Copolymer pour-point depressant for lubricating oil

A technology of copolymer and pour point depressant, which is applied in the field of copolymer type lubricating oil pour point depressant to achieve excellent pour point depressant effect and excellent pour point depressant effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

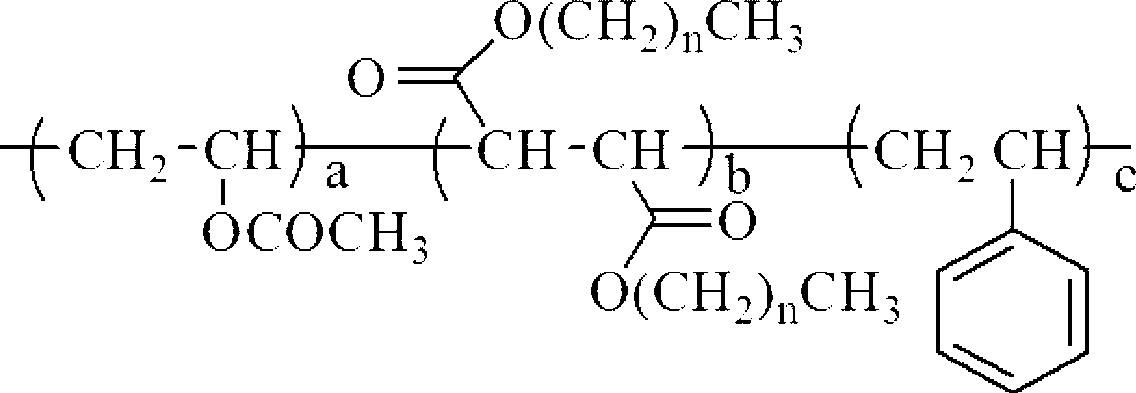

[0034] The present invention also provides the preparation method of above-mentioned triblock copolymer, and this method comprises the following steps:

[0035] (1) Add fumaric acid higher ester, vinyl acetate and styrene in the device, wherein, the molar fractions of fumaric acid higher ester, vinyl acetate and styrene are respectively 10-80%, fumaric acid higher ester, The sum of the mole fractions of vinyl acetate and styrene is 100%;

[0036] (2) adding consumption is the free radical polymerization initiator of 0.1-1% of the total mass of fumaric acid higher ester, vinyl acetate and styrene;

[0037] (3) be heated up to 70-80 ℃, react for 3-8 hours;

[0038] (4) underpressure distillation, remove excessive vinyl acetate, obtain light yellow, viscous liquid, i.e. triblock copolymer, that is, the copolymer type lubricating oil pour point depressant of single component;

[0039] The structural formula of described fumaric acid senior ester is In the formula, n is an inte...

Embodiment 1

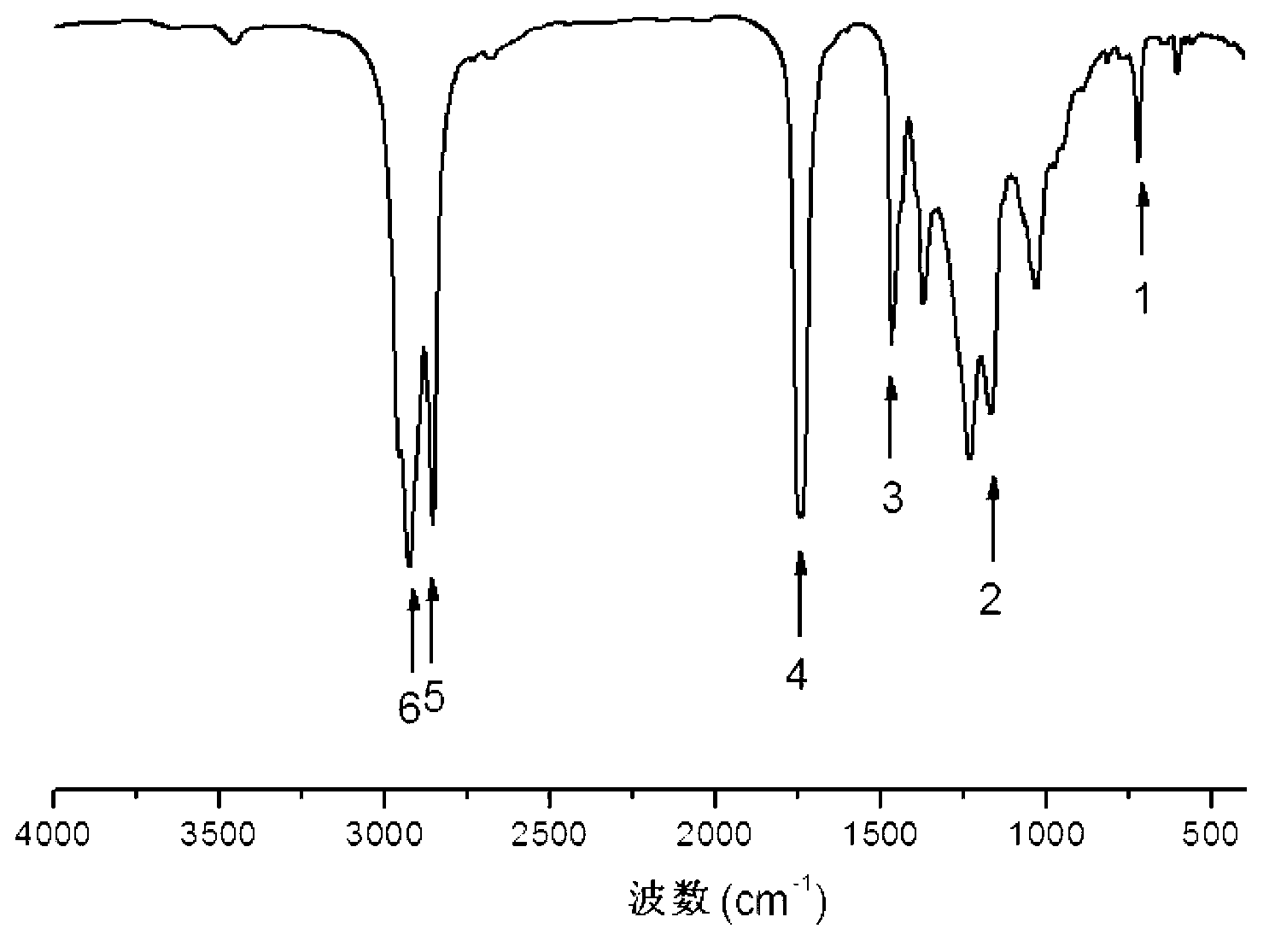

[0071] combine figure 2 Illustrative Example 1

[0072] The preparation method of single-component copolymer type lubricating oil pour point depressant:

[0073] (1) Add 0.08mol of myristyl alcohol and 0.08mol of fumaric acid into a reactor with a stirring device, add 60% of the total mass of myristyl alcohol and fumaric acid toluene, add myristyl alcohol and fumaric acid 1.5% of the total mass of p-toluenesulfonic acid was polymerized at a temperature of 130° C. for 6 hours to obtain a higher ester of fumaric acid;

[0074] (2) Add 0.08mol fumaric acid higher ester, 0.08mol vinyl acetate, 0.08mol styrene in the reactor equipped with stirring device and temperature sensing device, add fumaric acid higher ester, vinyl acetate and 0.5% dibenzoyl peroxide of the total mass of styrene, react at 70-80°C for 6 hours, and distill under reduced pressure to remove excess vinyl acetate to obtain a copolymer-type lubricating oil pour point depressant, viscosity average molecular weigh...

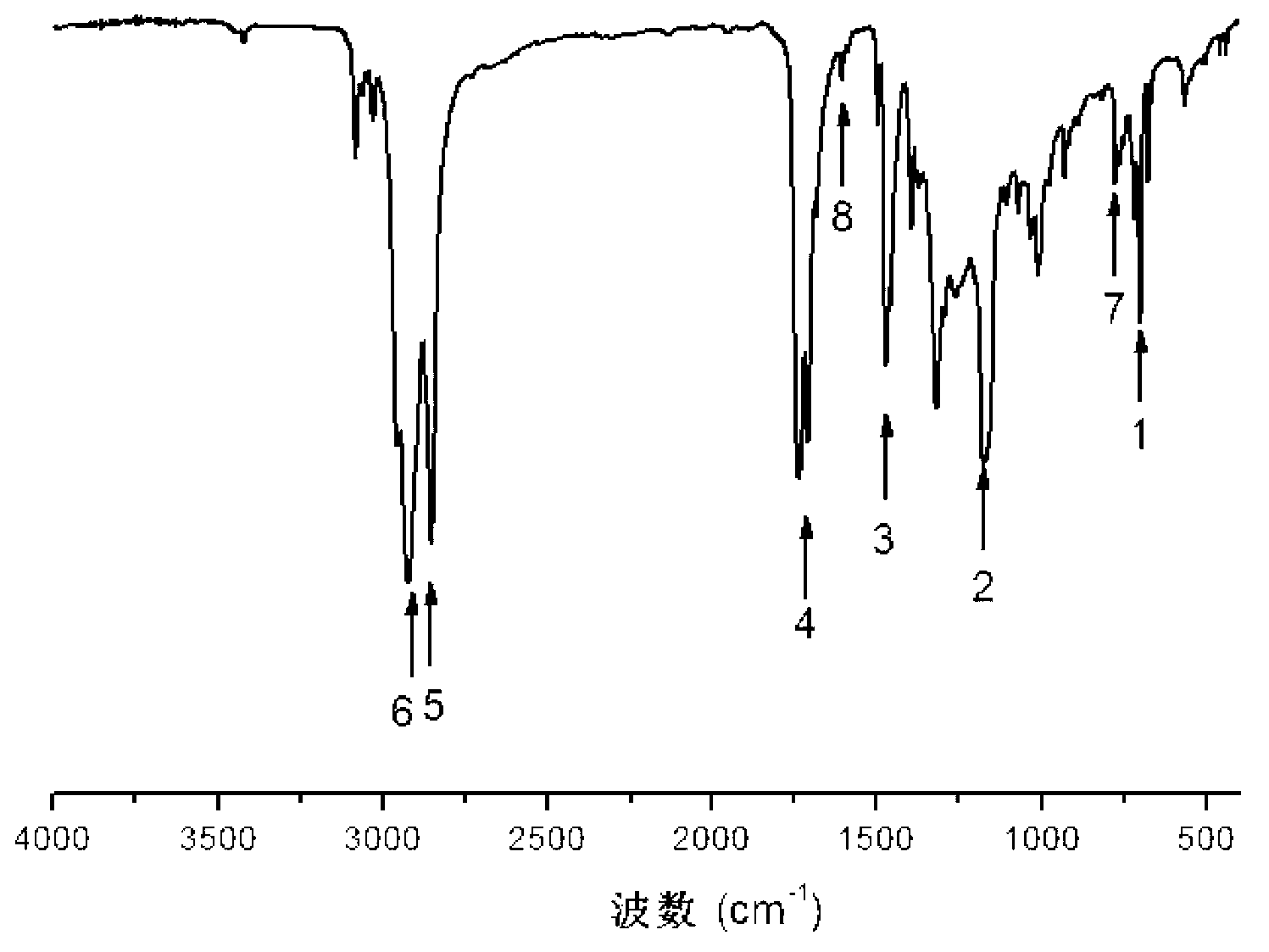

Embodiment 2

[0079] The preparation method of single-component copolymer type lubricating oil pour point depressant:

[0080] (1) Add 0.08mol of myristyl alcohol and 0.08mol of fumaric acid into a reactor with a stirring device, add toluene with 60% of the total mass of myristyl alcohol and fumaric acid, add myristyl alcohol and fumaric acid The p-toluenesulfonic acid of 1.5% of the total mass of the acid was polymerized for 5.5 hours at a temperature of 120° C. to obtain a higher ester of fumaric acid;

[0081] (2) Add 0.08mol of fumaric acid higher ester, 0.08mol of vinyl acetate, 0.04mol of styrene in the reactor equipped with stirring device and temperature sensing device, add fumaric acid higher ester, vinyl acetate React with 0.5% dibenzoyl peroxide of the total mass of styrene at 70-80°C for 4 hours, and distill under reduced pressure to remove excess vinyl acetate to obtain a copolymer-type lubricating oil pour point depressant, viscosity average The molecular weight is 55000, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com