Process for producing fluorescent composite microgel hypersensitive to temperature and pH

A microgel and sensitive technology, applied in the field of materials, can solve undisclosed problems and achieve the effect of not easy to agglomerate, simple operation and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

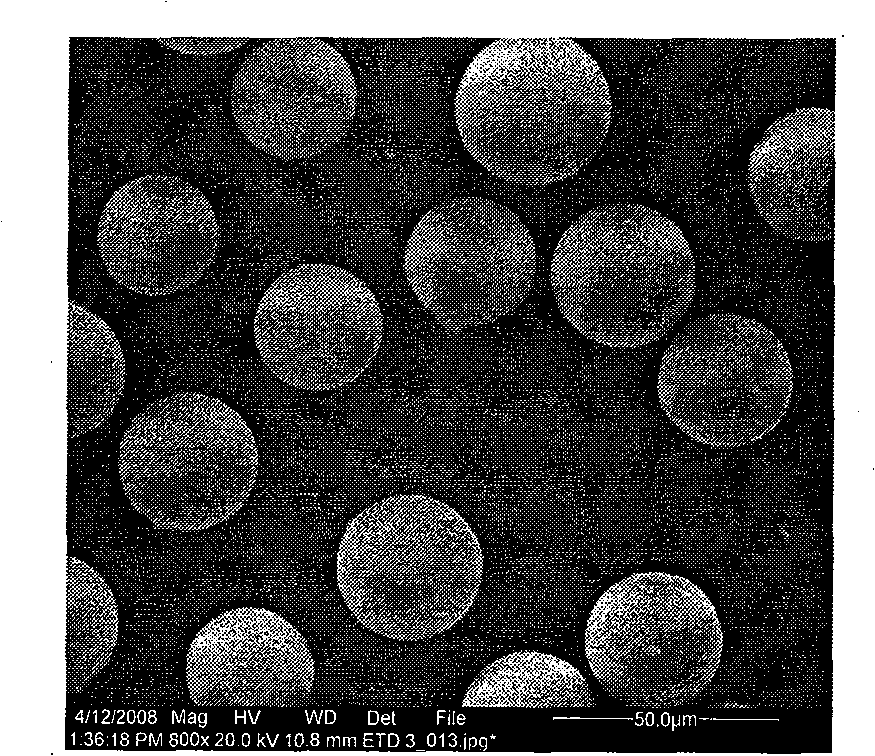

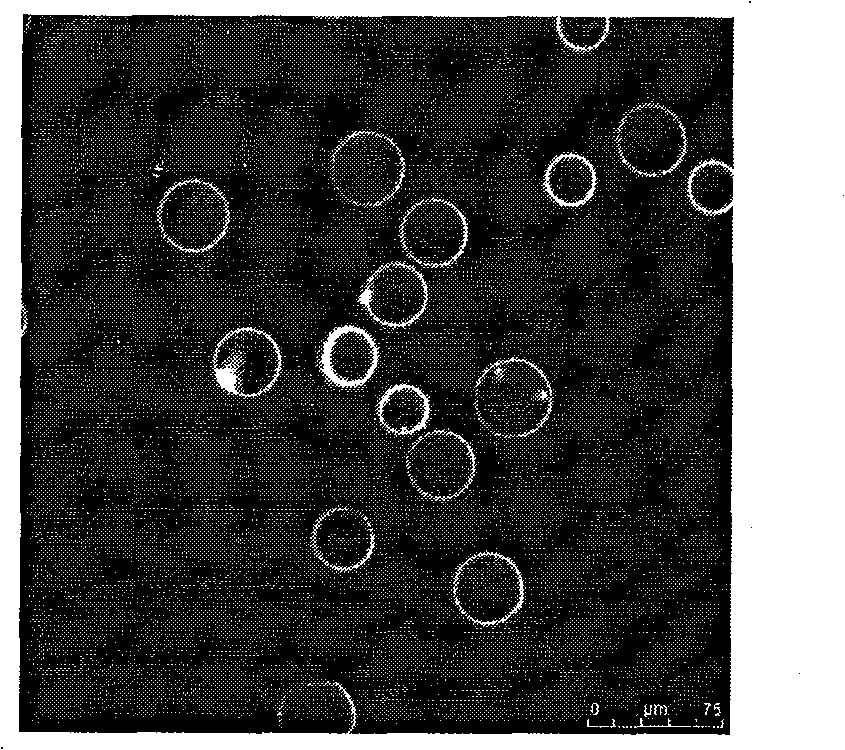

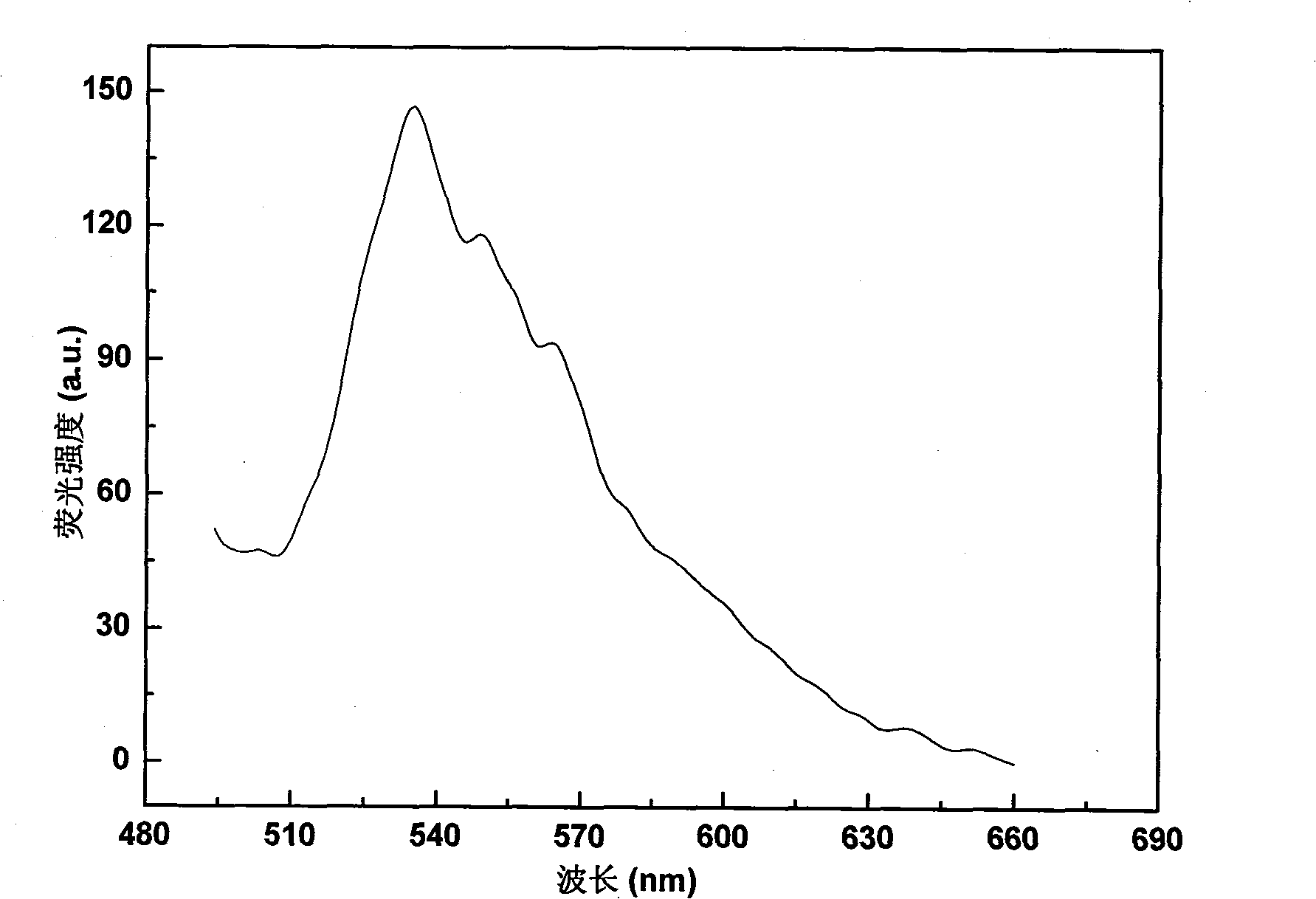

[0046] The process steps for preparing the fluorescent composite microgel sensitive to temperature and pH are as follows:

[0047] 1. Preparation of mixed surfactants

[0048] Weigh 0.047g Tween-80 and mix with 0.47g Span-80 to prepare mixed surfactant.

[0049] 2. Preparation of template oil phase

[0050] Add 0.517g of the mixed surfactant prepared in step 1 into a three-necked flask filled with 70mL of n-heptane, that is, the mass ratio of the mixed surfactant to n-heptane is 1:89 to prepare 46.675g of the template oil phase.

[0051] 3. Preparation of emulsion

[0052] Add 46.675g of the template oil phase prepared in step 2 into a three-necked flask, stir with a stirrer at a speed of 350-400 rpm, feed nitrogen at a flow rate of 2-3mL / min, and emulsify at 18-30°C for 60 minutes to prepare into an emulsion.

[0053] 4. Preparation of water phase

[0054]Weigh 0.069g of N,N'-methylenebisacrylamide, 0.96g of N-isopropylacrylamide, 0.11g of ammonium persulfate and 5.5mL o...

Embodiment 2

[0068] In the process step 6 of Example 1, weigh 0.1 g of N-isopropylacrylamide copolymerized methacrylic acid microgel and mix it with 0.55 mL of ammonia water with a mass concentration of 25% to 28%, that is, N-isopropylacrylamide The mass ratio of copolymethacrylic acid microgel to ammonia water with a mass concentration of 25% to 28% is 1:5, and it is left for 12 hours to make it fully swell, and 0.6 g of swollen N-isopropylacrylamide copolymethacrylate is prepared. Acrylic microgels. In process step 7, 1 mL of γ-aminopropyltriethoxysilane and 1.5 mL of n-heptane were mixed to prepare a mixed solution of γ-aminopropyltriethoxysilane and n-heptane. In process step 8, weigh 0.3g Span-80 and mix with 45mL n-heptane to make 30g of deposited oil phase, that is, the mass ratio of Span-80 to n-heptane is 1:100, and the 0.6g prepared in step 6 is swollen The N-isopropylacrylamide copolymerized methacrylic acid microgel was added to the 30g deposited oil phase emulsified for 40 mi...

Embodiment 3

[0070] In the process step 6 of Example 1, weigh 0.1 g of N-isopropylacrylamide copolymerized methacrylic acid microgel and mix it with 0.67 mL of ammonia water with a mass concentration of 25% to 28%, that is, N-isopropylacrylamide The mass ratio of copolymethacrylic acid microgel to ammonia water with a mass concentration of 25% to 28% is 1:6, and it is left for 12 hours to fully swell to prepare 0.7 g of swollen N-isopropylacrylamide copolymethacrylate Acrylic microgels. In the process step 7, 1 mL of γ-aminopropyltriethoxysilane was mixed with 4 mL of n-heptane to prepare a mixed solution of γ-aminopropyltriethoxysilane and n-heptane. In process step 8, 0.3g Span-80 was weighed and mixed with 55mL n-heptane to make 36.6g of sediment oil phase, that is, the mass ratio of Span-80 to n-heptane was 1:120, and the 0.7g prepared in step 6 The swollen N-isopropylacrylamide copolymerized methacrylic acid microgel was added to the 36.6g deposited oil phase emulsified for 40 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com