Microwave vacuum continuous drier with two drying chambers and method using the same

A microwave vacuum drying and microwave vacuum technology is applied in drying solid materials, heating to dry solid materials, drying and other directions, which can solve the problems of not being able to meet the needs of the production of traditional Chinese medicine factories, the temperature gradient cannot reach the water content, and the process is discontinuous. , to achieve the effect of easy and timely control, shortened drying cycle and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

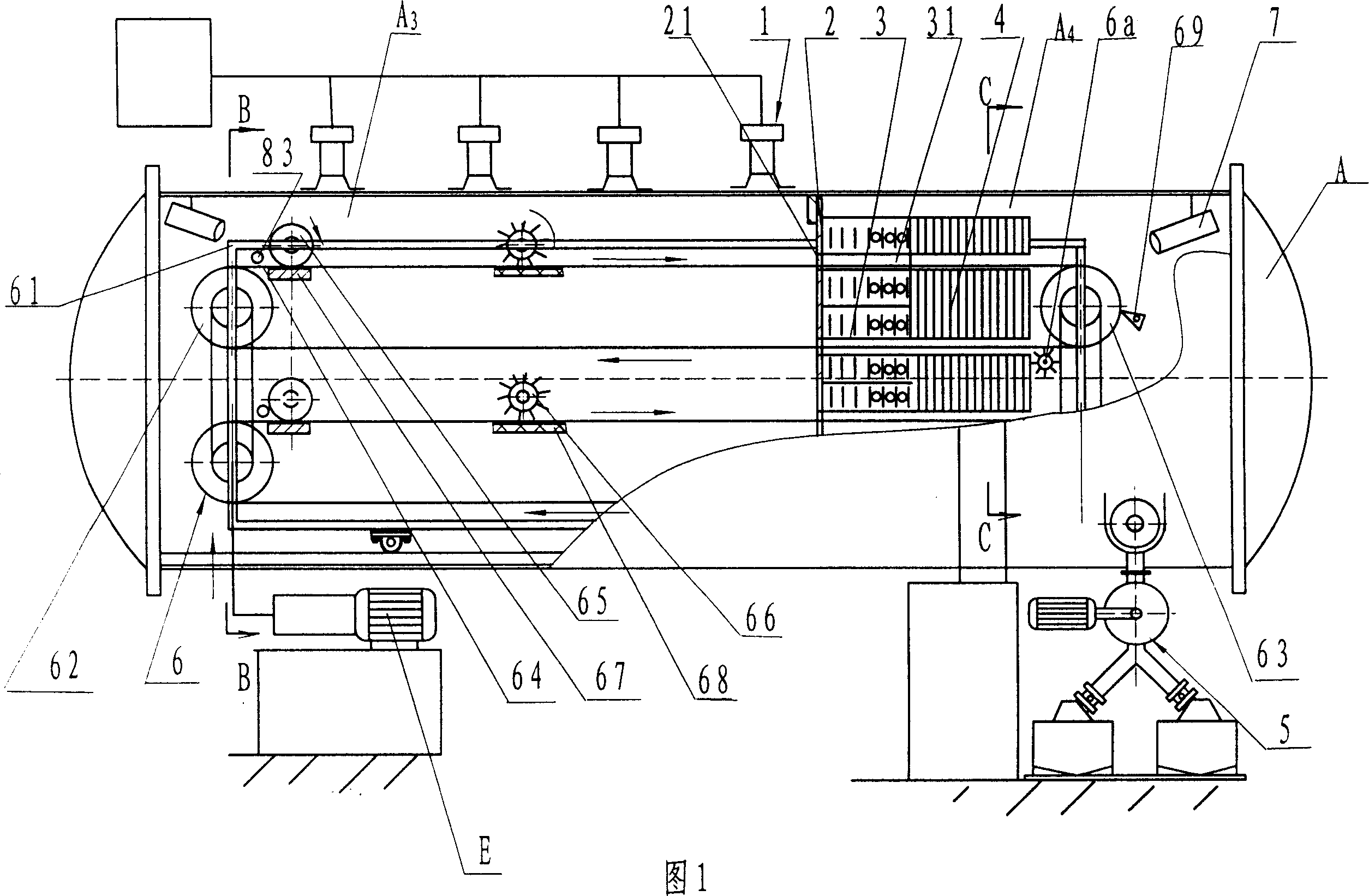

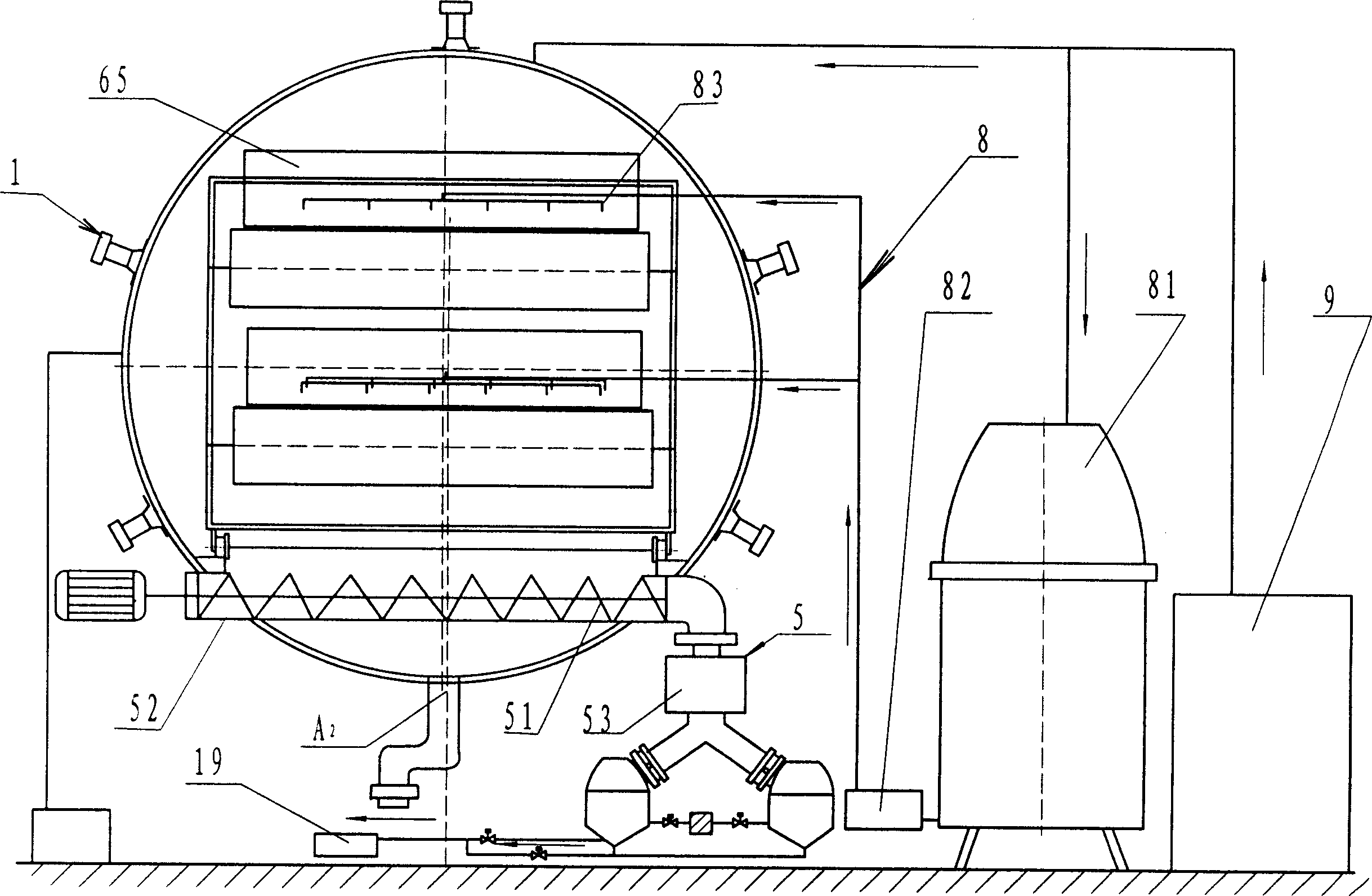

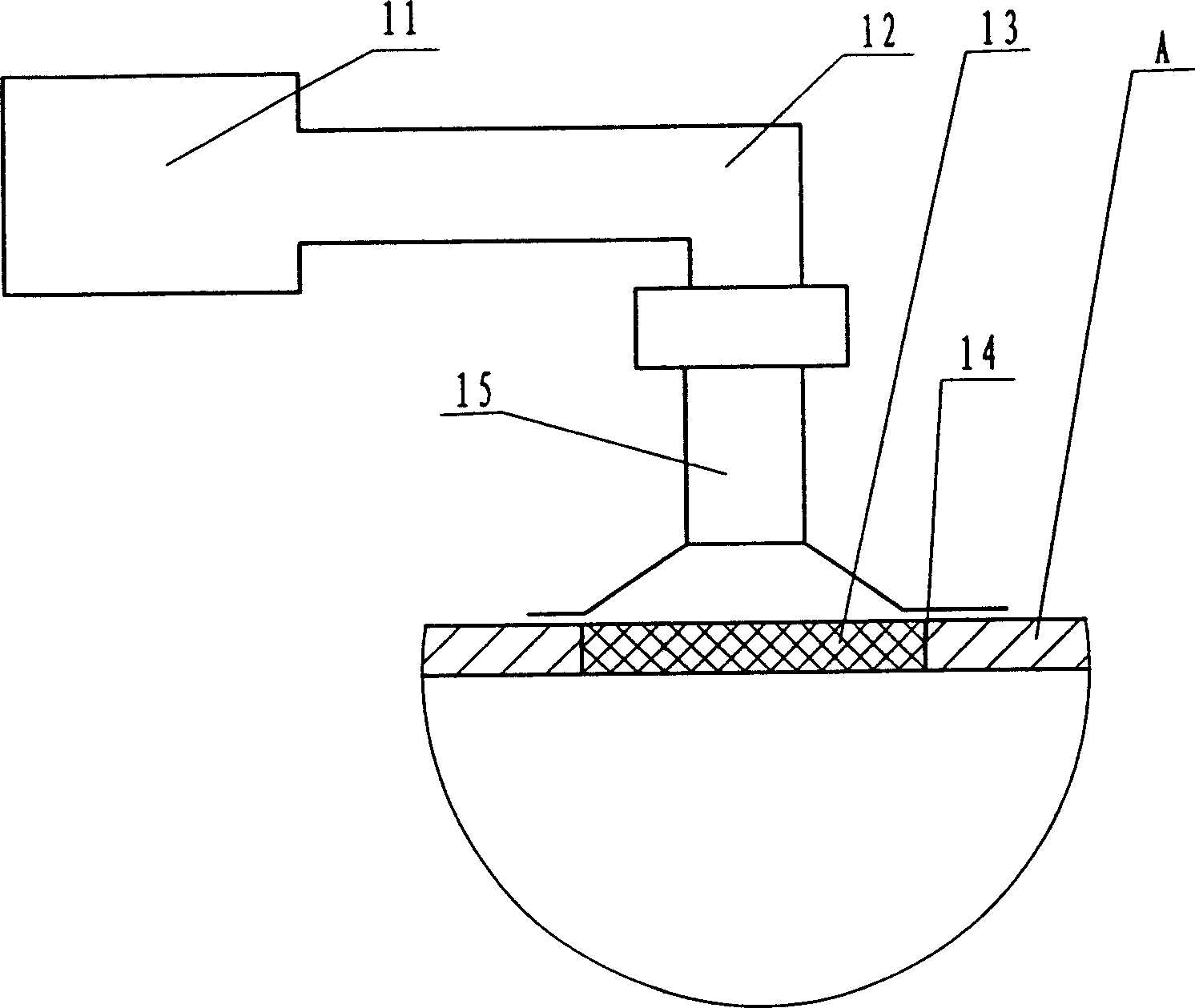

[0036] Embodiment: see Fig. 1, figure 2 , image 3 , Figure 4 . A microwave vacuum continuous dryer with double drying chambers, including a tank body A, a feeding system 8, a vacuum system 9, a conveying device 6 is provided in the tank body A, and a discharge device 5 is provided below the conveying device 6, There is a microwave vacuum drying chamber A in the tank A 3 , in a microwave vacuum drying chamber A 3 The wall of the tank body A is provided with a microwave heating system 1, and in the microwave vacuum drying chamber A 3 One side is provided with a partition plate 2 to form a vacuum cooling and solidification chamber A 4 ; The transmission belt 64 of the conveying device 6 passes through the window 21 provided on the partition board 2 . At one end of the tank A is a microwave vacuum drying chamber A 3 , the other end is the vacuum cooling solidification chamber A 4 , The partition plate 2 separates the two chambers, so that the temperature has an obvious g...

Embodiment 2

[0042] Embodiment 2: a microwave vacuum continuous dryer with double drying chambers, the cooling device 4 is provided with a condenser 43 below the transmission belt 64 . An anti-drip plate 42 is provided between the cooling device 4 and the transmission belt 64, and a water receiving tank 44 may be provided. 2 , so that the condensed water is discharged out of the tank through the water receiving tank. The anti-drip plate 42 is an inclined plate. The rest of the structure is the same as the previous example.

[0043] cold

[0044] The process flow of the present invention is to firstly vacuum the cavity and preheat the stirring tank, then suck the material to be processed into the stirring tank from the vacuum system, and preheat and stir the material in the stirring tank, and then the material is transported to the On the conveyor belt with a closed non-metallic inner cavity, it is evenly heated by a microwave generator, and the material is evenly rolled into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com