Circulating feeder

A feeder and tray technology, which is used in the stacking of objects, destacking of objects, conveyors, etc., can solve the problems of reducing production efficiency, increasing the number of shutdowns and changing materials, and spending more time, so as to achieve fast material changing. and loading and unloading operations, improve production efficiency, and save space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

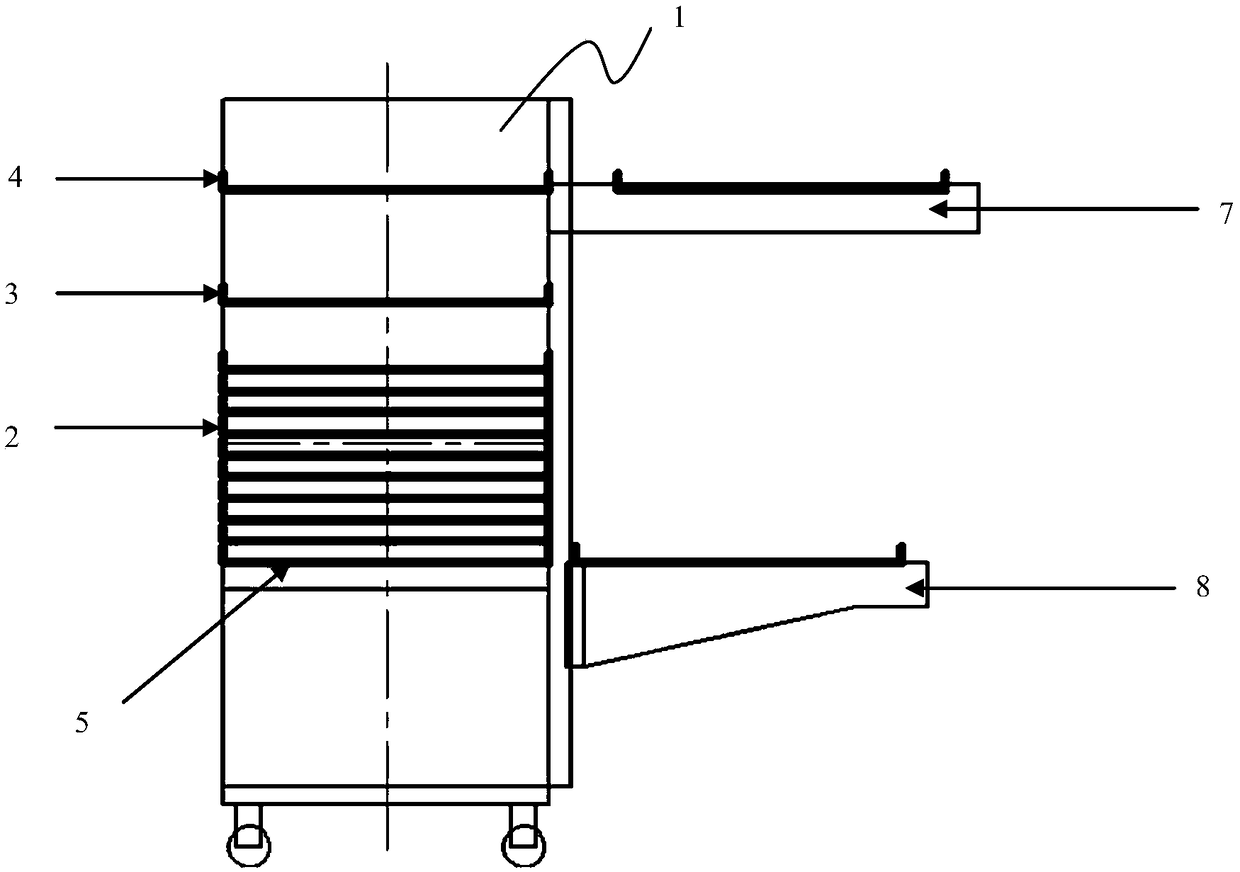

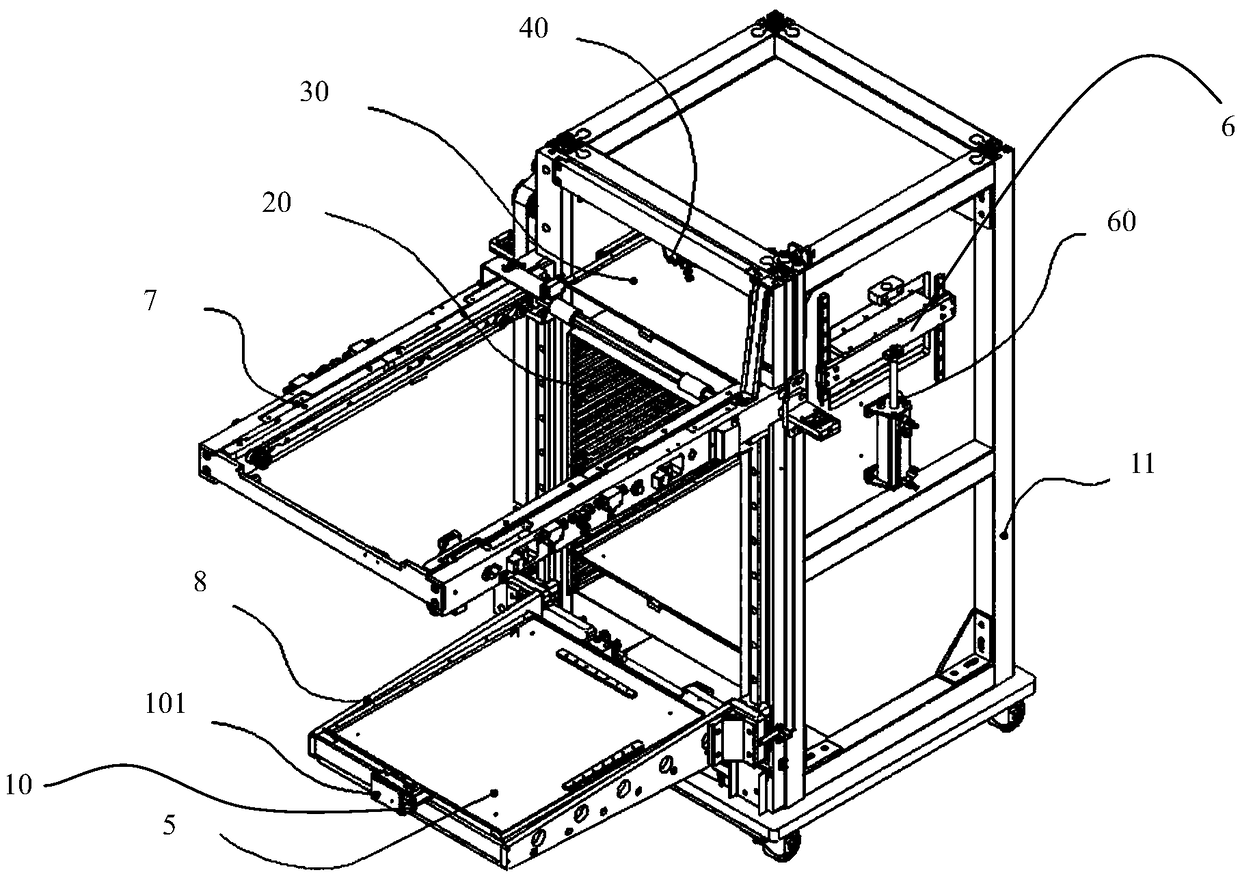

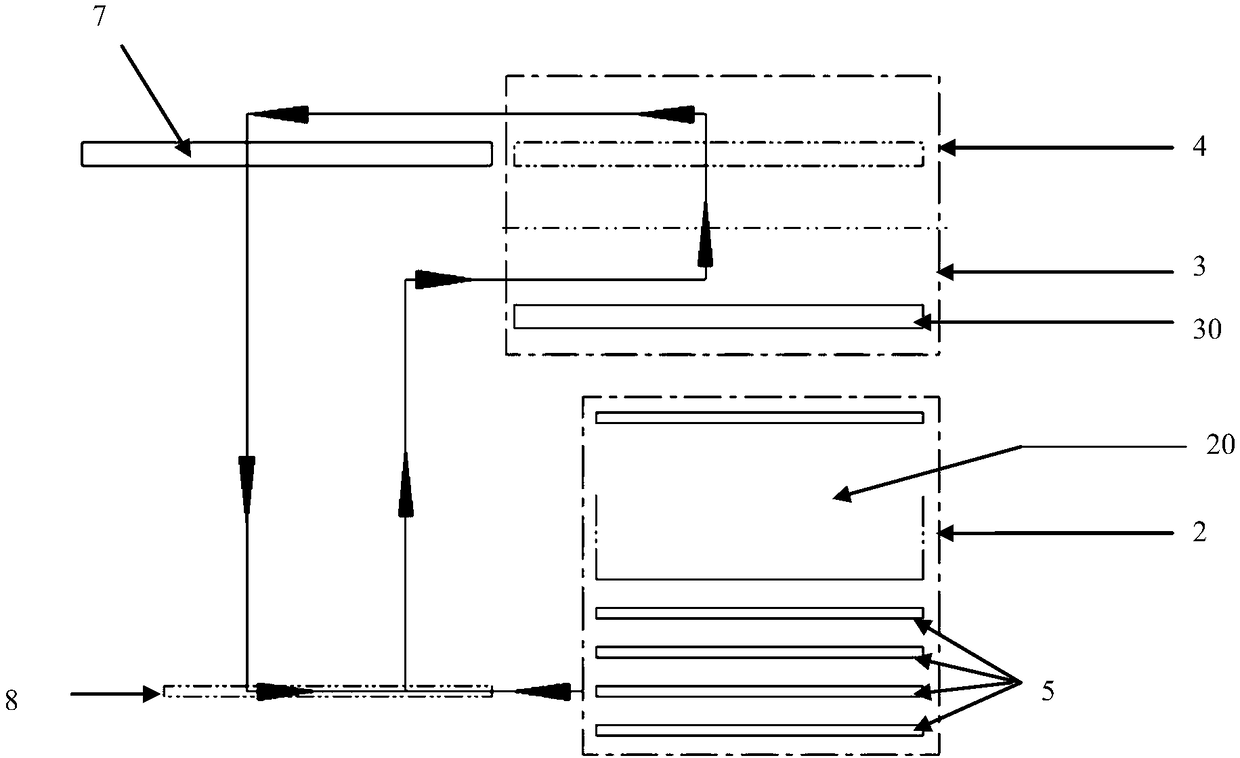

[0031] Such as Figure 1-3 The shown circulation feeder includes a device main body 1, on which a storage area 2, a temporary storage area 3 and a material waiting area 4 are arranged from top to bottom or from bottom to top, and a plurality of The trays 5 used to hold materials are layered and stored in each storage layer in the storage area 2, and the temporary storage area 3 is provided with a device for moving the trays 5 up and down from the temporary storage area 3 to the waiting area. The lifting device 6 of the material area 4 is provided with a conveying device 40 in the material area 4 .

[0032] It also includes a fixed arm 7 and a movable arm 8 arranged on the same side of the device main body 1, the fixed arm 7 is on one side of the waiting area 4, and the fixed arm 7 is provided with a host working position, so The movable arm 8 moves up and down through a traction device (not shown in the figure), and the movable arm 8 is provided with a horizontally moving dis...

Embodiment 2

[0051] On the basis of Embodiment 1, the following driving and transmission modes are preferred.

[0052] Preferably, said fetching and placing mechanism 10 adopts motor drive, belt transmission or screw rod transmission, and said taking and placing mechanism 10 is provided with a vacuum suction device or air claw clamping device for taking and placing discs for pushing, Pull tray 5.

[0053] Preferably, the traction device adopts motor drive, belt drive or screw drive, so as to drive the boom 8 to move up and down.

[0054] Preferably, the jacking device is driven by a cylinder or a motor to drive a screw, so as to lift the tray 5 from the temporary storage area 3 to the waiting area 4 .

[0055] Preferably, the conveying device adopts a motor-driven single-axis manipulator, and the single-axis manipulator grabs the tray 5, or adopts a belt drive, so as to send the tray 5 from the waiting area 4 to the working position 10 of the main machine.

[0056] Such as Figure 2-3 S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com