Method for preparing pure acrylate copolymer coating emulsion for building external wall elastic coating

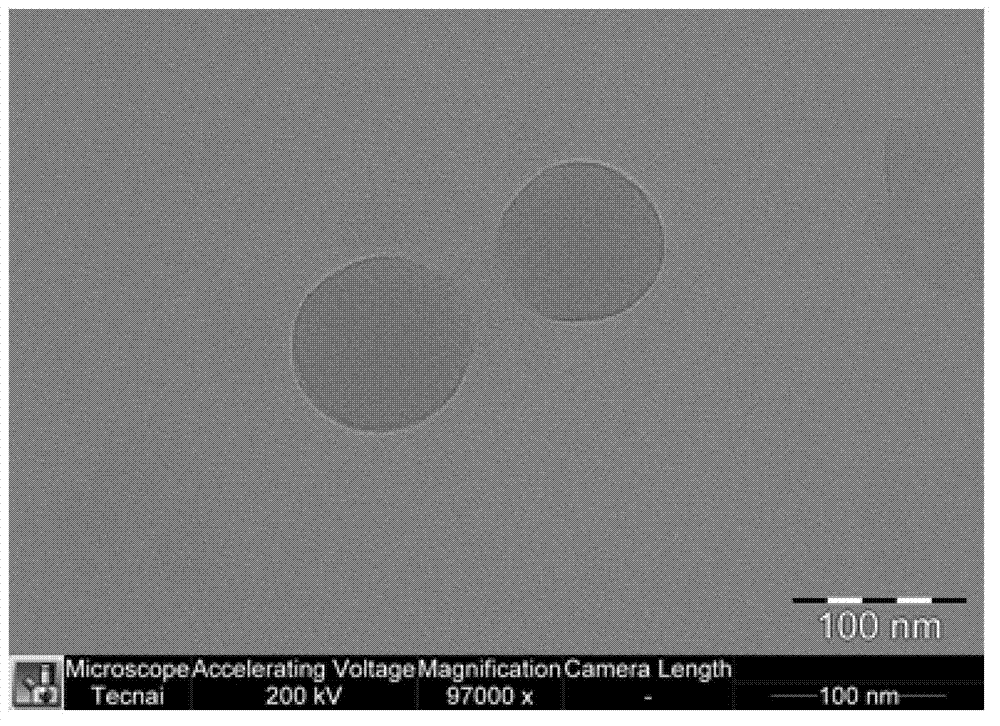

An elastic emulsion and elastic coating technology, which is applied in the direction of antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of poor stain resistance, poor low temperature flexibility, etc., and achieve narrow distribution and small particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

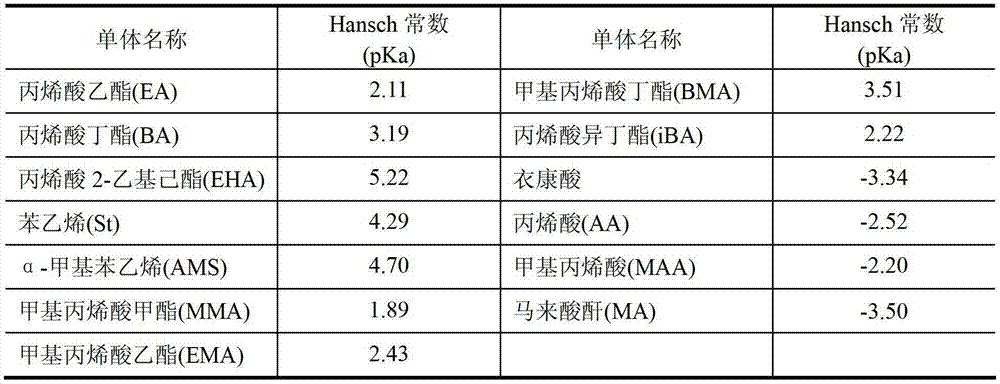

Method used

Image

Examples

Embodiment

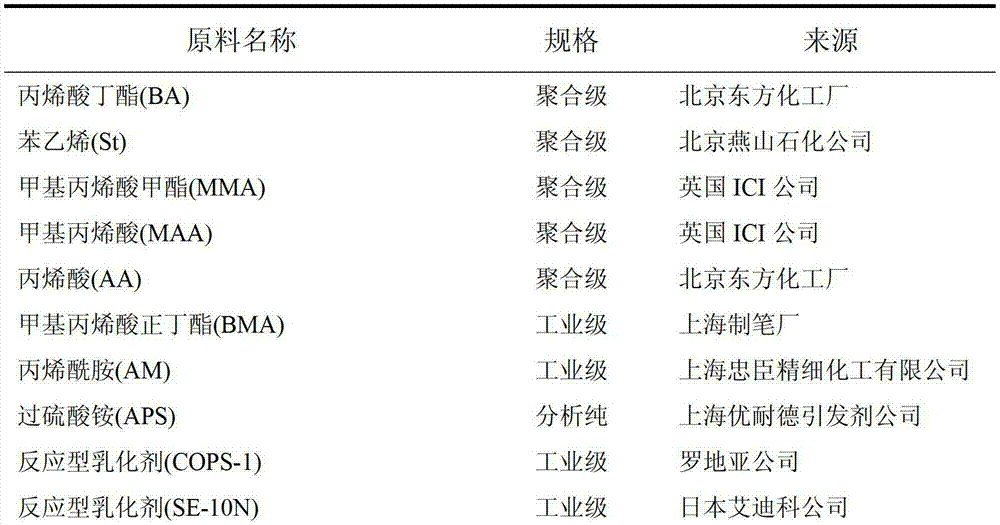

[0127] Ⅰ Preparation of seed emulsion

[0128] (1) Pre-emulsification Add metered deionized water (DW) to a 5000ml three-neck flask, start stirring, add metered % emulsifier, start to drop the metered monomer after 15 minutes, and continue high-speed stirring and emulsification for about 1 hour;

[0129] (2) Polymerization Add deionized water to a 1000ml four-neck flask equipped with stirring, reflux condenser, thermometer and constant pressure dropping funnel, start stirring, add the measured bottom emulsifier, when the temperature rises to 85°C, add the measured Initiator aqueous solution, wait for the temperature to reach the highest level and stabilize for 2-3 minutes, then start to add the pre-emulsion solution and the initiator aqueous solution dropwise, the temperature is controlled at 86-88°C during the dropping, and the total dropping time is controlled at 90-100 minutes ; After the dropwise addition, keep warm for 1h;

[0130] (3) Cool down to below 40°C and add mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com