Large-torque cone-hypocycloid speed reducer of rotary brush aeration machine

An aerator and high-torque technology, applied in water aeration, chemical instruments and methods, sustainable biological treatment, etc., can solve the difficulty of on-site inspection of oil quantity in the case of hard-toothed reducer, poor lubrication of bearings, service life Short and other problems, to achieve the effect of simple structure, improved bending ability and short axial dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

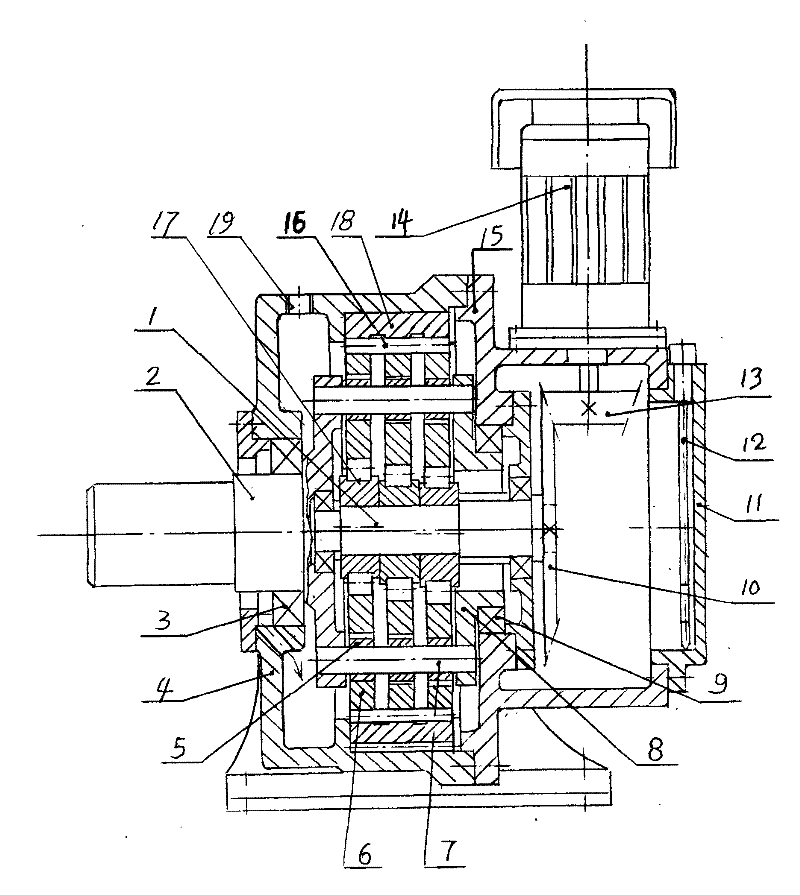

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

[0022] refer to figure 1 .A high-torque cone-pendulum reducer for a brush-type aerator, characterized in that it consists of a bevel gear pair installed in a small machine base (15) and a cycloid transmission member installed in a machine base (4) , the small frame (15) is connected to the end face of the frame (4), wherein:

[0023] (A) The bevel gear pair consists of a small bevel gear shaft (13) mounted on the small machine base (15) and a large bevel gear (10) connected to the output and extension end of the input shaft (1), and the small bevel gear shaft is connected to the motor ( 14);

[0024] (B) The cycloidal transmission includes an input shaft (1), an output shaft (2), three cycloidal wheels (6) whose phase angles are staggered by 120°, pin-toothed pins (16), three eccentric bearings (17), Composed of pin gear housing (18) and W output mechanism, the pin gear hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com