Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Achieving selective leaching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for comprehensively recovering copper and indium from lead matte

ActiveCN104357661AAchieving selective leachingAchieve separationProcess efficiency improvementOxygenBall mill

The invention discloses a method for comprehensively recovering copper and indium from lead matte. The method comprises the following steps: A, crushing lead matte block materials and then ball-milling to obtain lead matte powder; B, leaching the lead matte powder obtained by ball-milling in an autoclave by using sulfuric acid and continuously introducing oxygen in the leaching process; C, after leaching, carrying out solid-liquid separation to obtain leaching residues and leachates containing copper ions and indium ions; D, selectively extracting the copper ions in the leachates by using ZJ988, obtaining copper sulfate enrichment liquid by using a sulfuric acid-copper sulfate solution to perform reverse extraction on loaded organic phase, taking the copper sulfate enrichment liquid as an electrolyte of electro-deposit copper and obtaining cathode copper through a copper sulfate electro-deposition process; E, selectively extracting the indium ions by using P204, then obtaining indium chloride enrichment liquid by using a hydrochloric acid solution to perform reverse extraction on the loaded organic phase and replacing the indium chloride enrichment liquid by using a zinc plate or an aluminum plate to obtain sponge indium. The method has the benefits that the complete separation of the copper from the indium in the lead matte is realized, recovery rate of the valuable metal is high, and the environmental friendliness is realized.

Owner:YUNNAN COPPER CO LTD +1

Vanadium extraction method of high-calcium and high-phosphor vanadium slag clinker

InactiveCN104532009AAchieving selective leachingReduce pollutionProcess efficiency improvementPregnant leach solutionSlag

The invention provides a vanadium extraction method of a high-calcium and high-phosphor vanadium slag clinker. The method comprises the following steps: crushing, grinding and screening the high-calcium and high-phosphor vanadium slag clinker with greater than 7wt% of CaO and greater than 0.6wt% of P2O5 until the particle size is 0.050-0.154mm, wherein the mass ratio of CaO to V2O5 is greater than 0.7, then carrying out carbonation leaching in a Na2O3 solution with a concentration of 3-20wt% or a NaHCO3 solution with a concentration of 4-25wt%, wherein a solid-liquid ratio is 1:1mL / g-1:15mL / g, the leaching temperature is 50-99 DEG C, the leaching time is 30-120 minutes and the stirring rate is higher than 150 revolutions per minute during leaching; carrying out solid-liquid separation to obtain a vanadium-containing leaching liquid; and then preparing a vanadium product by using the existing mature process of precipitating vanadium and deaminizing. According to the method, the leaching operation process is simple; a leaching agent is low in cost; a high vanadium leaching rate can be achieved; the leaching of phosphor in the vanadium slag clinker can be avoided; and the effective vanadium extraction of the high-calcium and high-phosphor vanadium slag clinker can be implemented.

Owner:UNIV OF SCI & TECH BEIJING

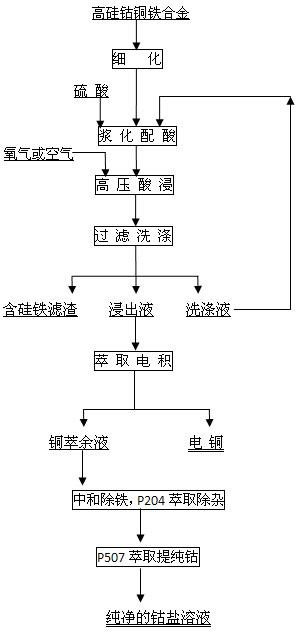

Method for extracting cobalt and copper from cobalt-copper-iron alloy

InactiveCN102321809AAchieving selective leachingPurification, iron removal and silicon removalProcess efficiency improvementMetal leachingRaffinate

The invention discloses a method for extracting cobalt and copper from cobalt-copper-iron alloy, and relates to a method for preparing electrical copper and high-purity cobalt salt from high-silicon cobalt-copper-iron alloy serving as a raw material. The method is characterized by comprising the following steps of: (1) levigating the alloy; (2) performing acid leaching on the levigated alloy under the conditions of heating, pressurizing and introducing oxygen; (3) filtering leached ore pulp, and washing leached residue; and (4) recovering copper from leachate by adopting an extraction-electrodeposition process, removing impurities from copper raffinate, and extracting the cobalt and nickel. The method has the advantages that: the pressure leaching is low in temperature, the consumption of a reagent is low, the selectivity is high, the leaching rate of valuable metals is high, most iron is inhibited in the residue, the leached ore pulp has high filter performance, the harmful impurity of silicon is totally solidified in the iron residue, and the method is an environment-friendly process which is easy to implement.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

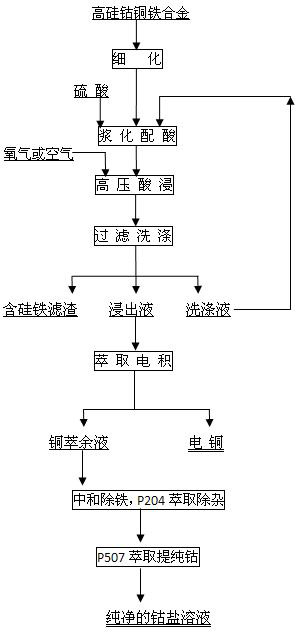

Two-stage selective heterogenite leaching method

InactiveCN106435176AGood effectEasy to operateProcess efficiency improvementSecondary stageAqueous solution

The invention discloses a two-stage selective heterogenite leaching method which is characterized by including the steps: (1) grinding: crushing and finely grinding heterogenite to enable 80% or more reaches the granularity of 200 meshes; (2) leaching copper at the primary stage: mixing 80% or more of the heterogenite with the granularity of 200 meshes and water to prepare 33% of ore pulp, adding sulfuric acid into the ore pulp, leaching for 0.5h-2.5h at the normal temperature, and performing solid-liquid separation after reaction is finished to obtain leaching liquid and copper leaching residues; (3) leaching cobalt at the secondary stage: mixing the copper leaching residues leached at the primary stage and sulfuric acid aqueous solution to prepare 20% of ore pulp, adding 1-2 times of iron powder into the ore pulp according to theoretical quantity, performing reaction at the temperature ranging from the normal temperature to 85 DEG C, mixing for 0.5h-3h, and performing solid-liquid separation after leaching is finished to obtain cobalt-rich leaching liquid and leaching residues. The addition of the sulfuric acid is equal to 10%-25% of the heterogenite by mass fraction, and the concentration of the sulfuric acid aqueous solution is 10g / L-30g / L.

Owner:SHENYANG RES INST OF NONFERROUS METALS

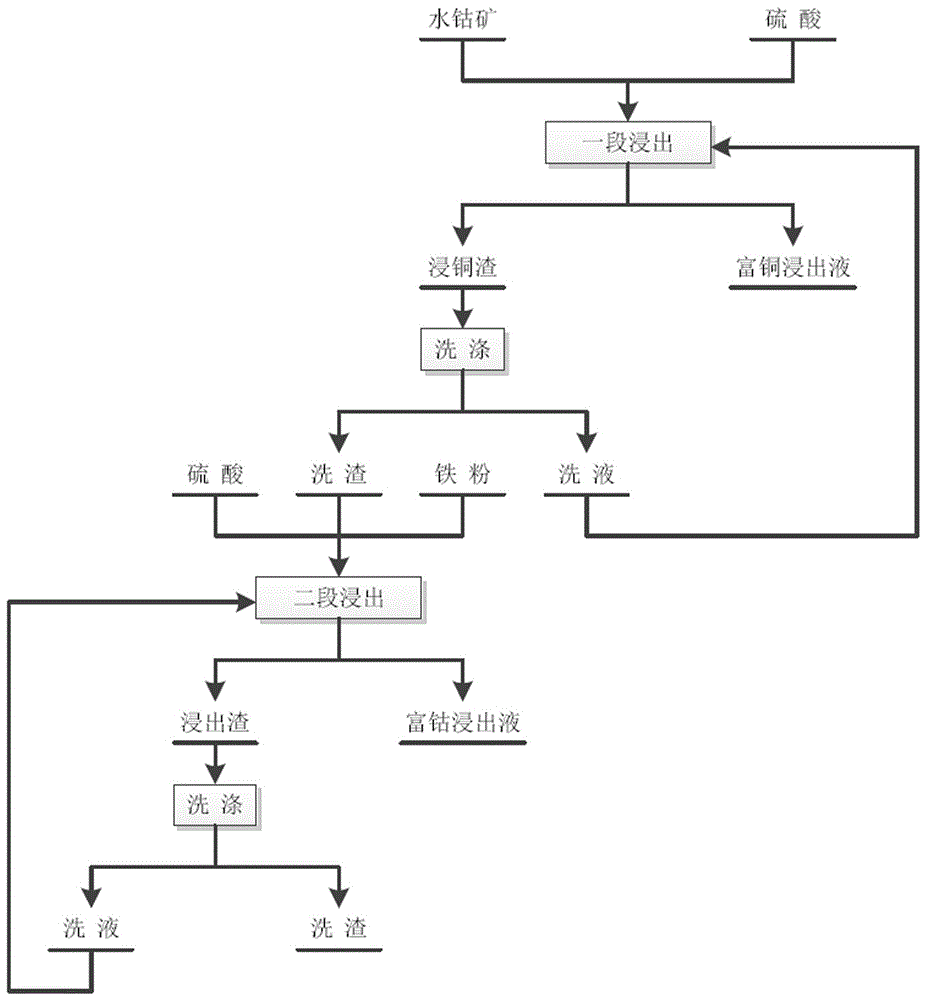

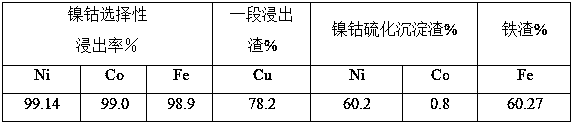

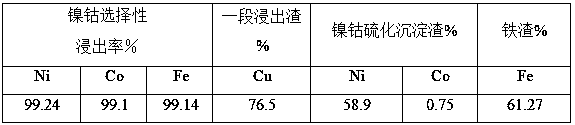

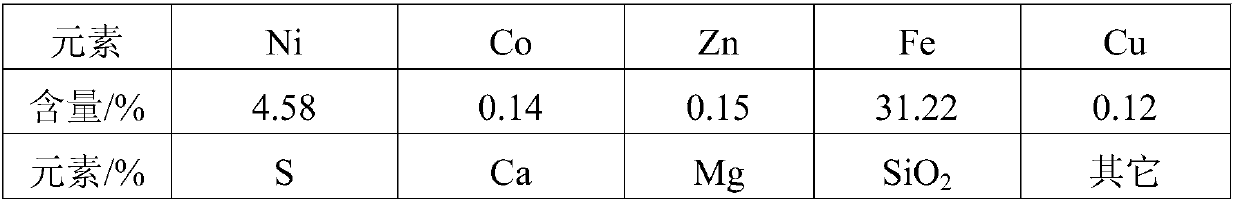

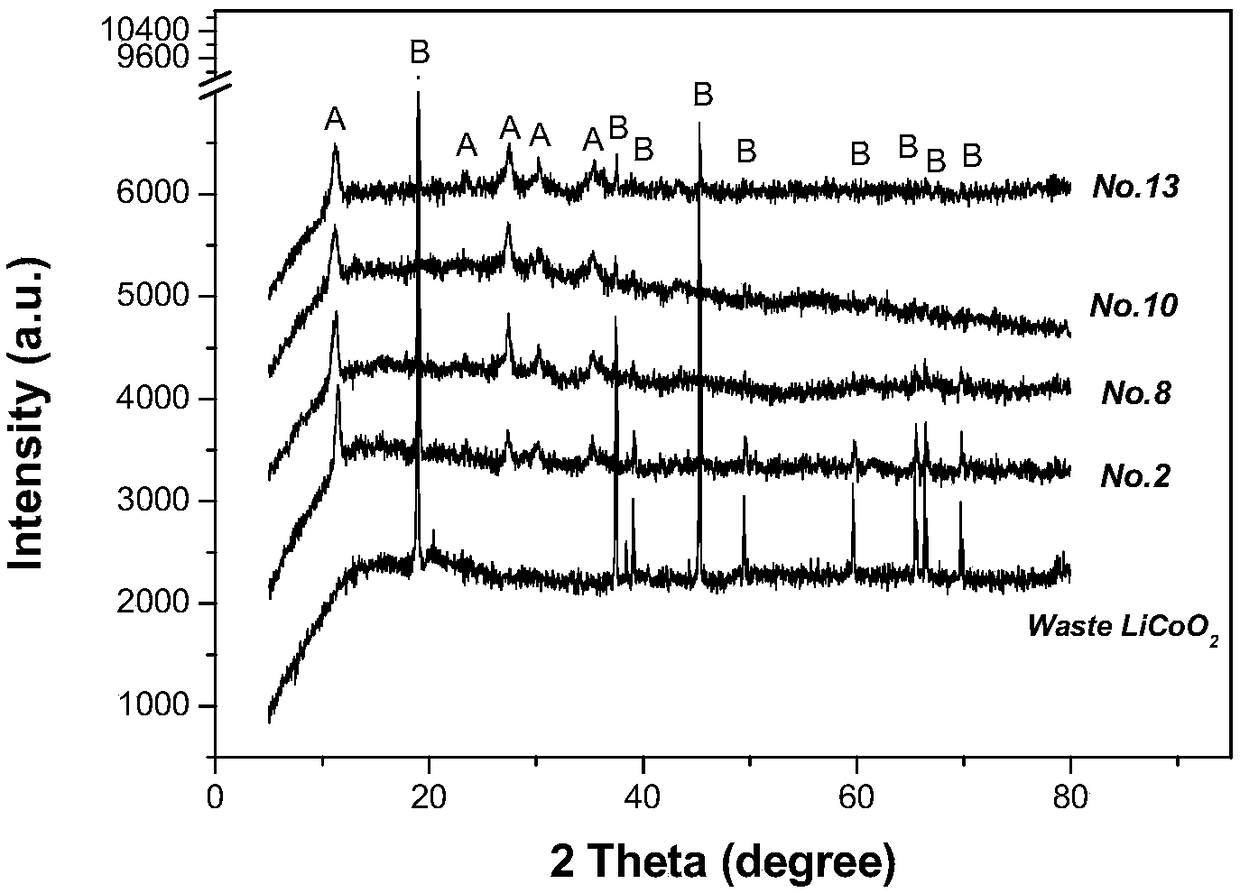

Method for directly separating nickel from copper by wet processing of low-grade nickel matte

ActiveCN107779595AHigh recovery rateAchieve recyclingProcess efficiency improvementHydrolysisHigh heat

The invention discloses a method for directly separating nickel from copper by wet processing of low-grade nickel matte. The method includes subjecting the low-grade nickel matte to primary countercurrent leaching by sulfuric acid to obtain primary leaching liquor containing nickel, cobalt and iron and primary leaching residues with main ingredients of copper sulphate and precious metals; subjecting the low-grade nickel matte to secondary countercurrent leaching by the primary leaching liquor to obtain secondary leaching liquor containing nickel, cobalt and iron and secondary leaching residues; precipitating hydrogen sulfide gas produced after two times of leaching and the secondary leaching liquor to obtain iron-containing precipitation liquor and nickel-cobalt sulfide precipitation residues; finally, subjecting the precipitation liquor to high-temperature oxidation, hydrolysis and iron removal. The method has the advantages that the whole technological process makes the nickel and the cobalt directly separated from the precious metals and the copper, so that the drawbacks such as high loss of the cobalt, the nickel and the precious metals, high material circulation rate and highenergy consumption are avoided in a process of bessemerizing the low-grade nickel matte into high-grade nickel matte; the traditional technology of separating the nickel from the copper through high-matte grinding flotation is omitted, so that production energy consumption is reduced, and a recovery rate of the nickel, the copper, the cobalt and the precious metals is increased.

Owner:JINCHUAN GROUP LIMITED

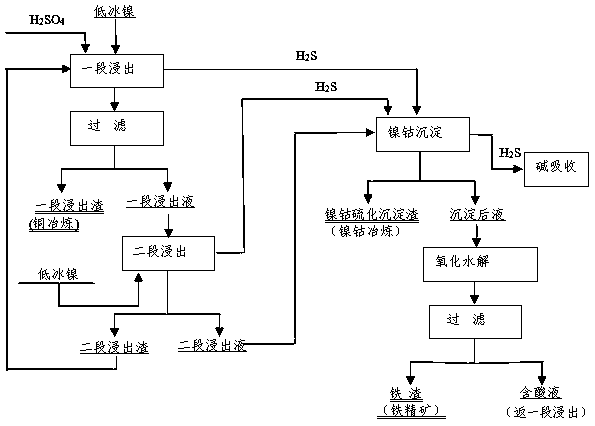

Method for preparing nickel sulfate by ordinary-pressure decomposed high ice nickel

InactiveCN110342590AAchieving selective leachingAchieve separationNickel sulfatesSelective leachingFiltration

The invention discloses a method for preparing nickel sulfate by ordinary-pressure decomposed high ice nickel. The method for preparing the nickel sulfate by the ordinary-pressure decomposed high icenickel comprises the following steps that (1) the high ice nickel is crushed and added into a 4-10 mol / L concentrated sulfuric acid solution, solid-liquid separation is carried out after reaction to obtain filter residues and filter liquor, and the obtained filter liquor is refilled to the concentration of sulfuric acid of 4-10 mol / L to return to ordinary-pressure decomposition of the high ice nickel; and (2) filtration washing is carried out after size mixing and stirring are carried out on the filter residue to obtain the filter liquor containing nickel, iron and cobalt and the cooper-bearing filter residue, the cooper-bearing filter residue is used for smelting cooper, and the filter liquor containing the nickel, the iron and the cobalt is returned to perform size mixing on the filter residue obtained in the step (1); and when the Ni<2+> concentration in the filter liquor containing the nickel, the iron and the cobalt is greater than or equal to 90g / L, evaporative crystallization iscarried out after neutralization deironing and extraction cobalt removal are carried out to obtain a nickel sulfate crystal. According to the method for preparing the nickel sulfate by the ordinary-pressure decomposed high ice nickel, selective leaching of the nickel and the cobalt in the high ice nickel can be realized under the ordinary pressure condition, the cooper exists in leaching residuein a sulfide form of the cooper, and the nickel and cooper separation in the high ice nickel is realized.

Owner:CENT SOUTH UNIV

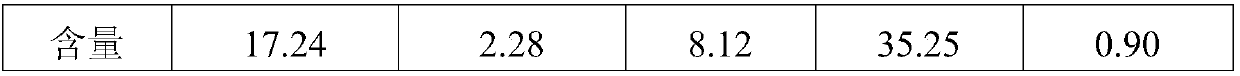

Method for separating Co (cobalt) and Li (lithium) from LiCoO2 (lithium cobalt oxide) of waste lithium batteries to prepare cobaltous phosphate

ActiveCN106395784AEasy to separateEfficient recyclingSolid waste disposalTransportation and packagingPregnant leach solutionPhosphate

The invention discloses a method for separating Co (cobalt) and Li (lithium) from LiCoO2 (lithium cobalt oxide) of waste lithium batteries to prepare cobaltous phosphate. The method comprises the following steps: (1) disassembling and peeling the waste lithium batteries to obtain anode and cathode active substances; (2) calcining and grinding the anode and cathode active substances to obtain LiCoO2-containing powder materials; (3) performing leaching on the LiCoO2-containing powder materials by mixed leaching liquid of H3PO4 and H2O2; neutralizing the obtained leaching liquid; performing solid-liquid separation to obtain cobaltous phosphate sediment and a lithium-containing solution. The method has the advantages that the LiCoO2 of typical waste lithium batteries is used as a raw material; the Co and the Li are effectively separated by a roasting and leaching method; the cobalt with high additional values is recovered for preparing the cobaltous phosphate (cobalt violet); the resource recycling and utilization of the LiCoO2 of the waste lithium batteries are realized.

Owner:CENT SOUTH UNIV

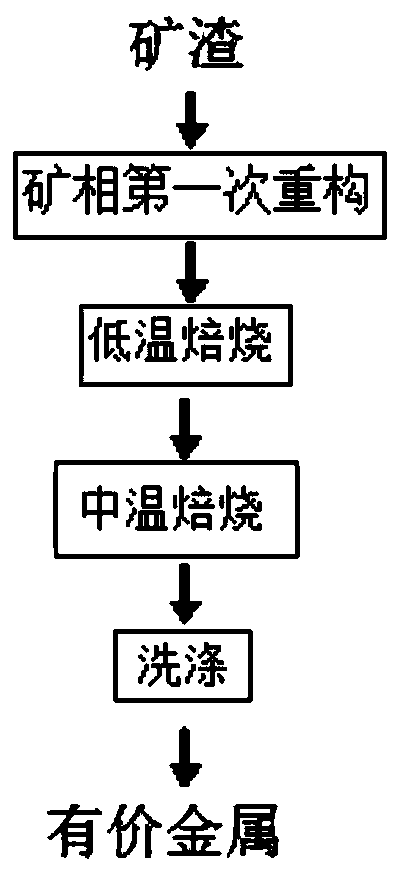

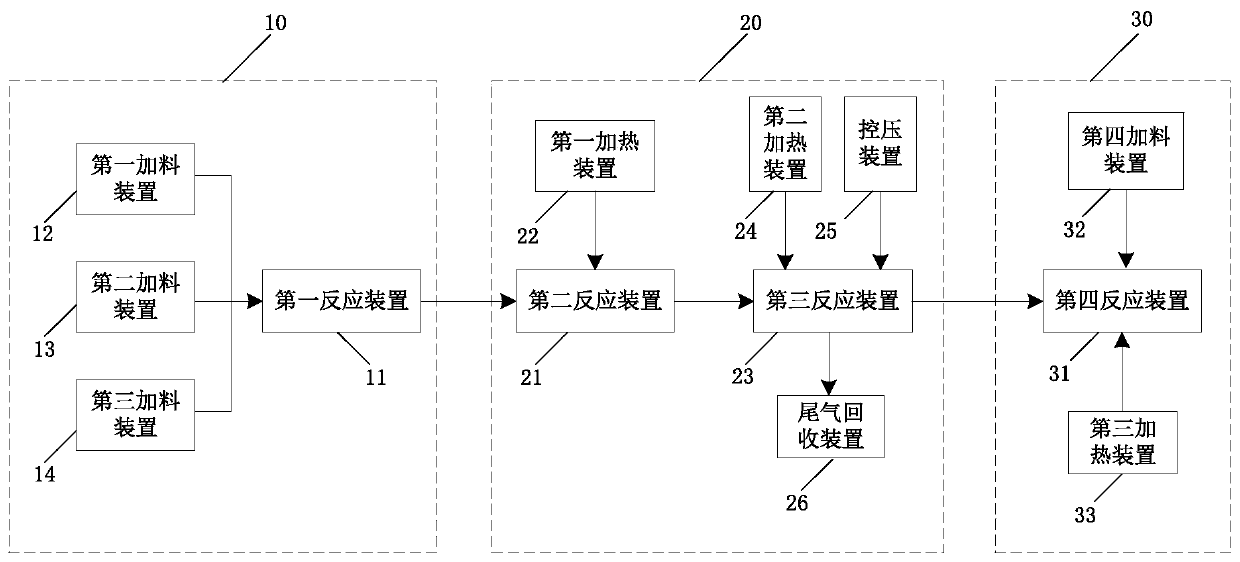

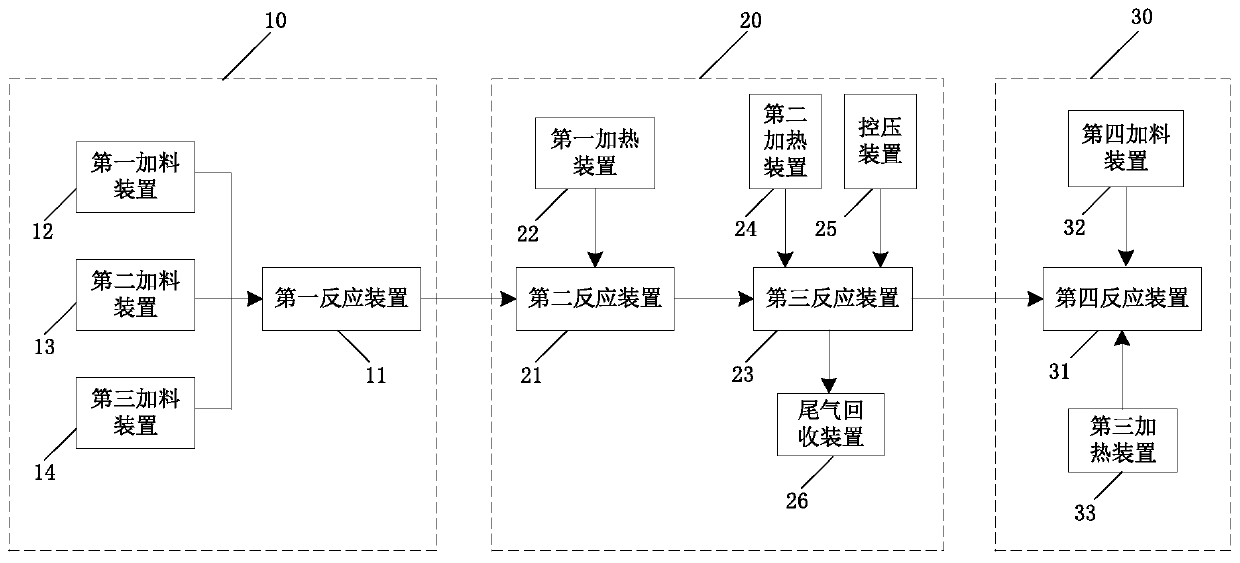

Method and device for selective leaching of valuable elements from slag

PendingCN109762998AAchieving selective leachingAvoid pyrolysisProcess efficiency improvementSelective leachingSlag

The invention provides a method and a device for selective leaching of valuable elements from slag. The method comprises the following steps: mixing the slag with the aqueous solution of a first ore phase reconstruction agent to obtain reconstructed mineral acid salt; carrying out low-temperature roasting on the reconstructed mineral acid salt and a second ore phase reconstruction agent to obtaina low-temperature roasting product; carrying out medium-temperature roasting on the low-temperature roasting product to obtain a medium-temperature roasting product; and washing the medium-temperatureroasting product to obtain leaching solution containing valuable elements. Under the action of the first ore phase reconstruction agent, first-time reconstruction of the slag is realized; under the action of the second ore phase reconstruction agent, low-temperature roasting is carried out to realize second-time reconstruction of the reconstructed mineral acid salt; through the medium-temperatureroasting process, the third-time reconstruction of the low-temperature roasting product is realized; and the leaching solution containing valuable elements is obtained through washing. Through three-time ore phase reconstruction process, the pyrolysis process of the valuable elements can be restrained during the roasting process to realize the purpose of selective leaching of valuable elements.

Owner:CHINA ENFI ENGINEERING CORPORATION

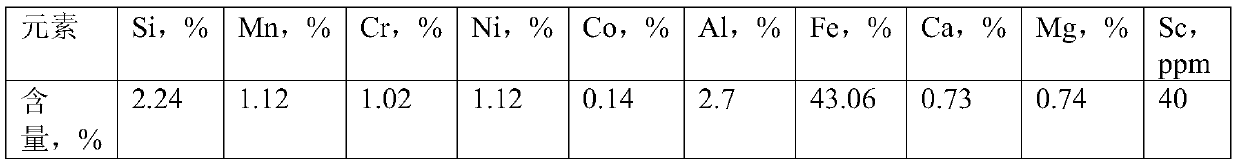

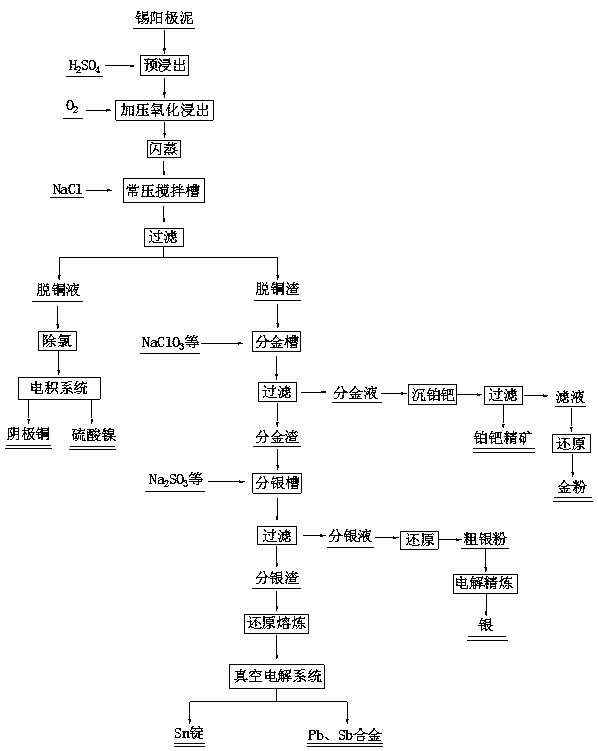

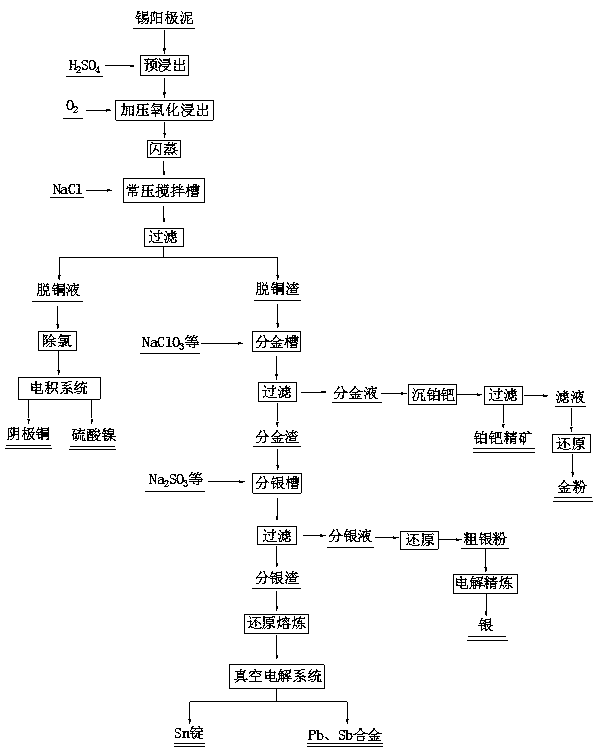

Treatment method of high-palladium high-tin high-copper regenerated tin anode slime

InactiveCN109971964AReduce labor intensityContinuous operationPhotography auxillary processesProcess efficiency improvementAutomatic controlClosed loop

The invention relates to a treatment method of high-palladium high-tin high-copper regenerated tin anode slime. The method comprises the following steps of (1) pre-leaching; (2) pressurized oxidationleaching; (3) precipitating silver; (4) separating gold; (5) separating silver; and (6) smelting in a tin-lead antimony-fire method. According to the treatment method, the copper and nickel in the high-palladium high-tin high-copper tin anode slime are effectively and selectively leached into the copper removal liquid, so that a cathode copper and nickel sulfate product can be obtained, the loss of silver in the pressurized oxidation leaching working sequence is effectively reduced through the silver precipitation operation, gold, silver and platinum and palladium are separated can be realizedthrough 'gold separation-silver separation' process, and tin and lead-antimony alloy products can be obtained by smelting through the tin-lead antimony-fire method. According to the treatment method,automatic control is easy to realize, effective separation and recovery of copper-nickel, tin-lead and antimony and noble metals can be realized, the whole process can realize closed-loop circulationof the smelting system, without emission of three wastes, and has the characteristics of good environmental effect, good economical efficiency and the like.

Owner:江西自立环保科技有限公司

Method for separating nickel, copper and iron from electroplating sludge

ActiveCN105779773AAchieving selective leachingPromote decompositionProcess efficiency improvementPregnant leach solutionTime range

The invention relates to a method for separating nickel, copper and iron from electroplating sludge. The method includes the following steps that a sulfuric acid solution and lignosulfonate are added into the electroplating sludge according to the mass ratio of the electroplating sludge to the sulfuric acid solution to the lignosulfonate being 1:2-5:0.002-0.005,and oxygen is led in, wherein the oxygen partial pressure ranges from 0.3 MPa to 0.7 MPa, the leaching temperature ranges from 100 DEG C to 150 DEG C, the pH of a leaching agent is controlled to range from 0.5 to 1.5, and the leaching time ranges from 1 hour to 5 hours; and after leaching is finished, filtering separation is carried out to obtain the leaching agent and leaching residues, the copper and the nickel are extracted through the leaching agent, and the leaching residues are stacked and accumulated. The method is easy to operate, and the aims of selective leaching of elements such as the copper and the nickel and separation of the iron can be further achieved. The leaching efficiency of the elements such as the copper and the nickel is high, and the decomposing effect is good. The method is suitable for treatment and utilization of the electroplating sludge.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

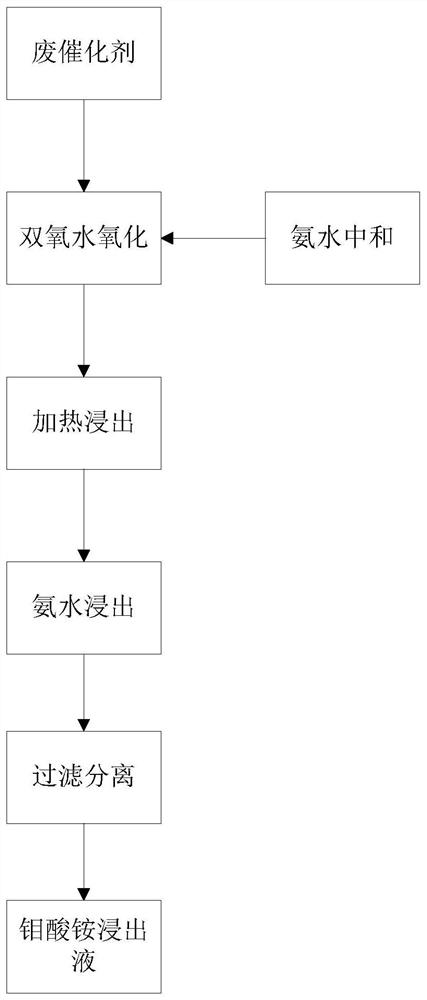

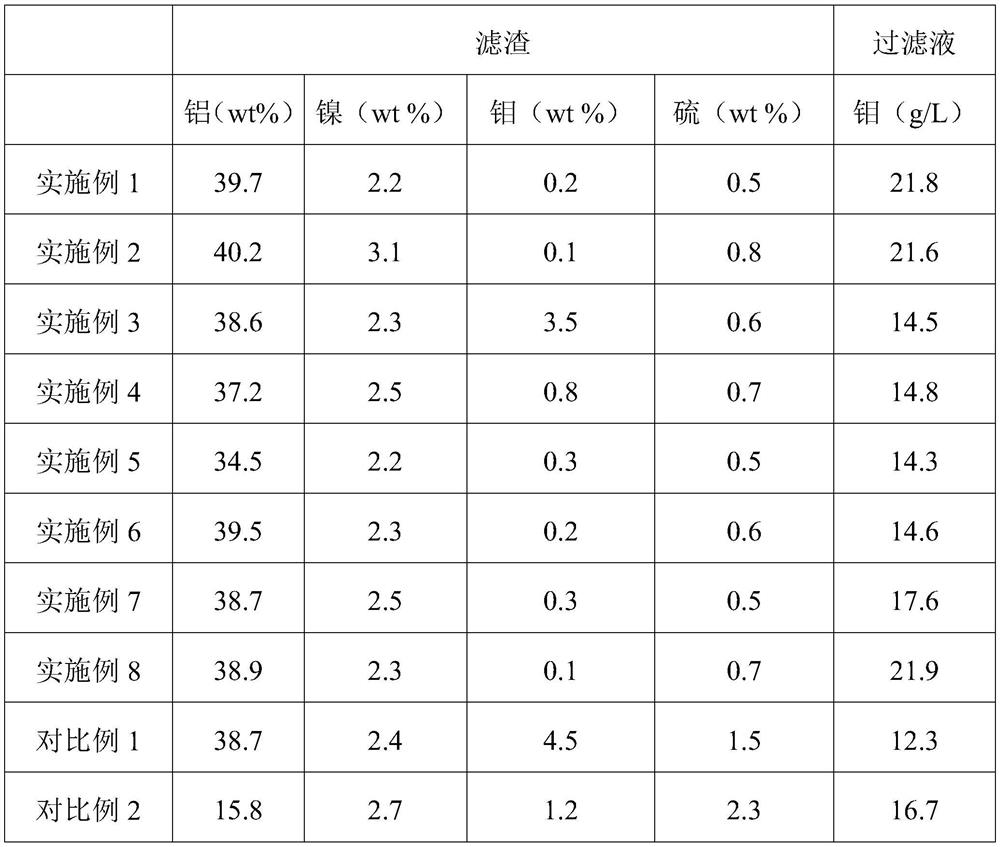

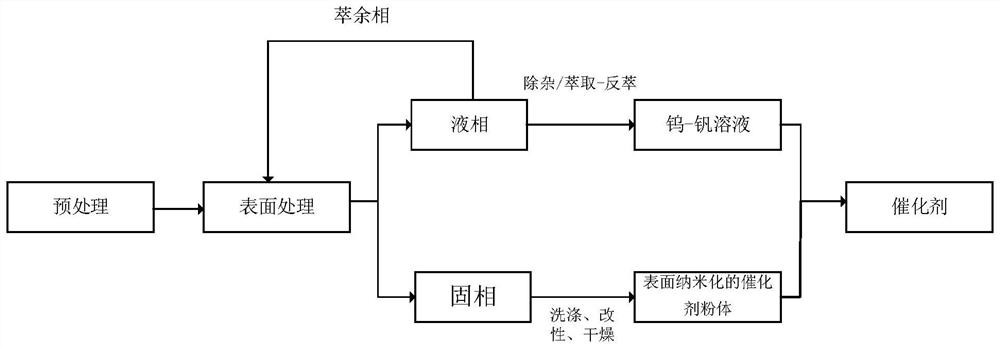

Method for recovering molybdenum from waste nickel-molybdenum catalyst

ActiveCN113564386AAvoid dissolving at the same timeAchieving selective leachingProcess efficiency improvementPregnant leach solutionPtru catalyst

The invention provides a method for recovering molybdenum from a waste nickel-molybdenum catalyst. The method comprises the following steps: (1) hydrogen peroxide and the waste nickel-molybdenum catalyst are mixed, and one-step reaction is carried out to obtain a leachate; and (2) ammonia water is added into the leachate obtained in the step (1) for a second-step reaction, then ammonia water is added for a third-step reaction, and molybdenum-containing filtrate is obtained after filtration. The method provided by the invention has the advantages of low temperature, no need of using a pressurized reactor, simple operation and low equipment investment. The produced ammonium molybdate solution can be recovered using conventional methods.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

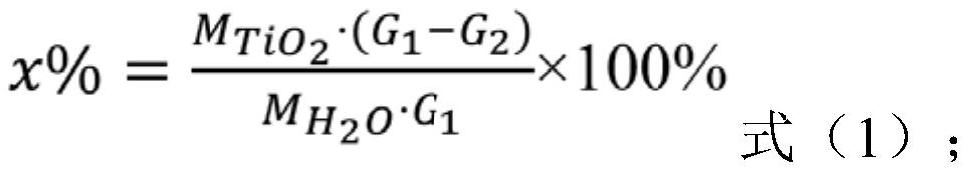

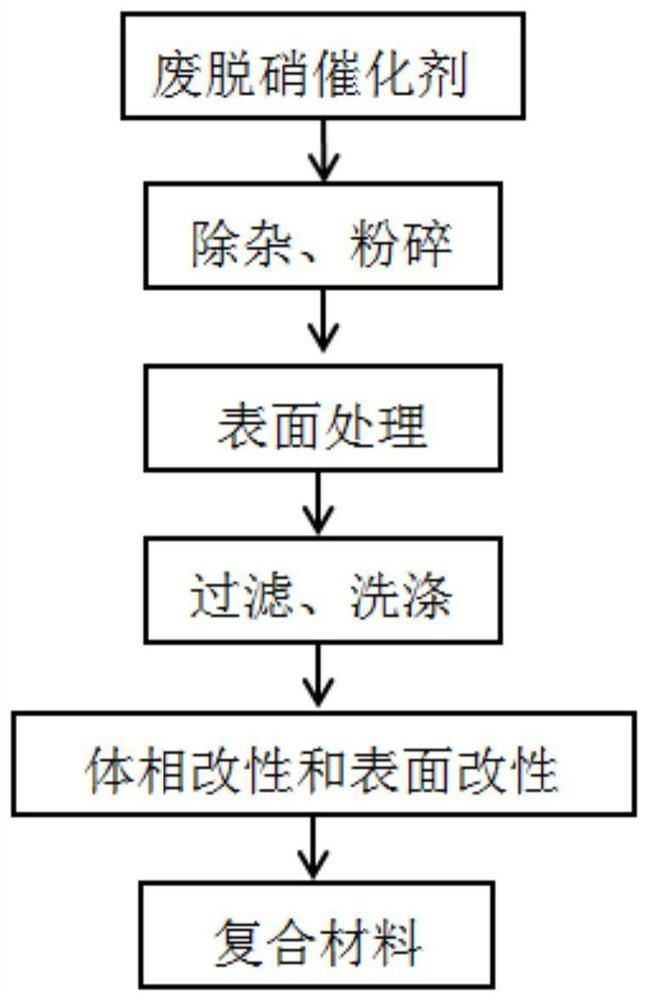

Denitration catalyst and preparation method thereof

ActiveCN111974378AImprove denitrification effectLarge specific surface areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention relates to the field of waste catalyst disposal, and discloses a denitration catalyst, a preparation method of the denitration catalyst and the denitration catalyst prepared by the method. The denitration catalyst comprises a titanium oxide carrier material, a metal active component and an auxiliary agent, wherein the carrier material comprises titanium oxide and nanocrystallized titanium oxide whiskers coating at least part of the outer surface of the titanium oxide, and based on the total weight of the carrier material, the content of the nanocrystallized titanium oxide whiskers is 5-30wt%. According to the denitration catalyst provided by the invention, the titanium oxide of which at least part of the outer surface is coated with the nanocrystallized titanium oxide whiskers is adopted as the carrier material, the denitration catalyst provided by the invention has excellent denitration catalytic activity, and meanwhile, the carrier material is obtained by recycling thewaste denitration catalyst, so that the cost of the denitration catalyst is obviously reduced, and the environmental pollution is reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Wet cleaning treatment method for lead chloride slag

InactiveCN108893616AAchieving selective leachingEfficient enrichmentPhotography auxillary processesProcess efficiency improvementSlagCoordination complex

The invention discloses a wet cleaning treatment method for lead chloride slag. The method comprises the following steps: 1, coordination leaching of lead chloride slag, namely performing coordinationleaching on the lead chloride slag by taking an ammonium acetate solution as a coordination leaching agent, and performing solid-liquid separation after leaching completion so as to obtain a leachingsolution containing a lead complex and leaching slag; 2, performing diaphragm electrodeposition on the leaching solution to extract lead, and performing diaphragm electrodeposition by taking the leaching solution containing the lead complex obtained in the step 1 as cathode liquor and taking an ammonium chloride solution as anode liquor so as to extract lead; and 3, performing post-treatment on an electrolytic stripped solution, returning the cathode electrolytic stripped solution obtained in the cathode chamber to be used for leaching after electrodeposition completion, adding a neutralizerinto an anode electrolytic stripped solution in the anode chamber to regulate the pH value, and returning to the step 2 to serve as the anode liquid for later use. According to the method, various lead chloride slag can be cleaned and efficiently treated, and the electric lead product with high purity is directly obtained. The wet cleaning treatment method disclosed by the invention has the outstanding advantages of being high in raw material adaptability, simple in process flow, clean, environment-friendly and the like.

Owner:YIYANG SHENGLI CHEM IND +1

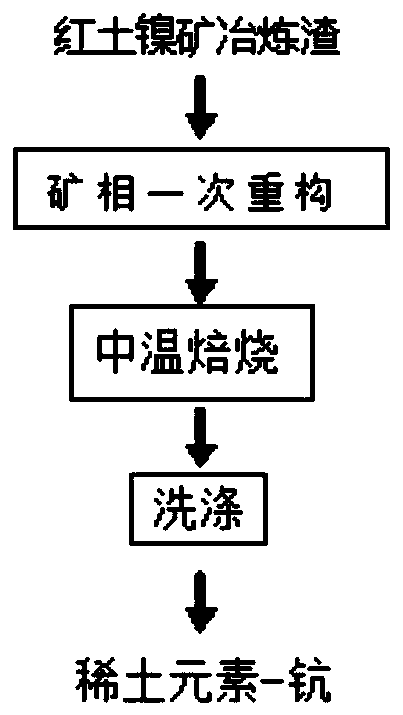

Method and device for selectively leaching scandium from laterite nickel ore smelting slag

PendingCN109777973AAchieving selective leachingAvoid pyrolysisProcess efficiency improvementPregnant leach solutionSlag

The invention provides a method and device for selectively leaching scandium from laterite nickel ore smelting slag. The method comprises the steps of mixing the laterite nickel ore smelting slag andan aqueous solution of a first ore phase refactoring agent to obtain refactoring mineral acid, wherein the first ore phase refactoring agent includes acid; carrying out intermediate-temperature roasting on the refactoring mineral acid to obtain an intermediate-temperature roasted product, wherein the temperature of the intermediate-temperature roasting process ranges from 500 DEG C to 800 DEG C; and washing the intermediate-temperature roasted product to obtain leaching liquid with scandium. With the treatment method, the pyrogenic decomposition process of the scandium element can be restrained through the ore phase refactoring process, and then the purpose of selectively leaching the scandium element from the laterite nickel ore smelting slag can be achieved.

Owner:CHINA ENFI ENGINEERING CORPORATION

Wet-process cleaning treatment method of lead plaster

ActiveCN108715936ALow recovery rateAchieving selective leachingPhotography auxillary processesProcess efficiency improvementPregnant leach solutionElectrolysis

The invention discloses a wet-process cleaning treatment method of a lead plaster. The method comprises the following steps that an acetate solution is taken as a coordination leaching agent to carryout coordination leaching on the lead plaster to obtain lead-containing leachate and leached residues; the leachate is used for extracting the lead by adopting a diaphragm electrodeposition technologywithout purifying; after the diaphragm electrolysis is completed, an negative electrode obtains more than 99.9% or above of the lead, an anode liquid and a cathode electrolysis barren solution can becombined and can be returned to serve as the coordination leaching agent, so that a closed cycle of a technological process is realized; according to the method, the lead plaster in a waste lead-acidstorage battery can be carried out efficient cleaning treatment, an electric lead product with relatively high purity can be directly obtained, and sulfur in the lead plaster is fixed in the leachingslag by a form of insoluble sulfate; according to the method, the technical scheme has the outstanding advantages of being high in raw material adaptability, simple in the technological process, highin valuable element recovery rate, clean and environment-friendly.

Owner:CENT SOUTH UNIV

Composite material as well as preparation method and application thereof

PendingCN112156816ALarge specific surface areaReduce moisture contentDispersed particle separationCatalyst regeneration/reactivationPtru catalystAlkali metal

The invention relates to the field of waste catalyst treatment, and discloses a composite material as well as a preparation method thereof, wherein the composite material comprises a spherical inner layer and a coating layer coating at least part of the outer surface of the spherical inner layer, the coating layer is whisker-shaped and / or columnar, and the content of the coating layer is 5-30 wt%based on the total weight of the composite material. The composite material has high specific surface area and low water content; the content of harmful elements such as alkali metal, arsenic, iron and phosphorus in the composite material is remarkably reduced. When the composite material provided by the invention is used for preparing the denitration catalyst, roasting is not needed, and therefore the investment and the operation cost are remarkably reduced. Meanwhile, according to the method provided by the invention, valuable elements in the waste catalyst do not need to be respectively extracted, so that the technological process is simplified, the emission of waste byproducts is reduced, and the secondary pollution is reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

A kind of method for wet cleaning treatment of lead plaster

ActiveCN108715936BLow recovery rateAchieving selective leachingPhotography auxillary processesProcess efficiency improvementElectrolysisChemistry

The invention discloses a wet-process cleaning treatment method of a lead plaster. The method comprises the following steps that an acetate solution is taken as a coordination leaching agent to carryout coordination leaching on the lead plaster to obtain lead-containing leachate and leached residues; the leachate is used for extracting the lead by adopting a diaphragm electrodeposition technologywithout purifying; after the diaphragm electrolysis is completed, an negative electrode obtains more than 99.9% or above of the lead, an anode liquid and a cathode electrolysis barren solution can becombined and can be returned to serve as the coordination leaching agent, so that a closed cycle of a technological process is realized; according to the method, the lead plaster in a waste lead-acidstorage battery can be carried out efficient cleaning treatment, an electric lead product with relatively high purity can be directly obtained, and sulfur in the lead plaster is fixed in the leachingslag by a form of insoluble sulfate; according to the method, the technical scheme has the outstanding advantages of being high in raw material adaptability, simple in the technological process, highin valuable element recovery rate, clean and environment-friendly.

Owner:CENT SOUTH UNIV

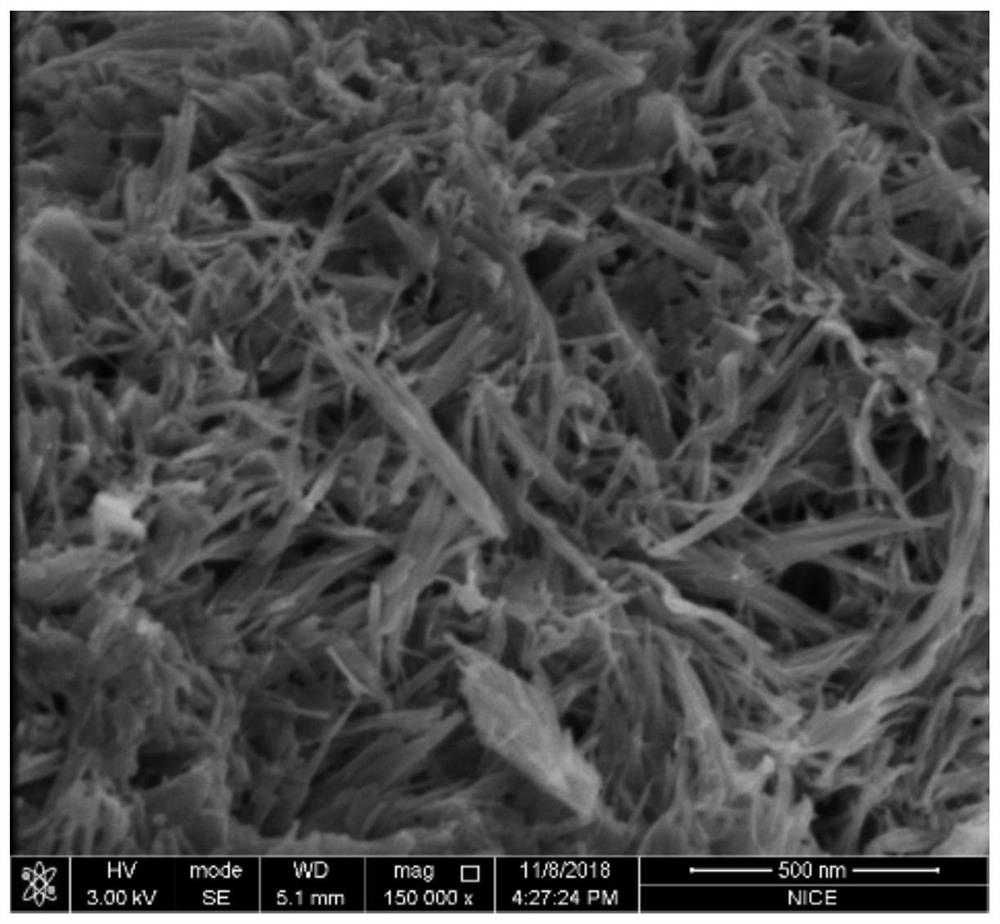

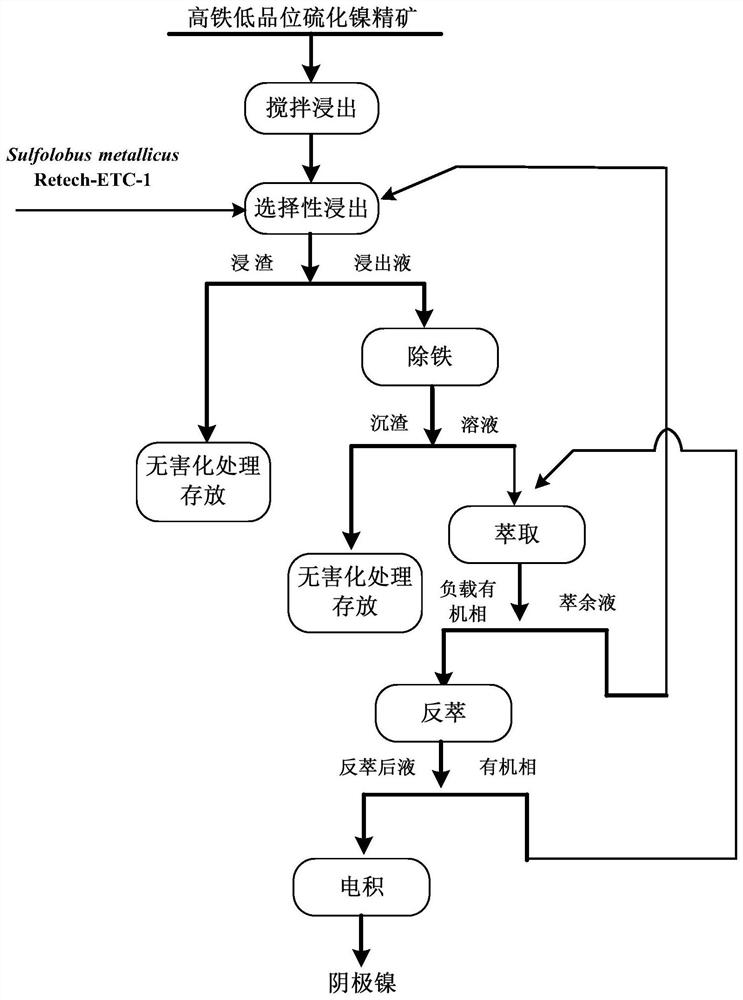

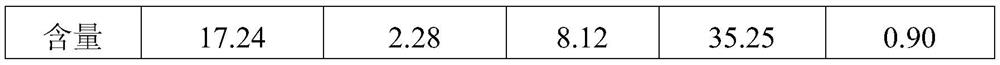

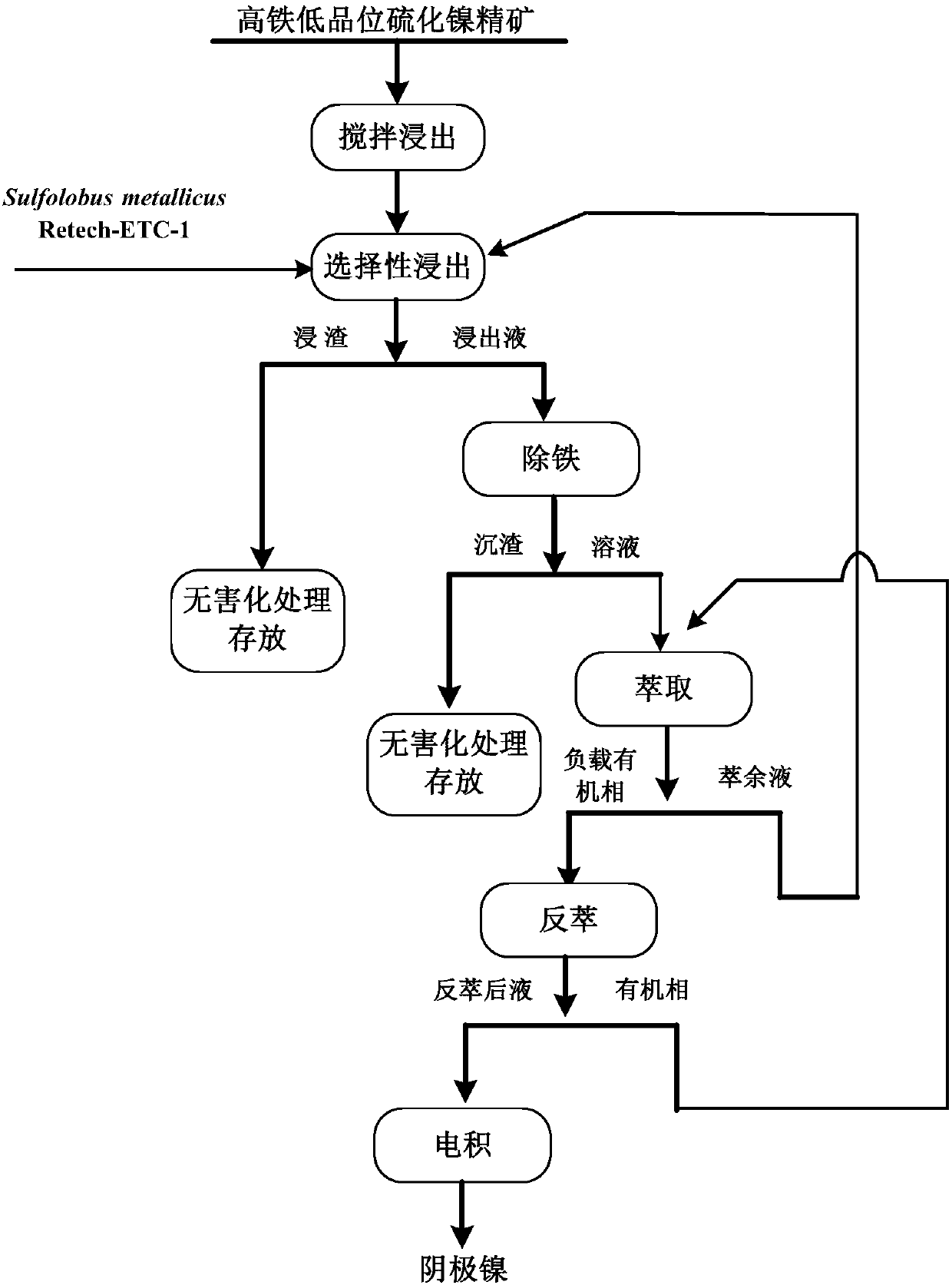

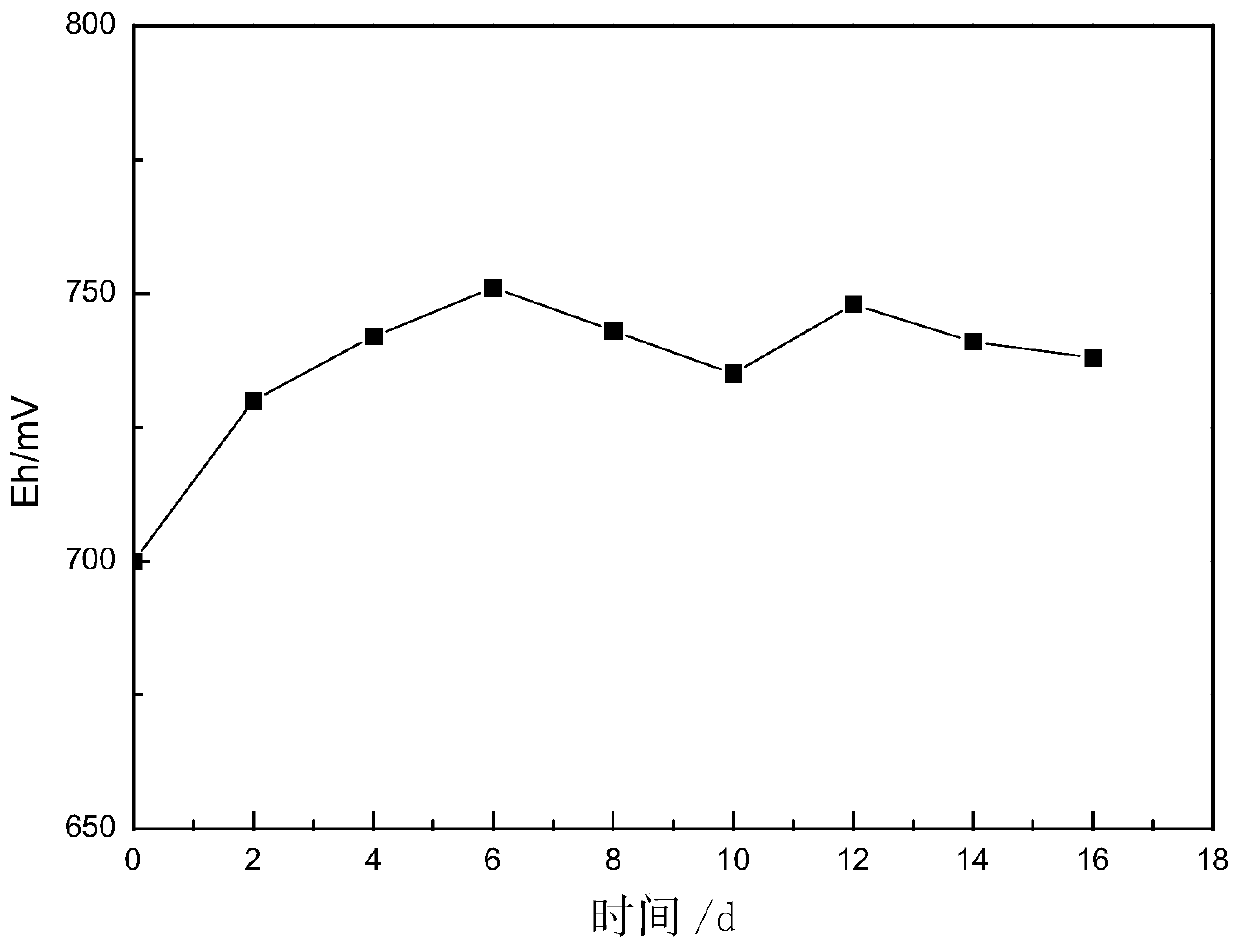

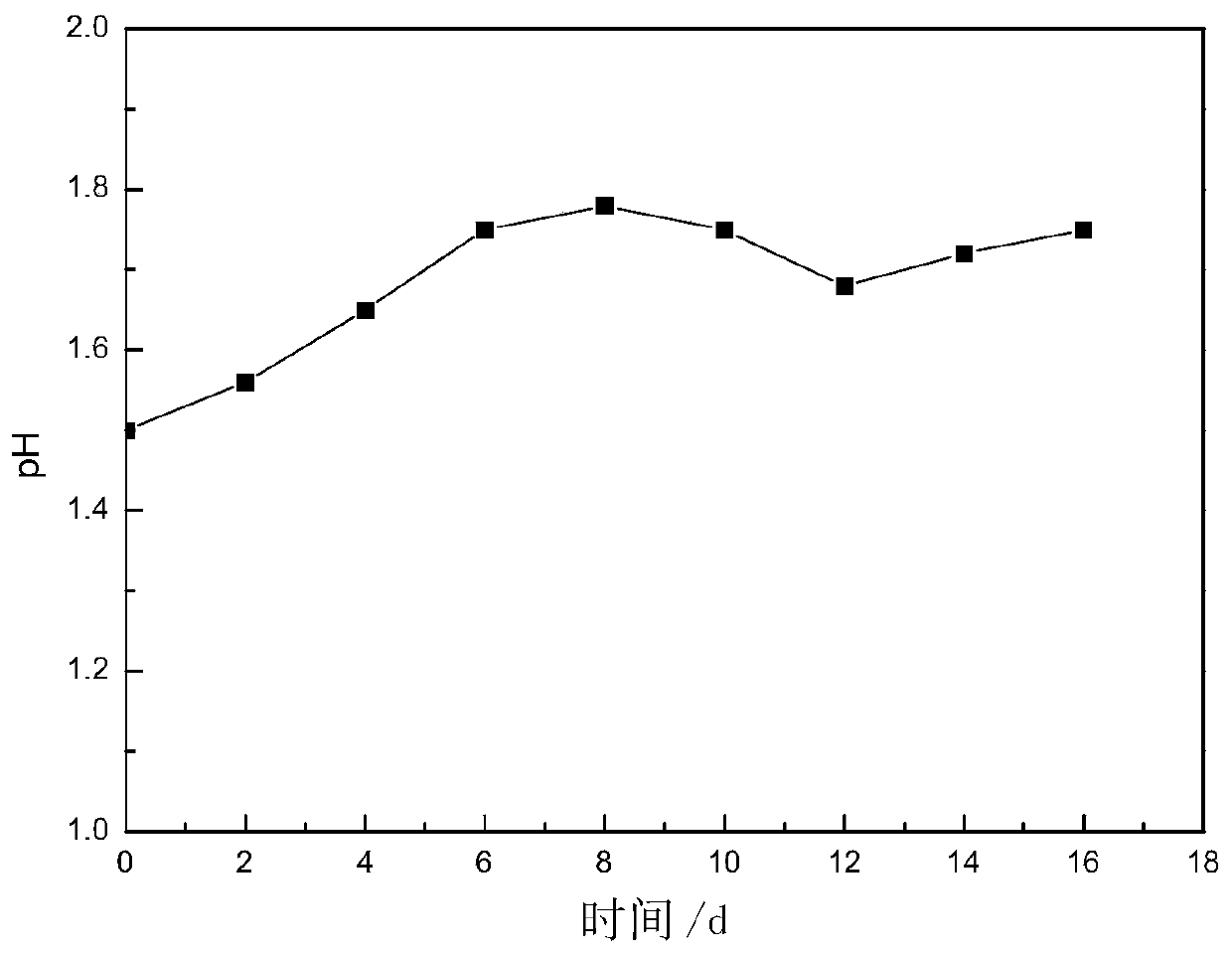

Selective bioleaching process of high-iron and low-grade nickel sulfide ore

ActiveCN109929996BEfficient leachingImprove leaching effectProcess efficiency improvementSelective leachingSmelting process

The invention provides a high-iron low-grade nickel sulfide ore selective biological leaching process. The process comprises the following steps of stirring and leaching, selective leaching, deironing, extraction, reverse extraction and electrodeposition, then obtaining a cathode nickel. According to the process, in particular with respect to a flotation nickel sulfide ore concentrate with high iron content and low nickel grade, a stirring biological leaching process is adopted, measures for controlling growth, pH value, temperature and ventilatory capacity of vulcanized bacteria are adopted,redox potential in the leaching process is controlled, dissolution of iron-containing sulfide minerals such as pyrite is effectively inhibited, and selective leaching of the nickel-containing sulfidemineral is realized. The process is short in procedure, simple in equipment, saving in investment, low in cost, free of pollution, high in valuable metal recovery rate and capable of treating low-grade nickel sulfide ore resources which cannot be treated by a pyrogenic process smelting process, utilization range of resources can be expanded, comprehensive recovery level of the nickel metal is improved, and economic benefits, social benefits and environmental benefits of the process is remarkable.

Owner:有研资源环境技术研究院(北京)有限公司

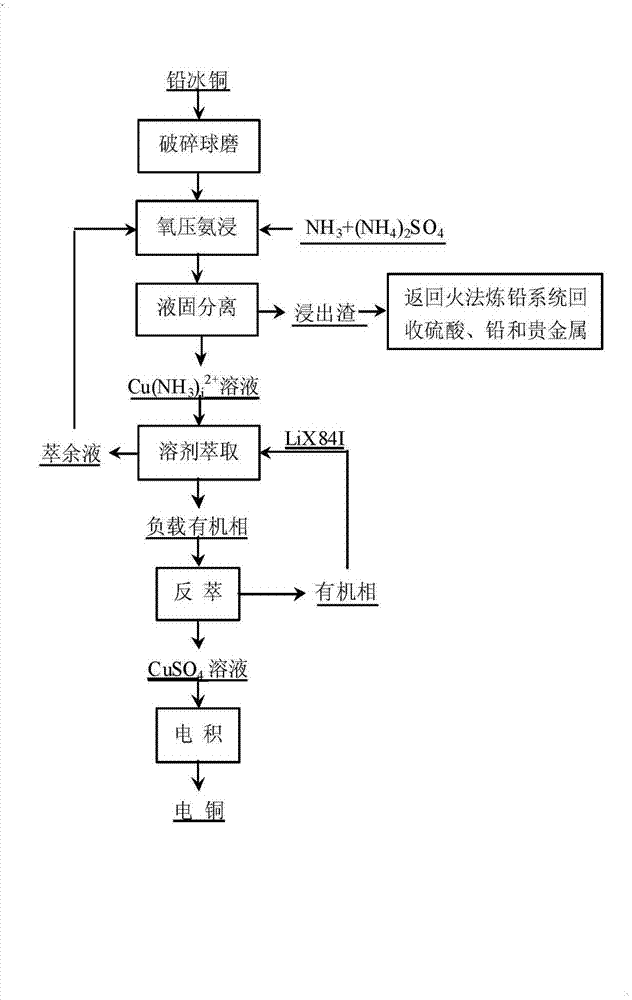

Method for separating copper from lead copper matte

ActiveCN102230083BAchieving selective leachingHigh recovery ratePhotography auxillary processesProcess efficiency improvementChemical reactionMetallic sulfide

The invention relates to a method for separating copper from lead copper matte, and belongs to the field of the wet-process metallurgy of non-ferrous metal. In the method, the lead copper matte is subjected to oxygen pressure leaching by adopting an NH3-(NH4)2SO4 alkalescent composite system at the temperature of between 110 and 200 DEG C; copper and NH3 undergo a coordination chemical reaction to enter solution, and other metal sulfides are converted into oxides / hydroxides and a sulfur element, the oxides / hydroxides and the sulfur element; and the copper and gold and silver are reserved in leaching residues, and the leaching residues return to a pyrometallurgical lead refining system and are subjected to batching to recover valuable elements such as lead, noble metal, simple substance sulfur. In copper-ammonia coordination solution, copper sulfate enrichment solution is obtained by the selective extraction of LiX84I and reextraction, and qualified cathode electrolytic copper is obtained by the conventional electrodeposition process of copper sulfate. By the method, the copper can be separated from the lead copper matte in one step, and the method is simple in a process, high in recovery rate of valuable metal, less in discharge of waste gas, waste water and waste residues, environment-friendly, low in requirement on equipment materials and safe and reliable in actual operation.

Owner:CHENZHOU YUTENG CHEM IND

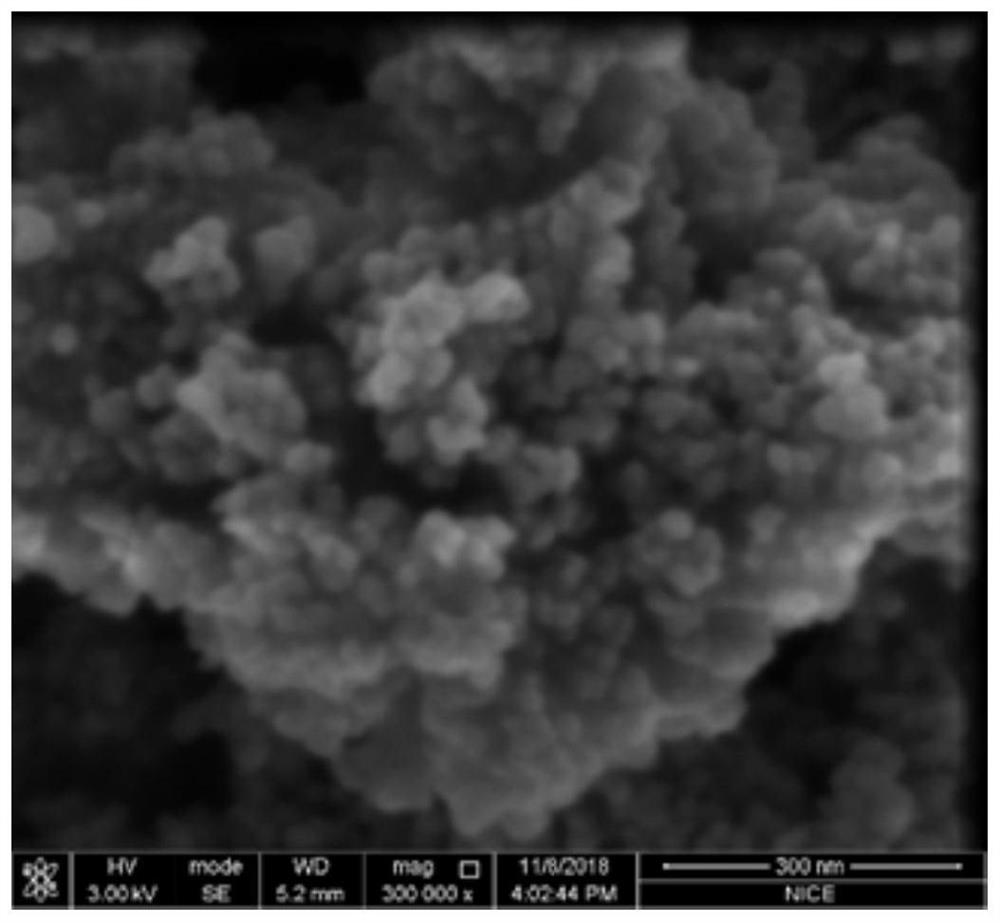

A strain of Penicillium oxalicum and its cultivation method and application

ActiveCN111304096BEfficient recyclingStrong leaching effectFungiMicroorganism based processesOxalateMicroorganism

The present invention provides a strain of Penicillium oxalicum SYJ-1, which is classified as Penicillium oxalicum (Penicillium oxalicum), and has been preserved in the General Microorganism Center of China Microbiological Culture Collection Management Committee on November 7, 2018. The preservation number is: CGMCC No. 16497. The Penicillium oxalicum of the present invention has a strong leaching effect on lithium cobalt oxide, an important component in waste lithium batteries, and can efficiently recycle lithium and part of cobalt at the same time under the condition of relatively high solid-liquid ratio, and is expected to achieve selective leaching. And to the common heavy metal Fe 2+ 、Ni 2+ , Mn 2+ 、Cu 2+ And lithium cobalt oxide has strong resistance, which further expands its application range. The invention provides excellent bacterial strain resources for the future development of bacterial agents that are resistant to heavy metals and efficiently recover cobalt and lithium in waste lithium batteries, and have great practical application significance.

Owner:DALIAN UNIV OF TECH

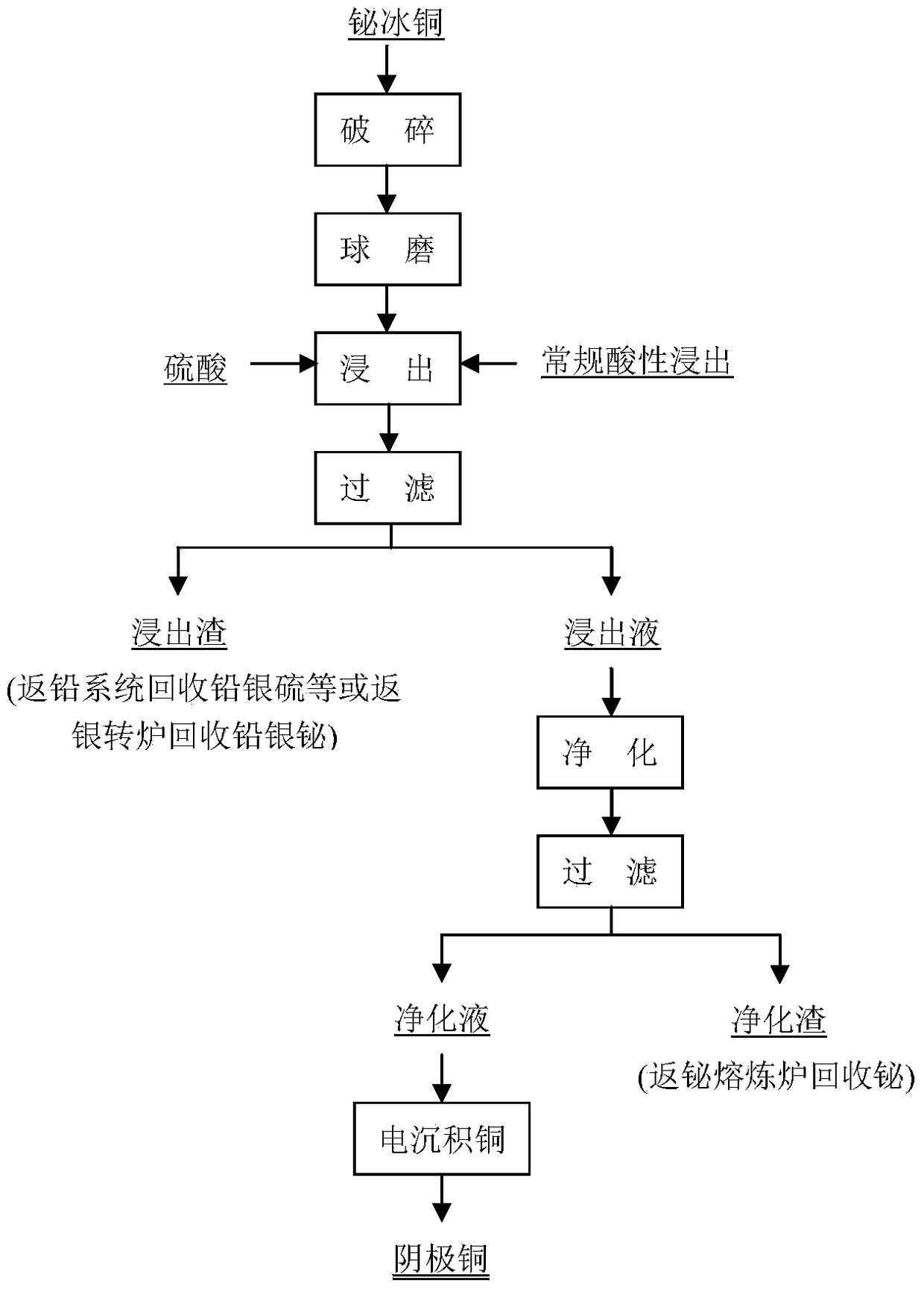

A kind of comprehensive recovery method of bismuth matte

ActiveCN105543479BAchieving selective leachingAchieve enrichmentPhotography auxillary processesProcess efficiency improvementRecovery methodLead smelting

The invention relates to a hydrometallurgy technology for separating copper and bismuth from bismuth matte produced by a bismuth pyrometallurgy system and obtaining qualified copper products and belongs to the field of nonferrous metals hydrometallurgy. Bismuth matte is crushed, ground, sieved to be below -80 meshes and sent to a leaching tank for acid oxidation leaching, a leaching liquid is purified by a purifying agent and subjected to conventional copper electro-deposition treatment sequentially, and national standard copper products are obtained; after enrichment, leaching residues containing valuable metals such as lead, silver, sulfur and the like return to a lead smelting system for recovery, purifying residues containing the bismuth return to a bismuth smelting system for recovery of the bismuth. The recovery rate of valuable metals such as the copper, the silver, the sulfur, the bismuth, the lead and the like is high, the investment is low, energy consumption is low, no pollution is caused, no three-wastes are produced, green production is realized, and current environmental protection requirements are completely met.

Owner:ZHUZHOU SMELTER GRP

High-iron low-grade nickel sulfide ore selective biological leaching process

ActiveCN109929996AEfficient leachingImprove leaching effectProcess efficiency improvementDissolutionSulfide minerals

The invention provides a high-iron low-grade nickel sulfide ore selective biological leaching process. The process comprises the following steps of stirring and leaching, selective leaching, deironing, extraction, reverse extraction and electrodeposition, then obtaining a cathode nickel. According to the process, in particular with respect to a flotation nickel sulfide ore concentrate with high iron content and low nickel grade, a stirring biological leaching process is adopted, measures for controlling growth, pH value, temperature and ventilatory capacity of vulcanized bacteria are adopted,redox potential in the leaching process is controlled, dissolution of iron-containing sulfide minerals such as pyrite is effectively inhibited, and selective leaching of the nickel-containing sulfidemineral is realized. The process is short in procedure, simple in equipment, saving in investment, low in cost, free of pollution, high in valuable metal recovery rate and capable of treating low-grade nickel sulfide ore resources which cannot be treated by a pyrogenic process smelting process, utilization range of resources can be expanded, comprehensive recovery level of the nickel metal is improved, and economic benefits, social benefits and environmental benefits of the process is remarkable.

Owner:有研资源环境技术研究院(北京)有限公司

A method for preparing cobalt phosphate by separating cobalt lithium from waste lithium battery lithium cobaltate

ActiveCN106395784BEasy to separateEfficient recyclingSolid waste disposalTransportation and packagingPregnant leach solutionPhosphate

Owner:CENT SOUTH UNIV

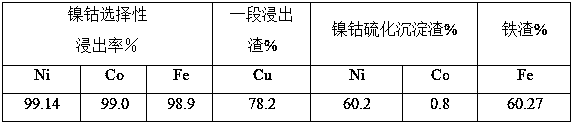

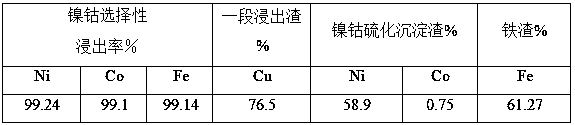

A method for directly separating nickel and copper by wet treatment with low nickel matte

The invention discloses a method for directly separating nickel from copper by wet processing of low-grade nickel matte. The method includes subjecting the low-grade nickel matte to primary countercurrent leaching by sulfuric acid to obtain primary leaching liquor containing nickel, cobalt and iron and primary leaching residues with main ingredients of copper sulphate and precious metals; subjecting the low-grade nickel matte to secondary countercurrent leaching by the primary leaching liquor to obtain secondary leaching liquor containing nickel, cobalt and iron and secondary leaching residues; precipitating hydrogen sulfide gas produced after two times of leaching and the secondary leaching liquor to obtain iron-containing precipitation liquor and nickel-cobalt sulfide precipitation residues; finally, subjecting the precipitation liquor to high-temperature oxidation, hydrolysis and iron removal. The method has the advantages that the whole technological process makes the nickel and the cobalt directly separated from the precious metals and the copper, so that the drawbacks such as high loss of the cobalt, the nickel and the precious metals, high material circulation rate and highenergy consumption are avoided in a process of bessemerizing the low-grade nickel matte into high-grade nickel matte; the traditional technology of separating the nickel from the copper through high-matte grinding flotation is omitted, so that production energy consumption is reduced, and a recovery rate of the nickel, the copper, the cobalt and the precious metals is increased.

Owner:JINCHUAN GROUP LIMITED

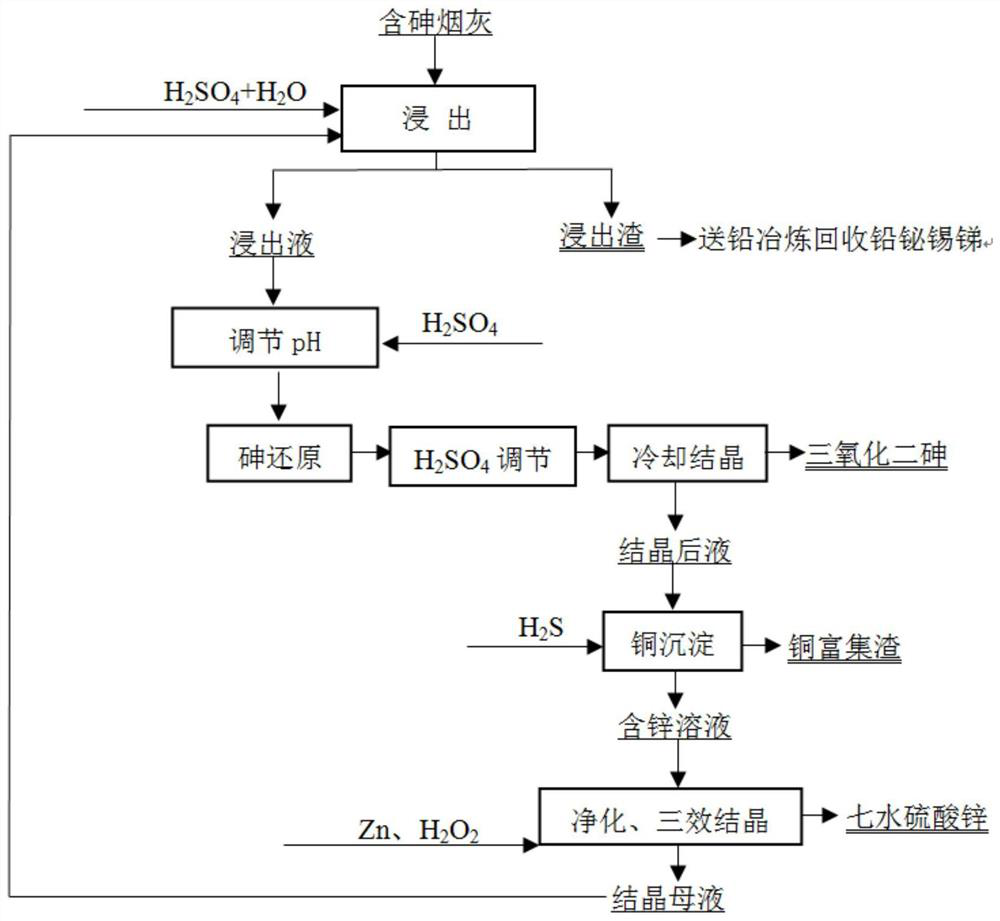

A method for recovering arsenic and valuable metals from arsenic-containing soot

ActiveCN113337720BAchieve recyclingHigh purityZinc sulatesArsenic oxides/hydroxides/oxyacidsLead smeltingIndustrial waste water

The invention discloses a method for recovering arsenic and valuable metals from arsenic-containing soot. The method is that arsenic-containing soot is leached by acid oxidation, arsenic, copper and zinc enter into solution, and bismuth, lead, antimony and tin enter into slag phase ; The leaching solution selectively reduces arsenic by sulfur dioxide gas and recovers arsenic in the form of arsenic trioxide, and the remaining copper and zinc-containing solution is sulfided and precipitated by hydrogen sulfide gas to obtain copper-enriched slag and zinc-containing solution; Concentrate and crystallize to obtain zinc sulfate heptahydrate product, and the crystallization mother liquor is returned to the leaching process of arsenic-containing soot; the method efficiently recovers arsenic in the arsenic-containing soot in the form of high-grade arsenic trioxide, and separates and recovers copper and zinc, and obtains lead, Bismuth, tin, antimony and other enriched slag are used as raw materials for lead smelting. In the whole production process, no industrial waste water is discharged, and no worthless hazardous waste is produced, which is beneficial to the comprehensive management of hazardous waste.

Owner:CENT SOUTH UNIV

Method for selective leaching of valuable metals in laterite nickel ore by chloride salt

The invention relates to the field of wet metallurgy on nonferrous metal, in particular to a method for extracting nickel, cobalt and manganese from laterite-nickel ore.The method includes steps of crushing, grinding and sieving ore samples to obtain ore samples with the granularity of 0.074-0.15 mm under the control; dissolving chloride in hydrochloric acid to obtain hydrochloric acid and chloride solution; directly leaching the laterite-nickel ore by the aid of the hydrochloric acid and chloride solution, controlling the leaching temperatures and the leaching time, and filling the laterite-nickel ore with oxidizing gas from the bottom to enhance leaching of valuable metals and restrain leaching of contaminating metals.The method has the advantages that nickel and the cobalt which are the valuable metals can be leached, leaching of iron can be restrained, and accordingly loss of the nickel and the cobalt due to precipitates generated by the iron in leach liquor in follow-up working procedures can be prevented; the nickel leaching rate can reach 83% at least, the cobalt leaching rate can reach 72% at least, the manganese leaching rate can reach 89% at least, but the iron leaching rate is only 11-19%, and accordingly leaching of the iron can be reduced to a great extent.

Owner:湖北长宸锂能循环科技有限公司

A kind of recycling method of metal indium in waste liquid crystal screen

ActiveCN109517991BImprove qualityEliminate pollutionProcess efficiency improvementIndium(III) hydroxideIndium

The invention belongs to the technical field of circular economy, and specifically relates to a method for recovering metal indium in waste liquid crystal screens. The method uses waste liquid crystal screens as raw materials and undergoes dismantling, crushing, liquid crystal separation, acid leaching, extraction, stripping, and adjustment. Indium hydroxide is obtained in the pH value process; through supercritical acetone cleaning, fractionation, and selective leaching of metals, the pollution-free and efficient recovery of indium in waste liquid crystal screens is realized. The method of the invention has the characteristics of high efficiency, environmental protection and easy industrial production, and has remarkable economic, environmental and social benefits.

Owner:UNIV OF SCI & TECH BEIJING

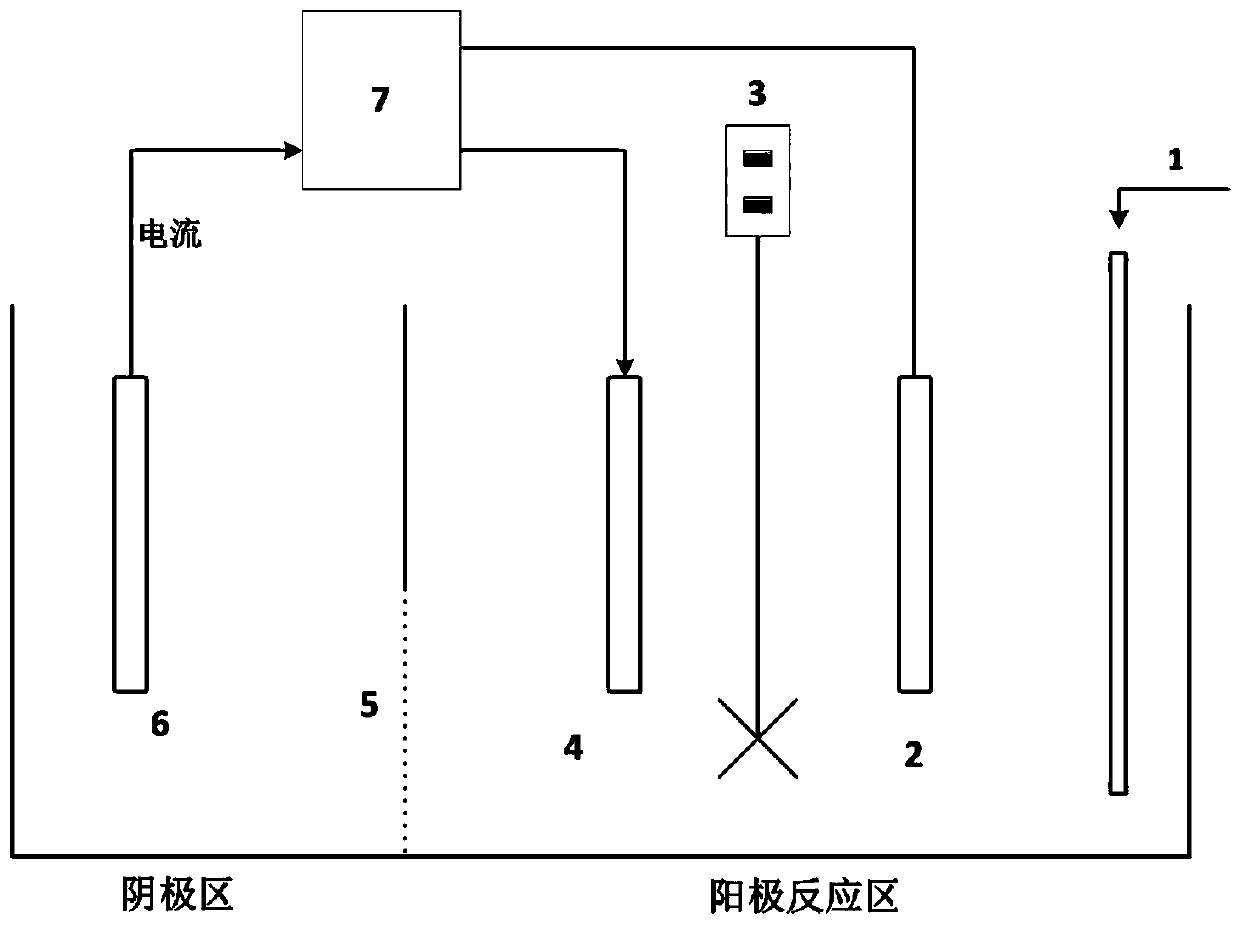

An electrochemical method and device for controlling bioleaching process

ActiveCN108239703BAchieving selective leachingReduce productionProcess efficiency improvementSelective leachingPyrite

The invention provides an electrochemical method and equipment which can control a bioleaching process. In the bioleaching process, oxidation-reduction potential of a leaching system is controlled electrochemically, pH value is maintained to be basically constant, and rapid oxidation of pyrite can be effectively controlled without influencing dissolution of a copper sulfide ore. The electrochemical method provided by the invention has the advantages that the oxidation-reduction potential in the leaching system can be accurately controlled and conditions are created for realizing selective leaching of the copper sulfide ore.

Owner:有研资源环境技术研究院(北京)有限公司

A kind of method for separating nickel copper iron from electroplating sludge

ActiveCN105779773BAchieving selective leachingPromote decompositionProcess efficiency improvementSulfonatePregnant leach solution

A method for separating nickel-copper-iron from electroplating sludge. It is characterized in that the steps are as follows: according to the electroplating sludge: sulfuric acid solution: lignosulfonate mass ratio 1:2~5:0.002~0.005, add sulfuric acid solution and lignosulfonate to the electroplating sludge, feed oxygen, When the oxygen partial pressure is 0.3~0.7MPa, the leaching temperature is 100~150℃, the pH of the leaching solution is controlled at 0.5~1.5, and the leaching time is 1~5h. Stockpile. The method of the invention is simple to operate and can realize the purpose of selectively leaching copper, nickel and other elements and separating iron in one step. The leaching rate of copper, nickel and other elements is high, and the decomposition effect is good. The method of the invention is suitable for the treatment and utilization of electroplating sludge.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

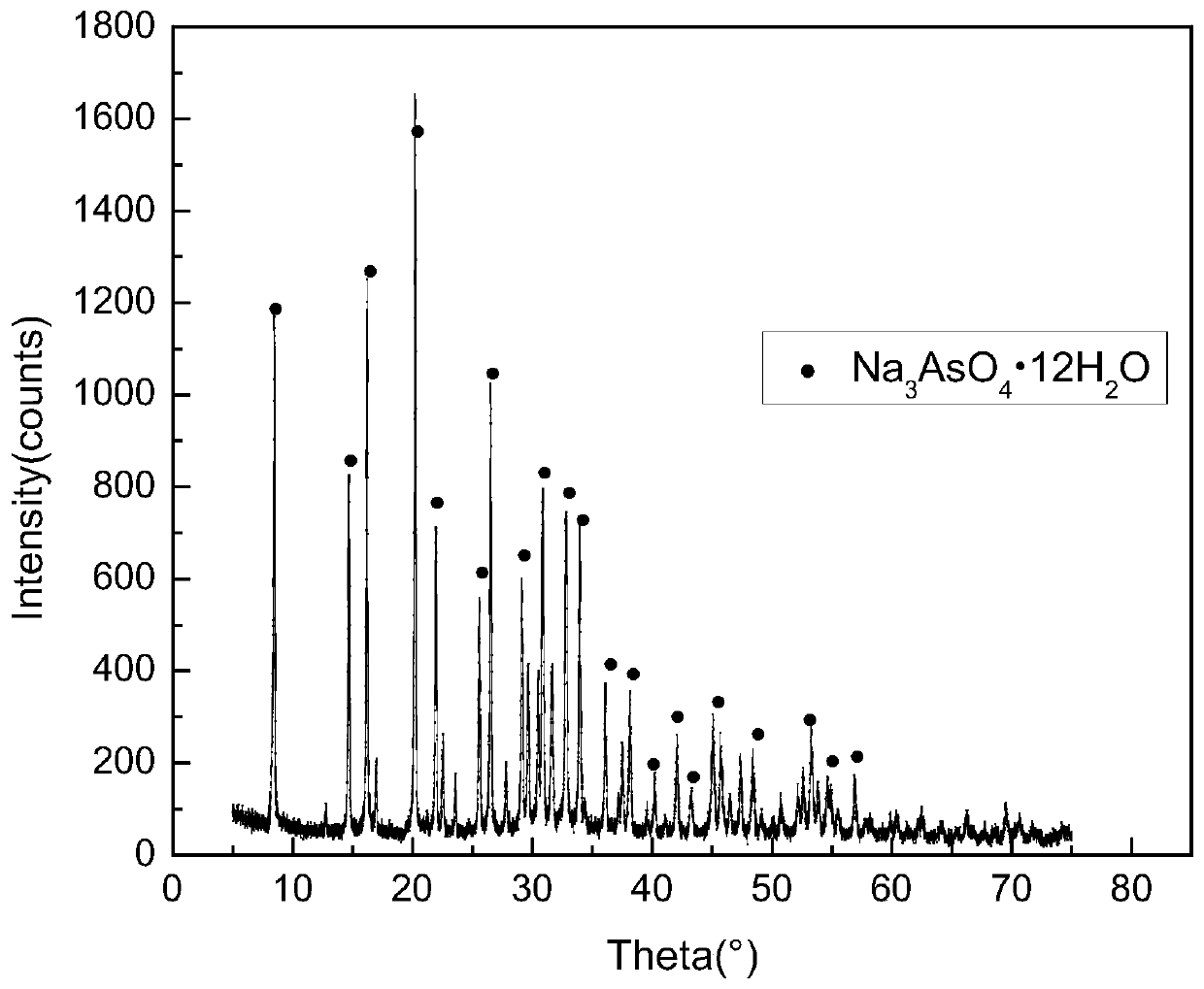

A method for extracting arsenic from arsenic-containing nickel-cobalt slag and preparing arsenate

ActiveCN108609653BEfficient selective oxidation leachingMild reaction conditionsArsenites/arsenatesProcess efficiency improvementArsenateSlag

The invention discloses a method for extracting arsenic from arsenic-containing cobalt-nickel slag and preparing arsenate. The method comprises the following steps: adding the arsenic-containing cobalt-nickel slag to aqueous alkali in a reactor to obtain slurry, introducing a gas oxidizing agent from the bottom of the slurry, and performing normal-pressure oxidation under stirring; performing solid-liquid separation to obtain filter residues and a arsenic-containing filtrate, and performing evaporative crystallization on the arsenic-containing filtrate to obtain arsenate crystals. Under the cooperative work of a stirring way, stirring speed, gas flow and a gas introducing way during oxidizing alkaline leaching, a reaction mechanism of total blending in a bath is realized. Oxidizing leaching of the arsenic-containing cobalt-nickel slag is performed by adopting cheap raw gas oxidizing agent such as air with an alkaline process, , efficient leaching can be realized under normal pressure and low temperature, technical production difficulty and technical production cost are reduced remarkably, and the method has great industrialization significance.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com