Essence microcapsule taking poly(n-butyl methacrylate) as capsule wall and preparation method thereof

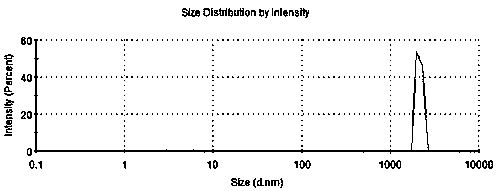

A technology of poly-n-butyl methacrylate and n-butyl methacrylate, which is applied in the chemical field, can solve the problems of uncontrollable, irregular structure, uneven particle size distribution, etc., and achieves regular morphology, uniform particle size, Significant technological progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of water phase:

[0033] Weigh 1g of PVA and 181.7g of deionized water, put 1g of PVA powder and 181.7g of deionized water in a beaker, and stir at 80°C for 10min under the action of an electric stirrer to completely dissolve the PVA powder to obtain an aqueous phase;

[0034] (2) Preparation of oil phase:

[0035] Weigh 8g of n-butyl methacrylate in a 250ml beaker, then add 8g of apple essence and 1g of crosslinking agent and place it on an electric stirrer and stir for 10min to make it completely dissolve in each other to obtain an oil phase;

[0036] (3) Preparation of emulsion

[0037] The oil phase is added to the water phase, and the water and oil two-phase mixture is sheared at a high speed for 3 minutes under the action of a high-speed homogenizer at 6600 rpm to form a uniform emulsion;

[0038] (4) Preparation of microcapsules

[0039] Place the obtained emulsion in a water bath and heat it at a constant temperature, stir evenly in an electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com