Nano SiO2 composite material thickened oil viscosity reducer and preparation method thereof

A thick oil viscosity reducer and composite material technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of waste of thin oil resources, strong selectivity, and low viscosity reduction rate of oil-soluble viscosity reducers , to achieve the effect of convenient storage and transportation, clean and pollution-free process, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

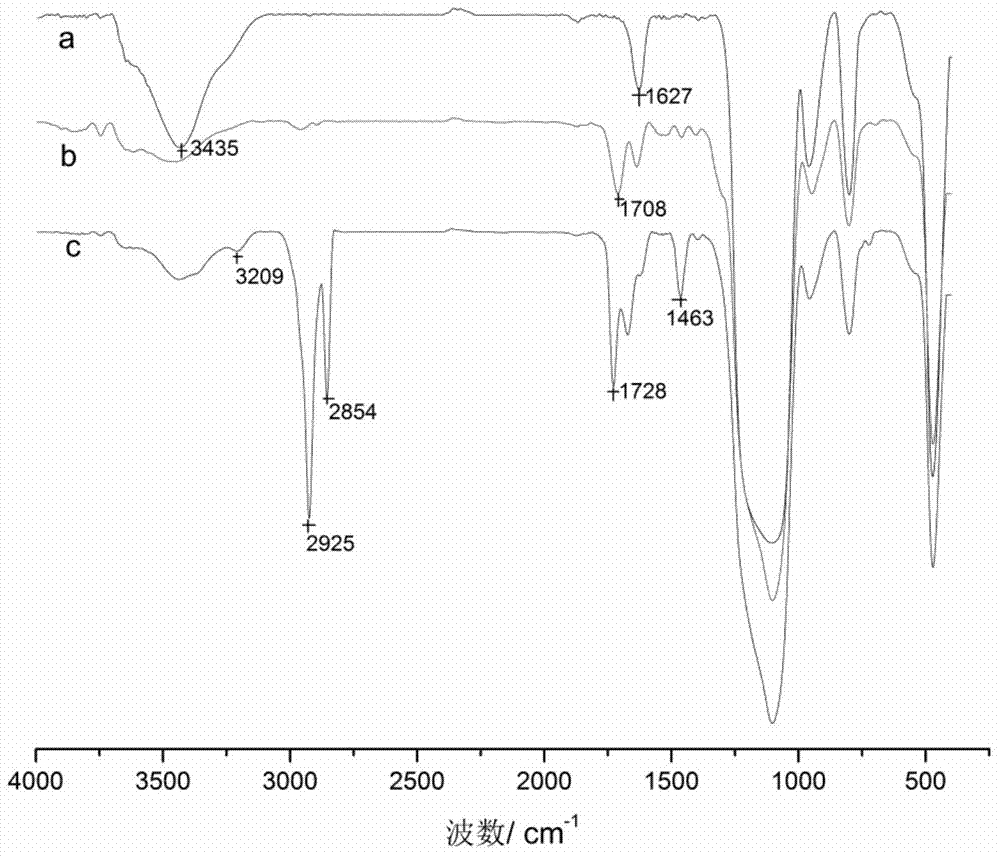

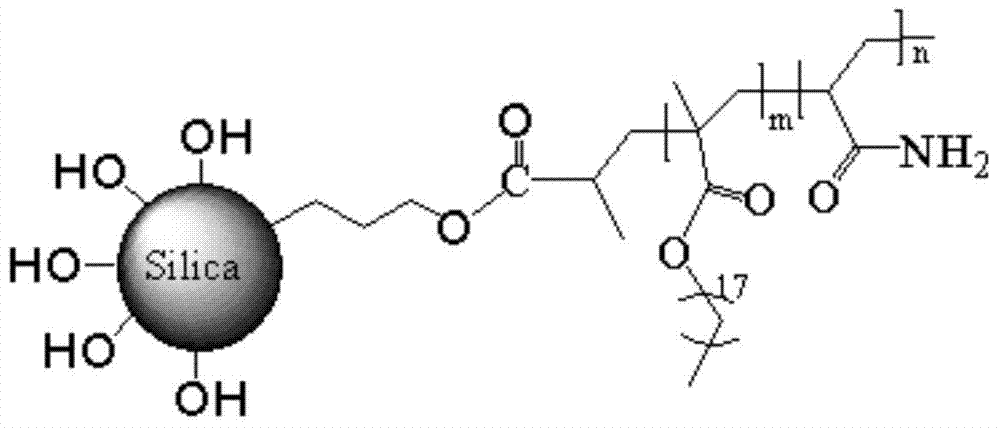

[0027] Embodiment 1: Nano (polyoctadecyl methacrylate-acrylamide) / SiO 2 The preparation method, the steps are as follows:

[0028] (1) Silane coupling agent KH570 on nano-SiO 2 Surface premodification of

[0029] Add 50ml absolute ethanol, 1ml acetic acid, 1ml distilled water, 1ml γ -Methacryloxypropyltrimethoxysilane (KH570), under stirring at room temperature, hydrolyzed for 2h. Add 2.5g nano-SiO 2 , heated to 50°C, and reacted for 3h under vigorous stirring. The reaction product was centrifuged (4000rpm), washed several times with absolute ethanol, and dried in vacuum at 30°C for 10 hours to obtain the pre-modified product nano KH570 / SiO 2 .

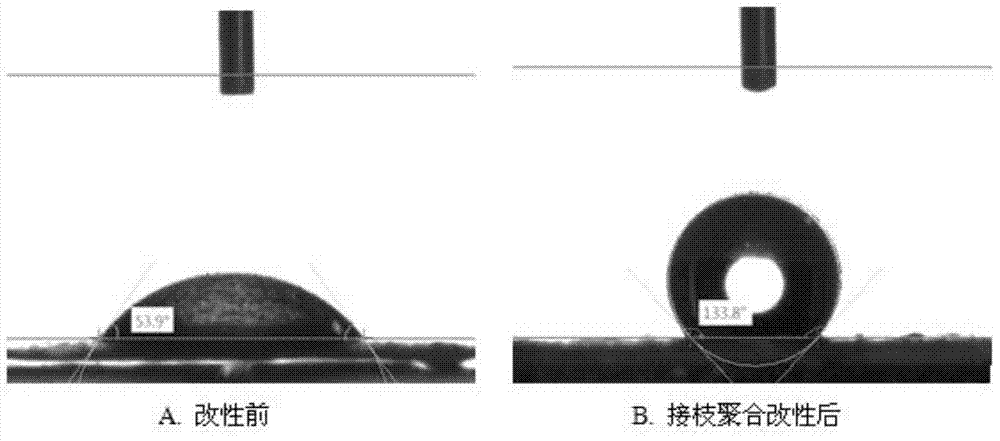

[0030] (2) Octadecyl methacrylate and acrylamide in nano-SiO 2 surface graft copolymerization

[0031] Disperse 2 g of the pre-modified product evenly in absolute ethanol, add a certain amount of stearyl methacrylate and acrylamide (the molar ratio is 1:1, the total amount is 1 / 5 of the pre-modified product), stir to dissolve ...

Embodiment 2

[0039] Embodiment 2: Nano (polyoctadecyl methacrylate-acrylamide) / SiO 2 The preparation method, step is the same as example 1, and difference is in (2) step, and the mol ratio of stearyl methacrylate and acrylamide is 3:1. Test method and dosage are the same as example 1.

[0040] The results are shown in Table 1. At 40°C, add nano-SiO 2 After the composite material viscosity reducer, the kinematic viscosity of heavy oil is changed from 198.88mm 2 the s -1 down to 62.19mm 2 the s -1 , The viscosity reduction rate is 68.73%, which is slightly lower than the viscosity reduction effect of the viscosity reduction agent synthesized in Example 1.

[0041] Table 1 Nano-SiO 2 Viscosity reduction test results of composite material viscosity reducer

[0042]

[0043]

[0044] The commercially available viscosity reducer EVA in the table is ethylene-vinyl acetate copolymer, nano viscosity reducer 1 is the nanocomposite material viscosity reducer synthesized in Example 1, an...

Embodiment 3

[0045] Embodiment 3: Nano (polyhexadecyl methacrylate-acrylamide) / SiO 2 The preparation method, step is the same as embodiment 1, and difference is in (2) step, replaces stearyl methacrylate with hexadecyl methacrylate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com