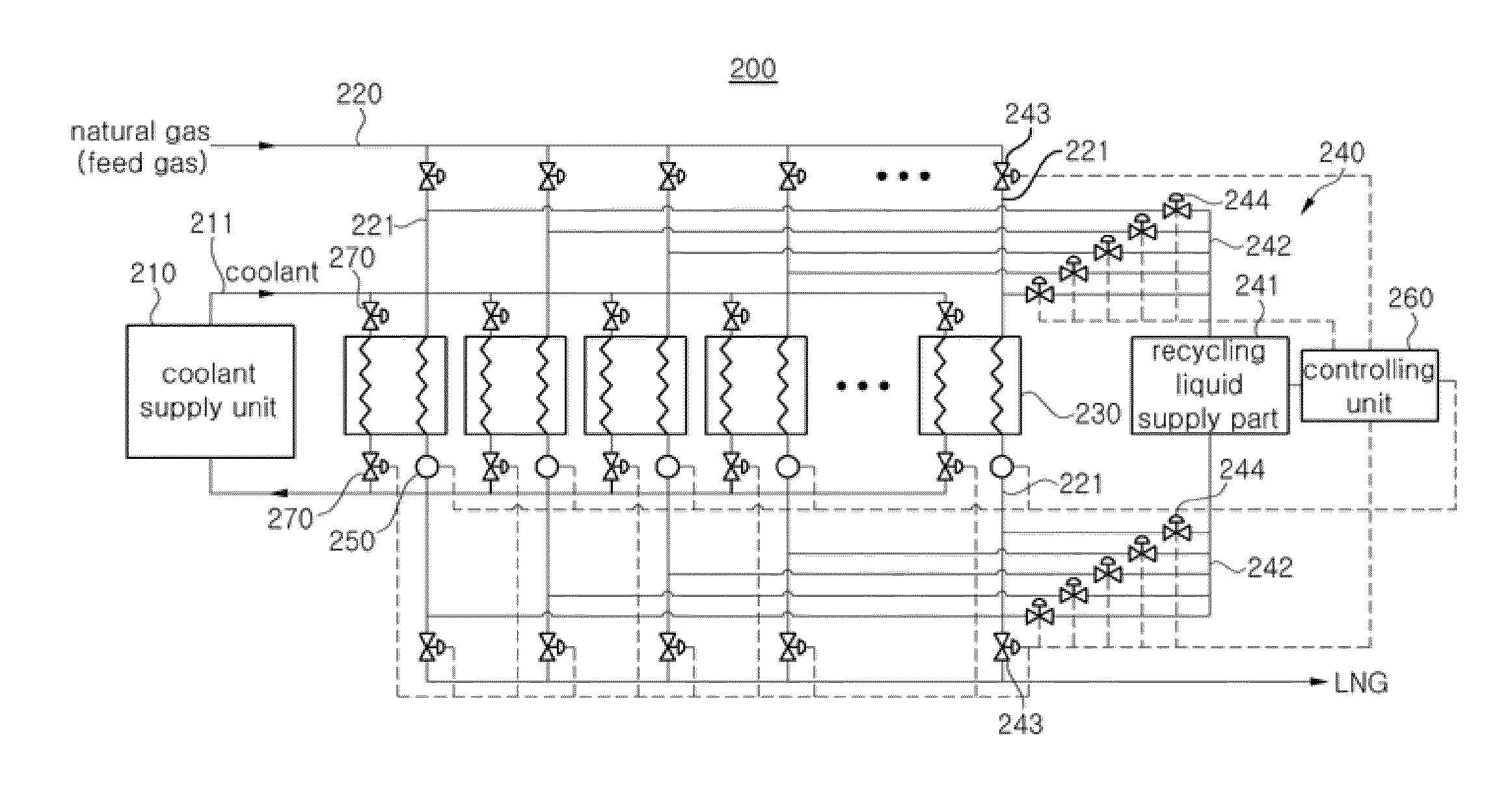

Method for producing pressurized liquefied natural gas, and production system used in same

InactiveUS20130219955A1Reduce expensesReduce plant construction costsSolidificationLiquefactionProcess engineeringNatural gas fuel

A method for producing pressurized liquefied natural gas and a production system therefor are provided. The method for producing pressurized liquefied natural gas includes: performing a dehydration process to remove water from natural gas supplied from a natural gas field, without a process of removing acid gas from the natural gas; and performing a liquefaction process to produce pressurized liquefied natural gas by liquefying the natural gas, which has undergone the dehydration process, at a pressure of 13 to 25 bar and a temperature of −120 to −95° C., without a process of fractionating natural gas liquid (NGL). Accordingly, it is possible to reduce plant construction costs and maintenance expenses and reduce LNG production costs. In addition, it is possible to guarantee high economic profit and reduce payback period in small and medium-sized gas fields, from which economic feasibility could not be ensured by the use of a conventional method.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

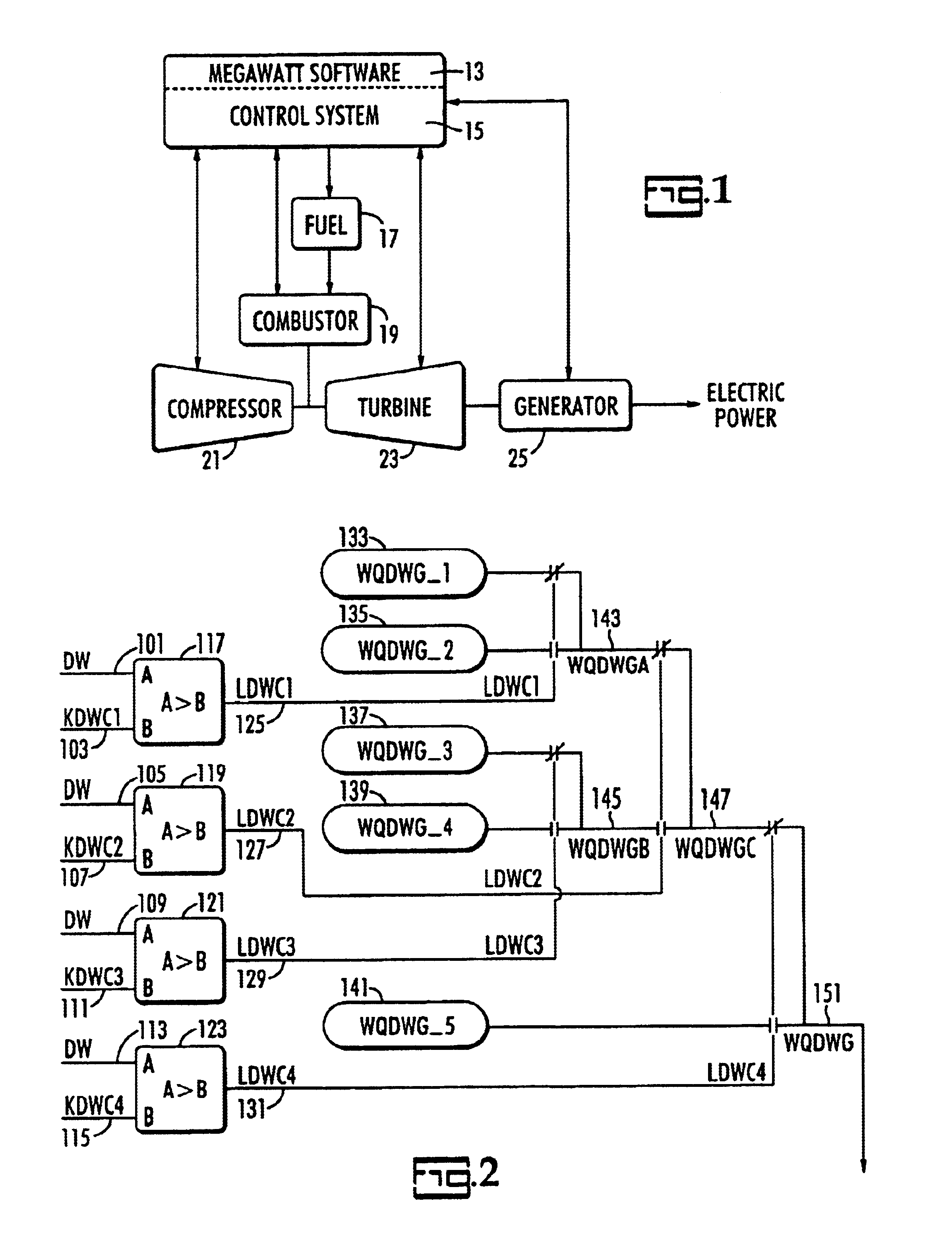

Software system for verification of gas fuel flow

InactiveUS6865890B2Improve accuracyGas turbine plantsTurbine/propulsion fuel controlCombustion systemSoftware system

A computerized system for accurate, independent verification of natural gas fuel flow in order to control H2O injection flows. The H2O is injected into a combustion system to control emissions. The system comprises:receiving gas turbine control parameters from a gas turbine control system;receiving control parameters from a megawatt transducer;calculating values based upon readings from said control system and said megawatt transducer;comparing said values to a megawatt reference curve;detecting an abnormal reading;starting a timing sequence during which said reading is monitored;transferring NOx and H2O water injection control to a megawatt module at completion of said timing sequence;alerting operator said transfer;allowing for return of control to said gas turbine control system once said abnormal reading is corrected.

Owner:WALKER RONALD STEVEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com