Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "Poly n-butyl methacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil absorbing fibre and perparing method thereof

InactiveCN1584148ABroaden the fieldLarger specific surface area for oil absorptionWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberBenzoyl peroxide

The invention relates to a kind of oil-absorbed fiber and its producing method. Its prescription is: 100% polymer monomer, 10-40% of potential gemel agent, 0.1-0.5% solicitation, 0.5-1% dispersant. Moreover the water-like body is 3-4 times more in volume than polymer monomer. The polymer monomer is methacrylate monomer involving butyl methacrylate, the potential gemel agent is 2-hydroxyethyl methacrylate, the solicitation is benzoyl peroxide, and dispersant is poly-vinyl-alcohol. The process is (1) use water-suspending polymerization to produce butyl methacrylate under 70-80 deg.C for blending and polymerizing for 8-10 hours. (2) dissolve the polymer into proper solvent to deploy 20-25% liquid and then insert potential gemal agent and solicitation to polymerize for 3-5 hours under 75-80 deg.C to obtain the original liquid. (3) take off dunking. (4) spin using one of wet or dry method or both, (5) treat with fibre for 10-60 minutes under 120-165 deg.C to obtain the production. The solvent discussed above is one of DMF, DMAC or dimethoxysulfoxide.

Owner:TIANJIN POLYTECHNIC UNIV

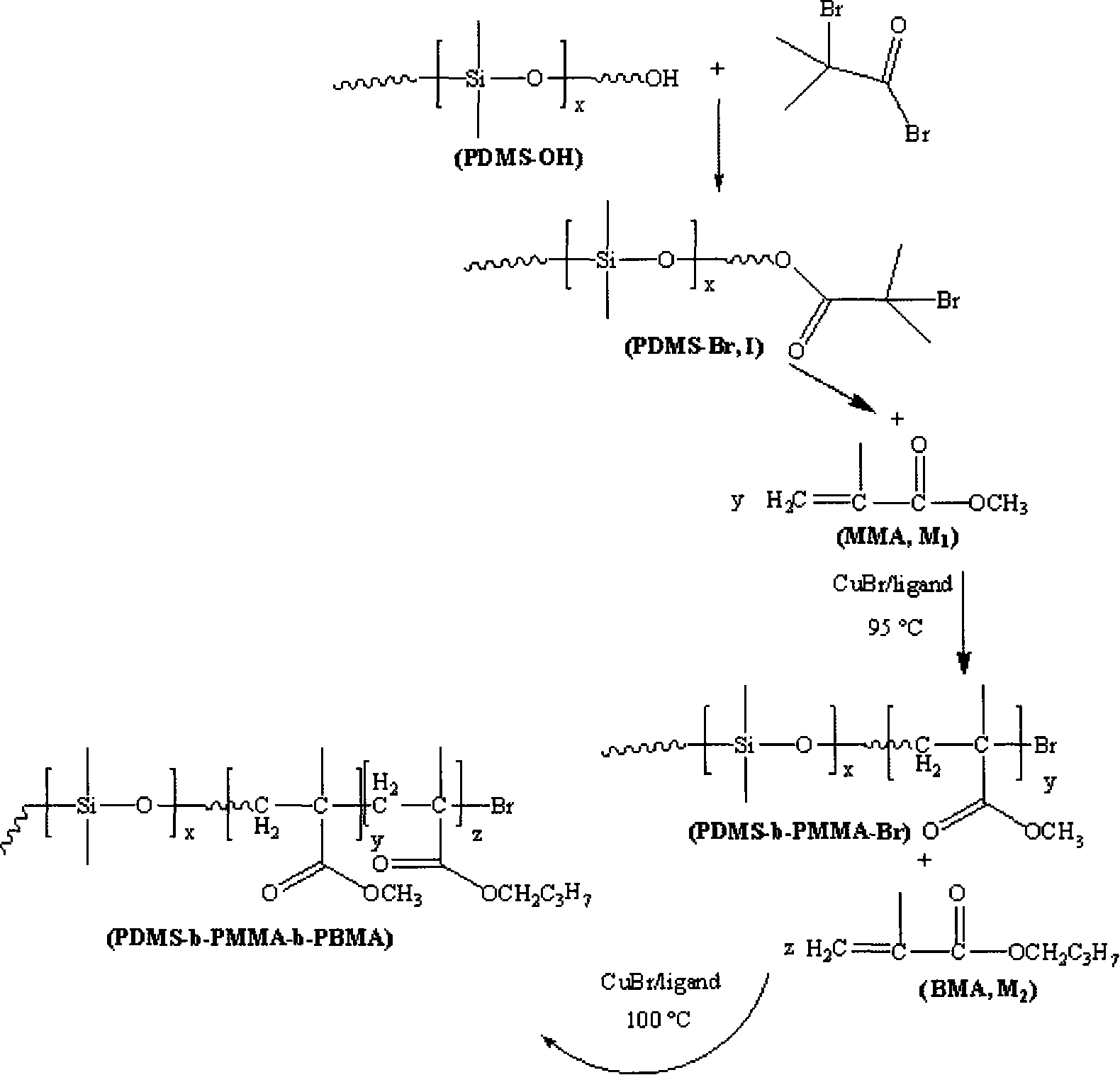

Silicon-acrylic tri-block copolymer with low surface energy and preparing method thereof

The invention relates to a silicon-acrylic three-block copolymer with low surface energy and a process for preparation, which relates to the synthesis of silicon-acrylic low-surface-energy three-block copolymer. The invention provides a silicon-acrylic three-block copolymer with low surface energy, whose structure of reaction product is accurate, and the original skeleton construction of each block is kept. The invention relates to a dimethyl silicone polymer-b- polymethyl methacryate-b-poly n-butyl methacrylate. And the process for preparation comprises first, preparing dimethyl silicone polymer macromolecule initiating agent of the dead ends of bromine atoms, second, preparing two-block macromolecule initiating agent of copolymer dimethyl silicone polymer-b-polymethyl methacryate, third, preparing two-block copolymer macromolecule initiating agent of dimethyl silicone polymer-b- polymethyl methacryate, finally, preparing three-block novel copolymer of dimethyl silicone polymer-b- polymethyl methacryate-b-poly n-butyl methacrylate.

Owner:XIAMEN UNIV

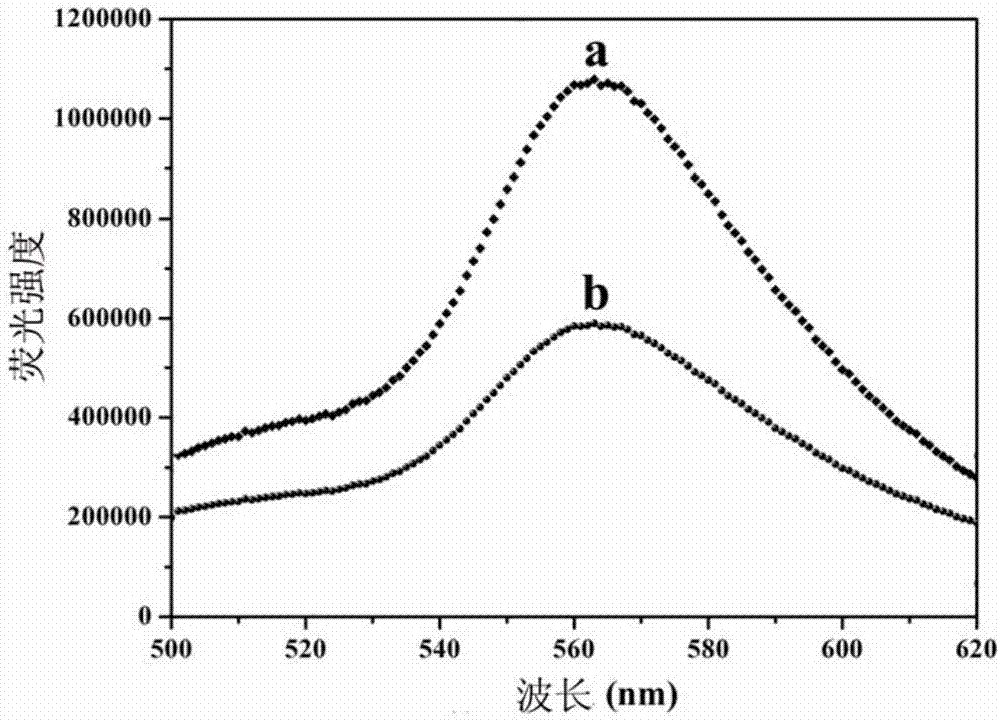

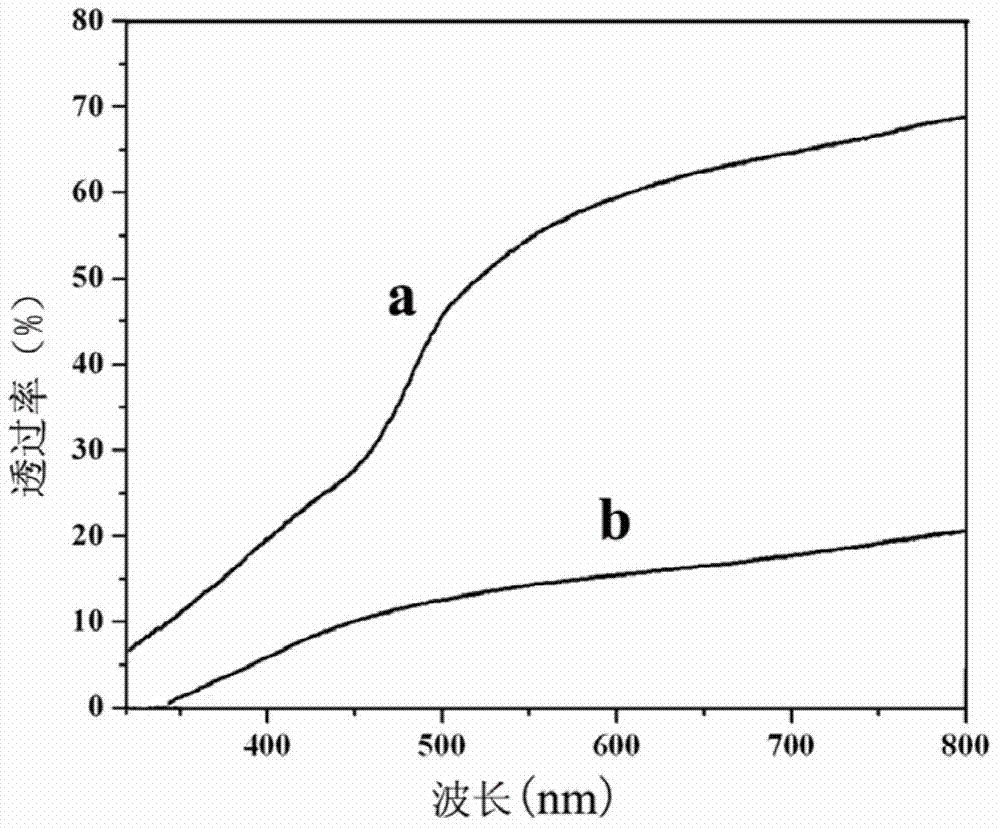

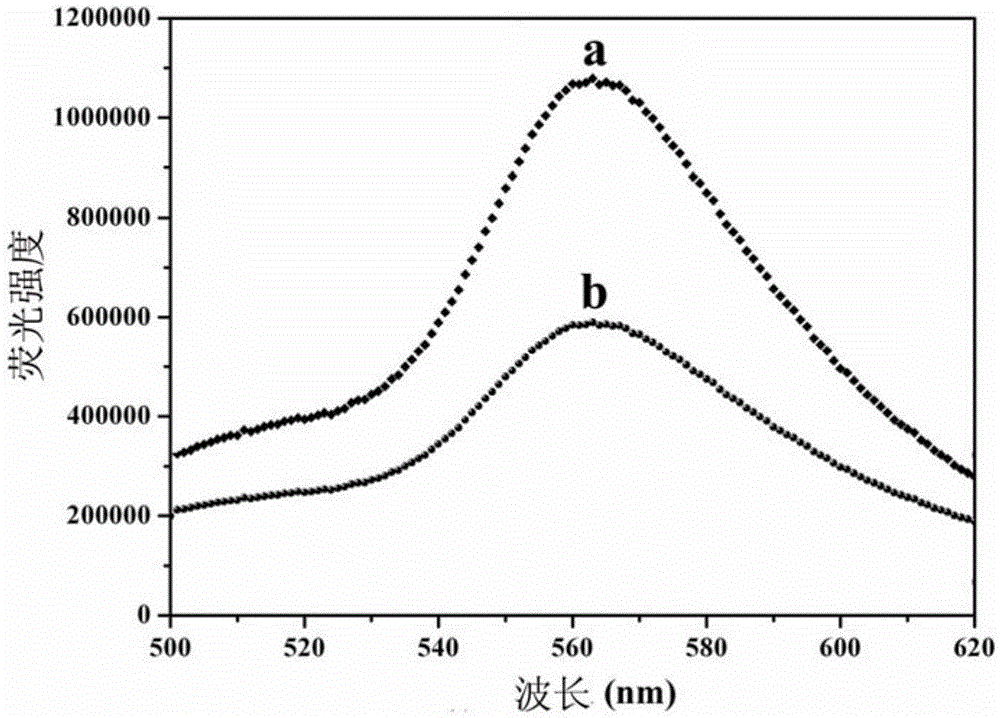

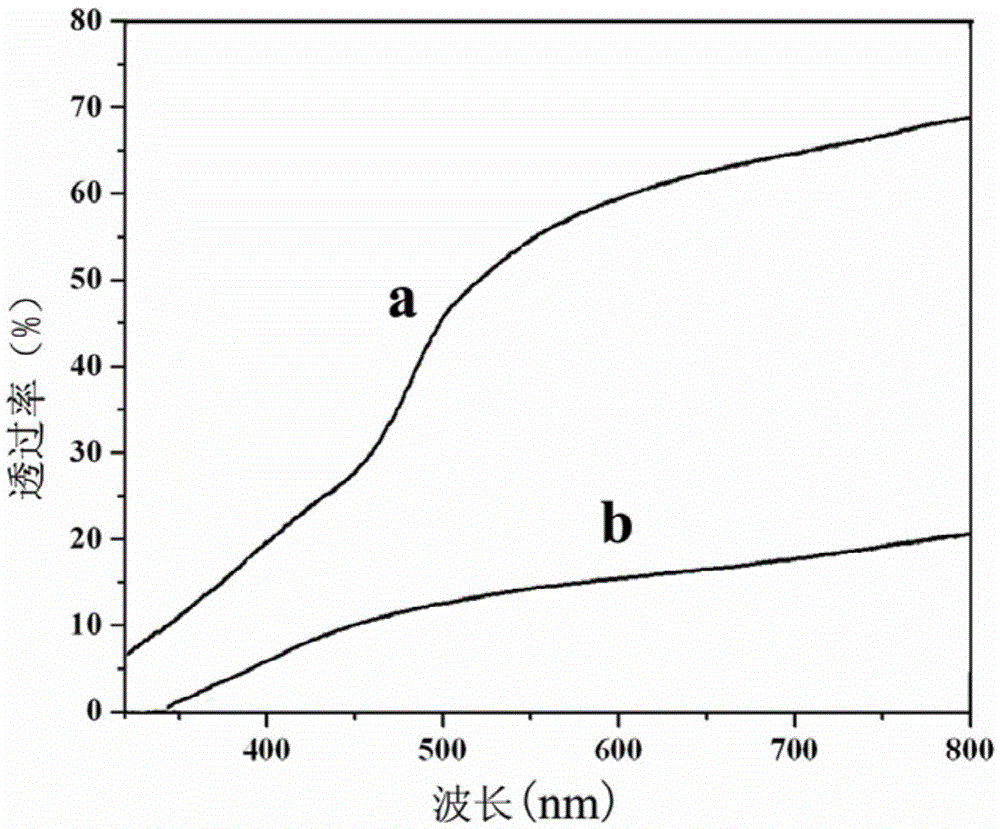

Quantum dot with high transparency and high fluorescence efficiency/epoxy resin nano composite material, preparation and applications thereof

ActiveCN103937158AHigh transparencyExcellent fluorescence performanceSemiconductor devicesEpoxyGlycidyl methacrylate

The invention discloses a quantum dot with high transparency and high fluorescence efficiency / epoxy resin nano composite material, preparation and applications thereof, and belongs to the technical field of nano composite material. Poly(n-butyl methacrylate-glycidyl methacrylate) P(BMA-GMA) amphiphilic two-section copolymer compatibilizer is introduced, the PBMA section of the P(BMA-GMA) copolymer is utilized to soak the oleic acid ligand on the quantum dot surface, the PGMA section of the P(BMA-GMA) is utilized to soak the epoxy substrate, and thus a good interface compatibilizing effect is achieved. The amphiphilic compatibilizing effect of the two-section copolymer is utilized to increase the interface compatibility of quantum dots in epoxy resin substrate, thus the quantum dots are evenly dispersed in the substrate, and the prepared quantum dot / epoxy resin nano composite material has excellent transparency and fluorescence performance, and has a wide application prospect in the field of white light packaging.

Owner:BEIJING UNIV OF CHEM TECH

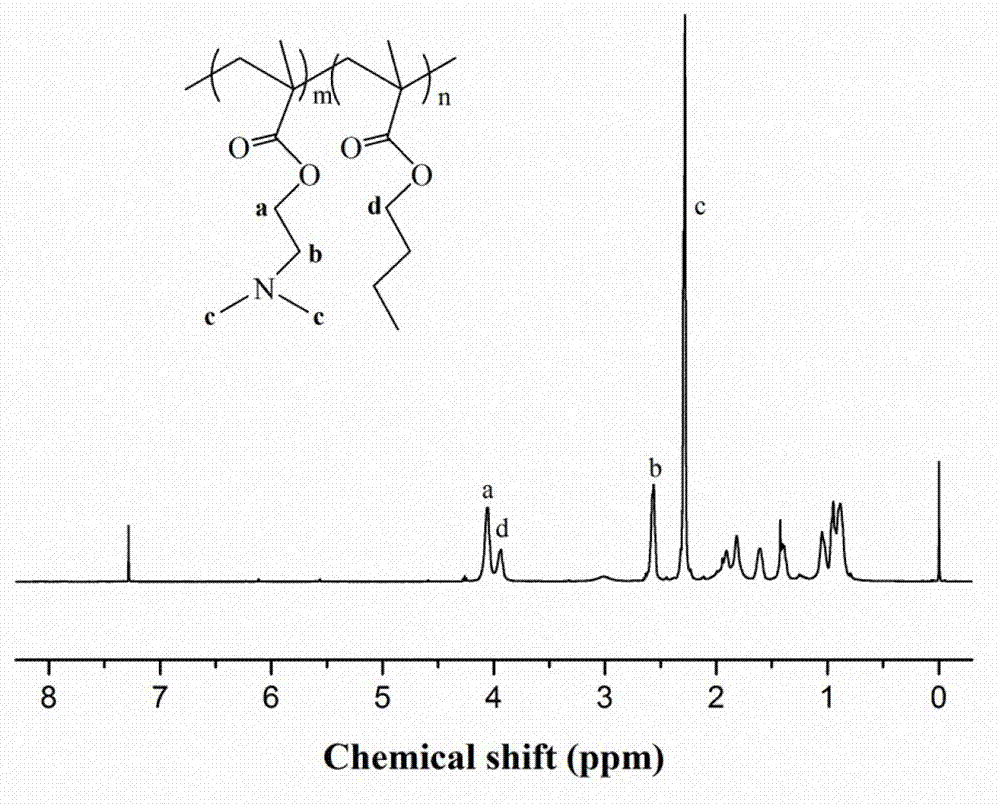

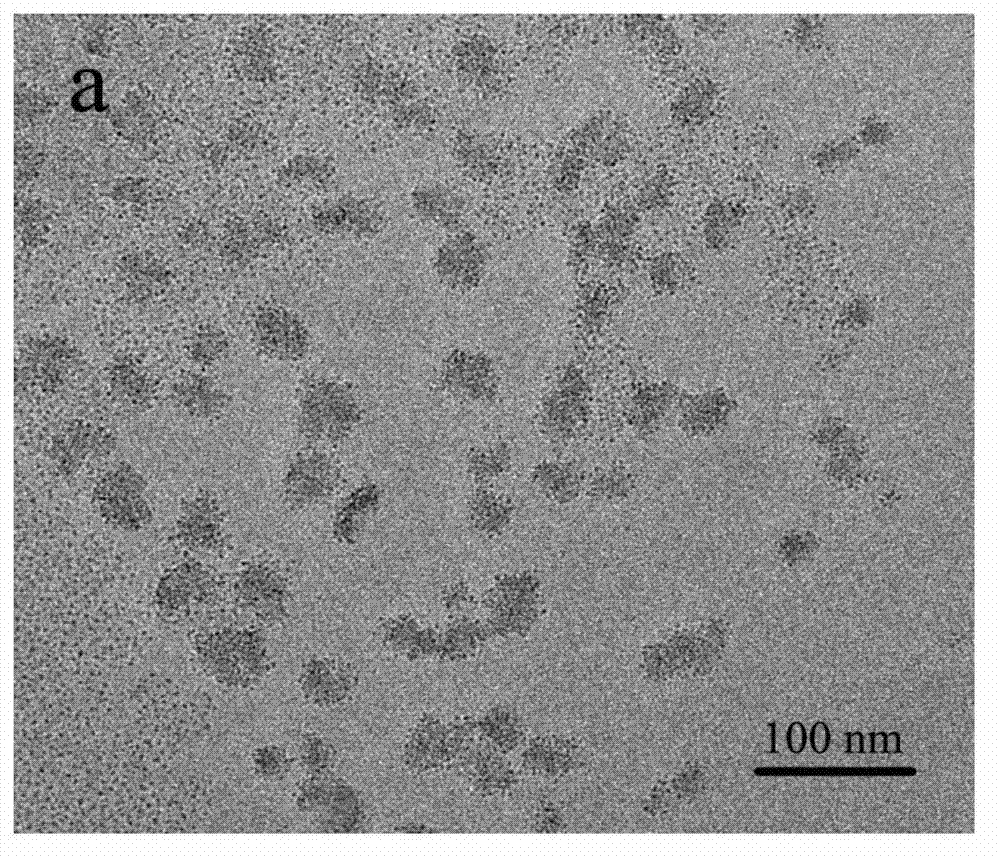

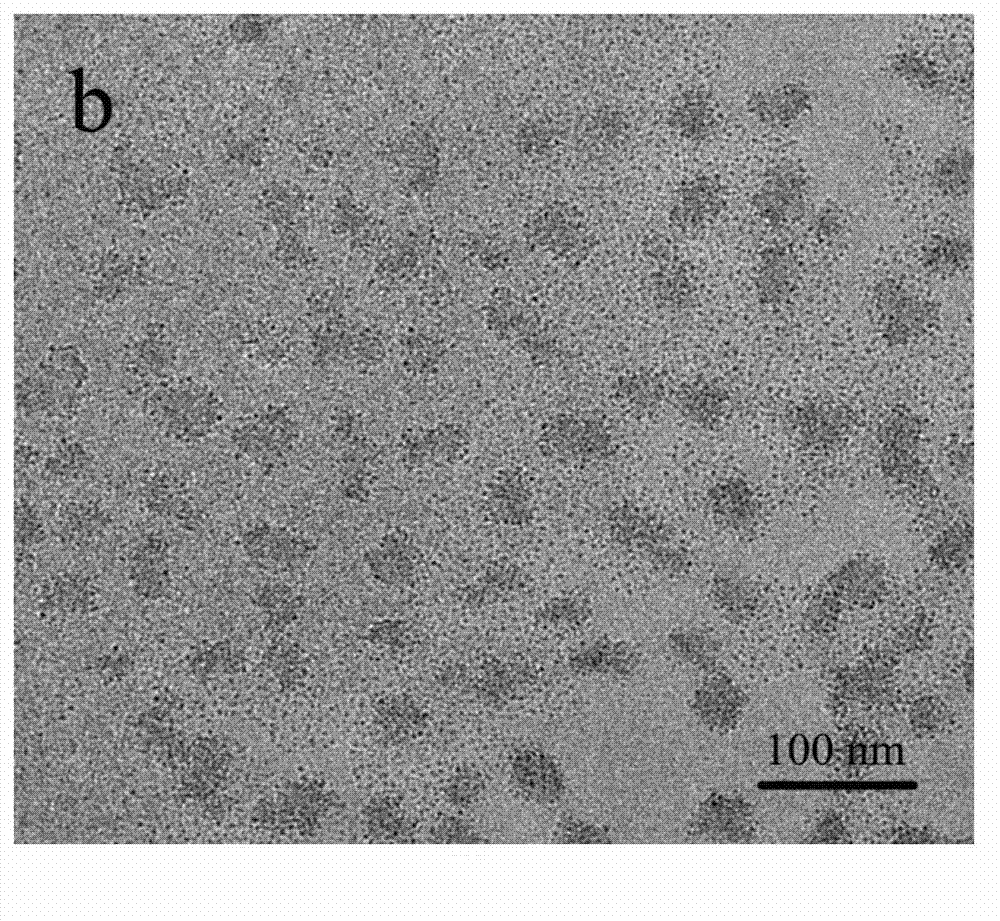

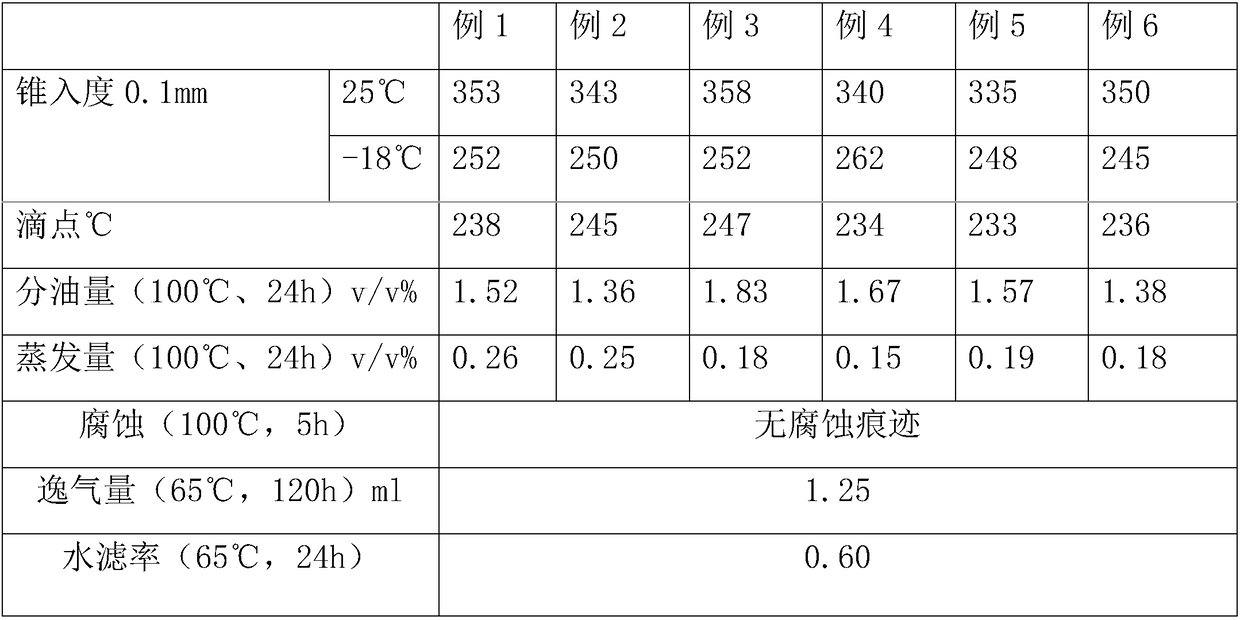

Segmented copolymer capable of being self-assembled into micelle and preparation method thereof

The invention discloses an amphipathic segmented copolymer capable of being self-assembled into micelle. The segmented copolymer is formed by taking poly-n-butyl methacrylate as a first block and taking PDMAEMA as a second block, namely, poly (butyl methacrylate-PDMAEMA) is prepared by a reversible addition-fragmentation chain transfer polymerization (RAFT) method. According to the segmented copolymer, the block length ratio can be adjusted in a planned mode by adjusting the molar ratio of butyl methacrylate to a PDMAEMA monomer to a chain transfer agent, and the amphipathic segmented copolymer is high in controllability, mild in reaction conditions and high in product purity. The segmented copolymer solution is subjected to microphase separation in a selective solvent, and a self-assembled micelle structure which has nanometer size, narrow distribution and protophobic solvent core and solvent shell is spontaneously formed. The segmented copolymer can be used for research in the field of biological medicines in a nano controlled release system.

Owner:XIAMEN UNIV

Novel ultraviolet-cured silk-screening snow printing ink

ActiveCN104559457AMeet environmental protection requirementsStrong adhesionInksPaperboardUltraviolet

The invention relates to novel ultraviolet-cured silk-screening snow printing ink which is characterized by being prepared from the following components: tripropylene glycol diacrylate, 1, 6-hexanediol diacrylate, trimethylolpropane triacrylate, polyaldehyde resin, poly-n-butyl methacrylate, poly{2-hydroxyl-2-methul-1-[4-(1-methyl vinyl)phenyl] acetone}, polyurethane acrylate, an organic silicon defoamer, a polyether organic silicon flatting agent, an active amine-assisted optical initiator and a wax powder. The printing ink printed and dried is still ultraviolet-cured silk-screening snow printing ink which is transparent and not yellowed as standing time of a printing material goes on and is good in adhesive force. The printing ink is particularly suitable for being used on a white paperboard or offset print light color ink and overlaid on silk-screening UV gloss oil and a silk-screening UV thick film to print, and is strong in adhesive force. Moreover, the printing ink detonated and rocketed is proper in pattern thickness, so that a transparent third-dimensional effect on a pattern of the printing material is obtained.

Owner:ZHEJIANG MINONG CENTURY GRP +1

Preparation method for flotation waste paper compound deinking agent

InactiveCN107033659AImproved flotation collectionImprove adsorption capacityPaper recyclingChemical paints/ink removersCross-linkBenzoyl peroxide

The invention discloses a preparation method for flotation waste paper compound deinking agent. The method comprises the steps that kaolin and nanocrystal cellulose are subjected to solution blending, grafting and crosslinking are conducted by taking butyl methacrylate as a monomer, taking benzoyl peroxide as an initiator and taking N,N-methylene bisacrylamide as a cross-linking agent, a kaolin / microcrystalline cellulose / poly-n-butyl methacrylate organic-inorganic hybrid material is prepared, the kaolin / microcrystalline cellulose / poly-n-butyl methacrylate organic-inorganic hybrid material and the components such as surfactant are compounded, and then the compound deinking agent is prepared. The waste paper compound deinking agent obtained through the method has the excellent adsorption and collection capacities for particle impurities such as printing ink, the flotation and collection effects of the deinking agent are improved, and the method is suitable for a flotation deinking technology.

Owner:天长市天达纸箱纸品厂

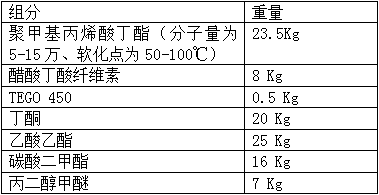

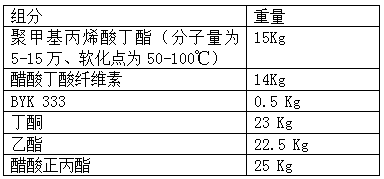

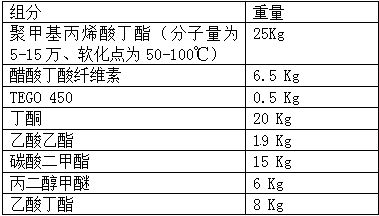

High-speed strippable aluminum paper transfer release coating

The invention provides a high-speed strippable aluminum paper transfer release coating. The high-speed strippable aluminum paper transfer release coating is composed of, by weight percentage, 15-25% of poly-n-butyl methacrylate, 5-14% of cellulose acetate butyrate, 0.5-1% of polyether modified polysiloxane, 23-25% of butanone, 20-23% of ethyl acetate and other solvent as balance. The high-speed strippable aluminum paper transfer release coating is prepared by stirring and dispersing the poly-n-butyl methacrylate, the cellulose acetate butyrate, and half of the butanone as well as the ethyl acetate inside a high-speed dispersing machine at a rotating speed of 500-1000 rpm / second for 30 minutes, controlling the temperature to be 40-50 DEG C, then continuing to mix in the rest of the butanoneand the ethyl acetate, the other solvent and the polyether modified polysiloxane for 30 minutes, cooling the mixture down to 20-30 DEG C, and performing filtering to obtain the high-speed strippablealuminum paper transfer release coating. The high-speed strippable aluminum paper transfer release coating is applied to transferring aluminum paper and released and sliced on a high-speed online stripping machine to avoid flying aluminum scraps and ensure intactness and cleanliness, avoids drops and is high in solvent resistance.

Owner:汕头市龙湖昌丰化工有限公司

Preparation method of graphene-modified hydrophobic oil-absorbing sponge

The invention provides a preparation method of graphene-modified hydrophobic oil-absorbing sponge. The preparation method comprises the following steps: washing polyurethane sponge in absolute ethanolfor 10-20min, and drying in a vacuum drying oven; preparing a graphene oxide solution; adding the graphene oxide solution and dimethylacetamide into a beaker respectively to obtain a dispersed mixedsolution; adding the dispersed mixed solution and polybutyl methacrylate into a three-necked flask respectively, placing in a water bath, and debubbling to obtain a homogeneous solution; immersing thewashed polyurethane sponge in the homogeneous solution for 10-30 minutes, taking out, and putting into a sealed container containing distilled water for 3-6 days; taking out the polyurethane sponge,then placing in distilled water for 24 hours, and then putting into a vacuum freeze dryer for 12-24 hours to obtain the graphene-modified hydrophobic oil-absorbing sponge. By the preparation method ofthe graphene-modified hydrophobic oil-absorbing sponge, the gap ratio is large, the oil-absorbing performance is high, the rebounding compressibility is good, and the selective adsorption thereof isimproved through hydrophobic modification of graphene.

Owner:JINAN JIAXING TECH

Polymer blend film inhibiting protein adsorption as well as preparation method and application thereof

The invention belongs to the field of polymers and in particular relates to a polymer blend film inhibiting protein adsorption as well as a preparation method and application thereof. The polymer blend film is prepared by carrying out blending and spin coating on polystyrene and n-butyl polymetharcylate in a mass ratio of (6:4) to (7:3). The thickness of the polymer blend film is 45-55nm. The polymer blend film can not appear dewetting phenomenon in solution, has excellent stability and also has superstrong protein adsorption inhibitory property; the preparation method is simple, high in operability and applicable to mass production; the polymer blend film is used for modifying (including coating) a medical in vivo implant material, an anti-protein adsorption layer is formed on the surface of the medical in vivo implant material, and in-vivo foreign body reaction induced by non-specific protein adsorption can be effectively avoided.

Owner:WUHAN UNIV OF TECH

Resin composition and its plastic product production method

ActiveCN1884365ANot easy to fall offAnti-acidLaser beam welding apparatusModel makingPoly(ethylmethacrylate)Thermal stability

The invention relates the resin composition and the plastic rubber product and preparing method, comprising 25%-90% base resin, 5-70% substance with butadienyl and 0.1-5% heat stability difference color. The base resin comprises polymethyl methacryate, polyethyl methacrylate, or poly-n-butyl methacrylate. The resin is used to carve word or pattern with laser ray, and the word has the advantages of environmental protection, high efficiency and low cost.

Owner:STARLIGHT PLASTIC MATERIAL SHENZHEN

Poly-n-butyl methacrylate/polyvinylidene fluoride vinyl compound dielectric film and preparation method thereof

ActiveCN104877278AIntermediate polarizabilityHigh dielectric constantDielectric lossPolyvinylidene difluoride

The invention discloses a poly-n-butyl methacrylate (PBMA) / polyvinylidene fluoride vinyl compound dielectric film. The film is formed by performing mixing and tape casting on florin-containing polymer and organic PBMA. The compound dielectric film is composed of, by mass percent, the components of 10%-30% of the organic PBMA and 70%-90% of the florin-containing polymer. The compound dielectric film is novel dielectric materials which are high in dielectric constant and low in dielectric loss. The compound dielectric film with the needed dielectric constant can be prepared by controlling the filler appending proportion. The compound dielectric film is simple in preparation technology, low in compound temperature and friendly to environment, and has a wide application prospect.

Owner:BEIJING UNIV OF CHEM TECH

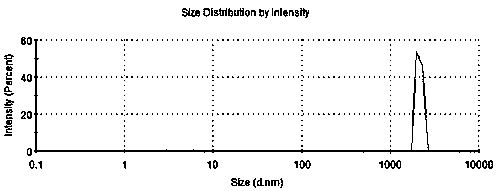

Essence microcapsule taking poly(n-butyl methacrylate) as capsule wall and preparation method thereof

InactiveCN108659956AExtended release timeRegular shapeEssential-oils/perfumesMicroballoon preparationN-Butyl methacrylatePoly n-butyl methacrylate

The invention provides an essence microcapsule taking poly(n-butyl methacrylate) as a capsule wall. The essence microcapsule is composed of 2.0-5.0% of essence, 2.0-5.0% of n-butyl methacrylate, 0.5-1% of emulsifier, 88.0-95.0% of deionized water, 0.5-1.0% of crosslinking agent and 0.1-0.2% of catalyst. The invention further provides a preparation method of the essence microcapsule. Compared withconventional microcapsule shells, the essence microcapsule has the advantage that nontoxic n-butyl methacrylate monomer is used as a wall material, so that higher safety and environment-friendliness are realized. The preparation method is simple and easy to implement, and the microcapsule prepared by the method is regular in shape, uniform in particle size and easy for industrial production.

Owner:SHANGHAI INST OF TECH

Styrene butadiene rubber used for preparing material delivery hoses

InactiveCN106519353AGood physical and mechanical propertiesHigh tensile strengthPolymer sciencePhosphate

The invention discloses a styrene butadiene rubber used for preparing material delivery hoses. The styrene butadiene rubber is prepared from, by weight, 100 to 130 parts of SBR, 100 to 110 parts of butadiene rubber, 50 to 55 parts of hydrogenated nitrile butadiene rubber, 4 to 5 parts of phenyltriethoxysilane, 3 to 5 parts of a filler, 5 to 7 parts of sodium citrate, 5 to 8 parts of tris(2,4-di-tert-butylphenyl) phosphate, 2 to 4 parts of silicon carbide whisker, 6 to 8 parts of polyethyleneglycol monooleate, 6 to 9 parts of m-xylylenediamine, 13 to 16 parts of an abrasion resistance improver, 15 to 26 parts of poly-n-butyl methacrylate, 2 to 5 parts of a plasticizer, and 30 to 40 parts of glycerinum. The styrene butadiene rubber is excellent in physical and mechanical properties, is capable of increasing product tensile strength and stress at definite elongation, and reducing compression deformation and dynamic heat build-up performance.

Owner:WUXI YONGXING METAL HOSE

Temperature-sensing color-changing insulating material

InactiveCN106674445AReduce the risk of safety hazardsExtended service lifeInksLinear low-density polyethyleneElectrical conductor

The invention discloses a temperature-sensing color-changing insulating material and belongs to the field of a cable insulating material. The temperature-sensing color-changing insulating material is used for coating a cable and wire conductor and consists of the following components in parts by weight: 11 to 20 parts of poly-n-butyl methacrylate, 10 to 20 parts of linear low-density polyethylene, 3 to 7 parts of polymethyl triethoxy silane, 0.5 to 3 parts of a silane coupling agent, 15 to 20 parts of trimethylolpropane triacrylate, 4 to 6 parts of 1,8-dinitrogen bicyclo(5,4,0)7-hendecene, 1 to 1.5 parts of an antioxidant, 15 to 20 parts of temperature-sensing color-changing printing ink and 5 to 10 parts of a flame retardant. According to the above technical scheme, the temperature-sensing color-changing insulating material can realize semiconductor heat accumulation in a lead and realize fault response through color change of an insulating layer coating the lead so as to reduce the risk of potential safety hazard in the inspection process of cables and wires.

Owner:STATE GRID SHANDONG TANCHENG POWER SUPPLY +1

A UV-curable screen printing snowflake ink

ActiveCN104559457BMeet environmental protection requirementsStrong adhesionInksPaperboardPrinting ink

The invention relates to novel ultraviolet-cured silk-screening snow printing ink which is characterized by being prepared from the following components: tripropylene glycol diacrylate, 1, 6-hexanediol diacrylate, trimethylolpropane triacrylate, polyaldehyde resin, poly-n-butyl methacrylate, poly{2-hydroxyl-2-methul-1-[4-(1-methyl vinyl)phenyl] acetone}, polyurethane acrylate, an organic silicon defoamer, a polyether organic silicon flatting agent, an active amine-assisted optical initiator and a wax powder. The printing ink printed and dried is still ultraviolet-cured silk-screening snow printing ink which is transparent and not yellowed as standing time of a printing material goes on and is good in adhesive force. The printing ink is particularly suitable for being used on a white paperboard or offset print light color ink and overlaid on silk-screening UV gloss oil and a silk-screening UV thick film to print, and is strong in adhesive force. Moreover, the printing ink detonated and rocketed is proper in pattern thickness, so that a transparent third-dimensional effect on a pattern of the printing material is obtained.

Owner:ZHEJIANG MINONG CENTURY GRP +1

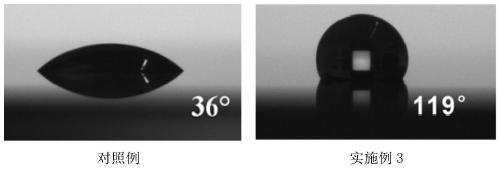

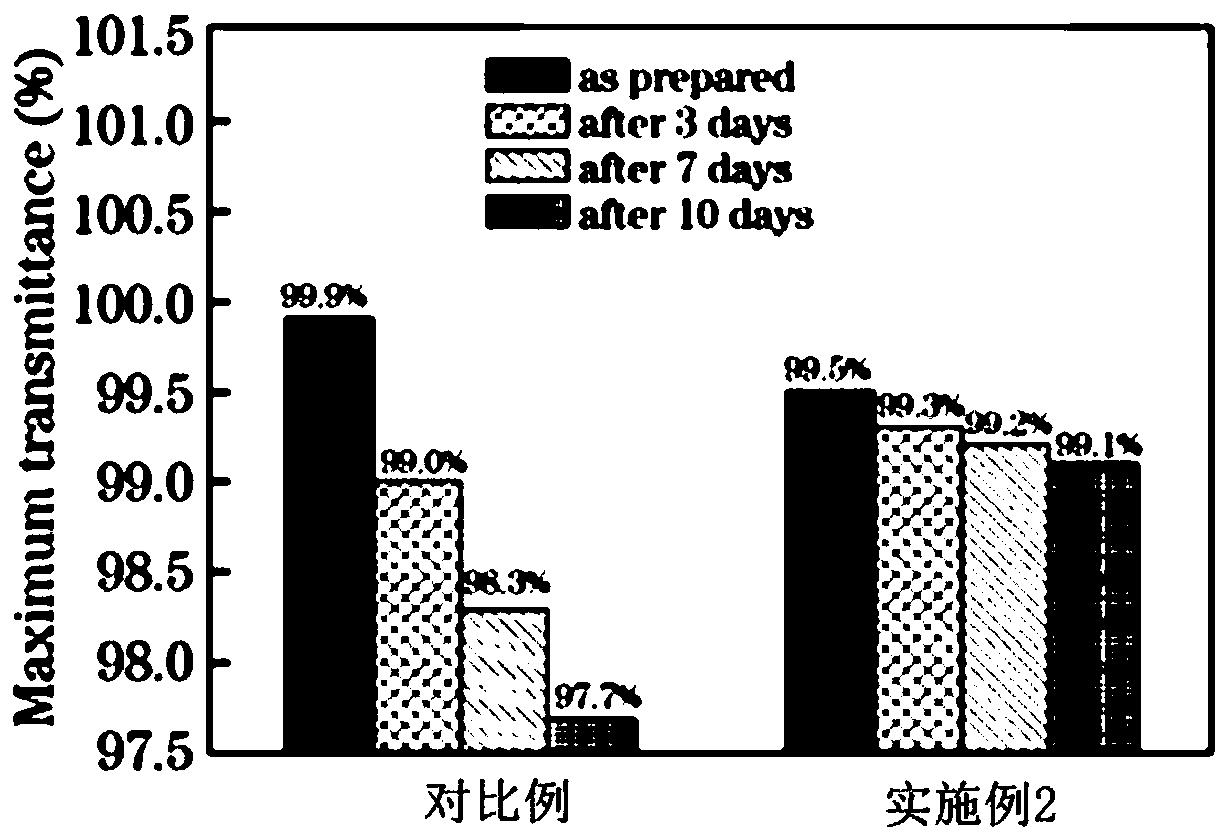

A kind of high-performance vacuum anti-reflection film and preparation method thereof

ActiveCN109401173BLower surface free energyImprove transmittanceCoatingsOptical elementsPolymer dissolutionSilicic acid

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Antistatic polyethylene masterbatch

InactiveCN106496731AImprove antistatic performanceReduce processing costsTetrafluoroboratePoly n-butyl methacrylate

The invention discloses antistatic polyethylene masterbatch. The antistatic polyethylene masterbatch is prepared from, by weight, 100-130 parts of high-density polyethylene, 18-24 parts of an ethylene-ethyl acrylate copolymer, 2-15 parts of calcium stearate, 1-5 parts of antimony dithiocarbamate, 2-4 parts of dibutyl phthalate, 12-18 parts of tetraethylammonium tetrafluoroborate, 15-26 parts of poly-n-butyl methacrylate, 10-15 parts of carboxymethylcellulose, 8-10 parts of octadecanol and 15-24 parts of white oil. The antistatic polyethylene masterbatch has the good antistatic property, is low in processing cost and simple in preparation technology and has the advantages that the color stability is improved, and a little color difference is generated when the antistatic polyethylene masterbatch is applied to PE product coloring, and the problems that existing PE masterbatch is instable in color, large in color difference and the like when the PE masterbatch is applied to coloring are solved.

Owner:苏州瑞斯格电子科技有限公司

Pipe thread sealant for tunnel construction

ActiveCN109401699AImprove wettabilityImprove the lubrication effectMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesEpoxyElastomer

The invention discloses a pipe thread sealant for tunnel construction. The pipe thread sealant is prepared from 30-40 parts of epoxy resin, 15-25 parts of PTMG (poly(tetramethylene ether) glycol polyols), 5-15 parts of TDI (2,4-toluene diisocynate), 5-10 parts of 3,3'-dichloro-4,4'-diaminodiphenylmethane, 1-5 parts of AIBN (azodiisobutyronitrile), 1-5 parts of PBMA (polybutyl methacrylate), 5-10 parts of styrene elastomers, 2-6 parts of poly(2,6-dimethyl-1,4-phenylene oxide), 5-10 parts of polyvinyl acetate, 5-15 parts of ceramic particles, 1-5 parts of silicon dioxide, 1-5 parts of an antioxidant and 1-3 parts of a tackifier. The pipe thread sealant is prepared from the epoxy resin as a main raw material and has good wettability, lubricity and waterproofness, all possible leakage paths ofa thread can be sufficiently filled with sealing grease, an elastoplastic polymer is formed by curing, a sealing layer is formed on the thread surface, so that the sealing part is free of holes and gaps, and meanwhile, the product has good heat resistance, cold resistance, high-pressure resistance and aging resistance.

Owner:CHONGQING JIAOTONG UNIVERSITY

Oil absorbing fibre and perparing method thereof

InactiveCN1255586CBroaden the fieldLarger specific surface area for oil absorptionMonocomponent synthetic polymer artificial filamentWet spinning methodsFiberBenzoyl peroxide

Owner:TIANJIN POLYTECHNIC UNIV

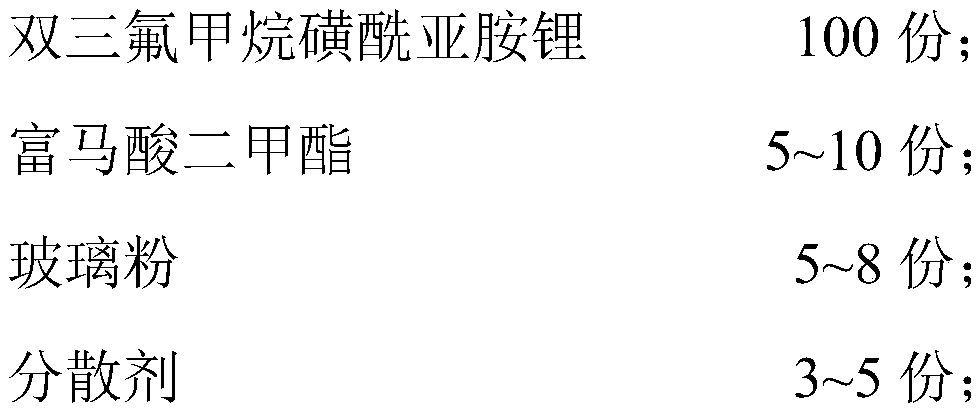

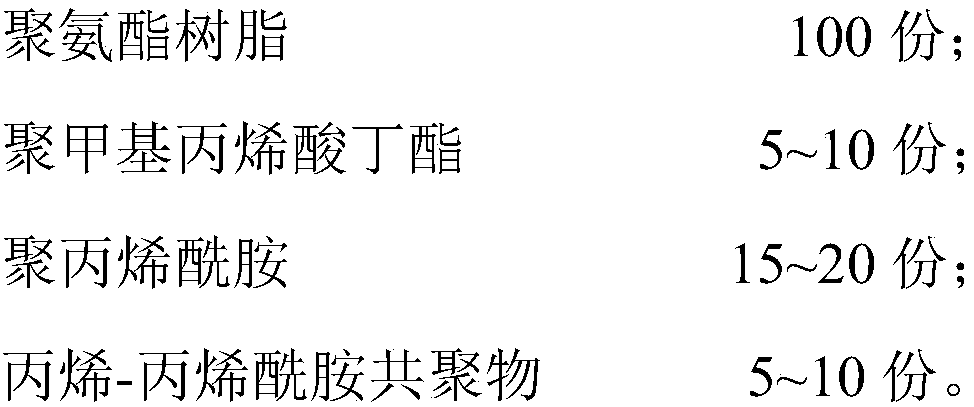

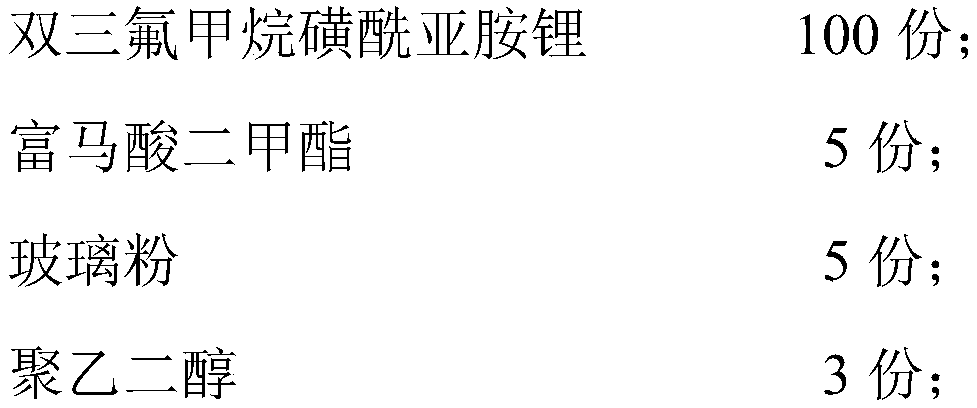

Antistatic protective film with stable viscosity

ActiveCN109401656AHigh bonding strengthImprove cohesionFilm/foil adhesivesPolyureas/polyurethane adhesivesTectorial membraneLithium

The invention discloses an antistatic protective film with stable viscosity. The antistatic protective film comprises a PET base material layer, antistatic layers arranged on the upper surface and thelower surface of the PET base material layer, and adhesive layers arranged on the outer surfaces of the antistatic layers; each antistatic layer is prepared from the following components in parts byweight: 100 parts of lithium bisimide, 5-10 parts of dimethyl fumarate, 5-8 parts of glass powder and 3-5 parts of a dispersant; and each adhesive layer is prepared from the following components in parts by weight: 100 parts of polyurethane resin, 5-10 parts of poly-n-butyl methacrylate, 15-20 parts of polyacrylamide and 5-10 parts of a propylene-acrylamide copolymer. Compared with the prior art,the protective film provided by the invention has the stable viscosity and good antistatic performance simultaneously, and can be used for packaging of electronic components.

Owner:东莞市卓华高分子材料有限公司

Water-soluble protective coating for heat treatment of non-ferrous metals

The invention relates to a water-soluble protective coating for heat treatment of nonferrous metals. The water-soluble protective coating comprises phosphate glass, ethanol, acetone, epoxy resin and poly(n-butyl methacrylate). According to the invention, phosphate glass and ethanol or acetone are mixed according to the ratio of 2:1, and the mixture undergoes ball milling for 8 hours; poly(n-butyl methacrylate) and epoxy resin are added after 8 hours of ball milling, and ball milling is carried out again for 30 min; and slurry is sieved through a sieve of 200-300 meshes. The metal protective coating isolates external atmosphere to protect a metal profile matrix from being oxidized and begins to protect from the low temperature 200 DEG C so as to form a wide protective temperature range. In the high temperature range of 400-600 DEG C, a good glass phase is formed such that the protective coating plays a good protection role. A water-soluble method is adopted after heat treatment so as to remove the coating. Thus, metal loss by post-treatment is minimized, and processes of post-treatment are simplified. During the application process, as drying speed is fast, operation time is saved and environmental pollution caused by post-treatment is reduced. The invention relates to an efficient reusable energy-saving environmentally-friendly annealing protective coating.

Owner:XIANYANG BREIT IND & TRADE

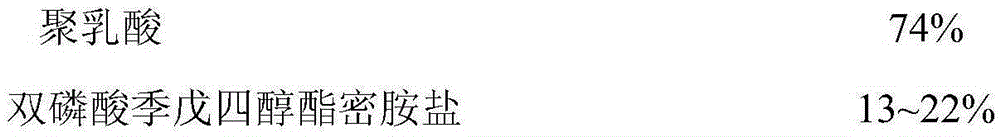

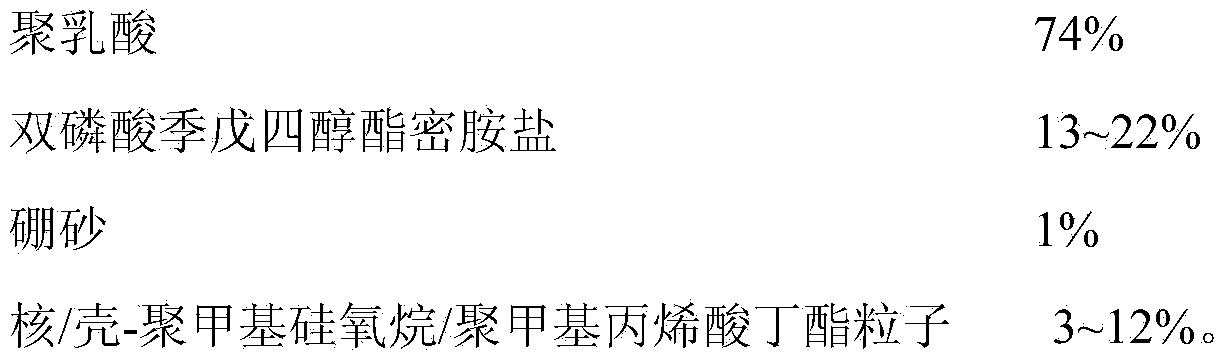

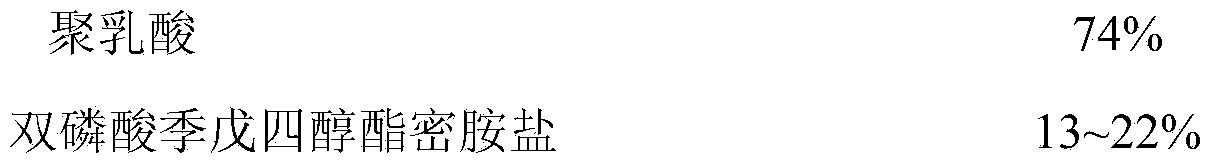

Borax-intumescent flame retardant synergistically modified polymethylsiloxane/polybutylmethacrylate polylactic acid material and its preparation

The invention discloses a synergistic modified methyl polysiloxane / poly-n-butyl methacrylate polylactic acid material of a borax-intumescent flame retardant and a preparation method of the synergistic modified methyl polysiloxane / poly-n-butyl methacrylate polylactic acid material. The biological material is prepared from the following raw materials in percentage by weight: 74% of polylactic acid, 13-22% of pentaerythritol diphosphate melamine salt, 1% of borax and 3-12% of core / shell methyl polysiloxane / poly-n-butyl methacrylate nanoparticles. Firstly, the core / shell methyl polysiloxane / poly-n-butyl methacrylate nanoparticles are synthesized by a seed emulsion polymerization method, and then the borax, the pentaerythritol diphosphate melamine salt and the polylactic acid are evenly mixed by virtue of a torque rheometer after being fully dried, and then are subjected to injection molding to form standard splines.

Owner:NANJING UNIV OF SCI & TECH

A quantum dot/epoxy resin nanocomposite material with high transparency and high fluorescence efficiency, its preparation and application

ActiveCN103937158BHigh transparencyExcellent fluorescence performanceSemiconductor devicesGlycidyl methacrylateFluorescence

Owner:BEIJING UNIV OF CHEM TECH

PC (polycarbonate) color master batch with anti-aging and anti-impact function

InactiveCN106496991AImprove anti-agingImprove impact resistancePolyethylene terephthalate glycolInstability

The invention discloses a PC color master batch with an anti-aging and anti-impact function. The PC color master batch is prepared from, by weight, 160-165 parts of PC, 12-18 parts of polyethylene terephthalate, 15-22 parts of coumarone resin, 15-20 parts of ethylene-vinyl acetate copolymer, 5-8 parts of tris-(2,4-di-tert-butyl-pheny)-phosphite, 3-5 parts of carbamide, 15-26 parts of poly-n-butyl methacrylate, 6-14 parts of dist coconut fatty acid monoethanol amide and 3-6 parts of lauryl betaine. The PC color master batch with the anti-aging and anti-impact function has excellent anti-aging and anti-impact performance, is low in processing cost and simple in preparation process, and has the advantages of higher color stability and small color difference when applied to coloring of PC products, and the problems of color instability, large color difference and the like during coloring of the existing PC color master batch are overcome.

Owner:苏州瑞斯格电子科技有限公司

Synergistic modified methyl polysiloxane/poly-n-butyl methacrylate polylactic acid material of borax-intumescent flame retardant and preparation of synergistic modified methyl polysiloxane/poly-n-butyl methacrylate polylactic acid material

InactiveCN104212139AHigh flame retardant levelImprove flame retardant performanceBiological materialsPoly n-butyl methacrylate

The invention discloses a synergistic modified methyl polysiloxane / poly-n-butyl methacrylate polylactic acid material of a borax-intumescent flame retardant and a preparation method of the synergistic modified methyl polysiloxane / poly-n-butyl methacrylate polylactic acid material. The biological material is prepared from the following raw materials in percentage by weight: 74% of polylactic acid, 13-22% of pentaerythritol diphosphate melamine salt, 1% of borax and 3-12% of core / shell methyl polysiloxane / poly-n-butyl methacrylate nanoparticles. Firstly, the core / shell methyl polysiloxane / poly-n-butyl methacrylate nanoparticles are synthesized by a seed emulsion polymerization method, and then the borax, the pentaerythritol diphosphate melamine salt and the polylactic acid are evenly mixed by virtue of a torque rheometer after being fully dried, and then are subjected to injection molding to form standard splines.

Owner:NANJING UNIV OF SCI & TECH

A polymer blend film that inhibits protein adsorption and its preparation method and application

Owner:WUHAN UNIV OF TECH

Composite material for large-diameter jacket head

InactiveCN105694289AImprove corrosion resistanceImprove pressure resistancePressure vesselsCarvacryl acetateTemperature resistance

The invention discloses a composite material for a large-diameter jacket head. The composite material comprises, by weight, 15-32 parts of TiN / Ti-B, 7-17 parts of Ti70Nb7.8Cu8.4Ni7.2Al6.6, 13-25 parts of Ti5Si3 / NiTi, 2-6 parts of Sm2O3, 1-5 parts of catalyst, 30-45 parts of chloroethylene / vinyl acetate and 28-41 parts of poly(n-butyl methacrylate). In this way, the composite material has higher corrosion resistance, high abrasion resistance, pressure resistance and high temperature resistance, and longer service life and is not prone to leakage or peeling.

Owner:WUXI XIZHOU END SOCKET MFG

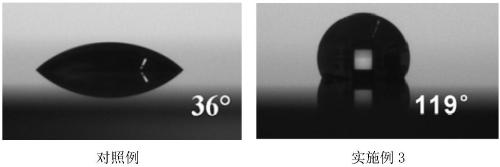

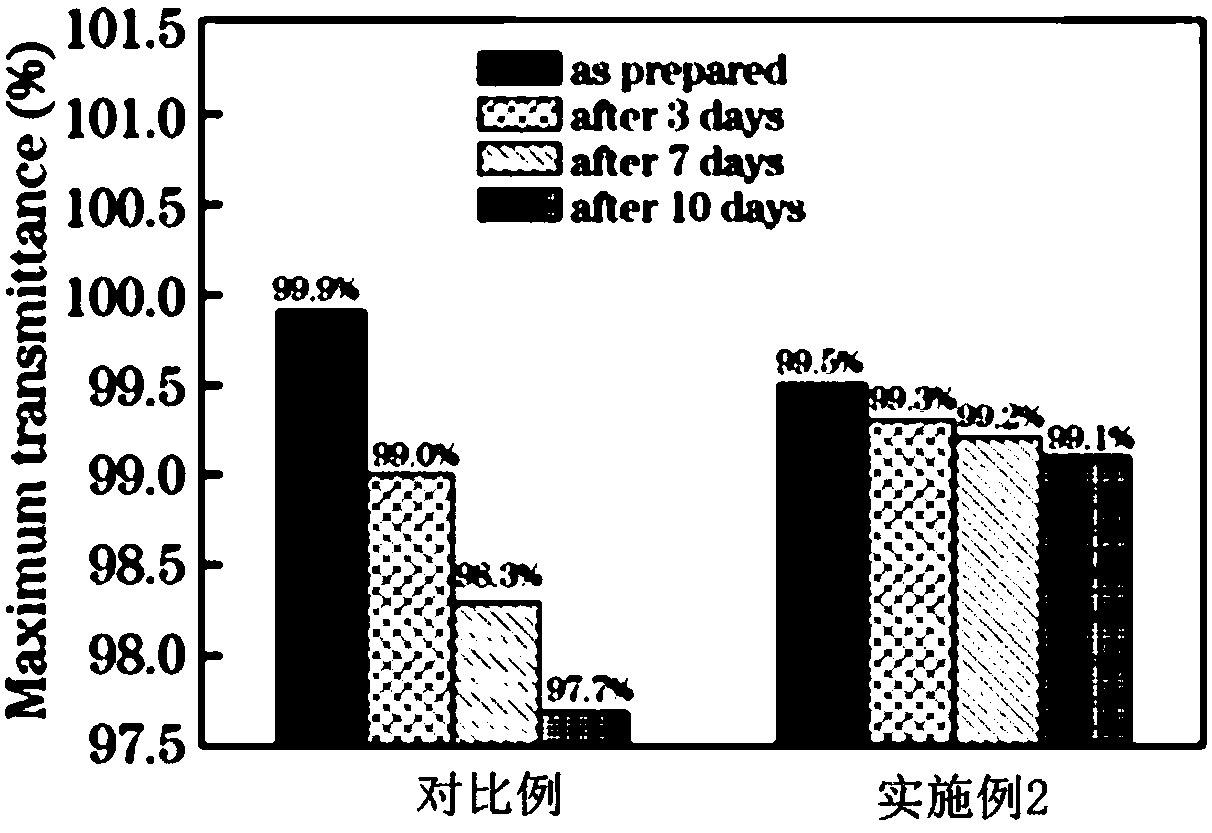

High-performance vacuum anti-reflection film and preparation method thereof

The invention discloses a high-performance vacuum anti-reflection film and a preparation method thereof, and belongs to the technical field of optical materials. According to the high-performance vacuum anti-reflection film and the preparation method thereof, tetraethyl orthosilicate and a modifier perfluorotriglycol dimethyl ether are reacted to obtain first sol, a dissolved poly(n-butyl methacrylate) block polymer is added into the first sol for reaction to obtain second sol, and the second sol is used for film-forming, so that the vacuum anti-reflection film is prepared. The vacuum anti-reflection film has low surface free energy, is not liable to adsorb pollutants of water vapor and the like, and has high transmittance (>99%) in a wave band of ultraviolet laser (at a wavelength of about 351 nm), high-energy output of third harmonic generation laser in a high-power laser device can be achieved, and the transmittance basically remains unchanged after the high-performance vacuum anti-reflection film is placed in a vacuum environment for several days.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

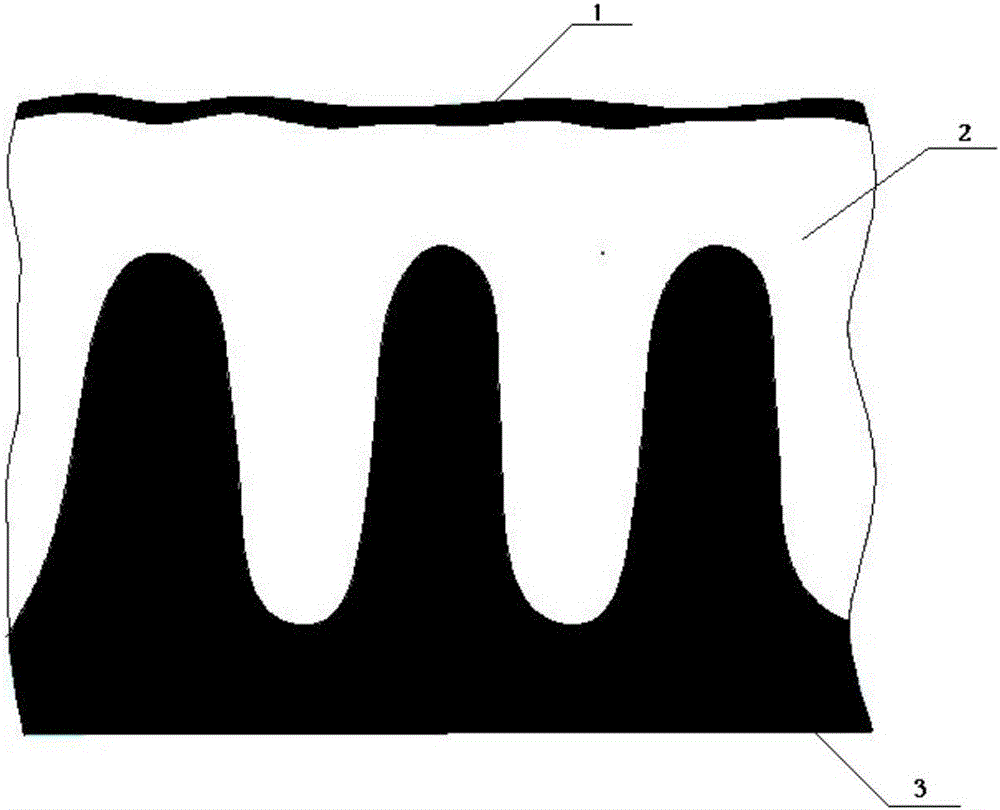

Honeycomb plate for kitchen marble and preparation method thereof

PendingCN111688286AImprove water resistanceDelay decayNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceToluene diisocyanate

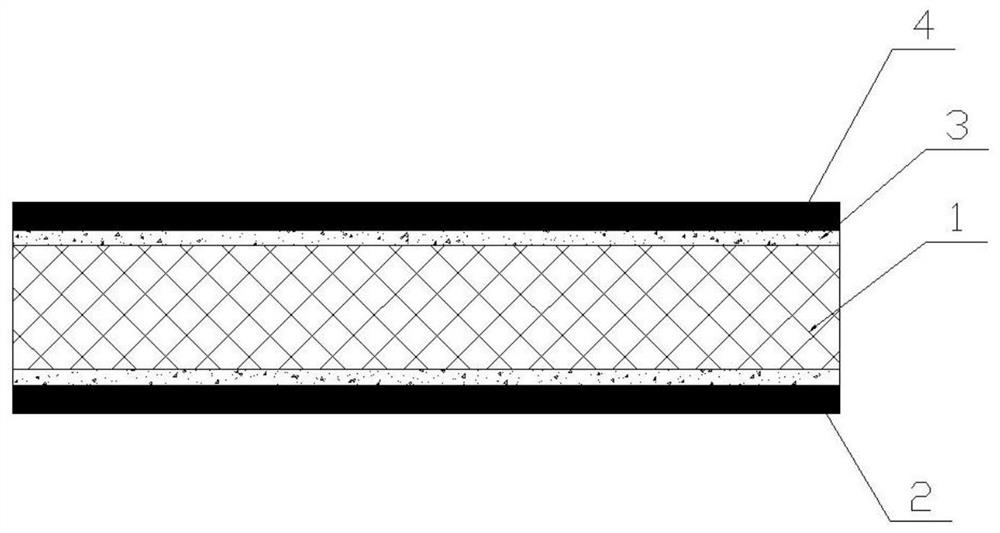

The invention belongs to the technical field of buildings, and particularly relates to a honeycomb plate for kitchen marble and a preparation method and application thereof. The honeycomb plate for the kitchen marble comprises an upper panel, an adhesive film, a plastic base material plate and a lower panel, the lower panel is connected with one side of the plastic base material plate through an adhesive film; the other side of the plastic base material plate is connected with the upper panel through the adhesive film; the plastic base material plate is of a honeycomb structure. The adhesive film is prepared from the following components in parts by weight: 12 to 20 parts of polytetrahydrofuran ether polyol, 12 to 18 parts of 2, 4-toluene diisocynate, 20 to 50 parts of epoxy resin, 20 to 30 parts of polyn-butyl methacrylate, 1 to 5 parts of oleyl disodium sulfosuccinate, 5 to 10 parts of glass fiber, 1 to 5 parts of a coupling agent, 10 to 15 parts of a curing agent and 25 to 90 partsof ethyl acetate. The honeycomb plate has better water resistance and lower attenuation, and can be applied to kitchens after being compounded with marble.

Owner:广州云凯复合材料有限公司

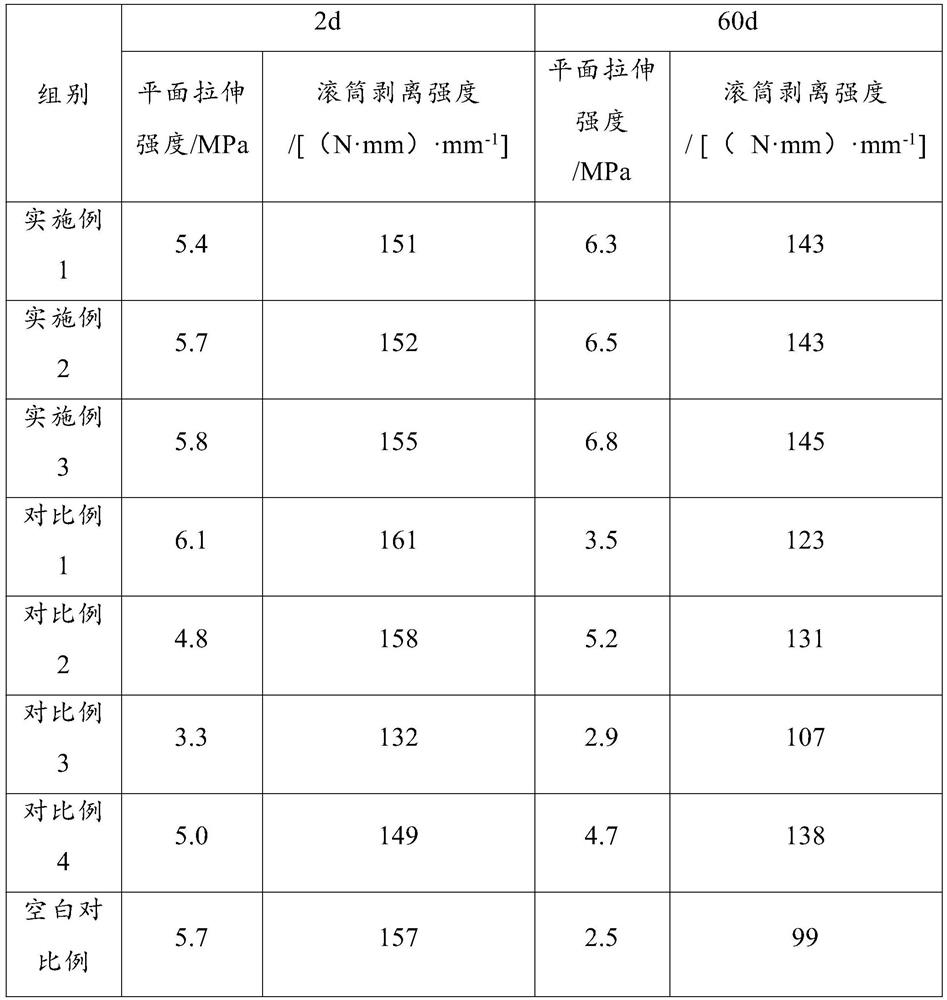

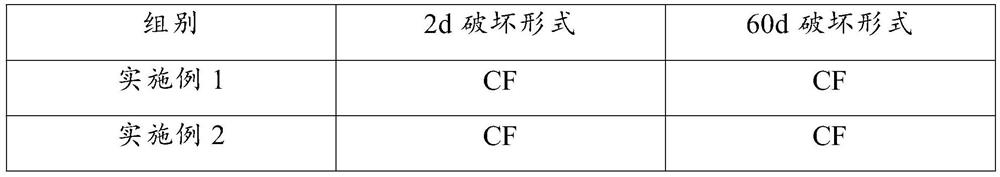

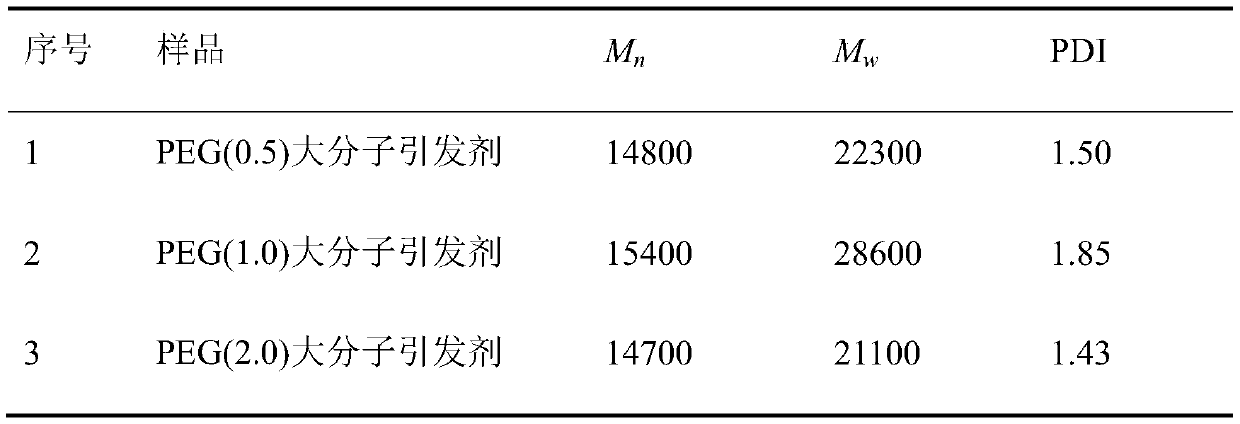

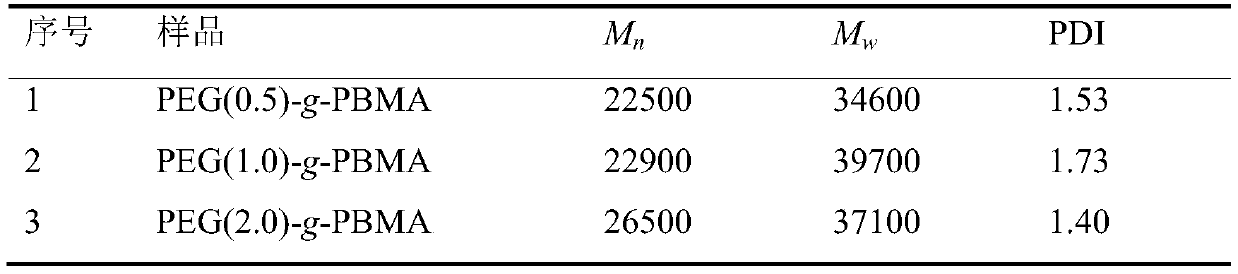

A kind of preparation method of polyethylene glycol graft polybutylmethacrylate amphiphilic graft copolymer

ActiveCN107857846BAdjustable graft densitySide chain molecular weight controllablePolymer sciencePolyethylene glycol

The invention relates to a preparation method of a polyethylene glycol grafted poly-n-butyl methacrylate amphiphilic grafted copolymer. The method comprises the steps of firstly, preparing a polyethylene glycol macromolecular initiator by using a micromolecular dyhydroxyl initiator and then utilizing a 'grafting from' strategy to prepare the amphiphilic grafted copolymer which is clear in structure and narrower in molecular weight distribution. The preparation method provided by the invention has the beneficial effects that the method is used for preparing the polyethylene glycol grafted poly-n-butyl methacrylate amphiphilic grafted copolymer which contains a hydrophilic main chain and hydrophobic side chains; the grafted copolymer synthesized by the method has the characteristics of beingadjustable in grafting density and controllable in molecular weight of chain segments of branch chains.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com