Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101 results about "Poly(methyl methacrylate)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Poly(methyl methacrylate) (PMMA), also known as acrylic, acrylic glass, or plexiglass as well as by the trade names Crylux, Plexiglas, Acrylite, Lucite, Perclax and Perspex among several others (see below), is a transparent thermoplastic often used in sheet form as a lightweight or shatter-resistant alternative to glass. The same material can be used as a casting resin, in inks and coatings, and has many other uses.

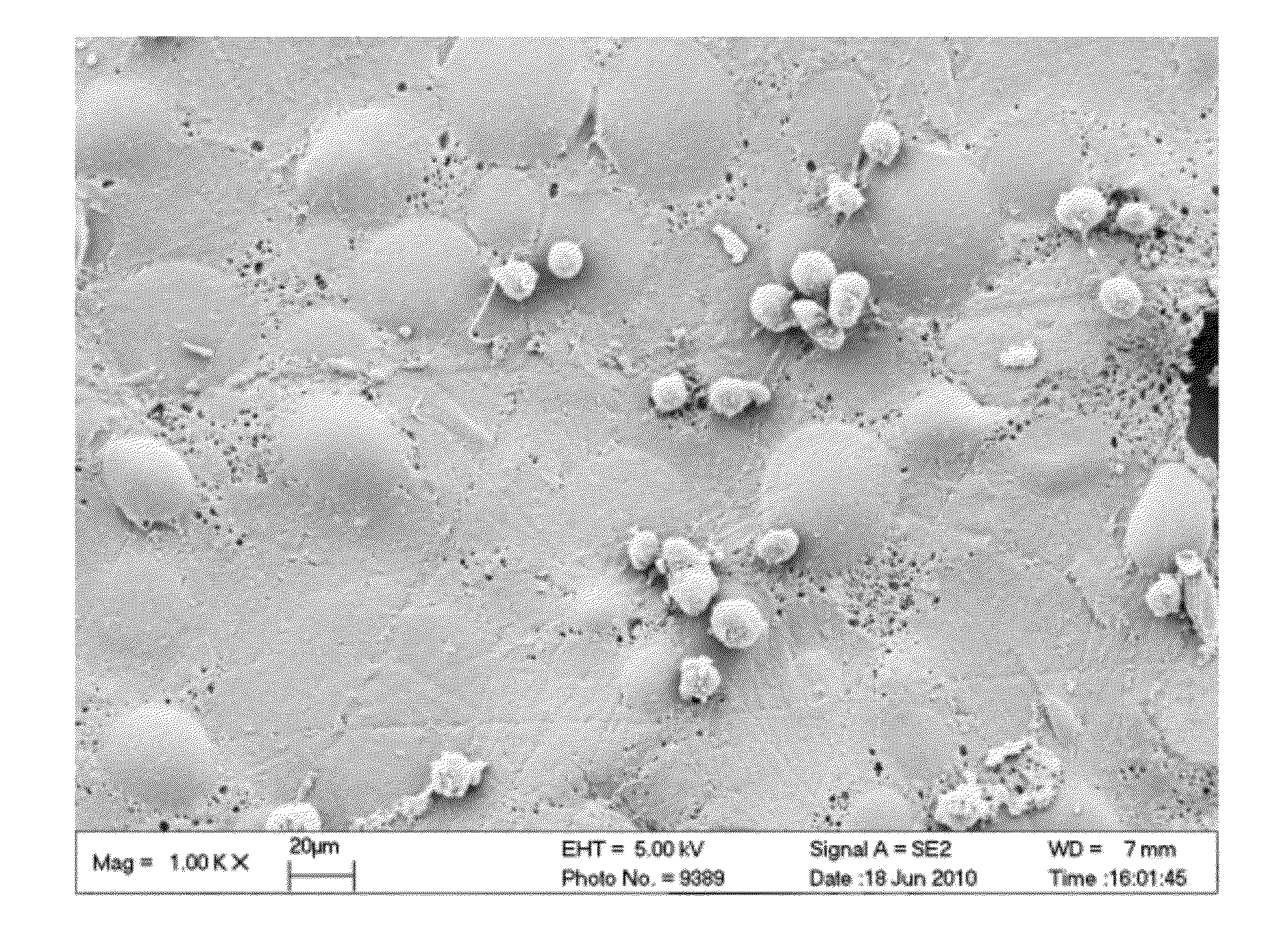

Smooth, flexible powder coatings

The present invention, a powder composition for making powder coatings comprising one or more than one curable polymer or resin and an agglomerate of a core-shell polymer, wherein the agglomerate of a core-shell polymer has an average particle size of from 5 to 190 microns, preferably from 10 to 127 microns. The powders in accordance with the present invention provide a cured powder coating that is flexible, smooth, and which may be applied in a thickness of only from 0.3 to 8 mils. In a preferred embodiment of making a powder in accordance with the present invention, the agglomerate is cryoground to form a reduced agglomerate prior to adding it into a powder as a post-blend or a powder-forming mixture as a preblend. The preferred core-shell polymer for use in accordance with the present invention comprises an acrylic impact modifier having a poly(methyl methacrylate) shell and a poly(butyl acrylate) core. Further, the preferred curable polymer or resin powder is an epoxy resin, wherein the powder composition is a low temperature curing one component powder composition which cures at from 107 to 149 degrees C.

Owner:ROHM & HAAS CO

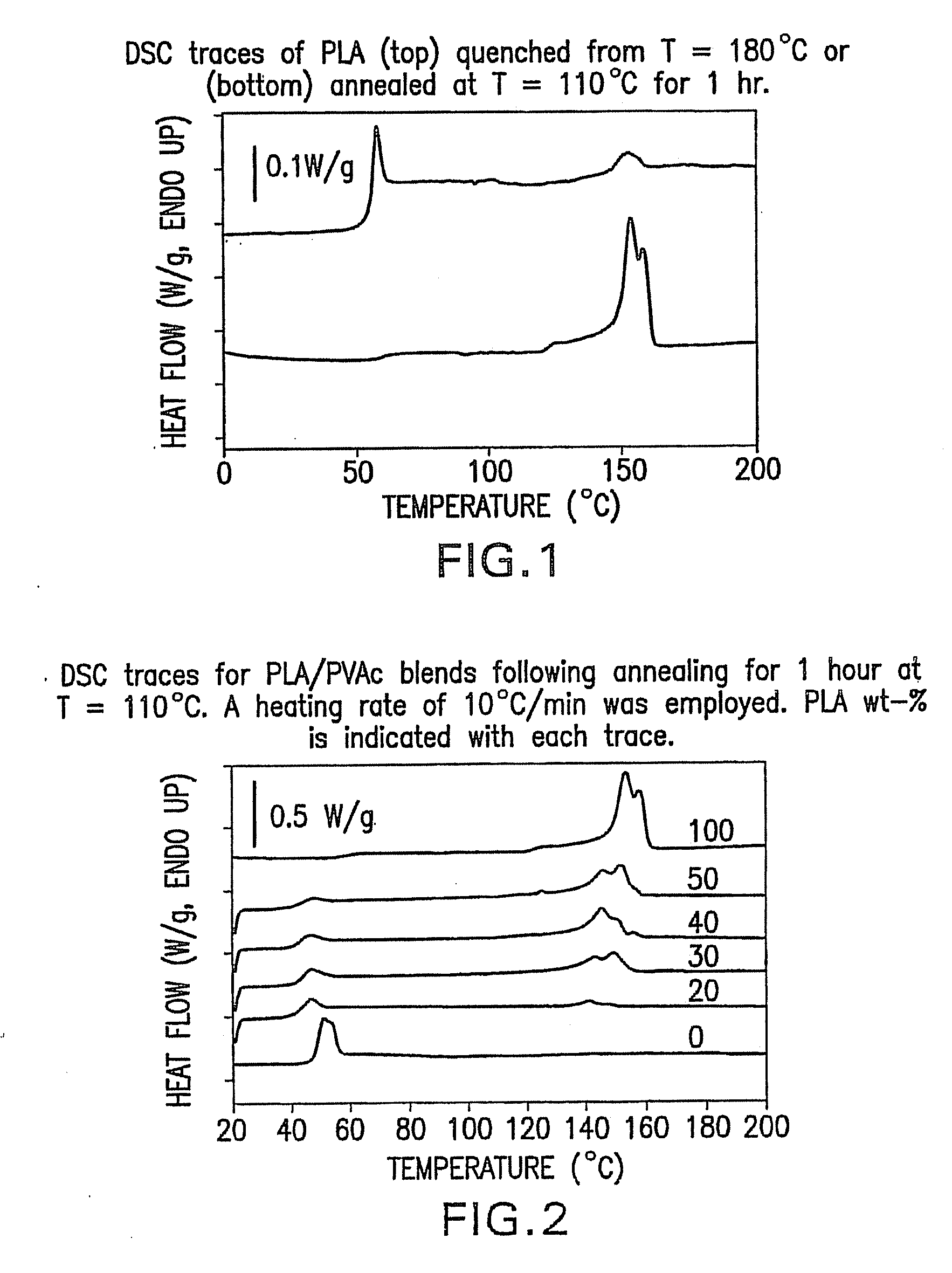

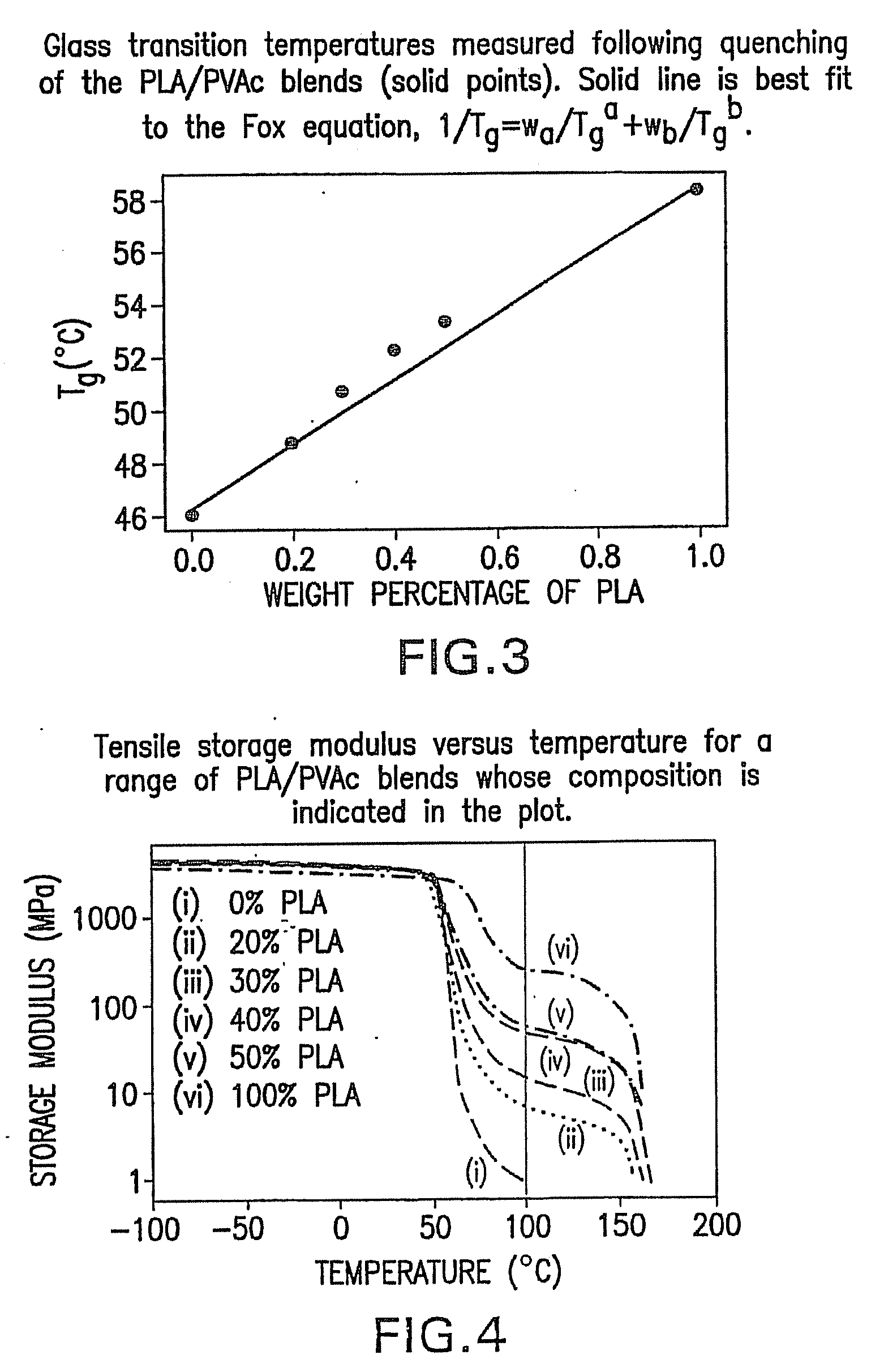

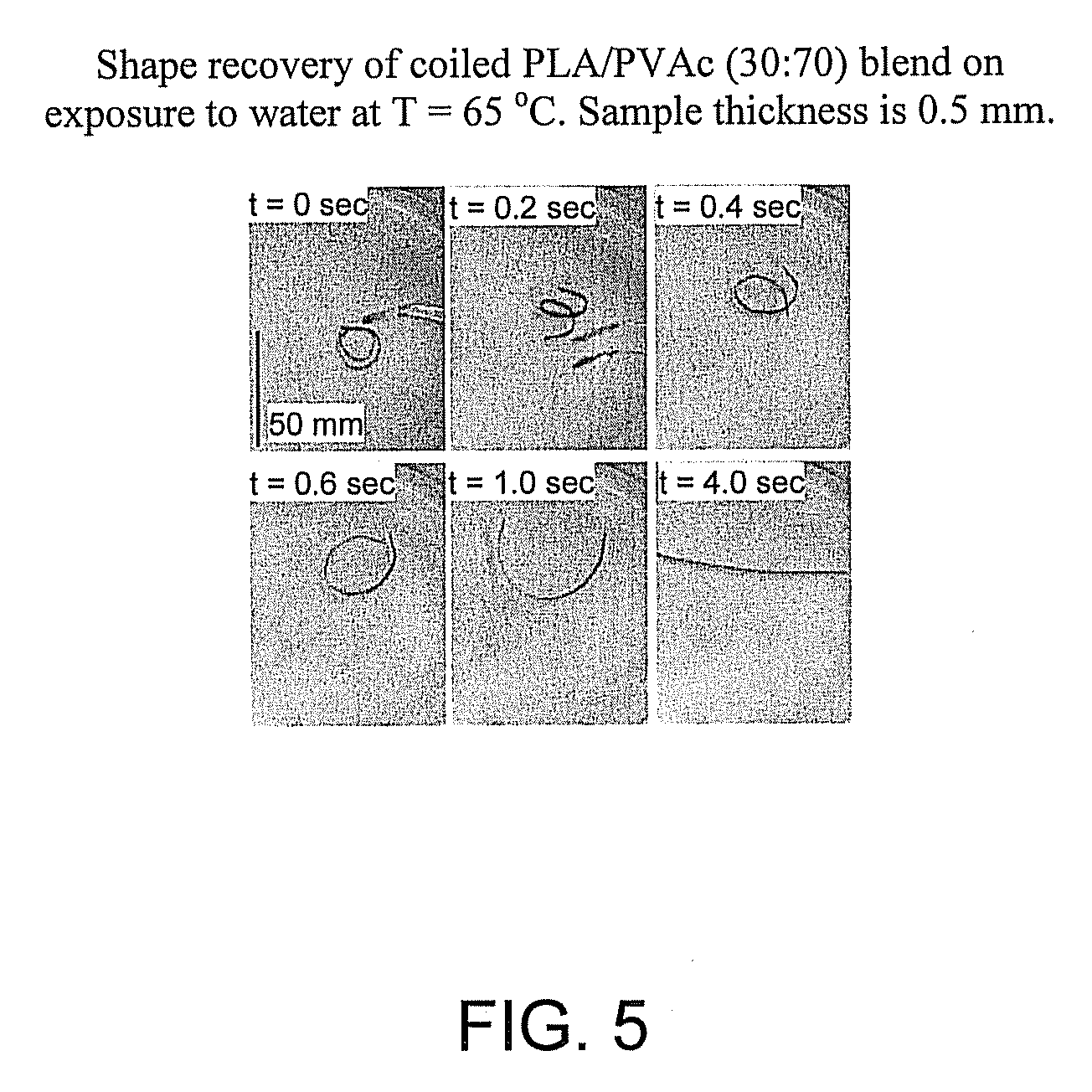

Blends of amorphous and semicrystalline polymers having shape memory properties

InactiveUS20040122174A1High modulusImprovement in critical temperatureDental impression compositionsPoly(methyl methacrylate)Ethyl acrylate

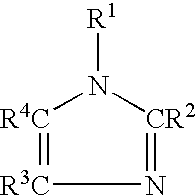

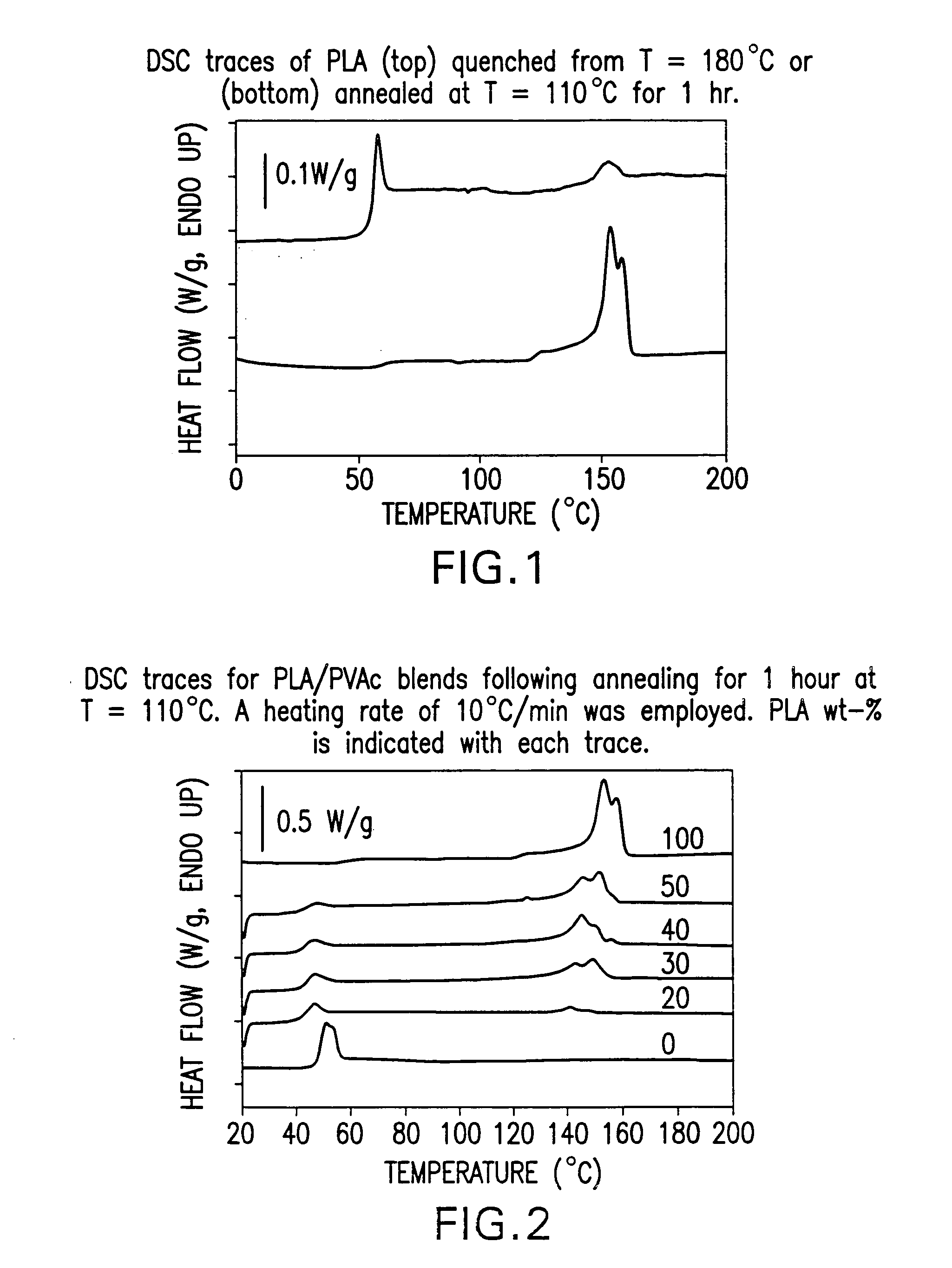

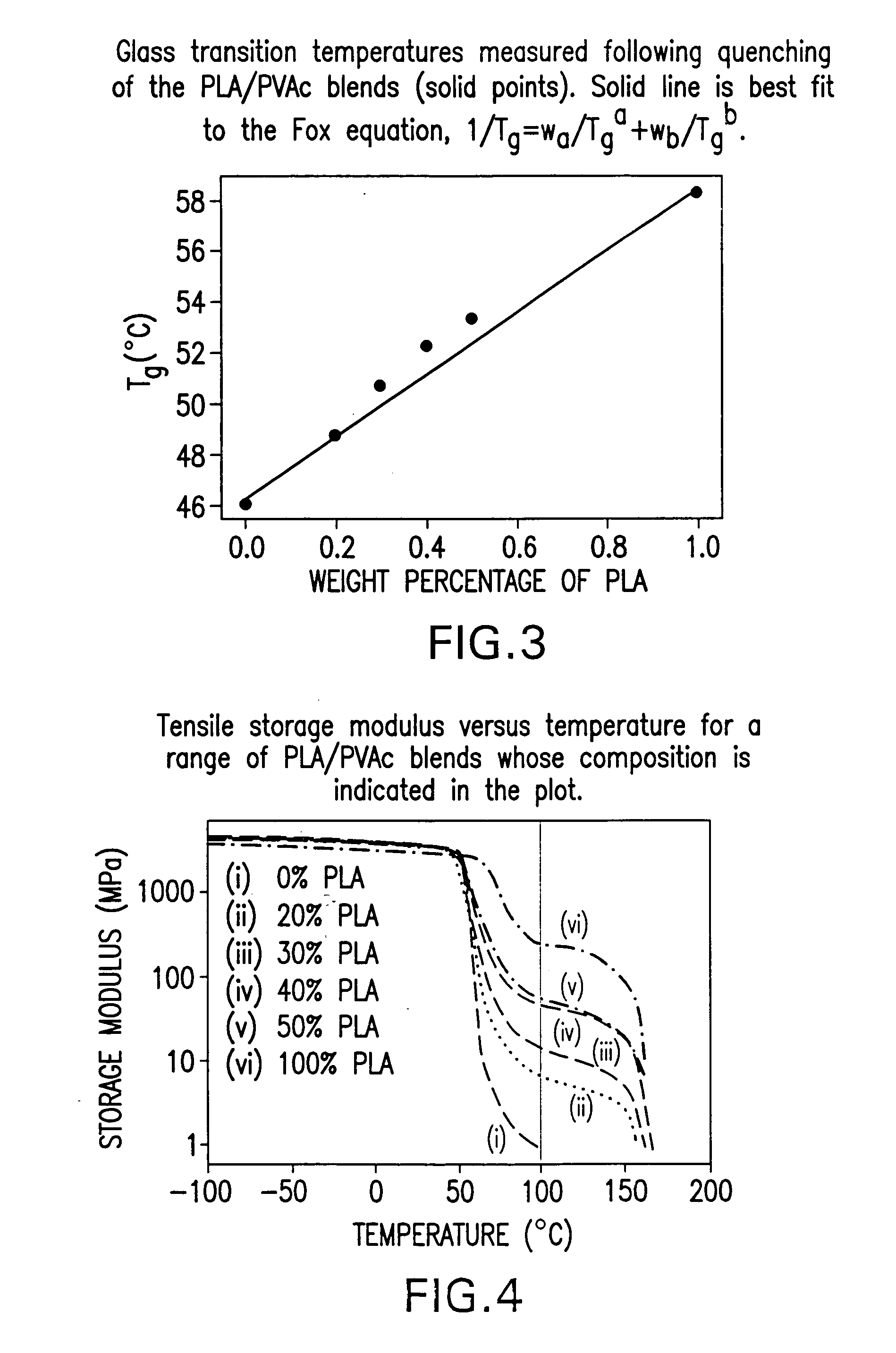

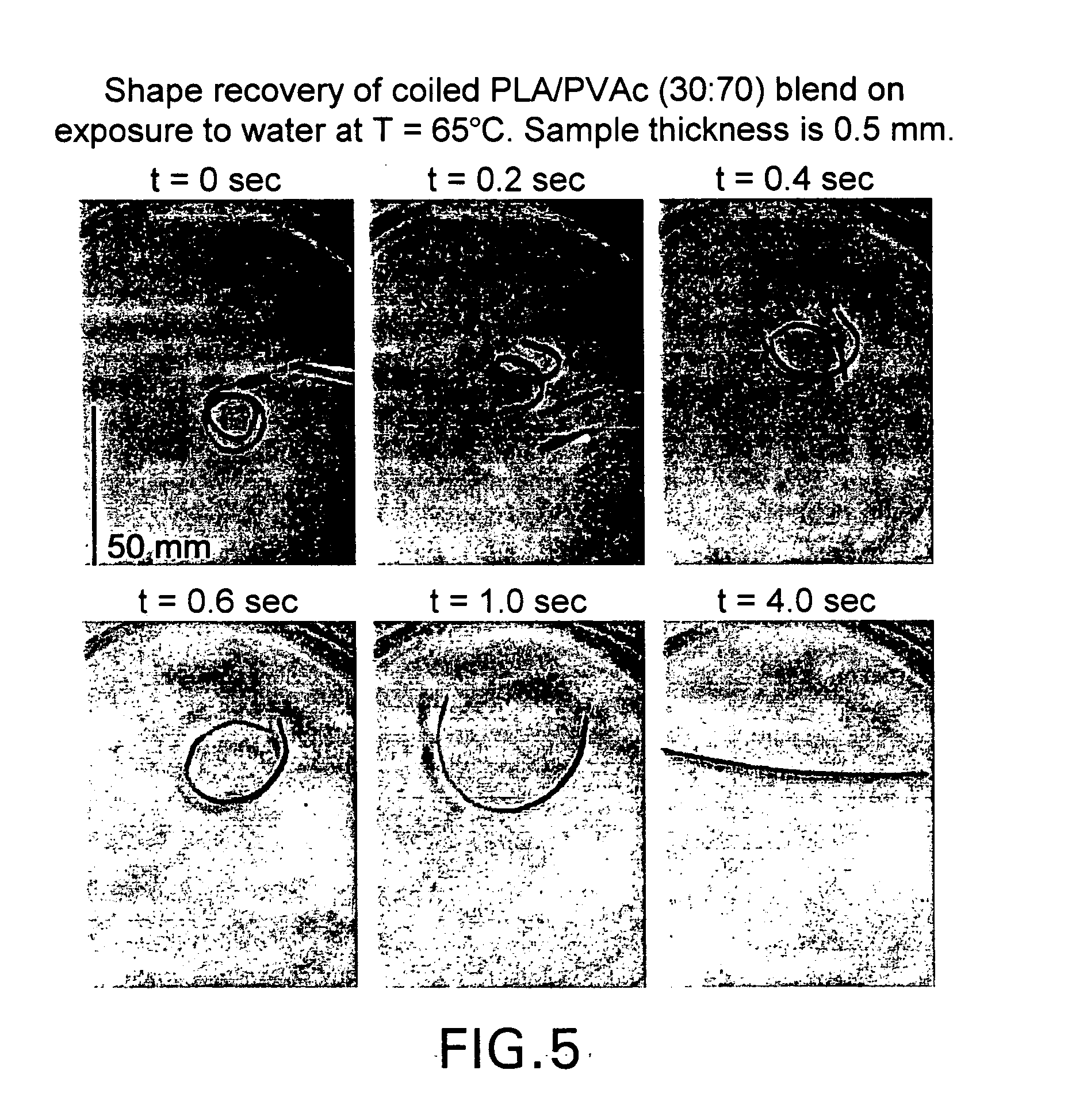

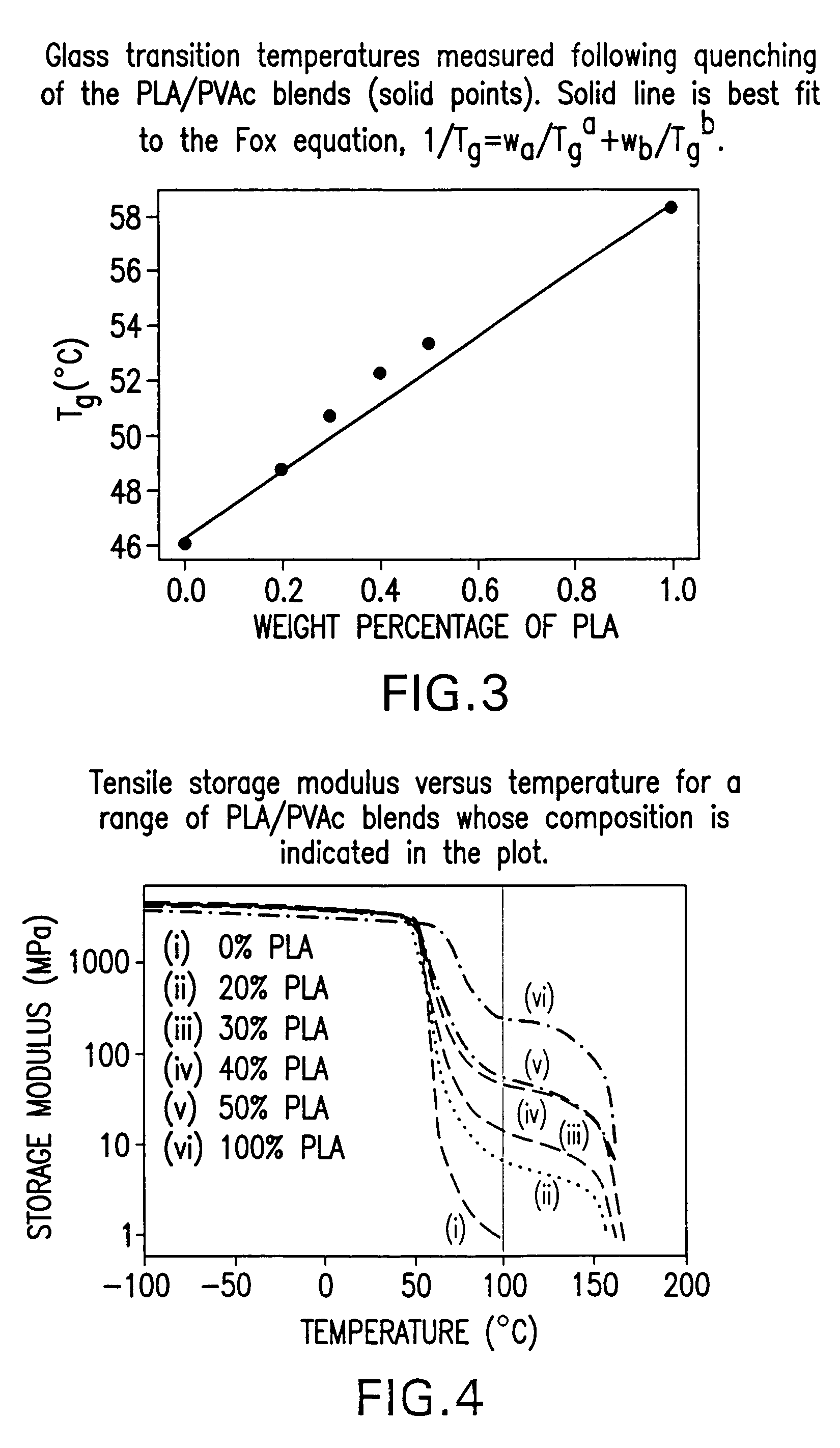

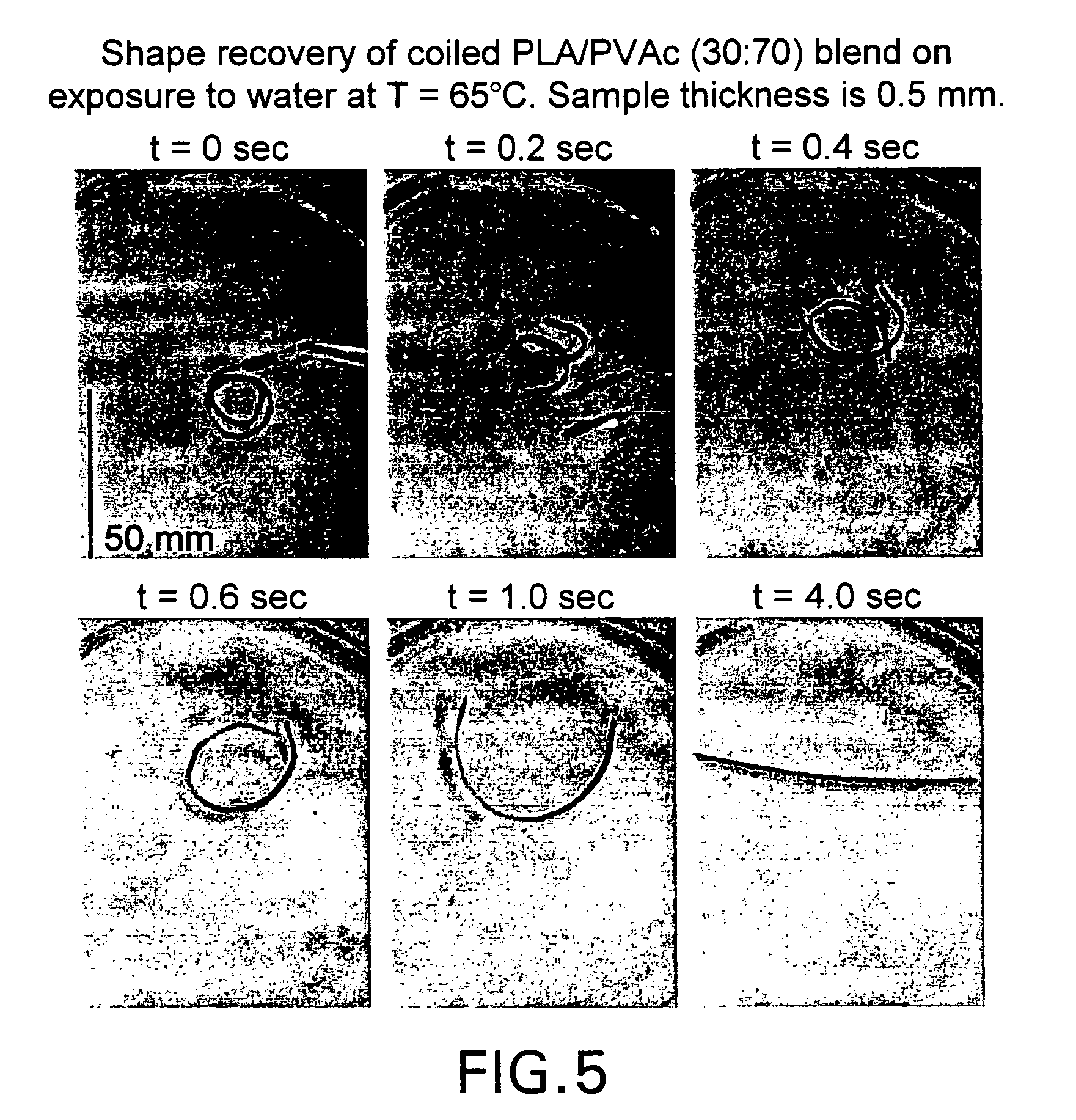

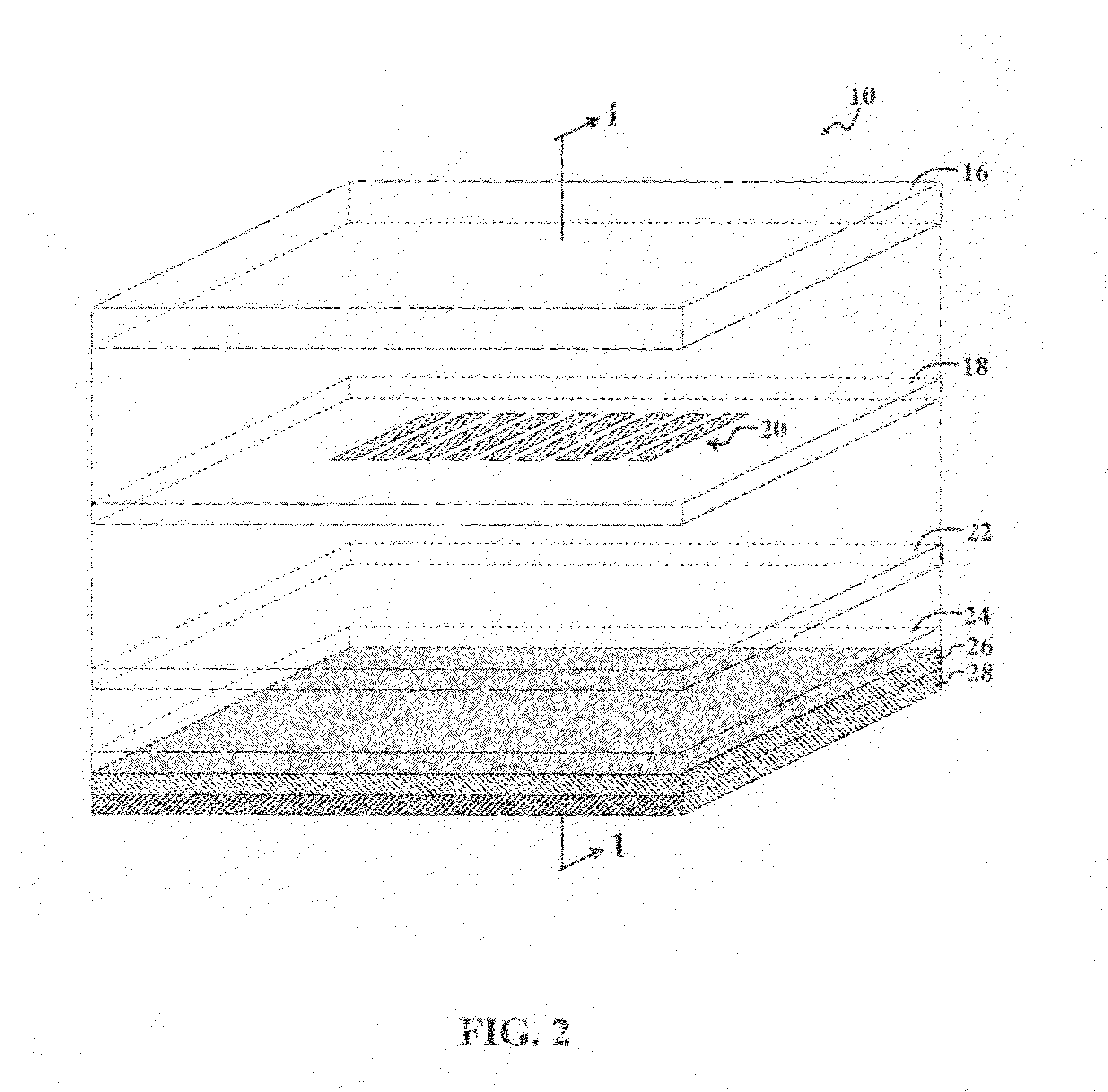

Blends of amorphous and semicrystalline polymers having shape memory properties were prepared by blending a crystalline polymer such as poly(vinylidene fluoride), polylactide, poly(hydroxxybutyrate), poly(ethylene glycol) polyethylene, polyethylene-co-vinyl acetate, poly(vinyl chloride), poly(vinylidene chloride) and copolymers of poly(vinylidene chloride) and poly(vinyle chloride) and an amorphous polymer such as poly(vinyl acetate), poly methyl acrylate, poly ethyl acrylate, atactic poly methyl methacrylate, isotactic poly methyl methacrylate, syndiotactic poly methyl methacrylate and other poly alkyl methacrylates. The method for preparing the polymeric materials and applications thereof, for example, as smart medical devices, are also disclosed.

Owner:UNIV OF CONNECTICUT

Hydrogenation method for unsaturated block copolymers and hydrogenated unsaturated block copolymers

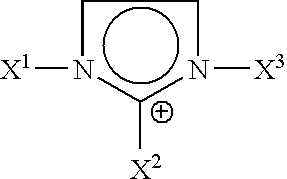

Use is made, for selectively hydrogenating the olefinic double bonds of block copolymers, at least one block of which comprises olefinic double bonds, using a catalyst based on a metal from Group VIII in a medium comprising an organic solvent for the copolymer and an ionic liquid as solvent for the catalyst, of a water-immiscible ionic liquid, preferably an ionic liquid for which the anion is the hexafluorophosphate anion and the cation is the 1-butyl-3-methylimidazolium (bmim+) or 1-ethyl-3-methylimidazolium (emim+) cation.Applied to poly(styrene)-b-poly(butadiene)-b-poly(methyl methacrylate) block copolymers, the poly(butadiene) block of which predominantly possesses a 1,4-microstructure, this process results in copolymers for which the degree of hydrogenation is at least equal to 50% and which exhibit a melting point of greater than 30 °C.

Owner:ATOFINA

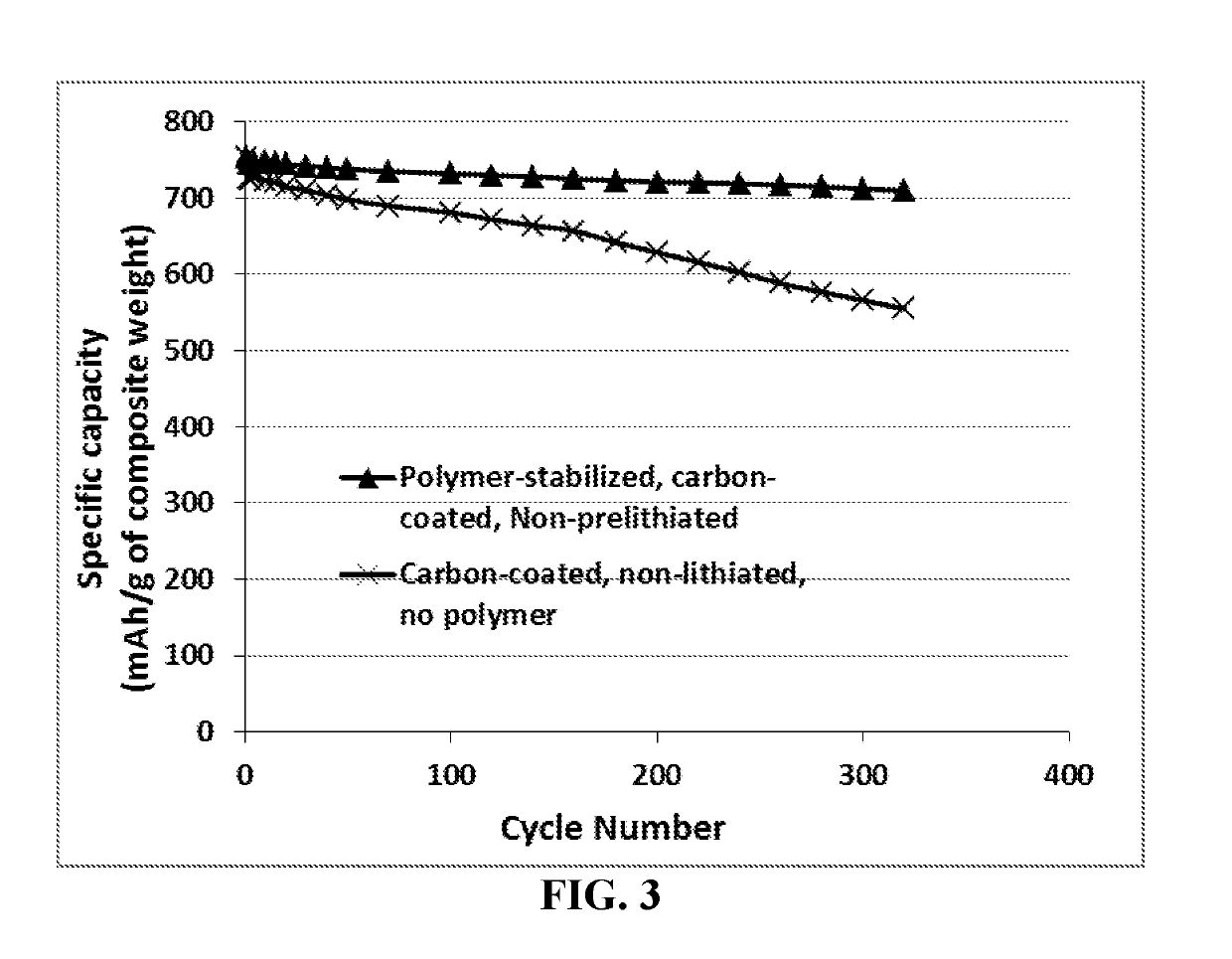

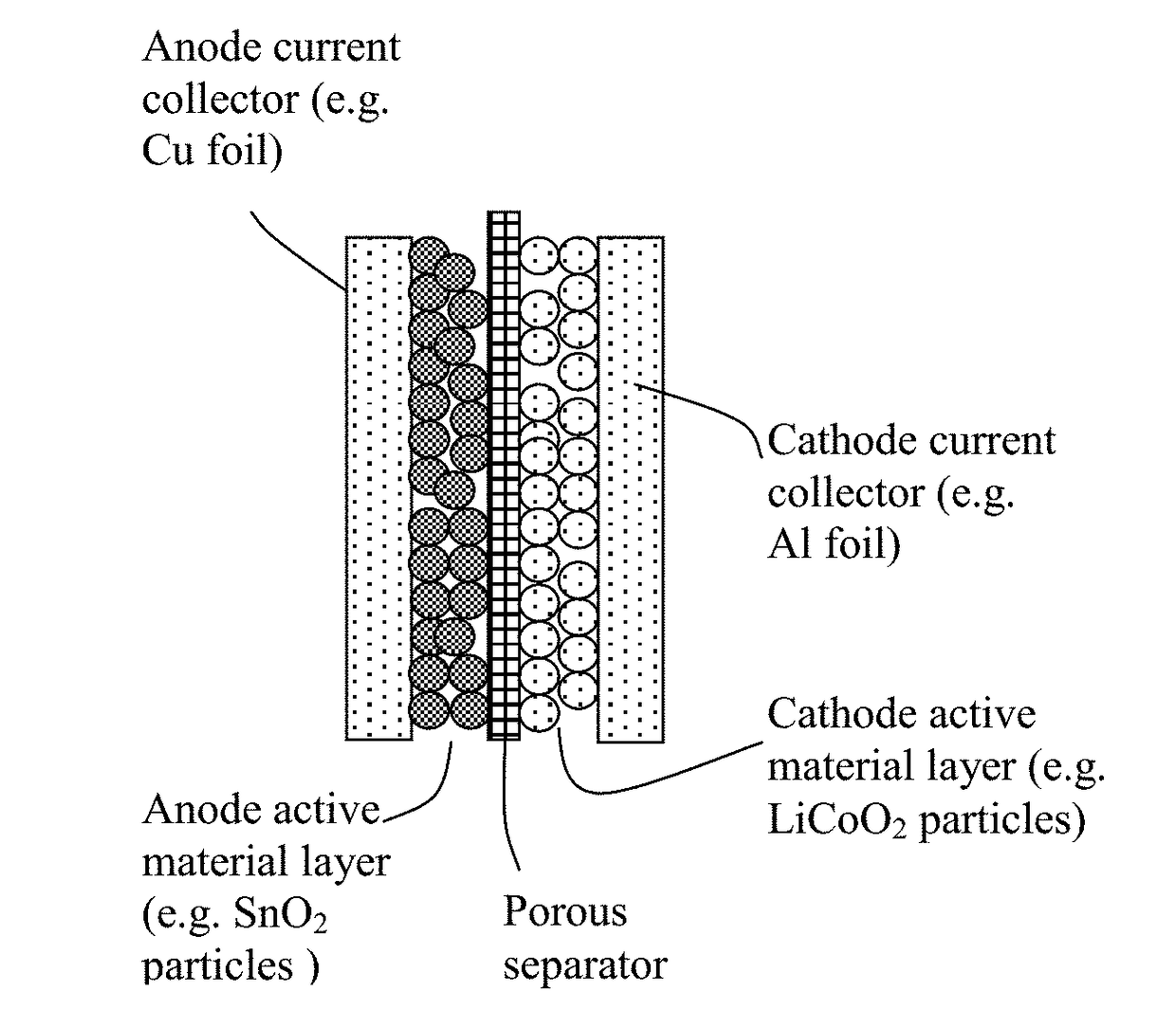

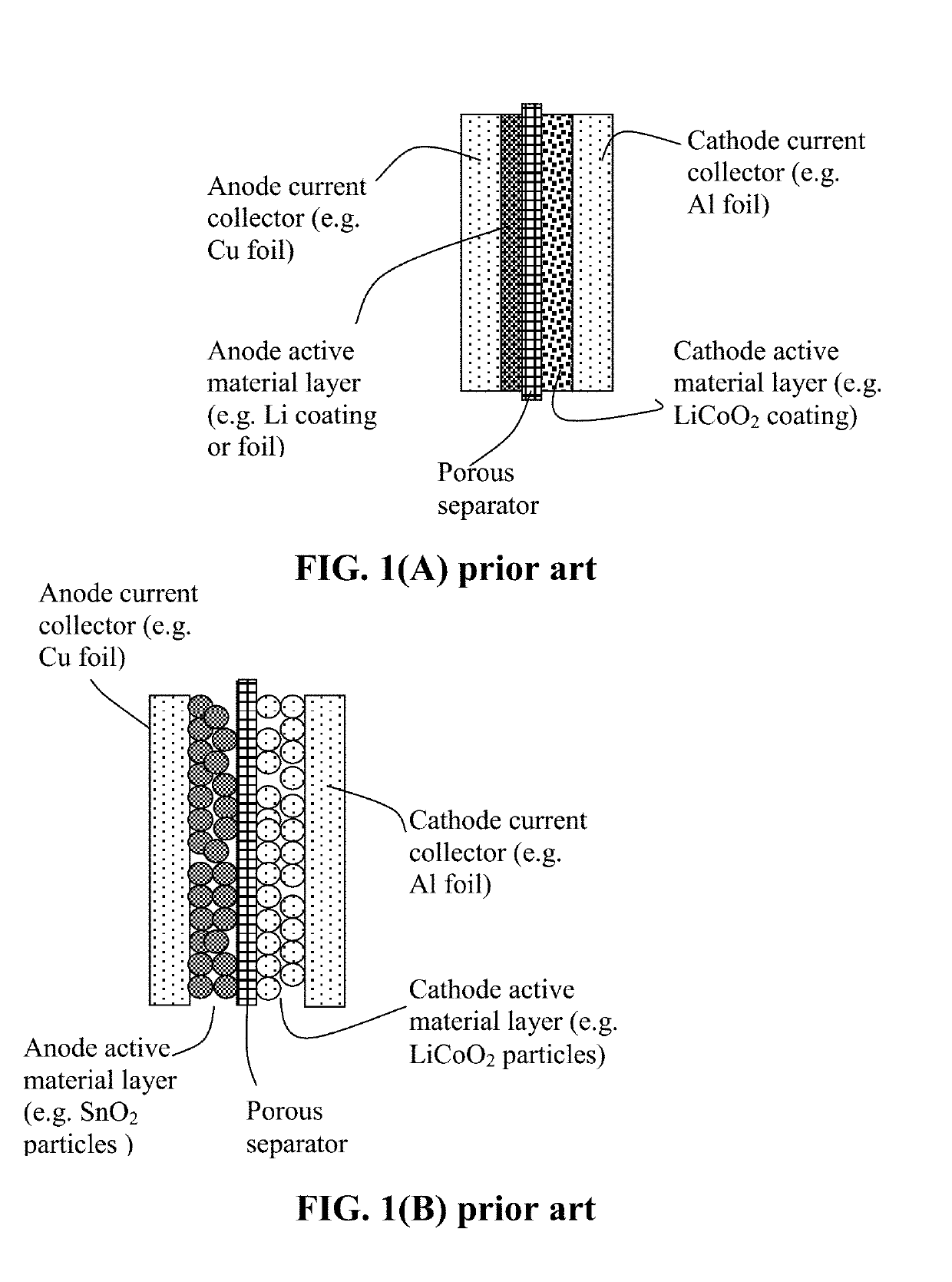

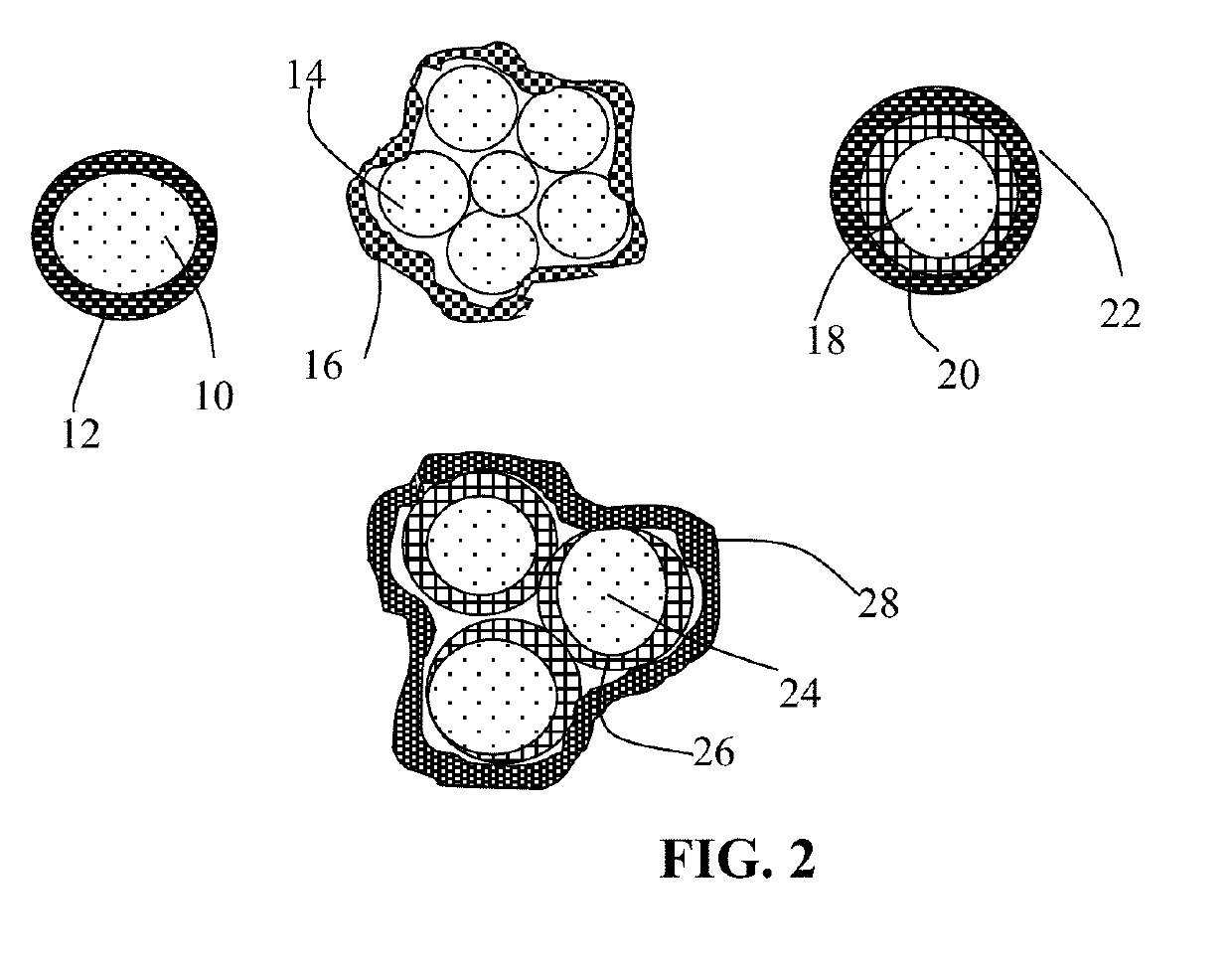

Encapsulated Anode Active Material Particles, Lithium Secondary Batteries Containing Same, and Method of Manufacturing

ActiveUS20180287142A1Improve lithium ion conductivitySolid electrolytesNegative electrodesParticulatesPolyethylene oxide

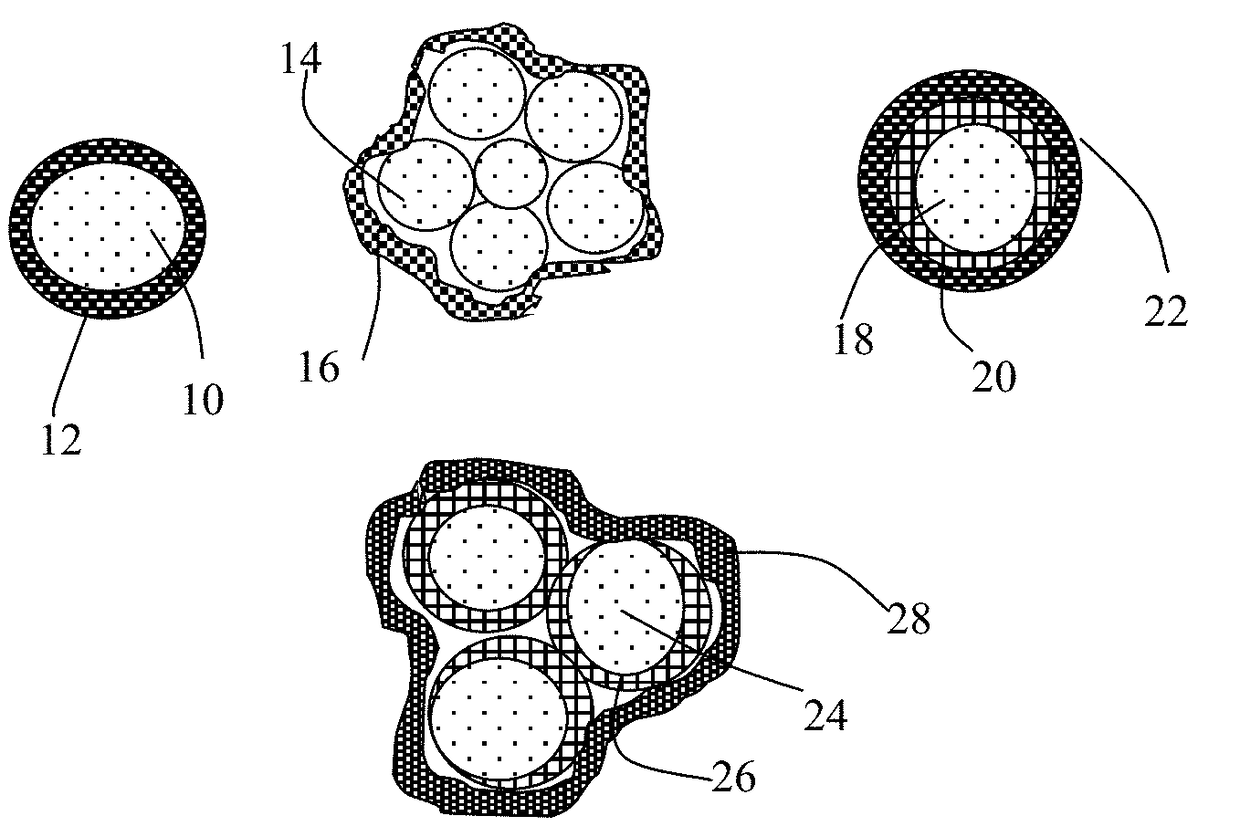

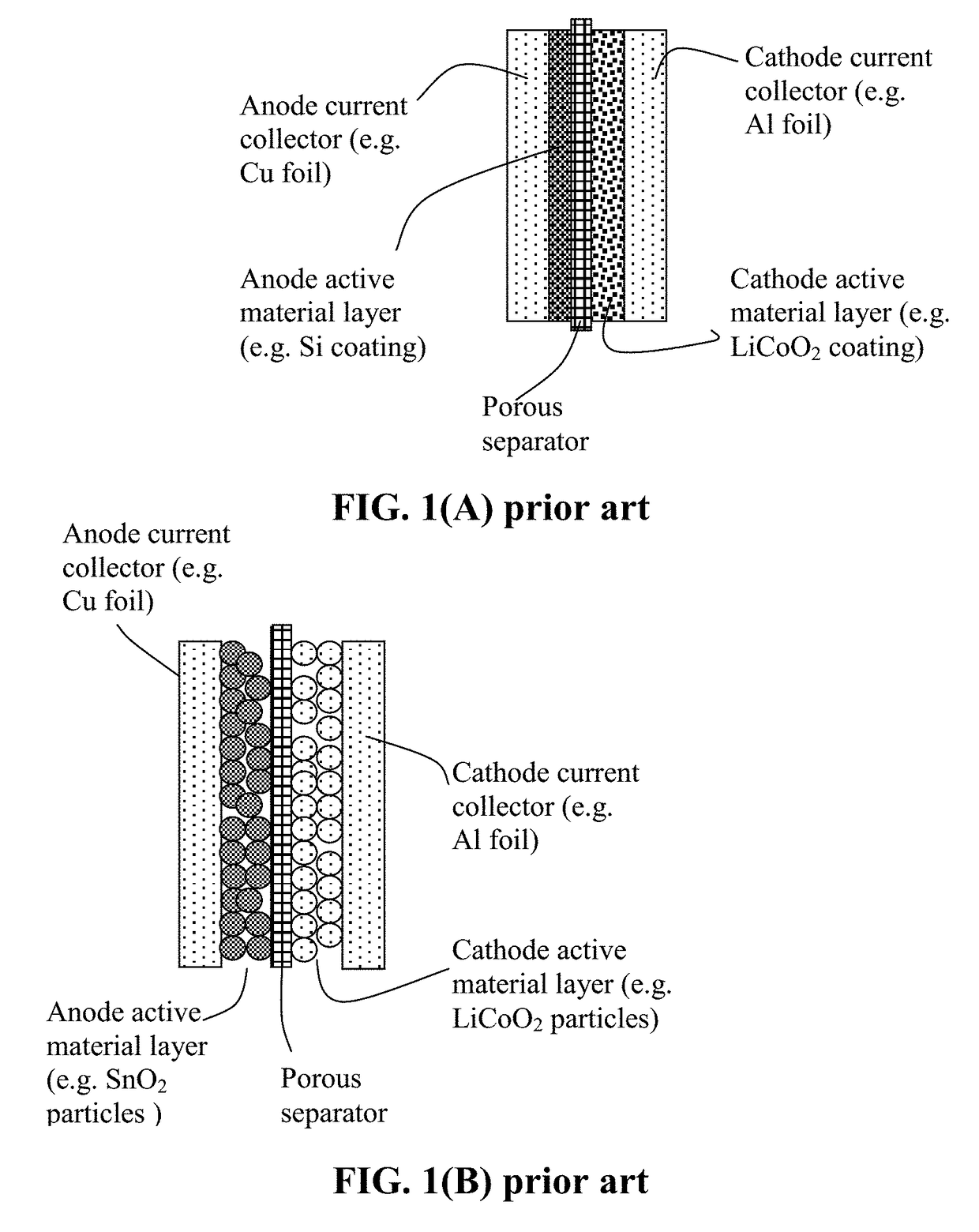

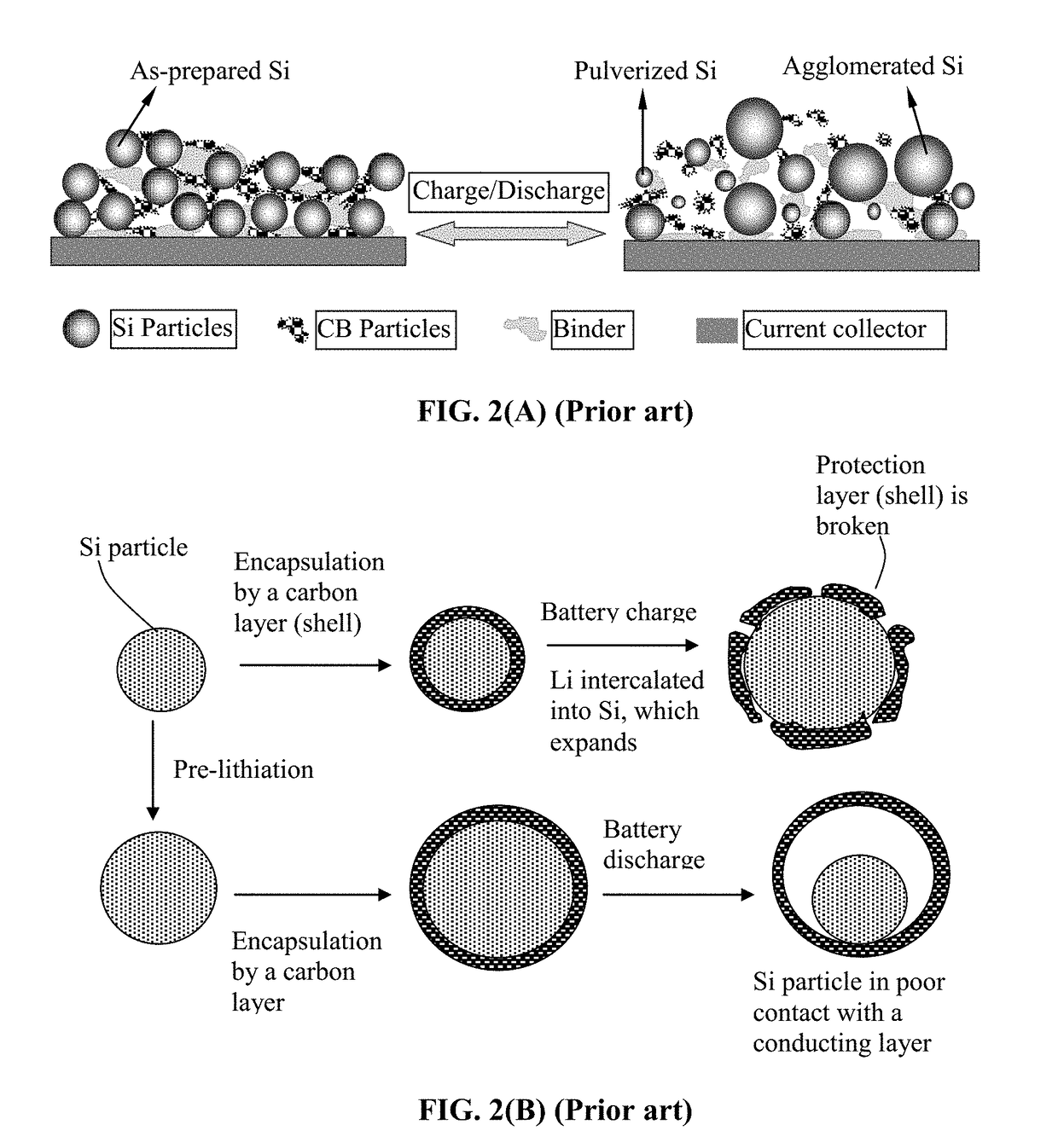

Provided is particulate of an anode active material for a lithium battery, comprising one or a plurality of anode active material particles being embraced or encapsulated by a thin layer of a high-elasticity polymer having a recoverable tensile strain no less than 5%, a lithium ion conductivity no less than 10−6 S / cm at room temperature, and a thickness from 0.5 nm to 10 μm, wherein the polymer contains an ultrahigh molecular weight (UHMW) polymer having a molecular weight from 0.5×106 to 9×106 grams / mole. The UHMW polymer is preferably selected from polyacrylonitrile, polyethylene oxide, polypropylene oxide, polyethylene glycol, polyvinyl alcohol, polyacrylamide, poly(methyl methacrylate), poly(methyl ether acrylate), a copolymer thereof, a sulfonated derivative thereof, a chemical derivative thereof, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

Photo-curable resin compositions and method of using the same in three-dimensional printing for manufacturing artificial teeth and denture base

ActiveUS20140239527A1Simple and easilyLow viscosityAdditive manufacturing apparatusImpression capsMeth-Oligomer

A composition includes a light-curable viscous mixture that includes: 0-50% by weight of a poly(methyl methacrylate) / methyl methacrylate solution; 5-20% by weight of at least one kind of multifunctional aliphatic (meth)acrylate; 5-40% by weight of at least one kind of aliphatic urethane (meth)acrylate oligomer; 25-65% by weight of at least one kind of difunctional bisphenol-A dimethacrylate; 0.1 to 5% by weight of at least one kind of a photoinitiator; 0.05 to 2% by weight of at least one kind of light stabilizer; and 0.1 to 3% by weight of color pigment based on the total weight of the composition.

Owner:DENTCA

Lenses having dispersed metal nanoparticles for optical filtering including sunglasses

InactiveUS20070298242A1Evenly dispersedSpectales/gogglesSynthetic resin layered productsMethylmethacrylatesPoly(methyl methacrylate)

Lenses appropriate for use as sunglasses and other optical filtering devices include one or more composite layers including metal nanoparticles dispensed in a polymer matrix. The entire lens can be a single layer of the composite or the composite can be a coating on one or both faces of the lens. Gold nanoparticles can be dispersed in a poly(methylmethacrylate) or polycarbonate polymer at 0.01 to 1 weight percent.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

Blends of amorphous and semicrystalline polymers having shape memory properties

InactiveUS7208550B2High modulusDental impression compositionsPoly(methyl methacrylate)Glycol synthesis

Blends of amorphous and semicrystalline polymers having shape memory properties were prepared by blending a crystalline polymer such as poly(vinylidene fluoride), polylactide, poly(hydroxxybutyrate), poly(ethylene glycol) polyethylene, polyethylene-co-vinyl acetate, poly(vinyl chloride), poly(vinylidene chloride) and copolymers of poly(vinylidene chloride) and poly(vinyle chloride) and an amorphous polymer such as poly(vinyl acetate), poly methyl acrylate, poly ethyl acrylate, atactic poly methyl methacrylate, isotactic poly methyl methacrylate, syndiotactic poly methyl methacrylate and other poly alkyl methacrylates. The method for preparing the polymeric materials and applications thereof, for example, as smart medical devices, are also disclosed.

Owner:UNIV OF CONNECTICUT

Material Trivial Transfer Graphene

ActiveUS20130248097A1Low costEfficient and reliableNanotechLamination ancillary operationsPolymeric surfacePoly(methyl methacrylate)

A method for transferring PMMA-coated graphene can transfer graphene to a wide variety of different substrate surfaces. It transfers graphene to different surfaces by using of Poly(methyl methacrylate) (PMMA), polymer such as sponge, and deionized (DI) water. This method comprises easy steps of coating CVD graphene with a layer of PMMA; placing the PMMA-coated CVD graphene onto a polymer to form a PMMA-coated CVD graphene on the surface of a polymer; putting this polymer with PMMA-coated CVD graphene in DI water, and finally scooping up the PMMA-coated CVD graphene with one target substrate. In this way, it transfers the CVD graphene to a target substrate surface.

Owner:PLOSS JR RICHARD S

Superlens and lithography systems and methods using same

InactiveUS20100033701A1Improve performanceInnovative designPhotomechanical apparatusOriginals for photomechanical treatmentLithographic artistNanoparticle

A superlens that includes, in one example embodiment, a positive-index material adjacent to a negative-index material, wherein the negative-index material includes aluminum. In a more specific embodiment, the positive-index material includes a dielectric layer, such as Poly(Methyl MethAcrylate) (PMMA), which is less than 50 nanometers thick. The negative-index material includes a smoothed aluminum layer less than 50 nanometers thick. The aluminum layer is disposed on the dielectric layer or vice versa, forming a superlens comprising the aluminum layer and the dielectric layer. In another embodiment, the superlens further includes plural aluminum layers separated by one or more layers of positive-index material. A mask is adjacent to the positive-index material. The mask may include one or more features that extend into a transparent substrate. The mask is positioned so that the positive-index material separates the mask from the smoothed aluminum layer. In an illustrative embodiment, the superlens is adapted for use with thermal lithography using nanoparticles.

Owner:LEE HYESOG +2

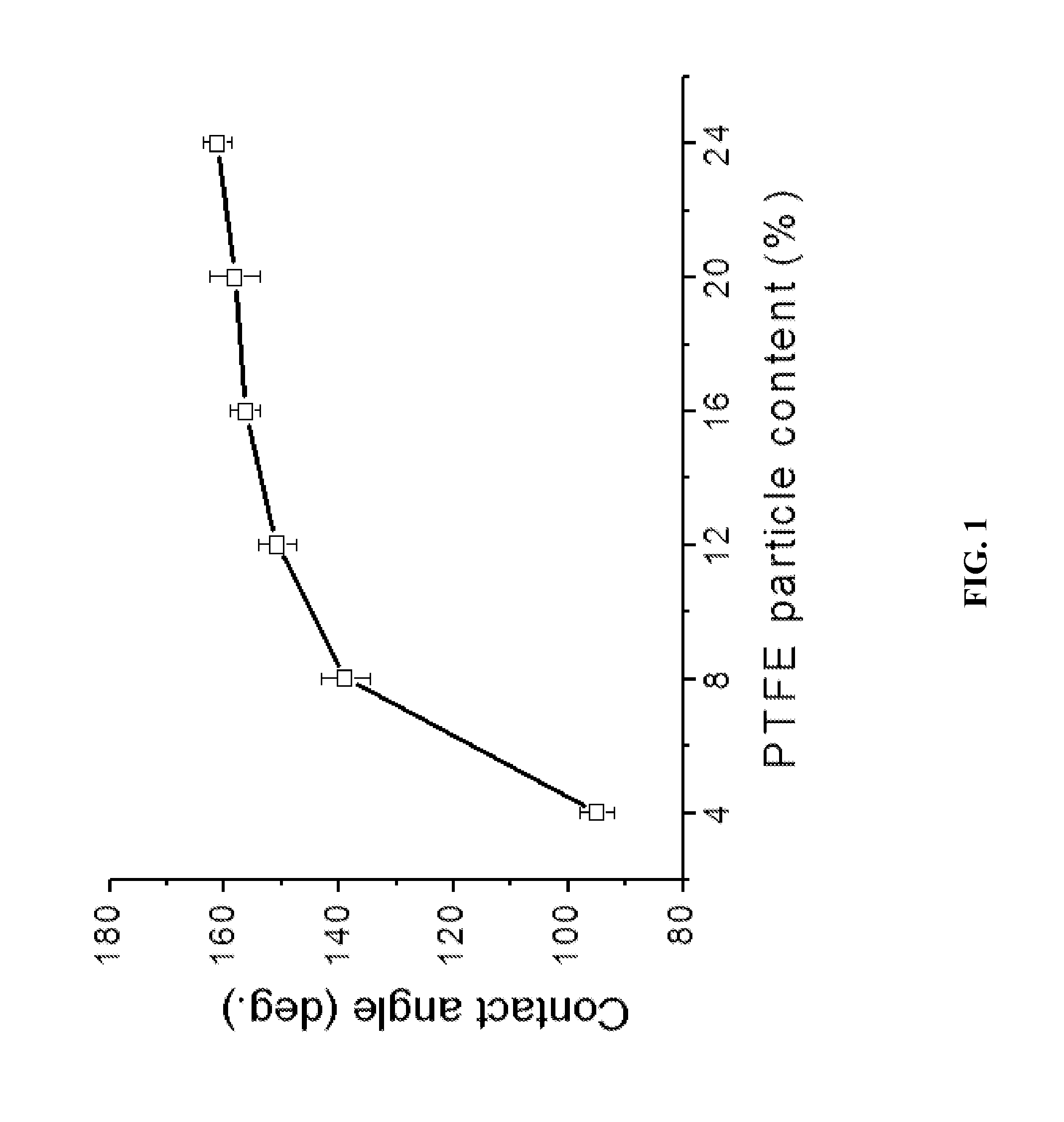

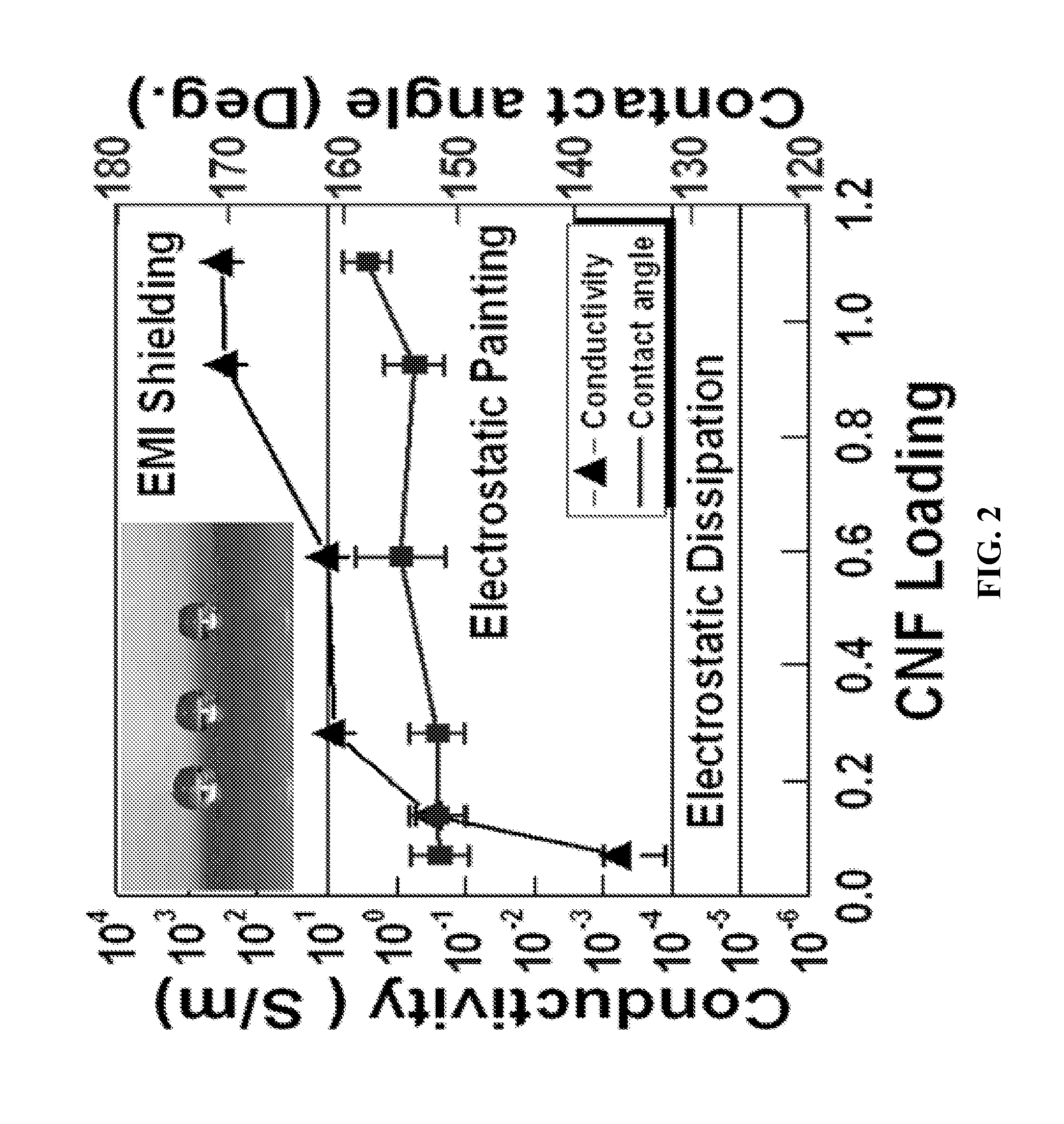

Liquid-repellent, large-area, electrically-conducting polymer composite coatings

InactiveUS20120261182A1Non-metal conductorsMaterial nanotechnologyTetrafluoroethyleneConductive polymer

A polymeric composition including a blend of poly(vinylidine fluoride) (PVDF), poly(methyl methacrylate) (PMMA), carbon nanofibers, and poly(tetrafluoroethylene) (PTFE) particles is described and claimed. The polymeric composition may be coated onto a substrate and dried to form a film adhered to the substrate. The film optionally exhibits an electrical conductivity of about 10 Siemens per meter (S / m) to about 310 S / m and an electromagnetic interference shielding of about 32 decibels. Further, a coated substrate is provided including a substrate and a film adhered to the substrate, where the film includes a polymeric composition comprising a blend of PVDF, PMMA, carbon nanofibers, and PTFE particles.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

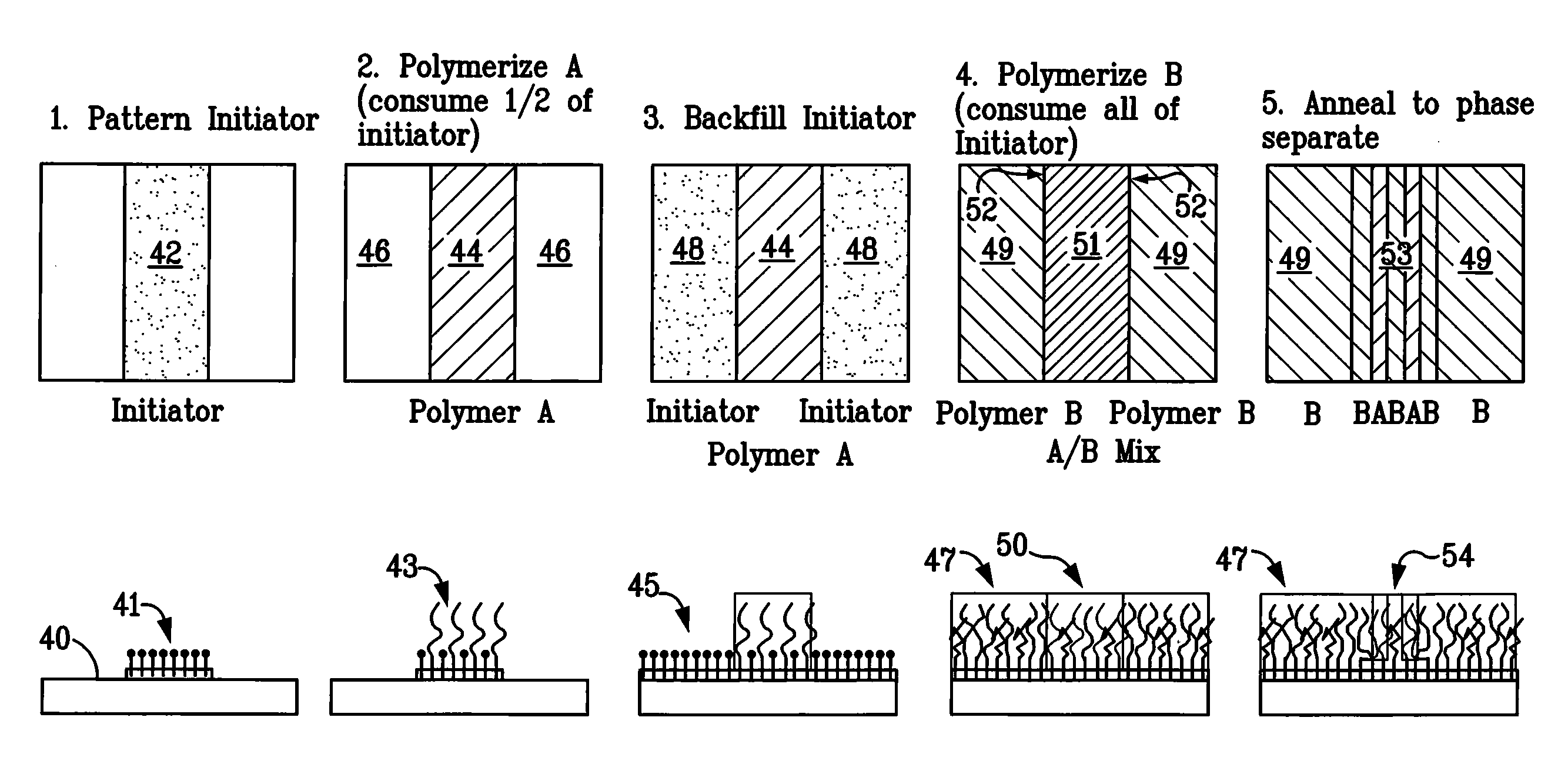

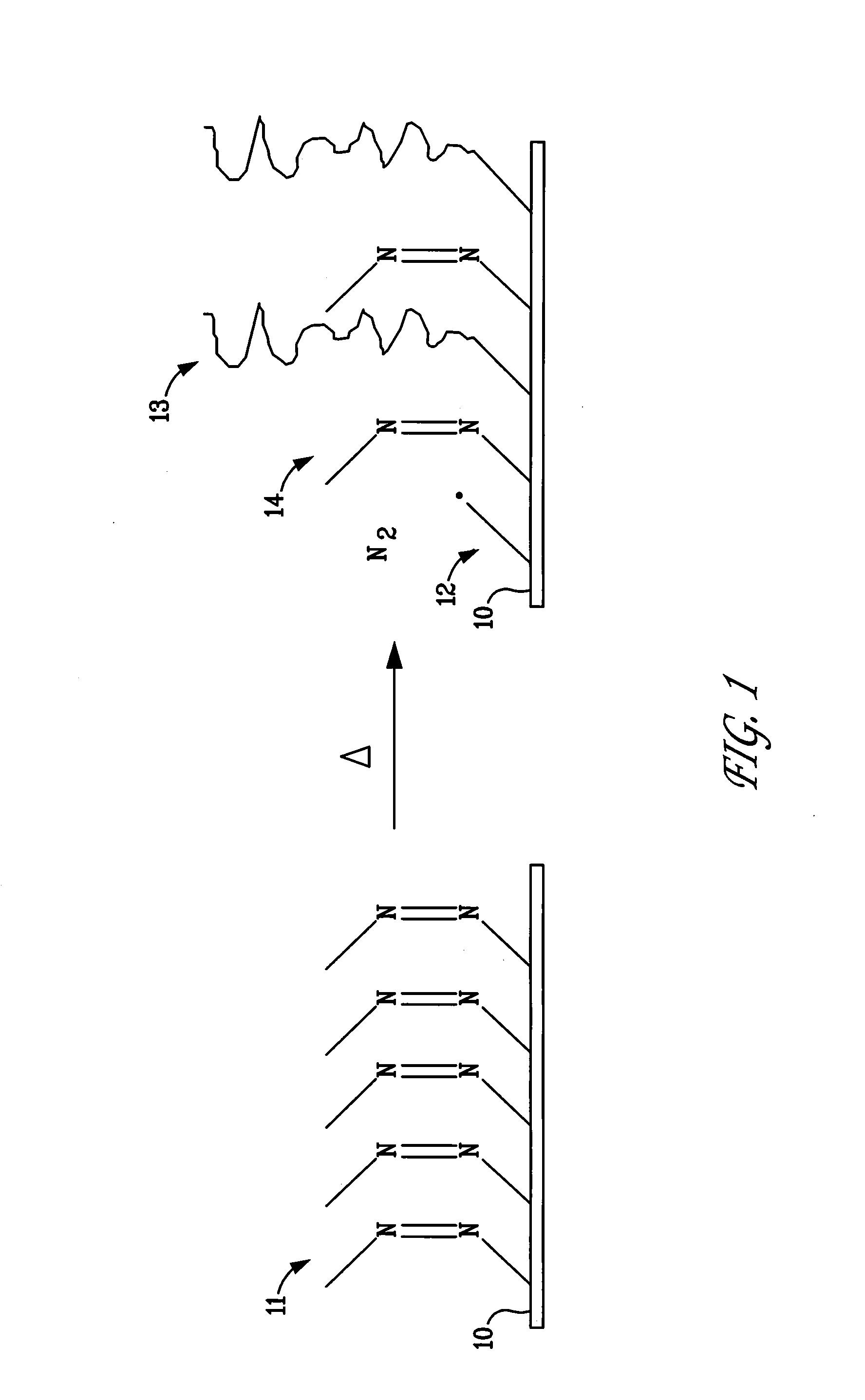

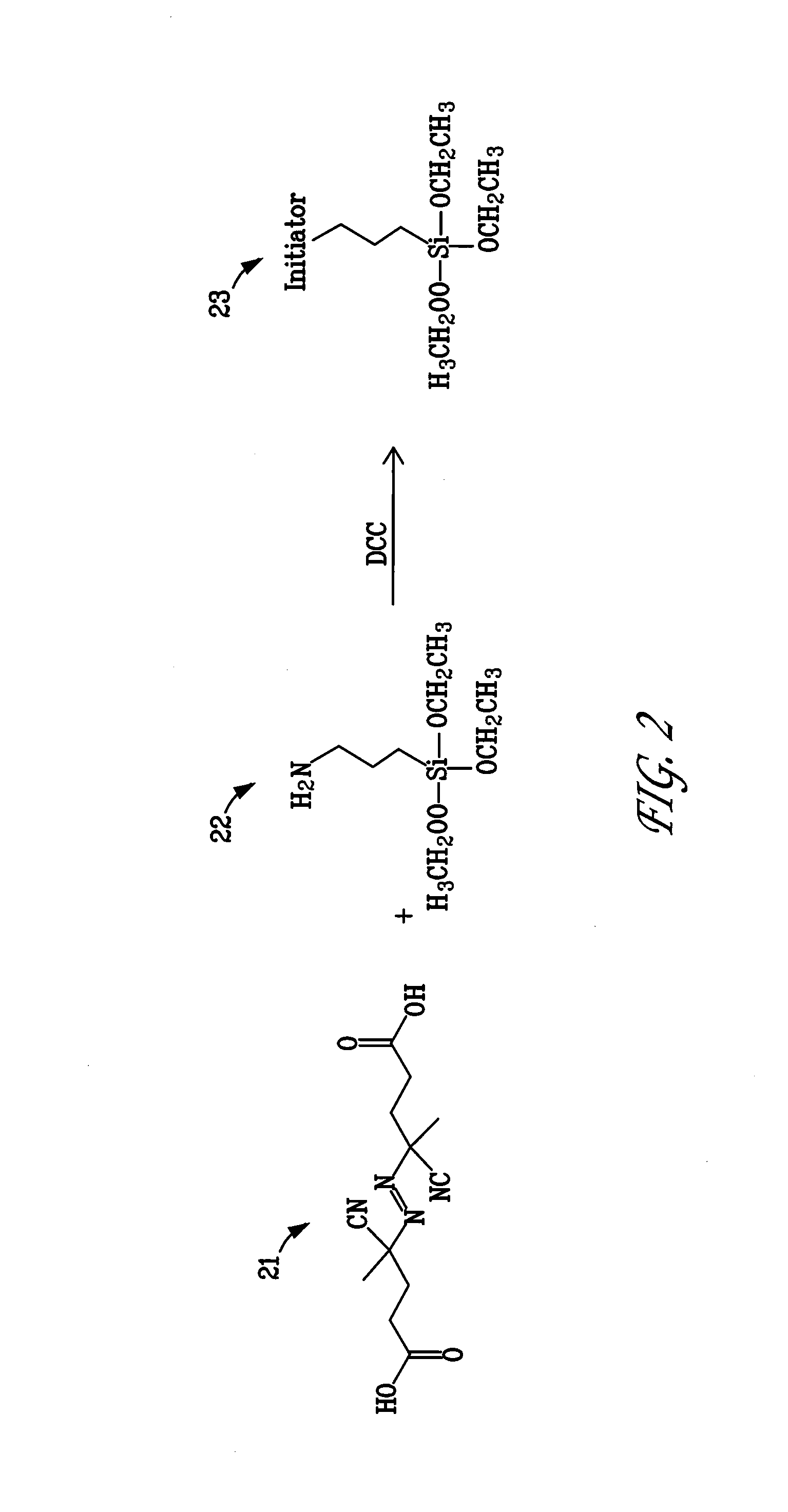

Nanopatterns by phase separation of patterned mixed polymer monolayers

Micron-size and sub-micron-size patterns on a substrate can direct the self-assembly of surface-bonded mixed polymer brushes to create nanoscale patterns in the phase-separated mixed polymer brush. The larger scale features, or patterns, can be defined by a variety of lithographic techniques, as well as other physical and chemical processes including but not limited to etching, grinding, and polishing. The polymer brushes preferably comprise vinyl polymers, such as polystyrene and poly(methyl methacrylate).

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

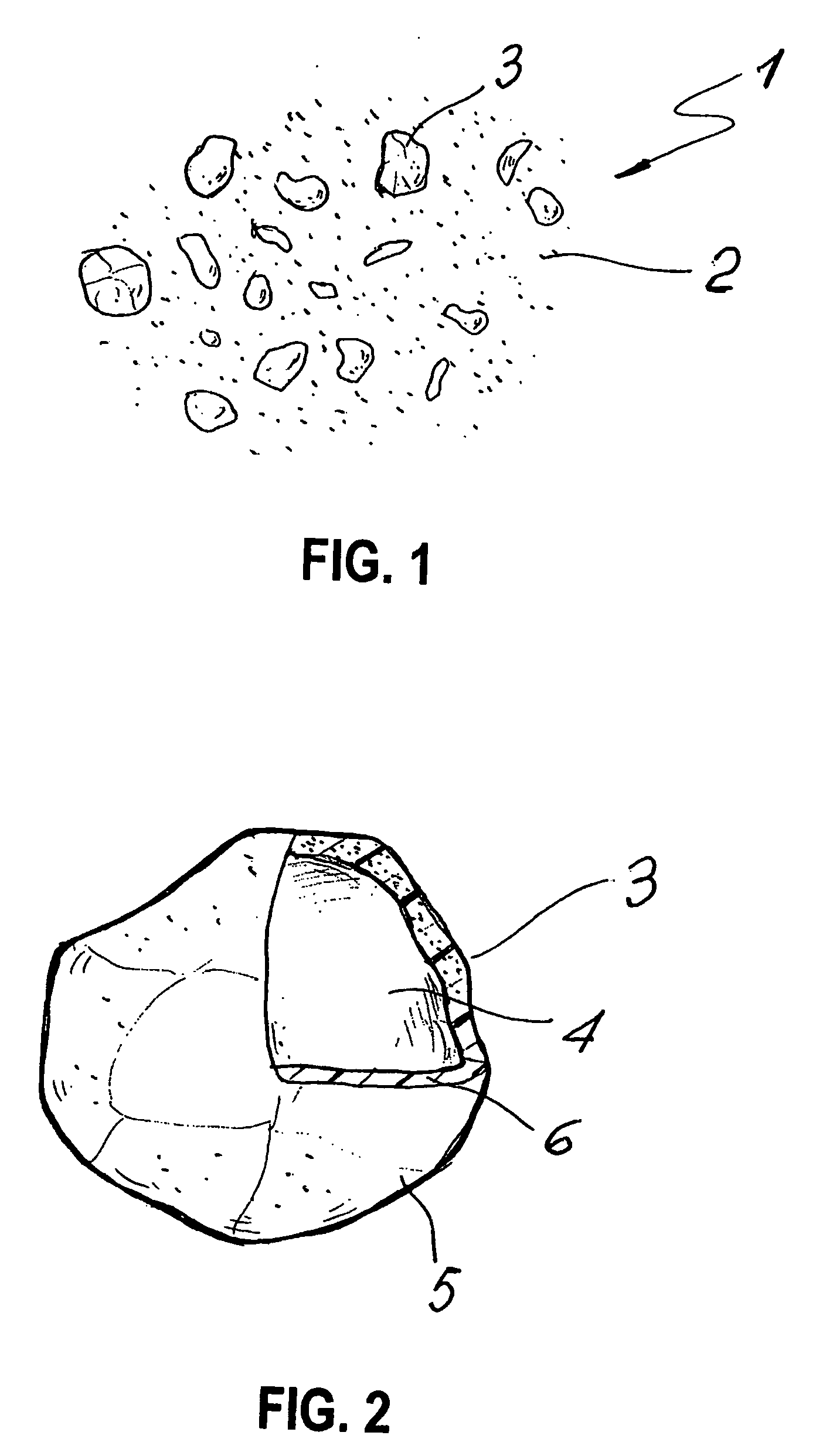

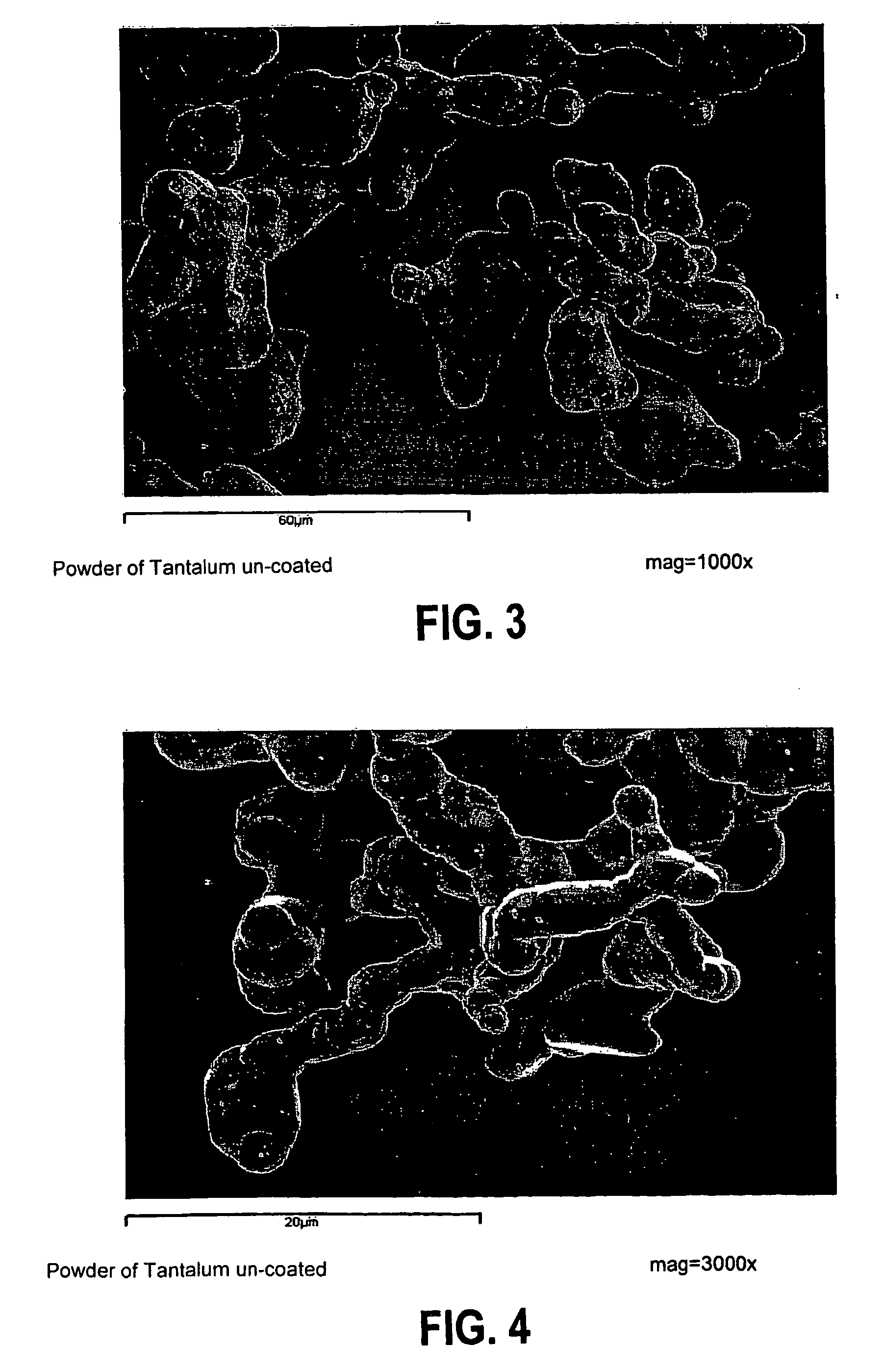

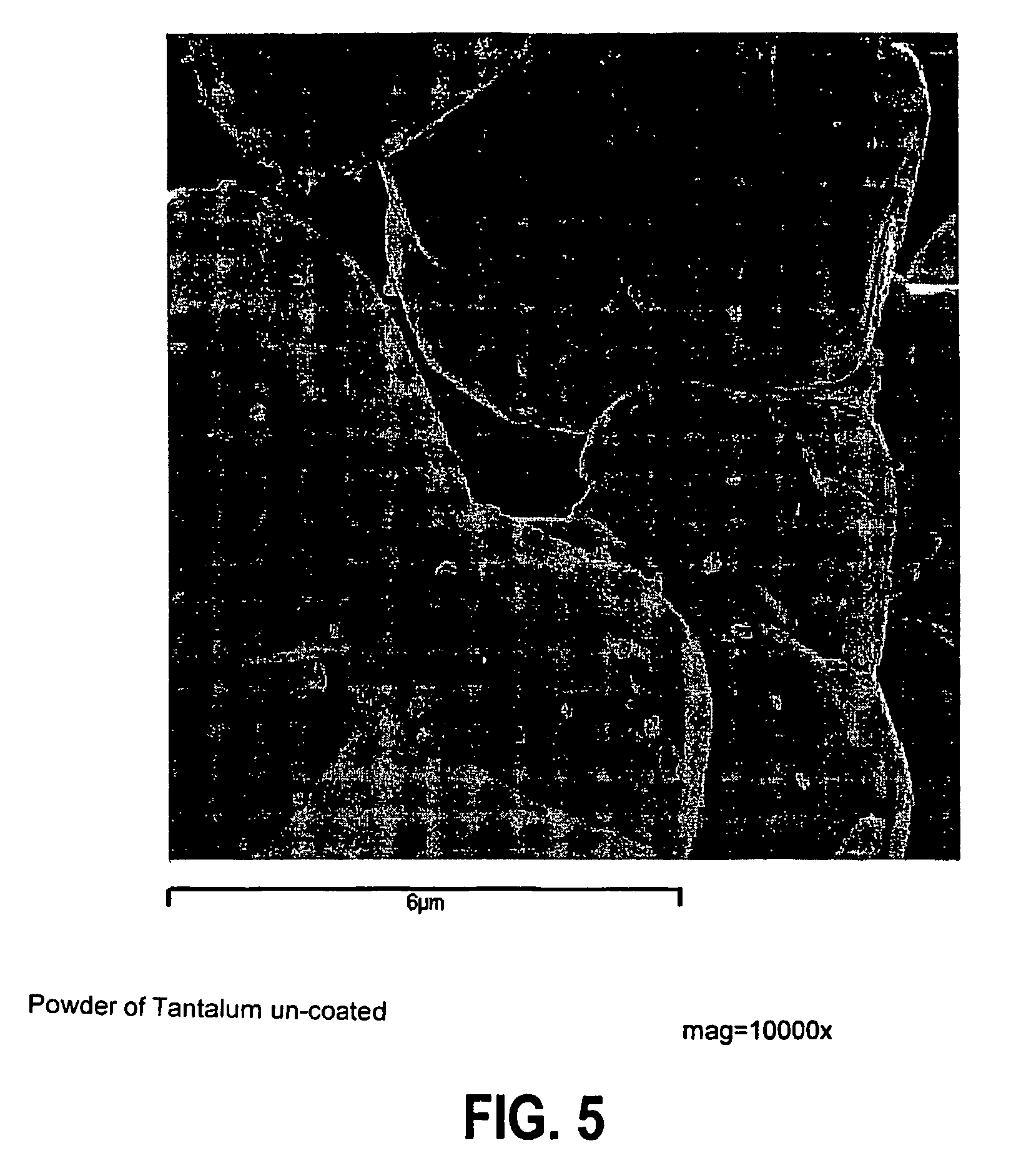

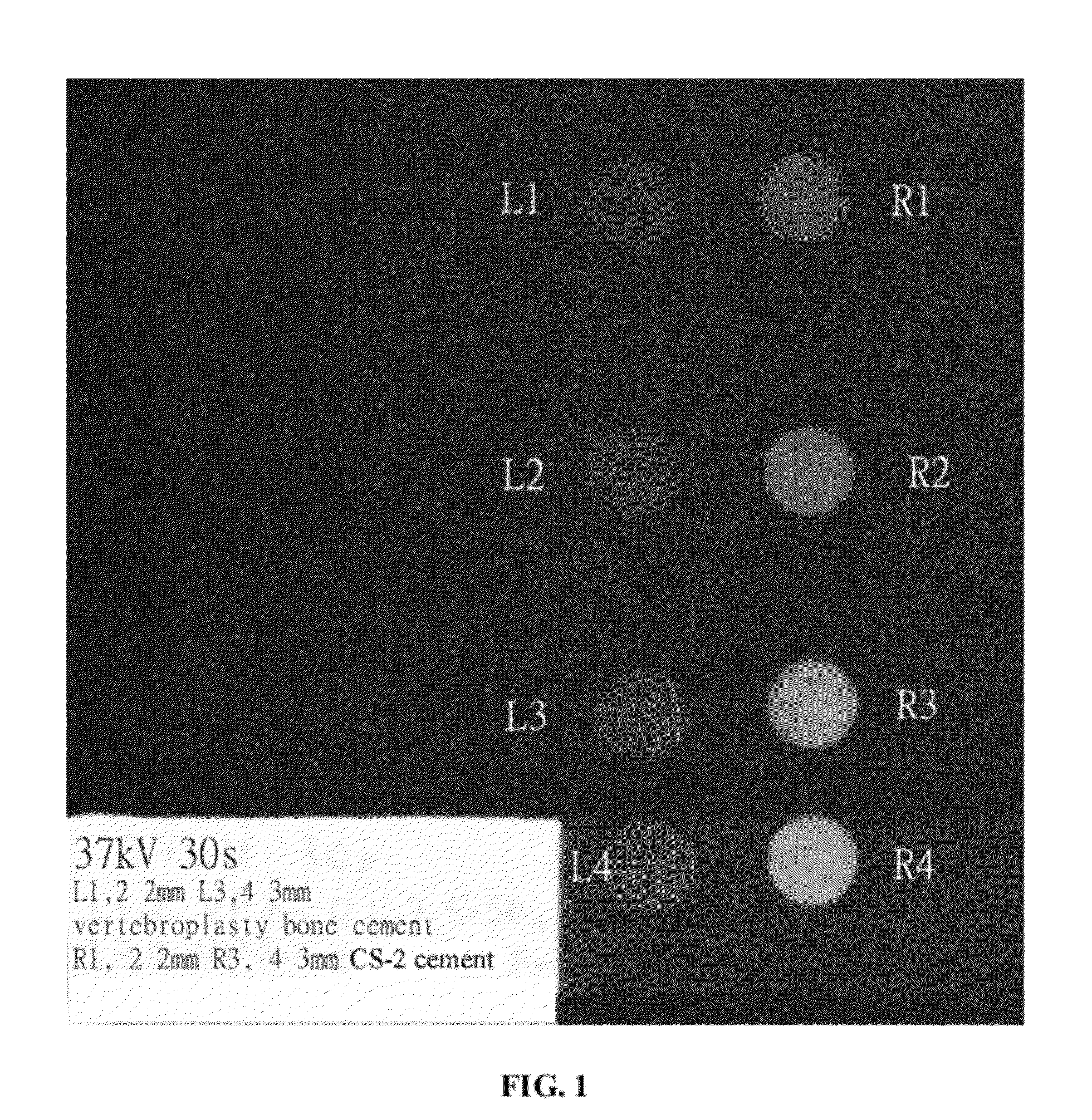

Bone cement containing coated radiopaque particles and its preparation

InactiveUS7186761B2Limited invasivenessConsiderable mechanical strengthCosmetic preparationsImpression capsX-rayMetal particle

An acrylic radiopaque bone cement for orthopedic use comprises a solid phase composed of a mixture of at least one poly(methyl acrylate)-based polymer, one free-radical polymerization initiator and one or more substances opaque to X-rays, and a liquid phase substantially composed of a mixture of at least one monomer, one accelerator and one stabilizer. The radiopaque substances comprise metallic tungsten and tantalum particles, compounds or mixtures thereof, covered with a polymer coating compatible with said bone cement. The coating layer of the particles of radiopaque substances is an acrylic polymer based on poly(methyl methacrylate). The amount of radiopacifying element is between 1% and 20% by weight, relative to the solid phase, preferably between 2% and 5% by weight, relative to the solid phase. The solid phase may additionally comprise one or more pharmacologically active substances. The method for its preparation consists in preparing the radiopacifying material by coating the metal particles with a layer of a polymer which is compatible with the matrix and exhibits oxygen barrier properties such that said layer does not dissolve completely in the liquid phase so as to keep its oxygen barrier properties at least partly unchanged.

Owner:TECRES SPA

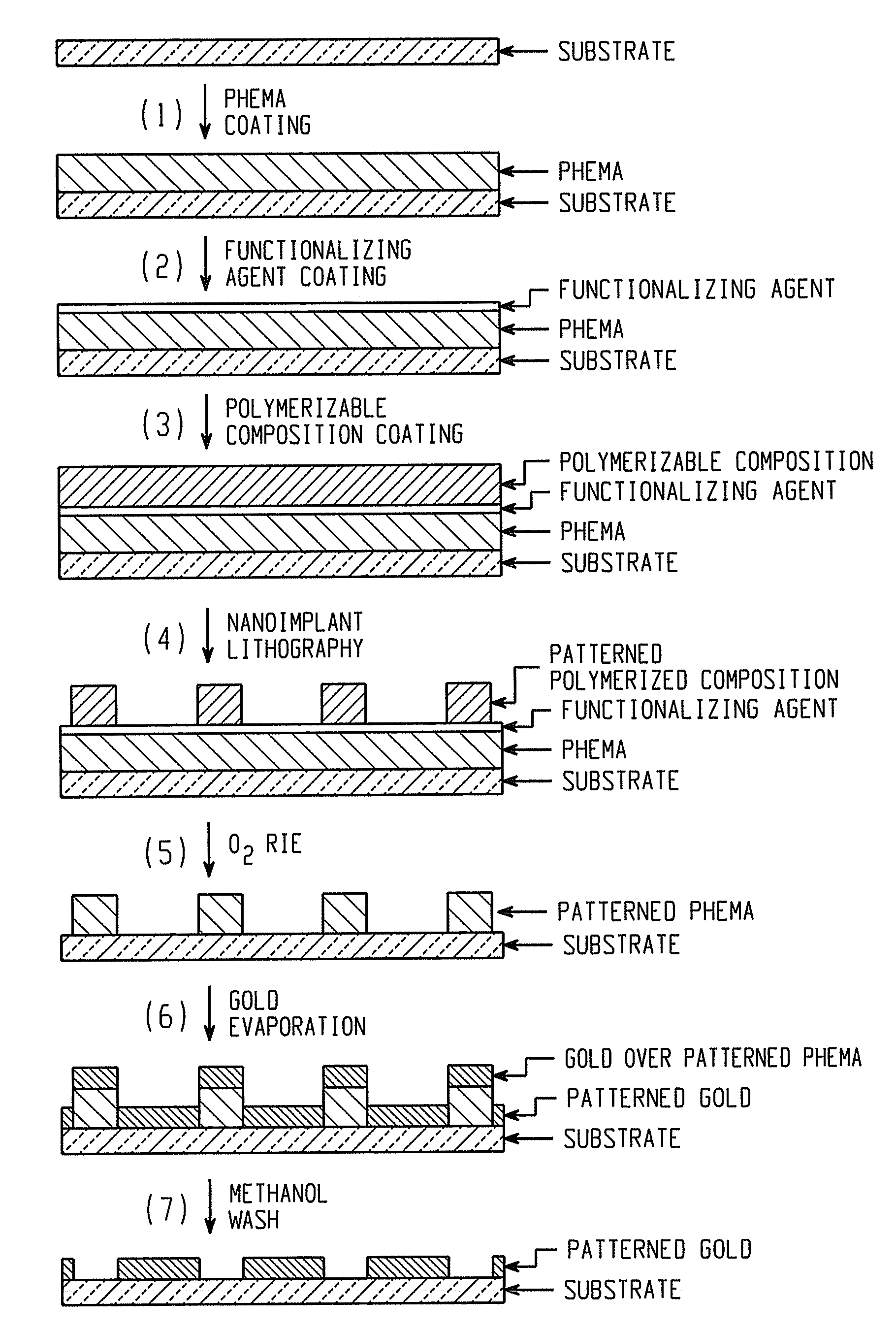

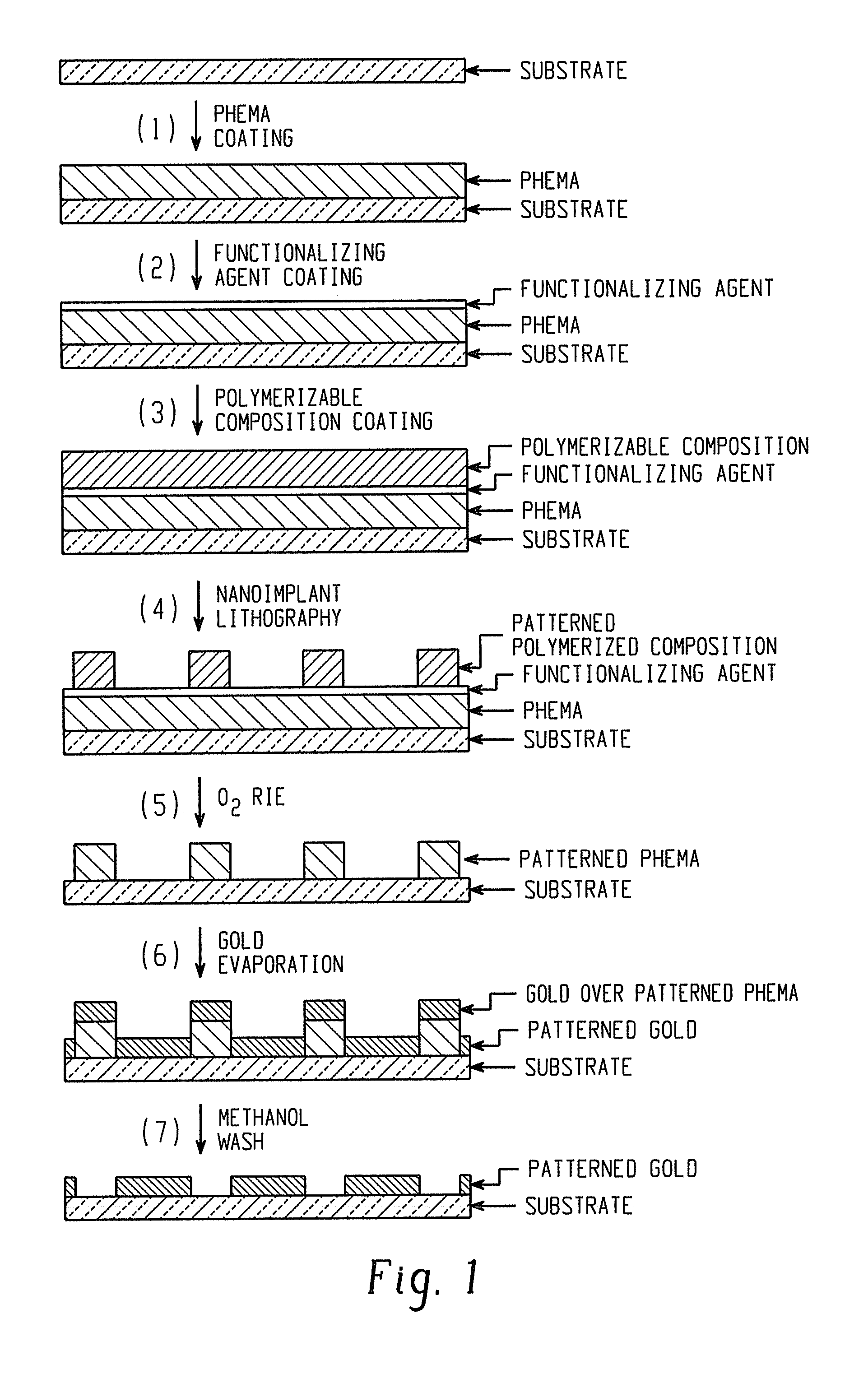

Article with phema lift-off layer and method therefor

A method of forming a patterned functional layer on a substrate using a poly(hydroxyethyl methacrylate) lift-off layer is described. The method can be used with substrates that would not tolerate the organic solvents required for processing of known poly(methyl methacrylate) lift-off layers. When used in combination with known nanoimprint lithography and step-and-flash imprint lithography techniques, the method can be used to generate patterned functional structures with dimensions as small as five nanometers.

Owner:UNIV OF MASSACHUSETTS

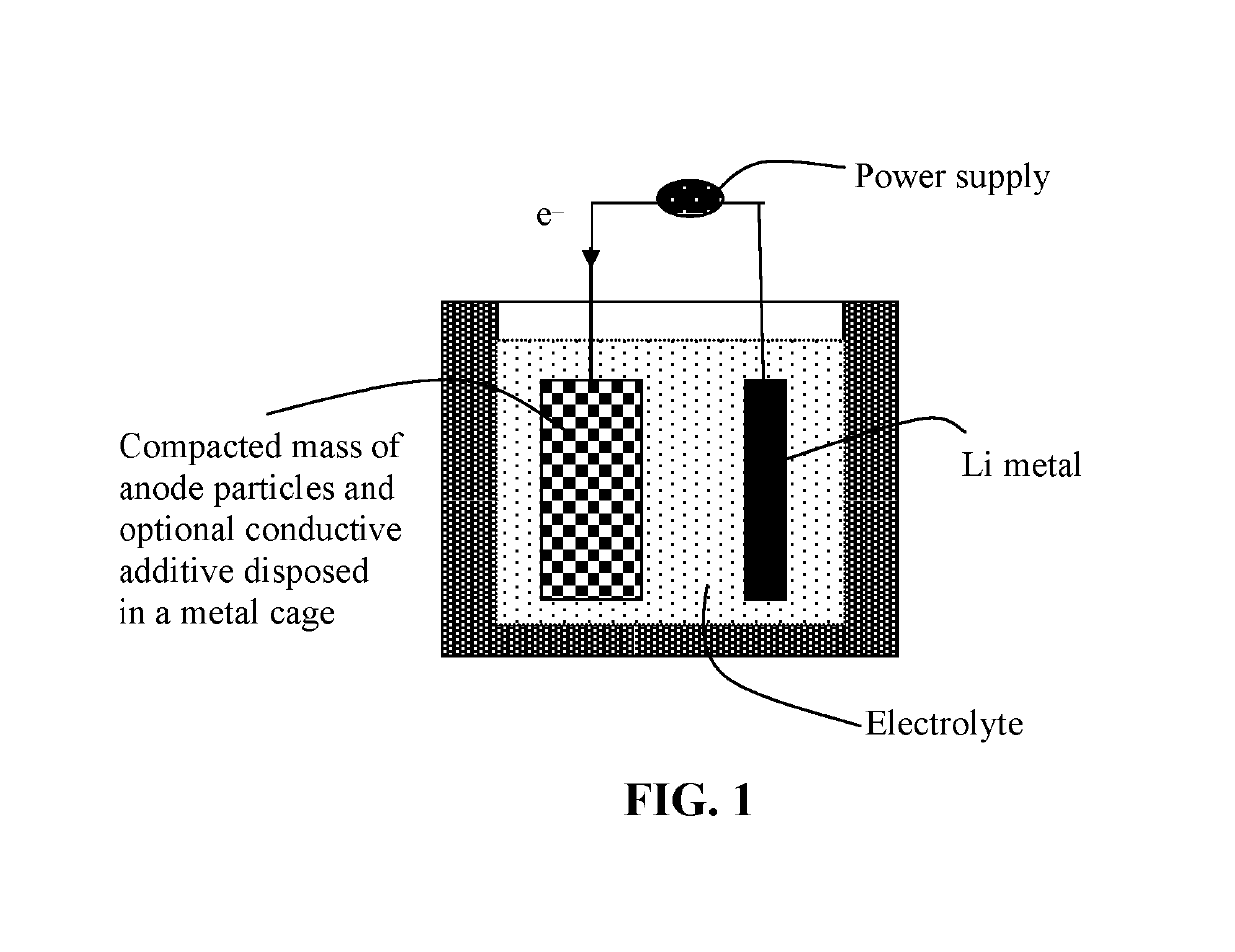

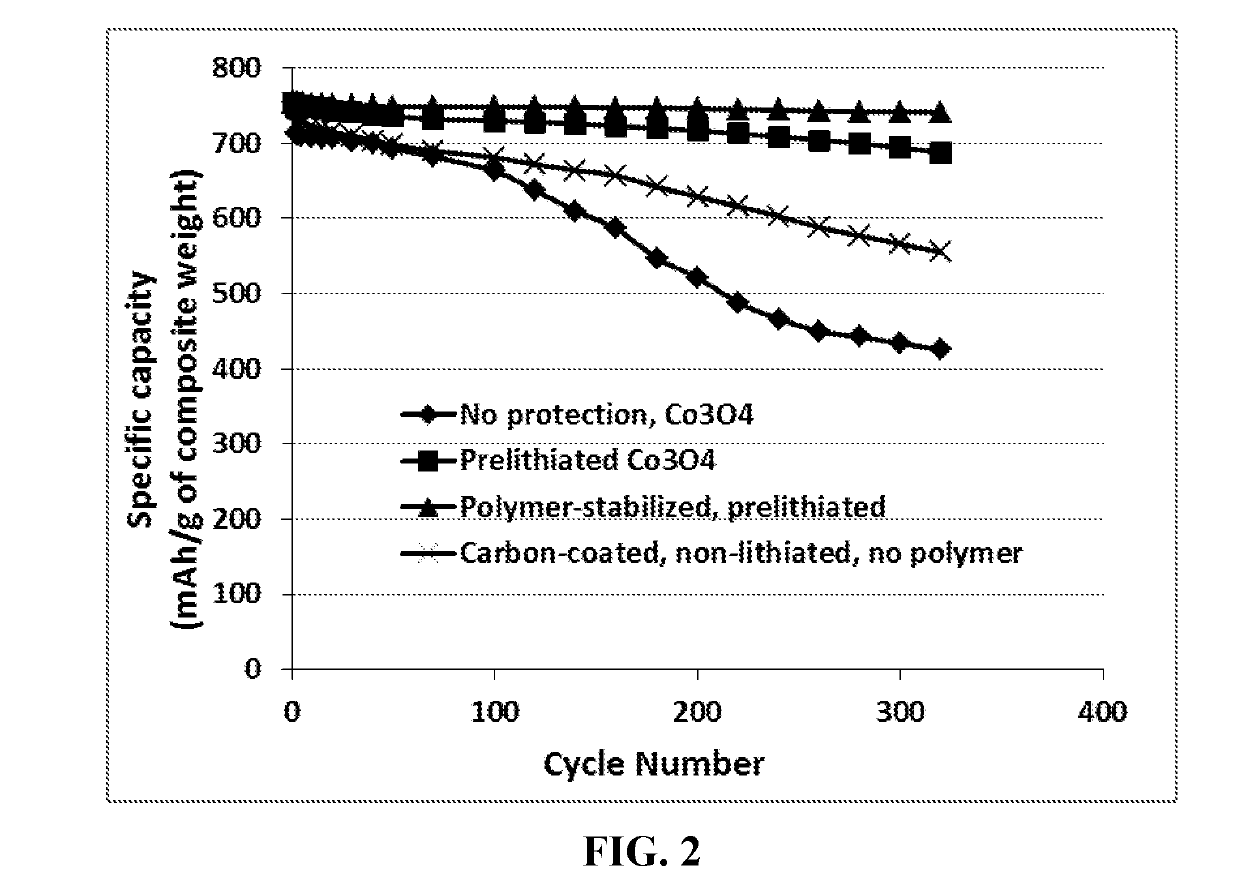

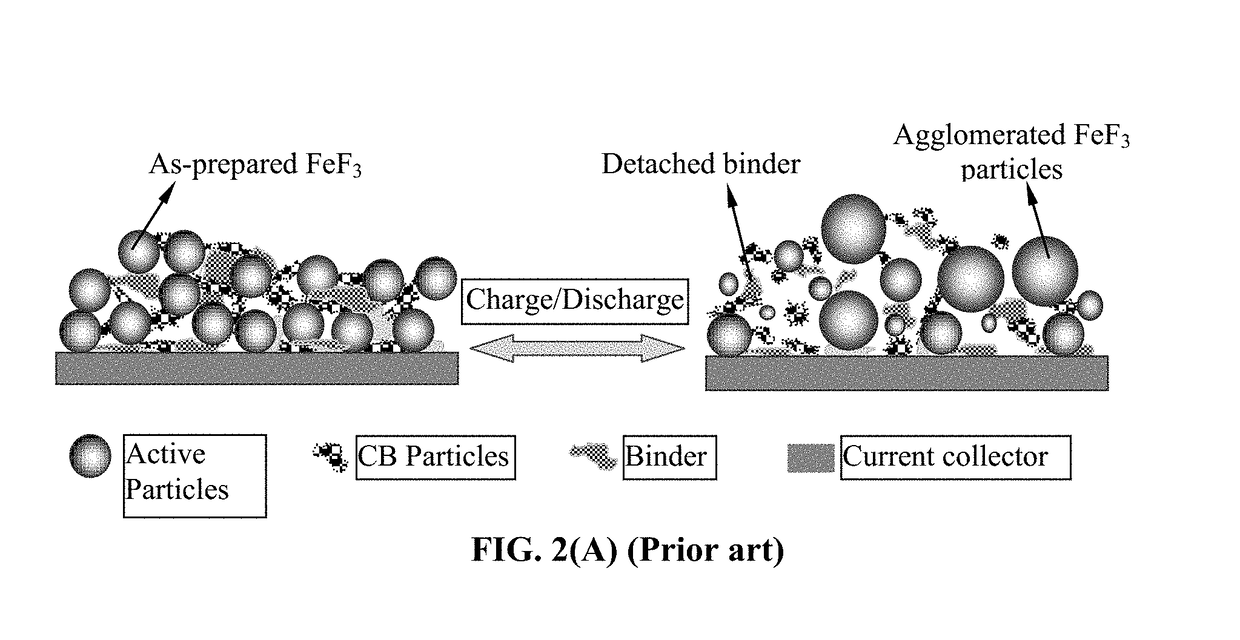

Surface-Stabilized Anode Active Material Particulates for Lithium Batteries and Production Method

ActiveUS20190115617A1High specific capacityLong charge-discharge cycle lifeElectrode manufacturing processesFinal product manufactureParticulatesPoly(ethylene glycol) dimethyl ether

Provided is a surface-stabilized anode active material particulate (for use in a lithium battery), comprising: (a) one or a plurality of prelithiated or un-prelithiated anode active material particles (with or without a coating of carbon, graphene, or ion-conducting polymer); (b) a protecting polymer layer that wraps around, embraces or encapsulates the one or plurality of anode active material particles, wherein the protecting polymer layer has a thickness from 0.5 nm to 5 μm, and a lithium ion conductivity from 10−8 S / cm to 5×10−2 S / cm at room temperature and the protecting polymer layer contains a polymer selected from poly(ethylene oxide) (PEO), polypropylene oxide (PPO), poly(acrylonitrile) (PAN), poly(methyl methacrylate) (PMMA), poly(vinylidene fluoride) (PVdF), poly bis-methoxy ethoxyethoxide-phosphazene, polyvinyl chloride, poly(vinylidene chloride), polydimethylsiloxane, poly(vinylidene fluoride)-hexafluoropropylene (PVDF-HFP), polyethylene glycol (PEG), a PEG derivative, polyethylene glycol methyl ether, polyethylene glycol dimethyl ether, a sulfonated polymer, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

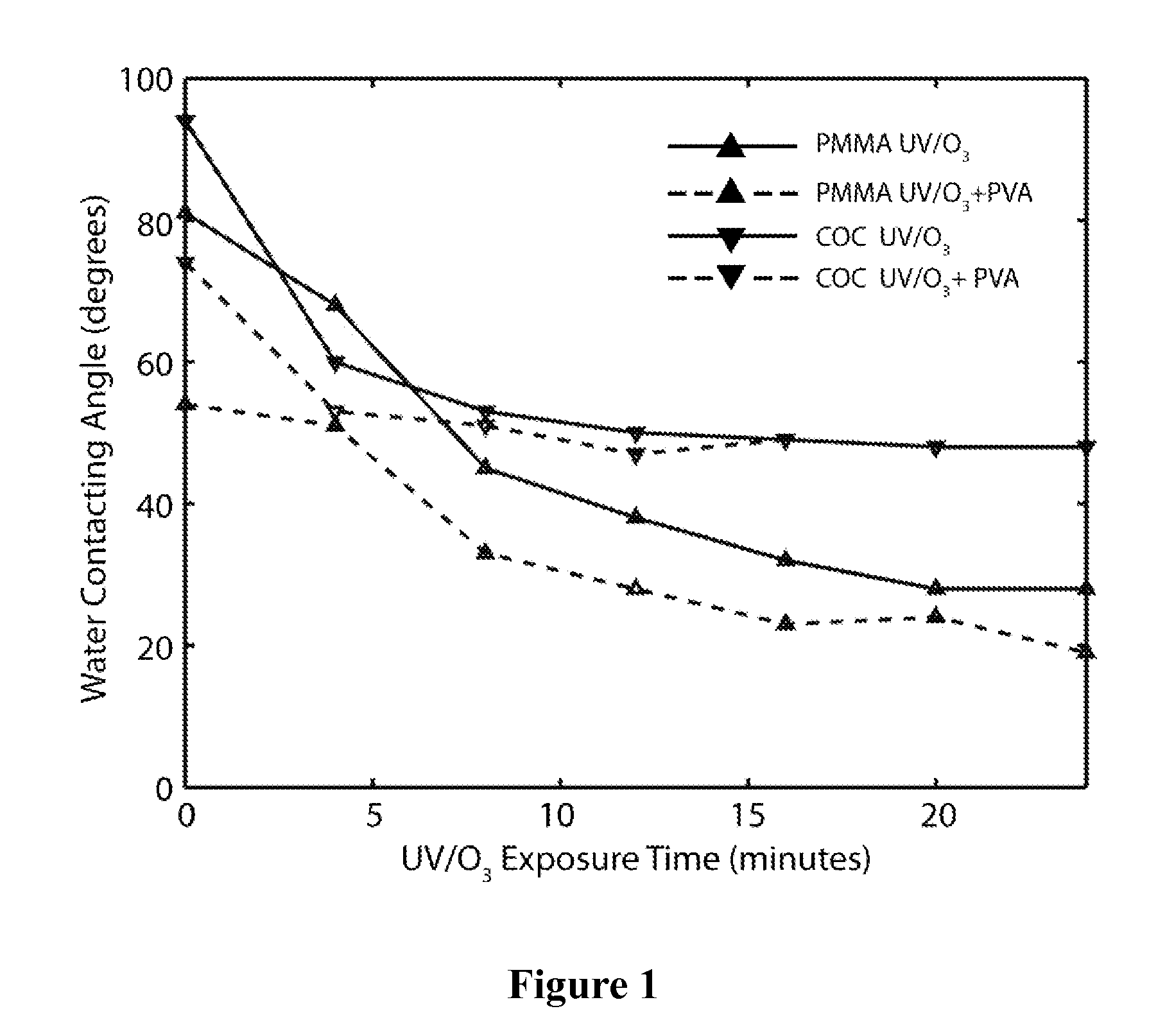

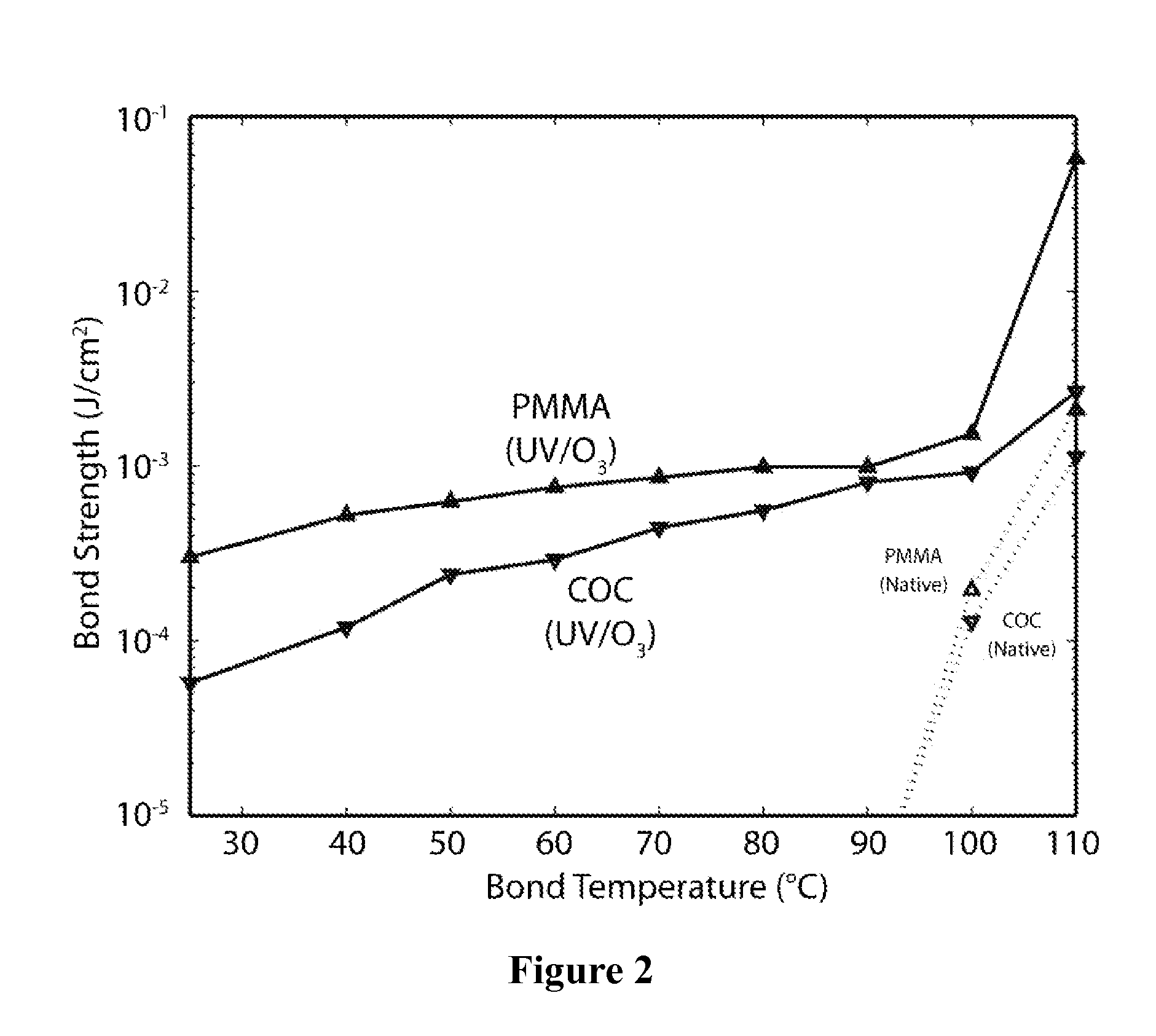

Low Temperature Polymer Bonding Using UV/Ozone Surface Treatment

InactiveUS20090227755A1High bonding strengthLow costPretreated surfacesGroup 3/13 element organic compoundsThermoplasticVitrification

The present invention relates to a method for bonding two surfaces to one another. The invention particularly pertains to the use of such method in which one of the surfaces is a polymeric plastic (and more preferably a polymeric thermoplastic (especially poly-(methyl methacrylate) (“PMMA”) or cyclic olefin copolymer (“COC”)). More particularly, the invention relates to treating at least one of the contacting surfaces with UV in the presence of oxygen to thereby generate ozone (O3) and atomic oxygen under conditions of temperature below that of the glass transition temperature of the polymeric plastic. The UV / O3-mediated bonding results in high bond strength and zero-deformation method. This bonding method can be applied to micro / nano-scale polymer devices, and particularly to microfluidic devices, for a low cost, high throughput, high yield advantage.

Owner:UNIV OF MARYLAND

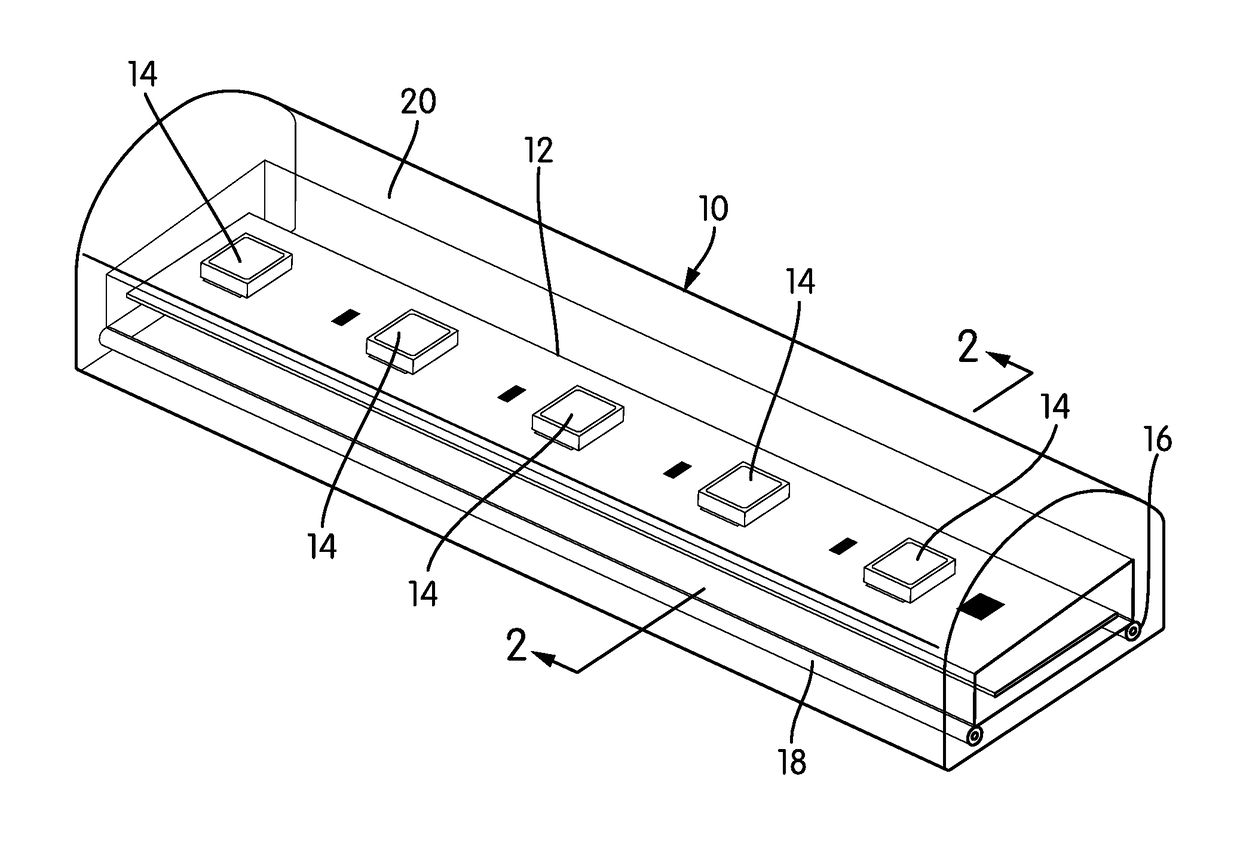

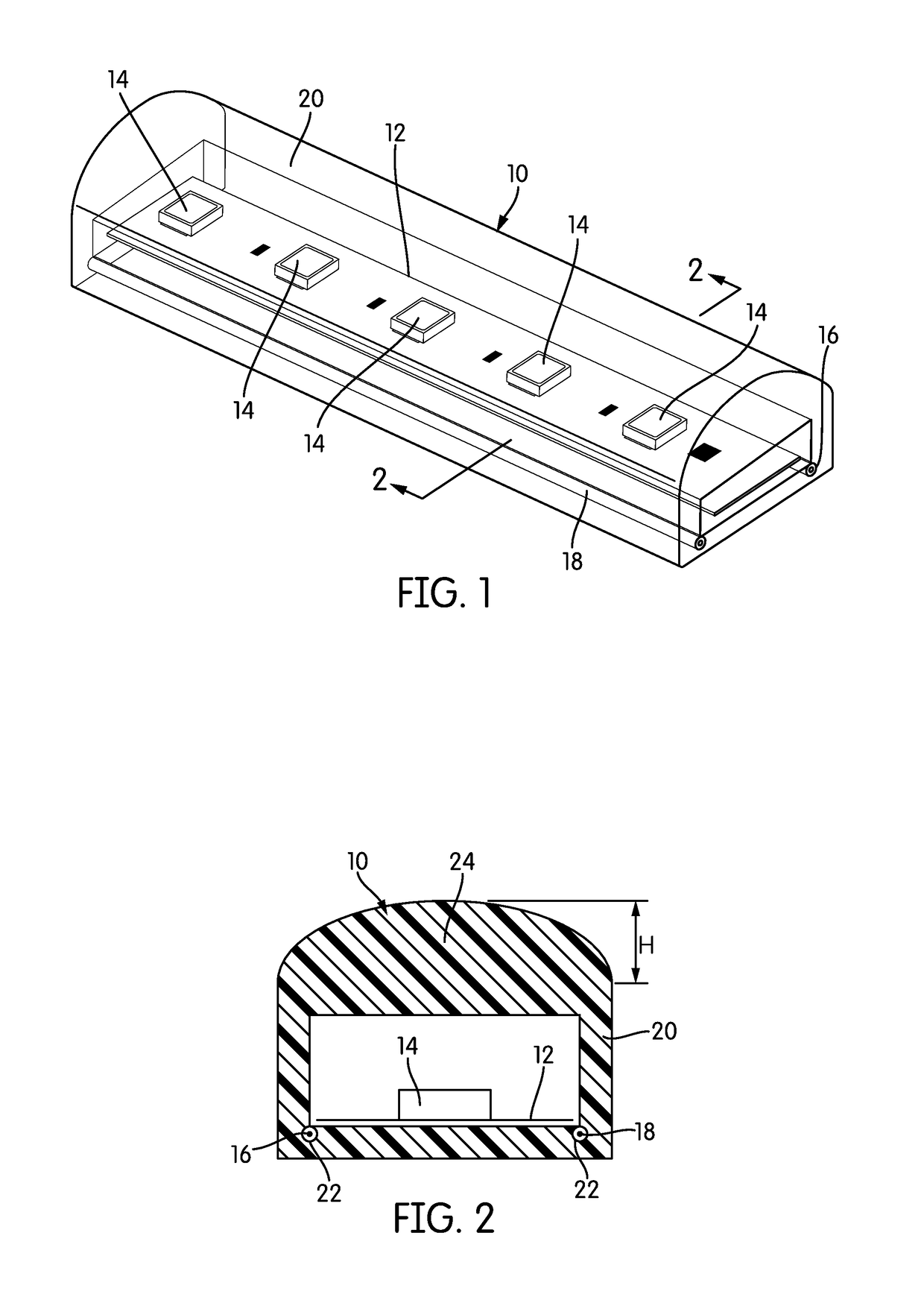

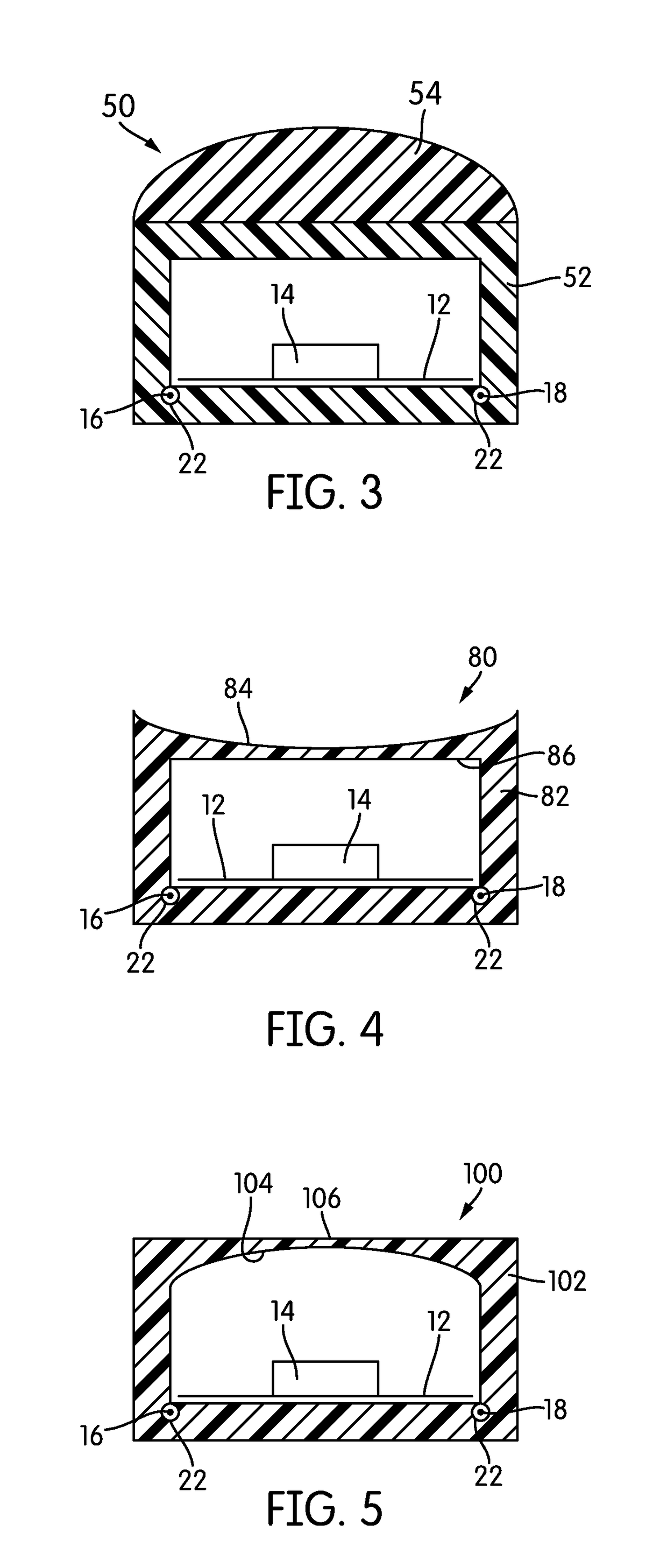

Linear LED Lighting with Built-In Light Modifiers

Linear LED lighting is disclosed. The linear LED lighting includes a flexible PCB on which a number of LED light engines are disposed, typically at a regular pitch. The PCB is surrounded by a flexible, translucent covering, which may be a plastic, such as poly(vinyl chloride) (PVC). The covering has a light modifying property or effect, typically lensing, diffusion, or a combination of the two. For example, the covering may form a plano-convex or plano-concave lens, or it may form a prism. Additionally or alternatively, the coating may include an additive that diffuses the light, or have a coating with that additive that does so. Exemplary additives include beads, microspheres, fibers, or other particles of glass and silica, as well as plastics like poly(methyl methacrylate), polycarbonate, and poly(ethylene terephthalate). In some embodiments, the covering may be mechanically modified to diffuse light, e.g., by an impressed pattern or by abrasion.

Owner:ELEMENTAL LED

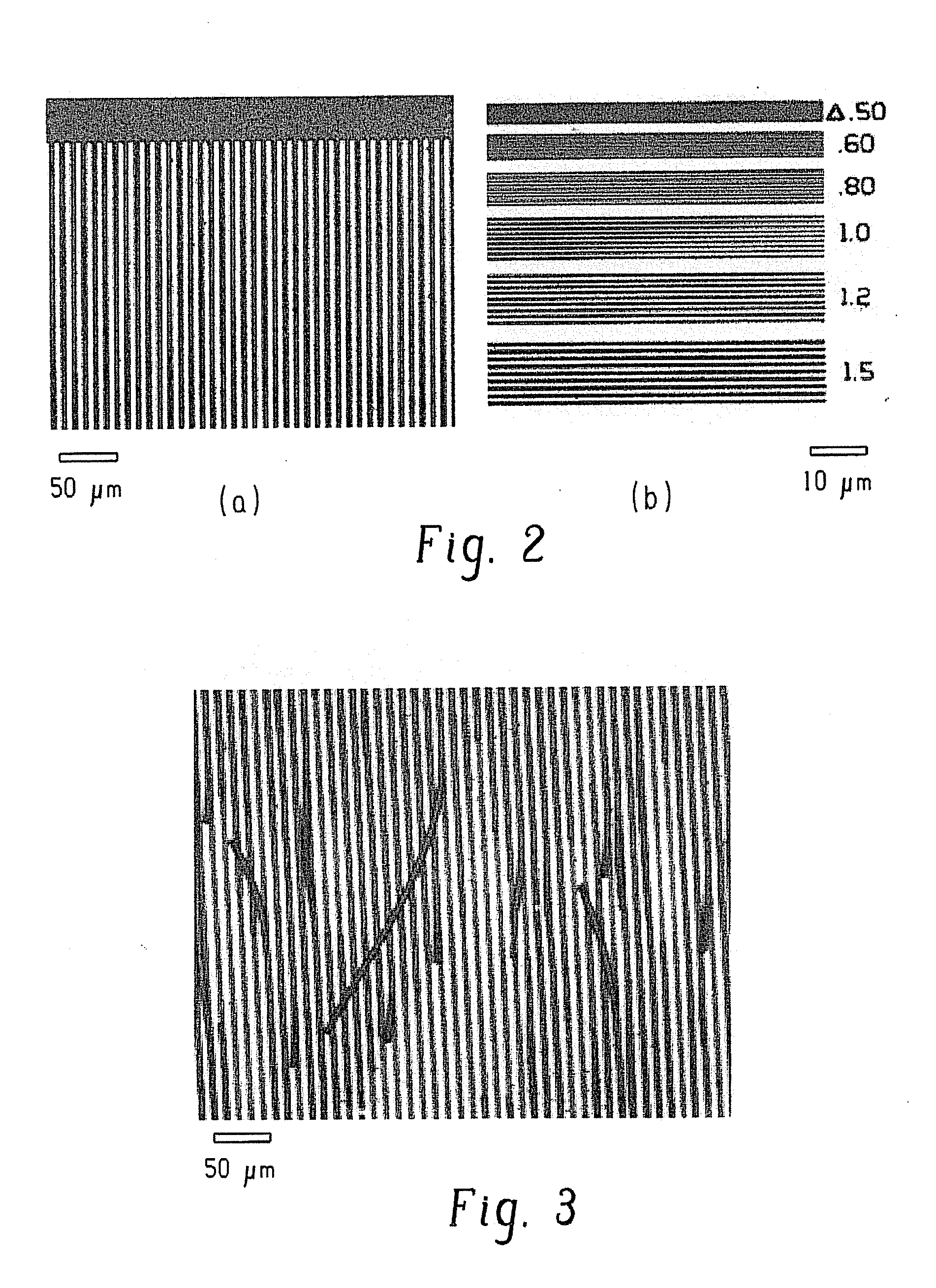

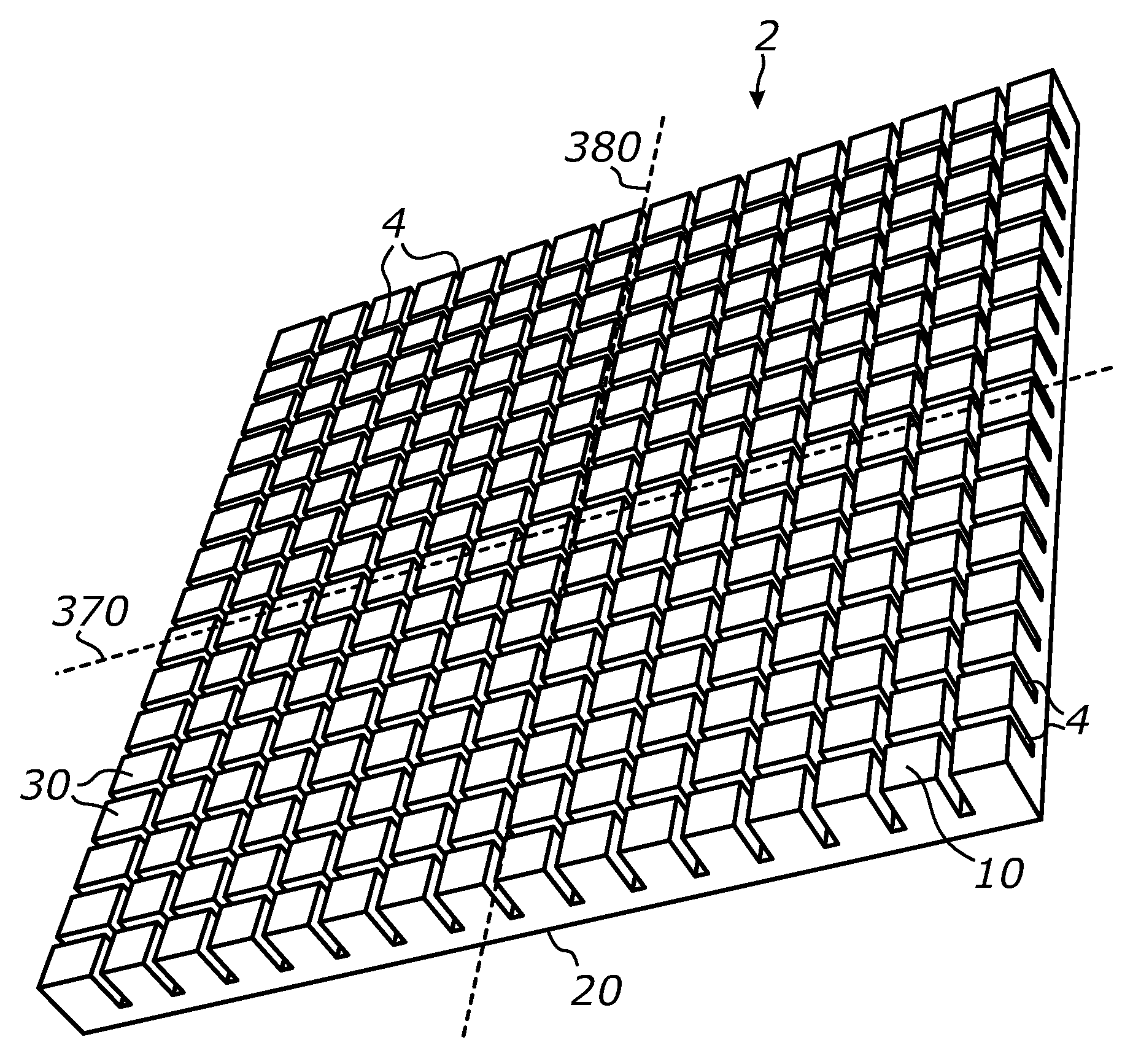

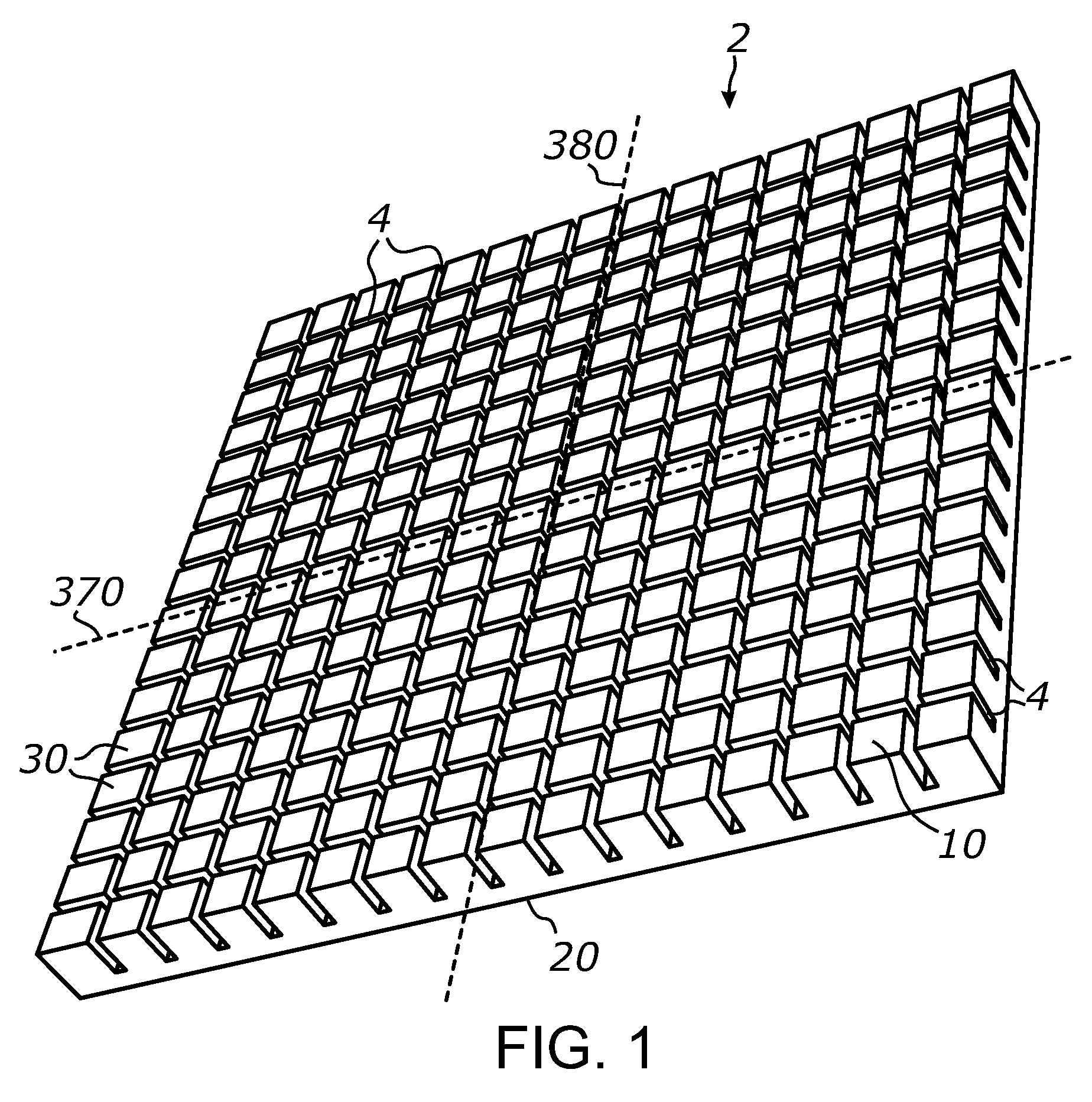

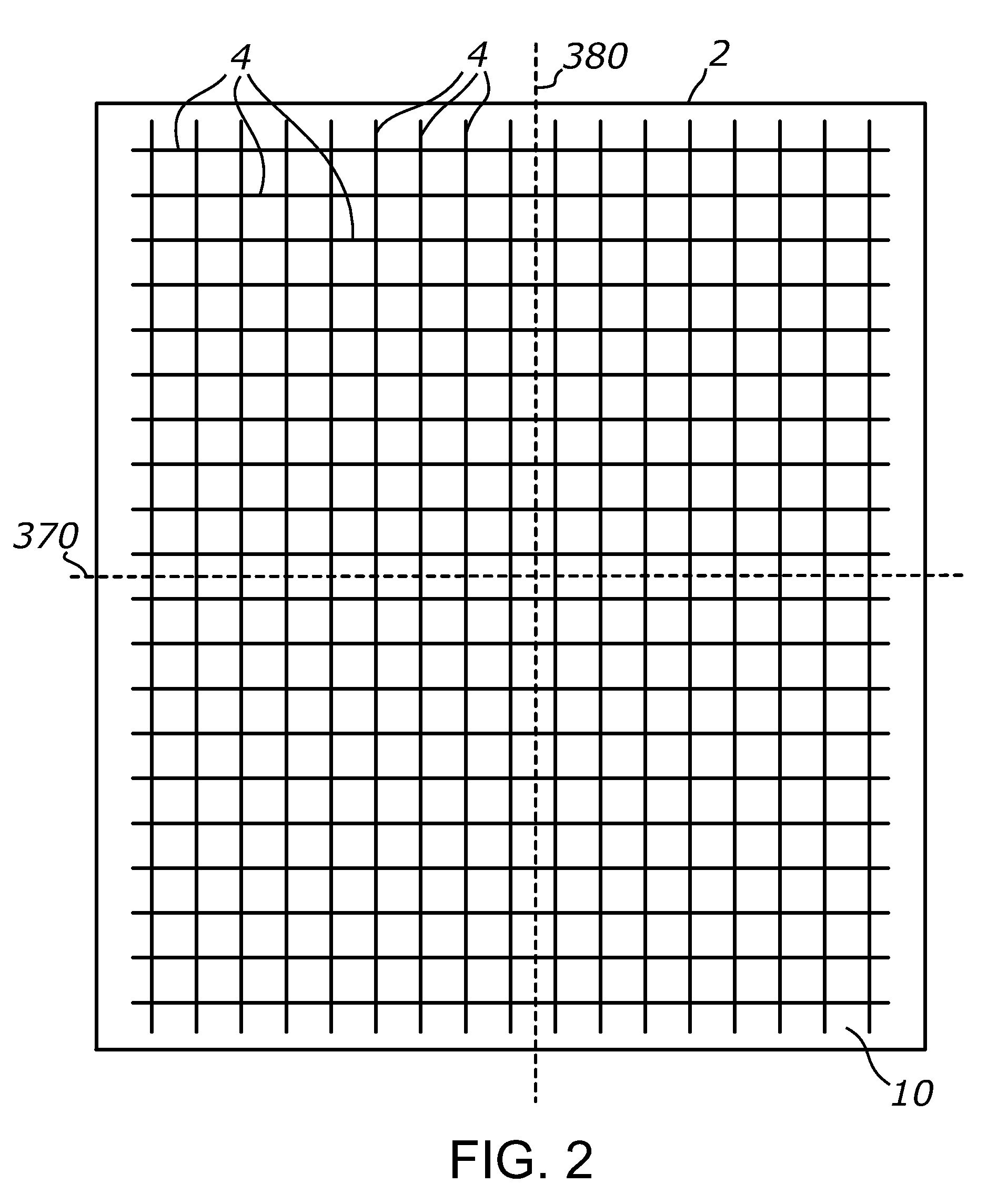

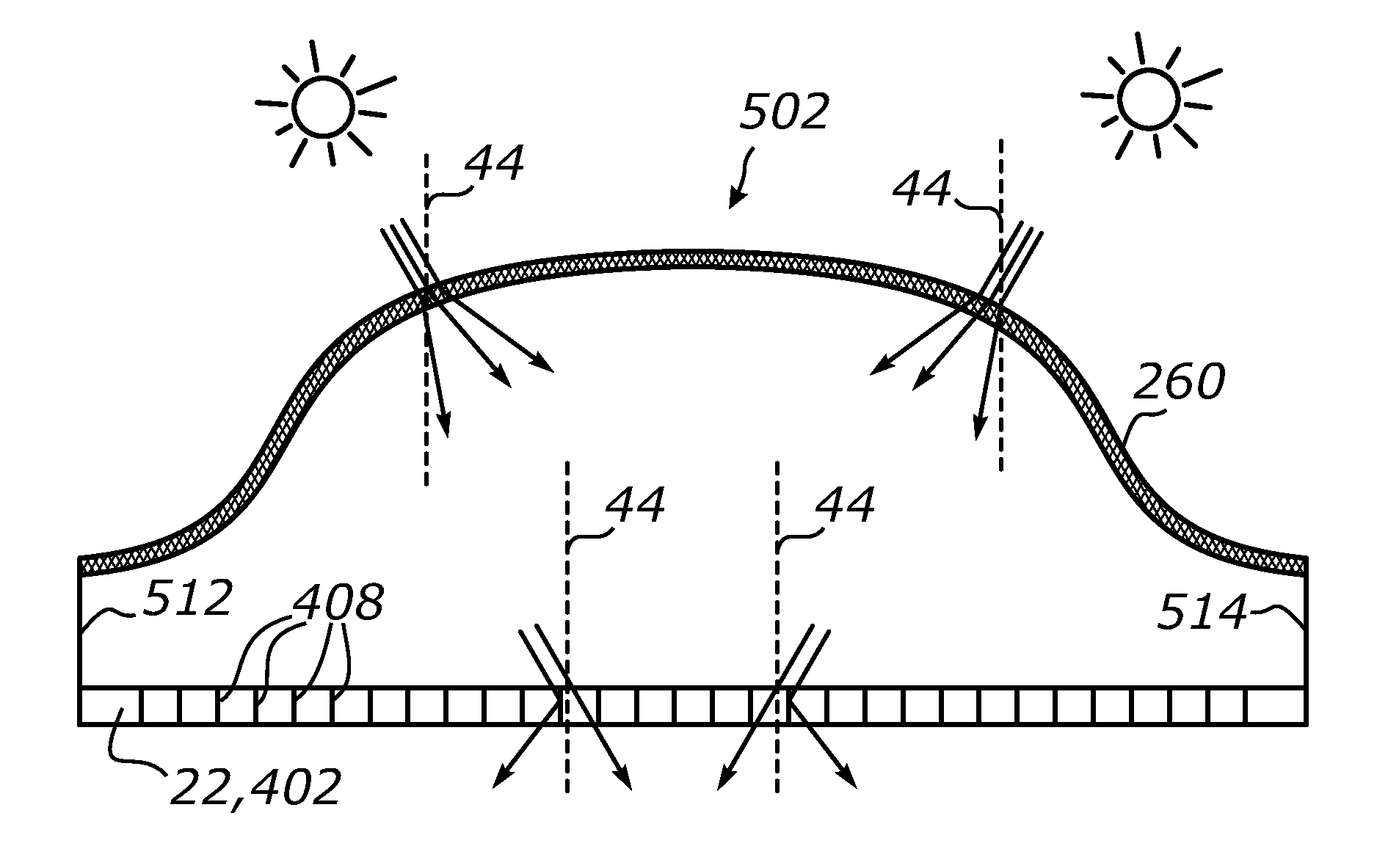

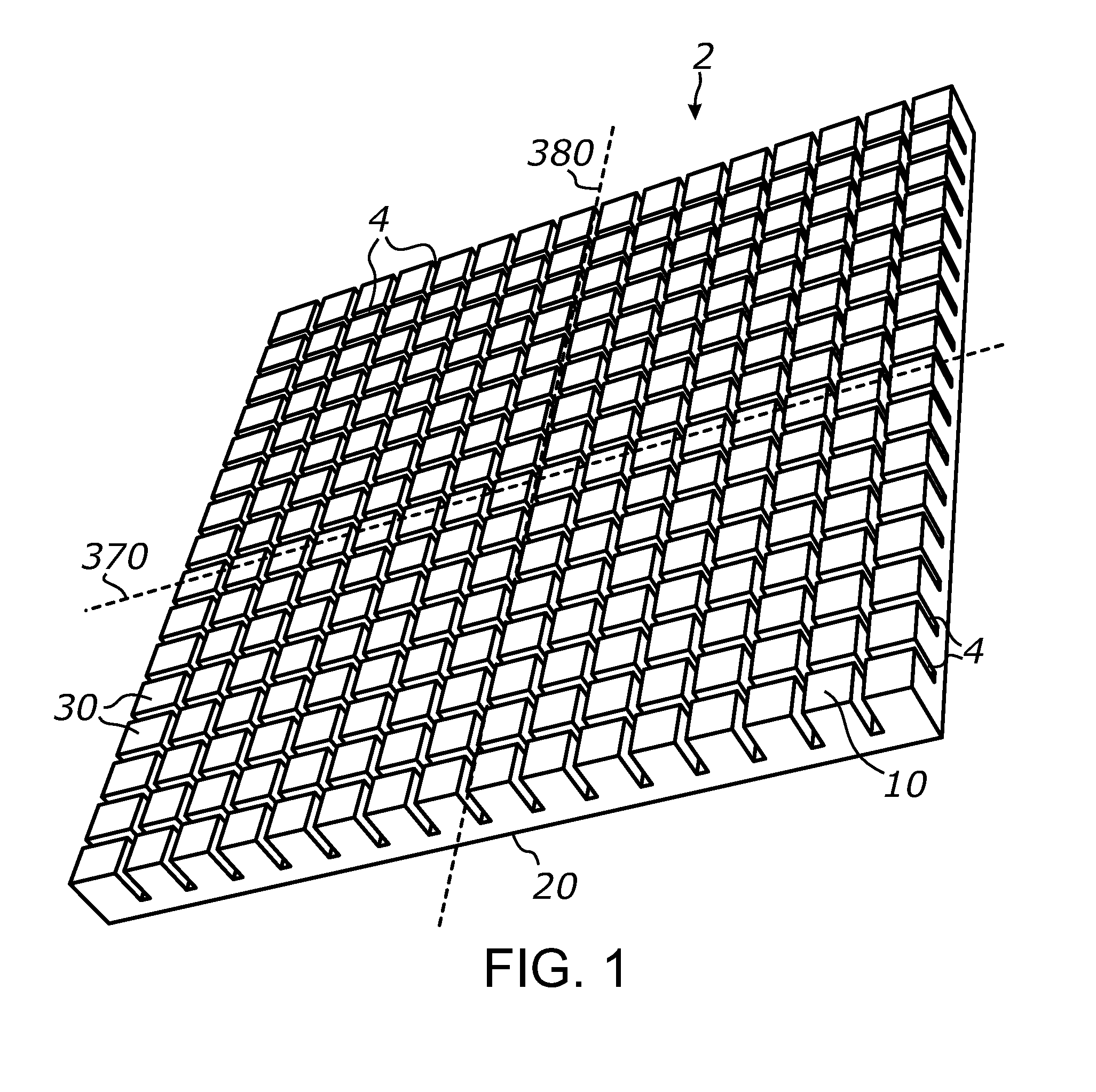

Optical article for illuminating building interiors with sunlight

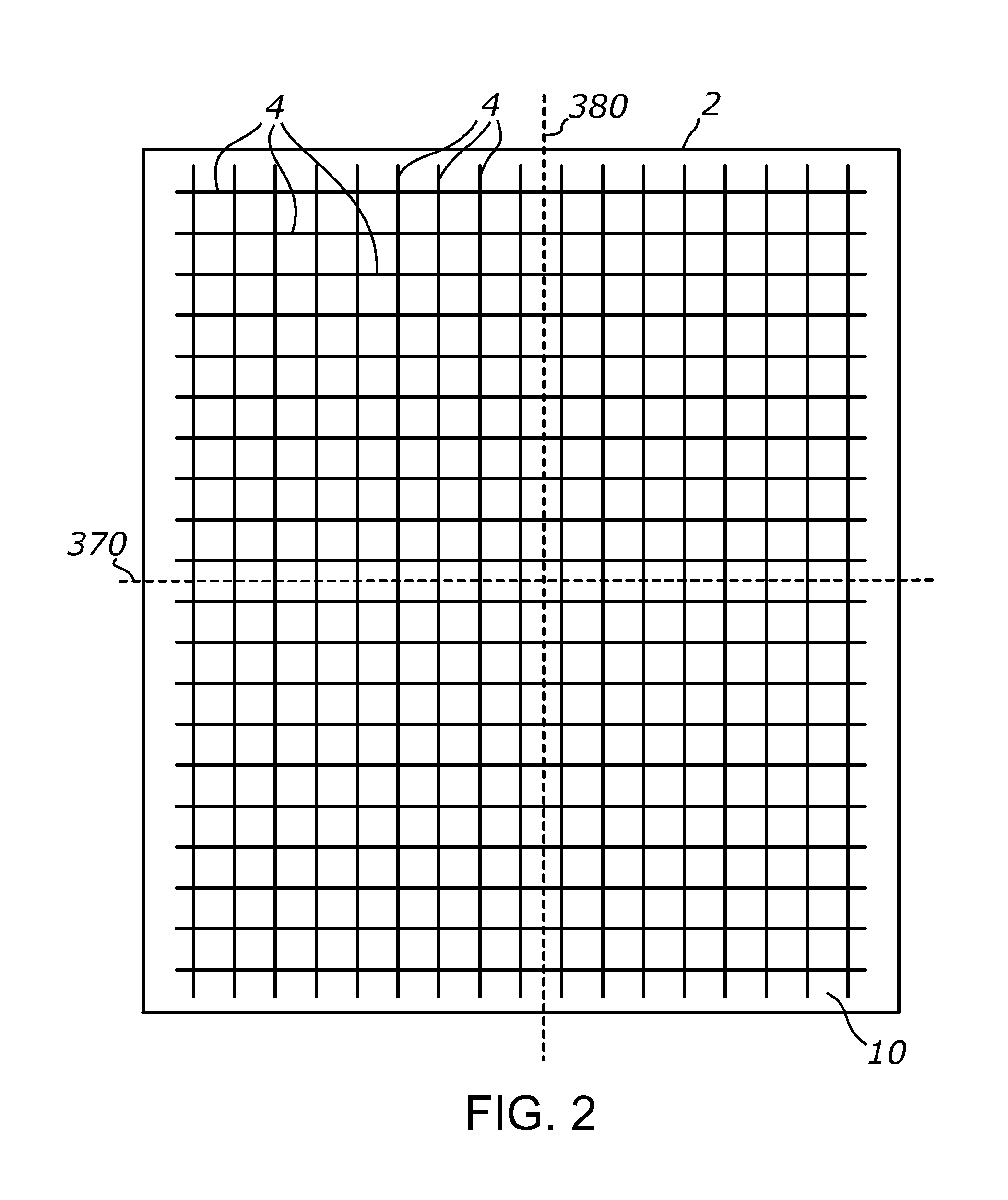

A sheet-form light-redirecting optical article for illuminating building interiors with sunlight. At least one embodiment comprises a sheet of optically transmissive rigid material, preferably Poly(methyl methacrylate), in which a plurality of deep and narrow parallel channels are formed and arranged in two perpendicular arrays. Each channel has opposing walls configured for reflecting light by means of a Total Internal Reflection (TIR). At least a portion of off-axis rays incident onto the surface of the sheet is redirected by the TIR walls of the light-guiding channels. At least one embodiment comprises a grid formed by intersecting specular reflectors and further comprises a light diffusing element optically coupled to the grid. Disclosed also are a method for making the intersecting arrays of light-redirecting channels.

Owner:S V V TECH INNOVATIONS

Optical article for illuminating building interiors with sunlight

A sheet-form light-redirecting optical article for illuminating building interiors with sunlight. At least one embodiment comprises a sheet of optically transmissive rigid material, preferably Poly(methyl methacrylate), in which a plurality of deep and narrow parallel channels are formed and arranged in two perpendicular arrays. Each channel has opposing walls configured for reflecting light by means of a Total Internal Reflection (TIR). At least a portion of off-axis rays incident onto the surface of the sheet is redirected by the TIR walls of the light-guiding channels. At least one embodiment comprises a grid formed by intersecting specular reflectors and further comprises a light diffusing element optically coupled to the grid. Disclosed also are a method for making the intersecting arrays of light-redirecting channels.

Owner:S V V TECH INNOVATIONS

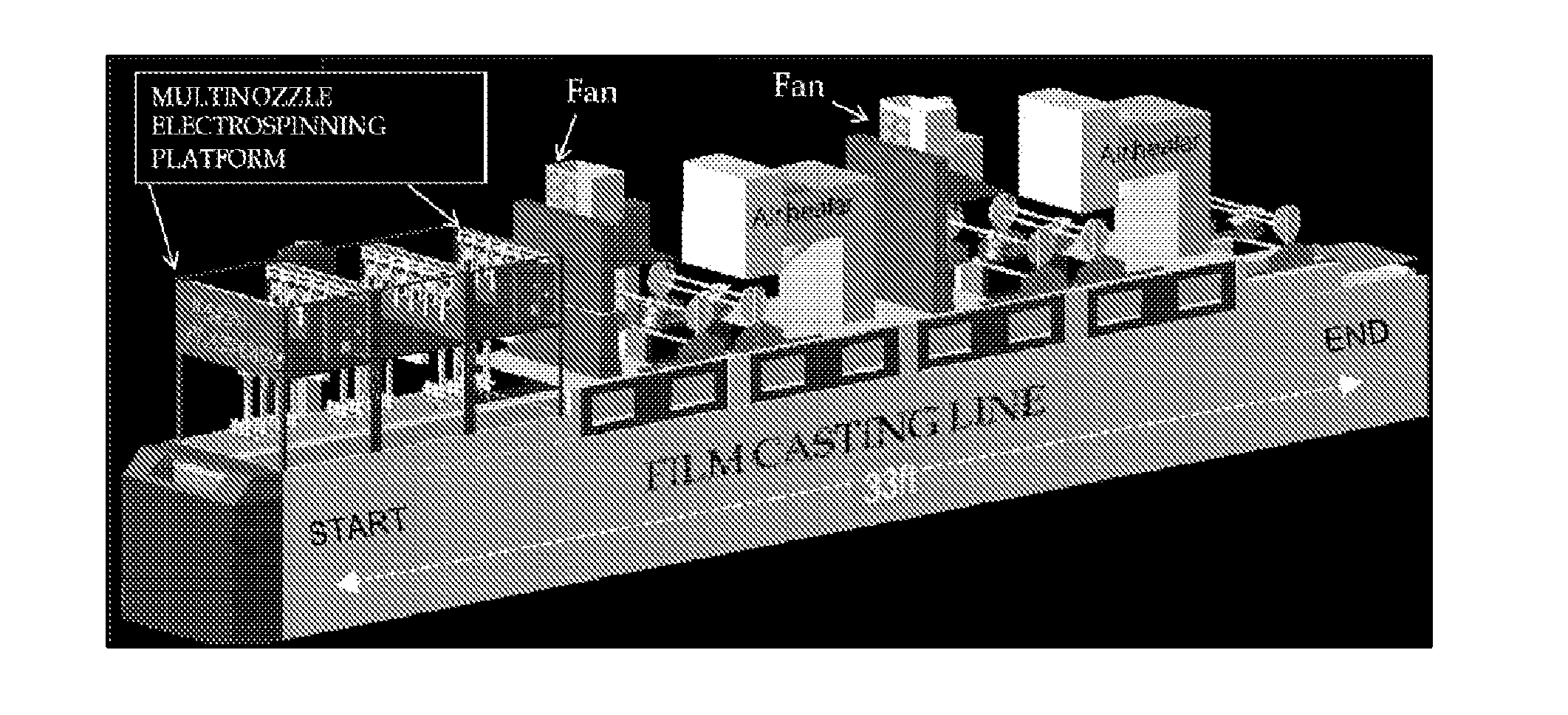

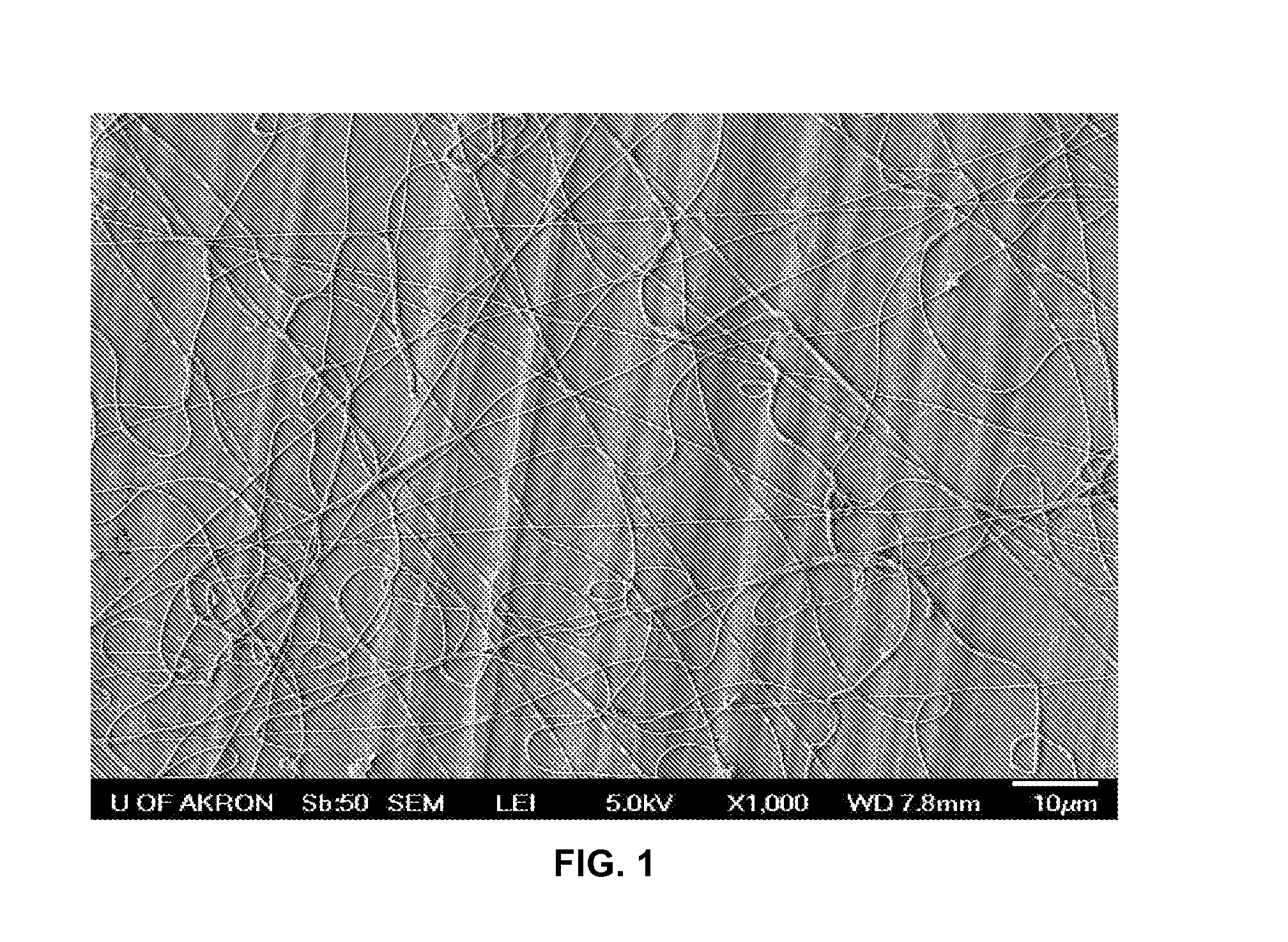

Manufacturing of multifunctional electrically conductive/transparent/flexible films

The present invention relates to a method for producing flexible, stretchable transparent and highly electrically conducting hybrid polymer films comprising electrically conductive electrospun nanofibers embedded in solution cast dielectric polymer films. In one embodiment, the present invention utilizes an electrically conductive nanofiber, or nanofiber structure, that is embedded in a suitable polymer film. In one embodiment, the electrically conductive nanofiber, or nanofiber structure, can be electrospun from a suitable polymer solution that contains a suitable amount of, for example, at least one conductive material. In one embodiment, the flexible polymer film portion of the present invention can be formed from poly(methyl methacrylate) (PMMA) or polyimide. In another embodiment, the present invention relates to flexible polymer films that have conductive structures embedded therein, wherein the flexible polymer film portion is form via a casting process to produce transparent films from, for example, polycarbonate, polyurethane and / or cyclopolyolefin polymer compositions.

Owner:THE UNIVERSITY OF AKRON

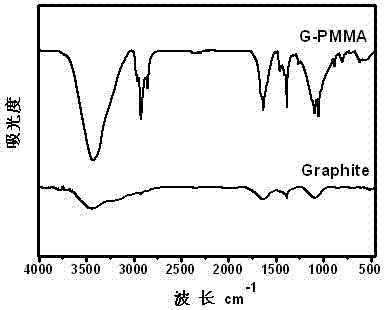

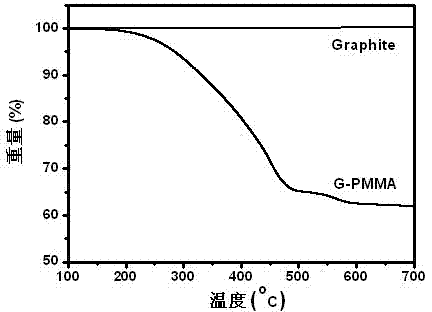

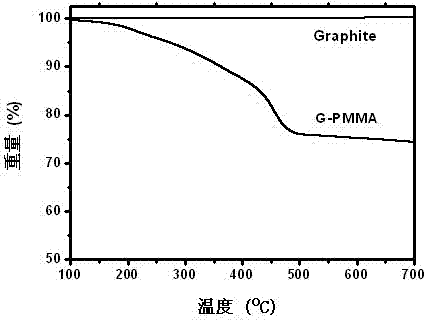

Graphene modified poly-methyl methacrylate composite and preparation method thereof

InactiveCN102408658AImprove thermal stabilityHigh breaking strengthPoly(methyl methacrylate)Young's modulus

The invention relates to a graphene modified poly-methyl methacrylate composite and preparation method thereof, wherein the method comprises the following steps: stripping graphite from 1-methyl-2-pyrrolidone by solvent ultrasonic method and preparing grapheme solution, and adding methymethacrylate and azodiisobutyronitrile and heating them, and reacting them; pouring the product into methanol, and sequentially centrifuging, washing and vacuum drying it to obtain graphene enhanced poly-methyl methacrylate composite. The 0.5% graphene enhanced poly-methyl methacrylate composite synthetized by one-step method in the invention, wherein the tensile strength is 115% higher than the pure poly-methyl methacrylate polymer, and Young modulus is raised by 221%, and excellent mechanical property is revealed. The thermogravimetric analysis displays shows that in comparison with the poly-methyl methacrylate, the temperature for the graphene enhanced poly-methyl methacrylate composite material comprising 0.5% of the invention when the thermogravimetric loss reaches 10% is raised by about 30 degrees centigrade, which means the composite material prepared by the invention has higher heat stability.

Owner:SHANGHAI JIAO TONG UNIV

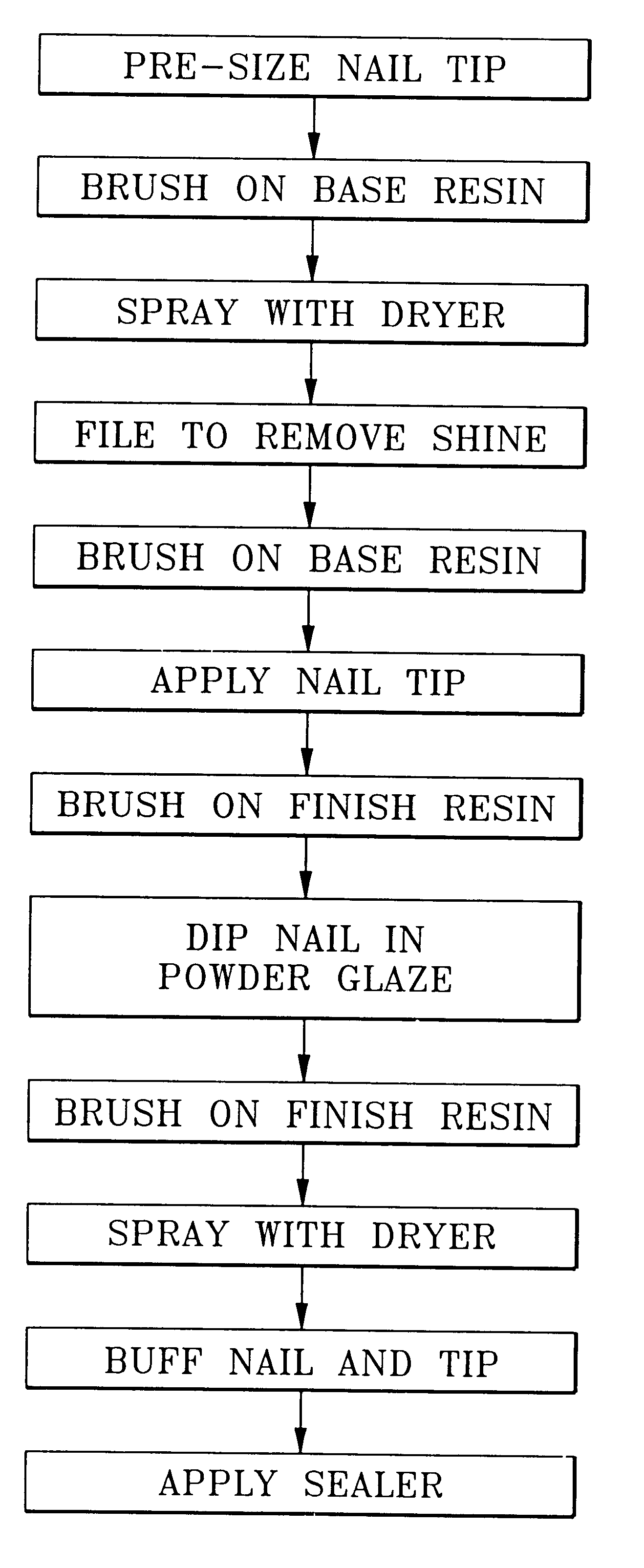

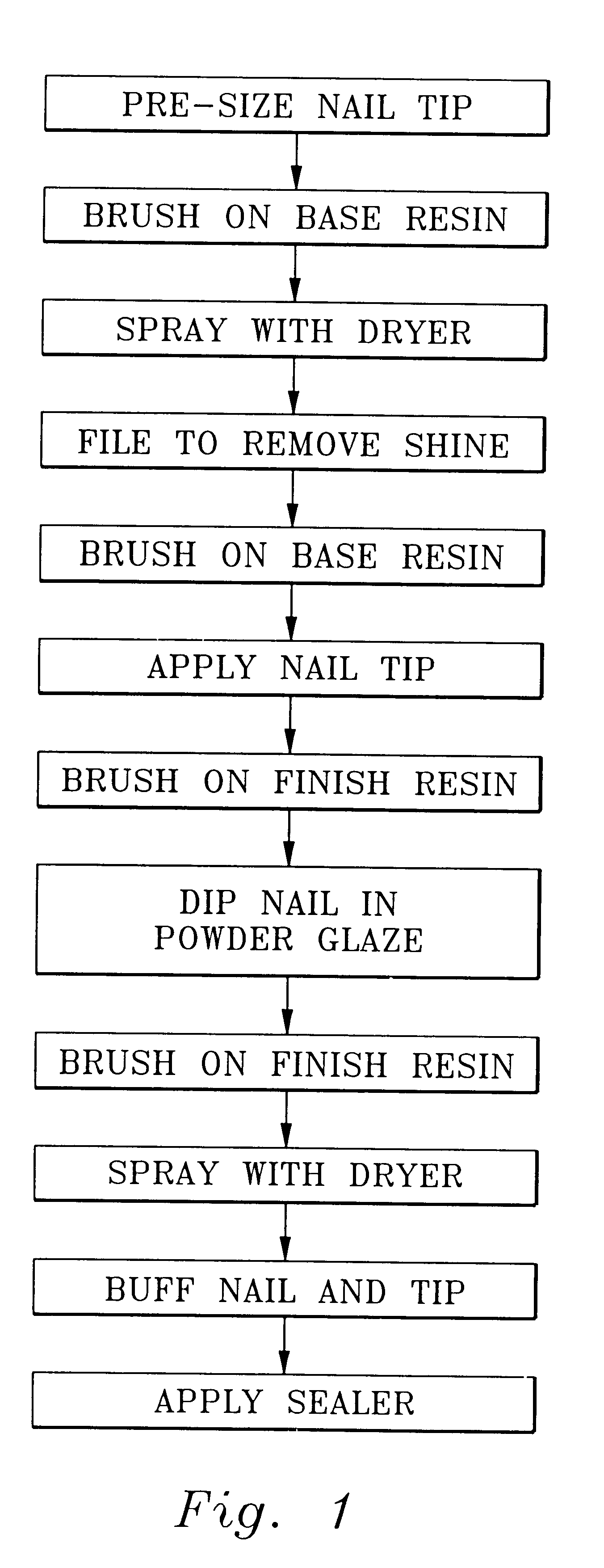

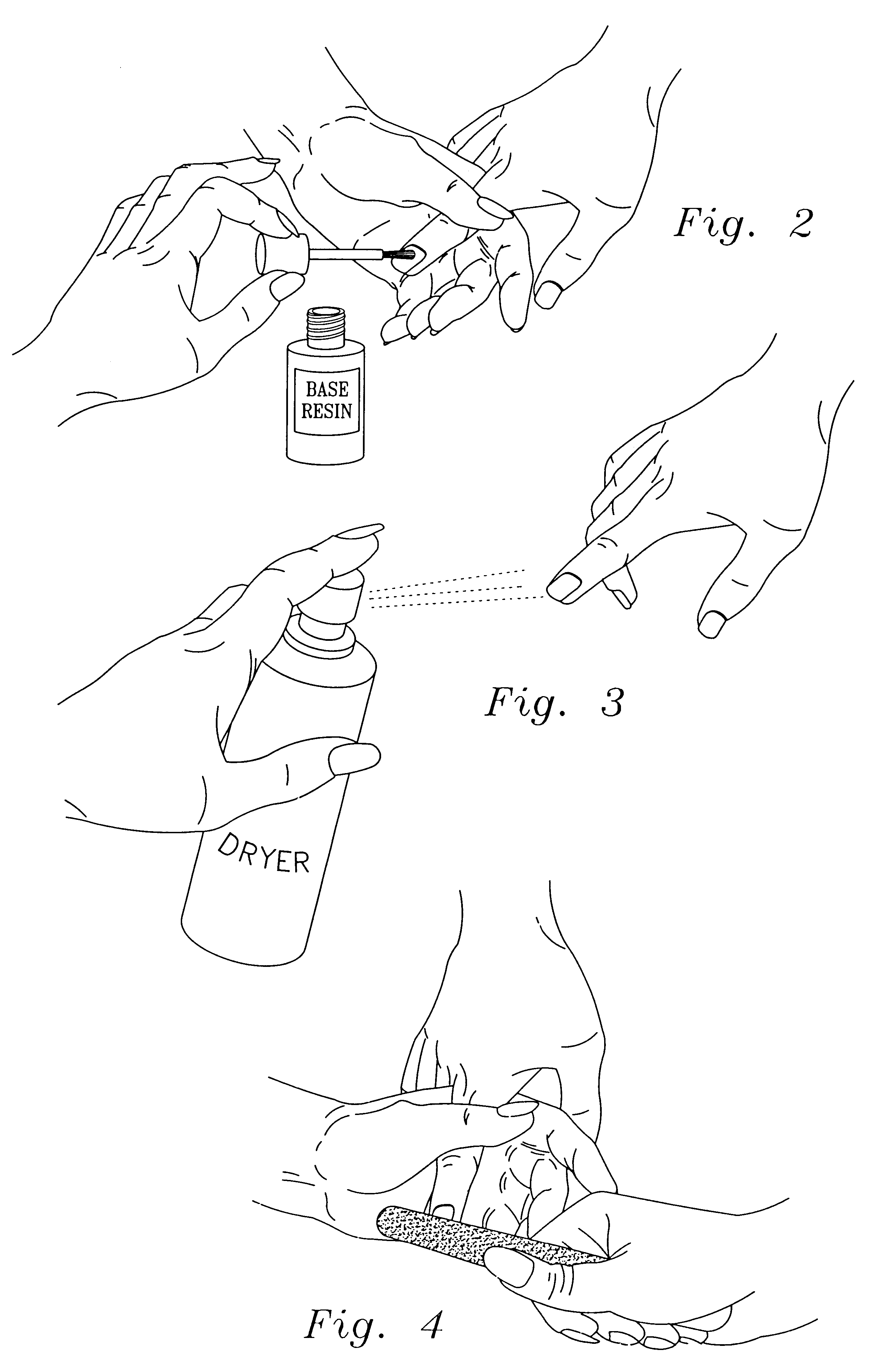

Method of applying nail tips and composition

InactiveUS6250311B1Easy to installAesthetically pleasingCurling devicesManicure/pedicureMethacrylateBenzoyl peroxide

This patent specification discloses a method and compositions for applying an artificial finger nail tip to a natural finger nail. The method applies: (i) multiple brush-on coatings of a mixture of ethyl-2-cyanoacrylate, poly methyl methacrylate, and hydroquinone; (ii) several spray coatings of an aromatic dryer of ethyl acetate and aromatic amines; and (iii) at least one dip of glaze powder of poly (ethyl or ethyl / methyl) methacrylate, benzoyl peroxide, and silica as an opaquing agent. The preferred method is very easy to perform and does not require any use of polymer solvents or grinding or filing steps.

Owner:BACKSCRATCHERS

Process for removing a contaminant from coal tar

InactiveUS20150136660A1Lower Level RequirementsRefining with metalsTreatment with plural serial stages onlyPolycyclic aromatic hydrocarbonSorbent

A process for removing at least one contaminant from coal tar is described. The process involves extraction with an extraction agent or adsorption with an adsorbent. The extraction agent includes at least one of amphiphilic block copolymers, inclusion complexes of poly(methyl methacrylate) and polycyclic aromatic hydrocarbons, cyclodextrins, functionalized cyclodextrins, and cyclodextrin-functionalized polymers, and the adsorbent includes exfoliated graphite oxide, thermally exfoliated graphite oxide or intercalated graphite compounds.

Owner:UOP LLC

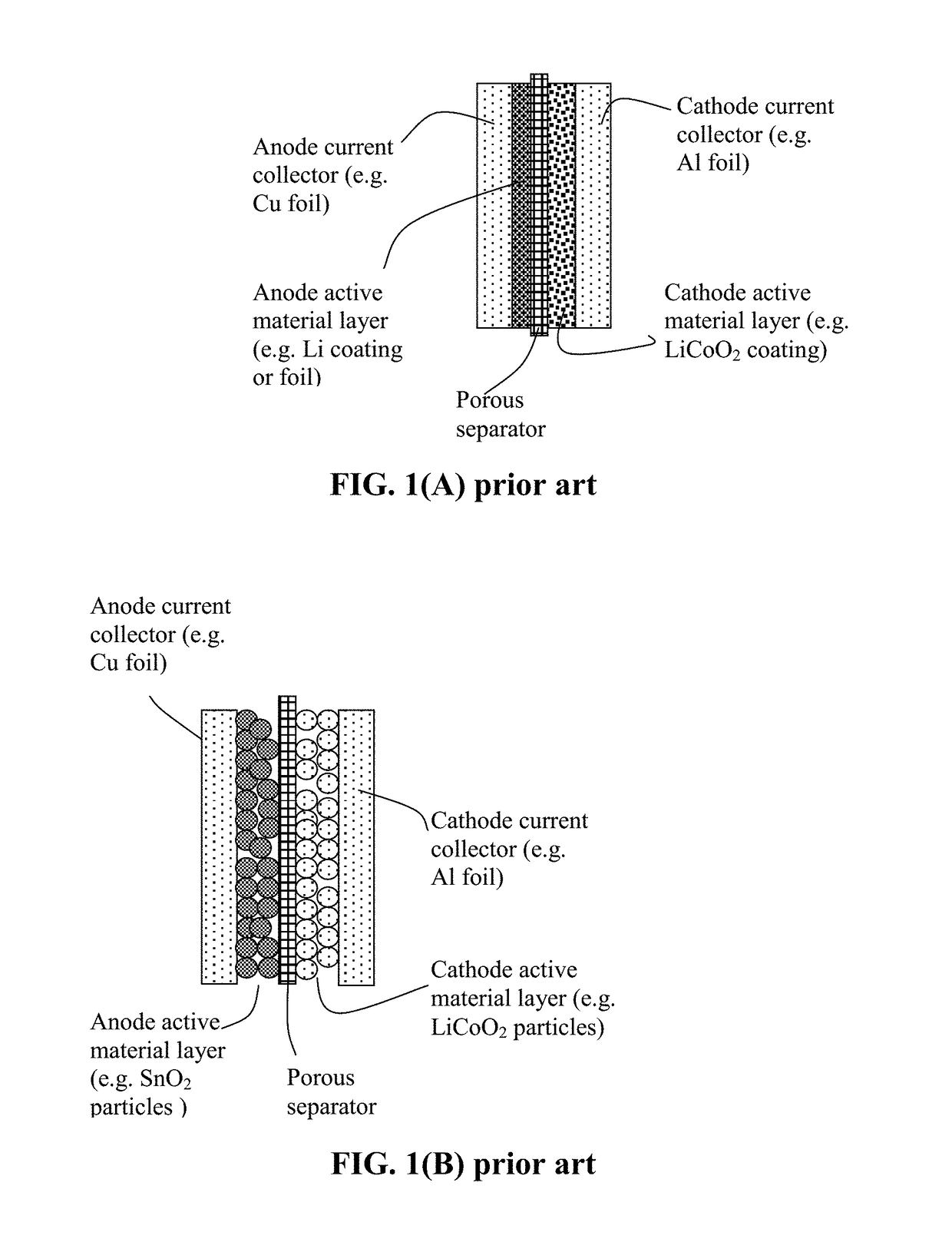

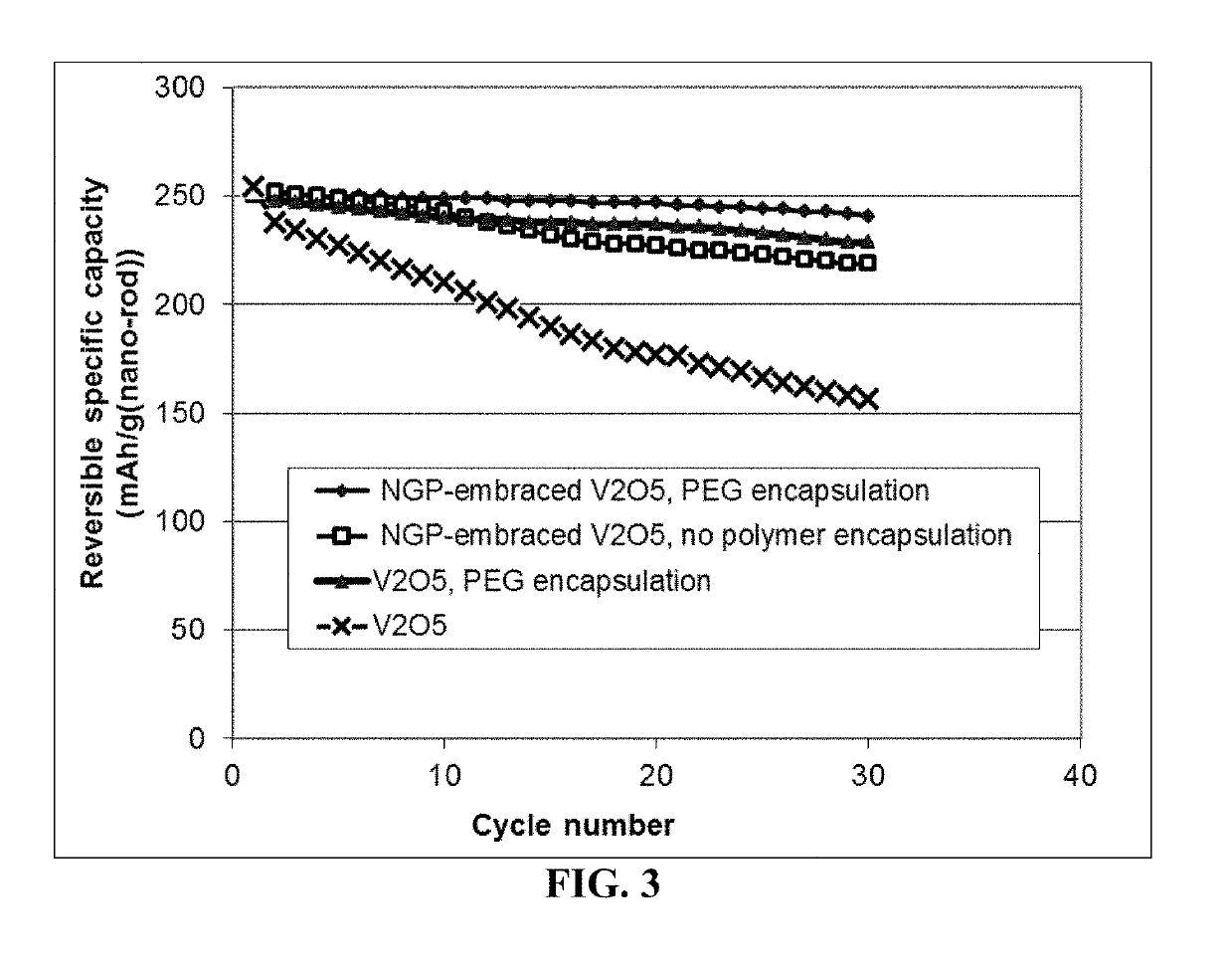

Encapsulated Cathode Active Material Particles, Lithium Secondary Batteries Containing Same, and Method of Manufacturing

ActiveUS20180294474A1High molecular weightInhibition of dissolutionSolid electrolytesCell electrodesParticulatesPolyethylene oxide

Provided is particulate of a cathode active material for a lithium battery, comprising one or a plurality of cathode active material particles being embraced or encapsulated by a thin layer of a high-elasticity polymer having a recoverable tensile strain no less than 5%, a lithium ion conductivity no less than 10−6 S / cm at room temperature, and a thickness from 0.5 nm to 10 μm, wherein the polymer contains an ultrahigh molecular weight (UHMW) polymer having a molecular weight from 0.5×106 to 9×106 grams / mole. The UHMW polymer is preferably selected from polyacrylonitrile, polyethylene oxide, polypropylene oxide, polyethylene glycol, polyvinyl alcohol, polyacrylamide, poly(methyl methacrylate), poly(methyl ether acrylate), a copolymer thereof, a sulfonated derivative thereof, a chemical derivative thereof, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

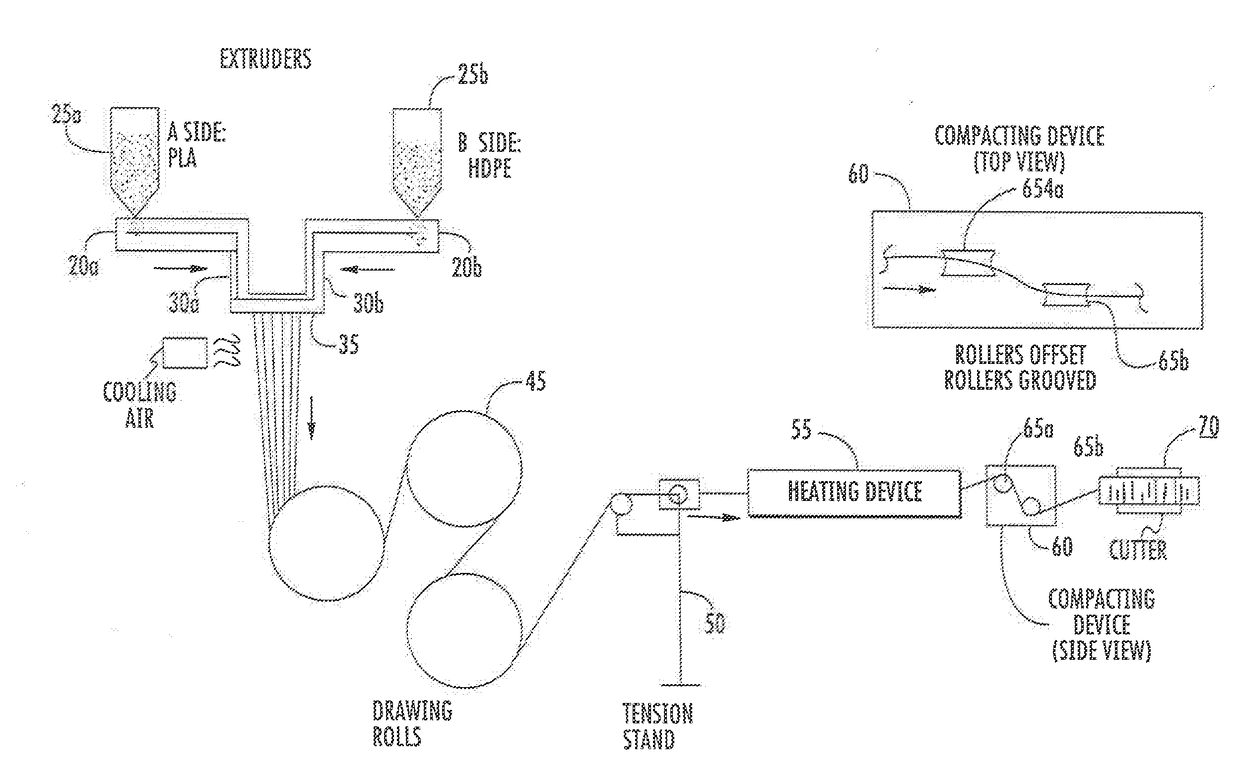

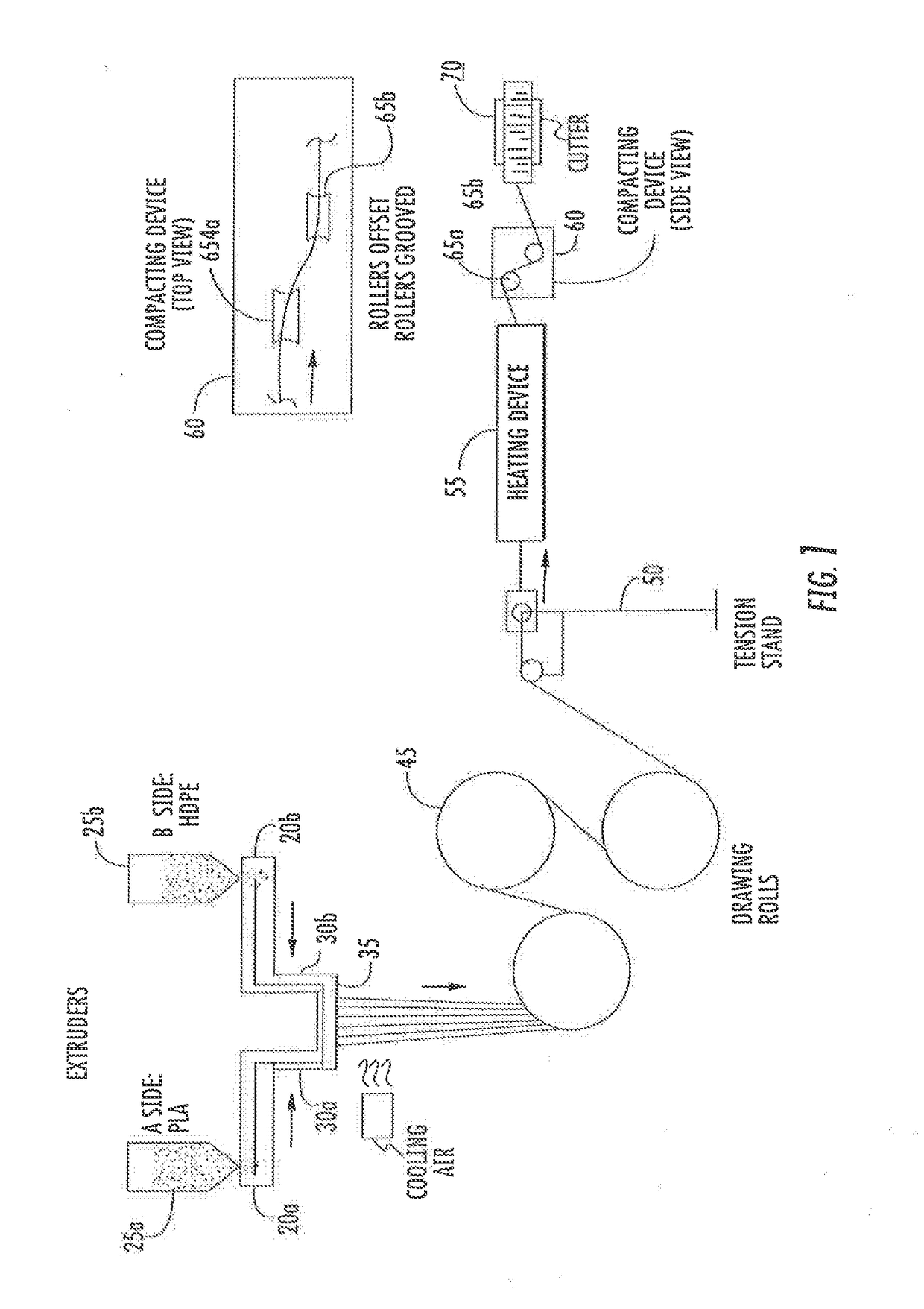

Bicomponent fiber additive delivery composition

InactiveUS20180223454A1Physical treatmentFilament/thread formingLow-density polyethylenePolyethylene terephthalate glycol

The biocomponent fiber functions as a carrier or vehicle for delivering additives to a polymer composition. The bicomponent fiber may be “splittable segmented pie” or “island-in-the-sea” construction with the sea being the low melt temperature component and the island being the high melt temperature component. The low melt temperature polymer may be selected from the group consisting of low density polyethylene (LDPE), high density polyethylene (HDPE), polylactic acid (PLA), polyhydroxyalkenoate (PHA), polypropylene (PP), polystyrene (PS), polyvinylidene fluoride, polybutylene succinate (PBS), low melt temperature polyethylene terephthalate, polytrimethylene terephthalate (PTT) and low melt temperature nylons. The high melt temperature component polymer is selected from the group consisting of polyethylene terephthalate (PET), co-polyester, polybutylene terephthalate (PBT), poly (methyl methacrylate) (PMMA), polytetrafluoroethylene (PTFE), polyether ether ketones (PEEK), polyphenylene sulfides (PPS), high melt temperature nylon, polylactic acid (PLA), including stereocomplex PLA, namely 100% PDLA, 100% PLLA or a 50 / 50 blend of 100% PDLA and 100% PLLA.

Owner:EARTH RENEWABLE TECH

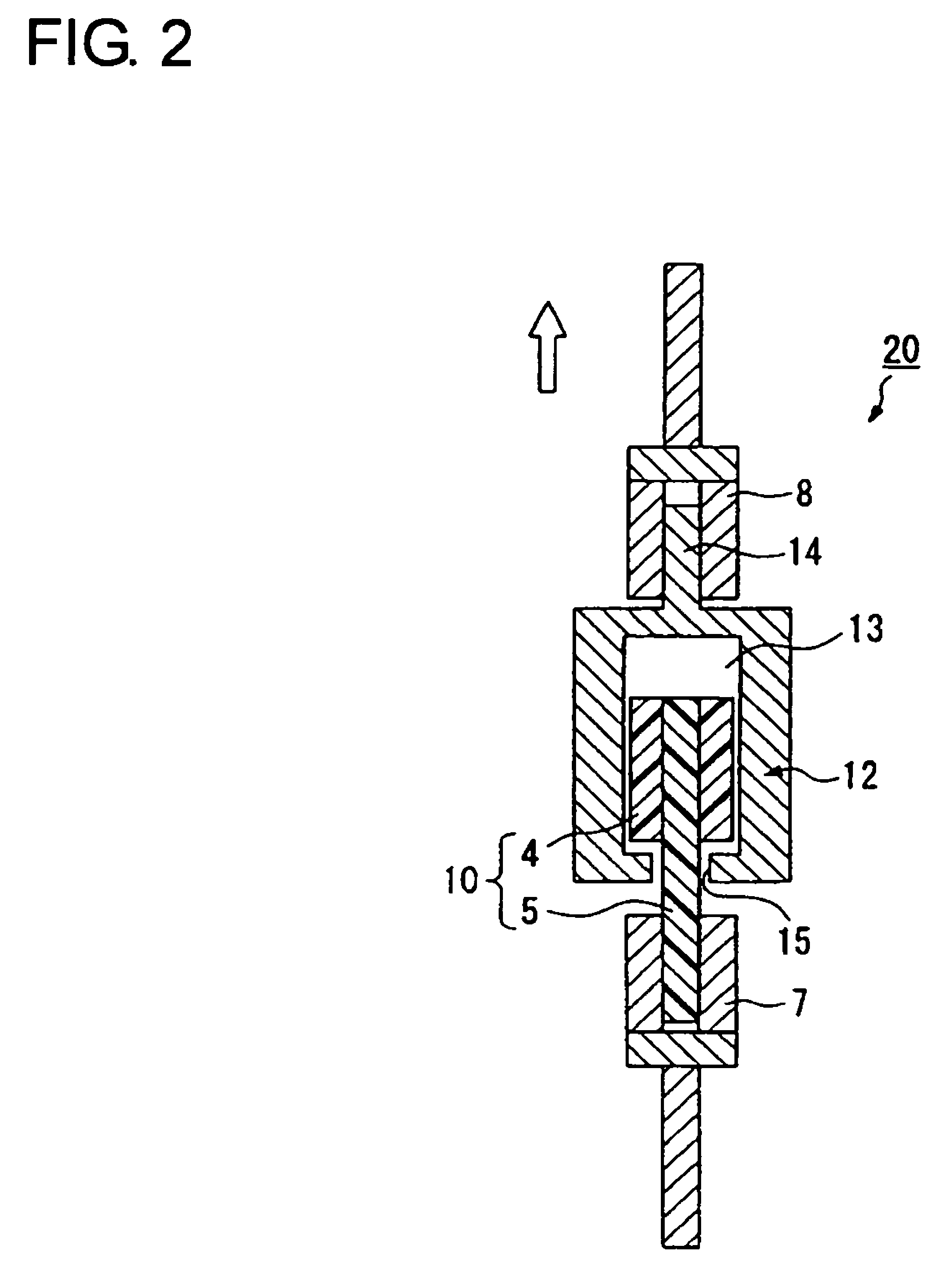

Method of making graded index polymeric optical fibers

InactiveUS6106745AImprove scalabilityReduced melt strengthOptical fibre with graded refractive index core/claddingOptical articlesFiberPolymer science

Disclosed is a method of making a graded index polymer optical fiber comprising a multicomponent spinning process employing spinning masses comprising a core spinning mass and a sheath spinning mass, the spinning masses comprising a polymer, a polymerizable monomer, and an initiator. The monomer in the core spinning mass has a higher refractive index than the monomer in the sheath spinning mass, and the spinning masses are extruded and cured. The spinning conditions are chosen such that the monomers are substantially contained within the fiber during extrusion and curing and the total of the spinning masses is intrinsically thread forming. The spinning masses may be extruded in, e.g., water. The core and the sheath polymer may be, e.g., poly(methyl methacrylate); the core monomer may be methyl methacrylate, and the sheath monomer may be 2,2,3,3-tetrafluoropropyl methacrylate; or the core and the sheath polymer may be, e.g., poly(styrene-co-acrylonitrile); the core monomer may be benzyl methacrylate, and the sheath monomer may be methyl methacrylate. The spinning masses are solutions of the polymer in the monomer having a polymer concentration of from 20 to 70% by weight.

Owner:AKZO NOBEL NV

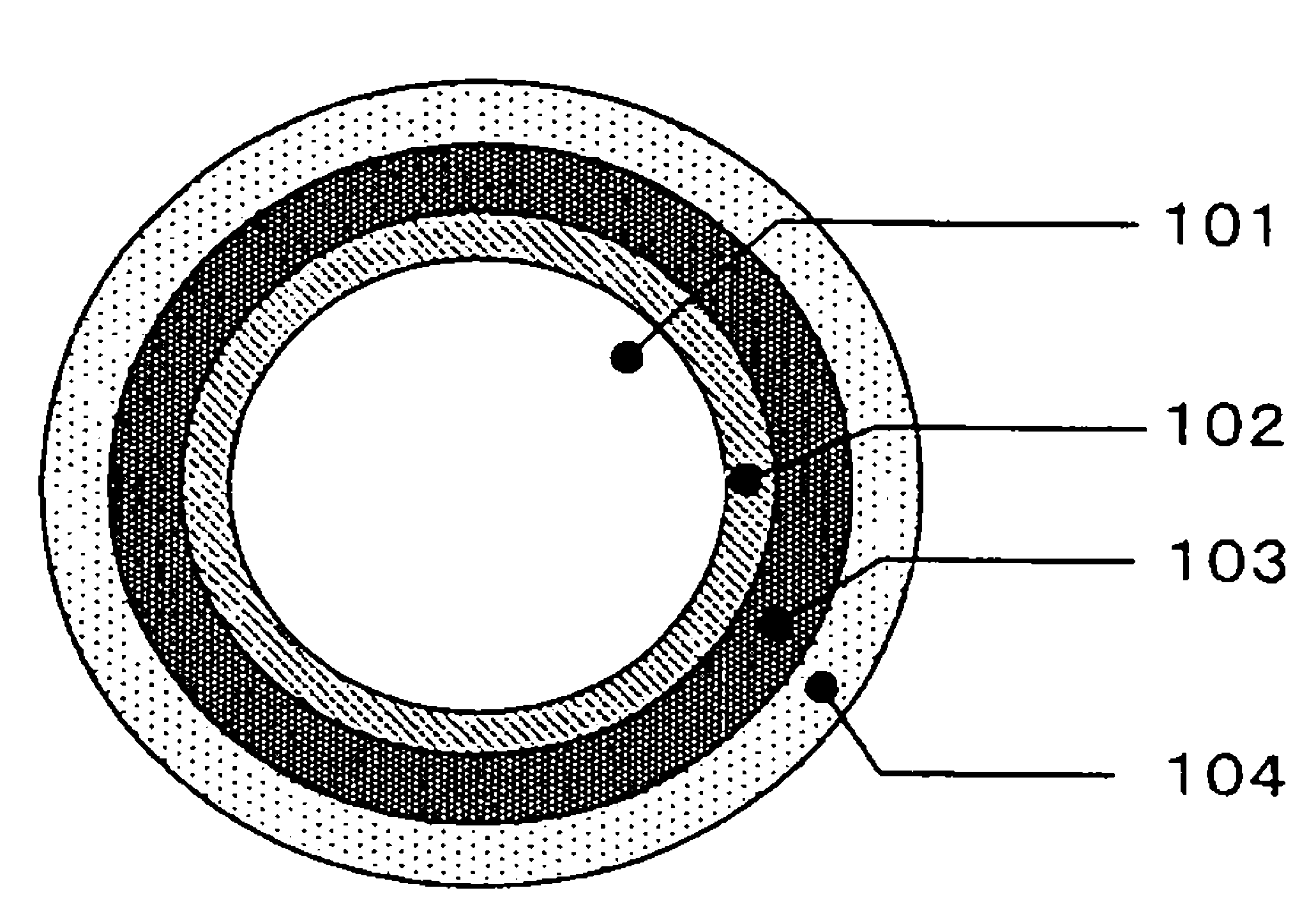

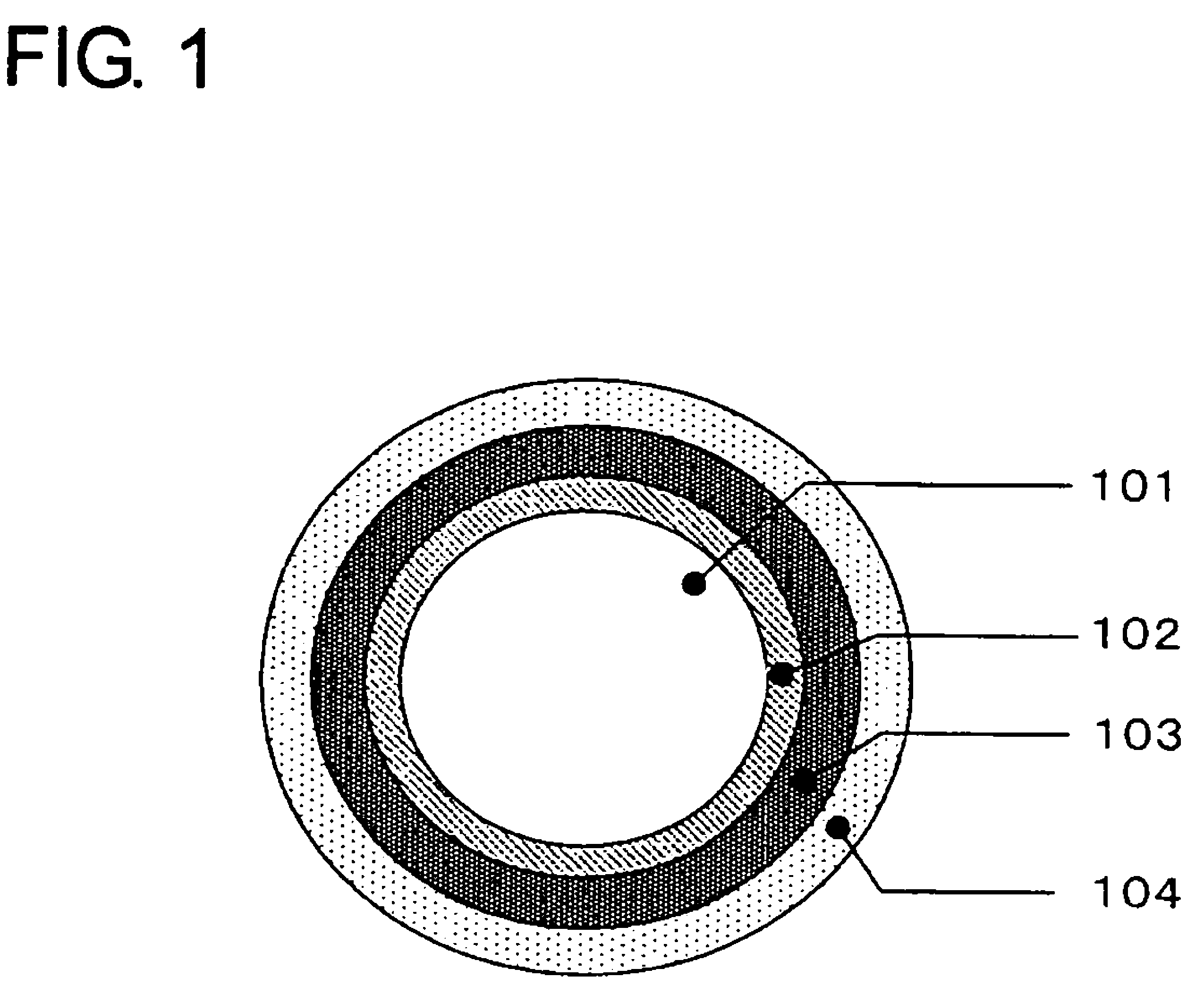

Plastic optical fiber cable and method of signal transmission using the same

ActiveUS8023789B2Improve transmission lossExcellent long-term heat resistanceOptical fibre with multilayer core/claddingFibre mechanical structuresPoly(methyl methacrylate)Engineering

Owner:MITSUBISHI CHEM CORP

Blends of amorphous and semicrystalline polymers having shape memory properties

InactiveUS20070135578A1High modulusDental impression compositionsPolyethylene glycolPoly(methyl methacrylate)

Owner:UNIV OF CONNECTICUT

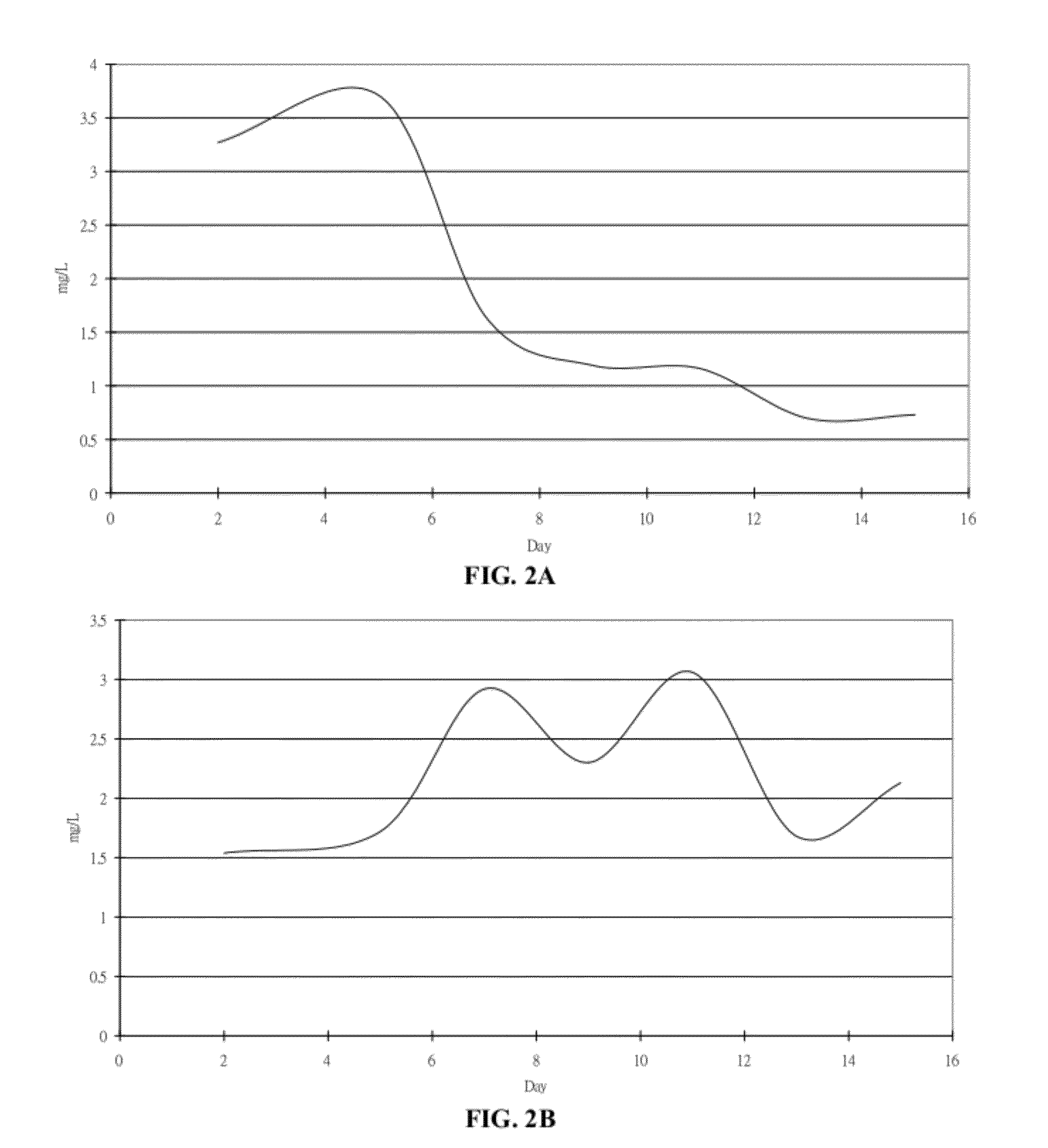

Strontium-containing bioactive bone cement

InactiveUS20120195848A1Sufficient radiopacityLow toxicityCosmetic preparationsImpression capsStrontiumPoly(methyl methacrylate)

The present invention provides bioactive bone cements that not only have sufficient radiopacity, low physiological toxicity, and requisite mechanism strength, but also promote local bone in-growth. The bone cement utilizes strontium salts as radiopacifiers, and comprises a powder component and a liquid component. In an embodiment, the powder component comprises a strontium salt, poly(methyl methacrylate) (PMMA), and a polymerization initiator; and the liquid component comprises methyl methacrylate (MMA) as reactive monomers and a polymerization accelerator.

Owner:THE UNIVERSITY OF HONG KONG

Surface-Stabilized Cathode Active Material Particles, Lithium Secondary Batteries Containing Same, and Method of Manufacturing

PendingUS20190115591A1Inhibition of dissolutionPositive electrodesLi-accumulatorsParticulatesMethacrylate

Provided is particulate of a cathode active material for a lithium battery, comprising one or a plurality of cathode active material particles being embraced or encapsulated by a thin layer of a high-elasticity polymer having a recoverable tensile strain no less than 5%, a lithium ion conductivity no less than 10−6 S / cm at room temperature, and a thickness from 0.5 nm to 10 μm, wherein the polymer contains an ultrahigh molecular weight (UHMW) polymer having a molecular weight from 0.5×106 to 9×106 grams / mole. The UHMW polymer is preferably selected from polyacrylonitrile, polyethylene oxide, polypropylene oxide, polyethylene glycol, polyvinyl alcohol, polyacrylamide, poly(methyl methacrylate), poly(methyl ether acrylate), a copolymer thereof, a sulfonated derivative thereof, a chemical derivative thereof, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

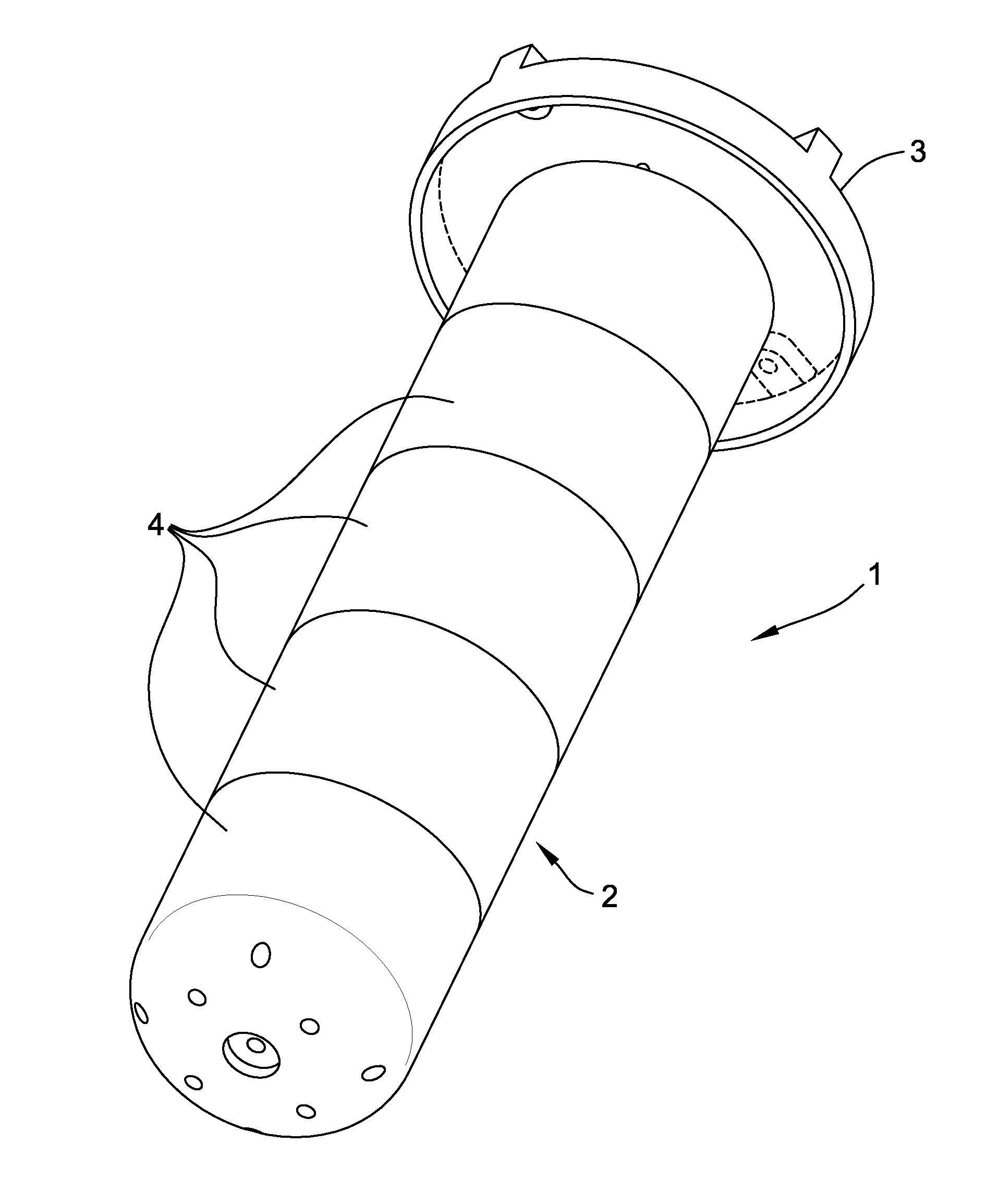

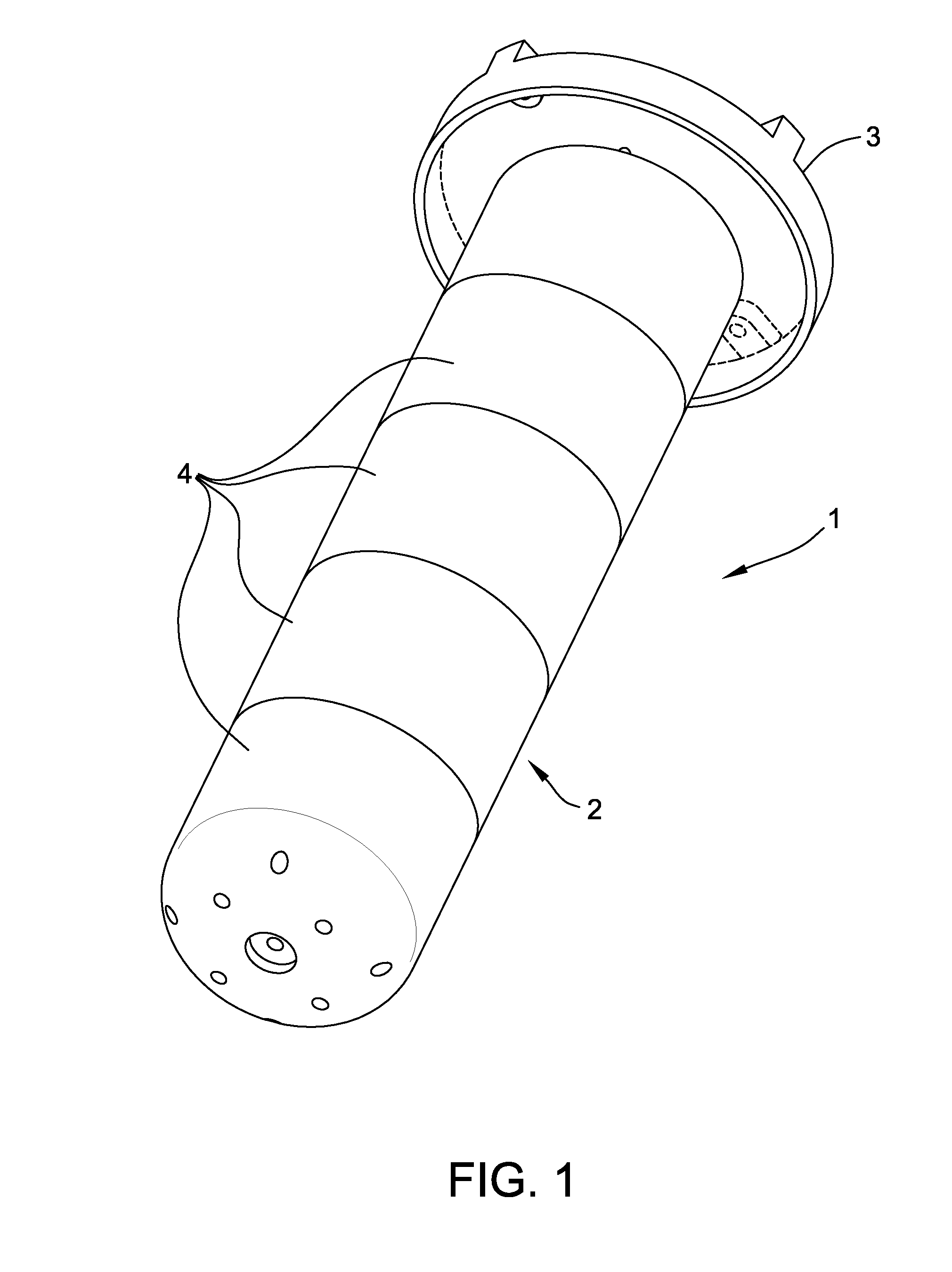

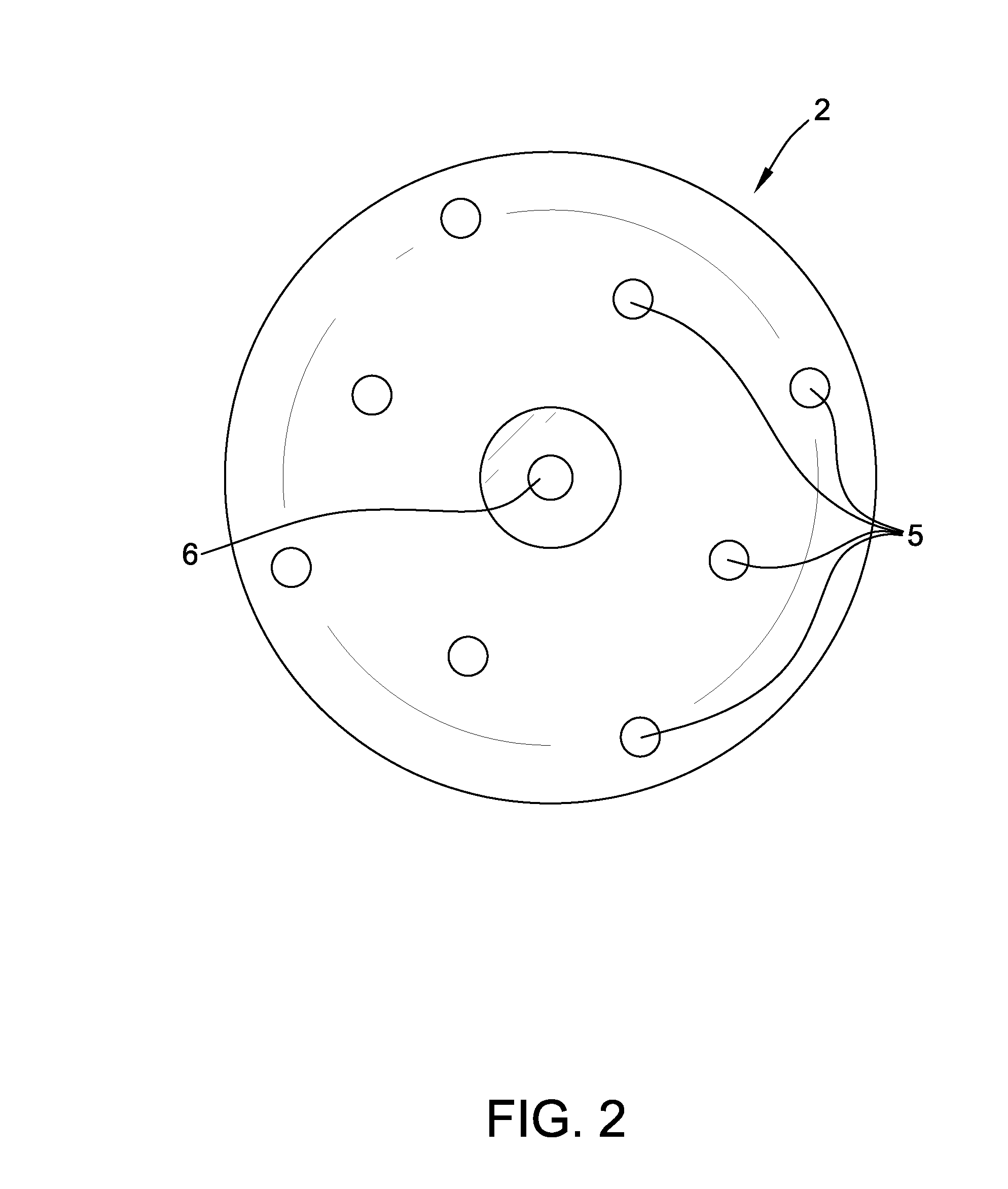

Devices and methods for treatment of cancers

ActiveUS20140309478A1X-ray/gamma-ray/particle-irradiation therapyBrachytherapyPoly(methyl methacrylate)

Devices and methods for brachytherapy treatment are disclosed. One aspect is a poly(methyl methacrylate) apparatus for brachytherapy treatment at the vaginal apex. Another aspect is a poly(methyl methacrylate) apparatus for brachytherapy treatment in the distal two-thirds of the vagina. Another aspect is a poly(methyl methacrylate) apparatus for brachytherapy treatment of cancers that are offset from the vaginal apex. Other aspects include methods for guiding needles for treatment of cancers at the vaginal apex, in the distal two-thirds of the vagina, and that are offset from the vaginal apex.

Owner:WASHINGTON UNIV IN SAINT LOUIS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com