Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

125results about How to "Solve moisture absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

One-way moisture-conducting cashmere and cashmere blended woven fabric or knitted product and processing method thereof

InactiveCN101649558ASolve moisture absorptionSolve the contradiction of dehumidificationVegetal fibresAnimal fibresEngineeringMoisture absorption

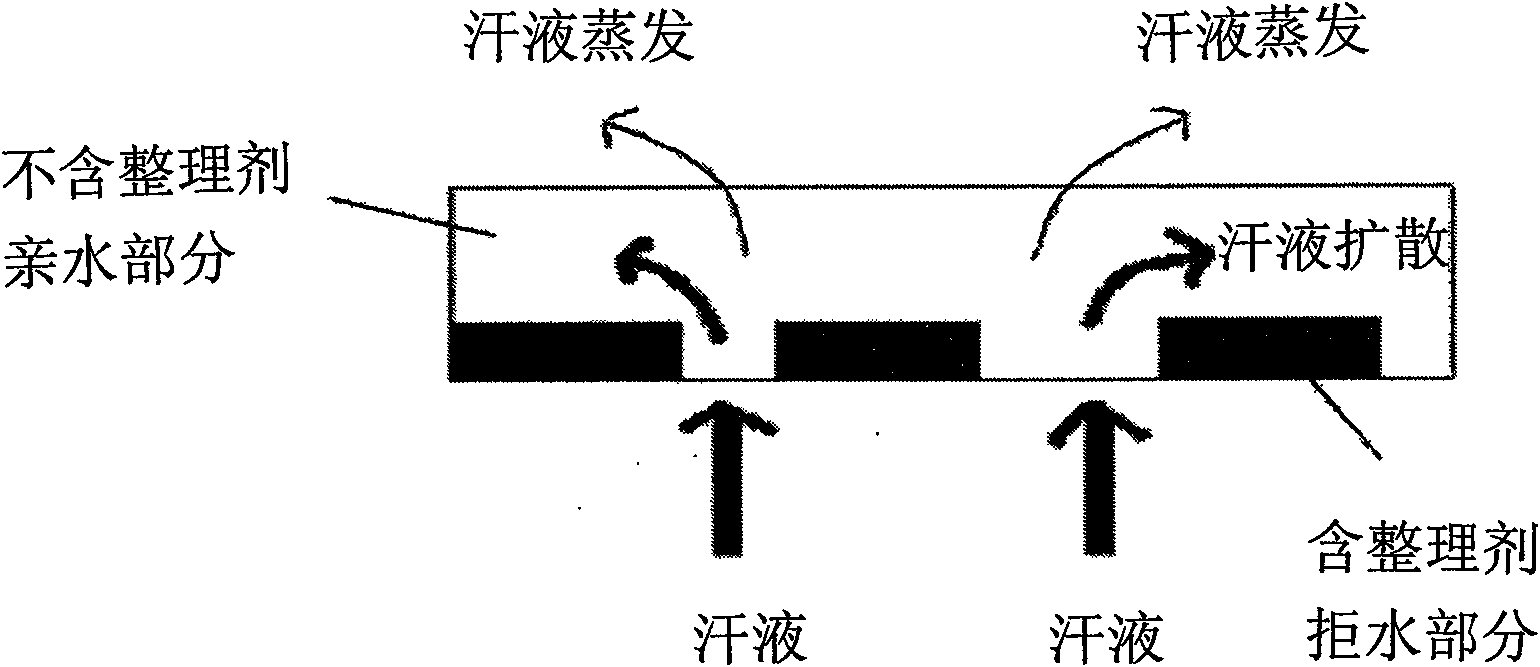

The invention relates to a one-way moisture-conducting cashmere and cashmere blended woven fabric or knitted product and a processing method thereof. A double-lateral surface structure with differenthydrophilic and hydrophobic properties is constructed at the front and reverse sides of the woven fabric product in a single-face liquid feeding way, wherein the front sides of the products are all hydrophilic sides with favorable hygroscopic property, hydrophobic areas with a hydrophobic structure are discontinuously distributed at the reverse side of the product, and the hydrophobic area occupies 20-80 percent of the total area of the lateral side. The processing method comprises the steps of preprocessing fabric, mixing printing paste and finishing agent, printing or feeding liquid at single side, drying, washing and shrinking, processing flexibly, drying again and finally ironing. The invention has the advantages of reasonably solving the contradiction between moisture absorption and moisture discharge as well as the contradiction between hydrophilic and hydrophobic of the fabric, ensuring favorable one-way moisture-conducting effect, achieving the aim of conducting sweat from oneside clinging to the skin to outside and maintaining relatively dry and comfortable efficiency at one side of the skin.

Owner:INNER MONGOLIA ERDUOSI CASHMERE PRODS

Vegetable insulating oil, and preparation method of vegetable insulating oil

InactiveCN102682869AImprove performanceReduce the temperatureLiquid organic insulatorsBase-materialsVegetable oilAnti oxidant

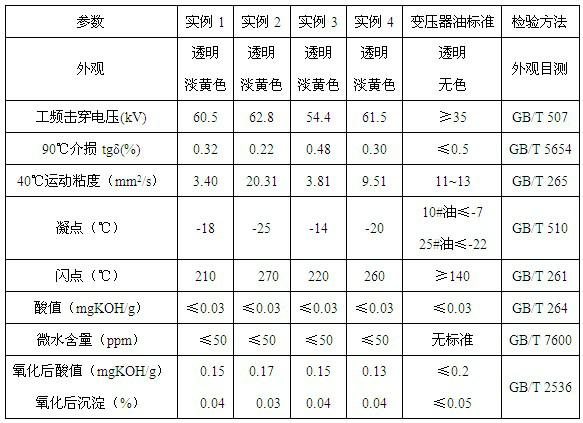

The invention relates to vegetable insulating oil based on vegetable oil, and a preparation method of the vegetable insulating oil. The insulating oil is prepared by the steps of using refined vegetable oil as raw material, carrying out ester exchange reaction on low-molecular alcohol, refining and washing after the reaction, rinsing, distilling under reduced pressure in order to remove water and alcohol, de-coloring, de-acidifying, filtering, de-watering deeply, finally adding antioxidant and pour point depressant. The insulating oil prepared by the method has the characteristics of high flashing point, low viscosity, low pour point, low acidity, low brackish water content, excellent dielectric constant, low dielectric loss and high breakdown voltage and has good physical and chemical performance and electrical performance.

Owner:CHINA ELECTRIC POWER RES INST

Compound water retention soil conditioner and preparation thereof

InactiveCN101723765AHigh organic contentSimple structureOrganic fertilisersUrea compound fertilisersYeastSoil organic matter

The invention relates to a soil conditioner, in particular to a compound water retention soil conditioner and preparation thereof. The soil conditioner comprises the components by weight parts: 100 to 200 parts of organic matter, 0.2 to 3 parts of active cover agent, 150 to 200 parts of acrylamide, 50 to 100 parts of starch, 20 to 50 parts of attapulgite, 20 to 40 parts of porous inorganic matter, 30 to 60 parts of clay, 0.5 to 2 parts of microorganism microbial inoculum, 100 to 150 parts of acid liquid, 2 to 4 parts of initiator, 0.5 to 1 part of crosslinking agent, 1 to 5 parts of urea and 0.03 to 1 portion of yeast. The compound soil conditioner reserves the advantage of water retention; at the same time, because equivalent organic materials, the porous inorganic matter, the clay and the like are added to the soil conditioner, the soil conditioner has the functions of modifying soil structure, enhancing the organic matter of soil and improving the pH value of the soil; and because humic acid is added, the soil conditioner has the function of a urease inhibitor to a certain degree and enhances the utilization efficiency of a fertilizer N applied together with the soil conditioner.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Method for preparing blocky ferric trichloride

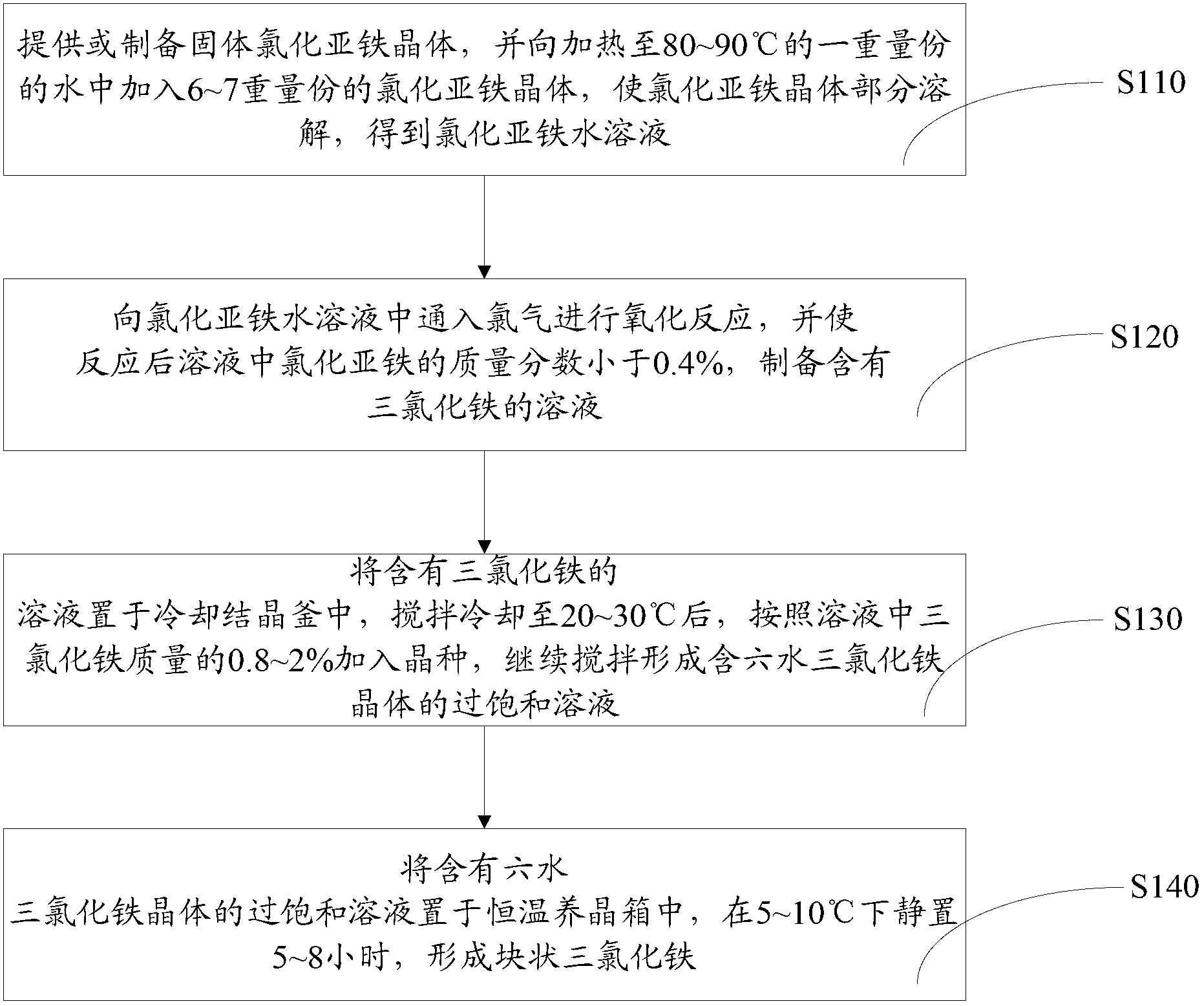

The invention relates to a method for preparing blocky ferric trichloride. Blocky ferric trichloride can be produced both under constant-temperature crystal growing condition at 5-10 DEG C and at high-temperature environment temperature by adjusting the parameters of crystal cooling and crystal growing. In addition, solid ferric trichloride is used as a raw material, and impurities in the traditional pickling waste liquid are prevented from being mixed into a product; and chlorine gas is used as an oxidizing agent and does not contain any impurity. Finally, the blocky ferric trichloride can be directly obtained through crystal growing, the area of blocky ferric trichloride in direct contact with the air is small, the problem that ferric trichloride absorbs moisture easily can be effectively solved, the quality guarantee period of the product is prolonged, and the blocky ferric trichloride is easy to store and transport.

Owner:3R ENVIRONMENTAL TECH CO LTD

Method for improving dried meat slice sensory quality

The present invention provides a method for improving dried meat slice sensory quality, and belongs to the technical field of food processing. According to the present invention, the method includes adding 1-5% by weight of trehalose in dried meat slice production, the trehalose wholy or partly replaces sucrose in the dried meat slice formula, and is added together with accessories or food additives in the process of salting, wherein the salting is at low temperature or room temperature, and then the dried meat slice is produced by a conventional dried meat slice production process or a meat paste production process. The method of the present invention can slow hardening of protein and decomposition and oxidation of unsaturated fatty acid, reduce non-enzymatic browning occurrence, improve drying speed of the meat slice, improve baking performance of the dried meat slice, improve rehydration performance of the dried meat slice, and achieve good sensory quality including good elasticity, bright color, delicate tissue, tender quality and good taste.

Owner:HANSHAN NORMAL UNIV

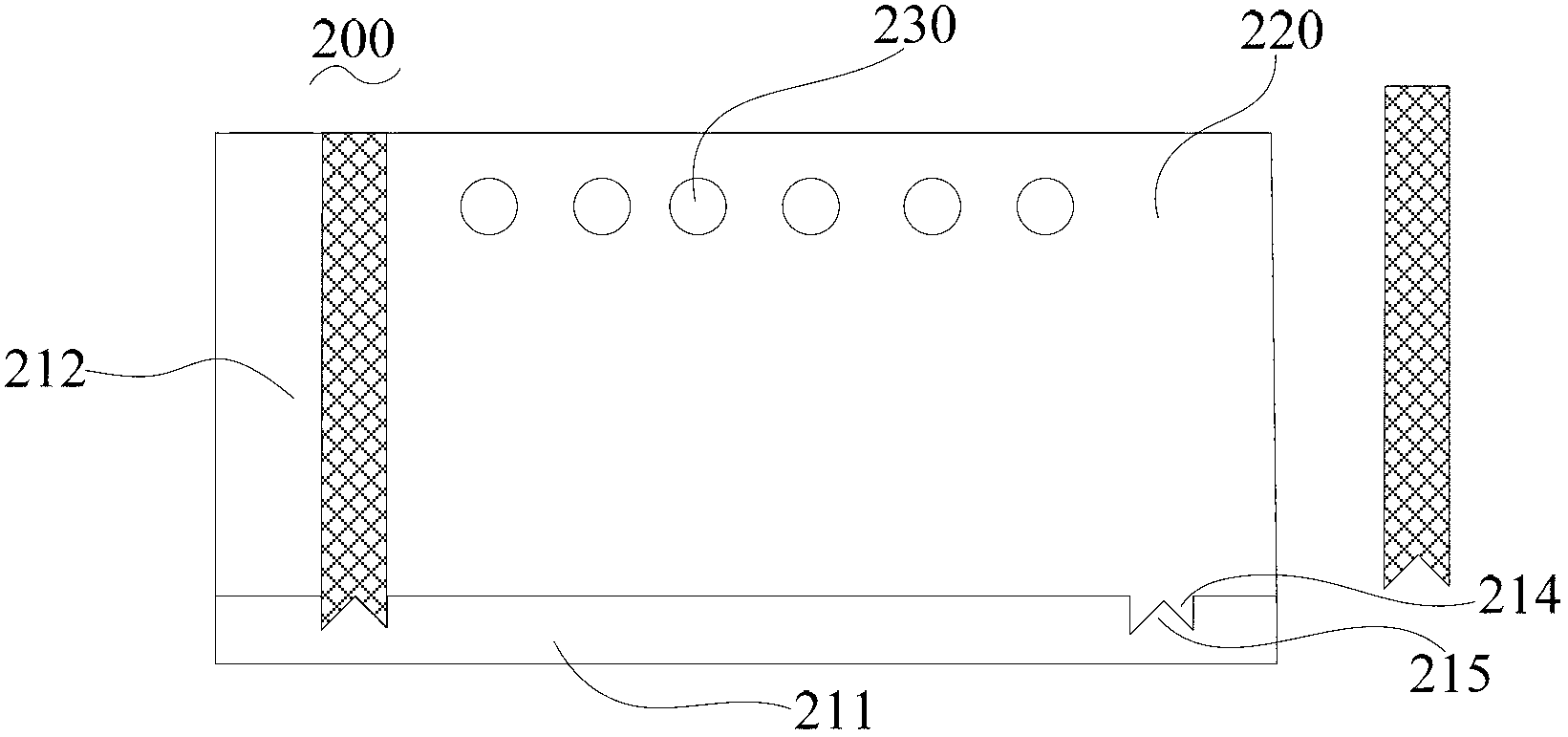

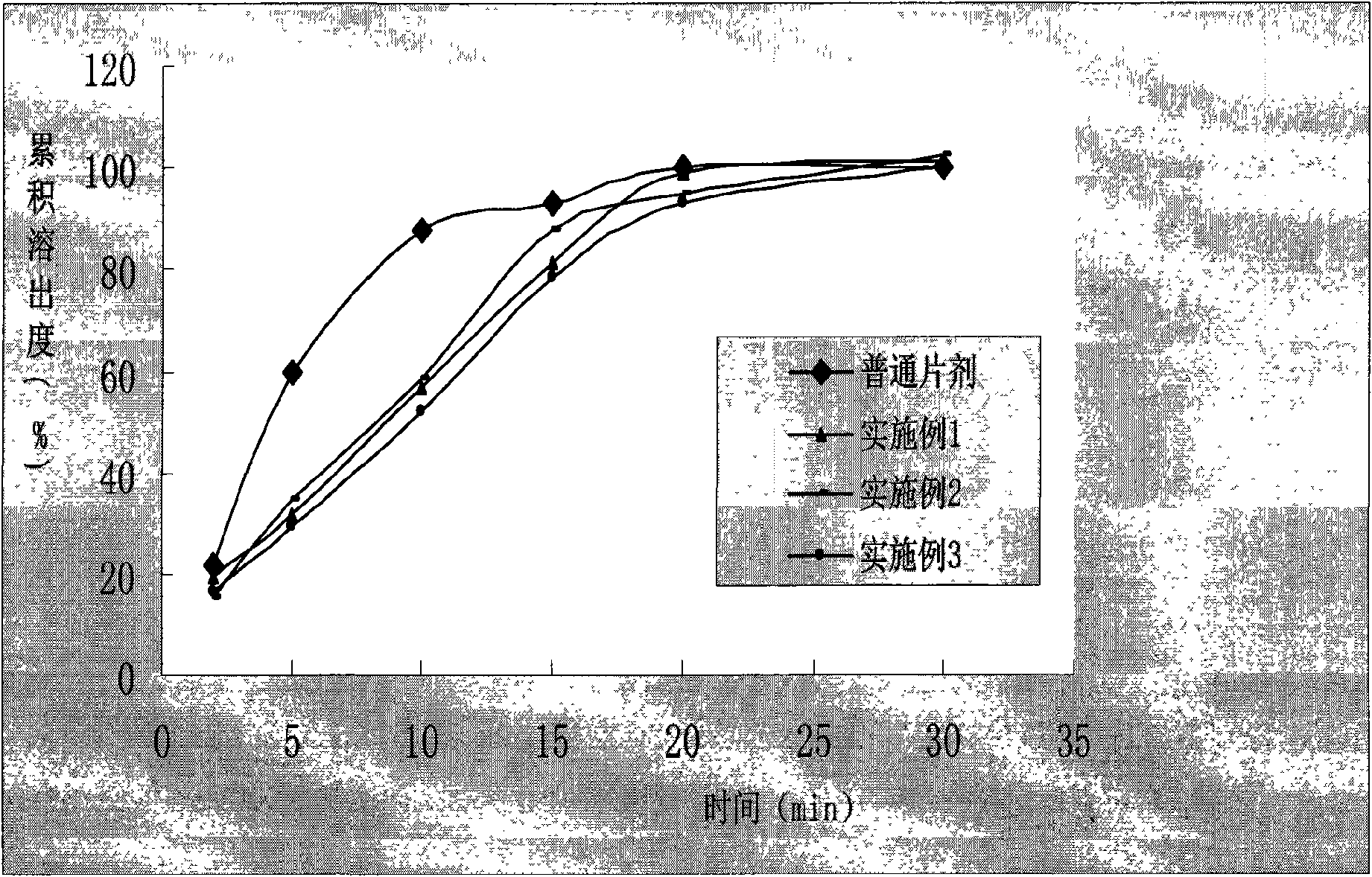

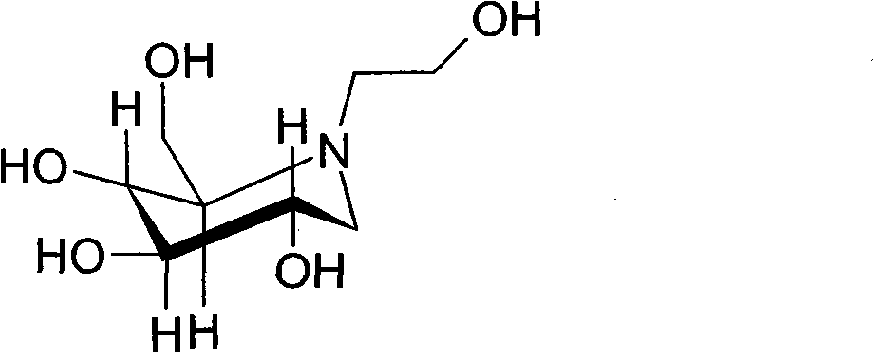

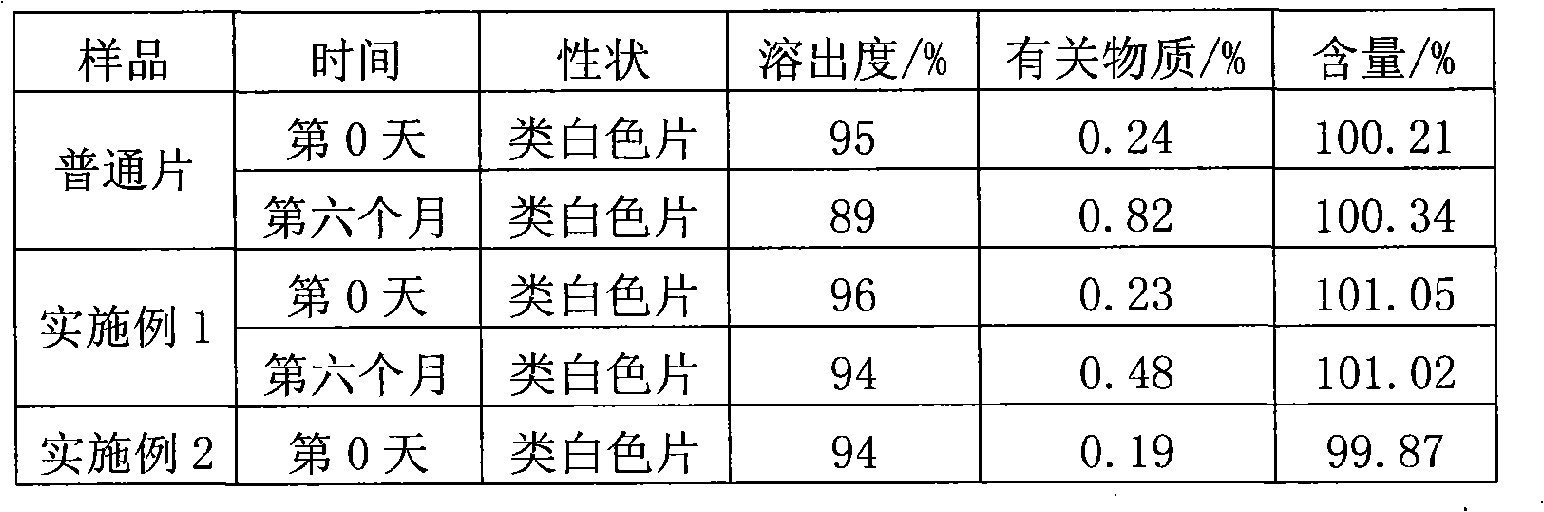

Migltol microcapsule tablet and preparation method thereof

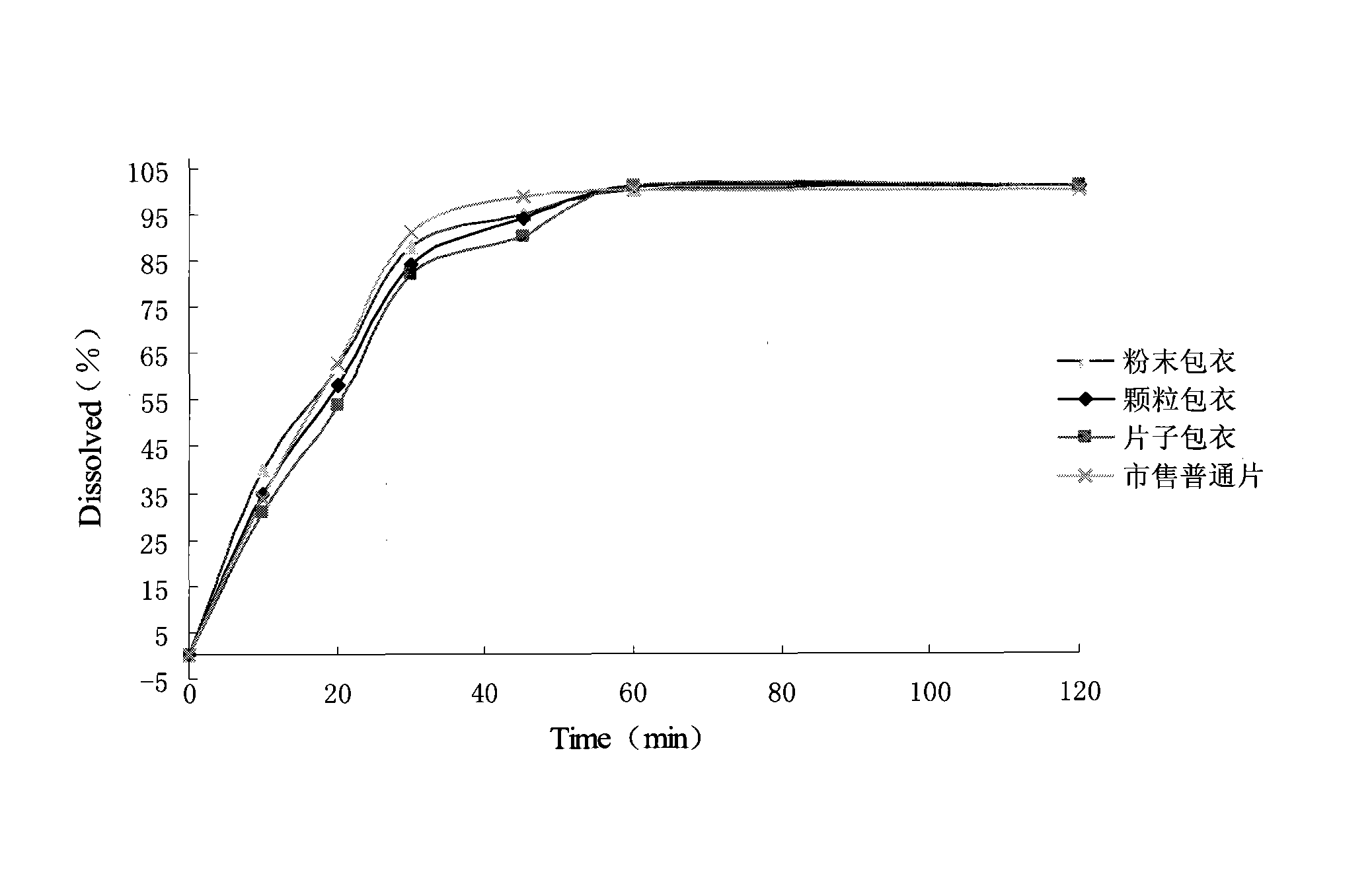

ActiveCN101574323ASmooth and fast dissolutionImprove bioavailabilityMetabolism disorderPill deliveryDiabetes mellitusMedicine

The invention relates to a migltol microcapsule tablet and preparation method thereof. Migltol is put in a fluidized bed; then capsule solution is continuously added to the fluidized bed after atomized by the nozzle of the fluidized bed, and migltol microcapsules are produced; the migltol microcapsule, disintegrating agent and thinner of the unit formula are uniformly mixed, and the mixture is tabletted according to routine techniques to produce the migltol microcapsule tablet. The preparation method of the invention can remarkably increase the stability of migltol, thus being more suitable for commercial process. The migltol microcapsule tablet of the invention can be steadily and rapidly released in bodies to perform the diabetes-treating function of migltol.

Owner:LUNAN PHARMA GROUP CORPORATION

Polymorphic nitro-compound fertilizer and production method thereof

The invention discloses a polymorphic nitro-compound fertilizer, relating to the technical field of agricultural fertilizers. The polymorphic nitro-compound fertilizer comprises the following raw materials in parts by weight: 30-150 parts of urea, 160-600 parts of nitramine phosphorus, 0-120 parts of ammonium sulfate, 180-250 parts of potassium sulphate, 100-200 parts of monoammonium phosphate and 1-10 parts of medium and micro fertilizers. The polymorphic nitro-compound fertilizer is produced by mixing, granulating and cooling the raw materials. The polymorphic nitro-compound fertilizer adopts scientific proportion, has complete nutrition, can continuously nourish crops at gradient so as to be more beneficial to the full absorption of the vegetable crops, and can remarkably promote the growth and high and stable yield of the crops, thus having strong market competitiveness.

Owner:STANLEY AGRI GRP CO LTD

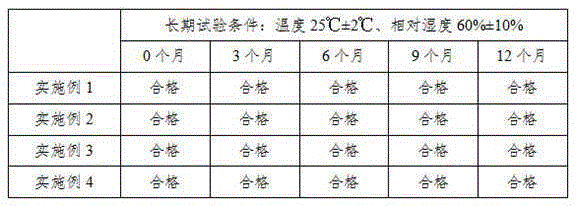

Super-hydrophobic high-transmittance SiO2 anti-reflecting thin film and preparation method thereof

The invention relates to a super-hydrophobic high-transmittance SiO2 anti-reflecting thin film and a preparation method thereof; a hybrid sol doped with trimethylchlorosilane is prepared by a sol-gel method; the surface of a glass slide is cleaned; a plating film is formed on the surface of the glass slide by a dip-coating method, and the super-hydrophobic high-transmittance SiO2 anti-reflecting thin film is obtained after the plating film is dried. Compared with the prior art, the preparation method has the advantages of simple manufacturing process and low cost, and the obtained sol has good uniformity and can be used for large-area film forming. Due to relatively high transmission, incident light transmission can be improved and the solar cell efficiency can be improved when the anti-reflecting thin film is used on a photovoltaic glass cover plate. Moreover, because the thin film has good hydrophobicity and has good self cleaning ability, the thin film is suitable for outdoor humid environments.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Chtiosnaoligosaccharide (COS) capsule and preparation method thereof

ActiveCN105380924ANeat appearanceImprove solubilityOrganic active ingredientsMetabolism disorderBiologyAlcohol ethyl

The invention belongs to the technical field of pharmaceutical preparations, and particularly relates to a chtiosnaoligosaccharide (COS) capsule and a preparation method thereof. The COS capsule comprises a content and a capsule shell. The content is mainly prepared from COS, microcrystalline cellulose, adhesive, calcium stearate, ethyl alcohol and superfine silica powder. The capsule shell is mainly prepared from hydroxypropyl starch, xanthan gum, a thickening agent, a plasticizer and water. The COS capsule is free from extraneous odor, and clean, tidy and smooth in appearance; both the weight deviation and the solubility of the COS capsule meet the related stipulations of Chinese pharmacopoeia. In addition, the capsule has good leakproofness and oxidation resistance, the problem that oxidation and moisture absorption can happen to COS easily is effectively solved, and long-term storage of the COS is facilitated.

Owner:GUANGDONG PHARMA UNIV

Special moisture preservation compound fertilizer for maize in arid and semi-arid area and preparation thereof

InactiveCN101462911AImprove anti-retrogradeIncrease investmentFertilizer mixturesAridHydroquinone Compound

A water retention compound fertilizer specially used for maize in arid-semiarid regions is characterized by being formed by mixing water retention agent and slow release fertilizer according to the weight ratio of 2-4:8-20; based on the effective content, the composition by weight of the compound fertilizer is N:P:K:Zn=1:0.15-0.45:0.27-0.47:0.08-0.1; the weight content of hydroquinone and / or dicyandiamide is 2.0-3.0% of the weight content of N in the fertilizer; the water retention agent is a mixed type water retention agent and comprises the components of 100-200 parts of organic matter, 0.2-3 parts of active sealing face agent, 150-200 parts of acrylamide, 50-100 parts of starch, 20-50 parts of attapulgite, 20-40 parts of perlite, 2-4 parts of evocating agent and 0.5-1 part of cross linker according to the parts by weight. The water retention compound fertilizer has low cost and convenient application, and can effectively play the role of water retention, fertilizer conservation andlong-effect yield growth.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Composite type soil water retention agent and preparation

InactiveCN101463247ASimple structureIncrease the granular structureOther chemical processesCellulose compoundsUrease Inhibitors

The invention relates to a soil water retaining agent, in particular to a starch and a cellulose compound water retaining agent and preparation thereof, comprising the ingredients, based on parts by weight of: 100-200 parts of organic substances, 0.2-3 parts of active covering agent, 150-200 parts of acrylamide, 50-100 parts of starch, 20-50 parts of attapulgite, 20-40 parts of perlite, 2-4 parts of initiators and 0.5-1 part of crosslinking agent. The compound soil water retaining agent of the invention simultaneously retains the advantages of starch and cellulose water retaining agents, and can play a role of improving the soil structure owing to the addition of equivalent organic materials therein; the addition of humic acid is capable of serving as a urease inhibitor to a certain extent, which enhances the utilization ratio of a fertilizer N that is applied along with the water retaining agent.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Special halogen-free flame-retardant master batch for polypropylene and preparation method for halogen-free flame retardant master batch

The invention discloses a special halogen-free flame-retardant master batch for polypropylene and a preparation method for the halogen-free flame retardant master batch. Components of the master batch comprise, in mass percent, 75-90% of phosphorus-nitrogen halogen-free flame retardant, 8-22% of carrier and 0.1-5% of modified ethylene bis-fatty acid amide. By the aid of the master batch, quality instability of materials due to non-uniform mixing of powder and granules is effectively avoided, easiness in generation of chippings or powder during granule cutting is avoided, production efficiency is improved, and production cost is lowered. Adopting a continuous banburying-extrusion production process leads production efficiency to be high. The master batch effectively solves the problems of easiness in moisture absorption, degradation and foaming of halogen-free flame retardant, so that storage time of the phosphorus-nitrogen halogen-free flame retardant is prolonged, and processability of the phosphorus-nitrogen halogen-free flame retardant is improved. Besides, the special halogen-free flame-retardant master batch for the polypropylene has the advantages of easiness in dispersion, high flame-retardant efficiency and low production cost, and has less influence on physical and mechanical properties, heat resistance, processability and surface color of composite materials than a special traditional halogen-free flame-retardant master batch for polypropylene.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS +1

Heat insulating pearlite material for outer wall and its prepn process

InactiveCN101088949AQuality assuranceReduce performanceSolid waste managementWeather resistanceHeat conducting

The present invention discloses one kind of heat insulating material for outer wall of building and its preparation process. The heat insulating material is prepared with acidified magnesia as heat insulating material additive in 5-15 weight portions and modified expanded perlite in 30-50 weight portions. The heat insulating material as one kind of excellent outer wall heat insulating material for building has low heat conducting coefficient, low water absorbing capacity, high weather resistance, high wind resistance and high impact strength.

Owner:刘贵堂

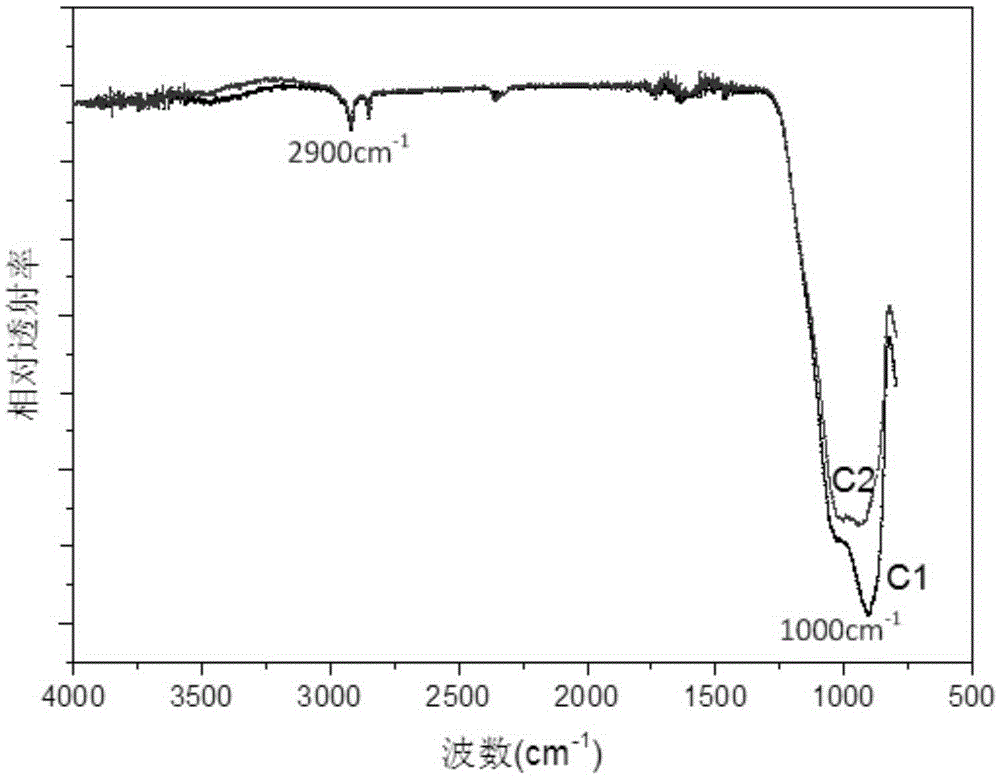

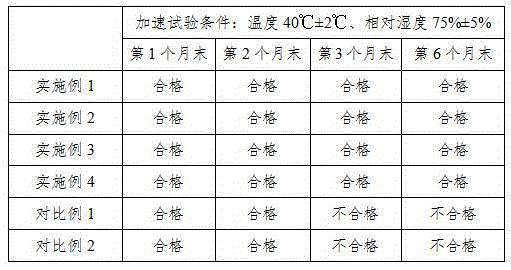

Preparation method of modified porous silicon dioxide moisture-proof anti-reflection coating

The invention discloses a preparation method of a modified porous silicon dioxide moisture-proof anti-reflection coating. The method comprises the following steps: firstly synthesizing multi-arm silane via siloxane containing epoxy group and siloxane containing primary amine or secondary amine through ring-opening addition reaction, taking multi-arm silane and silane monomers containing siloxane as common silicon source monomers, preparing a precursor solution of polysiloxane sol under an acid catalysis condition, then preparing a pore-forming agent solution, then preparing modified silicon dioxide sol, finally carrying out one-time film formation on a transparent substrate via the modified silicon dioxide sol through a dipping-pulling method to prepare the modified porous silicon dioxidemoisture-proof anti-reflection coating. The coating has a wide-spectrum reflection reduction effect, is flat and smooth in surface, excellent in abrasion resistance and weather resistance and excellent in moisture-proof function, has tightly stacked particles, has a thickness of 100-200nm, a section pore size of 5-10nm and a surface pore size of 10-40nm, and is beneficial to reversible adsorptionand desorption of water vapor.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Nonconsumable wood flame retardant and its preparation

InactiveCN1490137ASolve moisture absorptionAntisepticWood impregnation detailsFoaming agentPentaerythritol

An anti-losing flame-retarding agent for wood or other organic fibre materials is prepared from formaldehyde, urea, ammonia water, phosphoric acid, cyanuramide and / or guanidine phosphate and / or guanidine sulfate, and polyethanediol and / or pentacrythrite and / or dextrin.

Owner:陈万利 +3

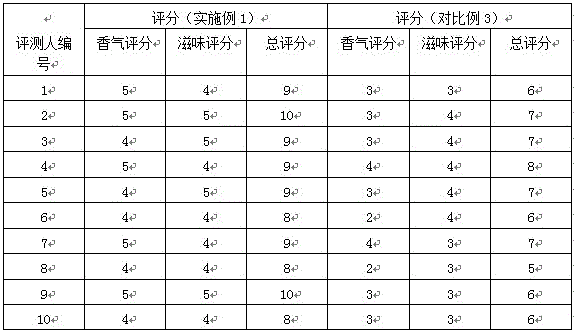

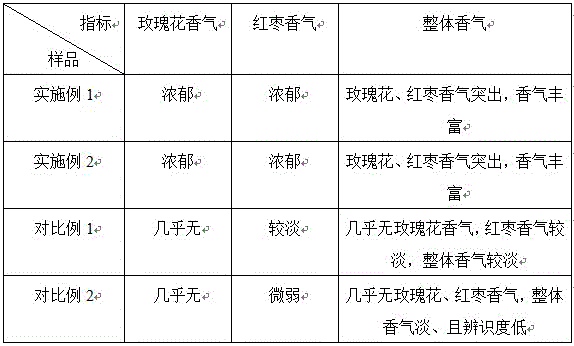

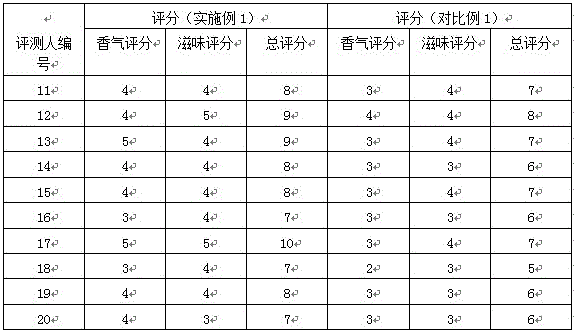

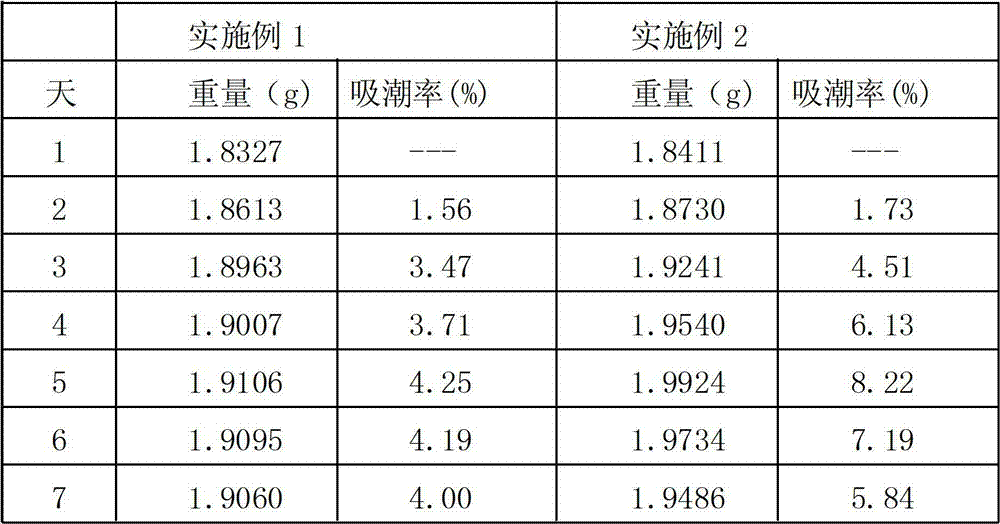

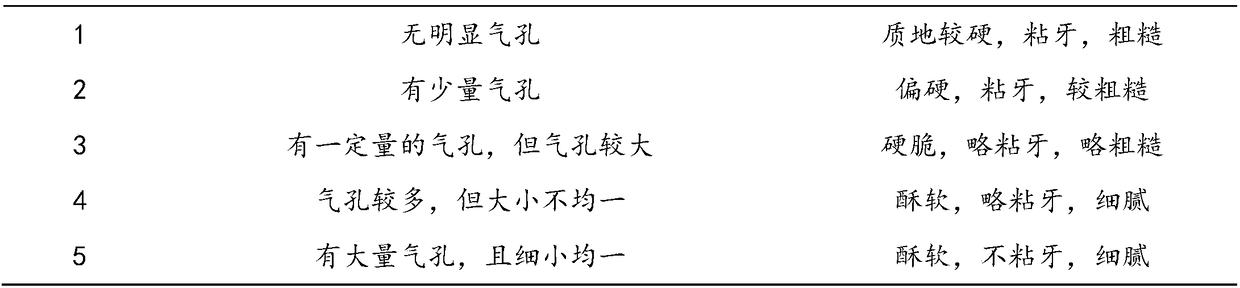

Preparation method of plant tablet candy

InactiveCN106417854ARetain natural aromaFast distillationConfectionerySweetmeatsAdditive ingredientBlack tea

The invention discloses a preparation method of plant tablet candy. The plant tablet candy is made up of 0.5 to 1.5 parts of rose, 0.5 to 1.5 parts of red dates, 0.5 to 1.5 parts of hawthorn, 0.05 to 0.2 part of mulberry, 0.1 to 0.5 part of licorice, 0.1 to 0.5 part of black tea, 0.5 to 1.5 parts of maltodextrin, 2 to 5 parts of white sugar, 0.05 to 0.2 part of magnesium stearate and 0.1 to 0.3 part of hydroxypropyl starch, wherein the rose is pulverized, the aromatic water is collected in advance, and the roses after the filtrate is extracted are extracted together with other ingredients, red dates, and black tea are treated with the microwave extraction process after pulverized. The preparation method can effectively retain the raw materials of their own natural aroma and the original taste, but also to maximize the retention of active ingredients, the prepared plant tablet candy is purely natural without additives, rich in aroma, sweet and sour in taste, full of flavor, unique in flavor, has health effects of beauty, tonifying qi and blood, nourishing spleen and promoting the digestion and others, and is beauty care best-quality goods.

Owner:GUANGDONG YIFANG PHARMA

Moistureproof film coating agent for traditional Chinese medicine tablets and preparation method thereof

InactiveCN102813934AImprove moisture resistanceSolve the problem of moisture absorptionInorganic non-active ingredientsPharmaceutical delivery mechanismOxideTraditional Chinese medicine

The invention relates to a moistureproof film coating agent for traditional Chinese medicine tablets and a preparation method thereof. The technical characteristic is that the film coating agent comprises the following components according to mass proportion: 20-50 portions of vinyl pyrrolidone-vinyl acetic ester copolymer, 10-30 portions of 5-15 centipoise hydroxypropyl methylcellulose, 10-20 portions of polyethylene glycol 6000, 1-5 portions of tween 80, 0-25 portions of ferric oxide, 0-20 portions of titanium dioxide and 0.1-30 portions of talc powder. The preparation method comprises the following steps: (1) the vinyl pyrrolidone-vinyl acetic ester copolymer, the 5-15 centipoise hydroxypropyl methylcellulose, the polyethylene glycol 6000, the ferric oxide, the titanium dioxide and the talc powder are put in a high-speed mixer for mixing; and (2) the tween 80 is evenly poured to and mixed with the materials in the high-speed mixer to prepare the finished products of moistureproof film coating agent for traditional Chinese medicine tablets. Various macromolecule film-forming materials are adopted to prepare the film coating agent, thus the moistureproof performance of traditional Chinese medicine tablets is enhanced, the problem of moisture absorption of traditional Chinese medicine is thoroughly resolved and the application range of film coating agent is enlarged.

Owner:TIANJIN PULLERSUN PHARMA AUXILIARY MATERIAL

Acarbose chewing tablets

InactiveCN101491506AOvercome the shortcomings of less selectivityDoes not affect disintegration propertiesOrganic active ingredientsMetabolism disorderMedicineMoisture absorption

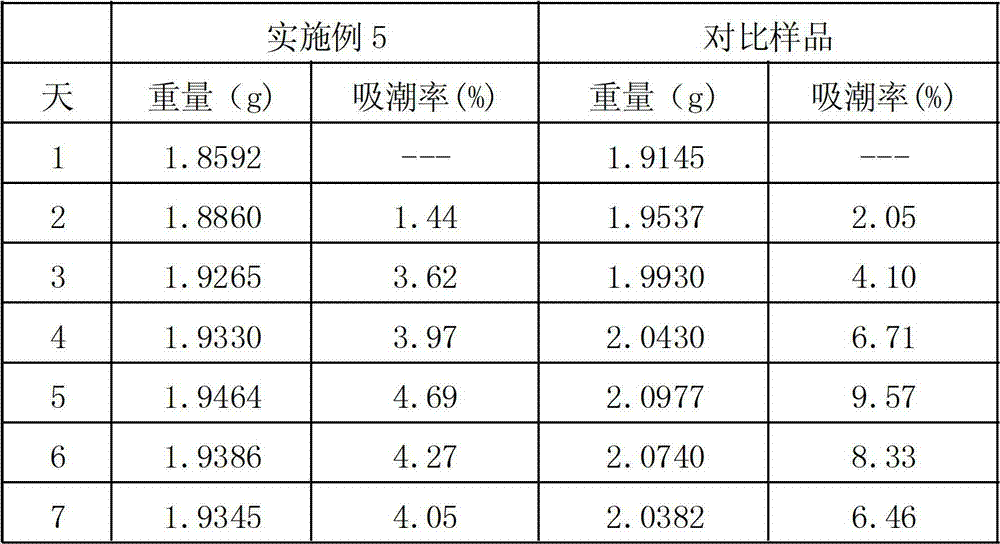

The invention relates to an acarbose moistureproof preparation and a method for preparing the same. The disclosed acarbose moistureproof preparation consists of acarbose, a medical auxiliary material and a moistureproof coating layer. Powders, particles or the medical auxiliary material are used to prepare a tablet core; and the tablet core is coated with a moistureproof coating material to form the acarbose, wherein the moistureproof coating material can be dissolved in stomach. The acarbose has the disadvantages of easily absorbing moisture and hardening so that the auxiliary materials with low price and high quality cannot be used. The method adopts coating technology, does not influence the disintegration property of the tablet core, greatly improves stability of a product in a humid environment, solves the problem of moisture absorption and increases selectivity of the auxiliary material.

Owner:HANGZHOU HUADONG MEDICINE GRP PHARMA RES INST

Preparation method of marine fish peptide suitable for piglet daily ration

InactiveCN112352870AImprove bitternessGood moisture absorptionProtein composition from fishAccessory food factorsFeed conversion ratioOligopeptide

The invention relates to a preparation method of marine fish peptide suitable for piglet daily ration; an enzyme engineering technology is applied to carry out directional enzymolysis on marine fish to generate nutritional oligopeptide, small peptide and other functional peptides, a fish protein peptide product is produced through special process treatment, and the fish protein peptide product hasthe advantages of high protein content, various amino acids and balanced content of various amino acids; the marine fish peptide can meet the requirements of growth and metabolism of piglets, contains a large amount of small peptide molecules, and is beneficial to absorption and utilization of the piglets; and the fish protein peptide contains low content of heavy metals and no aflatoxin, so thatpork cultured by taking the fish protein peptide as a piglet creep feed has low harm to human bodies. Through analysis on test results of creep feed tests and phagostimulant and preference tests, itfinds that addition of the fish protein peptide into the creep feed can effectively improve the phagostimulant, feed intake and average daily gain, reduces the feed conversion ratio, improves the utilization rate of the feed, and the fish protein peptide has a wide application prospect.

Owner:秦皇岛益尔生物科技有限公司

Method for preparing 3DP of integral sand mold

ActiveCN114054673AAvoid the problem of sharp drop in accuracyHigh strengthAdditive manufacturing apparatusSolid waste managementAlcoholPhysical chemistry

The invention discloses a 3DP preparation method of an integral sand mold, which comprises the following processes: 3DP molding is carried out by using a 3DP molding material and an inorganic binder, the obtained integral sand mold is subjected to standing curing, and the 3DP molding material is obtained by uniformly mixing sodium silicate powder, disodium hydrogen phosphate powder and 3D printing molding sand; the inorganic binder is obtained by adding sodium silicate powder into a mixed solution of absolute ethyl alcohol and deionized water until the sodium silicate powder is dissolved to be saturated and then filtering; the cured integral sand mold is subjected to vacuum infiltration, so that the integral sand mold fully absorbs the infiltration liquid; the integral sand mold is subjected to reinforced baking and then cooled, and coating spraying treatment is conducted on the surface of the integral sand mold; and the integral sand mold of which the surface is subjected to coating spraying treatment is dried so as to obtain the high-performance integral sand mold. According to the invention, sodium silicate can be used as a binder to carry out 3DP molding of the integral sand mold, and the high-performance integral sand mold with good performance is obtained through an adaptive post-treatment process.

Owner:XI AN JIAOTONG UNIV

Isostatic pressing electrical porcelain blank formula with non-plasticity clay used as raw material

The invention provides an isostatic pressing electrical porcelain blank formula with non-plasticity clay used as raw material. The formula comprises the following components, by weight, 48%-55% of alumina, 18%-25% of feldspar flux, 15%-25% of calcined clay and 5%-15% of viscous agents. The formula takes chemically-synthesized viscous agents as viscous materials to replace plastic clay used in existing ingredients. Therefore, the non-plasticity clay can be used to replace scarce plastic clay raw materials. The cost of blank materials is reduced. The dependence of isostatic pressing electrical porcelain blanks on one-off resources is reduced.

Owner:CHINA XD ELECTRIC CO LTD

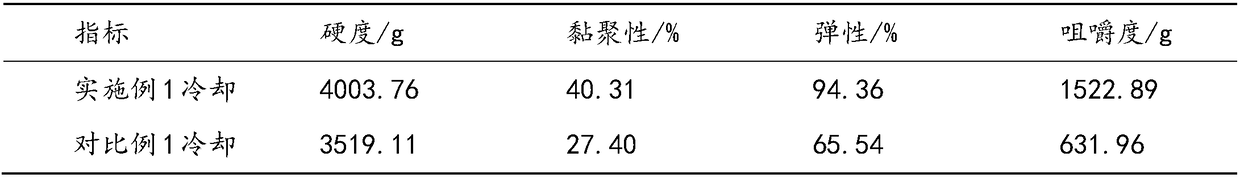

Nougat and preparation method thereof

InactiveCN108740250AGuaranteed StrengthImprove solubilityConfectionerySweetmeatsWater bathsPeanut kernel

The invention relates to the field of food processing, in particular to nougat and a preparation method thereof. The nougat is prepared from the following raw materials in parts by weight: 1.2 to 1.5parts of water, 0.5 to 0.9 part of gelatin, 0.3 to 0.6 part of egg white, 4 to 9 parts of white granulated sugar, 13 to 16 parts of syrup, 0.01 to 0.05 part of edible salt, 2 to 5 parts of cream, 3 to6 parts of milk powder, 0.01 to 0.03 part of vanillin and 10 to 15 parts of peanut kernel. The preparation method of the nougat provided by the invention concretely uses a water bath heating processand a program vacuum cooling process to realize the soft sticky and fine mouthfeel of the nougat; the product structure is complete; the storage time is long; the energy can be properly supplemented;the texture and the structure are relatively good.

Owner:成都喜相逢食品有限公司

Gypsum-based fireproof door core plate and preparation method thereof

InactiveCN111848088ASolve moisture absorption,Solve efficiency problemsFireproof doorsCeramicwareFiberFoaming agent

The invention provides a gypsum-based fireproof door core plate. The plate is characterized by comprising the following raw materials in parts by weight: 400-500 parts of phosphogypsum-based alpha high-strength gypsum, 0.1-1.5 parts of fibers, 5-8 parts of a foaming agent, 1-2 parts of a surfactant, 5-10 parts of an emulsion, 0.5-1 part of PVA and 180-250 parts of water. The dry density of the prepared fireproof door core plate is 280-400 kg / m<3>, wherein alpha-type high-strength gypsum uses the industrial byproduct phosphogypsum as a raw material, so the waste is turned into the wealth. The gypsum-based fireproof door core plate has the characteristics of good stability, high fire resistance, no corrosion to steel plates and high production efficiency, and effectively overcomes the defects of moisture absorption and low production efficiency of existing magnesite materials.

Owner:瓮福化工科技有限公司

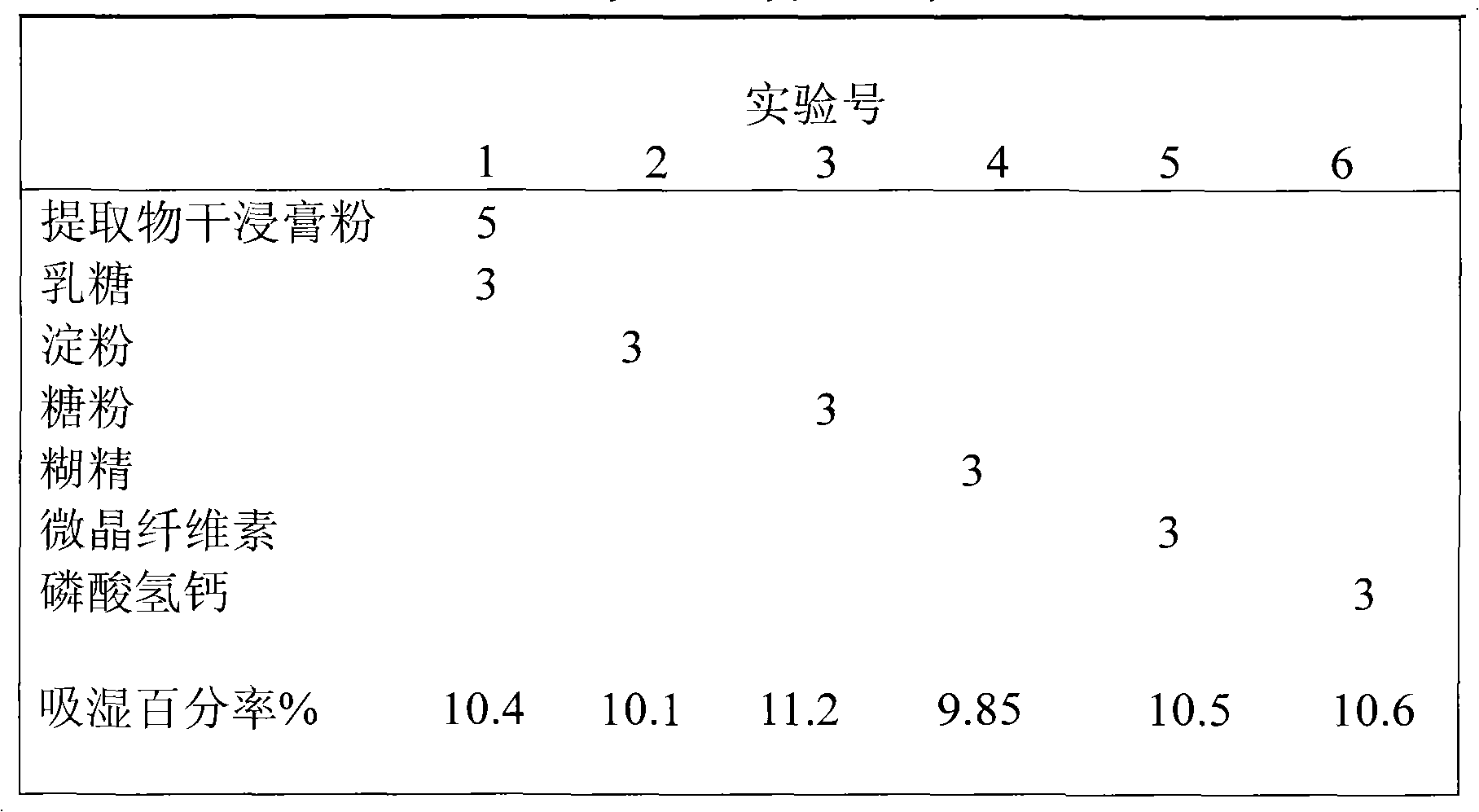

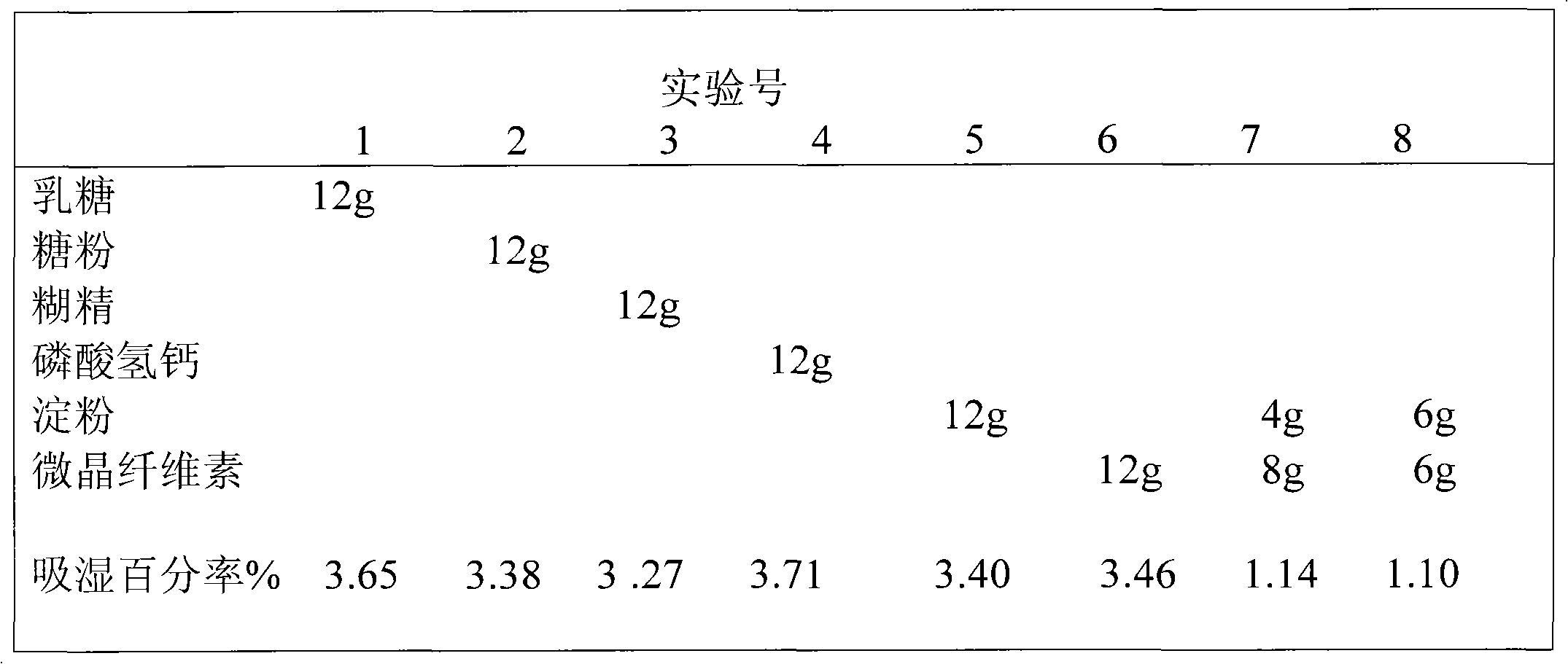

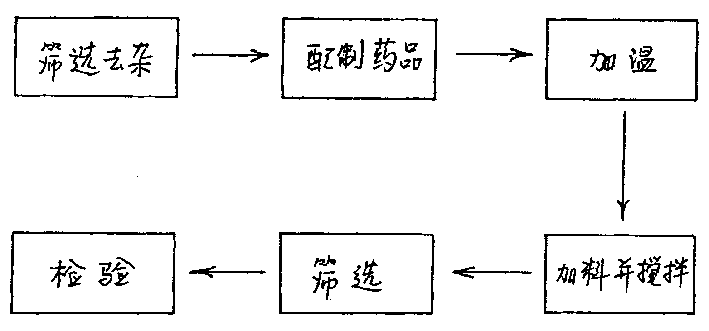

Dandeng Tongnao tablets and preparation process thereof

InactiveCN101829190ANot easy to changeGood disintegrationPill deliveryPharmaceutical non-active ingredientsMoisture absorptionMicrocrystalline cellulose

The invention discloses Dandeng Tongnao tablets and a preparation process thereof, relating to the field of traditional Chinese medicines, and characterized in that a specific auxiliary material combination is utilized to improve the moisture absorption capability of the tablets. The auxiliary material combination used in the invention is the combination of starch and microcrystalline cellulose. The dosages of the starch and the microcrystalline cellulose are respectively 40-60g and 60-80g in every 1000 Dandeng Tongnao tablets. The tablets prepared by the invention have better anti-moisture absorption ability.

Owner:九瑞健康股份有限公司

Novel oxidant for fireworks and preparation method thereof

The invention provides a novel oxidant for fireworks and a preparation method thereof in order to improve the performance price ratio of a fireworks powder oxidant. The novel oxidant for the fireworks is characterized in by comprises the following raw materials in part by weight: 5 to 7 parts of barium nitrate, 5 to 6 parts of potassium hyperchlorate, 3 to 10 parts of density degree regulator and 1 to 5 part of catalyst. The preparation method of the novel oxidant for the fireworks is characterized by comprising the following steps of: crushing the raw materials into 120 to 350 meshes respectively; and uniformly mixing the raw materials according to the proportions of the raw materials to obtain a special oxidant product. For a product produced by using the special oxidant, the bursting strength, the cost price and the proportion of the raw materials are close to those of potassium chlorate, the safety performance is close to that of the potassium hyperchlorate, and the performance price ratio of the product is significantly improved, so the product is highly praised and appreciated by users.

Owner:李忠良

Film coated glass bead for screen and its processing technology

InactiveCN1478747AExtended service lifeIncrease brightness factorProjectorsPolymer scienceHydrophobe

A coated glass bead for the screen features that its particle diameter is 0.05-0.25 mm and its external surface is coated by a methyl silica oil film. Its advantages are high hydrophobicity, high adhesion to screen, high uniformity of arranging on screen surface, and low adsorption to dust.

Owner:刘会年

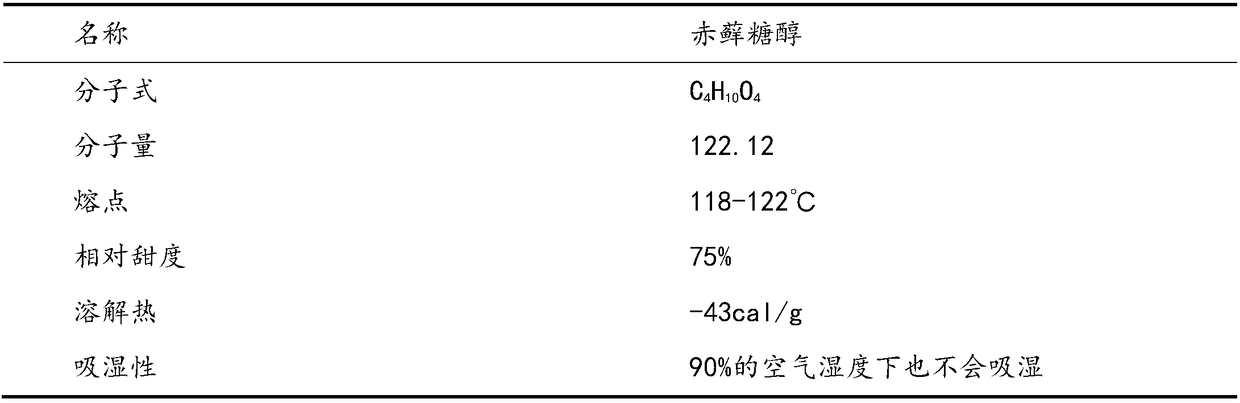

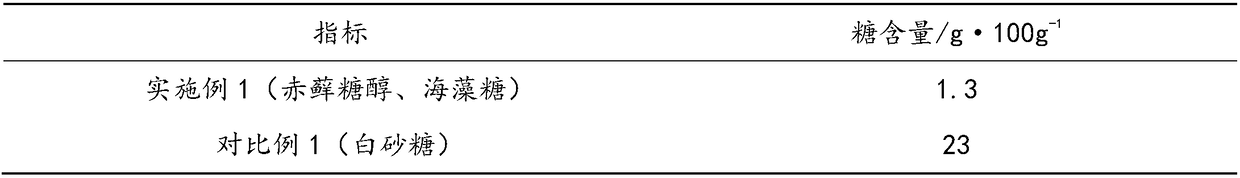

Low-sugar nougat and production method thereof

InactiveCN108770976APhysical and chemical indicators are controllableImproves stability and freshnessConfectioneryFood preservationReducing sugarVacuum cooling

The invention relates to the field of food processing, and concretely relates to a low-sugar nougat and a production method thereof. The low-sugar nougat comprises, by weight, 1.2-1.5 parts of water,0.5-0.9 part of gelatin, 0.3-0.6 part of egg white, 3-4 parts of erythritol, 5-6 parts of trehalose, 13-16 parts of syrup, 0.01-0.05 part of edible salt, 2-5 parts of cream, 3-6 parts of milk powder,0.01-0.03 part of vanillin and 10-15 parts of peanut kernels. Additionally, the addition of the trehalose and erythritol reduces the sugar content of the nougat, prevents the conversion of reducing sugar in the boiling process, and improves the stability and the fresh-keeping property of the product; and a water bath heating process and a programmed vacuum cooling process are adopted, so the nougat has the advantages of soft and fine taste, complete structure, long storage time, proper energy supplementation and good texture.

Owner:成都喜相逢食品有限公司

Moisture-proof preparation method for solvent-free solid preparation

ActiveCN102499891ASmall surface areaRoundness requirements are not highPharmaceutical product form changeHydrophilic coatingSolvent free

The invention relates to a moisture-proof preparation method for a traditional Chinese medicine solid preparation, in particular to a moisture-proof preparation method for solvent-free solid preparation of an easy moisture-absorption traditional Chinese medicine extract powder. The moisture-proof preparation method for the solvent-free solid preparation comprises the following steps: firstly, preparing traditional Chinese medicine extract spherical particles by the extrusion spheronization technology; then, evenly mixing 1-10% of water-proof coating material and 0-1% of hydrophilic coating material; carrying out hot-melting coating on the traditional Chinese medicine extract spherical particles by a traditional coating pan; in the coating process and when the coating process ends, adding 0-5% of lubricating agent to prevent particles from bonding; and cooling to obtain the solvent-free solid preparation after the coating process is finished. The moisture-proof preparation method has the outstanding advantages of solvent-free operation, wide applicability and the like and is suitable for preventing moisture for easily-hydrolyzed medicine, the compliance of production personnel is improved, and the environment is protected.

Owner:SHENYANG DONGXIN PHARMA CO LTD +1

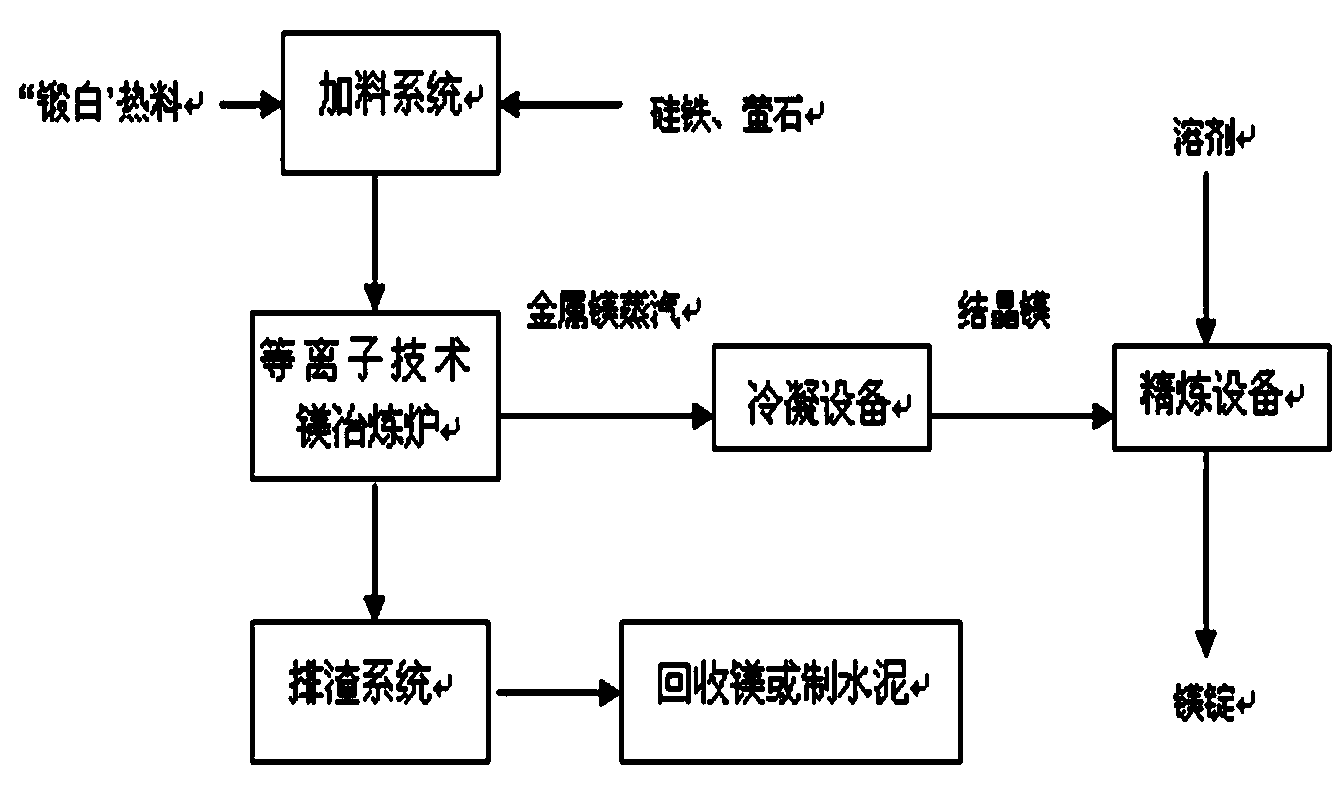

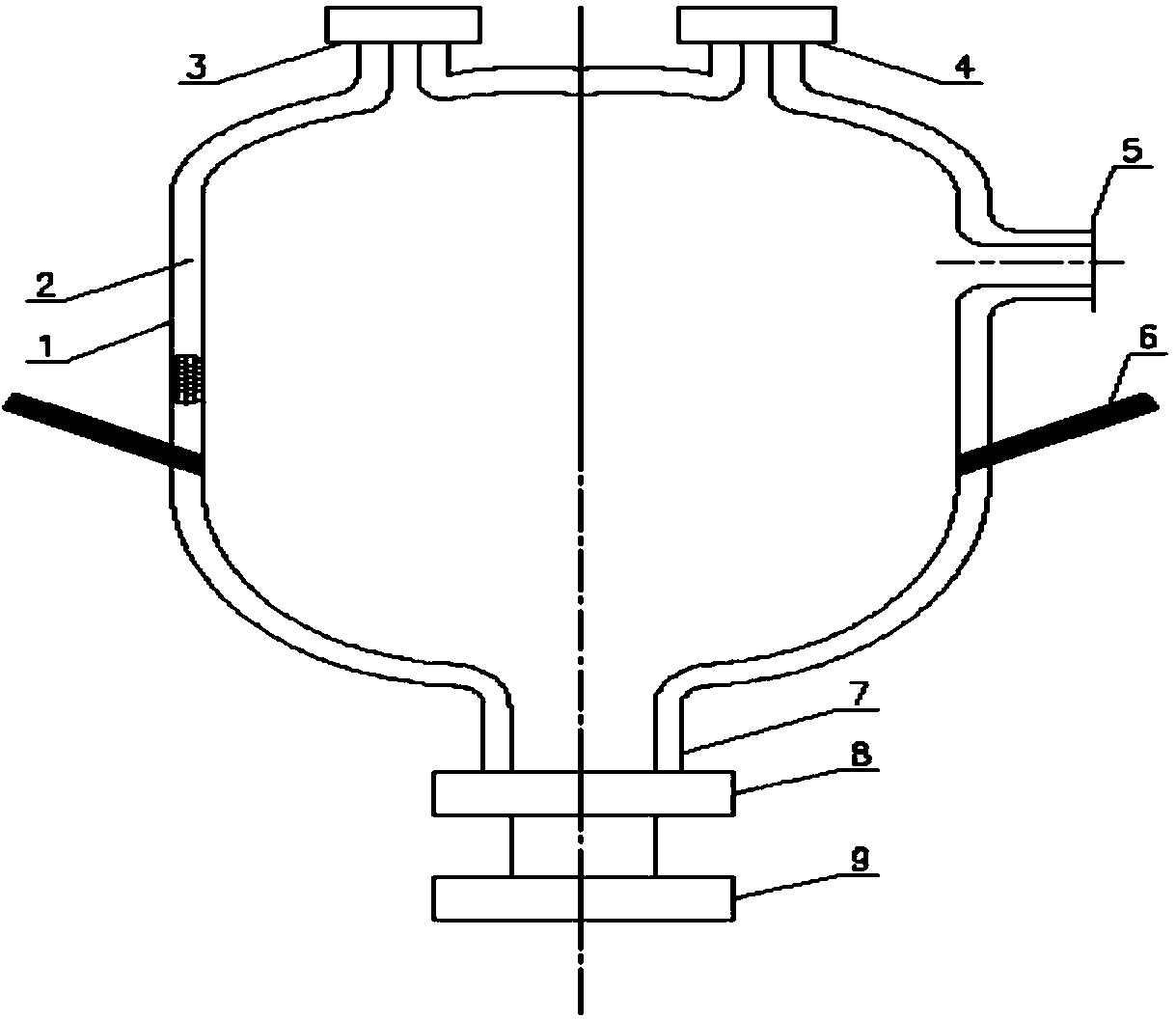

Magnesium metal smelting method and device employing plasma torch heating technology

InactiveCN103589879AHigh efficiency mass transfer and heat transfer processSolve moisture absorptionProcess efficiency improvementPlasma torchSlag

The invention relates to a magnesium metal smelting method and a device employing a plasma torch heating technology. The method comprises the steps that: 1, an inert gas shielded automatic charging system adds prepared raw materials for smelting magnesium metal into a plasma magnesium metal smelting furnace, 2, the raw materials perform continuous silicothermic reduction reaction in the smelting furnace to produce magnesium metal steam and reducing slag, a plasma torch provides a heat source for the reduction reaction, and 3, the magnesium metal steam from the smelting furnace enters a condenser to be condensed into crystal magnesium, the reducing slag is discharged by an inert gas shielded automatic deslagging system, the crystal magnesium can be refined continuously to form a magnesium ingot, and the reducing slag serves as a raw material of cement or is processed for recovery. The method and the device overcome the disadvantages of indirect heating and discontinuous production of a reduction pot, poor mass transfer and heat transmission during reduction, low heat efficiency and low production efficiency in the traditional magnesium smelting technology, a direct heating mode and continuous production are adopted, and the method and the device have a good energy-saving effect and a positive significance for environmental protection.

Owner:北京环宇冠川等离子技术有限公司

Ranitidine hydrochloride composition tablet medicine for treating digestive system diseases

InactiveCN104971053ASolve deliquescenceSolve moisture absorptionOrganic active ingredientsOrganic chemistrySilicic acidMedicine

The invention relates to a ranitidine hydrochloride composition tablet medicine for treating digestive system diseases and belongs to the technical field of medicines. The ranitidine hydrochloride composition is composed of ranitidine hydrochloride, calcium hydrogen phosphate, pregelatinized starch, aluminium-magnesium silicate and aerosol, wherein ranitidine hydrochloride is a new crystal form compound, and an X-ray powder differentiation pattern obtained through Cu-Kalpha radioactive measurement is shown as a Figure 1, so that the ranitidine hydrochloride adopted in the ranitidine hydrochloride composition tablet medicine is different from the ranitidine hydrochloride reported in the prior art. Experiments show that the tablet prepared from the ranitidine hydrochloride new crystal form compound can be used for solving the problem that ranitidine hydrochloride is extremely easy to deliquesce, high in possibility of moisture adsorption and colour change and poor in stability, and the composition is simple, so that adverse reactions are greatly reduced, and the stability, pharmaceutical effect and biological availability of a tablet preparation are improved.

Owner:QINGDAO LANSHENGYANG PHARMA & BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com