Method for directly separating nickel from copper by wet processing of low-grade nickel matte

A technology for wet processing and matte nickel is applied in the field of metallurgy, which can solve the problems of low cobalt recovery rate, high energy consumption, and large amount of material circulation, and achieve the effects of saving process cost, reducing production energy consumption, and simple process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

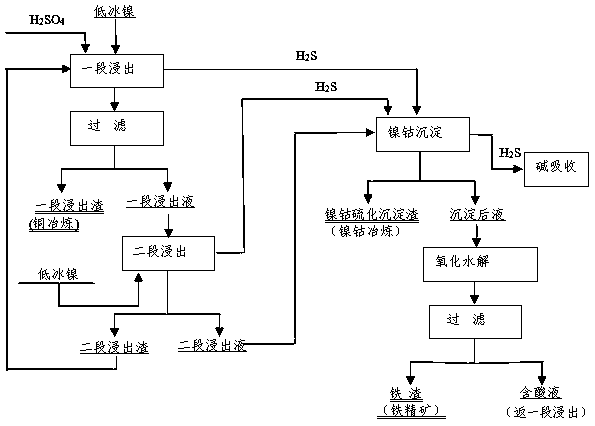

Method used

Image

Examples

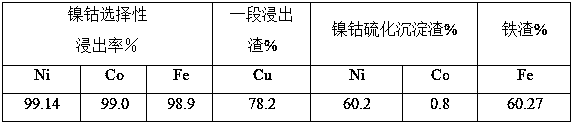

Embodiment 1

[0017] Low nickel matte, an intermediate material produced in the pyrometallurgy process of a smelter in a nickel-copper-cobalt metallurgy process, its main components account for 24.95% by mass of nickel, 17.52% of copper, 27.2% of iron, 0.42% of cobalt, and 24.96% of sulfur . The direct separation of nickel-copper by the low nickel matte wet process specifically includes the following steps:

[0018] A. One-stage leaching: use sulfuric acid to conduct one-stage countercurrent leaching of low-matte nickel with a particle size of 160 mesh. During the leaching process, the liquid-solid ratio is controlled at 4:1, the temperature is 80°C, and the time is 4 hours. After one-stage leaching, filter to obtain nickel-cobalt-iron The primary leaching solution and the primary leaching slag whose main components are copper sulfide and precious metals enter the copper smelting system.

[0019] B. Two-stage leaching: Use the first-stage leaching solution obtained from the first-stage lea...

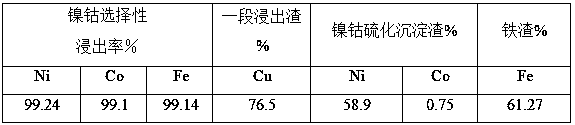

Embodiment 2

[0026] Low nickel matte, an intermediate material produced in the pyrometallurgy process of a nickel-copper-cobalt smelting process in a smelter, its main components account for 25.95% nickel, 16.52% copper, 30.2% iron, 0.50% cobalt, and 27.5% sulfur . The direct separation of nickel-copper by the low nickel matte wet process specifically includes the following steps:

[0027] A. One-stage leaching: use sulfuric acid to conduct one-stage countercurrent leaching of low-matte nickel with a particle size of 180 mesh. During the leaching process, the liquid-solid ratio is controlled at 5:1, the temperature is 90°C, and the time is 3 hours. After one-stage leaching, filter to obtain nickel-cobalt-iron The primary leaching solution and the primary leaching slag whose main components are copper sulfide and precious metals enter the copper smelting system.

[0028] B. Two-stage leaching: Use the first-stage leaching solution obtained from the first-stage leaching to carry out two-sta...

Embodiment 3

[0035] Low nickel matte, an intermediate material produced in the pyrometallurgy process of a nickel-copper-cobalt smelting process in a smelter, its main components account for 24.86% by mass of nickel, 16.4% of copper, 25.65% of iron, 0.43% of cobalt, and 25.81% of sulfur . The direct separation of nickel-copper by the low nickel matte wet process specifically includes the following steps:

[0036] A. One-stage leaching: Use sulfuric acid to conduct one-stage countercurrent leaching of low-matte nickel with a particle size of 100 mesh. During the leaching process, the liquid-solid ratio is controlled at 6:1, the temperature is 70°C, and the time is 4 hours. After one-stage leaching, filter to obtain nickel-cobalt-iron The primary leaching solution and the primary leaching slag whose main components are copper sulfide and precious metals enter the copper smelting system.

[0037] B. Two-stage leaching: Use the first-stage leaching solution obtained from the first-stage leach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com