Movable rapid refueling system

A refueling system and mobile technology, applied in tank trucks, motor vehicles, liquid distribution, etc., can solve the problems of inconvenient construction of conventional gas stations, failure of gas stations, inconvenient refueling, etc., to achieve fast and convenient refueling , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

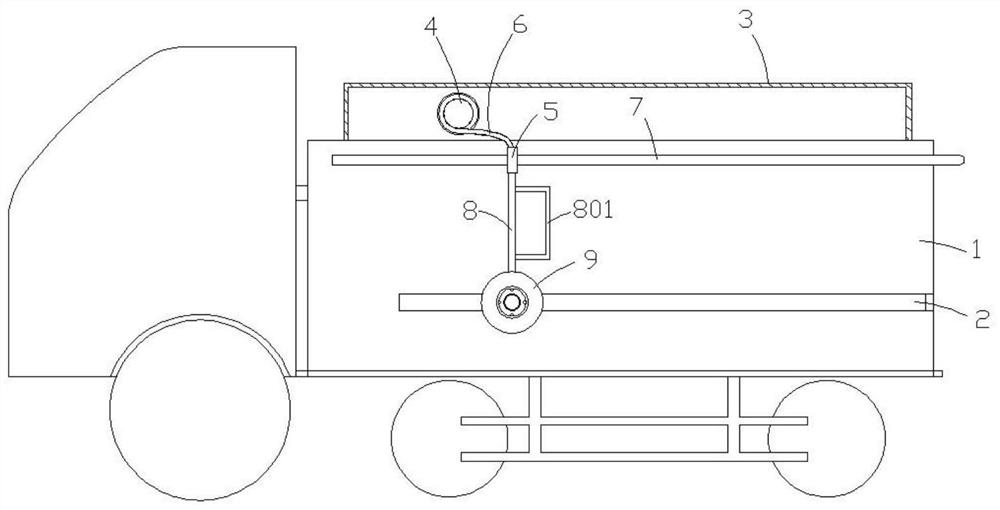

[0033] see Figure 1-2 ,, Figure 4-7 , a mobile fast refueling system, including a refueling truck equipped with an oil tank 1, an oil outlet assembly is slidably connected to the outside of the oil tank 1, a top cover 3 is installed on the top of the oil tank 1, and a winding column 4 is installed inside the top cover 3 A soft oil delivery pipe 6 is wound around the column 4, one end of the oil delivery pipe 6 communicates with the inside of the oil tank 1 through an oil pump, and the other end of the oil delivery pipe 6 is connected with the oil outlet assembly.

[0034] The oil outlet assembly includes a beam 7 fixed on the top of the outer wall of the oil tank 1 .

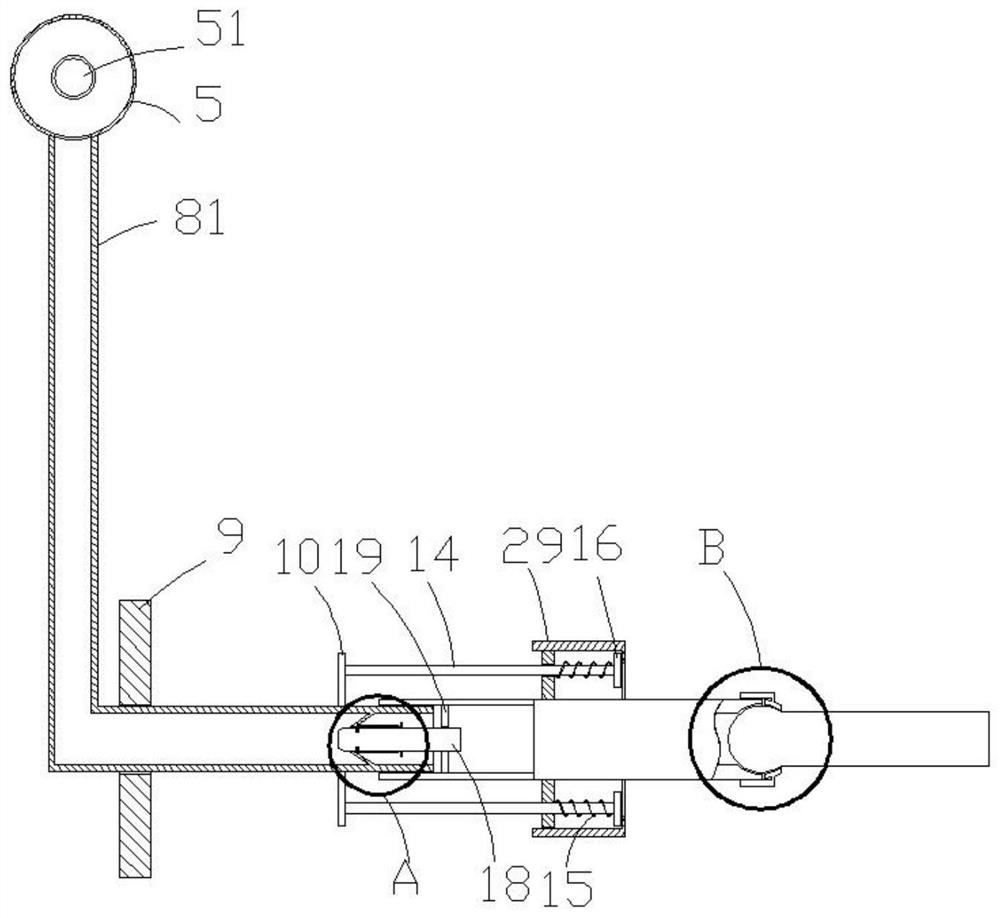

[0035] A collar 5, said collar 5 is slidably socketed outside the beam 7, and can slide along the extension direction of the beam 7, the collar 5 is a hollow structure, the inside of the collar 5 communicates with the oil delivery pipe 6, and the collar 5 is provided with an outlet oil hole.

[0036] A hard...

Embodiment 2

[0048] see image 3 , different from Embodiment 1, the clamping mechanism described in this embodiment includes a positioning sleeve 29, the inner wall of the positioning sleeve 29 has internal threads, the outer wall of the second convex plate 17 has external threads, and the positioning sleeve 29 is spirally sleeved on the second convex plate 17. On the outside of the second convex plate 17 , a flange is provided on the side of the positioning sleeve 29 close to the limiting block 16 , and the flange is used to compress the limiting block 16 .

[0049] This embodiment can be further improved. The annular plate of the fixed plug 18 is set as a plate-shaped structure that cannot pass through the oil. hole, the end of the plug 18 away from the tapered cylinder 30 passes through the annular plate 19, and opens an oil outlet hole communicating with the inside, so that the oil can be further filtered, and a filter element can be set in the plug 18 to Filter the oil passing throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com