Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

258 results about "Metal leaching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Leaching (metallurgy), a widely used extractive metallurgy technique which converts metals into soluble salts in aqueous media Dump leaching, an industrial process to extract metals from ore taken directly from the mine and stacked on the leach pad without crushing.

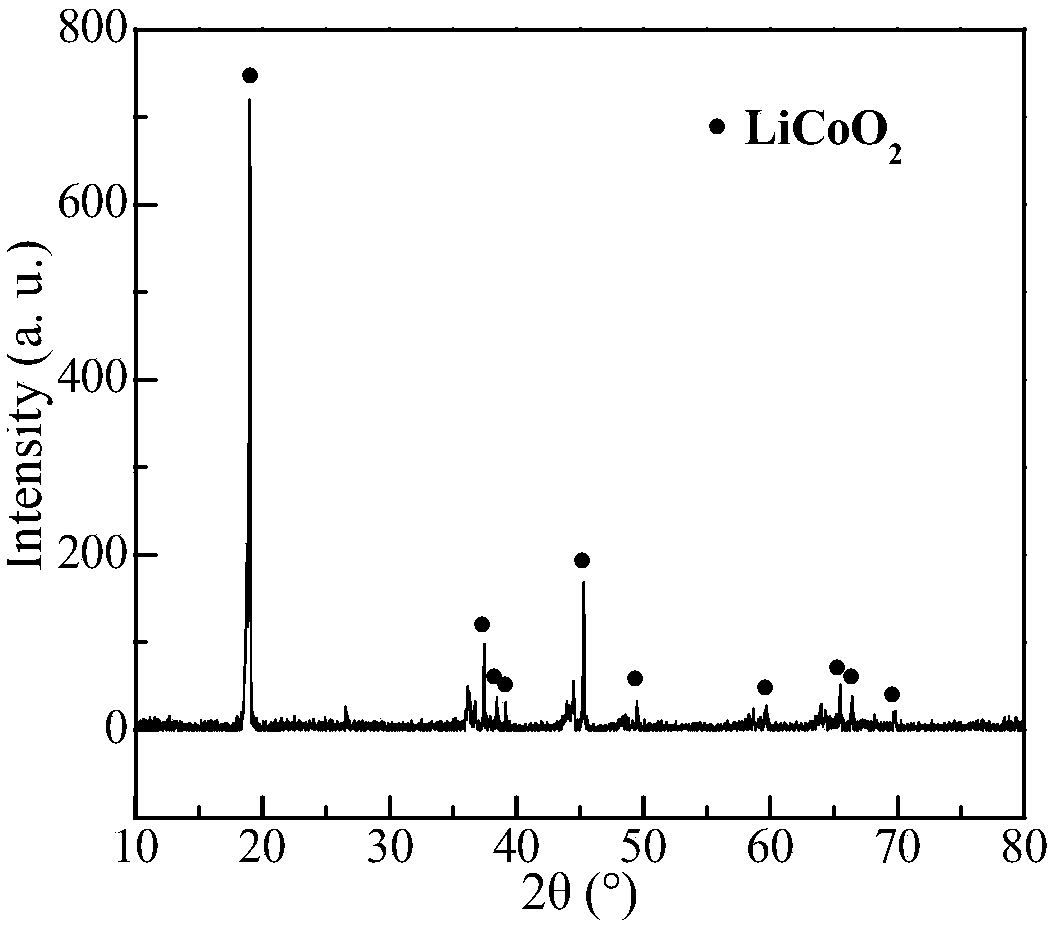

Method for directly roasting and processing spent lithium ion batteries and recycling valuable metals

InactiveCN101519726AImprove leaching rateEasily brokenProcess efficiency improvementCobaltSodium sulfate

The invention relates to a method for directly roasting and treating spent lithium ion batteries and recycling valuable metals, in particular to a method for recycling and treating spent lithium ion batteries using lithium cobalt oxide as an anode material. The method comprises the following steps: firstly, remove organic binder on an organic diaphragm material and an electrode material in the batteries by roasting at a temperature of 500 DEG C to 850 DEG C; crushing and mixing the roasted battery material with sodium sulfate (or potassium sulfate) and concentrated sulfuric acid before size mixing; carrying out secondary heat treatment in an electric stove at a temperature of 350 DEG C to 600 DEG C to convert metals in the spent lithium ion batteries, such as cobalt, copper, lithium, and the like into easily water-soluble sulfate which is leached by water or a dilute sulphuric acid solution; then, using an organic extracting agent to respectively extract the cobalt and the copper from a leaching solution and obtain a cobalt product and a copper product; using sodium carbonate to precipitate the metal lithium from the leaching solution after the cobalt and the copper are removed; and enabling the leaching solution to return treatment heat so as to secondarily treat materials. The invention has a metal leaching rate higher than 99.5 percent and a metal recovery rate higher than 99 percent.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

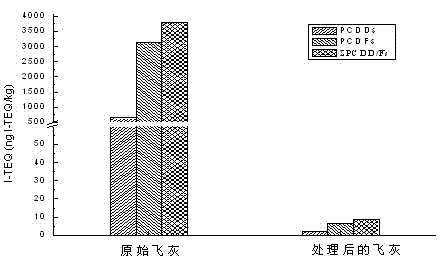

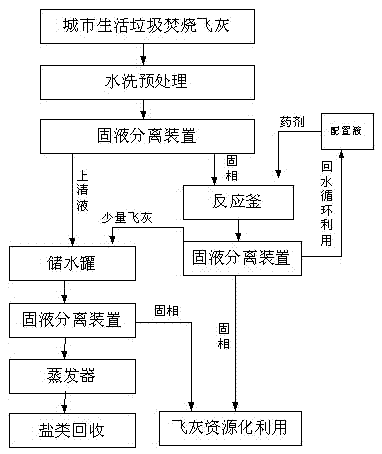

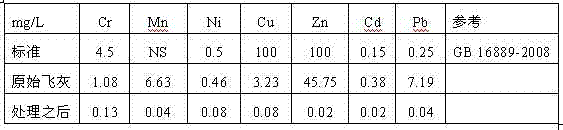

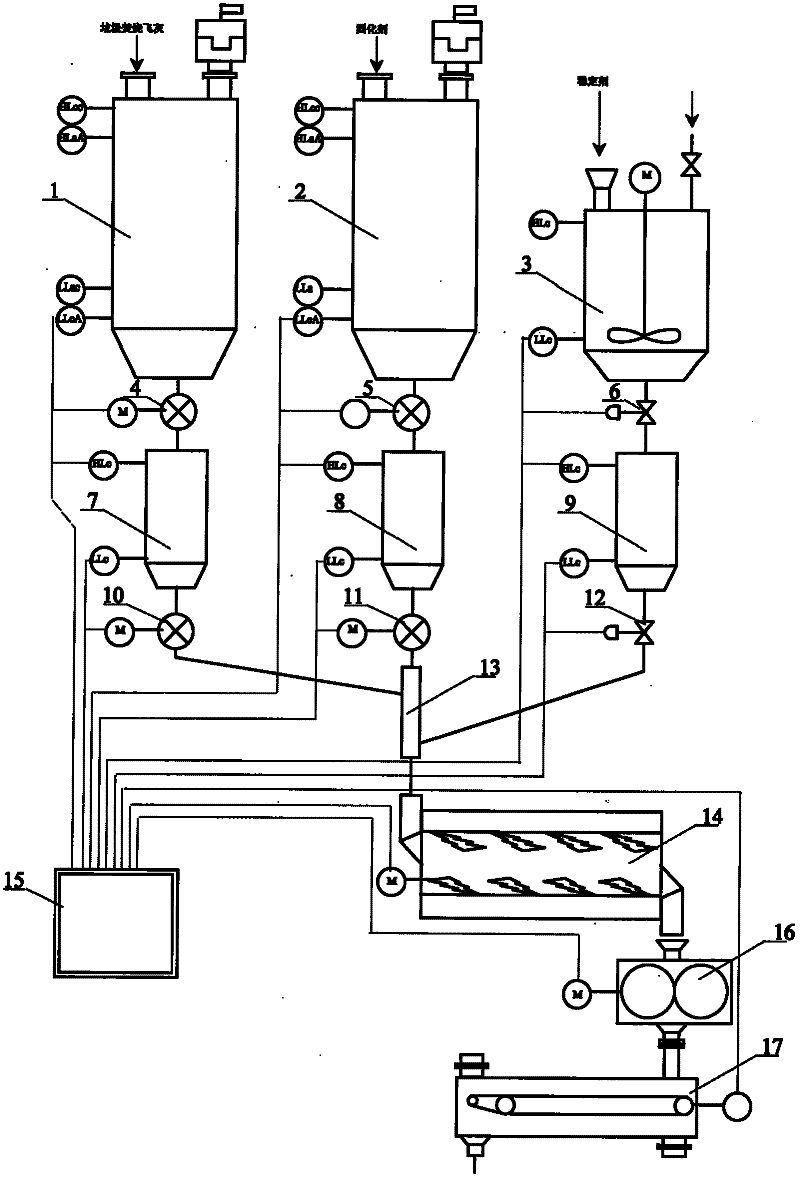

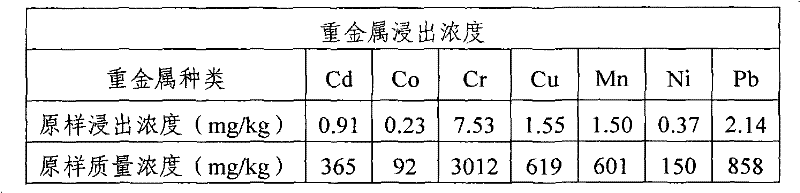

Harmless treatment method for urban garbage incineration fly ash

The invention discloses a harmless treatment method for urban garbage incineration fly ash. Due to the adoption of a treatment system and a method disclosed by the invention, heavy metals in incineration fly ash can be effectively stabilized and dioxin can be degraded; the leaching toxicity of heavy metals is fully accordant with the national standard; the toxicity of dioxin is removed by 99.9 percent; and meanwhile, the chloride ions in fly ash can be effectively removed, salt substances are recovered, and zero discharge of waste liquids is ensured. A process and the method have the remarkable characteristics of energy saving, environmental friendliness, remarkable economic benefit and remarkable social benefit; and meanwhile, the treated fly ash has novel physicochemical properties, canbe applied to the industries of environmental protection, construction and the like, and has application and popularization values.

Owner:ZHEJIANG UNIV

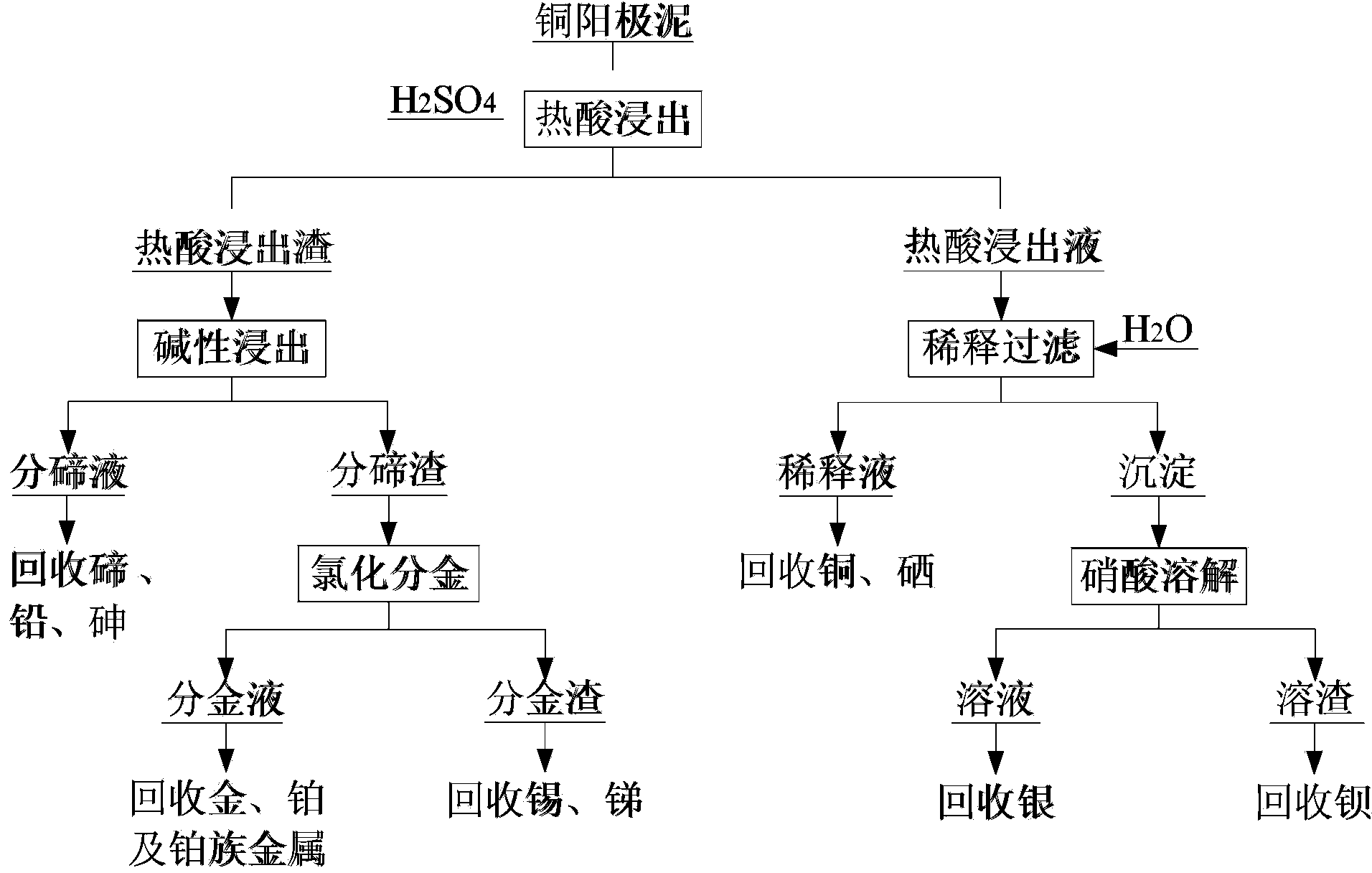

All-wet process pretreatment method for copper anode mud

InactiveCN103966450AReduce processingHigh enrichment rateProcess efficiency improvementPretreatment methodHydrometallurgy

The invention relates to a wet-process metallurgy technology in the metallurgical field and particularly relates to an all-wet process pretreatment method for copper anode mud. The all-wet process pretreatment method is as follows: firstly, carrying out hot acid leaching onto copper anode mud, leaching metals such as copper, selenium, sliver, barium, and the like and adding in liquor, leaving gold, tellurium, tin, platinum and platinum-family metals in leaching residue; by virtue of alkali leaching of hot acid leaching residue, leaching and enriching metals such as tellurium, lead, arsenic, and the like in liquor; carrying out chlorination on the obtained tellurium-separating residue for separating gold, enriching the gold, the platinum and the platinum-family metals in the liquor, enriching the tin and the antimony in residue; diluting the hot acid leaching liquor by water, enriching the copper and the selenium in diluted liquor, dissolving obtained precipitates by nitric acid, and filtering to obtain barium sulfate molten slag and sliver nitrate liquor. The all-wet process pretreatment method disclosed by the invention cancels a sulfating and roasting process which is high in energy consumption and great in pollution in the conventional copper anode mud treatment method, removes and openly recycles barium by the hot acid leaching before extracting the gold and the sliver, reduces treatment amount of the copper anode mud, and improves recovery rate of gold and sliver.

Owner:JIANGXI UNIV OF SCI & TECH

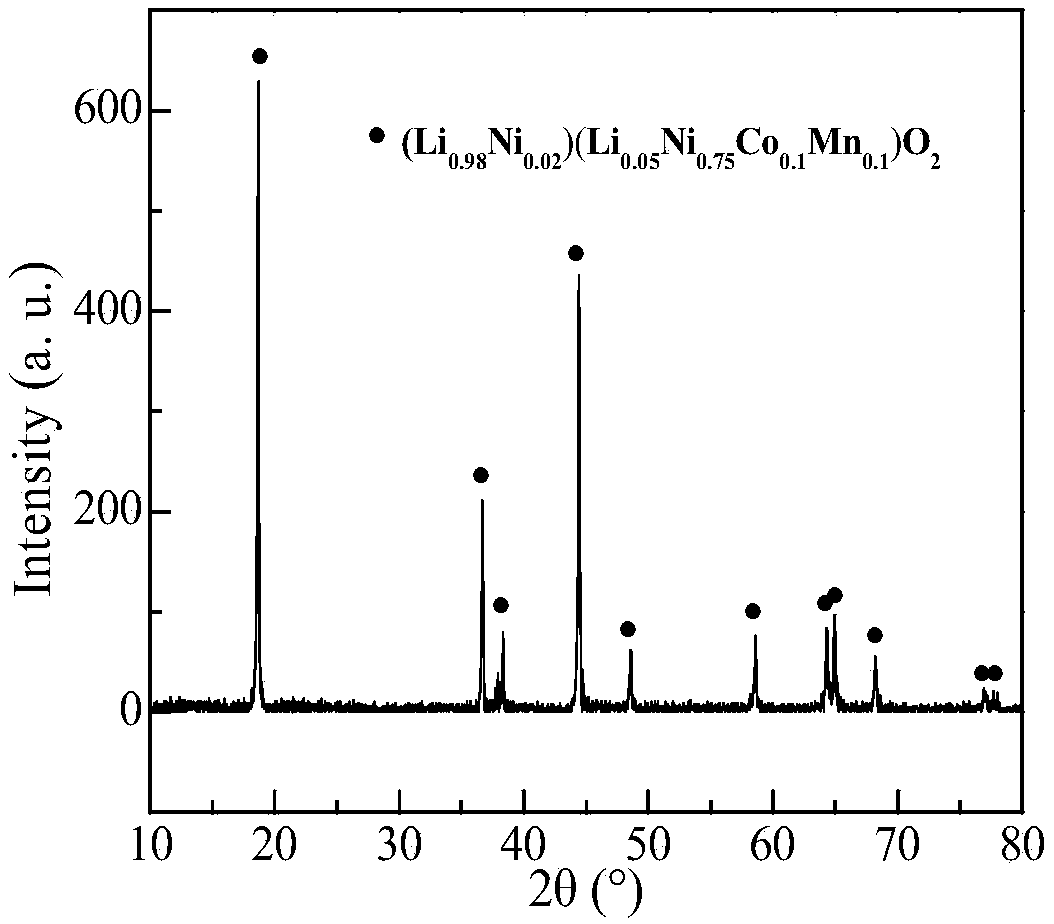

Method for recovering valuable metals from cathode materials of waste lithium ion batteries

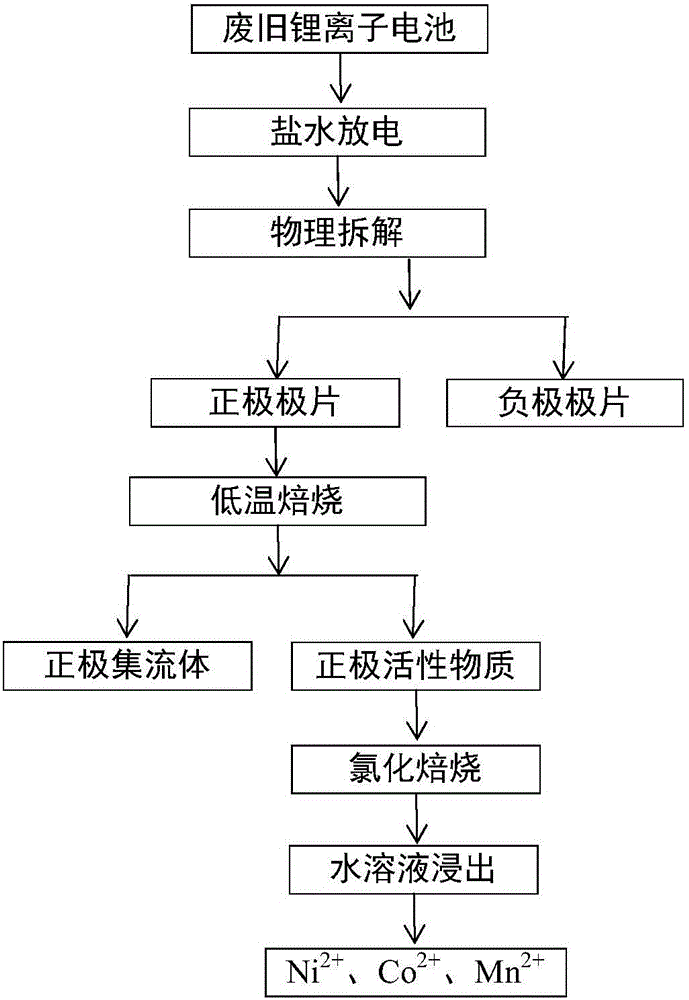

InactiveCN106848469AEfficient recyclingReduce recycling costsWaste accumulators reclaimingBattery recyclingMetal leachingChloride

The invention discloses a method for recovering valuable metals from cathode materials of waste lithium ion batteries. The method comprises the following steps: the waste lithium ion batteries are discharged and dismantled, and cathode plates are separated out; the cathode plates are subjected to pyrolysis for glue removal, and current collectors and active materials are separated out; the active materials are mixed with chloride for chloridizing roasting; a solid product of chloridizing roasting is leached with water, and aleachate containing valuable metal ions is obtained. The method overcomes the defect that a large quantity of mineral acids and bases is needed to be consumed in the traditional metal leaching and recovering process of the cathode materials of the waste lithium ion batteries, adopts simple process, is low in cost and environment-friendly and has great industrial application value.

Owner:CENT SOUTH UNIV +1

Cobalt nickel metallurgy wastewater sludge recycling method

ActiveCN104480317AEmission reductionHigh recovery rateProcess efficiency improvementSludgeAcid dissolution

The invention provides a cobalt nickel metallurgy wastewater sludge recycling method, and belongs to the field of waste recycling. The method comprises the following steps: carrying out acid dissolution reduction on cobalt nickel metallurgy wastewater sludge to leach out valuable metals in the wastewater sludge, displacing copper by using manganese powder to recover copper, precipitating zinc by using manganese sulfide to recover zinc, using a fluoride to remove calcium and magnesium from the obtained zinc removed solution, carrying out advanced impurity removal and cobalt nickel manganese enrichment by using a P2O4 extractant, and carrying out advanced impurity removal on the obtained solution rich in cobalt, nickel and manganese by using manganese sulfide to obtain a solution for preparing an NCM ternary precursor. The method allows nickel, cobalt, manganese, zinc, copper and other metals to be completely recovered and the obtained cobalt, nickel and manganese solution to be used to prepare the NCM ternary precursor as a raw material, avoids cobalt, nickel and manganese separation, and also has the advantages of simple process, substantial improvement of the metal recovery rate, low cost, harmlessness to environment, and industrialization prospect.

Owner:SHAOXING KEQIAO DRAINING

Method for processing copper anode slime in total wet manner

ActiveCN102965501ABig investmentHigh separation recovery rateProcess efficiency improvementElemental selenium/telluriumRaffinateTin

The invention discloses a method for processing copper anode slime in a total wet manner, relating to a total wet production process for recycling rare and precious metals from the copper anode slime in nonferrous metallurgy. The method comprises the steps of pressurizing the copper anode slime by a chloride medium at a high temperature and leaching to directly separate out valuable metals such as copper, stibium, bismuth, tellurium, and tin; and recycling tellurium, stibium, tin, bismuth, copper and the like from a pressurized lixivium in stages. The method is further characterized in that a selective extraction method is adopted to separate gold in a gold selenium chloride solution and the selenium is recycled from a gold raffinate. According to the method, the sulfating roasting with serious pollution and huge investment is avoided, but the sulfating roasting is carried out firstly for the copper anode slime in the conventional wet method or (pyrometallurgical process); the separation recovery rate of the metals is high, but the separation effect of tellurium, stibium, tin and bismuth in the conventional process is far from ideal; by adopting the method, the leaching problems of above metals can be solved in a single process and above metals can be recycled respectively from the lixivium; the recovery rate of the metals is 90-99% respectively; the copper separation and the tellurium separation can be simplified; and the operation flow is optimized in a better manner.

Owner:JIANGXI COPPER

Methods for improving the recovery of metal leaching agents

InactiveUS20050031512A1Promote recoverySolvent extractionSolid sorbent liquid separationMetal leachingRaffinate

Owner:COGNIS IP MANAGEMENT GMBH

Penicillium, as well as preparation method and application

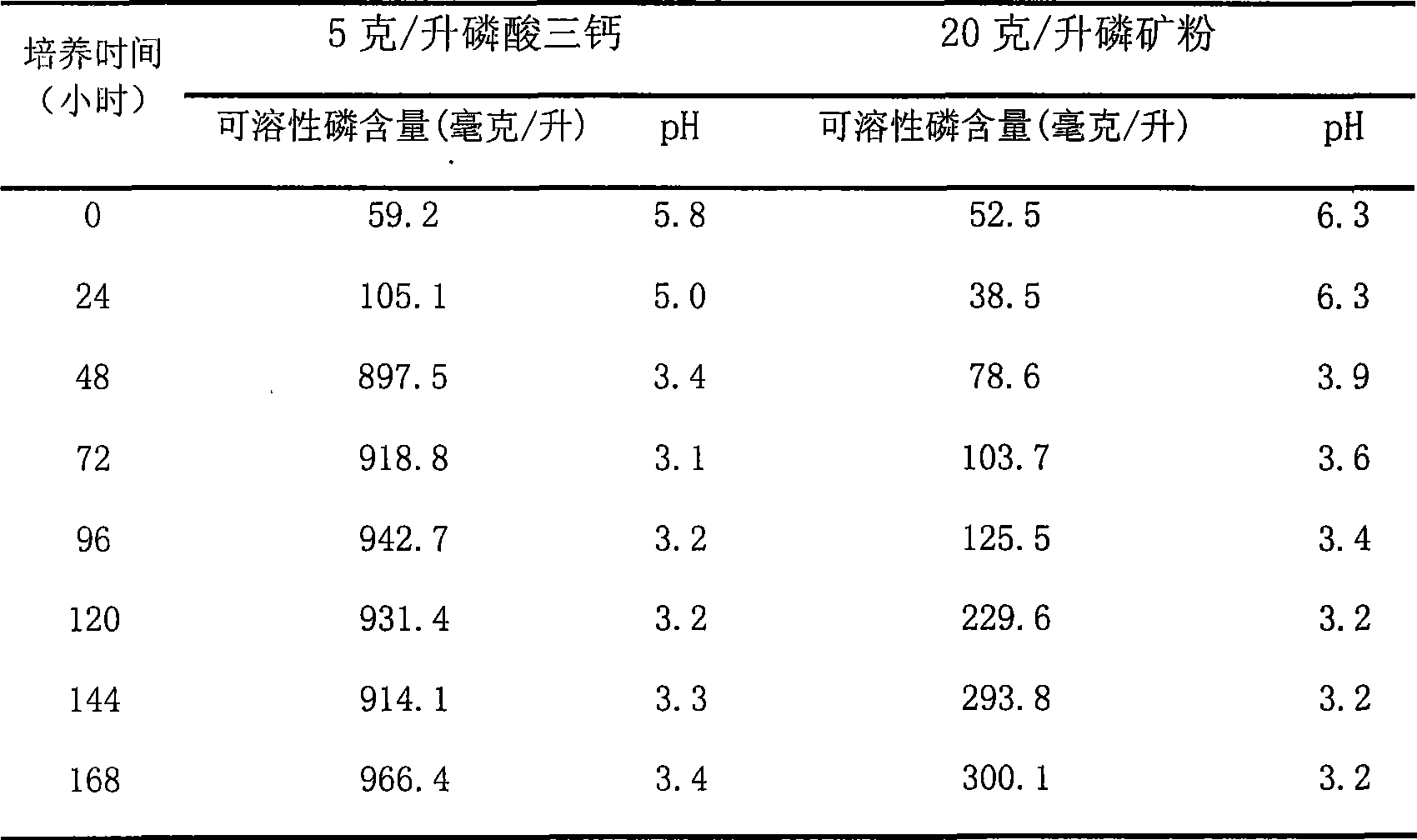

InactiveCN101434909AReach pollutionReduce pollutionFungiMicroorganism based processesEcological environmentPhosphate

The invention discloses a Penicillium, a preparation method and applications thereof, Penicillium fungus PSM11-5 is separated from a vanadium ore sample; insoluble tricalcium phosphate, sodium metavanadate, cobalt hydroxide and basic nickel carbonate are taken as indicating compounds; and a fungal strain is screened by testing the capability of decomposing the tricalcium phosphate, the sodium metavanadate, the cobalt hydroxide and the basic nickel carbonate. The Penicillium PSM11-5 is Penicillium sp.PSM11-5 CCTCCM208207. The strain is utilized for carrying out biological leaching of phosphorus and biological metallurgy, metals of phosphorus, vanadium, nickel, cobalt and the like are leached from lean ores, discarded ores, submarginal ores, difficult-to-mine ores, difficult dressing ores and refractory ores, thereby fully utilizing the mineral resources, reducing the metallurgical costs and protecting the ecological environment. The PSM11-5 is utilized for leaching the phosphorus from low-grade phosphate rock powder, a biological fertilizer is prepared to be applied to the soil, thereby leading the soil to contain higher content of soluble phosphorus which can be utilized by crops; the strain further leaches insoluble phosphorus which is deposited in the soil before, thereby reducing phosphorus fertilizer and reducing gas pollution caused by the phosphorus fertilizer and water pollution caused by the phosphorus fertilizer.

Owner:WUHAN INST OF VIROLOGY CHINESE ACADEMY OF SCI

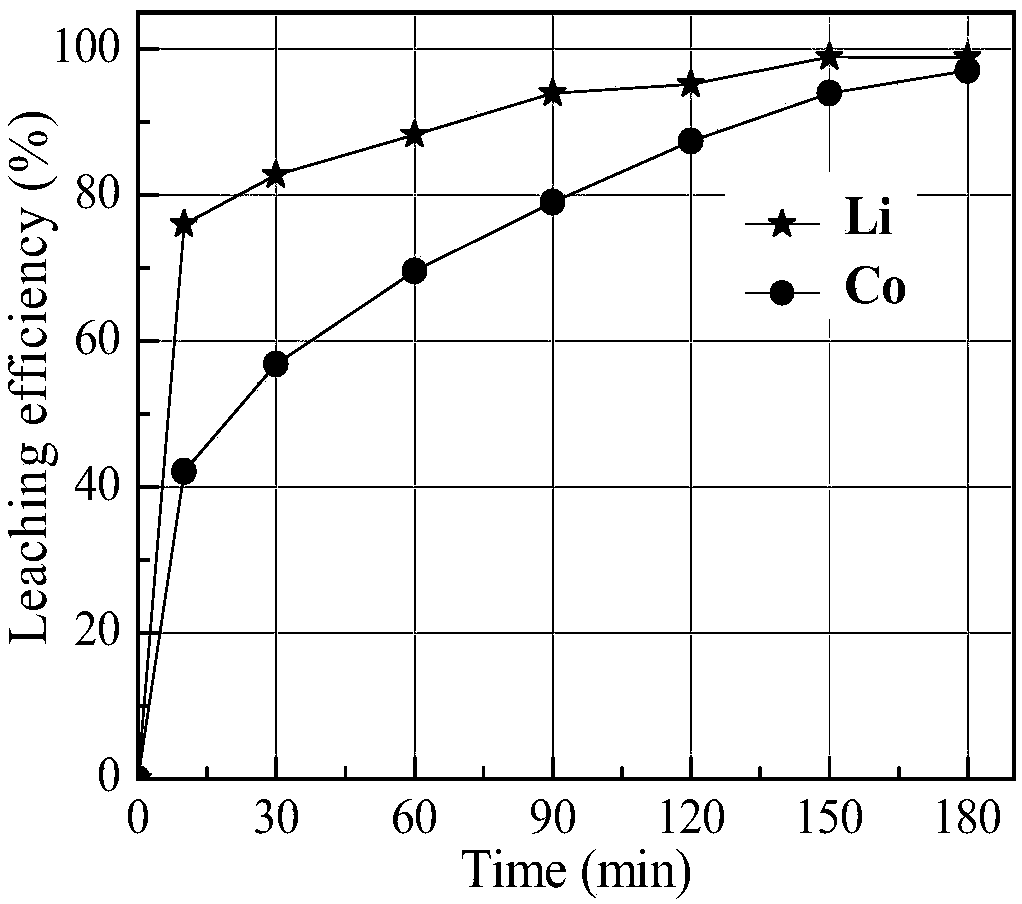

Method for leaching metals in anode material of waste lithium ion battery

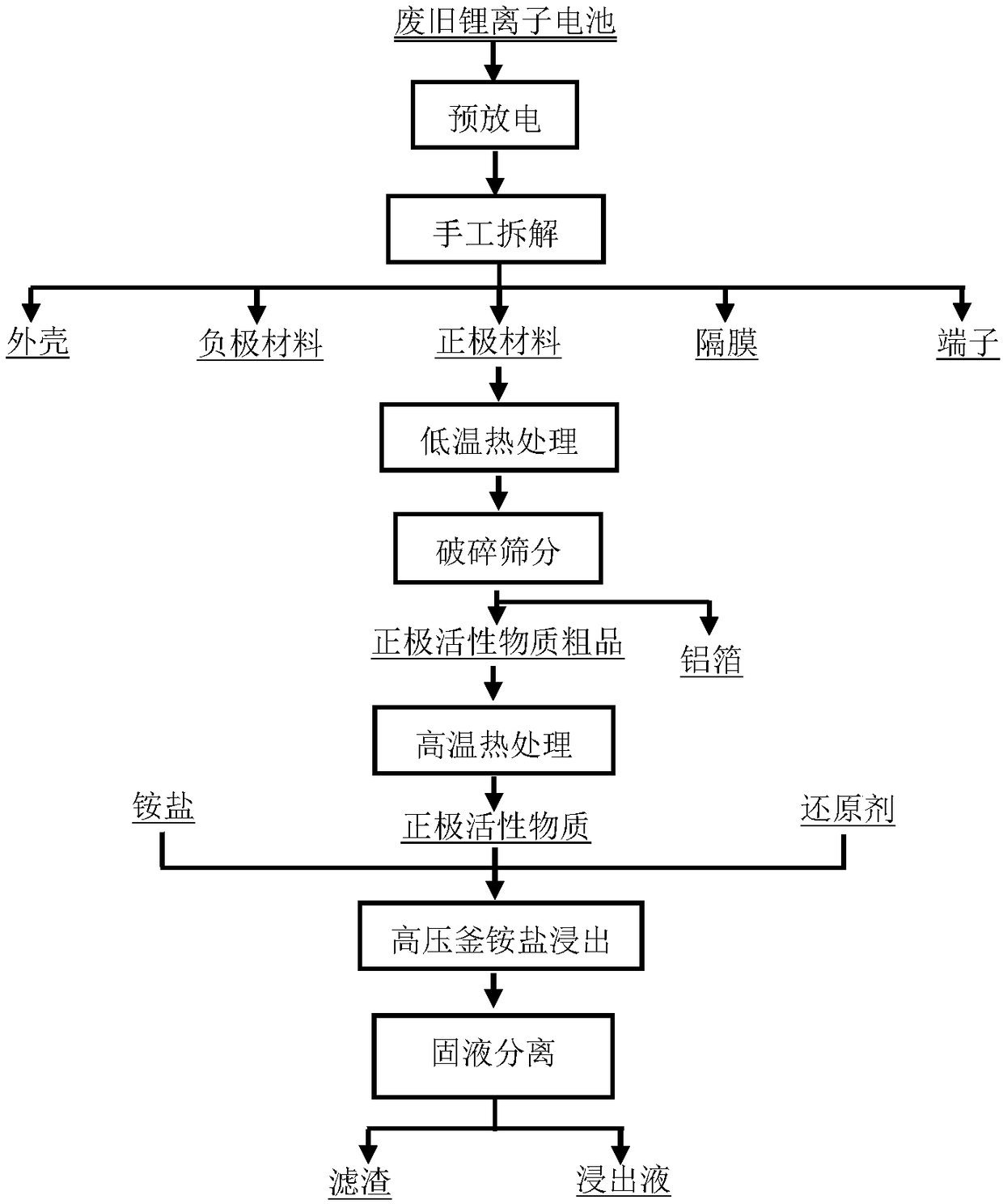

InactiveCN108486376AImprove leaching rateHigh selectivityWaste accumulators reclaimingProcess efficiency improvementManganeseHigh pressure

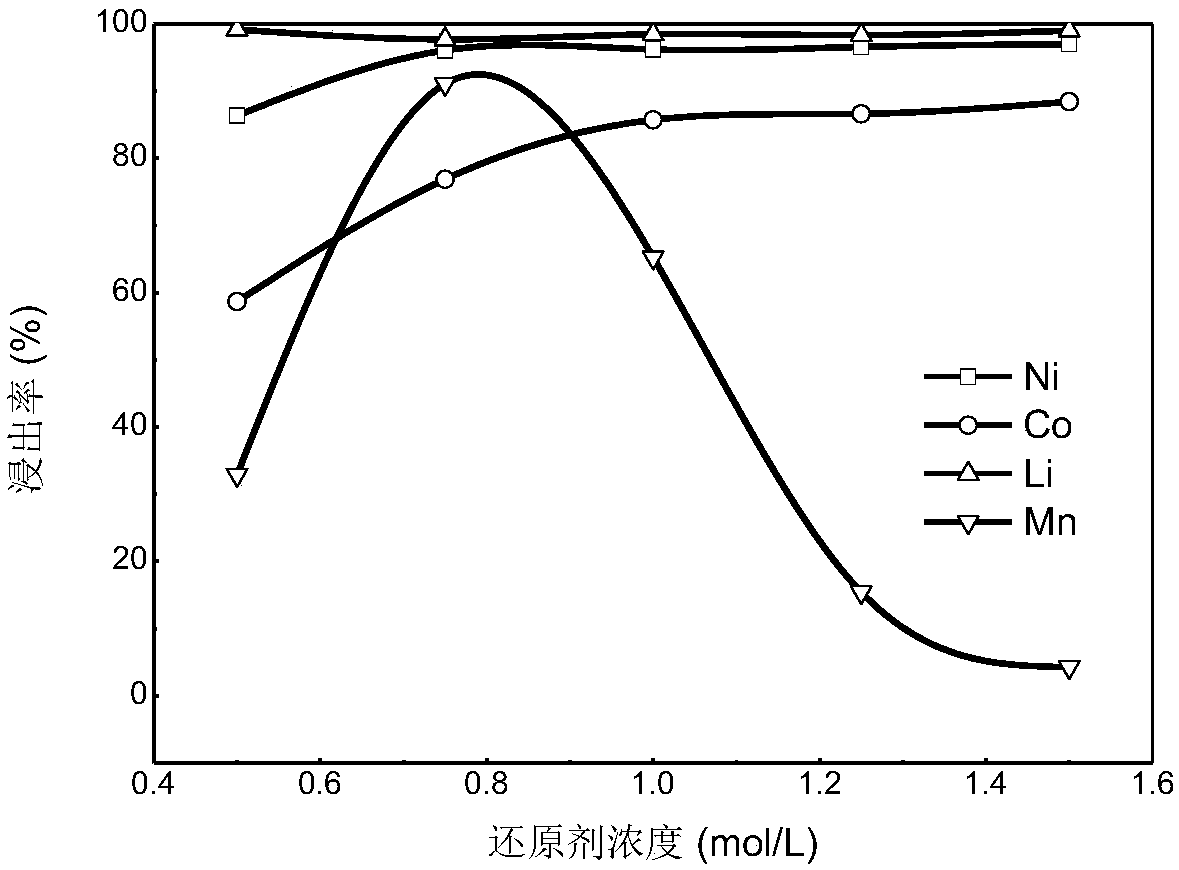

The invention relates to a method for leaching metals in an anode material of a waste lithium ion battery. The method for leaching the metals in the anode material of the waste lithium ion battery comprises the steps that anode active substances are obtained after the waste lithium ion battery is pretreated, then the anode active substances are made to react with an ammonium salt solution containing a reducing agent, solid-liquid separation is conducted after the reaction, and thus, leachate and filter residues are obtained. According to the method, the process is simple, the metal leaching rate is high, and the metal selectivity is high; by controlling the type and quantity of the reducing agent used in the leaching process, selective leaching of the metals can be achieved, for instance,when the anode material contains metals such as Li, Co and Mn, the reducing agent is ammonium sulfite, the leaching rate of Mn is 90% when the concentration of the reducing agent is 0.75 mol / L, and the leaching rate of Mn is 4% when the concentration of the reducing agent is 1.5 mol / L; the impurity content of the leachate is low, so that the cost for the subsequent impurity removal procedure is low; and the leaching process is conducted in a high-pressure kettle, emission of poisonous gas is avoided in the operation process, and the operation environment is good.

Owner:CENT SOUTH UNIV

Method of recycling metals from wasted lithium ion batteries

InactiveCN107293820AFast leachingReduce dosageWaste accumulators reclaimingBattery recyclingElectrochemical responseSodium-ion battery

The invention relates to the technical field of recovery of wasted lithium ion batteries, and particularly provides a method of recycling metals from wasted lithium ion batteries. The method includes the following steps: 1) recycling a cathode waste material of the lithium ion batteries, and processing the cathode waste material into electrode sheets; 2) with the electrode sheets as a cathode and an inert electrode as a counter electrode, performing an electrochemical reaction in an acidic electrolyte to leach-out metals, thus forming a solution containing metal ions; 3) regulating the pH of the solution to 9-10, fully stirring the solution, performing centrifugation to obtain a supernatant, adding 1,2,4,5-benzenetetracarboxylic acid to the supernatant, and performing a hydrothermal reaction at 100-160 DEG C for 5-12 h to form a metal organic composite material, wherein the metal is Ni and / or Co. Through the electrochemical method, metals in the cathode is leached out, wherein completeness of leaching is guaranteed; meanwhile, the leached metals are coordinated with organic substances to form a new lithium ion battery cathode or a positive pole of a super-capacitor. The method develops a new application direction of valuable metals in wasted cathodes.

Owner:广州盘太能源科技有限公司

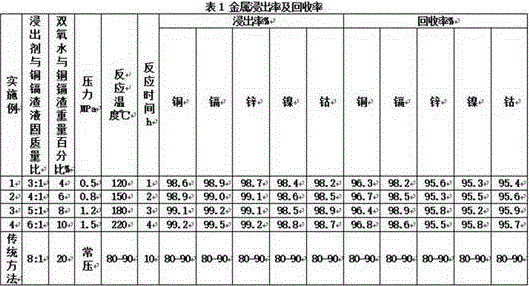

Comprehensive recovery method for valuable metal in copper-cadmium slag

InactiveCN106834696AImprove leaching rateHigh recovery ratePhotography auxillary processesProcess efficiency improvementRecovery methodMetal leaching

The invention discloses a comprehensive recovery method for valuable metal in copper-cadmium slag. The copper-cadmium slag serves as a raw material, Cu, Zn, Cd, Ni and Co in the slag are efficiently recycled through an all-wet technology of oxygen pressure sulfuric acid leaching and sequential extraction, metal covered with the copper-cadmium slag is fully exposed in acid through a pressurized high-temperature oxidation effect, the acid leaching process is reinforced, reasonable process steps and process parameters are adjusted, tendency distribution of all metal is controlled, the influences of Ni, Co, Fe and other elements in the slag on separation and extraction of Cu, Zn and Cd are avoided, and the metal leaching rate and recovery rate are increased. Meanwhile, waste liquid generated in the whole process course serves as a leaching agent to return to carry out leaching, so that environmental pollution is avoided. Compared with the prior art, the process flow is shortened, the leaching time is shortened, the leaching cost is reduced, the energy consumption in the whole process course is reduced, and the beneficial effects of high efficiency, environmental friendliness and low cost are achieved.

Owner:六盘水中联工贸实业有限公司

A gelation and consolidation process of waste incineration fly ash

The invention discloses a gelation and solidification process for waste incineration fly ash, which belongs to the field of environmental engineering. The gelation and consolidation process includes steps such as material backup, powder mixing, solid-liquid mixing, extrusion granulation, pellet curing, etc. After the fly ash and curing agent are measured, they are initially mixed through a diverter valve, and then mixed with a powerful mixer. The two are mixed evenly; the stabilizer is dissolved in water to make a solvent, which can ensure that the stabilizer and the mixed material are mixed evenly, thereby promoting the heavy metal capture more fully, which not only ensures the stabilization effect of the heavy metal in the fly ash; the stabilizer liquid Adding the atomizer to the powerful mixer can effectively control the amount of the stabilizer liquid, and promote the full mixing reaction of the mixed material and the stabilizer liquid. The concentration of heavy metals in the fly ash after treatment can meet the domestic garbage sanitary landfill. According to the requirements, it can be buried in sanitary landfill, which reduces the cost of fly ash treatment.

Owner:武汉致衡环境安全工程技术有限公司

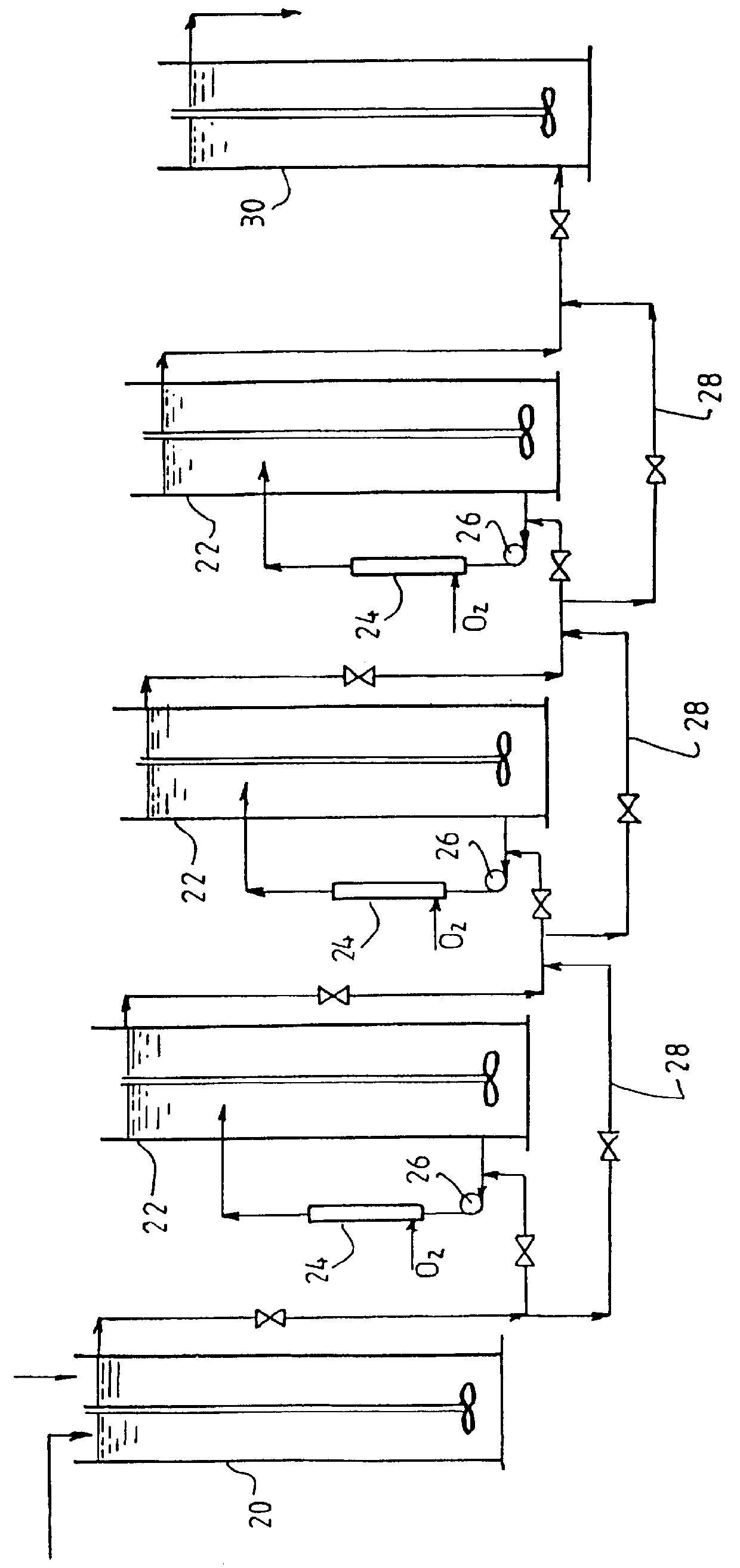

Leaching of mineral ores

A process for oxidation of ferrous ions in solution, and more particularly a process for improved base metal and / or uranium leaching from ores, concentrates or tailings using ferric ion as an oxidizing agent. A reaction vessel (10) holds a ferrous ion-containing solution, for example, a copper sulphide leach slurry or concentrate. An agitator (12) may be provided to promote leaching of the base metal into solution. Some of the ferrous ion-containing solution is drawn off from the reaction vessel (10) and pumped through an in-line mixer (14) via a feed pump (16). Oxygen is injected into the reactor (14) to facilitate oxidation of the ferrous sulphate to form ferric sulphate. The ferric ion-containing solution is then recirculated back to the reaction vessel (10) where the ferric ions are reused in the dissolution of copper sulphide into soluble copper sulphate. The two processes of ferrous oxidation and metal leaching can be conducted either simultaneously or sequentially to effect recovery of copper, other base metals or uranium from ores, concentrates or tailings.

Owner:ATOMAER

Leaching system and leaching method for valuable metal in waste lithium battery

ActiveCN107863583AReduce concentrationThe reduction effect is stableWaste accumulators reclaimingProcess efficiency improvementPregnant leach solutionMetal leaching

The invention belongs to the field of waste battery resource recycling, and discloses a leaching system and leaching method for valuable metal in a waste lithium battery. According to the leaching method, a sulfamic acid-glucose leaching agent is pre-heated, positive electrode powder is added, and stirring and leaching in a reaction kettle are performed, Co (III) and Mn (IV) are reduced to Co (II)and Mn (II) which are dissolved in a leaching liquid with Li<+> and Ni<2+>, Li, Co, Ni and Mn leaching rate in the waste battery positive electrode powder can reach 95% or above, and recycling or reusing of Li, Co, Ni and Mn can be achieved after further processing the leaching liquid. Compared with a traditional leaching liquid, the leaching system has the advantages of greenness, environmentalfriendliness, safe and controllable leaching process and relatively good industrial application prospect.

Owner:CENT SOUTH UNIV +1

Alkali breakdown process of molybdenum-vanadium multi-metal metallurgy smelting materials

InactiveCN101333601AWon't softenNon-adhesiveProcess efficiency improvementMetal leachingWorking environment

The invention provides a molybdenum-vanadium polymetallic metallurgy material alkaline decomposition method, the method is characterized in that: metallurgy materials are firstly added with lime for calcinations in order to avoid harmful gases such as SO2 produced in the baking process and mass impurities such as P, As and Si produced in the leaching process from entering the solution, and the baked sand obtained by calcinations can be added with a mixture of NaOH or Na2CO3 or NaOH and Na2CO3 and be leached out in water by agitation. The method has the advantages of low processing cost, high leaching rate of valuable metals and good working environment.

Owner:CENT SOUTH UNIV

Method for leaching valuable metals in waste circuit board by acidophilic bacteria mixed culture

InactiveCN101962712AEliminate Growth Inhibitory FactorsHigh recovery rateProcess efficiency improvementPregnant leach solutionMixed culture

The invention discloses a method for leaching valuable metals in a waste circuit board by acidophilic bacteria mixed culture, comprising steps of: (1) preparing metal concentrate powders from the waste circuit board; (2) preparing the acidophilic bacteria mixed culture: collecting acid mine drainage from a sulfide ore mine, inoculating the pit water to 9K culture medium according to the inoculation amount of 5-40% by volume, culturing the culture medium in shaking conditions until a large number of reddish-brown precipitates are produced, filtering the solution and obtaining the acidophilic bacteria mixed culture; (3) leaching metals in the metal concentrate powders by the acidophilic bacteria mixed culture. The method of the invention has the advantages of high target metal recovery, low energy consumption, improves the leaching yield of copper by 98% or more during 2 days and the leaching yield of zinc and aluminum by 90% or more during 4 days, simplifies the treatment process and reduces the cost without separating and purifying microbial strains, can recycle the leach liquor repeatedly and substantially realizes zero-pollution emission.

Owner:SOUTH CHINA UNIV OF TECH

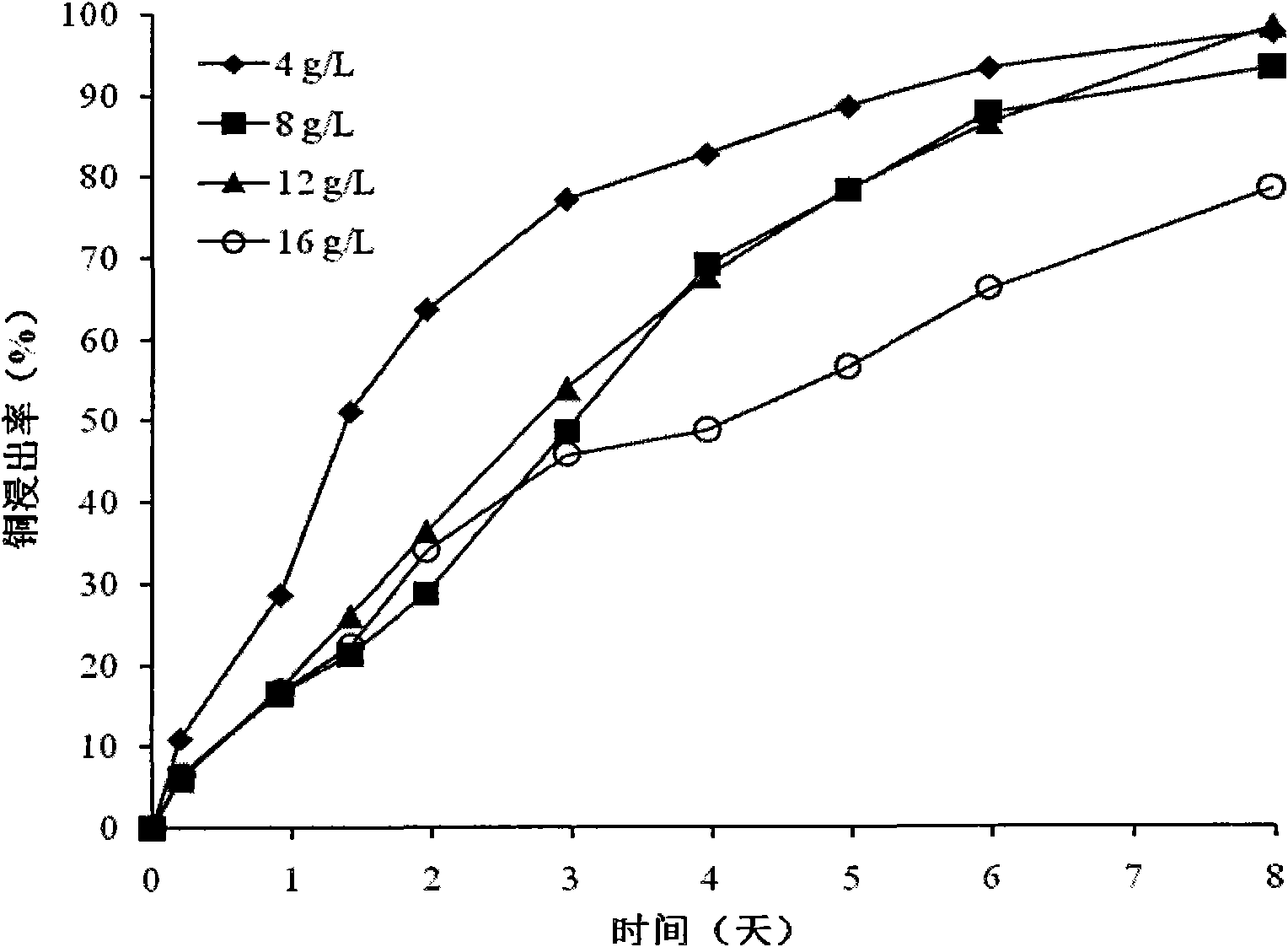

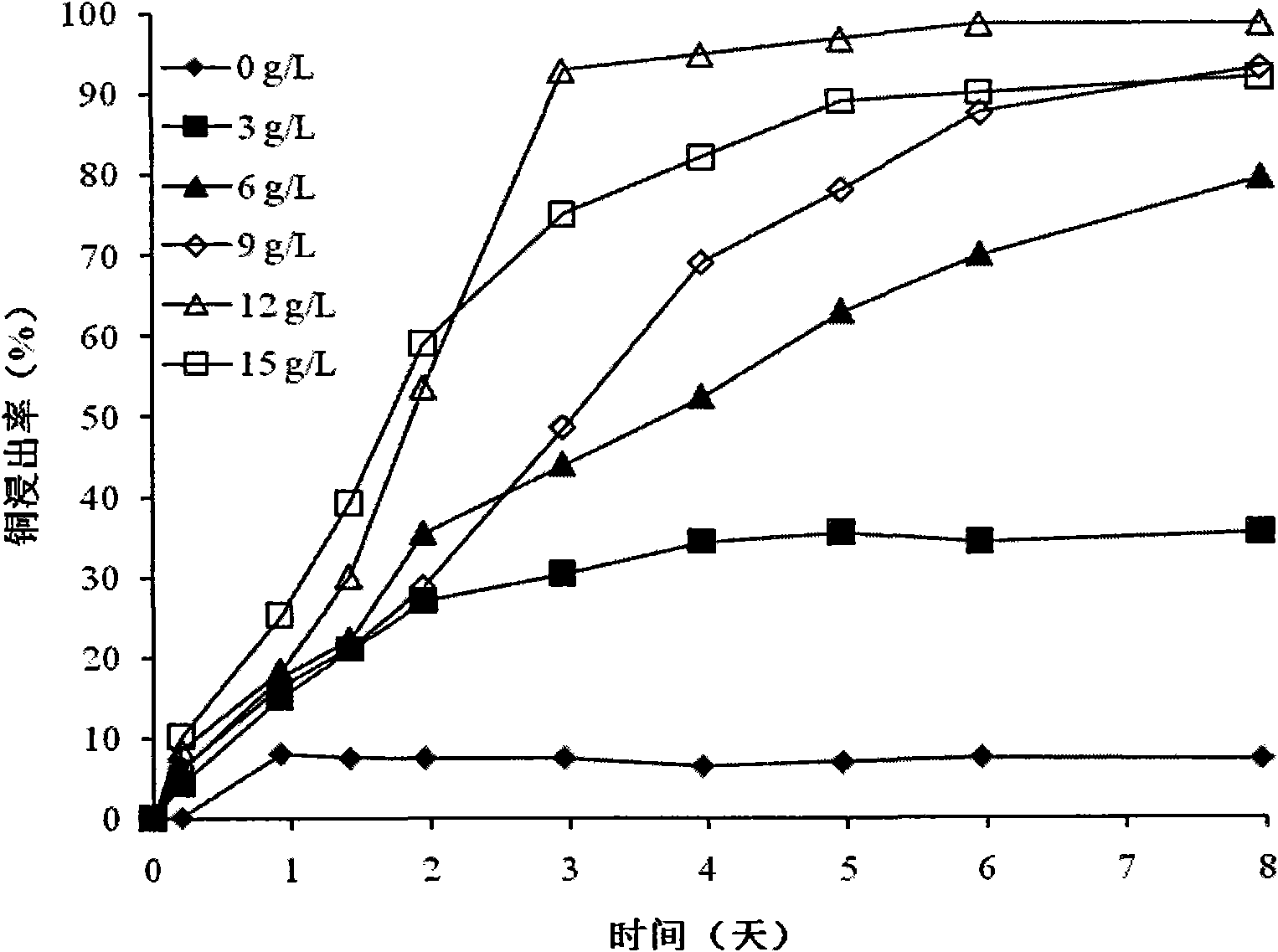

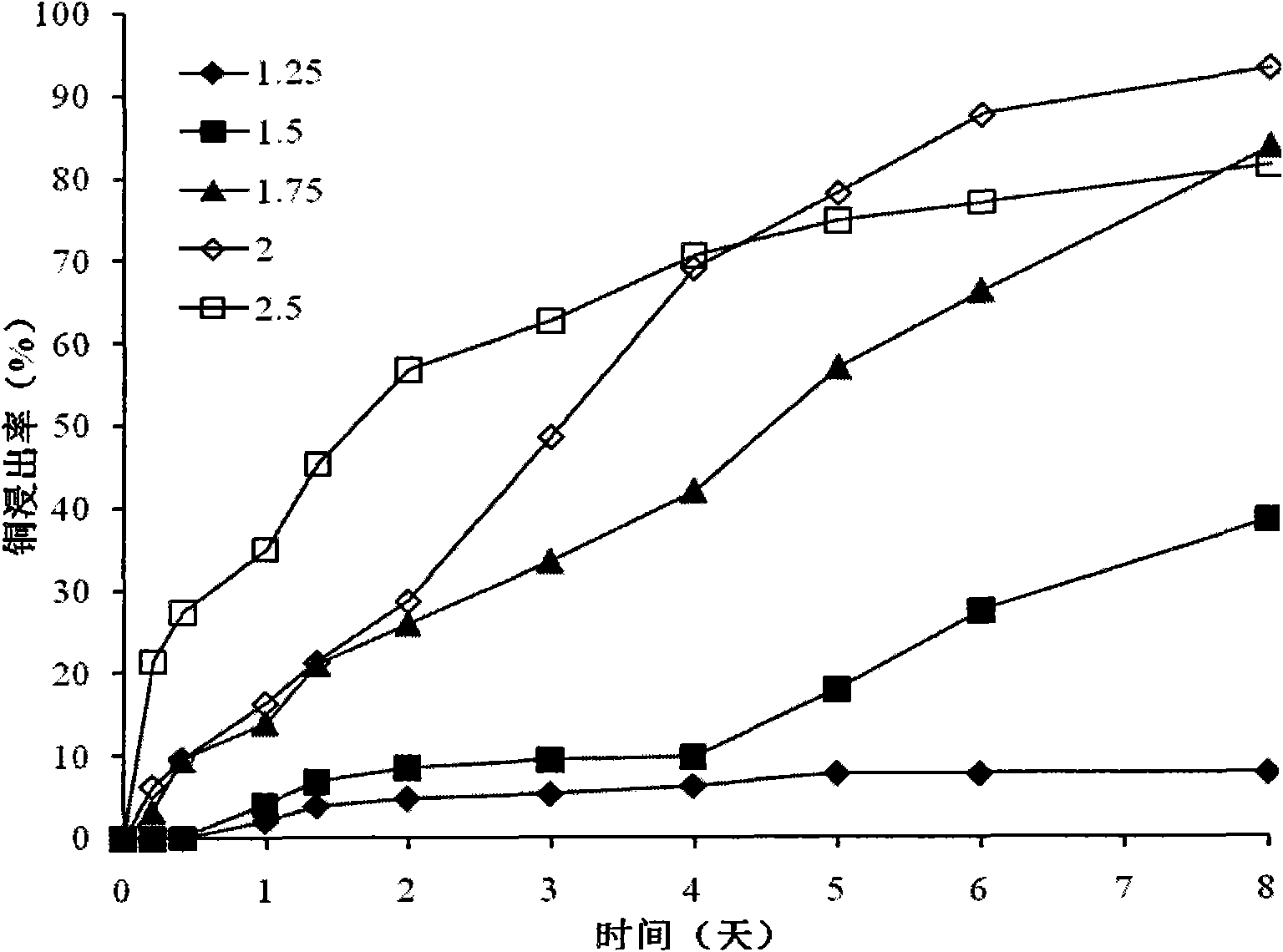

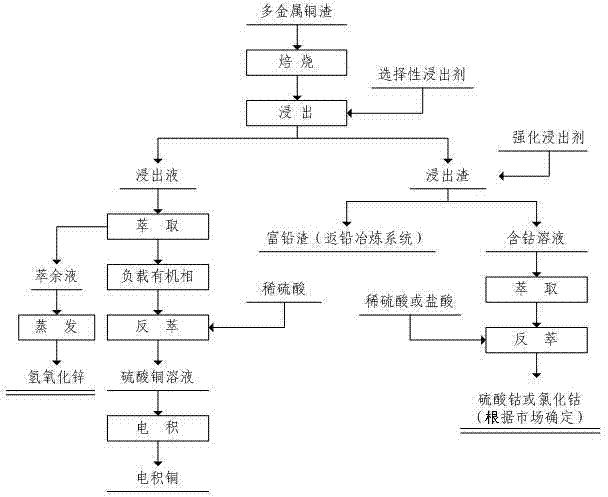

Method for producing electrodeposited copper from polymetallic copper slag

ActiveCN104846202AImprove leaching efficiencyHigh recovery ratePhotography auxillary processesProcess efficiency improvementZinc hydroxideLead smelting

The invention discloses a method for producing electrodeposited copper from polymetallic copper slag, which includes the following steps: the polymetallic copper slag is roasted to oxidize, so that the complex states of valuable metals in the polymetallic copper slag are transformed into oxides, changed into a state which can be selectively leached; leaching first adopts selective leaching agent to leach copper and zinc, the leachate is extracted, reextracted and electrodeposited, so that electrodeposited copper is obtained, and raffinate is vaporized and crystallized, so that zinc hydroxide is obtained; mechanical intensified leaching agent is then used for intensely leaching leaching residue, so that cobalt, nickel and the like in the leaching residue are leached, lead, iron and the like are enriched into the slag, the lead-rich slag is adopted as material for lead smelting, the leachate is extracted and reextracted, so that cobaltous sulfate or cobalt chloride is obtained, and if the nickel content in the leachate is overhigh, multi-stage extraction can be carried out to separate cobalt and nickel, so that nickel sulfate or nickel chloride is produced. The method can comprehensively recover a variety of metals, the leaching efficiency is high, the recovery rate is high, the method is environment-friendly, and is easy to implement, the method ensures that all the valuable metals in the polymetallic copper slag can be effectively separated and recycled, and the solid waste utilization rate can reach more than 99 percent.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

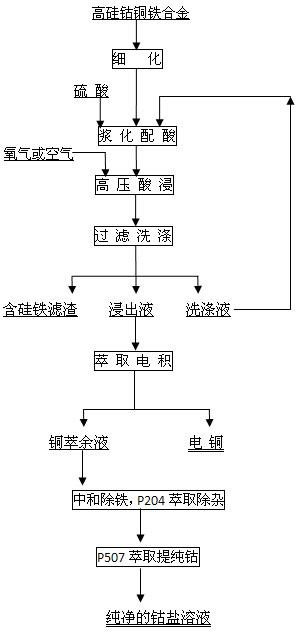

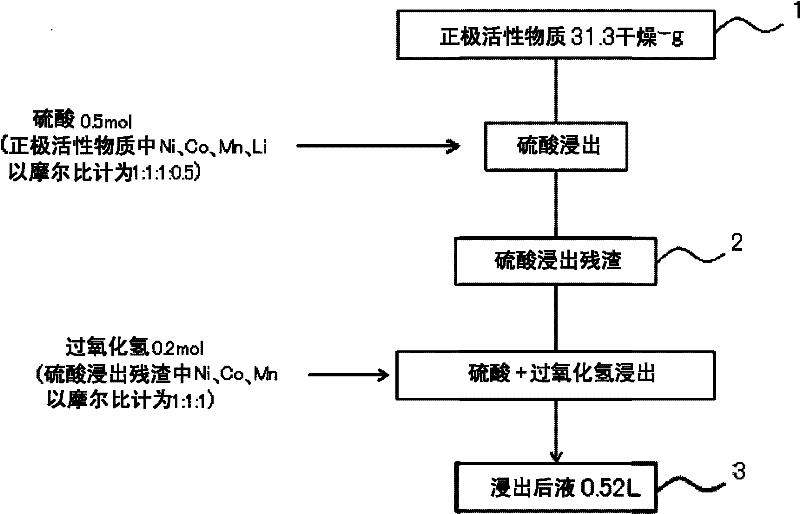

Method for extracting cobalt and copper from cobalt-copper-iron alloy

InactiveCN102321809AAchieving selective leachingPurification, iron removal and silicon removalProcess efficiency improvementMetal leachingRaffinate

The invention discloses a method for extracting cobalt and copper from cobalt-copper-iron alloy, and relates to a method for preparing electrical copper and high-purity cobalt salt from high-silicon cobalt-copper-iron alloy serving as a raw material. The method is characterized by comprising the following steps of: (1) levigating the alloy; (2) performing acid leaching on the levigated alloy under the conditions of heating, pressurizing and introducing oxygen; (3) filtering leached ore pulp, and washing leached residue; and (4) recovering copper from leachate by adopting an extraction-electrodeposition process, removing impurities from copper raffinate, and extracting the cobalt and nickel. The method has the advantages that: the pressure leaching is low in temperature, the consumption of a reagent is low, the selectivity is high, the leaching rate of valuable metals is high, most iron is inhibited in the residue, the leached ore pulp has high filter performance, the harmful impurity of silicon is totally solidified in the iron residue, and the method is an environment-friendly process which is easy to implement.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Method for recycling platinum group metals from iron carrier invalid automobile exhaust catalyst

ActiveCN104294048AEmission reductionReduce consumptionProcess efficiency improvementReaction temperatureMetal recycling

The invention discloses a method for recycling platinum group metals from an iron carrier invalid automobile exhaust catalyst. The method is characterized by comprising the following steps: (1) crushing an invalid catalyst, and collecting powder particles; (2) separating the powder particles and broken pieces in an ultrasonic cleaner; cleaning the surface of a metal piece, and performing combined filtration on a cleaned liquid and a liquid in the ultrasonic cleaner; (3) drying filter residues, roasting, and taking out solids; (4) crushing; (5) adding powder into a reaction kettle, adding hydrochloric acid according to a solid-to-liquid ratio of 1:(1-5), heating, introducing chlorine below the liquid level, filtering after reaction ends, and washing a filter cake by using deionized water which accounts for 0.5-5 times of the weight of solids under the conditions that the leaching reaction temperature of the platinum group metals is 40-90 DEG C and the reaction time is 2-10 hours to obtain a leaching liquid; and (6) sequentially performing extraction separation on the leaching liquid by using a Pd extraction agent, a Pt extraction agent and an Rh extraction agent, wherein the Pd extraction agent is one of diisoamyl sulfide, di-n-octyl sulfoxide and 2-hydroxy-5-octyl diphenylketoxime, the Pt extraction agent is trialkylamine, and the Rh extraction agent is tributyl phosphate.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

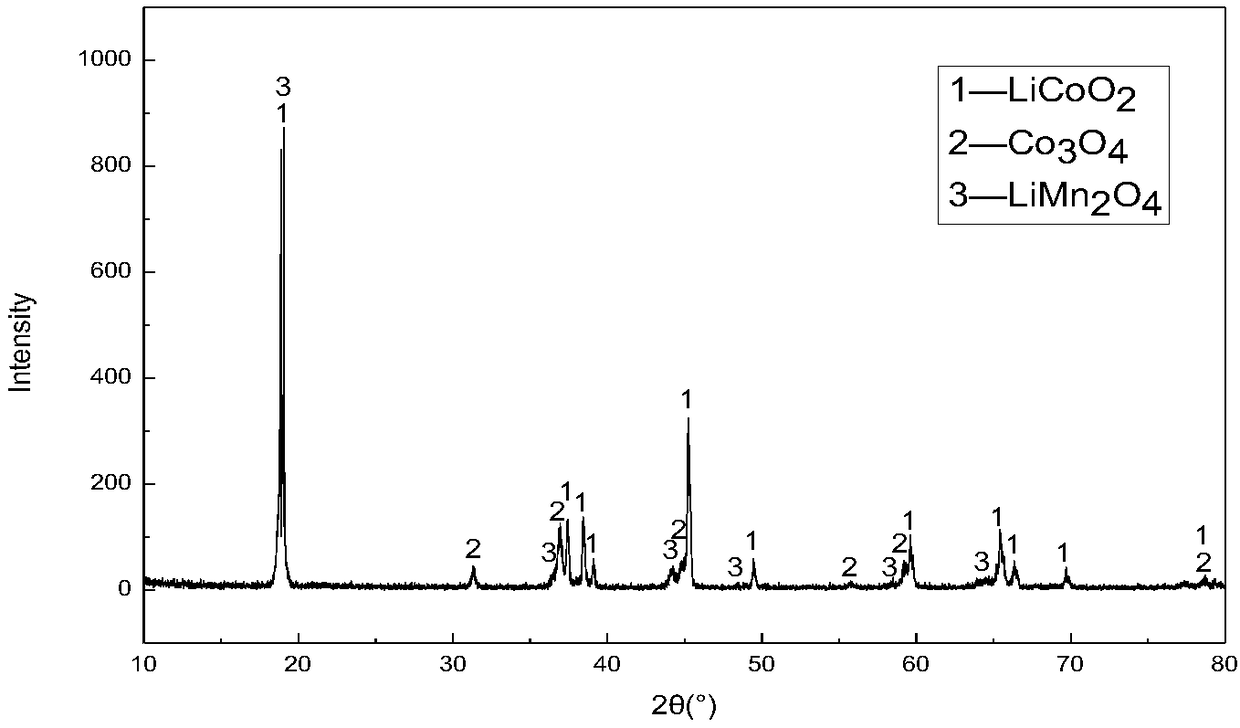

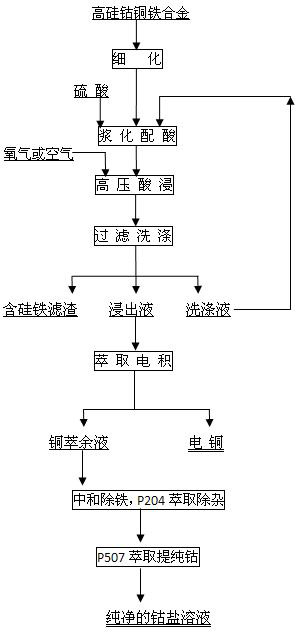

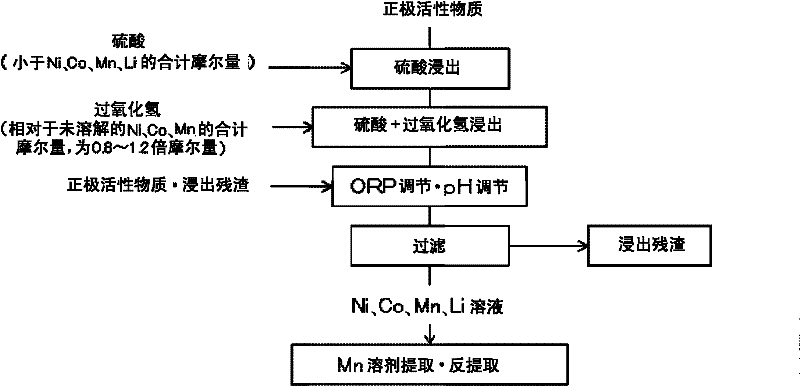

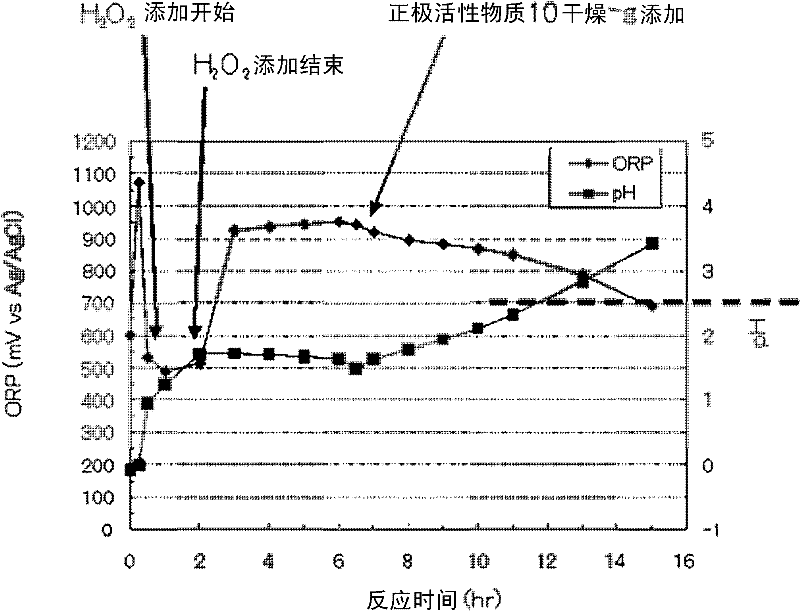

Method for leaching positive electrode active material

ActiveCN102544628ADoes not generate chlorine gasReduce usageWaste accumulators reclaimingProcess efficiency improvementManganeseSlurry

Nickel, cobalt and lithium are efficiently leached from the positive electrode active material of lithium-ion secondary cell, obtaining solution suitable for isolating various metals. The invention relates to a method for leaching positive electrode active material which leaches valued metals from the positive electrode active materials of a lithium-ion formed by composite oxide having transition metals including at least manganese. The method comprises a first process which is to dissolve soluble parts of sulfuric acid solution in the positive electrode active material, and a second process which is no solid-liquid separation is conducted after the first process, and adding hydrogen peroxide in sulfuric acid leaching slurry solution, and leaching unleached parts in the left sulfuric acid leaching slurry.

Owner:JX NIPPON MINING & METALS CO LTD

Self catalyzed reduction ammonia soaking process of deep sea polymetallic nodule in ammonia-ammonium chloride system

InactiveCN101020962AAutocatalytic reductionReduce consumptionProcess efficiency improvementHydrometallurgySeawater

The present invention is self catalyzed reduction ammonia soaking process of deep sea polymetallic nodule in ammonia-ammonium chloride system, and relates to method of optionally leaching out Ni, Cu, Co, Mo and other valuable metals from polymetallic nodule. The soaking process includes the following steps: leaching out ground polymetallic nodule in ammonia-ammonium chloride solution containing NH3 in 60-180 g / l, Cl- in 10-60 g / l and Cu+ over 4 g / l; concentrating and separating the leached out ore pulp; returning the supernatant to the leaching process and filtering and washing the underflow; oxidizing the leached liquid with air to eliminate impurity and returning the precipitate to the leaching process; and conventional extraction-electric depositing to recover Ni, Cu, Co, Mo and Zn from the oxidized leached solution. The process has simple leaching system, high metal leaching rate, low power consumption and other advantages.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Method of forming and immobilizing metal nanoparticles on substrates and the use thereof

A new, facile, low cost and easy-to-operate method of forming and immobilizing metal nanoparticles on substrates is invented. The method comprises steps of chemical modification of the substrates with chemical linkers, chelation of the metal ions to the modified substrates, the washing of the unbound metal ions and in-situ reduction of the metal ions to produce metal nanoparticles on the substrates with / without the finishing treatment of the metal nanoparticles functionalized substrates with minimum particles aggregations. The metal nanoparticles functionalized substrates generated by the method have wide applications, for example, as anti-microbial agents. The metal nanoparticles are strongly bonded to the substrates, resulting in low metal leaching to the environment.

Owner:AGPLUS TECH

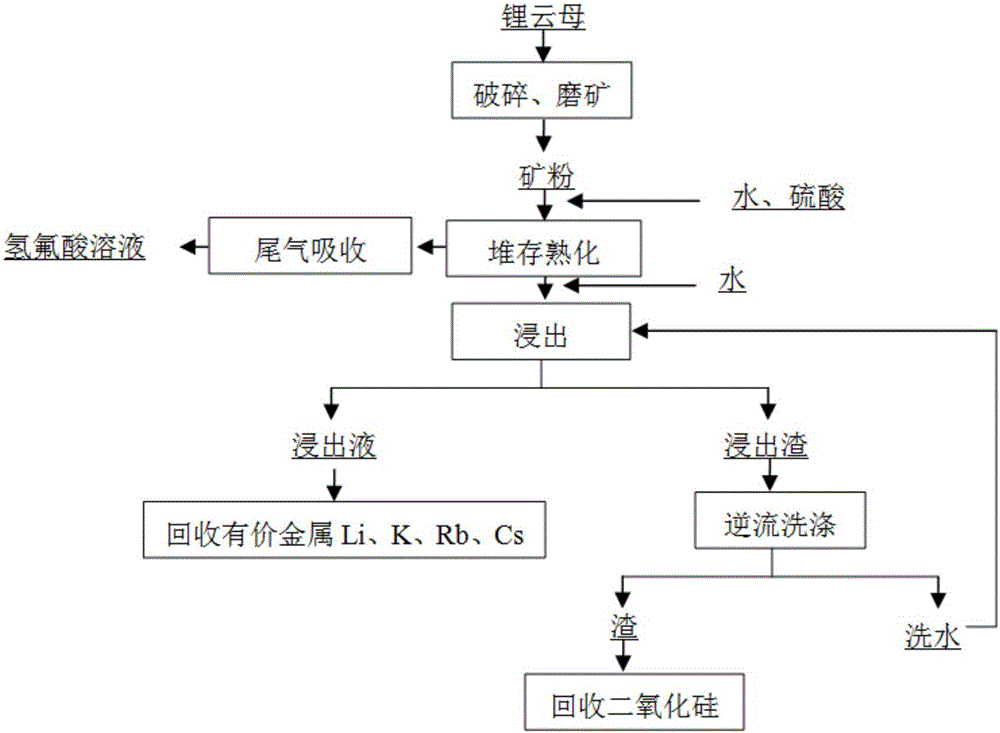

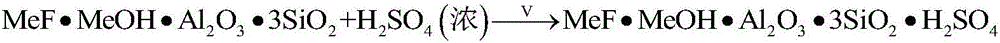

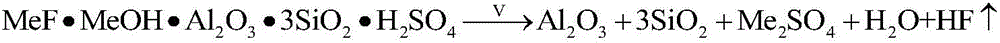

Method for lepidolite defluorination and valuable metal leaching

ActiveCN106086471AAvoid Roasting DefluorinationAvoid pressure leachingProcess efficiency improvementPregnant leach solutionMetal leaching

The invention discloses a method for lepidolite defluorination and valuable metal leaching. The method comprises the following steps that (1) lepidolite is crushed and levigated, mineral powder is obtained, and in the mineral powder, the mass of mineral powder with the particle size smaller than 0.074 mm accounts for 70% or above of the total mineral powder mass; (2) the mineral powder is added with concentrated sulphuric acid, the mineral powder and the concentrated sulphuric acid are uniformly mixed, and the mass ratio of the concentrated sulphuric acid to the mineral powder is 0.8-1:1; then water is added into the mineral powder and the concentrated sulphuric acid, the mass ratio of the water to the mineral powder is 0.08-0.1:1, the water, the mineral powder and the concentrated sulphuric acid are uniformly mixed, and mixed minerals are obtained; the mixed minerals are subjected to heat preservation and stockpiling for 20-30 h, defluorination is achieved, and curing minerals are obtained; and (3) the curing minerals are added with water to be leached out, the mass ratio of the water to the curing minerals is 1.0-2.5:1, leaching is conducted for 2-4 h under the condition that the temperature is 90 DEG C-100 DEG C, mineral pulp is filtered, and leached slag and leached liquid are obtained. According to the method for lepidolite defluorination and valuable metal leaching, stockpiling, curing and defluorination are conducted through self heating, technological processes are simplified, the production cost is substantially reduced, and equipment investments are decreased; the curing defluorination-water leaching technology is adopted, so that the defluorination rate and the valuable metal leaching rate are increased; and the defluorination rate is larger than 95%, and the leaching rate of lithium, the leaching rate of potassium, the leaching rate of rubidium and the leaching rate of cesium are larger than 90%.

Owner:HUNAN RES INST FOR NONFERROUS METALS

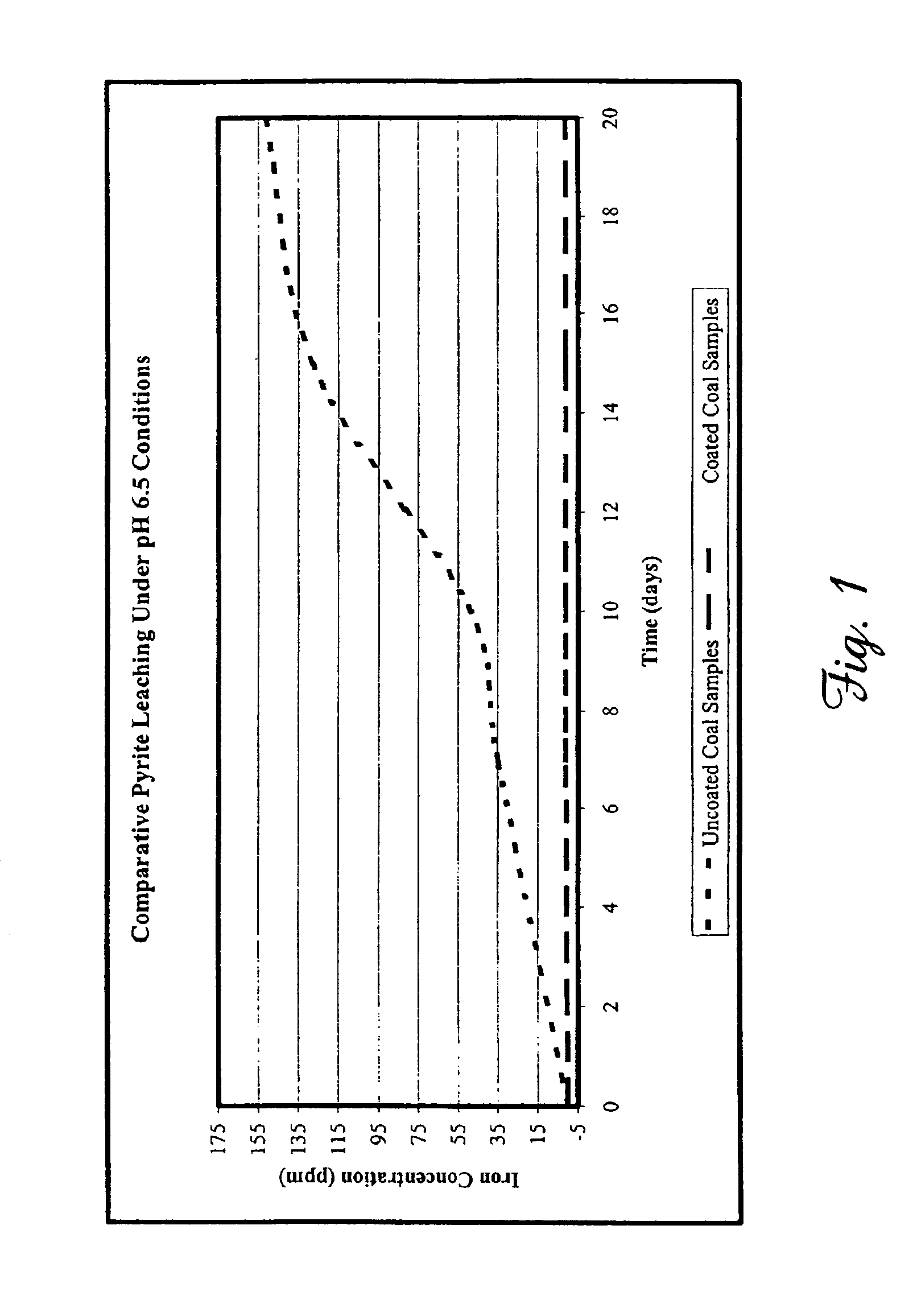

Method for prevention of solid dissolution through covalent ligand bonding

InactiveUS6852369B1Prevention of metal leachingImprove corrosion resistanceWaste water treatment from quariesLiquid surface applicatorsLithiumHydrogen

Methods for preventing dissolution of solid substrates, such as metal leaching from coal or corrosion of metal surfaces, are provided. The method comprises coating the solid substrate with a chelate ligand having the general structure: where n is an integer from 1-4, and X is selected from the group consisting of hydrogen, lithium, sodium, potassium, rubidium, cesium, and francium. A method for preventing metal leaching from coal, such as acid mine drainage or metal leachate in runoff from coal refuse piles, is also provided.

Owner:UNIV OF KENTUCKY RES FOUND

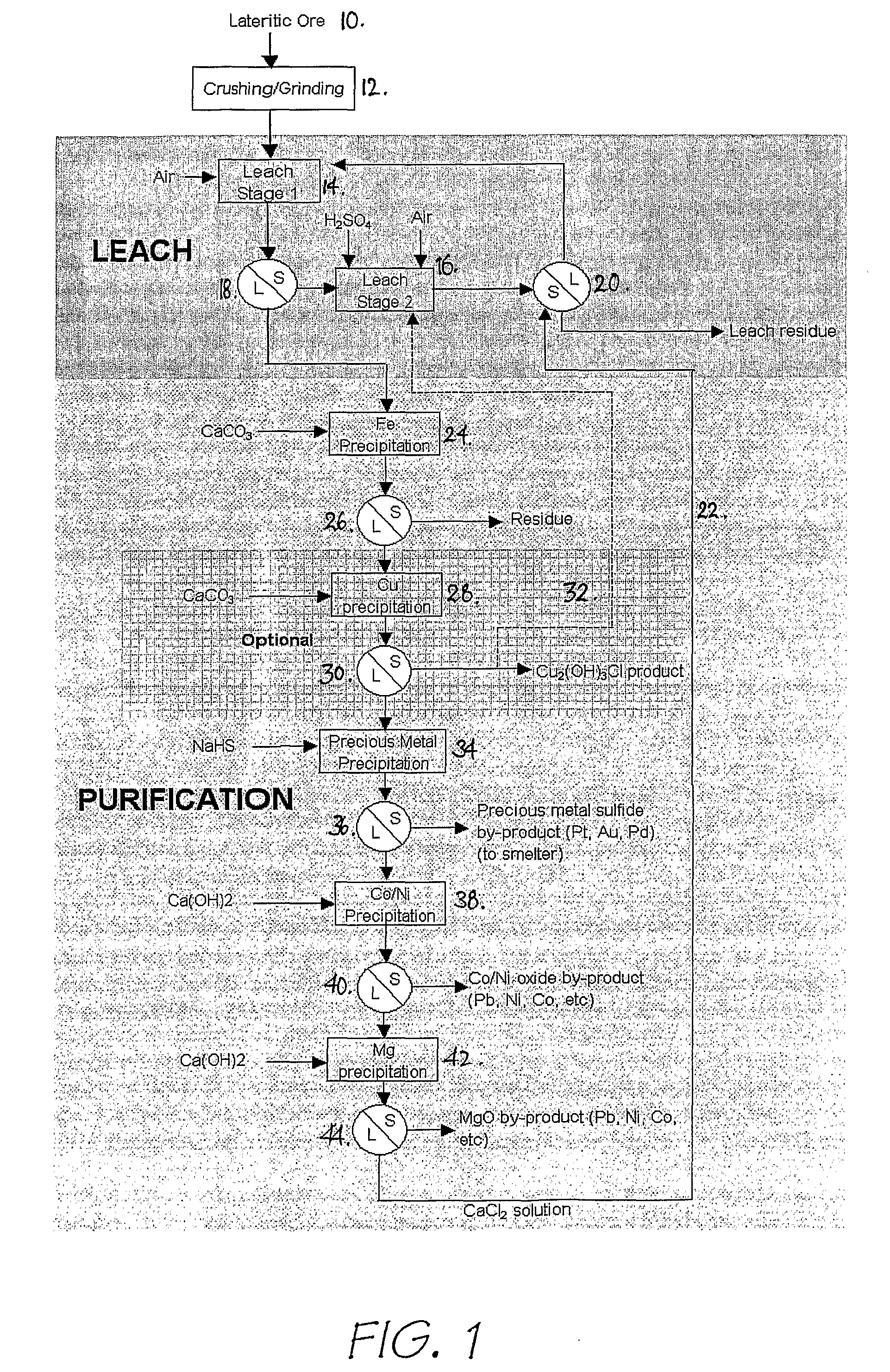

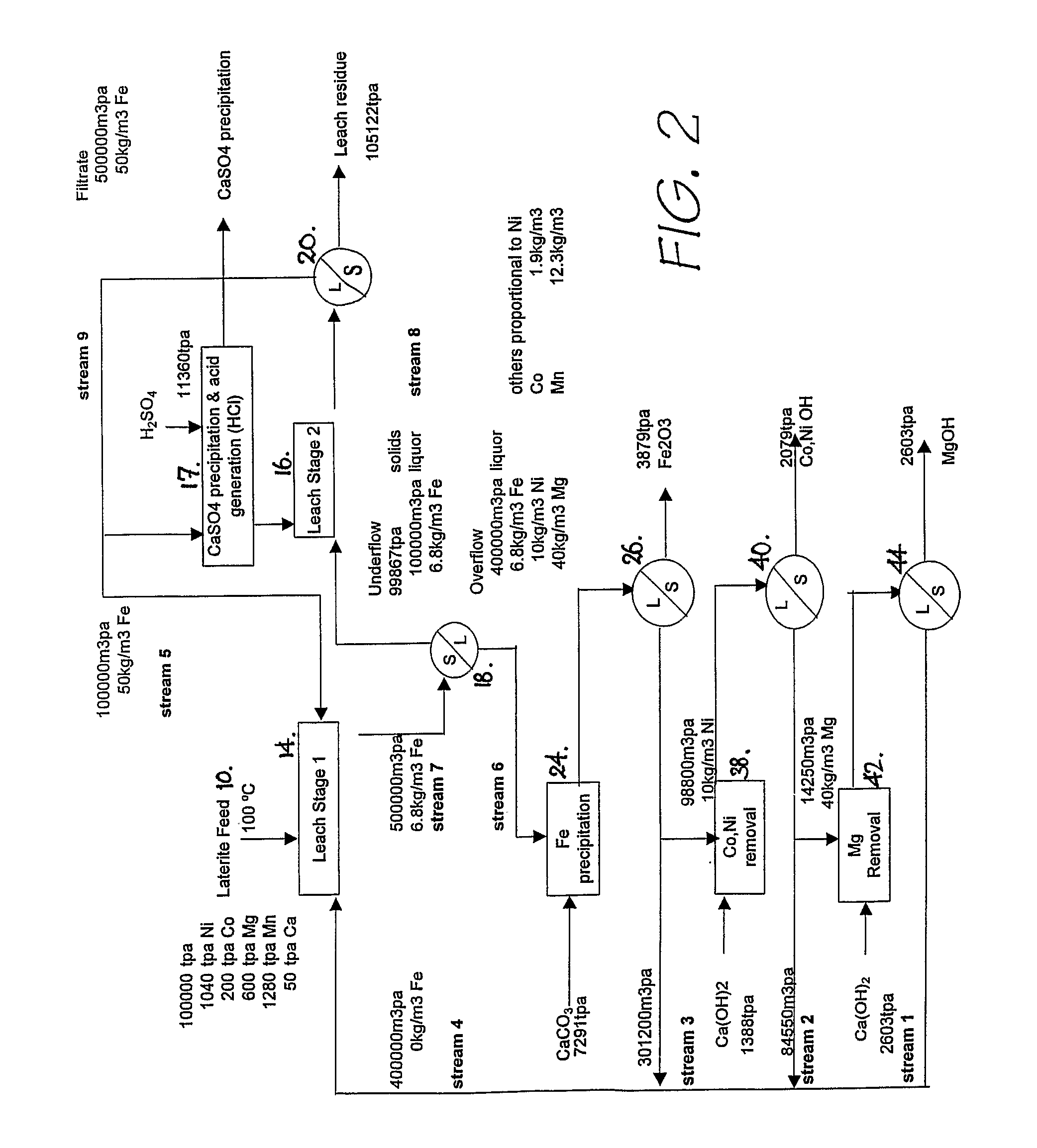

Recovery Of Metals From Oxidised Metalliferous Materials

ActiveUS20070295613A1Avoid recyclingMaximise retrievalPolycrystalline material growthFrom normal temperature solutionsMetal leachingMetallic materials

A process for recovering a target metal from an oxidised metalliferous material comprises the steps of: in an acid generation stage, adding sulfuric acid to a solution comprising a metal halide to generate an acidic aqueous halide solution; in a leaching stage that is separate to the acid generation stage, leaching the oxidised metalliferous material with the acidic aqueous halide solution to leach the target metal into solution; passing the solution from the leaching stage to a target metal recovery stage in which the target metal is recovered from the solution whilst the metal halide is retained in solution; and returning the solution with the metal halide therein from the target metal recovery stage to the acid generation stage.

Owner:INTEC INT PROJECTS

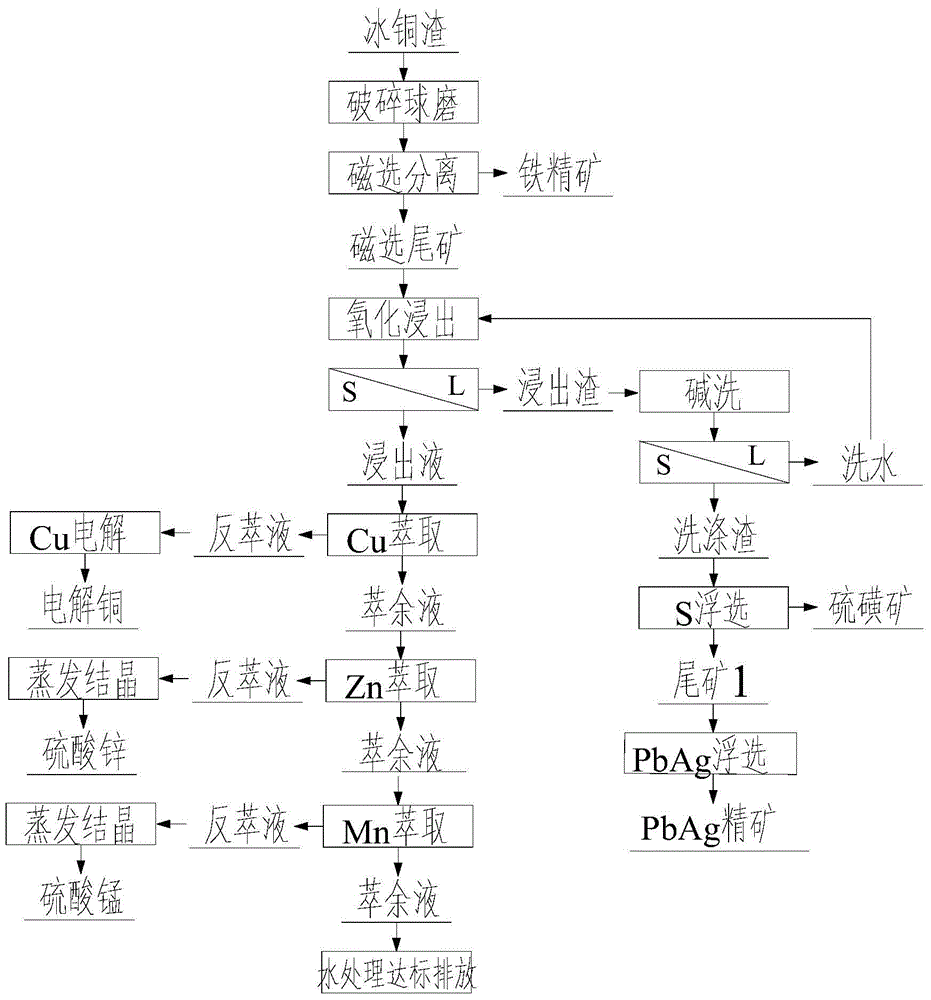

Comprehensive recovery process of low-grade matte slag metal resources

ActiveCN105695745AReduce subsequent leaching treatment ore volumeReduce manufacturing costPhotography auxillary processesSulfur preparation/purificationSlagManganese

The invention discloses a comprehensive recovery process of low-grade matte slag metal resources. The process comprises the following steps: 1) matte slag performs the crushing and the wet ball milling to reach 100% of particle sizes less than 0.074 mm, and is magnetically separated by a permanent magnetic separator; and magnetically separated tailing is dehydrated for metal leaching and extraction; 2) the magnetically separated tailing performs the oxide leaching to comprehensively leach and extract valuable metal; leaching liquid is extracted to recover Cu; and strip liquor passes through electrodeposition cathode copper plate; 3) copper raffinate removes iron by using a goethite method; after Fe is removed, supernatant is extracted to recover Zn, and the strip liquor is concentrated and crystallized to prepare zinc sulfate; the obtained raffinate is extracted to recover manganese; and the strip liquor is concentrated and crystallized to prepare manganese sulfate; 4) after the raffinate is absorbed by activated carbon to reduce COD, heavy metal is treated by sulfide precipitation; and 5) after leaching slag performs the alkali washing, elemental sulfur and a lead-silver sulfide ore are recovered by flotation. The process solves the difficulty of incomplete recycling of low-grade matte slag, realizes comprehensive recovery of low-grade matte slag resources, and is higher in environmental benefit and economic benefit.

Owner:GUANGZHOU ZHONGKE ZHENGCHUAN ENVIRONMENTAL PROTECTION TECH CO LTD

Method for leaching nickel and molybdenum from amorphous nickel-molybdenum sulfide mineral by oxidative conversion

InactiveCN103966432ALarge specific surface areaAchieve leachingProcess efficiency improvementChemical industryOxygen

The invention belongs to the field of metallurgical chemical industry, and particularly relates to a method for leaching nickel and molybdenum from an amorphous nickel-molybdenum sulfide mineral by oxidative conversion. According to the technical scheme, the method comprises the following steps: mixing the amorphous nickel-molybdenum sulfide mineral which is finely ground with water to prepare pulp; adding the pulp into a pressure kettle, introducing industrial oxygen, and performing temperature rising reaction under the pressure of 0.8-2.0 MPa and at the temperature of 110-200 DEG C; converting the nickel and the molybdenum into sulfates, dissolving the sulfates into a solution, and filtering the pulp to obtain a leachate containing nickel sulfate and molybdenum sulfate acyl. The characteristics of large specific surface area and high activity of the amorphous nickel-molybdenum sulfide mineral are fully utilized; under the condition that acid is not added, colloidal sulfide is directly converted into sulfuric acid and sulfate in an oxidative manner, so that the nickel and the molybdenum can be leached, the process flow is short, conventional roasting is not needed, harmful smoke pollution is avoided, the process is clean, the consumption of reagents is low, and the leaching rate of metal is high.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT

Method for recovering cobalt from inverse antimony purified cobalt residue

ActiveCN104726717AAvoid solutionRaise the pHProcess efficiency improvementMetal leachingHydrometallurgy

The invention relates to a method for recovering cobalt from inverse antimony purified cobalt residue. The inverse antimony purified cobalt residue of zinc hydrometallurgy is taken as a raw material, and the cobalt concentrate is prepared by use of the processes of leaching, iron removal and cobalt settlement. The reducing atmosphere of leaching the cobalt residue in sulfuric acid is controlled so that metals such as copper and germanium cannot be leached and only zinc, cadmium, cobalt and little iron can be leached; in this way, a relatively high pH value can be controlled during iron removal, the purpose of thorough iron removal can be achieved and the iron can be prevented from being oxidized and hydrolyzed into the cobalt concentrate during cobalt settlement; air serves as an iron removal oxidizing agent, while hydrogen peroxide serves as a cobalt settlement oxidizing agent, and no impurity is imported; and the method is advantageous for increasing the grade of the cobalt concentrate.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

Sol gel functionalized silicate catalyst and scavenger

This invention relates to materials suitable as metal scavengers and catalysts. The materials are prepared by functionalizing silicate materials such as silica or SBA-15 with a thiol or amine, or other functionalizing agent, in a sol gel process. In a preferred embodiment, the metal is palladium and the functionalizing agent is a thiol. The material may be used as a catalyst for the Suzuki-Miyaura and Mizoroki-Heck coupling reactions. The catalyst materials have extremely low metal leaching, are very stable, and are completely recyclable.

Owner:QUEENS UNIV OF KINGSTON

Recovery method of waste lithium ion battery negative electrode material

ActiveCN111430831AHigh recovery rateHigh lithium contentCarbon compoundsNegative electrodesMetal leachingElectrical battery

The invention discloses a recovery method of a waste lithium ion battery negative electrode material. The method comprises the following basic steps of 1) mixing the waste lithium ion battery negativeelectrode powder with molten salt; 2) carrying out heat treatment on the mixed powder at a temperature not lower than the melting point of molten salt; and 3) soaking the material subjected to heat treatment in water, uniformly stirring, carrying out solid-liquid separation, recovering lithium and other valuable metals by using the liquid phase, and drying the solid phase to obtain the regenerated negative electrode material. According to the invention, the purification and structure repair of the negative electrode material in the waste lithium ion battery negative electrode material and therecovery of valuable metals are realized. The method has the advantages of short treatment flow and low cost, and the obtained regenerated negative electrode material is high in purity, good in crystallinity and high in valuable metal leaching rate and is suitable for the large-scale production.

Owner:湖南烯富环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com