Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85 results about "Benzyl methacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

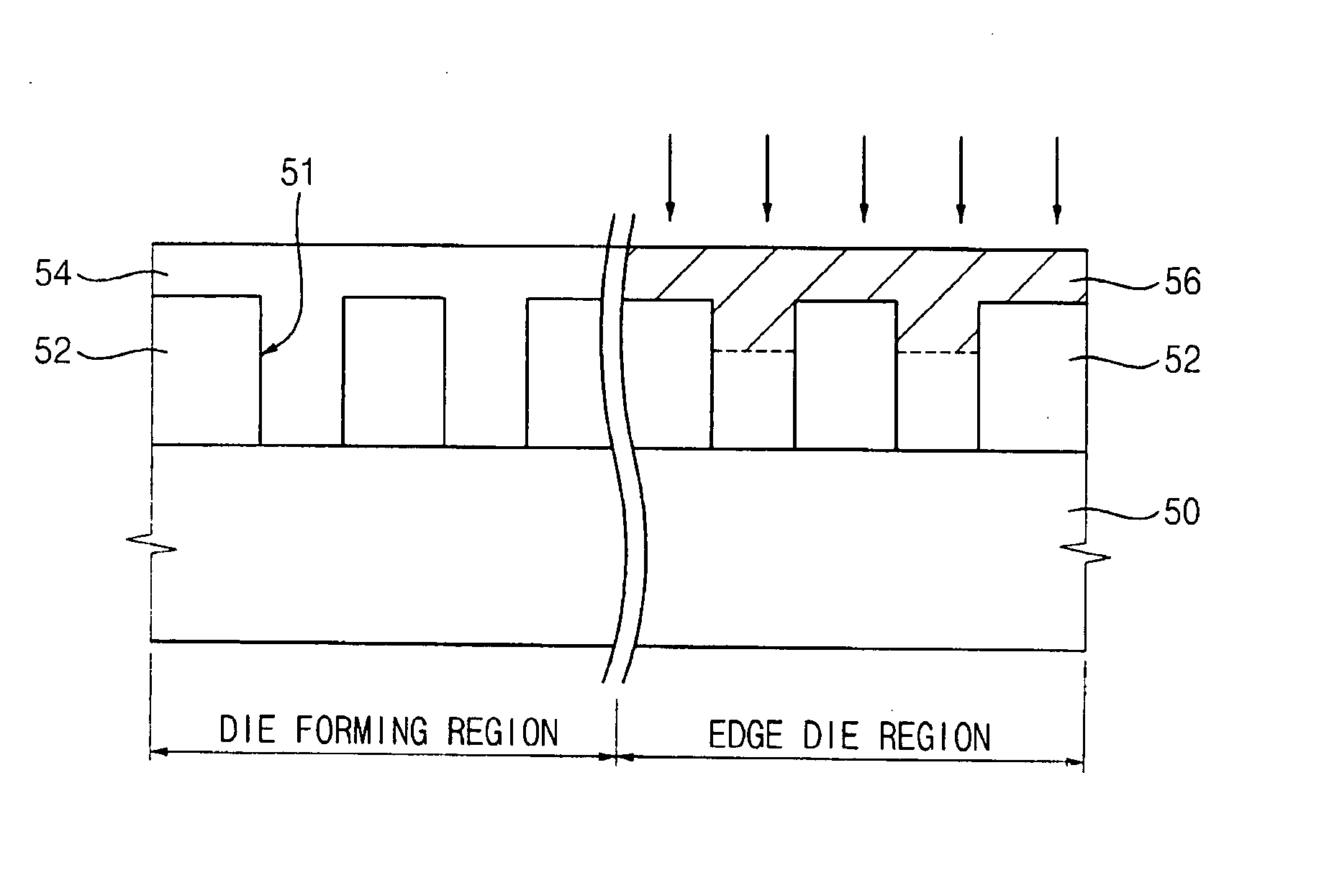

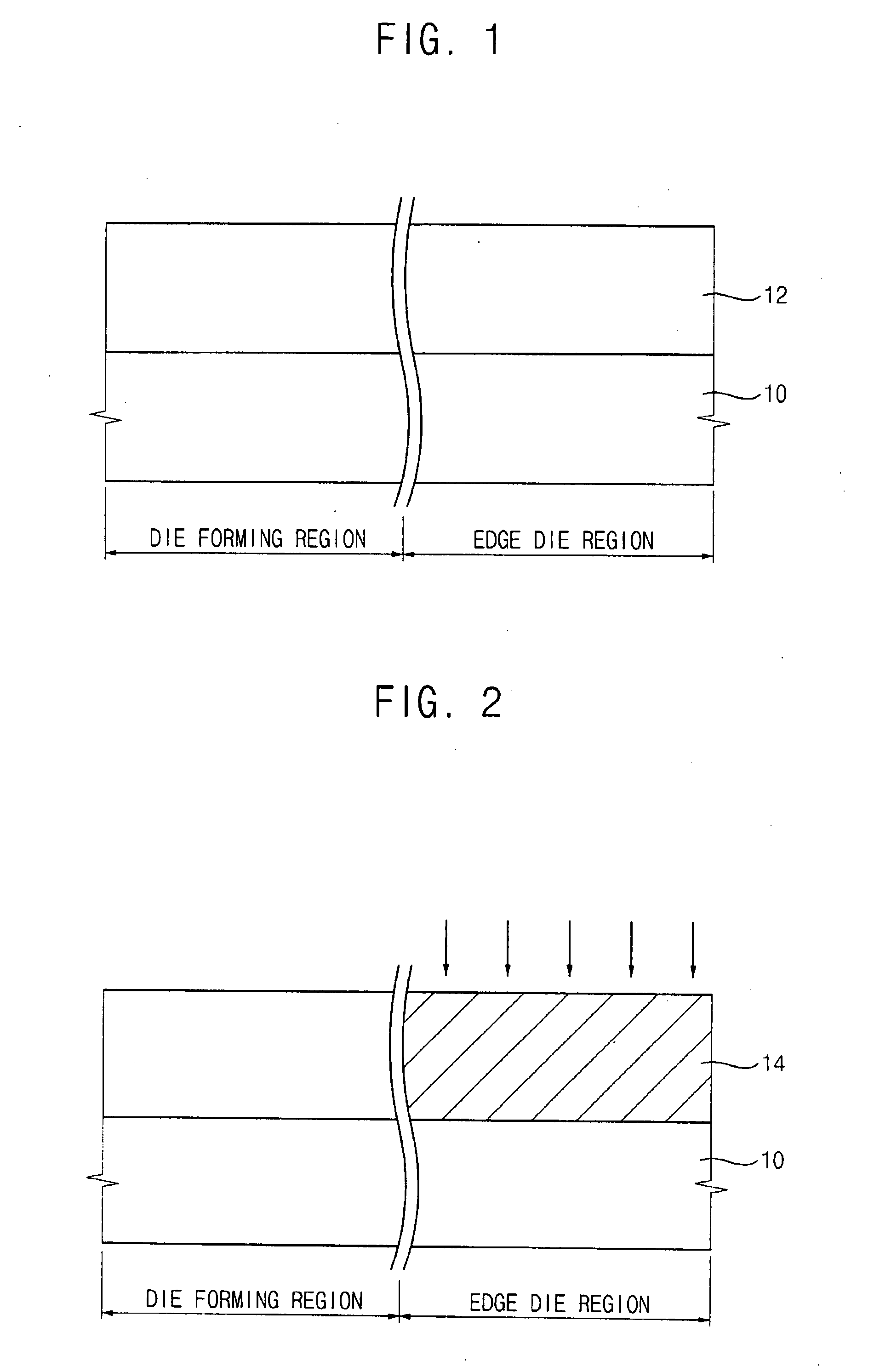

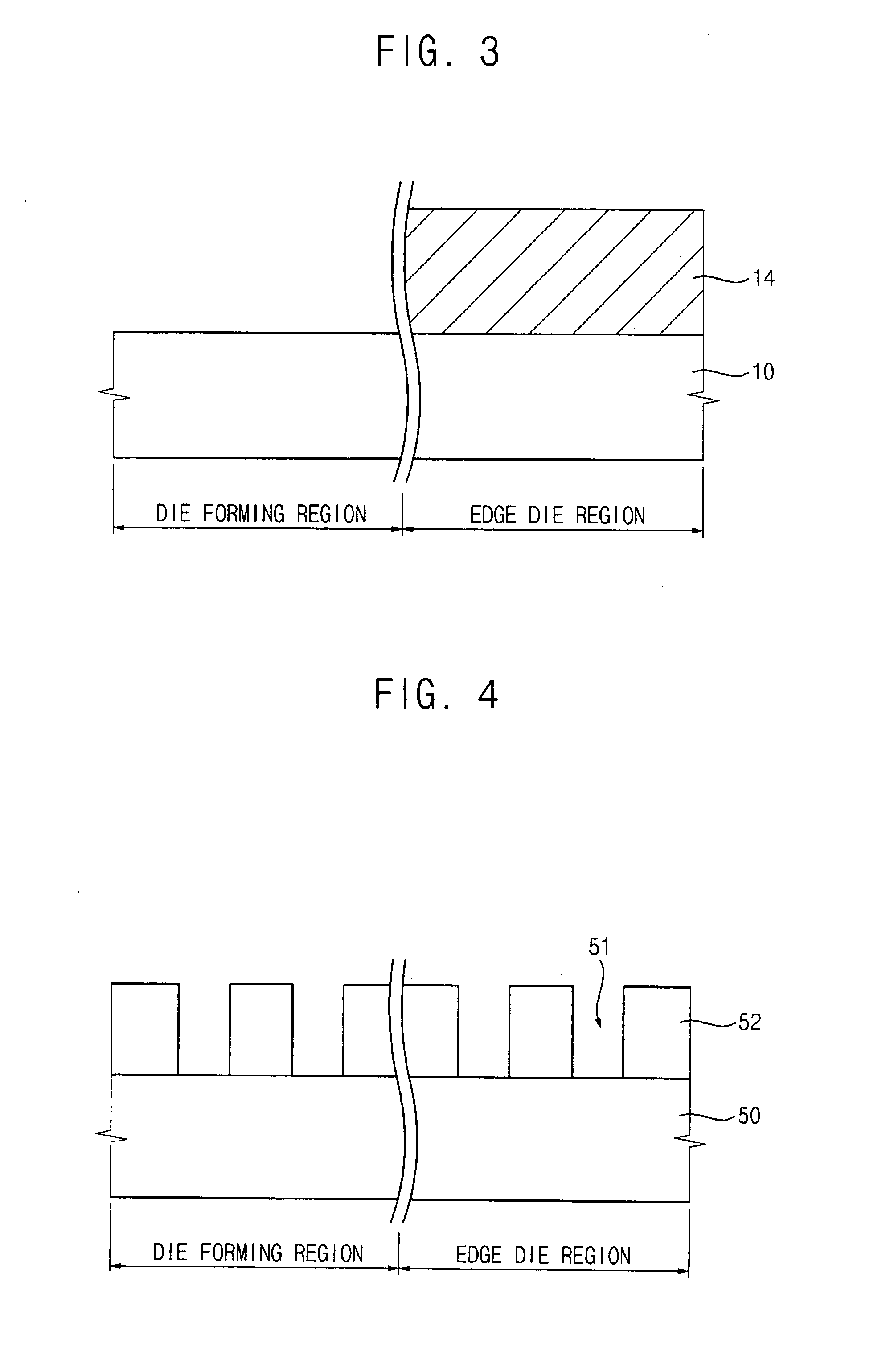

Polymer resin composition, related method for forming a pattern, and related method for fabricating a capacitor

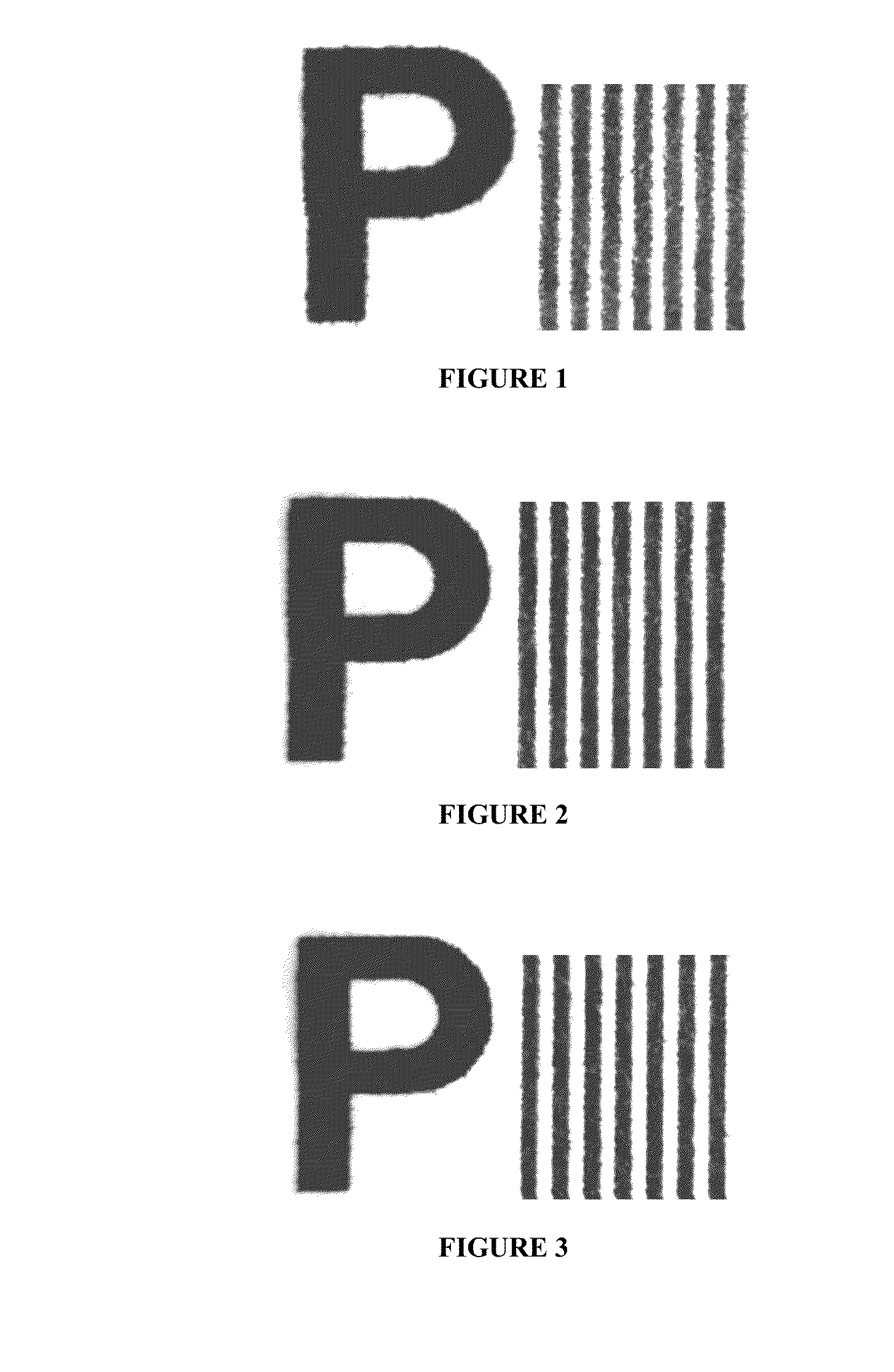

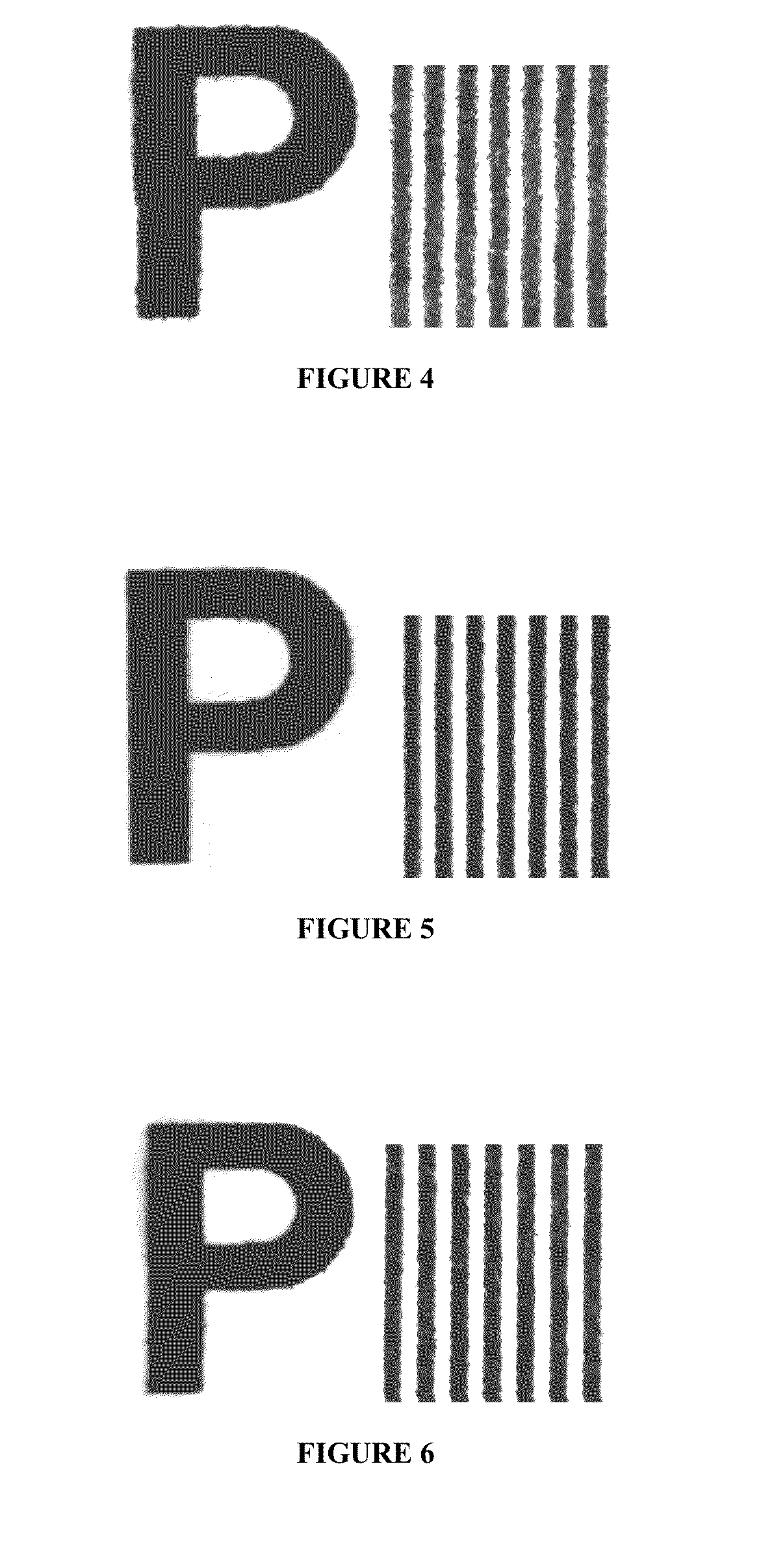

InactiveUS20070249117A1Reduce in quantityReduce processing timeSolid-state devicesSemiconductor/solid-state device manufacturingCross-link(Hydroxyethyl)methacrylate

Owner:SAMSUNG ELECTRONICS CO LTD

Ink jet ink composition

InactiveUS20050134665A1Increased durabilityIncrease resistanceMeasurement apparatus componentsInksSURFACTANT BLENDPolymer chemistry

An ink jet ink composition comprising an aqueous carrier medium, a surfactant, a pigment and a polymer, wherein the polymer contains benzyl methacrylate and is not associated with the pigment particles.

Owner:EASTMAN KODAK CO

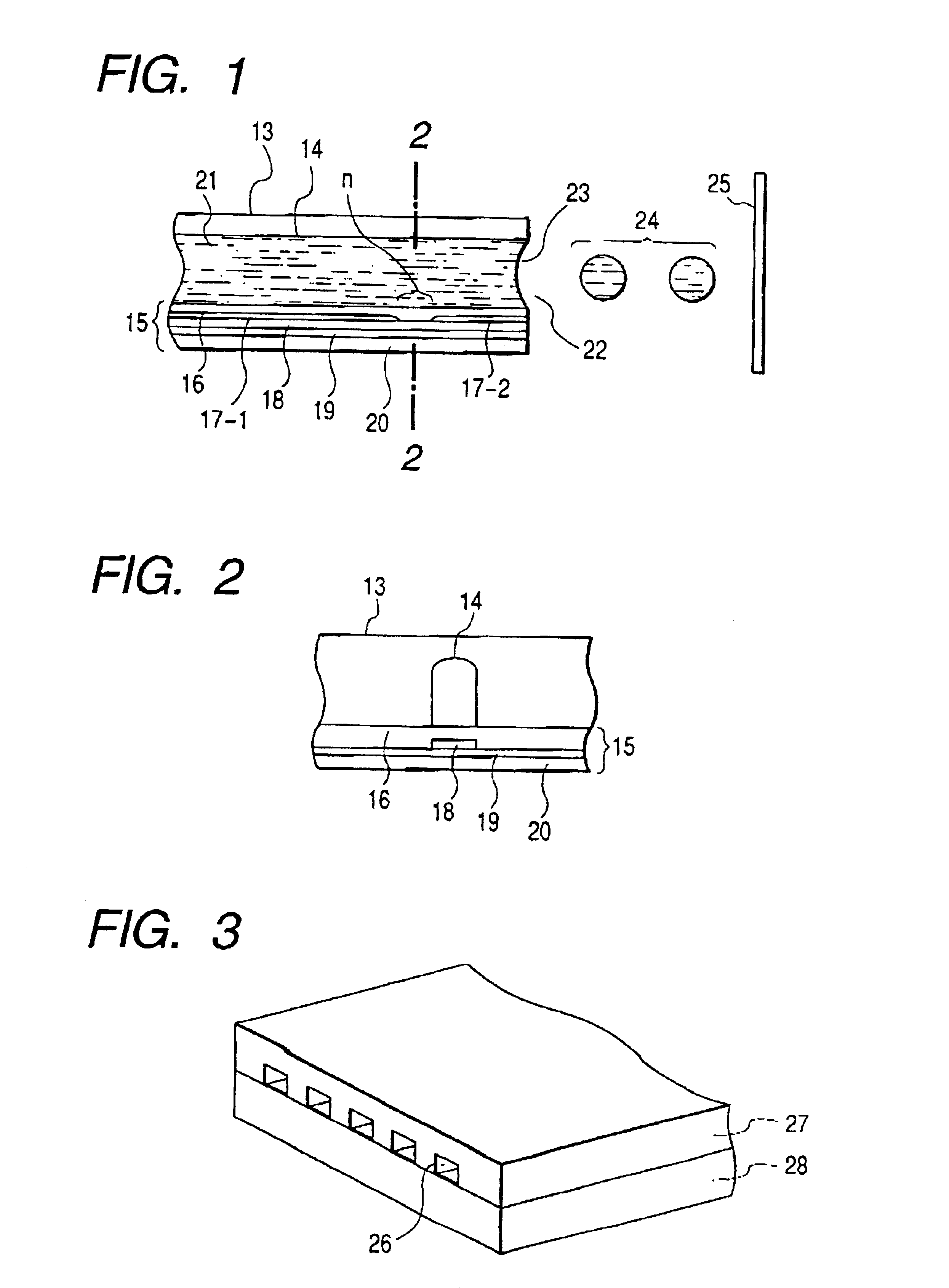

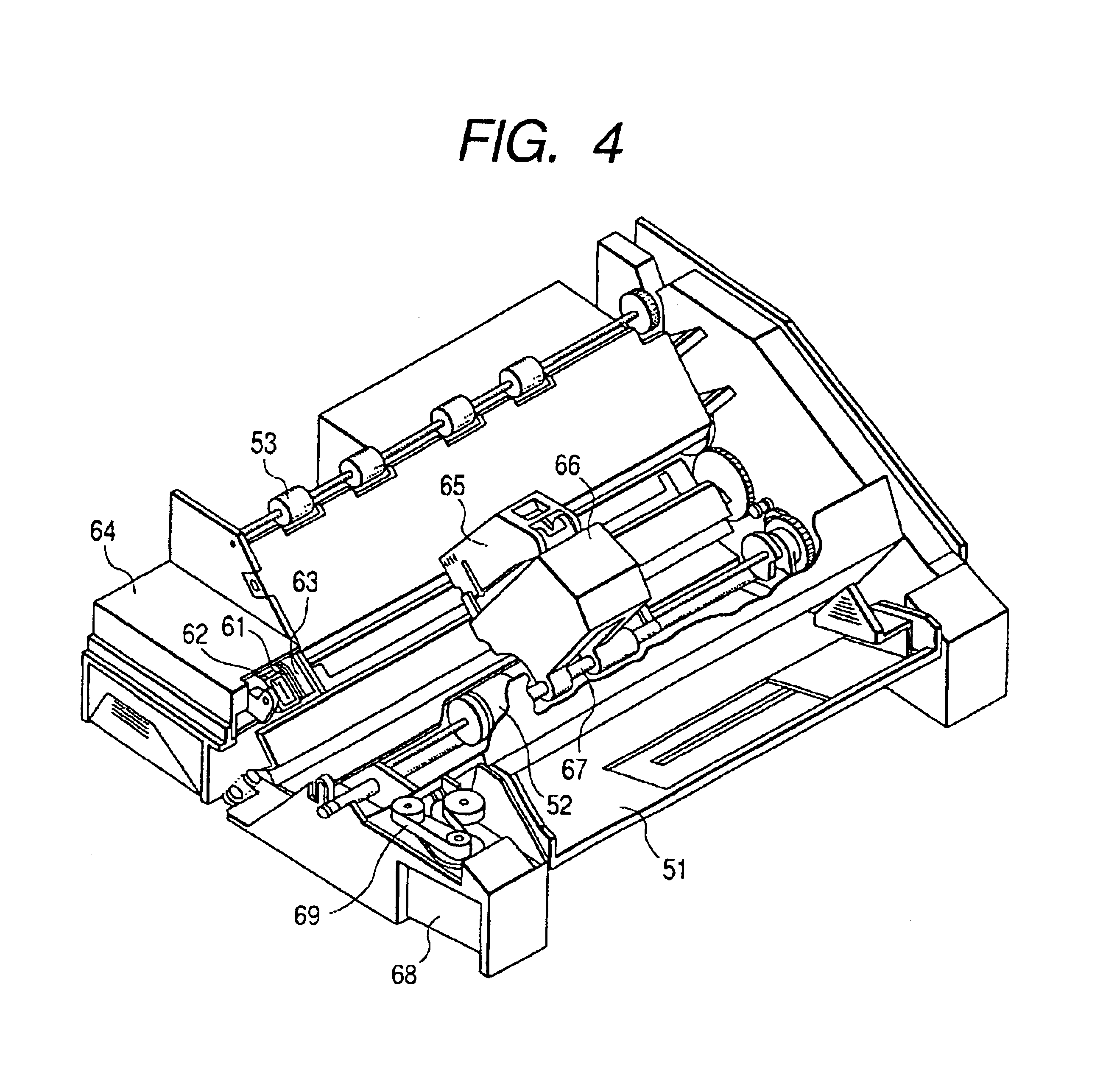

Ink-jet ink, ink set, method for ink-jet printing, ink-jet printing apparatus, ink-jet printing unit and ink cartridge

InactiveUS6860593B2High and uniform image densityGood body shapeMeasurement apparatus componentsDuplicating/marking methodsHigh densityAtomic group

An ink which includes a first pigment, a second pigment, a polymer dispersant and an aqueous medium; wherein the first pigment is a self-dispersing pigment having on its surface at least one anionic group bonded to the surface directly or via an atomic group, the second pigment is dispersed in the aqueous medium by the polymer dispersant, and the polymer dispersant contains benzylmethacrylate as a monomer unit. Diffusion of this ink in the printing medium is suppressed in the cross-sectional direction but not horizontal direction. Thus, the ink can form an ink dot that has a proper dot size, uniform and high density in the dot, with little feathering or blur.

Owner:CANON KK

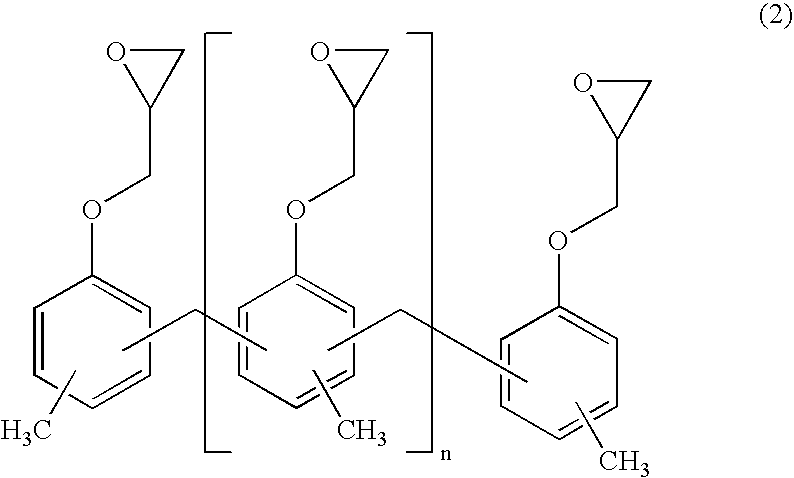

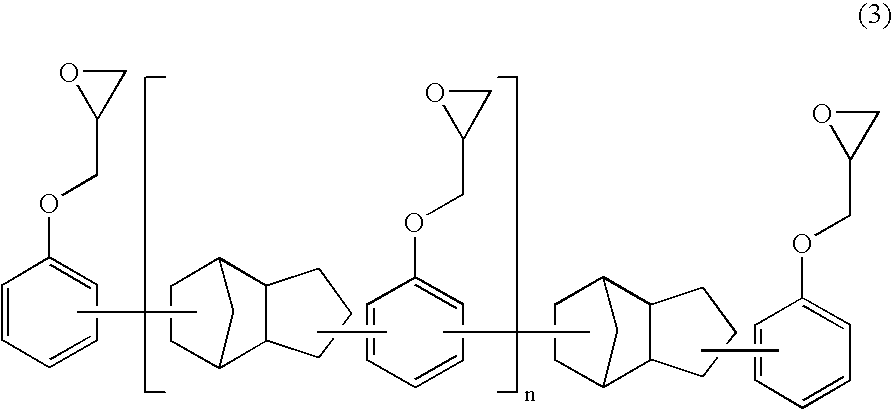

Adhesive Composition, Adhesive Sheet and Production Process for Semiconductor Device

ActiveUS20090004829A1Improve reliabilityFilm/foil adhesivesLayered productsSemiconductor chipBenzyl group

An adhesive sheet which can actualize a high package reliability wherein there is no separation at the adhesive interface and no package cracking, in a package in which a semiconductor chip being reduced in thickness is mounted under severe reflow conditions after exposure to a hot and humid environment. The adhesive sheet includes a base material and, formed thereon, an adhesive layer having an adhesive composition including an acrylic copolymer (A) containing 20 to 95% by weight of a structural unit derived from a benzyl(meth)acrylate, an epoxy thermosetting resin (B), and a thermosetting agent (C).

Owner:LINTEC CORP

Photosensitive resin composition and laminating article thereof

ActiveCN1940723AImprove dispersion stabilityHigh resolution performanceSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPolymer scienceMeth-

The purpose of the present invention is to provide a photosensitive film with good resolution after development, excellent dispersion stability to the developer, no aggregates, excellent flexibility of the cured film, hole capping and good etchant resistance. A photosensitive resin composition, a photosensitive resin laminate having a photosensitive resin layer composed of the composition, a method of forming a resist pattern using the laminate, and a method of producing a conductive pattern. The present invention solves the above-mentioned problems by providing the following photosensitive resin composition, that is, a photosensitive resin composition characterized in that it contains (a) binder resin: 10 to 90% by mass, and its carboxyl group content is The acid equivalent is 100 to 600, contains benzyl (meth)acrylate as a copolymerization component, and has a weight average molecular weight of 5,000 to 500,000, (b) photopolymerizable unsaturated compound: 5 to 70% by mass, (c) as photopolymerizable unsaturated compound: The specific compound of the polymerization initiator is 0.1 to 20% by mass.

Owner:ASAHI KASEI KK

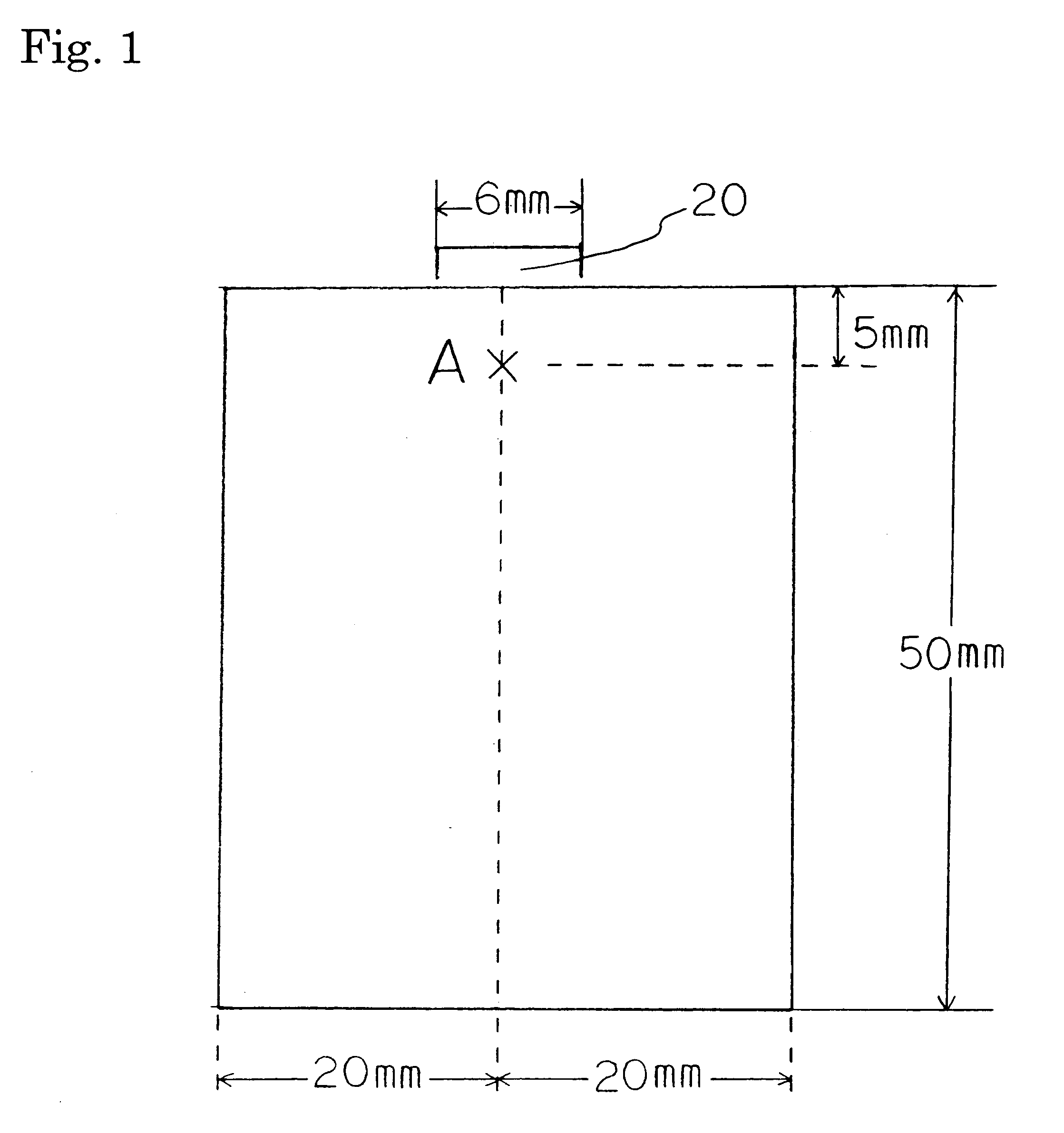

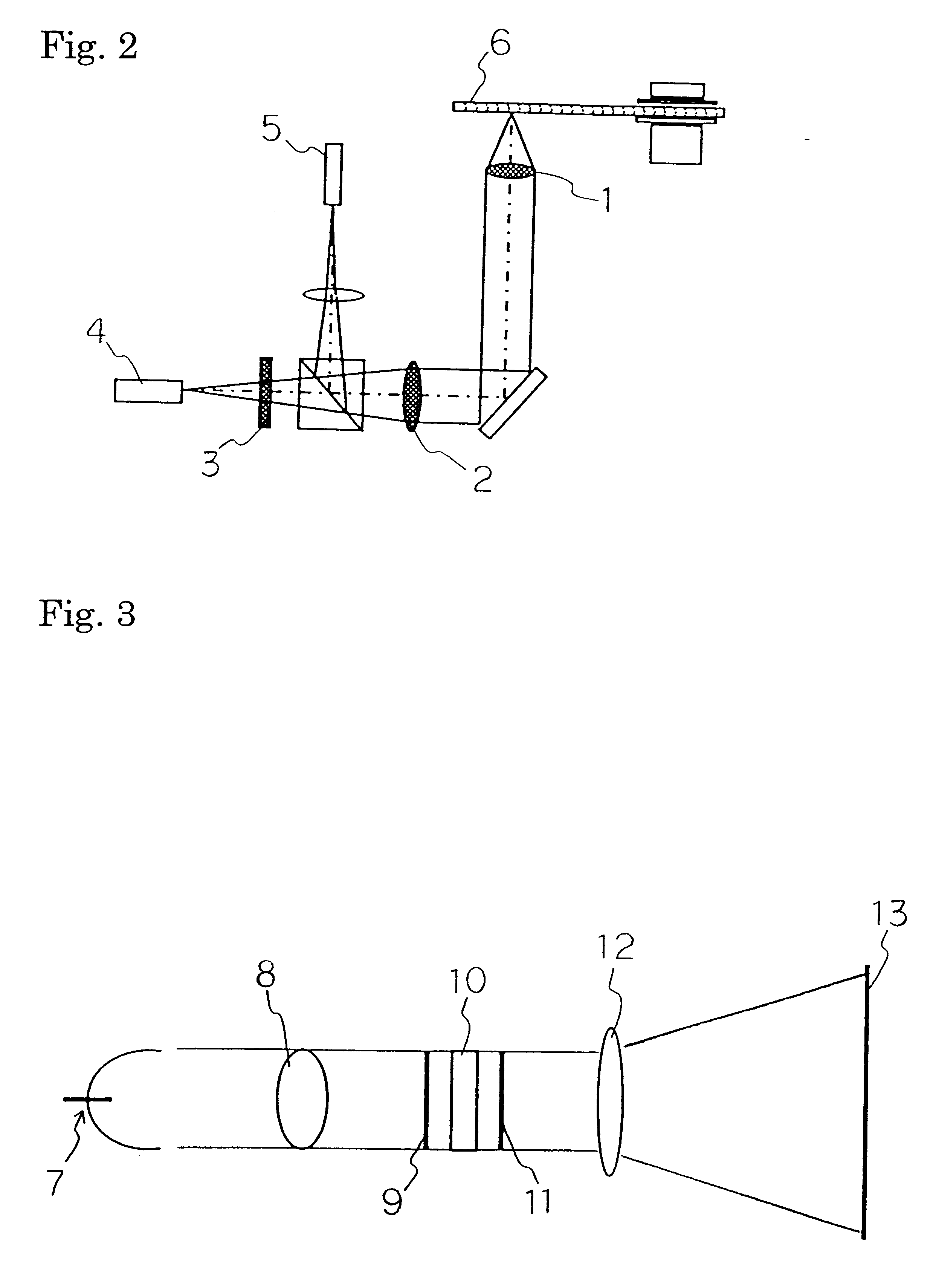

Process for the preparation of non-birefringent optical resin and optical elements made by using the resin prepared by the process

InactiveUS6277938B1Record information storageOptical record carriersAliphatic hydrocarbonBenzyl methacrylate

A process for the preparation of a non-birefringent optical resin, characterized by copolymerizing a monomer mixture consisting of the following monomers (A) to (E) at such a ratio as to give the resin having an absolute value of orientational birefringence of less than 1x10-6; wherein(A): 5 to 40 wt % of a methacrylic or acrylic ester having a C5-C22 aliphatic hydrocarbon group in the ester moiety;(B): 50 to 80 wt % of methyl methacrylate;(C): 5 to 40 wt % of an N-substituted maleimide;(D): 0 to 30 wt % of benzyl methacrylate;(E): 0 to 10 wt % of a monomer copolymerizable with these monomers, and optical elements made by using the resin prepared by this process.

Owner:KOIKE YASUHIRO

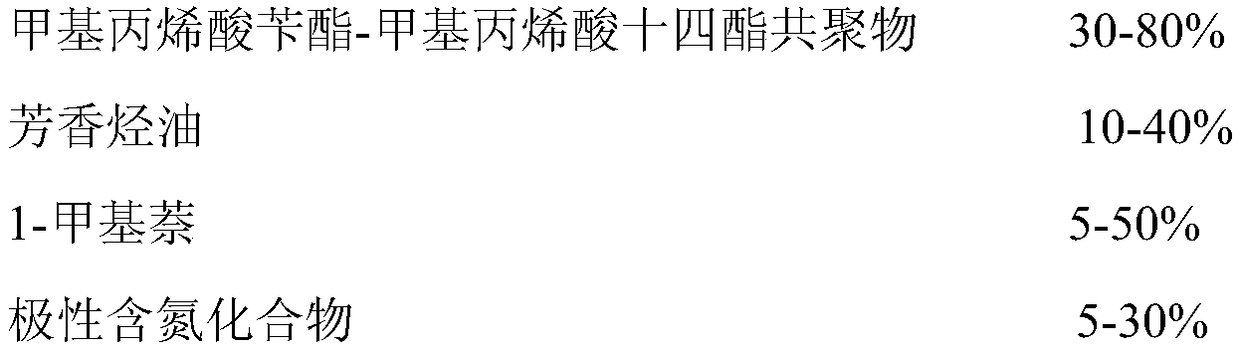

Wide-spectrum diesel pour point depressant composition, preparation method thereof and application of composition

InactiveCN109135846AIncrease polarityImprove solubilityLiquid carbonaceous fuelsFuel additivesPolymer scienceNitrogen

The invention discloses a wide-spectrum diesel pour point depressant composition, a preparation method thereof and an application of the composition. The pour point depressant composition comprises, in weight percent, 30-80% of benzyl methacrylate-methacrylic acid tetradecyl ester copolymers, 10-40% of arene oil, 5-50% of 1-methylnaphthalene and 5-30% of polar nitrogen-containing compounds. The raw materials are uniformly mixed according to predetermined weight percent to obtain the composition. The diesel pour point depressant composition can be rapidly dissolved in diesel oil, is high in spectrum and has remarkable pour point declining effect when being applied to different diesel, and a condensation point and a cold filter plugging point are reduced by 21-26 DEG C and 8-12 DEG C.

Owner:SHANGHAI INST OF TECH

Method of making graded index polymeric optical fibers

InactiveUS6106745AImprove scalabilityReduced melt strengthOptical fibre with graded refractive index core/claddingOptical articlesFiberPolymer science

Disclosed is a method of making a graded index polymer optical fiber comprising a multicomponent spinning process employing spinning masses comprising a core spinning mass and a sheath spinning mass, the spinning masses comprising a polymer, a polymerizable monomer, and an initiator. The monomer in the core spinning mass has a higher refractive index than the monomer in the sheath spinning mass, and the spinning masses are extruded and cured. The spinning conditions are chosen such that the monomers are substantially contained within the fiber during extrusion and curing and the total of the spinning masses is intrinsically thread forming. The spinning masses may be extruded in, e.g., water. The core and the sheath polymer may be, e.g., poly(methyl methacrylate); the core monomer may be methyl methacrylate, and the sheath monomer may be 2,2,3,3-tetrafluoropropyl methacrylate; or the core and the sheath polymer may be, e.g., poly(styrene-co-acrylonitrile); the core monomer may be benzyl methacrylate, and the sheath monomer may be methyl methacrylate. The spinning masses are solutions of the polymer in the monomer having a polymer concentration of from 20 to 70% by weight.

Owner:AKZO NOBEL NV

Water-and oil-repellent

InactiveUS20100224817A1Excellent textile feelingImproved textile feelingOther chemical processesLiquid repellent fibresHydrogen atomBULK ACTIVE INGREDIENT

A water- and oil-repellent includes, as an active ingredient, a fluorine-containing copolymer including as a copolymer unit (A) at least one of perfluoroalkylalkyl acrylates and corresponding methacrylates, (B) benzyl acrylate or benzyl methacrylate represented by the general formula: CnF2n+1CmH2mOCOCR═CH2 (wherein R represents a hydrogen atom or a methyl group; n represents 4, 5, or 6; and m represents 1, 2, 3, or 4), (C) a fluorine-free polymerizable monomer other than benzyl acrylate and benzyl methacrylate, and (D) a cross-linkable group-containing polymerizable monomer.

Owner:UNIMATEC CO LTD

Aqueous coloring agent dispersion for inkjet, ink composition, inkjet recording method, and colored body

InactiveUS20140363642A1Good storage stabilityHigh print densityLayered productsDecorative surface effectsLiquid mediumTellurium compounds

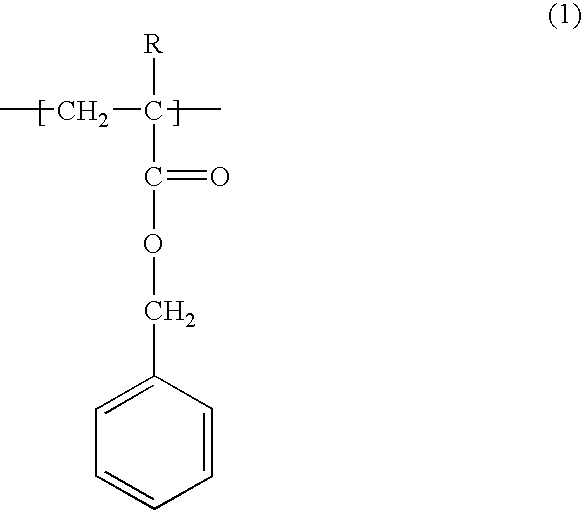

Provided are an aqueous coloring agent dispersion for inkjet which achieves high pigment concentration, exhibits favorable redispersion properties after drying, and does not exhibit changes in ink properties even when stored for a long time; and an ink composition using the aqueous coloring agent dispersion. This aqueous coloring agent dispersion contains a coloring agent (I), a liquid medium (II), and a polymer dispersion agent (III). The polymer dispersion agent (III) is an A-B block polymer obtained by copolymerizing via a living radical polymerization method, by using a mixture of an organic tellurium compound represented by formula (1) and an organic ditellurium compound represented by formula (2), or the like, as a polymerization initiator. Therein, the monomer for configuring the A block is at least one type of monomer represented by formula (3), and the monomer for configuring the B block is benzyl methacrylate and / or benzyl acrylate.

Owner:NIPPON KAYAKU CO LTD

Water-and oil-repellent

InactiveUS8680223B2Low in bioaccumulation potentialFeel goodOther chemical processesLiquid repellent fibresHydrogen atomBULK ACTIVE INGREDIENT

A water- and oil-repellent includes, as an active ingredient, a fluorine-containing copolymer including as a copolymer unit (A) at least one of perfluoroalkylalkyl acrylates and corresponding methacrylates, (B) benzyl acrylate or benzyl methacrylate represented by the general formula: CnF2n+1CmH2mOCOCR═CH2 (wherein R represents a hydrogen atom or a methyl group; n represents 4, 5, or 6; and m represents 1, 2, 3, or 4), (C) a fluorine-free polymerizable monomer other than benzyl acrylate and benzyl methacrylate, and (D) a cross-linkable group-containing polymerizable monomer.

Owner:UNIMATEC CO LTD

Water-and oil-repellent

InactiveUS20100249312A1Excellent textile feelingEnough waterOther chemical processesFilm/foil adhesivesHydrogen atomMethyl group

A water- and oil-repellent comprising an aqueous dispersion of a fluorine-containing copolymer including as a copolymerization unit (a) a perfluoroalkylalkyl (meth)acrylate represented by the general formula CnF2n+1CmH2mOCOCR═CH2 (wherein R represents hydrogen atom or methyl group; n represents 4, 5, or 6; and m represents 1, 2, 3, or 4), (b) benzyl (meth)acrylate, (c) a fluorine-free polymerizable monomer other than benzyl (meth)acrylate, and (d) a cross-linkable group-containing polymerizable monomer; and a blocked isocyanate added to the aqueous dispersion in a weight ratio of 0.05 to 3.0 to the weight of the solid content of the aqueous dispersion.

Owner:UNIMATEC CO LTD

Peptides having affinity for poly (benzyl methacrylate-co-methacrylic acid) potassium salt copolymers and methods of use

Peptides are provided that have binding affinity for poly(benzyl methacrylate-co-methacrylic acid) potassium salt copolymers (“BzMA-binding peptides”). The BzMA-binding peptides may be used to prepare peptide-based reagents suitable for use in a variety of applications. The peptide-base reagents may be used to couple benefit agents to a poly(benzyl methacrylate-co-methacrylic acid) potassium salt copolymer surface or may be used to couple a benefit agent comprising a poly(benzyl methacrylate-co-methacrylic acid) potassium salt copolymer surface to a target surface, such as a body surface.

Owner:EI DU PONT DE NEMOURS & CO

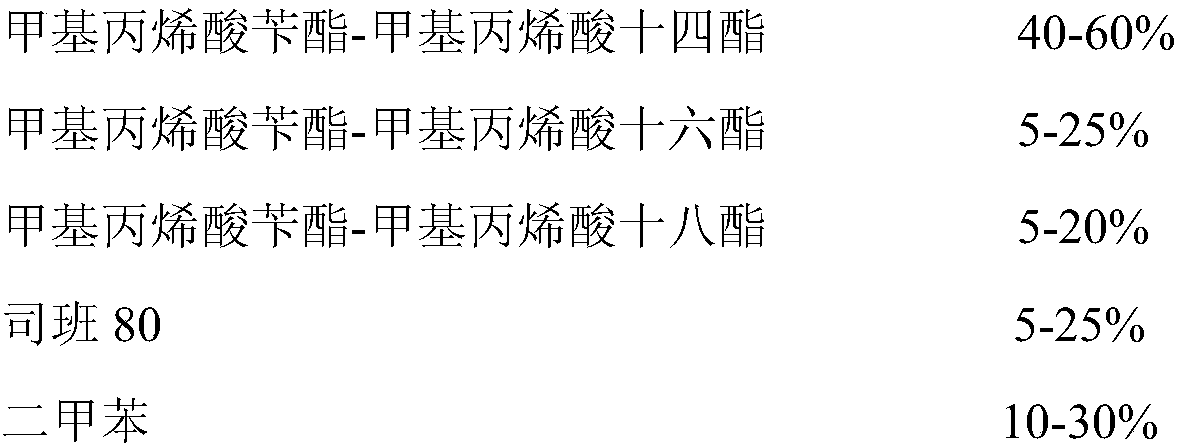

Diesel oil pour point depressant composition as well as preparation method and application thereof

ActiveCN109053951AEvenly dispersedImprove solubilityLiquid carbonaceous fuelsFuel additivesSolubilityNational standard

The invention discloses a diesel oil pour point depressant composition as well as a preparation method and application thereof. The diesel oil pour point depressant composition is prepared from the following components by mass percent: 40-60% of benzyl methacrylate-tetradecyl methacrylate, 5-25% of benzyl methacrylate-hexadecyl methacrylate, 5-20% of benzyl methacrylate-octadecyl methacrylate, 5-25% of span 80 and 10-30% of xylene. The diesel oil pour point depressant composition provided by the invention not only can effectively enhance the solubility of a pour point depressant in diesel oil,but also can effectively improve the low temperature flow performance of the diesel oil. After the obtained diesel pour point depressant composition is added into the commercially available diesel oil with model 0, the condensation point and cold filter point of the diesel oil with model 0 are respectively lowered by 22-26 DEG C and 8-11 DEG C, and the other properties of the diesel oil with model 0 can reach the national standards; the diesel oil pour point depressant composition can meet the requirement that various diesel-powered motor vehicles work normally at the low temperature.

Owner:湖南浩润科技有限公司

Water-and oil-repellent

InactiveUS20110257327A1Low in bioaccumulation potentialFeel goodOther chemical processesLiquid repellent fibresHydrogen atomBULK ACTIVE INGREDIENT

A water- and oil-repellent includes, as an active ingredient, a fluorine-containing copolymer including as a copolymer unit (A) at least one of perfluoroalkylalkyl acrylates and corresponding methacrylates, (B) benzyl acrylate or benzyl methacrylate represented by the general formula: CnF2n+1CmH2mOCOCR═CH2 (wherein R represents a hydrogen atom or a methyl group; n represents 4, 5, or 6; and m represents 1, 2, 3, or 4), (C) a fluorine-free polymerizable monomer other than benzyl acrylate and benzyl methacrylate, and (D) a cross-linkable group-containing polymerizable monomer.

Owner:UNIMATEC CO LTD

Aqueous Pigmented Black Inks Having a Unique Dispersant Mixture

InactiveUS20130005851A1Improve printing qualityImprove text qualityAntifouling/underwater paintsTransportation and packagingPhenyl EthersBenzyl methacrylate

The present invention relates to a unique polymer dispersant mixture to be incorporated into a carbon black ink formulation. More particularly, the a polymeric dispersant mixture consists of a first polymer dispersant having moieties of methacrylic acid; poly(propylene glycol)-4-nonylphenyl ether acrylate; and poly(ethylene glycol)2,4,6-tris-(1-phenylethyl)phenyl ether methacrylate in combination with a second polymer dispersant selected from the group consisting of a copolymer of methacrylic acid and benzyl methacrylate and a terpolymer of styrene, alpha-methyl styrene and acrylic acid. Carbon black inkjet inks having this particular polymer dispersant mixture exhibit improved text quality when compared to carbon black inks not having this polymer dispersant mixture.

Owner:LEXMARK INT INC

Synthesis method of bagasse xylan citrate-g-BMA with antitumor activity

InactiveCN110698594AGood water solubilityHigh anticancer activityAntineoplastic agentsPotassium persulfatePtru catalyst

The invention discloses a synthesis method of bagasse xylan citrate-g-BMA (benzyl methacrylate) with antitumor activity. The synthesis method comprises the following steps: firstly, synthesizing bagasse xylan-g-BMA by taking bagasse xylan as a main raw material, benzyl methacrylate as a grafting monomer and potassium persulfate as an initiator; and then performing catalytic esterification reactionin ionic liquid chlorinated-1-allyl-3-methylimidazole (AmimCl) by taking citric acid as an esterifying agent and sodium hypophosphite monohydrate as an esterification catalyst to synthesize the bagasse xylan citrate-g-BMA. The bagasse xylan is subjected to grafting, esterification and composite modification and two bioactive groups are introduced, so the water solubility and the heat stability ofthe bagasse xylan are improved, the antitumor activity of the bagasse xylan is further enhanced, and a certain application prospect in the aspects of development of anti-cancer medicines and the likeis achieved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Adhesive composition and adhesive sheet

ActiveUS7674859B2Improve reliabilityFilm/foil adhesivesSynthetic resin layered productsPolymer scienceMeth-

Owner:LINTEC CORP

Preparation method for spiropyran-based random copolymer P(SPMA-co-MAA)

InactiveCN105542066AAvoid toxic effectsImprove decomposition efficiencyAtom-transfer radical-polymerizationOxygen

The invention discloses a preparation method for a spiropyran-based random copolymer P(SPMA-co-MAA). The method comprises the steps that spiropyran-based acrylate and 2-nitryl benzyl methacrylate are subjected to atom transfer radical polymerization in an oxygen-free environment on the condition that copper halide, a ligand and an initiator exist, and an obtained intermediate polymer P(SPMA-co-NBM) is subjected to an NBM unit decomposition reaction under ultraviolet irradiation to obtain the spiropyran-based random copolymer P(SPMA-co-MAA). According to the method, the advantages that the reaction speed is higher, the reaction condition is mild, the operation process is convenient, and the product loss is little are achieved, the toxic action possibly caused to a catalyst due to the fact that atom transfer radical polymerization is performed by directly adopting methacrylic acid is effectively avoided, the defects that existing chemical hydrolysis is low in yield and complex in process are overcome, and the good developing prospect on functional polymers and the technical fields thereof is achieved.

Owner:CENT SOUTH UNIV

Method for producing an aqueous emulsion

InactiveUS20110086962A1Low bioaccumulation potentialGood effectOther chemical processesFibre treatmentPolymer scienceMeth-

Disclosed is a method for producing an aqueous emulsion containing a fluorine-containing copolymer comprising, as copolymerizable monomers, (A) at least one of a perfluoroalkylalkyl acrylate and a corresponding methacrylate represented by the general formula: CnF2n+1CmH2mOCOCR═CH2, wherein R is hydrogen or methyl group, n is 4, 5, or 6, and m is 1, 2, 3, or 4; (B) benzyl acrylate or benzyl methacrylate; (C) a fluorine-free polymerizable monomer other than benzyl acrylate and benzyl methacrylate; and (D) a crosslinkable group-containing polymerizable monomer; the copolymer being produced by previously subjecting 10 to 80 wt. % of the total weight of component (A) and 0 to 60 wt. % of the total weight of component (B) to a first polymerization reaction using an emulsion polymerization method; and then subjecting the remaining components to a second polymerization reaction using an emulsion polymerization method; wherein an emulsifier is used in the emulsion polymerization reaction in an amount of 21 to 150 parts by weight based on 100 parts by weight of the total weight of polymerizable monomers (A) and (B) used in the first polymerization reaction.

Owner:UNIMATEC CO LTD

Oil performance improver, and preparation method and application thereof

InactiveCN110144247AImprove low temperature fluidityImprove solubilityLiquid carbonaceous fuelsFuel additivesSolubilityPolymer science

The invention provides an oil performance improver. The oil performance improver comprises, by mass, 40-60% of benzyl methacrylate-tetradecyl methacrylate and 25-70% of a solvent; and the solvent is composed of 20-40% of dimethyl phthalate and 5-20% of cyclohexane, or the solvent is composed of 10-30% of n-butyl acetate, 5-20% of polyethylene glycol 200 and 10-20% of propylene glycol block polyether. The above diesel pour point depressant composition of the invention can effectively enhance the solubility of a pour point depressant in diesel, reduce the cost of the pour point depressant and effectively improve the low-temperature flow performance of the diesel.

Owner:SHANGHAI INST OF TECH

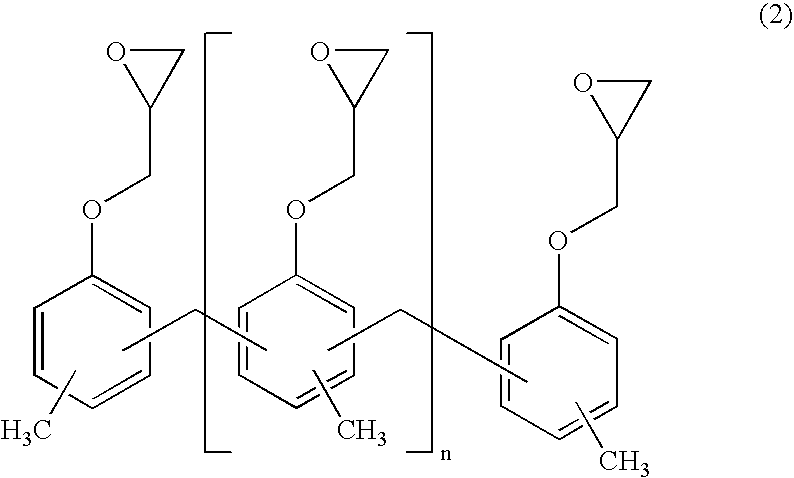

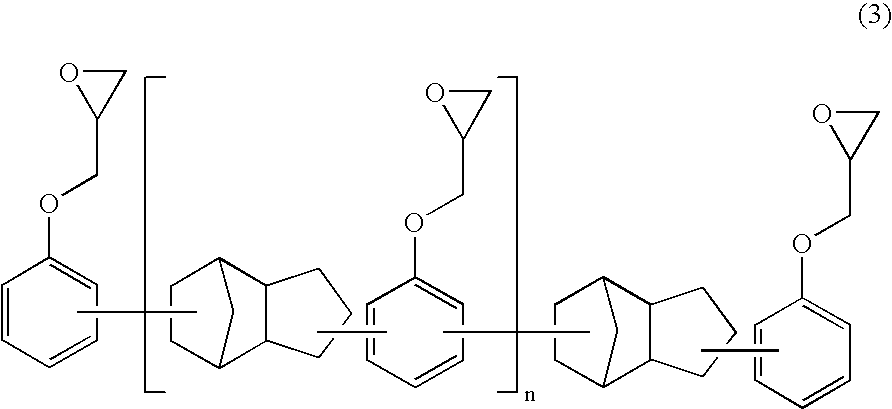

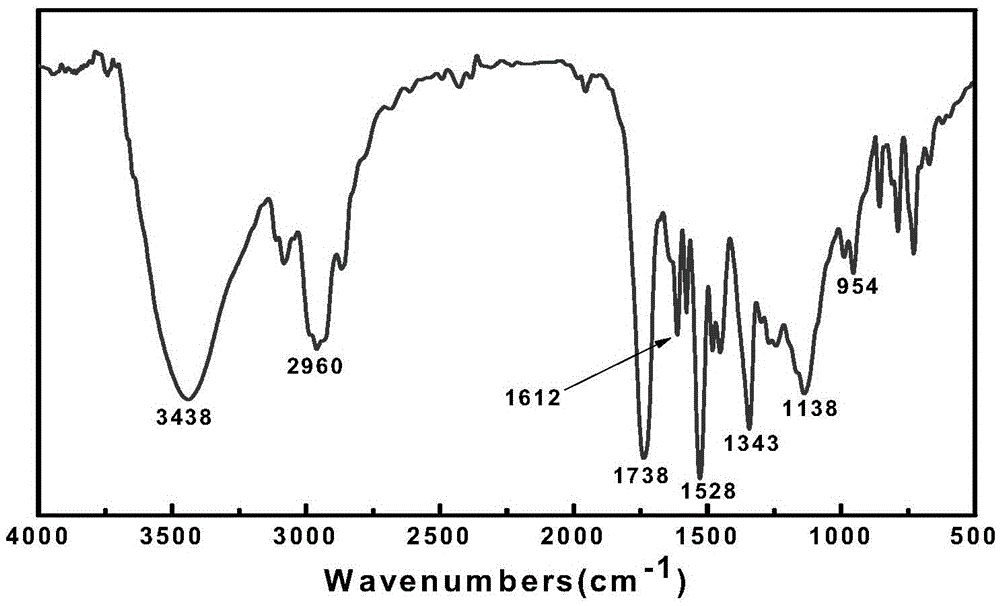

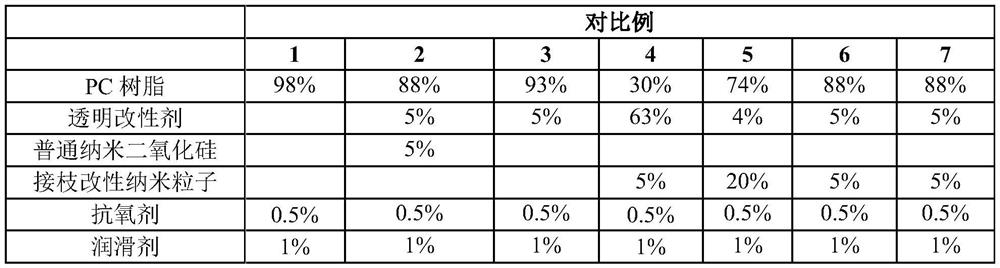

Modified polycarbonate composition, electronic equipment shell and preparation method of electronic equipment shell

ActiveCN111748189AImprove scratch resistanceImprove impact resistancePolymer scienceMethacrylate methyl

The invention relates to the field of plastic, and discloses a modified polycarbonate composition, an electronic equipment shell and a preparation method of the electronic equipment shell. The composition comprises polycarbonate, a transparency modifier and modified nano particles, wherein the modified nano particles are obtained by modifying inorganic nano particles having hydroxyl on the surfaces through a silane coupling agent and then polymerizing the modified inorganic nano particles with a monomer; the monomer comprises a high-refractive-index monomer or comprises a high-refractive-indexmonomer and a low-refractive-index monomer. The low-refractive-index monomer is selected from methyl methacrylate and / or cyclohexyl methacrylate, and the high-refractive-index monomer is one or moreselected from benzyl methacrylate, phenyl methacrylate, phenoxy ethyl acrylate, phenyl acrylate, benzyl acrylate, naphthyl methacrylate and naphthyl acrylate. The electronic equipment shell prepared from the composition provided by the invention has good impact toughness, high transparency and surface hardness.

Owner:BYD CO LTD

PC/PMMA alloy as well as preparation method and application thereof

The invention relates to a PC / PMMA alloy and a preparation method and application thereof. The alloy is prepared from the following raw materials in parts by weight: 60-95 parts of PC, 8-40 parts of polymethyl methacrylate copolymer and 0.1-1 part of compatilizer, wherein the polymethyl methacrylate copolymer is formed by copolymerizing a main body monomer and a comonomer according to a molar ratio of (1.5:1) to (4:1); the main body monomer is methyl methacrylate; the comonomer is selected from at least one of benzyl methacrylate, phenyl methacrylate and methyl methylphenylmethacrylate, and the refractive indexes of the polymethyl methacrylate copolymer and the PC are similar, and the compatilizer can improve the compatibility of the polymethyl methacrylate copolymer and the PC, so that the PC / PMMA alloy has the advantages of high transparency, high light transmittance, high hardness and scratch resistance.

Owner:GUANGZHOU HUAXINKE ENTERPRISE

Intelligent encapsulation acid and use method

The invention discloses an intelligent encapsulation acid and a use method thereof, wherein the encapsulation acid is composed of a core material and a shell material wrapping the core material, and the core material is a liquid acid; the liquid acid is an acidic liquid used in the oilfield exploitation process; the shell layer material is hydrophobic nanoparticles with the size of 10-500 nm, andthe nanoparticles are one or a combination of at least two of fumed silica, polystyrene, poly(benzyl methacrylate) and a fluorine-containing polymer. The encapsulation acid is used in an oil and gas production increasing process including acidification, acid fracturing and plug removal of an oil and gas reservoir, and when the encapsulation acid is used, after the encapsulation acid is carried toa target position of a stratum by adopting a carrying fluid, the encapsulation acid releases liquid acid to react with the stratum after encountering a release agent. In the invention, the liquid acidis converted into powder, so that corrosion to a container and a pipeline during acidification construction is avoided, the liquid acid is released after the powder acid reaches a target stratum; when the liquid acid reacts with the stratum, the effective acidification distance can be greatly increased.

Owner:四川省帕提科斯能源科技有限公司

Diesel oil pour point depressant composition and preparation method and application thereof

InactiveCN110257116AAct as a diluentLowering the freezing pointLiquid carbonaceous fuelsFuel additivesDispersityPolyethylene glycol

The invention relates to a diesel oil pour point depressant composition. The diesel oil pour point depressant composition comprises, by mass, 40-60% of benzyl methacrylate-maleic anhydride tetradecylamine, 10-30% of benzene solvent, 5-20% of polyethylene glycol, 10-30% of Tween. A preparation method of the diesel oil pour point depressant composition includes: S1, evenly mixing the ingredients by stirring at a temperature of 25-40 DEG C to obtain a primary mixed solution; S2, dispersing the primary mixed solution with an ultrasonic generator to obtain the diesel oil pour point depressant composition. Compared with the prior art, the diesel oil pour point depressant composition has the advantages of wide application range and can be applied to all diesel oil in the current market, dispersity of the pour point depressant in 0# diesel oil sold in the market can be improved, a condensation point of the 0# diesel oil can be lowered by 20-25 DEG C, and a cold filter plugging point of the 0# diesel oil can be lowered by 6-11 DEG C.

Owner:SHANGHAI INST OF TECH

LDPE composite flame-retardant plastic and preparation method thereof

InactiveCN103289173AReduce weightImprove flame retardant performanceDecabromobiphenyl etherAluminium hydroxide

The invention discloses LDPE composite flame-retardant plastic comprising the following components, by weight, 40-50 parts of LDPE, 40-50 parts of EVA, 70-75 parts of aluminium hydroxide, 10-12 parts of amorphous phosphorus, 30-33 parts of ammonium polyphosphate, 11-13 parts of dipentaerythritol, 0.25-0.31 parts of DCP, 3.5-3.8 parts of a coupling agent, 10-13 parts of benzyl methacrylate, 8-10 parts of methacrylic acid, 10-11 parts of dihydro dicyclopentadienyl acrylate, 10-20 parts of butadiene rubber, 1-2 parts of paraffin, 7-8 parts of hydrated zinc borate, and 10-12 parts of polybrominated diphenylether. The flame-retardant plastic provided by the invention has the advantages of good mechanical performance and high thermal stability. The plastic has excellent flame-retarding performance reaching a V-0 level. The density of the plastic is low, such that plastic weight can be reduced, and cost can be reduced. The elongation rate of the plastic is high.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

Environment-friendly printing technology for printing ink

The invention discloses an environment-friendly printing technology for printing ink. The environment-friendly printing technology includes steps of S10, printing the printing ink on base materials toform printed matters; S20, irradiating infrared light sources on the printed matters until films are formed by the printing ink. The printing ink comprises, by weight, 60-70 parts of water, 3-10 parts of latex binders, 1-5 parts of 2-pyrrolidinone, 1-3 parts of benzyl methacrylate, 10-20 parts of ethyl alcohol, 1-5 parts of citric acid and 0.5-6 parts of colorants. The environment-friendly printing technology in an embodiment of the invention has the advantages that the environment-friendly printing technology includes the simple technological steps, the water is used as a main solvent for the printing ink, solvents, such as benzene with severe pollution on environments and human bodies, in the printing ink are reduced to a great extent, and accordingly the environment-friendly printing technology is green and environmentally friendly; the printing ink is good in adhesion, low in film-forming temperature and high in film-forming speed, good printing effects can be realized, and the environment-friendly printing technology can adapt to printing diversified packaging boxes and is wide in adaptability.

Owner:SUZHOU TONGLI PRINTING TECH

Efficient biodiesel pour point depressant composition and preparation method and application thereof

InactiveCN110591779AImprove solubilityEvenly dispersedLiquid carbonaceous fuelsFuel additivesSolubilityDispersity

The invention relates to an efficient biodiesel pour point depressant composition. The efficient biodiesel pour point depressant composition is prepared from the following components in percentage bymass: 10-20% of dimethyl phthalate, 10-30% of diethyl phthalate, 5-20% of oleic alcohol ethoxylate and 40-60% of hexadecyl methacrylate-benzyl methacrylate-N-vinyl pyrrolidone. According to the efficient biodiesel pour point depressant composition, the dimethyl phthalate and the diethyl phthalate are used as good solvents, the surfactant oleic alcohol ethoxylate 1602 is used as a solubilizer, thesolvent base of a pour point depressant in biodiesel can be enhanced, the solubility and dispersity of the pour point depressant in diesel are improved, a condensation point and a cold filter pluggingpoint of the biodiesel are effectively reduced, and use of the biodiesel is popularized.

Owner:SHANGHAI INST OF TECH

Resin composition, and molded article and film thereof

ActiveCN108884292AImprove impact resistanceImprove bending resistanceSynthetic resin layered productsPolymer scienceMeth-

Provided is an acrylic resin composition capable of yielding a molded article or film having exceptional mechanical characteristics such as impact resistance and bending resistance, exceptional transparency or color tone, and suppressed retardation. In a resin composition including an acrylic resin and a graft copolymer, the graft copolymer includes the following inner layer and outer layer. Innerlayer: soft polymer (B) having, as structural units: a monomer mixture (b) comprising 40-99% by weight of an acrylic acid alkyl ester, 1-60% by weight of benzyl (meth)acrylate, and 0-40% by weight ofother monomers; and 0.1-5 parts by weight of polyfunctional monomers. Outer layer: hard polymer (C) having, as structural units: a monomer mixture (c) comprising 60-100% by weight of a methacrylic acid alkyl ester, 0-10% by weight of benzyl (meth)acrylate, and 40-0% by weight of other monomers; and 0-10 parts by weight of polyfunctional monomers.

Owner:KANEKA CORP

Polymer cement waterproof paint suitable for low-temperature environment and preparation method thereof

The invention relates to a polymer cement waterproof paint suitable for a low-temperature environment and a preparation method thereof. The waterproof paint comprises a liquid material and a powder material; wherein the liquid material comprises the following raw materials by weight: 15-30 parts of a composite emulsion, 20-35 parts of a plasticizer, 0.5-1 part of a dispersing agent, 0.1-0.5 part of a preservative and 8-15 parts of water; and the powder material comprises the following raw materials by weight: 30-40 parts of cement, 15-25 parts of filler and 0.5-2 parts of a water reducing agent. The liquid material in the waterproof paint is added with the composite emulsion, which is a composite core-shell structure of isooctyl acrylate, 4-(N, N-dimethylamino)benzyl methacrylate and glycidyl acrylate, and the core-shell structure enables the waterproof paint to still maintain excellent toughness at a low temperature.

Owner:潍坊市宇虹防水材料(集团)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com