Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

327 results about "N-Butyl methacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medicated coatings for implantable medical devices including polyacrylates

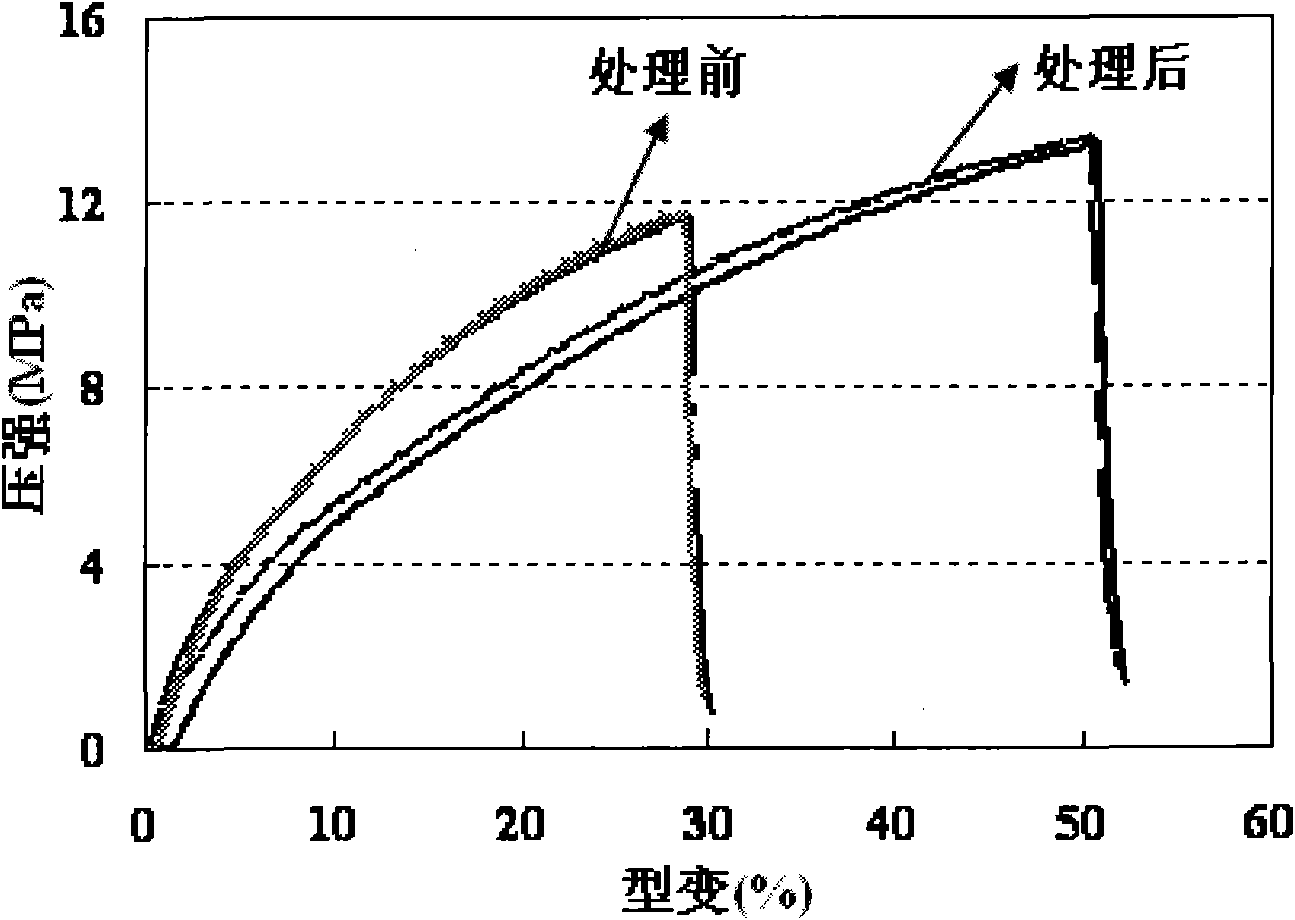

A polymer for a medical device, particularly for a drug eluting stent, is described. The polymer can be derived from n-butyl methacrylate and can have a degree of an elongation at failure from about 20% to about 500%

Owner:ABBOTT CARDIOVASCULAR

Oil absorbing fibre and perparing method thereof

InactiveCN1584148ABroaden the fieldLarger specific surface area for oil absorptionWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberBenzoyl peroxide

The invention relates to a kind of oil-absorbed fiber and its producing method. Its prescription is: 100% polymer monomer, 10-40% of potential gemel agent, 0.1-0.5% solicitation, 0.5-1% dispersant. Moreover the water-like body is 3-4 times more in volume than polymer monomer. The polymer monomer is methacrylate monomer involving butyl methacrylate, the potential gemel agent is 2-hydroxyethyl methacrylate, the solicitation is benzoyl peroxide, and dispersant is poly-vinyl-alcohol. The process is (1) use water-suspending polymerization to produce butyl methacrylate under 70-80 deg.C for blending and polymerizing for 8-10 hours. (2) dissolve the polymer into proper solvent to deploy 20-25% liquid and then insert potential gemal agent and solicitation to polymerize for 3-5 hours under 75-80 deg.C to obtain the original liquid. (3) take off dunking. (4) spin using one of wet or dry method or both, (5) treat with fibre for 10-60 minutes under 120-165 deg.C to obtain the production. The solvent discussed above is one of DMF, DMAC or dimethoxysulfoxide.

Owner:TIANJIN POLYTECHNIC UNIV

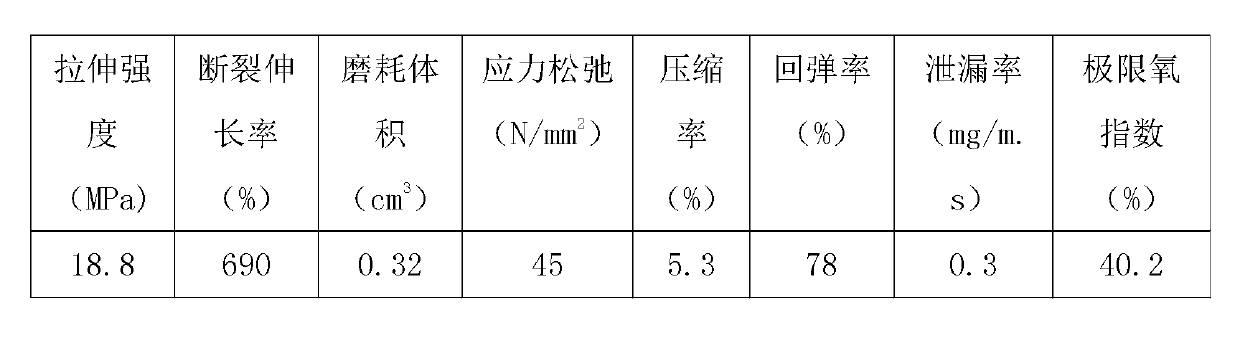

Nanometer attapulgite-modified chlorosulfonated polyethylene rubber gasket and preparation method thereof

The invention discloses a nanometer attapulgite-modified chlorosulfonated polyethylene rubber gasket. Raw materials for the nanometer attapulgite-modified chlorosulfonated polyethylene rubber gasket comprise, by weight, 135 to 145 parts of chlorosulfonated polyethylene rubber CSM2305, 10 to 15 parts of butyl rubber CBK139, 10 to 15 parts of Lanxess 2470 EPDM rubber, 2 to 5 parts of phthalate, 3 to 5 parts of propanediol sebacate polyester, 2 to 5 parts of n-butyl methacrylate, 3 to 4 parts of zinc oxide, etc. The gasket provided by the invention has the advantages of good high temperature resistance, sealing performance and flame resistance, excellent resistance to corrosion, small changes in its volume and hardness when working in mediums like an acid, an alkali and oil for a long time, no adherency onto the surface of a metal, a small friction coefficient, good wear resistance, flexibility of bonding with a sealing surface, good resistance to weathering ageing and ozone ageing, durability, etc.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

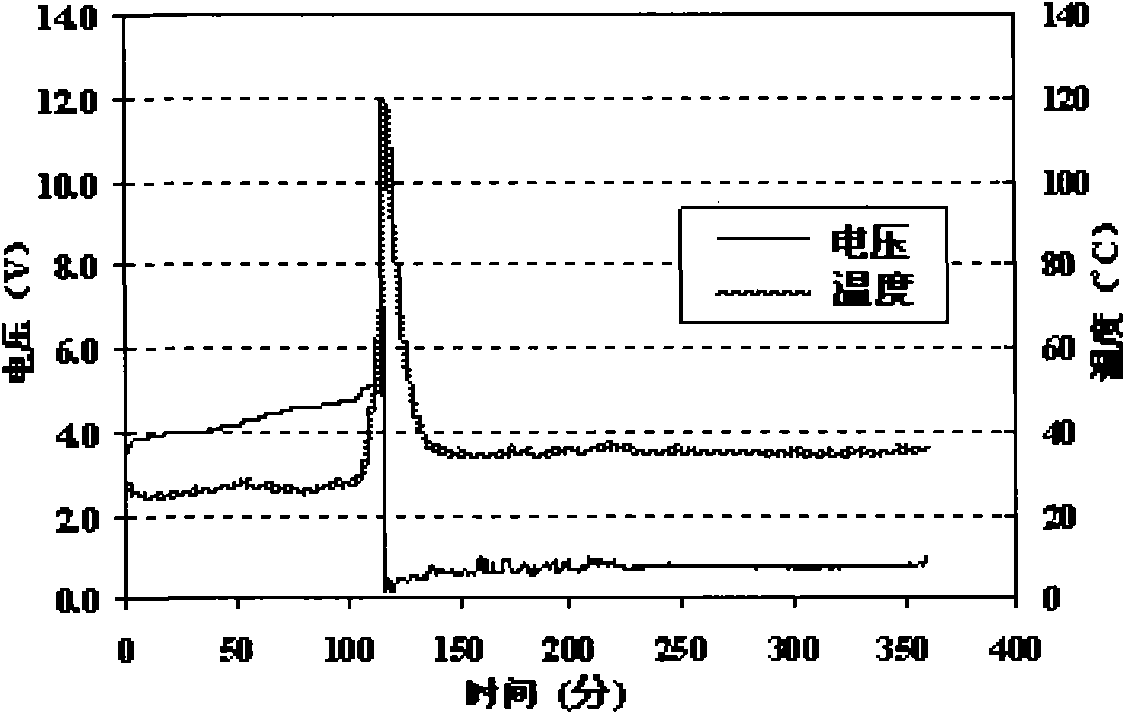

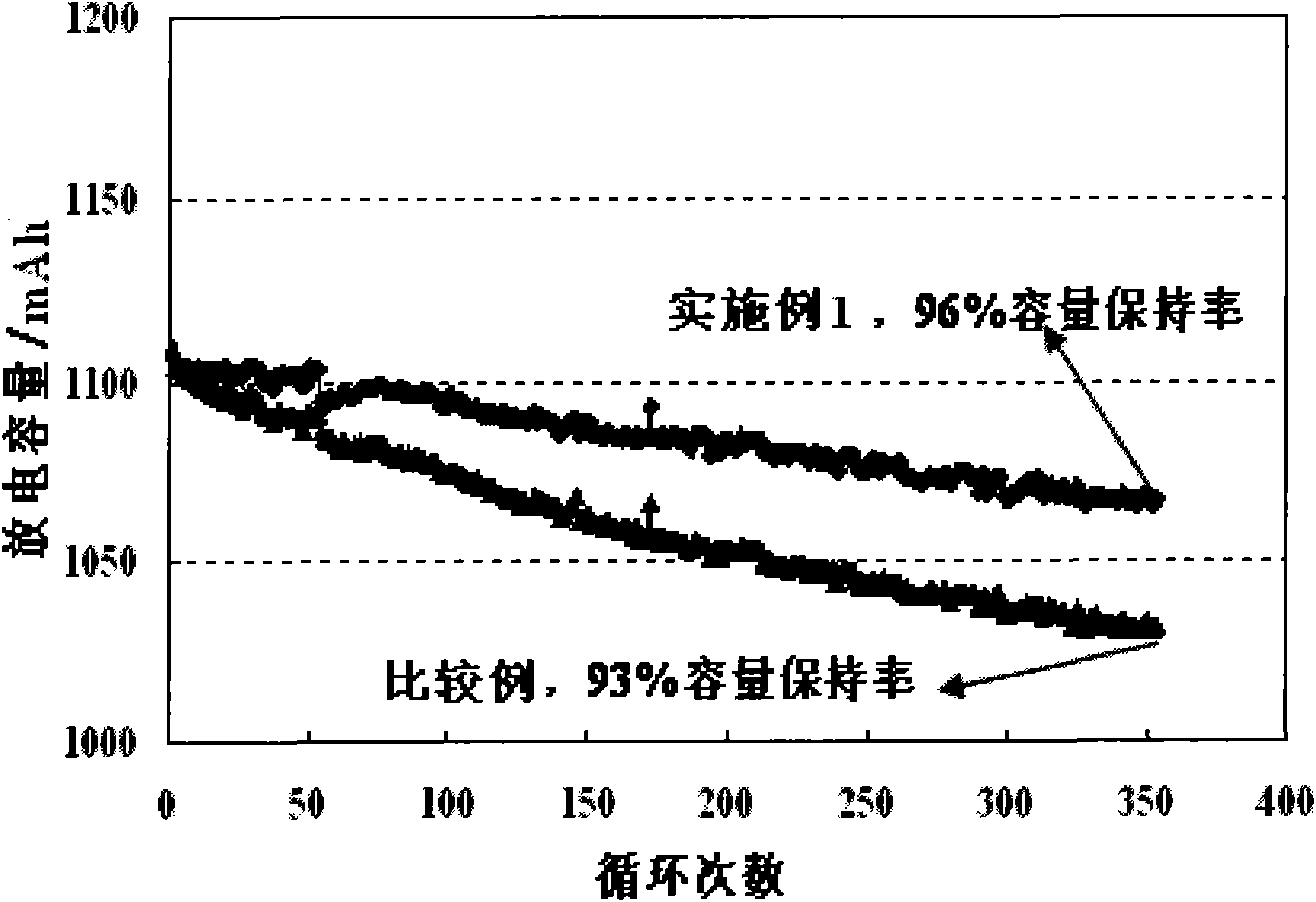

Polymer lithium ion secondary battery and isolating membrane thereof

ActiveCN101872853AImprove liquid absorption capacityStrong interfacial stabilityCell electrodesSecondary cellsPorous substrateAcrylonitrile

The invention discloses an isolating membrane of lithium ion secondary battery, comprising a porous substrate and a polymer coating distributed only on a surface of the porous substrate which faces an anode of the lithium ion secondary battery, wherein the polymer in the polymer coating is selected from poly(methyl methacrylate-acrylonitrile), poly(methyl methacrylate-vinyl acetate), poly(methyl methacrylate-acrylonitrile-vinyl acetate), poly(n-butyl methacrylate-styrene), or blends of the polymers. The polymer unit in the polymer coating of the isolating membrane of the lithium ion secondary battery contains carbonyl, wherein very strong effect exists between the carbonyl and oxygen in carbonic acid ester type organic solvent so as to have fine solution suction ability and good interface stability of lithium electrode or anode; the membrane has strong adhesive property and film formation, and can provide fine mechanical tensile strength; and the membrane has fine cycle performance and safety performance. The invention further discloses a polymer lithium ion secondary battery using the membrane.

Owner:DONGGUAN NEWPOWER ELECTRIC SCI & TECH +1

Surface sizing agent for paper making

InactiveCN101225623AImprove qualityMeet quality requirementsWater-repelling agents additionNon-macromolecular organic additionIsooctyl acrylateEmulsion

The invention relates to a surface sizing agent for paper making, which has the material formula with a plurality of components and weight percentages as follows: starch 6.5-8%, styrene 4.5-6%, acrylonitrile 4-5%, n-butyl methacrylate 5.5-6.5, methacrylic acid iso-octyl 2-3.5, iso-octyl acrylate 0.4-1%, hydrogen peroxide 0.2-0.5%, formic acid0.5-1%, ferrous sulfate 0.5-4%, n-dodecyl mercaptan 0.5-3%, amylase 0-0.2% and water the rest, wherein at least one is chosen from n-butyl methacrylate, methacrylic acid iso-octyl and iso-octyl acrylate. The appearance of the surface sizing agent is slight yellow emulsion, and the main component is styrene-acrylic copolymer which is easily soluble at normal temperature. The surface sizing agent for paper making has the advantages of greatly increasing paper surface intensity, decreasing hair and powder shedding, and improving the sizing degree, smoothness and printability of paper.

Owner:杨春先

Plastic-wooden composite tray and preparation method thereof

The invention discloses a plastic-wooden composite tray which is prepared from the raw materials in parts by weight: 50-60 parts of high density polyethylene, 20-30 parts of copolymerization polypropylene, 30-40 parts of modified wood meal, 40-50 parts of plastic renewable material, 20-30 parts of active calcium, 1-2 parts of zinc stearate, 1-2 parts of calcium stearate, 2-3 parts of n-butyl methacrylate, 0.3-0.5 part of polyethylene wax, 0.4-0.6 part of triethoxyvinylsilane, 0.3-0.4 part of antioxidant 1010, 0.4-0.6 part of anti-aging agent MB, 8-10 parts of foaming modifier, 4-8 parts of ACM, 4-8 parts of MBS, 25-30 parts of oxidized polyethlene wax, 0.2-0.3 part of foaming agent, 4-8 parts of TPE (Thermoplastic Polyurethane Elastomer), 8-12 parts of chlorinated polyvinyl chloride, 5-8 parts of glass fiber and 3-4 parts of semi-reinforced carbon black. The plastic-wooden composite tray produced by using the preparation method has the advantages of excellent mechanical property, capability of being sawed, planed and nailed, good durability, high repeated usage rate, capability of being recycled, resistance to insect biting, acid and alkaline resistance, aging resistance, and low water absorption and low deformation rate.

Owner:芜湖太平洋塑胶有限公司

High-temperature oil resistant nitrile rubber gasket and preparation method thereof

The invention discloses a high-temperature oil resistant nitrile rubber gasket, comprising the following ingredients in parts by weight: 35-145 parts of nitrile rubber N411, 30-35 parts of active chloride type acrylic rubber, 10-15 parts of SG-1 type polyvinyl chloride, 2-5 parts of triethyl citrate, 3-5 parts of epoxy butyl oleate, and 2-5 parts of n-butyl methacrylate. The nitrile rubber gasket disclosed by the invention has excellent oil resistance and solvent resistance, also has excellent compressibility and rebound resilience and weak permanent deformation, does not soften and not decompose at high temperature, does not harden and not crack at low temperature, has excellent corrosion property, can work for a long time in mediums of acid, alkali, oil and the like, has small change in volume and rigidity and can adhered on metal surfaces, and has the following advantages of low friction coefficient, excellent wearing resistance, flexibility of being combined with a seal surface, excellent weather aging and ozone aging resistance, endurance, and the like.

Owner:ANHUI RONGDA VALVE

Aqueous self-crosslinking copolymer dispersions, a process for preparing them and their use in binders for coating materials

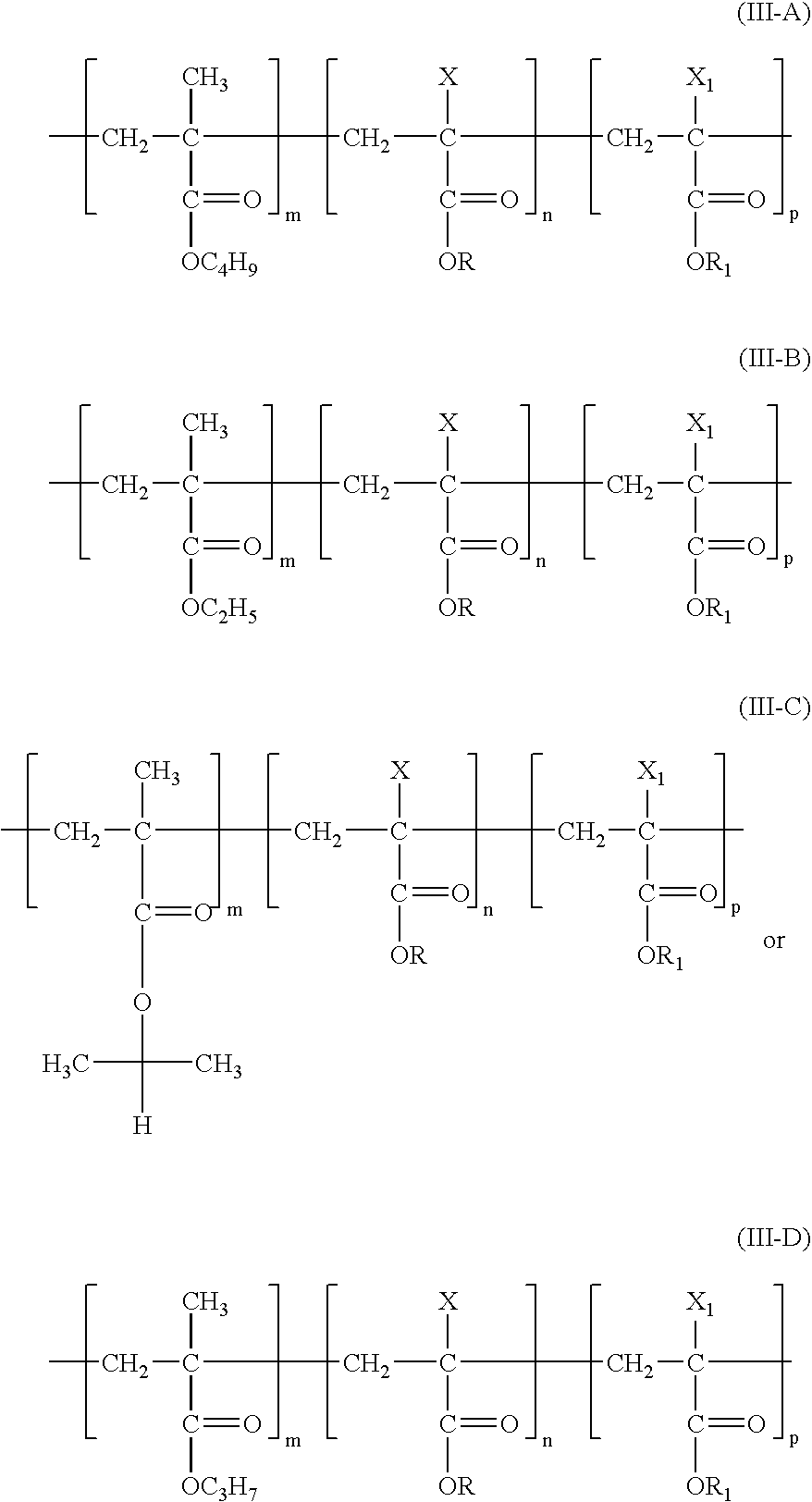

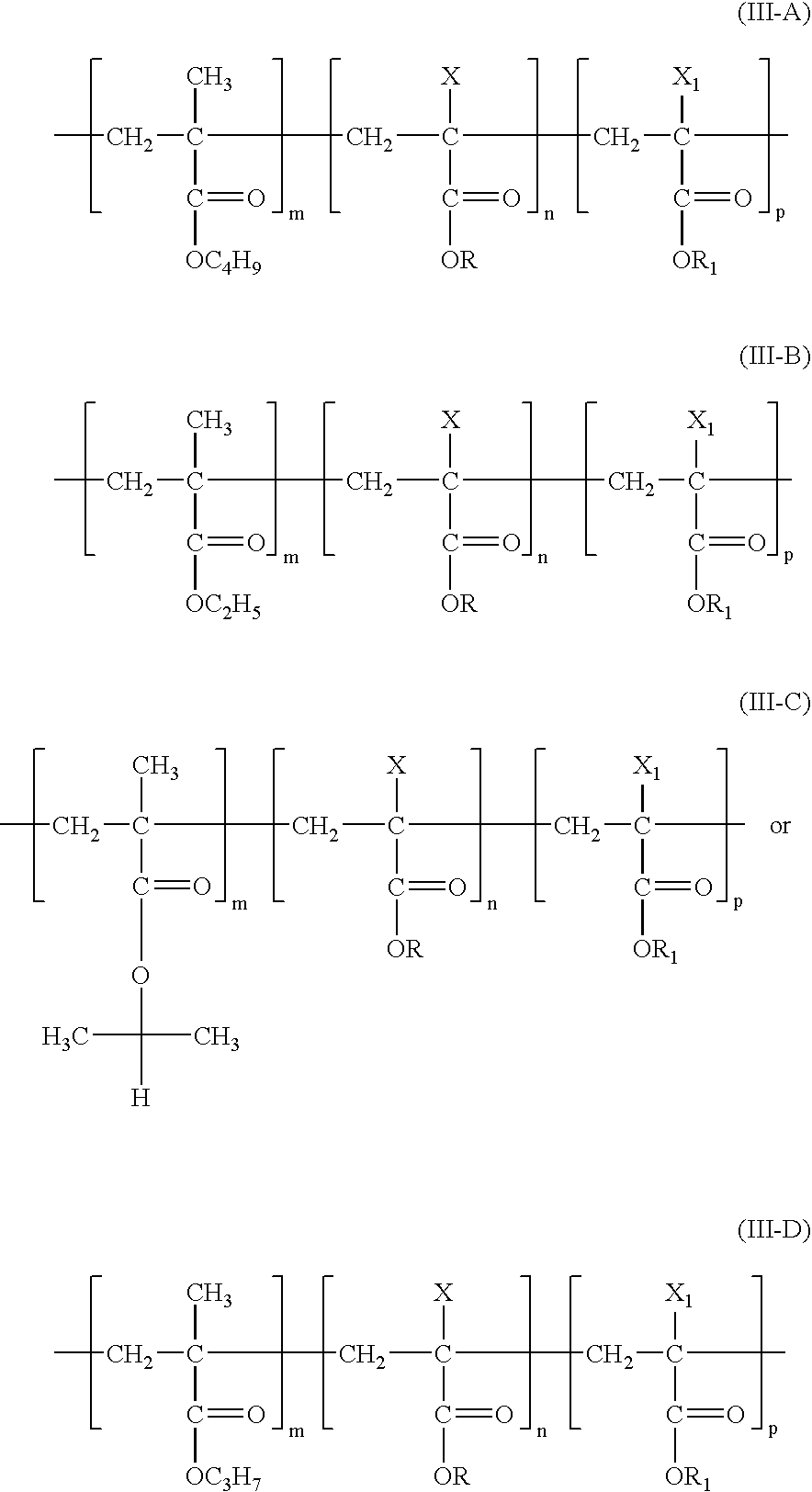

InactiveUS6515042B2Solve the lack of lifeHigh film hardnessLiquid surface applicatorsPlastic/resin/waxes insulatorsDicarboxylic acidCompound c

Aqueous self-crosslinking copolymer dispersions ABC obtainable by free-radically initiated copolymerization in the first stage of a monomer mixture A comprising olefinically unsaturated monomers A1 having carbonyl groups, unsaturated carboxylic acids or monoesters of unsaturated dicarboxylic acids A2, monomers A3 selected from vinylaromatic compounds, n-butyl methacrylate and also alkyl esters of unsaturated carboxylic acids or dialkyl esters of unsaturated dicarboxylic acids, esters A4 selected from alkyl esters of unsaturated carboxylic acids of dialkyl esters of unsaturated dicarboxylic acids, and other free-radically polymerizable monomers A5, and subsequent addition of a second monomer mixture B and further polymerization in the second stage, the mixture B comprising olefinically unsaturated monomers B1 corresponding to A1, esters B2 corresponding to A4, and monomers B3 corresponding to A5, and subsequently adding compounds C having hydrazine or hydrazide groups.

Owner:ALLNEX AUSTRIA GMBH

CBN (cubic boron nitride) resin grinding wheel and preparation method thereof

ActiveCN102814747ANot easy to fall offImprove heat resistanceAbrasion apparatusGrinding devicesPolyamideBoron nitride

The invention discloses a CBN (cubic boron nitride) resin grinding wheel and a preparation method of the CBN resin grinding wheel. The CBN resin grinding wheel is prepared from the following components in parts by weight, 50-60 parts of CBN grinding material, 5-10 parts of white corundum grinding material, 5-10 parts of silicon carbide powder, 5-15 parts of phenolic resin powder, 2-6 parts of phenolic resin liquid, 1-2 parts of n-butyl methacrylate, 5-10 parts of nano dolomite dust, 5-10 parts of nano quartz sand powder, 2-5 parts of micro polyamide wax mist and 2-5 parts of steel scrap powder. According to the CBN resin grinding wheel and the preparation method of the CBN resin grinding wheel, as a ceramic material is added into padding, the adhesive property is good, the grinding materials hardly fall off, the heat resistance and hardness of the resin grinding wheel are improved, and cracks formed by rigid grinding are reduced, thereby the use efficiency and service life of the resin grinding wheel are improved further; and in addition, as steel power is added, fast heat dissipation effect is achieved, a great deal of heat generated in a cutting process of the grinding wheel can be dissipated quickly, and the effect of lowering cutting temperature is achieved.

Owner:安徽威铭耐磨材料有限公司

Binding agents for polyurethane-based paints

InactiveUS6130308ASynthetic resin layered productsPretreated surfacesTERT-BUTYL METHACRYLATEN-Butyl methacrylate

PCT No. PCT / EP97 / 00149 Sec. 371 Date Aug. 20, 1998 Sec. 102(e) Date Aug. 20, 1998 PCT Filed Jan. 15, 1997 PCT Pub. No. WO97 / 29142 PCT Pub. Date Aug. 14, 1997The invention relates to coating compositions for the production of coatings which are resistant to condensed water and comprise binders based on a polyurethane resin PUR which comprises alpha, omega-polymethacrylatediols (A) as structural units. The alpha, omega-polymethacrylatediols (A) preferably consist of the monomer units methyl methacrylate, ethyl methacrylate, propyl methacrylate, n-butyl methacrylate, isobutyl methacrylate, tert-butyl methacrylate, n-pentyl methacrylate, amyl methacrylate, n-hexyl methacrylate, n-octyl methacrylate, 2-ethylhexyl methacrylate, n-decyl methacrylate, cyclopentyl methacrylate, cyclohexyl methacrylate, 4-tert-butylcyclohexyl methacrylate, cyclooctyl methacrylate, phenyl methacrylate or isobornyl methacrylate or mixtures thereof. The present invention additionally relates to processes for the preparation of such coating compositions and to their preferred use as fillers, basecoats and / or topcoats, especially in connection with automotive production-line finishing and / or refinishing.

Owner:BASF COATINGS AG

Attapulgite-modified polyvinyl chloride synthetic leather and manufacturing method thereof

InactiveCN102995446AGood flexibilityHas a natural and comfortable feelSynthetic resin layered productsLaminationEpoxySurface layer

The invention discloses attapulgite-modified polyvinyl chloride (PVC) synthetic leather. The attapulgite-modified PVC synthetic leather comprises a surface layer, a foamed layer, a bonding layer and a brushing fabric, and is characterized in that the surface layer is prepared by mixing the following raw materials in parts by weight to form slurry: 70 to 80 parts of SG-2 type PVC resin, 30 to 40 parts of SG-5 type PVC resin, 10 to 15 parts of triethyl citrate, 30 to 35 parts of epoxy butyl oleate, 20 to 25 parts of n-butyl methacrylate, 5 to 6 parts of PVC color paste, 1 to 2 parts of dibasic lead phosphate, 1 to 2 parts of tribasic lead sulfate and 5 to 10 parts of modified diatomite. Through the improvements of the formula and the process, the flexibility of the synthetic leather is improved, and the synthetic leather has a natural comfortable hand feeling similar to that of natural leather and is difficult to damage or tear after being used for 3 to 5 years.

Owner:HEFEI ANSHAN COATING FABRICS

Powder coating containing modified sepiolite powder and preparing method thereof

ActiveCN103059696AImproved surface levelingHigh gloss retentionPowdery paintsEpoxy resin coatingsLow-density polyethyleneEpoxy

The invention discloses a powder coating containing modified sepiolite powder and a preparing method thereof. The powder coating containing the modified sepiolite powder is composed of raw materials comprising modified epoxy resin, bisphenol S epoxy resin, linear low density polyethylene resin, modified sepiolite powder, polyethylene wax, film forming resin, polydimethylsiloxane, benzoin, silver powder, acrylic resin, superfine talcum powder, hexamine, 2,6-di-tert-butyl-4- dimethylamino methyl) phenol, n-butyl methacrylate and polyacrylamide. The powder coating is a green and environment-friendly coating, nontoxic and heat-resistant, contains no solvent, and discharges no volatile organic compound (VOC), and furthermore the modified sepiolite added in the powder coating enhances compatibility of the modified epoxy resin, the bisphenol S epoxy resin and the linear low density polyethylene resin, improves surface leveling of the powder coating, has high gloss retention, and enhances decorating performance of the powder coating, and therefore, an obtained finished product is high in pass percent, and industrialization mass production can be achieved.

Owner:CHUZHOU HONGYUAN SPRAYING

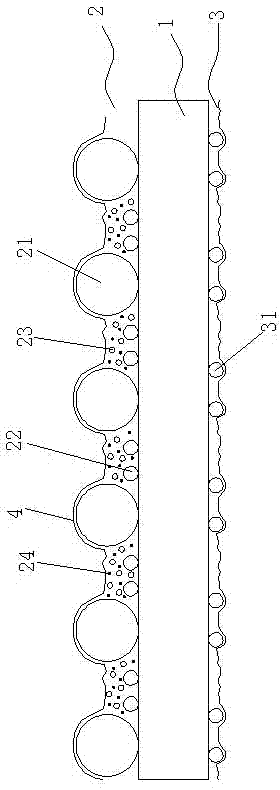

Scratch-resistant optical diffusion film and preparation method for same

The invention discloses a scratch-resistant optical diffusion film, which comprises a substrate layer, an optical diffusion layer and an anti-adhesion layer, wherein the optical diffusion layer comprises a resin film former, diffusion particles, a cross-linking agent and a solvent; the diffusion particles comprise organic particles and inorganic particles; the organic particles consist of large particles, medium particles and small particles; the large particles are PBMA (poly(n-butyl methacrylate)) particles or PIBMA (poly(isobutyl methacrylate) particles; the particle diameter ratio of the large particles to the medium particles is 5:1 to 3:1, and the mass ratio of the large particles to the medium particles is 1:6 to 1:3; the particle diameter ratio of the large particles to the small particles is 15:1 to 10:1, and the mass ratio of the large particles to the small particles is 1:1 to 1:3; the particle diameter ratio of organic particles to inorganic particles is 130:1 to 10:1, and the mass ratio of the organic particles to the inorganic particles is 50:1 to 5:1. The substrate layer, the surface optical diffusion layer and the anti-adhesion layer of the optical diffusion film are prepared by particle diffusion, dilution and drying and curing treatment. A preparation method is simple. A flexible contact surface is formed on the surface, so that high scratch resistance is achieved.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

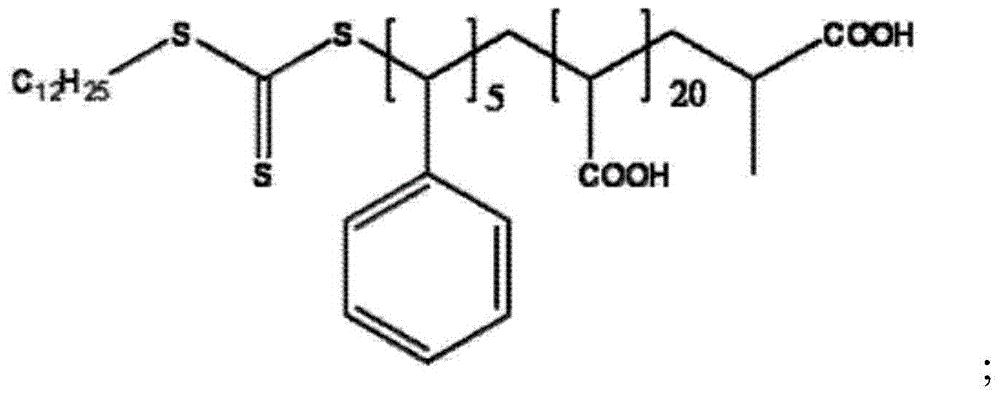

Biocompatibile monodisperse nano polymer carrier and its preparation and medicine-carrying method

InactiveCN101259279AGood biocompatibilityGood blood compatibilityOrganic active ingredientsPharmaceutical non-active ingredientsPhosphorylcholineCarrier system

The invention relates to a monodisperse nano-polymer carrier with biological compatibility and a method for preparation and carrying drug thereof. Firstly, a reversible addition fragmentation chain transfer (RAFT) polymerization method is used for preparing amphiphilic block copolymers with smaller polydispersity index, wherein the hydrophilic segment is methylacryoyloxyethyl phosphorylcholine (MPC) and the hydrophobic segment is n-butyl methacrylate (BMA). Then through the method of solvent evaporation, the amphiphilic block copolymers are used for preparing nano-polymer micelle, drugs are encapsulated in the micelle through physical action, thus obtaining the monodisperse nano-polymer carrier system with good biological compatibility.

Owner:SOUTHEAST UNIV

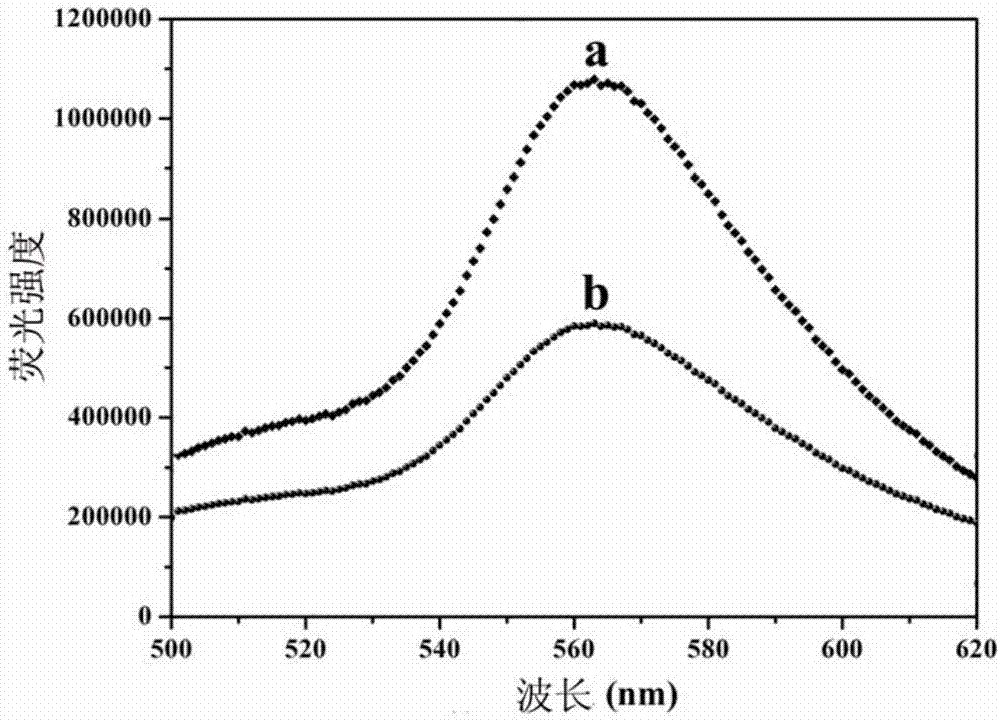

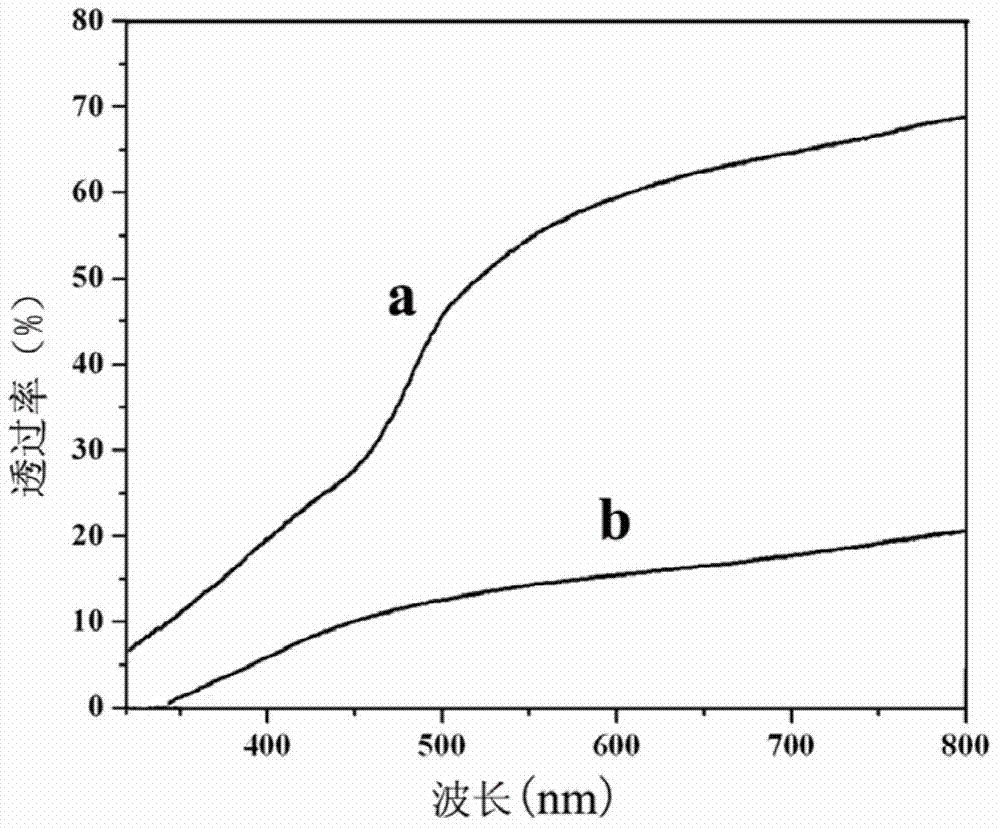

Quantum dot with high transparency and high fluorescence efficiency/epoxy resin nano composite material, preparation and applications thereof

ActiveCN103937158AHigh transparencyExcellent fluorescence performanceSemiconductor devicesEpoxyGlycidyl methacrylate

The invention discloses a quantum dot with high transparency and high fluorescence efficiency / epoxy resin nano composite material, preparation and applications thereof, and belongs to the technical field of nano composite material. Poly(n-butyl methacrylate-glycidyl methacrylate) P(BMA-GMA) amphiphilic two-section copolymer compatibilizer is introduced, the PBMA section of the P(BMA-GMA) copolymer is utilized to soak the oleic acid ligand on the quantum dot surface, the PGMA section of the P(BMA-GMA) is utilized to soak the epoxy substrate, and thus a good interface compatibilizing effect is achieved. The amphiphilic compatibilizing effect of the two-section copolymer is utilized to increase the interface compatibility of quantum dots in epoxy resin substrate, thus the quantum dots are evenly dispersed in the substrate, and the prepared quantum dot / epoxy resin nano composite material has excellent transparency and fluorescence performance, and has a wide application prospect in the field of white light packaging.

Owner:BEIJING UNIV OF CHEM TECH

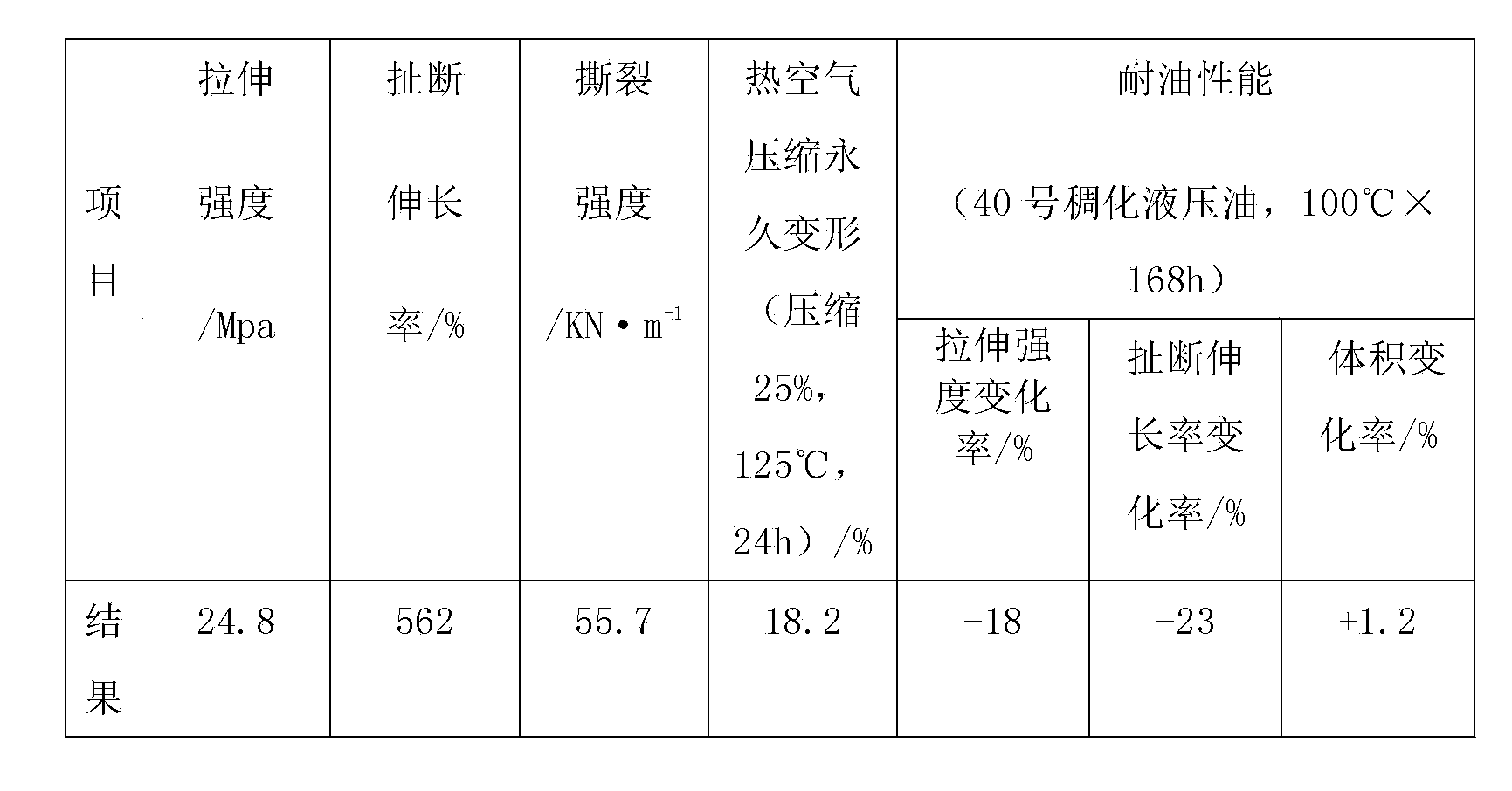

Sealing gasket for hydraulic cylinder and preparation method thereof

InactiveCN103408810AGood oil resistanceImprove temperature resistanceMicrocrystalline waxPolymer science

The invention discloses a sealing gasket for a hydraulic cylinder and a preparation method thereof. The sealing gasket is prepared from the raw materials including nitrile rubber, epichlorohydrin rubber, polyformaldehyde (POM), polyisobutene, 2,4-dichlorobenzoyl peroxide, 2,2'-disulfide dibenzo thiazine, dioctyl sebacate, n-butyl methacrylate, microcrystalline wax, modified wollastonite, nano sepiolite, calcium sulfate whiskers and the like. On the basis of blending of the nitrile rubber and the epichlorohydrin rubber, POM and polyisobutene are also added, so that the performances such as the oil resistance, the temperature tolerance, the abrasive resistance, the compressive strength and the like of the rubber can be improved; and the modified wollastonite is also added, so that the dispersibility of the wollastonite in the rubber can be obviously improved; and the performances such as the mechanical strength, the oil resistance, the abrasive resistance, the high thermal resistance and the like of a seal material are improved.

Owner:WUHU YINHONG HYDRAULIC COMPONENTS

Preparation method of fluorin modified crylic acid resin for helicopter skining paint

the invention discloses a fluorine modified acrylic resin and preparing method for helicopter covering paint, which comprises the following steps: blending composite monomer methacrylic acid borneol ester, n-butyl methacrylate, hydroxyethyl methacrylate, butyl acrylate, methacrylic acid and fluorine monomer in the composite solvent with xylene, propylene glycol methyl ether acetic ester, methyl isobutyl ketone and 100# solvent oil; dripping carbonic glycide ester to polymerize acted by trigger pentaphen peroxide to obtain the product.

Owner:ZHEJIANG UNIV +1

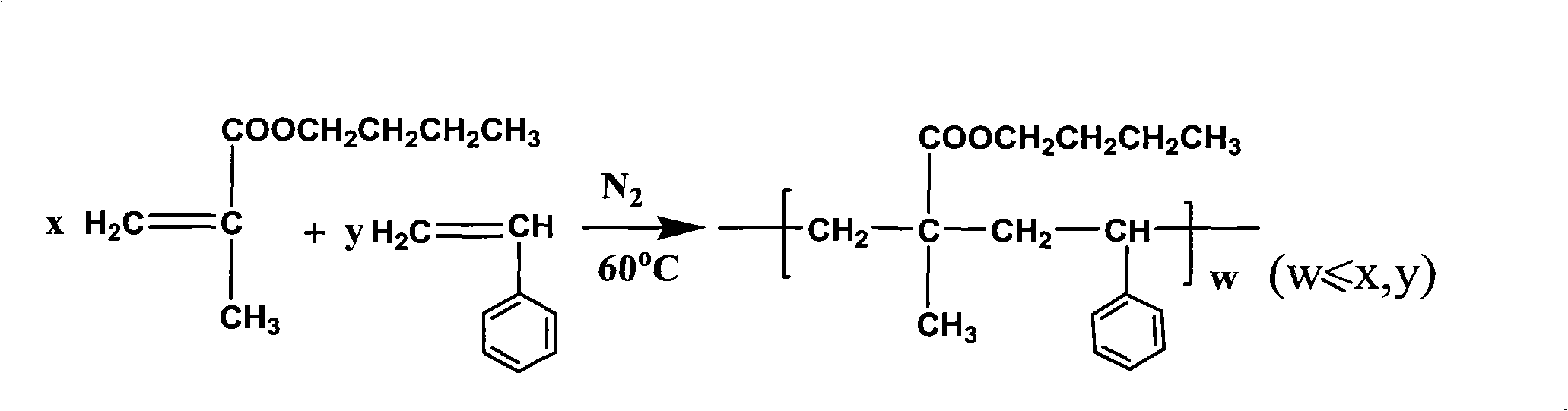

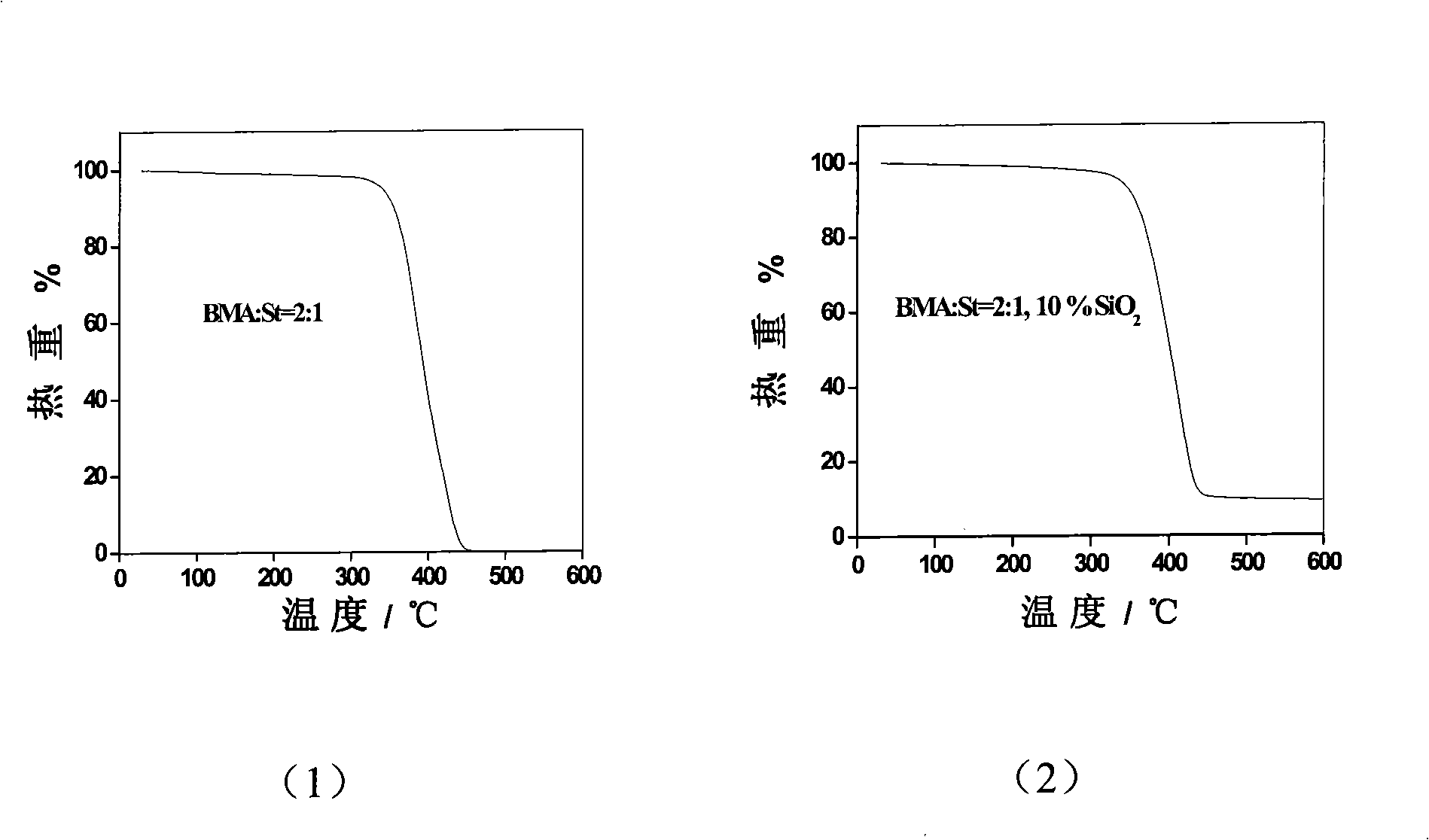

Self-supporting lithium ion battery gel polymer electrolyte and preparation method thereof

ActiveCN101409364ASimple preparation processShorten the timeFinal product manufactureSecondary cellsPolymer scienceDecomposition

The invention discloses a self-supported lithium ion battery gel polymer electrolyte and a preparation method thereof. In the invention, at first, a multi-polymer is obtained by polymerizing the latexes of a methacrylic acid N-Butyl Acetate monomer and a styrene monomer of different proportions; then under the condition of ultrasonic, 10 to 30 minutes after a certain amount of nanometer particles are dispersed in a tetrahydrofuran solvent, the powder of the polymer is dissolved into the liquor to obtain ropy gel; a self-supported lithium ion battery gel polymer membrane is obtained by a phase transfer method; the membrane is dipped into the electrolyte, thus obtaining the gel polymer electrolyte. The gel polymer electrolyte is good in thermal stability, has a high decomposition temperature, is simple in preparation technique and is suitable for the industrial production of the lithium ions of the polymer, with the raw materials easily gotten.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Polyvinyl chloride synthetic leather and manufacturing method thereof

InactiveCN102995449AGood flexibilityHas a natural and comfortable feelSynthetic resin layered productsLaminationPolyesterPolyvinyl chloride

The invention discloses polyvinyl chloride synthetic leather, which comprises a face layer, a foaming layer, a bonding layer and a brushing fabric. The polyvinyl chloride synthetic leather is characterized in that the face layer is made of slurry prepared from the following raw materials in parts by weight: 40-50 parts of SG-1 type PVC (polyvinyl chloride), 70-80 parts of SG-6 type PVC resin, 20-25 parts of phthalate, 15-20 parts of sebacic propylene glycol polyester, 20-25 parts of n-butyl methacrylate, 5-6 parts of PVC color paste, 1-2 parts of imarcaptoacetate dioctyltin, 1-2 parts of zinc stearate, 5-10 parts of light calcium carbonate and 35-50 parts of modified attapulgite. According to the invention, through formula and process improvement, the toughness of the synthetic leather is increased, and the polyvinyl chloride synthetic leather has natural and comfortable handfeel similar to that of natural leather; and the polyvinyl chloride synthetic leather is not easy to damage or tear within 3-5 years.

Owner:HEFEI ANSHAN COATING FABRICS

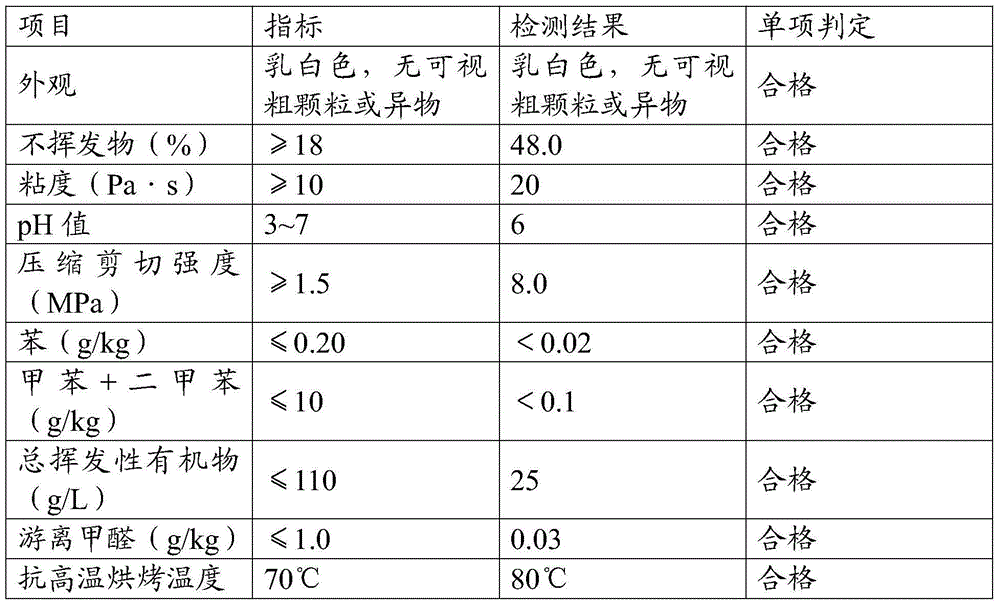

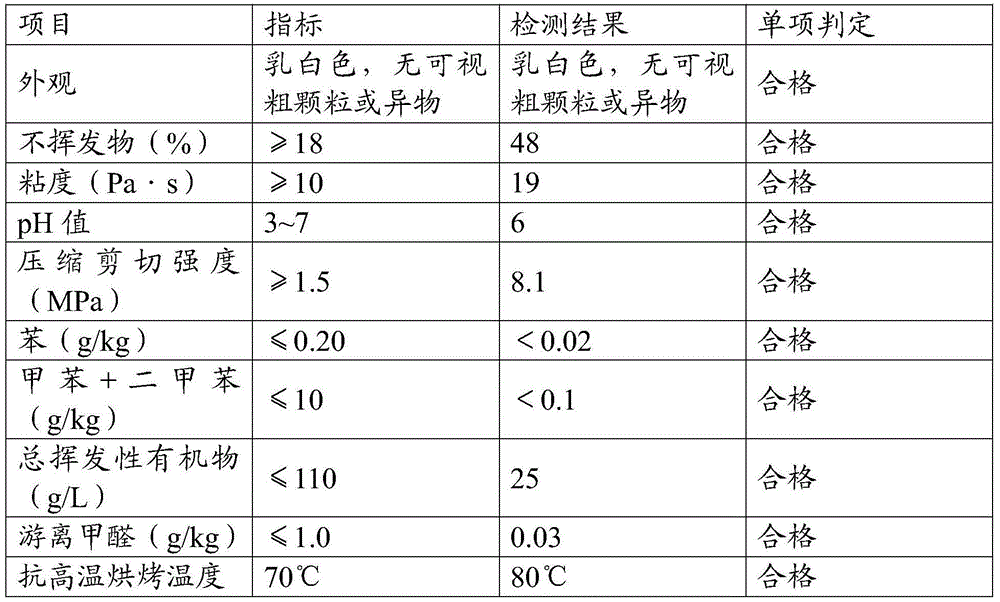

Veneer glue and preparation method thereof

ActiveCN104910836AGood anti-aging performanceNo smellMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesCarvacryl acetateRaw material

The invention discloses a veneer glue and a preparation method thereof. The veneer glue is composed of the following raw materials: vinyl acetate, vinyl versatate, n-butyl methacrylate, acrylic acid, methacrylic acid, an environment-friendly plasticizer, polyvinyl alcohol, a special cross-linking monomer, an environmentally reactive anionic emulsifying agent, an environmentally reactive nonionic emulsifying agent and deionized water. The veneer glue finished product does not contain formaldehyde, heavy metal, halide and the like, and meets the state promulgated Interior Decoration Material Adhesive Harmful Substance Limit GB18583-2008 standard. The veneer glue is nontoxic, odor-free, safe and reliable. When the glue is used in fireproof board and veneer binding, the veneer is prevented from yellowing, and has a good anti-aging effect. With the glue, the veneer is flexible, and can resist bending and glue failure. The veneer can resist glue failure after 7 days of soaking in 45 DEG C water.

Owner:佛山永恒达新型建材有限公司

Absorbing fiber and manufacturing method thereof

InactiveCN101698965ASmooth preparation processUniform grainOther chemical processesMonocomponent synthetic polymer artificial filamentFiber(Hydroxyethyl)methacrylate

The invention discloses an absorbing fiber and a manufacturing method thereof. The absorbing fiber comprises 100wt% of polymer monomer by mass percent, wherein n-butyl methacrylate monomer accounts for 70-90wt%, and methyl methacrylate monomer accounts for 10-30wt%; beta-hydroxyethyl methacrylate accounts for 10-20wt% of the polymer monomer (the following are the same); and benzoperoxide accounts for 0.1-0.5wt% of the total mass of the polymer monomer. The manufacturing method adopting the mass percent composition of the absorbing fiber comprises the following steps: 1, refining the methyl methacrylate and the n-butyl methacrylate in a reduced pressure distillation mode; 2, synthesizing methyl methacrylate / n-butyl methacrylate / beta-hydroxyethyl methacrylate multipolymer by using a water-phase suspension polymerizing method; 3 thoroughly drying the multipolymer, and adding 30-50wt% of N,N-dimethyl acetamide solvent according to the mass ratio of 3:7-1:1 to sufficiently swell the multipolymer for 24-48 hours; and 4 under the spinning temperature of 100-150 DEG C, preparing the absorbing fiber by using a gel spinning method and a double-screw spinning machine.

Owner:TIANJIN POLYTECHNIC UNIV

Method for preparing organic adsorption fiber

InactiveCN101342484AGood adsorption propertiesGood mechanical propertiesOther chemical processesMonocomponent synthetic polymer artificial filamentFiberAcrylonitrile

The invention relates to a method for manufacturing organic-matter adsorbing fibers. The technical process includes that 1) first monomer n-butyl methacrylate covering 50-90 percent of the total mass of the two monomers (the same below) and 50-10 percent of second monomer acrylonitrile and 0.1-1 percent of dispersing agent, 0.1-1 percent of initiator and two types of deionized water (monomer total volume: 3:1) are used to produce resin; 2) proper amount of solvent and the achieved resin are used to prepare spinning stock-solution; 3) the achieved spinning stock-solution is used for spinning by solution spinning technology, and nascent fiber is achieved; 4) after stretching treatment of the nascent fiber, the organic-matter adsorbing fiber is achieved. The invention has the advantages of that the manufacturing technique is simple, the prepared fiber is in three-dimensional mesh texture, and the fiber has sound organic-matter adsorbing capacity and mechanical property.

Owner:TIANJIN POLYTECHNIC UNIV

Water-borne acrylic compound adhesive and preparing method thereof

InactiveCN105907343AImprove stabilityHigh viscosityGraft polymer adhesivesFunctional monomerAdhesive

The invention discloses water-borne acrylic compound adhesive. The water-borne acrylic compound adhesive is prepared from the following raw materials in parts by weight: 5-10 parts of emulsifying agent, 0.2-0.6 part of initiating agent, 4-6 parts of hydroxyl-terminated polydimethylsiloxane organosilicone modifying agent, 20-30 parts of soft monomer, 0.5-0.7 part of buffering agent, 20-30 parts of hard monomer, 8-12 parts of functional monomer, 4-6 parts of pH conditioning agent and 70-90 parts of deionized water. The hard monomer is one or more than two kinds of methyl acrylate, methyl methacrylate, vinyl acetate, ethyl methacrylate and n-butyl methacrylate. The prepared water-borne acrylic compound adhesive is good in stability, high in viscosity, free of organic solvent, free of poison, favorable for environmental friendliness and health of operating workers and easy to convey and store. By means of adding various kinds of water-borne additives with excellent performance, foam of the water-borne acrylic compound adhesive during use is reduced, moistening and leveling property of emulsion on the surface of a plastic film is improved, the convenientce of operation is realized, the affinity between glue and a PET film is improved, and the peel strength is improved.

Owner:湖南省和祥润新材料有限公司

Highly reproducible agglutination immunoassay method and reagents

InactiveCN1449495AImmunoagglutination is stableUniform immunoagglutination reactionEnzymologyBiological testingAntigen2-methacryloyloxyethyl phosphorylcholine

The present invention provides an agglutination immunoassay, wherein the agglutination of insoluble carrier particles such as latex are stabilized and uniformized to give good reproducibility, and a reagent therefor. In the agglutination immunoassay which comprises allowing an antigenic substance in a sample to bind to insoluble carrier particles carrying substantially neither antigens nor antibodies thereon, and allowing an antibody or an antibody complex which reacts specifically to the antigenic substance to bind to the antigenic substance to give a selective agglutination of the insoluble carrier particles, a homopolymer prepared by polymerization of a monomer such as 2-methacryloyloxyethyl phosphorylcholine having a phosphorylcholine group and a vinyl group, or a copolymer prepared by polymerization of a monomer having a phosphorylcholine group and a vinyl group, with a monomer having a vinyl group such as n-butyl methacrylate is used.

Owner:KYOWA MEDEX CO LTD +2

Solvent-resistant corrosion-resistant rubber and preparation method thereof

The invention discloses a solvent-resistant and corrosion-resistant rubber and a preparation method thereof. The solvent-resistant and corrosion-resistant rubber consists of the following parts by mass: 30-50 parts of natural rubber, 20-30 parts of nitrile rubber, and 20-30 parts of fluorosilicone rubber 30 parts, 3-7 parts of active zinc oxide, 3-9 parts of PE wax, 4-10 parts of n-butyl methacrylate, 3-8 parts of epoxy resin, 0.3-1.2 parts of anti-aging agent, 1-part of resorcinol 3 parts, polytetrafluoroethylene 6‑10 parts, coumarone resin 2‑5 parts, stearic acid 3‑6 parts, white carbon black 8‑15 parts, sulfur 10‑15 parts, accelerator AM‑2 3‑ 5 parts, 0.1-0.3 parts of anti-scorch agent CTP, the present invention is prepared by two-stage mixing method. The solvent-resistant and corrosion-resistant rubber of the invention has good resistance to organic solvents, strong acid and alkali resistance, corrosion resistance, excellent wear resistance and high temperature resistance, simple preparation, low cost and certain promotion value.

Owner:安徽省含山县锦华氧化锌厂

Water-base ambient crosslinking acrylate wood paint resin and preparation method thereof

The invention relates to a water-base ambient crosslinking acrylate wood paint resin and a preparation method thereof. The resin comprises the following components: n-butyl acrylate, n-butyl methacrylate, methyl methacrylate, styrene, acrylic acid, diacetone acrylamide, adipic dihydrazide, potassium persulfate, emulsifier NP-40, emulsifier sodium dodecyl benzene sulfonate, ammonia and deionized water. The resin takes water as the diluent, is harmless to human bodies and the environment, has no pollution and does not contain harmful substances, such as triphenyl, formaldehyde and the like, the resin grain fineness is less than 100 nanometers, the paint film has high brightness and good hand feeling, and the resin can be used as the primer and finish paint for all kinds of water-base wood varnish and colored paints.

Owner:BEIJING CARL RES INST FOR CHEM IND

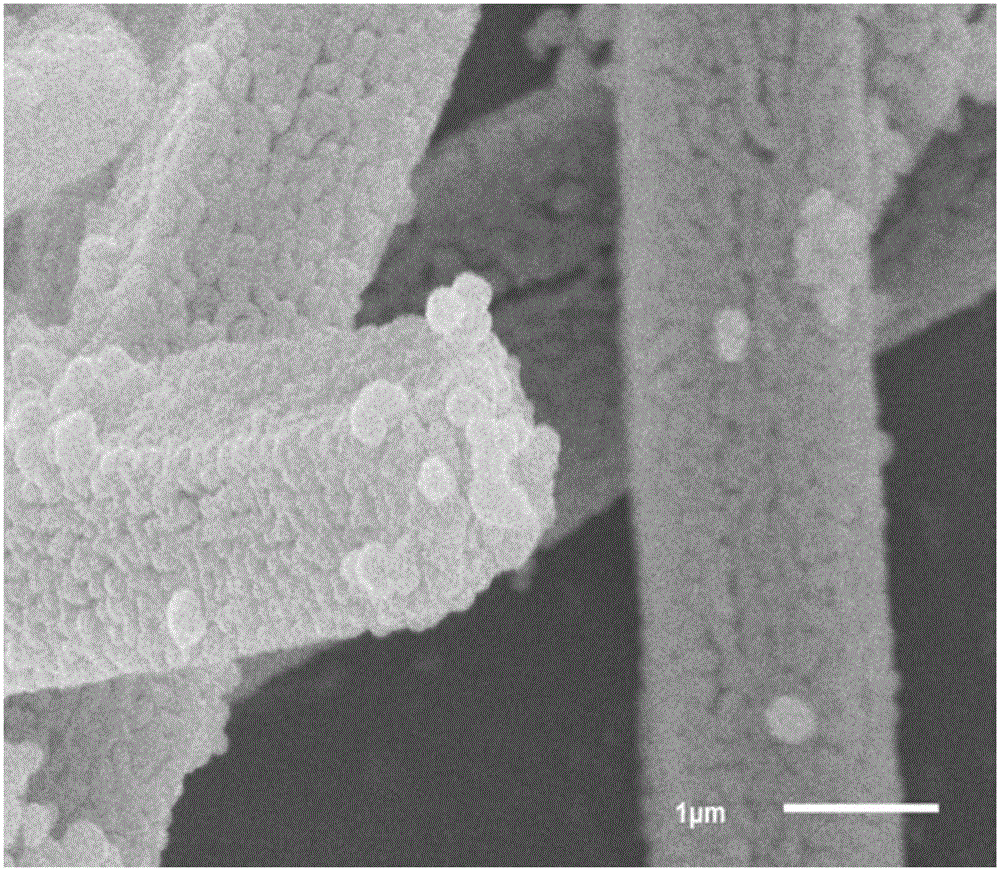

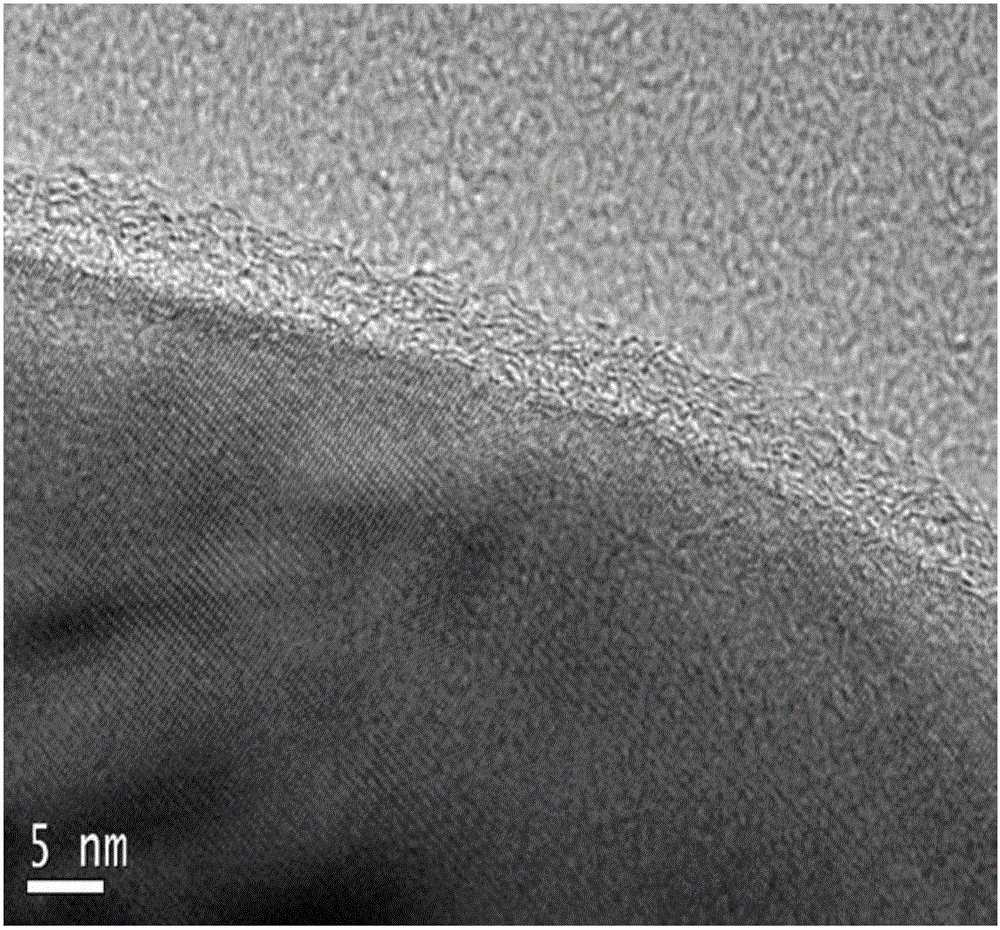

Application of block polymer as dielectric elastomer

ActiveCN105153624AExcellent electrostrictive performanceQuick responseIsooctyl acrylatePolymer science

The invention discloses an application of a block polymer as a dielectric elastomer. The structural general formula of the block polymer is B-C-D, wherein B and D are independently selected from a styrene homopolymer or a methyl methacrylate homopolymer; C is selected from a butyl acrylate homopolymer, a n-butyl acrylate homopolymer, a n-butyl methacrylate homopolymer, a isobutyl methacrylate homopolymer, a tert-butyl acrylate homopolymer, a 2-ethylhexyl acrylate homopolymer, an iso-octyl acrylate homopolymer, an ethyl acrylate homopolymer or a homopolymer of at least two kinds of butyl acrylate, n-butyl acrylate, n-butyl methacrylate, isobutyl methacrylate, tert-butyl acrylate, 2-ethylhexyl acrylate, iso-octyl acrylate and ethyl acrylate. The block polymer can have larger deformation under high-frequency driving without swelling by a solvent and can be used as the dielectric elastomer.

Owner:ZHEJIANG UNIV

Chlorosulfonated polyethylene rubber/chloroprene rubber gasket and preparation method thereof

ActiveCN102993585AImprove flame retardant performanceAccelerated corrosionPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsPolyesterSodium bicarbonate

The invention discloses a chlorosulfonated polyethylene rubber / chloroprene rubber gasket. The gasket comprises the following raw materials in parts by weight: 135-145 parts of chlorosulfonated polyethylene rubber CSM2305, 10-15 parts of chloroprene rubber S40V, 10-15 parts of SG-2 type PVC (polyvinyl chloride) resins, 2-4 parts of propanediol sebacate polyester, 3-5 parts of n-butyl methacrylate, 1-2 parts of sodium bicarbonate, 0.5-1 part of sulfur, 1-2 parts of calcium stearate and the like. The gasket has the beneficial effects that the gasket has good high temperature resistance, sealability, flame retardance and corrosion resistance and can work in such media as acid, alkali and oil for a long time; the volume and hardness of the gasket are small in variation; the gasket does not adhere to metal surfaces; and the gasket has small friction coefficient and good abrasion resistance and has the advantages of softness of bonding with sealing surfaces, good weathering aging and ozone aging resistance, durability and the like.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

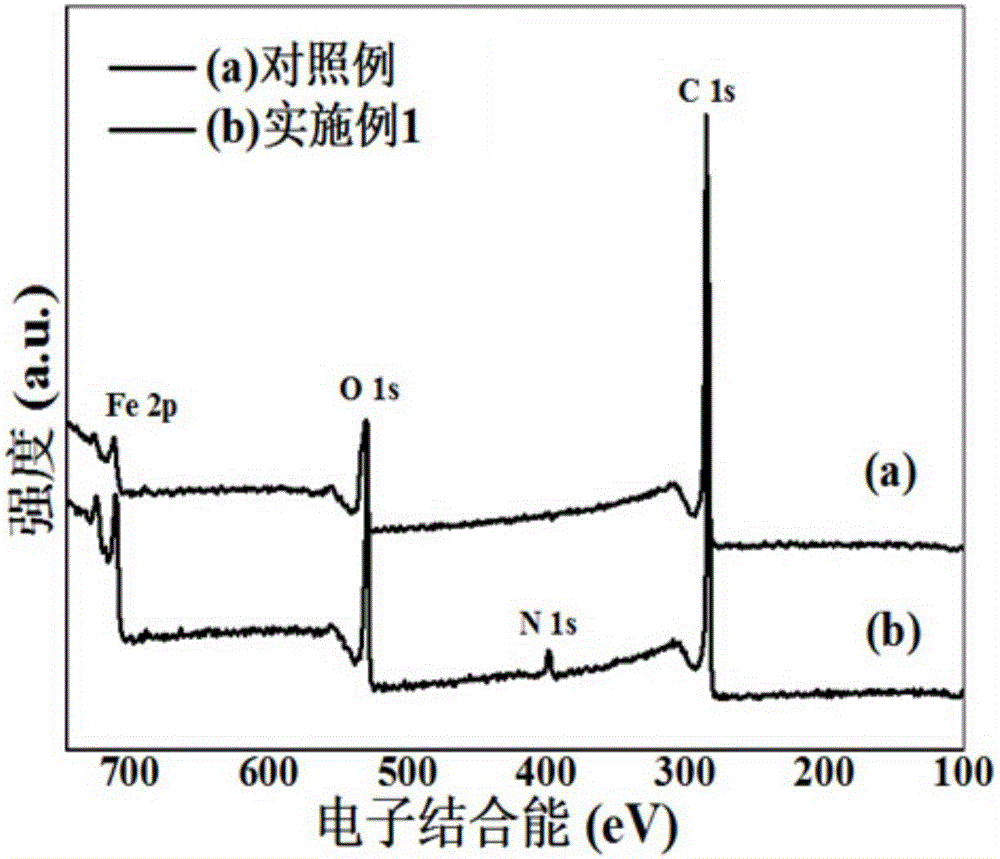

Nitrogen-doped carbon-coated iron oxide negative electrode material for lithium-ion battery and preparation

The invention belongs to the technical field of a negative electrode material for a lithium-ion battery, and discloses a nitrogen-doped carbon-coated iron oxide negative electrode material for the lithium-ion battery and a preparation method of the nitrogen-doped carbon-coated iron oxide negative electrode material. The method comprises the following steps of adding ferrite to a mixed solution of water and ethanol, stirring, dissolving, adding oxalate and stirring to obtain a turbid liquid; heating the turbid liquid to 120-220 DEG C for reaction for 8-15 hours to obtain a ferrous oxalate precursor; heating the ferrous oxalate precursor to 500-600 DEG C and burning the ferrous oxalate precursor for 4-8 hours to obtain an iron oxide; dissolving an emulsifier into water, adding n-butyl methacrylate, acrylonitrile and styrene, heating the solution to 55-65 DEG C, adding an initiator, stirring for 4-10 hours to obtain an emulsion and carrying out demulsification to obtain a polymer; and dispersing the polymer into an organic solvent, adding the iron oxide, stirring for 12-36 hours, separating to obtain a solid, heating the solid to 500-600 DEG C and burning the solid for 2-4 hours to obtain the nitrogen-doped carbon-coated iron oxide negative electrode material with excellent cycle performance and rate capability.

Owner:SOUTH CHINA NORMAL UNIVERSITY

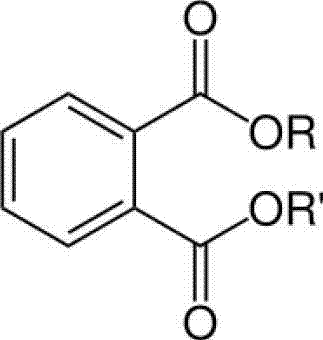

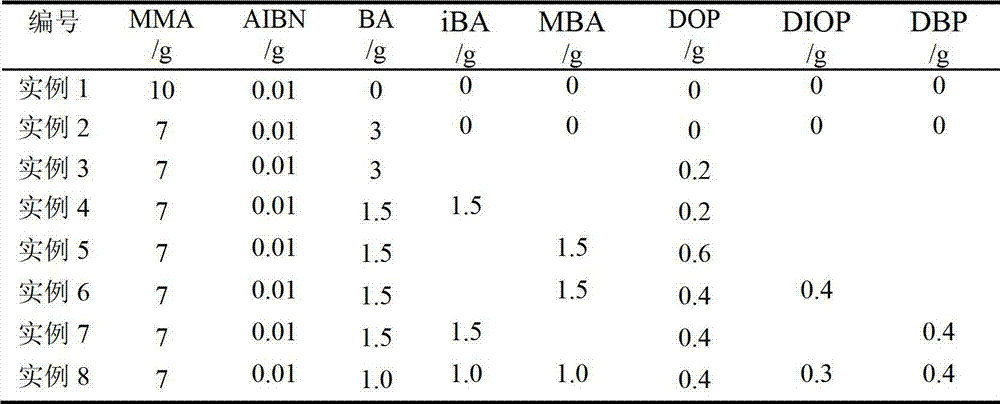

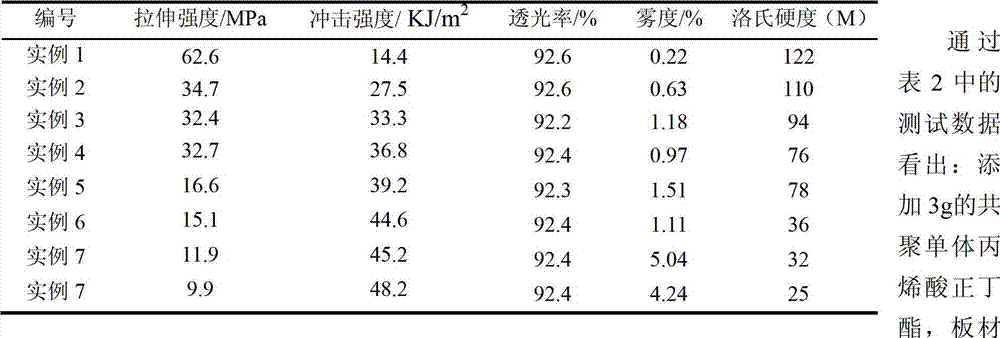

Preparation method of plasticized, copolymerized and modified organic glass

A plasticized, copolymerized and modified organic glass is prepared by copolymerizing methyl methacrylate, comonomer and plasticizer with a main body, and carrying out casting molding. The comonomer used belongs to butyl acrylate type, and includes n-butyl acrylate or n-butyl methacrylate; and the plasticizer belongs to phthalic acid esters, and includes Di-n-octyl phthalate (DOP), Diisooctyl ortho-phthalate (DIOP) and dibutyl phthalate (DBP). The preparation method is used for preparing an organic glass cast sheet with super flexibility and high light transmittance.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com