Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

723results about How to "Reduce the discharge of three wastes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

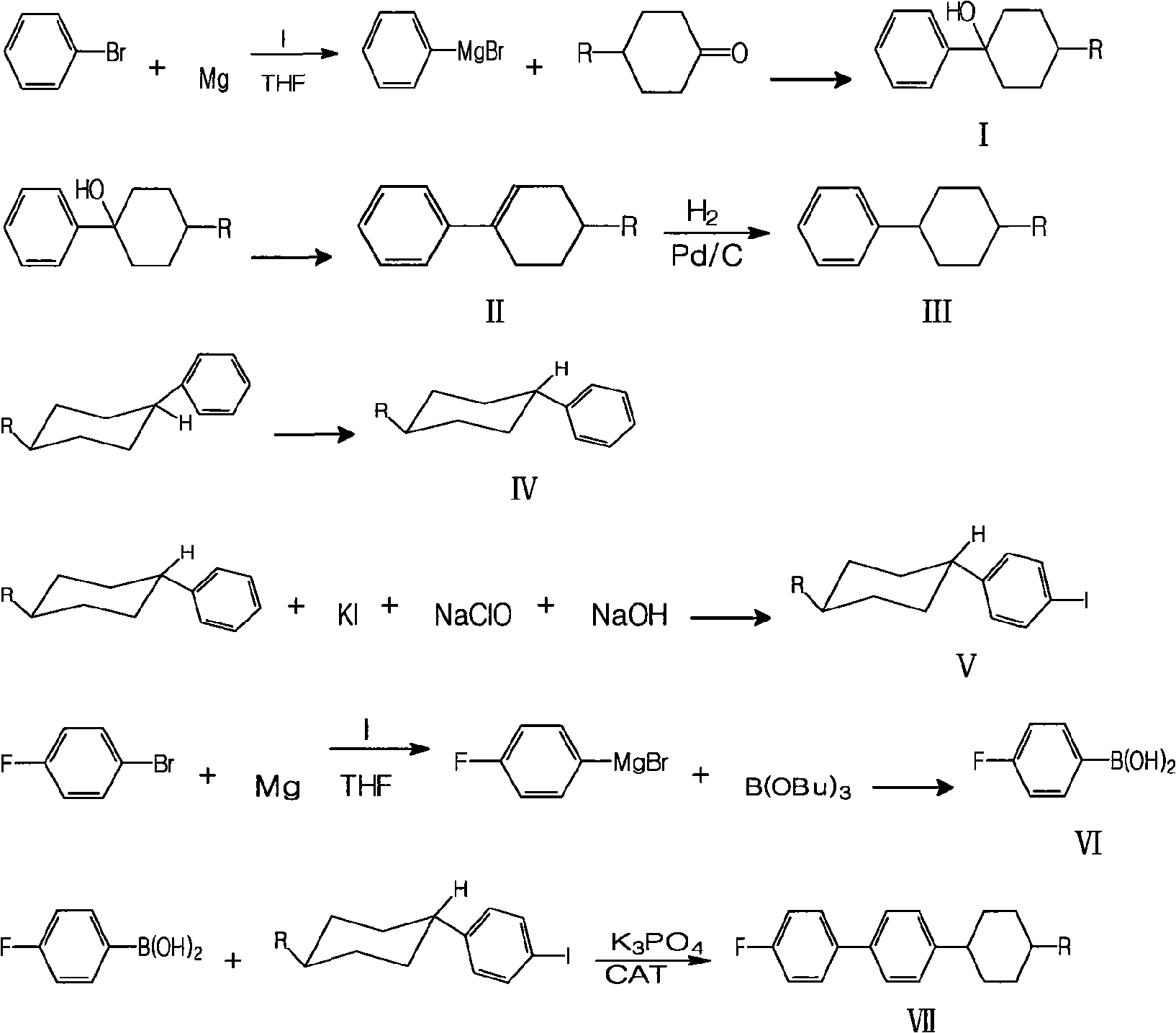

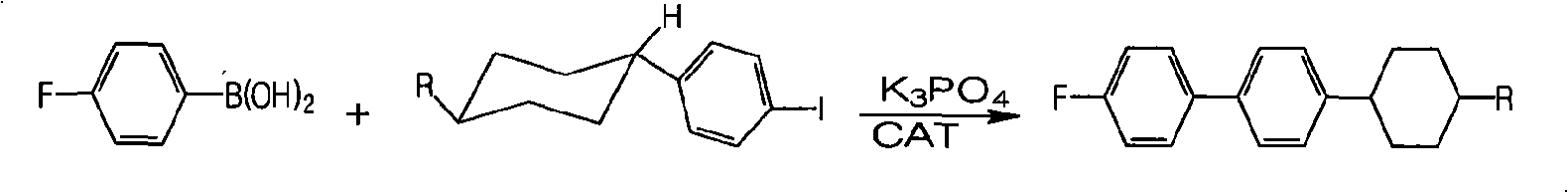

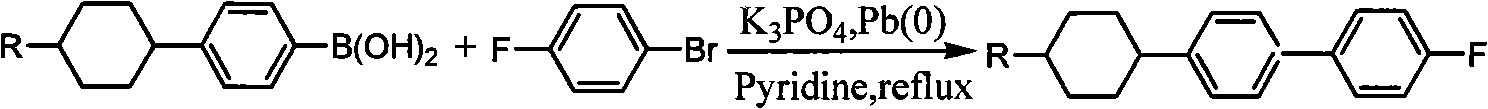

Method for synthesizing fluorine-containing antiform alkyl cyclohexyl biphenyl single liquid crystal

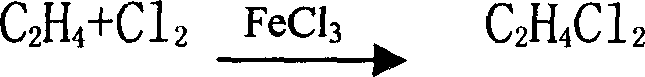

ActiveCN101560396AReduce usageHigh yieldLiquid crystal compositionsHalogenated hydrocarbon preparationCyclohexanoneIodide

The invention discloses a method for synthesizing fluorine-containing antiform alkyl cyclohexyl biphenyl single liquid crystal; in the method, bromobenzene and magnesium are selected to carry out Grignard reaction; then the reactants are coupled and hydrolyzed with alkyl cyclohexanone; dehydration, hydrogenation, transformation and iodization are carried out to synthesize alkyl cyclohexyl iodide; the Grignard reaction is carried out on fluorobromobenzene and magnesium, then low temperature coupling is carried out to synthesize p-fluoropheyl boric acid; finally, coupling reaction is carried out to synthesize the target compound; the method of the invention has the characteristics of use of highly active load catalyst, high yield, low production cost, little discharge of three wastes, reduction of generation of isomers and improvement of selectivity and yield of the target compound.

Owner:山东盛华新材料科技股份有限公司

Preparation method of amphoteric polyacrylamide dispersion liquid

The invention discloses a preparation method of amphoteric polyacrylamide dispersion liquid. The preparation method comprises the following steps: putting a main functional monomer into a mixed system comprising an amphoteric dispersion stabilizer, a chelating agent, a pH regulator and inorganic salt deionized water solution; initiating a reaction by virtue of an initiating agent; and preparing the amphoteric polyacrylamide dispersion liquid by virtue of a dispersion polymerization method. The dispersion liquid prepared by adopting a novel amphoteric polymer dispersion stabilizer has the characteristics of good stability, high molecular weight, high dissolution rate and the like, and a synthetic process of the dispersion liquid is environment-friendly and pollution-free and is low in energy consumption, and the product is nontoxic and noncorrosive, cannot generate secondary pollution and accords with the development direction of green and environment-friendly chemical assistants. The amphoteric polyacrylamide dispersion liquid has an application prospect in the fields of water treatment, papermaking, printing and dyeing, oil fields, mining, daily chemicals and the like.

Owner:JIANGSU FEYMER TECH

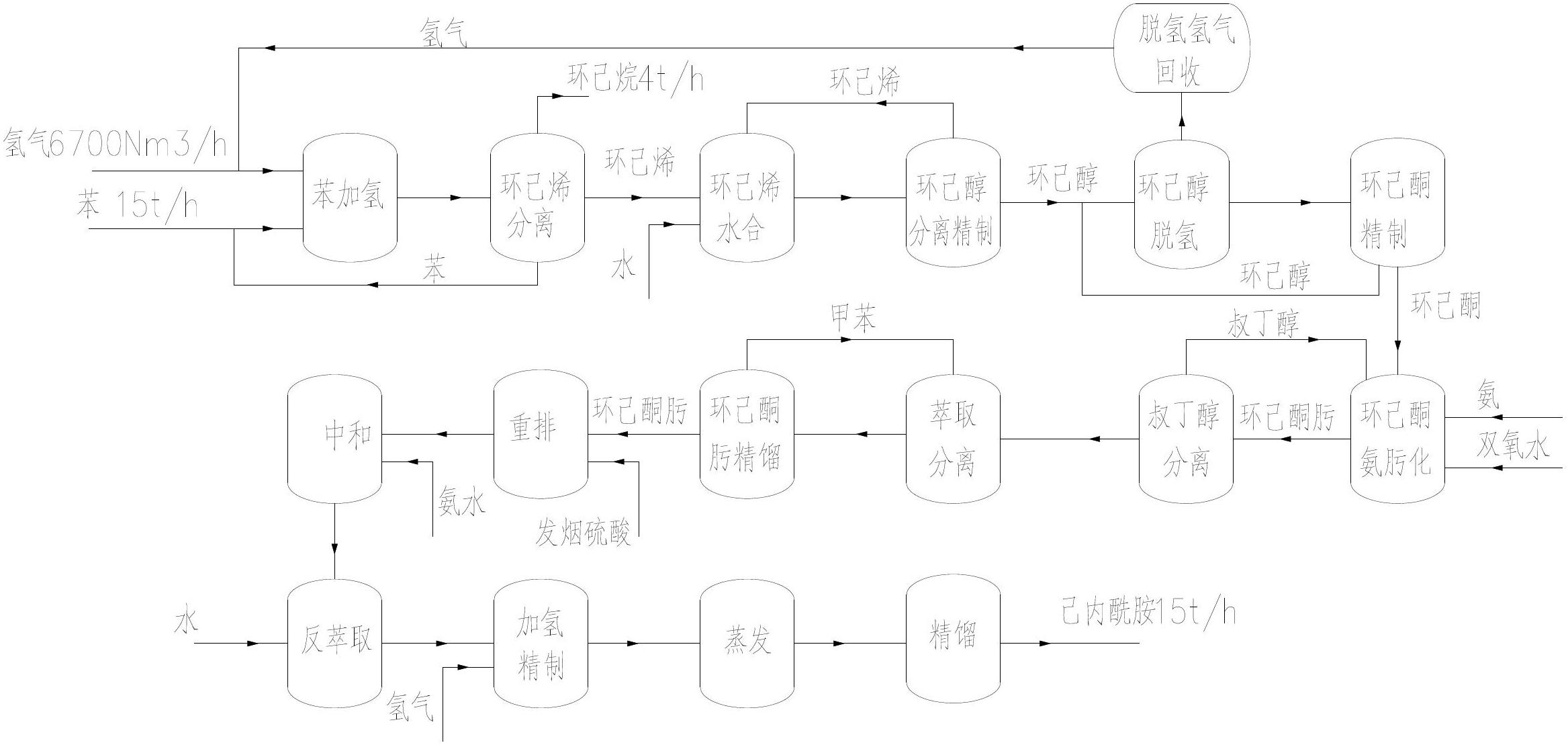

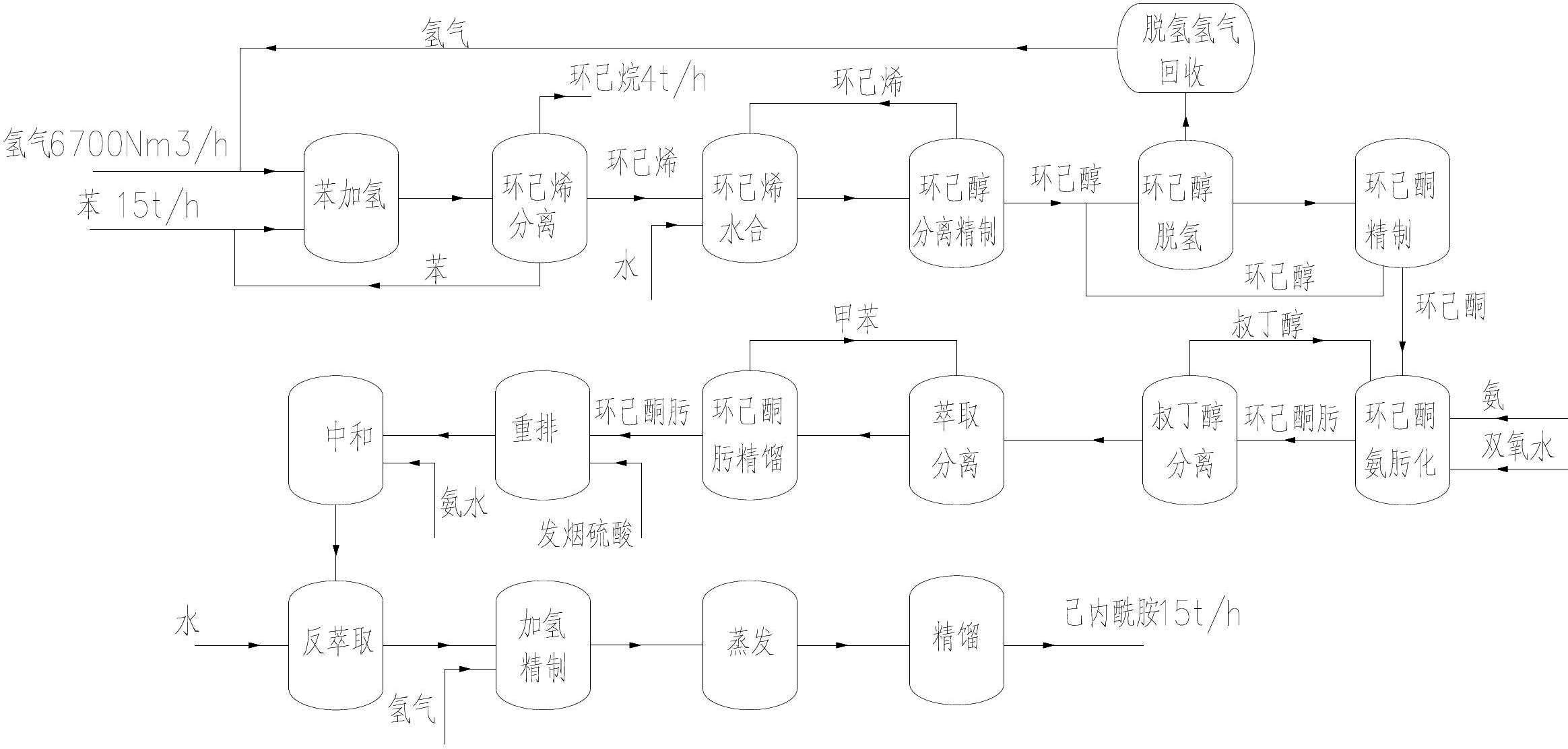

Method for producing caprolactam by taking high-purity benzene as raw material

ActiveCN102675176AAvoid it happening againQuality improvementLactams preparationHydration reactionCyclohexene

The invention provides a method for producing caprolactam by taking high-purity benzene as a raw material, and the method comprises the following steps of: A. preparing cyclohexene from the raw material benzene through hydrogenation; B. separating and purifying cyclohexene; C. carrying out hydration on the cyclohexene for preparing cyclohexanol; D. separating and purifying cyclohexanol; E. carrying out dehydrogenation on cyclohexanol for preparaing cyclohexanone; F. refining cyclohexanone; G. carrying out oximation on cyclohexanone so as to prepare cyclohexanone-oxime; H. refining cyclohexanone-oxime; I. carrying out rearrangement on refined cyclohexanone-oxime so as to prepare caprolactam; and J. refining caprolactam, wherein the high-purity benzene is adopted as a raw material, so that the purity of benzene is more than 99.95%, the sulphur content is less than 5ppm, and the methylbenzene is not more than 100ppm. The method has the beneficial effects that the high-purity benzene is adopted as a raw material, so that the impurity is less, and the product quality is high; the raw material is high in comprehensive utilization rate and low in hydrogen consumption; and the mass of the raw material and intermediate products generated in all the steps of reaction can be strictly controlled, so that the direct commercial value of the intermediate products is fully exerted, and the optimal quality of the product caprolactam can be reached.

Owner:CHINA TIANCHEN ENG +3

Novel continuous nitrification denitrating, abstraction, hydrogenation reduction production process for H acid

ActiveCN101367753ASmall footprintIncrease production capacityOrganic compound preparationSulfonic acid preparationNitro compoundReaction temperature

The present invention relates to a novel technology of continuous nitration and denitration, extraction, hydrogenation and reduction of H acid, and belongs to the technical field of H acid production. In the novel technology, H acid is prepared with liquid naphthalene through sulfonation, continuous nitration and denitration, extraction, hydrogenation and reduction, concentration, alkali fusion and separation of the H acid. The present invention not only solves the problems in the traditional technological process that the steps are more, the process is complex, the labor intensity of workers is high, the yield rate of the H acid is low and the pollution of wastewater is serious, but also eliminates the factors that the slightly inaccurate control over the reaction temperature and time of nitration and denitration can easily cause explosive polynitro compounds and thus hidden danger of security. The present invention has the advantages that the process is shortened, the byproducts are fewer, and the labor intensity is reduced. The continuous nitration and denitration has the advantages that the occupied area is small, the production capacity is high, the energy consumption is low, the yield rate is improved by 8 percent compared with the traditional process, about 1 ton of sulphuric acid is saves in production of one ton of the product, and the wastewater discharge is reduced. No iron ions are contained in the materials, the product quality of the H acid is improved, and the workshop production environment is obviously better.

Owner:CHUYUAN HIGH NEW TECH GRP

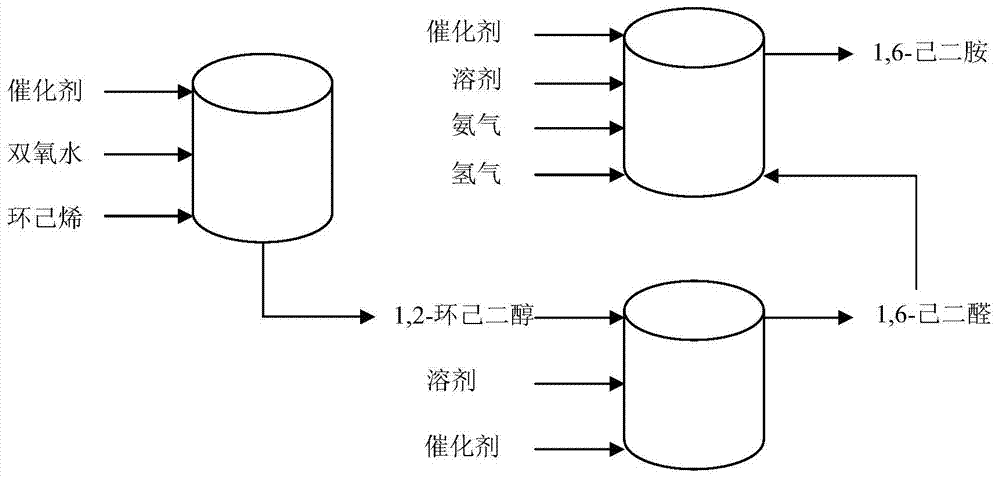

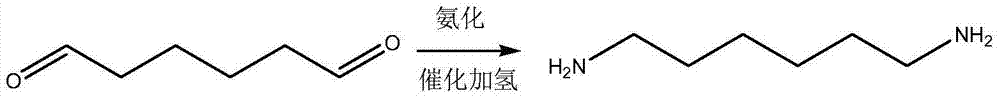

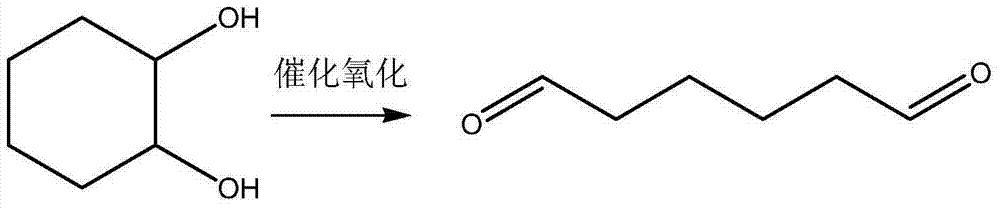

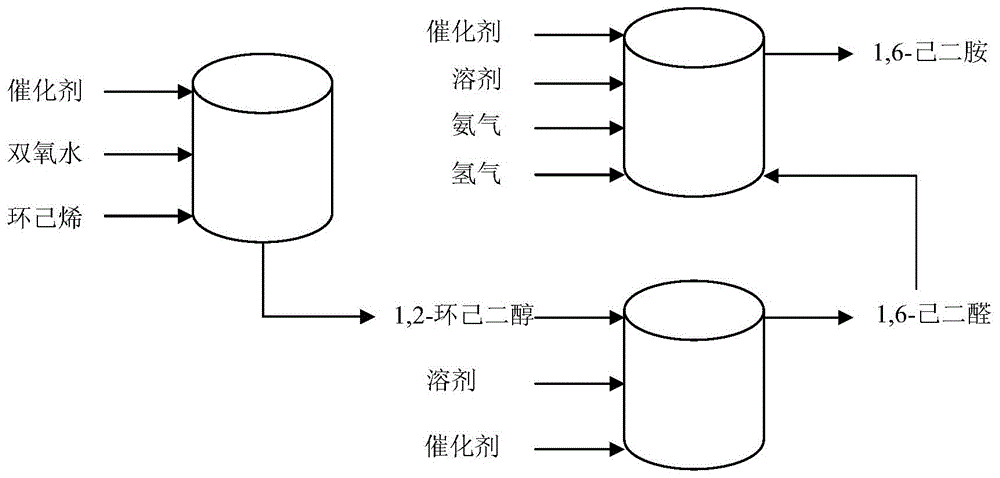

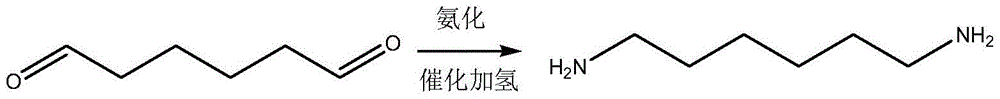

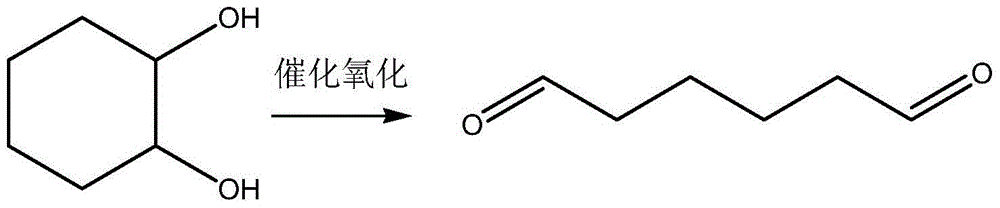

Preparation method of hexamethylenediamine

ActiveCN104262168AEasy to separateHigh catalytic activityPreparation by reductive alkylationHexamethylenediamineEnergy consumption

The invention discloses a preparation method of hexamethylenediamine. The method is used for preparing 1, 6-hexamethylenediamine by virtue of carrying out ammoniation and catalytic hydrogenation on 1, 6-adipaldehyde. The method is simple in process, low in cost, high in yield, low in energy consumption and free from industrial three wastes.

Owner:BEIJING RISUN TECH CO LTD

Use of southernwood extract as plant growth regulator and adverse-resistant agent

InactiveCN101258861AMake up for the defect of single ingredientAdjustable growthBiocidePlant growth regulatorsSOUTHERNWOOD ExtractAmbrosia artemisiifolia extract

The invention relates to a control agent and an anti-adversity agent of plant growth, which adopts southernwood, a Chinese traditional medicine, namely Artemisia annua L, as raw material, or adopts the secondary substances (also containing small amount of the artemisinin which is not completely extracted) which are abundant in the large amount of residues and concentrated mother solution after artemisinin is extracted by organic solvent. On the one hand, the invention does not influence the extraction of the artemisinin used for pharmaceuticals, on the other hand, the invention enhances the added value of the products of the southernwood, turns wastes into benefits and is good for environment protection and green production. The product of the invention is characterized by wide physiological effect, being safe and innoxious, being no pollution, being environment-friendly, easy obtaining of raw materials and low cost.

Owner:SOUTHWEST UNIV

Method for comprehensively recovering copper and indium from lead matte

ActiveCN104357661AAchieving selective leachingAchieve separationProcess efficiency improvementOxygenBall mill

The invention discloses a method for comprehensively recovering copper and indium from lead matte. The method comprises the following steps: A, crushing lead matte block materials and then ball-milling to obtain lead matte powder; B, leaching the lead matte powder obtained by ball-milling in an autoclave by using sulfuric acid and continuously introducing oxygen in the leaching process; C, after leaching, carrying out solid-liquid separation to obtain leaching residues and leachates containing copper ions and indium ions; D, selectively extracting the copper ions in the leachates by using ZJ988, obtaining copper sulfate enrichment liquid by using a sulfuric acid-copper sulfate solution to perform reverse extraction on loaded organic phase, taking the copper sulfate enrichment liquid as an electrolyte of electro-deposit copper and obtaining cathode copper through a copper sulfate electro-deposition process; E, selectively extracting the indium ions by using P204, then obtaining indium chloride enrichment liquid by using a hydrochloric acid solution to perform reverse extraction on the loaded organic phase and replacing the indium chloride enrichment liquid by using a zinc plate or an aluminum plate to obtain sponge indium. The method has the benefits that the complete separation of the copper from the indium in the lead matte is realized, recovery rate of the valuable metal is high, and the environmental friendliness is realized.

Owner:YUNNAN COPPER CO LTD +1

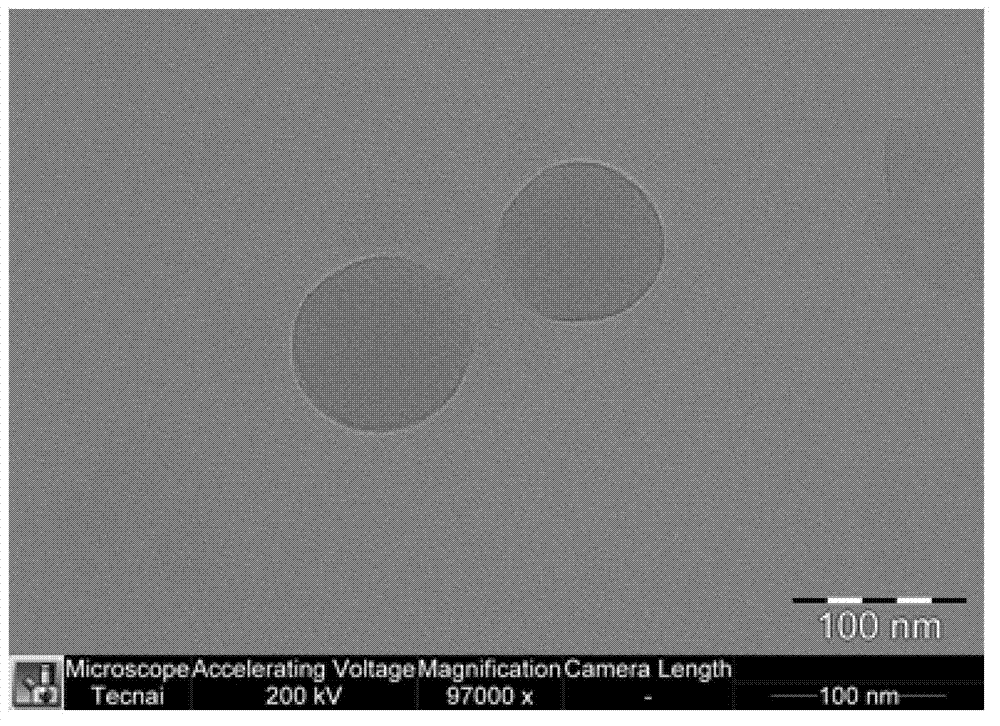

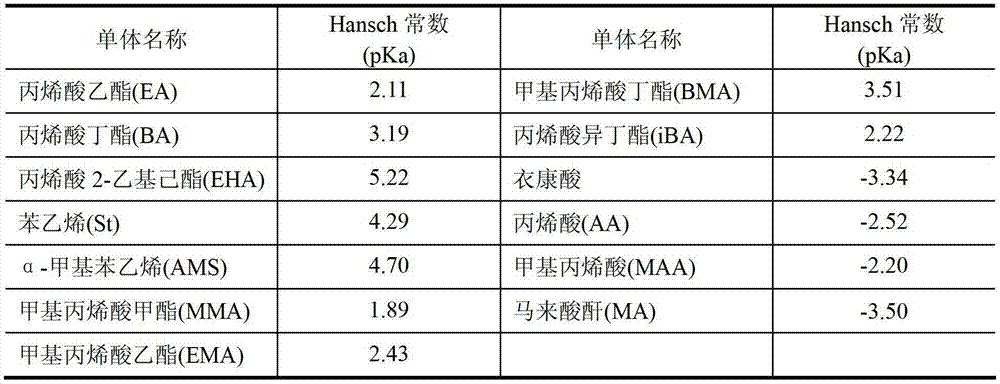

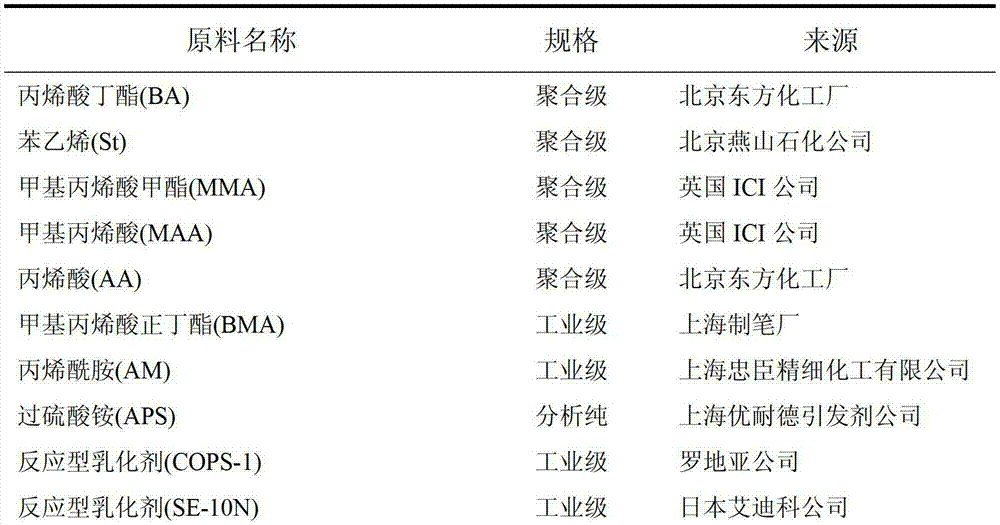

Method for preparing pure acrylate copolymer coating emulsion for building external wall elastic coating

ActiveCN103193917ASmall particle sizeNarrow distributionAntifouling/underwater paintsPaints with biocidesButyl acrylateEmulsion

The invention discloses a method for preparing a pure acrylate copolymer coating emulsion for a building external wall elastic coating, including a preparation method of a seed emulsion, a pure acrylate type elastic emulsion prepared from the seed emulsion and a preparation method thereof, as well as an elastic coating prepared from the elastic emulsion added with auxiliaries, a filler and the like, wherein the ratio (by wt) of comonomers St:MMA:BMA:BA of the copolymer of the seed emulsion is (32-42):(18-27):(18-27):(12-22); the hansch constant of the polymer of the seed emulsion is 3.00-3.81 pKa; and the elastic emulsion is obtained through seed polymerization of a monomer mixture which is composed of acrylic acid (AA), acrylamide (AM), butyl acrylate (BA), methyl methacrylate (MMA) and n-butyl methacrylate (BMA) in a monomer ratio (wt) of (0.8-5):(0.8-5):(25-45):(7-33):(7-33). As the elastic coating prepared from the pure acrylate type elastic emulsion prepared by the method provided by the invention is obviously improved in properties such as stain resistance, weather fastness, low-temperature elasticity, adhesiveness, water tolerance and the like, the elastic coating can be used as an external wall decorative coating high in requirement for durability and thus can be widely applied to the field of building coating.

Owner:HENGSHUI XINGUANG CHEM

Synthesis method of 5-bromo-2-chloro benzoic acid

ActiveCN105622382AEasy to operateHigh purityOrganic compound preparationCarboxylic compound preparationBenzoic acidChlorobenzilate

The invention provides a synthesis method of 5-bromo-2-chloro benzoic acid.The method includes the following steps of A, making 2-chlorine benzotrichloride and bromide reagents react under the effect of a catalyst to obtain 2-chloro-5-bromine benzotrichloride, wherein bromide reagents include one or more of bromine, N-bromosuccinimide, dibromohydantoin and hydrobromic acid; B, conducting hydrolysis reaction on 2-chloro-5-bromine benzotrichloride in the step A under the acid condition to obtain 5-bromo-2-chloro benzoic acid.According to the method, 2-chlorine benzotrichloride which is low in price and easy to obtain is adopted as the raw material, operation is easy, intermediates do not need to be purified, 5-bromo-2-chloro benzoic acid is synthesized through a one-pot method, purity is high, yield is high, three-waste emission is little, and production cost is low.It is shown through experiment results that 2-chloro-5-benzoic acid obtained according to the synthesis method has yield larger than 95% and purity of 80-92%.

Owner:苏州正济药业有限公司

Method for preparing polyol by using bio-oil and application

ActiveCN104341297AWide variety of sourcesPromote degradationOrganic compound preparationPolyureas/polyurethane adhesivesPtru catalystPotassium fluoride

The invention discloses a method for preparing polyol by using bio-oil. The method comprises the following steps: firstly performing methyl esterification, namely, performing ester exchange on biolipid and methanol under the catalysis of potassium fluoride loaded magnesium oxide solid alkali, converting the obtained product into fatty acid methyl ester with small molecular weight and byproduct glycerol, filtering to recycle the catalyst, and separating lower-layer glycerol; performing epoxidation on upper-layer fatty acid methyl ester in 30% of hydrogen peroxide under the catalysis of ionic liquid so as to form epoxidized fatty acid methyl ester.; then adding the glycerol in the methyl esterification process, continuously performing alkoxide ring-opening under the catalysis of ionic liquid, introducing hydroxyl, and finally separating liquid to recycle the ionic liquid catalyst, reducing pressure and distilling the upper-layer to remove water so as to obtain low-viscosity bio-oil-based polyol. The raw material is easily available, recyclable and good in biodegradability, the preparation process is environmental friendly, the industrial three-waste emission is small, the product structure and a hydroxyl value are adjustable, the application range is wide, and the environment influence level is low.

Owner:ZHEJIANG HENGFENG NEW MATERIAL

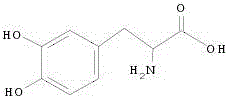

Trosine phenol lyase engineering bacteria as well as construction method thereof and application thereof

The invention relates to trosine phenol lyase engineering bacteria as well as a construction method thereof and application thereof. A tyrosine phenol lyase gene is constructed to express plasmids; chaperonin is introduced to express the plasmids to obtain the trosine phenol lyase engineering bacteria which are identified as escherichia coli FPLF8 (Escherichia coli HPLF8) preserved in China Center for Type Culture Collection on February 19, 2016, with a preservation number being CCTCCNO:M 2016065. The engineering bacteria can be synthesized into levodopa by fermentation and conversion, and are efficiently expressed; the expressed product is stable and high in activity, and can be synthesized into levodopa by conversion in the presence of related substrates; and the process is simple, the cost is low, the yield is high, emission of three wastes is a little, and the application value for industrial production is achieved.

Owner:ZHEJIANG UNIV OF TECH +2

Preparation method of solid phase synthesis cetrorelix

ActiveCN101284863AConvenient sourceReduce usagePeptide preparation methodsBulk chemical productionFreeze-dryingSide chain

A method for realizing the solid phase synthesis of cetrorelix comprises the following steps that: Fmoc-Linker-MBHA-Resin is used as a starting raw material and is connected in turn with amino acid with Fmoc-protecting groups according to a solid phase synthesis method, so as to obtain protective decapeptide resin; meanwhile, the Fmoc-protecting groups are divested in turn; one sort of HBTU / HOBT or DIC / HOBT is used as condensing agent to carry out synthesized peptide, thereby obtaining protective decapeptide resin; acetylation reaction is carried out, and then protecting group side chain divesting and peptide cutting are carried out synchronously to obtain cetrorelix acetate which is separated and purified through C18 or C8 chromatographic column; finally, cetrorelix acetate acetate or trifluoroacetate is obtained after freeze drying.

Owner:滨海吉尔多肽有限公司

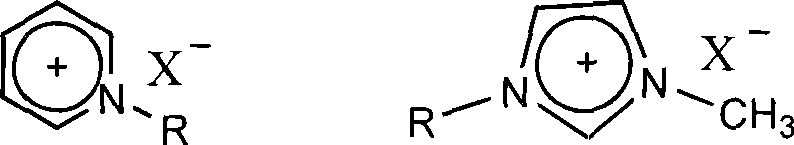

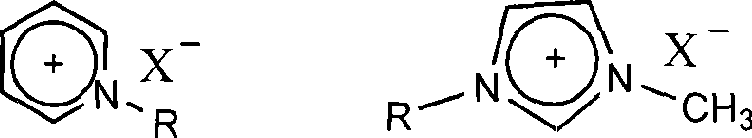

Chemical recovery method for waste polycarbonate material in ionic liquid surrounding

InactiveCN101429100ARelaxed reaction conditionsReduce the discharge of three wastesOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSolubilityHigh concentration

The invention relates to a novel method for generating bisphenol A and dialkyl carbonate by chemical degradation of waste polycarbonate (PC) to realize chemical recycling of the bisphenol A and the dialkyl carbonate. The method is characterized in that reusable ionic liquid such as chloridized 1-allyl-3-methylimidazole and bromized 1-butyl-3-methylimidazole is taken as a reaction medium and catalyst, and subjected to hydrolysis reaction or alcoholysis reaction at a temperature of between 60 and 170 DEG C; after reaction is over, bisphenol A products are obtained after extraction, distillation and other operations (as for alcoholysis reaction, the dialkyl carbonate is obtained simultaneously); reclaimed ionic liquid is directly reused without any treatment; and the yield of the bisphenol A is more than 93 percent. Compared with the prior art, the method has the characteristics that: firstly, the method overcomes the defects in the prior art that high-concentration inorganic strong acid / strong alkali is applied and can not be recycled; and secondly, due to adoption of the ionic liquid which has certain solubility on the PC as the reaction medium and the catalyst, the method relieves the reaction conditions on one hand and can realize reutilization of the ionic liquid on the other hand, and obviously solves the problems of equipment corrosion and environmental pollution.

Owner:QINGDAO UNIV OF SCI & TECH

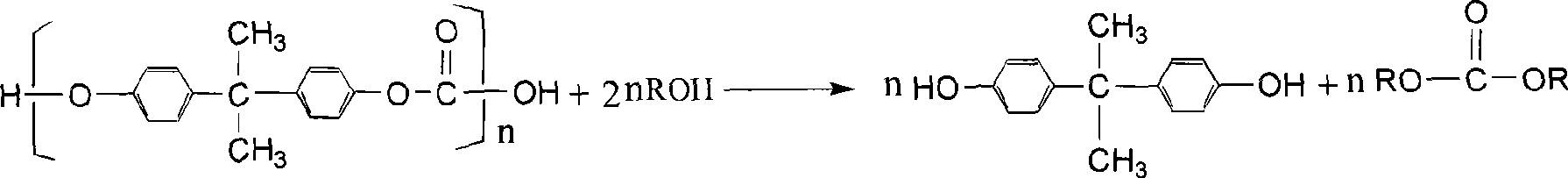

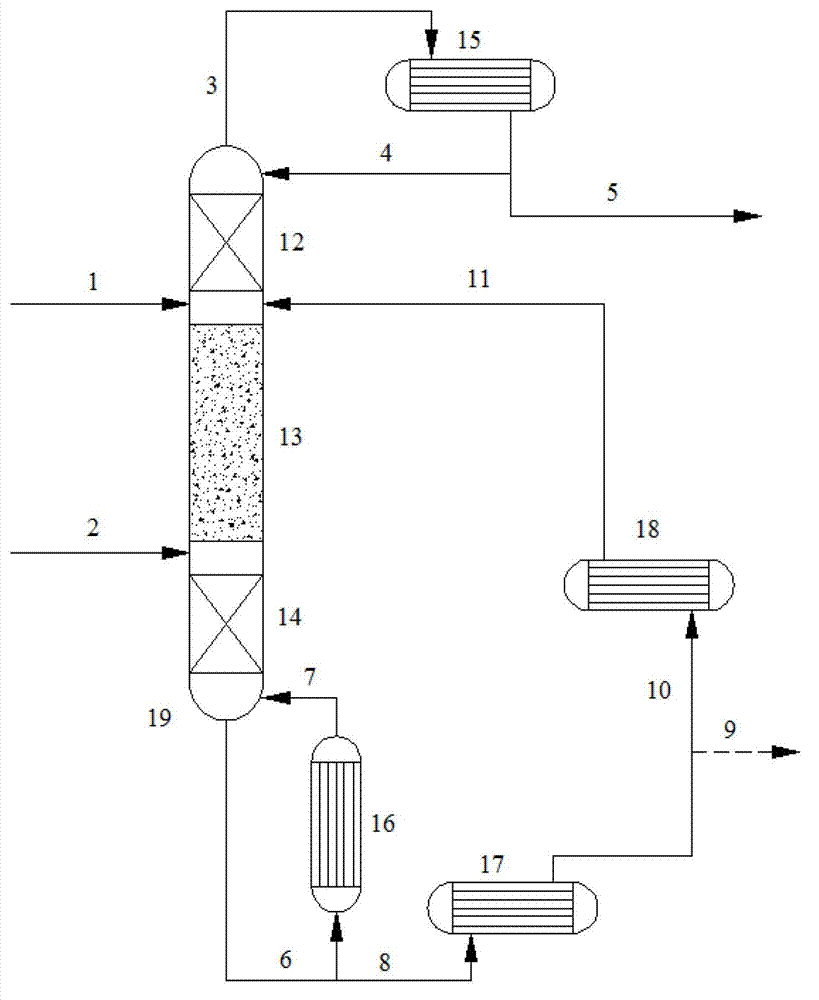

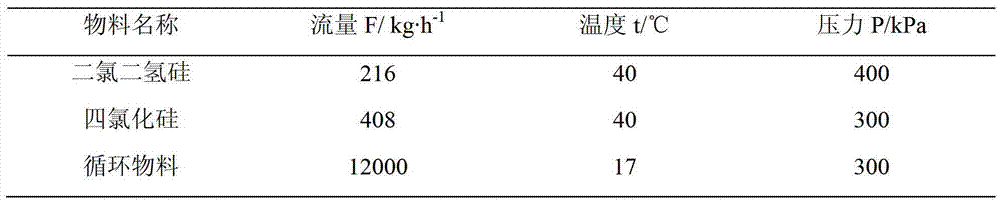

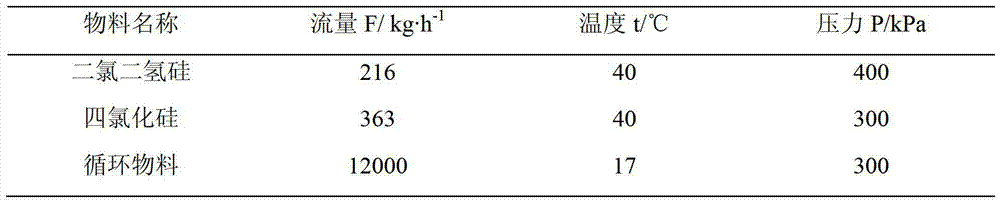

Method and device for treating dichlorosilane waste by utilizing reactive distillation

ActiveCN103086380AHigh yieldIncrease productionChemical industryHalogenated silanesReboilerReactive distillation

The invention relates to a method and a device for treating dichlorosilane waste by utilizing reactive distillation. A reactive distillation tower is divided to three segments, namely a distillation segment, a reaction segment and a stripping segment, wherein a tower top condenser is arranged on the top of the reactive distillation tower; a tower bottom reboiler is arranged at the bottom of the reactive distillation tower; a cooler is arranged at the bottom of the reactive distillation tower; an inlet of the cooler is connected with a tower bottom material outlet through a pipeline; an outlet of the cooler is connected with an inlet of a low-temperature cooler; and an outlet of the low-temperature cooler is connected to the reactive distillation tower through a pipeline. Raw materials silicon tetrachloride and dichlorosilane respectively enter the reactive distillation tower from the top and the bottom of the reaction segment to generate a disproportionated reaction in the reaction segment so as to produce trichlorosilane, and the trichlorosilane is continuously moved out of the reaction segment under the action of distillation separation; and the silicon tetrachloride in the materials of the tower returns back to the reactive distillation tower through external circulation from the top of the reaction segment so as to further react, and therefore the conversion rate of the reaction can be improved. The conversion rate of the dichlorosilane can achieve 98.50% and the purity of the trichlorosilane in the materials on the top of the tower can achieve 98.48%.

Owner:TIANJIN UNIV

Method for preparing teriparatide by fragment method and solid-liquid combination

InactiveCN105384809AHigh purityAvoid formingPeptide preparation methodsParathyroid hormonesDipeptideTarget peptide

The invention belongs to the field of polypeptide synthesis, relating to a method for preparing teriparatide by solid-liquid combination. The method adopts a liquid phase mode to synthesize a part of dipeptide and tripeptide fragments, feeding is performed by the synthesized dipeptide and tripetide fragments, 13 steps of solid phase coupled reaction are reduced, the coupling efficiency is greatly improved, not only is the generation of racemization impurities difficult to be purified and removed at the 34th site tail end avoided, but also the generation of missing peptides at multiple sites is avoided, and the purity of the final target peptide reaches 75 percent or more. Compared with the prior art, the method provided by the invention is simple in synthetic route, less in solid phase coupling steps, mainly solves the problems that a peptide sequence is too long and coupling is difficult, and that the missing peptides are easily generated, the fragment synthesis technology is well developed, the materiel cost is lowered, and the industrialized mass production can be carried out.

Owner:JINAN KANGHE MEDICAL TECH

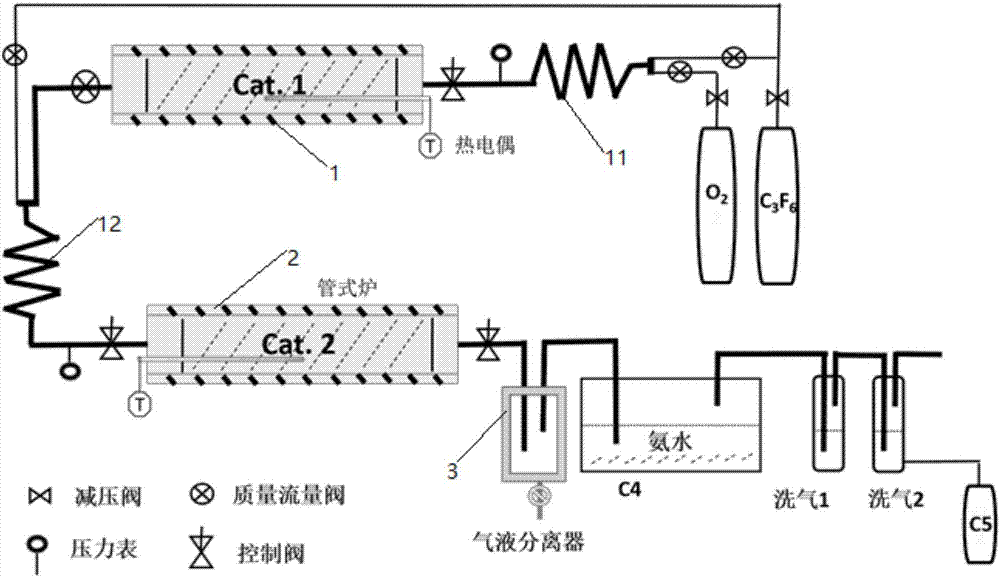

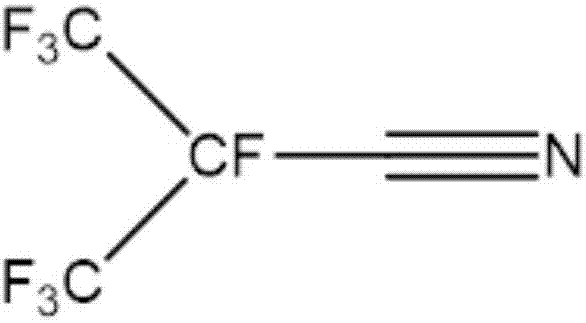

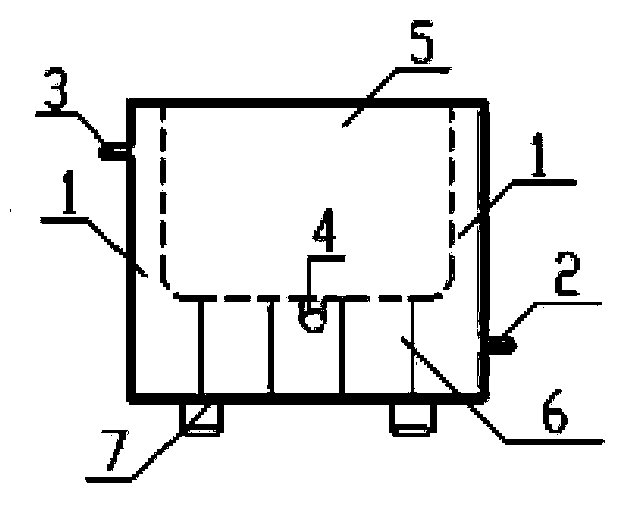

Environmentally-friendly insulating gas combined production technology and industrial production device thereof

ActiveCN106946669AReduce manufacturing costReduce the discharge of three wastesOrganic compound preparationCarboxylic acid amides preparationFixed bedProcess engineering

The invention discloses an environmentally-friendly insulating gas combined production technology and an industrial production device thereof. The combined production technology comprises the following steps: 1, carrying out a contact reaction on oxygen and HFP in a first fixed bed reactor under a catalyst condition or a catalyst-free condition; 2, mixing a gas product flowing out of the first fixed bed reactor with the HFP, allowing the gas product and the HFP to enter a second fixed bed reactor, and carrying out a contact reaction in the second fixed bed reactor under the action of a catalyst; and 3, carrying out separation on the effluent of the second fixed bed reactor to prepare a C5 product and a C4 product. Combined production of two novel environmentally-friendly insulating gases is realized from cheap raw materials comprising perfluoropropylene and oxygen at an atom economy of 80-90%, so the production cost is greatly reduced, and the discharge of three wastes in the production process is reduced.

Owner:STATE GRID CORP OF CHINA +3

Method and equipment for producing C4-C6 diacid low-carbon alcohol ester

InactiveCN101735049AResolution timeSolve the problem of energy consumptionOrganic compound preparationCarboxylic acid esters preparationAlcoholHigh energy

The invention belongs to the chemical field, in particular to method and equipment for producing C1-C2 low-carbon alcohol ester of C4-C6 diacid. The method is characterized by comprising the following steps of: adding a catalytic agent, C4-C6 diacid and C1-C2 alcohol to a dispensing kettle, stirring and heating to enable the solid diacid to be dissolved; and then continuously delivering feed liquid to an esterification reactor to carry out esterification reaction under the conditions of a certain pressure, a certain reaction temperature and the like; continuously delivering an obtained esterification reaction mixture to a flash evaporator for flash evaporation; separating out unreacted alcohol and generated water from the upper part of the flash evaporator; discharging the product ester and unreacted raw material acid from the lower part of the flash evaporator; and then rectifying to obtain the C1-C2 alcohol ester of the C4-C6 diacid. The invention has the characteristics of low energy consumption and continuous esterification production, and aims to solve the problems existing in the aspects of long time, high energy consumption and the like in the esterification reaction for traditionally producing the C1-C2 low-carbon alcohol ester.

Owner:SHENYANG POLYTECHNIC UNIV

Synthesis of ester ether compound with high acidolysis activity

InactiveCN1347869AReduce the discharge of three wastesSlow responseOrganic compound preparationCarboxylic acid esters preparationSolventActive point

The ester ether compound with high acidolysis activity is synthesized through the reaction between benzil acid (2,2-diphenyl glycolic acid) and phenols, each of which has at residual active point in its benzene ring, in the presence of p-toluene sulfonic-acid catalyst in 0.1-2 % and methyl benzene, dimethyl benzene and other benzene compound as solvent to synthesize a serial addition compound of benzil acid and phenols which may be further dewatered to produce lactone compound; and the etherification of the said addition compound or the lactone compound the ether compound, such as vinyl ethylether, dihydropyran, dihydrofuran, dihyidropyrrole, etc. at below 70 deg.c. The ester ether compound may be used as photothermal imaging information record material.

Owner:BEIJING NORMAL UNIVERSITY

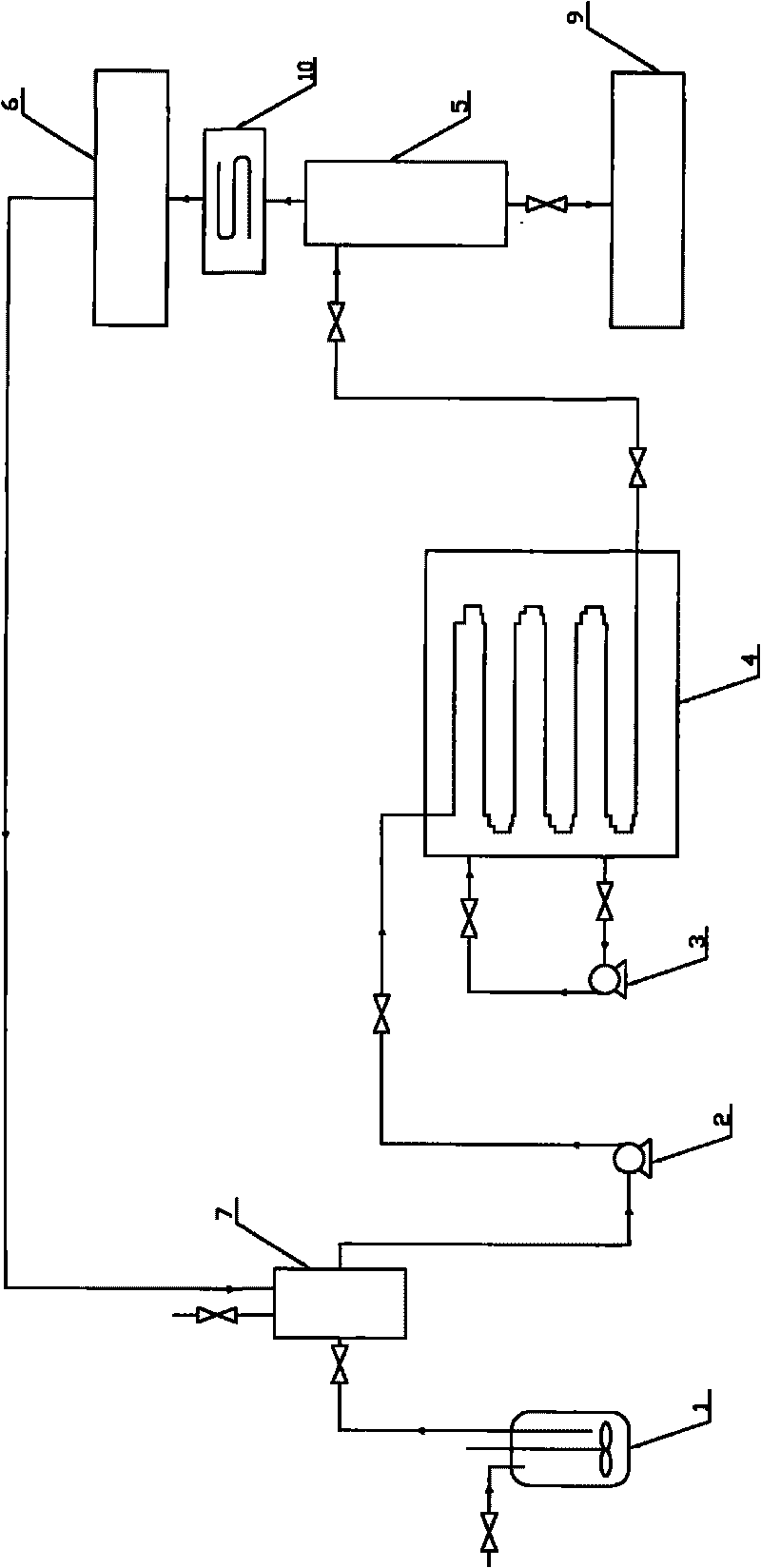

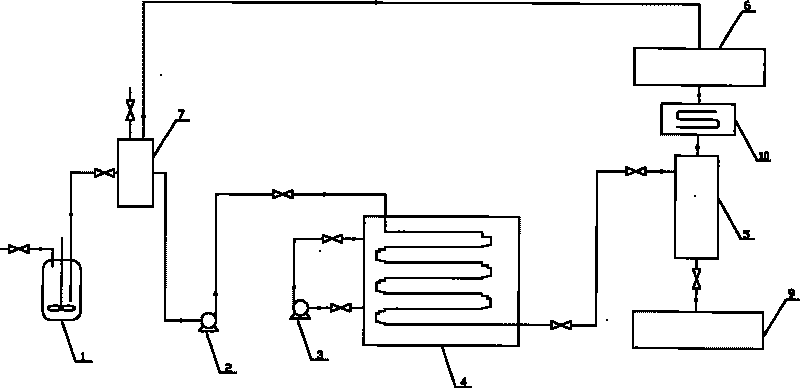

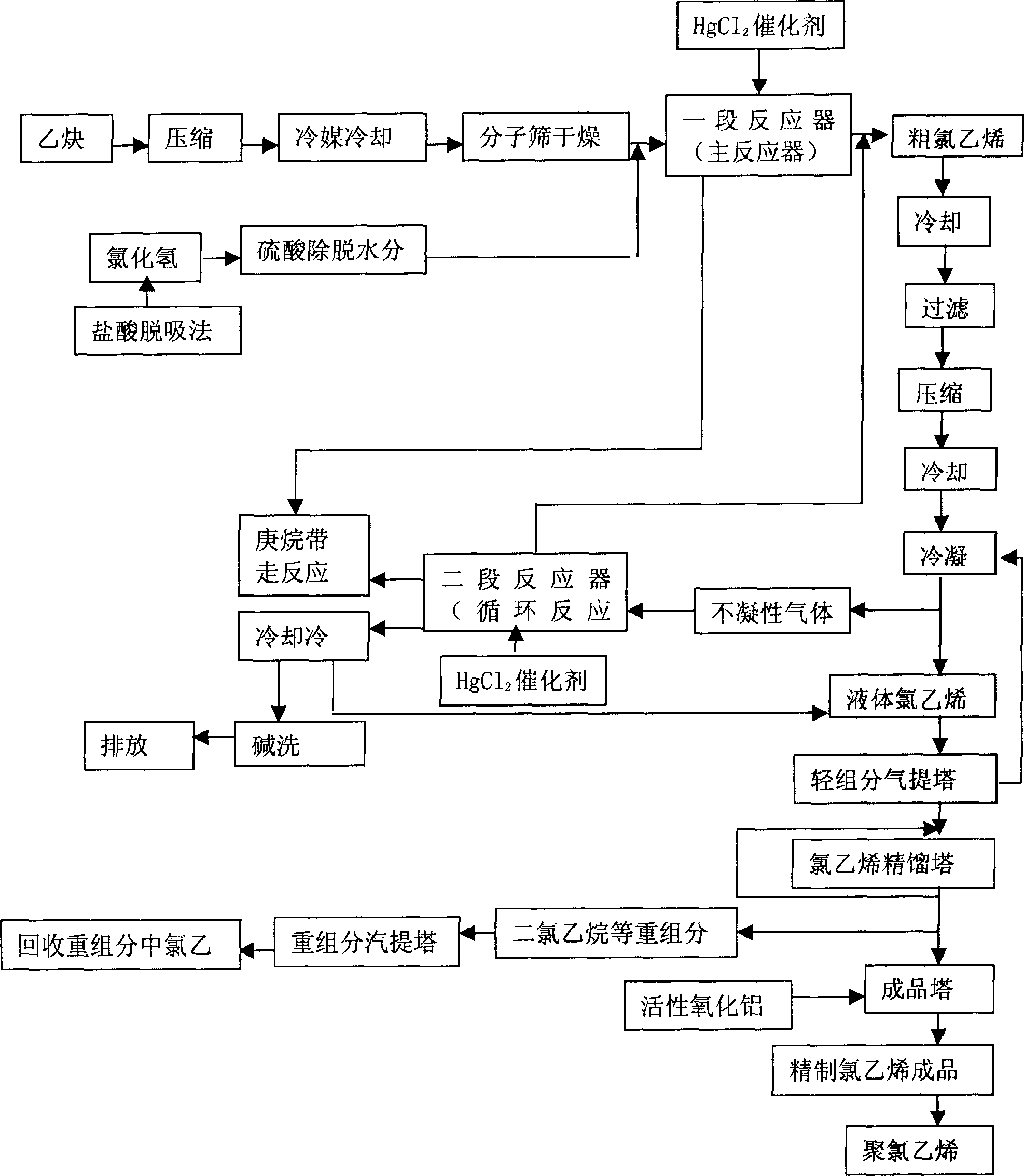

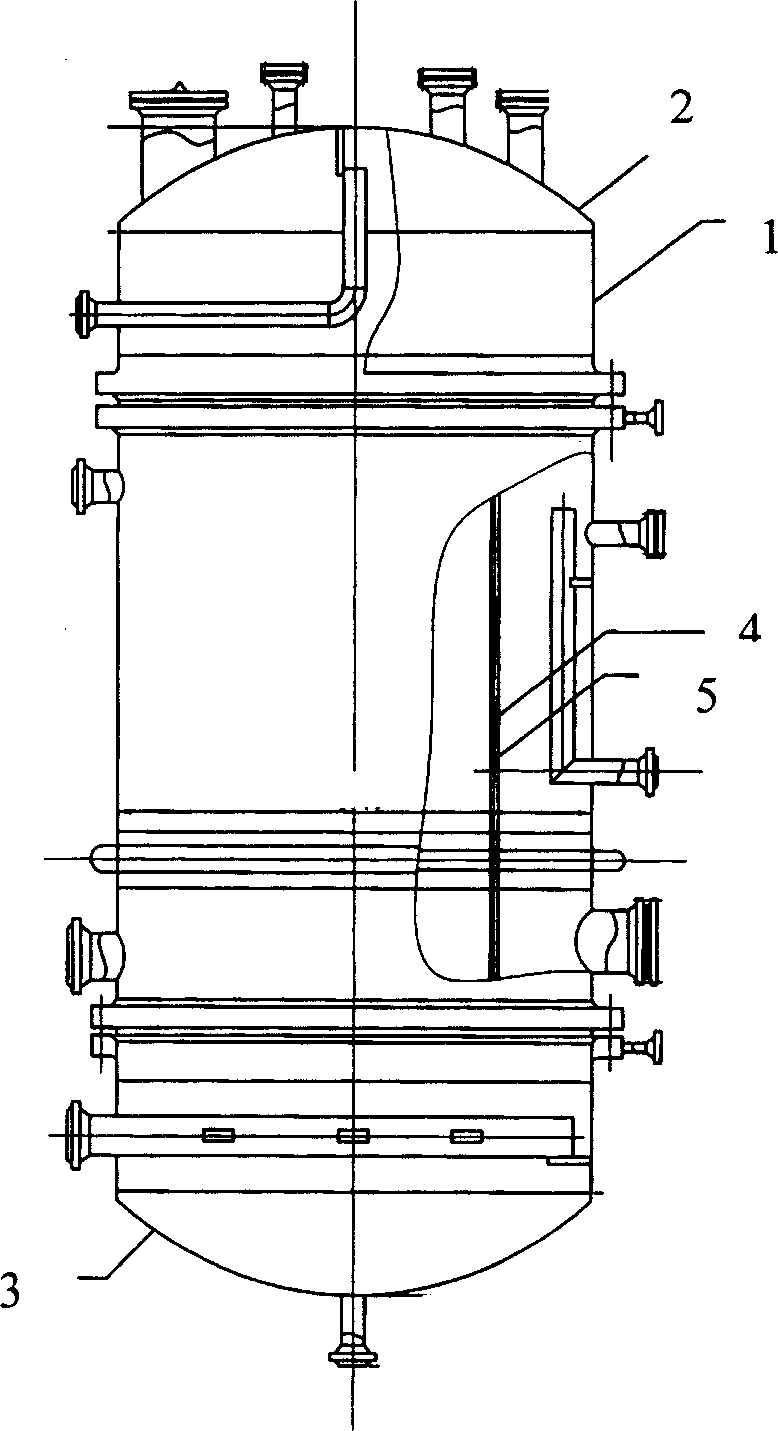

Process for producing vinyl chloride by acetylene method and dedicated device for realizing same

InactiveCN1884241ASmooth responseAvoid corrosionPreparation by halogen halide additionSewage treatmentUltimate tensile strength

The invention discloses a new method of chloroethylene through acetylene method and specific equipment, which comprises the following steps: disposing raw material gas strictly; reacting two-segment compensation; recycling heptane; cooling; radiating; providing specific catalyst and reactor to synthesize chloroethylene; disposing effluent with mercury to obtain high-purity chloroethylene monomer.

Owner:刘大军

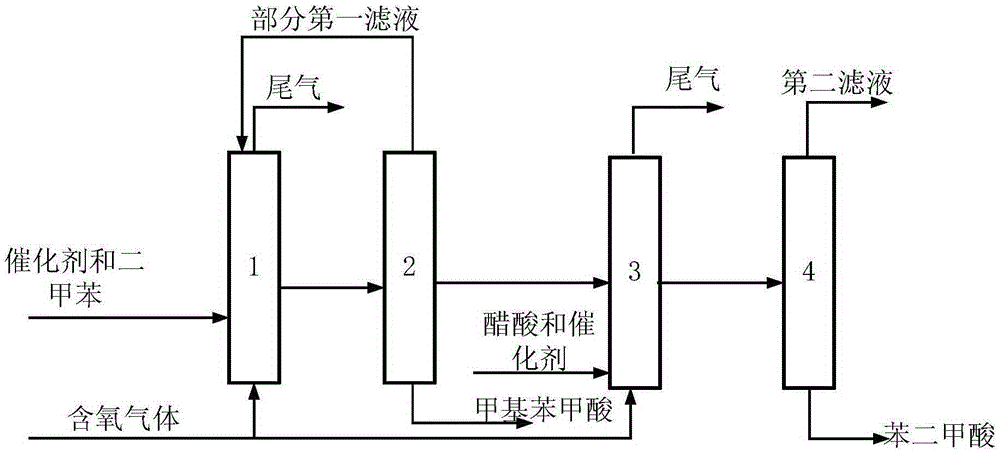

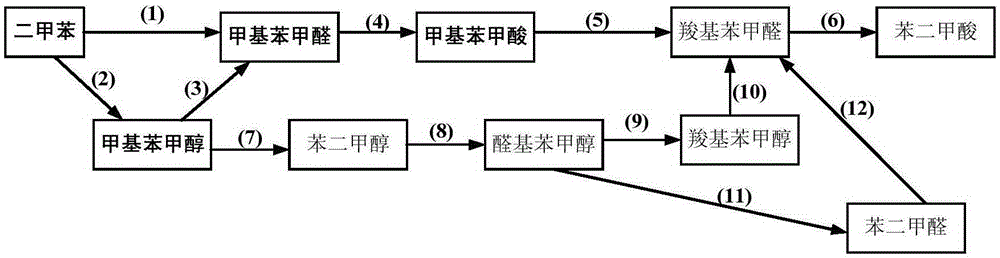

Co-production method for methyl benzoic acid and phthalic acid

ActiveCN105348067AHigh activityRealize online in-situ generationOrganic compound preparationCarboxylic compound preparationBenzoic acidAcetic acid

The invention discloses a co-production method for methyl benzoic acid and phthalic acid. The co-production method comprises the following steps: (1) continuously introducing fresh dimethylbenzene, a catalyst and oxygen-containing gas into a primary oxidation reactor for a reaction to obtain a primary oxidation reaction solution containing methyl benzoic acid and an eight-carbon oxygen-contained compound; (2) carrying out continuous cooling, crystallization and filtration on the primary oxidation reaction solution to obtain filter liquor and filter cake, circulating 1-98% of the filter liquor back the primary oxidation reactor continuously, and continuous rectifying the filter cake continuously, to obtain a low-boiling point front cut fraction, distillation raffinate and a methyl benzoic acid product separately; (3) adding the remaining filter liquor in the step (2) and the obtained front cut fraction and distillation raffinate in the step (2) into a secondary oxidation reactor continuously, and meanwhile continuously introducing a Co / Mn / Br catalyst, acetic acid and oxygen-containing gas into the secondary oxidation reactor for an oxidation reaction to obtain a secondary oxidation reaction mixture; and (4) continuously cooling, crystallizing and filtrating the secondary oxidation reaction mixture to obtain a filter liquor and a phthalic acid product. The co-production method has advantages of a simple process, a low cost, a high yield, good selectivity, good economic benefits, and environmental protection.

Owner:山东友道化学有限公司

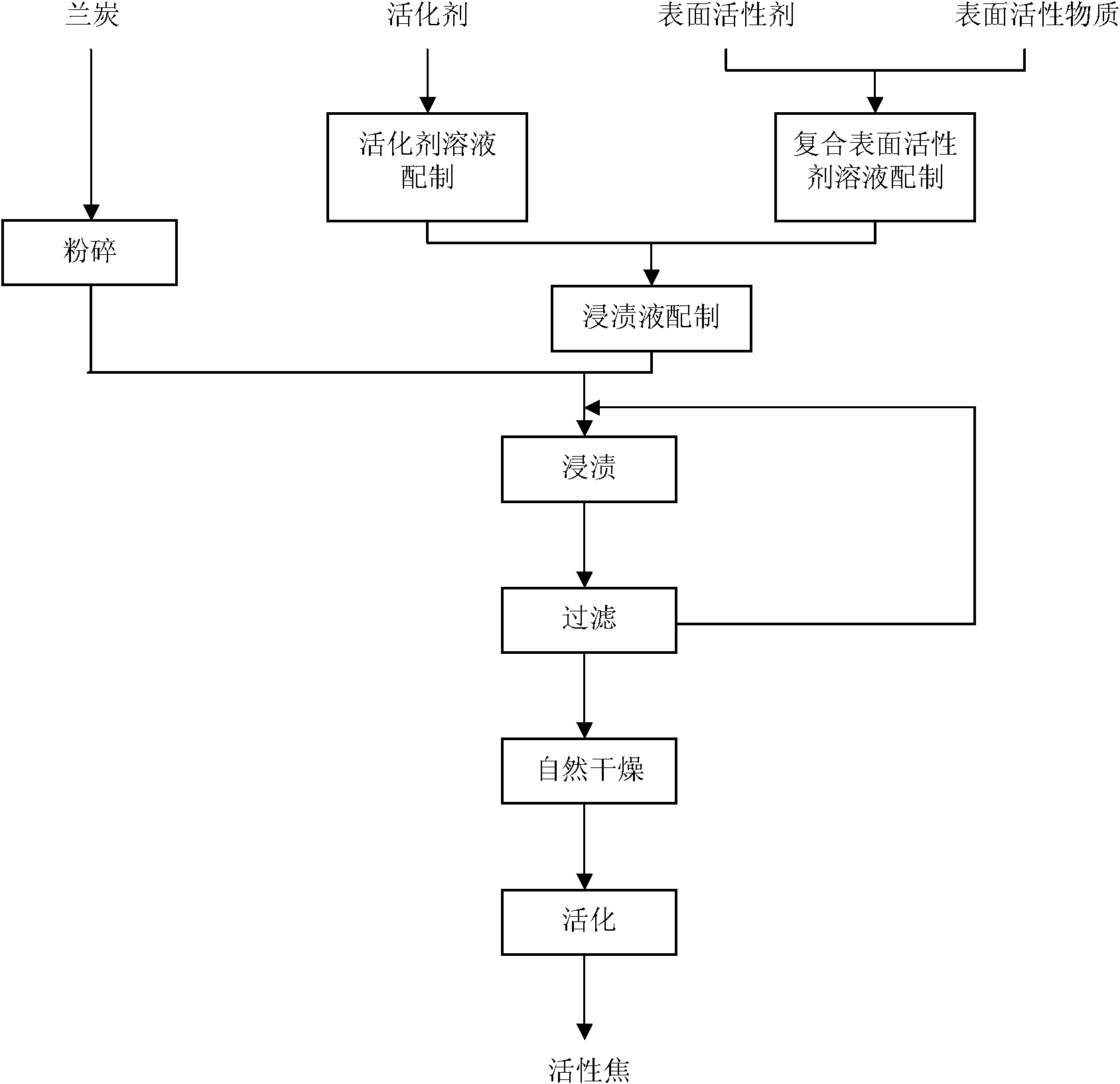

Activated coke for absorbing dioxin in flue gas and preparation method thereof

ActiveCN102728322ASolve spontaneous combustionAvoid disposition problemsOther chemical processesDispersed particle separationSorbentFlue gas

The present invention relates to an activated coke for absorbing persistent organic pollutant like dioxin in flue gas and a preparation method thereof by using coal quality semi coke as a raw material. The preparation method is as follows: crushing the coal quality semi coke; impregnating the coal quality semi coke with an impregnating solution containing metal hydroxide or alkali metal carbonate activator and compound surfactant, and naturally drying; and finally activating the impregnated and dried semi coke at 800-950 DEG C to prepare the activated coke for absorbing dioxin in flue gas. The activated coke has characteristics of developed porous structure, low manufacturing cost and good adsorption effect, etc.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Novel method for preparing battery grade lithium carbonate by using tantalum niobium tailings lithium mica

InactiveCN102139894AImprove utilization efficiencyReduce the impactCell electrodesLithium carbonates/bicarbonatesRubidiumNiobium

The invention provides a novel method for preparing battery grade lithium carbonate by using tantalum niobium tailings lithium mica. The method is characterized by comprising the following steps of: crushing lithium mica powder until granularity is 100 to 200 meshes, adding the crushed lithium mica powder and 30 to 70 percent sulfuric acid solution in a solid and liquid mass ratio of 1:(2-8) into a reaction device, reacting at the temperature of between 60 and 200 DEG C for 3 to 10 hours to obtain the sulfuric acid solution which contains Li<+>, and separating to remove fluorine-containing solution; performing filtering separation on the sulfuric acid solution which contains the Li<+>, and fully washing the filter residue with water to remove the filter residue and obtain filtrate which serves as mother liquor 1; changing the temperature of the mother liquor to be between 10 and 100 DEG C with stirring, separating solids, namely rubidium, caesium and alum, performing filtering separation, washing the filter residue, and recovering the filtrate as mother liquor 2; adding calcium hydroxide into the mother liquor 2, and controlling the pH value of the solution to between 2 and 7 to obtain solid and liquid mixed solution of neutralization reaction; performing filtering separation on the solid and liquid mixed solution, washing and filtering the filter residue, and recovering the filtrate as mother liquor 3; performing evaporation concentration on the mother liquor 3, controlling the concentration of the Li<+> in the solution to be between 40 and 65g / l, and filtering to obtain the filtrate serving as mother liquor 4; and blowing carbon dioxide into the mother liquor 4 at the temperature of between 95 and 105 DEG C under 2 atmospheres and performing lithium-sinking reaction for 40 to 100 minutes, filtering and mechanically separating to obtain lithium carbonate, washing with water, and drying to obtain the battery grade lithium carbonate product.

Owner:宜春银锂新能源有限责任公司

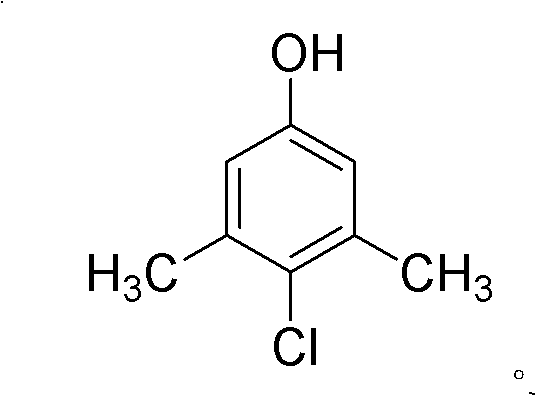

Green industrialized preparation method for 1-hydroxy-3,5-dimethyl-chlorobenzene

ActiveCN101823941AReduce usageHigh yieldOrganic chemistryOrganic compound preparationTemperature controlChlorobenzene

The invention discloses a green industrialized preparation method for 1-hydroxy-3,5-dimethyl-chlorobenzene. Water is used as a solvent; sulfuryl chloride or chlorine is used as a chlorinating agent; and a substrate 1-hydroxy-3,5-dimethyl benzene is subjected to chlorination reaction in a mode of multi-stage temperature control. By using the method, a catalyst with high cost and difficult reclamation can be saved, and the use of an organic solvent can be avoided, so that the discharge of waste gas (volatilization of the organic solvent) and waste substance (the catalyst) can be remarkably reduced during production and the industrialized production of the product is more environmentally-friendly and greener).

Owner:湖南瑞冠生物化工科技有限公司

A kind of preparation method of hexamethylenediamine

ActiveCN104262168BEasy to separateHigh catalytic activityPreparation by reductive alkylationHexamethylenediamineEnergy consumption

The invention discloses a preparation method of hexamethylenediamine. The method is used for preparing 1, 6-hexamethylenediamine by virtue of carrying out ammoniation and catalytic hydrogenation on 1, 6-adipaldehyde. The method is simple in process, low in cost, high in yield, low in energy consumption and free from industrial three wastes.

Owner:BEIJING RISUN TECH CO LTD

Activity enhanced ketoreductase mutant, coding sequence and preparation method thereof

ActiveCN104342411ASignificantly high specific enzyme activityMild reaction conditionsBacteriaMicroorganism based processesStatineButyric acid ethyl ester

The invention relates to an activity enhanced ketoreductase mutant, which is derived from wild-type ketoreductase of Candida magnoliae, can transform 4-chloroacetoacetic acid ethyl ester into (S)-4-chloro-3-hydroxy butyric acid ethyl ester, and has one or more mutations of E9R, S42Q, T190L and E234M. The ketoreductase mutant provided by the invention has obvious high specific enzyme activity, which is increased by 2-20 times than wild-type ketoreductase. According to the invention, the reaction conditions are mild, the requirement for equipment is low, the production process has need for high temperature or cooling, the energy consumption is low, and as enzyme catalysis has high efficiency and specific selectivity, production of the statin drug key intermediate (S)-4-chloro-3-hydroxy butyric acid ethyl ester by the method generates no by-product, and purification can be convenient. In addition, most solvents involved in the reaction of the invention are water, thus having low discharge of three wastes, and being green and environment-friendly.

Owner:NANJING NUOYUN BIOLOGICAL TECH CO LTD

Production method of N-phosphono methyliminodiacetic acid

InactiveCN101284847AReduce the discharge of three wastesHigh yieldGroup 5/15 element organic compoundsChemistryMother liquor

The invention discloses a method for manufacturing N-phosphonomethyliminodiacetic acid (PMIDA). The method comprises the following steps: (1) IDA disodium salt source is reacted with sulphuric acid to obtain IDA monosodium salt solution; (2) the IDA monosodium salt solution is then reacted with sulphuric acid to separate out iminodiacetic acid (IDA), and reaction mother liquor is treated by liquid alkali to obtain Na2SO4 after evaporated dehydration; moreover, the mother liquor is treated as the raw material of the step (2); (3) the IDA is mixed with phosphorous acid and formaldehyde to generate PMIDA through reaction under the condition of sulphuric acid, wherein the PMIDA is obtained through cooling crystallization and filtration after formaldehyde-containing waste water is separated through evaporation; the mother liquor is treated as the raw material of PMIDA; the formaldehyde-containing waste water separates concentrated and reclaimed concentrated formaldehyde through a pervaporation membrane separating device, and the separated concentrated formaldehyde is treated as formaldehyde raw material; and discharged water is used for reclaimed water recovery after resin treatment. The invention reclaims the byproduct of Na2SO4 and makes effective use of resources such as PMIDA, IDA, formaldehyde, sulphuric acid and water in the production waste water of PMIDA.

Owner:捷马化工股份有限公司

Enzyme engineering method for producing gamma-aminobutyric acid

InactiveCN102242161AReduce the discharge of three wastesMicroorganism based processesFermentationOrganic filmSodium acetate

The invention discloses an enzyme engineering method for producing gamma-aminobutyric acid, belonging to the technical field of a fermentation method for producing enzymes. The method disclosed by the invention comprises the following steps of: inducing by using lactose as an inducer for producing enzymes, filtering through a ceramic film for collecting thalli, and washing the thalli instantly; then, adding an acetic acid-sodium acetate buffer solution into the thalli, and adding a small amount of substrate glutamic acid many times to enable the glutamic acid to be converted into gamma-aminobutyric acid; then, filtering and removing the thalli instantly by adopting the ceramic film, and decoloring by adopting a rolled organic film; and finally, carrying out triple-effect concentration, stopping concentrating until the content of the concentrated product reaches 550-600g / L, pouring the concentrated solution into a vacuum concentration crystallizing tank, continuing to concentrate, stopping heating until the content of the product reaches 700-900g / L, and naturally cooling and growing the grain for 1-1.5 hours under the normal pressure to obtain a columnar or powdered crystal. The purity of the crystal obtained by primary crystallization is greater than or equal to 99.0%, and the yield of the crystal is greater than or equal to 85%. The method disclosed by the invention is a clean production process and has low emission of the three wastes, and the residues of the thalli can be used as feed proteins.

Owner:山东恩贝生物工程有限公司

Method for processing foods by ultrasonic waves and ultrasonic food processor

ActiveCN103918954AGuaranteed nutritionKeep the flavorFood shapingCleaning using liquidsHazardous substanceUltrasonic machining

The invention discloses a method for making foods by ultrasonic waves. According to the technical scheme, in the food processing process, the temperature is between -5 DEG C and 95 DEG C, and the adopted ultrasonic frequency is 20-200 KHz. The novel method has the beneficial effects of no production of harmful substances during processing, short production period, few production procedures, saving of places and workers as well as water and power and reduction of three-waste emission, and is capable of keeping the nutrition, flavor and safety of foods.

Owner:重庆鸿紫圆光生物科技有限公司

Preparation method of perfluorohexane

PendingCN107604378ASimple processLow costElectrolysis componentsElectrolytic organic productionHydrogen fluoridePower flow

The invention discloses a preparation method of perfluorohexane. The preparation method comprises the following steps that (1) by weight, hexafluoropropylene dimer, anhydrous hydrogen fluoride and electrolytic addition agents are prepared into an electrolyte for standby application; (2) the electrolyte is subjected to electrolytic dehydration for standby application; and (4) the dehydrated electrolyte is continuously added into an electrolytic bath to be subjected to electrofluorination reaction, a gaseous product obtained after electrolysis is condensed and rectified, and thus a perfluorohexane product is obtained. The advantages that the process is simple, the cost is low, the current efficiency is high, the operation cycle is long, and the product quality is stable are achieved.

Owner:ZHEJIANG JUSHENG FLUOROCHEM

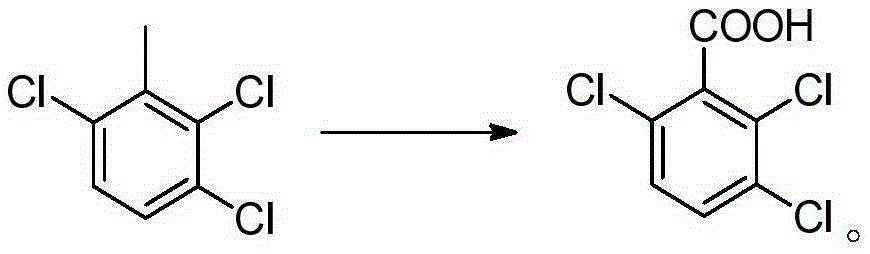

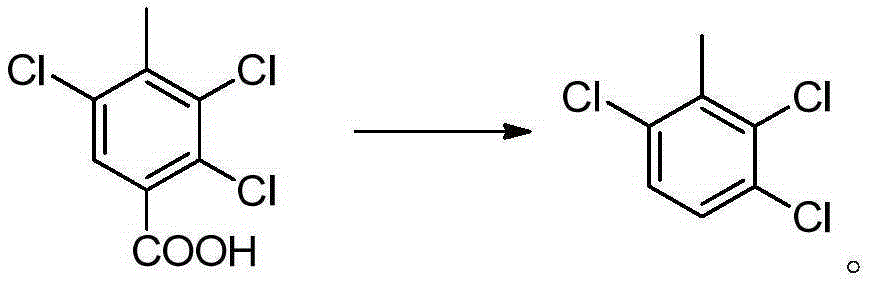

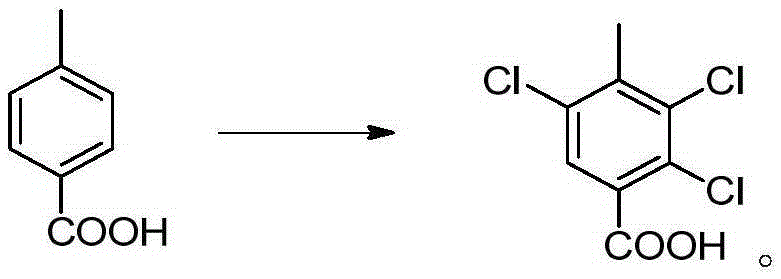

Synthesis methods of 3, 6-dichloro-2-methoxybenzoic acid and its intermediate

InactiveCN105294419AWide variety of sourcesSimple processOrganic compound preparationCarboxylic preparation by ozone oxidationSynthesis methods2-methoxybenzoic acid

The invention discloses synthesis methods of 3, 6-dichloro-2-methoxybenzoic acid and its intermediate. The invention provides the synthesis method of 2, 3, 6-trichlorobenzoic acid. The synthesis method comprises that in the presence of a catalyst, 2, 3, 6-benzotrichloride and an oxidation reagent undergo an oxidation reaction to produce 2, 3, 6-trichlorobenzoic acid. The synthesis methods have simple processes, a high conversion rate, a high yield, high product purity, a low production cost and environmental friendliness and are suitable for industrial production.

Owner:JIANGSU LIANHE CHEM TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com