Preparation method of modified porous silicon dioxide moisture-proof anti-reflection coating

A technology of porous silica and silica, applied in the direction of coating, etc., can solve the problems of poor controllability, short timeliness, and decreased anti-reflection performance of the preparation method, and achieve flexible and controllable pore structure, mild preparation conditions, The effect of improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation method of a kind of modified porous silica moisture-proof and anti-reflection coating of embodiment 1, comprises the following steps:

[0048] (1) Synthesis of multi-arm silane precursor

[0049] Add 10 mL of 3-(2,3-glycidoxy)propyltrimethoxysilane and 4.45 mL of N,N-bis-[(3-triethoxysilylpropyl)aminocarbonyl]polyethoxyane into three wells 300 mL of ethanol was added to the flask as a reaction solvent, and under nitrogen protection, the reaction was stirred at 60 °C for 48 h. After the reaction, the reaction solution was transferred to a beaker, evaporated and concentrated, and the ethanol solvent was removed to prepare the four-arm silane precursor TS- 1. Its chemical reaction formula is:

[0050]

[0051] (2) Preparation of the precursor solution of polysiloxane sol

[0052] 88mmol of tetraethoxysilane and 12mmol of tetra-arm silane precursor TS-1 were added to a three-necked round-bottomed flask, and 22.19mL of absolute ethanol, 1.8mL of deionize...

Embodiment 2

[0060] A kind of preparation method of modified porous silicon dioxide anti-humidity anti-reflection coating of embodiment 2, comprises the following steps:

[0061] (1) Synthesis of multi-arm silane precursors

[0062] Add 20mL of 3-(2,3-glycidoxy)propyltriethoxysilane and 10mL of N,N-bis-[(3-triethoxysilyl)propyl]ethylenediamine into a three-necked flask, and then Add 600mL of ethanol as the reaction solvent, under the protection of nitrogen, stir the reaction at 70°C for 72h, after the reaction is completed, transfer the reaction solution to a beaker, evaporate and concentrate, remove the ethanol solvent, and prepare the four-arm silane precursor TS-2, its chemical The reaction formula is:

[0063]

[0064]

[0065] (2) Preparation of precursor solution of polysiloxane sol

[0066] Add 197.37mmol of tetraethoxysilane and 2.63mmol of four-arm silane precursor TS-2 into a three-necked round-bottomed flask, add 44.38mL of absolute ethanol, 3.6mL of deionized water and ...

Embodiment 3

[0074] The preparation method of a kind of modified porous silicon dioxide anti-humidity anti-reflection coating of embodiment 3 comprises the following steps:

[0075] (1) Synthesis of multi-arm silane precursors

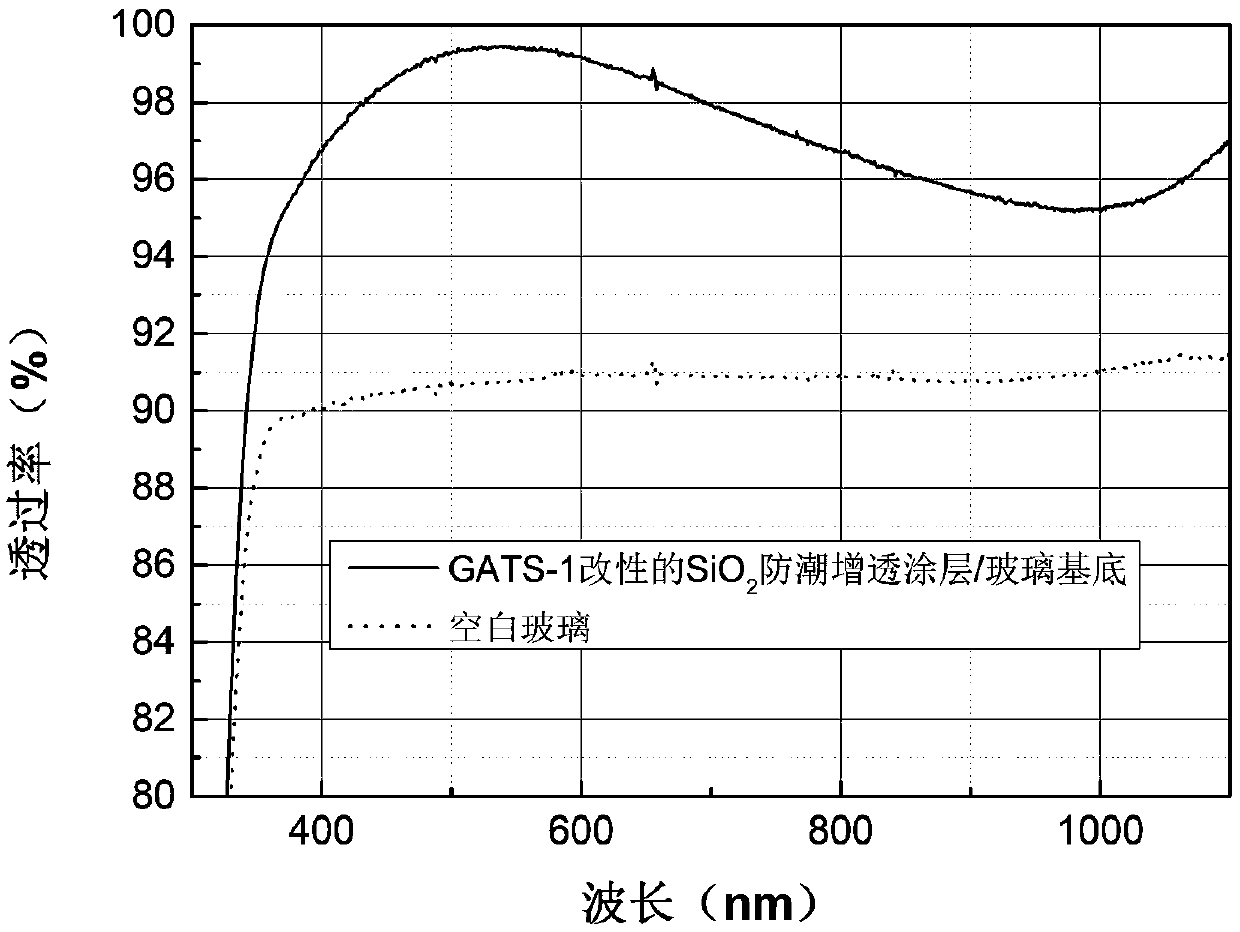

[0076] Add 4.42mL of 3-(2,3-glycidoxy)propyltrimethoxysilane and 2.43mL of 3-aminopropyltriethoxysilane into a three-necked flask, then add 150mL of ethanol as a reaction solvent, and under the protection of argon , stirred and reacted at 60°C for 24 hours. After the reaction, the reaction solution was transferred to a beaker, evaporated and concentrated, and the ethanol solvent was removed to prepare the three-arm silane precursor GATS-1. The chemical reaction formula is:

[0077]

[0078] (2) Preparation of precursor solution of polysiloxane sol

[0079] Add 485mmol of tetraethoxysilane and 6mmol of three-arm silane precursor GATS-1 into a three-neck round-bottomed flask, add 120mL of absolute ethanol, 9.2mL of deionized water and 0.028mmol of acetic acid, re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com