Process for producing vinyl chloride by acetylene method and dedicated device for realizing same

A technology of vinyl chloride and acetylene method, applied in hydrogen halide addition preparation, organic chemistry and other directions, can solve the problems of ethylene raw material price increase, production and development restrictions, etc., to achieve high production intensity, large production capacity, and improved reaction speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

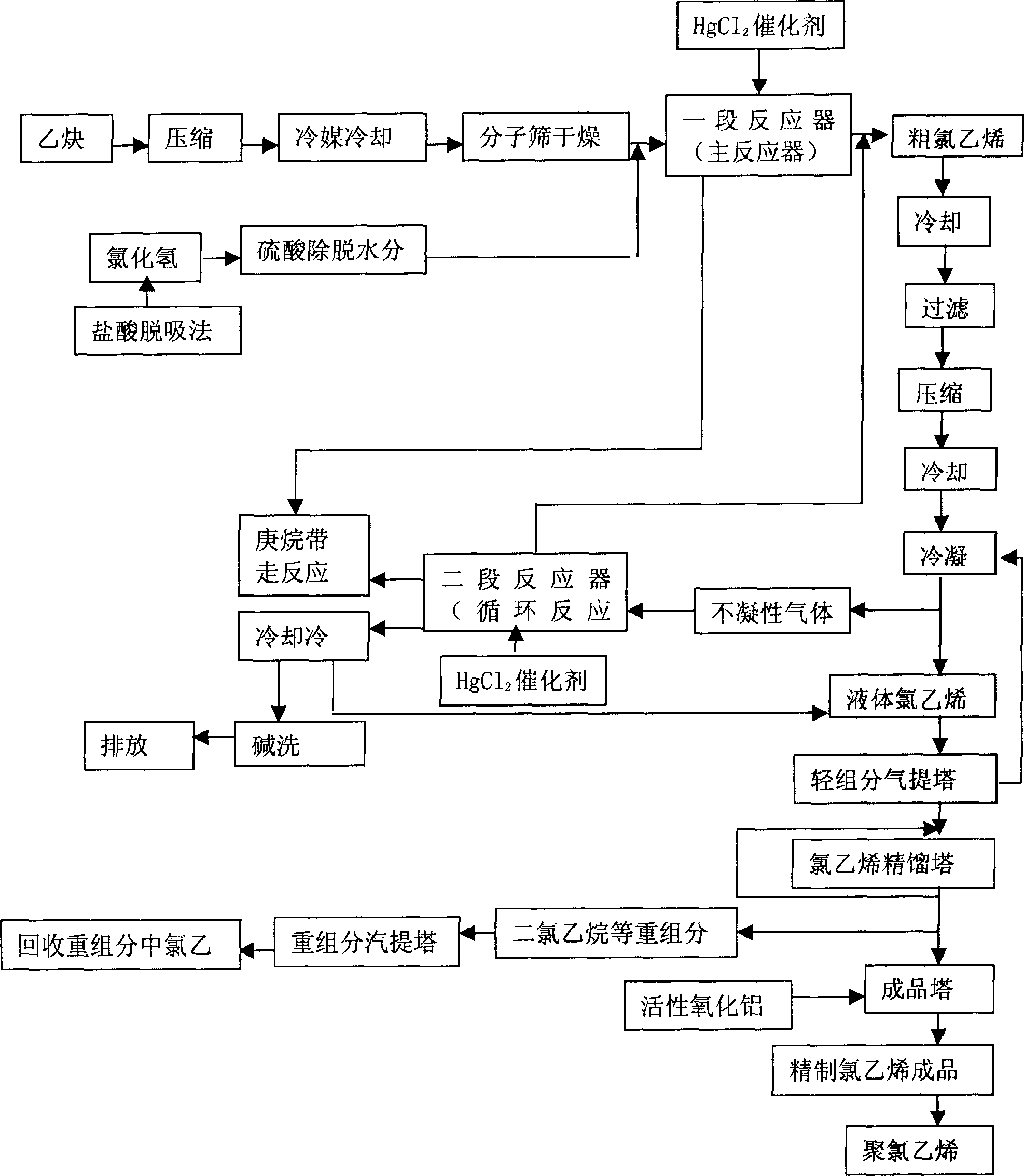

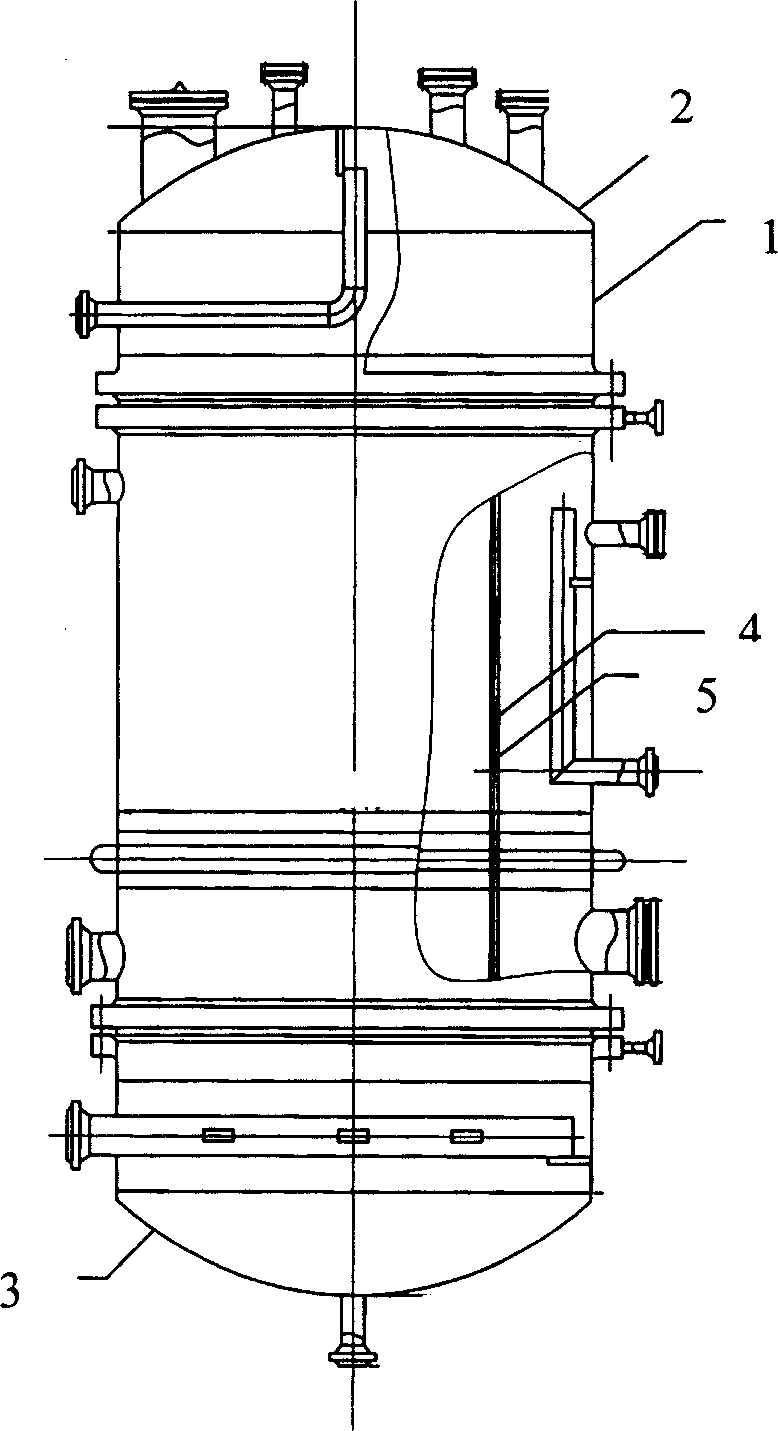

[0069] like figure 1 , figure 2 A new method for the production of vinyl chloride by an acetylene process, comprising the following steps:

[0070] (1) prepare raw material acetylene and hydrogen chloride respectively;

[0071] The acetylene is cleaned and neutralized to deal with the impurities in the acetylene. After boosting the pressure to 107KPa, the acetylene is cooled to 2-5°C through a tube-and-tube heat exchanger using Freon as the refrigerant, and a large amount of moisture entrained in the acetylene gas is removed at a low temperature. , and then enter the carbon steel drier filled with aluminosilicate molecular sieve, through the adsorption of moisture by the molecular sieve, the moisture content of acetylene gas is extremely low, reaching below 10ppm;

[0072] Hydrogen chloride is produced by the known hydrochloric acid desorption method, the purity is higher than 99.95% and does not contain free chlorine, and the water contained in hydrogen chloride is removed...

Embodiment 2

[0094] Such as figure 1 , figure 2 Process flow sheet and reactor of the present invention, with embodiment 1, difference is:

[0095] Described step (1): for preparing acetylene and hydrogen chloride respectively: the acetylene gas is compressed and dried at a low temperature so that the moisture content of the acetylene gas reaches below 10 ppm; hydrogen chloride without free chlorine is adopted, and sulfuric acid is used as a circulation fluid to remove moisture to make the hydrogen chloride The water content is below 10ppm;

[0096] Said step (2): said acetylene and hydrogen chloride are mixed in a volume ratio of 1: 1.02; the crude vinyl chloride gas is cooled to 45°C; said first-stage reactor pressure is 80KPa (G), and said second-stage reactor The pressure is 270KPa(G).

[0097] Said step (3): the temperature of the stripper tower kettle is 32°C, the tower top temperature is 0°C, and the pressure is 312KPa (G);

[0098] The temperature at the bottom of the rectific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com