Coal quality improvement apparatus for microwave low temperature dehydration and desulfurization

A low-temperature dehydration and microwave technology, used in solid fuels, lighting and heating equipment, drying and other directions, can solve the problems of slow growth of desulfurization bacteria and long desulfurization time, and achieve high microwave synthesis power, strong operability, and safety performance. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

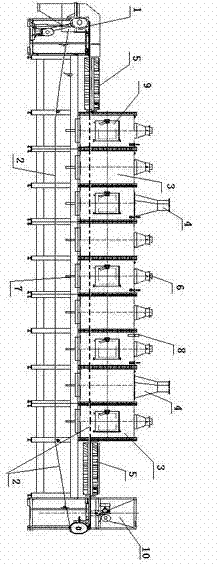

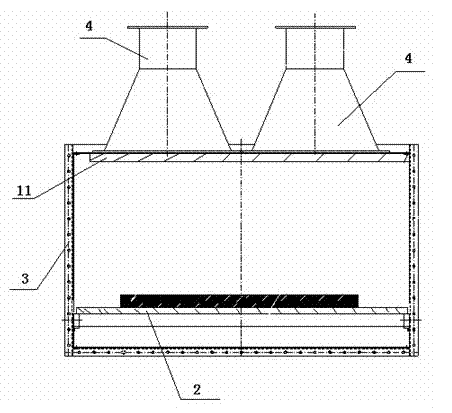

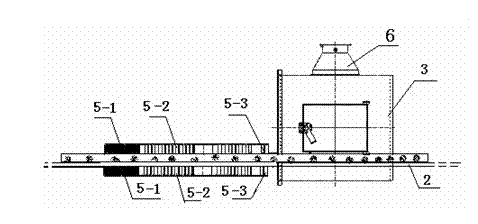

[0028] Such as Figure 1 to Figure 3As shown, the microwave low-temperature dehydration and desulfurization coal upgrading device of the present invention includes a continuous tunnel transmission device (1), a coal transmission belt (2), a microwave cavity (3), and is installed in the microwave cavity (3) The energy feed port (4) at the top, the microwave leakage suppression device (5) installed at the two ends of the microwave cavity (3), the microwave energy of the continuous wave magnetron enters the microwave cavity (3) through the energy feed port (4), and the The upper part of the microwave cavity (3) is provided with a pumping port (6), the bottom of the microwave cavity (3) is connected with an inflator (7) for protective gas, and a plurality of continuous combinations of the microwave cavity (3) Constitute a microwave combination cavity. And the other end of the continuous tunnel transmission device (1) is connected with the coal feeding device (10).

[0029] The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com