A kind of preparation method of refrigerating machine oil base oil

A technology for refrigerating machine oil and base oil, which is used in base materials, petroleum industry, processing hydrocarbon oil, etc., can solve problems such as few research reports, and achieve the effects of high economic value, simple and environmentally friendly process, and easy preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The hydrogenation reaction catalyst is loaded into the hydrotreating fixed-bed reactor for presulfurization, and the presulfurized catalyst is ready for use. The hydrogenation reaction catalyst components and their proportions by weight of the catalyst are: 25.2% of nickel oxide, 2% of molybdenum oxide, 4.5% of cobalt oxide, 3% of tungsten oxide, 15% of silica carrier, and the balance of alumina carrier, Catalyst average pore size 100 , The specific surface area is 350m 3 / g, the pore volume is 0.3cm 3 / g, the strength is 200N / mm.

[0020] The pre-sulfurization process conditions are: use carbon disulfide CS which accounts for 2% of the weight of the vulcanized oil 2 And the remaining kerosene is used as vulcanized oil, and hydrogen gas is passed under the hydrogen partial pressure of 6MPa, the vulcanization temperature is 280°C, and the space velocity is 0.5h -1 , the volume ratio of hydrogen to oil is 1000:1, and the vulcanization time is 50 hours.

[0021] The ...

Embodiment 2~10

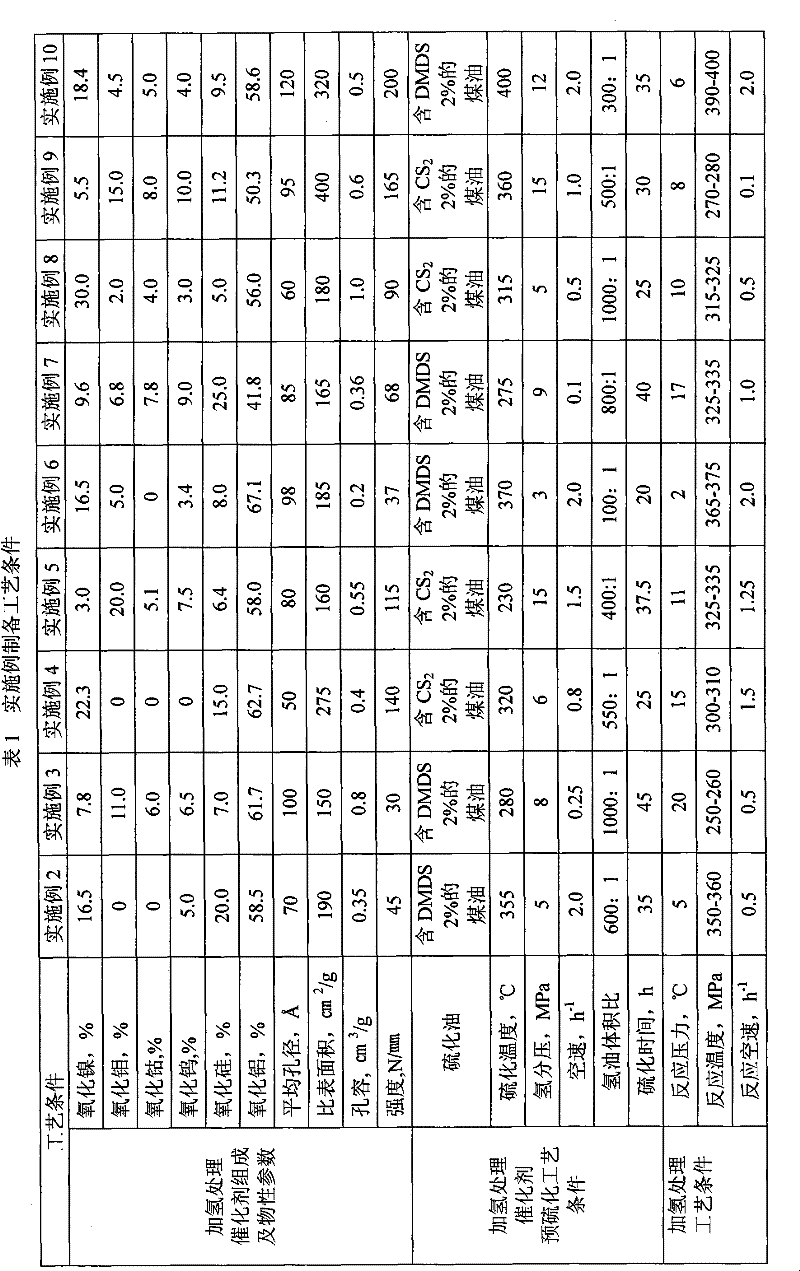

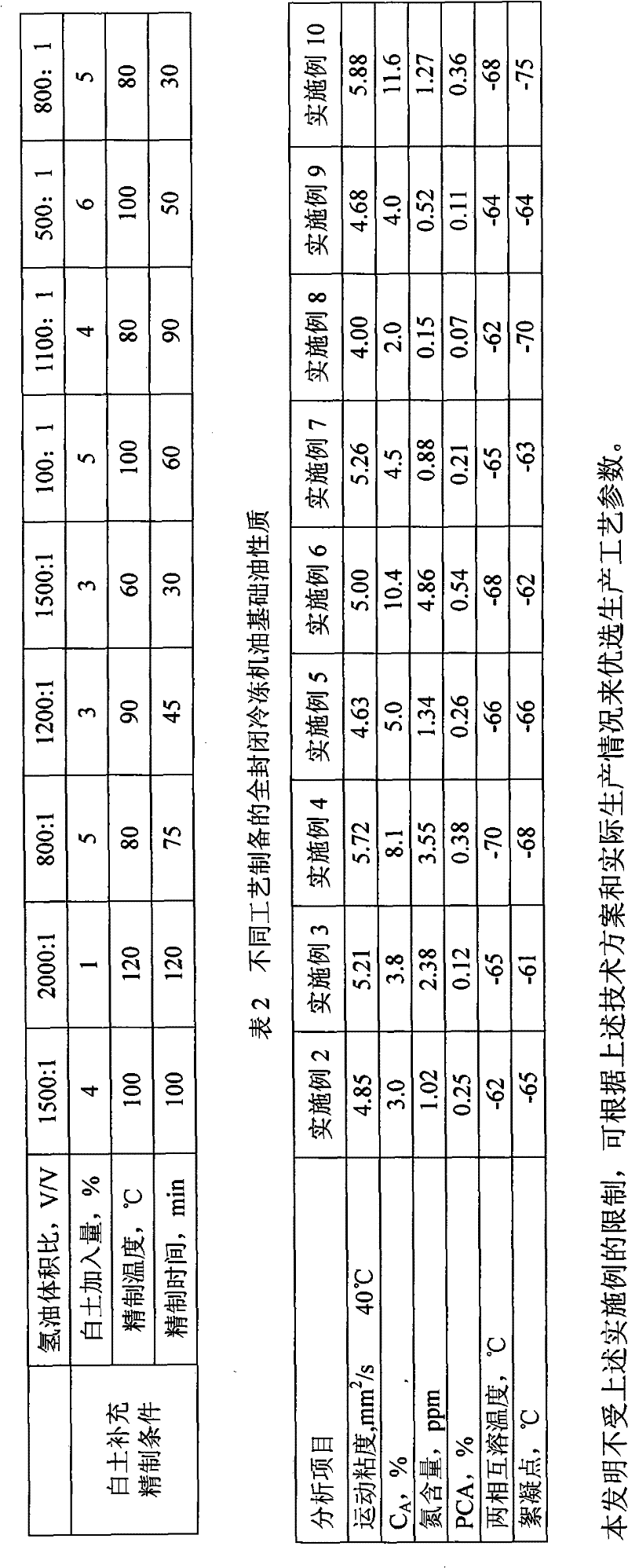

[0024] According to the preparation process of Example 1 and the method for analyzing the properties of refrigerating machine oil, the preparations of Examples 2 to 10 were carried out, wherein the preparation process conditions of "hydrogenation-clay supplementation refining" are shown in Table 1, and the cutting process conditions of oil produced after hydrogenation Same as in Example 1, the properties of the prepared refrigerating machine oil base oil are shown in Table 2.

[0025]

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com