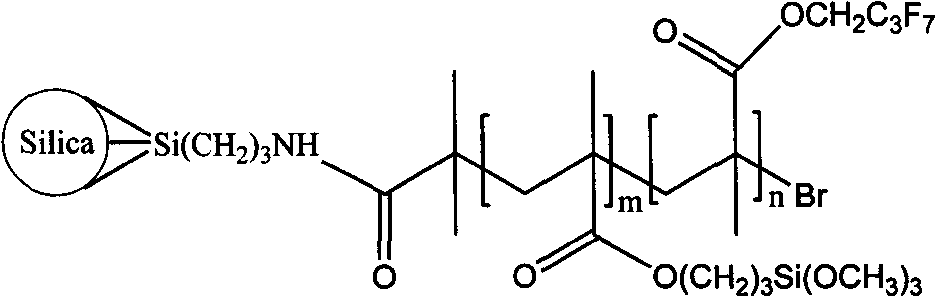

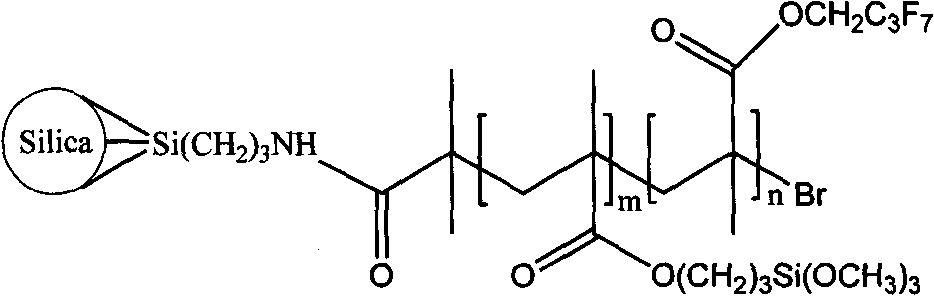

Super hydrophobic silicon-fluorine polymer/nanometer silica hybridization nanometer material and preparation method thereof

A nano-silica, fluorosilicon polymer technology, applied in antifouling/underwater coatings, biocide-containing paints, coatings, etc., can solve the problems of poor resistance to chemical media, low effect, difficult to achieve, etc., to achieve Stable properties, excellent performance and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Preparation of nano silica modified by silane coupling agent:

[0038] In a dry two-necked flask equipped with a reflux condenser, add 1 part of nano-silica, 200 parts of dry toluene and 1 part of 3-aminopropyltrimethoxysilane in molar ratio sequentially. Connect an argon bag to the other end of the condenser tube, vacuumize and fill with an inert gas to remove the air in the system, and react under reflux at 80°C in an oil bath for 12h. After cooling down, centrifuge, pour off the upper solvent, wash with toluene and acetone ultrasonically in order to remove the adsorbed silane coupling agent, and vacuum-dry at 45°C for 24 hours to obtain nano-silica modified by silane coupling agent.

[0039] 2) Preparation of nano silicon dioxide atom transfer radical surface initiator:

[0040] Add 1 part of silane coupling agent-modified nano-silica and 200 parts of toluene in molar ratio to the two-necked bottle treated by the baking bottle, seal the vacuum and repeat the oper...

Embodiment 2

[0046] 1) Preparation of nano silica modified by silane coupling agent:

[0047] In a dry two-necked flask equipped with a reflux condenser, 1 part of nano-silica, 250 parts of dry toluene and 1.5 parts of 3-aminopropyltrimethoxysilane were sequentially added in molar ratio. A nitrogen bag was connected to the upper end of the condenser tube, vacuum-filled with an inert gas to remove the air in the system, and reflux reaction at 110° C. in an oil bath for 18 hours. Centrifuge after cooling down, pour off the upper solvent, wash with a large amount of toluene and acetone in order to remove the adsorbed silane coupling agent, and vacuum dry at 45°C for 24 hours to obtain nano-silica modified by silane coupling agent.

[0048] 2) Preparation of nano silicon dioxide atom transfer radical surface initiator:

[0049] Add 1 part of nano-silica modified by silane coupling agent and 250 parts of toluene in molar ratio to the baked two-necked bottle, seal the vacuum and repeat the oper...

Embodiment 3

[0053] 1) Except that the reaction temperature is 120° C., the reflux time is 24 h, and the toluene is 300 parts, the others are the same as step 1) in Example 1.

[0054] 2) Except that toluene is 300 parts, triethylamine is 5 parts, 2-bromoisobutyryl bromide is 2.5 parts, reaction temperature is 30° C. and reaction time is 30 h, the others are the same as step 2) in Example 1.

[0055] 3) Except for 30 parts of methacryloxypropyltrimethoxysilane, 300 parts of toluene, 8 hours of reaction time, and 50° C. of drying temperature, the procedure is the same as step 3) in Example 1.

[0056] 4) Except that the monomer is 20 parts, the toluene is 300 parts, and the reaction time is 12 hours, the others are the same as step 4) in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com