Method and device for treating dichlorosilane waste by utilizing reactive distillation

A technology of dichlorodihydrosilane and reactive distillation, which is applied in the field of reactive distillation, can solve problems such as complicated process and many circulation flows, and achieve the effects of increasing yield and output, increasing conversion rate, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

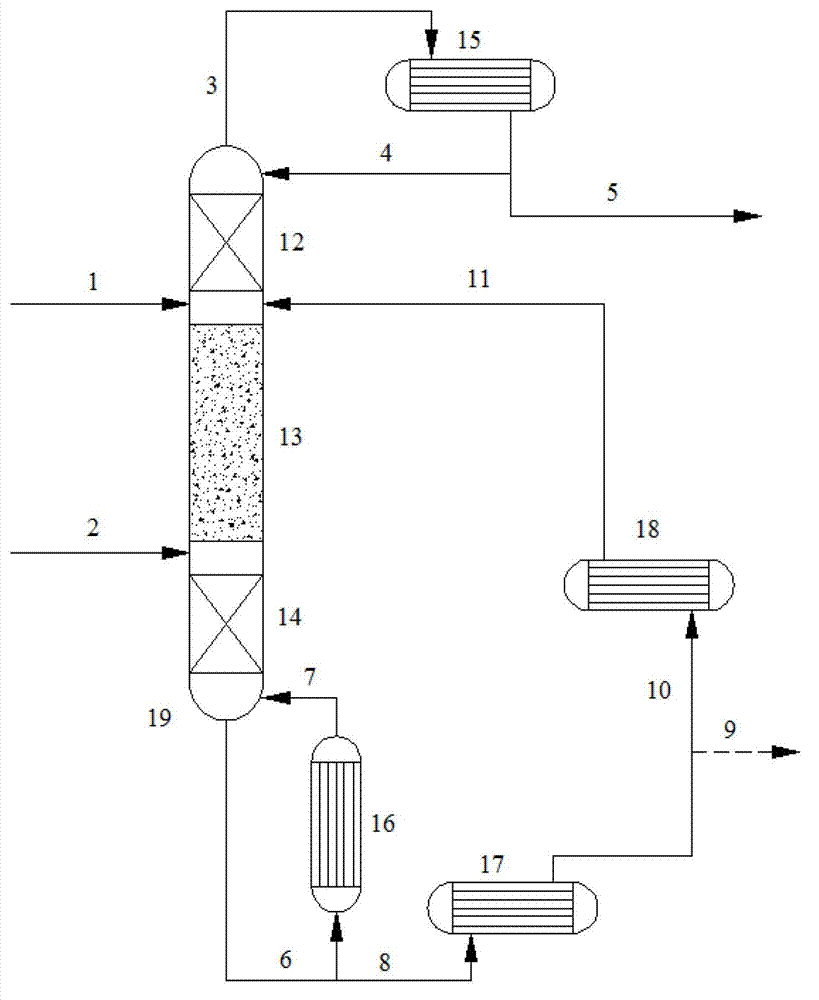

Image

Examples

Embodiment 1

[0023] 1,700 tons / year of dichlorodihydrosilane waste will be treated by reactive distillation, and 5,000 tons / year of trichlorosilane will be produced.

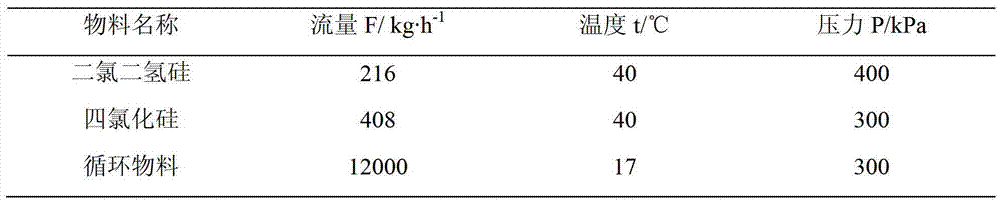

[0024] The feed conditions of dichlorodihydrosilane, silicon tetrachloride and recycled materials are shown in Table 1.

[0025] Table I

[0026]

[0027] The operating pressure of the reactive distillation tower is 150kPa, the pressure drop of the whole tower is 20kPa, the output at the top of the tower is 624kg / h, the return flow at the top of the tower is 4500kg / h, the diameter of the tower is 0.9m, and the amount of catalyst is 0.1m 3 / m 3 Packing, spray density is 25m 3 / (m 2 h), the heights of the rectifying section, the reaction section and the stripping section packing are 4m, 8m and 4m respectively. The feed position of dichlorodihydrosilane is at the bottom of the reaction section, and the feed position of silicon tetrachloride and circulating materials is at the top of the reaction section.

[0028] Indust...

Embodiment 2

[0030] 1,700 tons / year of dichlorodihydrosilane waste will be treated by reactive distillation, and 5,000 tons / year of trichlorosilane will be produced.

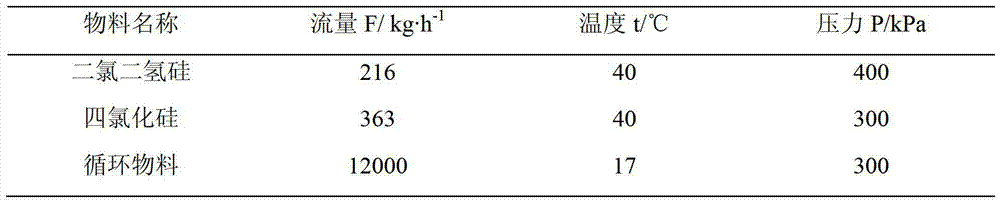

[0031] Adjust the feed molar ratio of dichlorodihydrosilane to silicon tetrachloride to be 1:1, and the feed conditions of dichlorosilane, silicon tetrachloride and recycled materials are shown in Table 2.

[0032] Table II

[0033]

[0034] The operating pressure of the reactive distillation tower is 150kPa, the pressure drop of the whole tower is 20kPa, the output at the top of the tower is 579kg / h, the return flow at the top of the tower is 5000kg / h, the diameter of the tower is 0.9m, and the amount of catalyst is 0.1m 3 / m 3 Packing, spray density is 25m 3 / (m 2h), the heights of the rectifying section, the reaction section and the stripping section packing are 4m, 8m and 4m respectively. The feed position of dichlorodihydrosilane is at the bottom of the reaction section, and the feed position of silicon tetrachlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com