Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

237results about How to "Improve pour point depressing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for improving the lubricating properties of base oils using isomerized petroleum product

InactiveUS20050247600A1Increase viscosityImprove pour point depressing effectHydrocarbon purification/separationSolid fuelsChemistryBoiling point

A method for improving the lubricating properties of a isomerized distillate base oil having a kinematic viscosity at 100 degrees C. between about 2.5 cSt and about 8 cSt, the method comprising blending with said isomerized distillate base oil a sufficient amount of a pour point depressing base oil blending component to reduce the pour point of the resulting base oil blend at least 3 degrees C. below the pour point of the distillate base oil wherein the pour point depressing base oil blending component is an isomerized petroleum derived base oil containing material having a boiling range above about 1050 degrees F.; also lubricating base oil blends prepared according to the process; and the pour point depressing base oil blending component.

Owner:CHEVROU USA INC

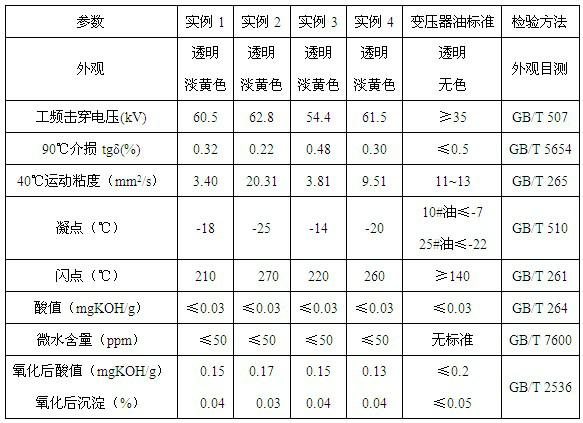

Vegetable insulating oil, and preparation method of vegetable insulating oil

InactiveCN102682869AImprove performanceReduce the temperatureLiquid organic insulatorsBase-materialsVegetable oilAnti oxidant

The invention relates to vegetable insulating oil based on vegetable oil, and a preparation method of the vegetable insulating oil. The insulating oil is prepared by the steps of using refined vegetable oil as raw material, carrying out ester exchange reaction on low-molecular alcohol, refining and washing after the reaction, rinsing, distilling under reduced pressure in order to remove water and alcohol, de-coloring, de-acidifying, filtering, de-watering deeply, finally adding antioxidant and pour point depressant. The insulating oil prepared by the method has the characteristics of high flashing point, low viscosity, low pour point, low acidity, low brackish water content, excellent dielectric constant, low dielectric loss and high breakdown voltage and has good physical and chemical performance and electrical performance.

Owner:CHINA ELECTRIC POWER RES INST

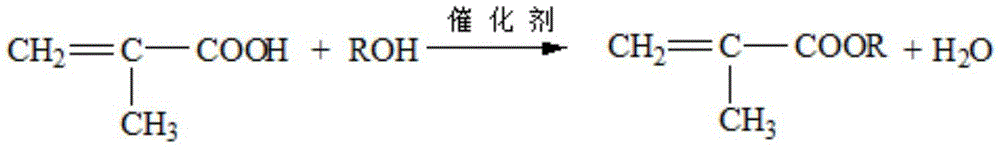

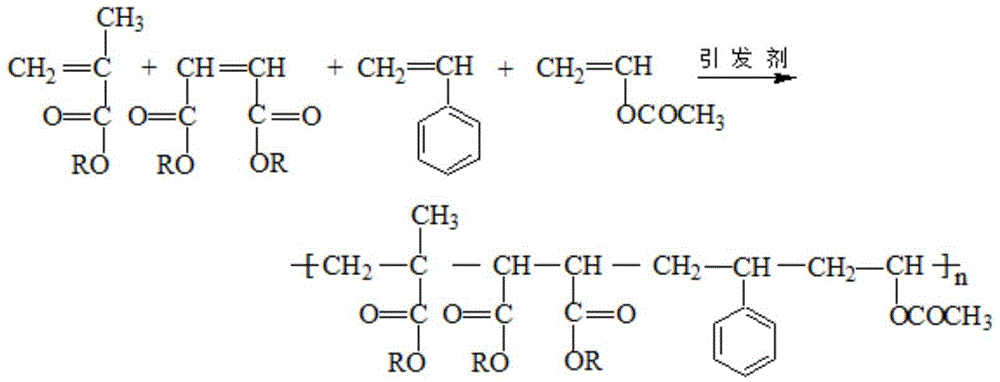

Synthesis method of polymethacrylate pour point depressant

The invention discloses a synthesis method of a polymethacrylate pour point depressant. The method comprises the following steps: (1) synthesizing hexadecyl methacrylate; (2) synthesizing a polymer, proportioning and adding the hexadecyl methacrylate, styrene and maleic anhydride in a ratio of (2-10):(1-5):(1-5) into a three-mouth flask filled with magnetite, by taking toluene as a solvent, adding an initiator benzoyl peroxide, and heating for completely dissolving the reactants, starting to stir, according to the difference of carbon numbers of polycarbonates, maintaining the internal temperature of the three-mouth flask at 65-90 DEG C, and carrying out reaction for 4-8 h; and (3) removing toluene by reduced pressure distillation. The method disclosed by the invention achieves the beneficial effects that the polymethacrylate pour point depressant synthesized by using the method is high in purity, high in yield, and good in pour point depressing effect; and the selection scope of the pour point depressant to base oil is expanded, and the low-temperature fluidity of lubricating oil can be improved well.

Owner:QINGDAO BAIZHONG CHEM TECH

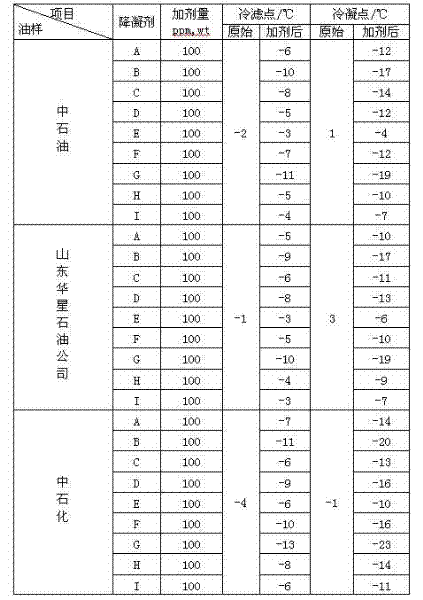

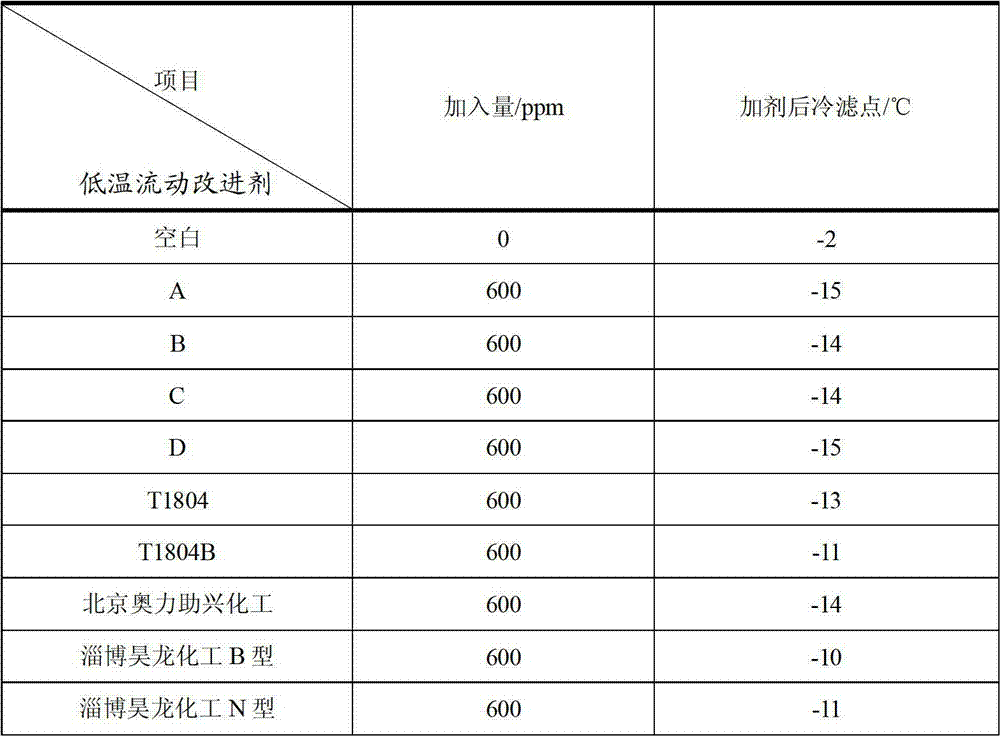

Diesel pour point depressant and preparation method thereof

ActiveCN102559302AUniversalGood fluidity at low temperatureLiquid carbonaceous fuelsControl theoryCold filter plugging point

The invention belongs to the field of diesel additive and particularly relates to a diesel pour point depressant and a method for preparing the diesel pour point depressant. The diesel pour point depressant overcomes the defects of the prior pour point depressant and can be used for greatly reducing the cold filter plugging point and the pour point of diesel. In addition the diesel pour point depressant can be widely applied to various diesels, thereby having low limitation.

Owner:山东星火知识产权服务有限公司

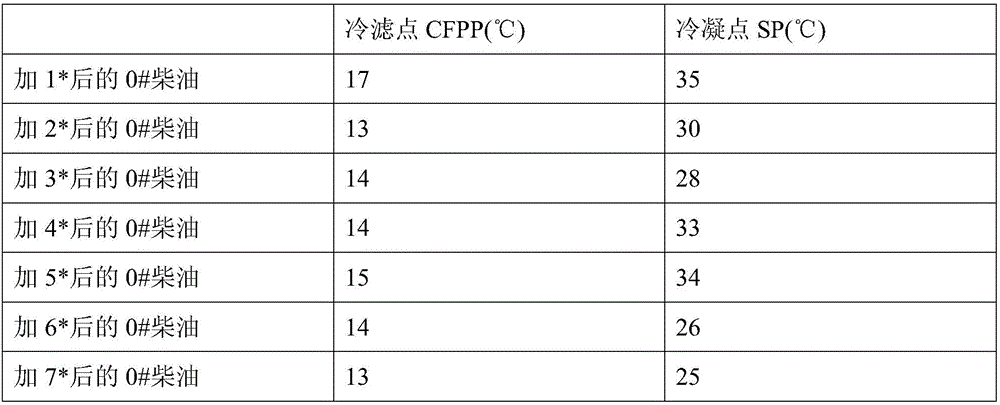

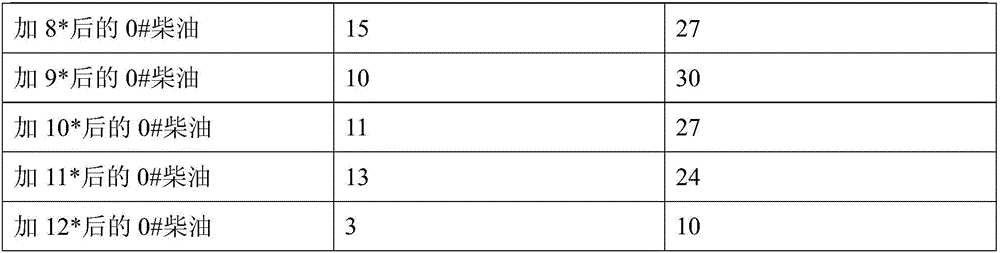

Diesel oil pour-point depressant and preparation method and application thereof

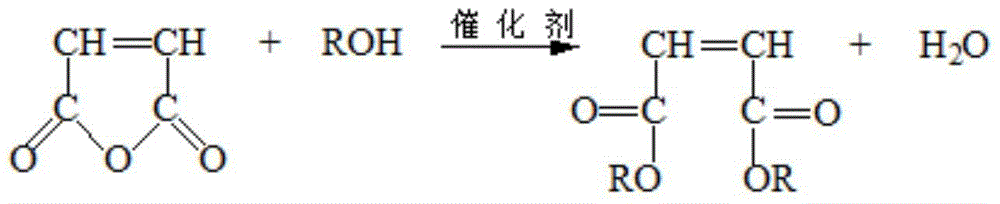

InactiveCN104530305ASolve the problem of poor broad spectrumComposite strongLiquid carbonaceous fuelsMethacrylatePtru catalyst

The invention discloses a diesel oil pour-point depressant and a preparation method thereof, wherein the diesel oil pour-point depressant is prepared by the steps: carrying out an aminolysis reaction on a methacrylate maleic anhydride copolymer and higher fatty amine for 6 h with toluene as a solvent and p-toluenesulfonic acid as a catalyst and at a reflux temperature, adding methanol having the same volume as the reaction liquid volume into the obtained reaction liquid, producing a white precipitate, removing a supernatant, washing the obtained white precipitate with toluene, carrying out methanol precipitation to remove the catalyst p-toluenesulfonic acid, then controlling the temperature at 50 DEG C, and carrying out vacuum drying to obtain the diesel oil pour-point depressant. The diesel oil pour-point depressant solves the problems that a (methyl) acrylate pour-point depressant has poor adaptability with diesel oils with different carbon chains, at the same time, makes the reaction of maleic anhydride more diversified, provides another possibility for combination of a maleic anhydride pour-point depressant with the (methyl) acrylate pour-point depressant, effectively improves the condensation point and the cold filter plugging point of No.0 diesel oil, and enables the cold filter plugging point to be superlatively reduced by 11-12 DEG C.

Owner:SHANGHAI INST OF TECH

Diesel oil pour-point and viscosity reducer, and preparation method thereof

InactiveCN103642546AGood fluidity at low temperatureImprove pour point depressing effectLiquid carbonaceous fuelsFuel additivesActive agentEthyl acetate

The invention discloses a diesel oil pour-point and viscosity reducer, and a preparation method thereof. The diesel oil pour-point and viscosity reducer comprises following ingredients, by weight, 20 to 30 parts of ethylene-vinyl acetate copolymer, 10 to 20 parts of styrene-maleic acid octadecanol ester copolymer, 10 to 20 parts of polymethacrylate, 5 to 10 parts of a nonionic surfactant, 5 to 10 parts of ethyl acetate, 5 to 10 parts of maleic anhydride, and 25 to 30 parts of solvent oil No.200. The diesel oil pour-point and viscosity reducer is capable of avoiding defects of existing pour-point depressants and viscosity reducers that viscosity reducing rate is low, application is restricted, pour-point reducing amplitude, and viscosity reducing amplitude are both small; is capable of reducing cold filter plugging point, pour point and viscosity of diesel oil greatly; and can be widely used for various diesel oils; and limitation is less.

Owner:JINAN DEV ZONE XINGHUO SCI & TECH RES INST

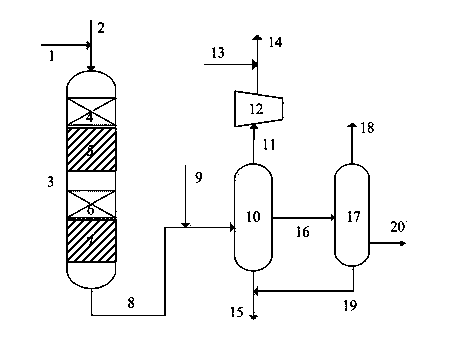

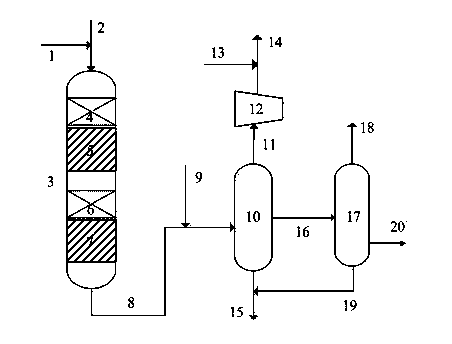

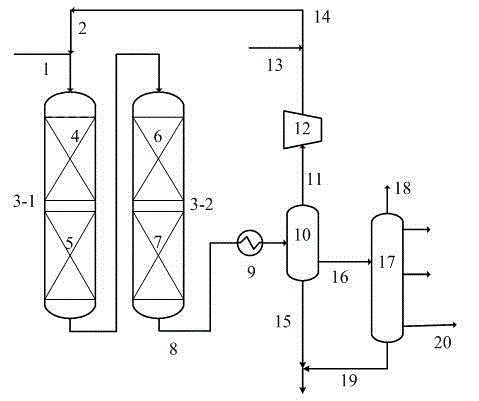

Method for producing diesel oil with low condensation point by catalyst gradation technology

ActiveCN103805257ALow yieldGuaranteed yieldTreatment with hydrotreatment processesHydrogenation reactionSulfur

The invention discloses a method for producing diesel oil with a low condensation point by catalyst gradation technology. The method comprises the following steps: mixing a diesel oil raw material with hydrogen, orderly passing through at least two hydrogenation reaction zones connected in series, wherein in the material flowing direction, each hydrogenation reaction zone orderly comprises a hydro-refining dewaxing catalyst composite bed layer filled with a mixture of a hydro-refining catalyst and a hydro-upgrading isodewaxing catalyst, and a hydrodewaxing catalyst bed layer; performing separation and fractionation of the reaction effluent from the last hydrogenation reaction zone to obtain the diesel oil product with a low condensation point. The method of the invention reasonably combines and utilizes the temperature increase of the hydro-refining and hydro-upgrading dewaxing process with the temperature decrease of the hydrodewaxing process, improves the diesel oil yield and the cetane value while producing diesel oil with a low condensation point and low sulfur, reduces the hot-spot temperature of the device, prolongs the running period, also reduces the cold hydrogen consumption or the combustion gas loss of a heating furnace, and saves operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

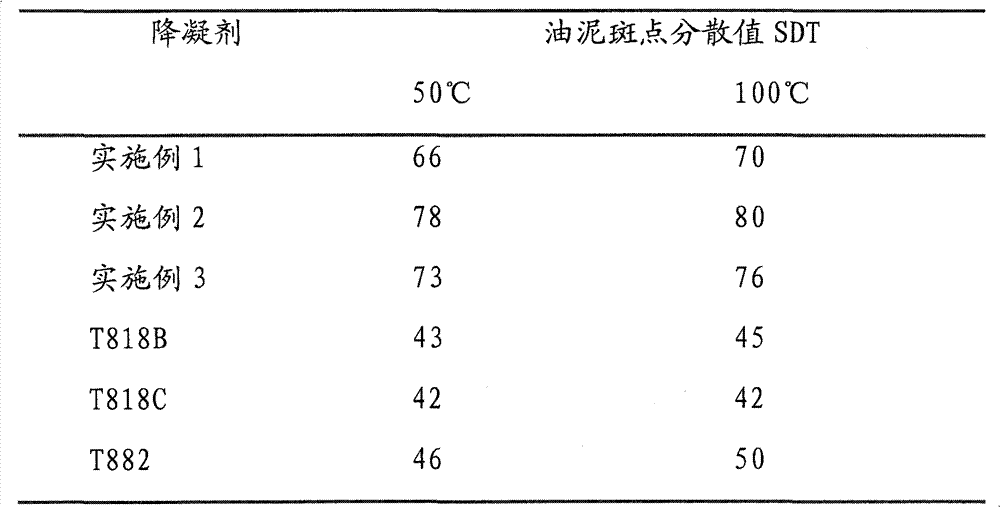

Diesel fuel pour-point depressant dispersant and preparation method thereof

ActiveCN101709233AIncreased sensitivityImprove pour point depressing effectLiquid carbonaceous fuelsFuel additivesPolyethylene glycolDepressant

The invention discloses a diesel fuel pour-point depressant dispersant and a preparation method thereof. The dispersant comprises the following components by weight percentage: 0-20% of Tween, 0-20% of polyethylene glycol, 0-10% of vinyl alcohol butyl ether, 0-10% of polar nitrogenous compounds and 50-80% of Span-80. The raw materials are weighed and mixed according to the weight percentage, and then the materials are stirred in a stirring tank with the speed of 100rpm for 30 min at the temperature of 50 DEG C, and the dispersant is prepared. In the invention, a new dispersant mixture is prepared by combining and mixing various kinds of dispersants uniformly, and then is used with the pour-point depressant according to a certain proportion, thereby improving the sensitivity of the pour-point depressant and the effect of pour point depression.

Owner:SHANGHAI INST OF TECH

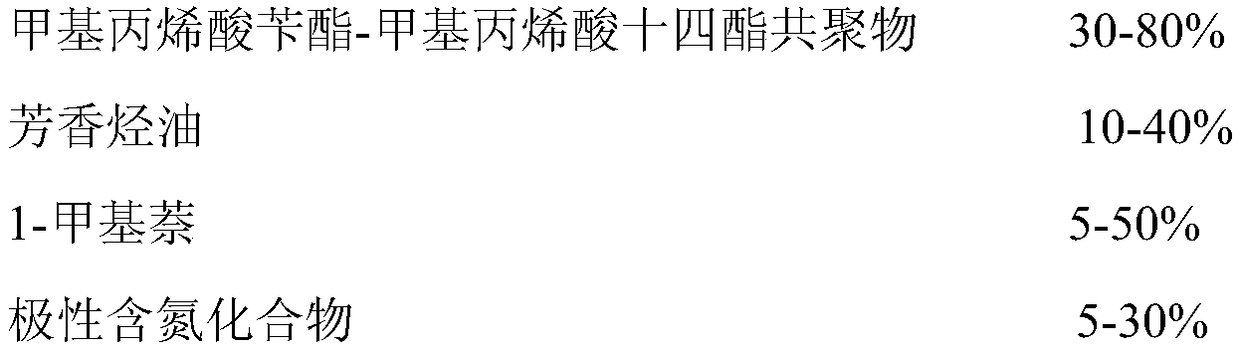

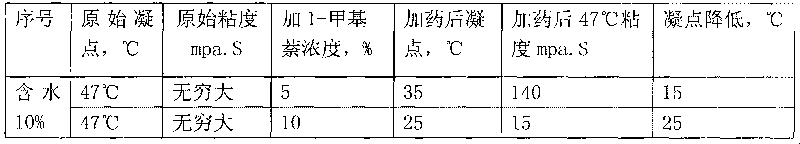

Wide-spectrum diesel pour point depressant composition, preparation method thereof and application of composition

InactiveCN109135846AIncrease polarityImprove solubilityLiquid carbonaceous fuelsFuel additivesPolymer scienceNitrogen

The invention discloses a wide-spectrum diesel pour point depressant composition, a preparation method thereof and an application of the composition. The pour point depressant composition comprises, in weight percent, 30-80% of benzyl methacrylate-methacrylic acid tetradecyl ester copolymers, 10-40% of arene oil, 5-50% of 1-methylnaphthalene and 5-30% of polar nitrogen-containing compounds. The raw materials are uniformly mixed according to predetermined weight percent to obtain the composition. The diesel pour point depressant composition can be rapidly dissolved in diesel oil, is high in spectrum and has remarkable pour point declining effect when being applied to different diesel, and a condensation point and a cold filter plugging point are reduced by 21-26 DEG C and 8-12 DEG C.

Owner:SHANGHAI INST OF TECH

Preparation method of diesel oil pour point reducer composition

InactiveCN1475512AGood pour point depressing effectObvious filtering effectPipeline systemsSolventPrimary alcohol

A composite pour depressor for diesel oil is prepared through polymerizing reaction of styrene on maleic acid anhydride in organic solvent at 80-90 deg.C for 3-5 hr under action of trigger (peroxide or azo compound), open-loop esterifying reaction on primary alcohol at 130-160 deg.C for 3-7 hr under the existance of catalyst (toluenesulfonic acid or sulfuric acid), and mixing with the toluene or xylene arylhydrocarbon solvent. Its advantage is high pour depressing effect.

Owner:PETROCHINA CO LTD

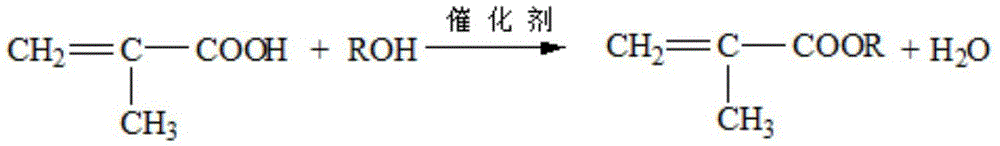

Preparation method of diesel oil pour point depressant

InactiveCN106279514ALower condensation pointImprove low temperature fluidityLiquid carbonaceous fuelsFuel additivesMaleic anhydrideSolvent

The invention discloses a preparation method of a diesel oil pour point depressant. The method includes the following steps of firstly, weighing high alcohols, catalyst, polymerization inhibitor and solvent to be sequentially added into a reactor and stirred till solids are completely dissolved, then adding methacrylic acid, and conducting reduced pressure distillation, alkali washing and water washing on the product after reaction ends to obtain methylacrylic acid high-carbon ester; secondly, weighing methylacrylic acid high-carbon ester, maleic anhydride, initiator and solvent to be evenly mixed, conducting reacting at a certain reaction temperature under the protection of nitrogen, adding aromatic amine and catalyst after reaction, changing the reaction temperature for reaction for a certain period of time, conducting reduced pressure distillation on the reaction liquid after reaction ends, then adding an excessive amount of methyl alcohol to generate white precipitates, removing supernate, and conducting washing and vacuum drying on the obtained white precipitates through methyl alcohol to obtain the diesel oil pour point depressant. The prepared diesel oil pour point depressant can remarkably reduce the condensation point of diesel oil and improve the low-temperature flowability of diesel oil; the raw materials are easy to obtain, the synthesis method is simple, and the additive dosage is small.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

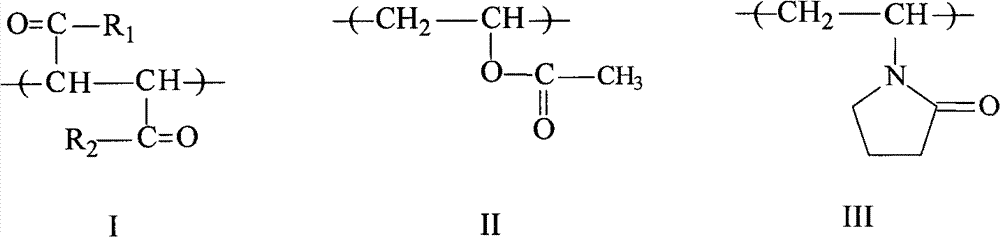

Polymer used in lubricating oil pour point depressing, lubricating oil pour point depressant, and preparation method thereof

The invention relates to a polymer used in lubricating oil pour point depressing, a lubricating oil pour point depressant, and a preparation method thereof. The polymer provided by the invention is a random copolymer of fumarate, vinyl acetate and vinyl pyrrolidone. The polymer has a certain dispersion effect, and a good pour point depressing effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Combined process method for producing clean diesel oil with low condensation point

ActiveCN103805258AGuaranteed yieldRealize comprehensive utilizationTreatment with hydrotreatment processesFractionationLiquid gas

The invention discloses a combined process method for producing clean diesel oil with a low condensation point. The method comprises the following steps: mixing a diesel oil raw material with hydrogen, orderly passing through at least two hydrogenation reaction zones connected in series, wherein in the material flowing direction, each hydrogenation reaction zone orderly comprises a hydro-upgrading catalyst bed layer, and a hydrodewaxing catalyst composite bed layer filled with a mixture of a hydrodewaxing catalyst and a hydro-refining catalyst; performing separation and fractionation of the reaction effluent from the last hydrogenation reaction zone to obtain the clean diesel oil product with a low condensation point, and a few light naphtha and liquefied gas products. The method of the invention reasonably combines and utilizes the temperature decrease of the hydrodewaxing process with the temperature increase of the hydro-refining and hydro-upgrading process, improves the diesel oil yield while producing diesel oil with a low condensation point and low sulfur, reduces the hot-spot temperature of the device, prolongs the running period, also reduces the cold hydrogen consumption or the combustion gas loss of a heating furnace, and saves operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing hydrogenated diesel oil with low condensation point by gradation technology

ActiveCN103805251ALow costRealize comprehensive utilizationTreatment with hydrotreatment processesHydrogenation reactionSulfur

The invention discloses a method for producing hydrogenated diesel oil with a low condensation point by gradation technology. The method comprises the following steps: mixing a diesel oil raw material with hydrogen, orderly passing through at least two hydrogenation reaction zones connected in series, wherein in the material flowing direction, each hydrogenation reaction zone orderly comprises a hydro-refining hydro-upgrading catalyst composite bed layer filled with a mixture of a hydro-refining catalyst and a hydro-upgrading catalyst, and a hydrodewaxing catalyst bed layer; performing separation and fractionation of the reaction effluent from the last hydrogenation reaction zone to obtain the diesel oil product with a low condensation point. The method of the invention reasonably combines and utilizes the temperature decrease of the hydrodewaxing process with the temperature increase of the hydro-upgrading process, improves the diesel oil yield while producing diesel oil with a low condensation point and low sulfur, reduces the hot-spot temperature of the device, prolongs the running period, also reduces the cold hydrogen consumption or the combustion gas loss of a heating furnace, and saves operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Broad-spectrum wax-proof pour point depressant for crude oil

The invention provides a broad-spectrum wax-proof pour point depressant for crude oil. Octadecyl acrylate, methacrylic acid docosane ester, styrene and maleic anhydride are mixed according to certain proportion and then react for 4 to 4.5 hours at a temperature of between 120 and 125 DEG C to form an agent A; 3-ethyl toluene and fatty alcohol-polyoxyethylene ether are mixed according to certain proportion and then react for 2 to 2.5 hours at a temperature of between 60 and 65 DEG C to form an agent B; and the agent A and the agent B are mixed, the temperature of the mixture is kept constant for 1 to 1.5 hours at a temperature of between 80 and 85 DEG C, and then the mixture is permitted to stand for 1.5 to 2 hours to form the pour point depressant. The pour point depressant has wide application range and good pour point depression effect, effectively improves the liquidity of the crude oil, is safe and reliable, has good environmental benefit, and can increase the yield of the crude oil, reduce the times of thermally washing the well and reduce the production cost of oilfields.

Owner:PANJIN LIAOHE OILFIELD YULONG RUIDA PETROLEUM TECH CO LTD

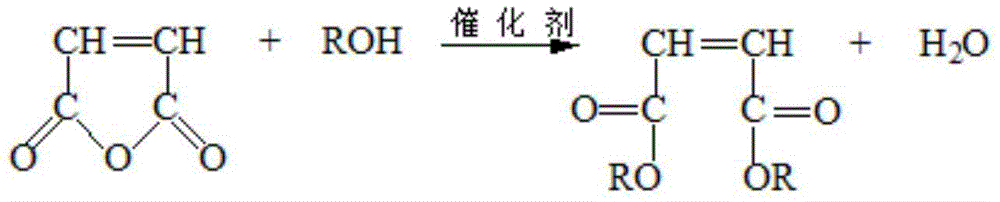

Preparation method of binary polymer wax oil pour point reducer

InactiveCN102079799AGood pour point depressing effectStable performanceDrilling compositionWaxSolvent

The invention discloses a preparation method of a binary polymer wax oil pour point reducer, relating to a preparation method of a chemical preparation. The preparation method is characterized in that the wax oil pour point reducer is formed by the steps of firstly esterifying maleic anhydride and octadecanol and then polymerizing with vinylacetate. The preparation method comprises the steps of: firstly, preheating the maleic anhydride, the octadecanol and a methylbenzene mixed solution used as a solvent and a water carrying agent to be clear, adding a catalyst, continuously heating to be boiled, reacting, then carrying out reduced pressure distillation to obtain the dioctadecyl maleic anhydride; and then mixing the dioctadecyl maleic anhydride with the vinylacetate and an initiating agent BPO (benzoyl peroxide), and polymerizing the dioctadecyl maleic anhydride with the vinylacetate to obtain a final product of a dioctadecyl maleic anhydride-vinylacetate polymer (PMVA). The novel pour point reducer has excellent wax oil pour point reducing effect and more stable performance, and is applied to the fields of extraction and transportation of petroleum.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Process for improving the lubricating properties of base oils using isomerized petroleum product

InactiveUS7655132B2Improve pour point depressing effectReduce pointsHydrocarbon purification/separationSolid fuelsPetroleum productBase oil

A method for improving the lubricating properties of a isomerized distillate base oil having a kinematic viscosity at 100 degrees C. between about 2.5 cSt and about 8 cSt, the method comprising blending with said isomerized distillate base oil a sufficient amount of a pour point depressing base oil blending component to reduce the pour point of the resulting base oil blend at least 3 degrees C. below the pour point of the distillate base oil wherein the pour point depressing base oil blending component is an isomerized petroleum derived base oil containing material having a boiling range above about 1050 degrees F.; also lubricating base oil blends prepared according to the process; and the pour point depressing base oil blending component.

Owner:CHEVROU USA INC

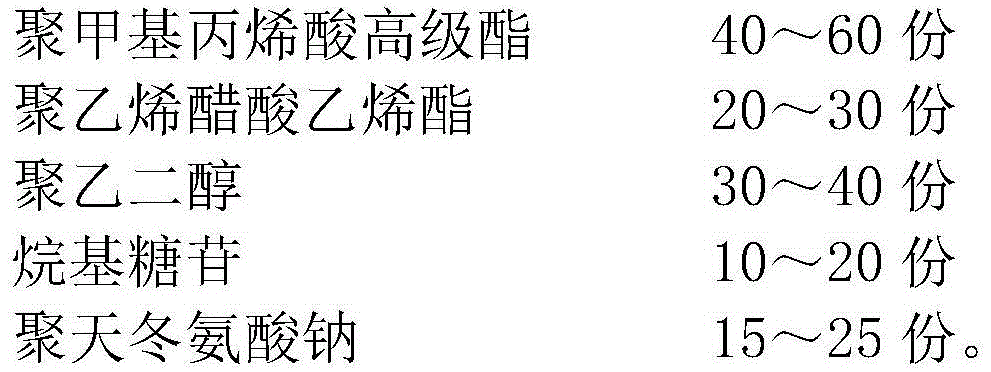

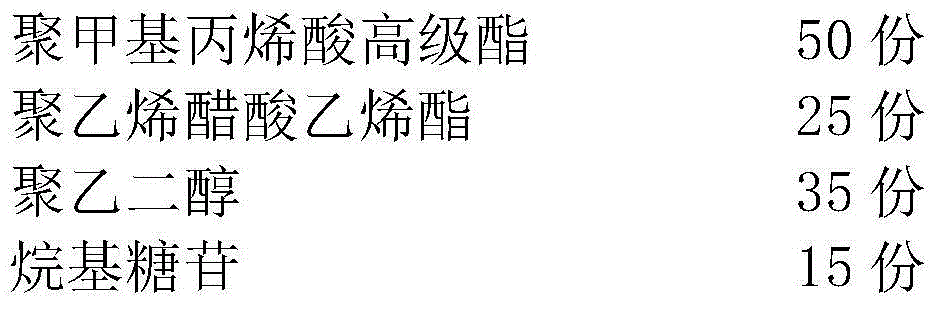

Diesel oil pour point depressant

InactiveCN104910977AGood dispersionLowering the freezing pointLiquid carbonaceous fuelsFuel additivesPolyethylene vinyl acetatePolyethylene glycol

The invention relates to the technical field of pour point depressants and particularly relates to the technical field of a diesel oil pour point depressant. The diesel oil pour point depressant is prepared from the following raw materials in parts by weight: 40-60 parts of high polymethacrylate, 20-30 parts of polyethylene vinyl acetate, 30-40 parts of polyethylene glycol, 10-20 parts of alkyl glycoside and 15-25 parts of sodium polyaspartate. According to the diesel oil pour point depressant disclosed by the invention, the pour point depression effect is remarkably improved, the cold filter plugging point and pour point of all diesel oil can be effectively lowered, particularly the sensitivity to high-wax-content and narrow-fraction diesel oil is relatively good, the flowing property of the high-wax-content and narrow-fraction diesel oil is better improved under low-temperature conditions, the diesel oil pour point depressant is environment-friendly and has an excellent market value, and the problems of the existing diesel oil pour point depressants in China petrochemical industry that the pertinence is high, the performance is single and the broad-spectrum performance is poor are solved.

Owner:马健

Nano compound pour point depressant and preparation method thereof

InactiveCN105969433ABroaden the crystallization temperature rangeCompact arrangementLiquid carbonaceous fuelsFuel additivesMontmorilloniteCold filter plugging point

The invention discloses a nano compound pour point depressant and a preparation method thereof. The nano compound pour point depressant disclosed by the invention is compounded from a nano material and a polymer pour point depressant by a melting and blending method. A montmorillonite nano material modified by cetyl trimethylammonium bromide is compounded with the polymer pour point depressant in a certain mass ratio by adopting the melting and blending method so as to obtain the nano compound pour point depressant. The pour point depression effect of the nano compound pour point depressant is further enhanced on the basis of pour point depression of the original pour point depressant. When the nano compound pour point depressant is applied to 0# diesel oil, the pour point depression effect is superior to that of a commercially available pour point depressant, and the cold filter plugging point and the condensation point are respectively reduced by 12-20 DEG C and 18-26 DEG C.

Owner:SHANGHAI INST OF TECH

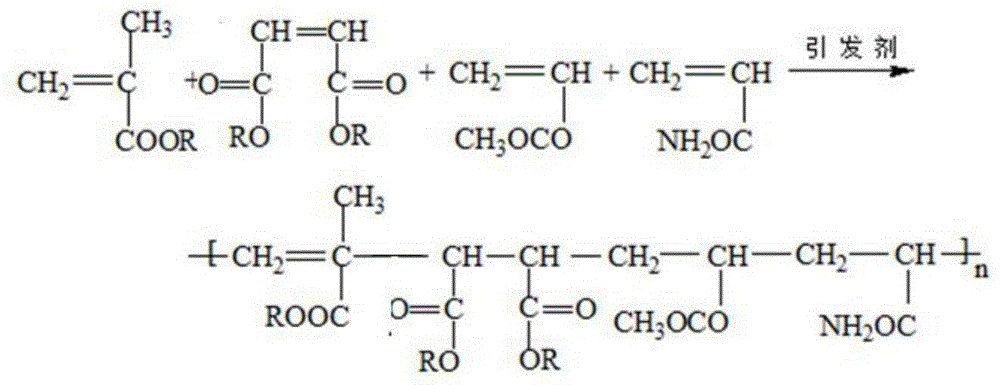

Preparation method of quadripolymer pour point depressant for diesel oil

ActiveCN105524211AImprove pour point depressing effectSolve the problem of poor pour point depressing effectLiquid carbonaceous fuelsMaleic anhydrideSolvent

The invention discloses a preparation method of a quadripolymer pour point depressant for diesel oil. The preparation method at least comprises steps as follows: a, in the presence of a solvent, methacrylic acid higher alcohol ester is synthesized with methacrylic acid and higher alcohol used as raw materials; b, in the presence of a solvent, maleic anhydride higher alcohol ester is synthesized with maleic anhydride and higher alcohol used as raw materials; c, in the presence of a solvent, methacrylic acid higher alcohol ester, maleic anhydride higher alcohol ester, vinyl acetate and styrene are taken as monomers, an initiator is added, and the quadripolymer pour point depressant for diesel oil is prepared, wherein the molar ratio of methacrylic acid higher alcohol ester to maleic anhydride higher alcohol ester to vinyl acetate to styrene is 4:(1.8-2.2):(2.8-3.2):(0.8-1.2). The preparation method has the benefits as follows: the quadripolymer pour point depressant is adopted to replace an existing homopolymer pour point depressant, and the pour point depression effect of the quadripolymer pour point depressant is better than that of the single-component homopolymer pour point depressant obviously.

Owner:LIAONING PETROCCHEM VOCATIONAL & TECH COLLEGE

Hydroisomerization pour-point-depressing deep-coupling process for producing low-pour-point diesel oil

ActiveCN105087063AImprove combustion effectRealize cleaner productionTreatment with hydrotreatment processesIsomerizationHydrogenation reaction

The invention discloses a hydroisomerization pour-point-depressing deep-coupling process for producing low-pour-point diesel oil. The process comprises the following steps: mixing a diesel oil raw material and hydrogen; then successively allowing the mixture to pass through at least two tandem hydrogenation reaction zones, wherein each hydrogenation reaction zone successively includes a composite catalyst bed layer filled by a mixture of a hydrodewaxing catalyst and a hydro-upgrading isomerization pour-point-depressing catalyst, and a hydrofining catalyst bed layer according to a flow direction of the materials; and finally, subjecting an obtained reaction effluent of the last hydrogenation reaction zone to separation and fractionation so as to obtain the low-pour-point diesel oil. The method provided by the invention reasonably utilizes temperature rise in upgrading pour-point-depressing process and temperature drop in hydrodewaxing process, so clean low-pour-point diesel oil is produced; meanwhile, the yield and cetane number of the diesel oil are improved; hot-spot temperature of a device is reduced; and operation cycle is prolonged; moreover, consumption of cooled hydrogen and fuel gas loss of a heating furnace are reduced, and operation cost is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

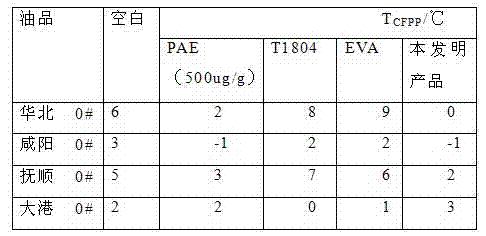

Low-temperature fluidity improver for diesel oil

ActiveCN102766491ALower cold filter pointImprove liquidityLiquid carbonaceous fuelsFuel additivesChemical industryCompound a

The invention relates to the technical field of chemical industry, and relates to a low-temperature fluidity improver for diesel oil, in particular to the low temperature fluidity improver for diesel oil, which is capable of significantly reducing the cold filter plugging point of the diesel oil. The low-temperature fluidity improver is obtained by compounding a proper main agent and proper auxiliary agents and then uniformly mixing. The low-temperature fluidity improver with the ratio is better in sensitivity for most of diesel oil, and particularly can reach better decompression effect for the diesel with higher wax content and narrower boiling range.

Owner:山东京博众诚清洁能源有限公司

Pour point depressant for crude oil

ActiveCN101735788ALower the freezing point of crude oilSatisfy depressing needsDrilling compositionDepressantMethyl group

The invention discloses a pour point depressant for crude oil. The depressant is prepared from methylnaphthalene, wherein the methylnaphthalene is 1-methylnaphthalene, any one in mixed methylnaphthalene or a mixture of 1-methylnaphthalene and mixed methylnaphthalene in any ratio; or the methylnaphthalene is a mixture prepared from 2-methylnaphthalene dissolved in 1-methylnaphthalene or mixed methylnaphthalene at normal temperature and pressure or a mixture prepared from 2-methylnaphthalene dissolved in a mixed solution of 1-methylnaphthalene and mixed methylnaphthalene in any ratio under normal temperature and pressure, and the maximum content of the 2-methylnaphthalene in the mixture is not more than the saturation concentration of the 2-methylnaphthalene in the solution at normal temperature and pressure. The invention can greatly decrease the pour point of crude oil in different oil fields, can be widely used for solving the problem of depressing the pour point of crude oil in various phases of oil recovery, gathering and storage and transportation in different oil fields, can lower the cost for depressing the pour point of crude oil, and has the advantages of less toxic and side effects, high safety, simple production, low cost, strong applicability, easy popularization and application and the like.

Owner:盘锦河升大地石油科技有限公司

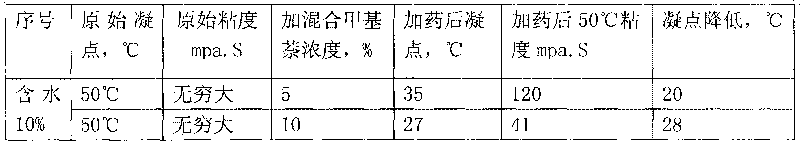

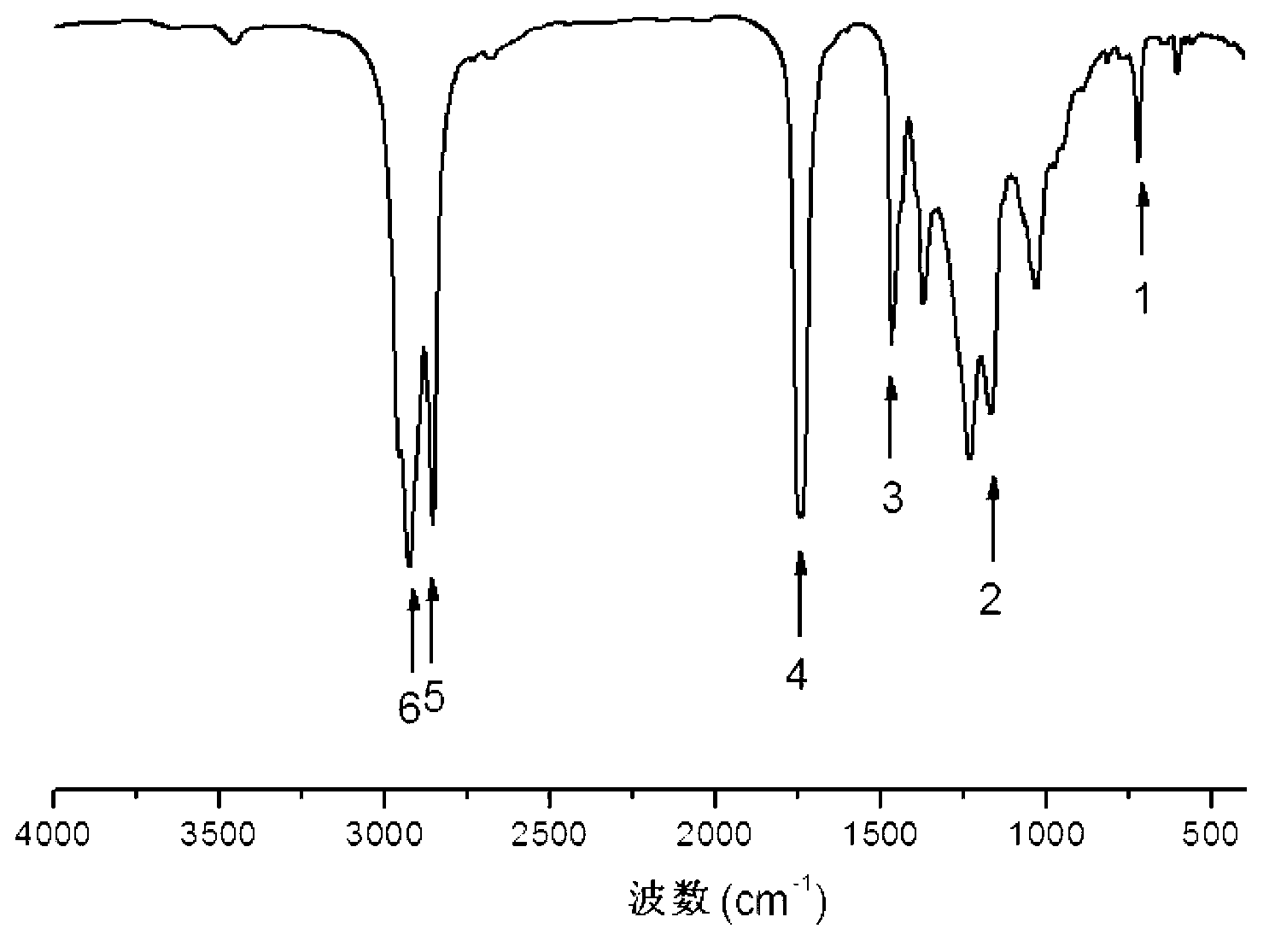

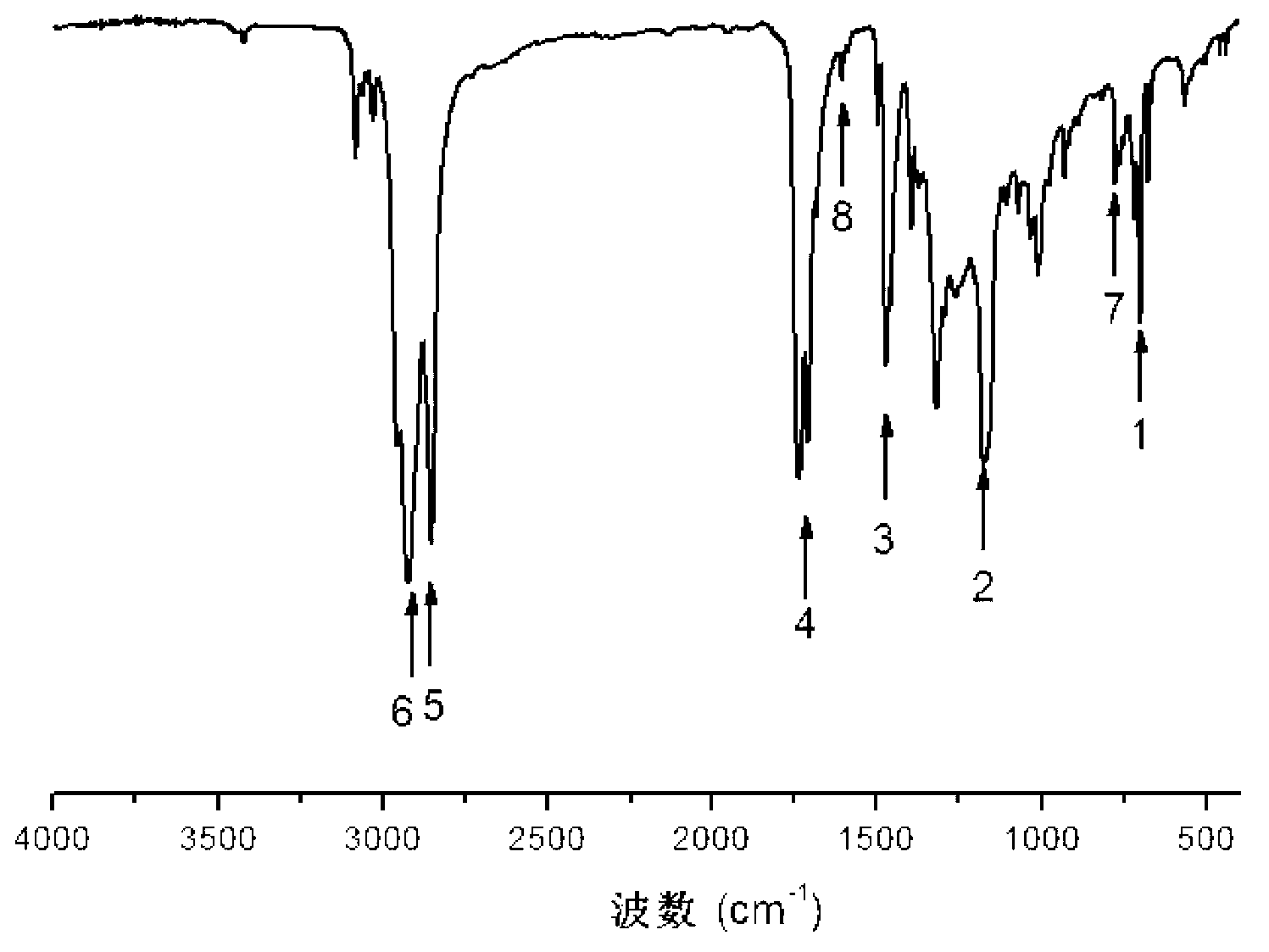

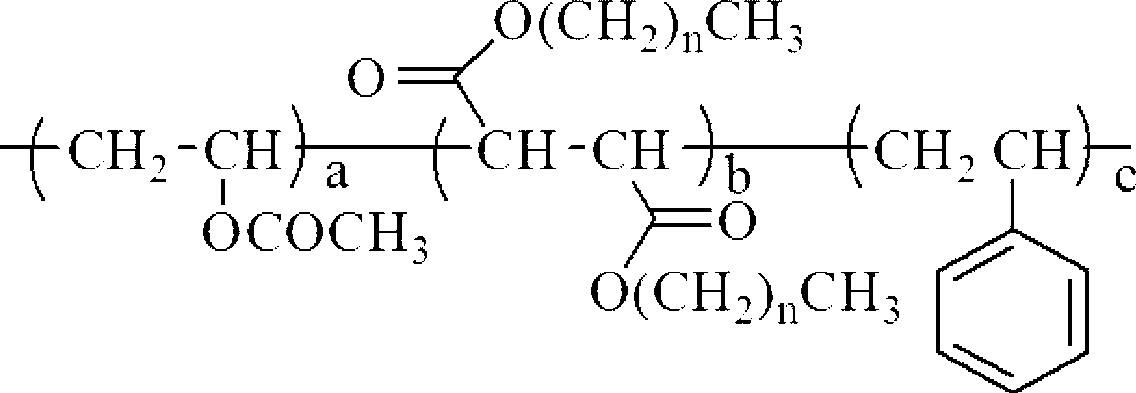

Copolymer pour-point depressant for lubricating oil

InactiveCN103012650AImprove pour point depressing effectLubricant compositionStructural formulaPour point

The invention provides a copolymer pour-point depressant for lubricating oil to further improve pour-point depression effects of conventional pour-point depressants. The copolymer pour-point depressant is a triblock copolymer or a mixture of a plurality of triblock copolymers. A structural formula of the triblock copolymer is described in the specification; in the structural formula, n is an integer in a range of 7 to 17, a, b and c are integers in a range of 1 to 1000, respectively, and viscosity-average molecular weight of the triblock copolymer is 10000 to 500000. The invention also provides a preparation method for the triblock copolymer. The pour-point depressant provided by the invention has excellent pour-point depression effects and enables a pour point to be reduced by 32 DEG C.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +1

Method for producing hydrogenated diesel oil with low freezing point

ActiveCN104611033AHigh yieldIncrease cetane numberTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenation reactionHeating furnace

The invention discloses a method for producing hydrogenated diesel oil with a low freezing point. The method comprises the following steps: mixing a diesel oil raw material with hydrogen, allowing the obtained mixture to sequentially go through at least two serially connected hydrogenation reaction zones, wherein the hydrogenation reaction zones sequentially comprise a pour point reduction modified catalyst composite bed layer filled with a hydrodewaxing catalyst and a hydroupgrading catalyst and a hydrodewaxing catalyst bed layer along a material flow direction; and separating a reaction effluent obtained from the last hydrogenation reaction zone, and fractioning to obtain a diesel oil product with a low freezing point. The method reasonably combines the temperature decrease of the hydrodewaxing process and the temperature rise of the hydroupgrading process, so the diesel oil with a low freezing point is produced, the yield and the cetane value of the diesel oil are improved, the hot spot temperature of a device is reduced, and the running period is prolonged; and the consumption of cold hydrogen or the combustion gas loss of a heating furnace is reduced, so the operating cost is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Biodiesel pour point reducer composition containing Tween surfactant and preparation method thereof

InactiveCN102690692AImprove pour point depressing effectImprove low temperature fluidityLiquid carbonaceous fuelsBiodieselActive agent

The invention discloses a biodiesel pour point reducer composition containing a Tween surfactant and a preparation method thereof. The biodiesel pour point reducer composition containing the Tween surfactant is formed by mixing Tween series surfactants and a biodiesel pour point reducer, wherein the materials comprise the following components by weight percent: 5 to 10 percent of Tween 20, 0 to 5 percent of Tween 40, 5 to 10 percent of Tween 60, 40 to 60 percent of Tween 80 and 0 to 50 percent of biodiesel pour point reducer. The preparation method comprises the following steps of: mixing the raw materials and stirring the raw materials in a thermostatic water bath condition, and controlling the rotating speed to 300 revolutions per minute for 15 minutes so as to obtain the biodiesel pour point reducer composition containing the Tween surfactant. The biodiesel pour point reducer composition is added into biodiesel, so that the cold filter plugging point of the biodiesel is reduced by 7 to 12 DEG C, the condensation point of the biodiesel is reduced by 7 to 13 DEG C, and the low temperature fluidity of a biodiesel product is improved.

Owner:SHANGHAI INST OF TECH

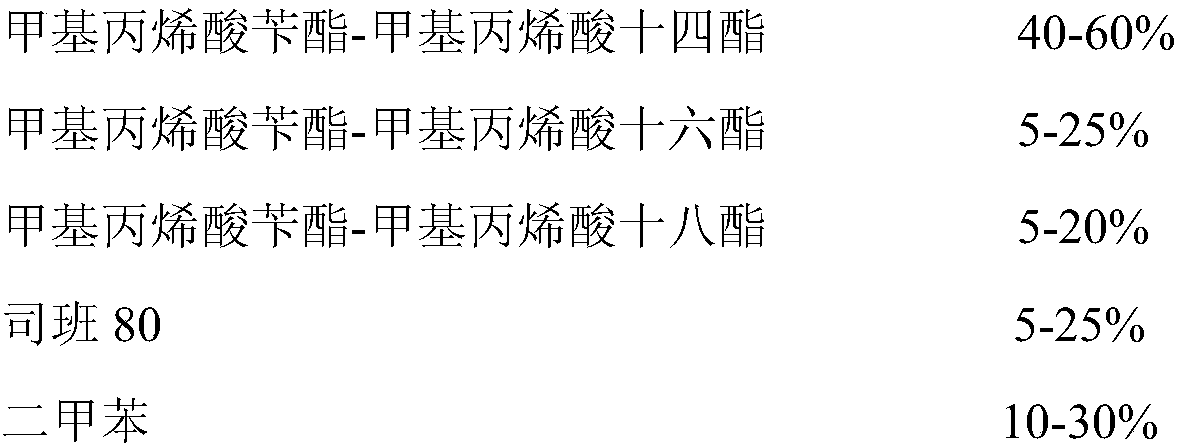

Diesel oil pour point depressant composition as well as preparation method and application thereof

ActiveCN109053951AEvenly dispersedImprove solubilityLiquid carbonaceous fuelsFuel additivesSolubilityNational standard

The invention discloses a diesel oil pour point depressant composition as well as a preparation method and application thereof. The diesel oil pour point depressant composition is prepared from the following components by mass percent: 40-60% of benzyl methacrylate-tetradecyl methacrylate, 5-25% of benzyl methacrylate-hexadecyl methacrylate, 5-20% of benzyl methacrylate-octadecyl methacrylate, 5-25% of span 80 and 10-30% of xylene. The diesel oil pour point depressant composition provided by the invention not only can effectively enhance the solubility of a pour point depressant in diesel oil,but also can effectively improve the low temperature flow performance of the diesel oil. After the obtained diesel pour point depressant composition is added into the commercially available diesel oil with model 0, the condensation point and cold filter point of the diesel oil with model 0 are respectively lowered by 22-26 DEG C and 8-11 DEG C, and the other properties of the diesel oil with model 0 can reach the national standards; the diesel oil pour point depressant composition can meet the requirement that various diesel-powered motor vehicles work normally at the low temperature.

Owner:湖南浩润科技有限公司

Nanometer compound binary polymer pour point reducer and preparation method thereof

ActiveCN106281497AImprove low temperature fluidityServe as depressantLiquid carbonaceous fuelsFuel additivesCompound aPolymer science

The invention discloses a nanometer compound binary polymer pour point reducer and a preparation method thereof. The nanometer compound binary polymer pour point reducer is formed by compounding a nanometer material and a binary polymer pour point reducer through a solvent blending method. The method includes the following steps of esterifying methacrylic acid and multi-carbon alcohol, copolymerizing the product with maleic anhydride to obtain the binary polymer pour point reducer, and finally compounding the nanometer SiO2 material modified by a silane coupling agent KH570 with the binary polymer pour point reducer through the solvent blending method to obtain the nanometer compound binary polymer pour point reducer. The nanometer compound binary polymer pour point reducer is stable in performance and outstanding in effect, and the pour point reducing effect is further enhanced on the basis of pour point reducing of an existing binary polymer pour point reducer. When the pour point reducer is applied to 0# diesel oil, the filtering point and the condensation point of 0# diesel oil can be reduced by 10-17 DEG C and 24-35 DEG C respectively, and the pour point reducing effect is better than that of the existing binary polymer pour point reducer.

Owner:SHANGHAI INST OF TECH

Preparation method of quadripolymer diesel pour point depressant

ActiveCN105542063AImprove pour point depressing effectSolve the problem of poor pour point depressing effectLiquid carbonaceous fuelsFuel additivesMethacrylateDepressant

The invention discloses a preparation method of a quadripolymer diesel pour point depressant. The preparation method at least comprises the following steps: a. under the condition of a solvent, preparing higher alcohol methacrylate by using methacrylic acid and higher alcohols as raw materials and p-toluenesulfonic acid as a catalyst; b. under the condition of a solvent, preparing maleic higher alcohol ester by using maleic anhydride and higher alcohols as raw materials and p-toluenesulfonic acid as a catalyst; c. under the condition of a solvent, preparing the quadripolymer diesel pour point depressant by using higher alcohol methacrylate, maleic higher alcohol ester, vinyl acetate and acrylamide as monomers and then adding an initiator. The preparation method has the beneficial effects that the quadripolymer pour point depressant is adopted instead of existing homopolymer pour point depressants and has obviously better pour point depressing effects than the single component homopolymer pour point depressants.

Owner:LIAONING PETROCCHEM VOCATIONAL & TECH COLLEGE

Heat conduction fluid composition produced by using recovered oil

ActiveCN104726182AProtect environmentSave resourcesHeat-exchange elementsLubricant compositionAntifoam agentOil can

The invention provides a heat conduction fluid composition produced by using recovered oil. The lubricating oil consists of the following raw materials in parts by weight: 100.0 parts of recovered base oil, 0.01-99.0 parts of other base oil, 0.01-10.0 parts of viscosity modifier, 3-10.0 parts of clearing agent, 1.0-5.0 parts of dispersing agent, 0.5-3.0 parts of oxidation and corrosion inhibitor, 1.0-5.0 parts of antirust agent, 1.0-10.0 parts of anticoking agent, 1.0-10.0 parts of antisludging agent, 0.5-3.0 parts of metal deactivator and 0.0001-0.01 part of antifoaming agent. The heat conduction fluid composition produced by using the recovered oil can meet the performance requirement that the initial boiling point level of heat conduction fluid is 240, 280, 300, 320 and 340 in GB23971-2009.

Owner:XINJIANG FUKE OIL PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com