Curing agent and construction method of weak soil

A construction method and curing agent technology, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of difficult sludge dehydration and low bearing capacity of consolidated bodies, and achieve low production costs and reduced use Quantity, the effect of huge social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 Get each raw material component of soft soil solidifying agent by following weight ratio:

[0029] The powder raw material is: P.O42.5 ordinary Portland cement.

[0030] The raw material composition of the solution is: anionic polyacrylamide 5kg, pulp waste liquid 45kg, cement retarder 45kg, OP-10 industrial emulsifier 2.0kg, carrageenan 0.5kg, xanthan gum 0.5kg, sodium α-olefin sulfonate 2.0kg, mixed with 3 times water to make a liquid.

[0031] Calculate the amount of water needed to be added to the cement according to the water-cement ratio of 0.45, mix it with the liquid agent evenly, and then mix it with cement to make a cement slurry for use. The ratio of cement and liquid agent is about 50:1, and use the prepared cement slurry to solidify the sludge. Knot treatment test. The test uses the silt blowing and land reclamation silt from Lingang New District, Tianjin. It has been determined that the water content of the silt is about 100%, and the organi...

Embodiment 2

[0033] Embodiment 2 Get each raw material component of soft soil solidifying agent by following weight ratio:

[0034] The powder raw materials are: 15kg of Portland cement clinker, 74kg of water-quenched slag, 2kg of lime, 5kg of gypsum, 3kg of sodium fluoride, and 1kg of sodium fluorosilicate. The above raw materials are crushed and mixed to obtain a powder;

[0035] The raw materials of the solution are: 15kg of amphoteric polyacrylamide, 40kg of pulp waste liquid, 40kg of cement retarder, 2.0kg of OP-10 emulsifier, 2.5kg of α-olefin sulfonate, 0.5kg of carrageenan, and 3 times water Mix to make a liquid.

Embodiment 3

[0037] Embodiment 3 Get each raw material component of soft soil solidifying agent by following weight ratio:

[0038] The powder raw materials are: Portland cement clinker 10kg, active water-quenched slag 83kg, lime 3kg, gypsum 3kg, sodium fluorosilicate 1kg;

[0039] The raw materials of the solution are: polyacrylamide 6kg, pulp waste liquid 60kg, caustic soda 2kg, cement retarder 30kg, OP-10 emulsifier 1.5kg, α-olefin sulfonate 0.5kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

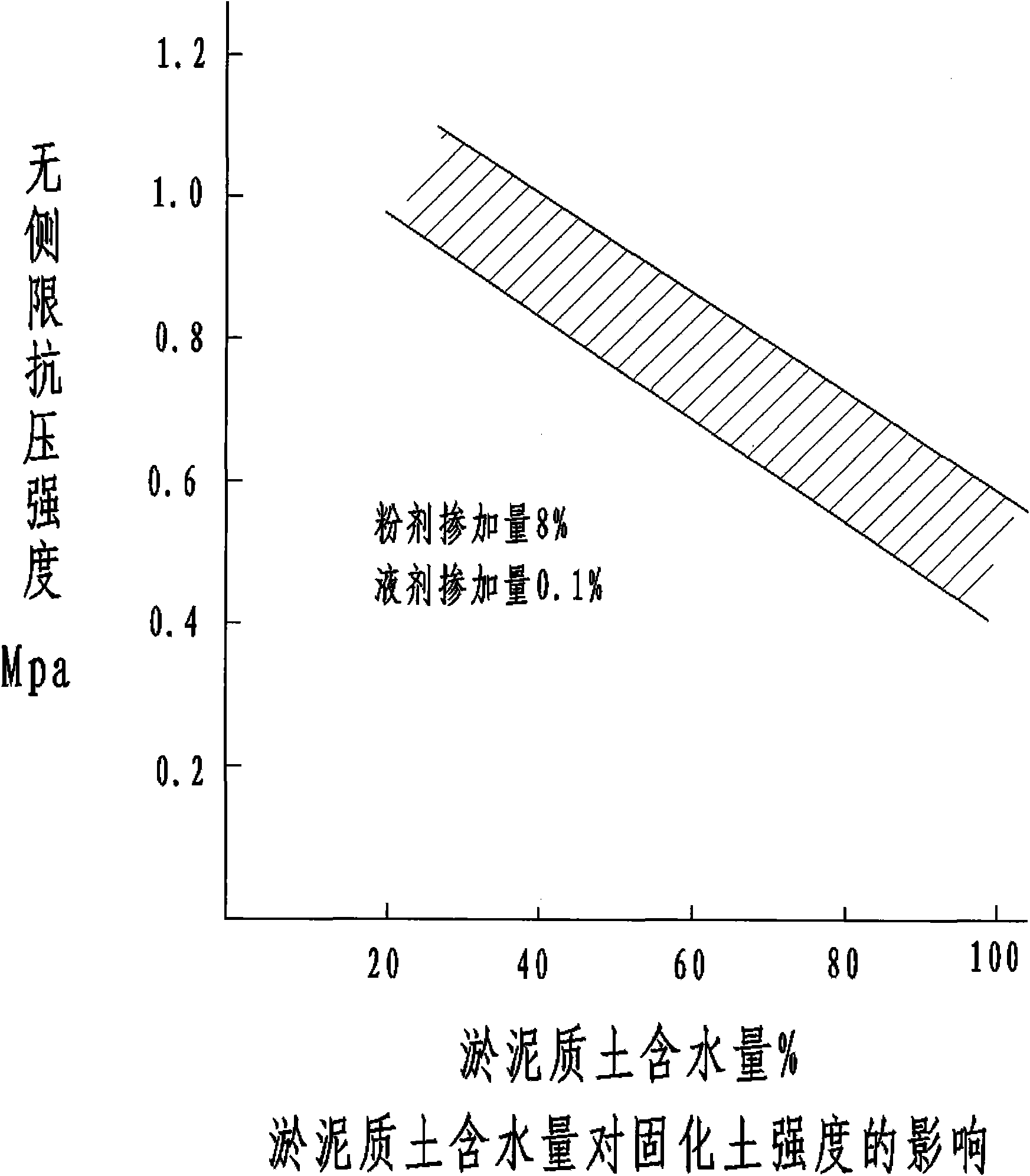

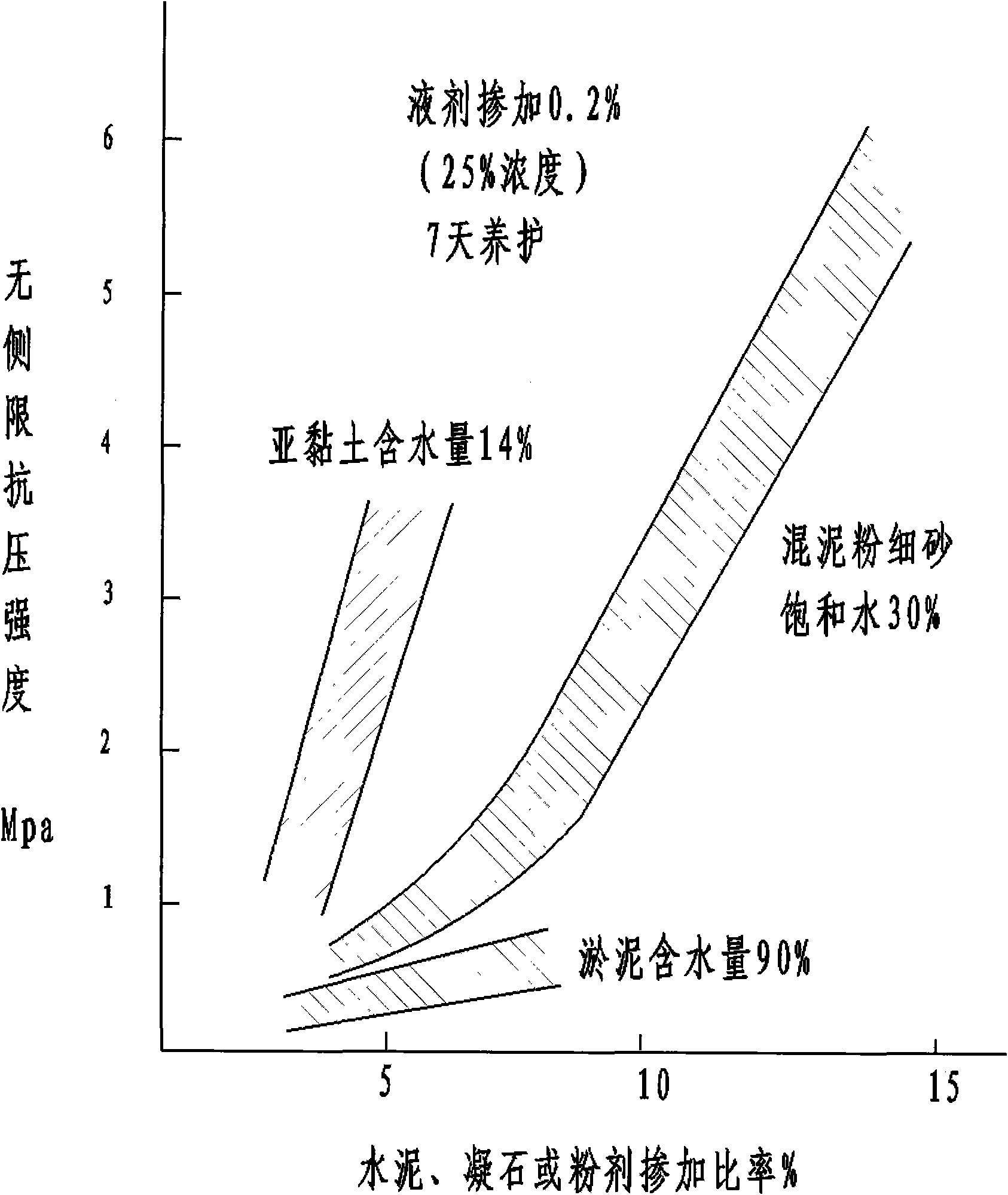

| Strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com