Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

494 results about "Vacuum cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum cooling is a rapid cooling technique for any porous product which has free water and works on the principle of evaporative cooling. Vacuum cooling is generally used for cooling food products having a high water content and large porosities, due to its efficacy in losing water from both within and outside the products. This is the most widely used technique for rapid cooling of food product which has been proven to be one of the most efficient and economical method of cooling and storage of vegetables, fruits, flowers & more.

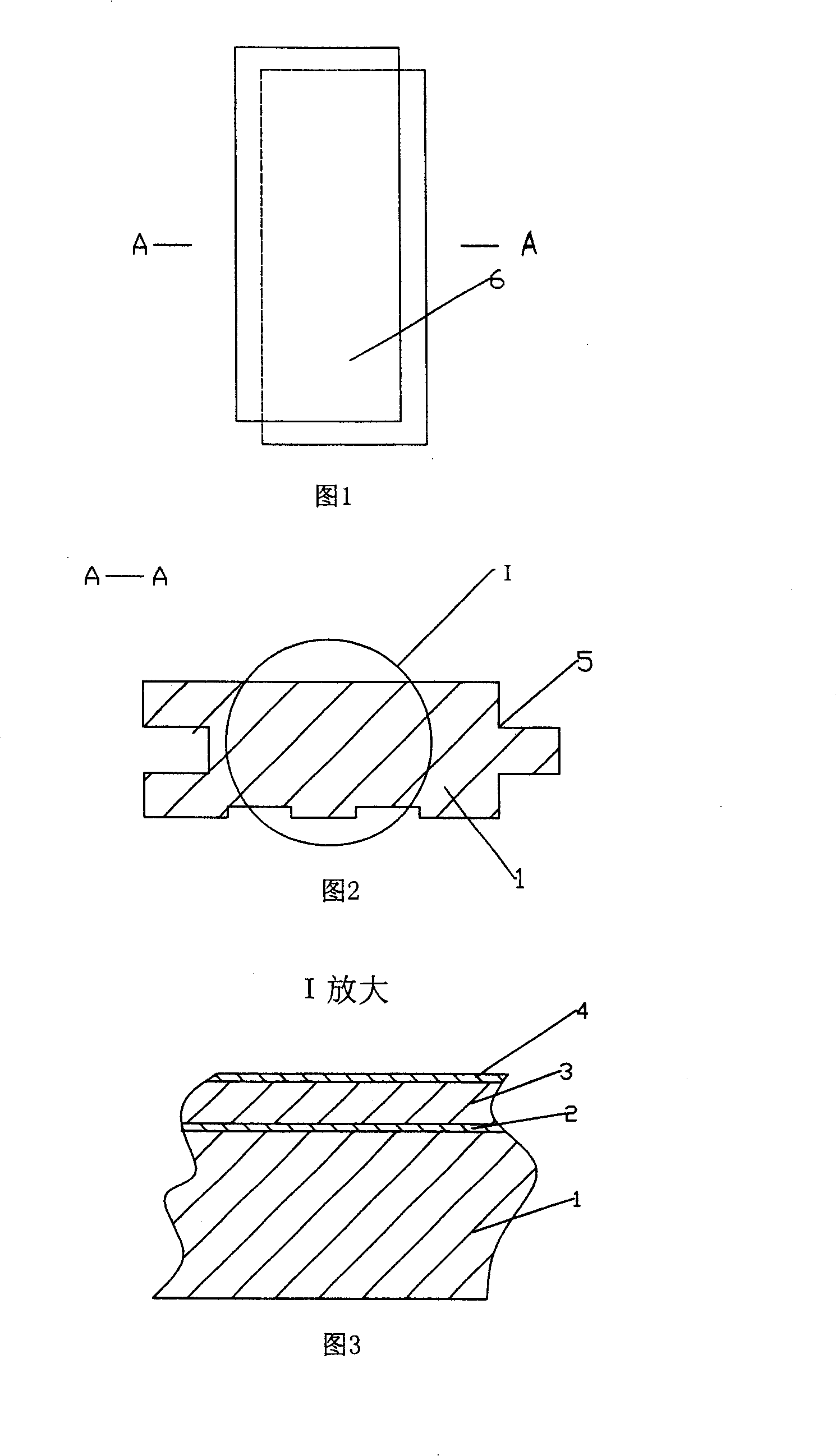

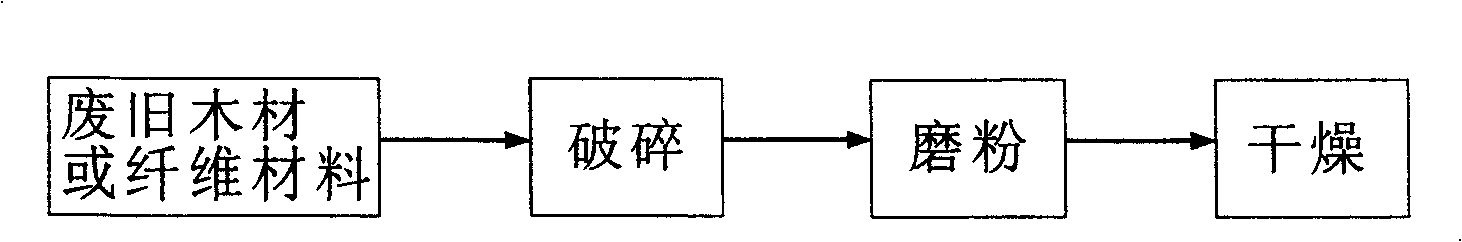

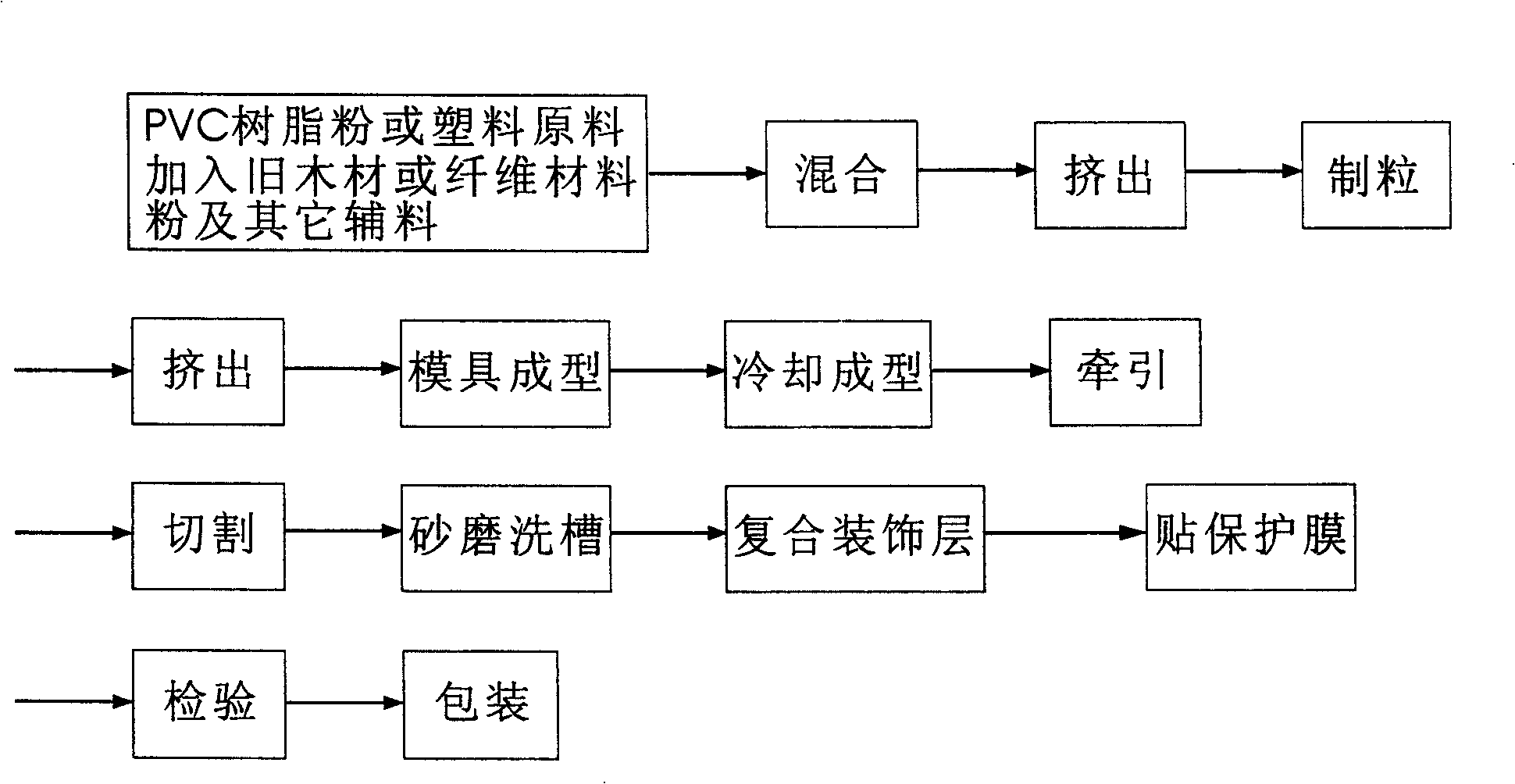

Wear-resistant wood plastic floor and its production technology

The present invention is wear-resistant wood-plastic floor board and its production process, and belongs to the field of decoration material technology. Polyvinyl chloride resin or plastic material is added with waste wood powder or fiber material powder, active calcium carbonate, assistant, stuffer, etc, and the mixture is pelletized, and further treated through extruding, molding, vacuum cooling, settling, drawing and cutting to form the basic wood-plastic board. The basic wood-plastic board is polished, groove milled and covered with surface decoration layer to form the wear resistant wood-plastic floor board product. The wear resistant wood-plastic floor board is beautiful, wear resistant, fireproof, waterproof, non-skid, anticorrosive and environment friendly and has high strength, heat insulation, electrical insulation and other advantages.

Owner:无锡市中德装饰新材料有限公司

Polyvinyl chloride antistatic dust-proof modified window section bar and producing method thereof

The invention discloses a kind of window PCE shaped material with antistatic and dustproof function and its manufacturing method. It raw materials are composes of PVC resin powder, antistatic agent, impact modifier, stabilizer, filler and processing aid in accordance with the weight ratio of 100:0.2-20:1-10:2-8:5-20:1-10. Then it heats and stirs the raw materials at a temperature of 100 ~ 130deg.C in the high-speed mixer, and then it slowly cools the mixture to room temperature and transfers the materials to the extruder, finally it achieves the shaped material through extrusion molding mold, vacuum cooling, traction and cutting.

Owner:LG HAUSYS TIANJIN

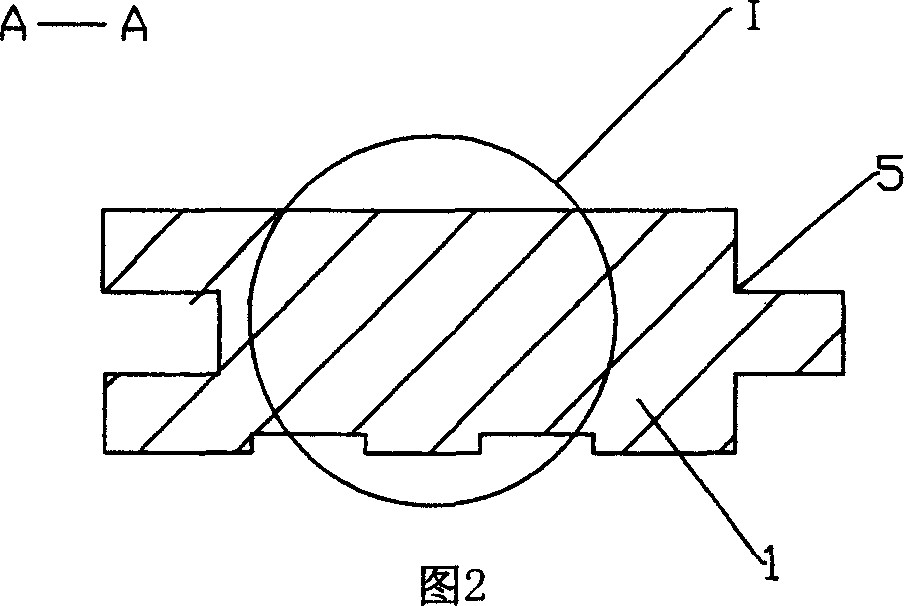

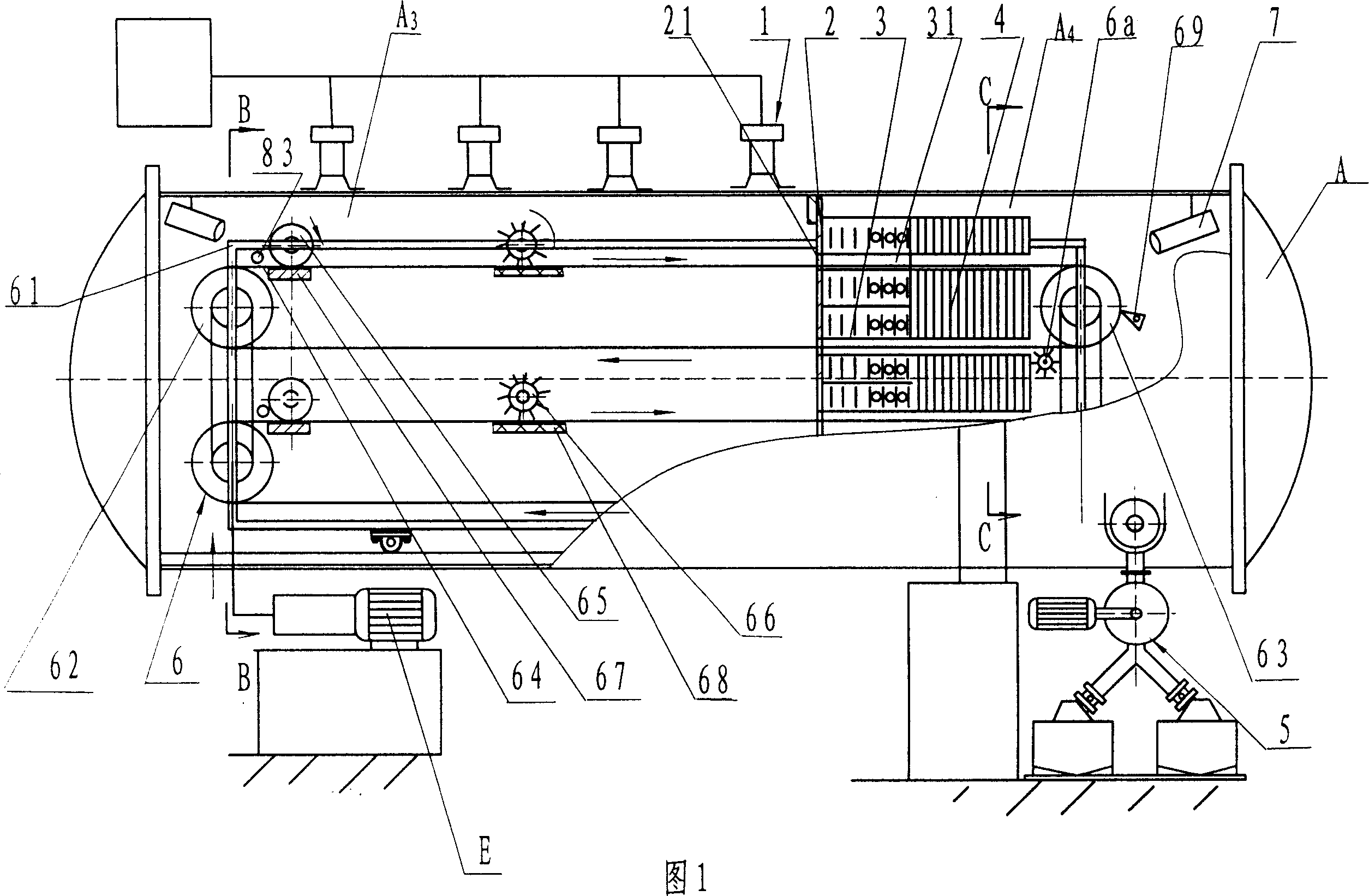

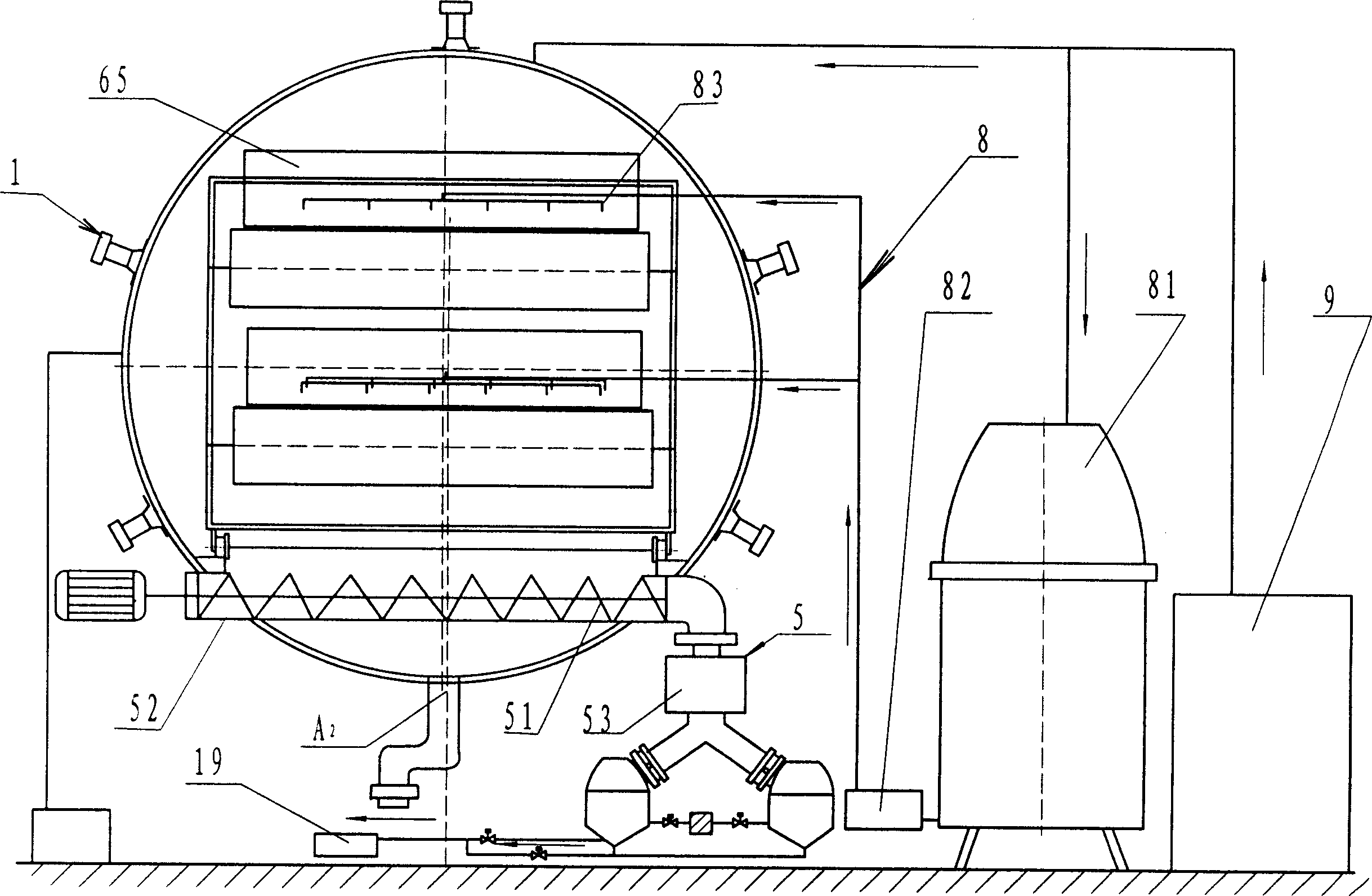

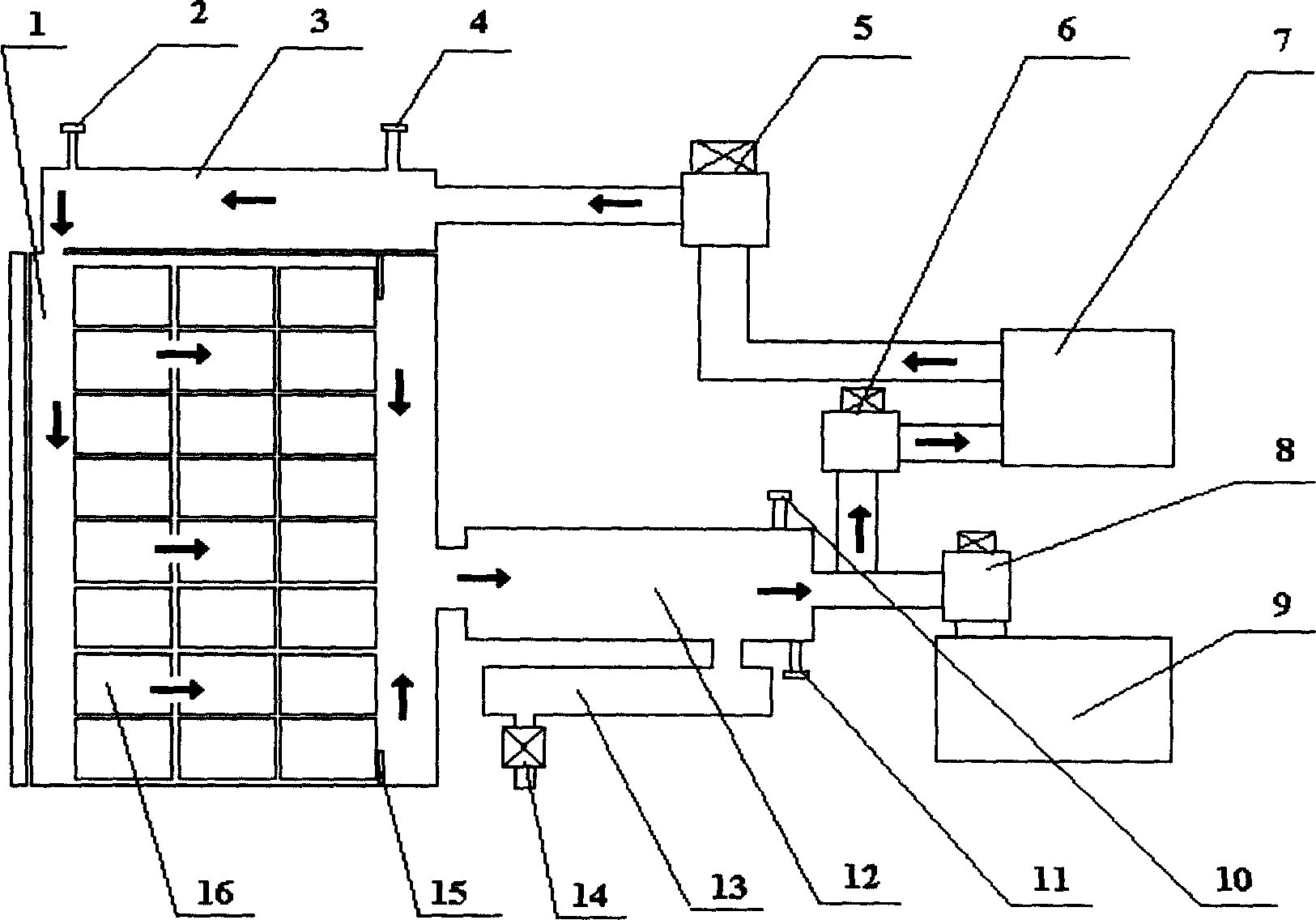

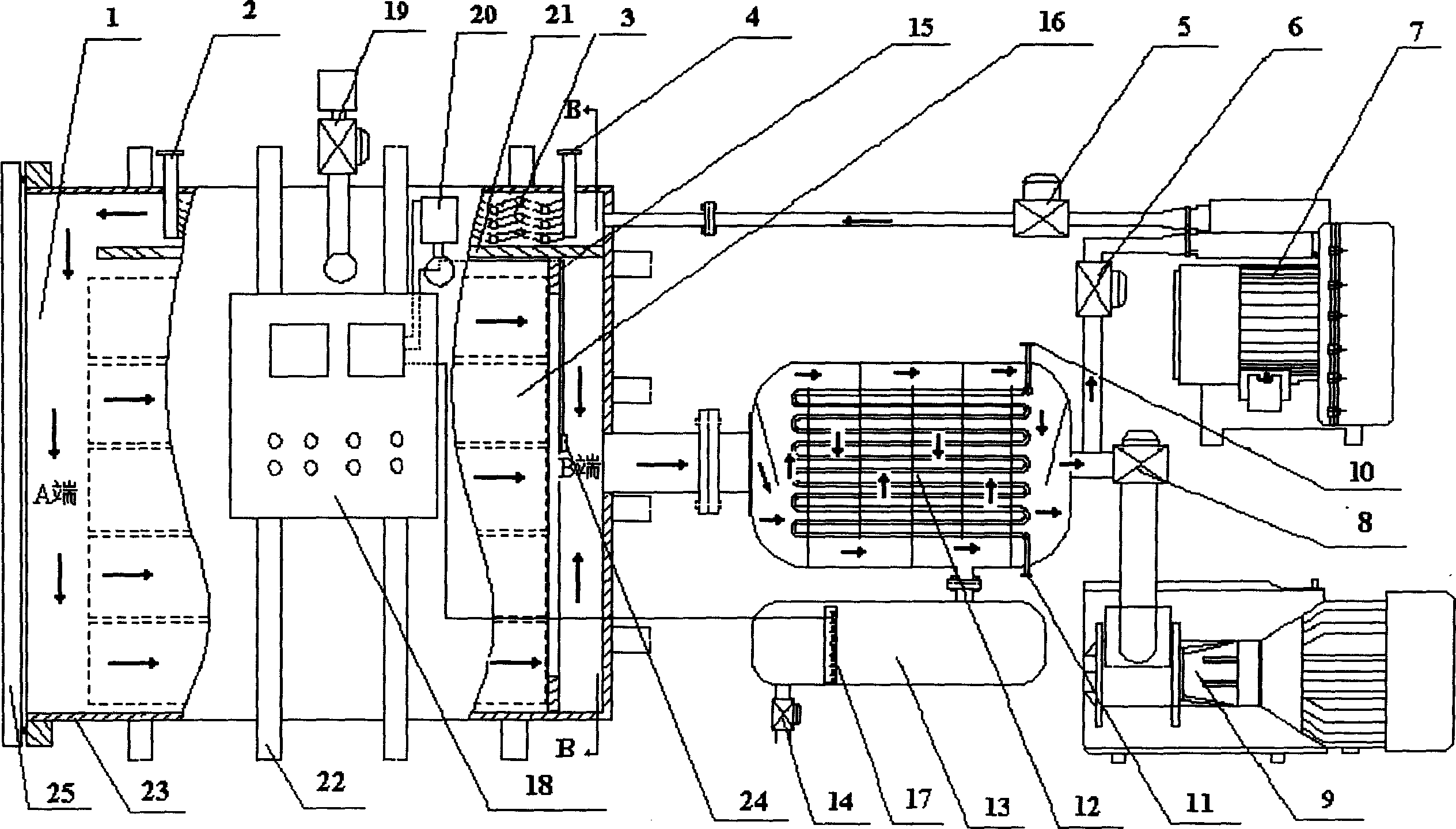

Microwave vacuum continuous drier with two drying chambers and method using the same

InactiveCN1908560ADehydration fastHeating evenlyDrying solid materials with heatHearth type furnacesEngineeringMicrowave irradiation

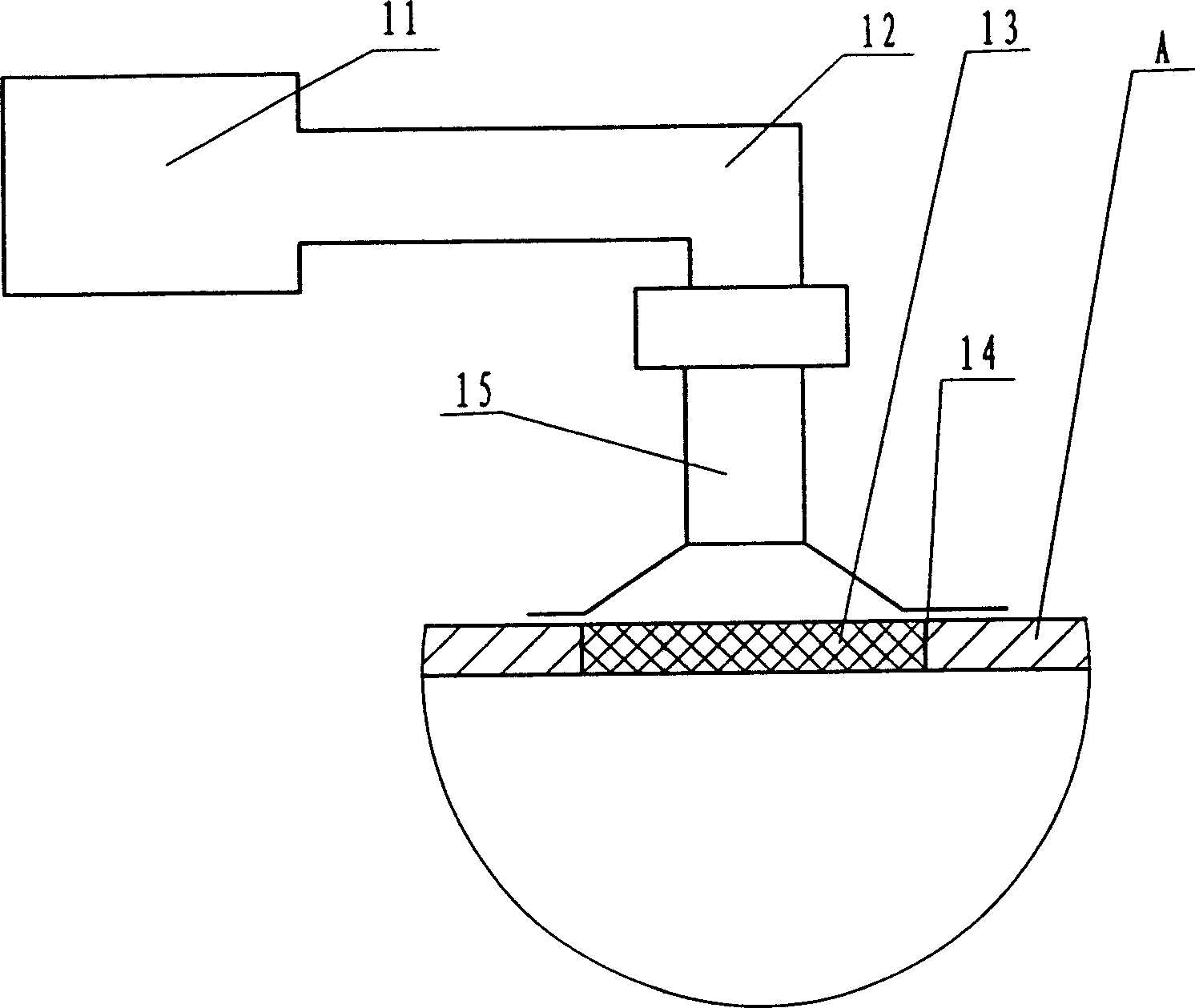

The present invention mainly relates to the structure of a microwave drier, especially a structure of a microwave vacuum drier. A microwave vacuum continuous drier with two drying chambers, includes a tank (A), a hoisting system (8), a vacuum system (9), wherein a delivery device (6) is disposed in the tank (A), and a discharging device (5) below the delivery device (6), characterized by including a microwave vacuum drying chamber (A3) in the tank (A), a microwave heater system (1) on the wall of the tank (A) of the microwave vacuum drying chamber (A3), a separating plate (2) on one side of the microwave vacuum drying chamber (A3) to form a vacuum cooling solidifying chamber (A4). The driving belt (64) of the delivery device (6) traverses the window (21) arranged on the separating plate (2). On one end of the tank (A) is arranged with the microwave vacuum drying chamber (A3) and on the other end is the vacuum cooling solidifying chamber (A4). The separating plate (2) separates the two chambers to make the temperature have the obvious gradient. The invention adopts the way of microwave radiation heating, utilizing the characters of microwave high efficiency, easy to control, antisepsis, sterilization, fast heating, even heating, fast dehydration, preserving to reduce the power waster and advance the efficiency.

Owner:TIANSHUI HUAYUAN PHARMA EQUIP TECH

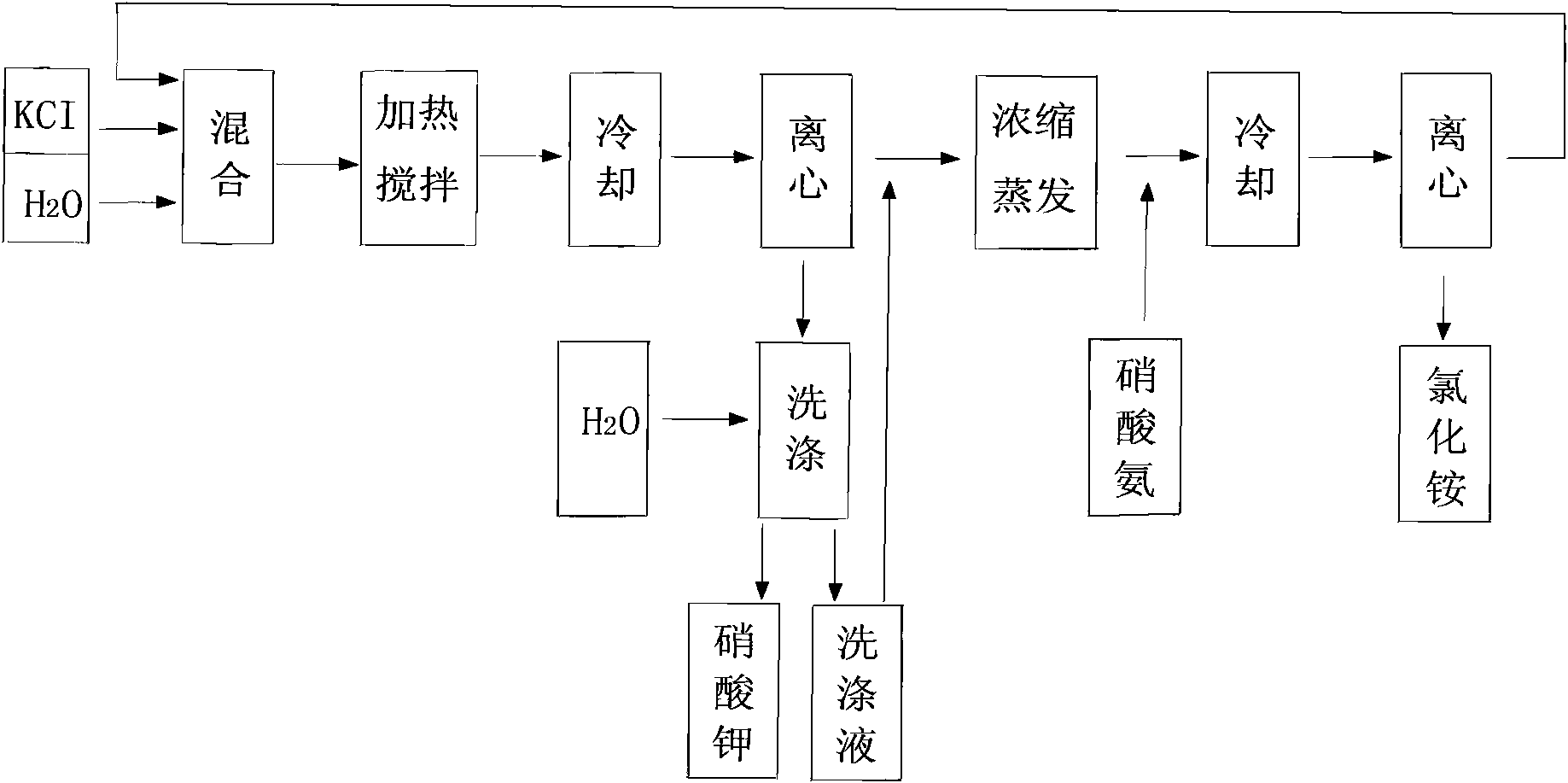

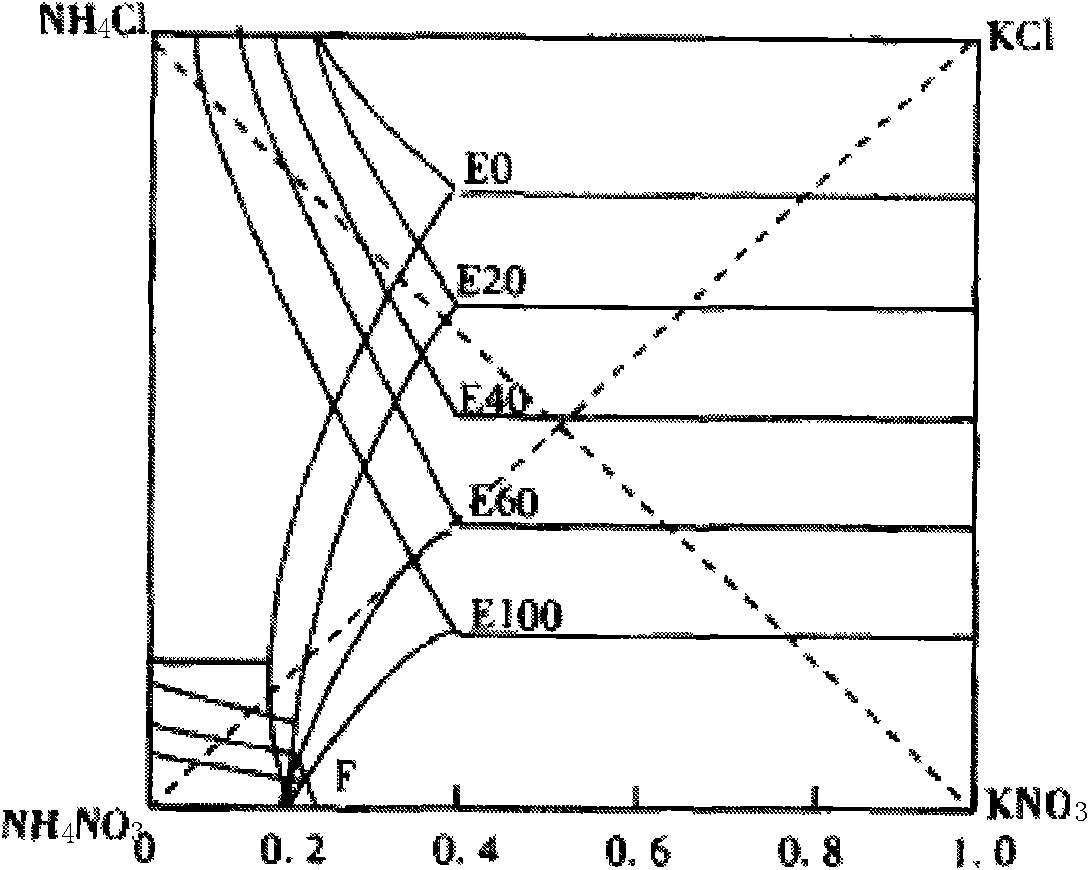

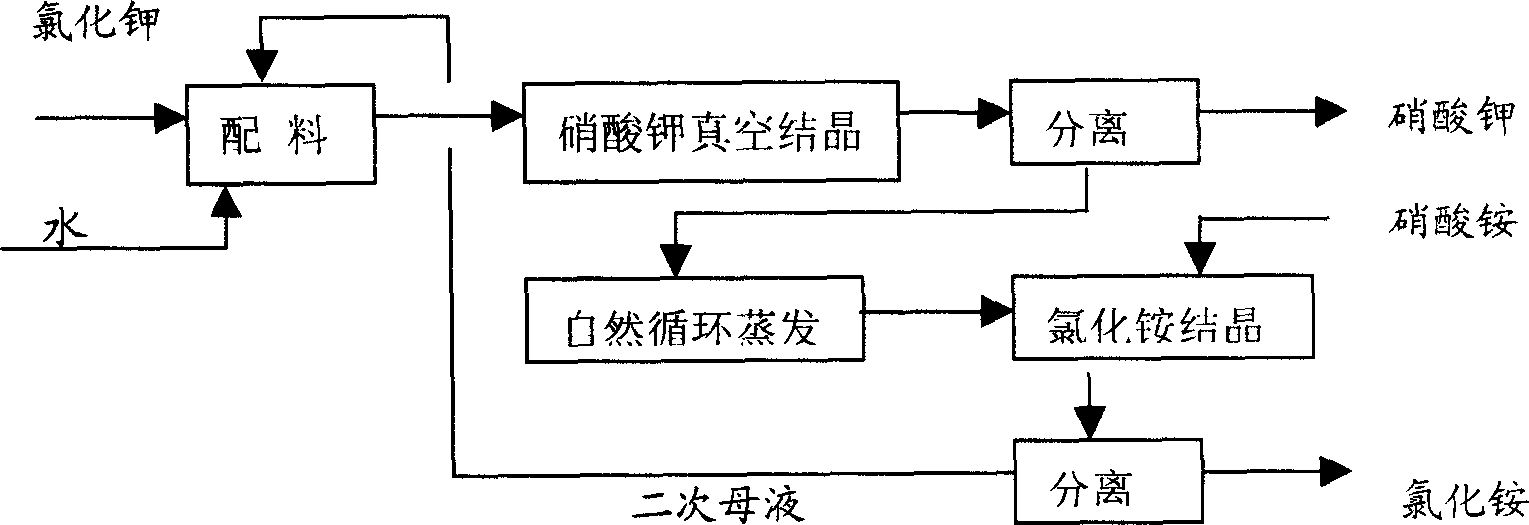

Method for preparing potassium nitrate and ammonium chloride employing double decomposition reaction

InactiveCN101628723ACreate pollutionRealize the concentrated evaporation processAlkali metal nitrate preparationAmmonium halidesDecompositionIon exchange

A method for preparing potassium nitrate and ammonium chloride employing double decomposition reaction comprises the following steps: dissolving ammonium nitrate and potassium chloride in water according to a defined ratio at 110 DEG C, continuously adding potassium chloride and water, heating while stirring to ensure that potassium nitrate is in supersaturation state, after stopping heating, cooling the solution in a vacuum cooling crystallizer to 36-40 DEG C to separate potassium nitrate crystal, placing the potassium nitrate crystal in a centrifugal machine with a filter cloth lining to obtain coarse potassium nitrate, then washing the potassium nitrate with cold water, drying to obtain the finished potassium nitrate; in addition, adding ammonium nitrate in mother solution I and cleaning solution to adjust solution concentration so that ammonium chloride can reach supersaturation state, using a vacuum concentration device to perform negative pressure evaporation, separating and precipitating ammonium chloride by centrifuging and obtaining a solid ammonium chloride product, wherein, when dissolving ammonium nitrate and potassium chloride, the ratio of ammonium ion to chlorine ion is 1:2 and when using the centrifugal machine to obtain the coarse potassium nitrate, the separated mother solution is another mother solution I sharing the same saturation point of potassium nitrate and ammonium chloride. The solution of feed liquid circular reaction overcomes the defects of the prior art that the price of potassium nitrate used in reaction is high, the resource of potassium nitrate is in short supply and the cost of devices used in ion-exchange method is high, thus being applicable to the production of potassium nitrate.

Owner:湖南丹化农资有限公司

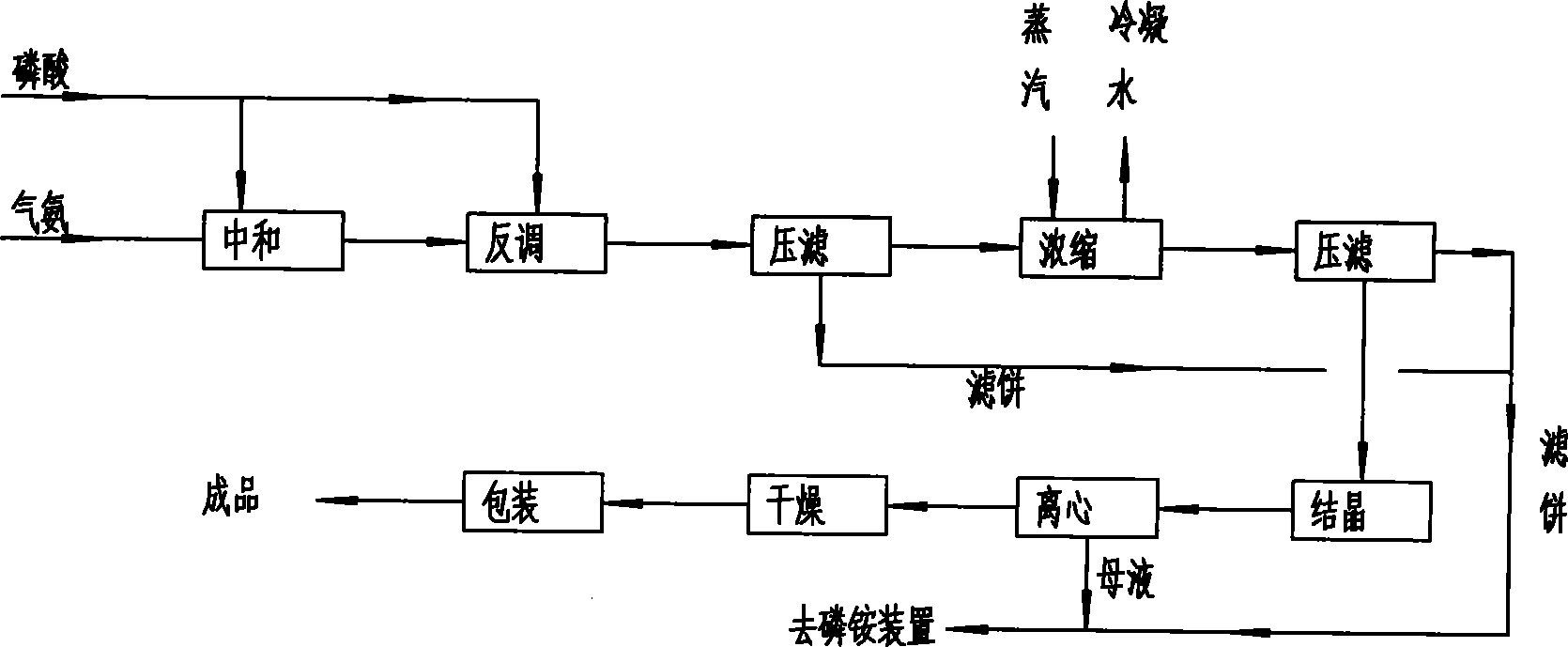

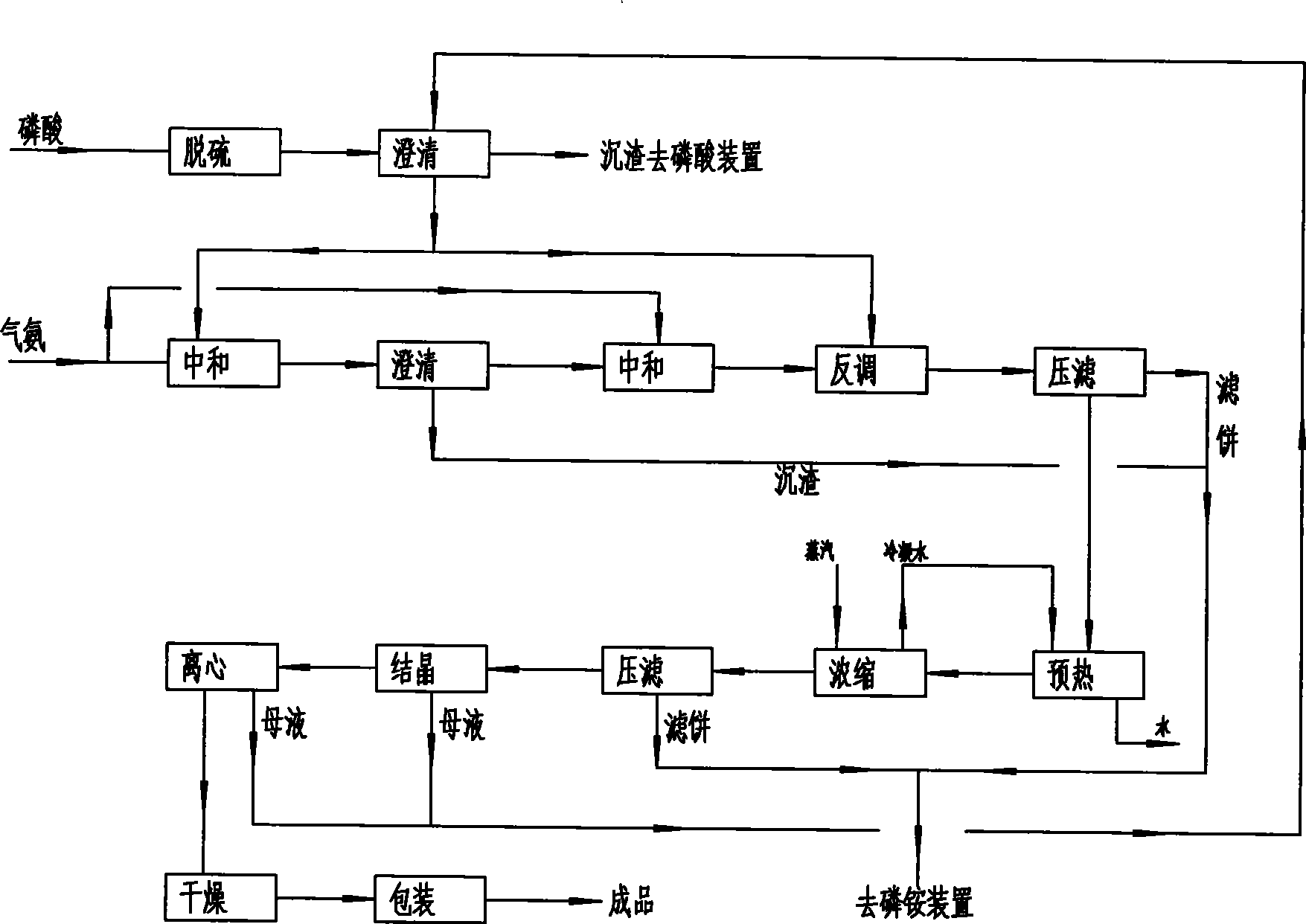

Process for continuous production of technical grade mano-ammonium phosphate with wet-process and phosphoric acid

ActiveCN101367512AReduce labor intensityReduced pressure filter loadPhosphatesPhosphatePhosphoric acid

The invention relates to a craftwork for producing the industrial-level monoammonium phosphate consecutively with the phosphoric acid by wet process, which adopts the following steps: 1) phosphoric acid and phosphorite pulp are desulfurized to get the desulfurized phosphoric acid; 2) the acid is undertaken the first neutralization action to get a neutralized material pulp clarifying solution; 3) after the second neutralization reaction, the solution is reacted with the desulfrized phosphoric acid to get a secondary neutralized material pulp with the pH value being adjusted; 4) the secondary neutralized material pulp with the pH value being adjusted is primarily filtered to get a primary filtering solution and a primary filtering mass; 5) the primary filtering solution is secondarily concentrated and press filtered to get the secondary filtering solution; 6) the obtained secondary filtering solution is dissolved through the grain refining, is cooled down in vacuum, is crystallized, is centrifugally separated and dried to get the finished product of the industrial-level monoammonium phosphate. The invention has the advantages that the operation during the production process is consecutive; the labor intensity of the worker is reduced; the leakage rate of the ammonia is low and the loss is small; the secondary neutralized raw material solution is clear solution, so that the viscosity is low and the loss of the ammonia is small; the neutralization and the press filtering load is reduced; the crystallization production capacity is large; the heat energy is adequately used, thereby reducing the consumption of the vapor.

Owner:HUBEI XIANGYUN GROUP CHEM

Wear-resistant wood plastic floor and its production technology

The present invention is wear-resistant wood-plastic floor board and its production process, and belongs to the field of decoration material technology. Polyvinyl chloride resin or plastic material is added with waste wood powder or fiber material powder, active calcium carbonate, assistant, stuffer, etc, and the mixture is pelletized, and further treated through extruding, molding, vacuum cooling, settling, drawing and cutting to form the basic wood-plastic board. The basic wood-plastic board is polished, groove milled and covered with surface decoration layer to form the wear resistant wood-plastic floor board product. The wear resistant wood-plastic floor board is beautiful, wear resistant, fireproof, waterproof, non-skid, anticorrosive and environment friendly and has high strength, heat insulation, electrical insulation and other advantages.

Owner:无锡市中德装饰新材料有限公司

Process for treating wastewater comprising high-concentration ammonium salt and sodium salt

ActiveCN101935128AWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentSolubilityHigh concentration

The invention provides a process for separating out high-purity ammonium salt and sodium salt by combining evaporation concentration crystallization and cooling crystallization aiming at wastewater comprising high-concentration ammonium salt and sodium salt according to characteristic difference that solubility of the ammonium salt and the sodium salt varies along with temperature. In the process, the wastewater is pretreated, molar weight proportion of Cl<-> and NH<4+> in the wastewater is adjusted, and high-purity sodium salt and ammonium salt are recovered by high-temperature evaporation concentration crystallization and vacuum cooling crystallization respectively. The wastewater which is subjected to evaporative condensation is recycled in a production system, and the separated ammonium salt and sodium salt are used by factories as raw materials, so the comprehensive utilization and absolute treatment of a wastewater resource are ensured, and economic benefit and social benefit of the factories are improved. The process is suitable for treating the wastewater which comprises high-concentration ammonium salt and sodium salt and is produced in wet metallurgy enterprises and salty chemical enterprises.

Owner:SHANGHAI CN WATER

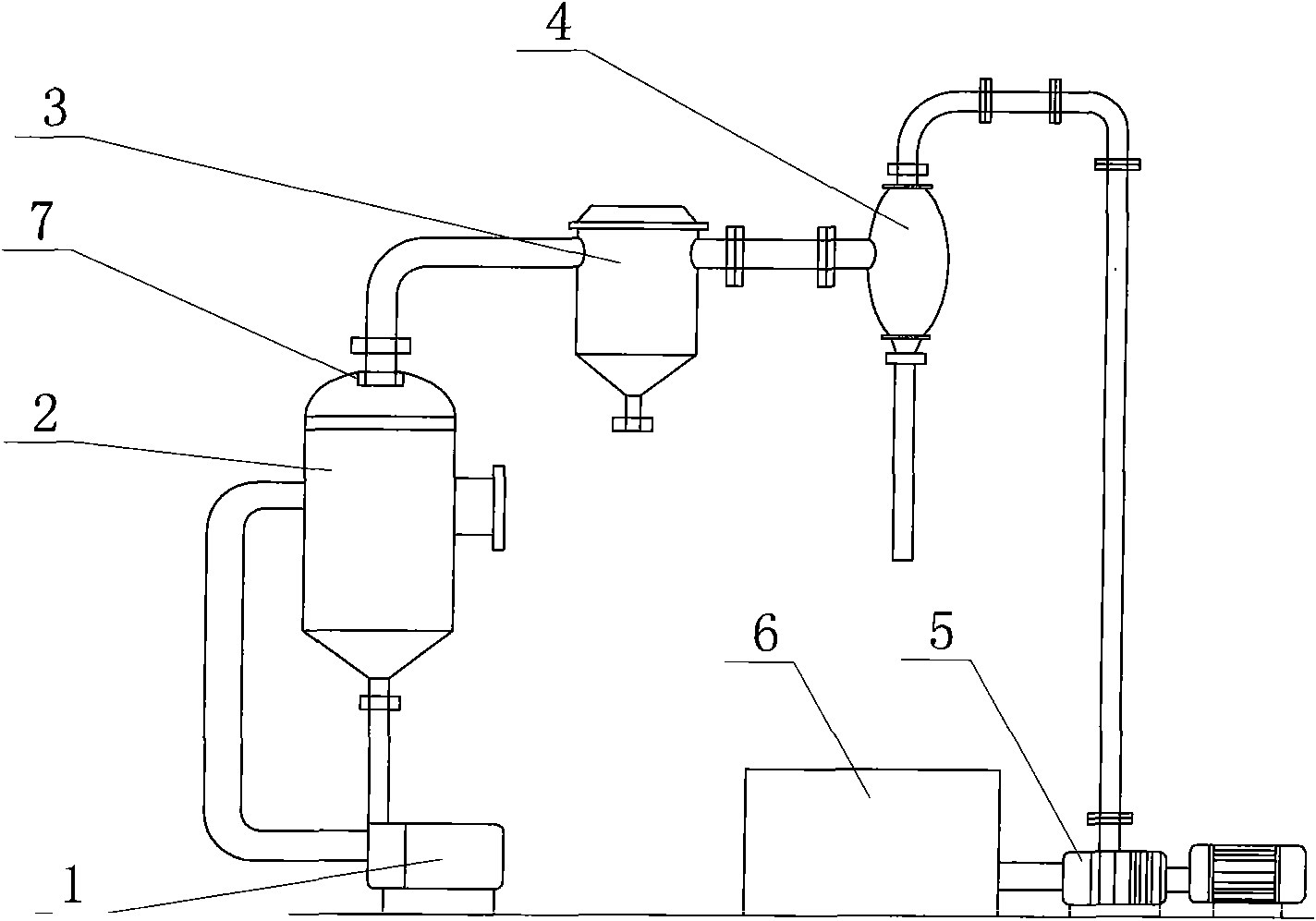

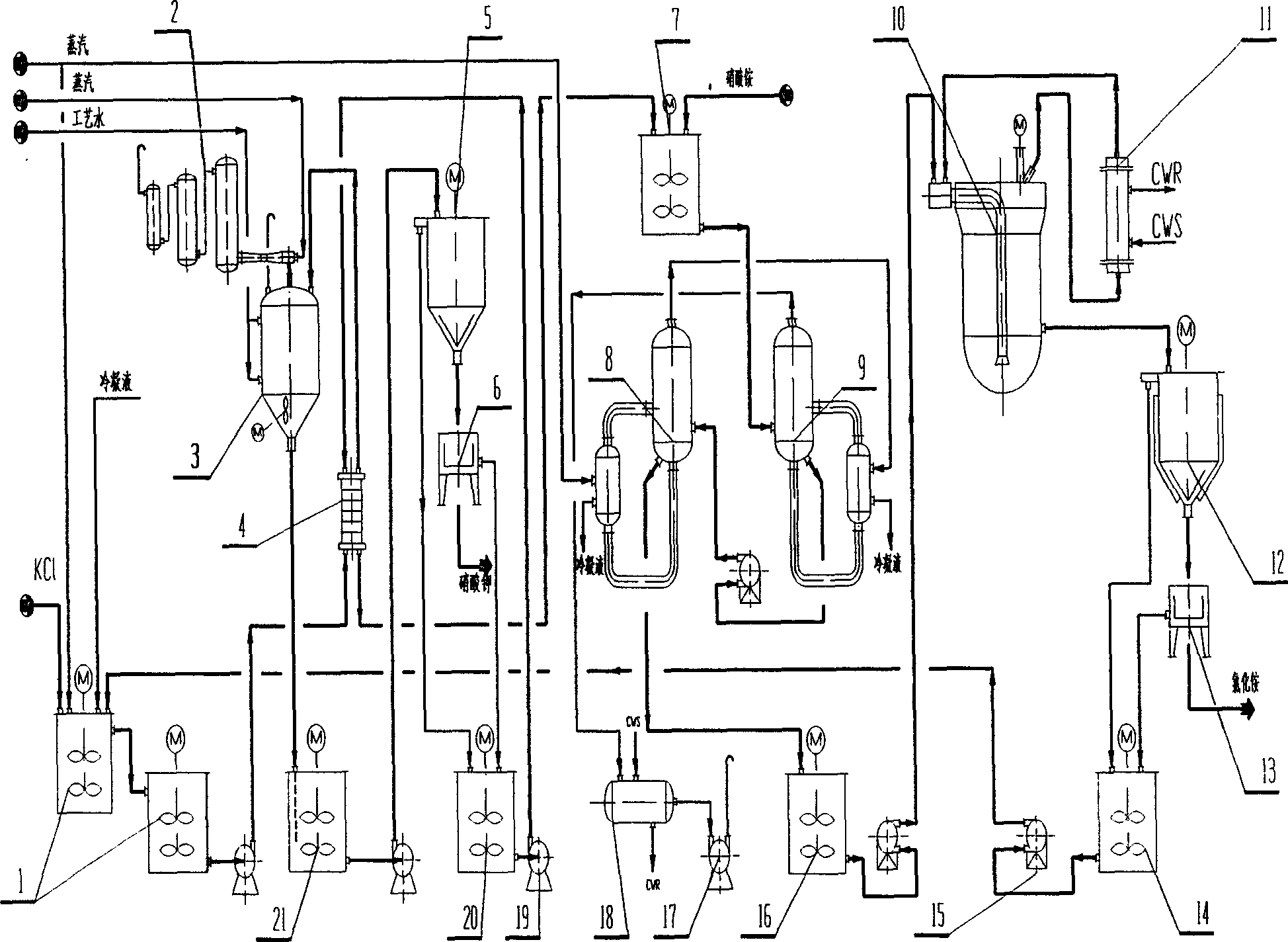

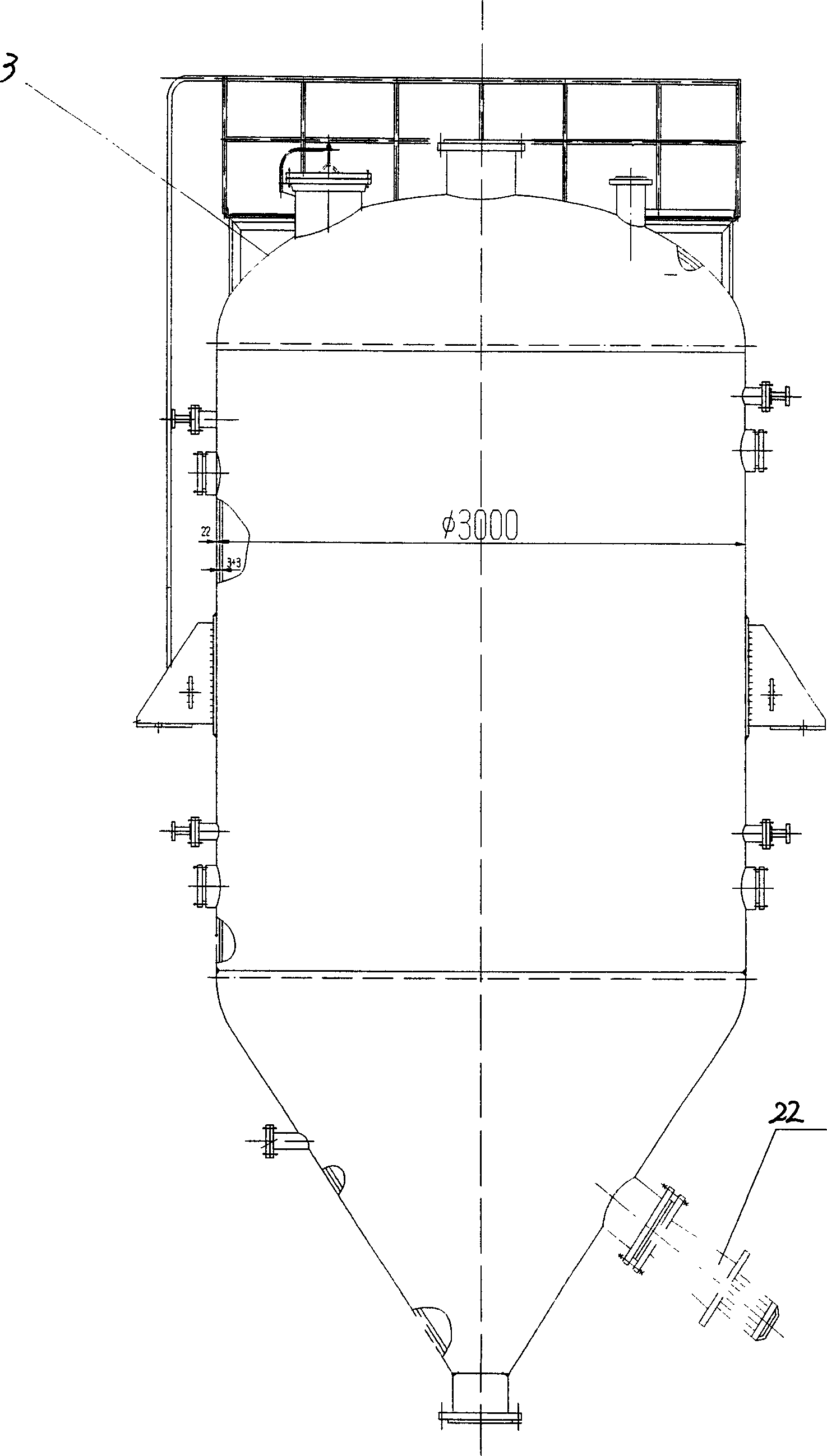

Process for preparing potassium nitrate by double decomposition method

ActiveCN1827526ALess process equipmentEasy to manufactureAlkali metal nitrate preparationCyclic processAmmonium nitrate

The invention provides a metathesis method for preparation of potassium nitrate. After raw potassium chloride, ammonium nitrate and craft water finish their preparation at a certain ratio, they are input into vacuum cooling crystallizer. Then potassium nitrate is separated by crystallization and grows up. The crystallized liquid thickens by the thickening apparatus and continuously separates potassium nitrate as aim products by centrifugal machine. After the separated mother liquid exchanges heat with the reacting liquid, it is input into natural circulation evaporator to concentrate, adopting backward feed and dual effect concentration with constant pressure in the first chamber and negative pressure in the second chamber. Through cooling crystallization, thickening by the thickening apparatus, the concentrated liquid continuously separates ammonium chloride as by-products. The gained secondary mother liquid returns to preparation groove. Repeating this cyclic process, we could sequentially get solid potassium nitrate and ammonium chloride.The invention has improved production stability and product quality a lot and reduced raw material consumption and energy consumption, with simple and serial flow process. The invention has realized the mass production.

Owner:EAST CHINA ENG SCI & TECH

Special poultry meat fine and deep processing method

InactiveCN101961114AImprove sterilization efficiencyExtend heating timeMeat/fish preservationSlaughtering/stunningDeep processingFood item

The invention relates to a food processing method, in particular to a special poultry meat fine and deep processing method. In the invention, high-technology content special duck meat deep processed new products and special convenient and quick poultry meat green products are developed by using technology for preserving raw material duck meat with edible multifunctional preservation films, ultrasonic rapid penetration salting promoting technology, energy-saving, emission-reducing and environmentally-friendly microwave assisted sterilization technology, vacuum cooling technology, vacuum oil frying technology, infrared roasting technology and the like.

Owner:赵保雷

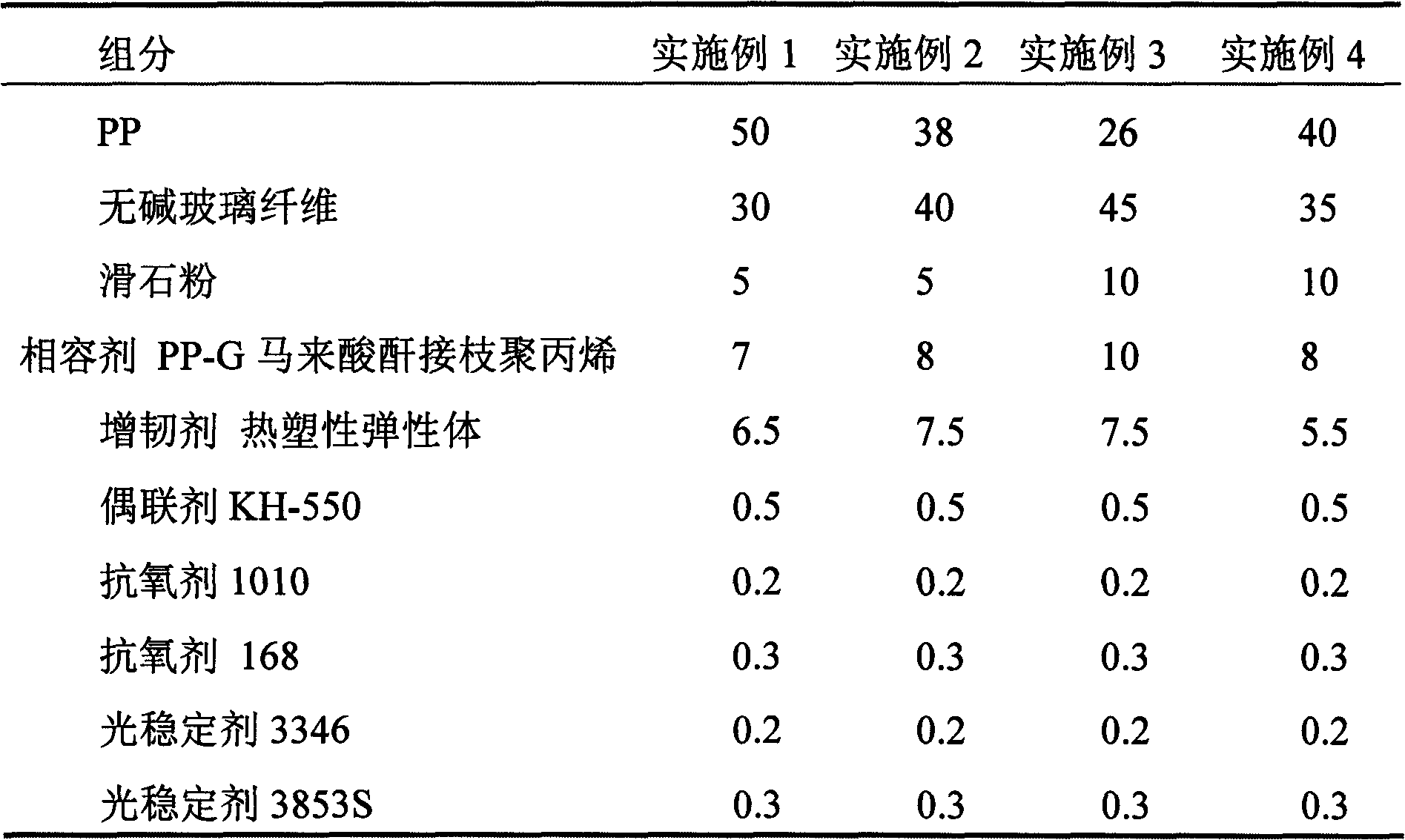

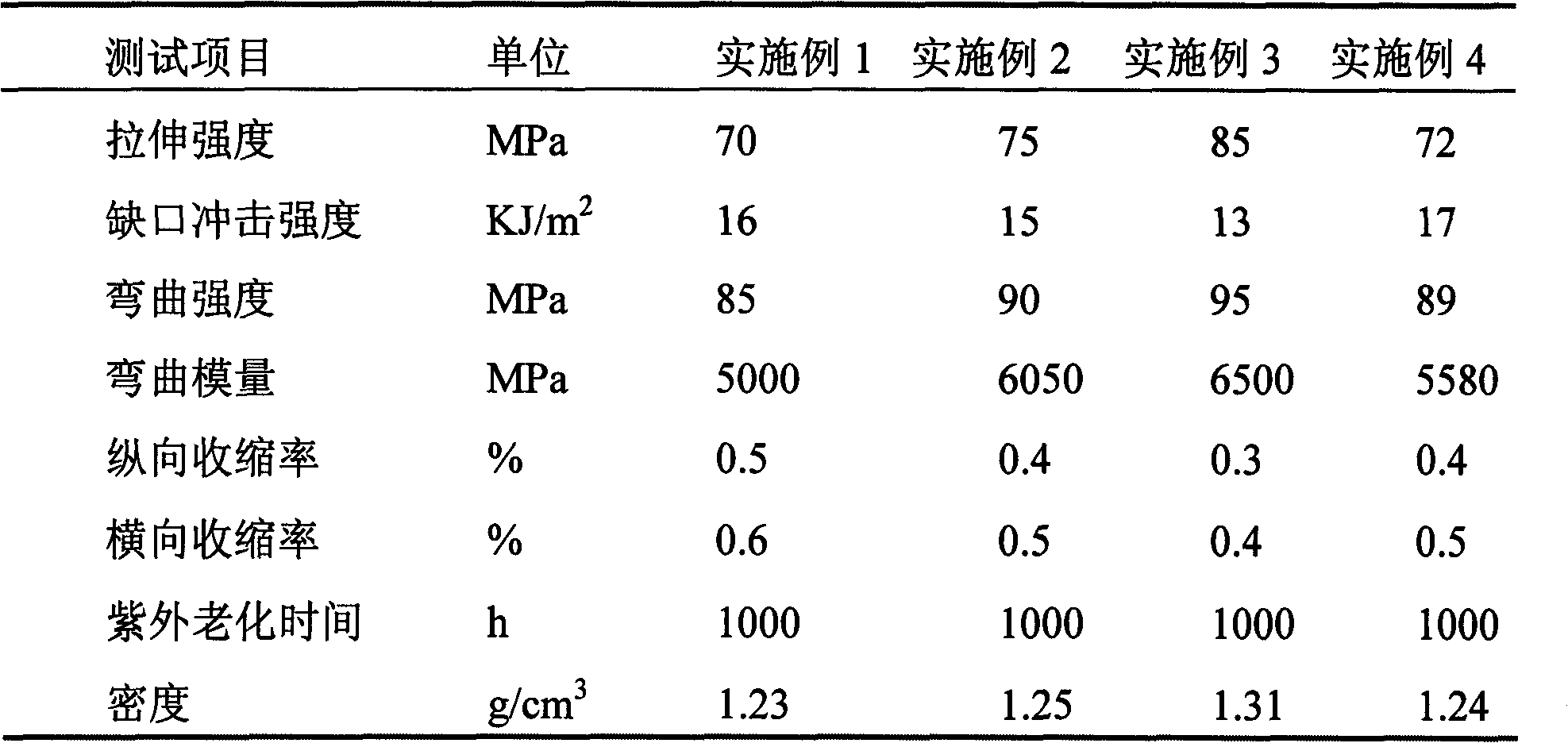

Thermoplastic composite material for hollow building templates and manufacture method thereof and application thereof

InactiveCN103160030AImprove rigidityImprove toughnessForming/stuttering elementsGlass fiberAntioxidant

The invention relates to a thermoplastic composite material for hollow building templates and a manufacture method thereof and application thereof. By weight, 20-55 parts of polypropylene, 30-50 parts of glass fiber, 5-10 parts of inorganic filler, 5-10 parts of flexibilizer, 5-10 parts of compatilizer, 0.1-0.5 part of coupling agents, 0.1-0.3 part of antioxidant and 0.2-0.3 part of light stabilizing agents are mixed for 3-5 minutes in a high-speed mixer, and extruded from a double-screw extruder to form the thermoplastic composite material. The thermoplastic composite material is smelted, extrude-molded, vacuum-cooling-molded, primarily dragged, heated to eliminate stress, secondarily dragged and cut into the hollow building templates meeting requirements. Compared with the prior art, the thermoplastic composite material has the advantages of being high in strength, roughness and size stability, and the like.

Owner:上海铂砾耐材料科技有限公司

PVC foaming architectural decoration material and preparation technique thereof

The invention relates to a PVC foaming construction decorative material and a preparation technique thereof. The preparation technique comprises the following steps: PVC plastics which are waste and are screened and ground, calcium carbonate, a stabilizer, an antioxidant, a lubricant, a foaming agent, a modifier, a foaming modifier, a dispersing agent, a colorant and the like are added into a high mixing machine according to the weight in sequence, mixed for 5 to 10 minutes, then placed into a low-temperature mixing machine for 5 to 10 minutes when being heated to be 120 to 125 DEG C; discharging is carried out when the temperature is 35 to 45 DEG C; the obtained materials are extruded by a parallel conical twin-screw extruder, molded, cooled in vacuum, pulled, film-stuck, cut and inspected and then the finished product of foaming plastic product is obtained. The invention is applicable to families, hotels, offices and entertainments, is the most ideal home decorative material with environment protection and is also the most practical home floor material.

Owner:胡大忠

Sealed system and continuous process for making food products

InactiveUS6994016B1Minimizes damage and leachingProduction of water becomes so profuseAir-treating devicesMilk preservationWater productionEngineering

A system and a process for making food products, such as dehydrated potato products, with reduced water usage, and reduced waste water production, are provided. The system includes a precooker, a cooler and a cooker having sealed process chambers in flow communication with one another, and augers for moving the food product through the process chambers. In addition, valves seal the process chambers, and transfer the food product between the process chambers at a controlled rate. The process includes the steps of precooking the food product using steam, cooling the food product using vacuum cooling and conduction cooling in combination, and then cooking the food product using steam. The process also includes the steps of moving the food product at the controlled rate using the valves, and mixing the food product during the precooking, cooling and cooking steps.

Owner:MILES WILLARD TECH

Three-stage composite pretreating method for delaying fresh time of putresible fruit and vegetable

InactiveCN1709075AReduce weight lossExtend fresh storage periodFruits/vegetable preservation by freezing/coolingCellular respirationPretreatment method

The present invention relates to a three-stage combined pretreatment method for prolonging fresh-keeping period of putrefactive fruit and vegetable. Said method includes the following processes: according to conventional method selecting fruit and vegetable, washing and grading, controlling water content, quickly vacuum cooling so as to reduce respiration action of fruit and vegetable, utilizing high-pressure mixed gas to make water content be structured to deactivate enzyme activity of fruit and vegetable, finally applying nano silver antibacterial film to reduce putrefactive rate of fruit and vegetable so as to implement invented goal.

Owner:JIANGNAN UNIV

Method for preparing plastic wood compound material/rigid foam composite and light weight type wall plate

The invention relates to a method for manufacturing a composite light wall made from WPC material / rigid foam. The method comprises two procedures of the molding of the outer layer of a hollow wall member and the on-site filling of a core layer. After being mixed and plasticated, wood fiber material, polymer material, various accessory ingredients and additives are made into the granular WPC material by a screw extruder. After being added into the screw extruder, the granular material is made into the outer layer of the wall member. With the completion of processes of hand piece, vacuum cooling, shaping, traction and cutting, the outer layer of the hollow wall member is obtained. A froth placer is used for performing on-site rapid rigid aeration for polyurethane material that is filled into the outer layer of the wall member, thus making a composite light wall plate made from the WPC material / rigid foam. The method for manufacturing the composite light wall made from the WPC material / rigid foam avoids the problem that the core layer and the outer layer of the wall member can not be extruded simultaneously and the core layers with different densities can be filled and foamed according to the strength of the wall member and on-site requirements, thus ensuring the transverse compressive strength of the wall member. The method for manufacturing the composite light wall made from the WPC material / rigid foam is convenient and flexible and has wide application range.

Owner:JIANGSU SIFANG MACHINERY GROUP +1

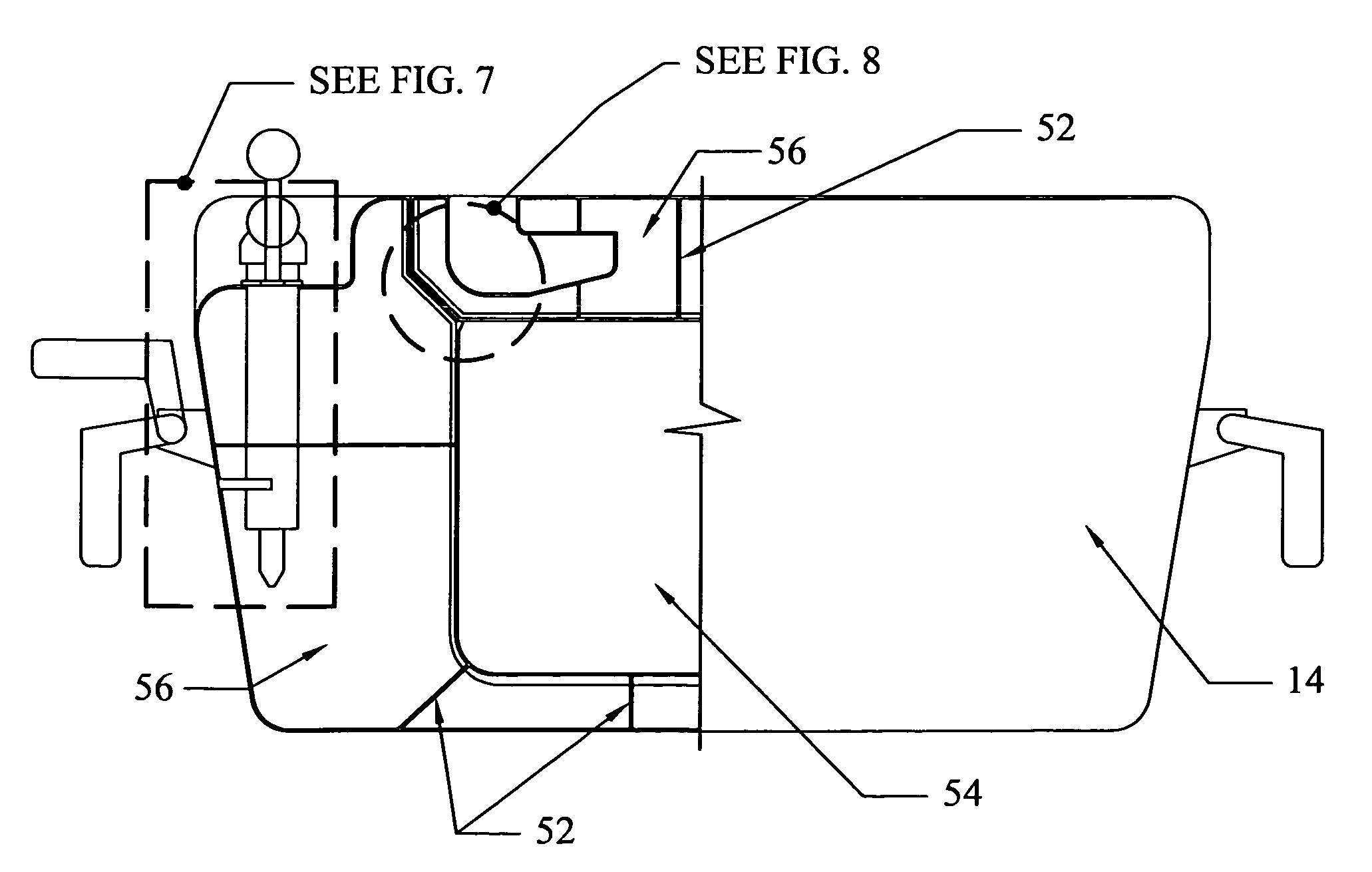

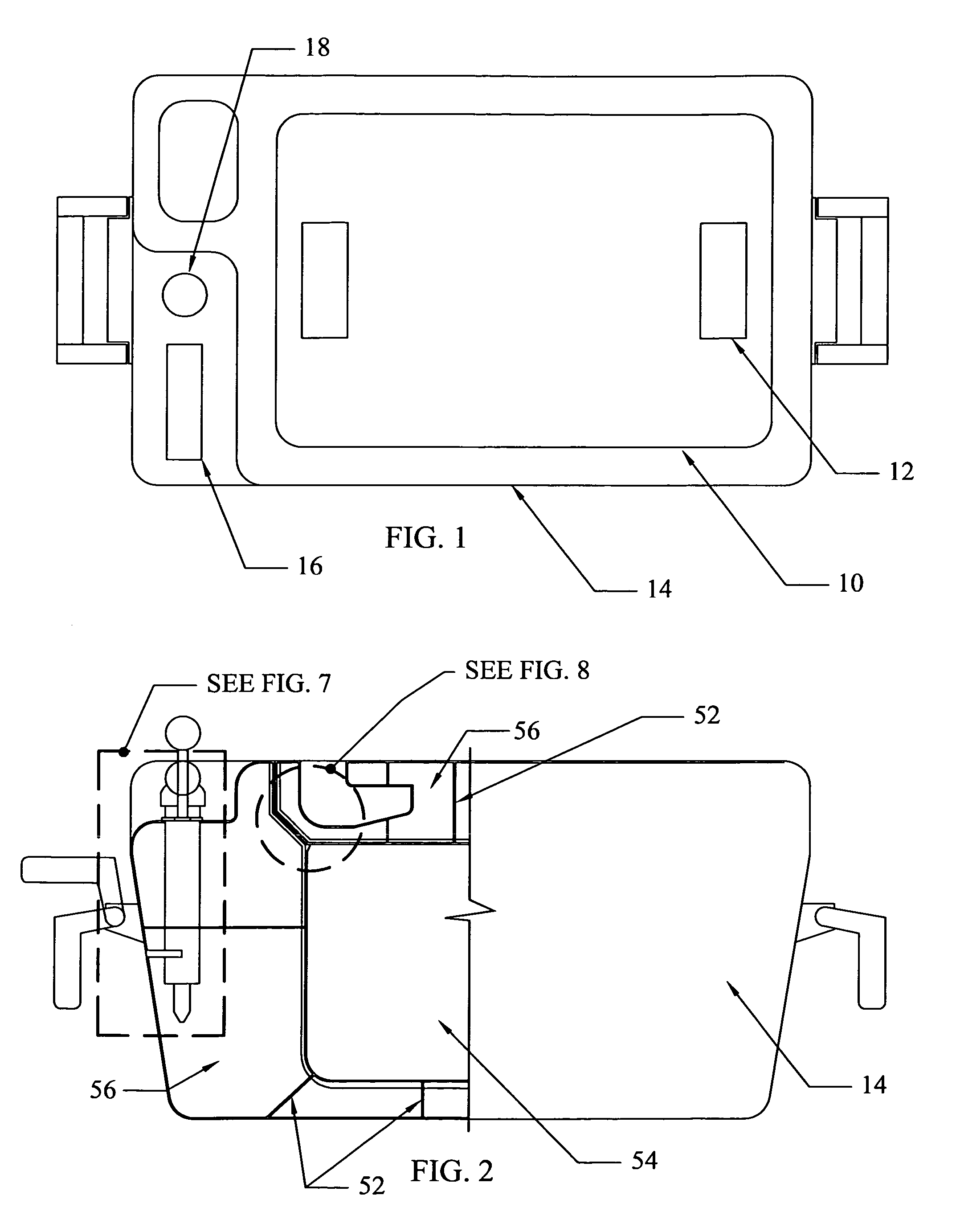

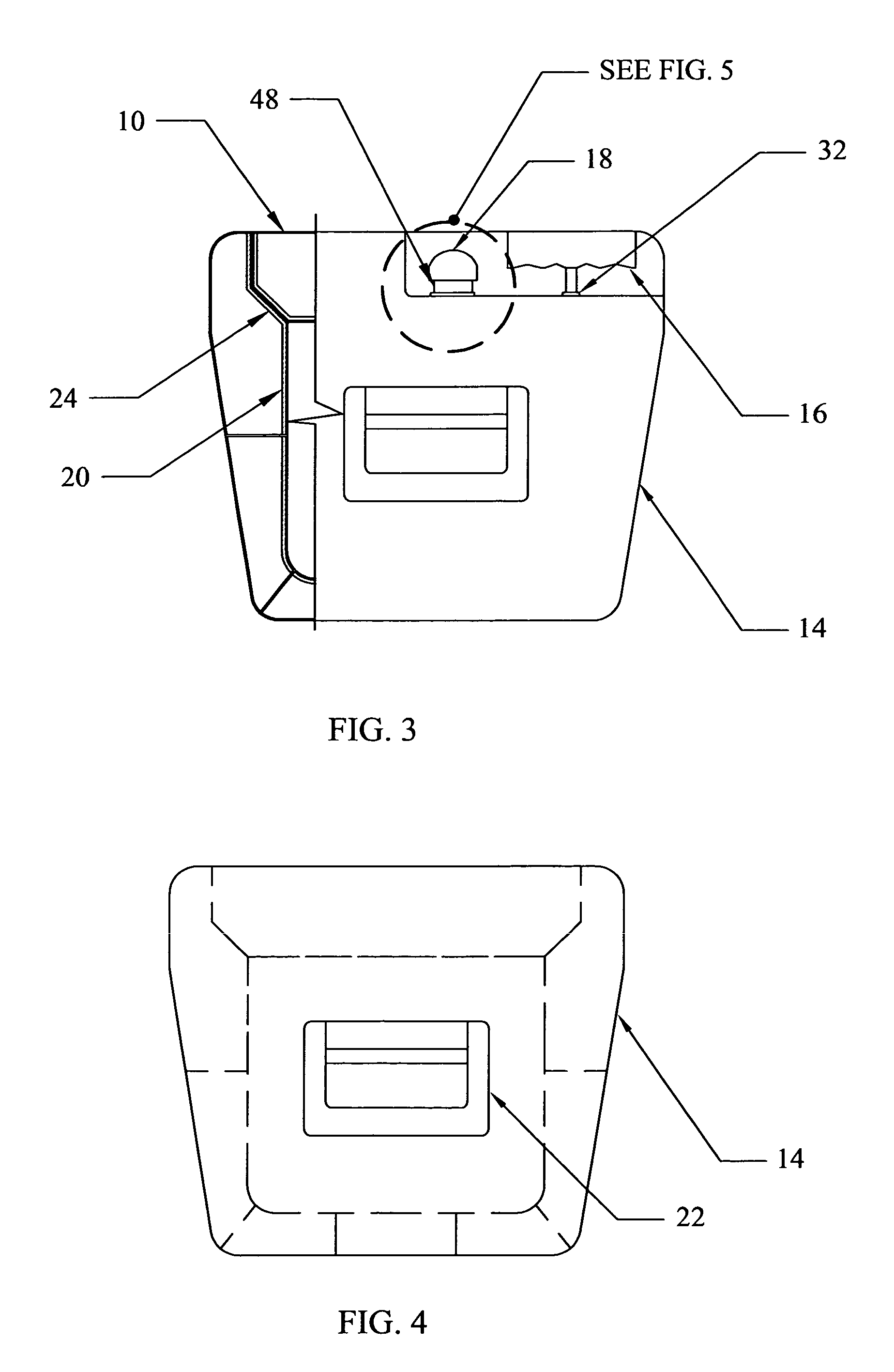

Vacuum cooler

ActiveUS9296543B2Domestic cooling apparatusLighting and heating apparatusSystems designDecomposition

A portable, durable, lightweight cooler system designed to maintain beverages, food, medical supplies, drugs, and other heat sensitive products at existing temperatures with substantially reduced heat gain or loss from the surrounding environment for extended periods of time, when no power source is available. This container is designed to greatly reduce radiant heat transfer along with conductive and convective heat transfer while diminishing decomposition effects of stored items and thus maintaining freshness. This system includes a cooler housing, a reinforced lid, a radiation reflective material application, and a system to remove air from the containment area, thus creating a vacuum within the cooler itself and sealing the lid to the cooler housing. Upon actuation of a vacuum release device, air is reintroduced into the containment area thus allowing the lid to be removed and the stored products be accessed.

Owner:H E B LP

Method for preparing electronic grade non-selenium manganomanganic oxide from dialogite

InactiveCN101348280AReduce power consumptionLess investmentManganese oxides/hydroxidesLower gradeLow graded

Owner:花垣县科信新材料有限责任公司

Continuous edible fungus sterilizing equipment

The invention belongs to the technical field of edible fungus and particularly relates to continuous edible fungus sterilizing equipment. The continuous edible fungus sterilizing equipment comprises a spiral feeding machine, an edible fungus sterilizing, cooling and inoculating all-in-one machine, a storage warehouse and a bagging machine, wherein the edible fungus sterilizing, cooling and inoculating all-in-one machine comprises a transversely-arranged cylindrical shell; a stirring device is arranged in the cylindrical shell; a jacket is arranged on the cylindrical shell; a steam inlet, a cooling water outlet, a condensed water outlet and a cooling water inlet are formed in the jacket; a steam inlet and a fungus adding opening are formed in the cylindrical shell; the cylindrical shell is communicated with a vacuum cooling system; a discharging opening of the cylindrical shell is communicated with a feeding opening of the storage warehouse; a discharging opening of the storage warehouse is communicated with a feeding opening of the bagging machine. According to the continuous edible fungus sterilizing equipment provided by the invention, only one equipment space is needed in the edible fungus sterilizing, cooling and inoculating processes, so that the space is saved, the continuous production is realized, the labor efficiency is greatly improved, the labor strength is reduced, the energy consumption is reduced, and the ambient air pollution is eliminated.

Owner:ZHUCHENG XINZHENGDA MACHINERY CO LTD

Vacuum freezing dried extraction method of natural plant dye

InactiveCN101037543ADoes not destroy biochemical propertiesSolve the problem of poor staining reproducibilityNatural dyesFreeze-dryingLiquid extract

The invention provides a method of extracting natural plant dye, which uses dye-containing plant as raw material to obtain pulverulent natural plant dye by water extraction, vacuum cooling and drying. The method includes steps: (1) abstraction: weight ratio of water and plant of 1:5-15, extraction temperature of 40-90 DEG C, extraction time of 20-60 min, extraction frequency of 1-3, combining extraction liquid; (2) precooling: temperature of minus 20 - minus 50 DEG C, time of 1-5 h; (3) vacuum freeze drying: temperature of minus 45 - minus 55DEG C, vacuum degree of 10-20Pa, time of 15-20 h. Outstanding character of the invention is: 1. preparing pulverulent product and not destructing original biochemical property of natural plant dye; 2. solving problem of bad staining reproducibility of natural plant dye liquid extracted by existent technique and increasing staining reproducibility of the natural plant dye liquid; 3. solving problem of conservation of the natural plant dye liquid and capable of storing the natural plant dye liquid for a long time.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Production process of refined potassium chloride

InactiveCN101962198AIncrease the precipitation rateEasy to processAlkali metal halide purificationRoom temperatureChloride potassium

The invention discloses a production process of refined potassium chloride, in particular to a process for refining 90% potassium chloride into more than 97% food grade potassium chloride. The process comprises the following steps of: adding 90% potassium chloride into a potassium chloride saturated solution (circulating solution) at room temperature to obtain a supersaturated solution; filtering the supersaturated solution by using a coarse filter, heating to 100-105 DEG C, and fully dissolving potassium chloride; filtering the high temperature saturated solution by using a heat insulating filter to obtain a refined saturated solution; cooling and crystallizing the refined saturated solution by a vacuum cooling crystallizer, dewatering by a centrifugal machine, and drying by a drying bed to obtain refined food grade potassium chloride, and returning the mother solution separated from the centrifugal machine back to the system to be used as a circulating solution. The method can be used for effectively removing soluble impurities and insoluble substances in the 90% potassium chloride product, and the content of the product achieves more than 97% and reaches the standard of food grade potassium chloride. The invention has the advantages of simple equipment, short process flow, no environment pollution and easy realization of industrialization.

Owner:天津长芦汉沽盐场有限责任公司

Processing method of freshwater crayfish pre-prepared products

The invention discloses a processing method of freshwater crayfish pre-prepared products. The method includes the steps of firstly, selecting and grading; secondly, cleaning; thirdly, frying; fourthly, vacuum cooling; fifthly, soaking with seasoning liquids; sixthly, nitrogen-filled packing; seventhly, quick-freezing; eighthly, performing cold storage. The method has the advantages that the crayfish is soaked with special cleaning fluids to allow the crayfish to spit out dirt in the intestine line, and complex manual intestine line removing is avoided; high-temperature fast frying and special soaking with special seasoning liquids are used, and the difficulties that crayfish meat protein deteriorates easily, flavor substances lose easily and flavor cannot enter the crayfish in subsequent processing are solved; the vacuumizing and nitrogen filling freshness keeping technology is used, and the crayfish is prevented from being oxidized by oil acid during storage.

Owner:洪湖市万农水产食品有限公司

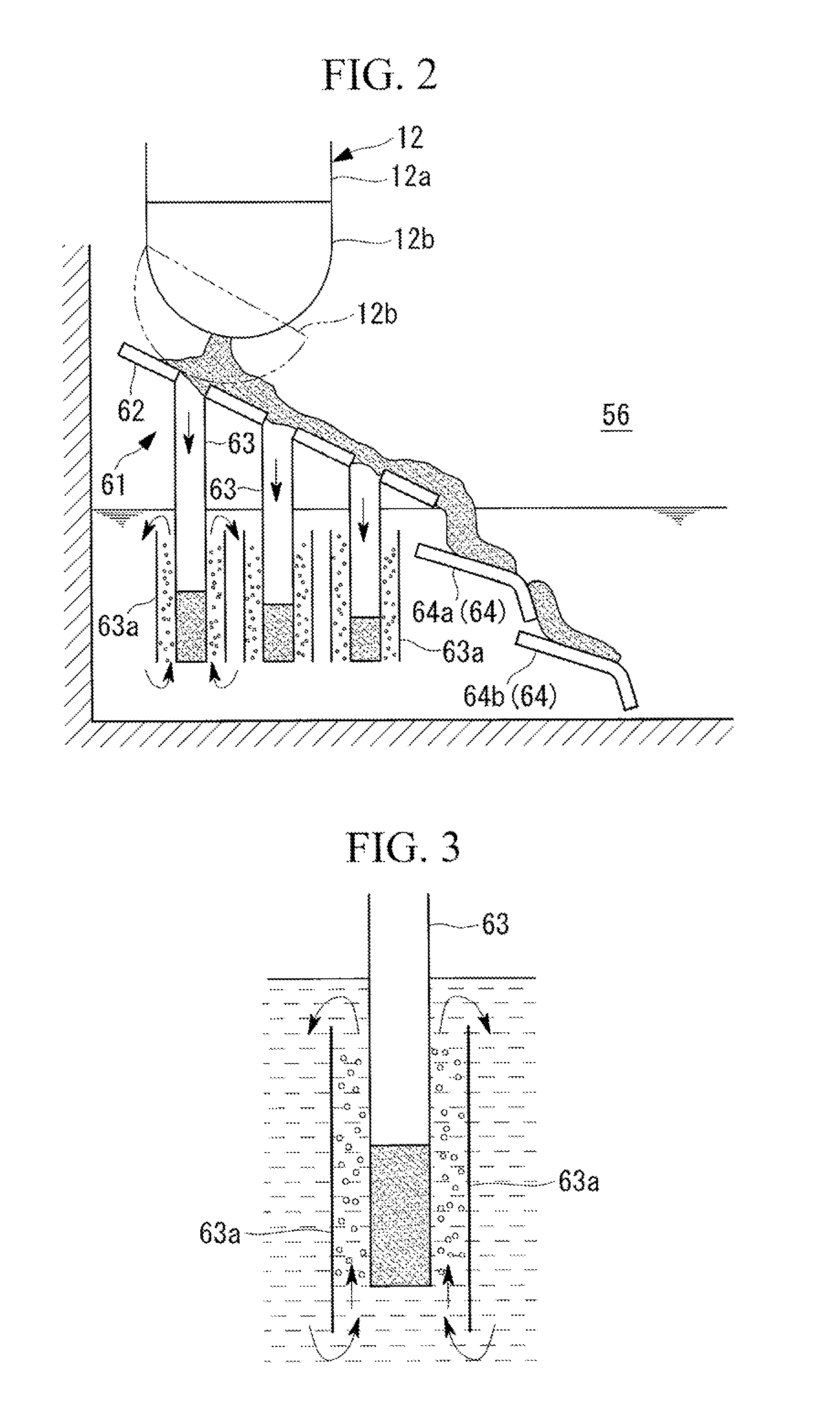

Corium cooling structure, reactor containment vessel provided with the same, and nuclear power plant provided with the same

InactiveUS20120269312A1Avoid accumulationImprove cooling efficiencyNuclear energy generationEmergency protection arrangementsNuclear plantNuclear power

An object is to provide a corium cooling structure that is capable of accumulating corium and debris that have flowed out from a reactor in small divided portions and of sufficiently cooling the high-temperature corium and debris, a reactor containment vessel provided with the same, and a nuclear power plant provided with the same. A capture portion that captures the corium that has flowed out from a reactor and a plurality of pipe portions that are provided in a coolant storing portion and into which the corium flows via the capture portion are provided.

Owner:MITSUBISHI HEAVY IND LTD

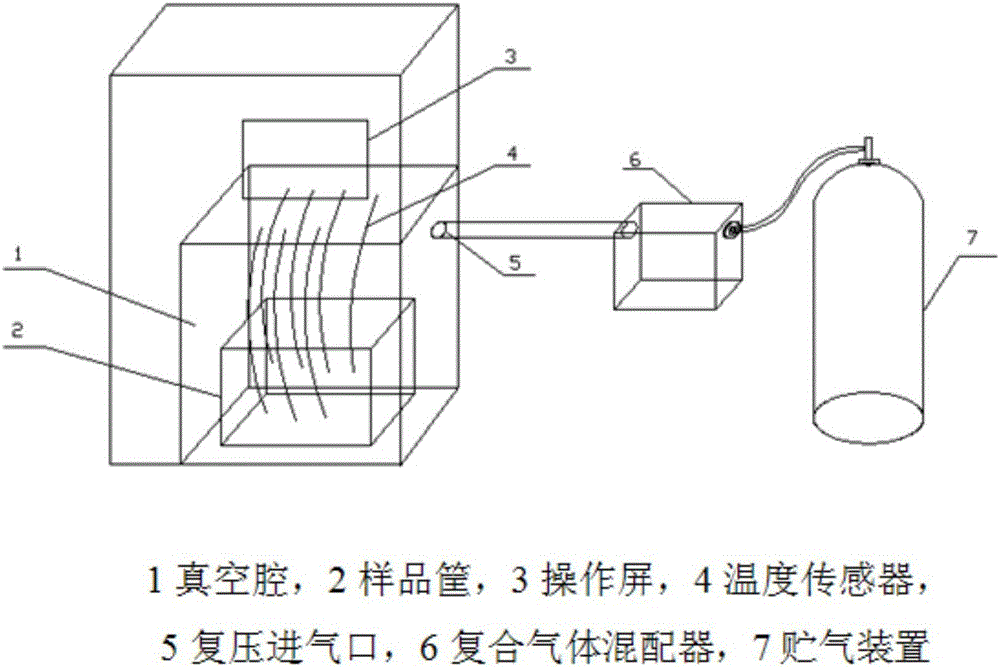

Edible fungus antistaling method and apparatus

InactiveCN1810131ANo pollutionDoes not damage appearanceFruits/vegetable preservation by freezing/coolingBiotechnologyContamination

Edible fungus antistaling method and apparatus are disclosed. The method includes dehumidifying fresh edible fungus with circulating wind inside a sealed vacuum processing chamber to reach set temperature and water content, and fast vacuum freezing to further eliminate water of edible fungus. The said method can maintain the metabolism of edible fungus and reach required temperature and water content of edible fungus without contamination and damage to look of edible fungus. The method and apparatus has low power consumption, results in homogeneous temperature and water content inside and outside the edible fungus, controls water content in edible fungus in 70-88 % and makes edible fungus capable of being preserved and transported at low temperature for long period.

Owner:上海大生泰保鲜设备有限公司

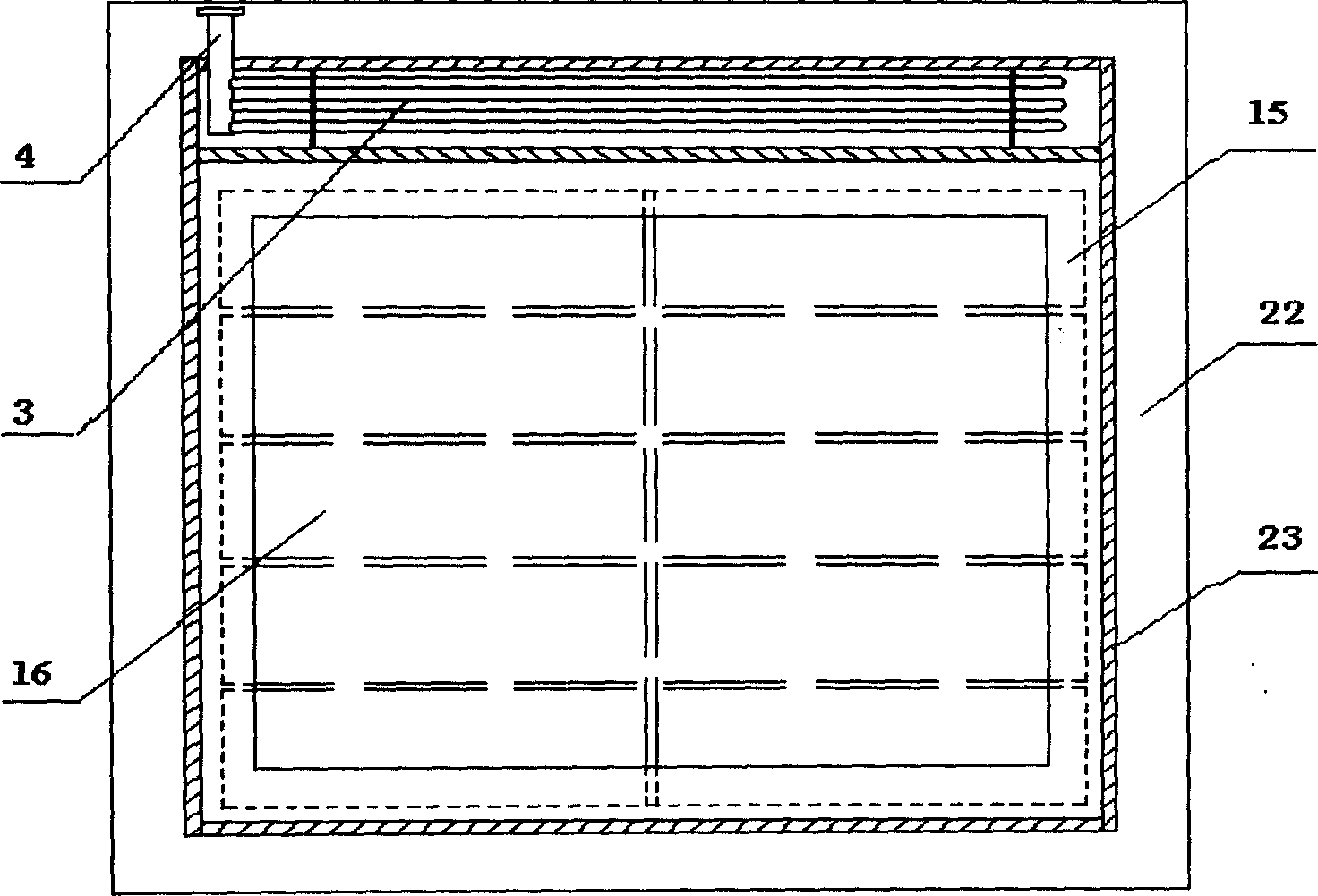

Drum-type vacuum freeze-drying machine

InactiveCN101498544AFast dryingDry evenlyDrying using combination processesDrying solid materials with heatInsulation layerDrive shaft

The invention relates to a drum-type vacuum cooling dryer which comprises a circular drying drum, a heat insulation layer, an electric heater, a refrigerating unit, a cold trap and a vacuum pump. One end of the drum is provided with a drying-drum transmission shaft while the other end is provided with a sealing door; the end of the drying drum with the sealing door supports against a rotatable roller of the drying drum; a vacuumizing port communicating with the inside of the drying drum is arranged inside the drying-drum transmission shaft, and the tail end of the drying-drum transmission shaft is provided with a movable vacuum sealing assembly communicating with the vacuumizing port; a movable vacuum sealing element is arranged in the movable vacuum sealing assembly; the heat insulation layer wraps around the drying drum and is not in contact with the drying drum; the electric heater is arranged between the heat insulation layer and the drying drum; and the refrigerating unit, the cold trap and the vacuum pump are mutually connected by vacuum pipes. The drum-type vacuum cooling dryer has high drying speed, uniform drying and low drying cost.

Owner:GUANGDONG YONGLI MACHINERY EQUIP CO LTD

Method for preserving fresh plants by synchronously combining vacuum precooling with gas conditioning technique

InactiveCN105746685ADecrease breathing rateRelieve pressureGaseous food ingredientsFood ingredient for microbe protectionRespiratory metabolismRefrigerated temperature

Owner:SOUTH CHINA UNIV OF TECH

Diffusion welding process for heat exchanger core

ActiveCN106825894AQuality improvementReduce brittle phaseNon-electric welding apparatusRoom temperatureEngineering

The invention discloses a diffusion welding process for a heat exchanger core. The diffusion welding process comprises the following steps: (1) pre-welding pre-treatment: feeding the well assembled heat exchanger core into a diffusion welding furnace, and vacuumizing the interior of the furnace to be below 0.01 Pa; (2) diffusion welding: raising the temperature to 800-850 DEG C at the speed of 15-20 DEG C / min, keeping the temperature for 30 min, after that, raising the temperature to 1,100-1,150 DEG C at the speed of 10-15 DEG C / min, keeping the temperature for 3 h, and performing vacuum cooling to the room temperature, wherein the pressure (8-9.5 MPa) exerted before is kept in the first 2 h and reduced to 4-6 MPa in the last 1 h; and (3) postweld heat treatment: raising the temperature of the heat exchanger core to 1,150-2,000 DEG C, keeping the temperature for at least 20 h, and after that, reducing the temperature in a water quenching manner. According to the diffusion welding process, such parameters as welding temperature, diffusion time and pressure are controlled, the step of heat treatment after diffusion welding is added, so that brittle phases easily generated during diffusion welding are reduced, and the quality of a welded joint of the heat exchanger core is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Industrial process of pot-stewed meat food

InactiveCN101019615AAvoid pollutionShorten the timeFood preservationFood preparationEngineeringAir conditioning

The industrial process of producing pot-stewed meat food includes the following steps: pre-treatment of material, scalding, pot-stewing in soy sauce, vacuum cooling in a constant temperature cleaning shop to below 10 deg.c, cutting with a high speed slicing machine in a constant temperature cleaning shop, weighing and packing in box, and final packing in an air conditioning and preserving package machine. The present invention has high production efficiency, and the pot-stewed meat food has stable quality, long preservation period and other advantages.

Owner:徐少东

Method of manufacturing gradual-change bore diameter stainless steel antipriming pipe

ActiveCN101428346AImprove breathabilityGuaranteed filtration accuracyFiltration separationPolyvinyl alcoholSS - Stainless steel

The invention provides a preparation method for a stainless steel perforated pipe with gradually-varied aperture, the invention adopts the preparation process that stainless steel powder is mixed with a certain polyvinyl alcohol solution to prepare stainless steel powder suspension, and getter is added into the suspension and poured into a two-piece-type opening and closing rigid pipe die made of stainless steel after even stirring, which centrifugally takes shape on a centrifuge, thereby preparing a green body of the stainless steel perforated pipe with gradually-varied aperture grads; the green body is dried in a blast-type baking oven, and then the demoulding is performed; the green body of the stainless steel perforated pipe after drying is sintered in a vacuum stove, the sintering atmosphere adopts vacuum, and the stainless steel perforated pipe with gradually-varied aperture grads is prepared after cooling. The invention has the advantages that the demoulding attainment rate of the green body of the stainless steel perforated pipe with gradually-varied aperture is greatly enhanced, and the filtering precision of the perforated pipe is ensured; meanwhile, the air transmission coefficient of the stainless steel perforated pipe with gradually-varied aperture is enhanced, and the preparation method solves the phenomenon of the reciprocal relationship between the filtering precision of the stainless steel perforated pipe and the transmission performance in the filtration, separation and application process.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Production technique of EPS (expandable polystyrene) foam articles

The invention discloses a production technique of EPS (expandable polystyrene) foam articles. The production technique is characterized by comprising the following steps: pre-foaming, curing, feeding, preparing mould, heating and forming, water cooling, vacuum cooling, demoulding, trimming, drying, trimming, packaging and storing in warehouse, and the production technique improves the compressed air, water circular cooling and drying process. The technique disclosed by the invention has simple and reasonable technique procedures and utilizes two paths of compressed air supply systems, so that the pipeline pressure is very stable, an electromagnetic valve acts flexibly, a cylinder switching valve quickly and reliably acts, and a cooling water circulating system can quickly cool to improve the cooling efficiency, save the electric energy and vapor and reasonably utilize the energy sources; besides, a mixed mode of high and low temperature air is used, so that the articles are not deformed or expanded irrespective to the foaming density, the drying time is shortened and the resources are reasonably utilized.

Owner:安徽艾柯泡塑股份有限公司

Processing method for prolonging shelf life of instant box convenience rice at normal temperature

A processing method for prolonging shelf life of instant box convenience rice at normal temperature belongs to the technical field of deeply processing agricultural products. By adopting staging vacuum fast cooling technology and high-power electron beam cold sterilization technology, the processing method mainly comprises the steps of: selecting rice with proper amylose as raw materials, conducting cleaning and soaking, stewing, staging vacuum cooling and packaging sealing, and then carrying out high-power electron beam sterilization, thus obtaining instant box convenience rice capable of being stored for nine months at normal temperature. The processing method has the advantages that: the stewed rice is fast cooled by adopting a vacuumizing method, thus being capable of not only reducing aging of instant convenience rice, but also removing moisture on the surface of the product, and reducing secondary pollution probability of microorganism; cold sterilization to the instant convenience rice by adopting high-power electro beam processing can leads the product to be sterile, thus not only improving the shelf life of the product, but also leading the product to have no high-temperature treated can taste or stewing taste compared with the existing high-temperature sterilization technology, and further being capable of better showing the characteristics of original color, fragrance and flavor of the fresh rice.

Owner:上海束能辐照技术有限公司

Making method for soft magnetic alloy compound material with high magnetic conductivity

InactiveCN101236818AHigh resistivityImprove permeabilityInorganic material magnetismIntermediate frequencyQuenching

The invention discloses a preparation method for high magnetic conductivity soft magnetic alloy composite materials, comprising the followings steps: firstly, ferrum, aluminum, silicon and titanium with a purity more than 99.9 weight percent are taken as raw materials and laid into a medium frequency vacuum induction furnace for smelting, and a master alloy is obtained; secondly, the master alloy after smelting is laid into a quick quenching device; an alloy ingot casting is quickly poured on a water-cooling roll wheel which rotates at high speed after arc remelting under the protection of high purity inert gases, and a quickly condensed sheet band or a quickly condensed sheet is obtained; thirdly, flat processing is performed by adoption of the ball milling technology, and flat powder is obtained; fourthly, the flat powder is laid into a stainless steel tube which is then vacuumized and filled with inert protective gases, and then the stainless steel tube is laid into a tube furnace for heating and cooling along with the furnace; fifthly, the flat powder and binding agents are mixed and milled for processing the flaky high magnetic conductivity soft magnetic materials which are then laid into a heat treatment furnace for heating, heat preservation and vacuum cooling. The preparation method for the high magnetic conductivity soft magnetic alloy composite materials is simple in technology and suitable for large-scale mass production; a magnet has high magnetic conductivity; the magnetic shielding effect is greatly improved.

Owner:ZHEJIANG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com