Non-contact refueling system

A refueling system and non-contact technology, which is applied in special dispensing devices, packaging, dispensing devices, etc., can solve the problem that refueling cannot be paid quickly and electronically

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

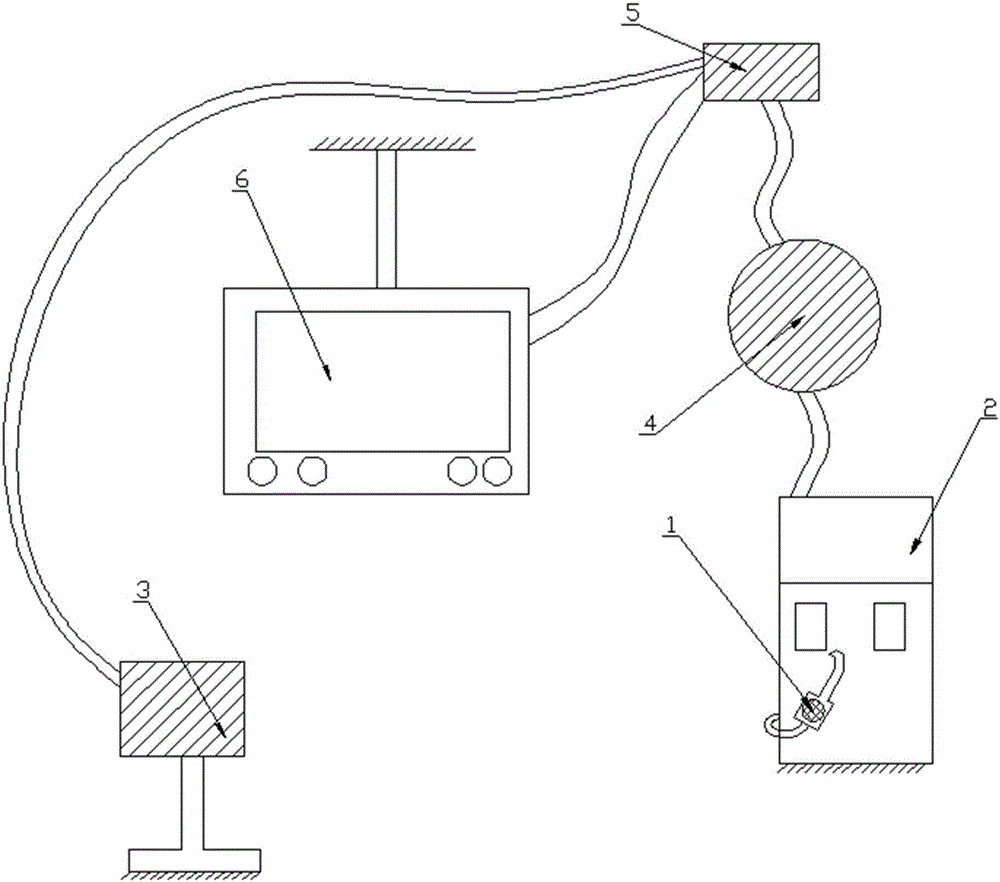

[0025] figure 1 It is a schematic structural diagram of a non-contact refueling system provided by the embodiment of the invention;

[0026] Such as figure 1 As shown, the RFID tag includes a first RFID tag 1 and a second RFID tag;

[0027] The fuel gun 2 is affixed with a first RFID tag 1 that can be identified by a first RFID reader-writer 4. The first RFID reader-writer 4 is located in a gas station, and a second RFID reader-writer for reading vehicle information is also provided in the gas station. Device 3, the second RFID label is affixed on the car;

[0028] In the case of automobile refueling, the first RFID reader-writer 4 is used to calculate the distance between the refuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com