Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about How to "Quick refueling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

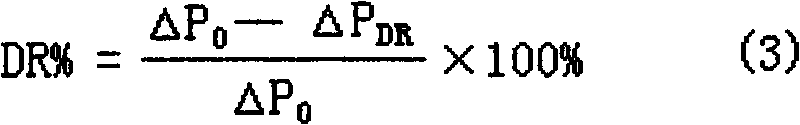

Preparation method for oil soluble drag reducer

InactiveCN102408506ALess investmentQuick loading and unloadingPipeline systemsPolymer scienceZiegler–Natta catalyst

The invention discloses a preparation method for oil soluble drag reducer, which is characterized in that high purity an alpha-olefin material is obtained through implementing absorption and distillation pretreatment on alpha-olefin mixture; a Ziegler-Natta catalyst is added for prepolymerization to lead the viscosity of a liquid to be capable of preventing the catalyst from sinking; then polymerization reaction is implemented under a lower temperature between 10 DEG C between zero and 0 DEG C and finished until a conversion rate of monomer reaches 95 percent; then a drag reducing polymer is cut and a dispersing agent is added; then the drag reducing polymer is frozen by liquid nitrogen and is crushed to a granularity of 129 meshes under a low temperature; then the dispersing agent is dispersed, and the drag reducing polymer is mixed with a thickening agent and an aqueous surfactant liquid to prepare a finished product of stable drag reducer suspension. The drag reducing polymer copolymerized through the preparation method has high molecular weight, is easy to crush under low temperature, has fast solution velocity, is not adhered on the wall of an oil pipeline and has high drag reducing rate.

Owner:TIANJIN VOCATIONAL INST

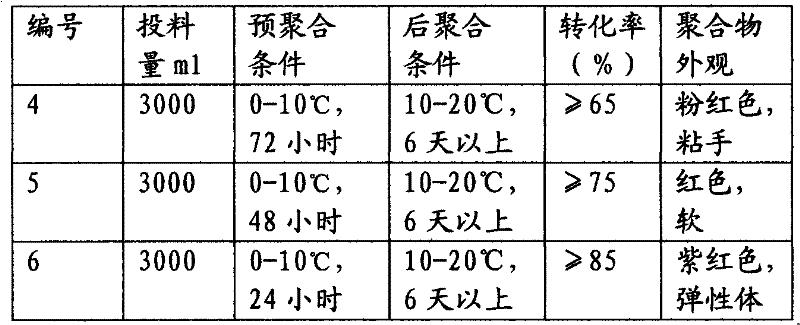

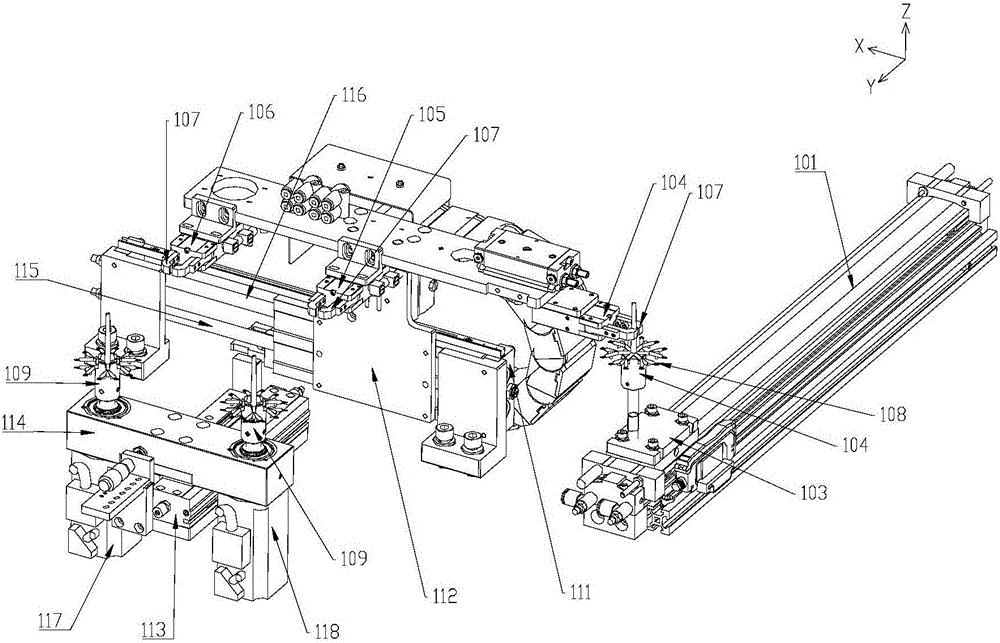

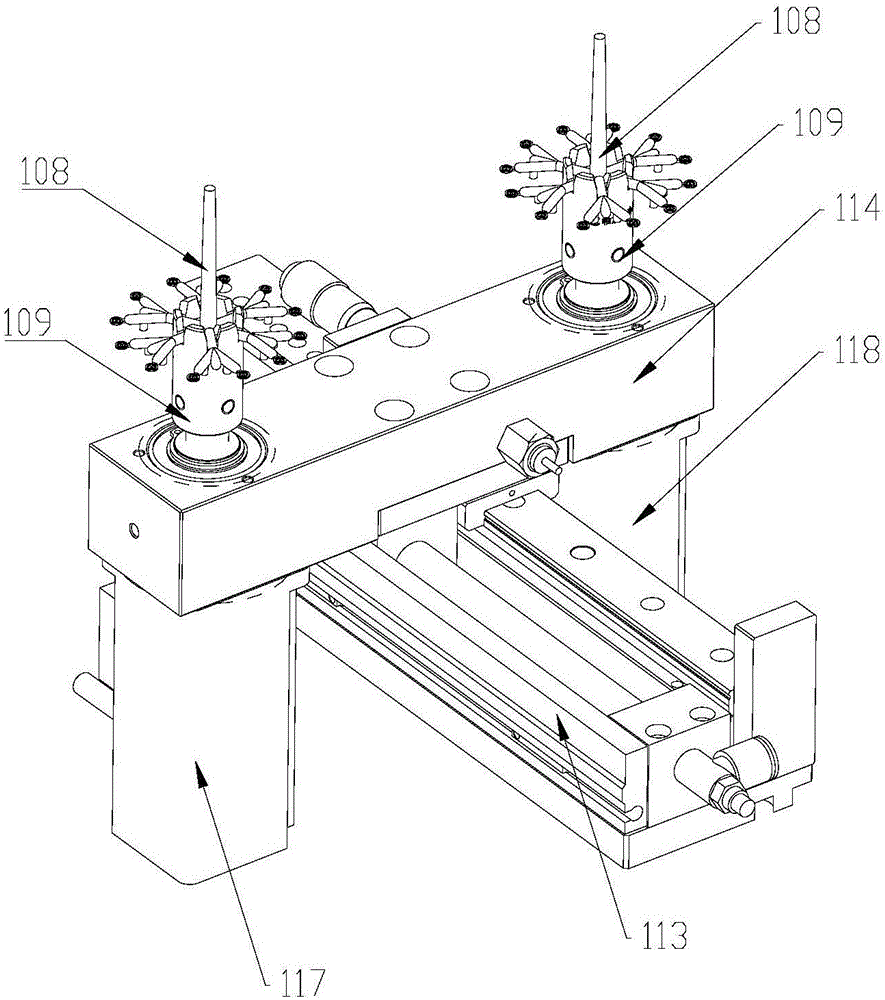

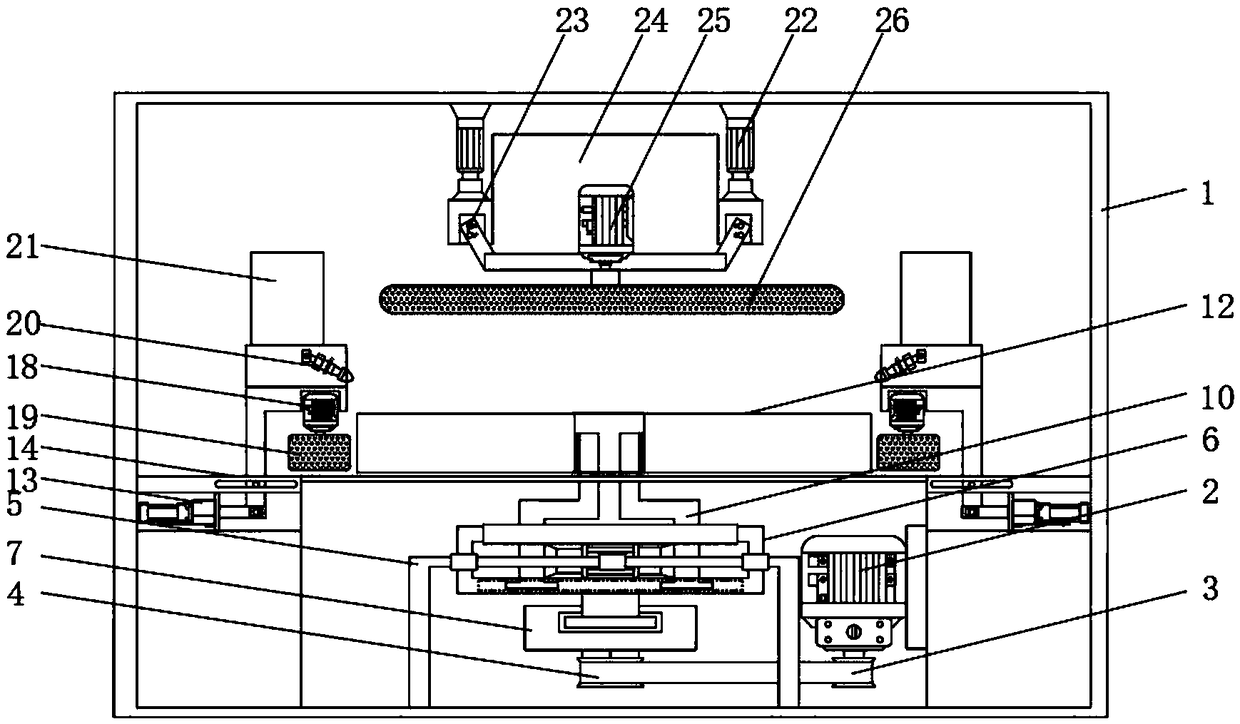

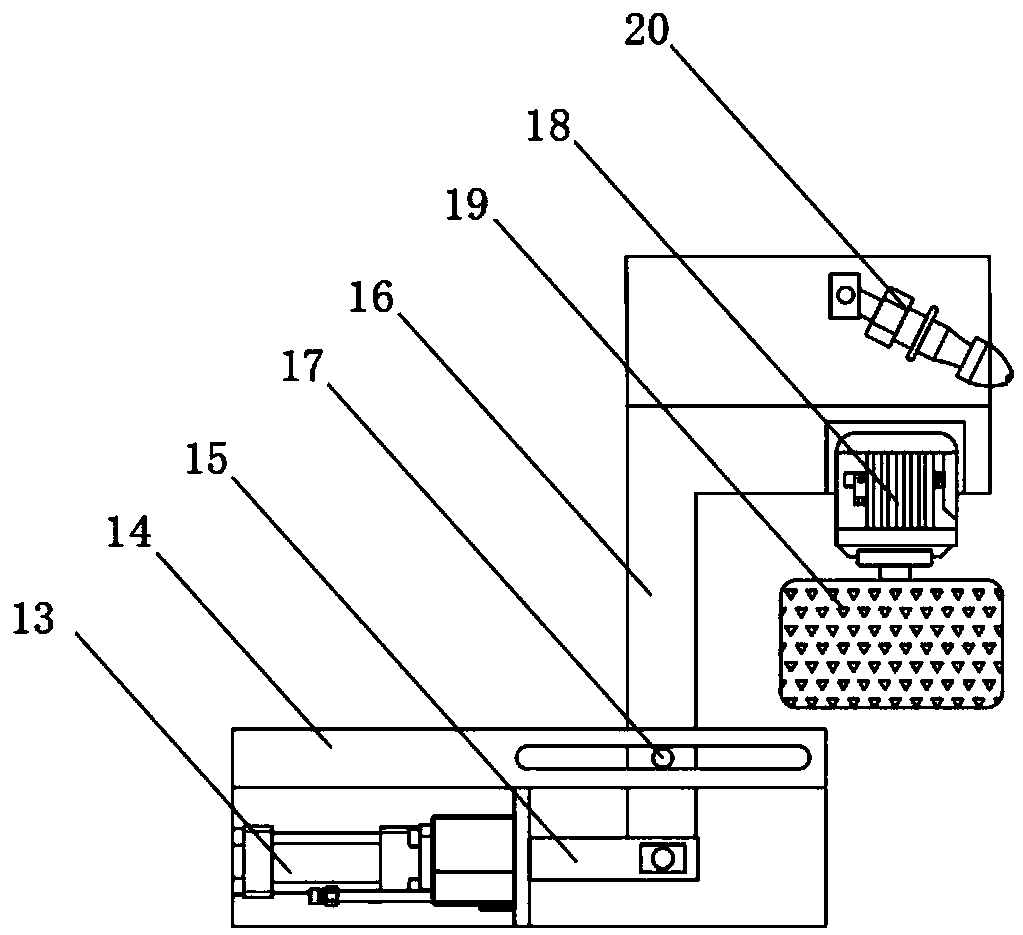

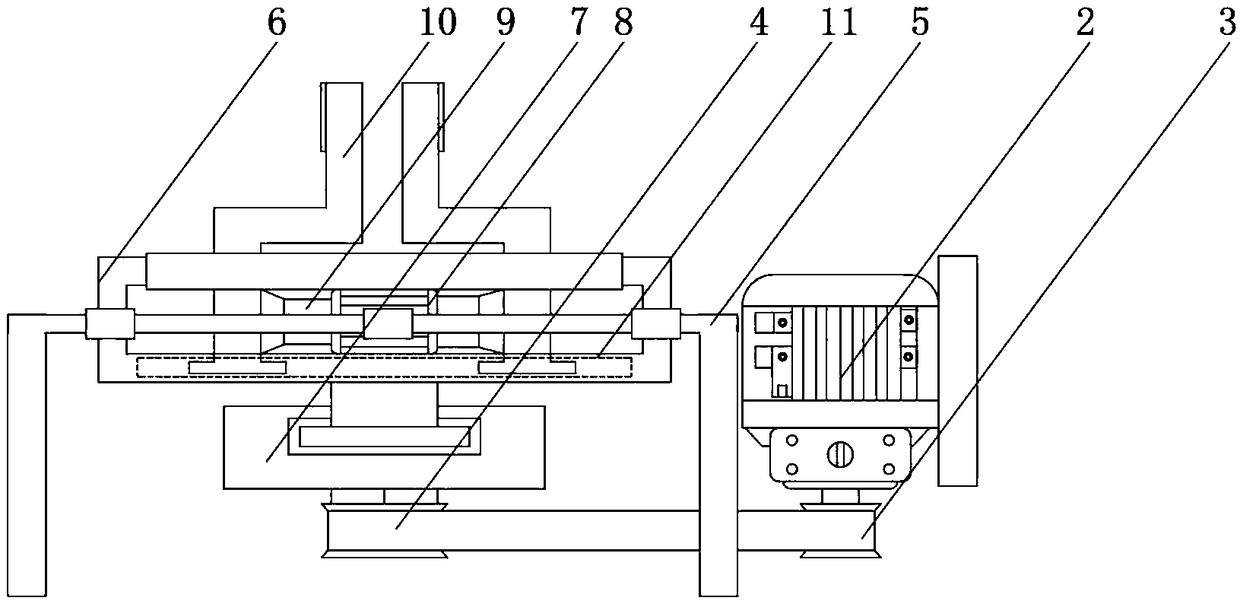

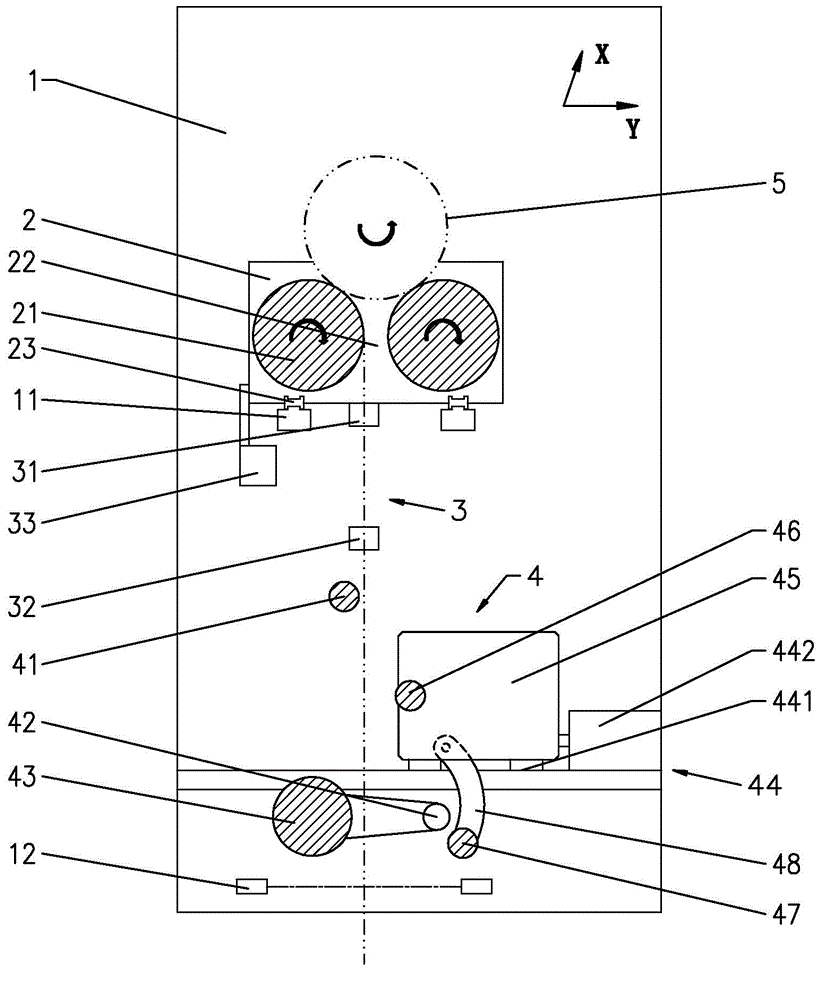

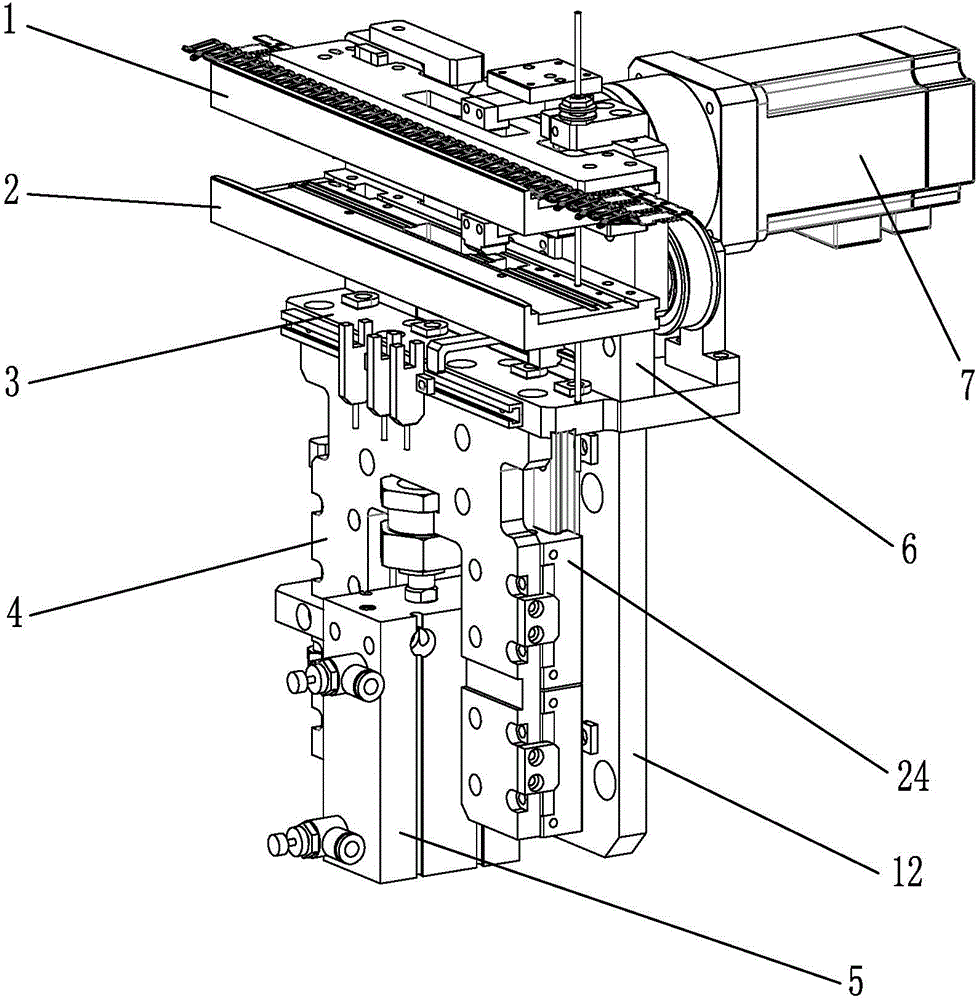

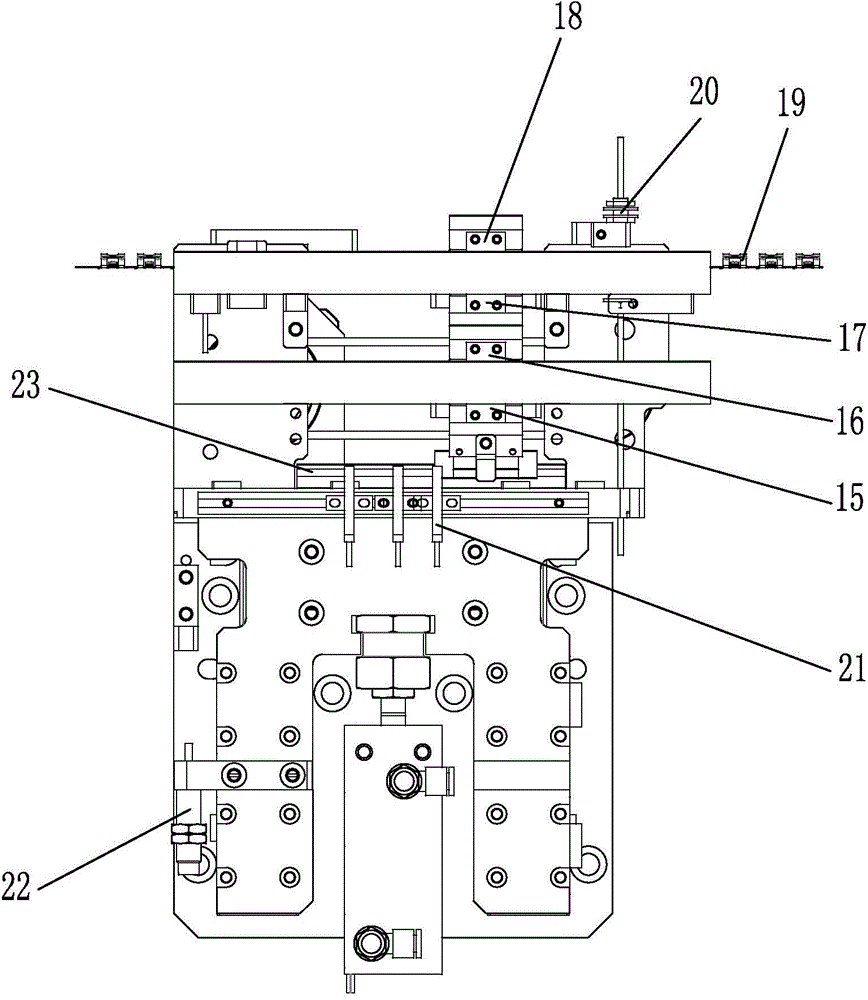

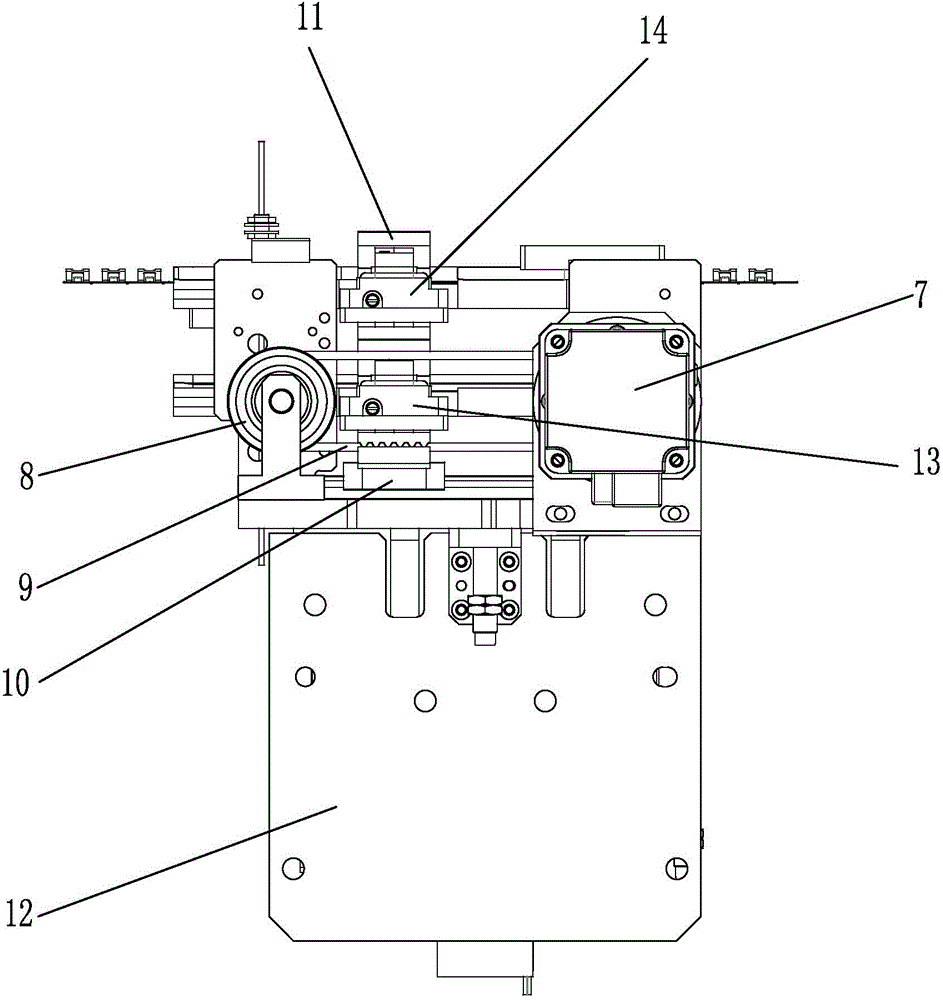

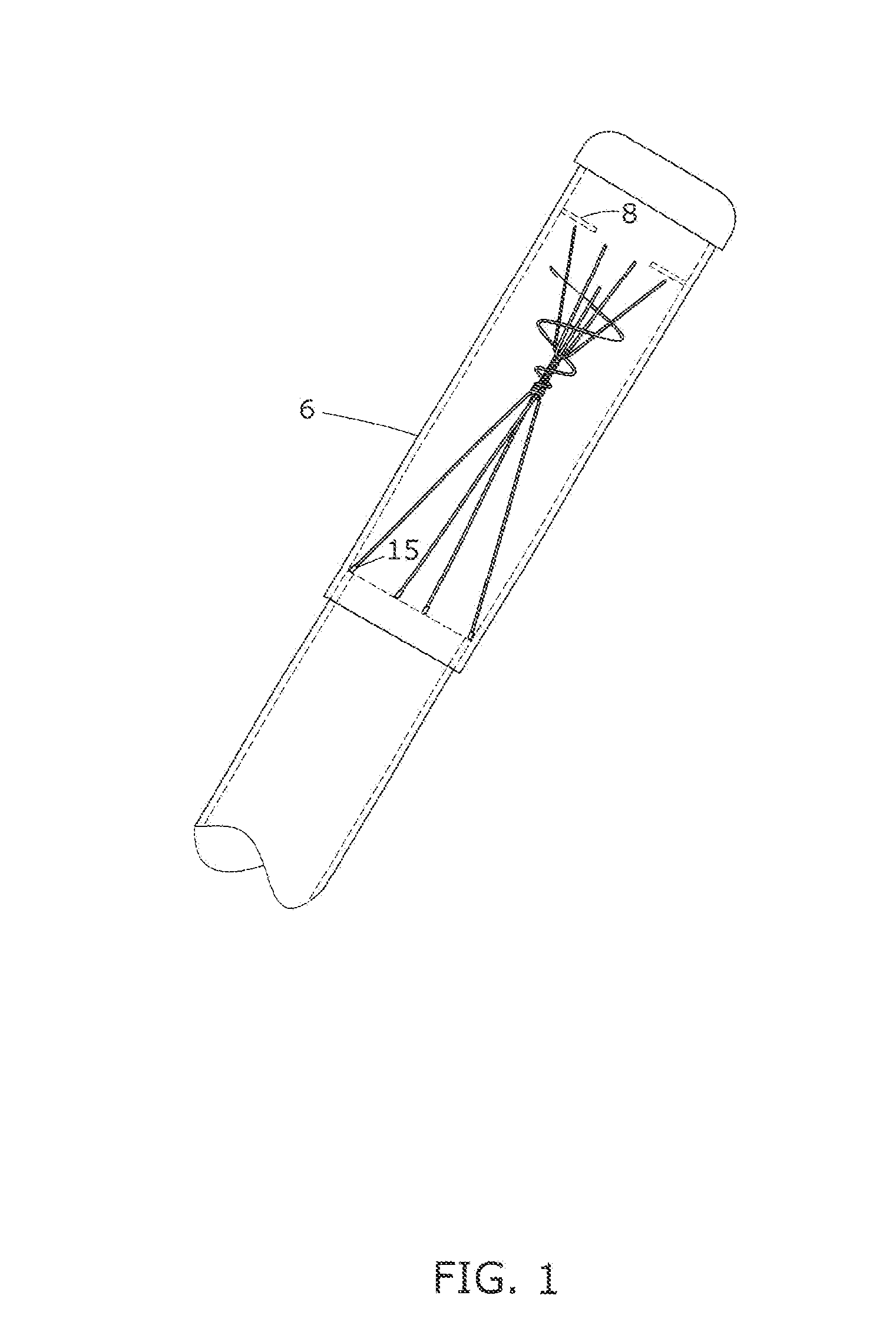

Shearing machine for injection molding lenses

InactiveCN106393217AImprove cutting efficiencyStable job qualityMetal working apparatusInjection molding machineMechanical engineering

The invention relates to a shearing machine for injection molding lenses. The shearing machine is characterized in that a feeding device comprises a positioning mechanism and a conveying device, and the conveying device comprises first swinging devices; each first swinging device comprises a clamping part for clamping injection molding parts, the multiple first swinging devices are configured to be capable of conveying the injection molding parts, and the positioning mechanism is configured to receive the injection molding parts conveyed from the conveying device for shearing; a shearing device comprises a first cutter, a second cutter and a drive device for driving the first cutter and the second cutter to do opposite or contrary motion, wherein the first cutter is opposite to the second cutter; a discharging device comprises a suction device for sucking and arranging the injection molding lens; and a warehousing device comprises a warehousing frame provided with an open end and capable of moving in the Z axis direction, the warehousing frame is provided with a supporting portion for supporting trays, and the supporting portion is of a multi-layer structure.

Owner:GOERTEK INC

Automobile brake disc grinding device

InactiveCN108942525AEasy to fixEasy side grindingGrinding machinesGrinding/polishing safety devicesEngineeringRotating disc

The invention discloses an automobile brake disc grinding device. The grinding device comprises a working frame, the lower part of the interior of the working frame is fixedly connected with a rotating motor, the rotating motor is connected with a belt wheel I in the rotating mode through an output shaft, the belt wheel I is connected with a belt wheel II in the rotating mode through a belt, the bottom of the inner wall of the working frame is fixedly connected with a rotating frame, a rotating mounting disc is connected with the inner side of the rotating frame in a rotating mode, a rotatingdisc is arranged at the bottom of the rotating mounting disc, the bottom of the rotating disc is fixedly connected with the belt wheel II, and the inner side of the rotating mounting disc is connectedwith a brake disc mounting base in a sliding way. The grinding device relates the technical field of automobile part machining. According to the automobile brake disc grinding device, the purpose ofgrinding the brake disc is achieved, grinding efficiency of the brake disc can be improved due to multi-azimuth grinding at the same time; a controllable pushing device is used, so movement of the grinding machine is convenient; material changing can be carried out rapidly when the grinding work is stopped, and workload of workers is reduced.

Owner:ANHUI TIANYU AUTO PARTS MFG

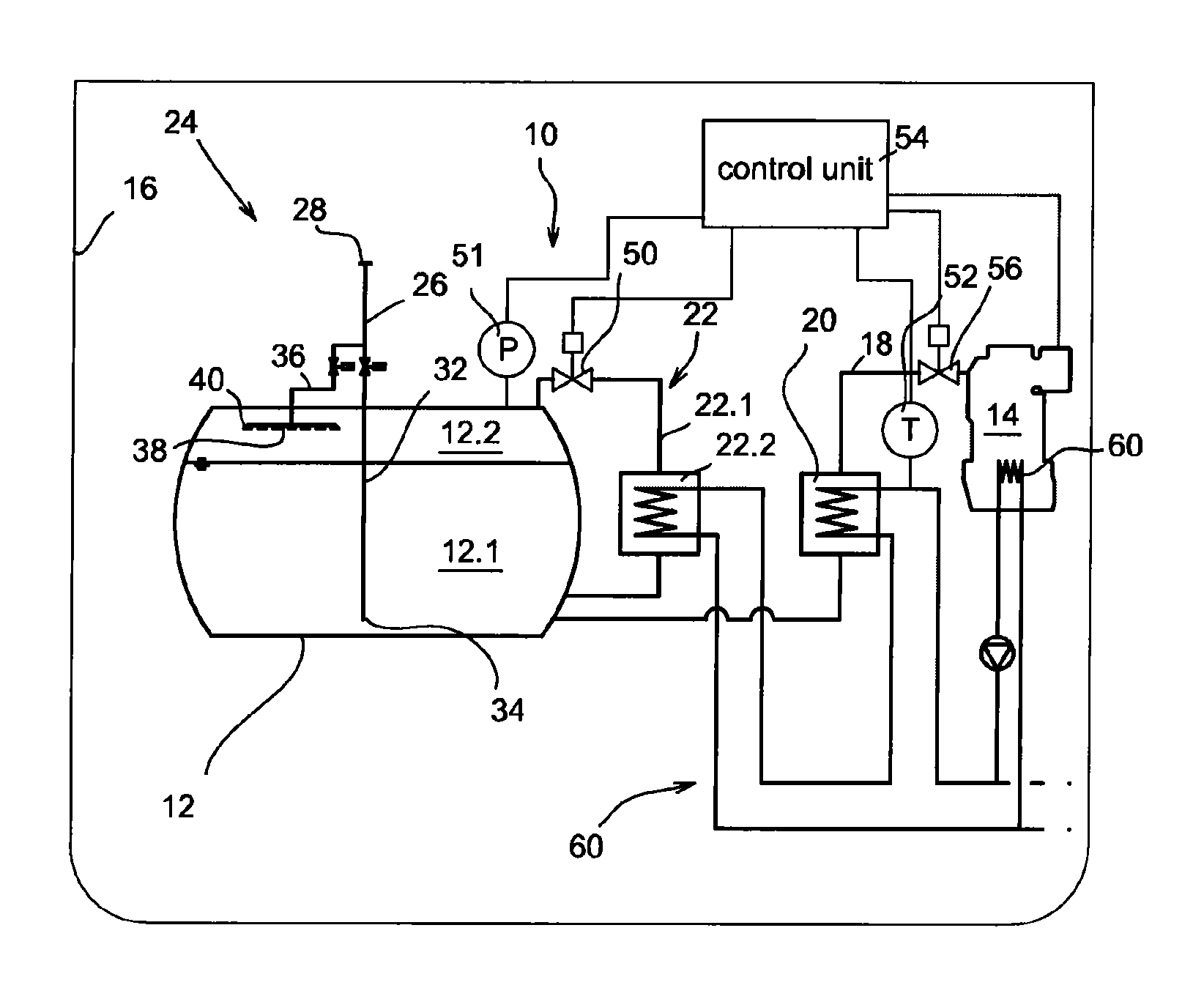

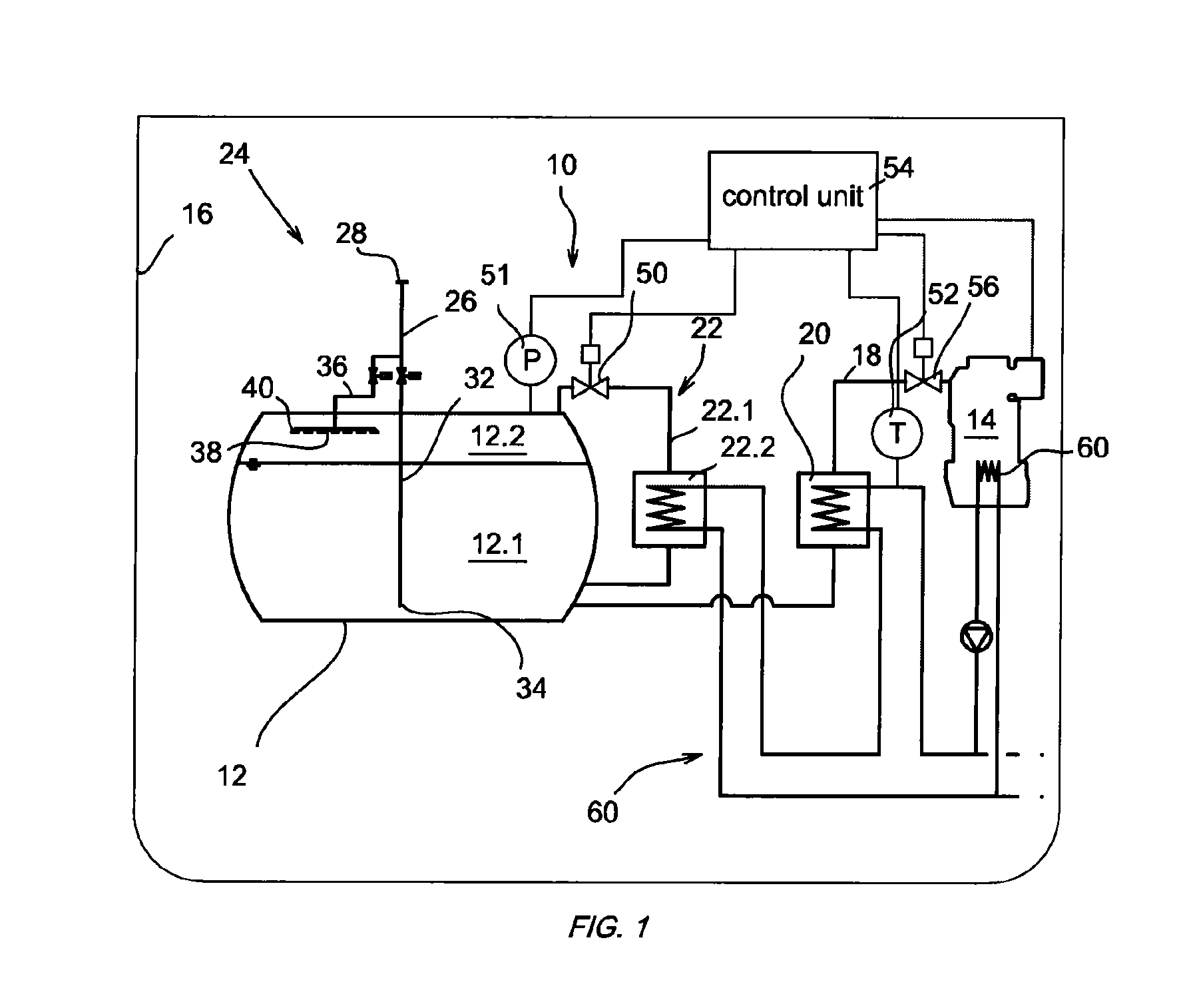

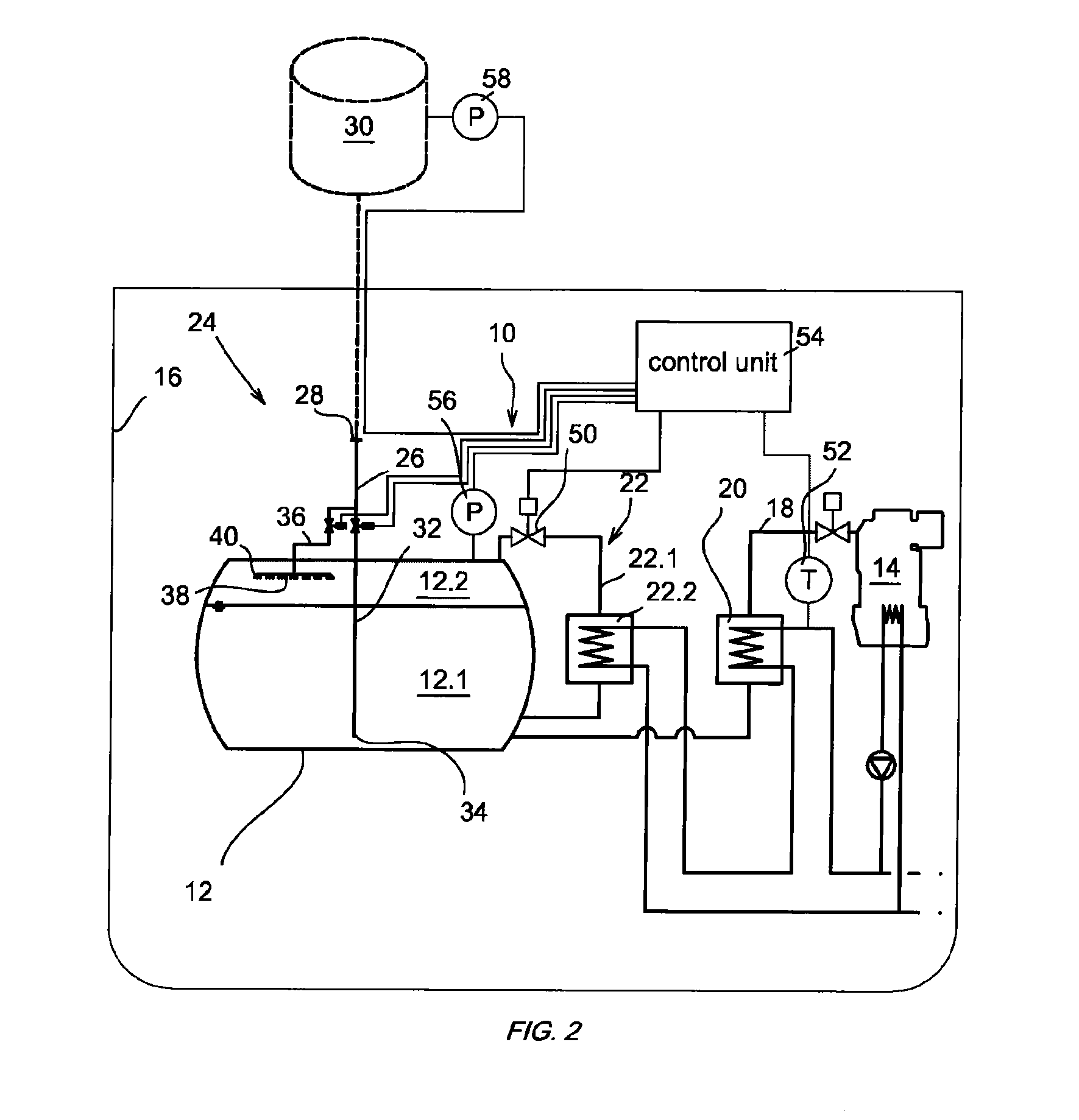

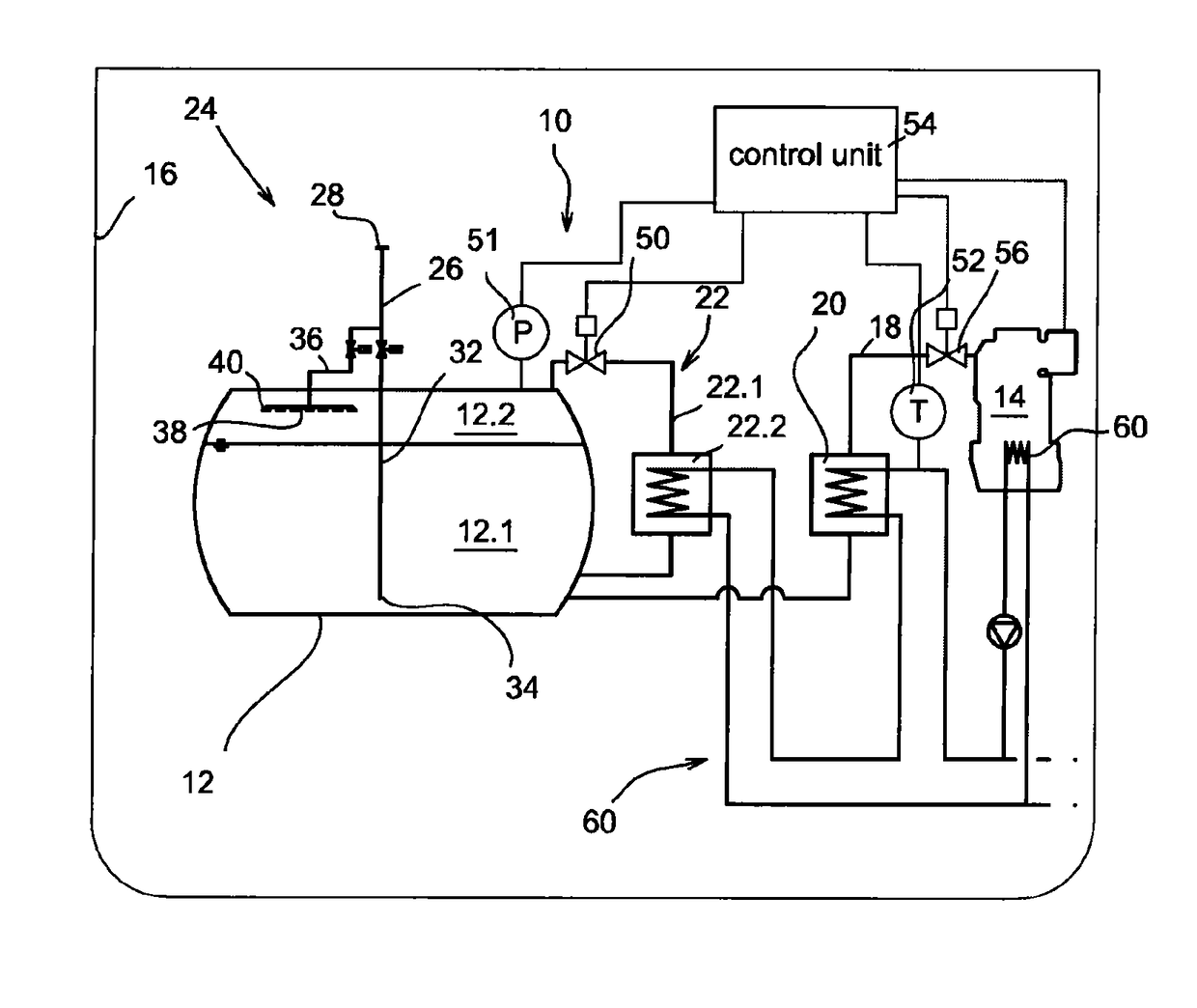

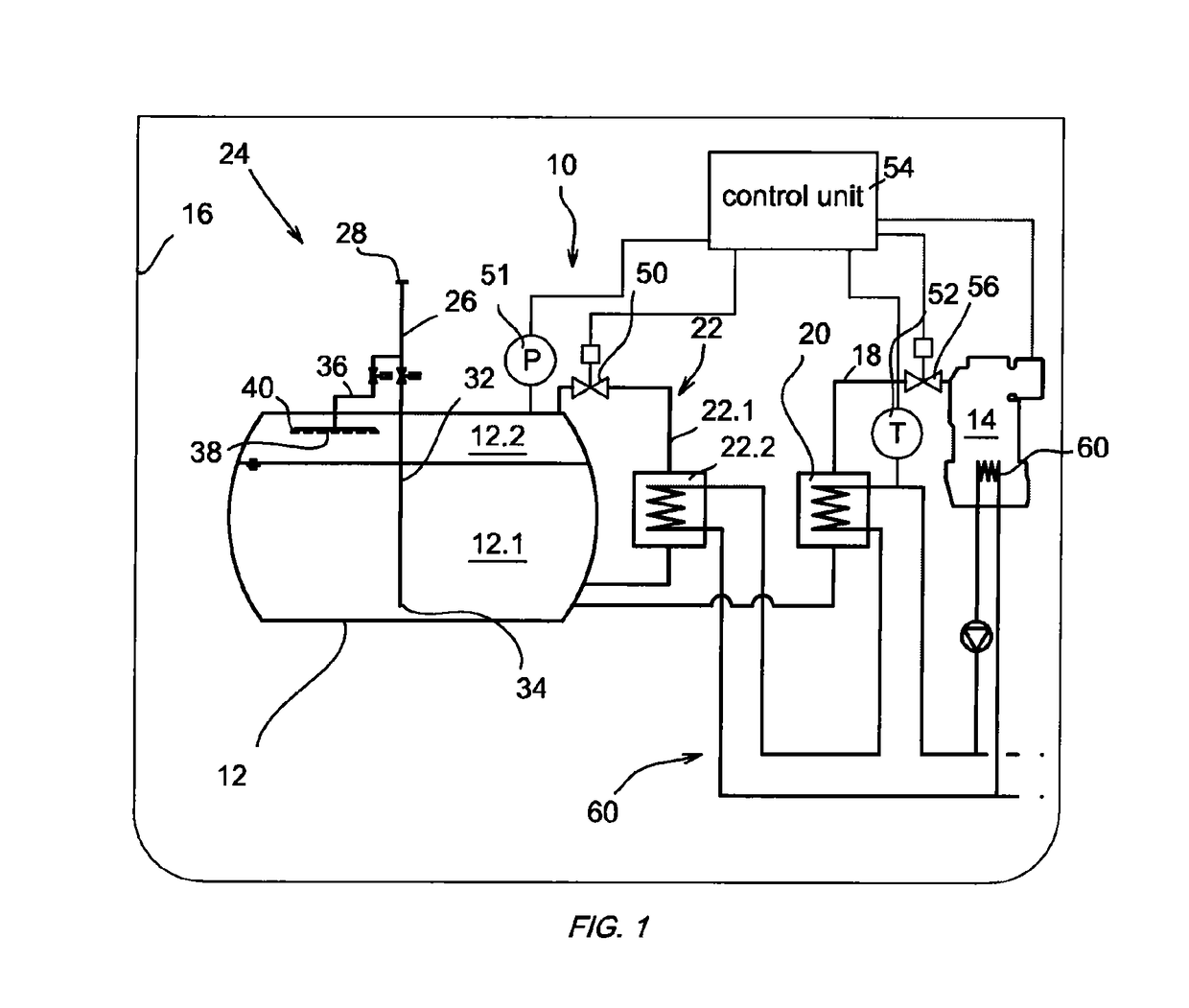

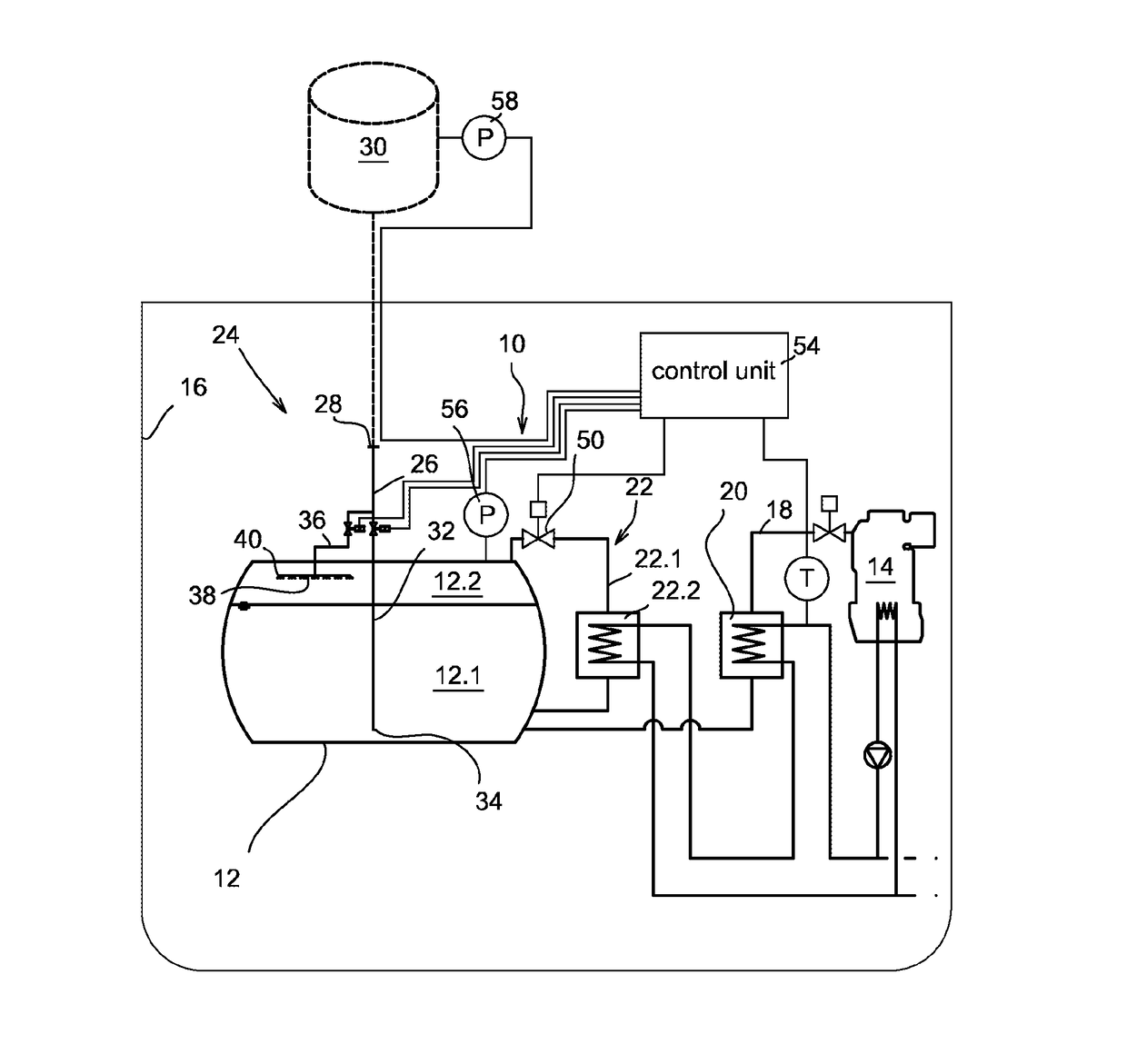

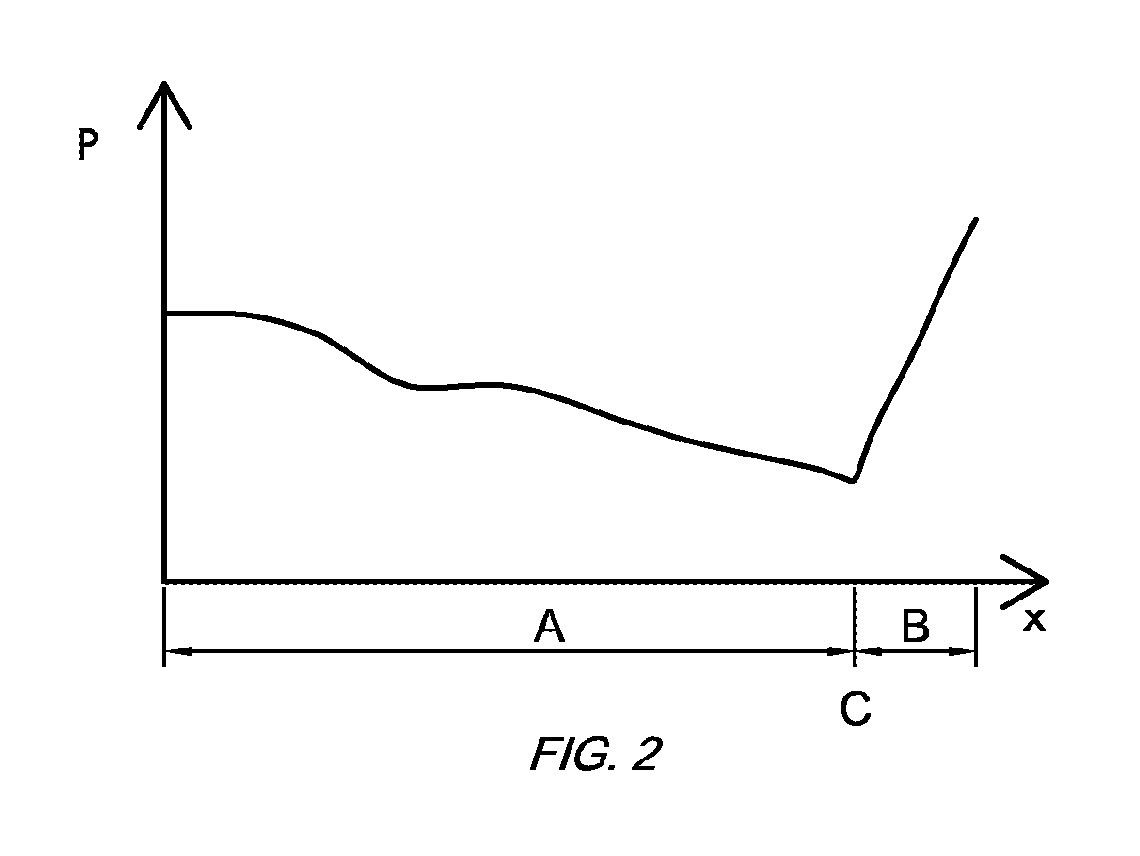

Method of starting gas delivery from a liquefied gas fuel system to a gas operated engine and a liquefied gas fuel system for a gas operated engine

ActiveUS20150315949A1Maintain pressureQuick refuelingInternal combustion piston enginesExhaust apparatusFuel tankProduct gas

A method for starting gas delivery from a liquefied gas fuel system includes a fuel tank filled with liquefied gas by a filling procedure and the filling procedure resulting in the pressure in the tank being at least at an operational pressure required by the engine. The method pressure in the tank is controlled by controlling the operation of a pressure build up system including the pressure build up evaporator which is arranged in a conduit leading from the bottom section of the tank to the upper section of the tank. The pressure build up system is controlled by controlling the flow rate of the evaporated gas in the conduit while the heat transfer medium is allowed to flow unconstrained through the pressure build up evaporator.

Owner:WARTSILA FINLAND OY

Rotating disc type cup type beverage packaging device

The invention discloses a rotating disc type cup type beverage packaging device. The rotating disc type cup type beverage packaging device comprises a packaging box. A servo motor is arranged in the packaging box. The servo motor fixes a rotating disc through a rotating rod. A cap dropping groove and a bottom supporting box are arranged on the circumference of the rotating disc. A push lever and acap pushing piece are arranged on one side of an opening of the top of the cap dropping groove. A cup storage sleeve and a cap storage tube are arranged on the inner top surface of the packaging boxthrough a fixing clamping slot in a clamped mode. A pressing plate is arranged on the front of the cap storage tube. A cup pressing air pump and a cap pressing air pump are fixed to both sides of thetop surface of the packaging box. A water tank support plate is fixed to a rear plate of the interior of the packaging box. Multiple beverage boxes are arranged on the two sides of the top surface ofthe water tank support plate. Multiple water suction pumps are fixed to the centre of the top surface of the water tank support plate, and discharging tubes are connected to the water outlet ends of the water suction pumps. A fetching port is formed in the center of a front plate of the packaging box, and a control box is installed at the right side of the front plate of the packaging box. According to the rotating disc type cup type beverage packaging device, the whole process of automatic cup dropping, automatic beverage adding, automatic cap pressing and automatic discharging is achieved.

Owner:深圳前海量子聚合电子商务有限公司

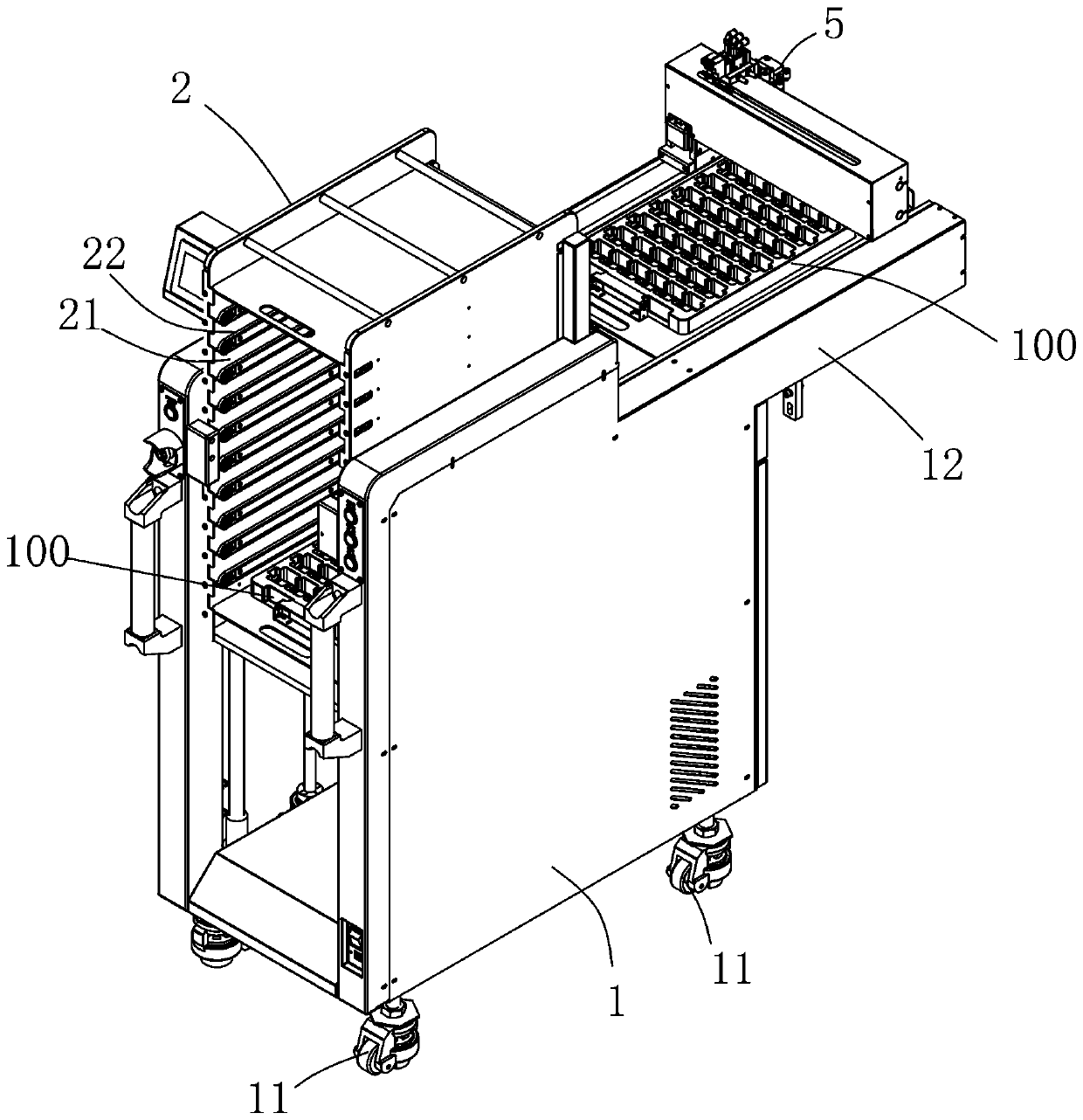

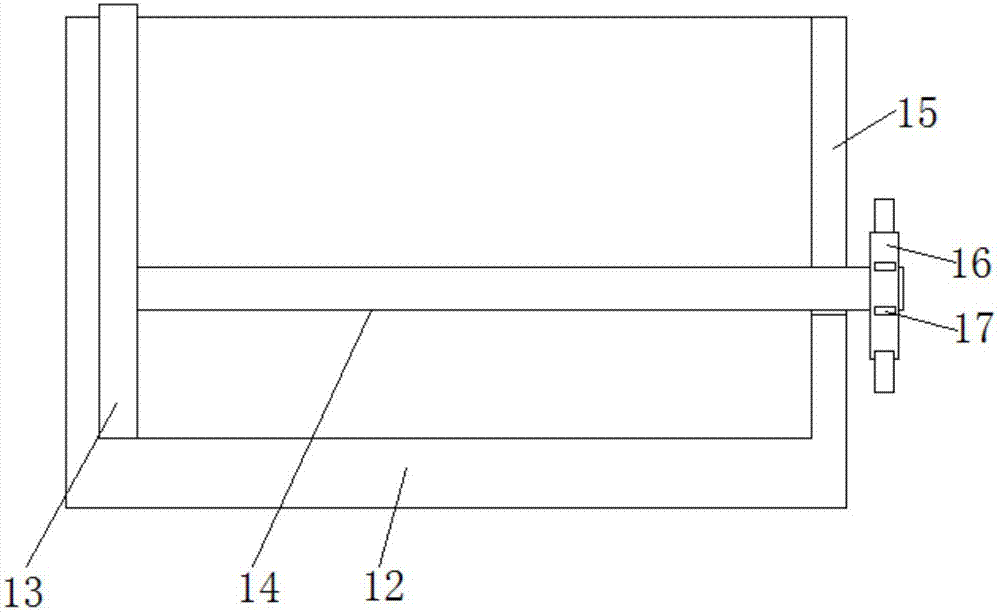

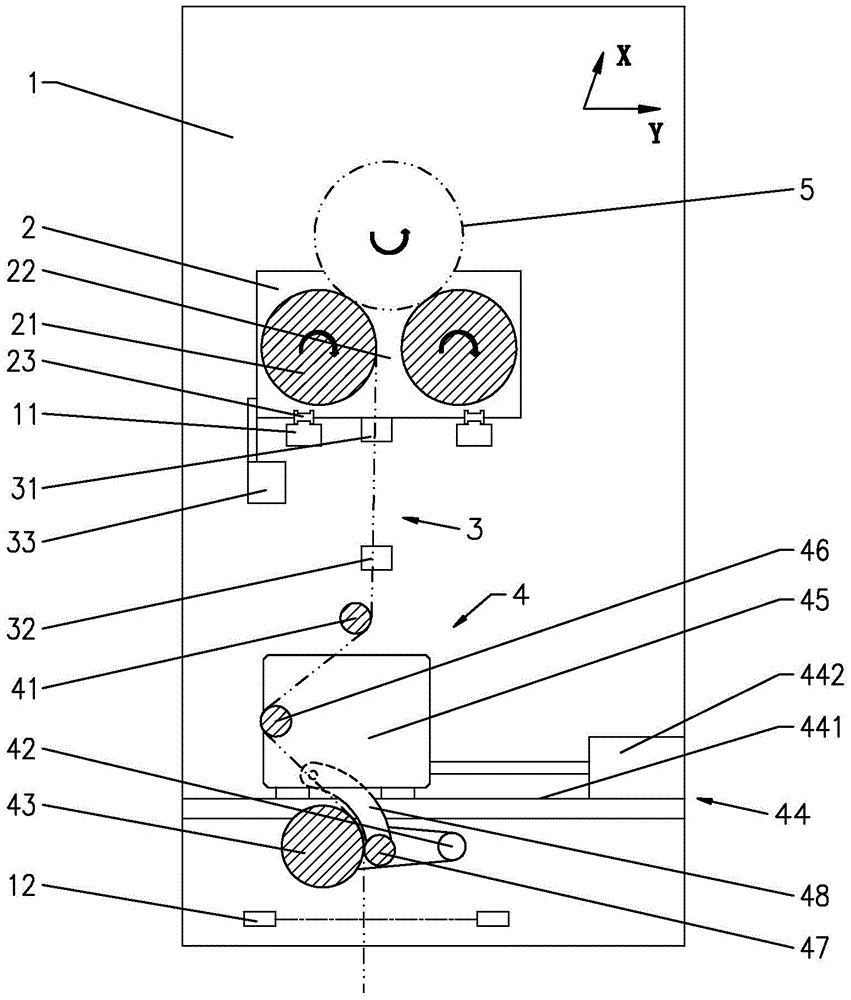

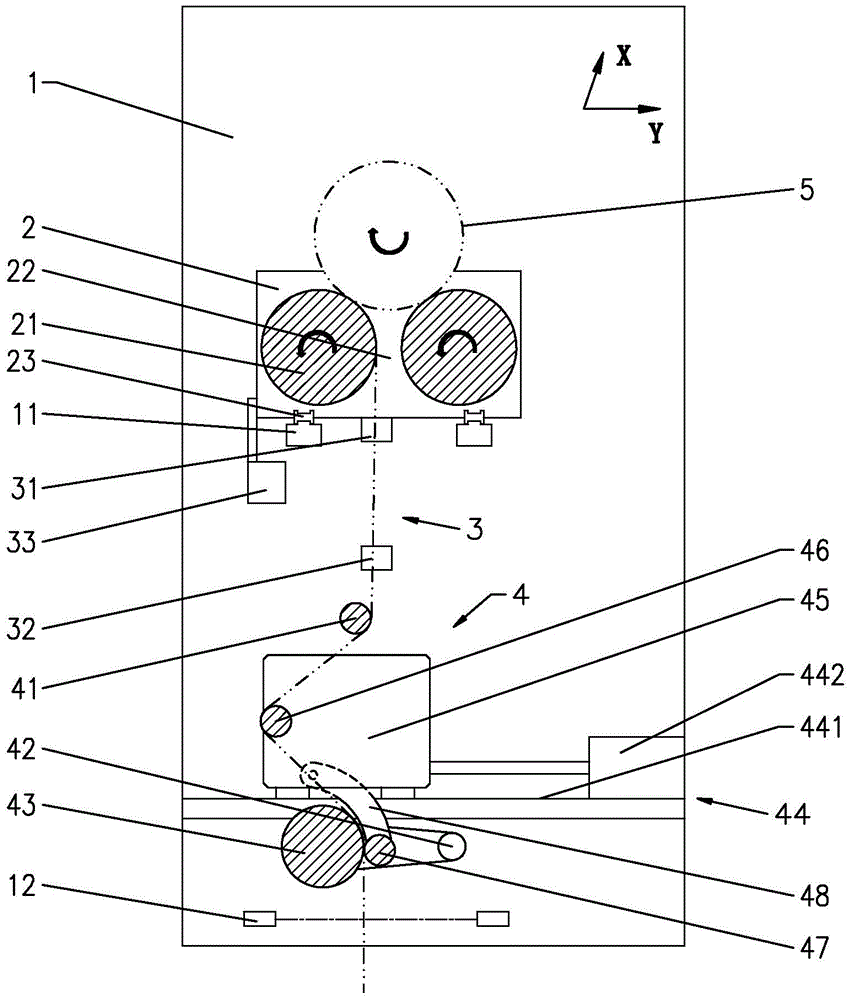

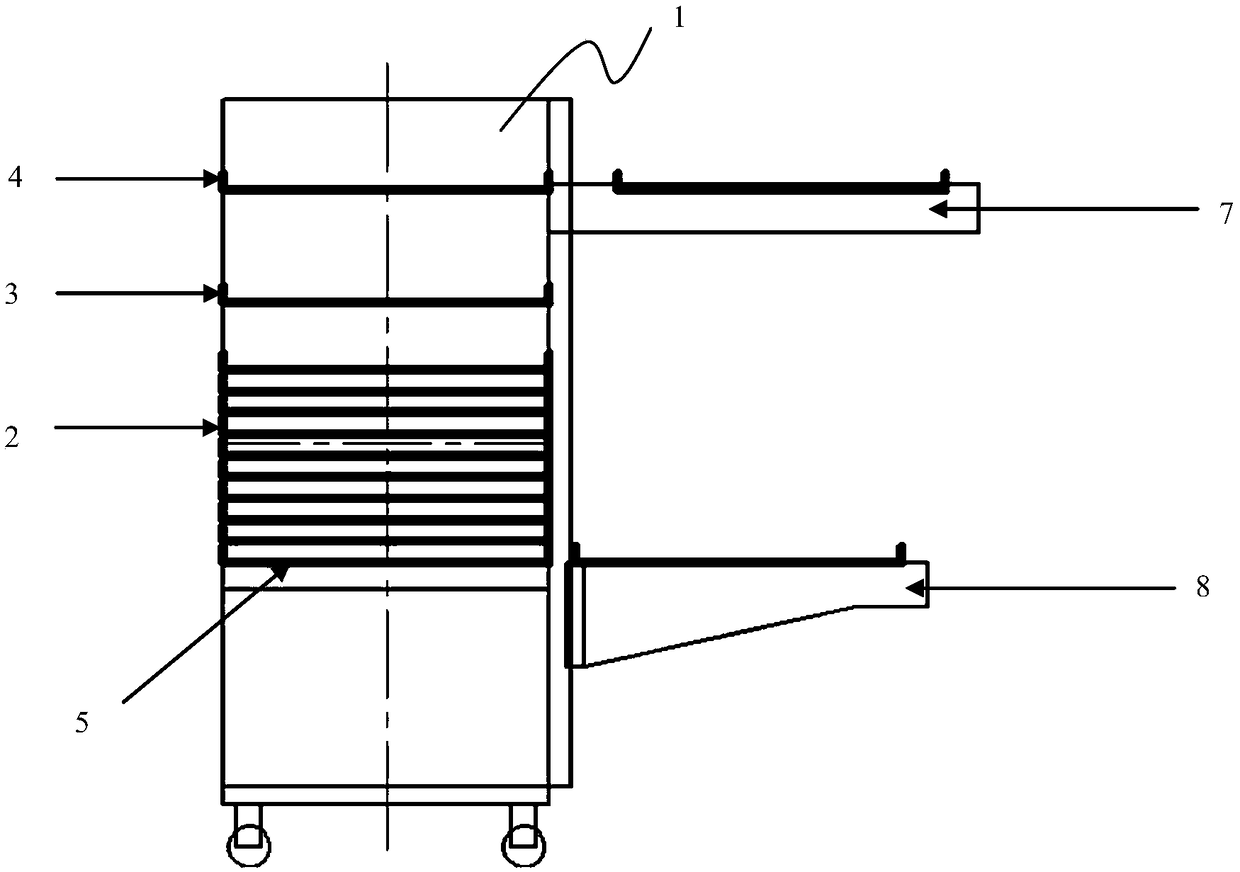

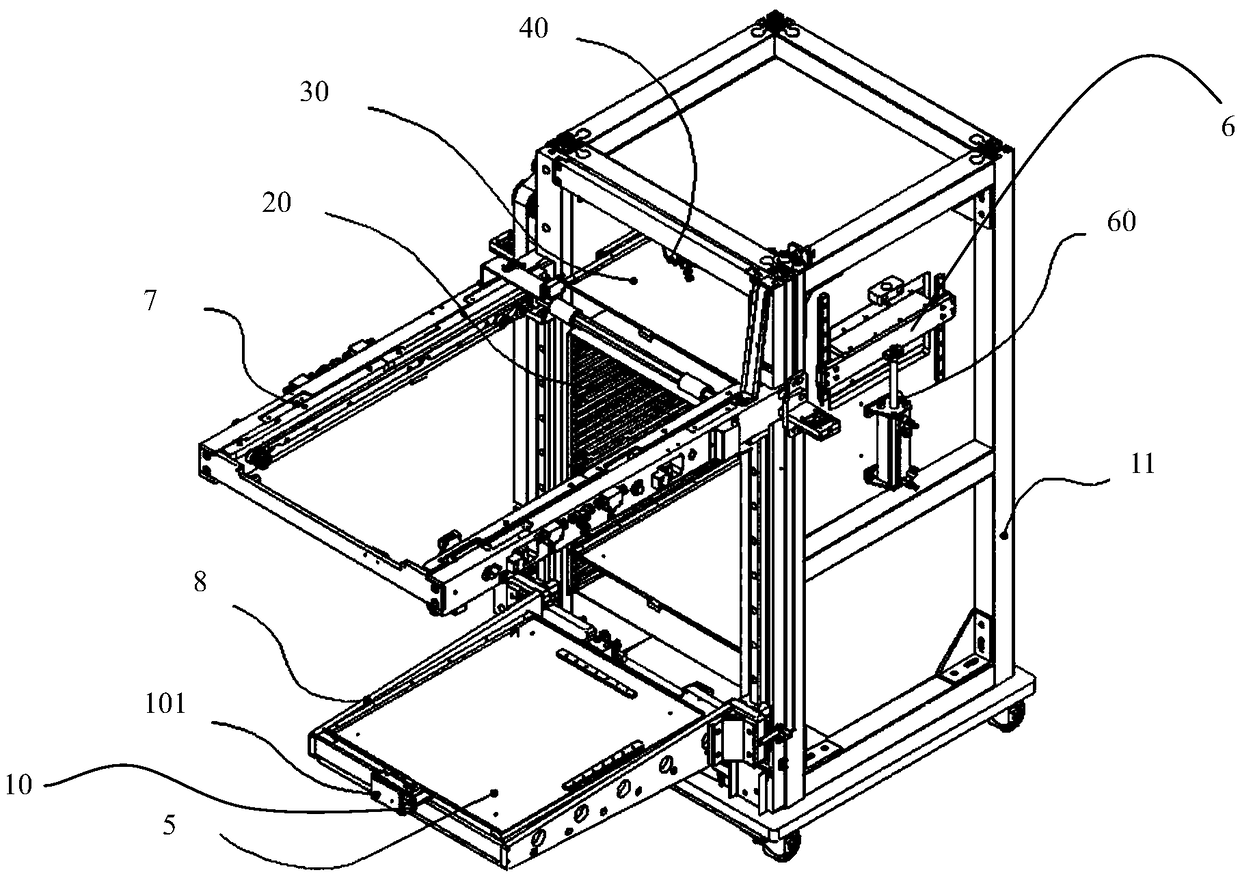

Open multilayer feeder

PendingCN110228681ARealize switchingQuick refuelingConveyorsElectrical componentsReciprocating motionEngineering

The invention relates to an open multilayer feeder. A base is provided with a working platform in a certain height; a material box is assembled on the base correspondingly, and driven by a lifting mechanism to rise and fall; the material box is provided with a plurality of material placing layers in the lifting direction, and each material placing layer is provided with a first conveyor belt; plastic sucking disks of the corresponding layers are output through the first conveyor belts; second conveyor belts are assembled on the working platform, connected with the first conveyor belts in the corresponding heights in the material box, and driven by the same driving mechanism; a feeding fixture is arranged at the second end of the working platform, and XY mechanical pickup hands are assembled on the working platform and do reciprocating motion; and materials on the plastic sucking disks are picked up through the XY mechanical pickup hands, and placed on the feeding fixture. According tothe open multilayer feeder, switching of the multiple plastic sucking disks in the material box is achieved, and the materials are changed quickly; and in combination with the XY mechanical pickup hands, the materials in the plastic sucking disks are placed on the feeding fixture for use by an irregular plug-in machine. The open multilayer feeder is simple in structure, low in investment cost, andstable and reliable in operation.

Owner:东莞市德速达精密设备有限公司

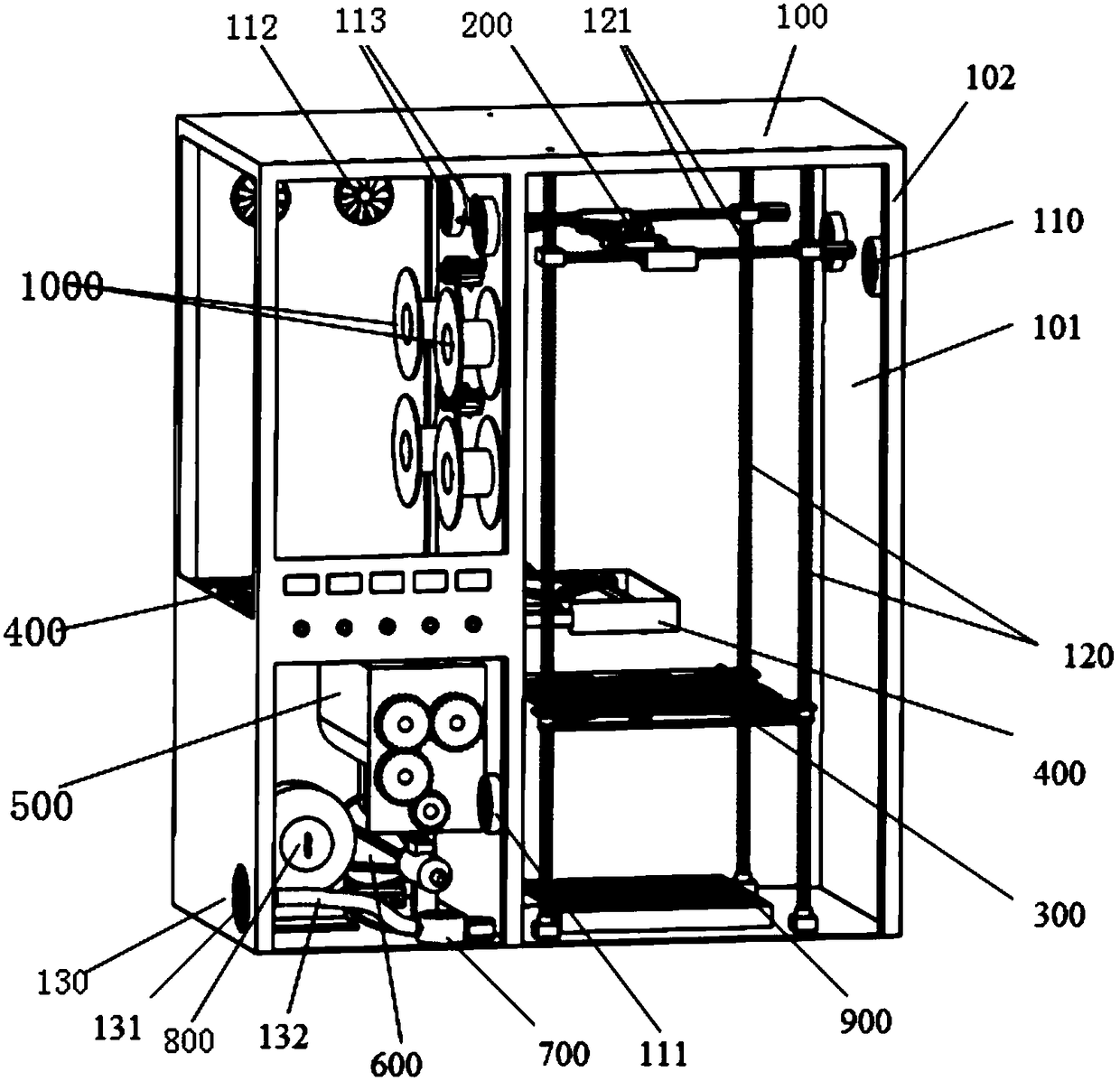

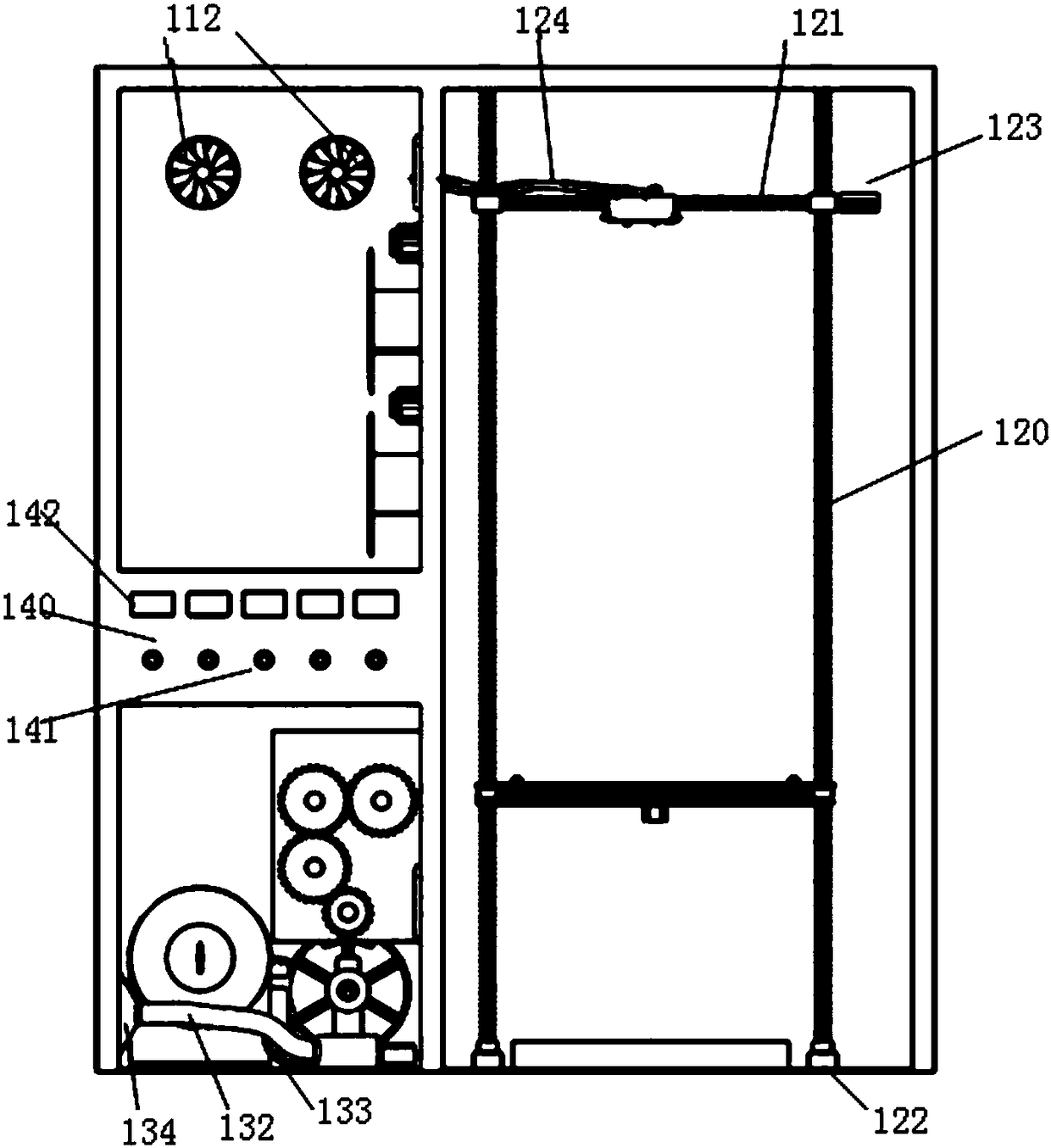

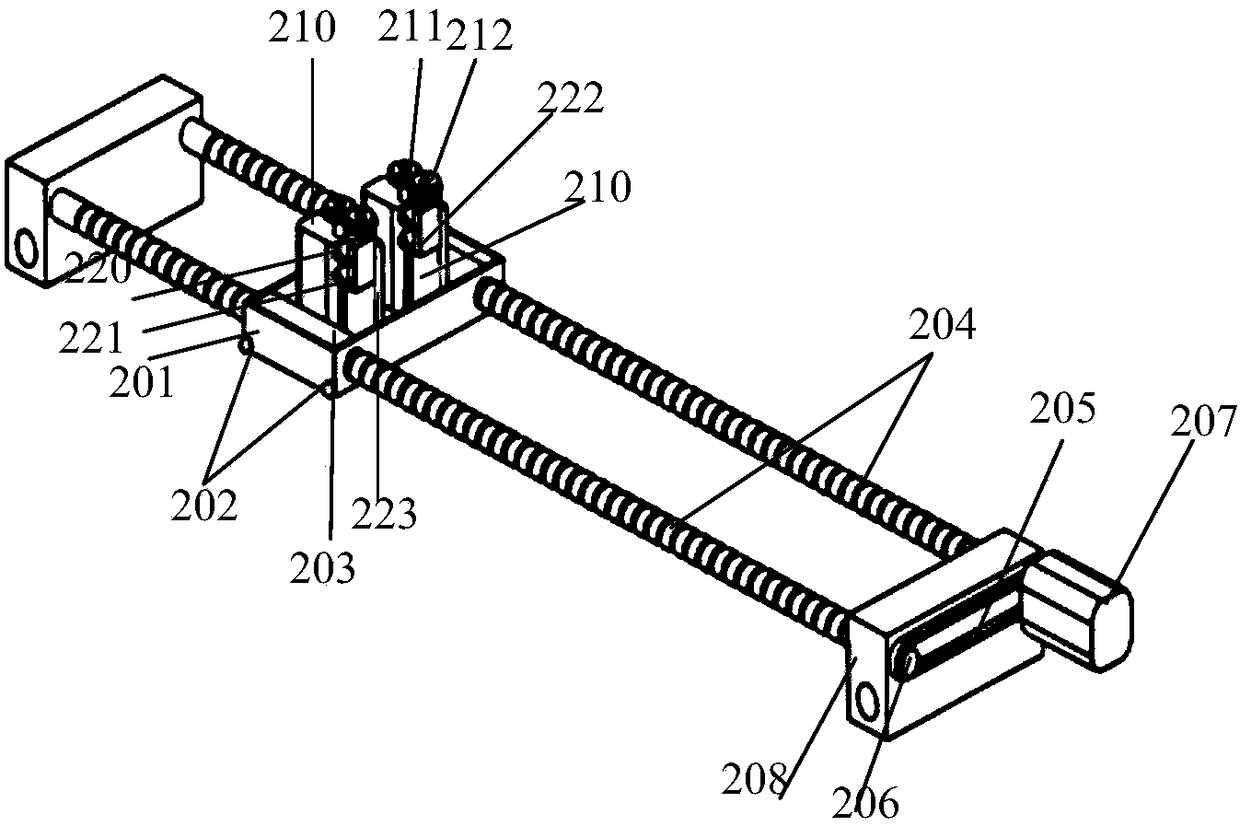

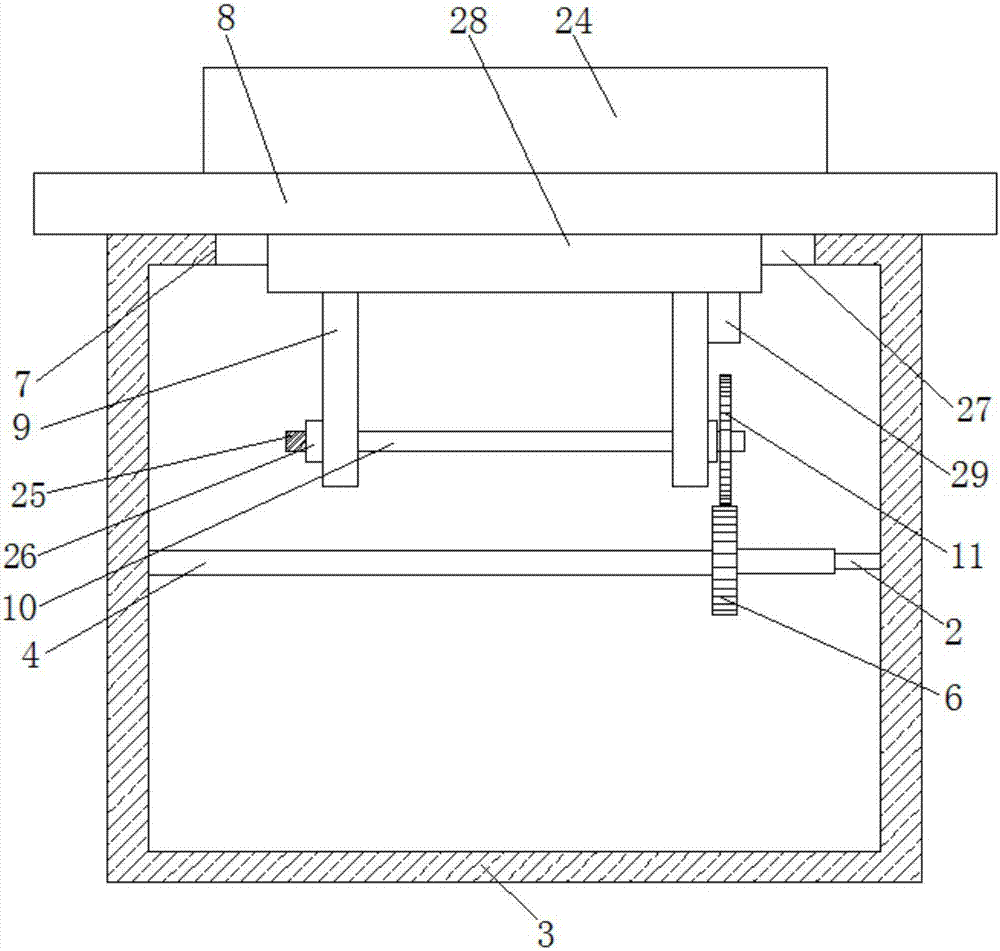

3D (Three Dimensional) printing machine with material recycling and planting cleaning device

ActiveCN108312538AEfficient crushingGuaranteed source of cool airAdditive manufacturing apparatusManufacturing environment conditioningSpray nozzleScrap

The invention discloses a 3D (Three Dimensional) printing machine with a material recycling and planting cleaning device. The 3D printing machine is provided with a crushing device; a crushing rolleris provided with crushing teeth and can be used for crushing waste materials with a relatively great grain diameter; the 3D printing machine is provided with a smashing device, the smashing device isinternally provided with a spiral tapered saw tooth crushing cutter for effectively crushing the waste materials and conveying the waste materials into a melting cavity; a fuse wire strong-wind cooleris arranged and is used for effectively cooling a fuse wire and conveying the cooled wire into a wire winding device; the recycled waste materials can be directly collected and stored by the wire winding device and also can be directly used as raw materials of the printing machine to be input. The 3D printing machine is provided with double printing heads; a printing spraying nozzle adopts doublefeeding openings and each feeding opening is provided with an electronic control valve; the feeding openings can be automatically switched to realize rapid material exchange; a printing platform cleaning device is arranged and can be used for automatically cleaning a printing platform; the cleaned waste materials are directly conveyed into the crushing device and the printing efficiency is accelerated. By adopting the 3D printing machine disclosed by the invention, the recycling and reutilization of the 3D printing waste materials are realized, the utilization rate of the raw materials is improved and the material waste problem is effectively solved.

Owner:HEFEI UNIV OF TECH

Winding and tightening device of fabric cloth

The invention discloses a winding device for textile cloth, which comprises a base, a motor is fixedly installed on the top of the base, and a winding box is fixedly installed on the top of the base and behind the motor through bolts, and the two sides of the winding box All are in the shape of openings, the output end of the motor runs through the winding box and is fixedly connected to one end of the rotating shaft, and the other end of the rotating shaft is movably connected to one side of the inner wall of the winding box through a shaft seat. In the present invention, by setting the placement box, the rotating rod is passed through the loosely wrapped drum to the plugboard, and then the plugboard is put into the placement box. After the plugboard is put into the placement box, the motor is started, and when the motor is working, The fabric will be separated from the slack roller and wound onto a new roller. When the fabric is detached from the slack roller, the rotating rod will be rotated, and the resistance generated by the cooperation of the rotating wheel and the fixed block will tighten the fabric. This makes the fabric more compact when wound on the new drum.

Owner:梅明会

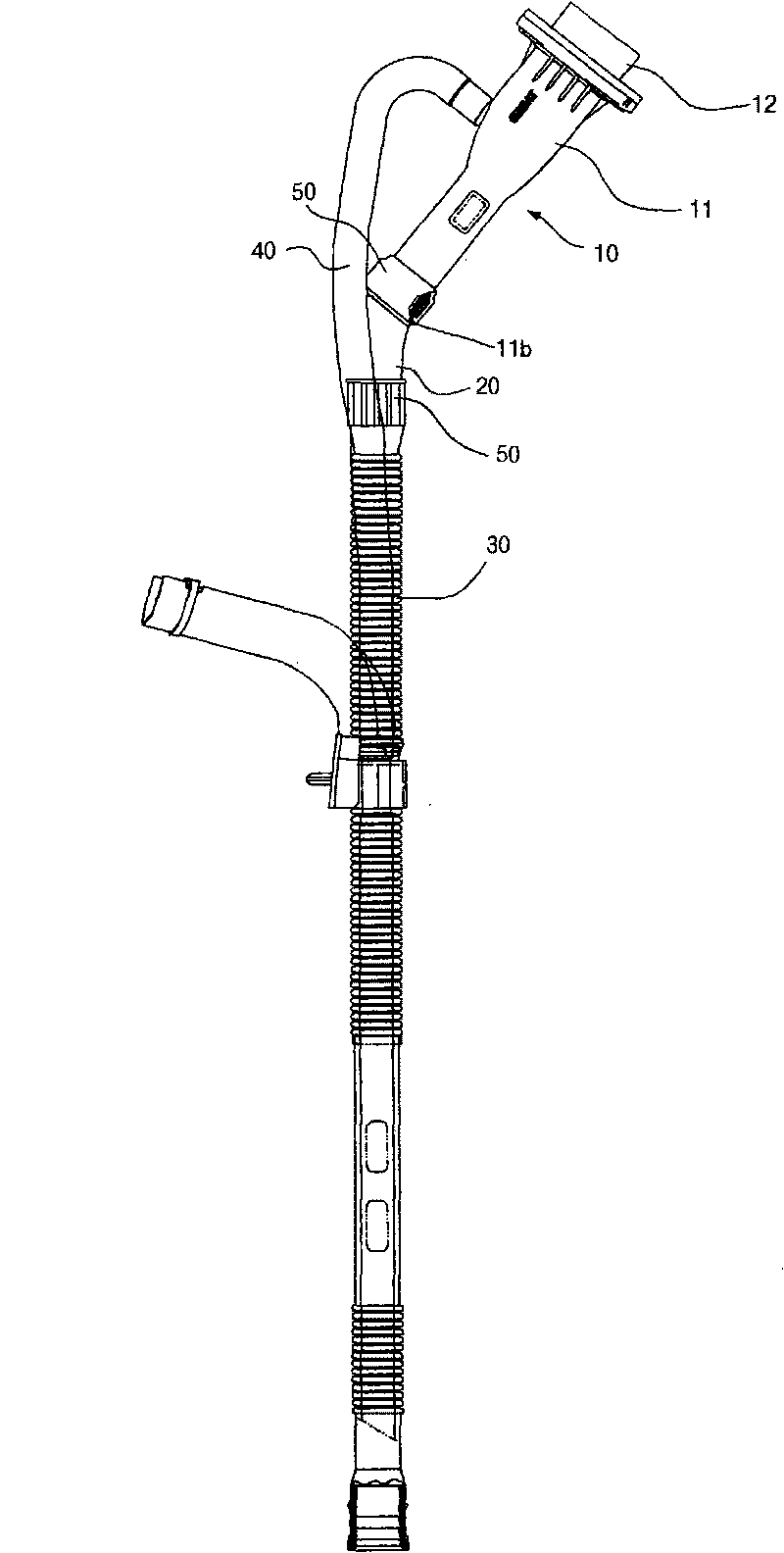

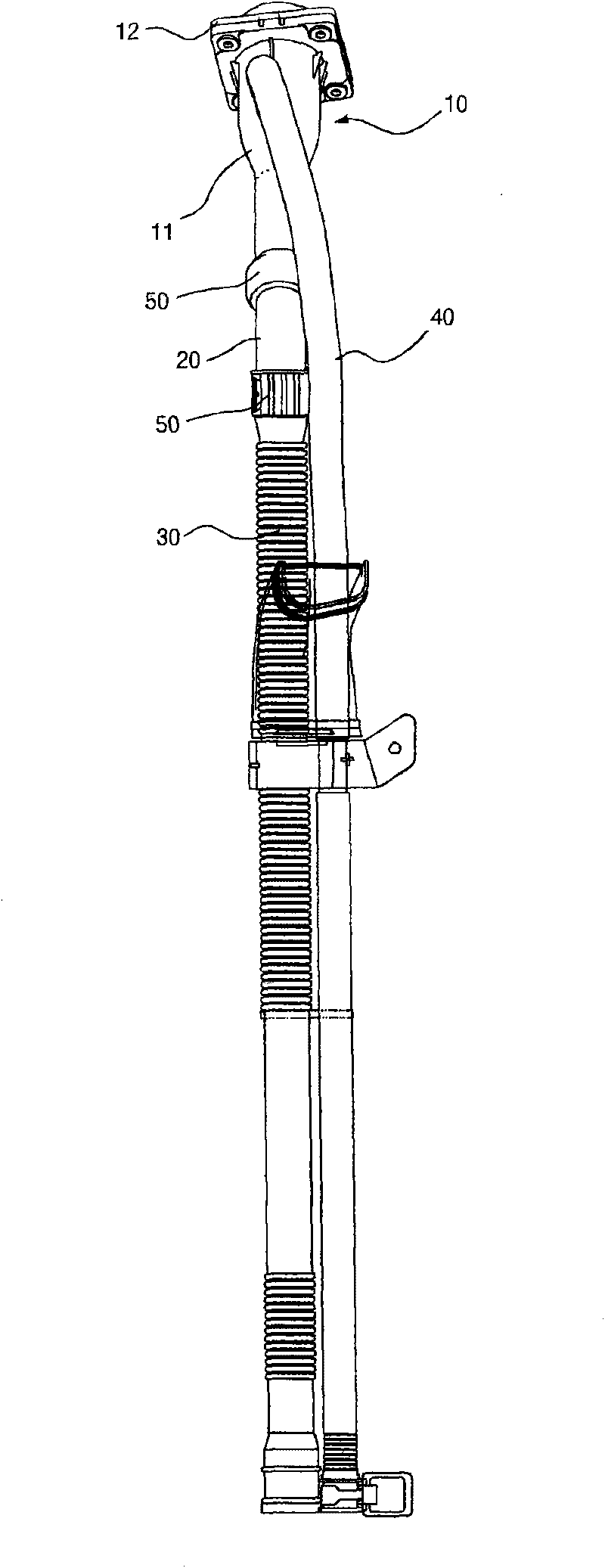

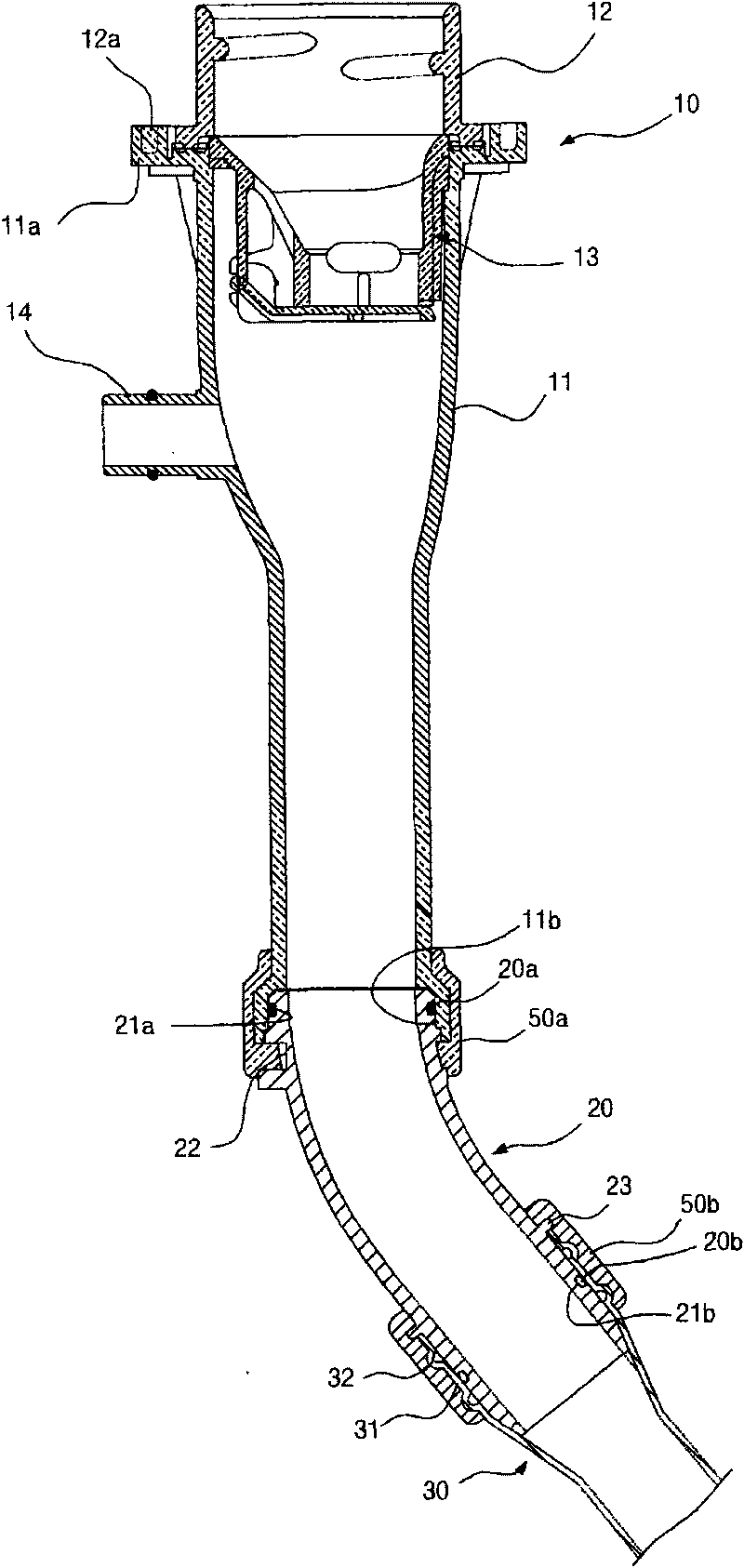

Filler pipe for motor vehicle

InactiveCN101734235AQuick refuelingVehicle servicing/repairingFuel supplyMotor vehicle partFuel tank

The invention provides a special filler pipe for a motor vehicle, solving the technical problem that when a oiling gun is inserted into a funnel neck to oil a fuel tank, the delay phenomenon is generated when the fuel oil penetrates through a first bending portion such as a corrugated pipe, and the fuel oil can not smoothly flow into the fuel tank. The invention is characterized in that a guard ring is arranged in the funnel neck, the funnel neck, a filter and a petroleum pipeline are connected in order, wherein the funnel neck and the filter, the filter and the petroleum pipeline are connected by a convex-concave structure, the petroleum pipeline is corrugated. The invention has the beneficial effect that no any resistance is generated in the filter and the petroleum pipeline in oiling, and the fuel is added to the fuel tank quickly.

Owner:KFTC BEIJING

Method of starting gas delivery from a liquefied gas fuel system to a gas operated engine and a liquefied gas fuel system for a gas operated engine

ActiveUS9863370B2Maintain pressureQuick refuelingInternal combustion piston enginesExhaust apparatusFuel tankEngineering

Owner:WARTSILA FINLAND OY

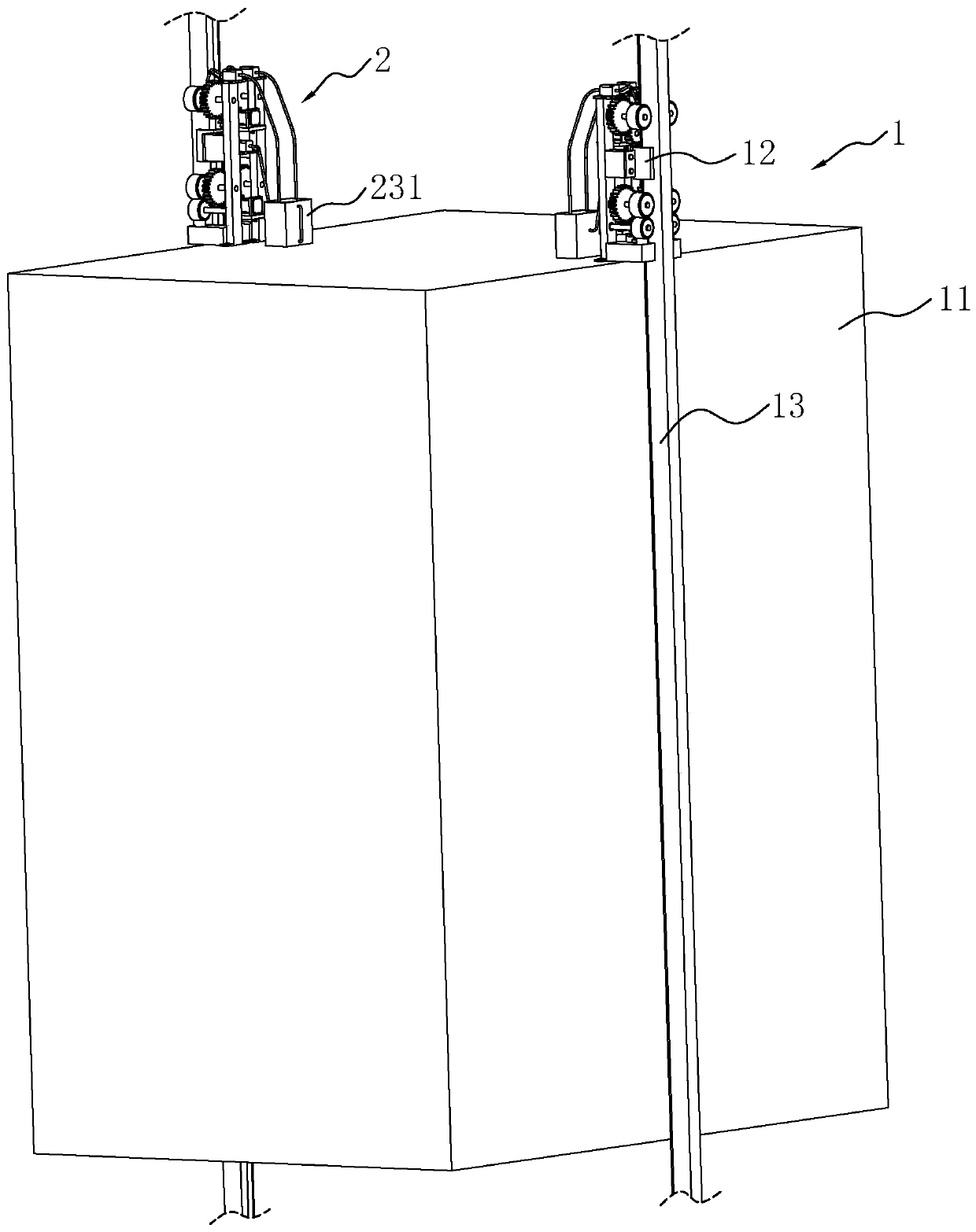

Material collection and discharging mechanism

ActiveCN104310087ARealize continuous feedingDatum edge flushWebs handlingEngineeringMechanical engineering

The invention discloses a material collection and discharging mechanism, which comprises a machine frame, wherein a first movement frame is arranged above the machine frame, and is provided with two power rolls, the two power rolls are driven by a first power device, a material collection and discharging gap is formed between the two power rolls, a correction mechanism is arranged between the first movement frame and the machine frame, a tension mechanism is arranged under the machine frame, and comprises at least one fixing roll and a traction roll, the traction roll is driven by a second driving device, a second movement frame is arranged on the machine frame, is driven by a Y-axis movement mechanism, and is provided with at least one movement roll, the movement roll and the fixing roll are vertically staggered, and the second movement frame is also provided with a press roll. The material collection and discharging mechanism has the advantages that the flexible material can be discharged from a material coil and can be collected onto the material coil; the structure is simple, and the cost is low.

Owner:GOERTEK INC

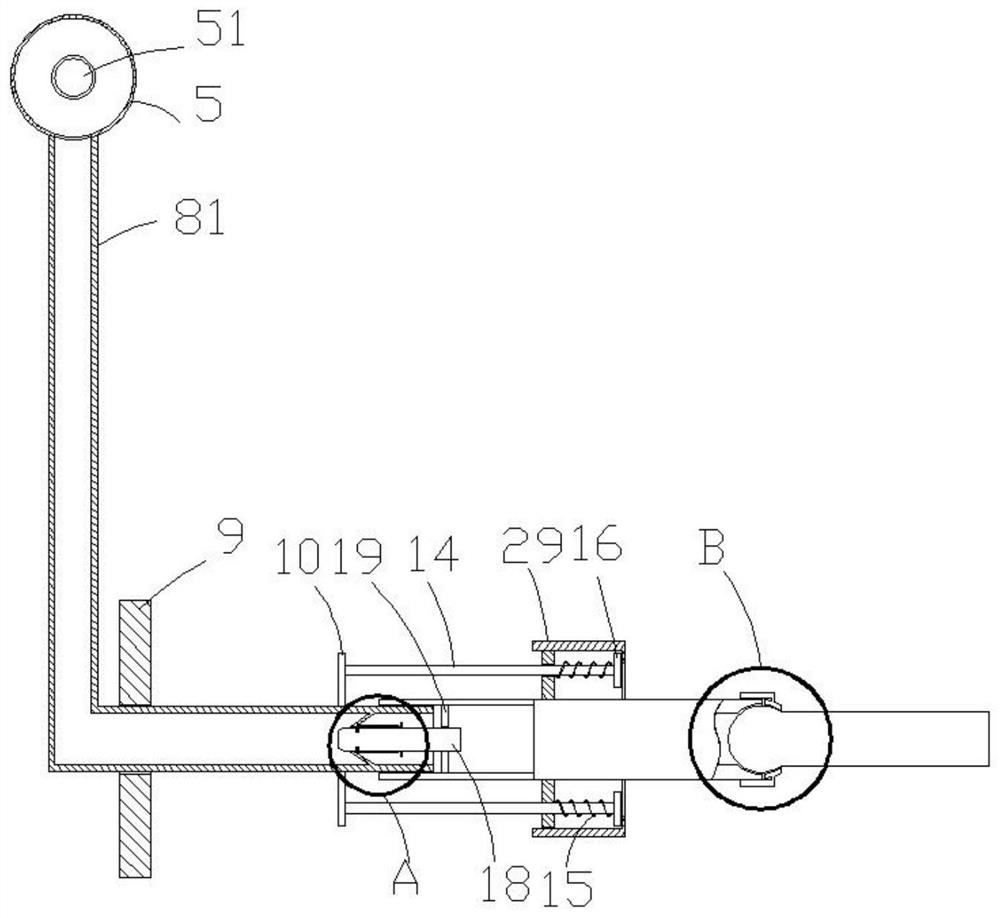

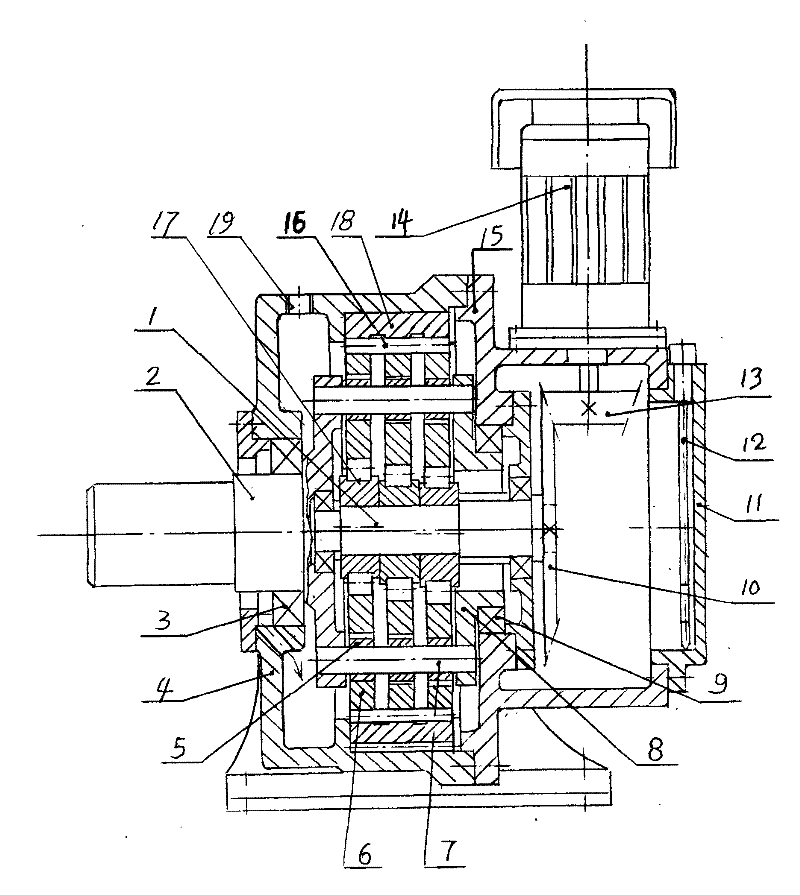

Oil filling mechanism for elevator sliding guide shoes

InactiveCN111115411AQuick refuelingReduce coefficient of frictionElevatorsControl theoryAutomotive engineering

The invention relates to an oil filling mechanism for elevator sliding guide shoes. According to the technical scheme, the oil filling mechanism is arranged on an elevator, wherein the elevator comprises a lift car, a plurality of guide shoes arranged on the outer wall of the lift car and a guide rail in sliding connection with the guide shoes; the plurality of guide shoes comprise flexible partsin sliding connection with the guide rail and fixing parts fixed to the sides, deviating from the guide rail, of the flexible parts and fixed to the lift car; the flexible parts are in a U shape withopenings facing the guide rail; and a plurality of oil outlets are uniformly distributed in the contact faces, making contact with the guide rail, of the flexible parts. The oil filling mechanism comprises a connecting channel arranged in the flexible parts and communicating with the plurality of oil outlets, an oil outlet pipe arranged at the ends, deviating from the flexible parts, of the fixingparts and communicating with an inlet of the connecting channel, and an oil supply assembly for supplying oil to the oil outlet pipe, and the oil supply assembly is arranged on the lift car. The oilfilling mechanism has the beneficial effect that oil filling can be conveniently conducted on the guide shoes in the elevator running process.

Owner:北京联合通力电梯有限公司

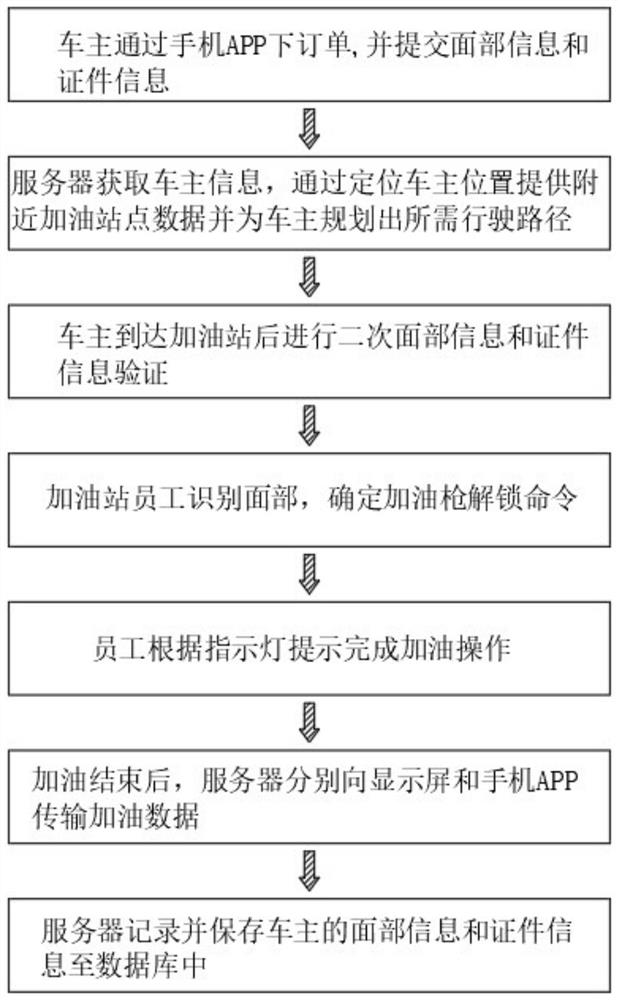

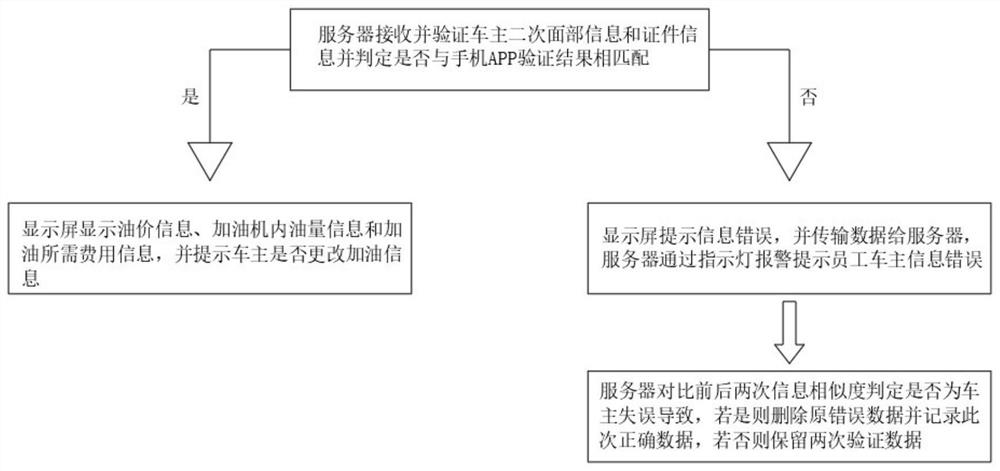

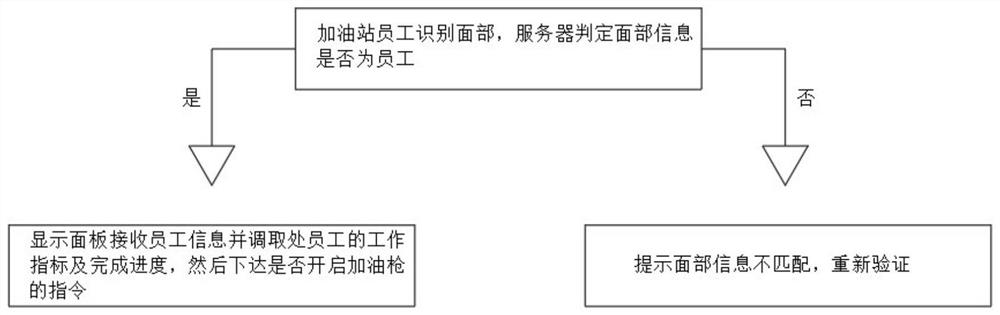

Working method for realizing real-name refueling based on Internet of Things technology

ActiveCN111833531AQuick refuelingGuarantee normal progressParticular environment based servicesOffice automationData transportVoucher

The invention provides a working method for realizing real-name refueling based on an Internet of Things technology. The real-name refueling method mainly comprises face recognition and certificate information verification. Whether the vehicle owner face information is consistent with the certificate information or not is judged through comparison of the database, furthermore order issuing is realized, secondary verification after arriving at the gas station prevents unexpected conditions in the midway driving process, an order placing person and a refueling person are ensured to be the same person, a server records and stores the information of a vehicle owner so as to facilitate next refueling, meanwhile, whether an oil gun unlocking command is issued or not can be judged by judging thematching degree of the face and the certificate information twice, error records are automatically deleted or stored according to the matching degree condition, and refueling data can be directly transmitted to a mobile phone APP of a vehicle owner after refueling is completed. Compared with existing direct payment refueling, refueling is safer, meanwhile, a user does not need to queue up to waitfor a voucher, the refueling speed is increased, and a phenomenon of fuel stealing can be prevented through locking of the refueling gun.

Owner:宋阳

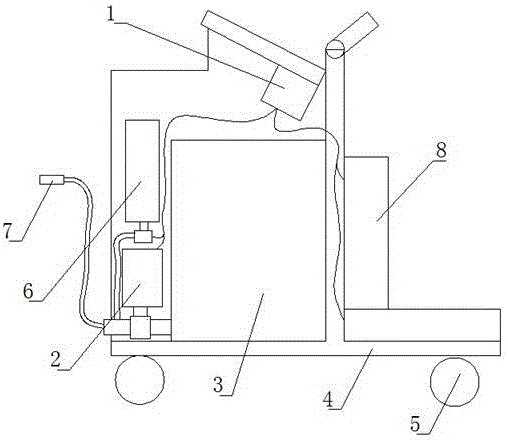

Portable fuelling robot

The invention relates to a small fuelling and carrying mechanism and filling mechanism in a fuelling station, in particular to a portable fuelling robot. The portable fuelling robot comprises a controller, a rack, a walking mechanism, an oil pump, an oil tank and a fuelling gun; the controller, the oil pump and the oil tank are installed on the rack separately, the walking mechanism is used for driving the rack to move, and the oil pump communicates with the oil tank and the fuelling gun separately; the oil pump and the walking device are electrically connected with the controller separately. Therefore, quick fuelling of the fuelling station can be conveniently and quickly achieved, the fuelling modes of the fuelling station can be increased, vehicle fuelling can be convenient, the fuelling pressure of the fuelling station can be relieved, and the fuelling efficiency of the fuelling station can be improved. According to the portable fuelling robot, the design is simple and safe, the stability is high, quickness can be achieved, the fuelling flexibility is improved, miniaturization and safety of fuelling equipment can be achieved through the structure, and then a small quick fuelling tool is provided.

Owner:PANZHIHUA JIUDINGZHIYUAN INTPROP OPERATION CO LTD

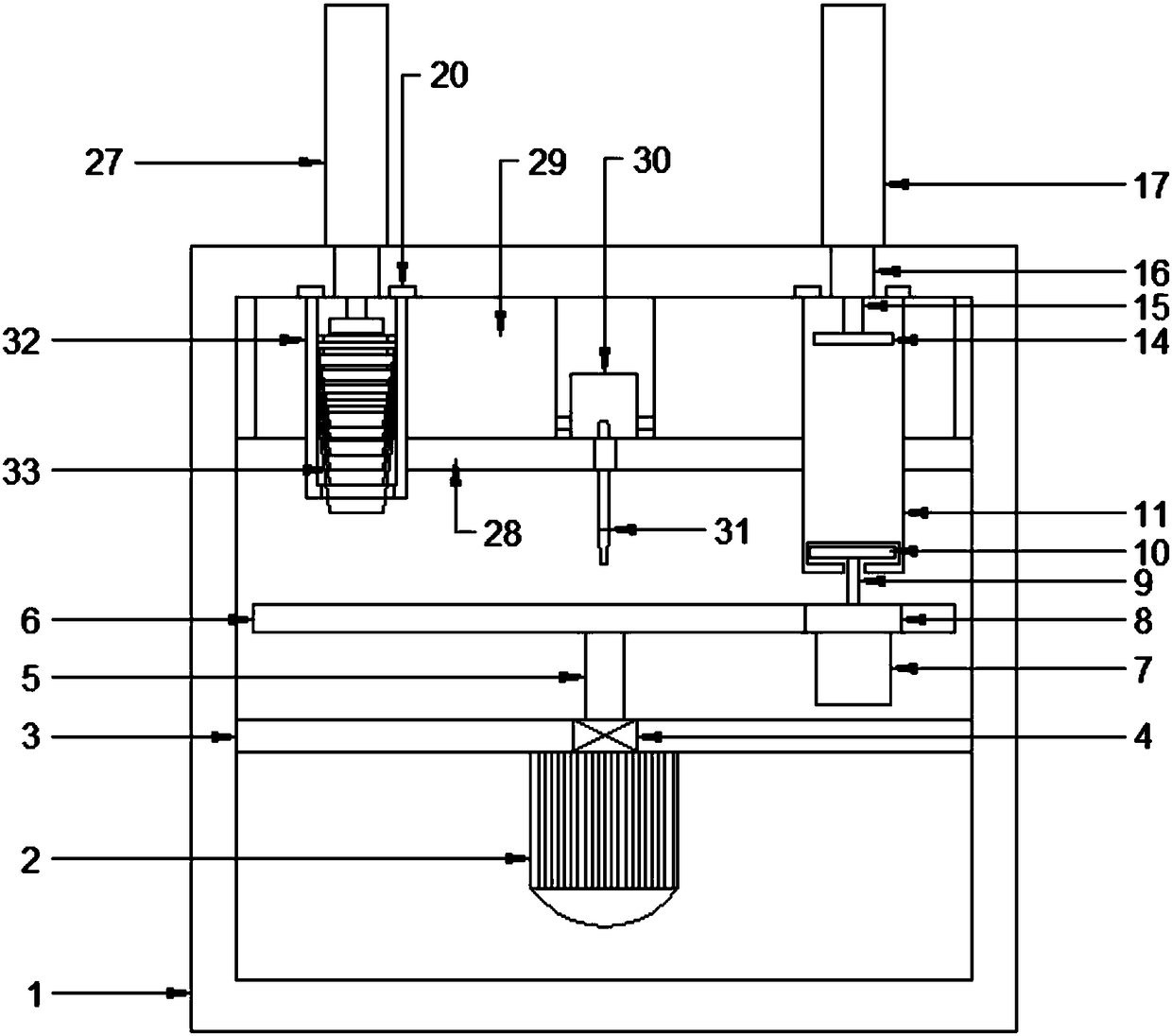

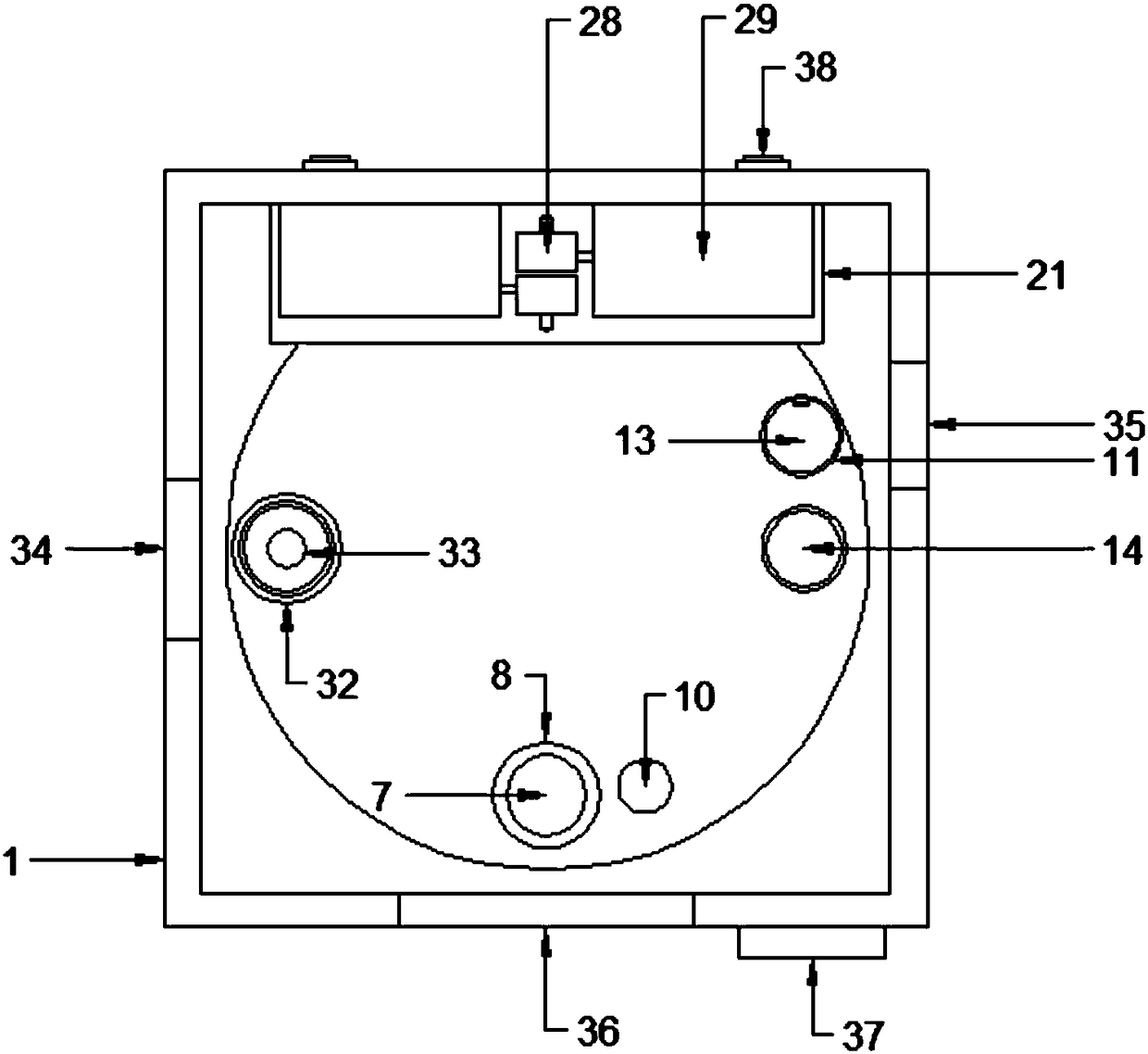

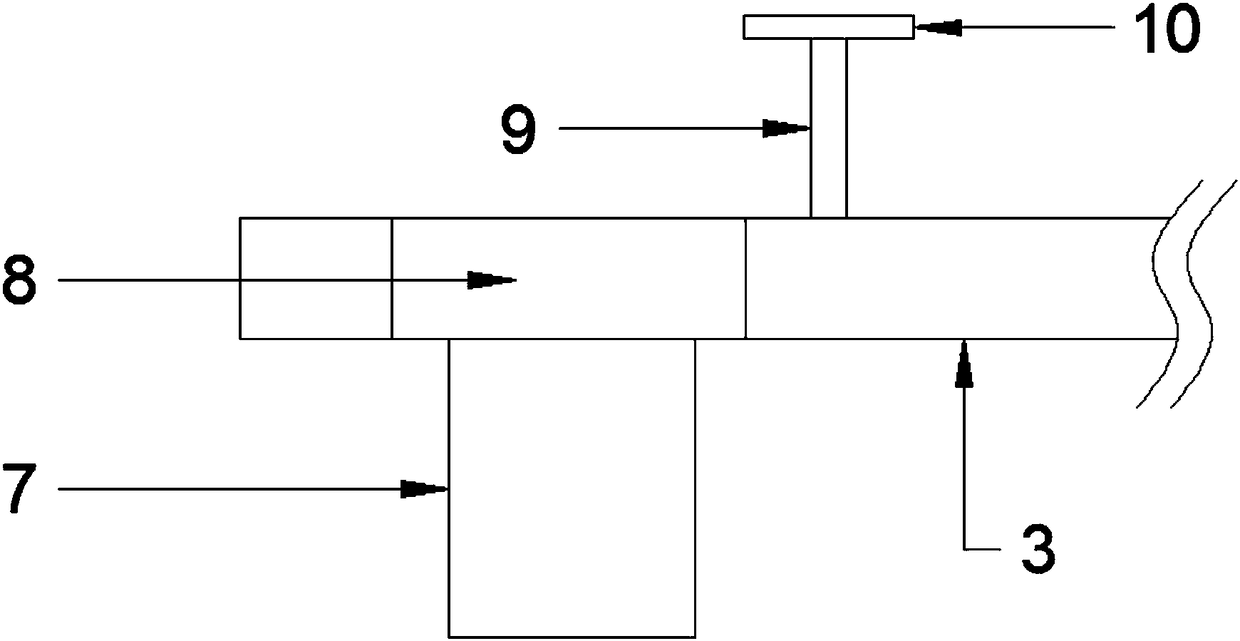

Deep sea hydraulic station

PendingCN112503041AAchieve pressure balancePressure oil in timeFluid-pressure actuator safetyFluid-pressure actuator testingBrushless motorsHydraulic cylinder

The invention provides a deep sea hydraulic station. The deep sea hydraulic station comprises a box body, a radial pump, a direct-current brushless motor, a stacked three-position four-way electromagnetic reversing valve, a stacked hydraulic control one-way valve, a stacked overflow valve, a hydraulic cylinder, an energy accumulator, a pressure sensor, a direct-acting overflow valve and an integrated block plug-in overflow valve. The radial pump, the direct-current brushless motor, the stacked three-position four-way electromagnetic reversing valve, the stacked hydraulic control one-way valve,the stacked overflow valve, the energy accumulator, the pressure sensor, the direct-acting overflow valve and the integrated block plug-in overflow valve are all located in the box body. The deep seahydraulic station has the advantages of being compact in structure, good in sealing performance, stable, safe and capable of adapting to the special deep sea environment.

Owner:杭州瀚陆海洋科技有限公司

Automatic quality inspector and control method thereof

InactiveCN109366567AVersatilePerfect automationImage enhancementImage analysisRolling paperDisplay device

The invention discloses an automatic quality inspector and a control method thereof and relates to the technical field of detection devices. The automatic quality inspector comprises a rack, and an unreeling device, a detection mechanism, a button operating platform for excluding defective coiled printing materials, a slitting mechanism, a main control computer, a display device and a rolling device arranged on the rack. The rolling device comprises a first rolling mechanism and a second rolling mechanism. The first rolling mechanism comprises a first rolling air shaft and a first feeding roller corresponding to the first rolling air shaft. The second rolling mechanism comprises a second rolling air shaft and a second feeding roller corresponding to the second rolling air shaft. The automatic quality inspector provided with the unreeling device, the detection mechanism, the button operating platform for excluding defective coiled printing materials, the slitting mechanism, the main control computer, the display device and the rolling device has the advantages of being multiple in function, high in automaton and high in detection precision, and can replace roll paper quickly, so that the production efficiency is improved effectively.

Owner:GUANGZHOU PULISI TECH CO LTD

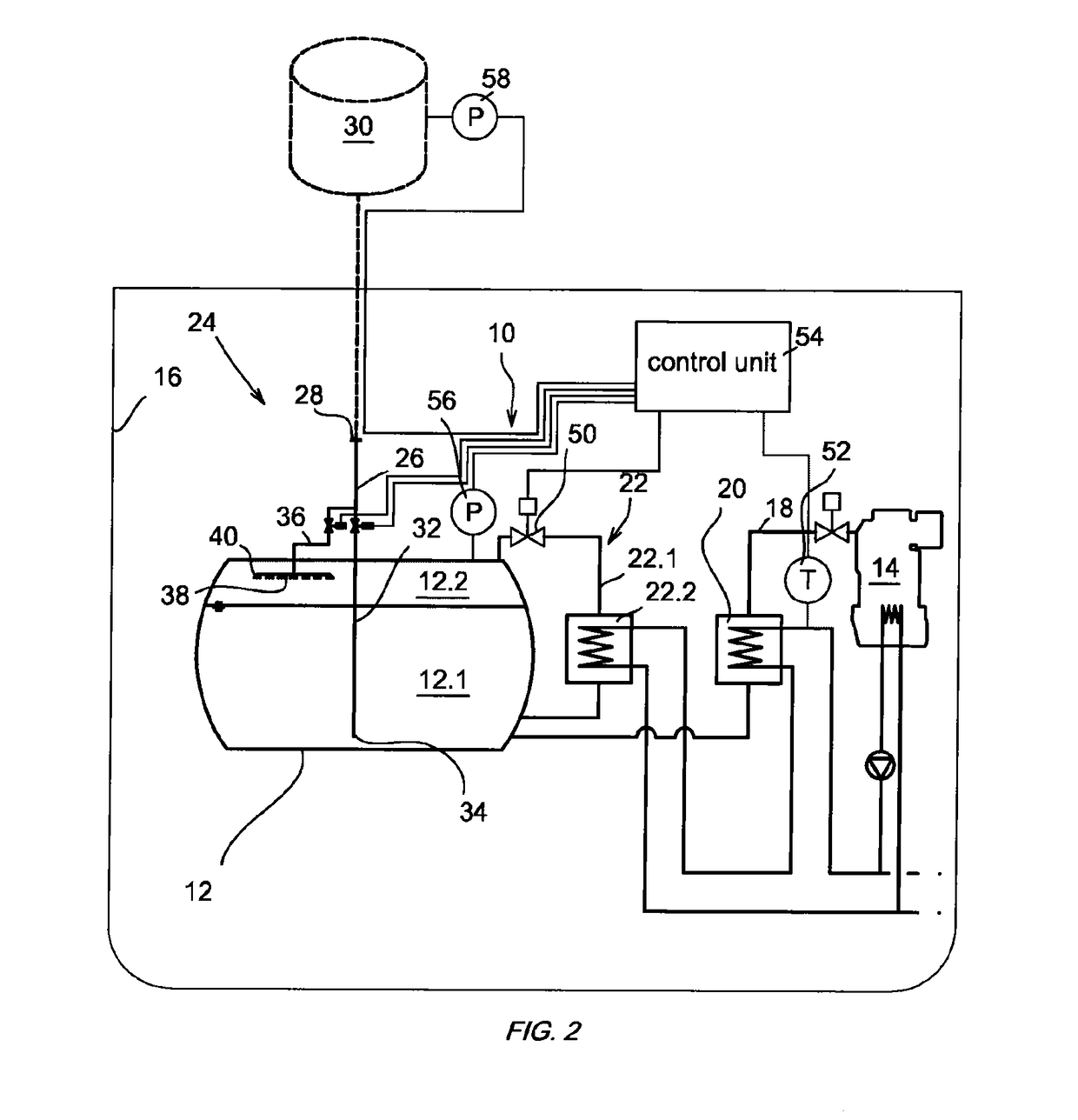

Method of filling a fuel tank with liquefied gas and liquefied gas system

A method for filling a fuel tank with liquefied gas includes liquefied gas being brought into the tank so that gas in introduced to a lower section of the tank below the surface of the liquefied gas in the tank, and during a first phase of the filling procedure while gas is introduced to a lower section of the tank the pressure of the tank is maintained below a predetermined set pressure by spraying of liquefied gas into a gas space in the upper section of the tank above the surface of the liquefied gas in the tank. At a predetermined state of the filling procedure a second phase of the procedure is initiated during which the spraying liquefied gas into a gas space in the upper section of the tank is decreased and the second phase is practiced until a predetermined filling stage of the tank is reached.

Owner:WARTSILA FINLAND OY

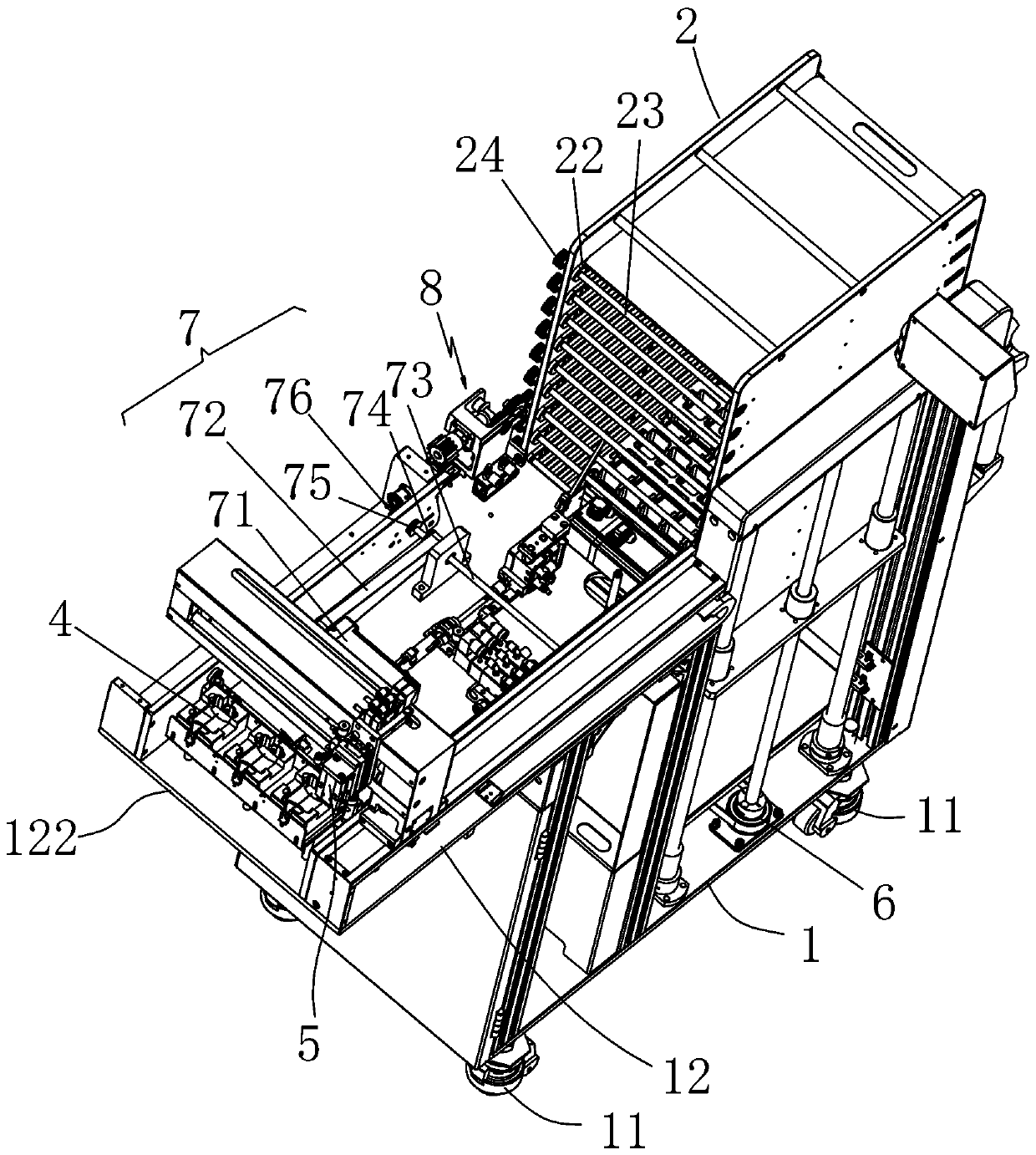

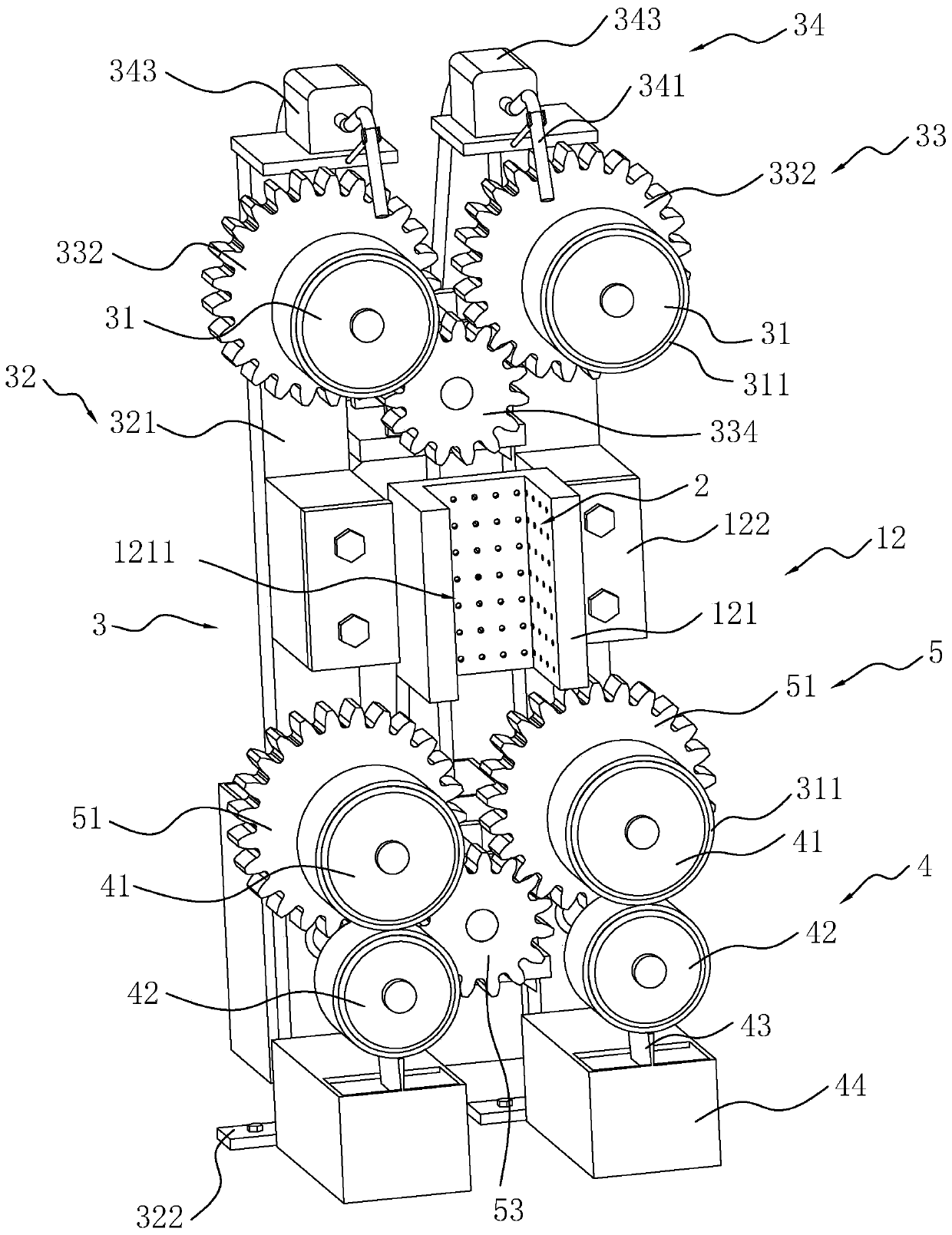

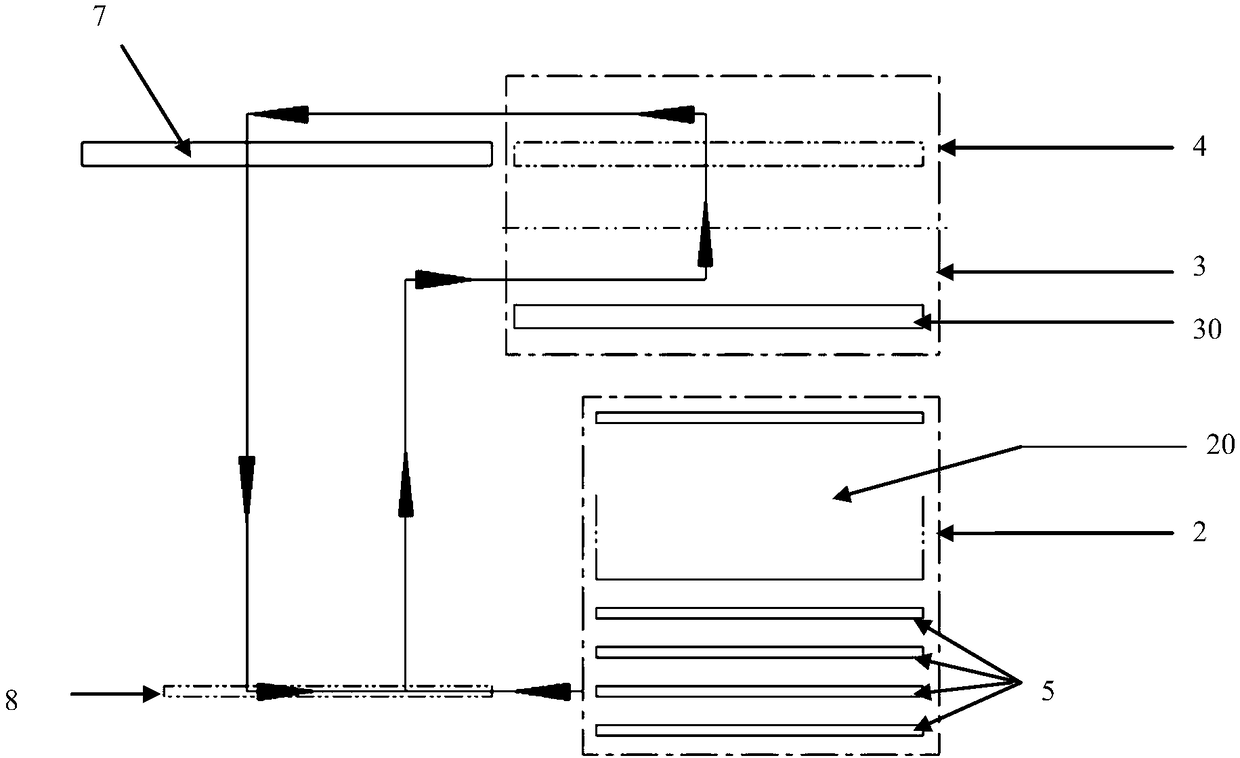

Circulating feeder

PendingCN108773647ASolve the problem of automatic switching without stoppingQuick refuelingConveyorsStacking articlesEngineeringTemporary storage

A circulating feeder comprises a stereoscopic storage area, a temporary storage area, a waiting area, a fixed arm and a movable arm. During working, the movable arm moves to one side of the storage area, material discs are pulled out from corresponding storage layers in the storage area to the movable arm, then the movable arm moves to one side of the temporary storage area, the material discs areconveyed from the movable arm into the temporary storage area, automatically move from the temporary storage area to the waiting area and then are conveyed from the waiting area to main machine working stations on the fixed arm for taking operation; and when the discs need to be replaced, the movable arm moves to the position near the fixed arm, the treated material discs are taken out from the main machine working stations and move to one side of the storage area to be conveyed into the storage area, and the action cycle is repeated. According to the circulating feeder, the material discs ofdifferent materials can be stored in the storage area, non-stop automatic switching of the various materials is achieved, through cooperative action of the movable arm and the temporary storage area,quick feeding and discharging operation is achieved, the production efficiency is improved, and through stereoscopic up-down arrangement, the occupied space of the circulating feeder is saved.

Owner:SHENZHEN HANJIANG AUTOMATION SCI & TECH CO LTD

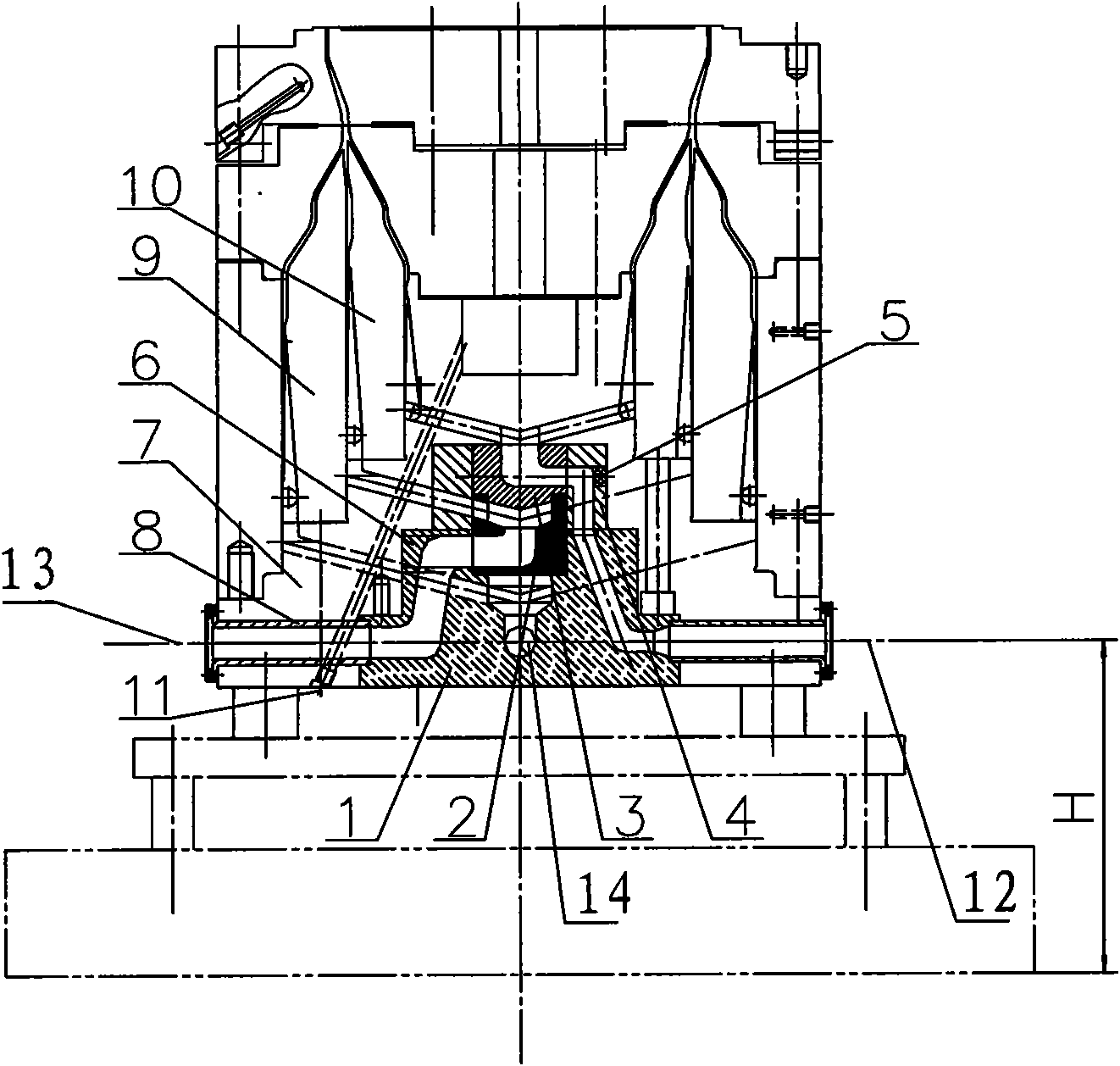

Triple extrusion die head with low center

InactiveCN101670657AReduce die heightShorten the length of the runnerEngineeringMechanical engineering

The invention discloses a triple extrusion die head with a low center, wherein, an inner layer feed inlet (12), a middle layer feed inlet (13) and an outer layer feed inlet (14) are positioned in a same plane and the center-height of which is H. The invention overcomes the defects that the runner of the existing triple extrusion die head has long length, the amount of polymer accumulated in the center of a die is large, the time needed for changing the resin or the color is long, and the cooling efficiency is low and the like. The distribution design of the invention reduces the height of thedie head, shortens the length of the runner, improves the cooling efficiency, ensures more convenient operation of the film pulling, reduces the amount of polymer accumulated in the die head, and leads the changing of the material or the color more rapid.

Owner:武汉新中德塑机股份有限公司

High-speed feeding mechanism

InactiveCN104803160AFast loadingQuick refuelingControl devices for conveyorsMechanical conveyorsEngineeringHigh velocity

The invention discloses a high-speed feeding mechanism comprising a feeding railway switching device and a feeding device, wherein the feeding railway switching device is connected with the feeding railway switching device, the feeding railway switching device comprises a first feeding railway and a second feeding railway which can be switched under driving of a sliding panel driving device, when the material on one feeding railway is exhausted, the material on the other feeding railway is early taken in place, thus the first feeding railway and the second feeding railway can be directly switched and an automatic machine does not stop to feed or exchange the material.

Owner:SUZHOU HANCHUAN CO LTD AKA HARMONTRONICS

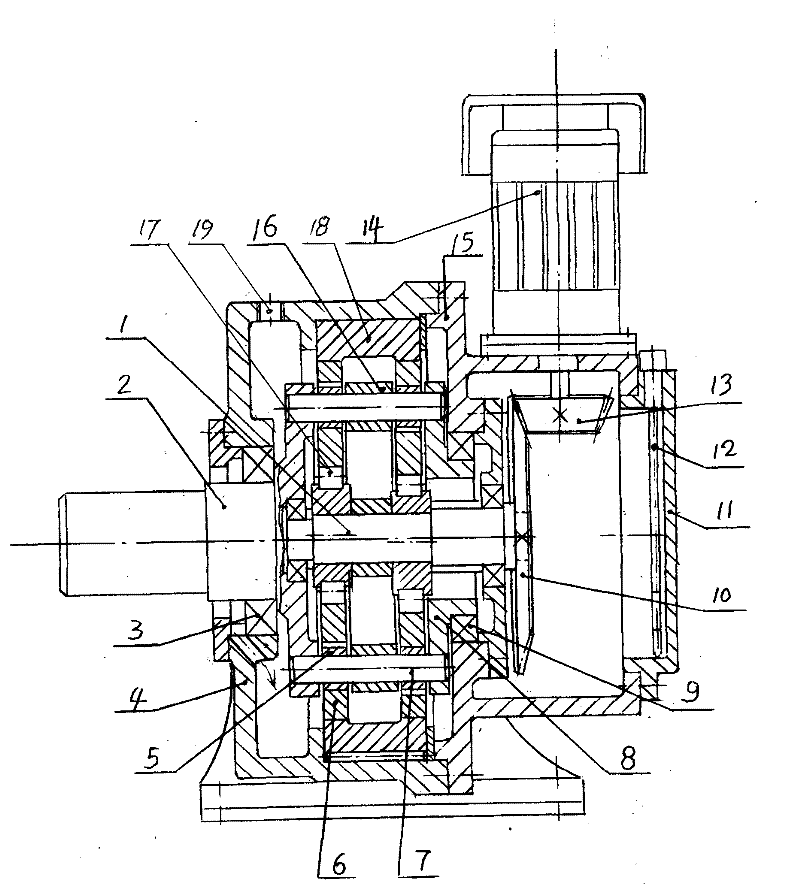

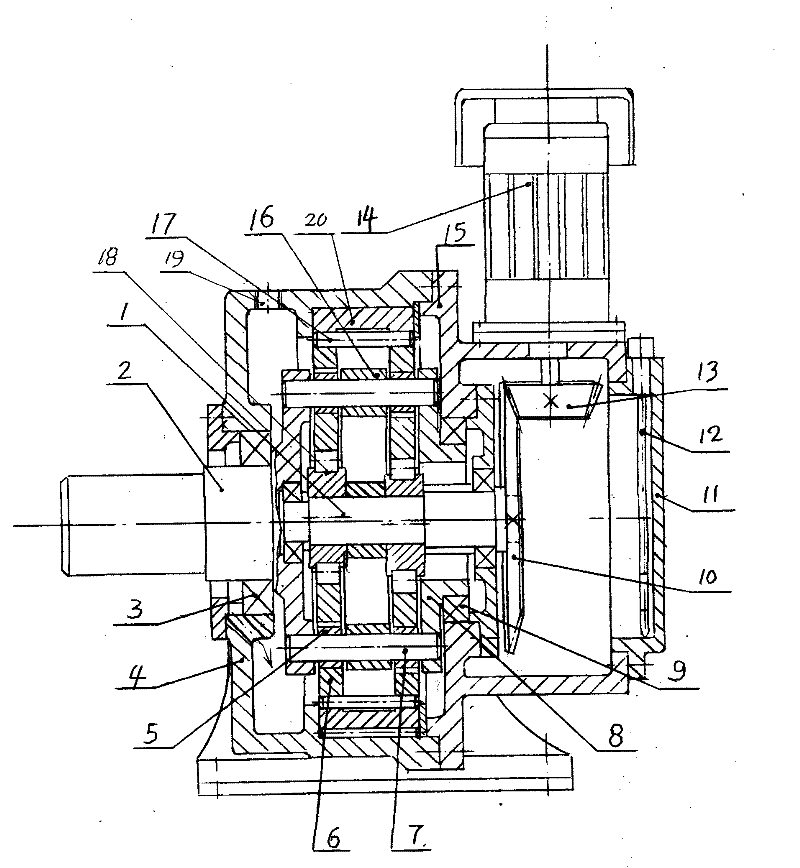

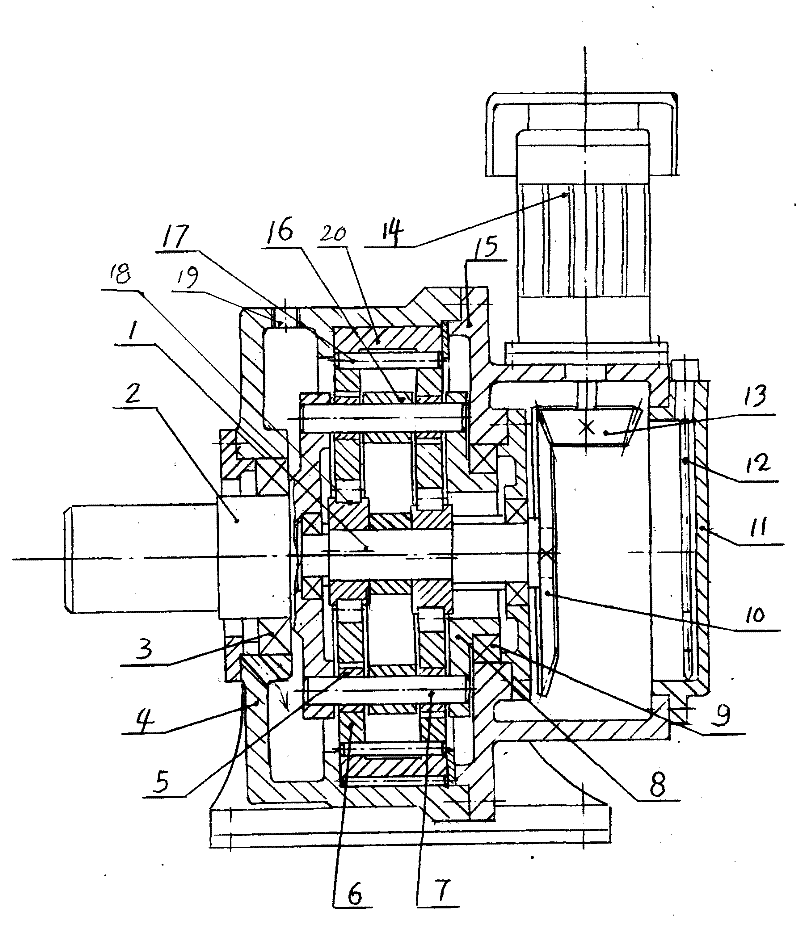

Cone-hypocycloid speed reducer of rotary brush aeration machine

InactiveCN102442732ANovelty embodimentEmbody practicalityTreatment using aerobic processesWater aerationReduction driveGear wheel

The invention relates to the technical field of speed reduction of aeration machines, in particular to a cone-hypocycloid speed reducer of a rotary brush aeration machine. The cone-hypocycloid speed reducer is characterized by comprising a bevel gear pair and a hypocycloid drive, wherein the bevel gear pair comprises a drive bevel gear and a driven bevel gear; the hypocycloid drive comprises a hypocycloid gear ring, a cycloidal wheel and a W output mechanism, wherein a screw hole with a ventilation cap is formed on an engine base, an oil return hole is arranged in a bearing hole of the engine base, the oil return hole is located below a space between an oil seal and a bearing, the hypocycloid gear ring is connected to an inner hole of the engine base, an oil feeding hole is arranged in a round end cover on the small end face of the engine base, an oil scale is arranged in the hole, and the oil scale is drawn to check the oil quantity and refuel rapidly. The cone-hypocycloid speed reducer of the rotary brush aeration machine has the advantages that: (a) hypocycloid wheel teeth are continuous, so that the overload capacity is larger than external gearing transmission of a parallel shaft; (b) the price of the hypocycloid speed reducer is less than a half of a planetary speed reducer, so that the cost is 30-35% lower than that of the planetary speed reducer; and (c) the oil quantity in the speed reducer can be rapidly checked and the oil can be rapidly refueled to the speed reducer in both dirty and exposed environments.

Owner:吴小杰

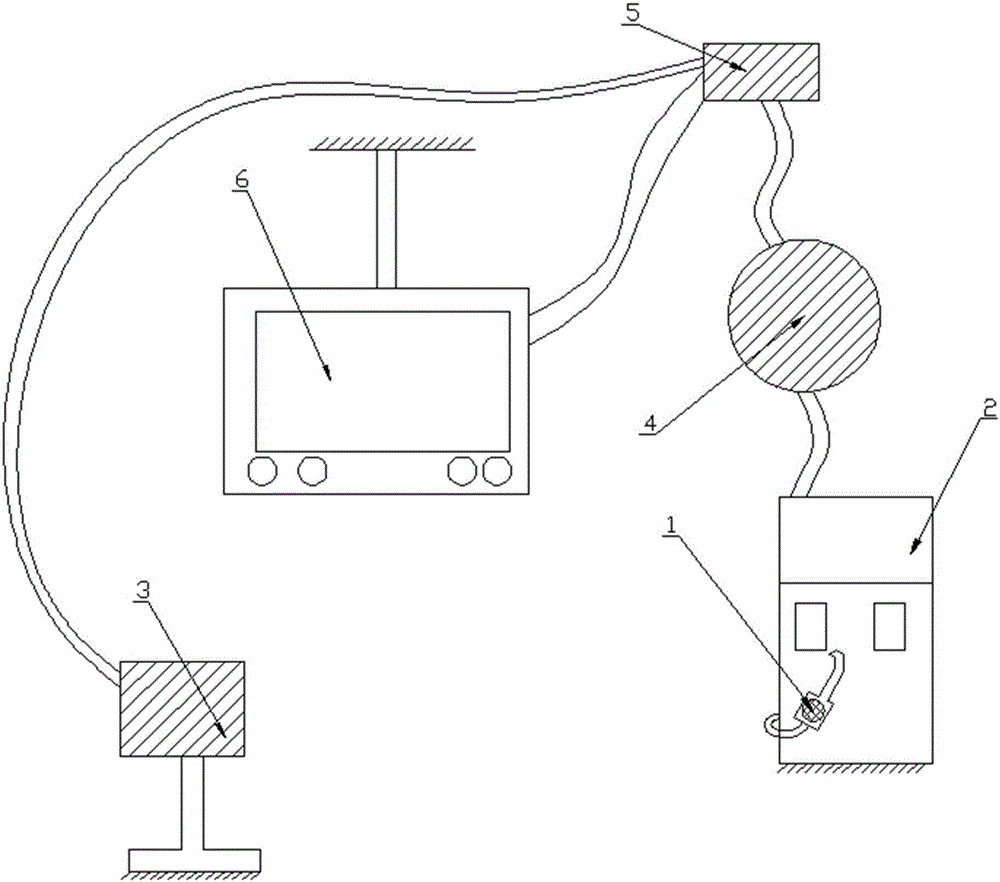

Non-contact refueling system

The invention provides a non-contact refueling system. The non-contact refueling system is characterized by comprising RFID tags, a refueling gun, RFID reader-writers and a processor; the first RFID tag which can be identified by the first RFID reader-writer is pasted on the refueling gun; the first RFID reader-writer is located in a refueling station; the refueling station is further internally provided with the second RFID reader-writer used for reading the automobile information; the second RFID tag is pasted on an automobile; and the first RFID reader-writer is electrically connected with the processor. According to the non-contact refueling system, the automobile information is identified and processed within the first time; during the refueling process of the automobile, the RFID reader-writers scan the RFID tags on the refueling gun and the automobile; after refueling is completed, the processor gives a result through processing; and after working personnel checks the result with a user, the processor deducts the automobile fuel cost prestored in the user RFID tags, the user does not need to get off the automobile, and the functions of rapid refueling and intelligent payment are achieved.

Owner:天津市技友先达科技股份有限公司

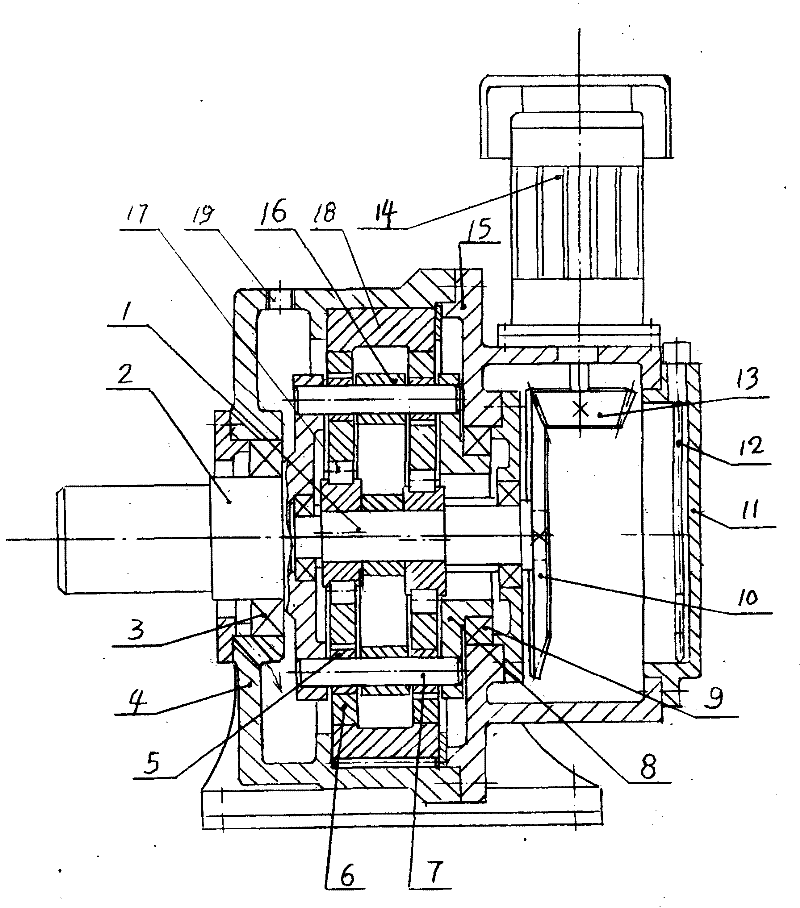

Cone-cycloid speed reducer for rotary brush type aerator

InactiveCN102442731ANovelty embodimentEmbody practicalityTreatment using aerobic processesWater aerationEngineeringPlanet

The invention relates to the technical field of speed reduction of an aerator. A cone-cycloid speed reducer for a rotary brush type aerator is characterized by being composed of a bevel gear pair and a cycloid transmission, wherein the bevel gear pair comprises a driving bevel gear and a driven bevel gear; the cycloid transmission comprises a needle toothed shell, a needle pin, a cycloid gear and a W output mechanism; a screw hole for mounting a vent cap is formed on a base; an oil return hole is formed in a base bearing hole; the oil return hole is located under a place between an oil seal and a bearing; the needle toothed shell is linked in a base inner hole; an oil filling hole is formed in a circular end cap on a small end face of the base; an oil scale is mounted in the oil filling hole; and the oil scale is pulled out for checking oil volume and quickly filling oil. The cone-cycloid speed reducer has the beneficial effects that: (a) the cycloid gear is free from tooth breaking, so that the overload capacity is higher than engaging transmission outside a parallel shaft; (b) the cost of the cycloid speed reducer is less than a half of the cost of a planet reducer, so that the cost is reduced by about 30-35%; and (c) the oil volume in the reducer can be quickly checked and the oil can be quickly filled under a dirty open-air condition.

Owner:吴小杰

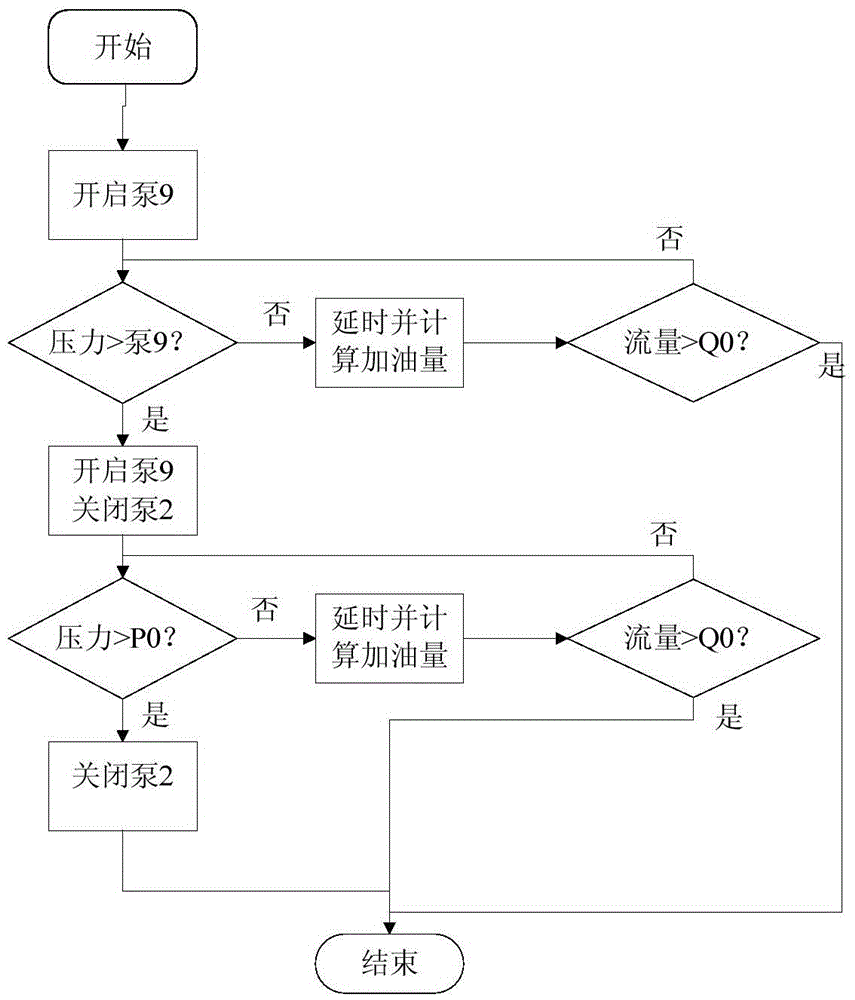

Refueling control system and method for refueling pump of fuel tank of power station

ActiveCN105731350ASolving electric refueling problemsRealize uninterrupted oil supplyLiquid transferring devicesStopped workToggle switch

The invention relates to a refueling control system and method for a refueling pump of a fuel tank of a power station. Main devices comprise a storage battery, a fuel pump, an upper liquid level switch, a lower liquid level switch, a contactor, a relay, toggle switches, an indicator lamp and a safety part. An automatic refueling manner and a manual refueling manner are set, and two work manners are selected by the toggle switches. When the automatic refueling manner is selected and the liquid level of the fuel tank is on the lower liquid level, the refueling pump starts to work; and when refueling is carried out till the liquid level is on the upper liquid level, the refueling pump stops working. When the manual refueling manner is selected and the liquid level of the fuel tank is lower than the upper liquid level, the refueling pump starts to work; and when refueling is carried out till the liquid level is on the upper liquid level, the refueling pump stops working. According to the refueling control system and method, the problem about electric refueling of the fuel tank of the power station is solved, and the function of ceaseless fuel supply during work of the power station is achieved.

Owner:JIANGXI QINGHUA TAIHAO SANBO ELECTRICAL MACHINE

Large torque cone-hypocycloid speed reducer of rotary-brush aerator

InactiveCN102444693AImprove bending resistanceSimple structureWater aerationToothed gearingsReduction driveEngineering

The invention relates to the technical field of aerator speed reduction. A large torque cone-hypocycloid speed reducer of a rotary-brush aerator is disclosed, and is characterized by being composed of a bevel gear pair and a hypocycloid transmission. The bevel gear pair comprises a drive bevel gear and a driven bevel gear; the hypocycloid transmission comprises a hypocycloid gear ring, a cycloid gear and a W output mechanism; a screw hole installed with a vent cap is disposed on a stand; an oil return hole is disposed in a stand bearing hole; the oil return hole is located below a space between an oil seal and a bearing; the hypocycloid gear ring is connected to a stand inner hole; an oil filling hole is disposed in a circular end cover on a small stand end surface; an oil level gauge is installed in the hole; and the oil level gauge can be pulled out to check an oil quantity and rapidly fill oil. The large torque cone-hypocycloid speed reducer of a rotary-brush aerator has the following advantages that: (a) the hypocycloid gear teeth cannot be broken, so that the overload capacity is greater than the external meshing transmission of a parallel shaft; (b) the price of a cycloid speed reducer is lower than a half of a planet speed reducer, so that the cost is 30-35% lower than the latter; and (c) an oil quantity in the speed reducer can be rapidly checked, and oil can be rapidly filled in a dirt and outdoor environment.

Owner:吴小杰

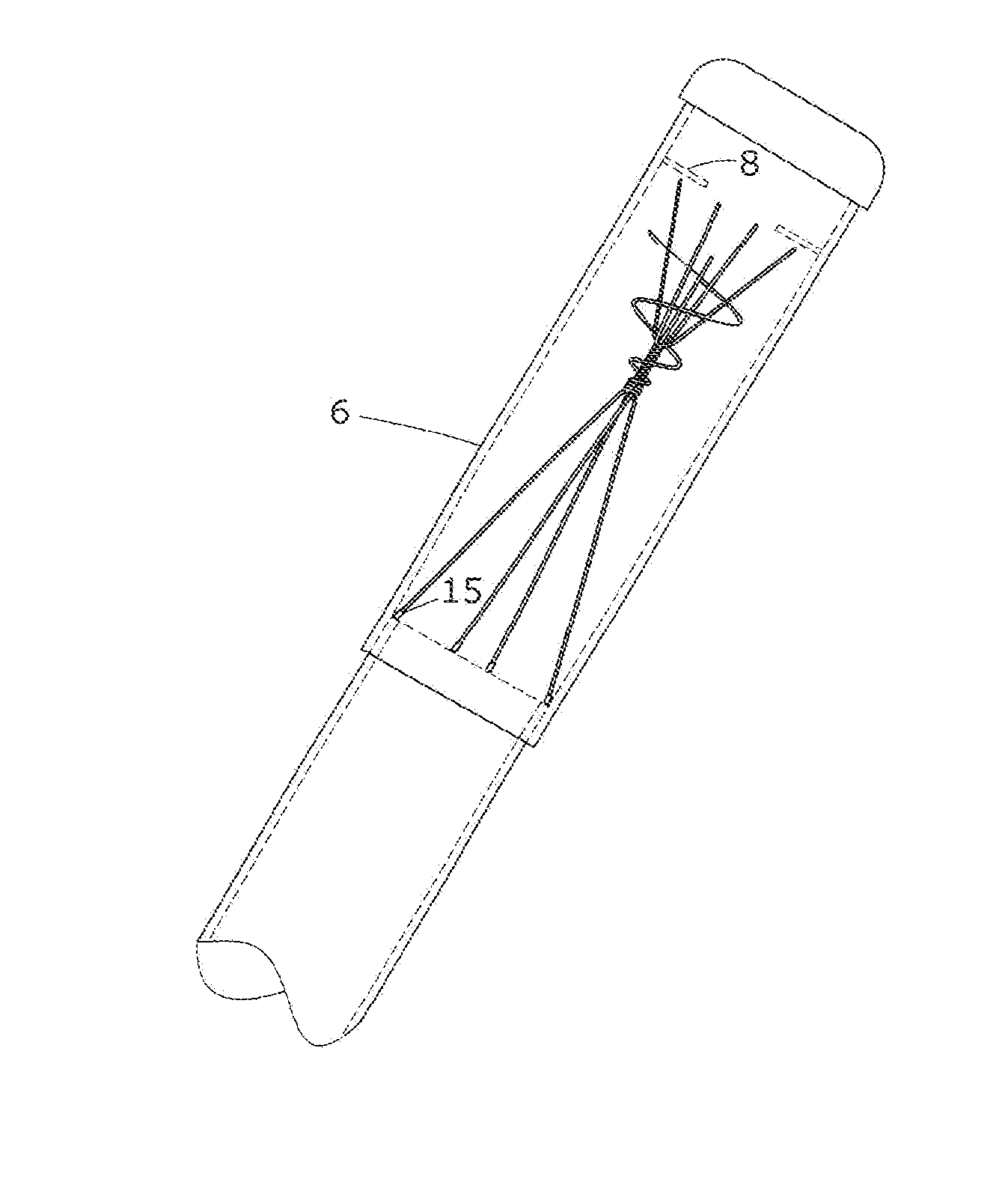

Anti-Siphon Device

InactiveUS20150202957A1Prevent Fuel TheftReduce manufacturing costClosures to prevent refillingLiquid materialMobile vehicleSiphon

The invention comprises a device that can be inserted into an inlet for a gasoline or diesel fuel tank, and which, after being inserted, prevents thieves from using siphons to steal gasoline from the tank. Embodiments of the device can protect the fuel supplies of automobiles, trucks, boats, and other motor vehicles. The invention uses “locking legs”, a unique feature, which lock against the flanges of the inlet and ensure that the device cannot be easily removed from the inlet after insertion. Embodiments of the device also use a “hose spear” which punctures thieves' siphons, and makes them unable to remove gasoline or other liquids from the tank. The device can be used to stop theft of other liquids. The invention also includes a process of protecting liquids from theft using a device with “locking legs”, and a process for inserting the device into an inlet.

Owner:KNEISLEY ROBERT

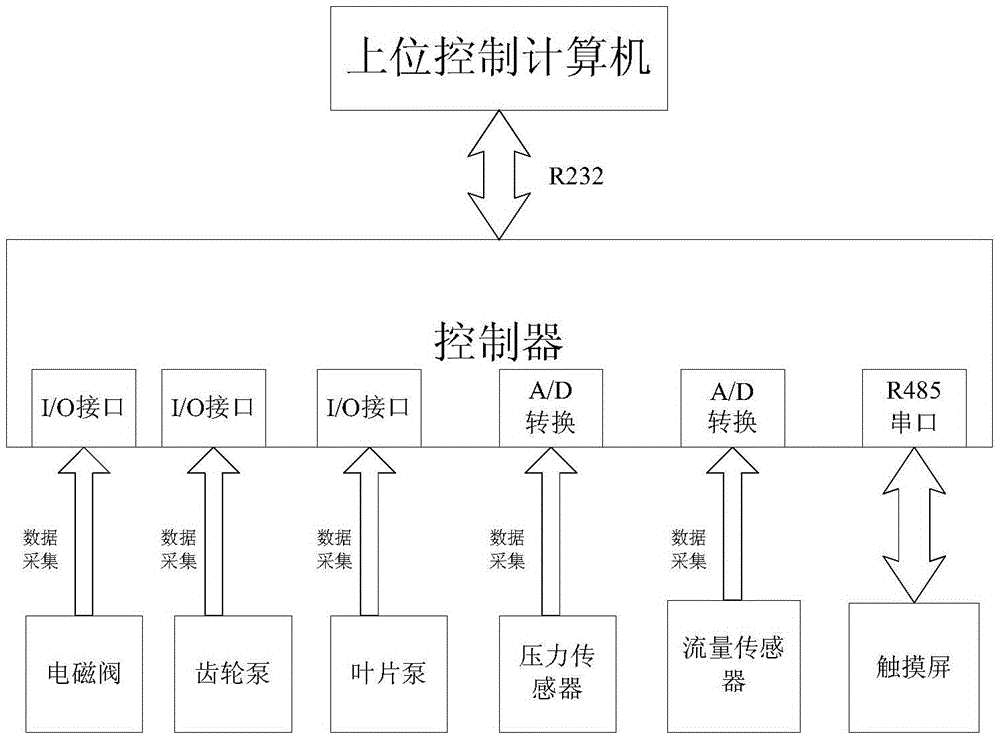

Automatic oiling device and method for unmanned underwater vehicle

InactiveCN106800269AQuick refuelingHigh degree of automationLiquid transferring devicesMarine engineeringFuel tank

The invention relates to an automatic oiling device and method for an unmanned underwater vehicle. The automatic oiling device for the unmanned underwater vehicle comprises an oiling structure unit and a controlling unit connected with the oiling structure unit; the oiling structure unit comprises an inlet oil filter, a pump switching pipeline and a safe valve which are connected in sequence, and the safe valve is in parallel connection with the pump switching pipeline; an oil inlet filter inlet is used for inputting oil; the pump switching pipeline is connected with the control unit; the control unit is used for being connected with an oil tank of the underwater vehicle according to set information, feedback signals of a sensor and actions of the oiling structure unit. According to the method, a pump is automatically switched through senor detection for oiling. According to the automatic oiling device and method for the unmanned underwater vehicle, the design is novel, under the cooperation effects of the oiling structure unit and the control unit, the unmanned underwater vehicle can be automatically oiled in a timed, quantitative and booked mode, using is easy, and the automation degree is high.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Jet-propelled catapult car

The invention relates to a jet-propelled catapult car for an aircraft carrier. A few high-power jet engines of the jet-propelled catapult car are installed in a tracked sliding flat car, the size of the jet-propelled catapult car is much smaller than that of a steam catapult, a technology of the jet-propelled catapult car is simpler than a technology of an electromagnetic type catapult, and faults cannot occur easily.

Owner:ZHONGNENG SHIHUA BEIJING ENERGY SAVING SCI & TECH

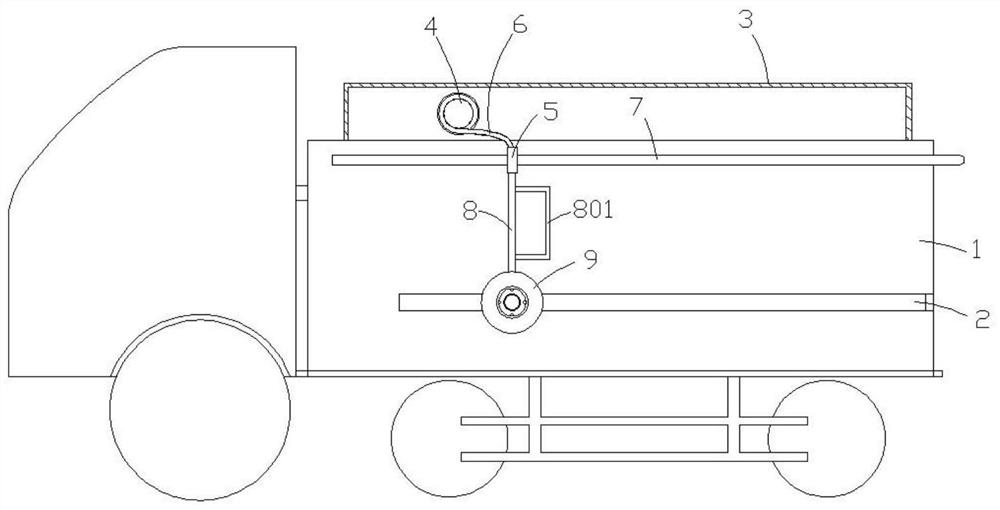

Movable rapid refueling system

ActiveCN111943124AQuick refuelingEasy to refuelTank vehiclesLiquid flow controllersMarine engineeringLantern

The invention discloses a movable rapid refueling system. The movable rapid refueling system comprises a refueling vehicle provided with an oil tank, wherein an oil outlet assembly is slidably connected to the outer side of the oil tank; a top cover installed at the top of the oil tank; a winding column installed in the top cover; a soft oil conveying pipe is wound around the winding column; one end of the oil conveying pipe communicates with the interior of the oil tank through an oil pump; the other end of the oil conveying pipe is connected with the oil outlet assembly; the oil outlet assembly comprises a cross beam and a lantern ring; the cross beam is fixed to the top of the outer wall of the oil tank; the lantern ring is slidably connected outside the cross beam in a sleeving mannerand capable of sliding in the extending direction of the cross beam; the lantern ring is of a hollow structure; the interior of the lantern ring communicates with the oil conveying pipe; an oil outlethole is formed in the lantern ring, and a hard oil conveying pipe is arranged on the lantern ring; the top end of the hard oil conveying pipe is connected with the oil outlet hole; and a conical barrel is fixed into the bottom end of the hard oil conveying pipe. The movable rapid refueling system facilitates movable refueling, and is capable of rapidly adjusting the position according to oiling points; and moreover, oil conveying pipelines are arranged in order, so that repeated use is facilitated, pipeline knots cannot be caused, and the operation is simple and convenient.

Owner:临夏海螺水泥有限责任公司 +3

Large-torque cone-hypocycloid speed reducer of rotary brush aeration machine

ActiveCN102442733AImprove bearing capacityImprove overload capacityTreatment using aerobic processesWater aerationGear wheelReduction drive

The invention relates to the technical field of speed reduction of aeration machines, in particular to a large-torque cone-hypocycloid speed reducer of a rotary brush aeration machine. The large-torque cone-hypocycloid speed reducer is characterized by comprising a bevel gear pair and a hypocycloid drive, wherein the bevel gear pair comprises a drive bevel gear and a driven bevel gear; the hypocycloid drive comprises a pin wheel housing, a needle pin, three cycloidal wheels and a W output mechanism, wherein a screw hole with a ventilation cap is formed on an engine base, an oil return hole isarranged in a bearing hole of the engine base, the oil return hole is located below a space between an oil seal and a bearing, the pin wheel housing is connected to an inner hole of the engine base, an oil feeding hole is arranged in a round end cover on the small end face of the engine base, an oil scale is arranged in the hole, and the oil scale is drawn to check the oil quantity and refuel rapidly. The large-torque cone-hypocycloid speed reducer of the rotary brush aeration machine has the advantages that: (a) hypocycloid wheel teeth are continuous, so that the overload capacity is larger than external gearing transmission of a parallel shaft, and bearing capacities of three bearings can be increased by 50 percent; (b) the price of the hypocycloid speed reducer is less than one third of a hard tooth surface, so that the cost is 50-55% lower than that of the hard tooth surface; and (c) the oil quantity in the speed reducer can be rapidly checked and the oil can be rapidly refueled to the speed reducer in both dirty and exposed environments.

Owner:JIANGSU TAILONG MACHINERY GRP CO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com