Efficient biodiesel pour point depressant composition and preparation method and application thereof

A diesel pour point depressant and biodiesel technology, which is used in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of lowering condensation point, lower cold filter point, and unsatisfactory pour point depressant effect, and achieve product yield High, improve dispersibility, enhance the effect of pour point depressurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The method for measuring the cold filter plugging point in the present invention is based on "SH / T0248-2006 Diesel and Civil Heating Oil Cold Filtering Point Measurement Method", and the method for measuring the freezing point is based on "GB510-83 Petroleum Products Freezing Point Measurement".

[0027] Raw materials used in the following examples:

[0028]

[0029] The preparation method of hexadecyl methacrylate-benzyl methacrylate-N-vinylpyrrolidone used in the following examples is: from hexadecyl methacrylate, benzyl methacrylate and N-vinylpyrrolidone in a single The volume molar ratio is 10:1:1, the reaction temperature is 120°C, toluene is used as the solvent, and benzoyl peroxide is used as the initiator to react for 8 hours. The molecular Mw of the polymer tested by GPC was 74,566 g / mol, Mn was 38257 g / mol, and Mw / Mn was 1.949. The product hexadecyl methacrylate-benzyl methacrylate-N-vinylpyrrolidone was subjected to nuclear magnetic characterization as figure 1 ...

Embodiment 2

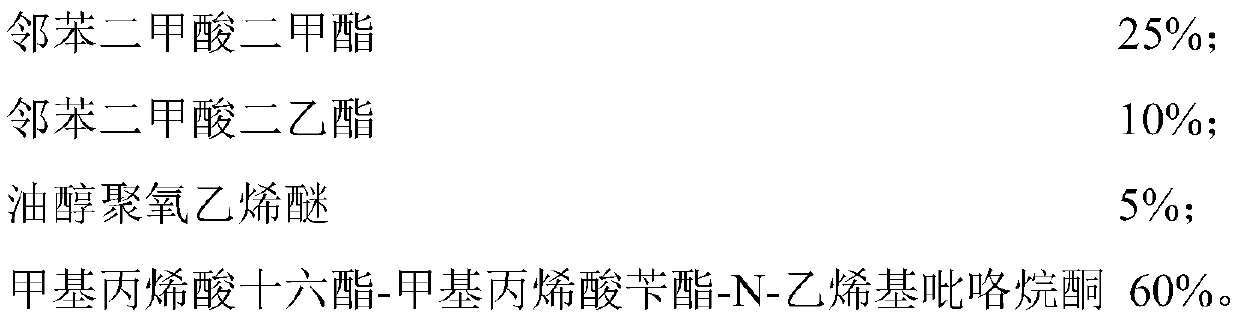

[0037] The biodiesel pour point depressant composition in this embodiment consists of the following mass percentage components:

[0038]

[0039] The pour point depressant is hexadecyl methacrylate-benzyl methacrylate-N-vinylpyrrolidone.

[0040] The method for preparing the above-mentioned pour point depressant composition for diesel fuel is: combining dimethyl phthalate, diethyl phthalate, oleyl alcohol polyoxyethylene ether 1602 and cetyl methacrylate-benzyl methacrylate The ester-N-vinylpyrrolidone is mixed and stirred uniformly at a temperature of 25° C. according to a ratio, and ultrasonically dispersed for 15 minutes to obtain a high-efficiency biodiesel pour point depressant composition.

[0041] The application of the above-mentioned biodiesel pour point depressant composition in biodiesel pour point depressant, the ratio of biodiesel pour point depressant composition: biodiesel is calculated by mass ratio, preferably 0.5%, and the pour point depressant of biodiesel The com...

Embodiment 3

[0044] The biodiesel pour point depressant composition in this embodiment consists of the following mass percentage components:

[0045] A high-efficiency biodiesel pour point depressant composition, in terms of mass percentage, consists of the following components:

[0046]

[0047] The pour point depressant is hexadecyl methacrylate-benzyl methacrylate-N-vinylpyrrolidone.

[0048] The method for preparing the above-mentioned pour point depressant composition for diesel fuel is: combining dimethyl phthalate, diethyl phthalate, oleyl alcohol polyoxyethylene ether 1602 and cetyl methacrylate-benzyl methacrylate The ester-N-vinylpyrrolidone is mixed and stirred uniformly at a temperature of 25° C. according to a ratio, and ultrasonically dispersed for 15 minutes to obtain a high-efficiency biodiesel pour point depressant composition.

[0049] The application of the above-mentioned biodiesel pour point depressant composition in biodiesel pour point depressant, the ratio of biodiesel pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com