Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2135 results about "Polymethacrylic Acids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

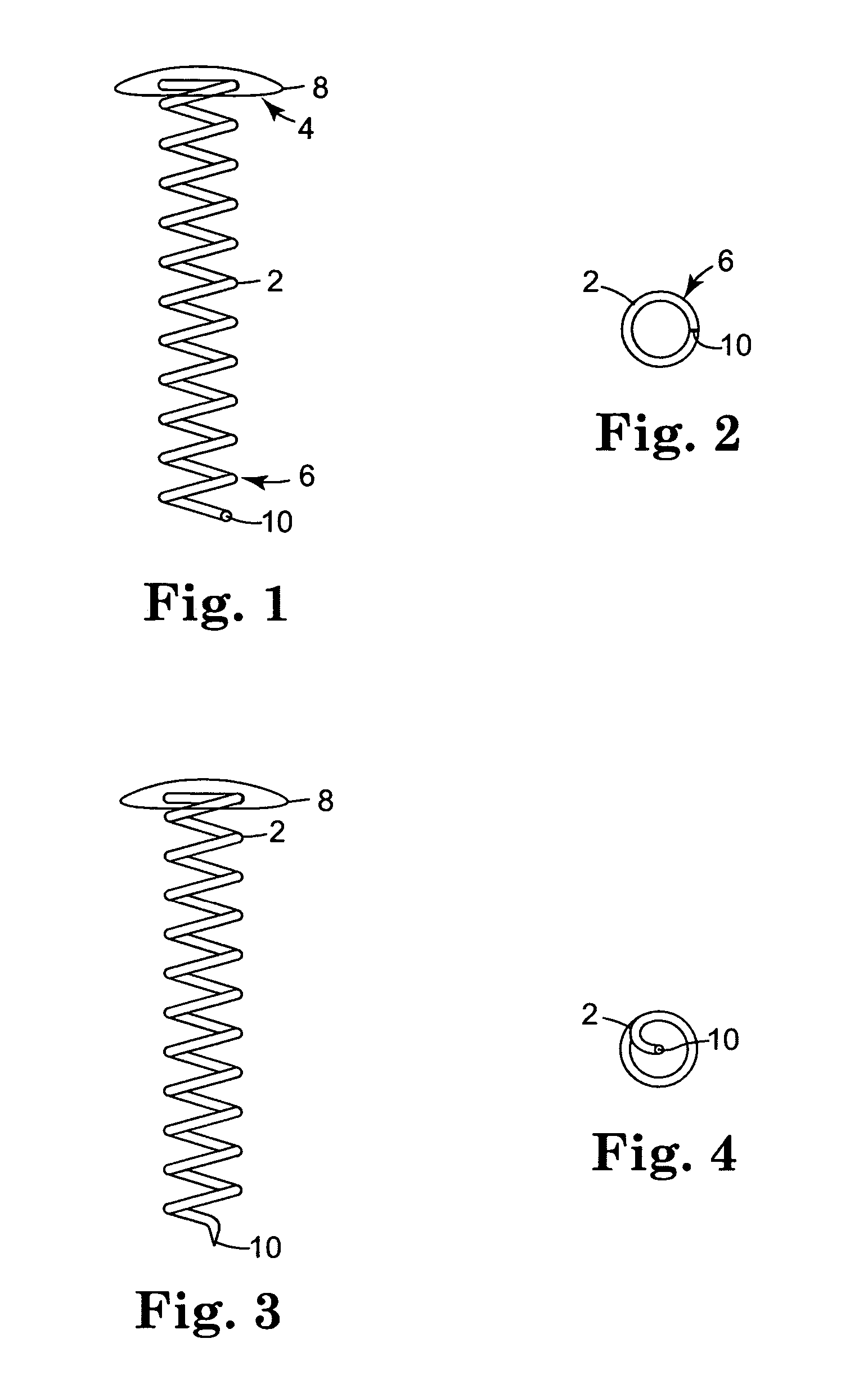

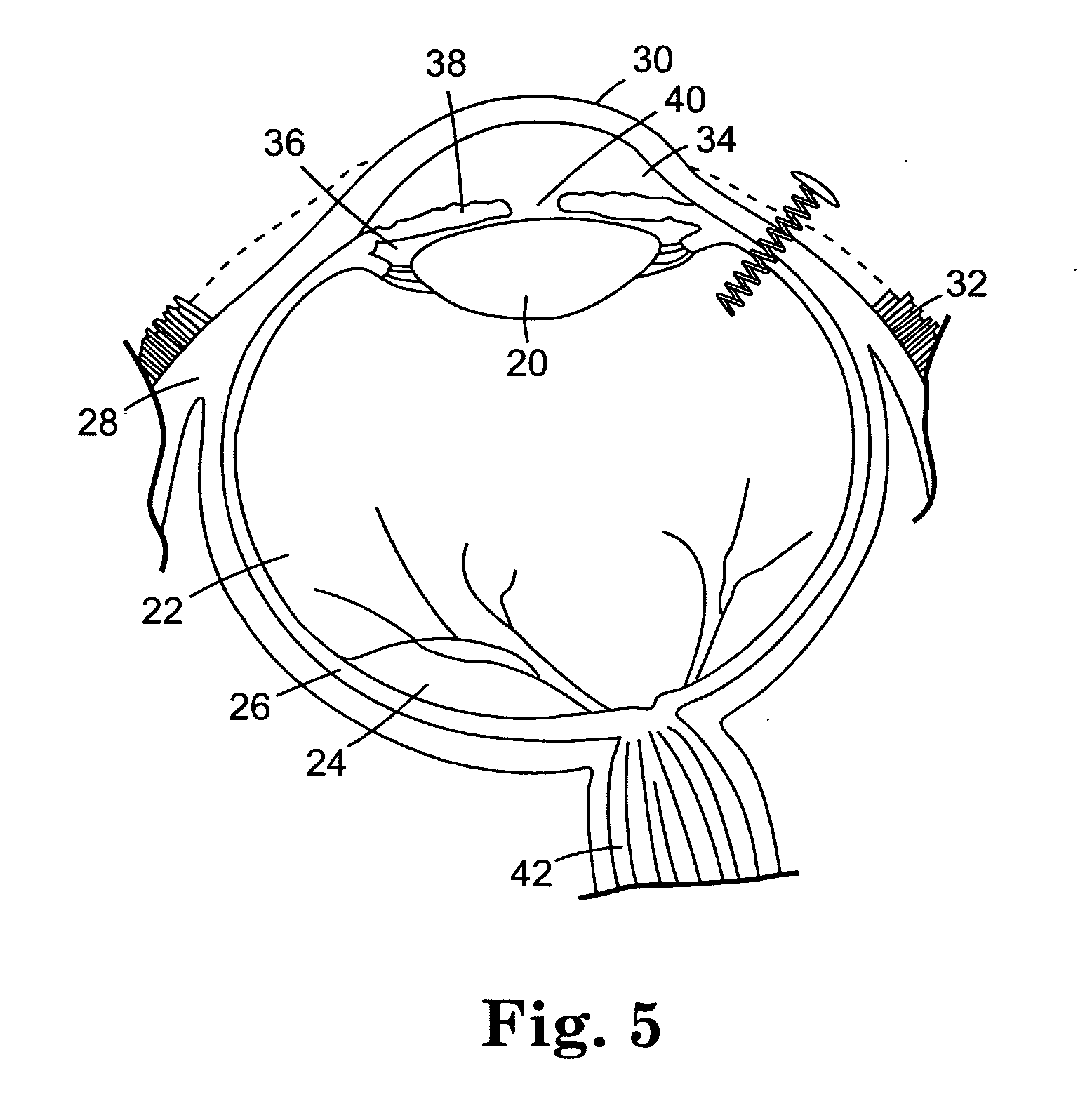

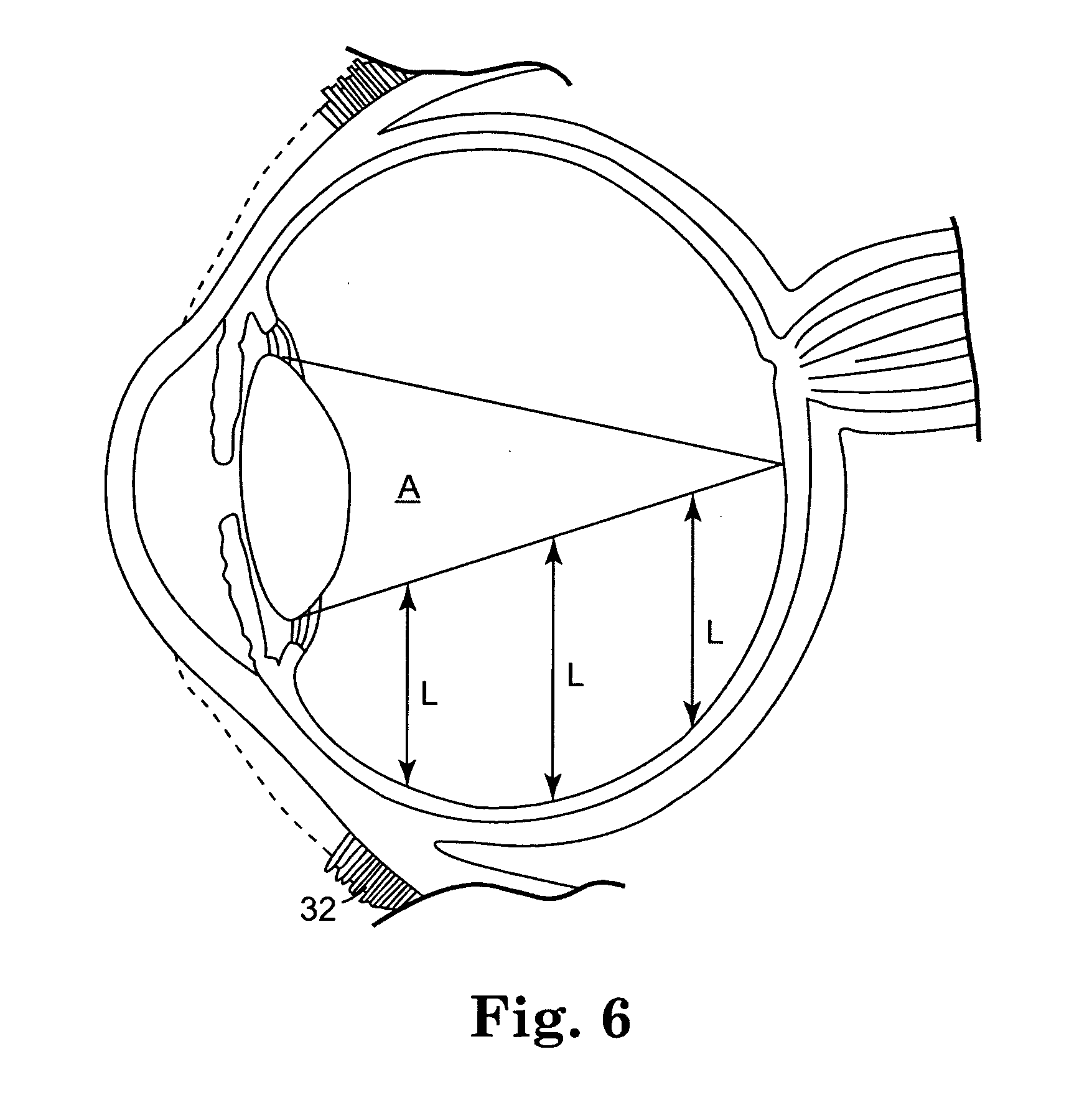

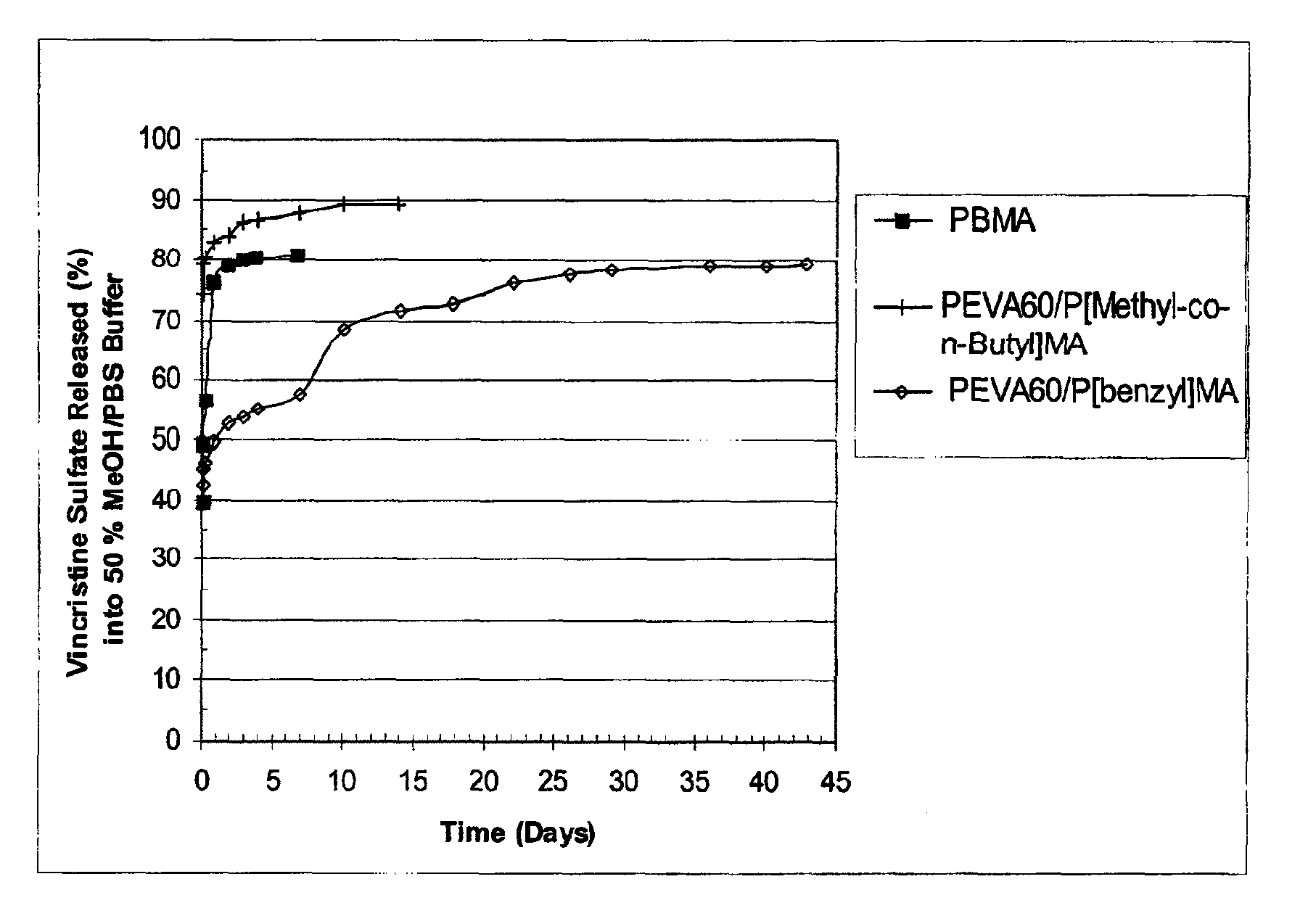

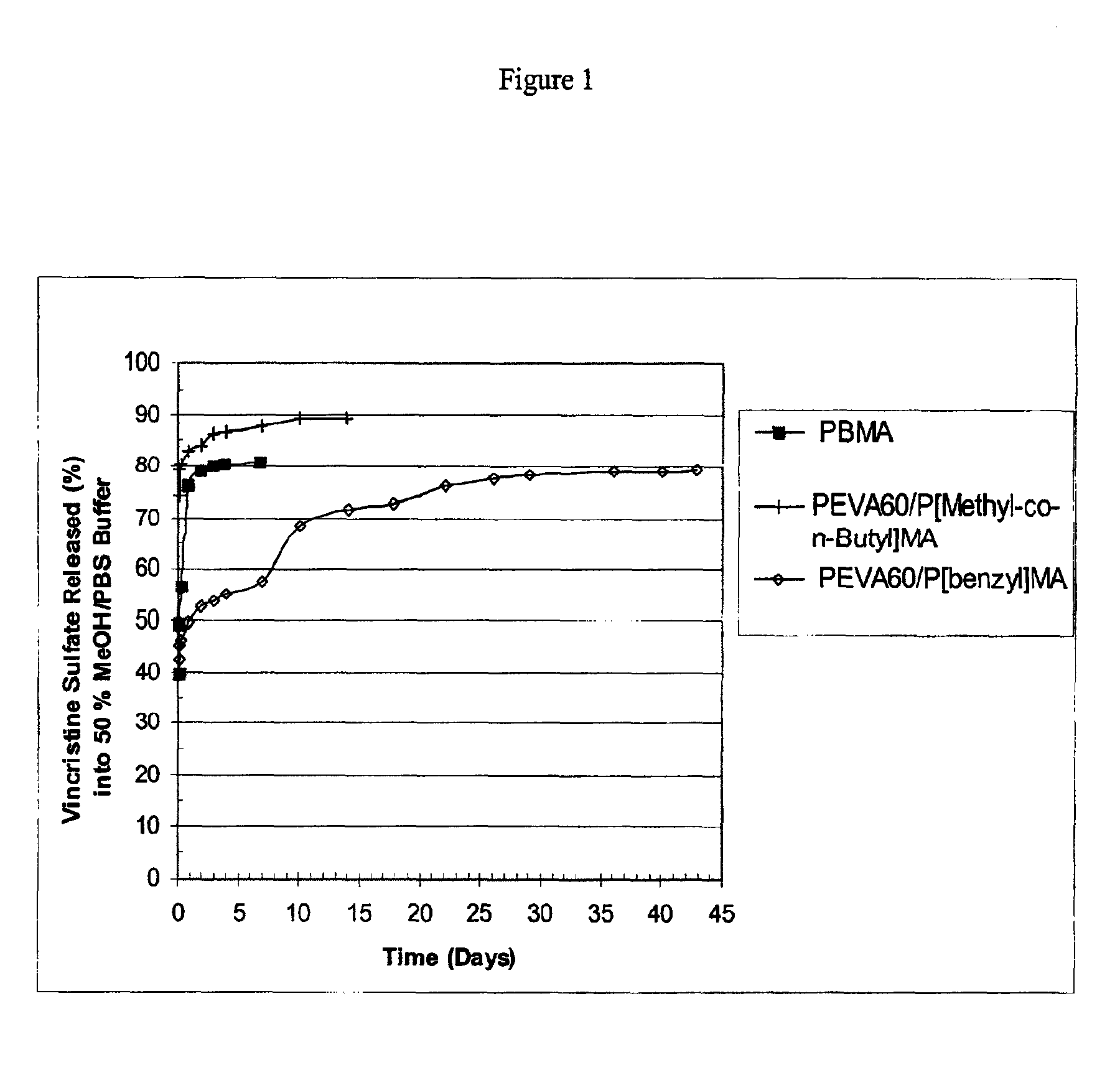

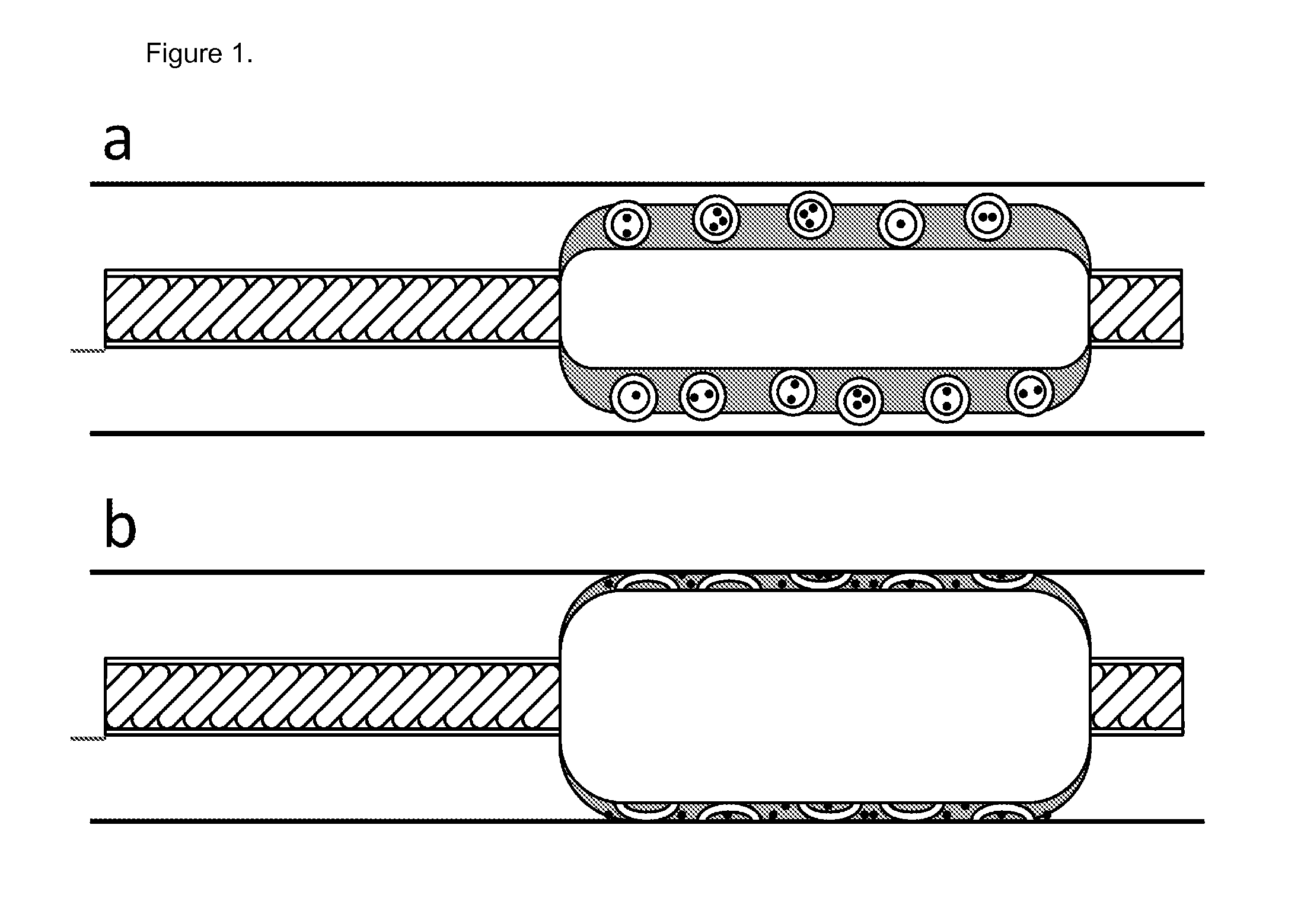

Controlled release bioactive agent delivery device

InactiveUS20050019371A1Minimize damageInterference minimizationOrganic active ingredientsSenses disorderControlled releaseMeth-

Owner:SURMODICS INC

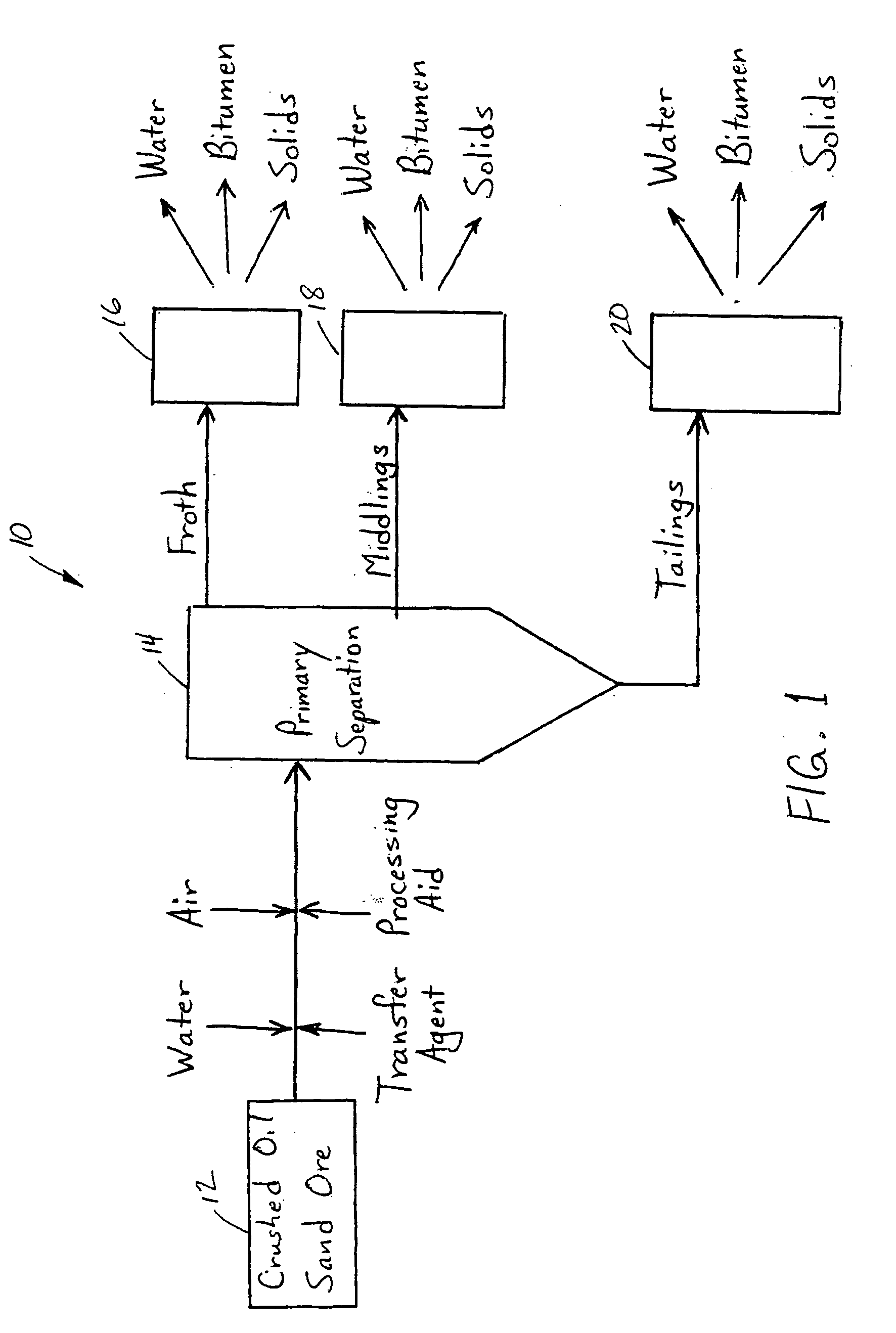

Processing aids for enhanced hydrocarbon recovery from oil sands, oil shale and other petroleum residues

InactiveUS20050194292A1Liberation of additionalPromote recoveryDewatering/demulsification with chemical meansLiquid hydrocarbon mixture productionHydrocotyle bowlesioidesSlurry

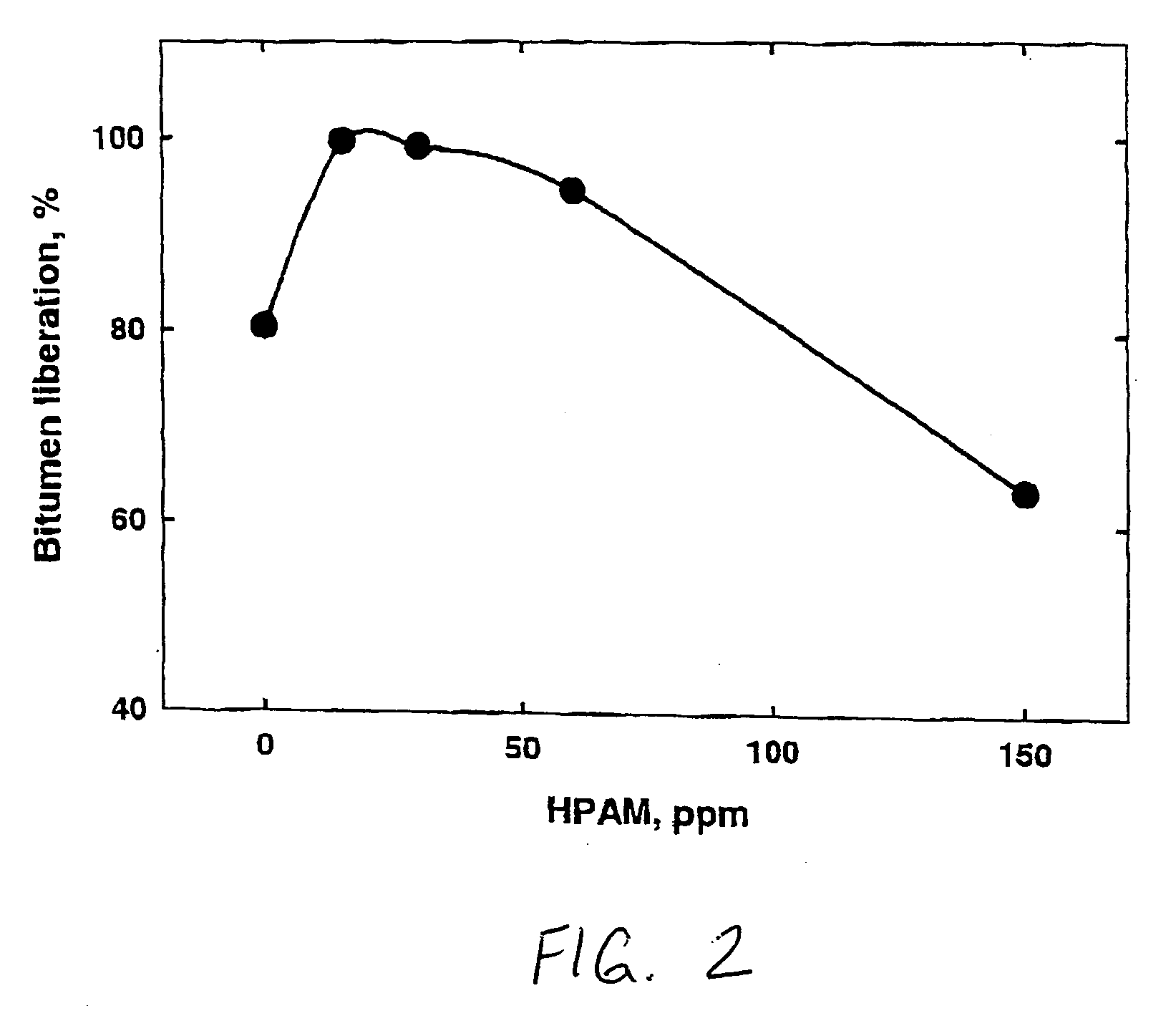

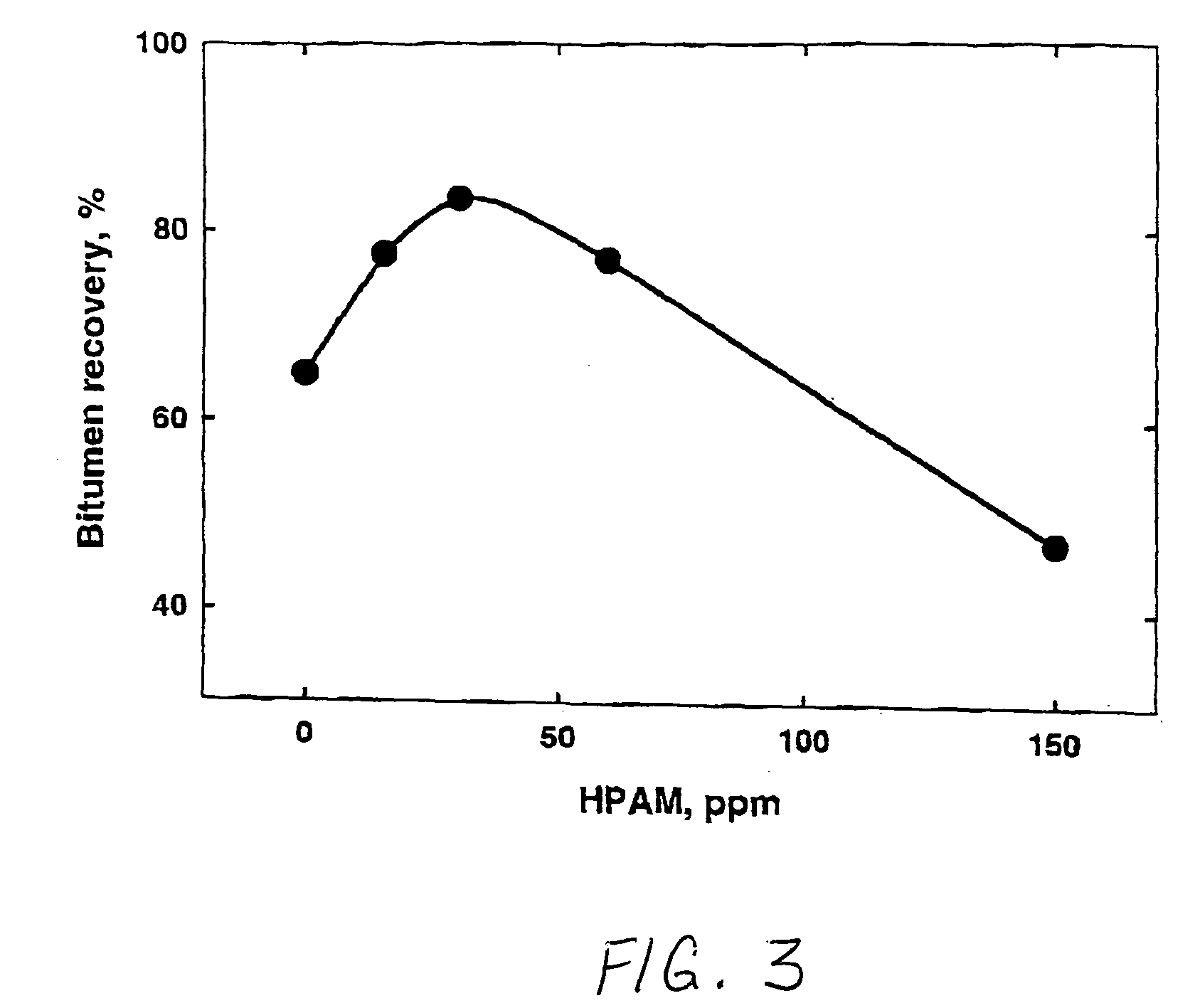

A method of improving hydrocarbon recovery from oil sands, oil shale, and petroleum residues includes adding a polymeric or nonpolymeric processing aid capable of sequestering cations, such as the multivalent calcium, magnesium and iron cations. The hydrocarbons are preferably contacted with the processing aid before a primary separation of the hydrocarbons in order to increase bitumen recovery. A processing aid is provided in an effective amount to increase the liberation of the hydrocarbons from inorganic solids, particularly when the source is a poor processing ore. Preferred processing aids include citric acid or a polymeric acid selected from polyacrylic acid, polymethacrylic acid, salts of these acids, partial salts of these acids, and combinations thereof. The processing aids significantly increase the hydrocarbon recovery typically with concentrations less than 50 ppm and the polymeric processing aids can also provide beneficial flocculation of solids in tailings slurry.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA

Polyvinylidene fluoride weather resistant coating compositions including polymethyl methacrylate

InactiveUS6362271B1Improve adhesionReduce the shrinkage of the polyvinylidene fluorideMixing methodsCoatingsMethacrylatePolymethyl methacrylate

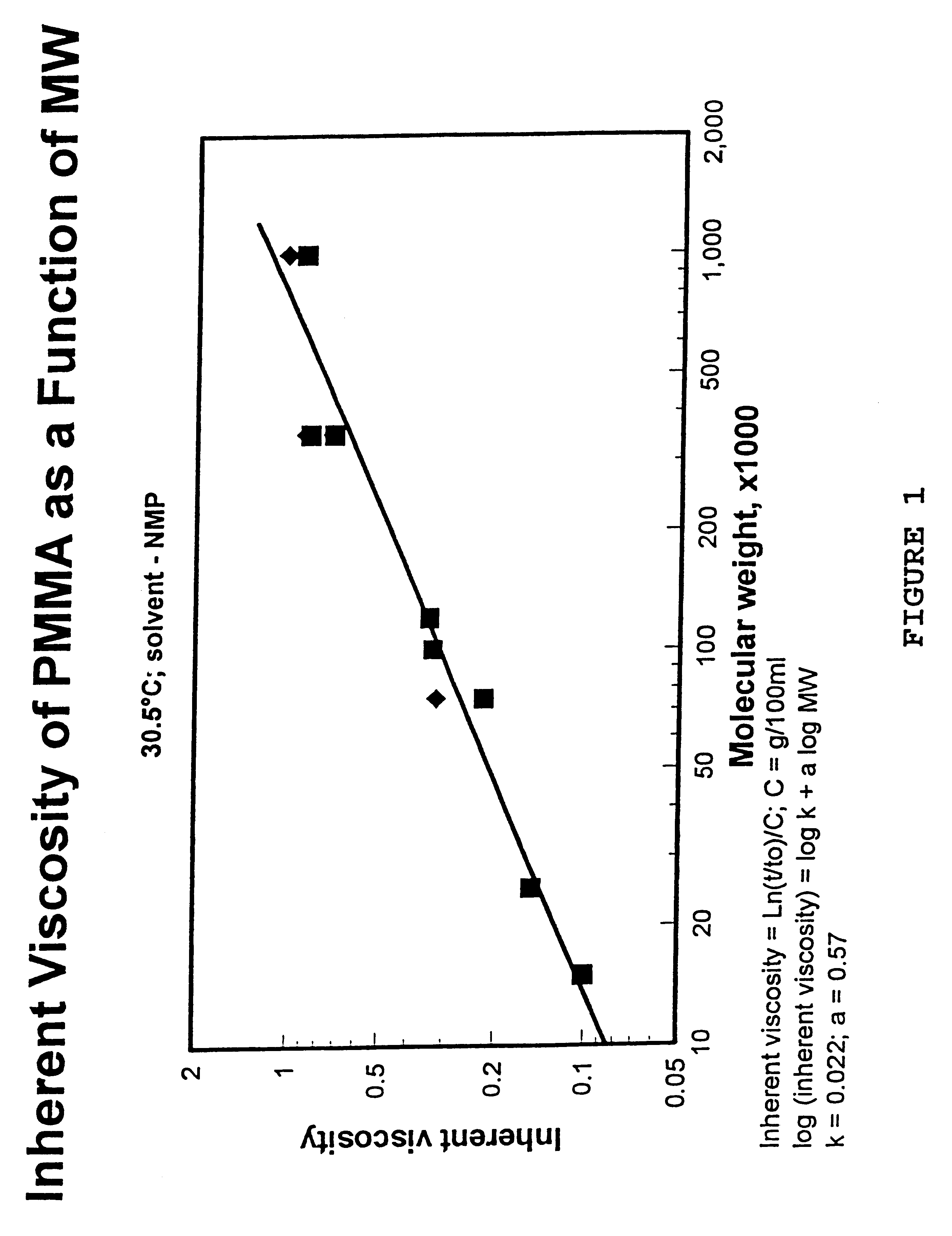

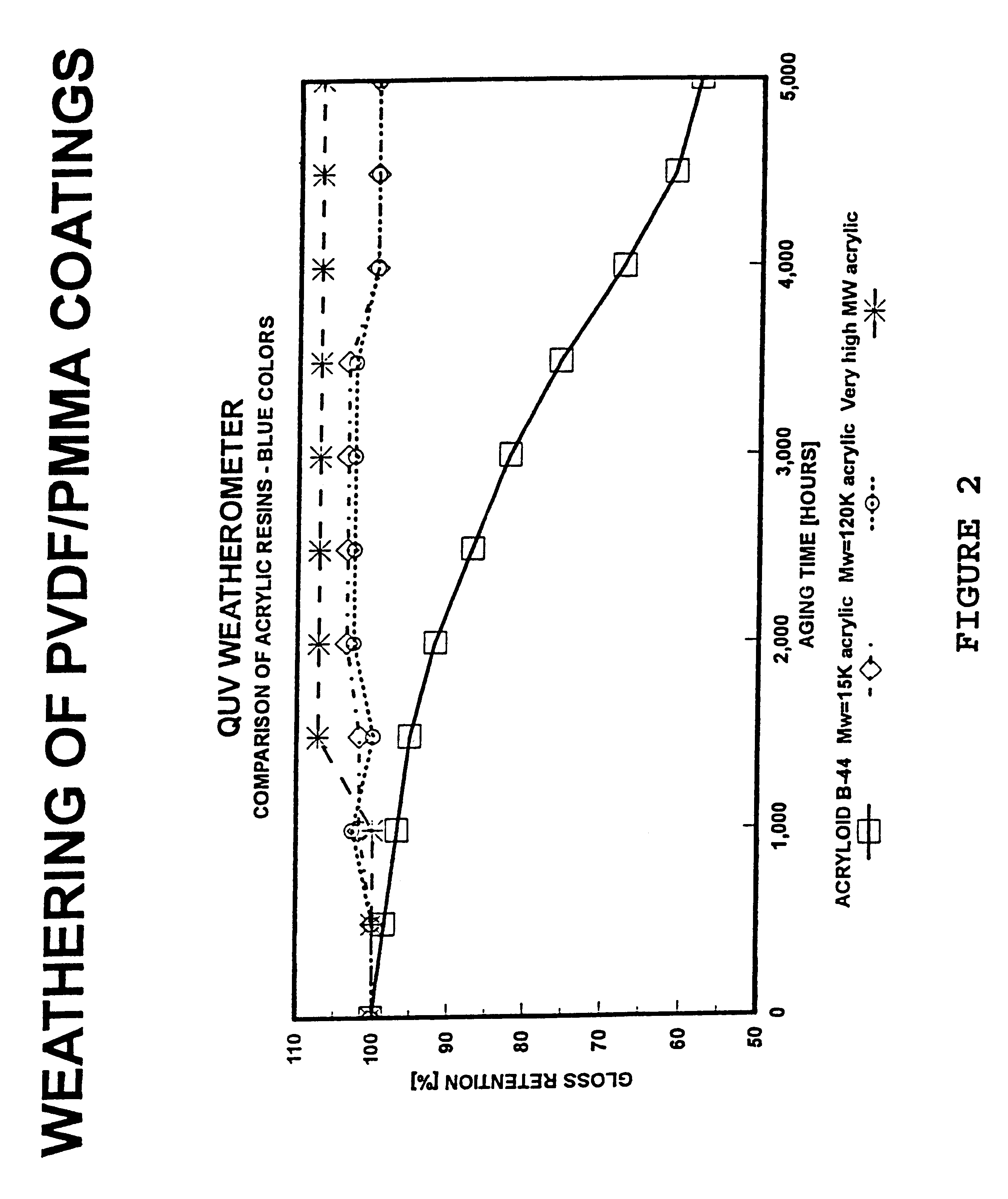

A weather resistant coating composition comprising a miscible polymer blend of highly crystalline polyvinylidene fluoride polymer and polyalkyl methacrylate, such as PVDF and PMMA. The miscible blend comprises from about 50 weight percent to about 90 weight percent polymer comprising polyvinylidene fluoride and from about 10 weight percent to about 50 weight percent polyalkyl methacrylate. The polyalkyl methacrylate having a molecular weight within the range of about 25,000 grams per mole to about 200,000 grams per mole. The crystallinity of the polyvinylidene fluoride polymer is about 20% to about 70%. The weather resistant coating has excellent and unexpected physical characteristics, including solvent resistance and gloss retention.

Owner:SOLVAY SOLEXIS

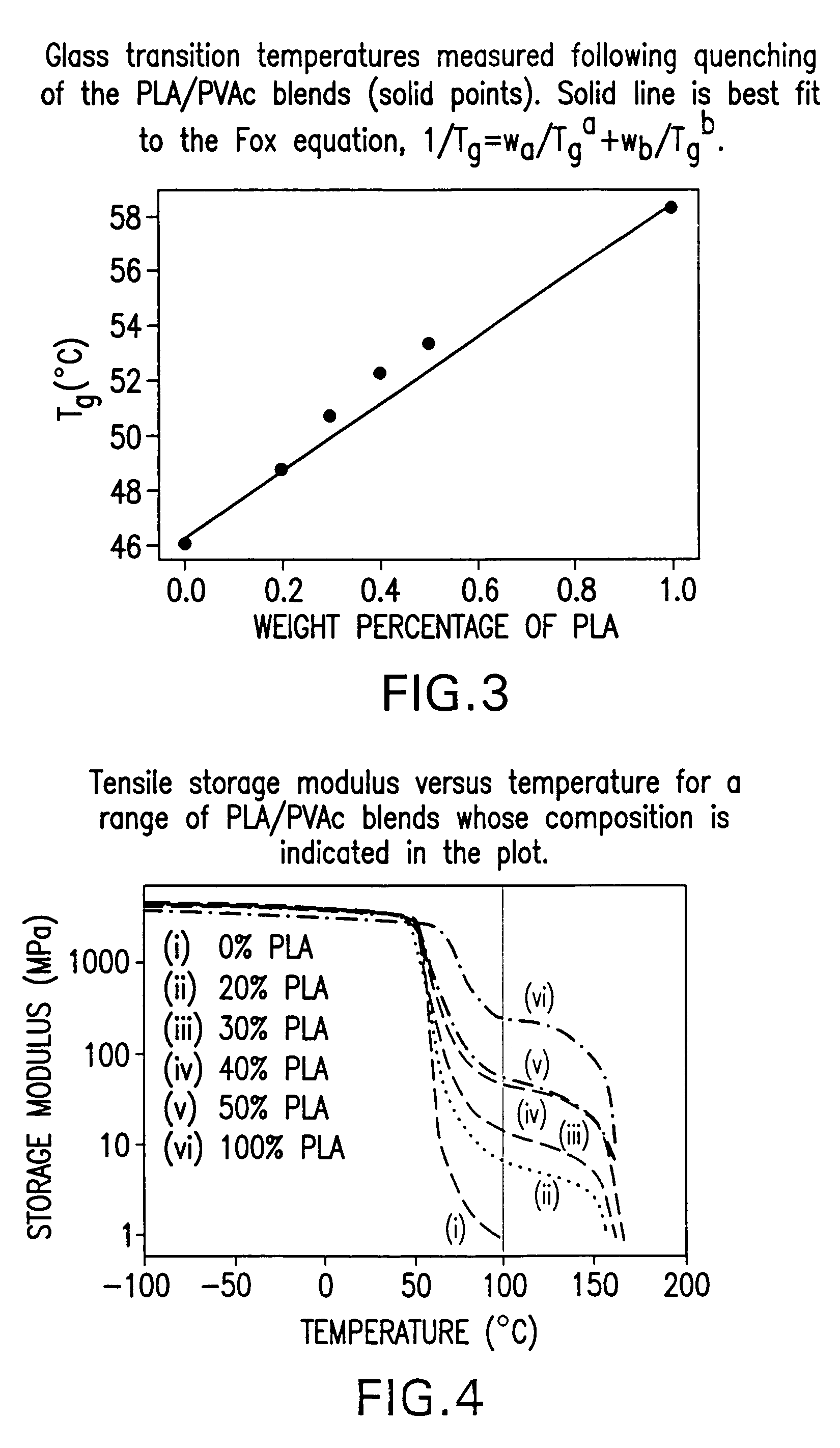

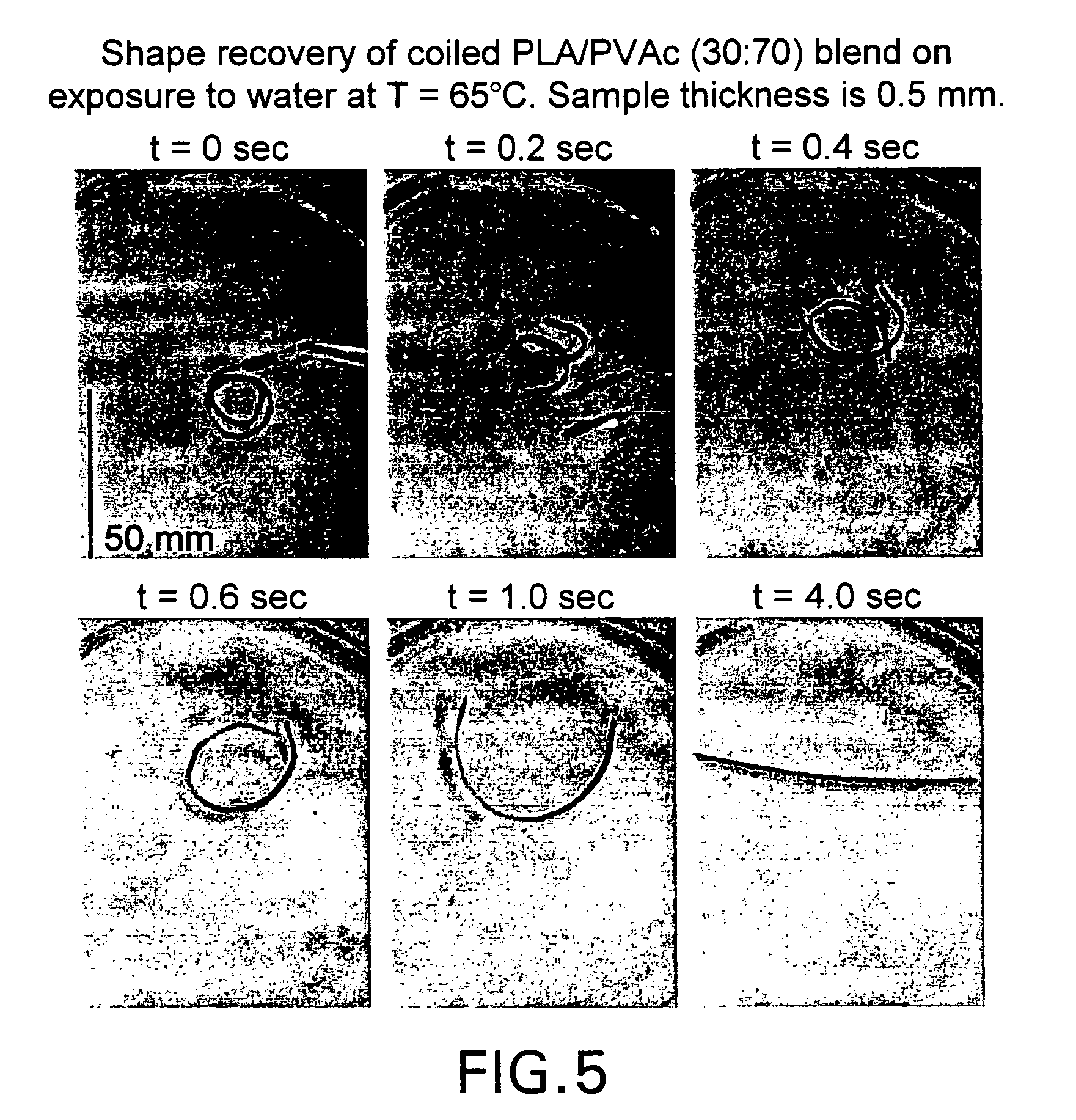

Blends of amorphous and semicrystalline polymers having shape memory properties

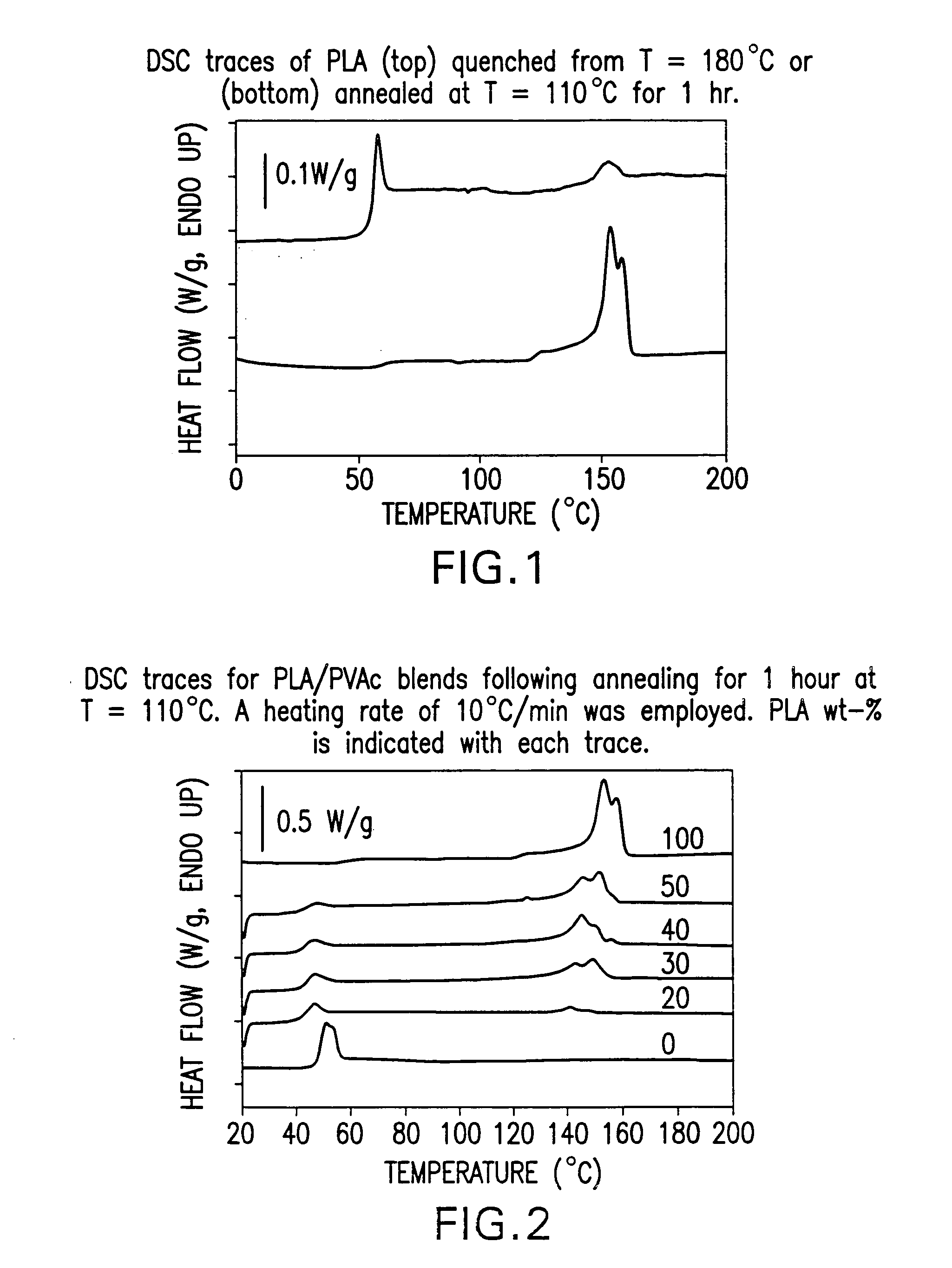

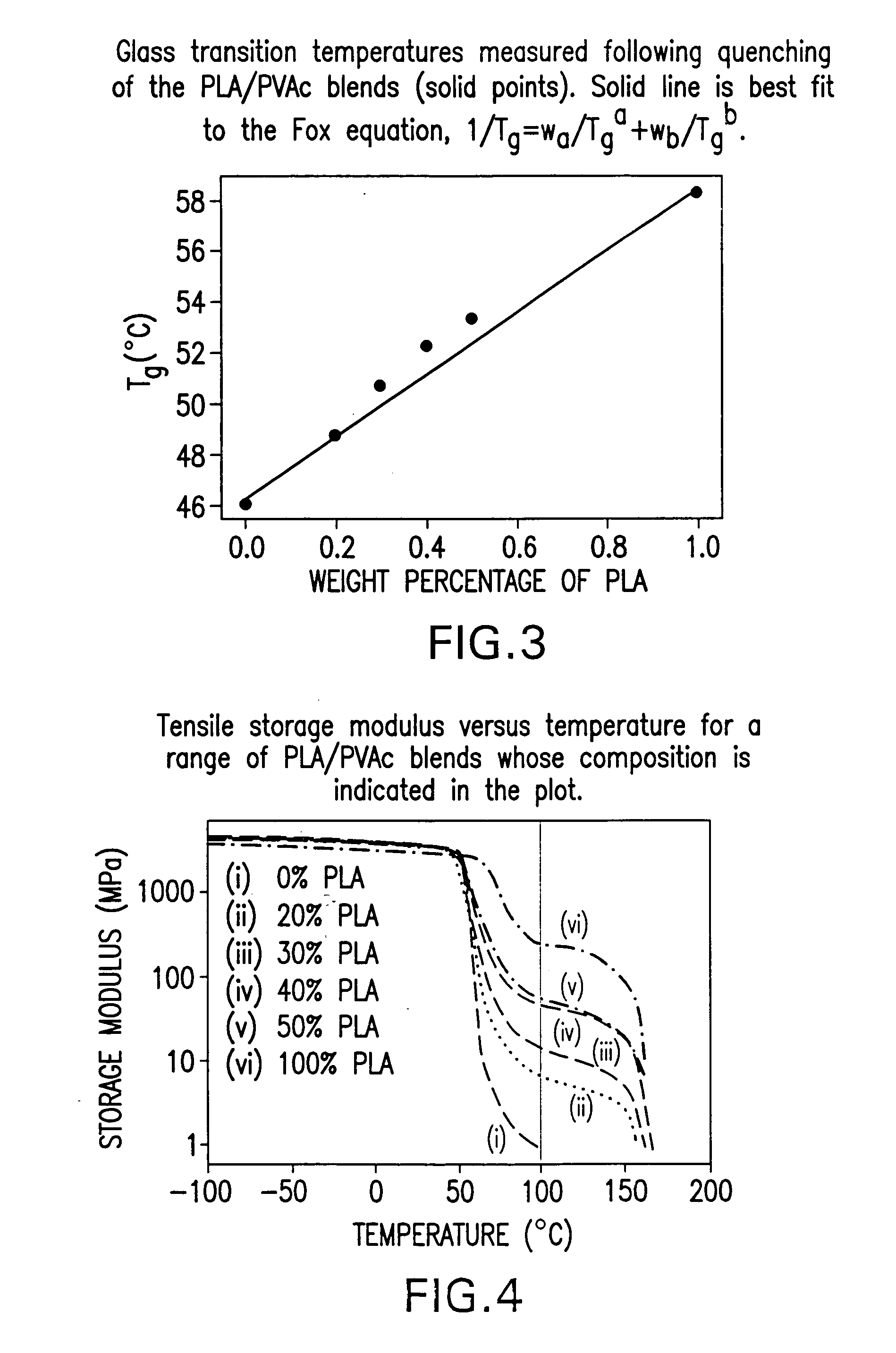

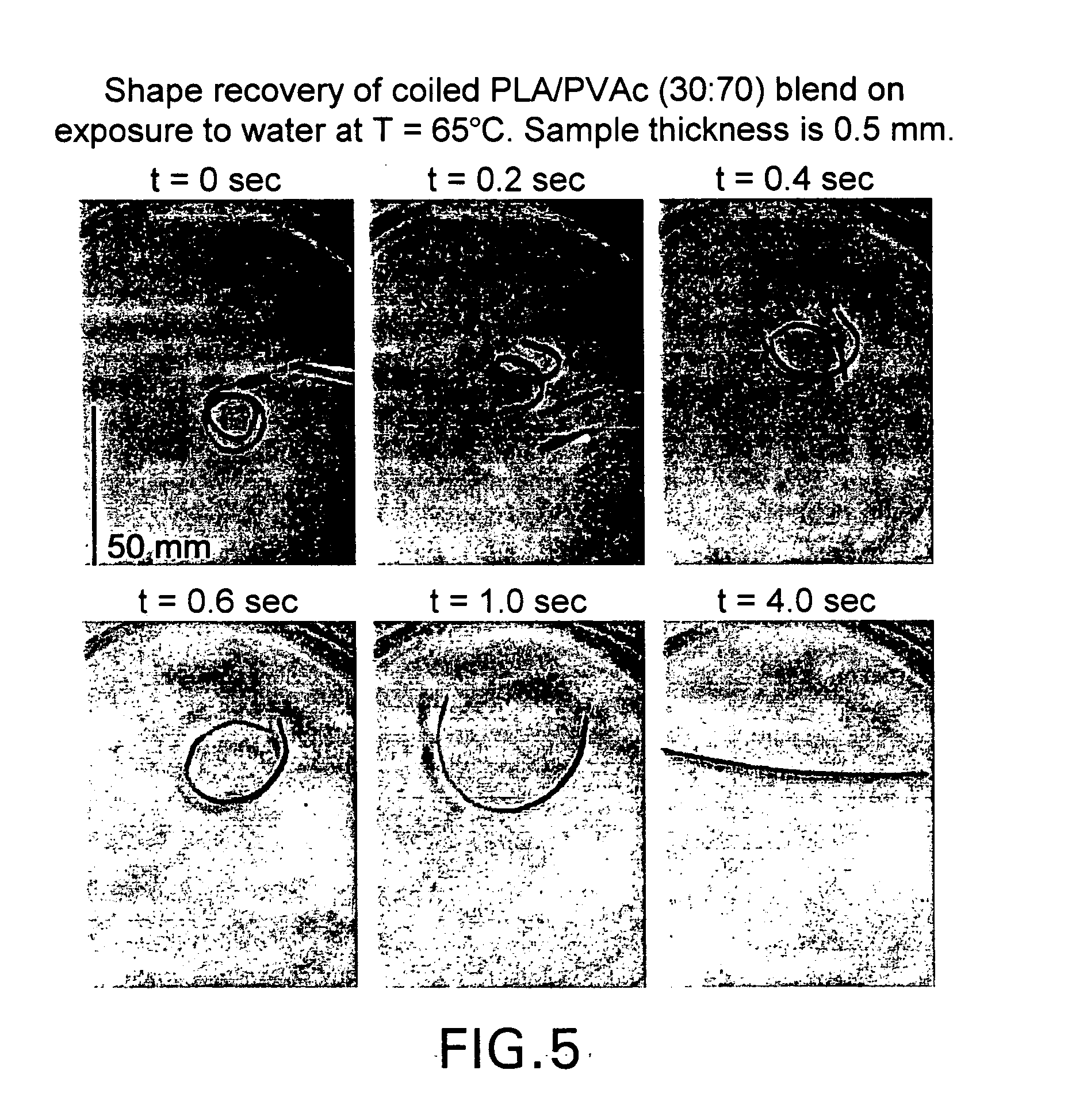

InactiveUS20040122174A1High modulusImprovement in critical temperatureDental impression compositionsPoly(methyl methacrylate)Ethyl acrylate

Blends of amorphous and semicrystalline polymers having shape memory properties were prepared by blending a crystalline polymer such as poly(vinylidene fluoride), polylactide, poly(hydroxxybutyrate), poly(ethylene glycol) polyethylene, polyethylene-co-vinyl acetate, poly(vinyl chloride), poly(vinylidene chloride) and copolymers of poly(vinylidene chloride) and poly(vinyle chloride) and an amorphous polymer such as poly(vinyl acetate), poly methyl acrylate, poly ethyl acrylate, atactic poly methyl methacrylate, isotactic poly methyl methacrylate, syndiotactic poly methyl methacrylate and other poly alkyl methacrylates. The method for preparing the polymeric materials and applications thereof, for example, as smart medical devices, are also disclosed.

Owner:UNIV OF CONNECTICUT

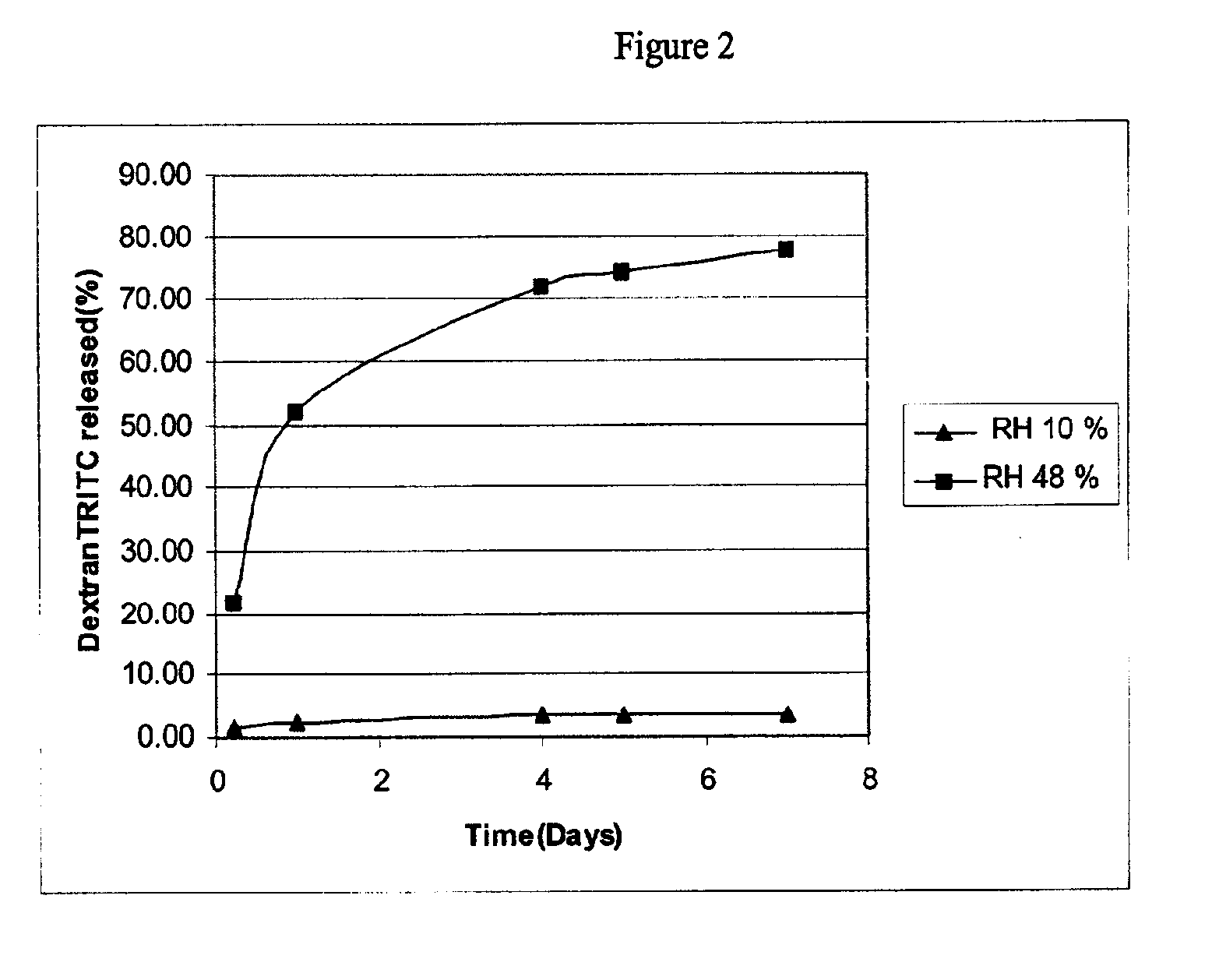

Bioactive agent release coating and controlled humidity method

A coating composition in the form of a one or multi-part system, and method of applying such a composition under conditions of controlled humidity, for use in coating device surfaces to control and / or improve their ability to release bioactive agents in aqueous systems. The coating composition is particularly adapted for use with medical devices that undergo significant flexion and / or expansion in the course of their delivery and / or use, such as stents and catheters. The composition includes the bioactive agent in combination with a first polymer component such as polyalkyl(meth)acrylate, polyaryl(meth)acrylate, polyaralkyl(meth)acrylate, or polyaryloxyalkyl(meth)acrylate and a second polymer component such as poly(ethylene-co-vinyl acetate).

Owner:SURMODICS INC

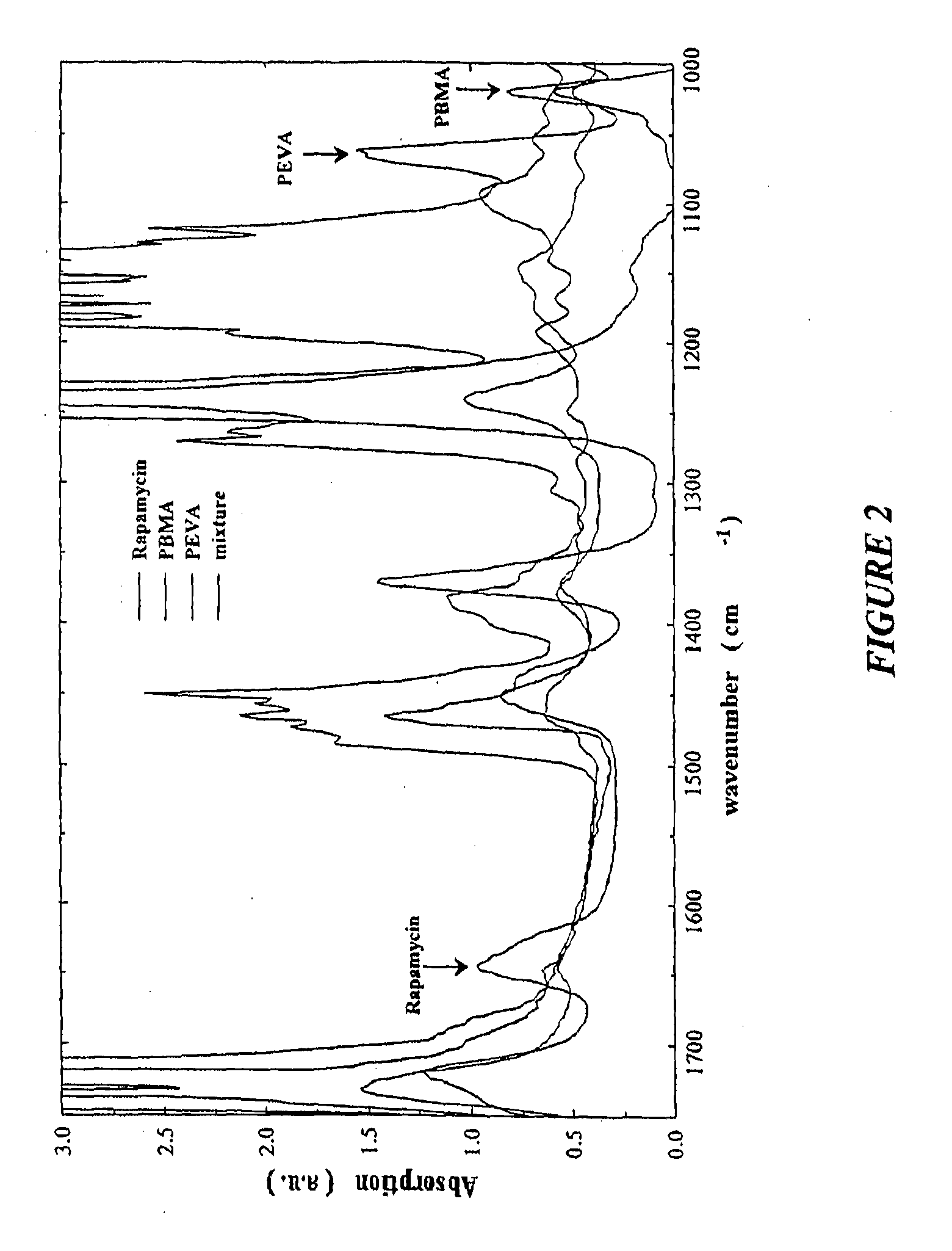

Stent with polymer coating containing amorphous rapamycin

InactiveUS20090062909A1Extensive adhesionBulk propertiesStentsSurgeryPolymer coatingsPolybutyl methacrylate

A coated coronary stent, comprising: a stainless steel sent framework coated with a primer layer of Parylene C; and a rapamycin-polymer coating having substantially uniform thickness disposed on the stent framework, wherein the rapamycin-polymer coating comprises polybutyl methacrylate (PBMA), polyethylene-co-vinyl acetate (PEVA) and rapamycin, wherein substantially all of the rapamycin in the coating is in amorphous form and substantially uniformly dispersed within the rapamycin-polymer coating.

Owner:MICELL TECH INC

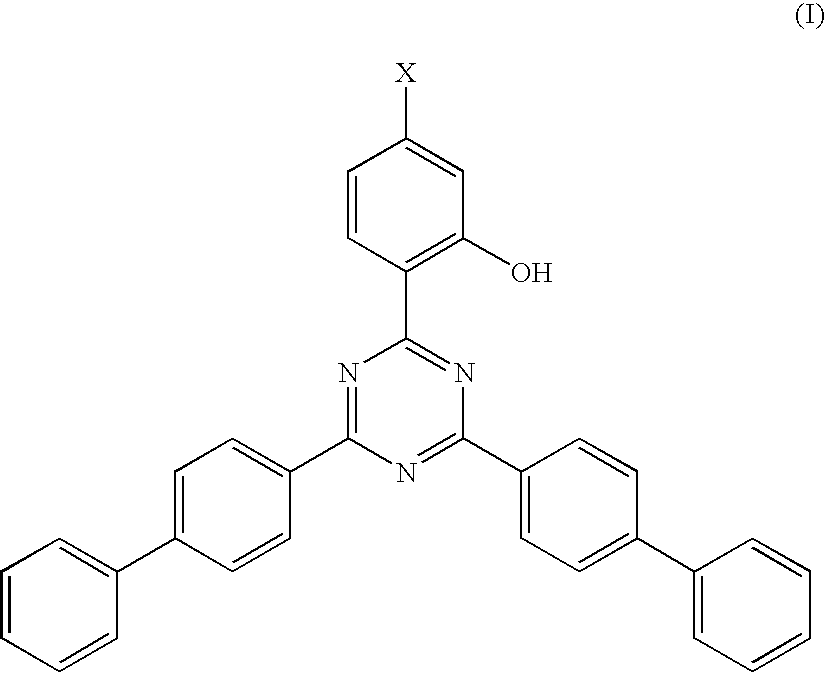

UV-stabilized polycarbonate moldings

A multi-layered product in the form of sheet, film or a three dimensional molded article is disclosed. The product comprised a first layer (A) having a thickness of 1 μm to 2 mm containing polyalkyl (meth)acrylate and 0.01 to 20 percent relative to the weight of said first layer of a UV stabilizer and a second layer (B) that contains polycarbonate. The stabilizer conforms to formula (I) wherein X denotes OR1; OCH2CH2OR1; OCH2CH(OH)CH2OR1 or OCH(R2)COOR3, R1 is branched or unbranched C1-C13 alkyl, C2-C20 alkenyl, C6-C12 aryl or —CO—C1-C18 alkyl, R2 is H or branched or unbranched C1-C8 alkyl, and R3 is C1-C12 alkyl; C2-C12alkenyl or C5-C6 cycloalky. The product is characterized by its optical transparency and resistance to yellowing and is most suitable for glazing applications.

Owner:COVESTRO DEUTSCHLAND AG

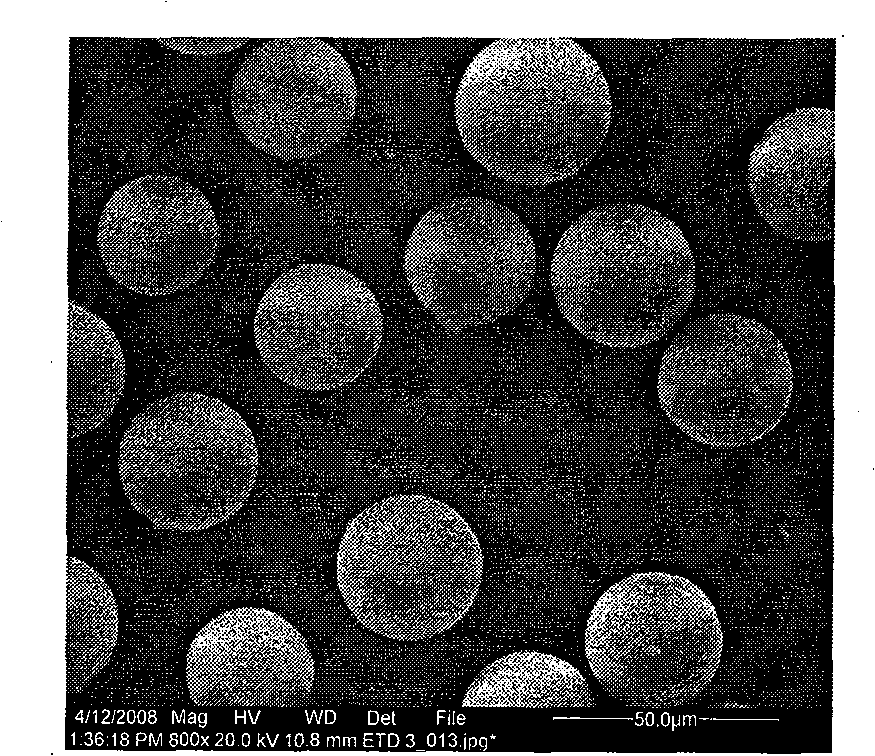

Preparation of monodisperse porous polymer microsphere

The invention provides a preparation method of a monodisperse porous polymer microsphere. After a second stage of swelling of two-stage seed swelling polymerization, remnant monomer separation technology is adopted to avoid the aggregation of the microspheres and the generation of secondary particles, thereby greatly improving the stability of preparing monodisperse porous polymer microsphere through the two-stage seed swelling polymerization. The two-stage seed swelling polymerization can stably prepare the following monodisperse porous polymer microspheres: P(St-co-DVB) (PSD for short) and P(St-co-DVB-co-MMA) (PSDA for short), wherein, St is referred to as styrene, DVB as divinybenzene, MMA as methyl methacrylate, AN as acrylonitrile and co as copolymerization. The monodisperse porous polymer microsphere PSDA prepared by the method can be seen in an attached drawing.

Owner:芜湖万隆新材料有限公司

Blends of amorphous and semicrystalline polymers having shape memory properties

InactiveUS7208550B2High modulusDental impression compositionsPoly(methyl methacrylate)Glycol synthesis

Blends of amorphous and semicrystalline polymers having shape memory properties were prepared by blending a crystalline polymer such as poly(vinylidene fluoride), polylactide, poly(hydroxxybutyrate), poly(ethylene glycol) polyethylene, polyethylene-co-vinyl acetate, poly(vinyl chloride), poly(vinylidene chloride) and copolymers of poly(vinylidene chloride) and poly(vinyle chloride) and an amorphous polymer such as poly(vinyl acetate), poly methyl acrylate, poly ethyl acrylate, atactic poly methyl methacrylate, isotactic poly methyl methacrylate, syndiotactic poly methyl methacrylate and other poly alkyl methacrylates. The method for preparing the polymeric materials and applications thereof, for example, as smart medical devices, are also disclosed.

Owner:UNIV OF CONNECTICUT

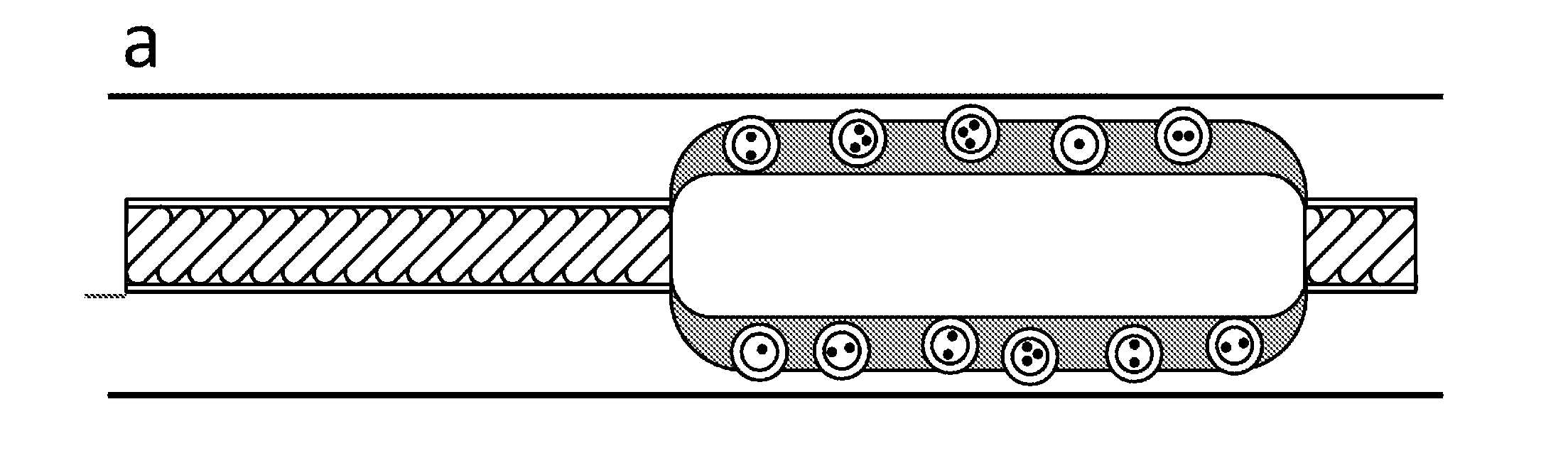

Balloon catheter comprising pressure sensitive microparticles

InactiveUS20120083734A1Improve brittlenessEffective treatmentSurgeryDilatorsPolyesterPoly(N-isopropylacrylamide)

The invention provides a solution to the above mentioned problem in that it provides a catheter balloon comprising a flexible coating on its outer surface wherein a plurality of microparticles are contained wherein said coating comprises a material selected from the group consisting of poly(N-vinyl-pirrolidone, poly(N-vinyl-pirrolidone-co-butylacrylate), poly(-vinyl pyridine), polyacrylamides, e.g. poly(N-isopropylacrylamide), poly(amido-amines), poly(ethylene imine), poly(ethylene oxide-block-propylene oxide), poly(ethylene oxide-block-propylene oxide-block-ethylene oxide), poly(styrene-block-isobutylene-block-styrene), poly(hydroxystyrene-block-isobutylene-block-hydroxystyrene), polydialkylsiloxanes, polysaccharides, polyacrylates and polyalkylmethacrylates, e.g. polymethylmethacrylate and poly(2-hydroxyethylmethacrylate) and wherein said microparticles comprise a material selected from the group consisting of polyesters, e.g. poly(lactic acid), poly(lactic-co-glycol acid), poly(glycolic acid), poly(3-hydroxybutyrate), poly(3-hydroxyvalerate), poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and polycaprolactone, polyamides, polysaccharides, polyurethanes, polyalkylmethacrylates and polyacrylates, e.g. polymethylmethacrylate and poly(2-hydroxyethylmethacrylate) and wherein the microparticles comprise a pharmaceutically active compound.

Owner:ENCAPSON

Method for reducing sag in drilling, completion and workover fluids

InactiveUS6861393B2Reduce saggingHigh viscosityDrilling compositionBorehole/well accessoriesWell drillingFluid viscosity

A method is disclosed for reducing sag in drilling and completion fluids and in workover fluids. The method employs a drilling fluid comprising a low molecular weight polyalkyl methacrylate with an average molecular weight ranging from about 40,000 to about 90,000. This additive does not result in increased viscosity of the fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

Paste-like detergent formulation comprising branched alkoxylated fatty alcohols as non-ionic surfactants

ActiveUS20110094044A1Low viscosityOrganic detergent compounding agentsSurface-active detergent compositionsPolyethylene glycolOil phase

The invention relates to a hydrous, paste-like cleaning or detergent composition comprising an emulsion having an aqueous phase and an oil phase, the composition comprises based on the whole concentrate 1 to 50 wt-% of one or more alkalinity source, 1 to 60 wt-% of a guerbet alcohol ethoxylate of the formula R1—(OC2H4)n—OH, wherein R1 is a branched C9 to C20 alkyl group and n is from 2 to 10, 1 to 30 wt-% of a linear alkoxylated fatty alcohol of the formula R2—(OC2H4)x—(OC3H6)y—OH, wherein R2 is a linear C10 to C16 group and n is from 3 to 7 and m is from 3 to 7, 0.01-10 wt-% of one or more crosslinked or partly crosslinked polyacrylic acid or polymethacrylic acid or mixtures thereof, 1-10 wt-% of a thickener system comprising the following components: 1-5 wt-% of a polyacrylate, 0-5 wt-% of a swellable phyllosilicate, 0-2 wt-% of a polyethylene glycol with the provision that the thickener system comprises at least two of these components, and the rest up to 100 wt-% is water.

Owner:ECOLAB USA INC

Oil absorbing fibre and perparing method thereof

InactiveCN1584148ABroaden the fieldLarger specific surface area for oil absorptionWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberBenzoyl peroxide

The invention relates to a kind of oil-absorbed fiber and its producing method. Its prescription is: 100% polymer monomer, 10-40% of potential gemel agent, 0.1-0.5% solicitation, 0.5-1% dispersant. Moreover the water-like body is 3-4 times more in volume than polymer monomer. The polymer monomer is methacrylate monomer involving butyl methacrylate, the potential gemel agent is 2-hydroxyethyl methacrylate, the solicitation is benzoyl peroxide, and dispersant is poly-vinyl-alcohol. The process is (1) use water-suspending polymerization to produce butyl methacrylate under 70-80 deg.C for blending and polymerizing for 8-10 hours. (2) dissolve the polymer into proper solvent to deploy 20-25% liquid and then insert potential gemal agent and solicitation to polymerize for 3-5 hours under 75-80 deg.C to obtain the original liquid. (3) take off dunking. (4) spin using one of wet or dry method or both, (5) treat with fibre for 10-60 minutes under 120-165 deg.C to obtain the production. The solvent discussed above is one of DMF, DMAC or dimethoxysulfoxide.

Owner:TIANJIN POLYTECHNIC UNIV

Aqueous coating composition

An aqueous coating composition comprising (a) 10 to 60 wt % of an aqueous dispersion comprising water and one or more water-dilutable binders selected from the group of polymethacrylic, polyacrylic, polyester, polyurethane, hybride polyacrylic / polyester or polyacrylic / polyurethane, epoxy modified binders, with linear, branched or star structure and any mixtures thereof, the amount of said water constituting at least 15 wt % based on the total weight of said component a), (b) 5 to 40 wt % of one or more water-dispersible polyisocyanates or mixtures of water-dispersible and water-emulsifiable polyisocyanates, blocked or unblocked, (c) 5 to 70 wt % of filler material, (d) 1 to 40 wt % of a ground polymer material, (e) 0 to 15 wt % of organic co-solvents, (f) 0.01 to 15 wt % of additives, pigments and fillers, and (g) 3 to 30 wt % of water and the invention is directed to a process for applying the aqueous coating to substrates to form decorative surfaces and to the resulting coated substrates.

Owner:AXALTA COATING SYST IP CO LLC

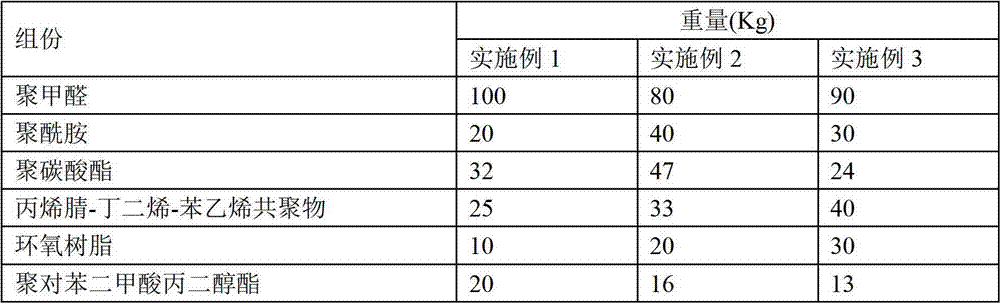

Engineering plastic with high wearing resistance

InactiveCN102875956AGood mechanical propertiesReduce wear ratePolyethylene glycolPolymethyl methacrylate

The invention provides an engineering plastic with high wearing resistance. The engineering plastic is made from the following raw materials by weight: 80-100 parts of polyformaldehyde, 20-40 parts of polyamide, 20-50 parts of polycarbonate, 25-40 parts of acrylonitrile-butadiene-styrene copolymer, 10-30 parts of epoxy resin, 12-20 parts of polytrimethylene terephthalate, 1-5 parts of diphenylmethane bismaleimide, 10-15 parts of polyphenyl ether, 20-40 parts of polyether-ether-ketone, 10-20 parts of polytetrafluoroethylene, 5-10 parts of melamine, 4-12 parts of boric acid alkanolamide, 2-6 parts of polyethylene glycol, 4-12 parts of phenolic ether phosphomonoester, 5-15 parts of polymethyl methacrylate, 10-20 parts of organic silicone oil, 5-10 parts of silane coupling agent, 3-5 parts of zinc stearate, 10-20 parts of glass fibre, 12-20 parts of graphite, 5-10 parts of silicon carbide whisker, 5-8 parts of nanometre titanium oxide, 4-6 parts of diphenyl ketone, 3-8 parts of butylated hydroxyanisole and 15-30 parts of filler. The engineering plastic provided by the invention has a good wear-resisting property.

Owner:SUZHOU YUNYUAN NETWORK TECH

Simulated mussel protein environment-friendly lithium ion battery adhesive

ActiveCN103342974AImprove adhesionEasy transferCell electrodesAcid polymer adhesivesAdhesiveLithium-ion battery

The invention relates to a preparation method and application of an environment-friendly lithium ion battery, and in particular relates to a simulated mussel protein environment-friendly lithium ion battery adhesive. By simulating the molecular structure and action mechanism of mussel protein, histidine and dopamine are connected to polyacrylic acid, polymaleic acid, sodium alginate, sodium carboxymethylcellulose, carboxymethyl chitin, carboxymethyl chitosan, abietic acid and other natural or synthesized polymer to prepare a series of aqueous adhesives. The adhesive has a good adhering effect for various cathode materials such as carbon black, graphite and silicon. By adopting the adhesive provided by the invention, various properties of a lithium ion battery can be obviously improved, and especially cycle property of a silicon cathode material in a battery can be obviously improved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

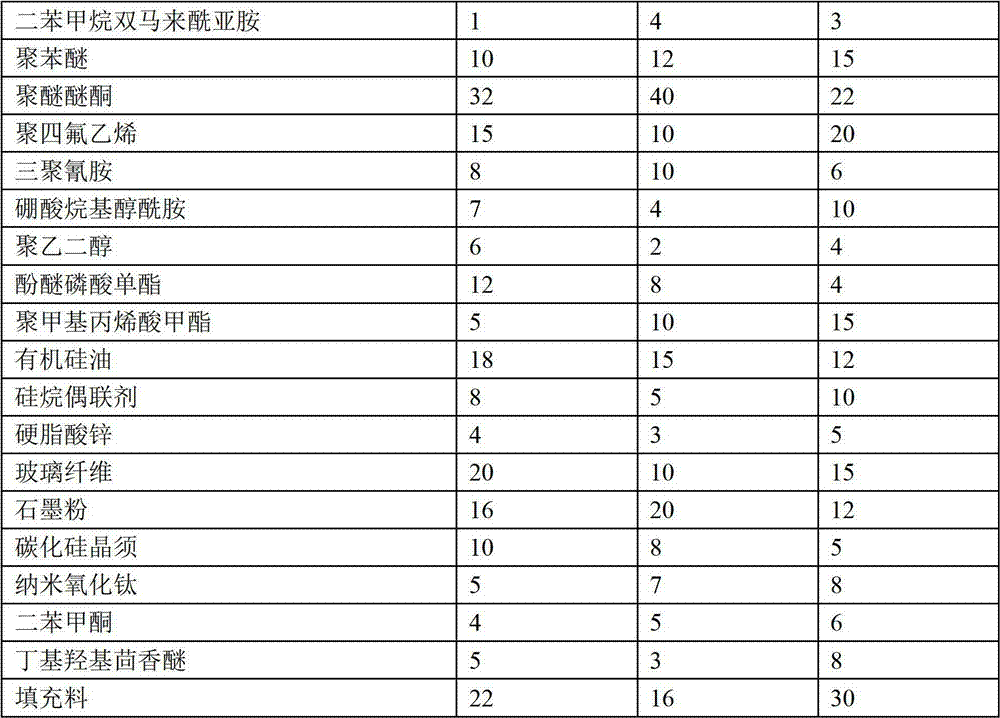

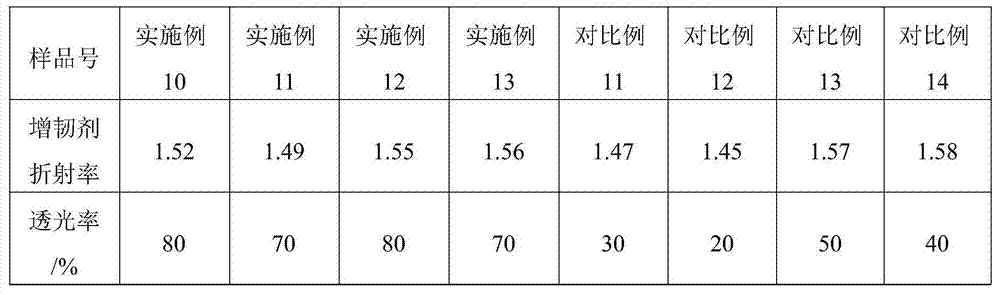

Heat-resistant scratch-resistant high-transmittance PMMA alloy resin composition and preparation method thereof

The invention relates to a heat-resistant scratch-resistant high-transmittance PMMA alloy resin composition. The composition is prepared from the following raw materials in parts by weight: 10-94 parts of polymethyl methacrylate, 5-70 parts of special heat-retardant agent for PMMA, 1-45 parts of a flexibilizer, 0-80 parts of a fluidity regulator, 0.1-1 part of an antioxidant, 0.1-2 parts of a lubricating agent and 0.001-1.0 part of an additive, wherein the special heat-retardant agent for PMMA refers to a maleic anhydride-styrene-methyl acrylate terpolymer MAH-St-MMA. The maleic anhydride-styrene-methyl acrylate terpolymer, polymethyl methacrylate and fluidity regulator used in the invention have good compatibility, and high transparency is achieved after blending; and moreover, the flexibilizer with refractive index consistent with that of a blended matrix resin is selected, and by virtue of the conventional double screw molding, the prepared alloy resin has the advantages of high transmittance, scratch resistance and heat resistance.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

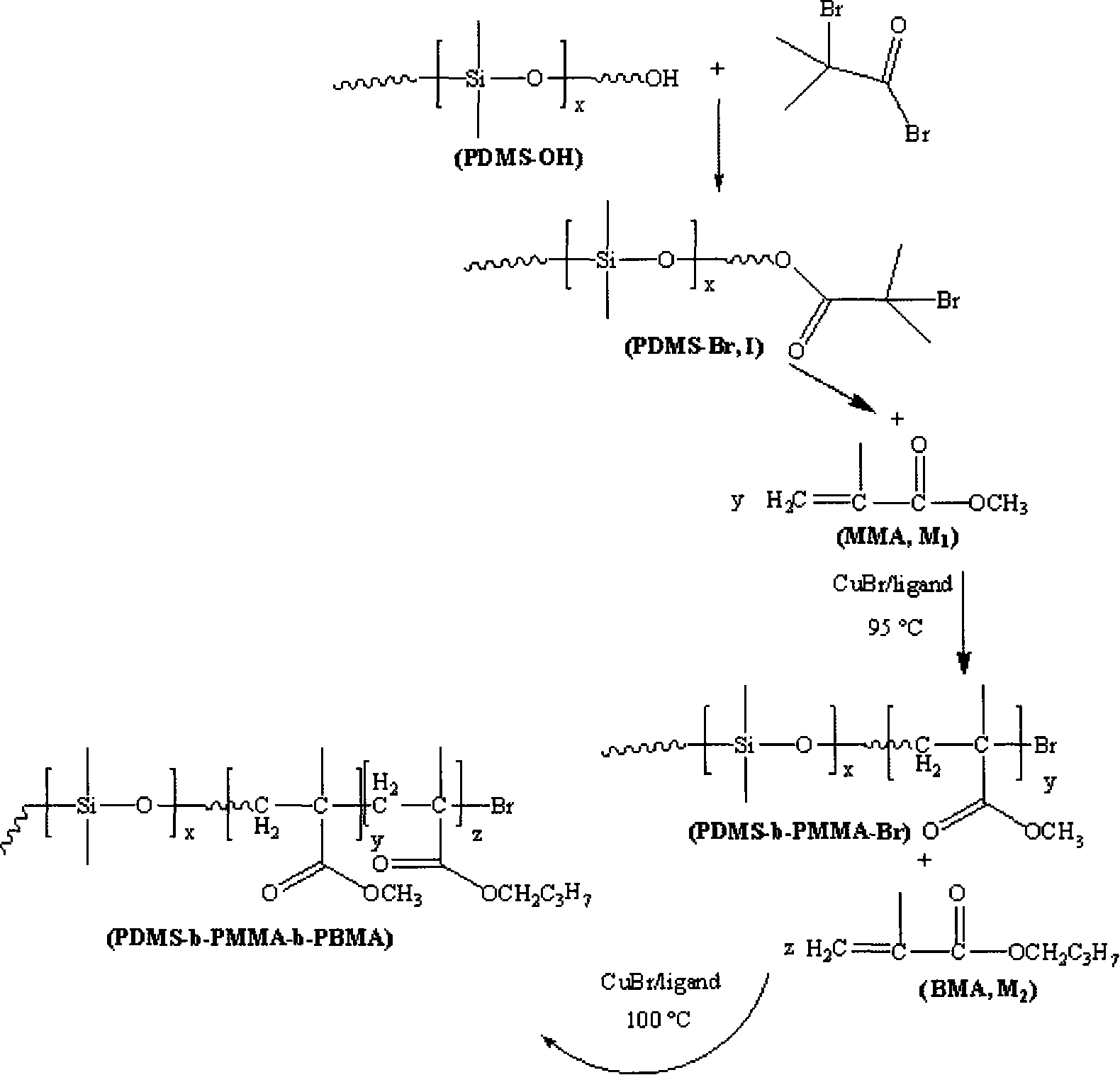

Silicon-acrylic tri-block copolymer with low surface energy and preparing method thereof

The invention relates to a silicon-acrylic three-block copolymer with low surface energy and a process for preparation, which relates to the synthesis of silicon-acrylic low-surface-energy three-block copolymer. The invention provides a silicon-acrylic three-block copolymer with low surface energy, whose structure of reaction product is accurate, and the original skeleton construction of each block is kept. The invention relates to a dimethyl silicone polymer-b- polymethyl methacryate-b-poly n-butyl methacrylate. And the process for preparation comprises first, preparing dimethyl silicone polymer macromolecule initiating agent of the dead ends of bromine atoms, second, preparing two-block macromolecule initiating agent of copolymer dimethyl silicone polymer-b-polymethyl methacryate, third, preparing two-block copolymer macromolecule initiating agent of dimethyl silicone polymer-b- polymethyl methacryate, finally, preparing three-block novel copolymer of dimethyl silicone polymer-b- polymethyl methacryate-b-poly n-butyl methacrylate.

Owner:XIAMEN UNIV

Fluorine-contained film and preparation method thereof

InactiveCN101696309AImprove mechanical propertiesGood weather resistancePolymer sciencePolyvinylidene difluoride

The invention relates to a fluorine-contained film and a preparation method thereof. The fluorine-contained film is prepared from the following raw materials in parts by weight: 50-90 polyvinylidene fluoride polymer, 10-40 polymethacrylic acid resin and 0.5-10 additives. The fluorine-contained film prepared by the technical scheme provided by the invention has ideal mechanical performance and weatherability and excellent optical performance, wherein the ideal mechanical performance refers to longitudinal tensile strength larger than 130MPa, longitudinal at-break elongation larger than 95 percent, longitudinal tensile modulus larger than 2000MPa, transversal tensile strength larger than 150MPa, transversal at-break elongation larger than 80 percent and transversal tensile modulus larger than 2000MPa.

Owner:CHANGSHU TOP SOLAR MATERIAL

Preparation method of nano particles with high refractive index and polymer nano composite film material

The preparation method of nano composite film material by using nano microparticles with high refractive index and polymer includes the following three steps: preparing ZnS nano microparticles for surface modification, preparing organic polymer monomer and polymer with high refractive index and preparing nano composite film. In the organic solvent of zinc metal salt the organic small molecule surface modifier with function group is added, and the hydrogen sulfide gas is introduced to synthesize ZnS nano colloidal microparticles, and the polymer base material for combining ZnS nano microparticles can be polymethyl methacrylate, polybutyl methacrylate, polystyrene, epoxyresin, polymer large monomer, optimally can be polyurethane oligomer and polyurethane acrylate large monomer with high refractive index, finally the above-mentioned materials can be made into the invented nano composite film.

Owner:JILIN UNIV

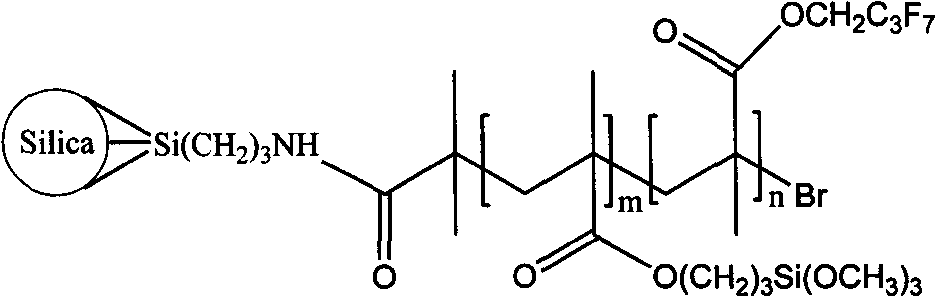

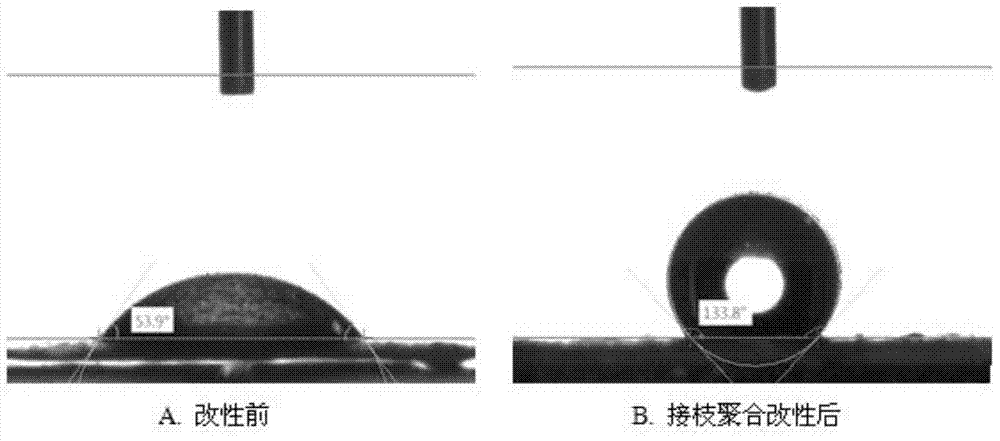

Super hydrophobic silicon-fluorine polymer/nanometer silica hybridization nanometer material and preparation method thereof

InactiveCN101805434ARaise the access pointGood dispersionAntifouling/underwater paintsPaints with biocidesSilicon dioxidePolymethacrylic Acids

The invention relates to a super hydrophobic silicon-fluorine polymer / nanometer silica hybridization nanometer material and a preparation method thereof, relating to a super hydrophobic nanometer material and a preparation method thereof. The invention provides the super hydrophobic silicon-fluorine polymer / nanometer silica hybridization nanometer material with mild reaction condition, definite reaction product structure as well as simple and convenient operation and the preparation method thereof. The preparation method comprises the following steps of: firstly, preparing nanometer silica modified by a silane coupling agent; secondly, preparing a nanometer silica atom transfer radical surface initiator; thirdly, preparing a SiO2-poly-Methacryloxypropyltrimethoxysilane macromolecule initiator; and finally preparing the silicon-fluorine polymer / nanometer silica hybridization nanometer material. The silicon-fluorine polymer / nanometer silica hybridization nanometer material has excellent high temperature resistance, ultraviolet resistance, infrared radiation resistance, oxidative degradation resistance, chemicals resistance and contamination resistance. Polymethyl 2-propenoic acid, 2,2,3,3,4,4,4-heptafluorobutyl ester has very low surface energy and very good hydrophobicity, wherein the surface energy can be as low as 0.5-1.5mN / m, and the hydrophobic angle can be over 150 degrees.

Owner:XIAMEN UNIV

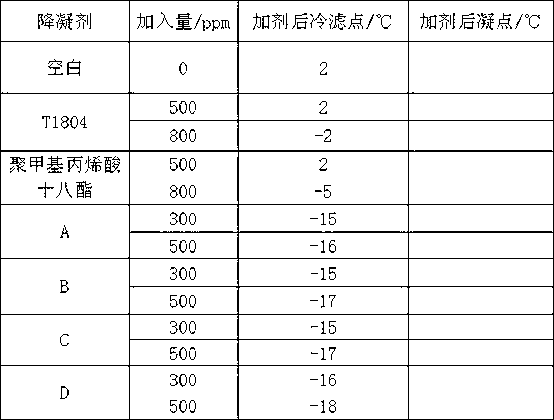

Pour point depressant for diesel oil

ActiveCN103289760APrevent mutual stickingAvoid generatingLiquid carbonaceous fuelsFuel additivesWaxNitrogen

The invention discloses a pour point depressant for diesel oil, wherein polymethylacrylic acid higher ester is used as a host agent, and an arene compound, span, twain and a polar nitrogen-containing compound are used as an assistant. The substances are uniformly mixed and used for effectively reducing the cold filter plugging point of all diesel oils, and are especially better in perceptibility to diesel oils with high wax content and narrow fraction. In low temperature condition, the flowing property of diesel oils with high wax content and narrow fraction is better increased. The pour point depressant is simple to prepare, low in cost and remarkable in effect, has excellent market value, and can be used for solving the problem that the pour point depressant for diesel oil in the petrochemical industry in China is strong in pertinence, single in function and poor in broad spectrum.

Owner:SHANDONG JINGBO PETROCHEM

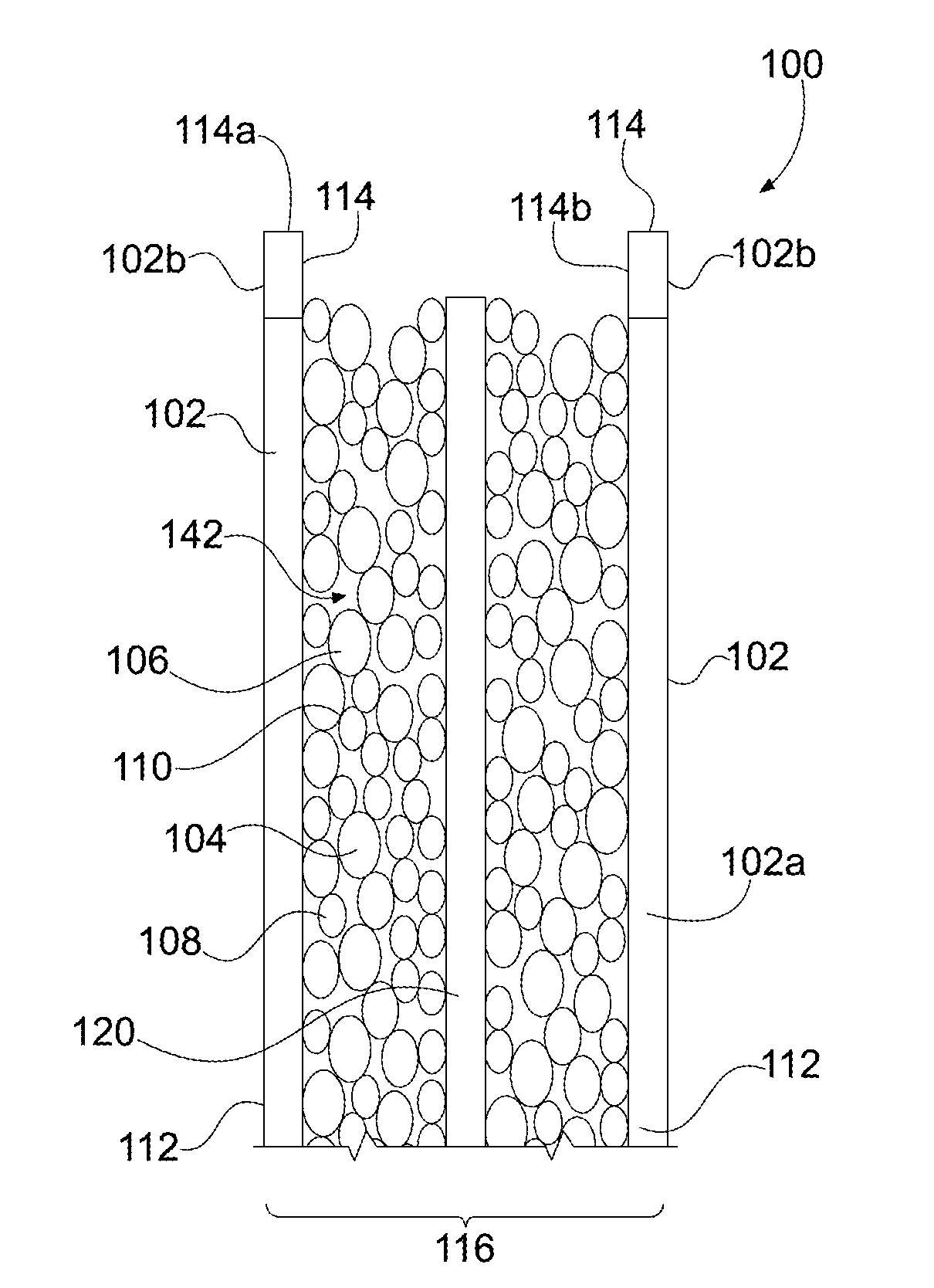

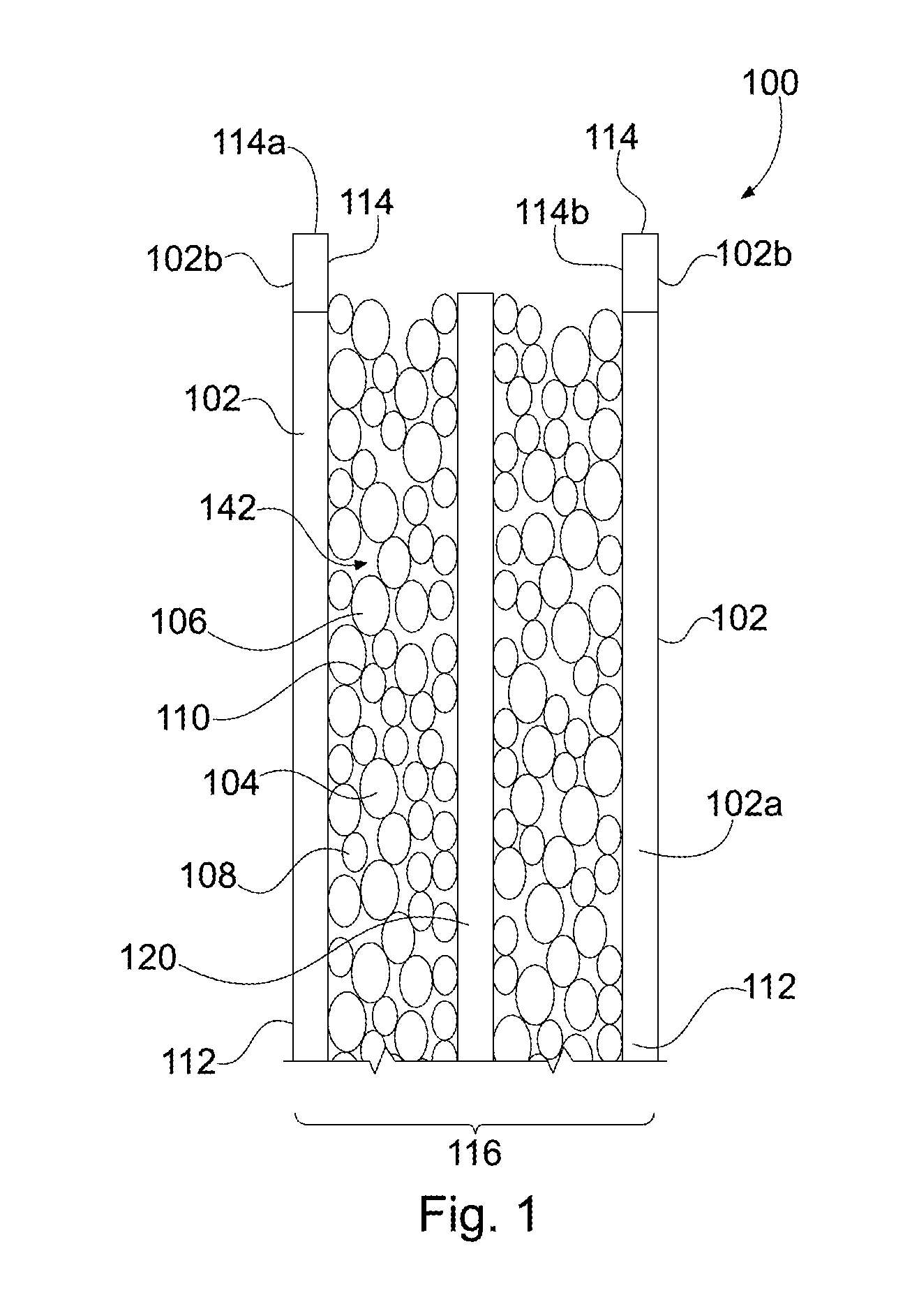

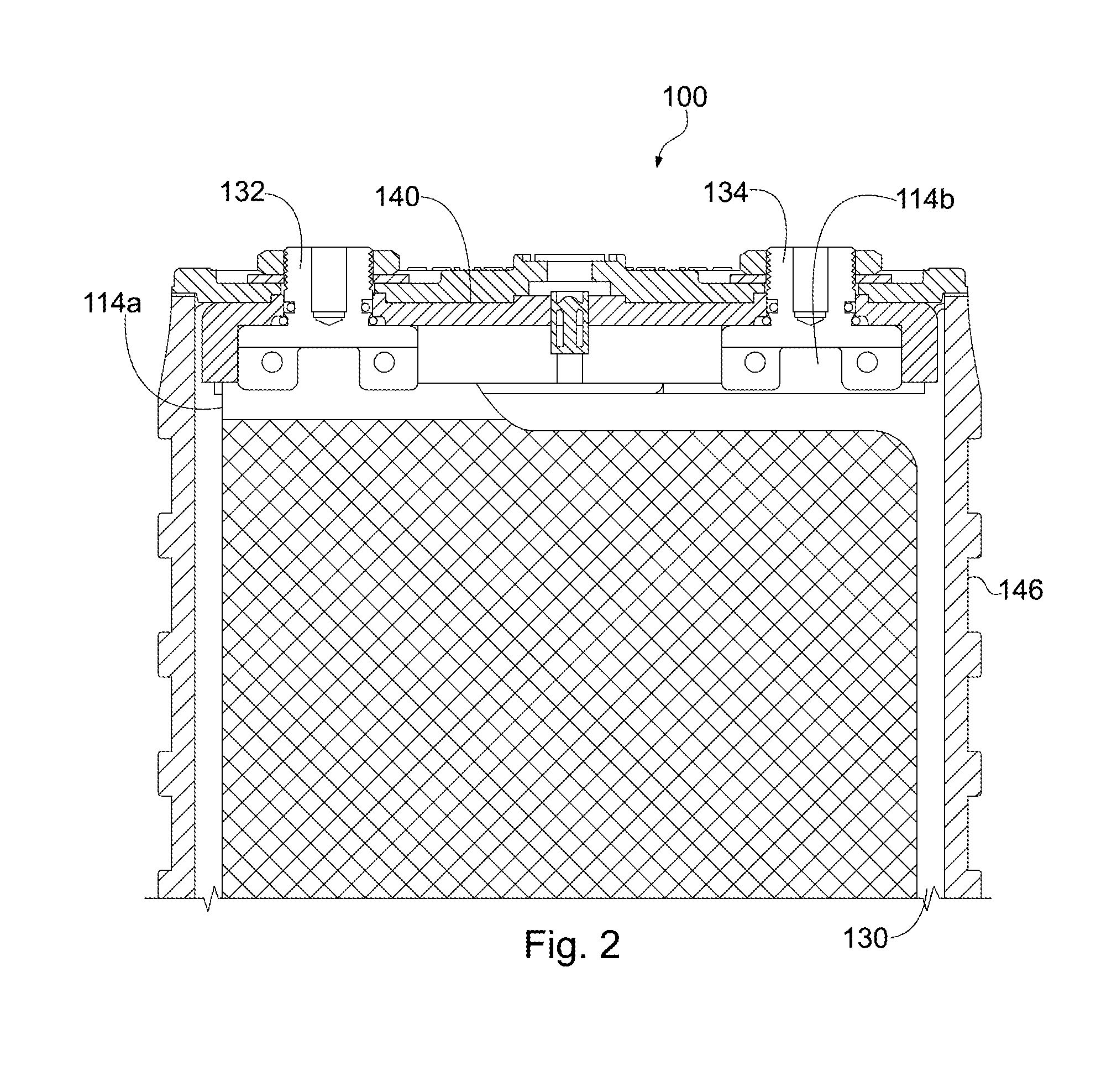

Large format ultracapacitors and method of assembly

InactiveUS20110141661A1Large specific surface areaHybrid capacitor electrodesLiquid electrolytic capacitorsPolyethylene oxidePolyvinyl alcohol

A capacitor includes a plurality of electrode substrates, with each of the plurality of electrode substrates having a coated portion and an uncoated portion. The coated portion is coated with a coating material that includes a high surface area activated carbon material, a water soluble binder selected from the group consisting of: poly vinyl alcohol, poly acrylic acid, polymethacrylic acid, polyethylene oxide, polyacrylamide, poly-N-isopropylearylamide, poly-N,N-dimethylacrylamide, polyethyleneimine, polyoxyethylene, polyvinylsulfonic acid, poly (2-methoxyethoxyethoxyethylene), butadiene-acrylonitrile, and combinations thereof, and a water soluble thickener. A separator is inserted between adjacent substrates of the plurality of electrode substrates. The capacitor further includes an electrolyte. A method of manufacturing the capacitor is also provided.

Owner:INT BATTERY

Aqueous nickel welding paste for stainless steel brazing

The invention relates to an aqueous nickel welding paste for stainless steel brazing, which has the characteristics that: the welding paste is formed by 90-96 percent of brazing filler metal and 4-10percent of paste binders by weight percentage; the brazing filler metal comprises 4-18 percent o f Cr, 0.2-4 percent of Fe, 0.01-0.1 percent of C, 0.1-5 percent of Si, 5-10 percent of P and remainingamount is Ni. The paste binder is formed by the following constituents by weight percentage: 28-58 percent of mixture of carboxymethylcellulose with 10000-1000000 molecular weight and methylcellulose,40-70 percent of aqueous solvent and 1-10 percent of lubricants; or the paste binder is formed by 25-55 percent of one or a plurality of polyacrylamide with 1000-10000 molecular weight, polyacrylic acid, polymethylacrylic acid and copolymer, polyvinyl alcohol or polyoxyethylene, 40-70 percent of aqueous solvent and 1-10 percent of lubricants. The welding paste is the aqueous nickel welding pastewhich is convenient for automatic feeding, is easy to clear and has consistent color of a welding line and stainless steel; therefore, the aqueous nickel welding paste is suitable for stainless steelbrazing.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

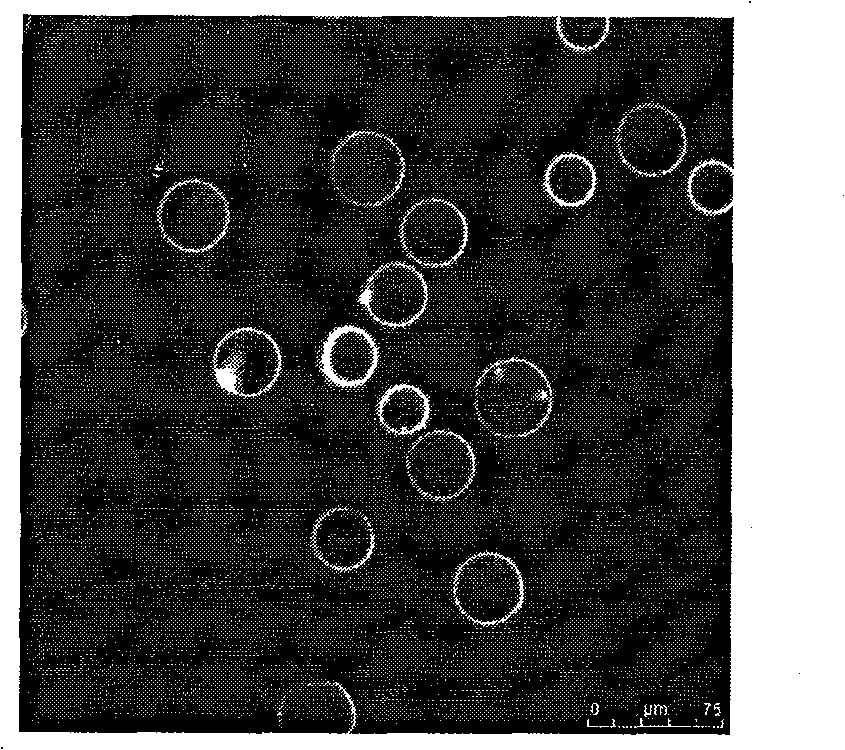

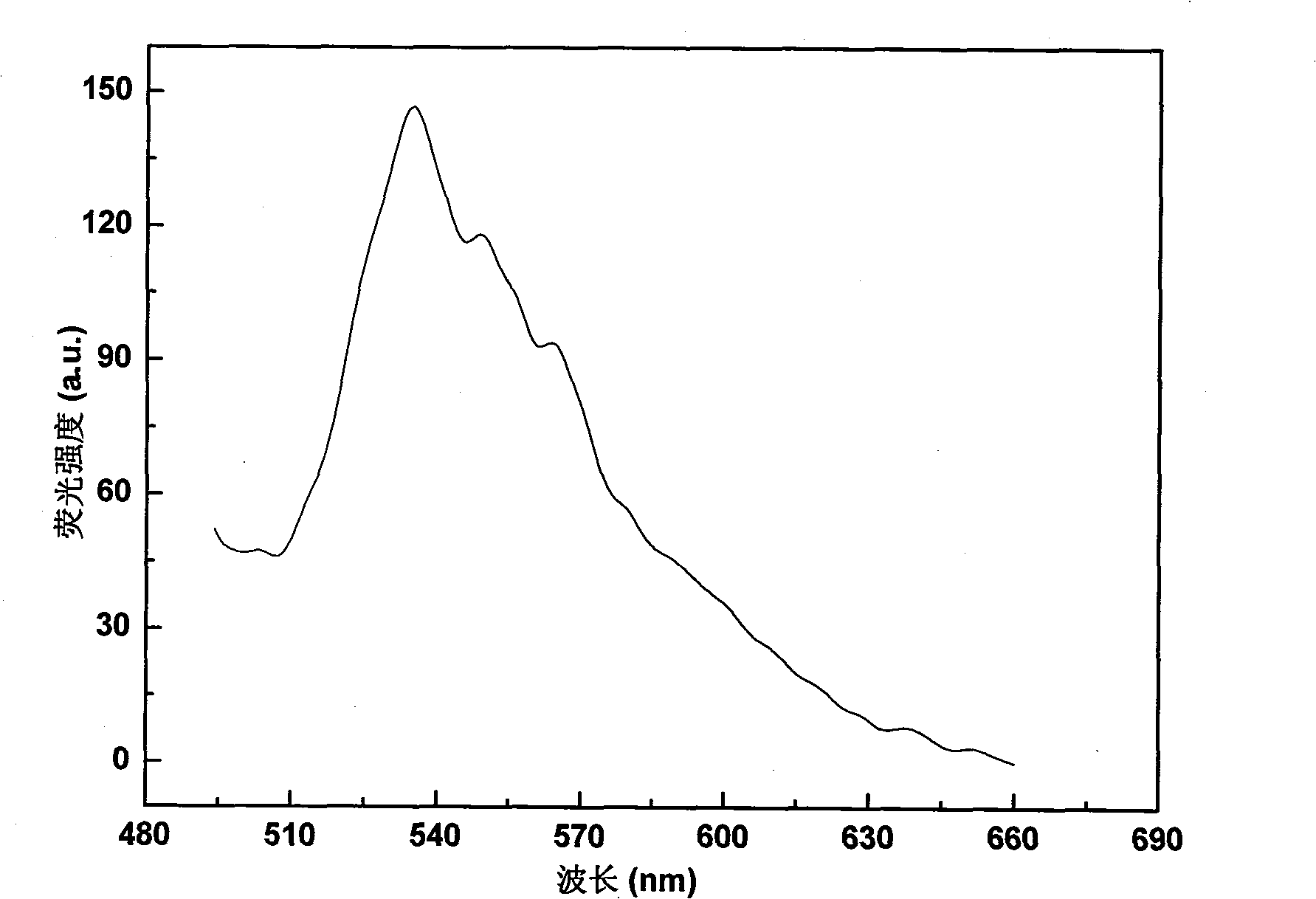

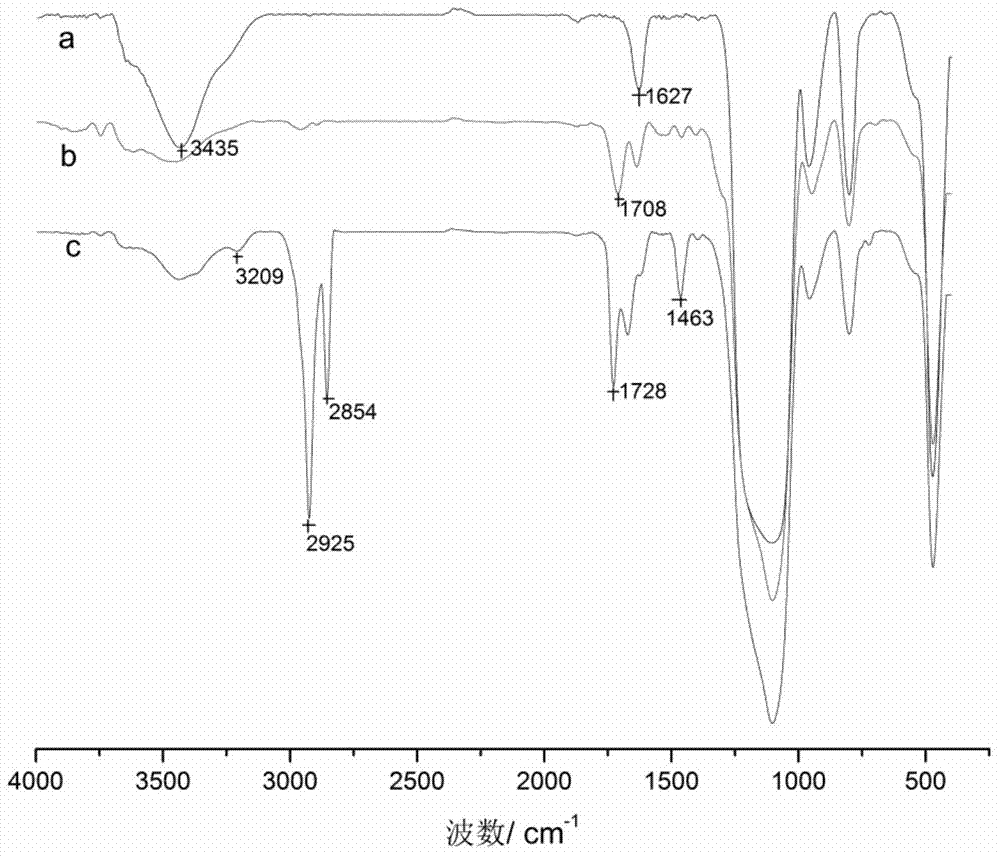

Process for producing fluorescent composite microgel hypersensitive to temperature and pH

The invention discloses a preparation method of fluorescent complex microgel which is sensitive to temperature and pH. The method comprises the technical steps of preparing a mixed surface active agent, preparing the oil phase of a template, preparing an emulsive liquid, preparing a water phase, preparing N-isopropyl acryl amide copolymerized methacrylic acid microgel, preparing turgid N-isopropyl acryl amide copolymerized methacrylic acid microgel, preparing a mixed liquid of Gamma-aminopropyl triethoxy silane and normal heptane, preparing a silicon dioxide polymer complex microballoon decorated by a surface deposited amino group, preparing a mixed liquid of fluorescein isothiocyanate and absolute ethyl alcohol as well as preparing the fluorescent complex microgel. In the invention, the fluorescein isothiocyanate with high quantum yield and good optical stability is adopted as fluorescent matter; the prepared fluorescent complex microgel is sensitive to temperature and pH; and the size of the prepared fluorescent complex microgel is in a micron range and is hard to be aggregated. The method has the advantages of reasonable design, practical technique and easy operation; moreover, reactions are carried out under normal temperature and the like; the method can be applied to the fields of controlled release of medicament, biological probe, chemical separation, and the like.

Owner:SHAANXI NORMAL UNIV

Transparent and toughened polymethyl methacrylate (PMMA) material and preparation method thereof

The invention discloses a transparent and toughened polymethyl methacrylate (PMMA) material and a preparation method thereof. The transparent and toughened PMMA material comprises the following components in percentage by weight: 70 to 80 percent of polymethylmethacrylate, 20 to 30 percent of toughening agent, 0.5 to 1 percent of lubricant and 0.2 to 0.6 percent of antioxidant. The transparent and toughened PMMA material of the invention has high transparency, high toughness and high liquidity and further expands the application field of PMMA materials.

Owner:SHENZHEN KEJU NEW MATERIAL

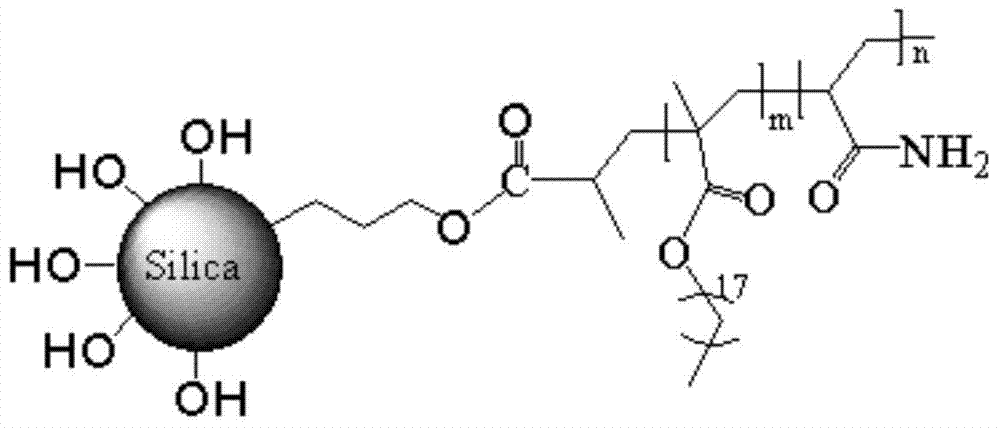

Nano SiO2 composite material thickened oil viscosity reducer and preparation method thereof

InactiveCN104327225AImprove hydrophobicityGood viscosity reduction effectDrilling compositionMaterials preparationNano sio2

The invention discloses a nano SiO2 composite material thickened oil viscosity reducer and a preparation method thereof, which belongs to the technical field of nano SiO2 composite material preparation and application thereof. The viscosity reducer is nano (polymethacrylate higher alcohol-acrylamide) / SiO2 composite material. The preparation method comprises the following steps: 1)pre-modifying the surface of the nano SiO2 by a silane coupling agent; and 2)performing graft copolymerization of (methyl)acrylate higher alcohol and acrylamide on the surface of nano SiO2 to obtain the (polymethacrylate higher alcohol-acrylamide) / SiO2 composite material powder. The nano viscosity reducer has the advantages of good viscosity reducing effect, low cost, simple production and no pollution during a cleaning process. Through the experiment, the viscosity reducing rate of the nano viscosity reducer to the high wax thickened oil at Daqing dandong station is 72.10% at 40 DEG C.

Owner:SHANDONG UNIV

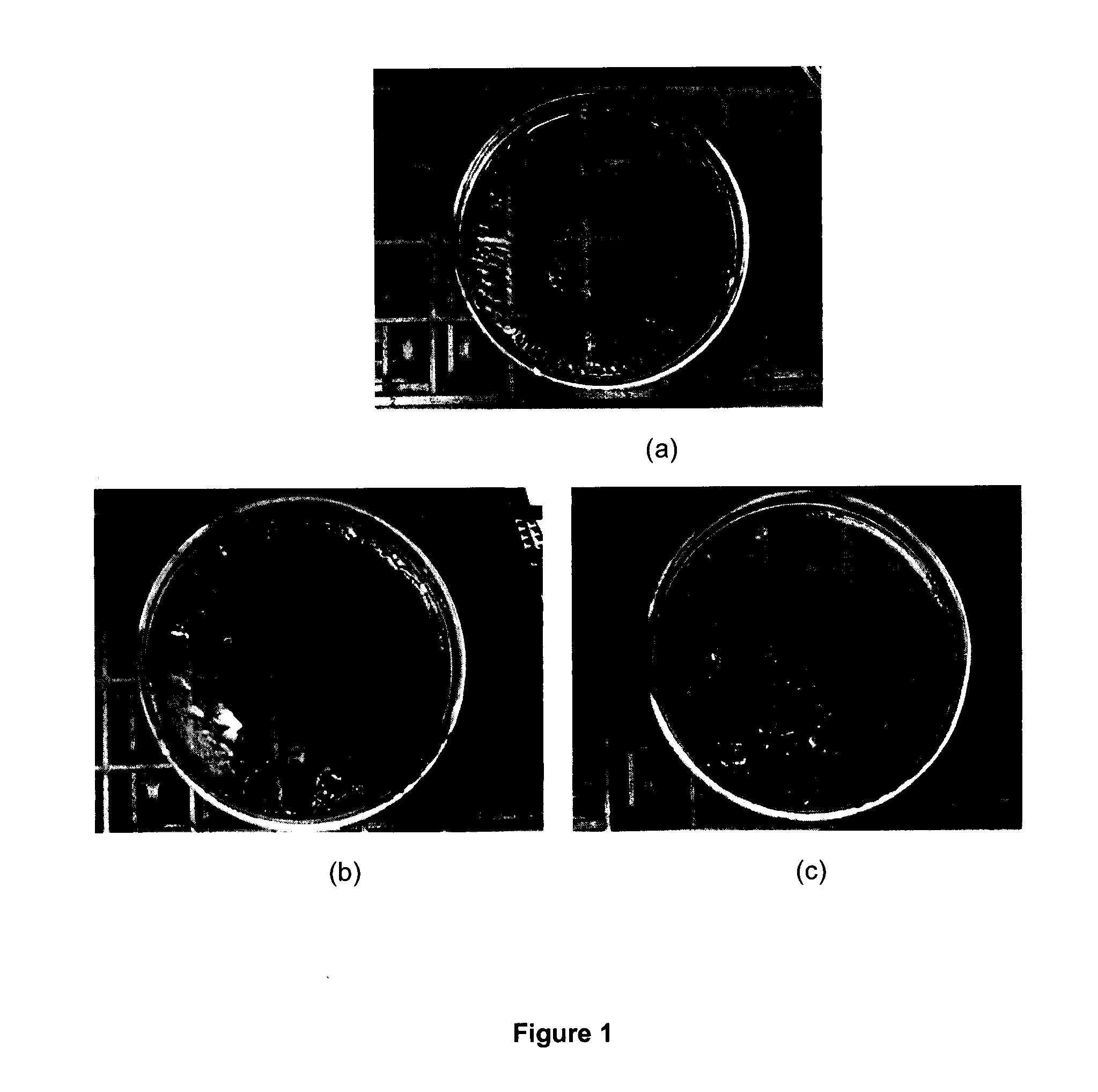

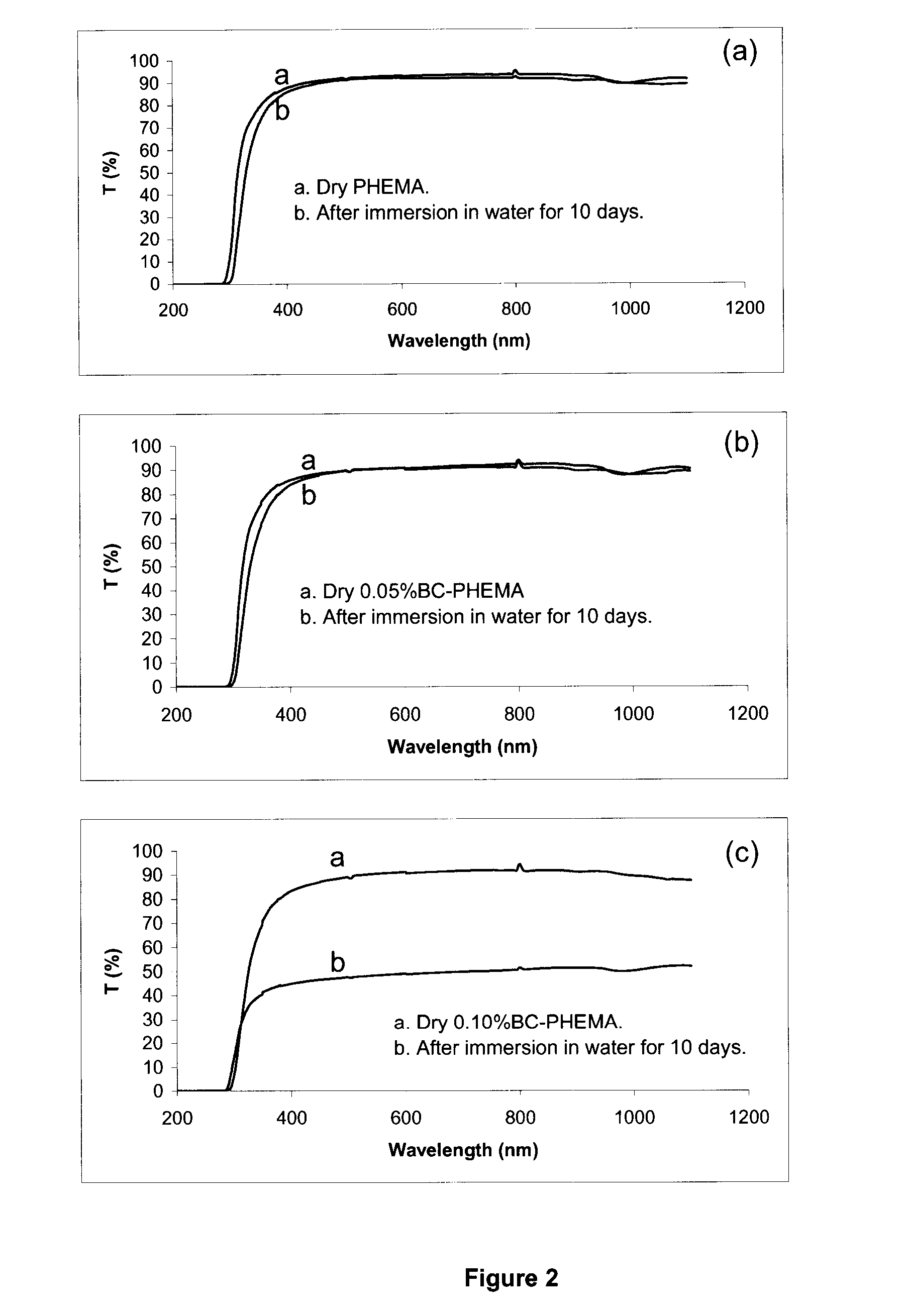

Transparent bacterial cellulose nanocomposite hydrogels

InactiveUS20130011385A1High mechanical strengthEnhanced interactionOrganic active ingredientsBiocidePolymer scienceWater insoluble

A transparent polymeric nanocomposite hydrogel is provided, wherein the polymeric nanocomposite hydrogel is made from a water insoluble polymer, i.e. poly(2-hydroxyethyl methacrylate) (PHEMA) or / and crosslinked PHEMA and a water insoluble nanofiber, i.e., bacterial cellulose (BC). Disclosed is a synthetic route for polymeric nanocomposites hydrogels. The preferred polymeric nanocompositions are produced through free radical polymerization of HEMA monomer in the presence of bacterial cellulose with an assistance of ultrasound to enhance the mixing of bacterial cellulose, initiator, and the monomers. The polymeric nanocomposite hydrogel is then formed by immersion of the dry polymeric nanocomposite in water. Disclosed is a high transmittance polymer nanocomposite hydrogel with a preferred BC loading less than 0.1%, water content of about 40% in weight, good mechanical integrity and strength. The disclosed polymer nanocomposite hydrogel and compositions pertain to hydrogel applications, particularly contact lenses and optic components for biosensor.

Owner:AXCELON BIOPOLYMERS COPRORATION

High-hardness scratch-resistant high-gloss modified polypropylene (PP) material

The invention discloses a high-hardness scratch-resistant high-gloss modified polypropylene (PP) material, belonging to the technical field of high polymer materials. The high-hardness scratch-resistant high-gloss modified PP material is prepared from the following raw materials in parts by weight: 40-80 parts of homopolymerized or copolymerized PP, 5-30 parts of polymethyl methacrylate (PMMA), 15-20 parts of barium sulfate, 5-10 parts of glass fiber, 0.5-10 parts of modifier, 5-20 parts of compatilizer and 0.2-0.8 part of coupling agent. PP is compatible with PMMA to ensure that the mechanical strength of the material is improved, meanwhile, the surface hardness and corrosion resistance of the product are improved, and the surface gloss of the product is increased; inorganic fillers of glass fiber and barium sulfate are filled into the modified PP material disclosed by the invention to ensure that the mechanical performance of the product is further improved, and meanwhile, the glossiness of the product is improved; various antioxidants, weather resistance agents, antistatic agents and anti-freezing agents are added into the modified PP material disclosed by the invention to ensure the service life of the product, prevent the product from aging, and ensure that the product can adapt to various environments and can be normally used under rigorous conditions.

Owner:杭州金州高分子科技有限公司

Polyurethane dispersion with high film hardness, process for preparing it, and its use

InactiveUS20020193507A1Wide scope for variationHigh film hardnessPolyurea/polyurethane coatingsPolyurethane dispersionPolymer science

A description is given of a polyurethane (hybrid) dispersion with high film hardness, high flexibility and good emulsion stability which comprises the following reaction components: (A) from 3 to 25% by weight of a polyol component consisting of (i) from 2 to 20% by weight of a polymeric polyol having two or more polyisocyanate-reactive hydroxyl groups and a molar mass of from 500 to 4 000 daltons (ii) from 0.5 to 5% by weight of a low molecular mass polyol having two or more polyisocyanate-reactive hydroxyl groups and a molar mass of from 50 to 500 daltons (B) from 3 to 30% by weight of an anionically modifiable 1,2-polymethacrylatediol, (C) from 2 to 20% by weight of a polyisocyanate component, (D) from 0 to 6% by weight of a solvent component, (E) from 0.15 to 1.5% by weight of a neutralizing component composed of at least one organic or inorganic base, (F) from 0 to 1% by weight of a chain extender component composed of one or more polyamines having two or more polyisocyanate-reactive amino groups, and, optionally (G) from 5 to 40% by weight of a monomer component, (H) from 0.01 to 1.5% by weight of an initiator component, and water as the remainder.

Owner:TH GOLDSCHMIDT AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com