Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3690 results about "Microwave irradiation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microwave irradiation can be used for sharps, such as needles, knives and wastes containing pieces of metal, as well as soft materials containing blood and body fluids, such as gauze, bandages, drapes, gowns and beddings.

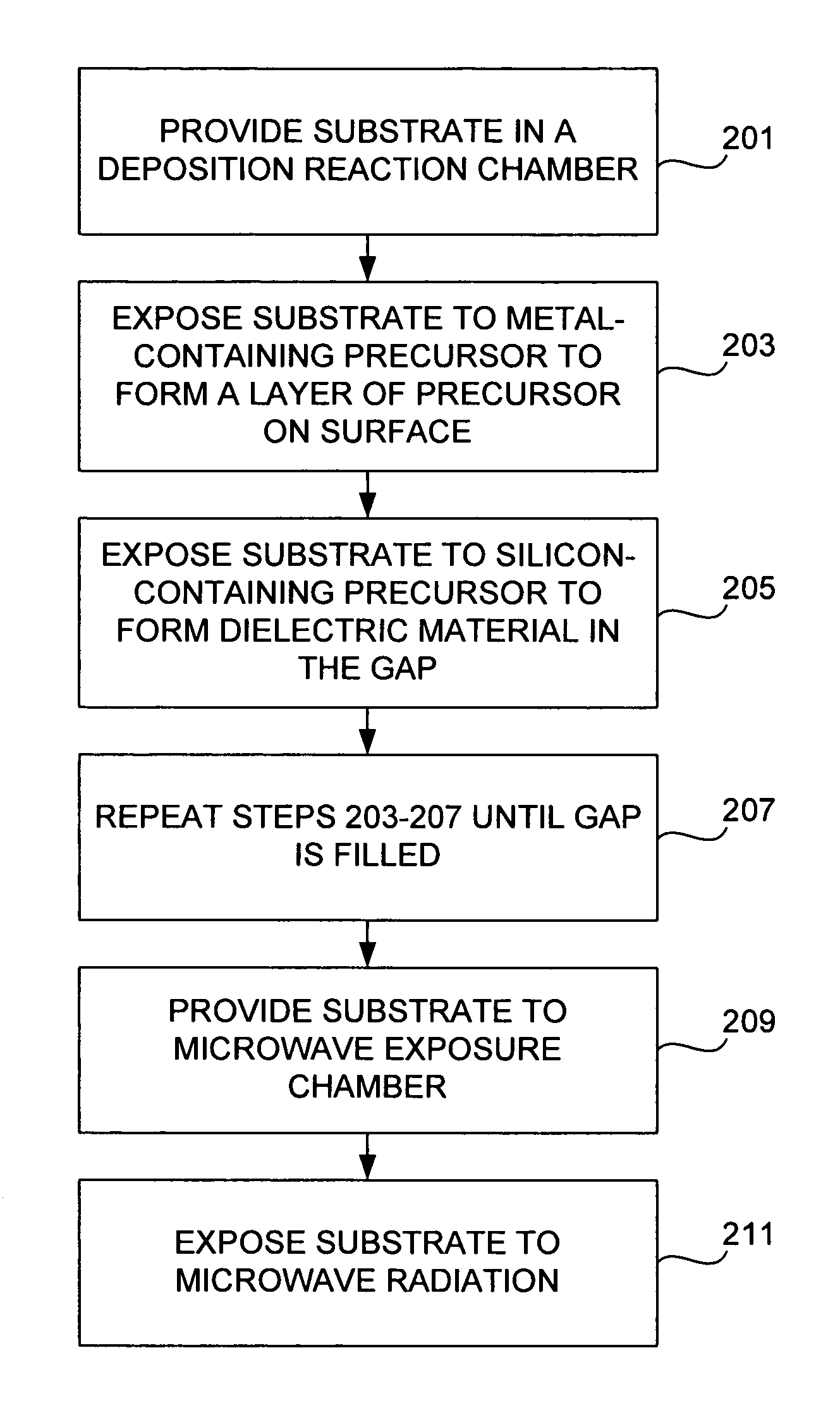

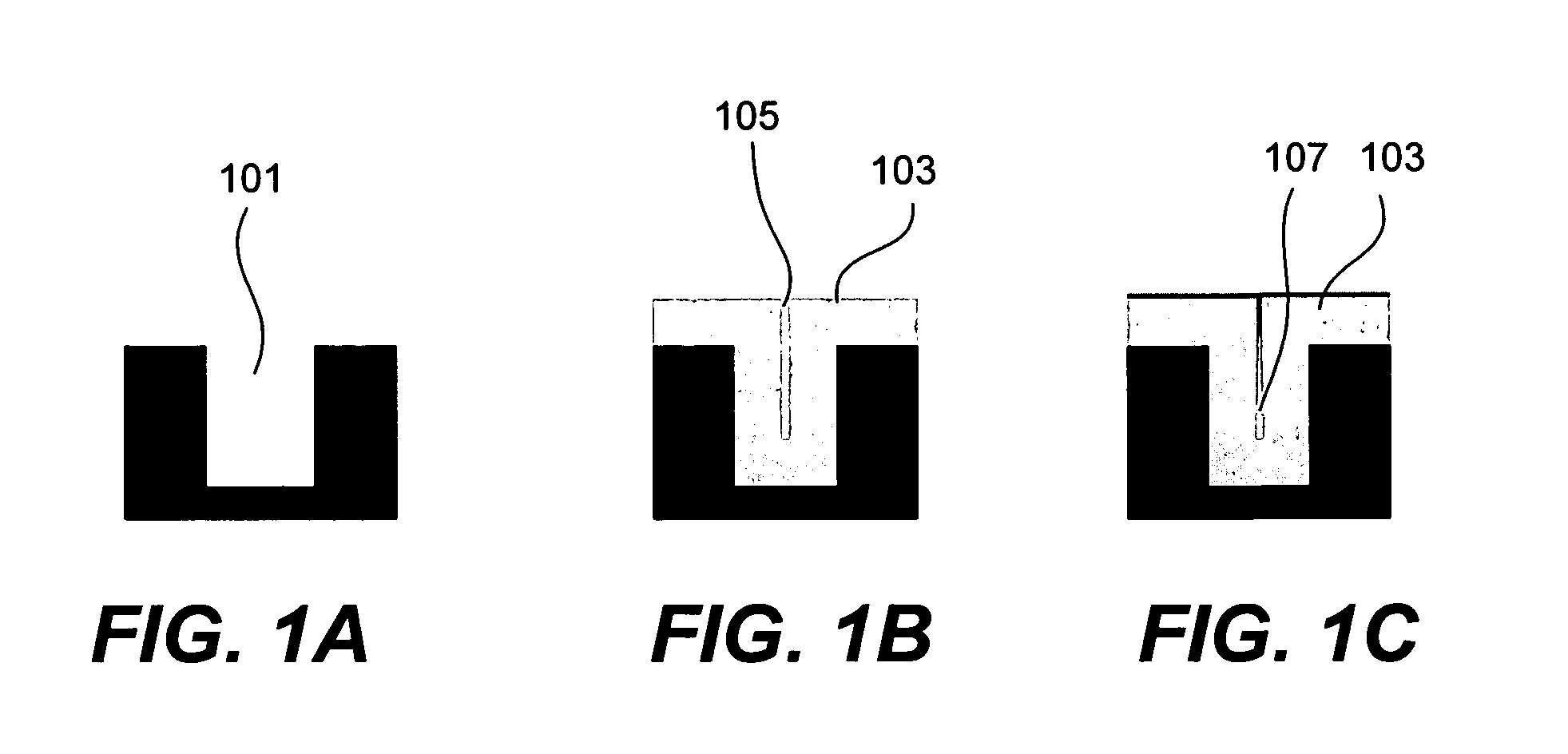

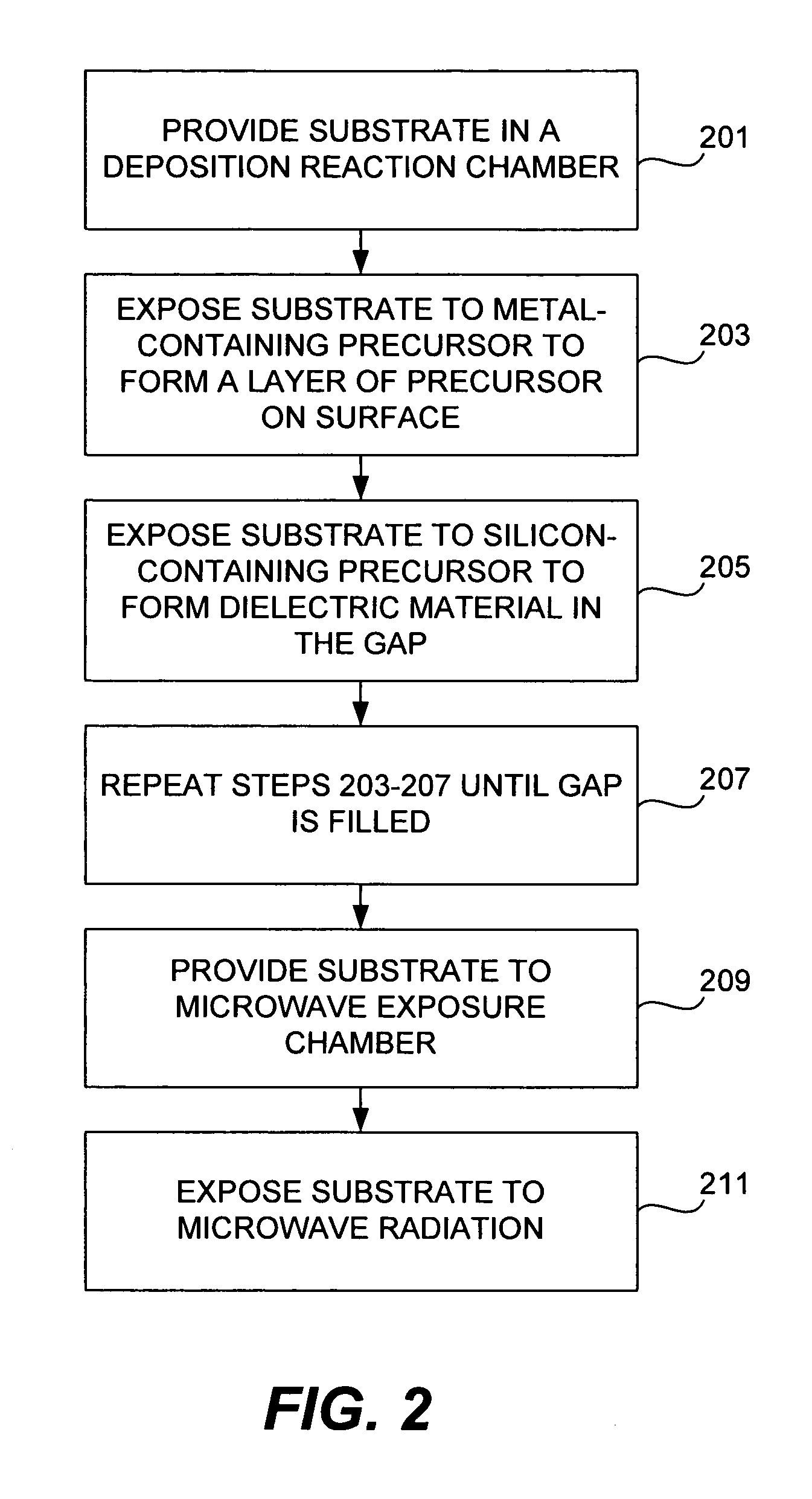

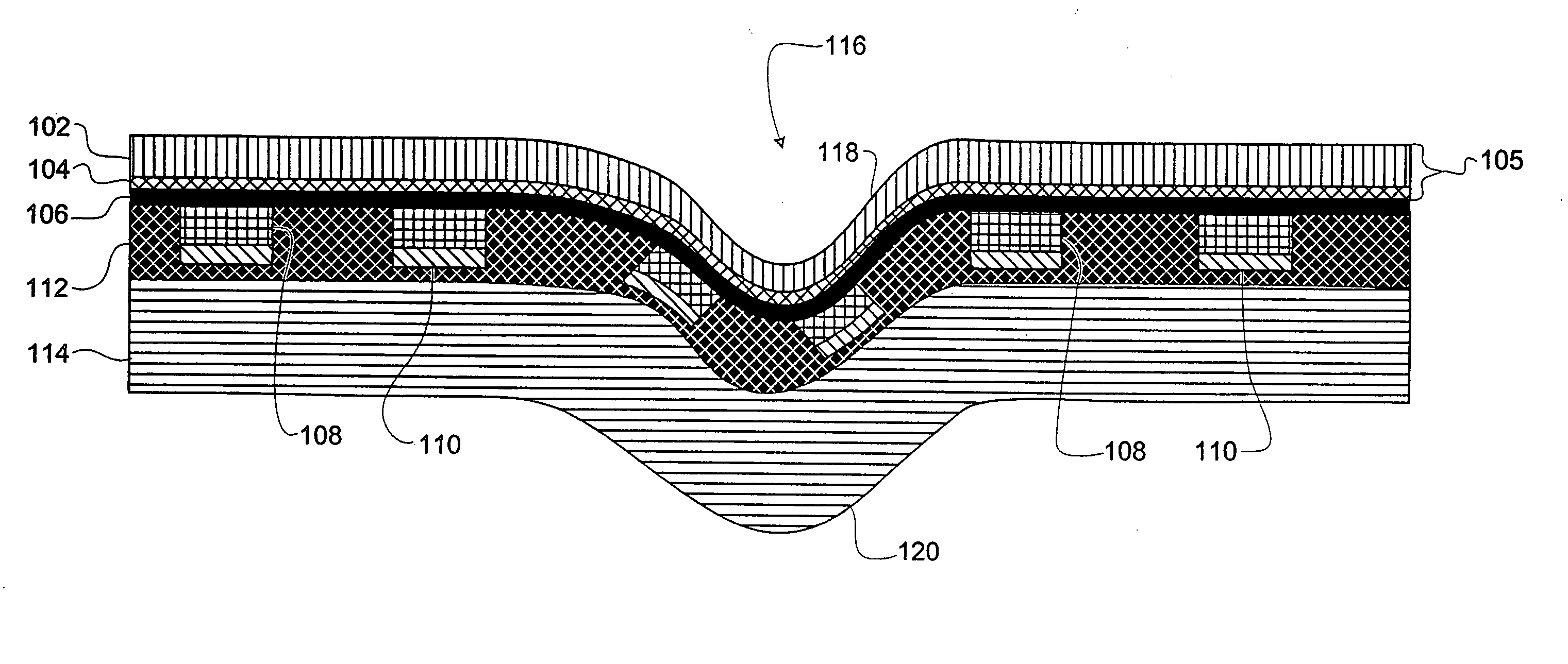

Hydroxyl bond removal and film densification method for oxide films using microwave post treatment

ActiveUS7589028B1High densityImprove film propertiesRadiation applicationsSemiconductor/solid-state device manufacturingDielectricMicrowave

Methods of forming dielectric films with increased density and improved film properties are provided. The methods involve exposing dielectric films to microwave radiation. According to various embodiments, the methods may be used to remove hydroxyl bonds, increase film density, reduce or eliminate seams and voids, and optimize film properties such as dielectric constant, refractive index and stress for particular applications. In certain embodiments, the methods are used to form conformal films deposited by a technique such as PDL. The methods may be used in applications requiring low thermal budgets.

Owner:NOVELLUS SYSTEMS

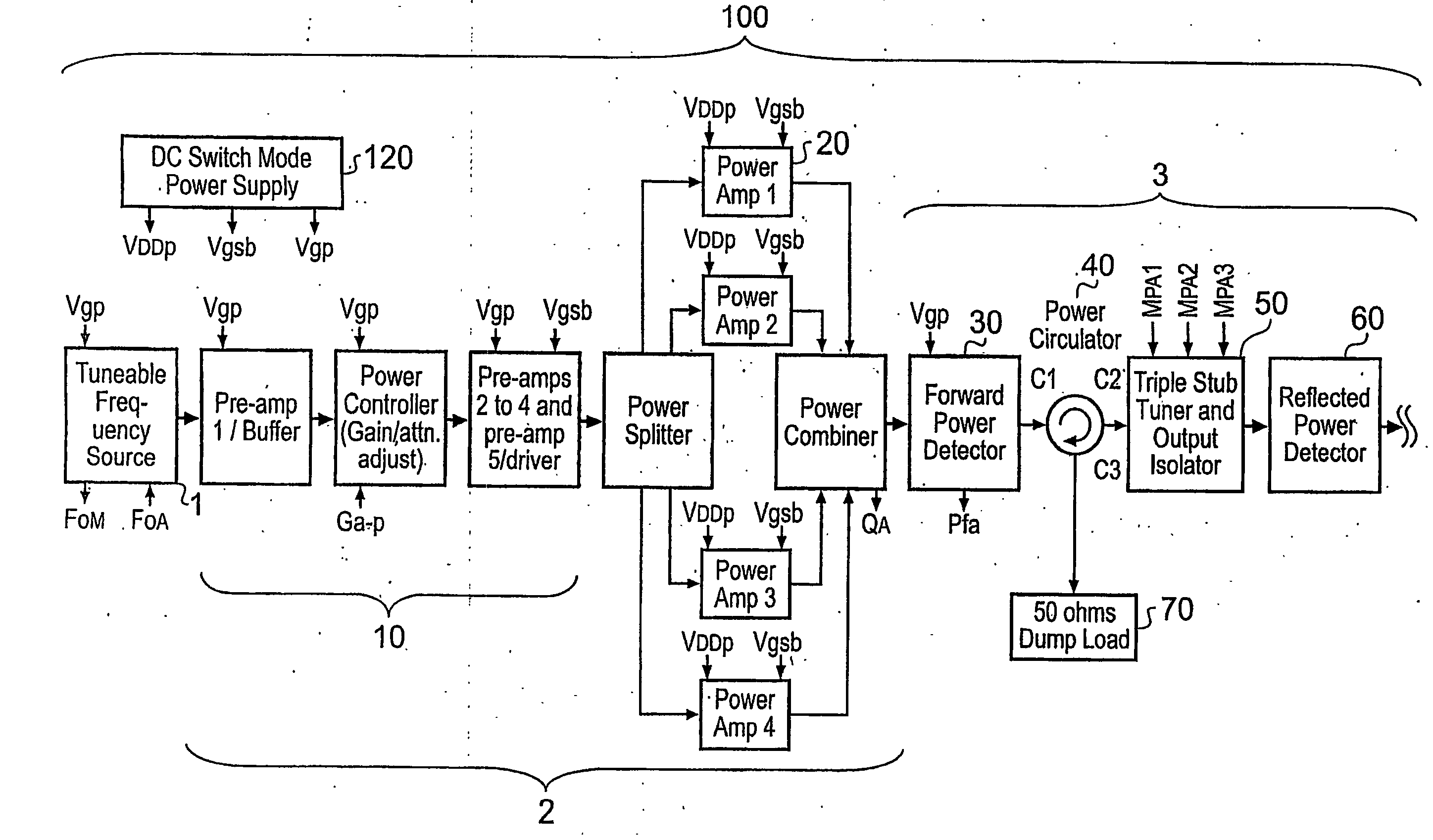

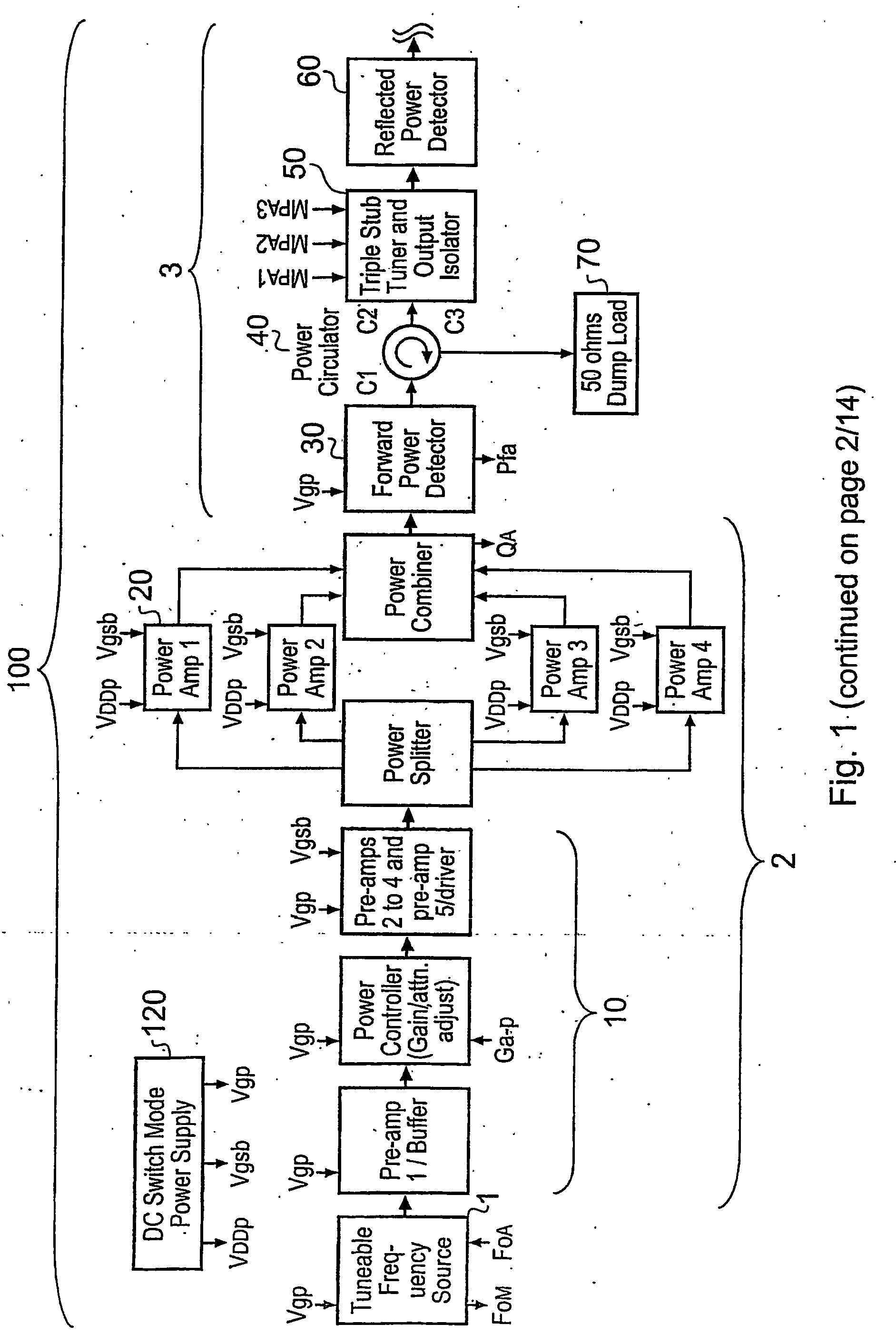

Tissue ablation apparatus and method of ablating tissue

InactiveUS20060155270A1Improve energy efficiencyQuantity minimizationSurgical instruments for heatingSurgical instruments using microwavesLocal oscillatorElectrical impedance

An apparatus and method for ablating tissue is disclosed. The apparatus comprises a source of microwave radiation (1), a probe (5) for directing the microwave radiation into tissue, one or more detectors for detecting the power and phase of the microwave radiation and an impedance adjuster (50) for adjusting impedance so as to minimize the amount of microwave radiation which reflected back through the probe. The detector or detectors use a local oscillator (230) to derive the phase information. A modulator for modulating the microwave radiation to a cutting frequency is also disclosed.

Owner:MEDICAL DEVICE INNOVATIONS

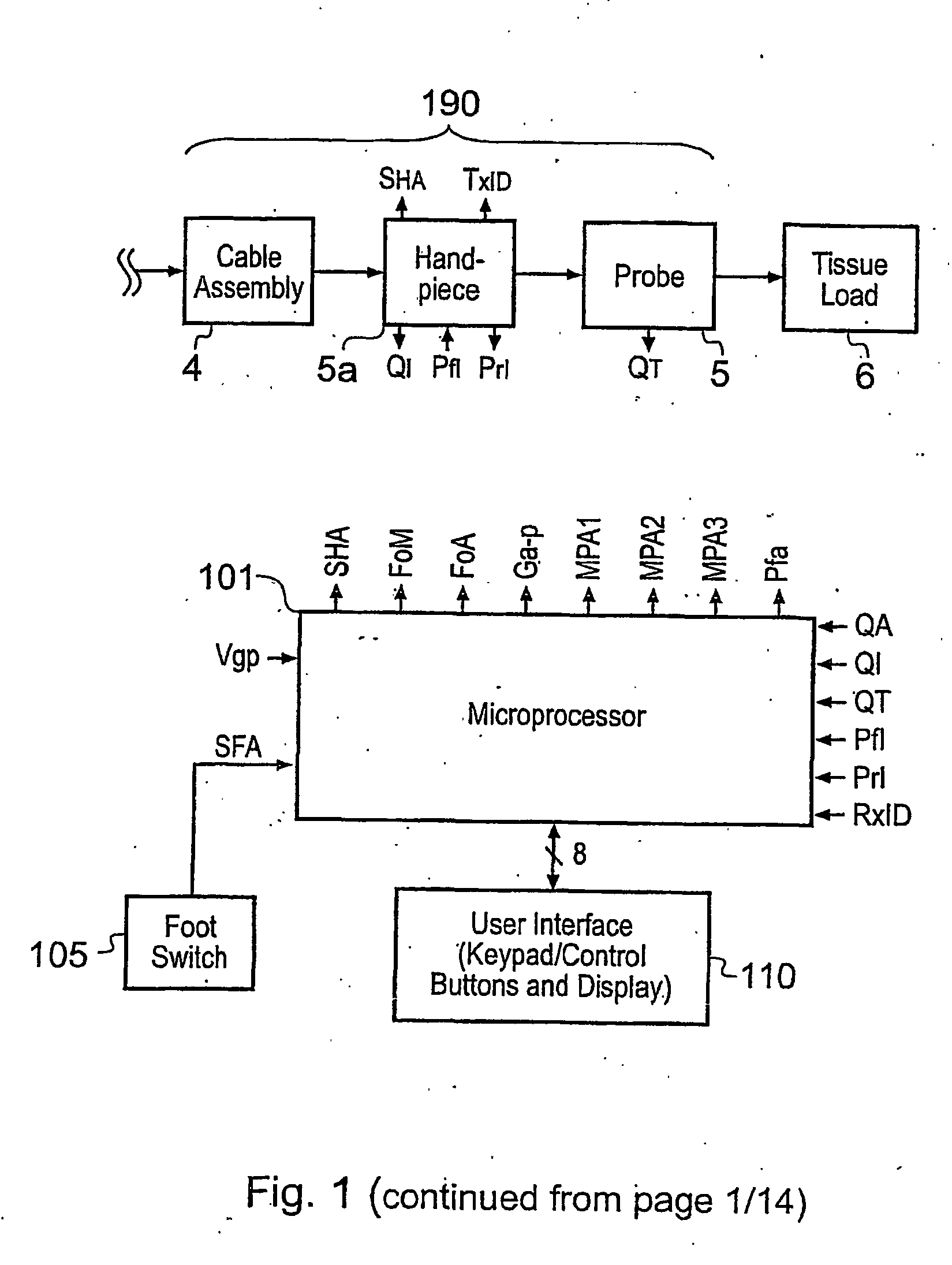

Method of producing electronic device material

InactiveUS20040048452A1High densityLow electron temperatureElectric discharge tubesSemiconductor/solid-state device manufacturingDevice materialEngineering

A process for producing an electronic device material of a high quality MOS-type semiconductor comprising an insulating layer and a semiconductor layer excellent in the electrical characteristic. The process includes: a step of CVD-treating a substrate to be processed comprising single-crystal silicon as a main component, to thereby form an insulating layer; and a step of exposing the substrate to be processed to a plasma which has been generated from a process gas on the basis of microwave irradiation via a plane antenna member having a plurality of slots, to thereby modify the insulating film by using the thus generated plasma.

Owner:TOKYO ELECTRON LTD

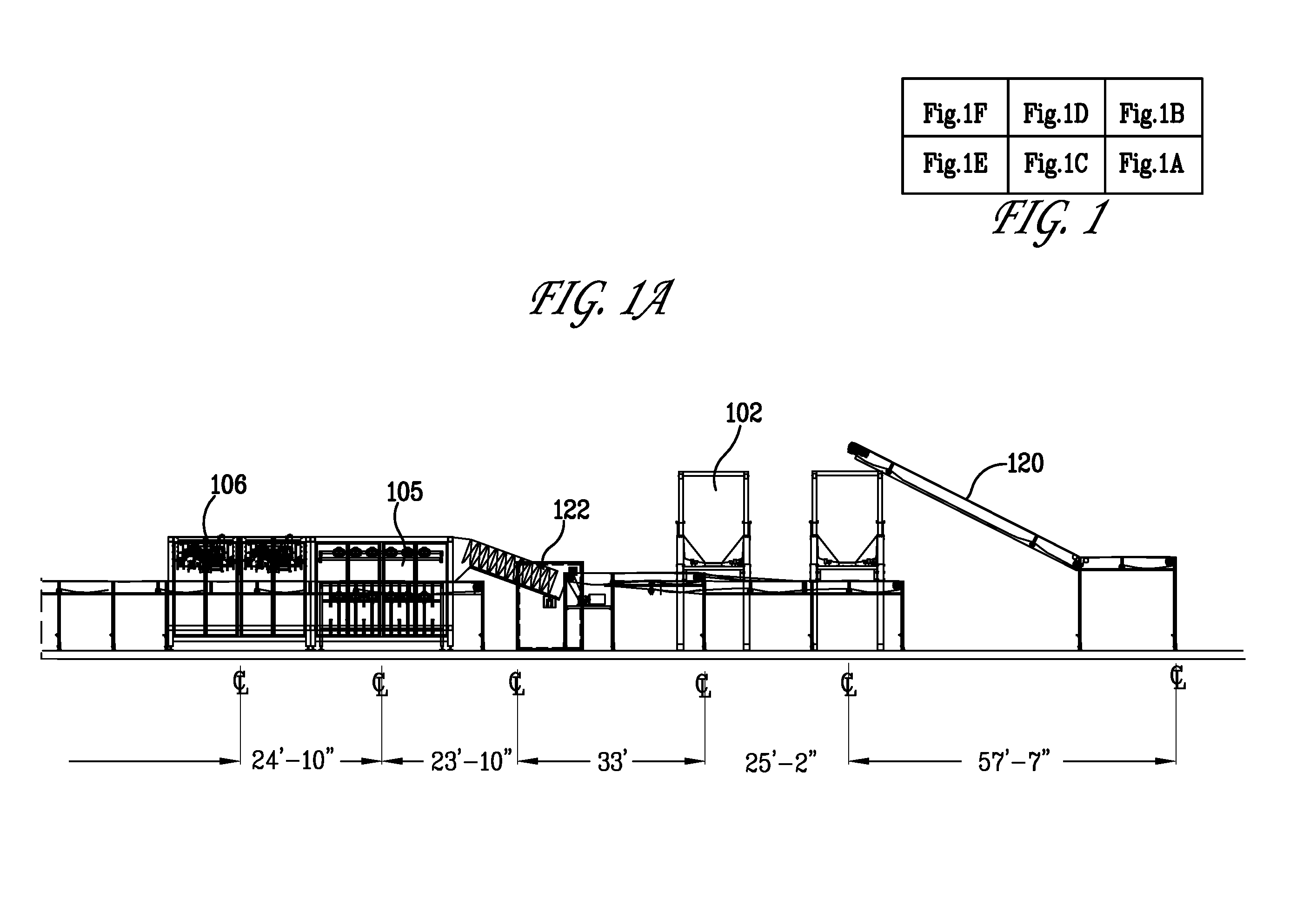

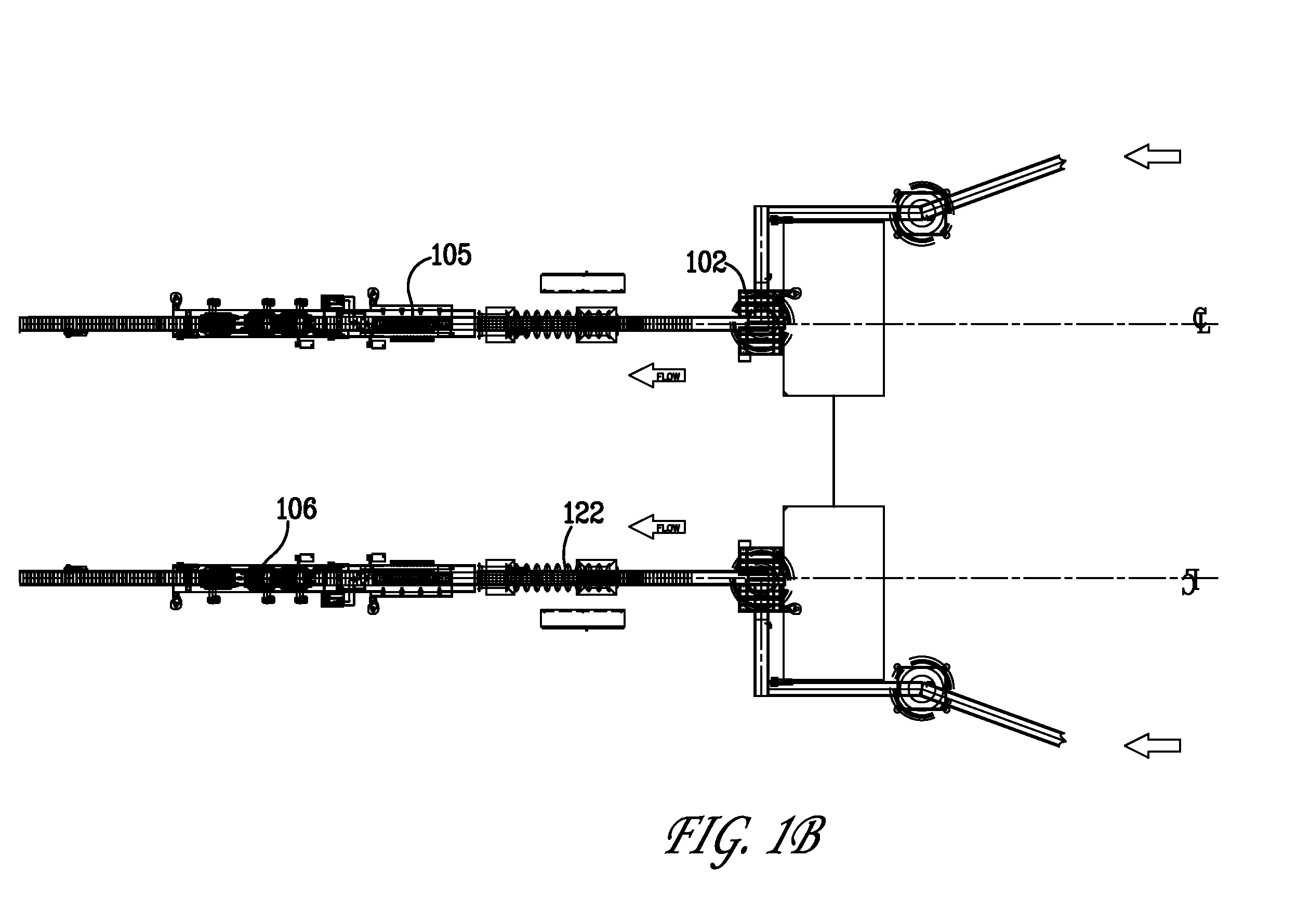

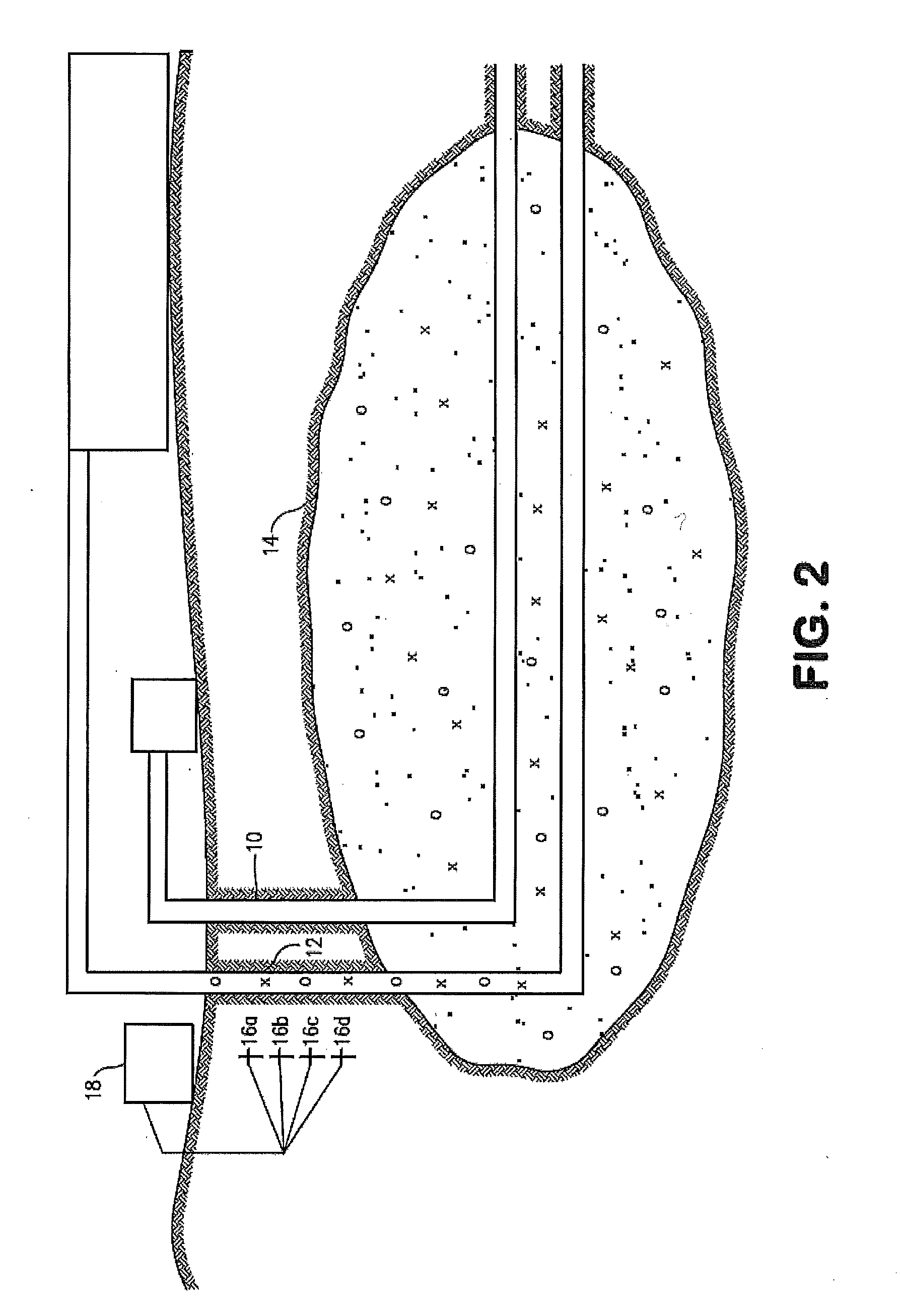

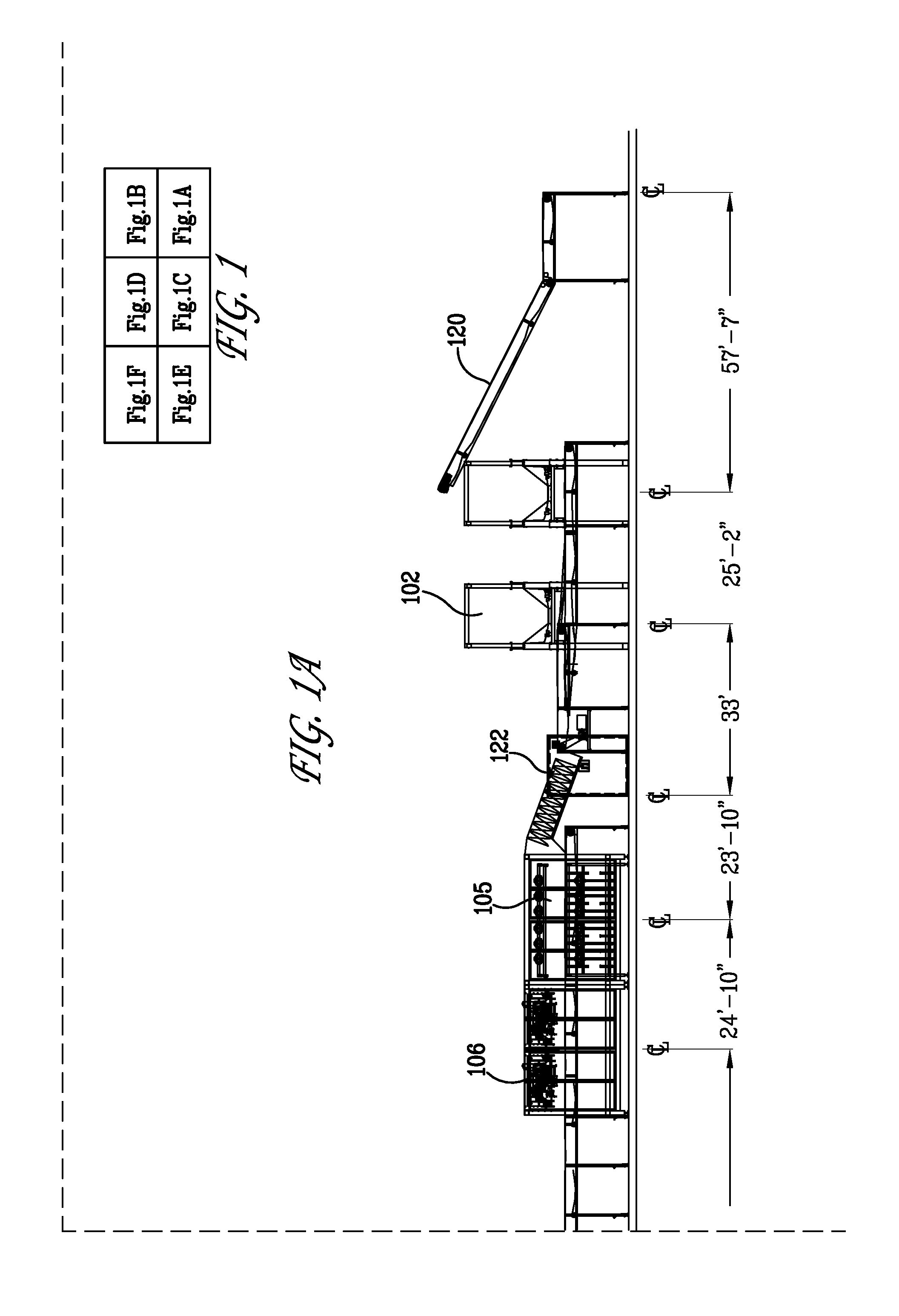

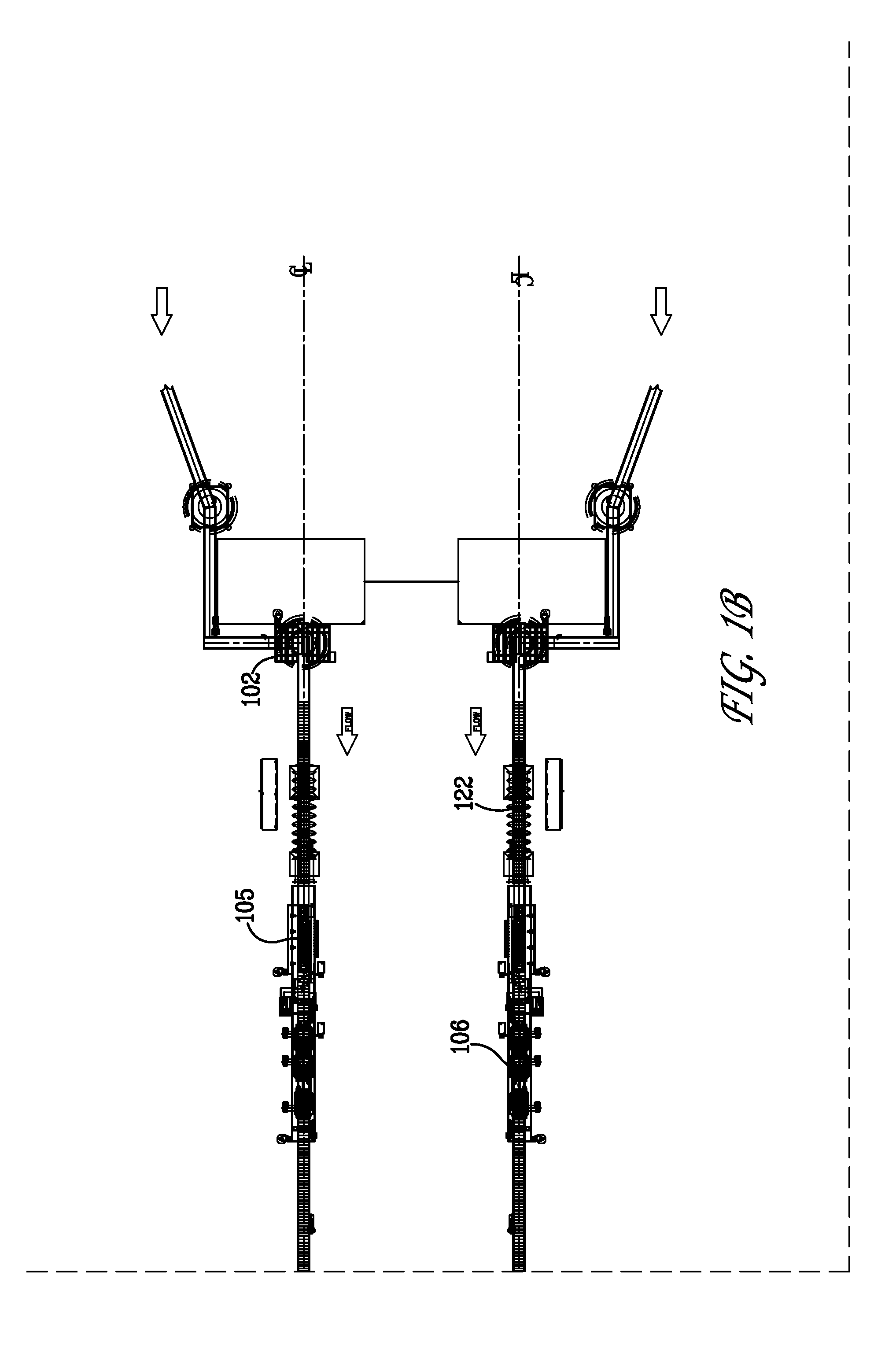

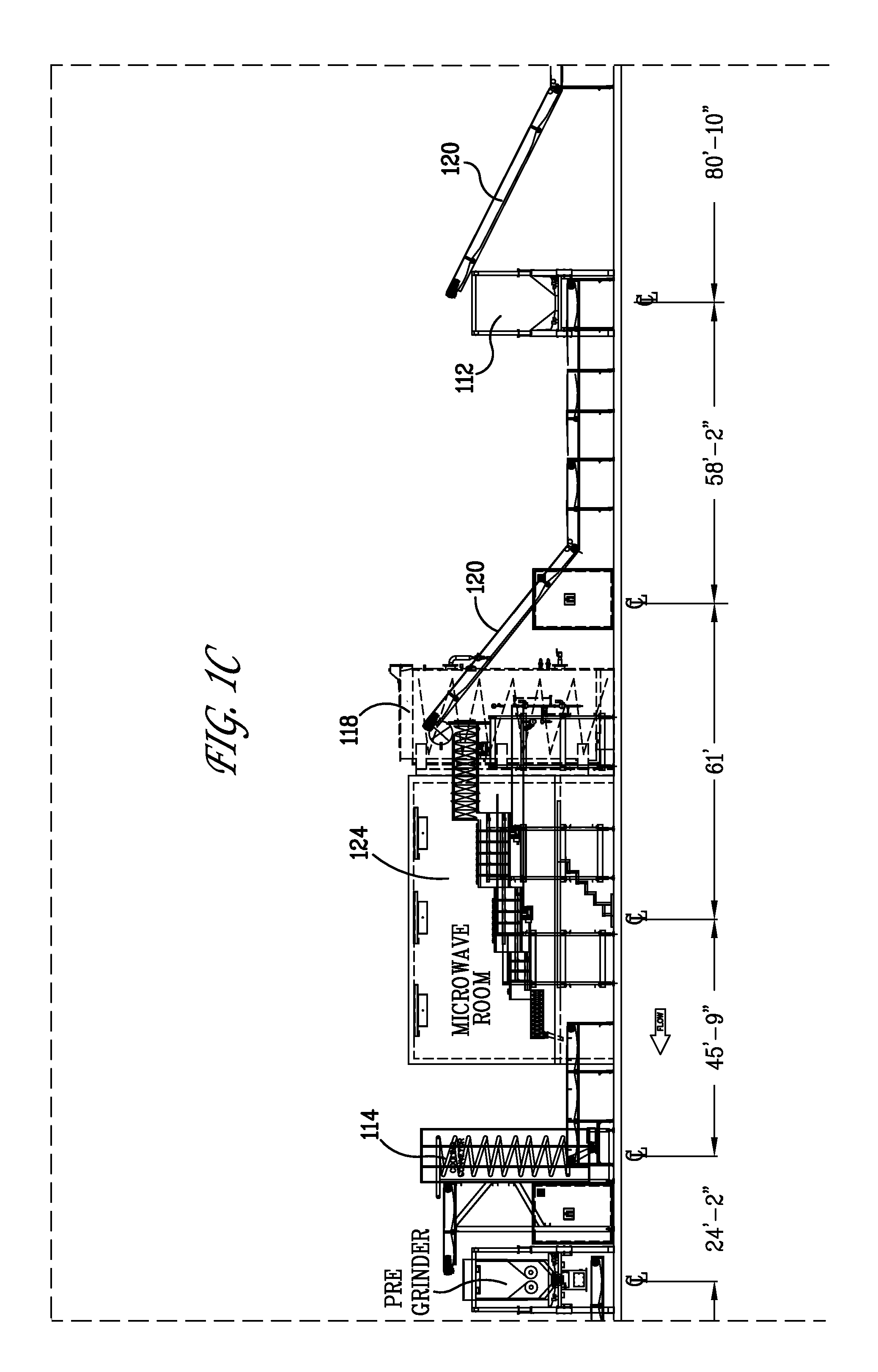

Microwave-based recovery of hydrocarbons and fossil fuels

InactiveUS20070131591A1Organic compounds purification/separation/stabilisationHydrocarbon oil cracking processHydrocotyle bowlesioidesPetroleum

The present invention provides methods for decomposing and extracting compositions for the recovery of petroleum-based materials from composites comprising those petroleum-based materials, comprising subjecting the compositions and / or composites to microwave radiation, wherein the microwave radiation is in the range of from about 4 GHz to about 18 GHz. The present invention also provides for products produced by the methods of the present invention and for apparatuses used to perform the methods of the present invention.

Owner:UNIVERSAL ALTERNATIVE FUELS INC +1

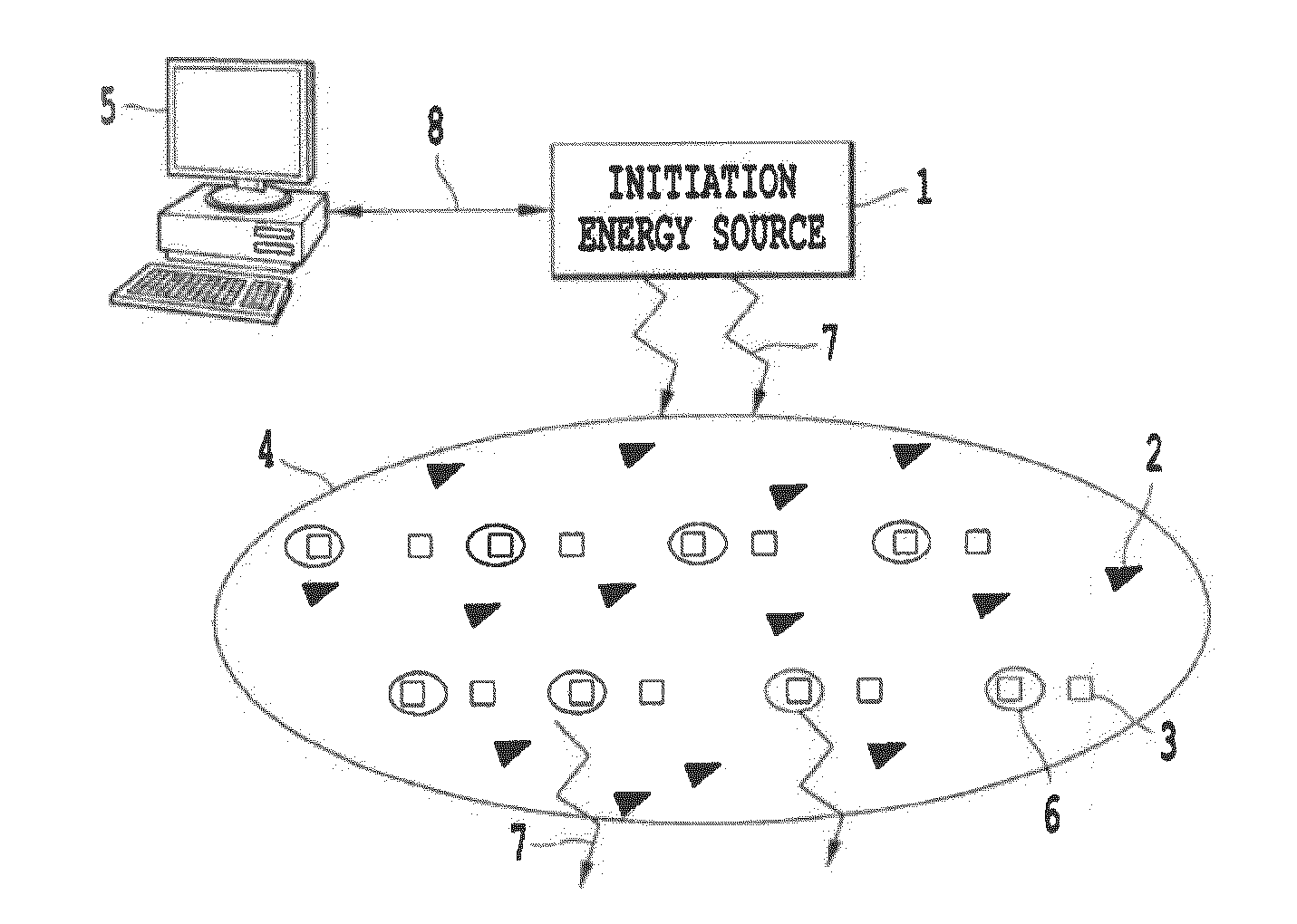

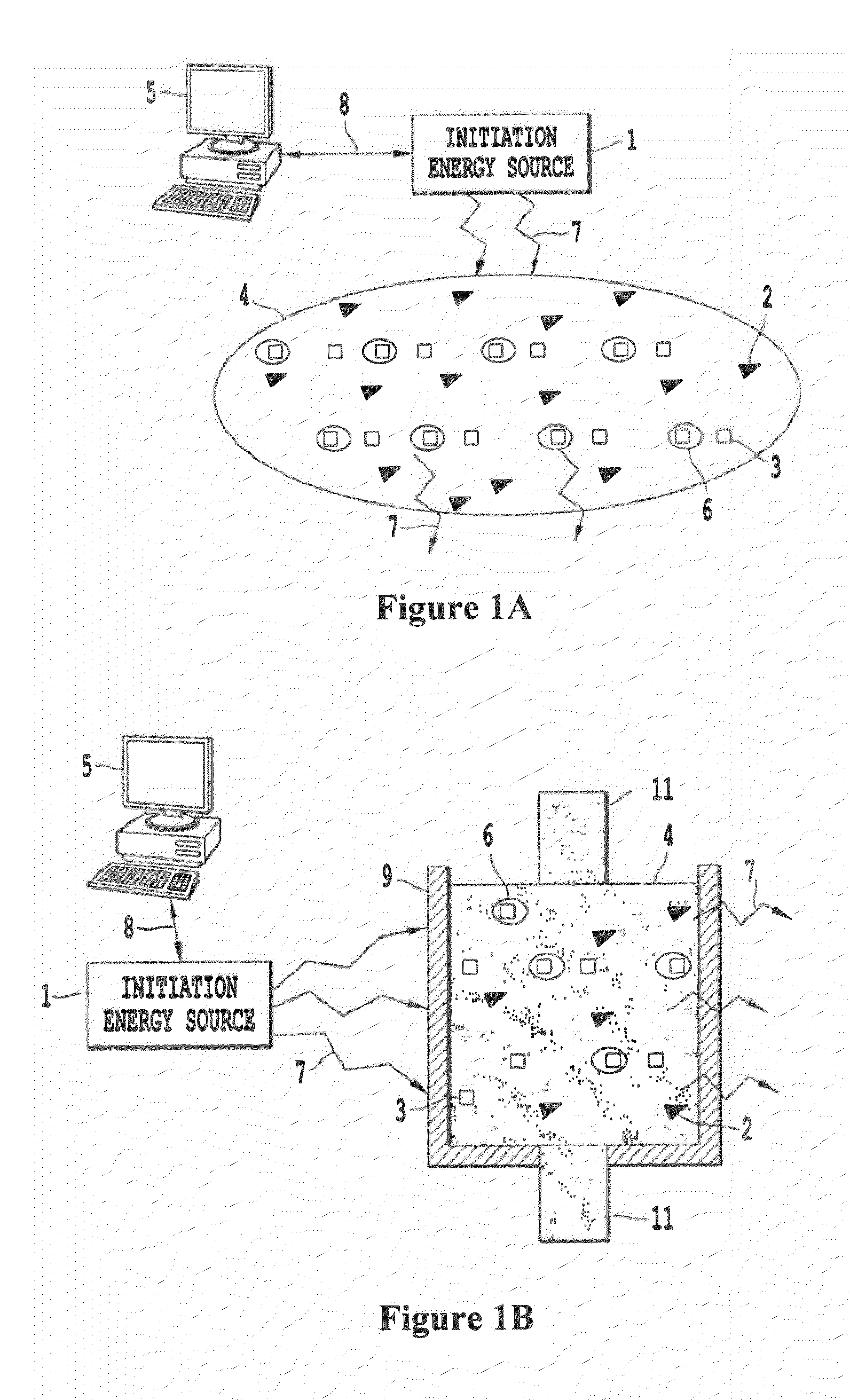

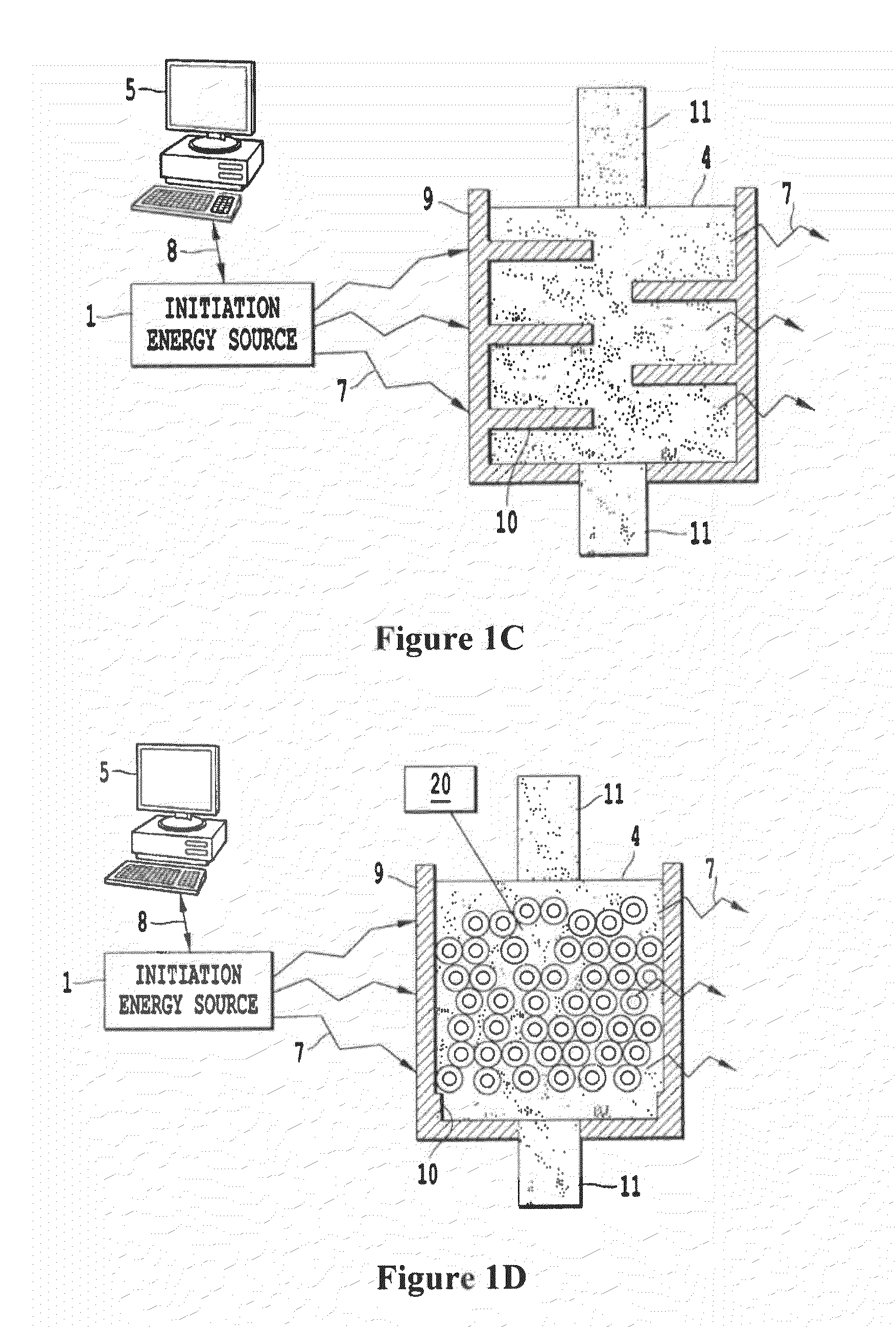

Up and down conversion systems for production of emitted light from various energy sources including radio frequency, microwave energy and magnetic induction sources for upconversion

Methods and systems for producing a change in a medium. A first method and system (1) place in a vicinity of the medium at least one upconverter including a gas for plasma ignition, with the upconverter being configured, upon exposure to initiation energy, to generate light for emission into the medium, and (2) apply the initiation energy from an energy source including the first wavelength λ1 to the medium, wherein the emitted light directly or indirectly produces the change in the medium. A second method and system (1) place in a vicinity of the medium an agent receptive to microwave radiation or radiofrequency radiation, and (2) apply as an initiation energy the microwave radiation or radiofrequency radiation by which the agent directly or indirectly generates emitted light in the infrared, visible, or ultraviolet range to produce at least one of physical and biological changes in the medium.

Owner:IMMUNOLIGTHT LLC +1

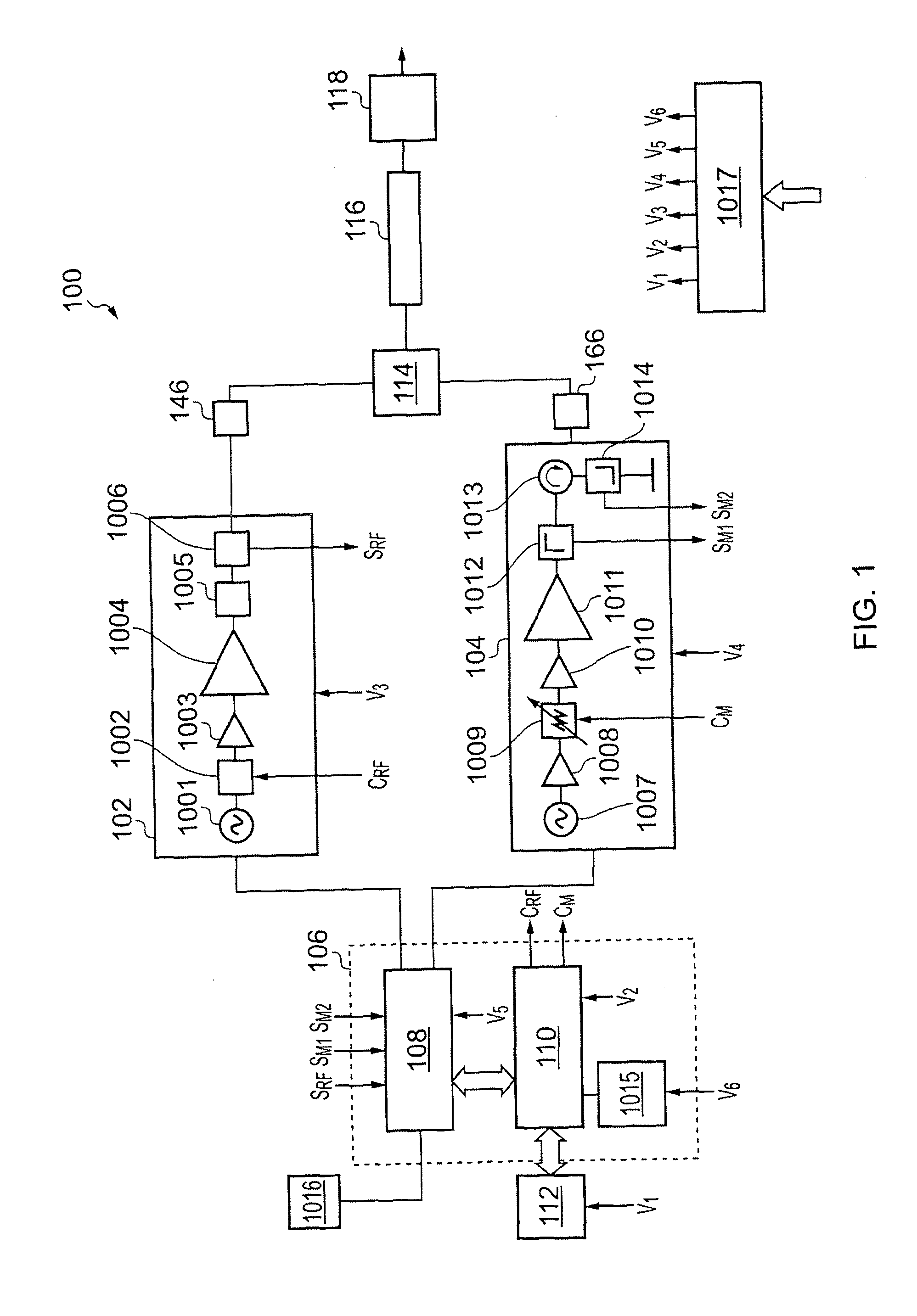

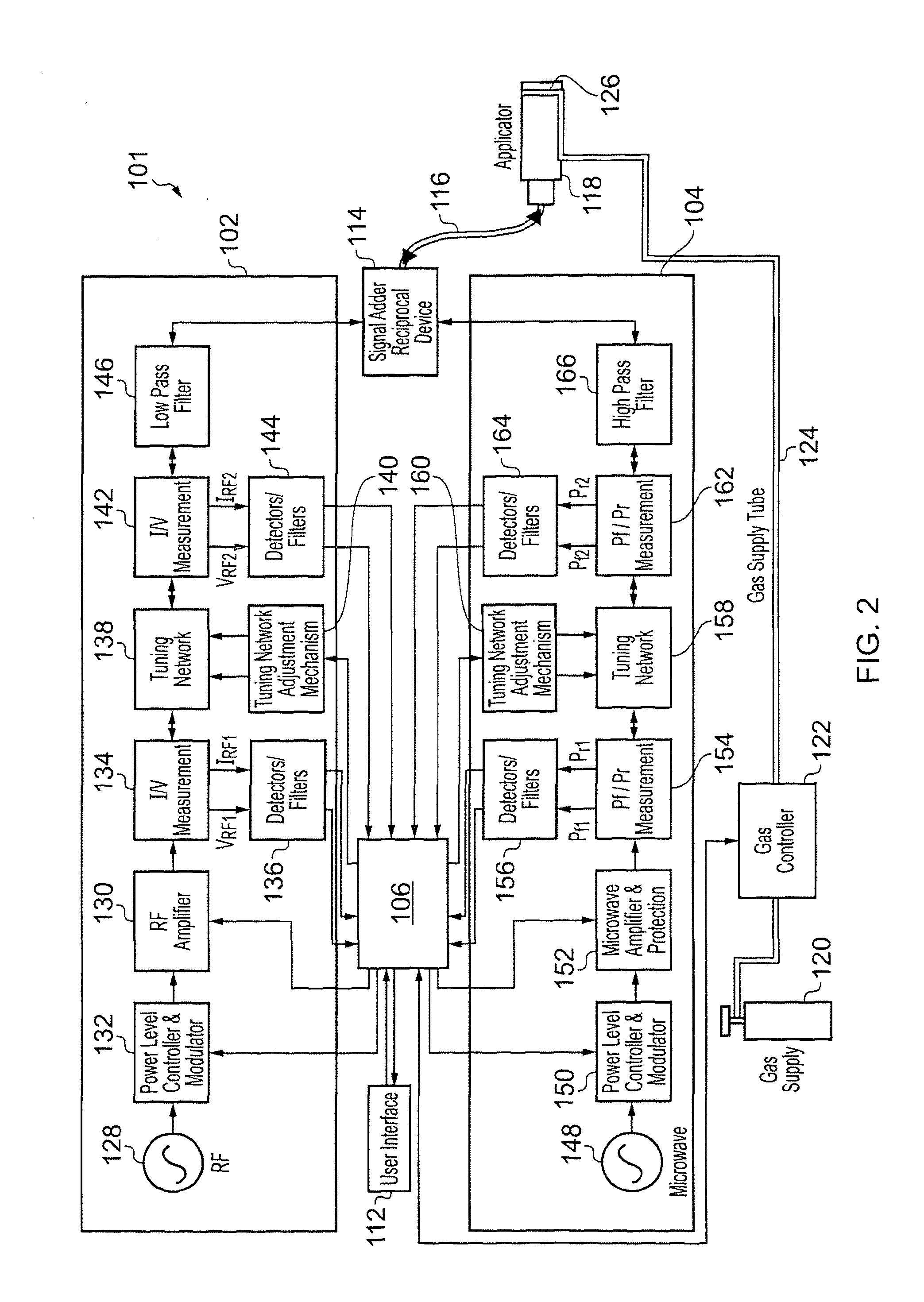

Electrosurgical apparatus for RF and microwave delivery

ActiveUS20130267943A1High materialAvoid bleedingCatheterSurgical instruments for heatingRadio frequency energyMedicine

A control system for electrosurgical apparatus in which the energy delivery profile of both RF EM radiation and microwave EM radiation delivered to a probe is set based on sampled voltage and current information of RF energy conveyed to the probe and / or sampled forward and reflected power information for the microwave energy conveyed to and from the probe. The energy delivery profile for the RF EM radiation is for tissue cutting (without requiring a sharp blade) and the energy delivery profile for the microwave EM radiation is for haemostasis or sealing or coagulation or ablation of tissue. The RF EM radiation and microwave EM radiation may be applied separately or simultaneously.

Owner:CREO MEDICAL LTD

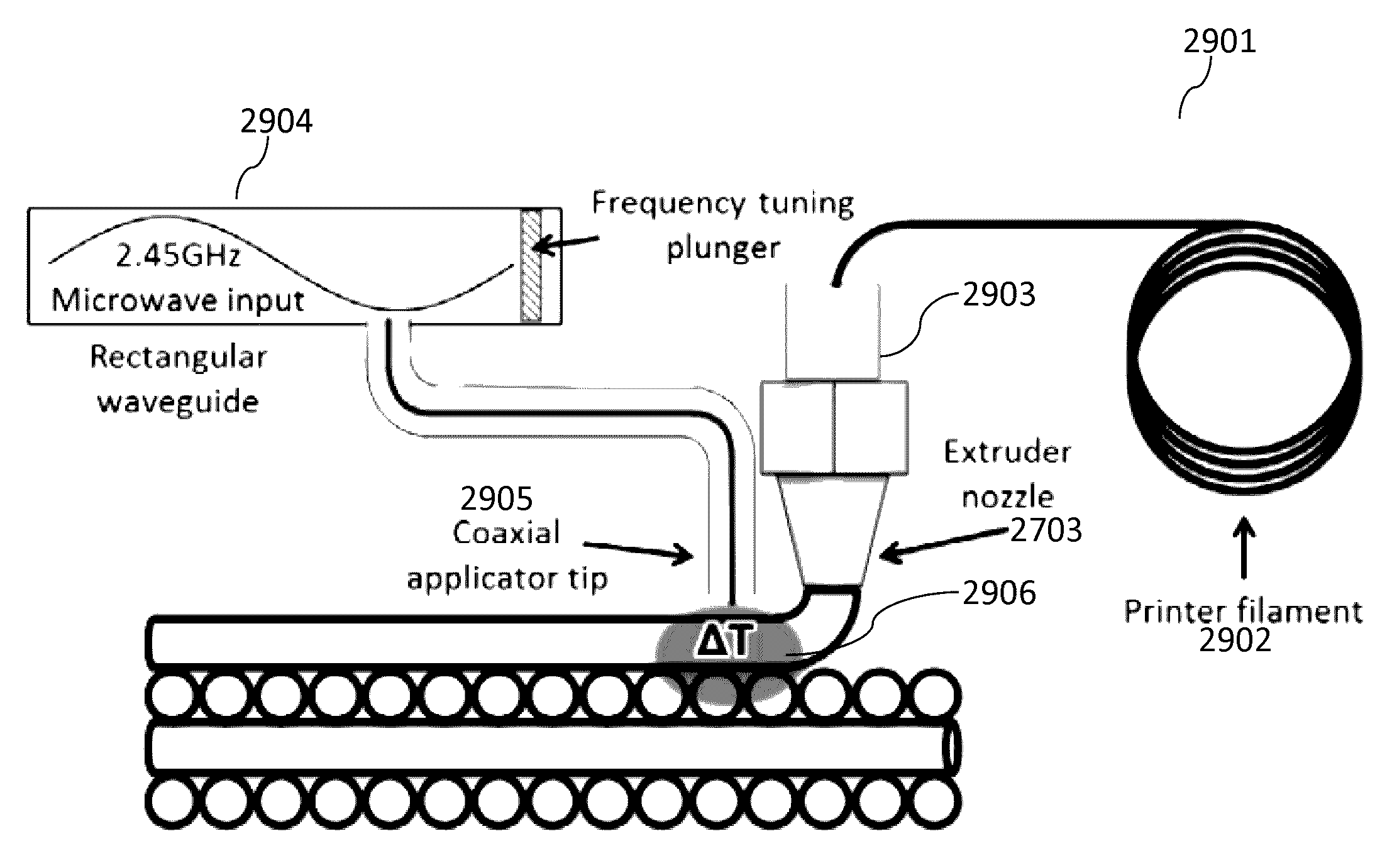

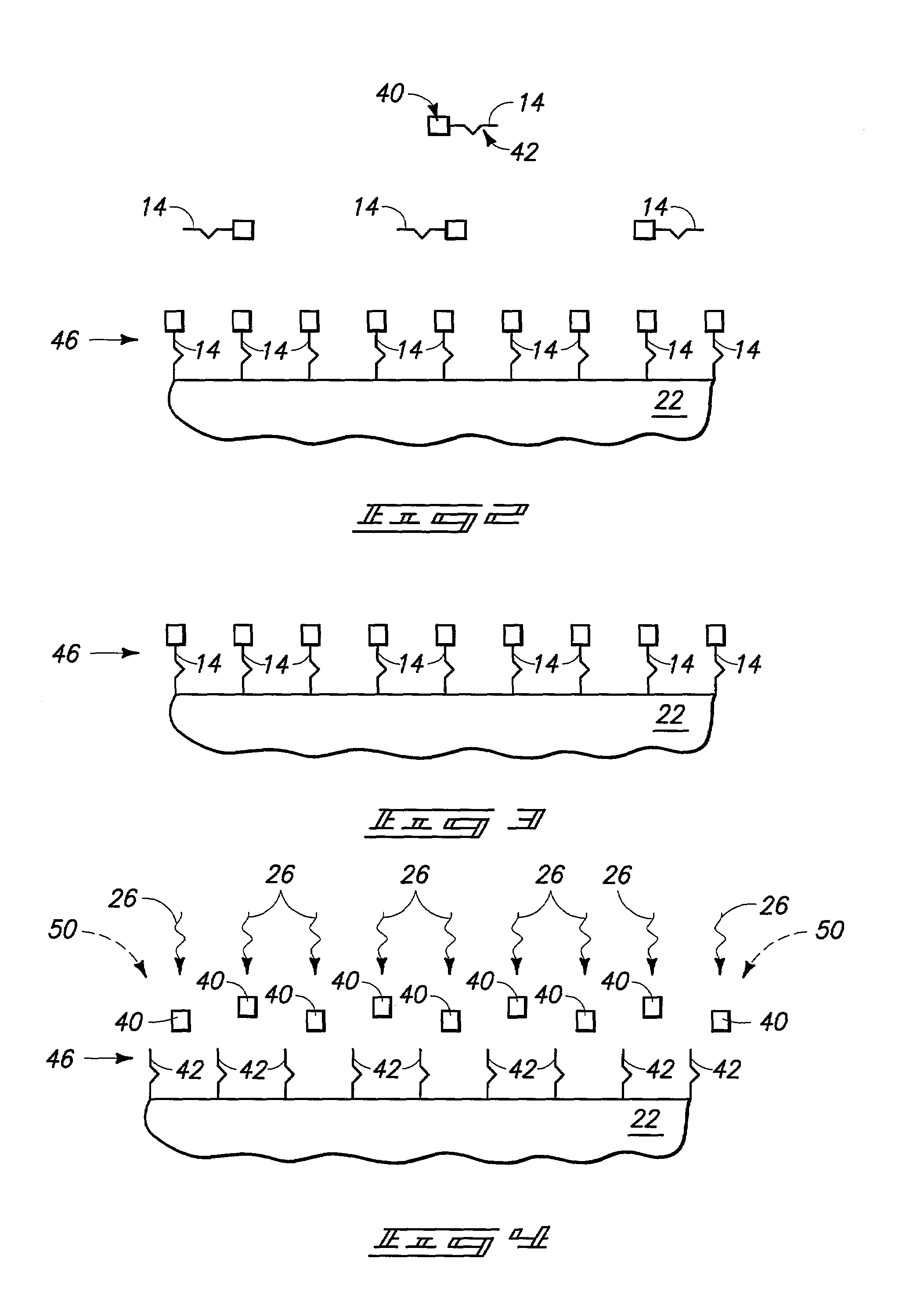

Microwave-induced localized heating of cnt filled polymer composites for enhanced inter-bead diffusive bonding of fused filament fabricated parts

ActiveUS20160325491A1Increase inter-bead bond strengthImprove mechanical propertiesMaterial nanotechnologyElectroconductive/antistatic filament manufacture3d printCarbon nanotube

A microwave-induced heating of CNT filled (or coated) polymer composites for enhancing inter-bead diffusive bonding of fused filament fabricated parts. The technique incorporates microwave absorbing nanomaterials (carbon nanotubes (CNTs)) onto the surface or throughout the volume of 3D printer polymer filament to increase the inter-bead bond strength following a post microwave irradiation treatment and / or in-situ focused microwave beam during printing. The overall strength of the final 3D printed part will be dramatically increased and the isotropic mechanical properties of fused filament part will approach or exceed conventionally manufactured counterparts.

Owner:TEXAS TECH UNIV SYST

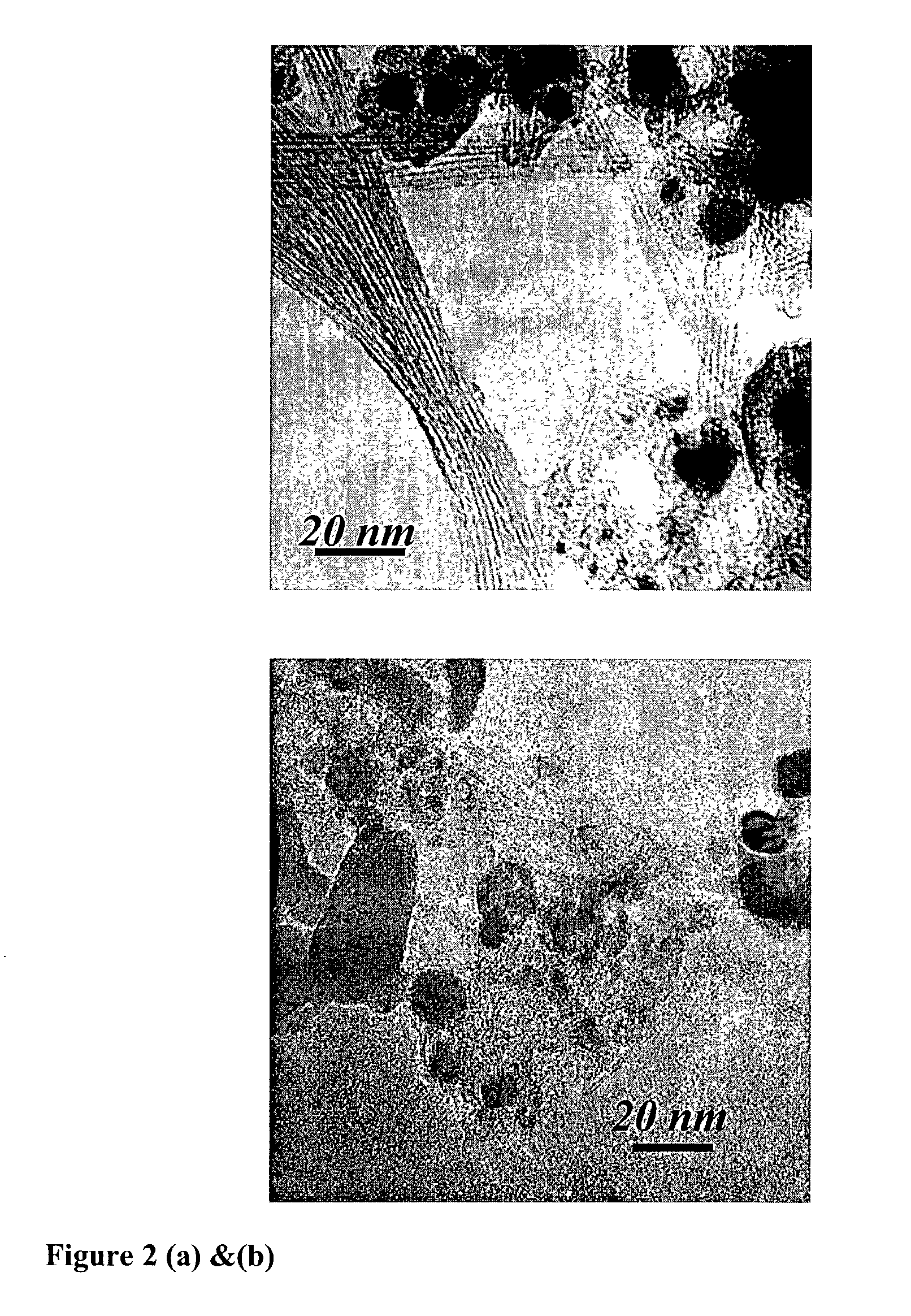

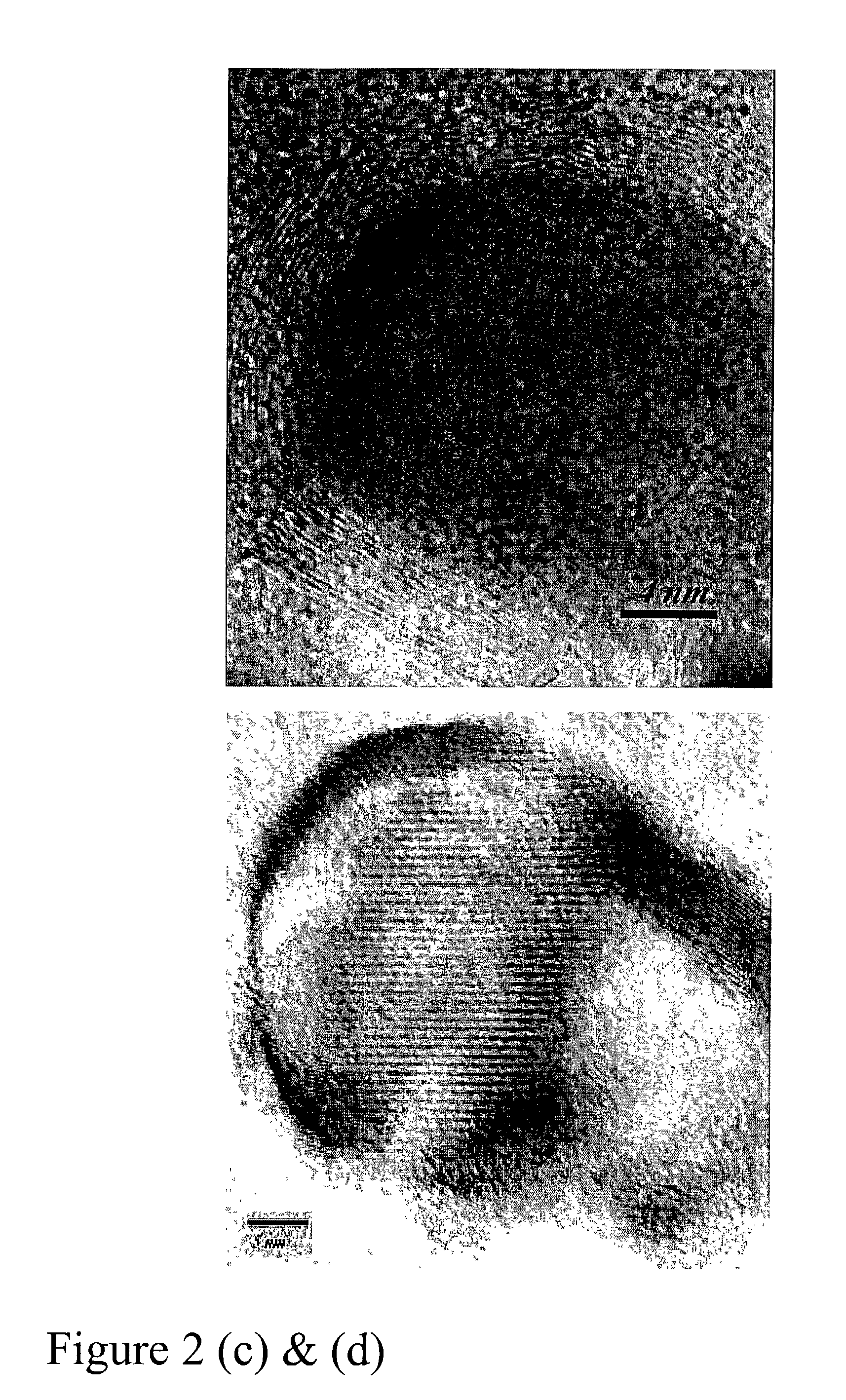

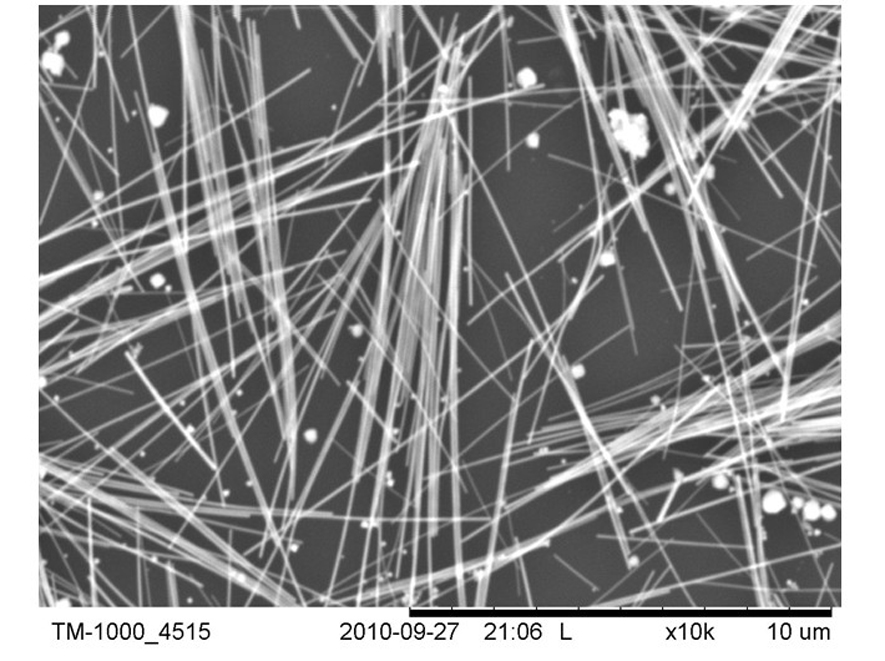

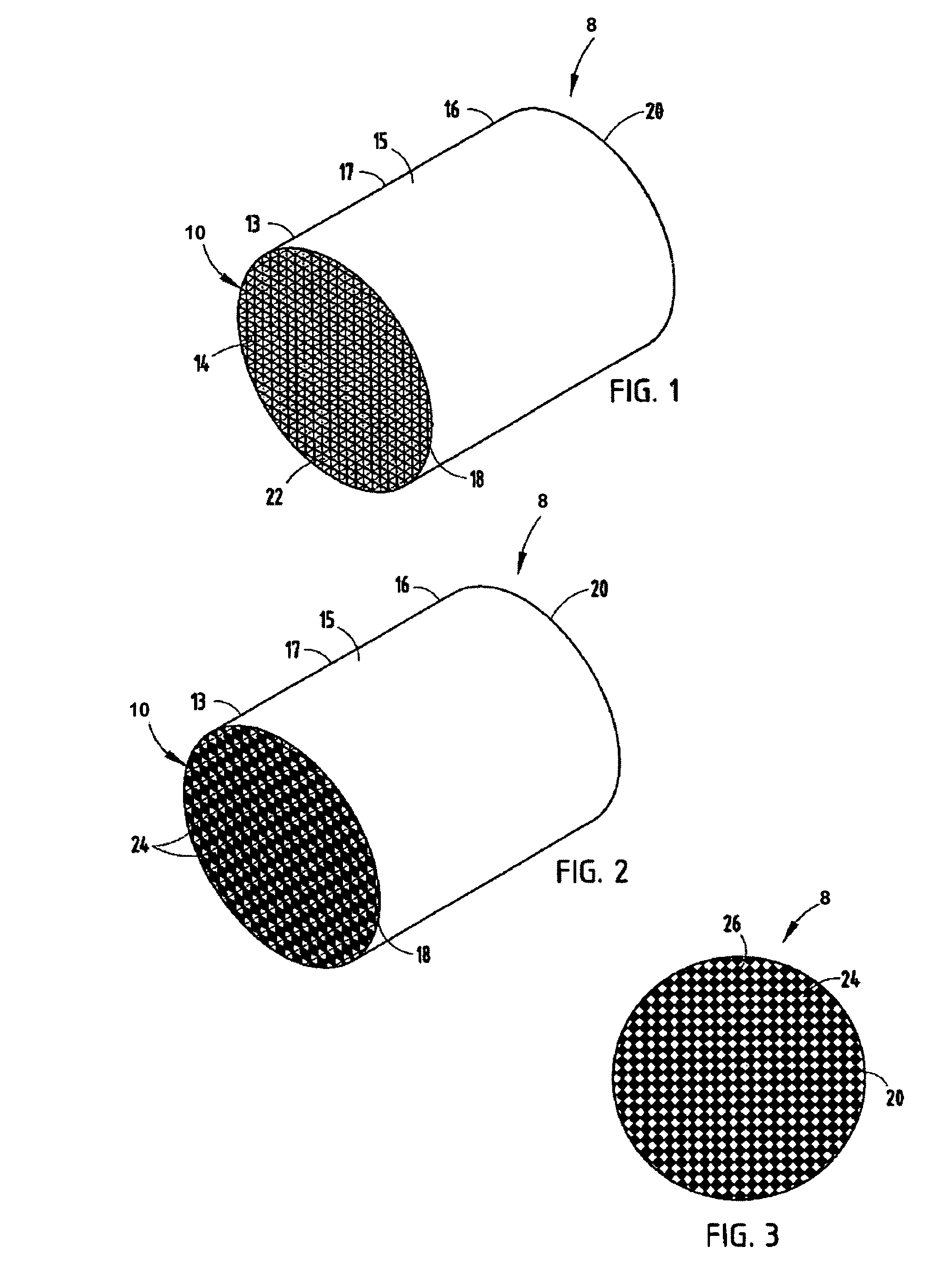

Method of purifying nanotubes and nanofibers using electromagnetic radiation

Disclosed are methods of purifying mixtures comprising nanofibers and / or nanotubes and residual catalyst particles that are covered by outer layers of the nanotube or nanofiber material. The mixtures are exposed to electromagnetic radiation, which induces localized heating in the residual catalyst particles. The localized heating creates breaches in the outer layers. Thereafter, the residual catalyst particles may be removed under relatively mild conditions that do not significantly affect the structural integrity of the nanotubes or nanofibers. The methods of the invention have been used to particular advantage in the purification of single wall carbon nanotubes (SWNTs) synthesized using metal catalysts. For these SWNTs, microwave radiation is preferably used to induce the localized heating, the outer layers are preferably removed at least in part by carrying out the localized heating under air, and the residual catalyst may be removed by exposure to relatively dilute aqueous acid.

Owner:PENN STATE RES FOUND

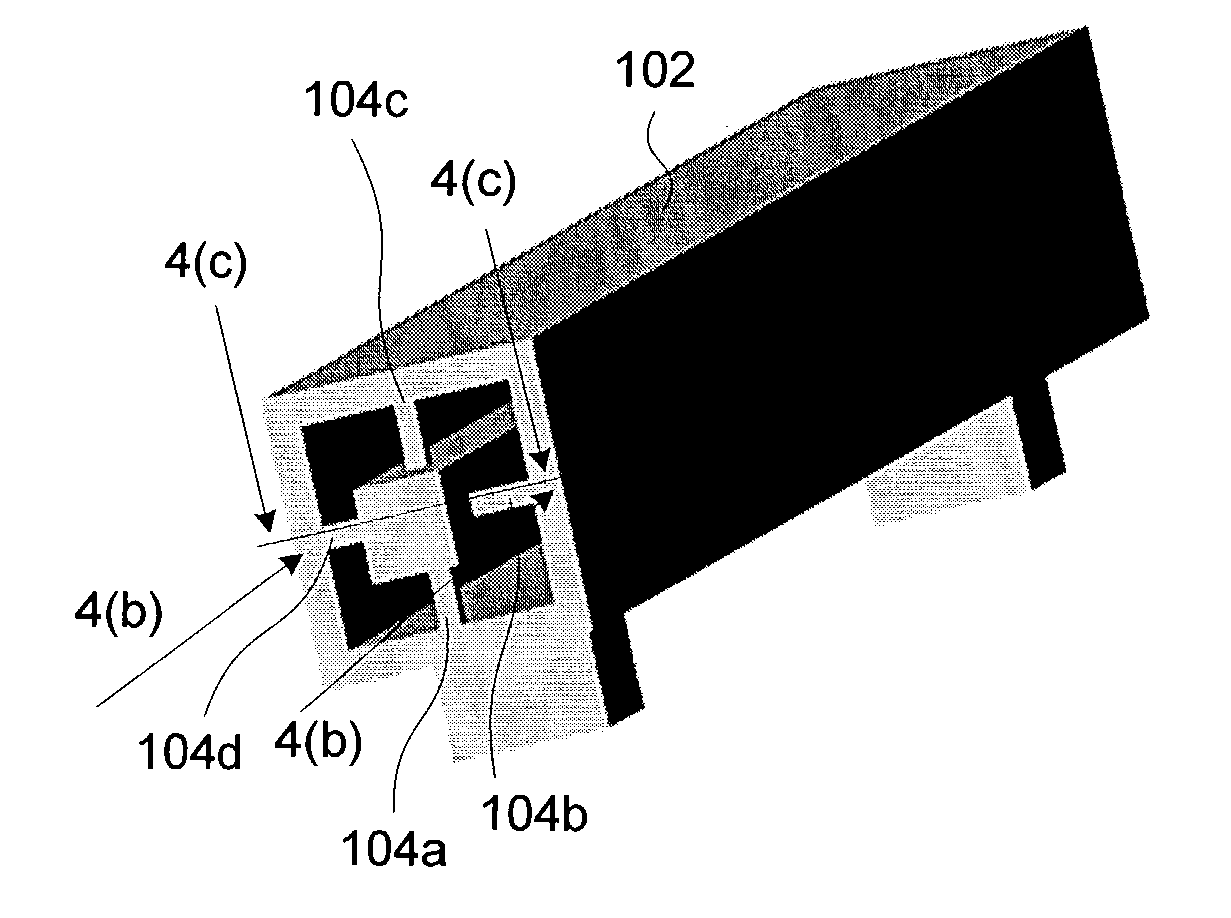

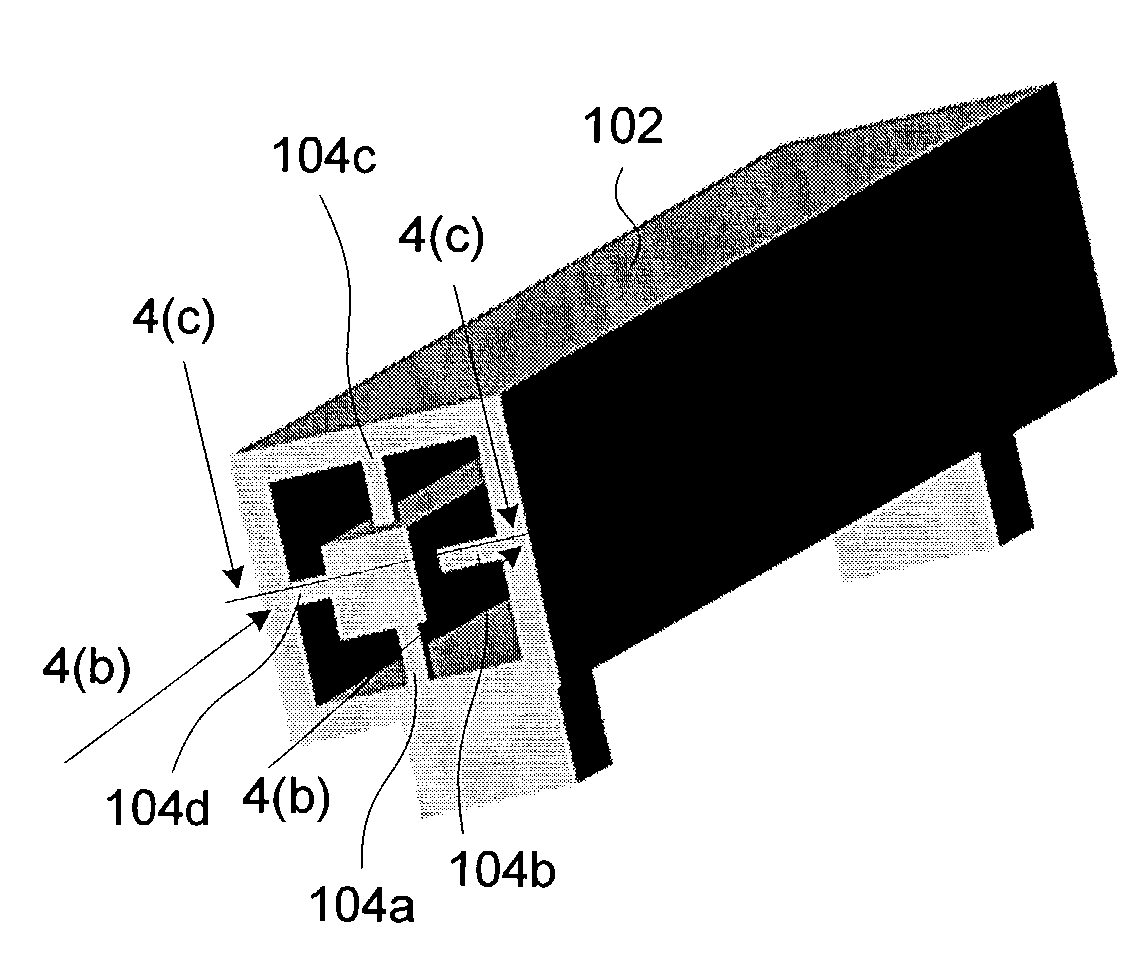

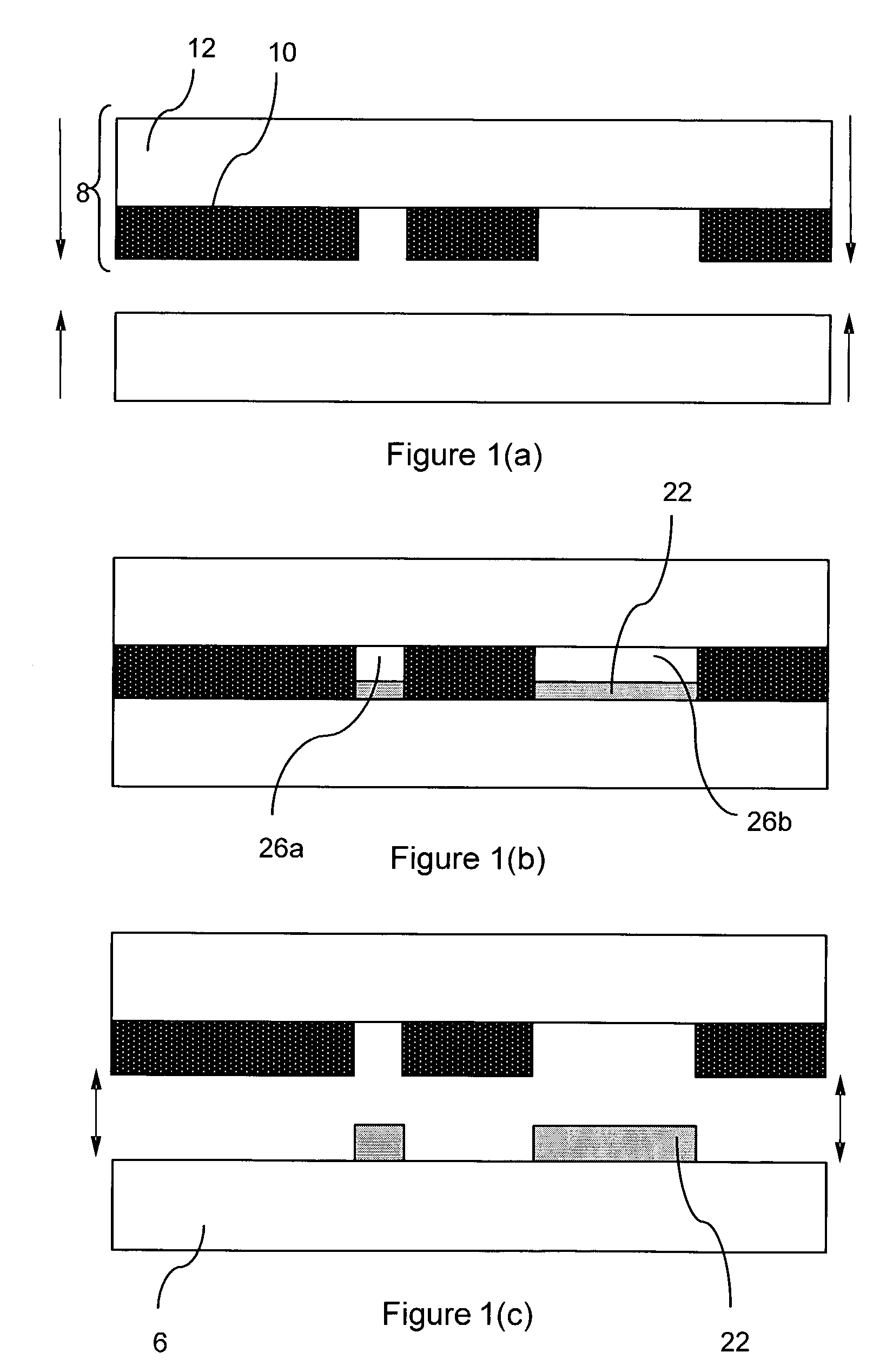

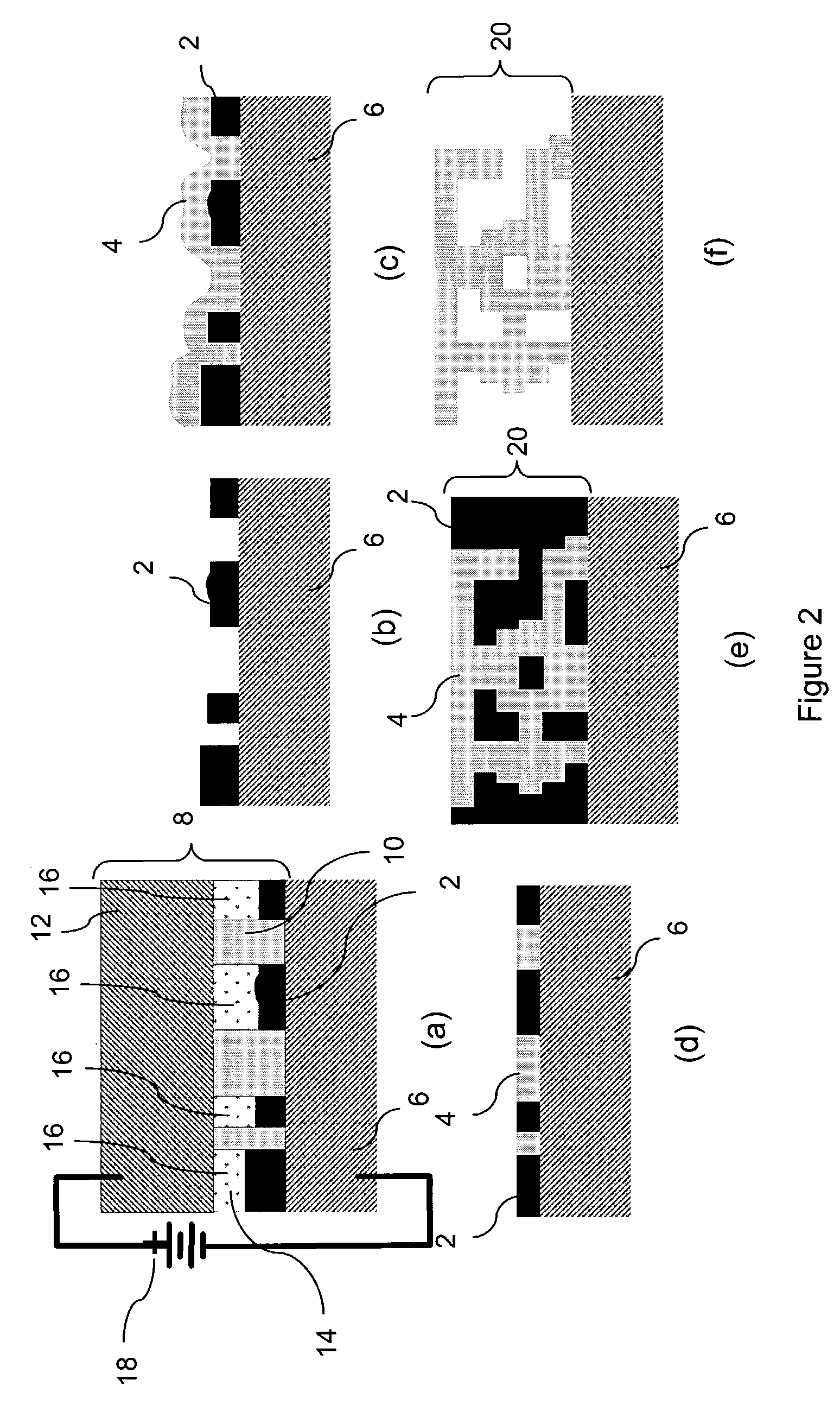

Miniature RF and microwave components and methods for fabricating such components

ActiveUS20030222738A1Add depthAcceleration measurement using interia forcesAdditive manufacturing apparatusElectricityInductor

RF and microwave radiation directing or controlling components are provided that may be monolithic, that may be formed from a plurality of electrodeposition operations and / or from a plurality of deposited layers of material, that may include switches, inductors, antennae, transmission lines, filters, and / or other active or passive components. Components may include non-radiation-entry and non-radiation-exit channels that are useful in separating sacrificial materials from structural materials. Preferred formation processes use electrochemical fabrication techniques (e.g. including selective depositions, bulk depositions, etching operations and planarization operations) and post-deposition processes (e.g. selective etching operations and / or back filling operations).

Owner:MEMGEN

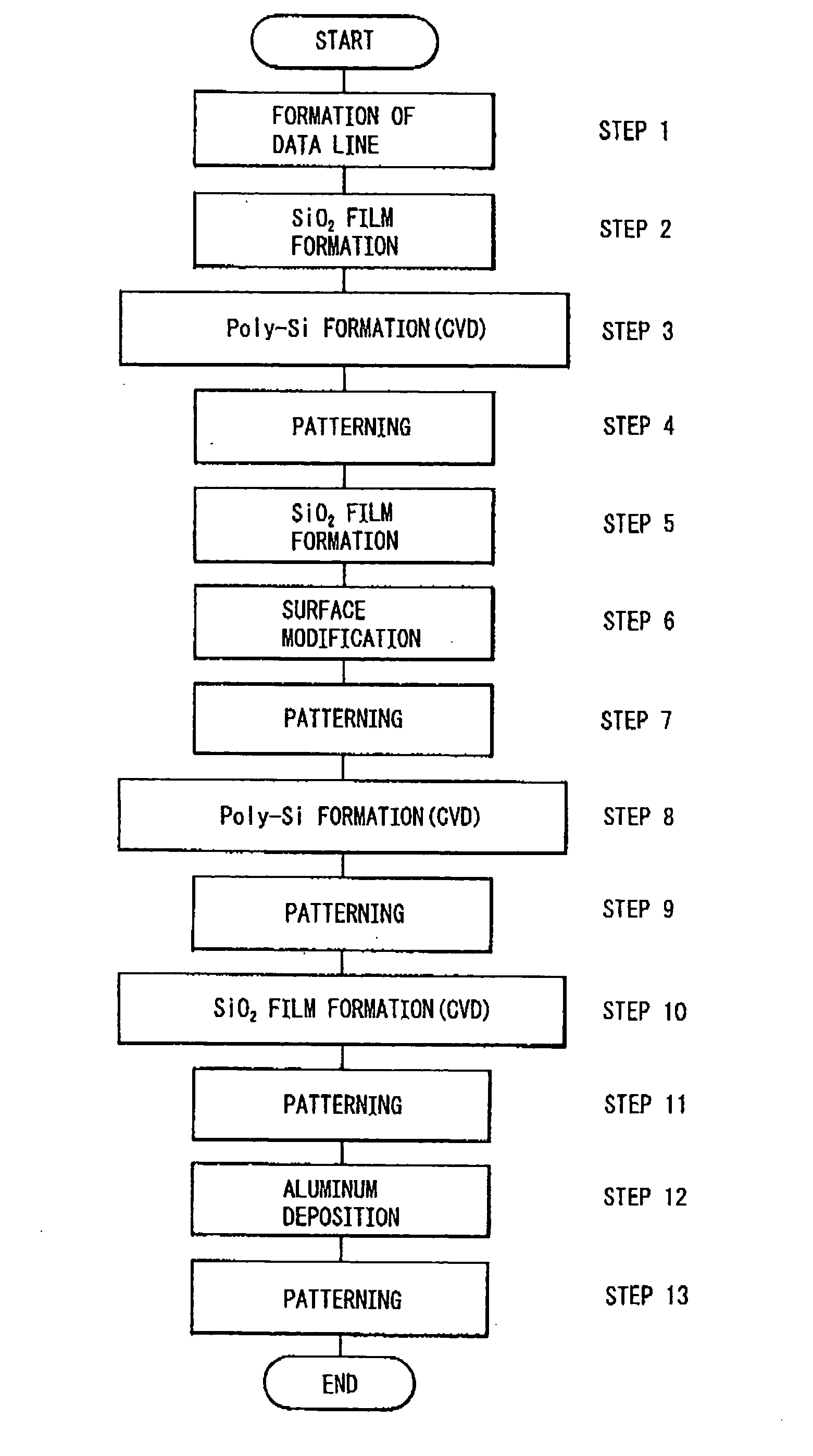

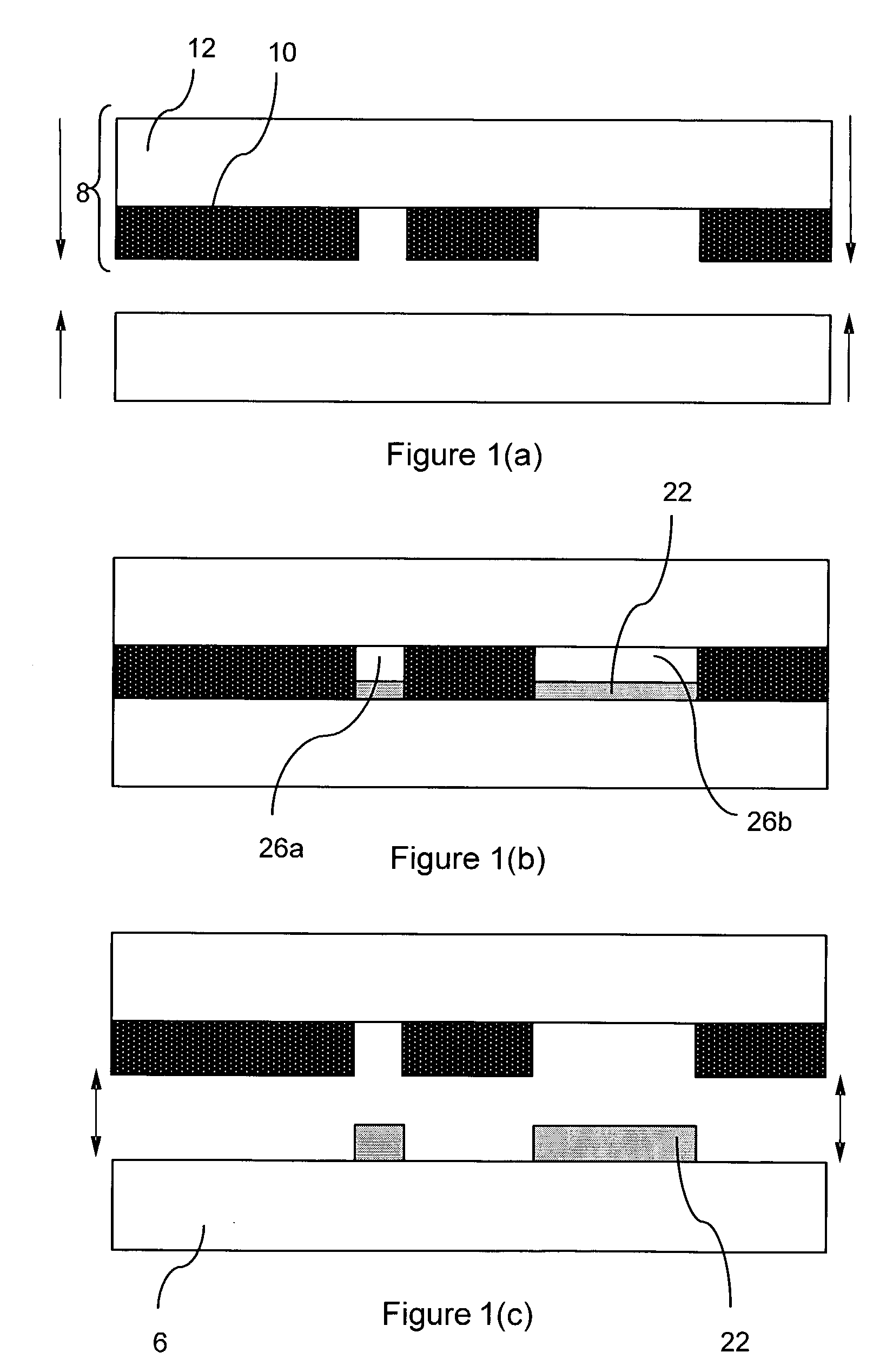

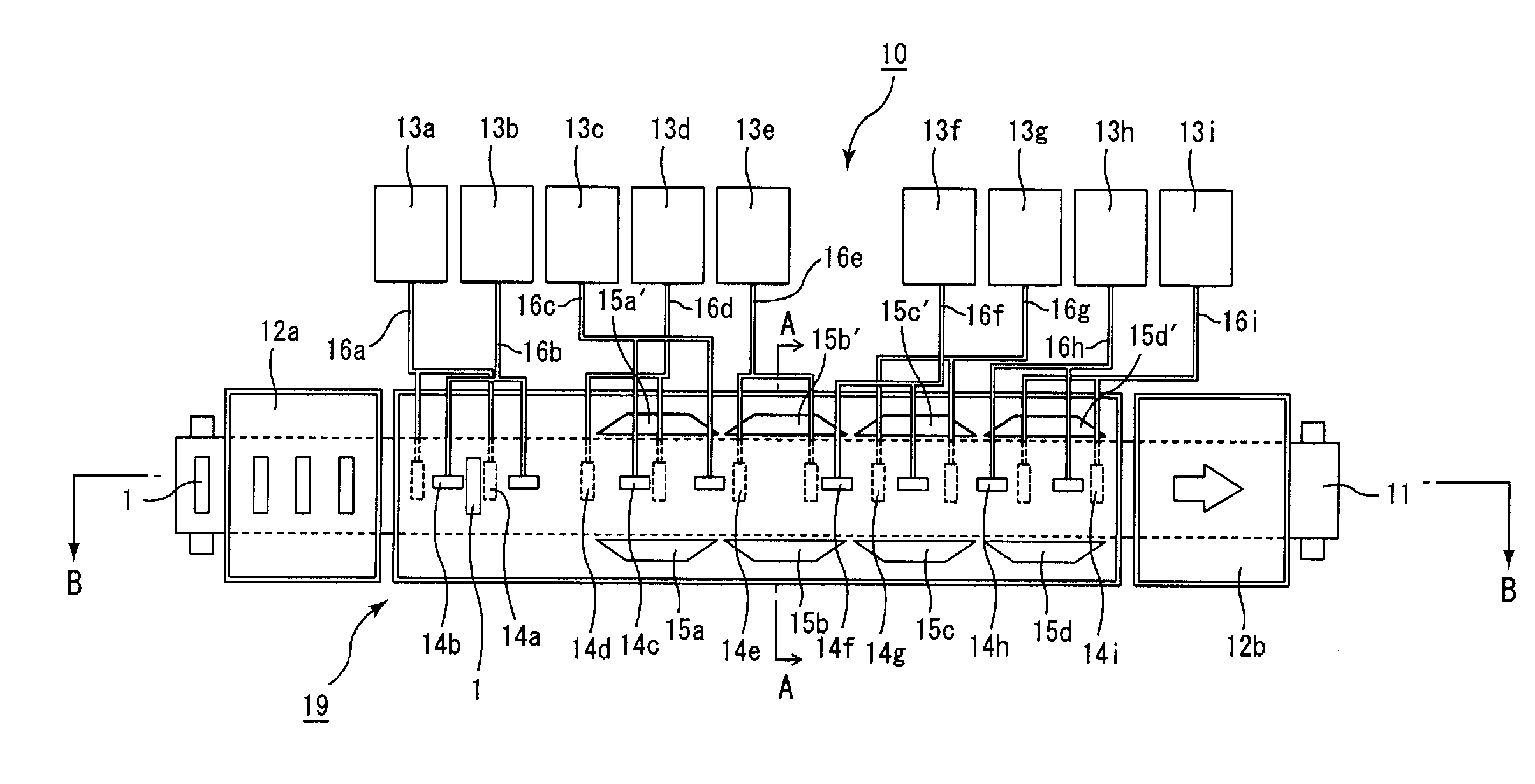

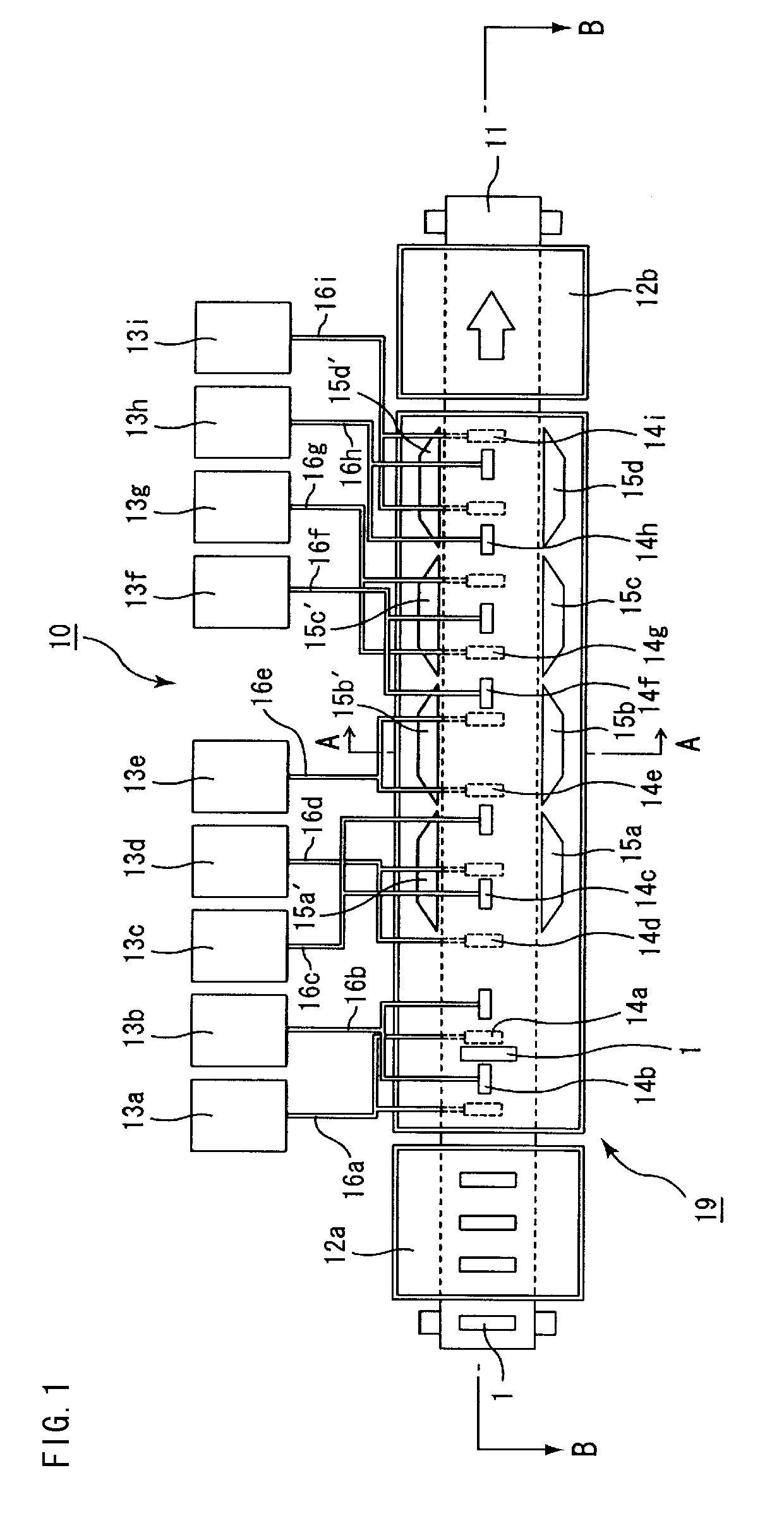

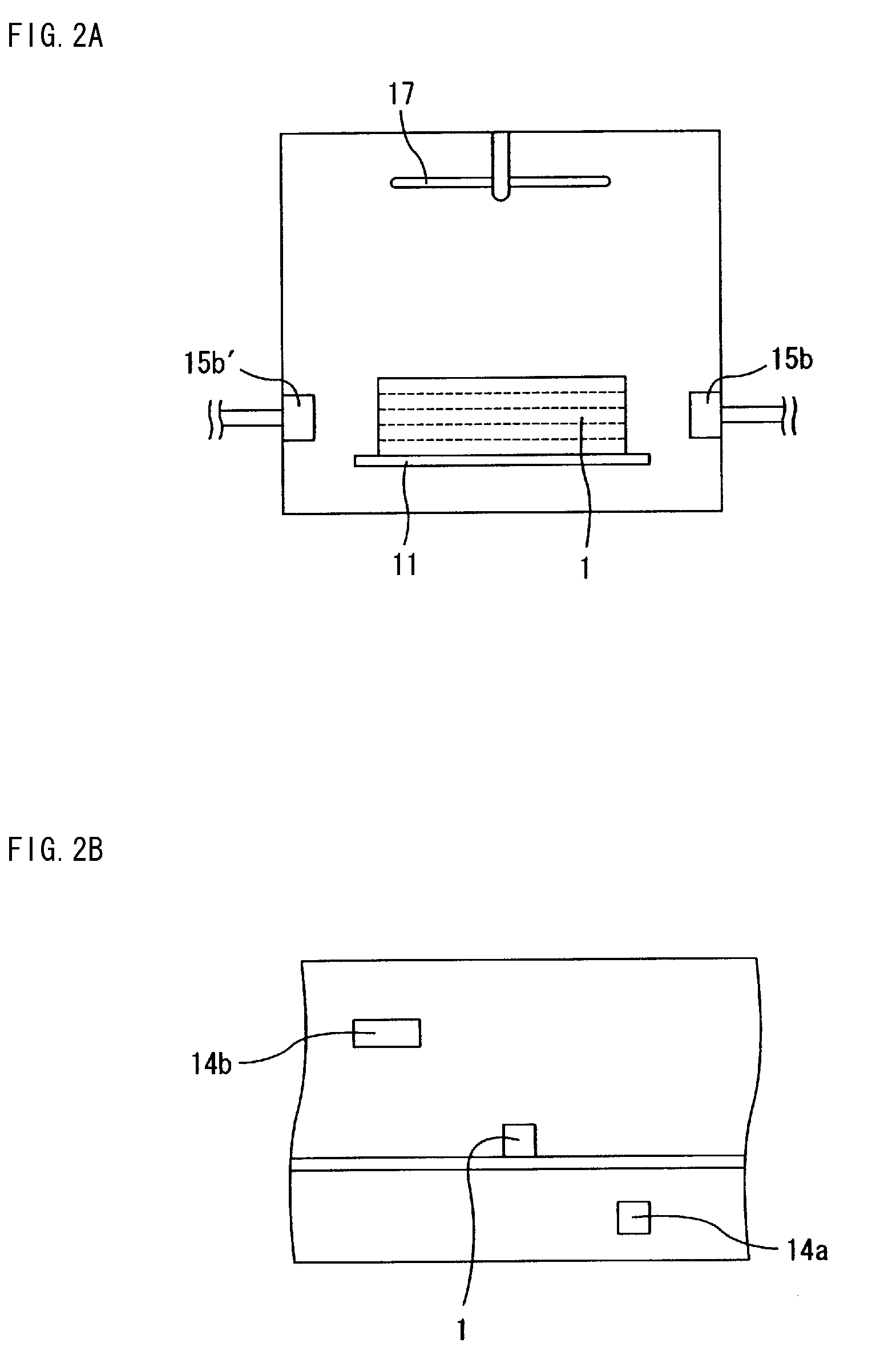

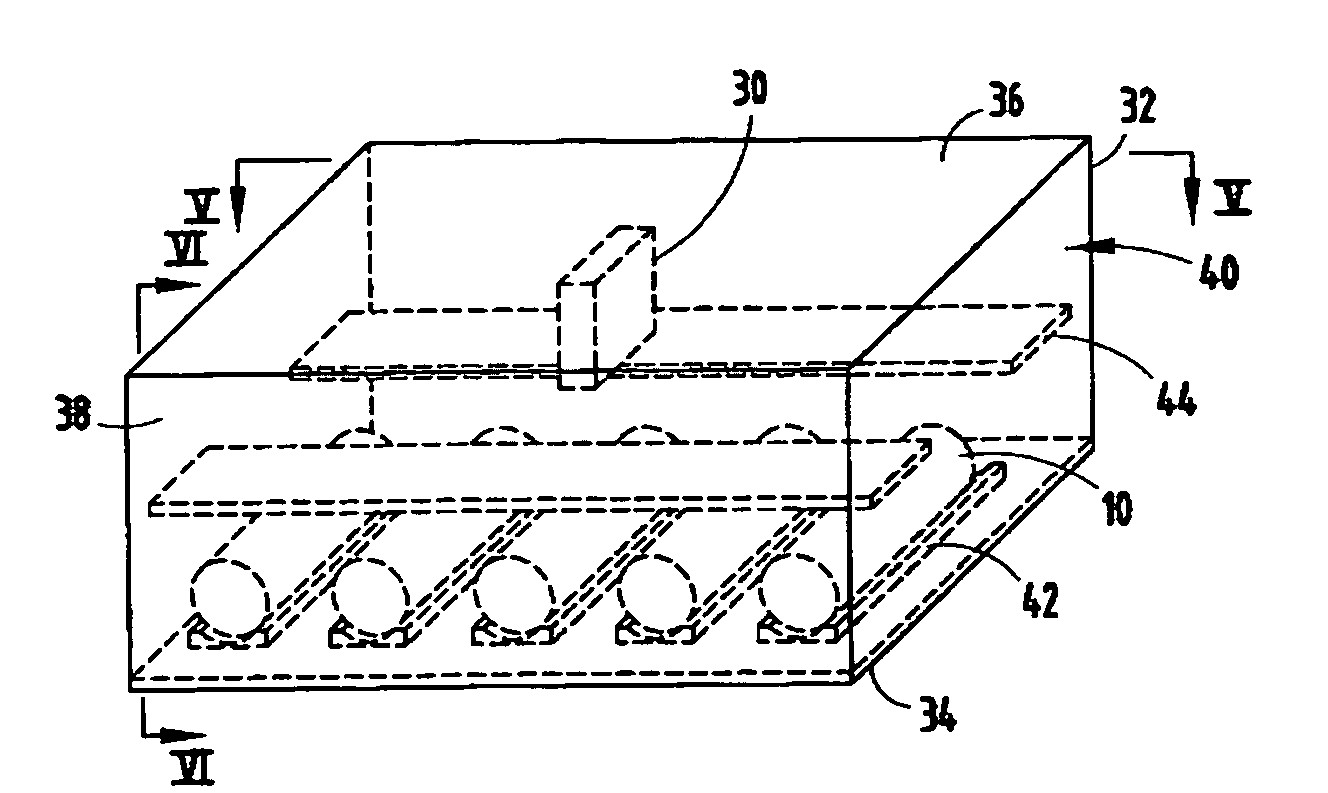

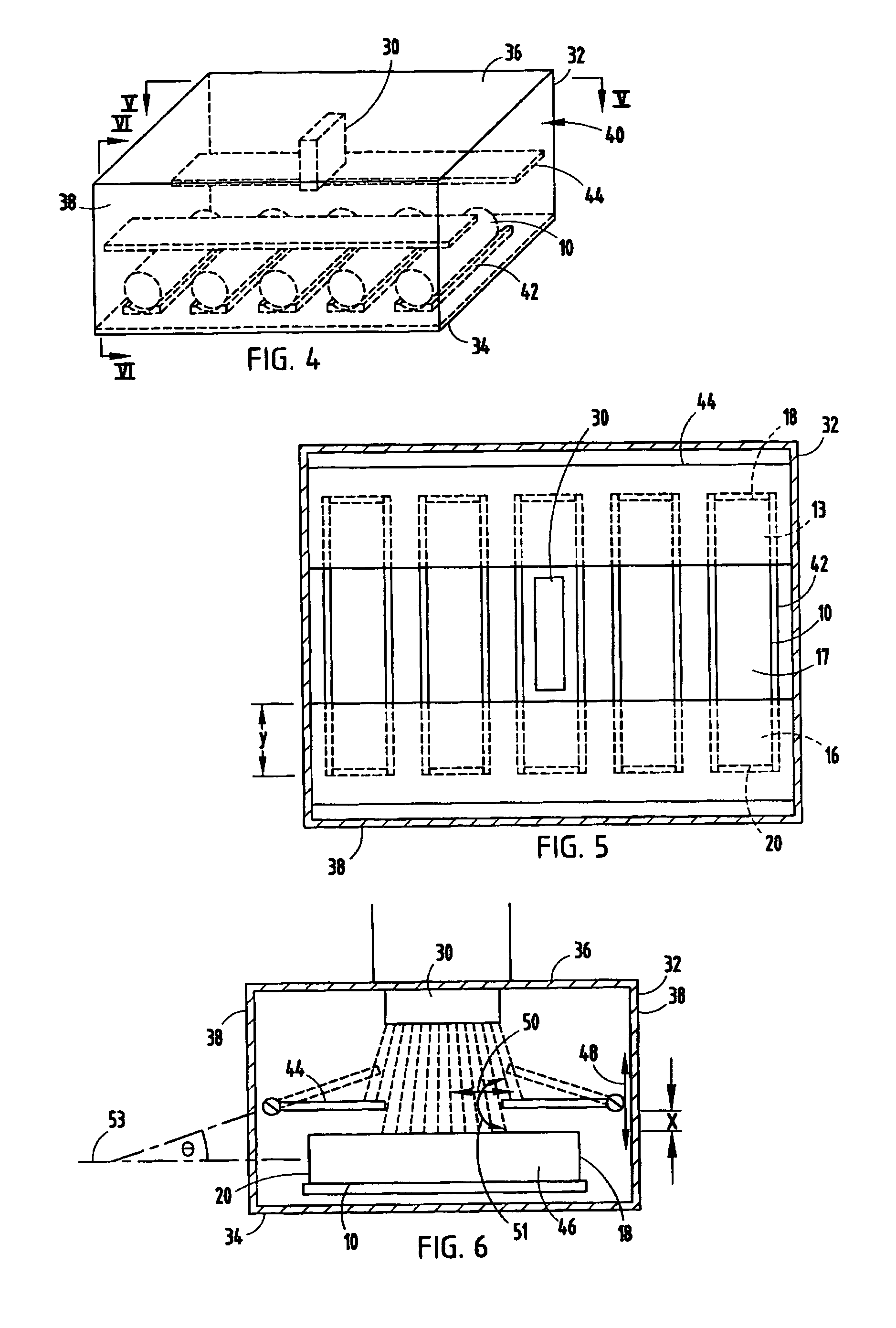

Drying apparatus, method for drying ceramic molded body, and method for manufacturing honeycomb structure

InactiveUS20080136062A1Remove moistureDrying solid materials with heatDrying gas arrangementsCeramic moldingIrradiation

A drying apparatus including a conveying member configured to convey an item to be dried, a plurality of microwave irradiation portions disposed alternately at an upper side and a lower side of the conveying member, and a plurality of hot air blowing portions. The microwave irradiation portions are configured to irradiate the item to be dried with microwaves in an alternating manner from the upper side and the lower side. The hot air blowing portions are configured to apply hot air to the item to be dried in parallel with irradiation of the microwaves by the microwave irradiation portions.

Owner:IBIDEN CO LTD

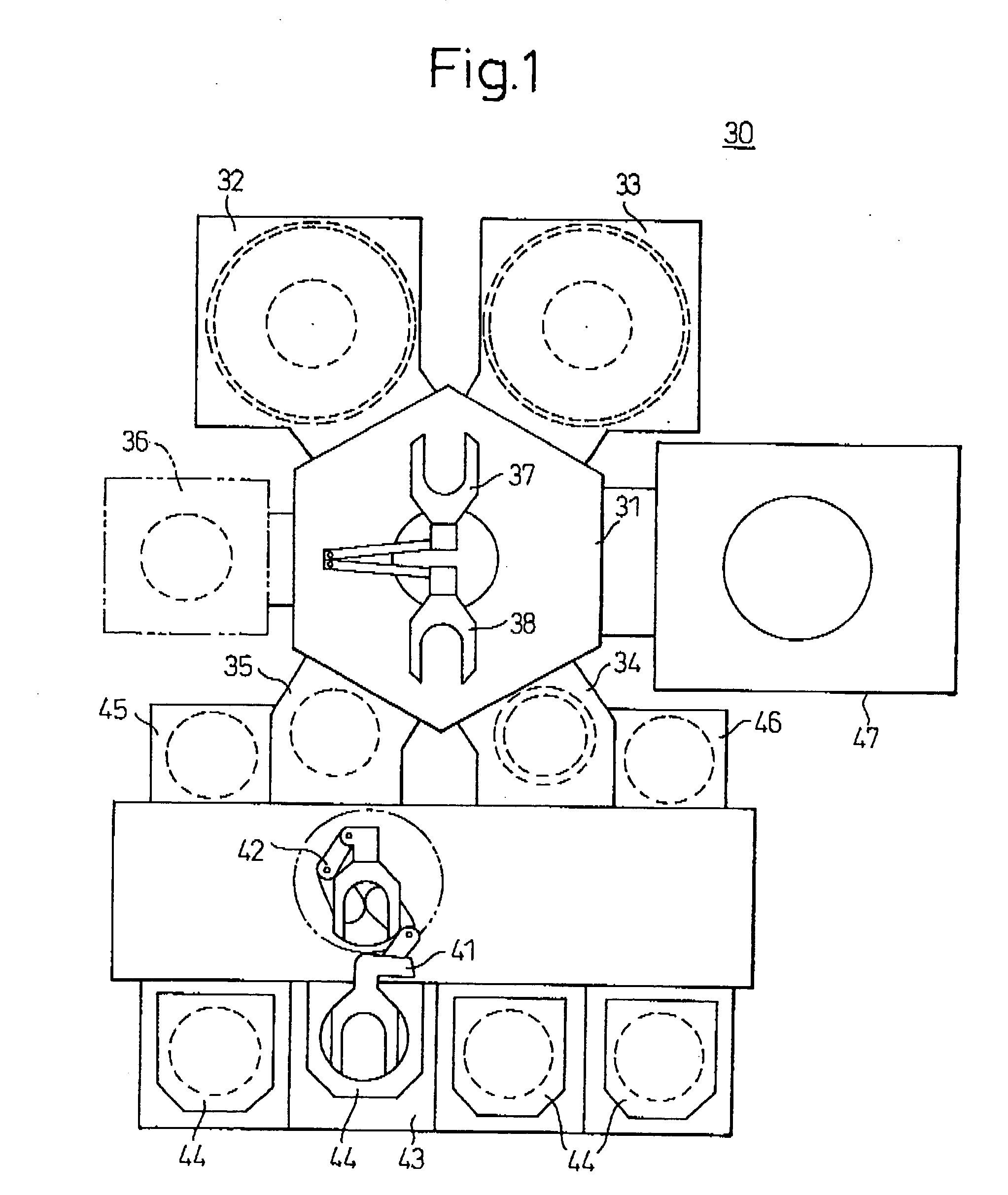

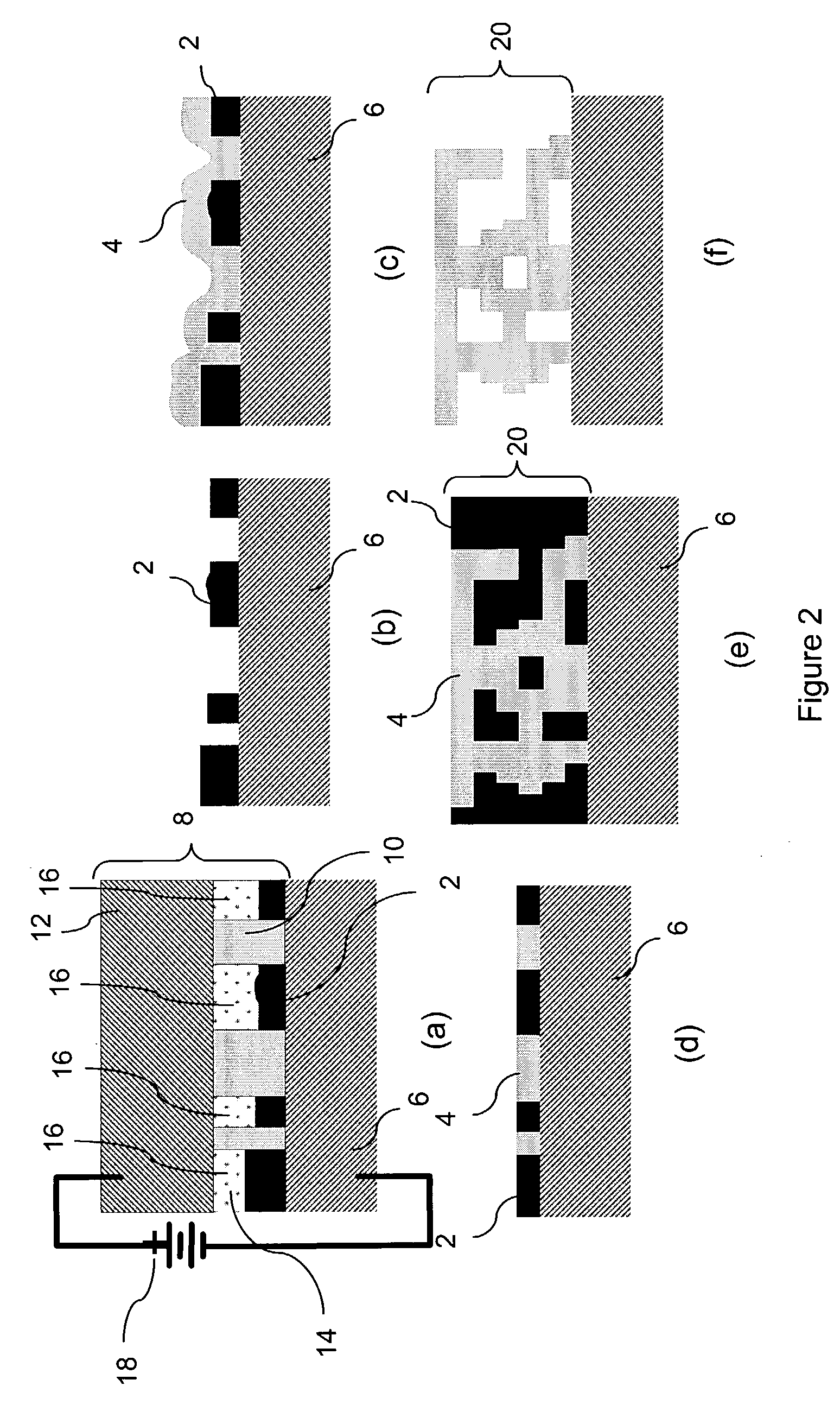

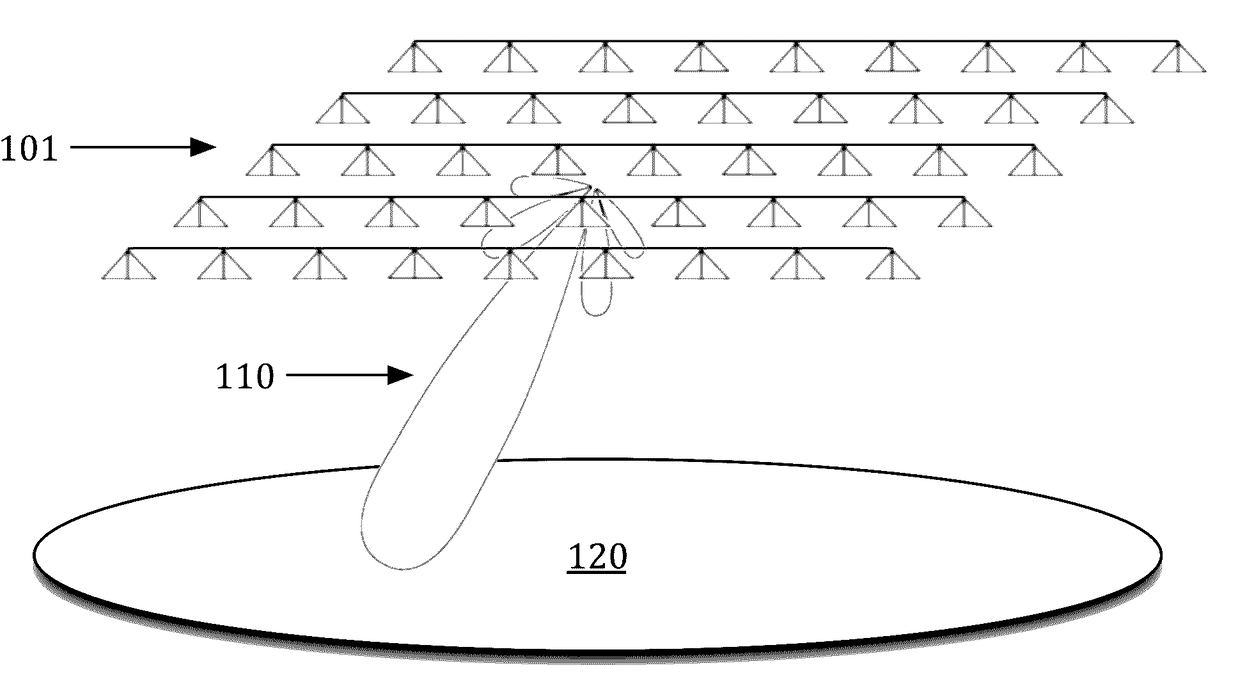

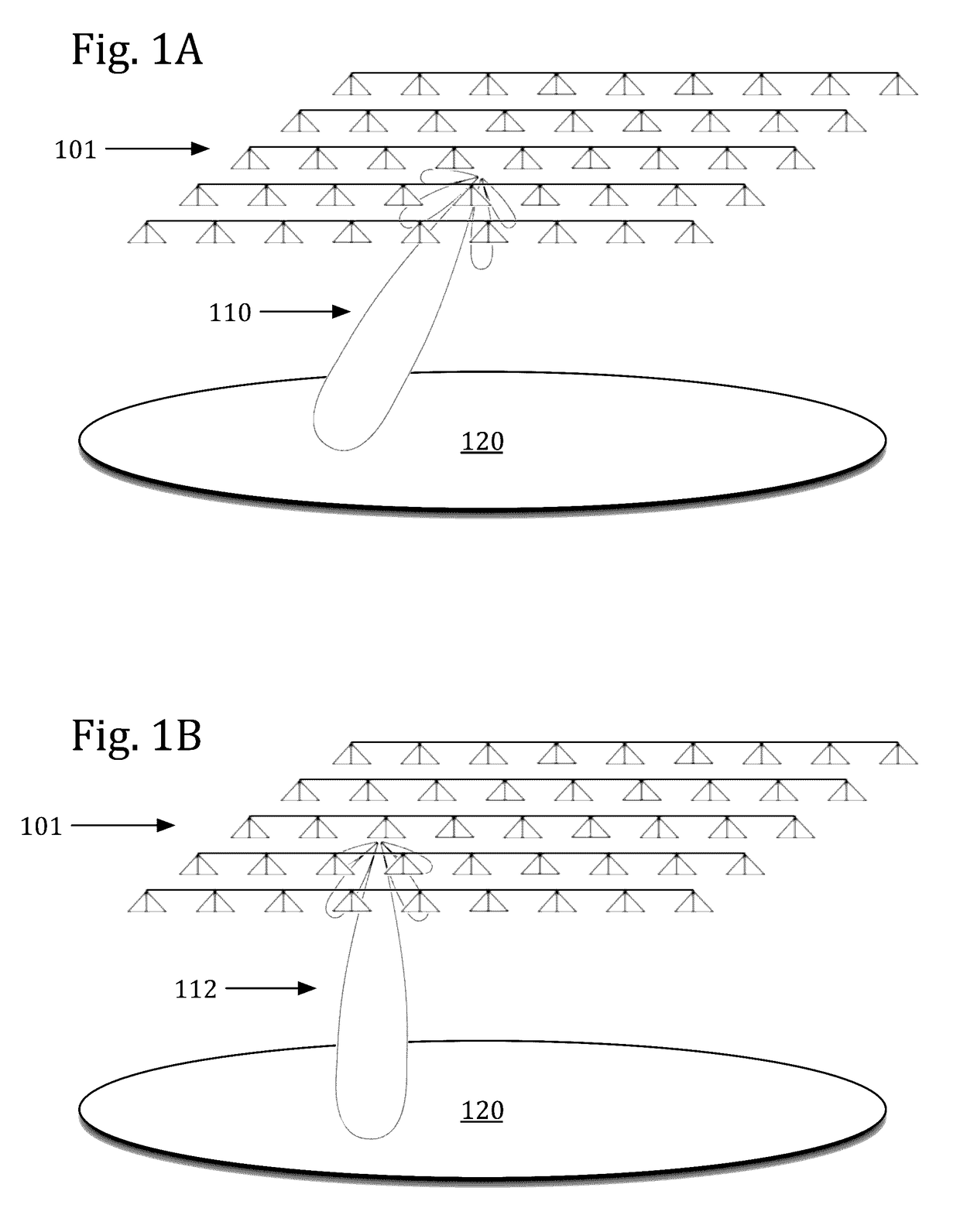

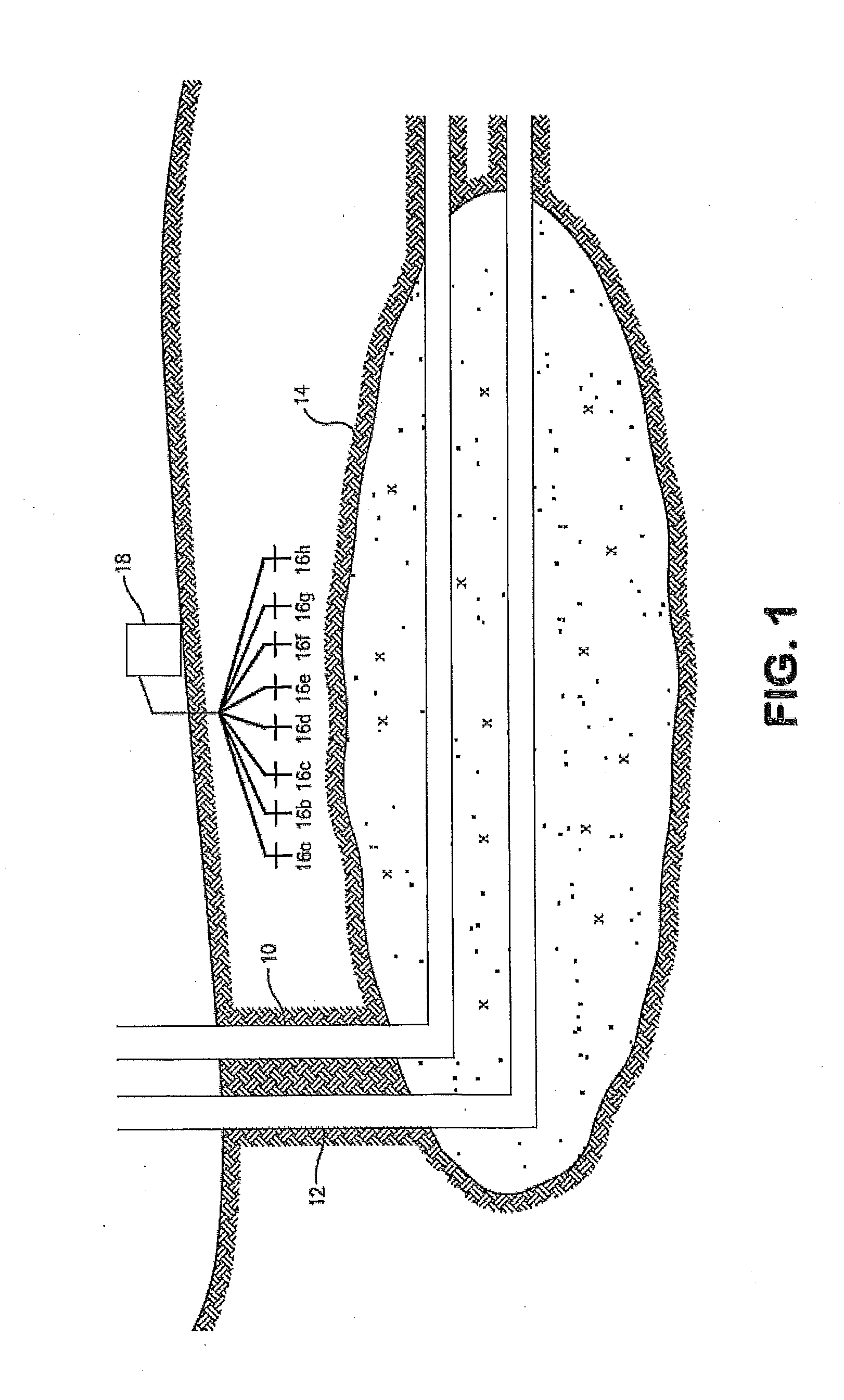

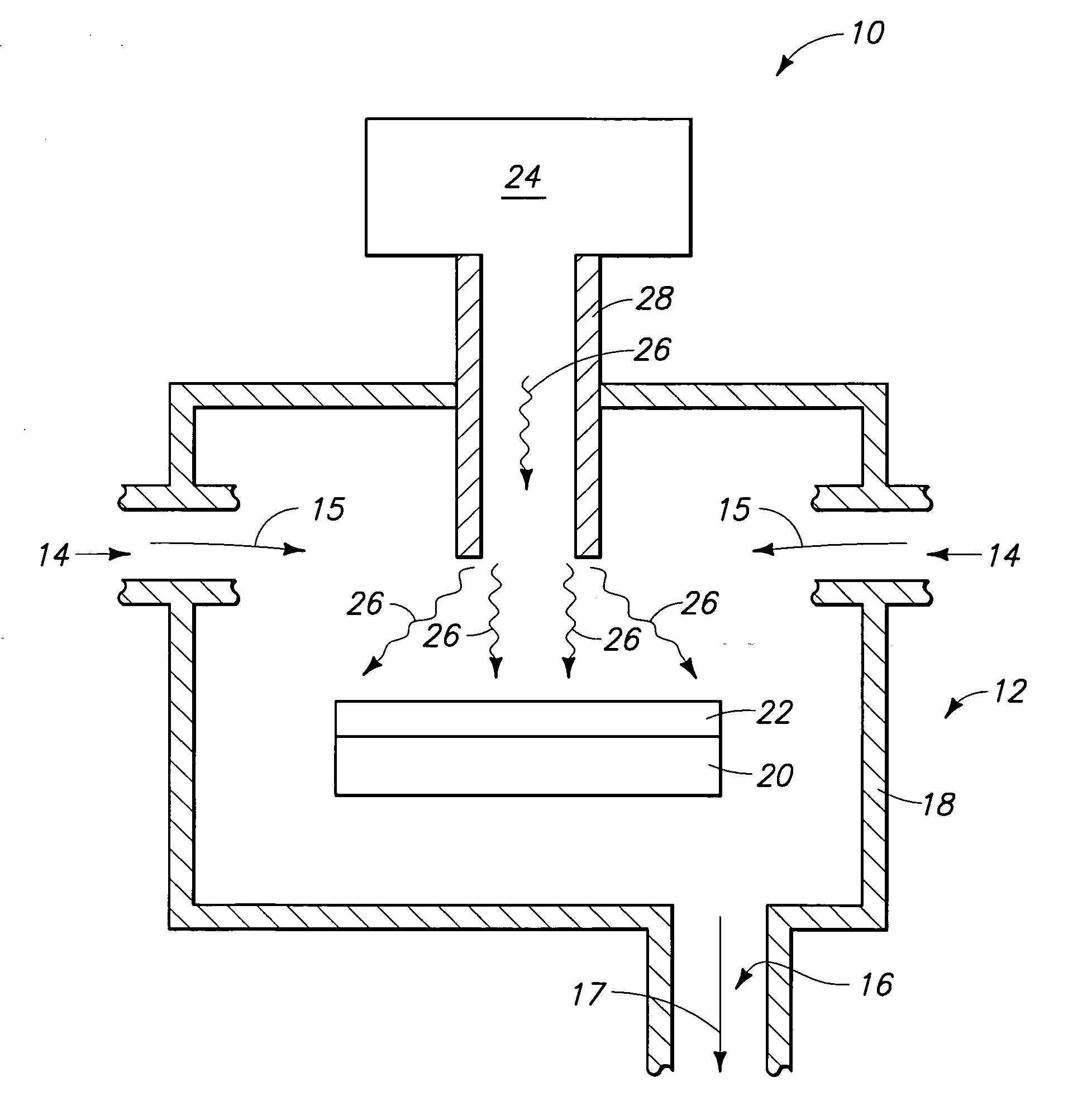

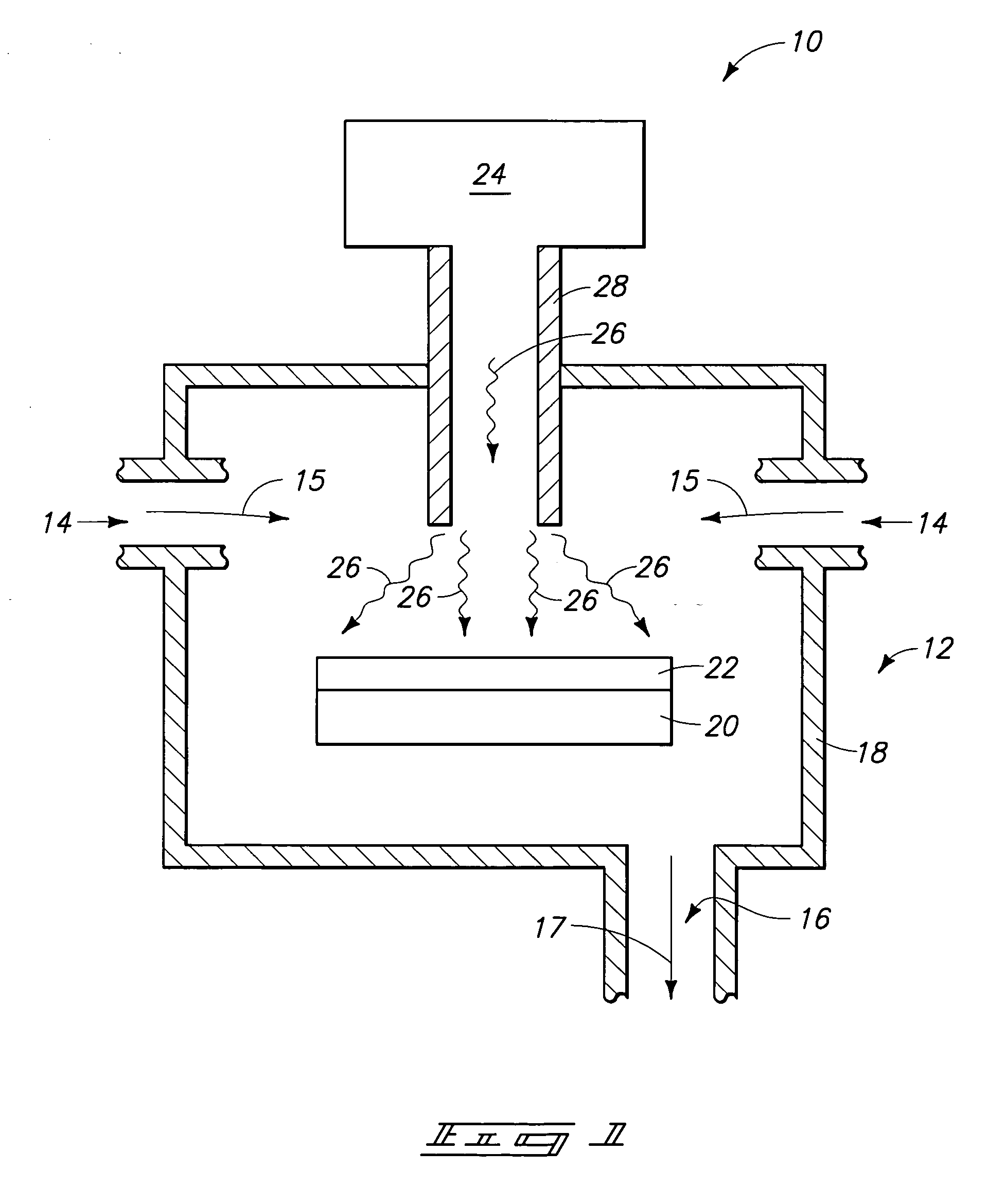

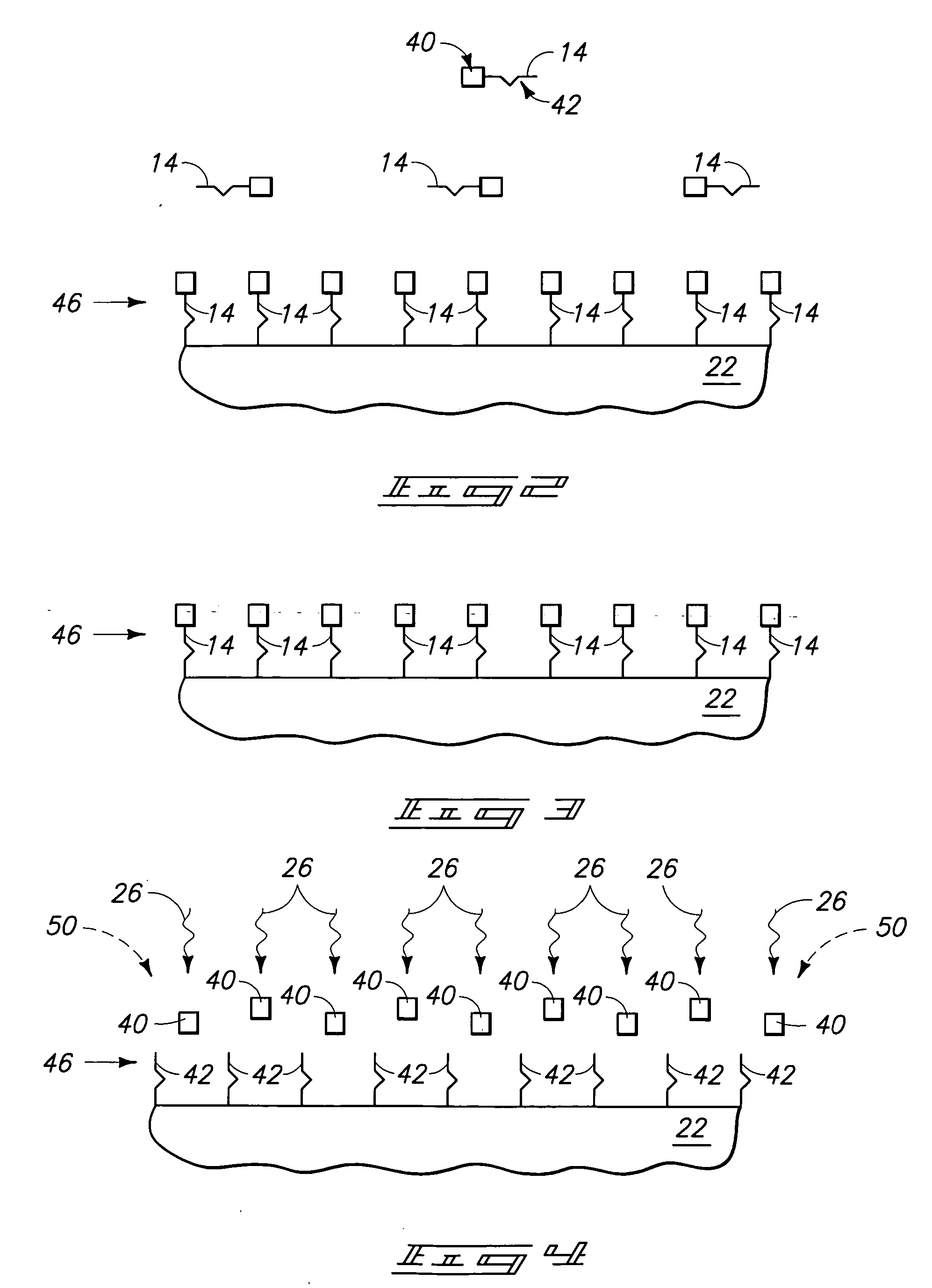

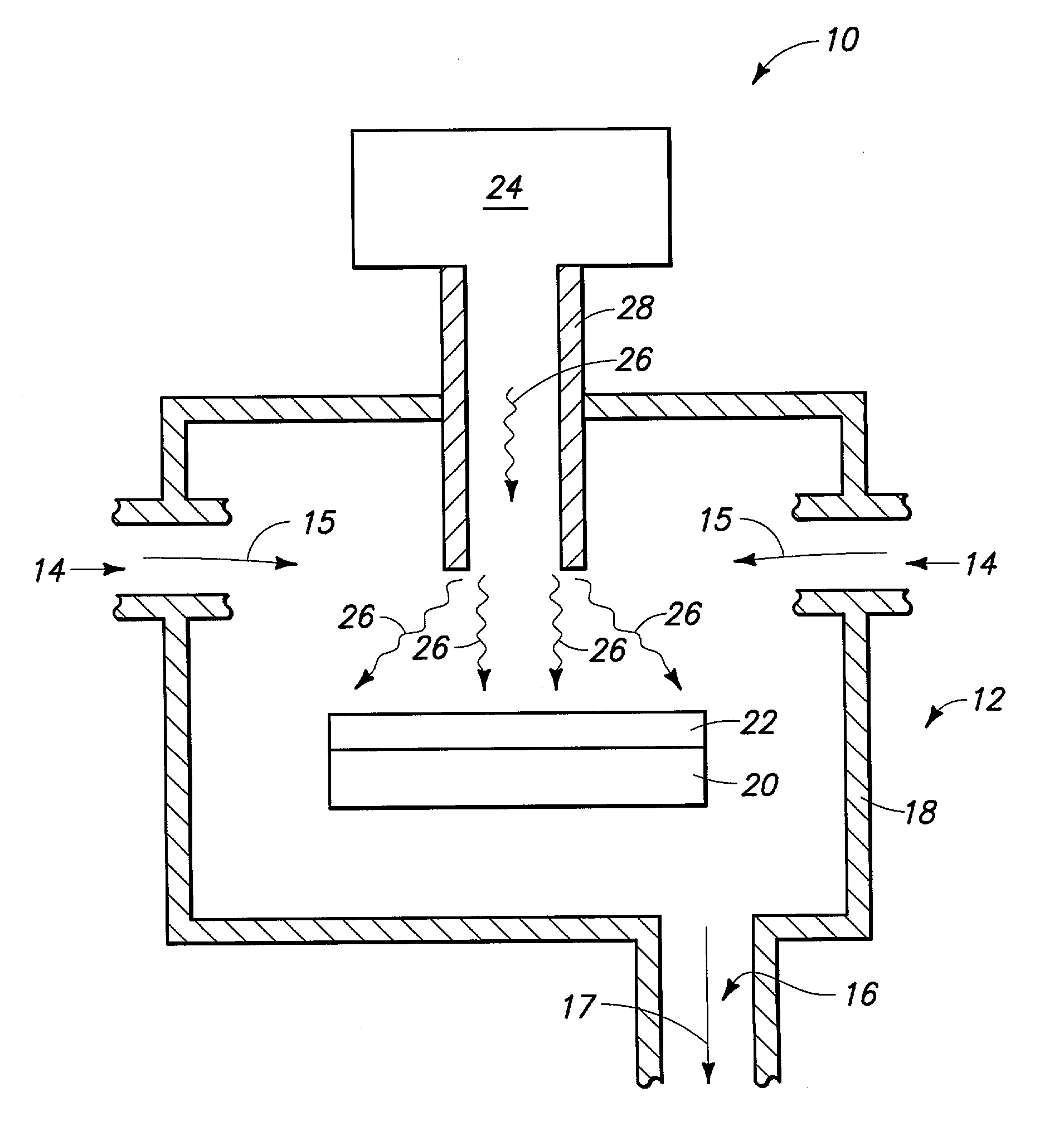

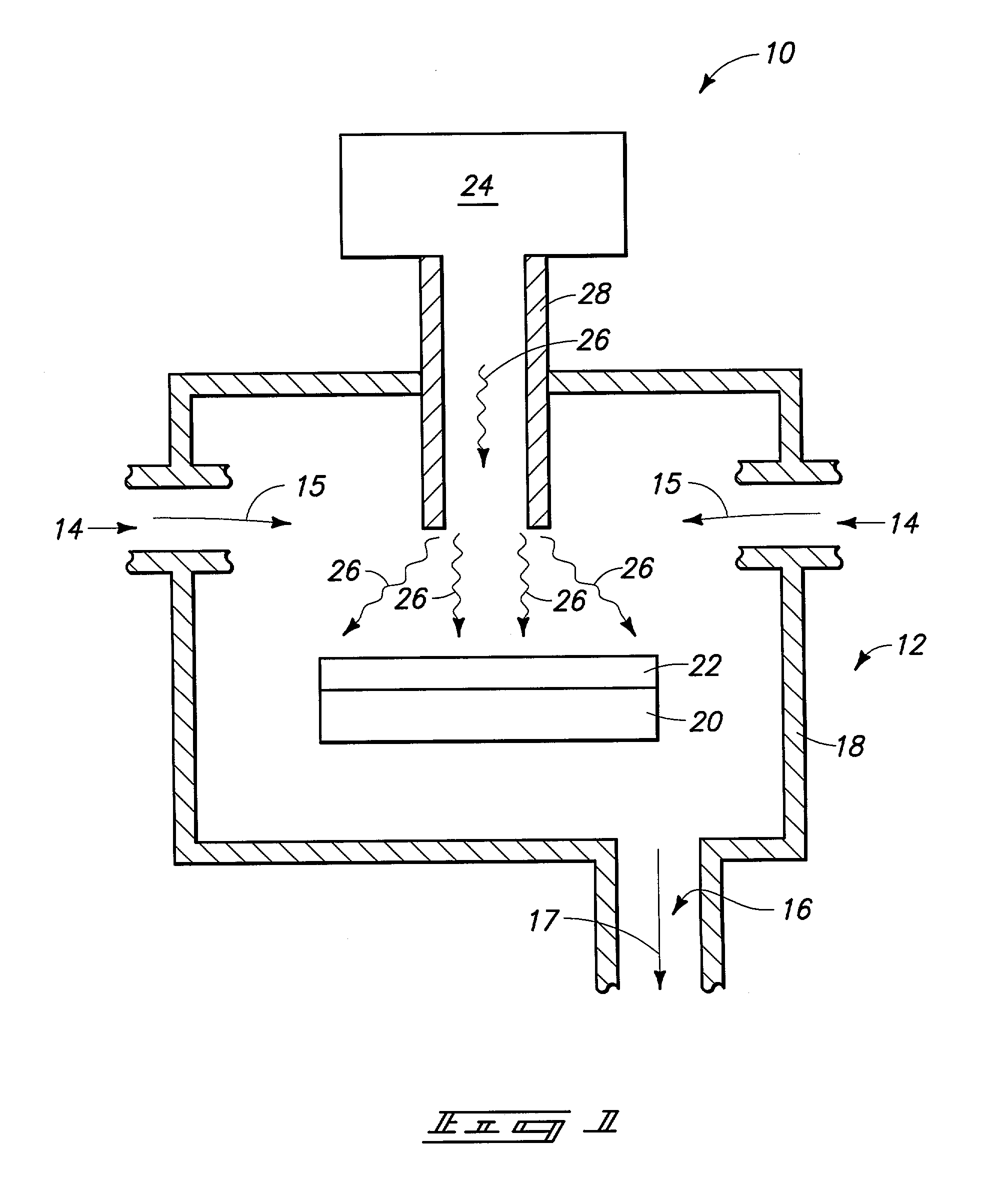

Computer addressable plasma density modification for etch and deposition processes

Disclosed herein are methods of modifying a reaction rate on a semiconductor substrate in a processing chamber which utilize a phased-array of microwave antennas. The methods may include energizing a plasma in a processing chamber, emitting a beam of microwave radiation from a phased-array of microwave antennas, and directing the beam into the plasma so as to cause a change in a reaction rate on the surface of a semiconductor substrate inside the processing chamber. Also disclosed herein are particular embodiments of phased-arrays of microwave antennas, as well as semiconductor processing apparatuses which include a phased-array of microwave antennas configured to emit a beam of microwave radiation into a processing chamber.

Owner:LAM RES CORP

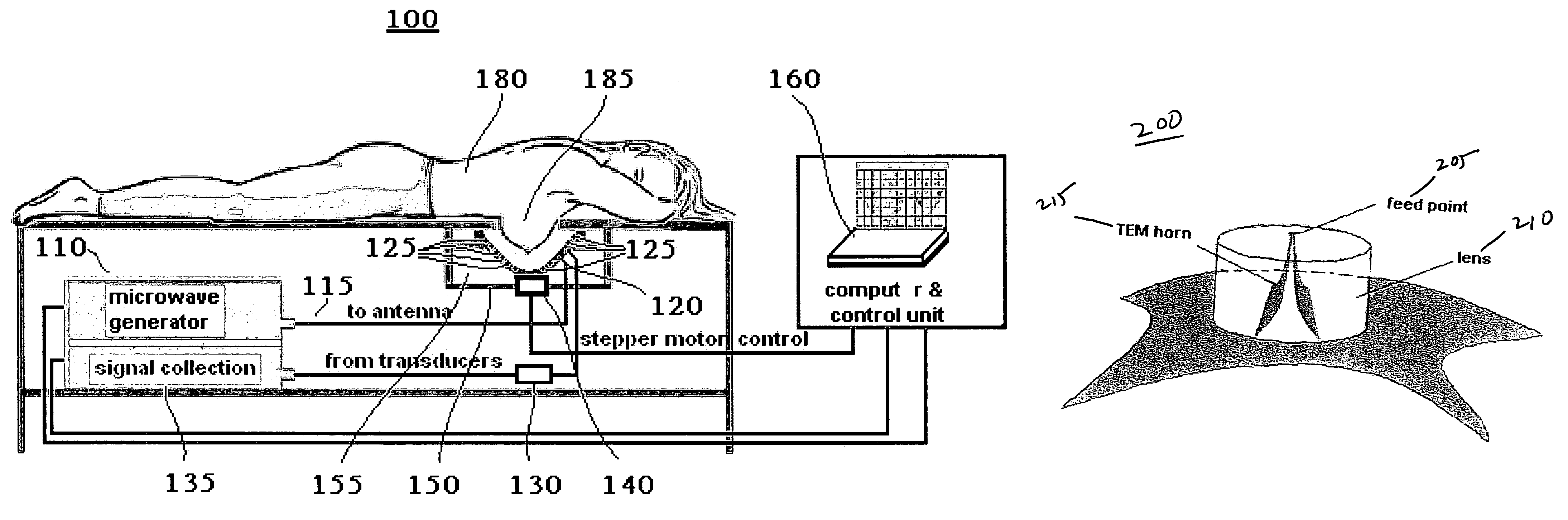

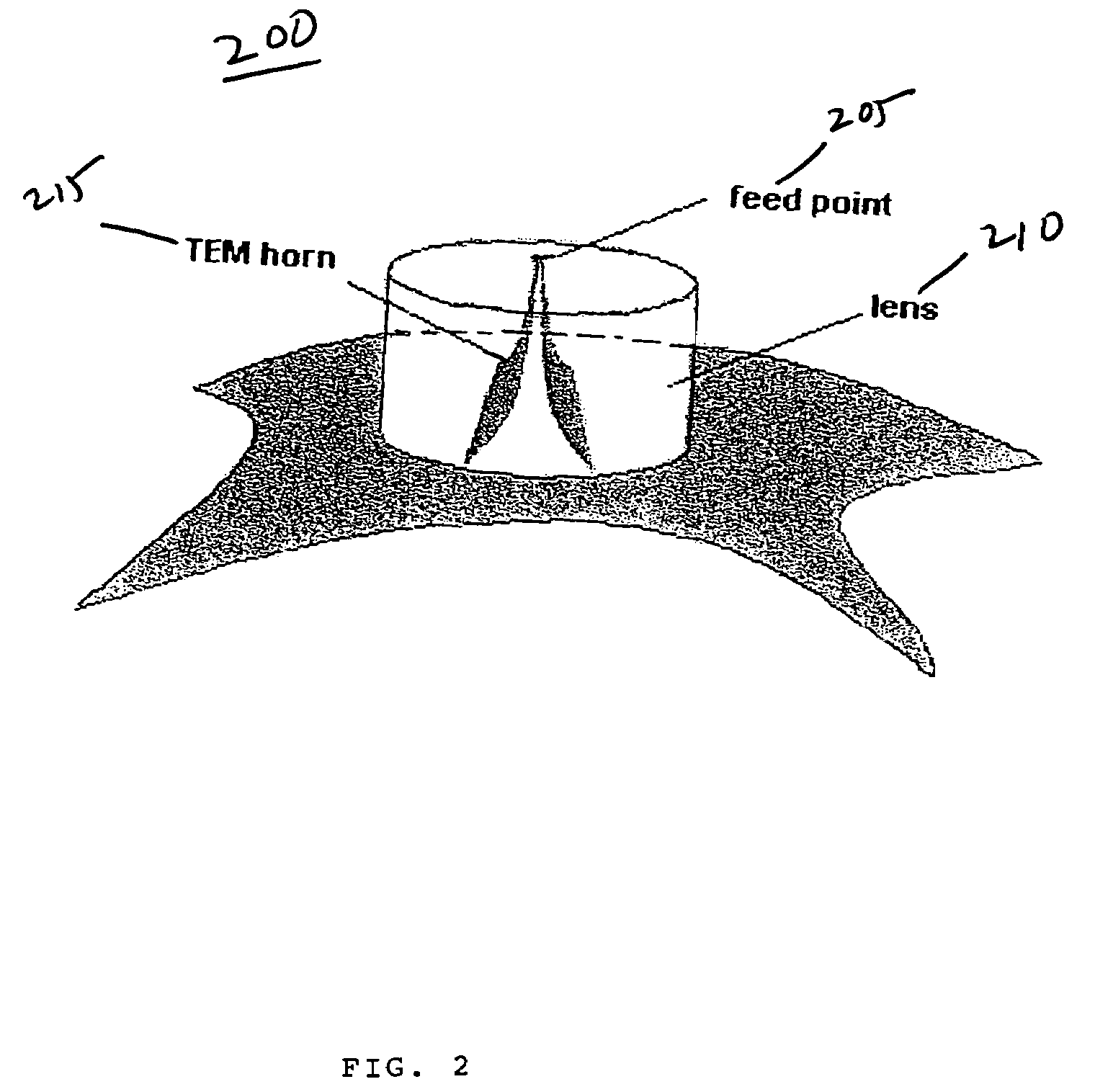

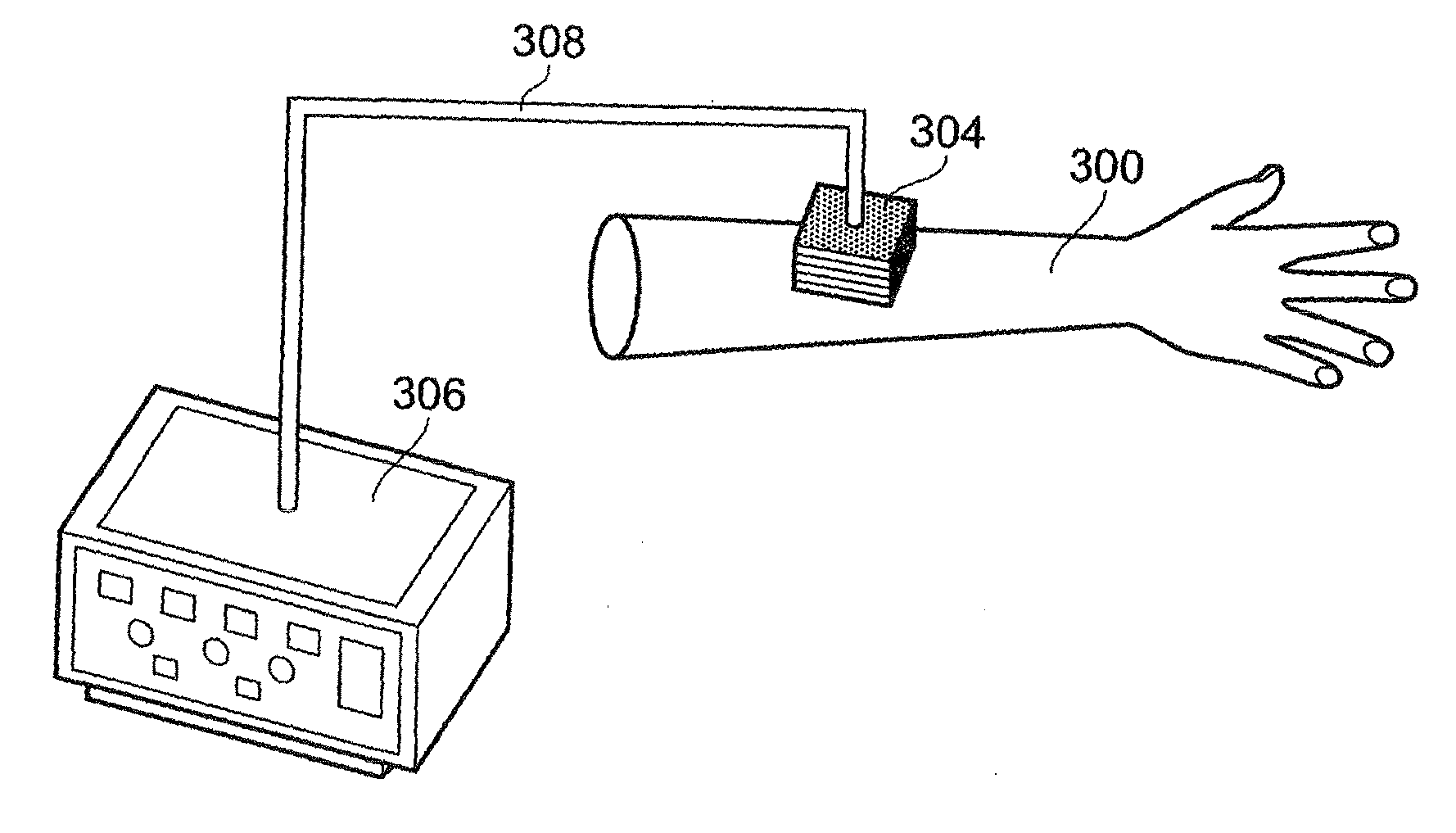

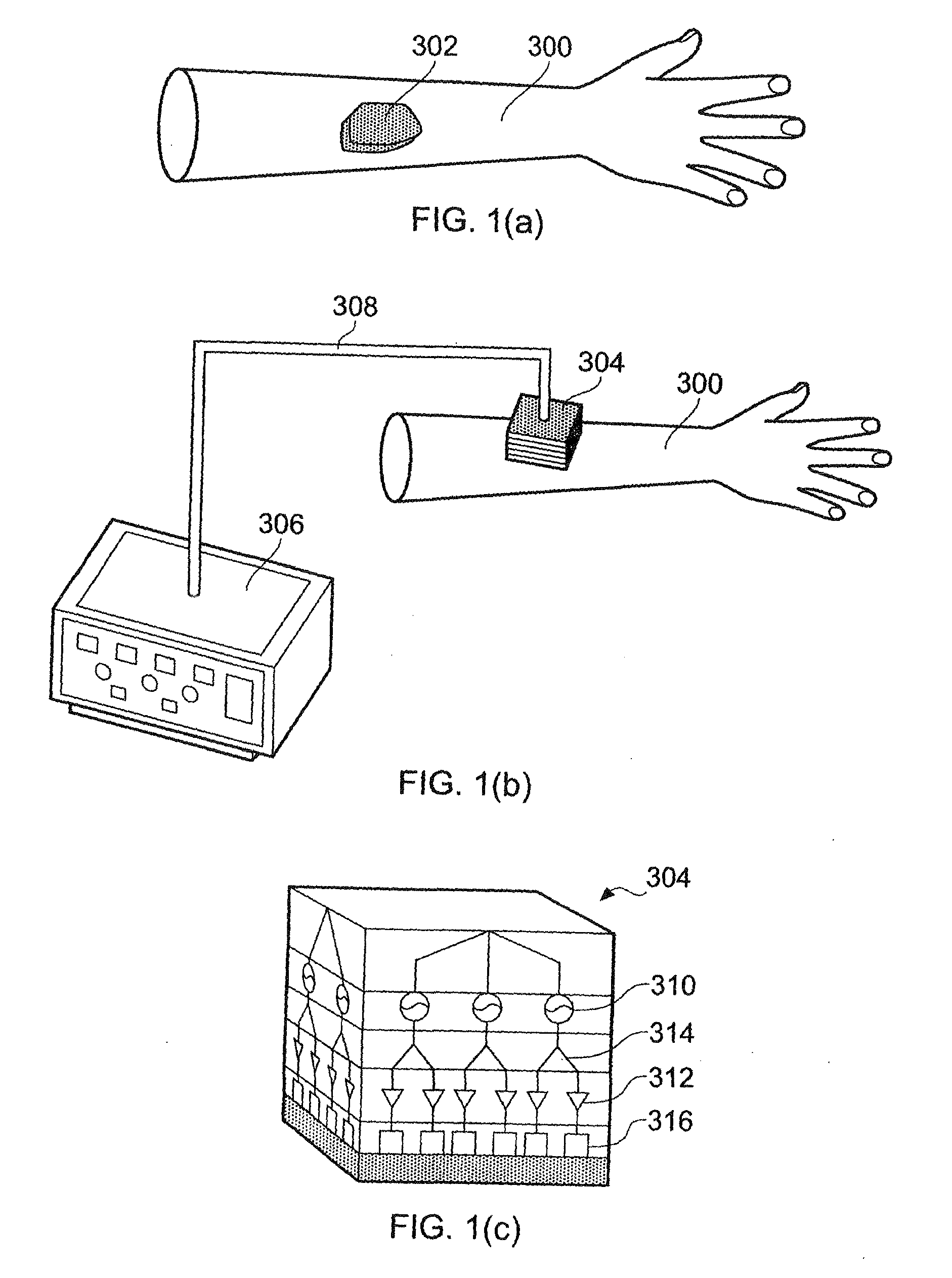

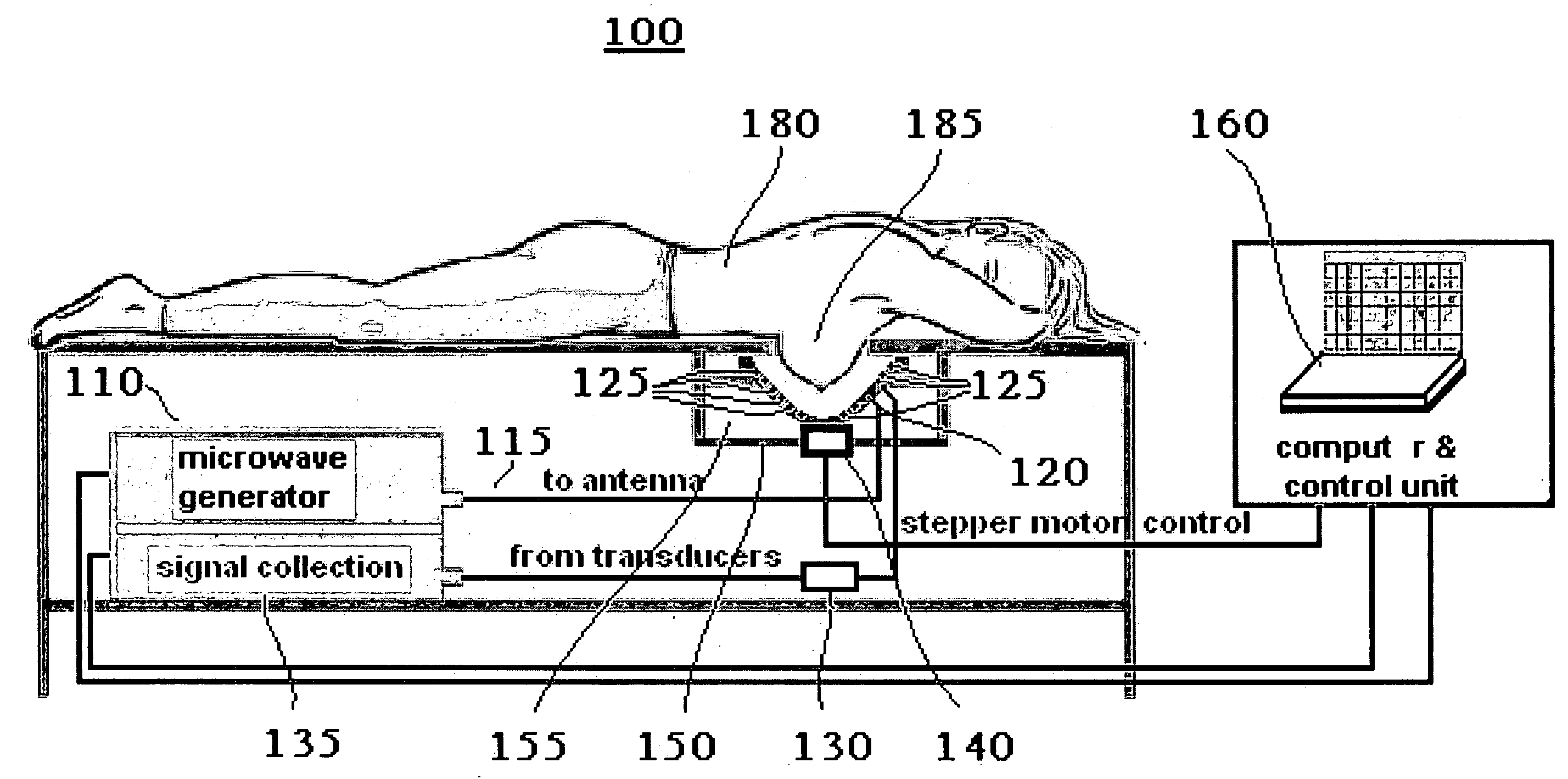

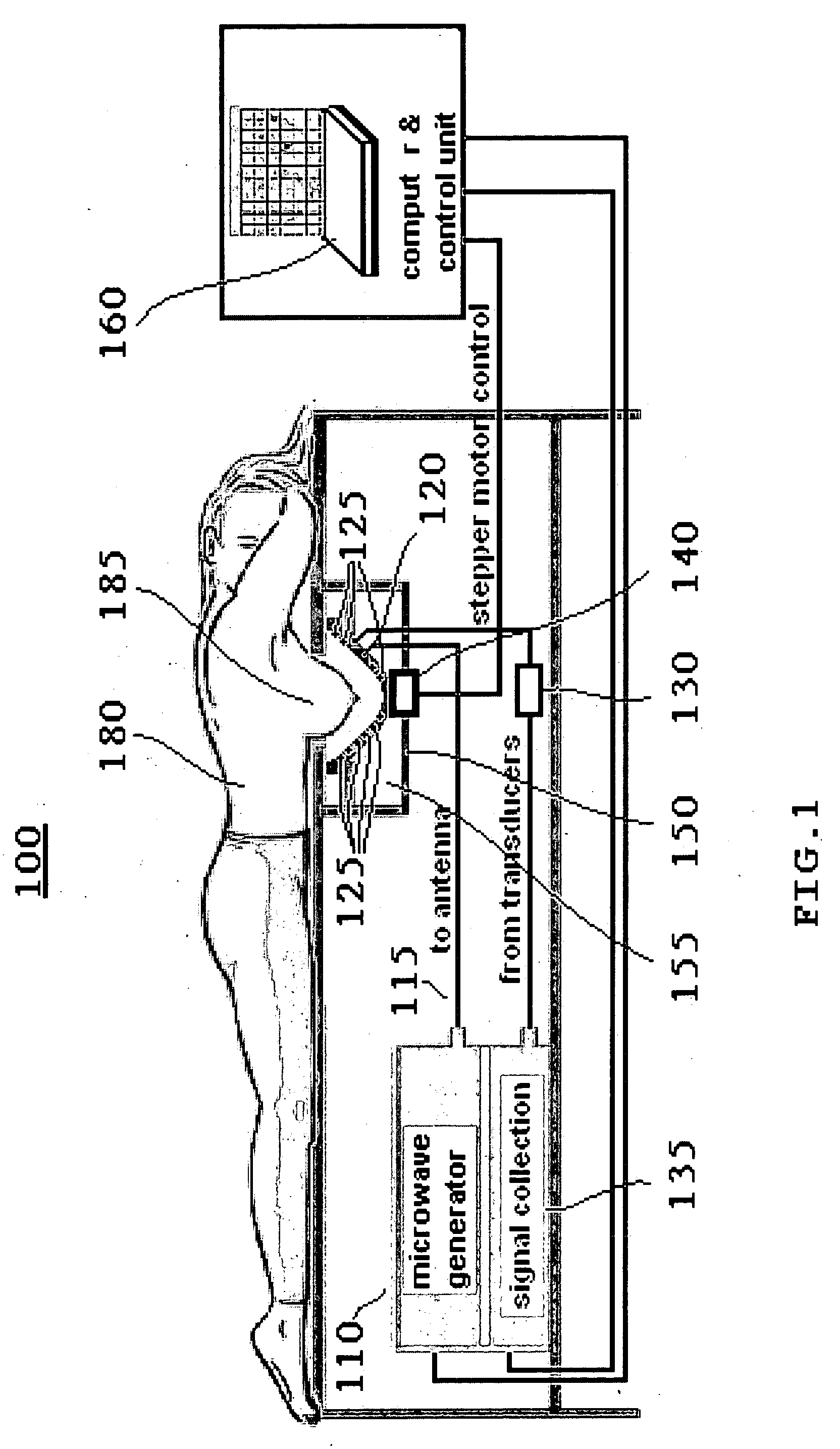

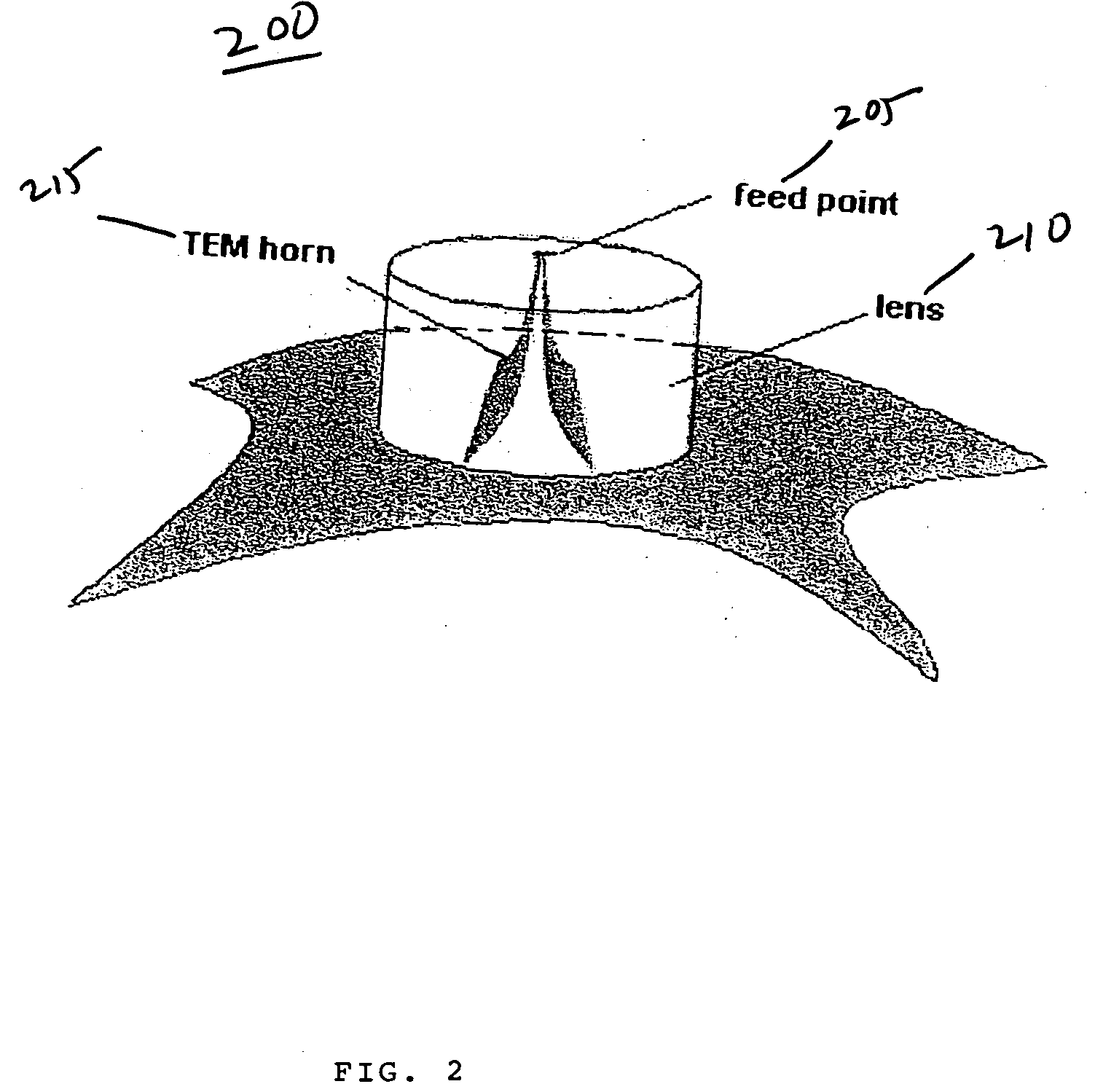

Multi-frequency microwave-induced thermoacoustic imaging of biological tissue

A method and system for examining biological tissue includes the steps of radiating a tissue region with a plurality of microwave radiation pulses. The microwave pulses are swept across a range of microwave frequencies. In response to the swept frequency microwave pulses, the tissue region emits a plurality of thermoacoustic signals. At least one image of the tissue region is formed from the plurality of thermoacoustic signals. The signals can be ultrawideband signals.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

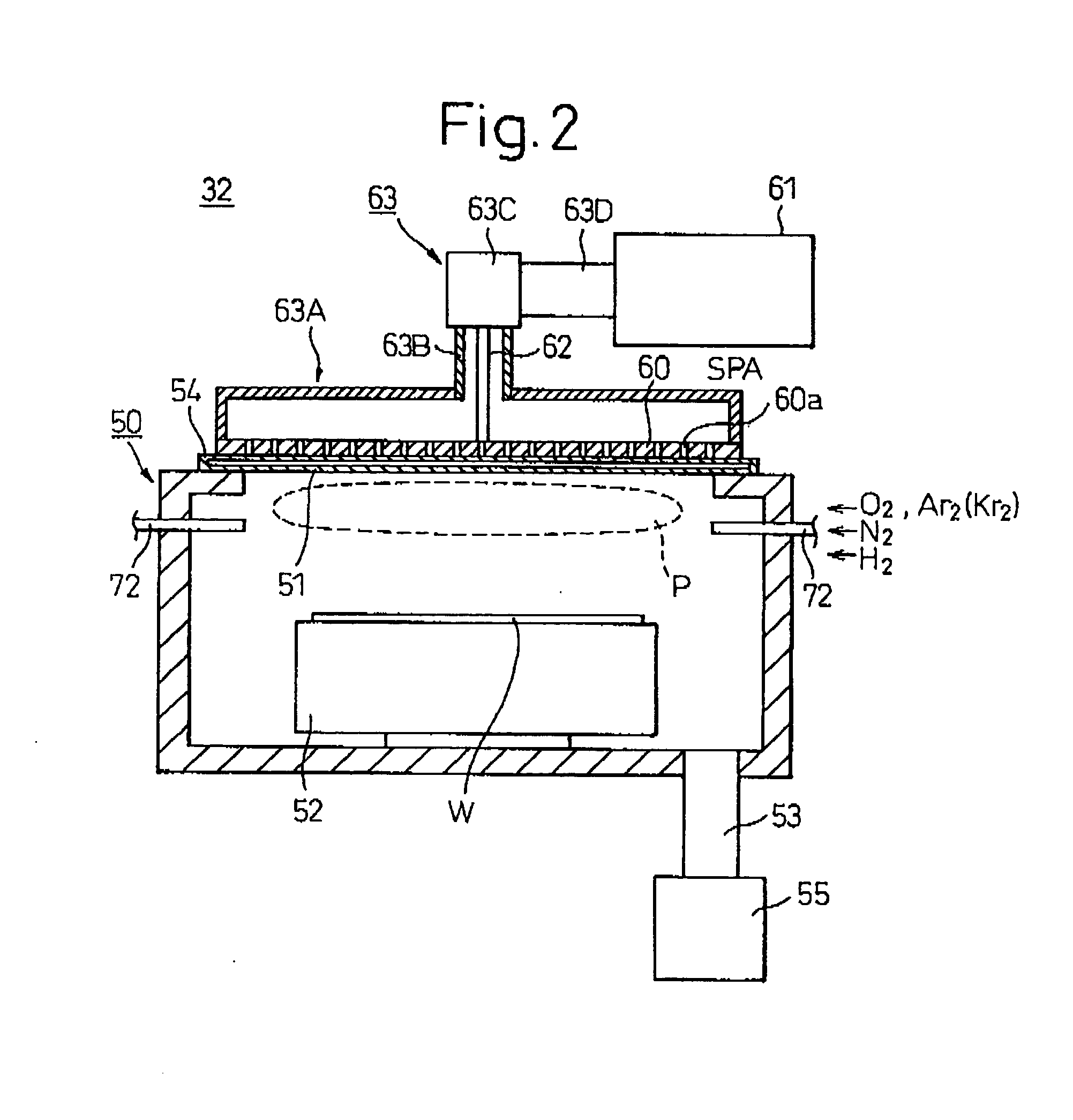

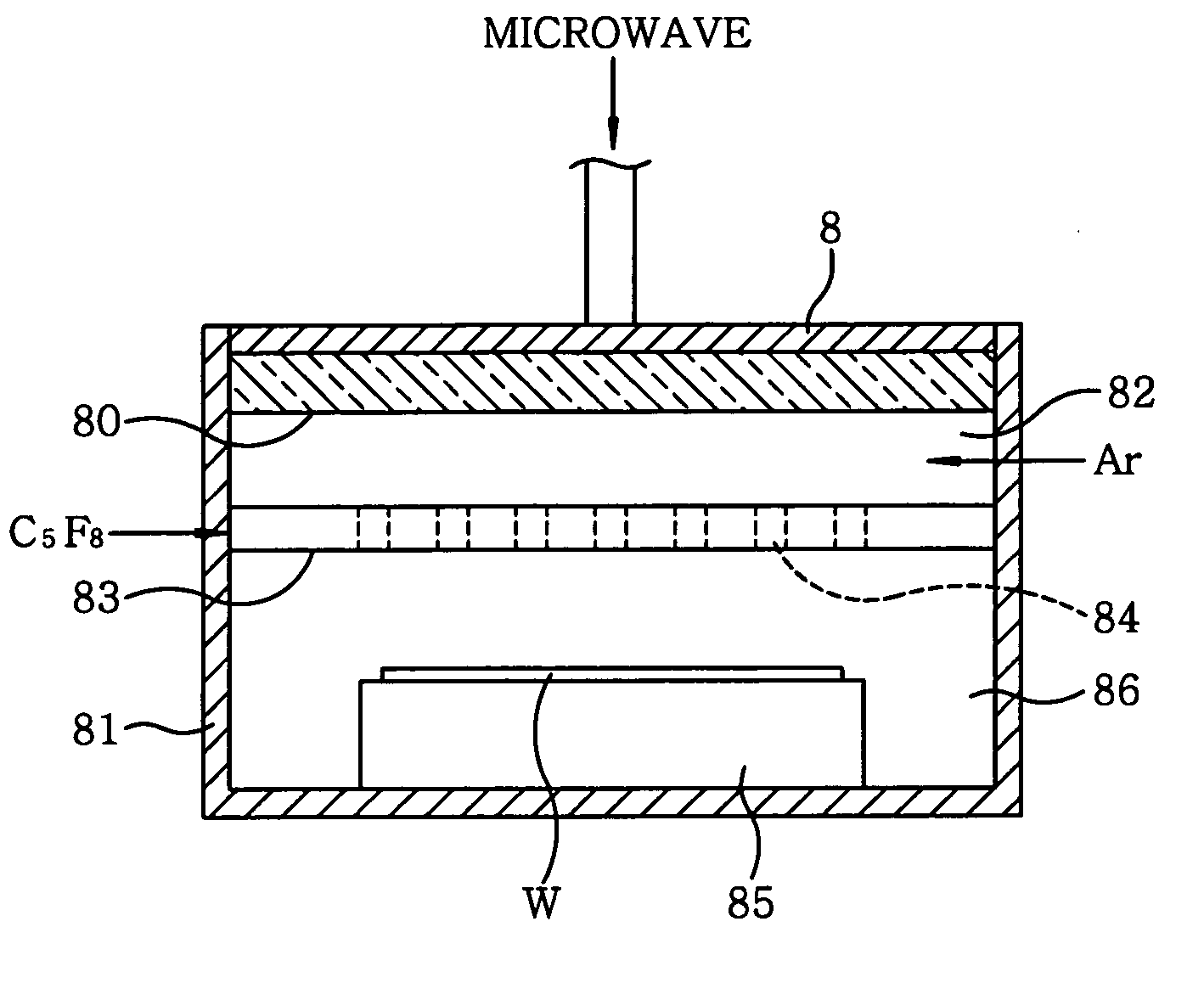

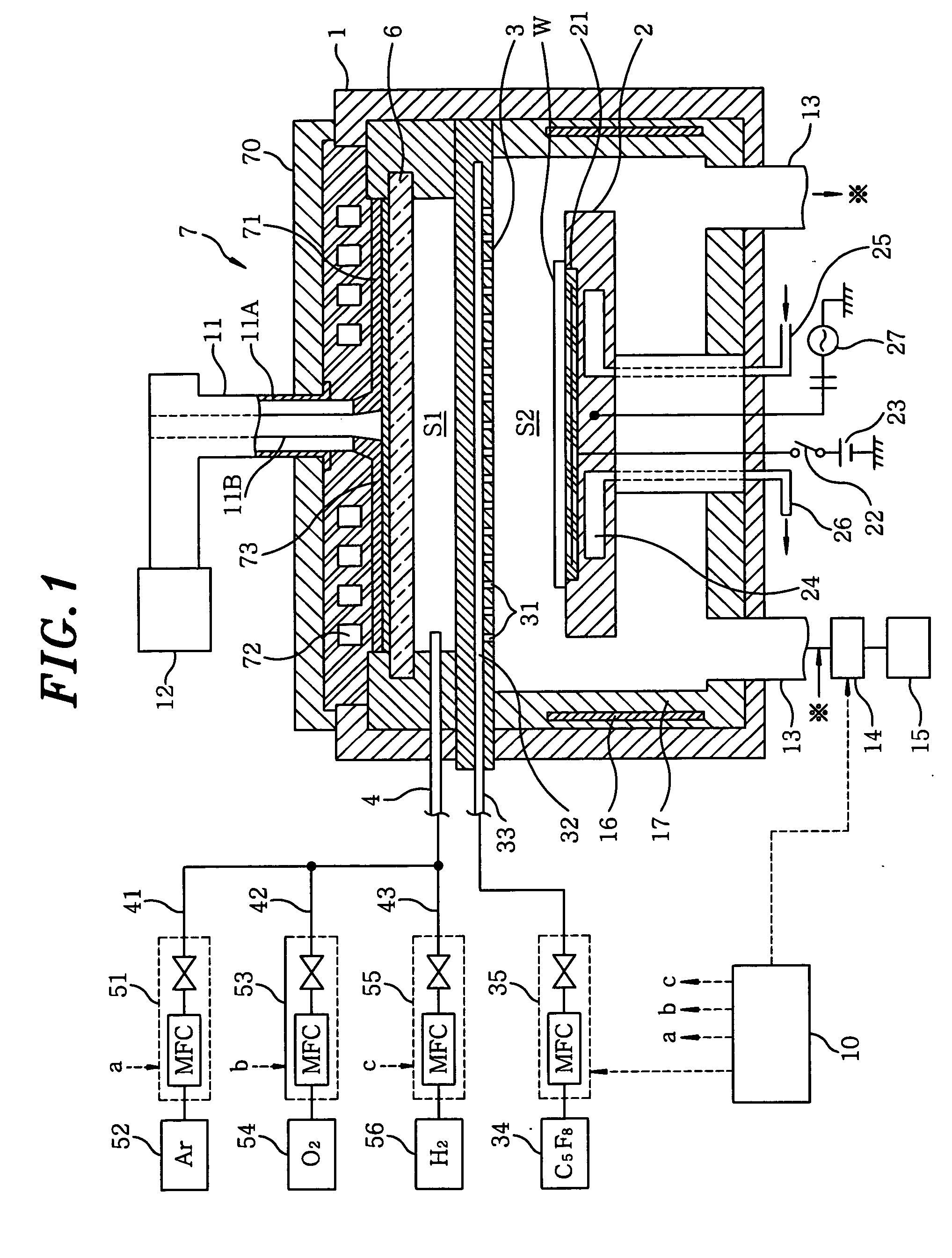

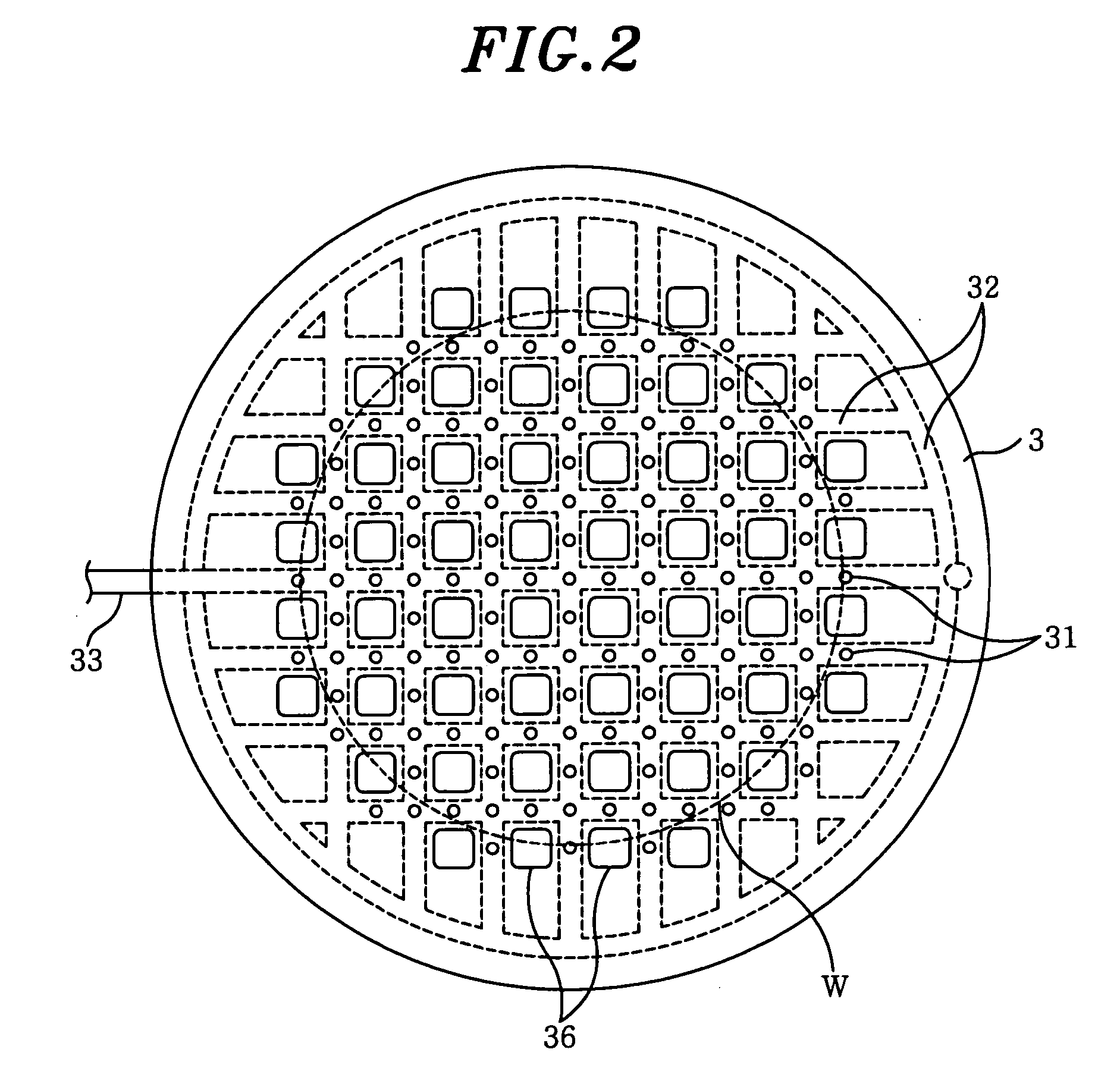

Plasma processing method and plasma processing apparatus

InactiveUS20070077737A1High densityLow electron temperatureElectric discharge tubesSemiconductor/solid-state device manufacturingCarbon filmEngineering

A microwave is radiated into a processing chamber (1) from a planar antenna member of an antenna (7) through a dielectric plate (6). With this, a C5F8 gas supplied into the processing chamber (1) from a gas supply member (3) is changed (activated) into a plasma so as to form a fluorine-containing carbon film of a certain thickness on a semiconductor wafer (W). Each time a film forming process of forming a film on one wafer is carried out, a cleaning process and a pre-coating process are carried out. In the cleaning process, the inside of the processing chamber is cleaned with a plasma of an oxygen gas and a hydrogen gas. In the pre-coating process, the C5F8 gas is changed into a plasma, and a pre-coat film of fluorine-containing carbon thinner than the fluorine-containing carbon film formed in the film forming process is formed.

Owner:TOKYO ELECTRON LTD

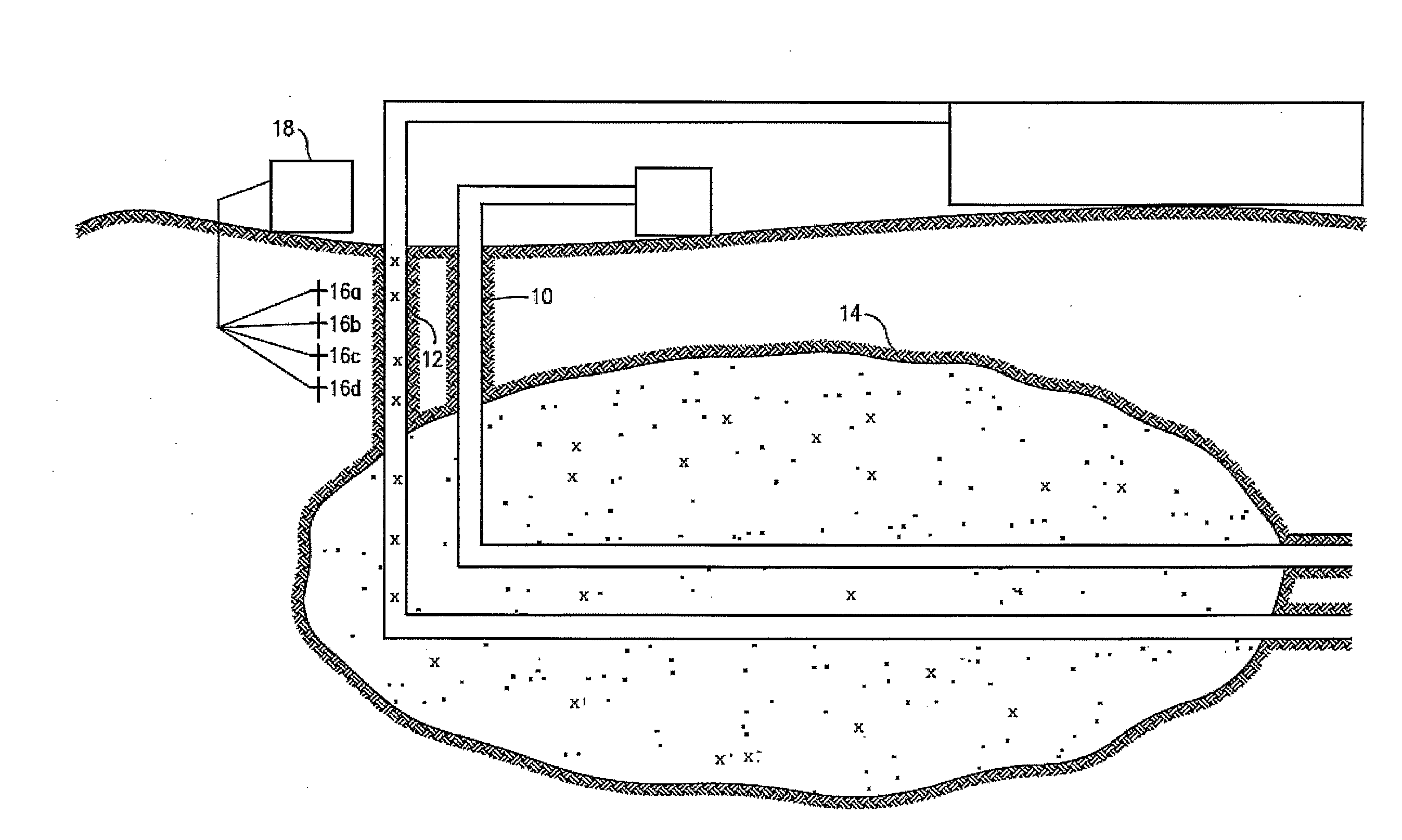

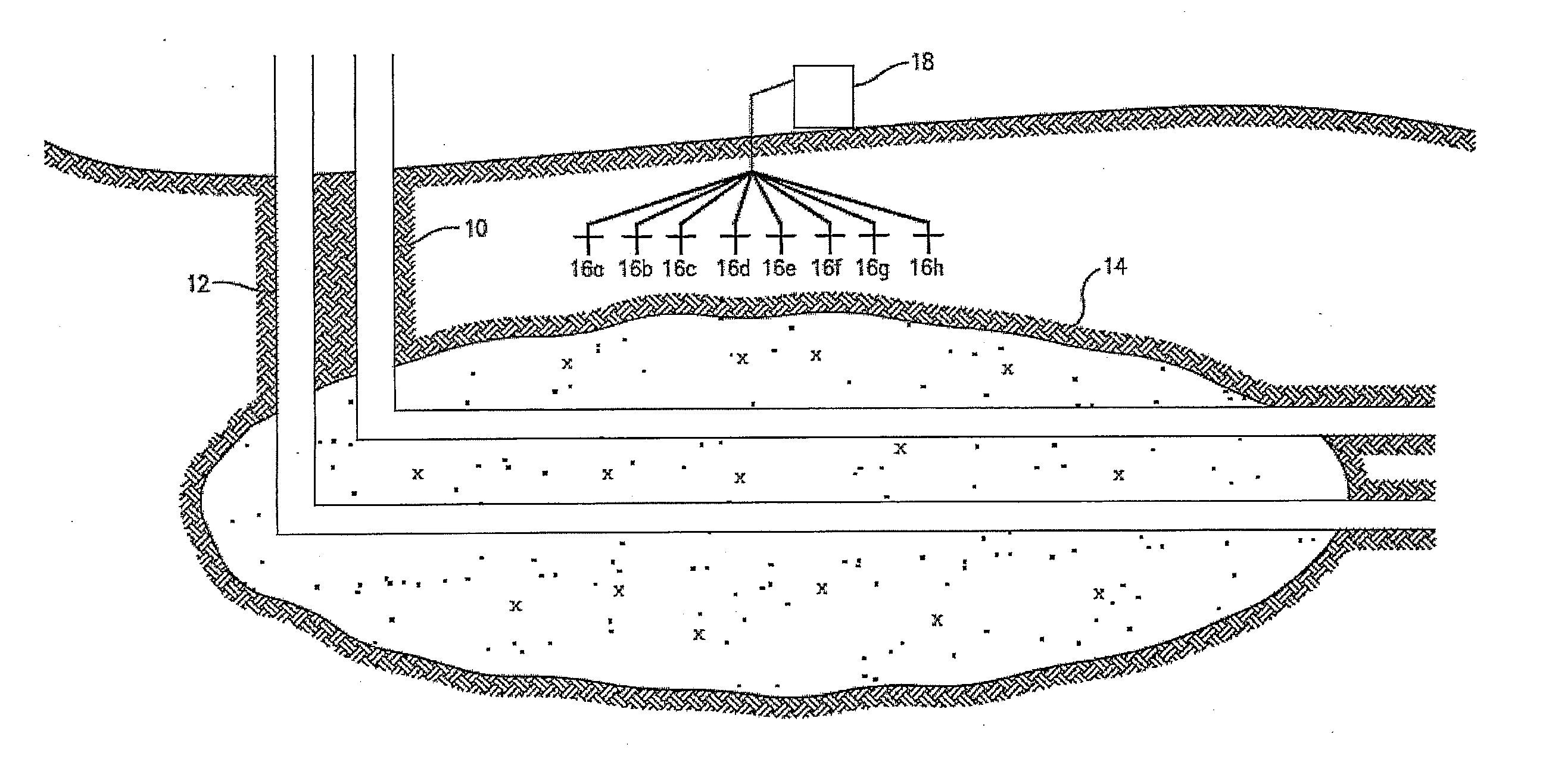

In-situ upgrading of heavy crude oil in a production well using radio frequency or microwave radiation and a catalyst

A method for heating heavy oil inside a production well. The method raises the subsurface temperature of heavy oil by utilizing an activator that has been injected below the surface. The activator is then excited with a generated microwave frequency such that the excited activator heats the heavy oil.

Owner:CONOCOPHILLIPS CO

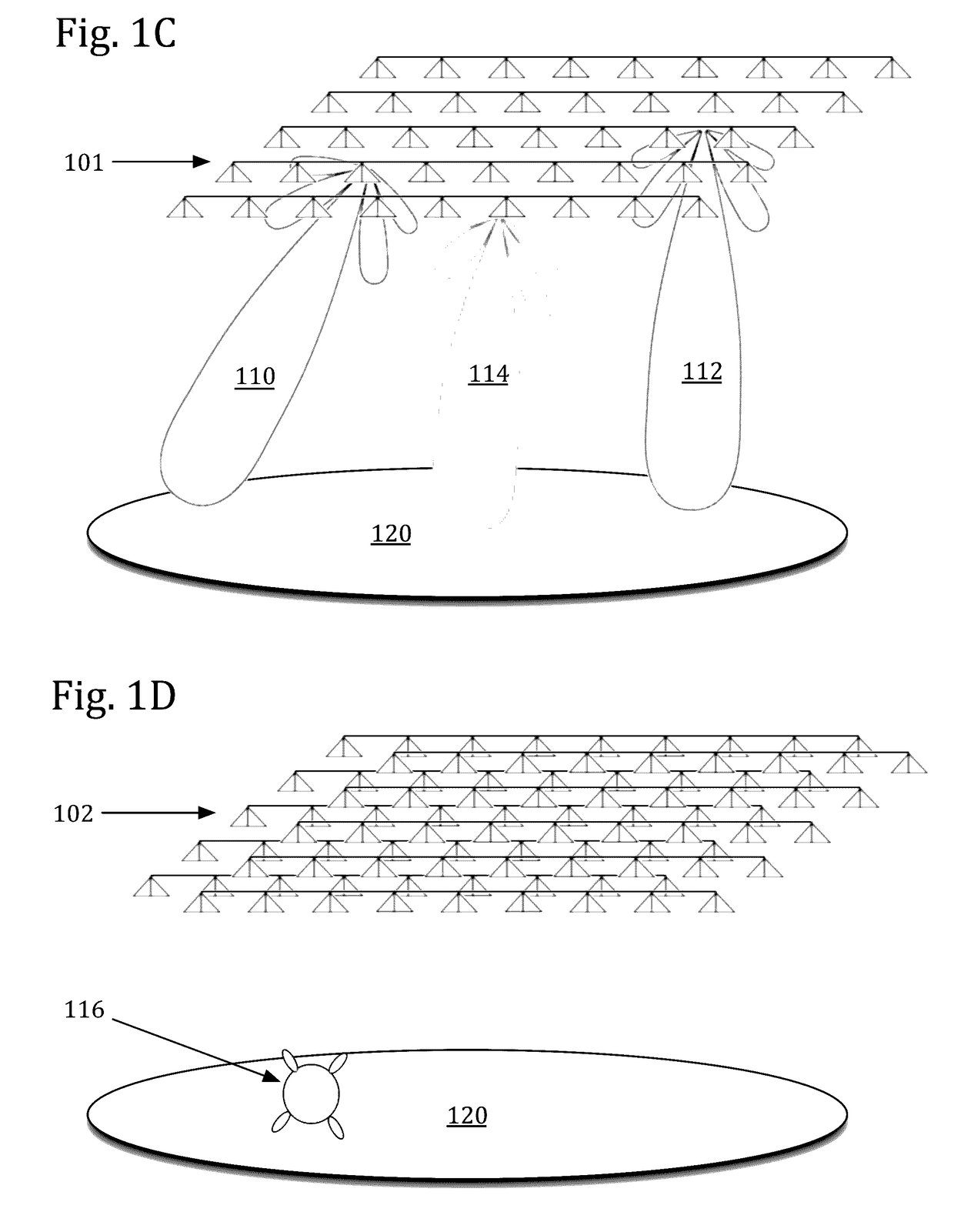

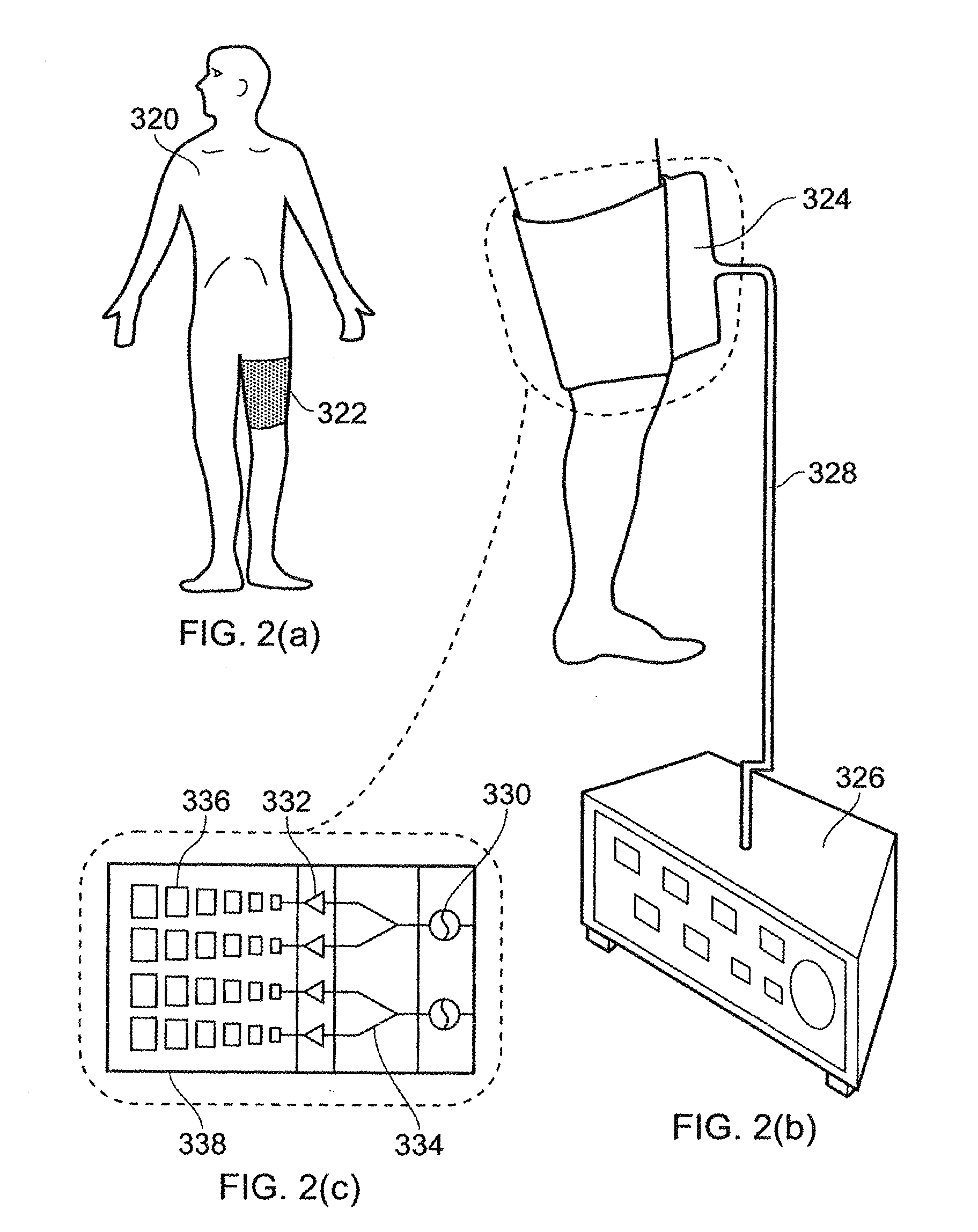

Microwave array applicator for hyperthermia

InactiveUS20100036369A1Reduce the amount requiredIncrease surface areaMicrowave therapySurgical instruments for heatingEngineeringElectromagnetic field

Apparatus (10) for treating skin tissue with microwave radiation (e.g. having a frequency of 1 GHz to 300 GHz) is disclosed in which an array of radiating elements (18), e.g. patch antennas are arranged on a flexible treating surface (16) for locating over and conforming with a region of skin tissue (24) to be treated. The radiating elements (18) receive microwave energy from a feed structure and are configured to emit outwardly a electromagnetic field which permits the region of skin to a substantially uniform penetration depth. Each radiating element (18) may have an independently controllable power supply to permit relative adjustment of the field across the treatment surface. Each radiating element may have a monitoring unit to allow adjust based on detected reflected power. Each independently controllable power supply may include a dynamic impedance matching unit.

Owner:UNIV OF WALES BANGOR

Miniature RF and microwave components and methods for fabricating such components

InactiveUS7259640B2Small sizeReduce manufacturing costAcceleration measurement using interia forcesAdditive manufacturing apparatusPhysical chemistrySelective deposition

Owner:MEMGEN CORP

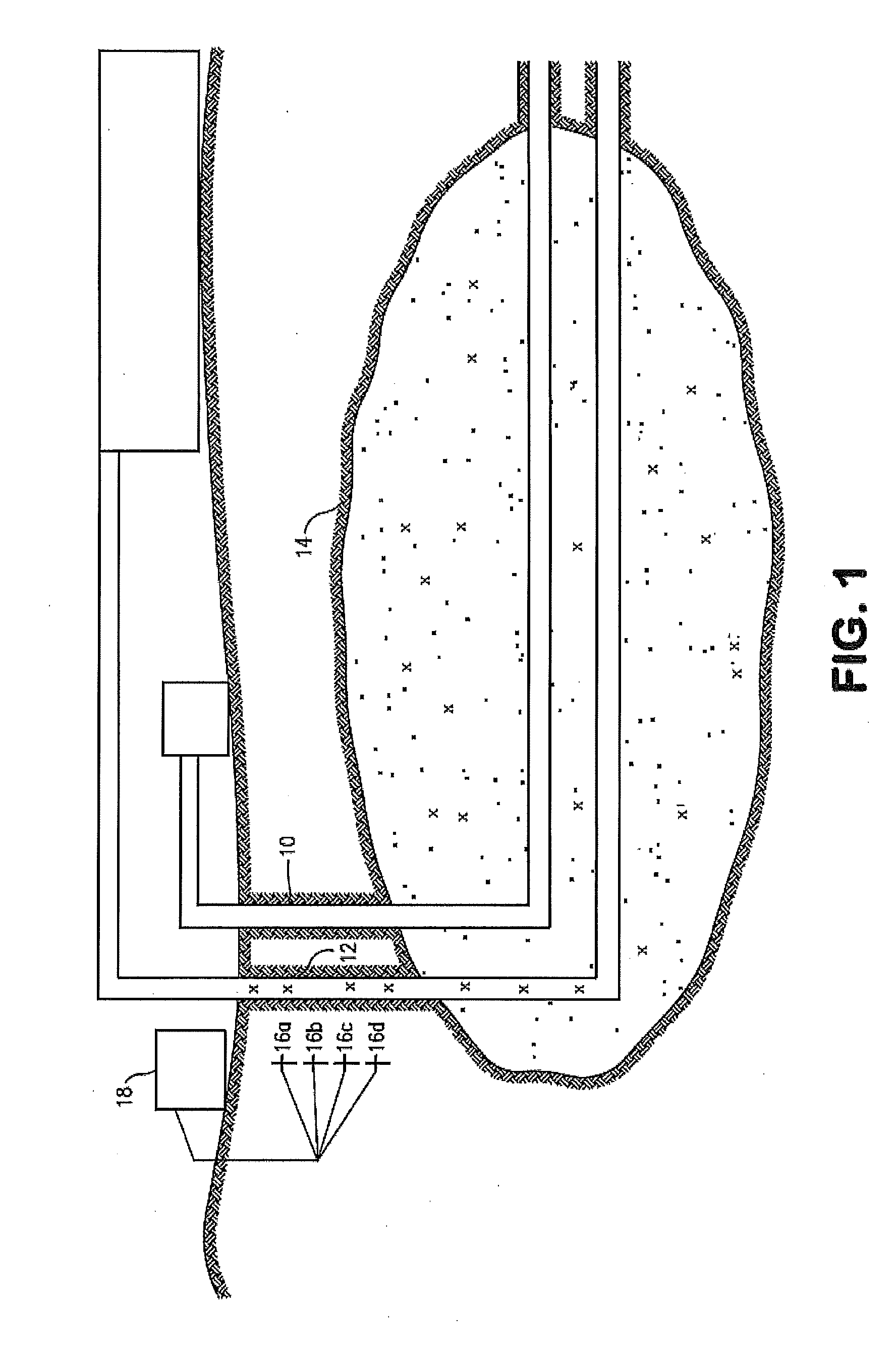

Accelerating the start-up phase for a steam assisted gravity drainage operation using radio frequency or microwave radiation

A method for preheating a formation prior to beginning steam assisted gravity drainage production. The method proceeds by forming a steam assisted gravity drainage production well pair within a formation. A preheating stage is then begun by injecting an activator into the formation. The preheating stage is then accomplished by exciting the activator with radio frequencies. This is followed by beginning the steam assisted gravity drainage operation.

Owner:CONOCOPHILLIPS CO

Method and apparatus for fabrication and sintering composite inserts

InactiveUS6011248AInhibit migrationNot adversely propertyMechanical apparatusLinings repairWear resistantWear resistance

The present disclosure is directed to the fabrication of a highly wear layer either directly upon an article or tool support structure or body, or as a wear resistant insert or element which is subsequently attached to the tool body. The wear material is formed by sintering particulate material using the absorption of microwave energy as a means of heating. The disclosure also encompasses post manufacture annealing, using heating by microwave radiation, of both highly wear resistant inserts and composite articles which consist of a wear resistant layer and a body. The wear resistant material, whether fabricated directly upon an article or fabricated separately and subsequently affixed to an article, provides an abrasive wear surface and greatly increases the life of the article. Microwave sintered wear resistant surfaces for mills, drills, grinders, brakes, bearings, saw blades and other articles and assemblies are disclosed.

Owner:PENN STATE RES FOUND +1

Microwave-based recovery of hydrocarbons and fossil fuels

InactiveUS7629497B2Organic compounds purification/separation/stabilisationHydrocarbon oil cracking processPetroleumFossil fuel

The present invention provides methods for decomposing and extracting compositions for the recovery of petroleum-based materials from composites comprising those petroleum-based materials, comprising subjecting the compositions and / or composites to microwave radiation, wherein the microwave radiation is in the range of from about 4 GHz to about 18 GHz. The present invention also provides for products produced by the methods of the present invention and for apparatuses used to perform the methods of the present invention.

Owner:UNIVERSAL ALTERNATIVE FUELS INC +1

Atomic layer deposition methods and chemical vapor deposition methods

InactiveUS20060231017A1Polycrystalline material growthFrom chemically reactive gasesGas phaseChemisorption

The invention includes atomic layer deposition methods and chemical vapor deposition methods. In a particular aspect of the invention, a source of microwave radiation is provided proximate a reaction chamber. At least a fragment of a precursor material is chemisorbed on a substrate within the reaction chamber while not exposing the precursor material to microwave radiation from the source. Excess precursor material is removed from the chamber, and the chemisorbed material is subsequently exposed to microwave radiation from the source within the reaction chamber.

Owner:MICRON TECH INC

Multi-frequency microwave-induced thermoacoustic imaging of biological tissue

InactiveUS20050107692A1Improving Impedance MatchingDiagnostic recording/measuringSensorsThermoacousticsRadiation pulse

A method and system for examining biological tissue includes the steps of radiating a tissue region with a plurality of microwave radiation pulses. The microwave pulses are swept across a range of microwave frequencies. In response to the swept frequency microwave pulses, the tissue region emits a plurality of thermoacoustic signals. At least one image of the tissue region is formed from the plurality of thermoacoustic signals. The signals can be ultrawideband signals.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Atomic layer deposition methods and chemical vapor deposition methods

InactiveUS7374617B2Polycrystalline material growthFrom chemically reactive gasesGas phaseChemical vapor deposition

The invention includes atomic layer deposition methods and chemical vapor deposition methods. In a particular aspect of the invention, a source of microwave radiation is provided proximate a reaction chamber. At least a fragment of a precursor material is chemisorbed on a substrate within the reaction chamber while not exposing the precursor material to microwave radiation from the source. Excess precursor material is removed from the chamber, and the chemisorbed material is subsequently exposed to microwave radiation from the source within the reaction chamber.

Owner:MICRON TECH INC

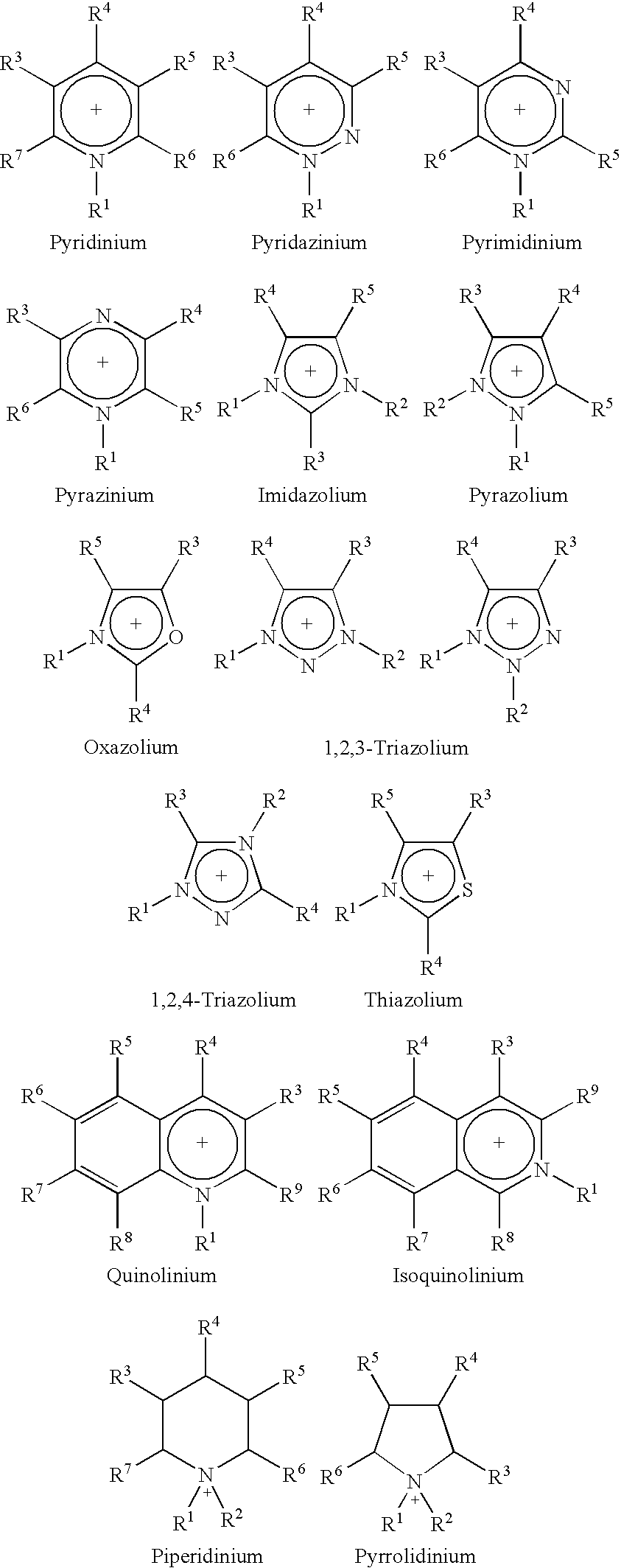

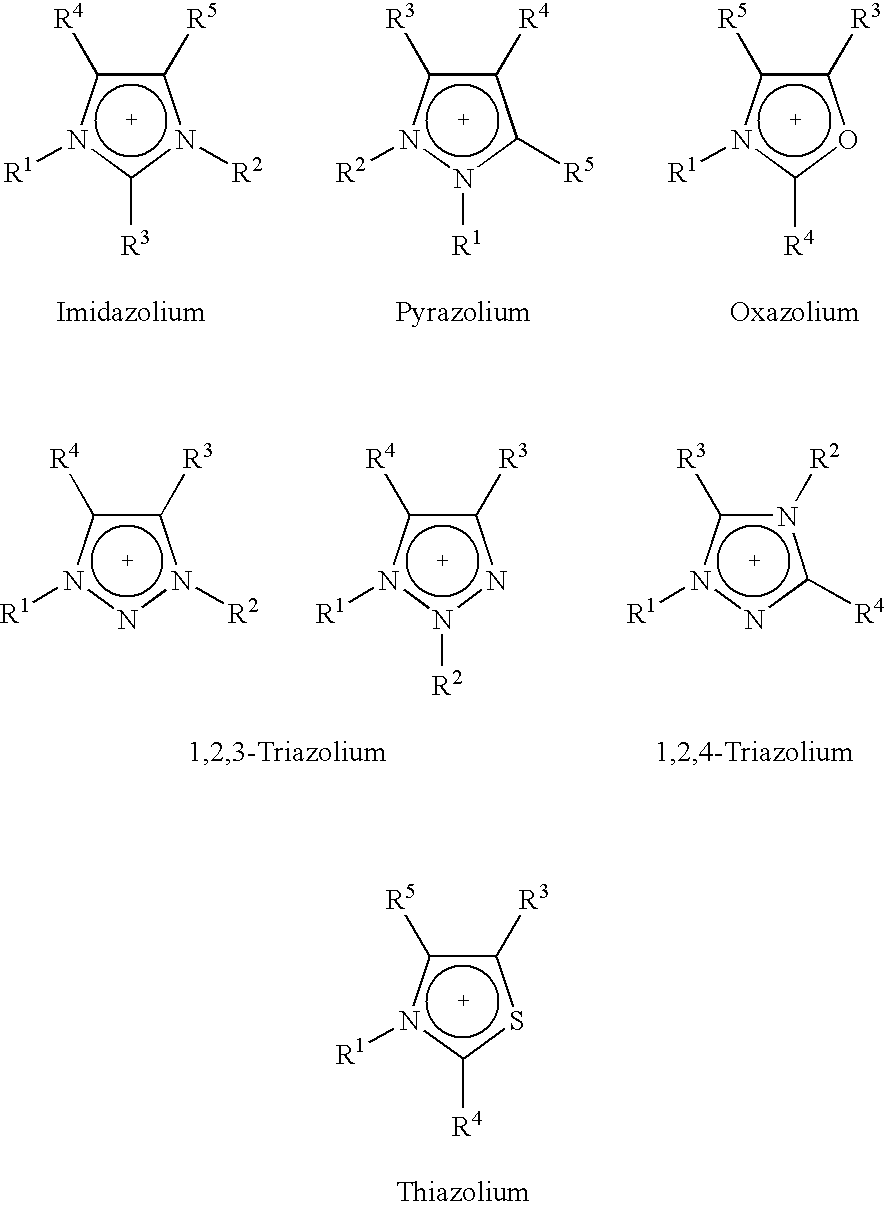

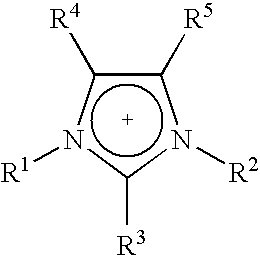

Dissolution Method

The invention relates to a method for dissolving wood, straw and other natural lignocellulosic materials in an ionic liquid solvent under microwave irradiation and / or under pressure. The invention also relates to the resulting solution and to methods for separating cellulose and other organic compounds, such as lignin and extractives, from the solution.

Owner:VESA MYLLYMAKI +1

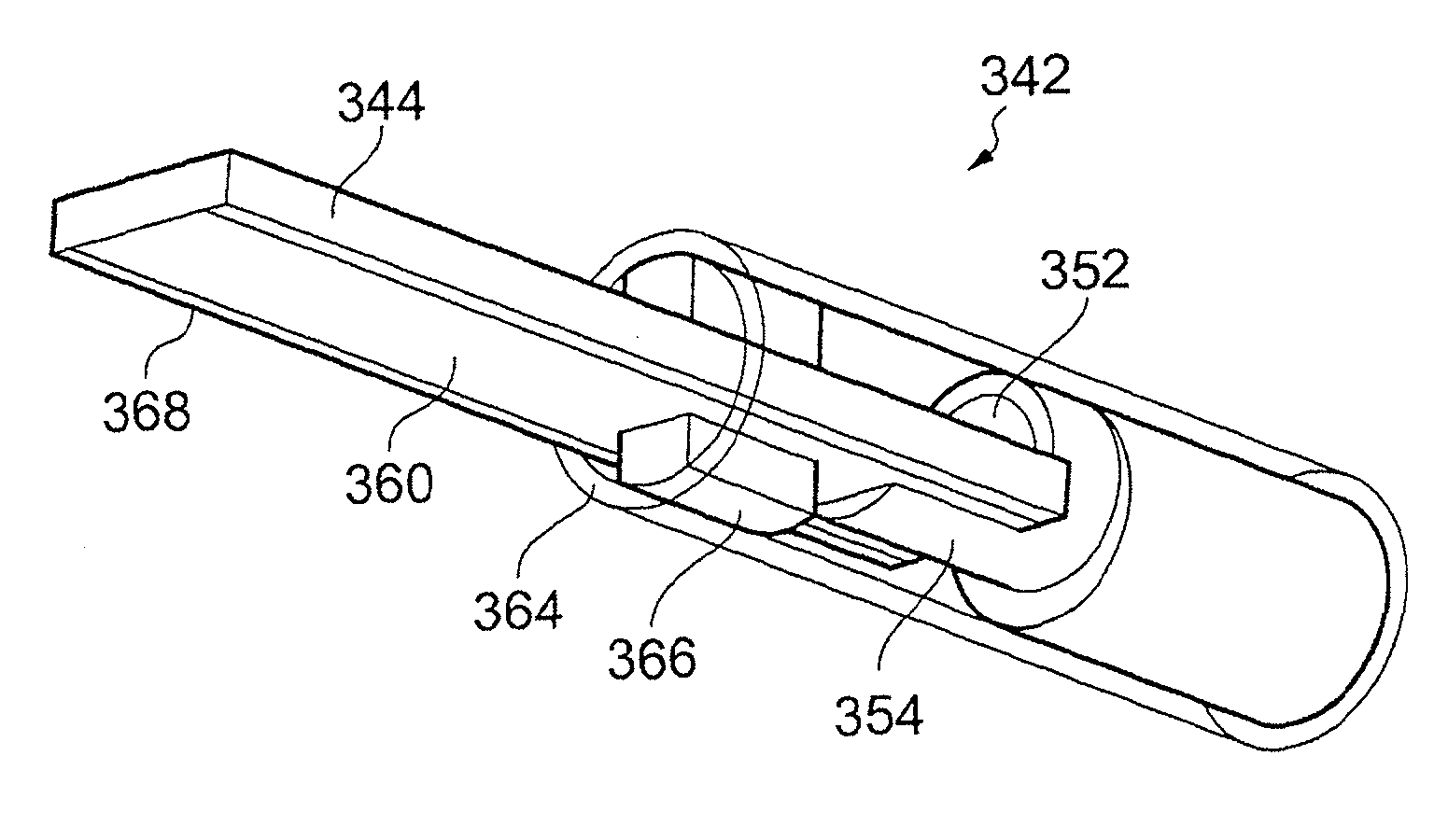

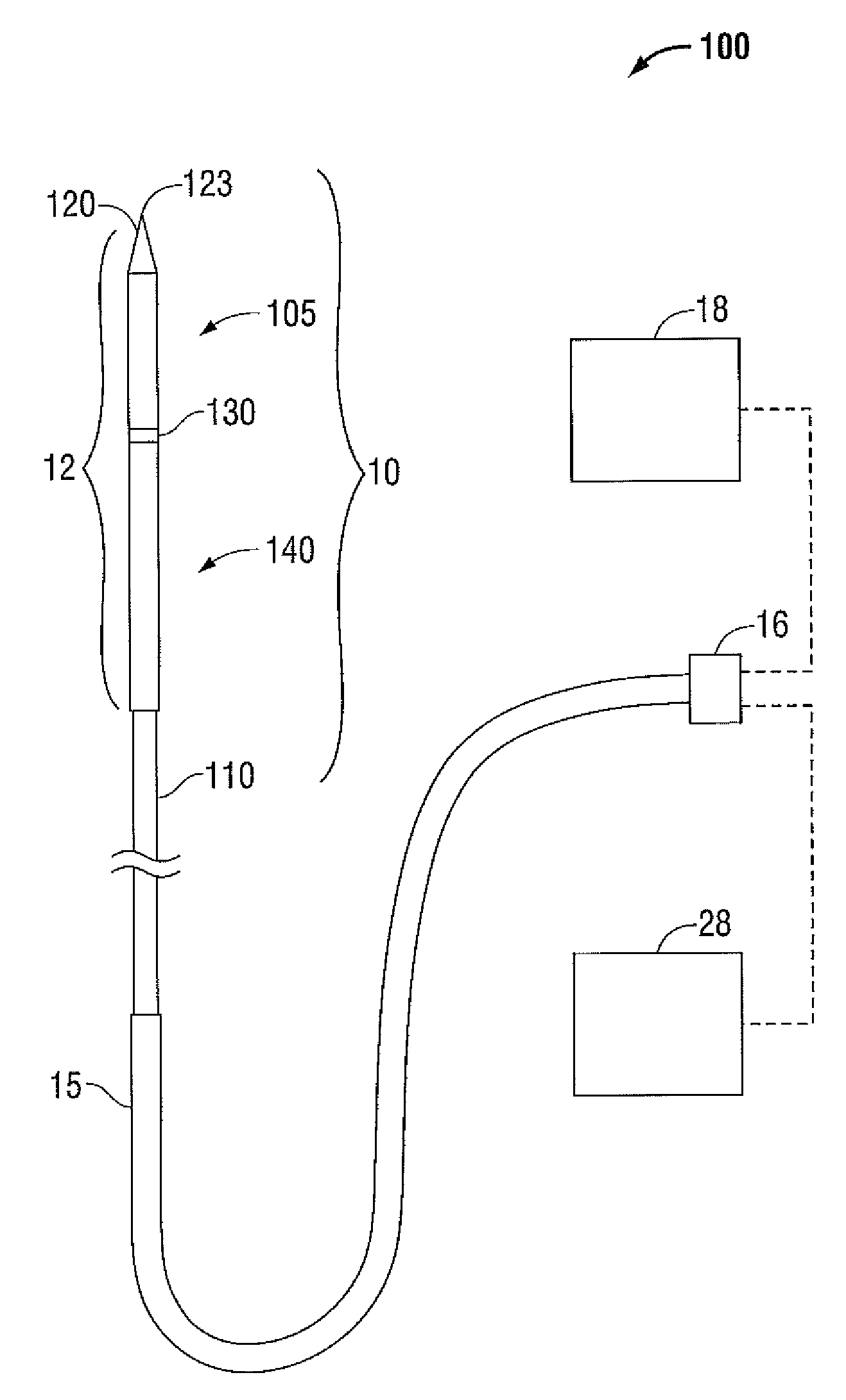

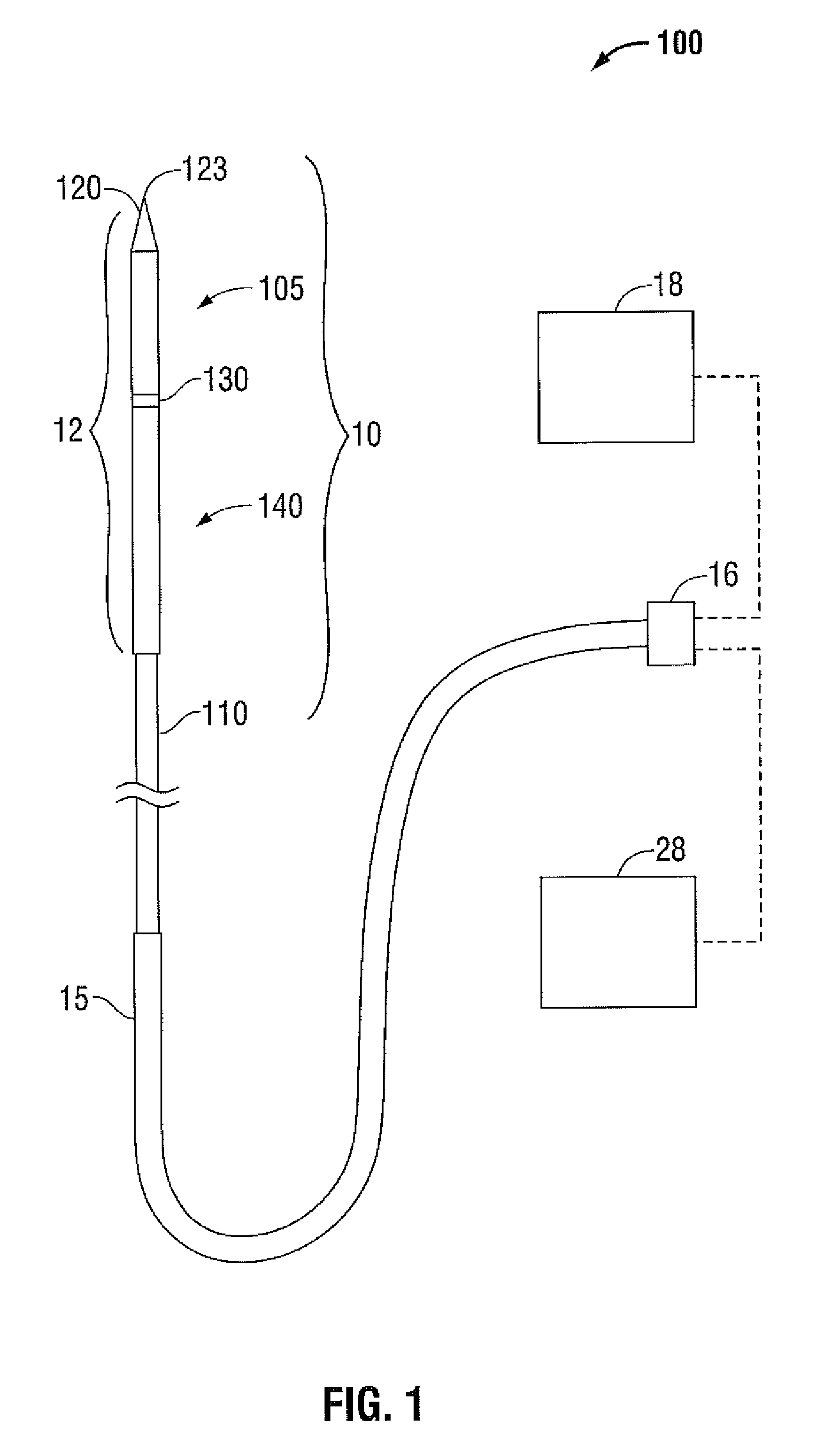

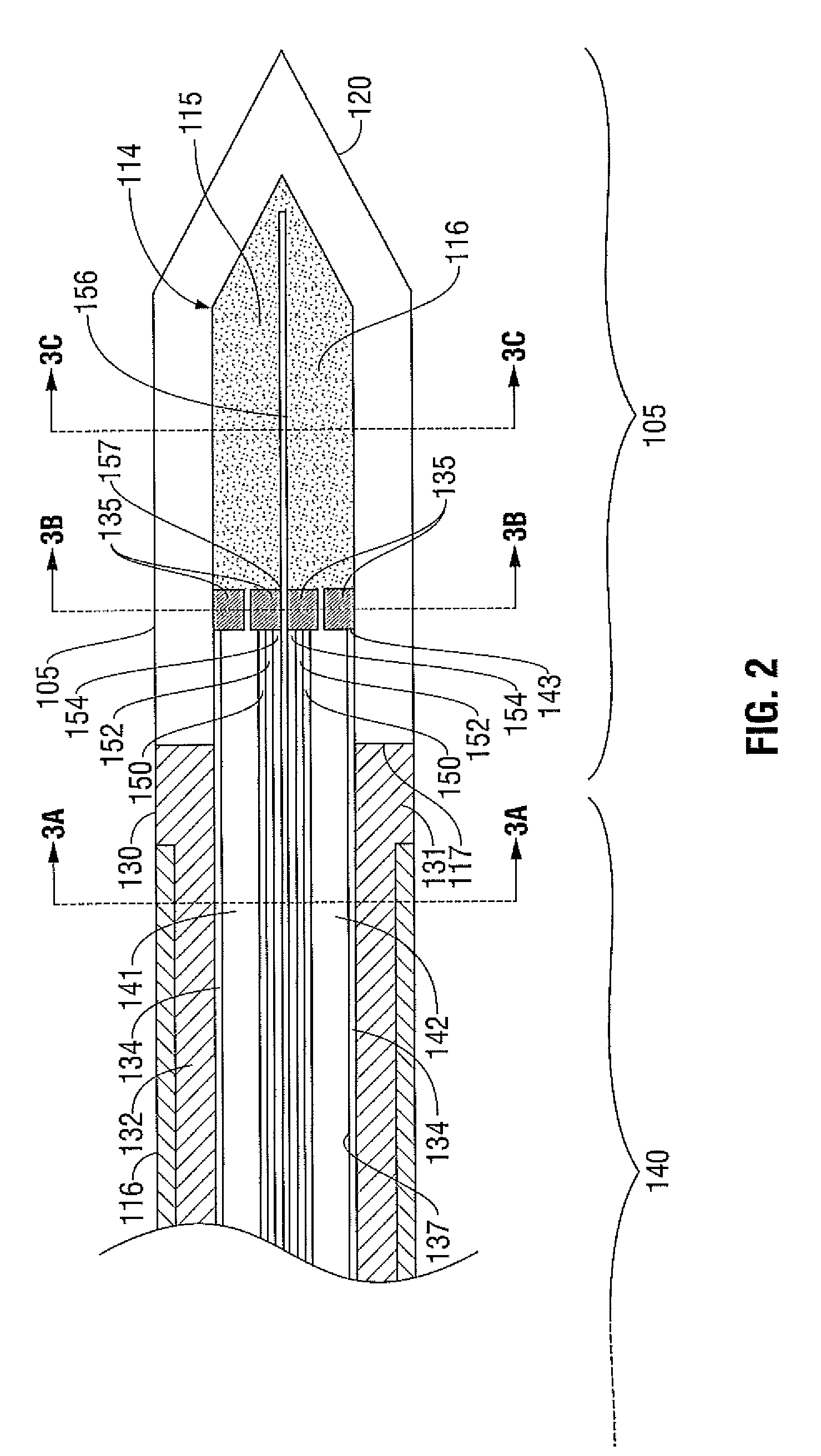

Perfused Core Dielectrically Loaded Dipole Microwave Antenna Probe

ActiveUS20110066144A1Improve power delivery performance powerImprove power power handlingElectrotherapySurgical needlesCouplingCooling chamber

A microwave surgical ablation probe having an arrangement of coolant channels in fluid communication with a cooling chamber disposed within the distal end of the probe is disclosed. A hypotube having one or more longitudinal ribs extending radially inward from an inner surface thereof is coaxially disposed around a coaxial feedline. The longitudinal ribs of the hypotube engage an outer sheath of the feedline to define a fluid inflow channel to deliver coolant to the cooling chamber, and a fluid outflow channel to receive fluid from the cooling chamber. The cooling chamber may be formed from porous ceramic or porous metallic material that provides structural support to the probe while permitting coolant to circulate therethrough. The probe includes dielectric and choke members that are adapted to control the microwave radiation pattern (e.g., ablation shape), and which may provide improved coupling of the probe to tissue.

Owner:TYCO HEALTHCARE GRP LP

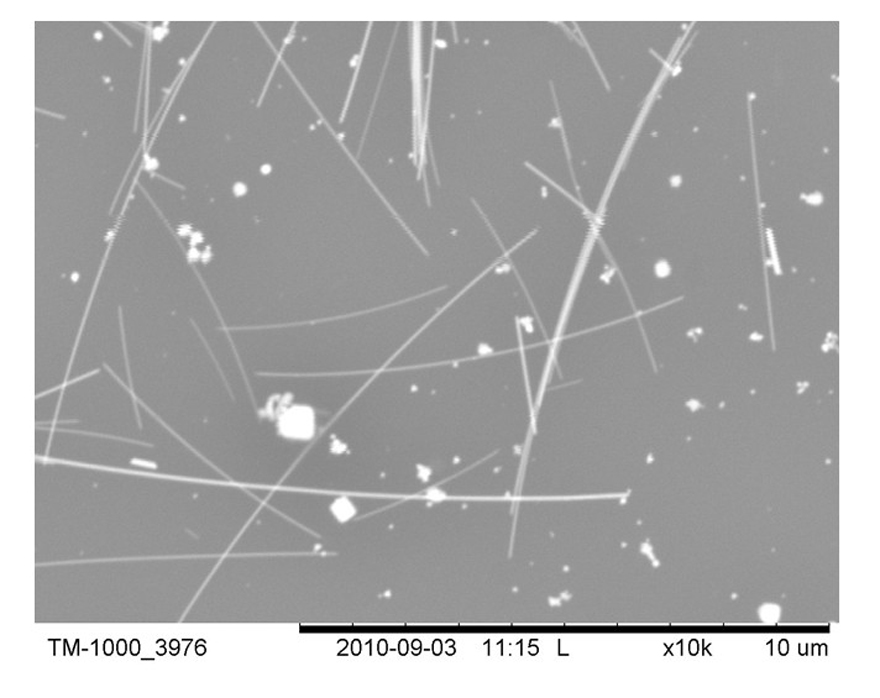

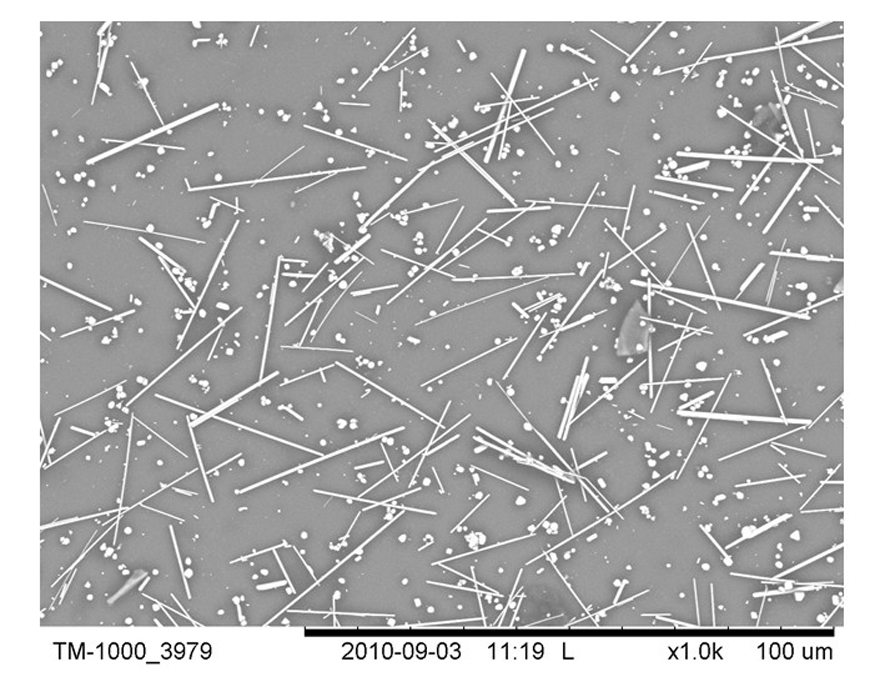

Method for preparing silver nanometer wire with controllable wire diameter by cation control microwave method

ActiveCN102029400APolycrystalline material growthSingle crystal growth detailsMicrowave methodDiameter ratio

The invention provides a method for preparing silver nanometer wire with controllable wire diameter by a cation control microwave method, aiming at solving the problems of rough wire diameter, low diameter ratio and the like during preparation of the silver nanometer wire by the traditional microwave method. The method comprises the following steps of: (1) adding a mixture of silver nitrate powder and a dispersing agent into ethylene glycol and preparing a solution reaction system containing silver ions; (2) adding a cation control agent in the solution reaction system containing silver ions and evenly stirring to obtain a reaction precursor; and (3) irradiating the reaction precursor under microwave, centrifuging, ultrasonically washing and drying the solution prepared through microwave irradiation to obtain the silver nanometer wire powder with controllable wire diameter. The invention has the advantages of simple preparation method, high efficiency and low cost and ensures that the high-quality silver nanometer wire can be prepared repeatedly within wide range of reaction condition. By using a soft template method, the size of the wire diameter is controlled by using the cation control agent without introducing any impurity.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

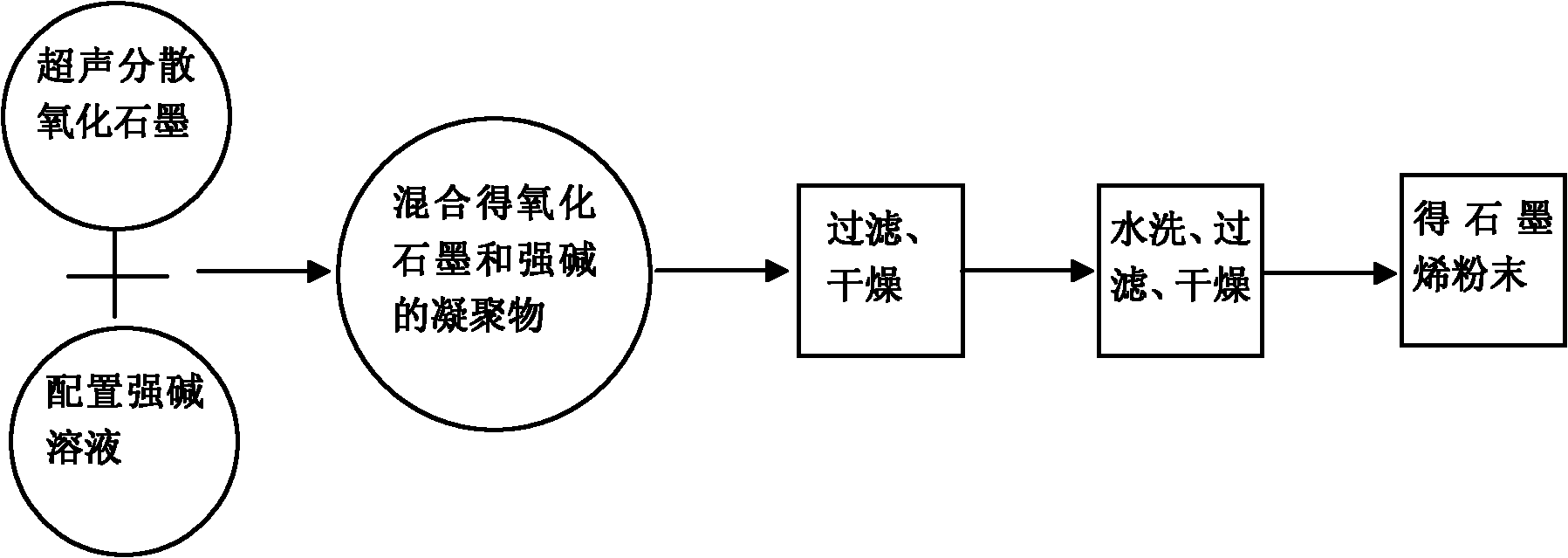

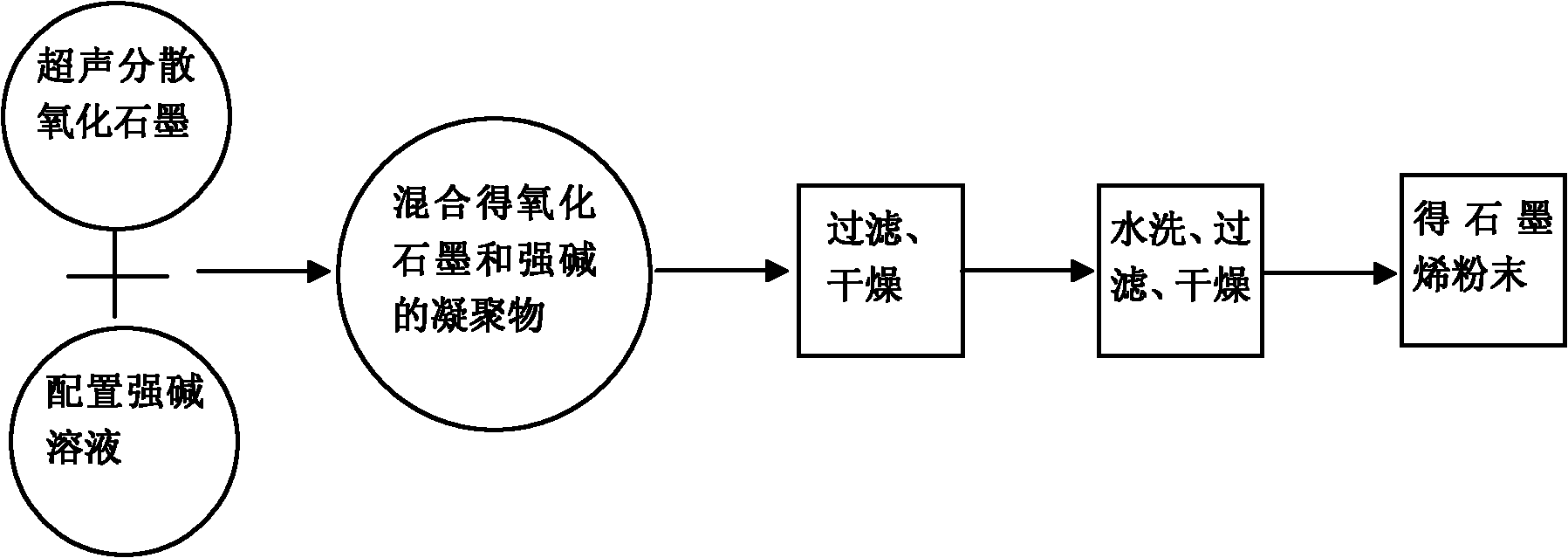

Method for preparing high-specific surface area graphene material by utilizing strong base chemical treatment

ActiveCN102070140AHigh specific surface areaHigh conductanceMaterial nanotechnologyGraphiteChemical treatmentCvd graphene

The invention relates to a method for preparing a high-specific surface area graphene material by utilizing strong base chemical treatment and belongs to the technical field of preparation of graphene materials. By reacting strong base with carbon at high temperature to further perform chemical treatment on graphene powder obtained through thermal treatment or microwave irradiation, nano-scale micropores are rapidly and massively corroded on the surface of graphene, and the specific surface area is greatly improved. Meanwhile, the graphene can be reduced through high-temperature treatment; therefore, high conductivity of the obtained material is guaranteed.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

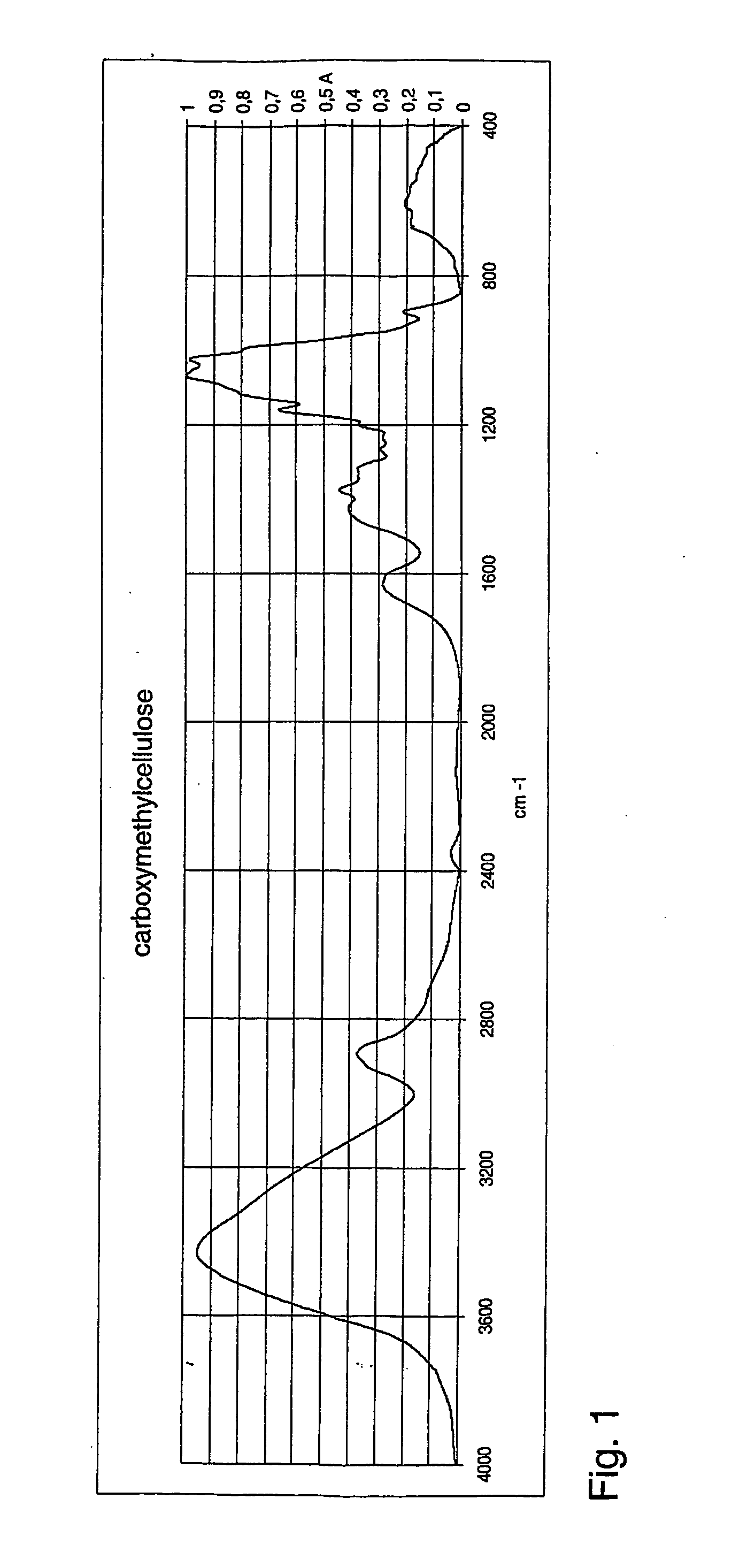

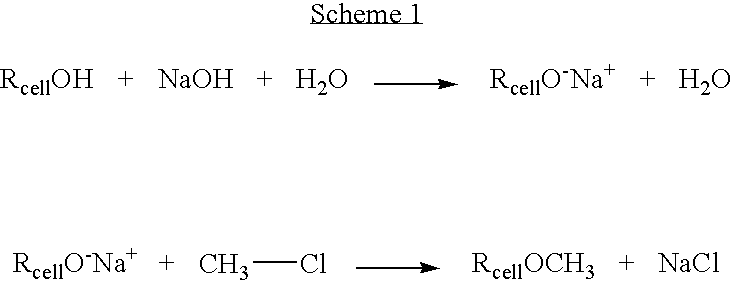

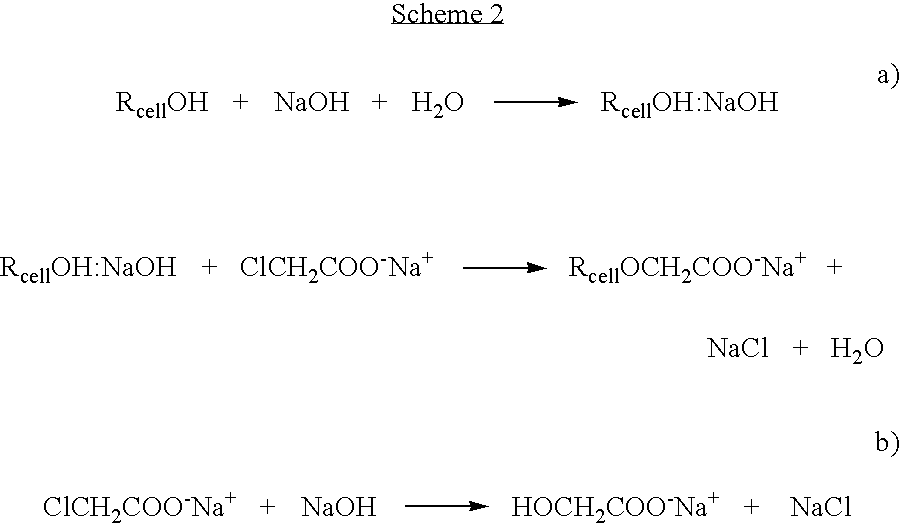

Method for preparing a cellulose ether

InactiveUS20070112185A1Efficient and economic reactionPrevent degradationBulk chemical productionCelluloseOrganic base

The invention relates to a method for preparing a cellulose ether. The method comprises mixing cellulose with an ionic liquid solvent to dissolve the cellulose, and then treating the dissolved cellulose with an etherifying agent in the presence of an inorganic base to form a cellulose ether, and subsequently separating the cellulose ether from the solution, wherein both the dissolution and the etherification are carried out in the absence of an organic base and in the substantial absence of water. Microwave irradiation and / or pressure can be applied to assist in dissolution and etherification.

Owner:OYL KEMIRA

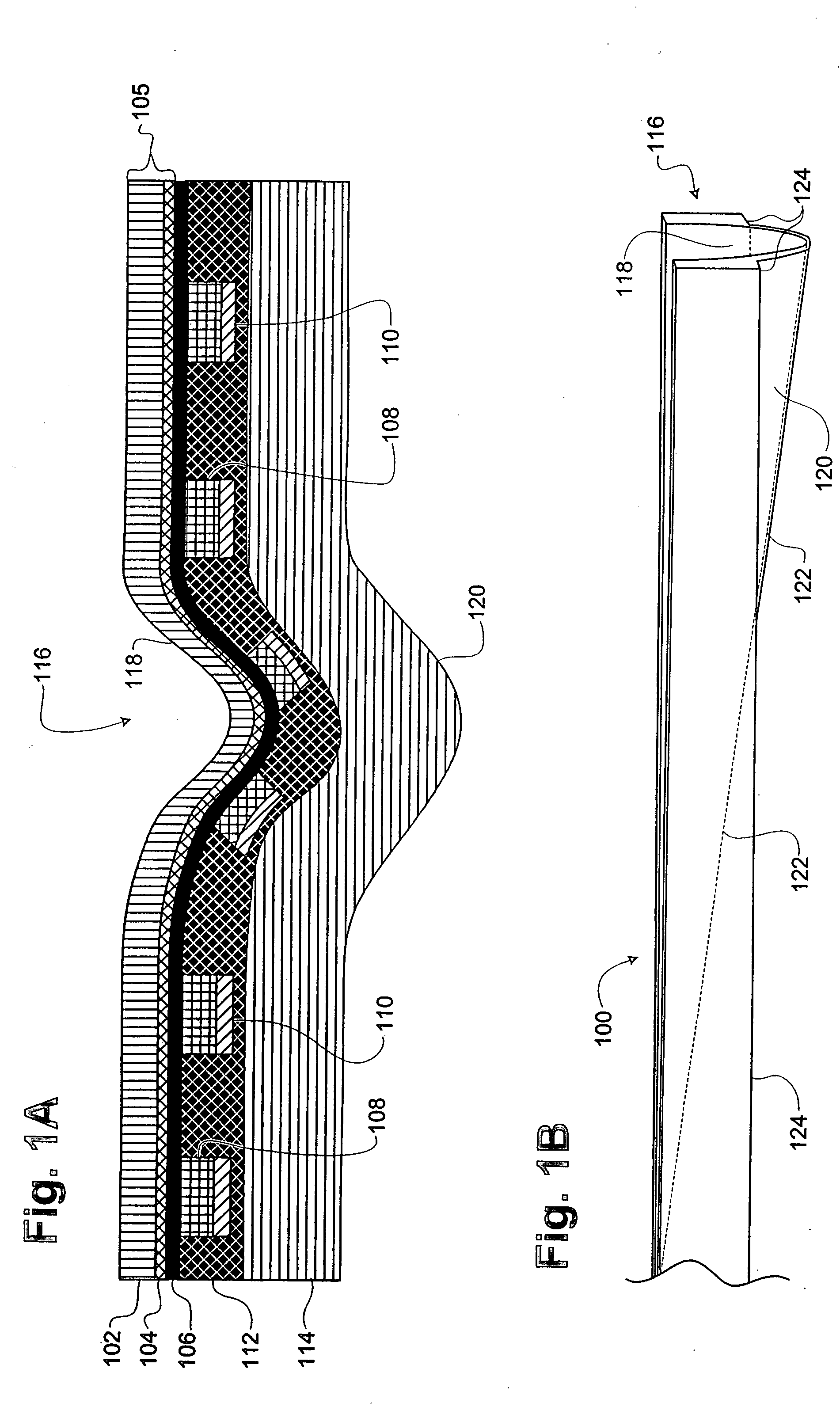

Microwave packaging with indentation patterns

InactiveUS20060011620A1Improve cooking resultsGood cooking effectMilk preparationReady-for-oven doughsCooking & bakingEngineering

Indentation patterns in microwave packaging materials can enhance the baking and browning effects of the microwave packaging materials on food. The indentation patterns can provide venting to either channel moisture from one area of the food product to another, trap moisture in a certain area to prevent it from escaping, or channel the moisture completely away from the food product. The indentation patterns can cause the microwave packaging material underneath a food product to be slightly elevated above the cooking platform in the base of a microwave. The indentation patterns can lessen the heat sinking effect of the cooking platform by providing an air gap for insulation. Elevating the base of the microwave packaging material further allows more incident microwave radiation to propagate underneath the microwave packaging material to be absorbed by the food product or by microwave interactive materials in the microwave packaging material that augment the heating process.

Owner:GRAPHIC PACKAGING INT

Microwave drying of ceramic structures

ActiveUS7596885B2Dry evenlySimple structureDielectric heatingDrying solid materials with heatStructural degradationMetallurgy

Owner:CORNING INC

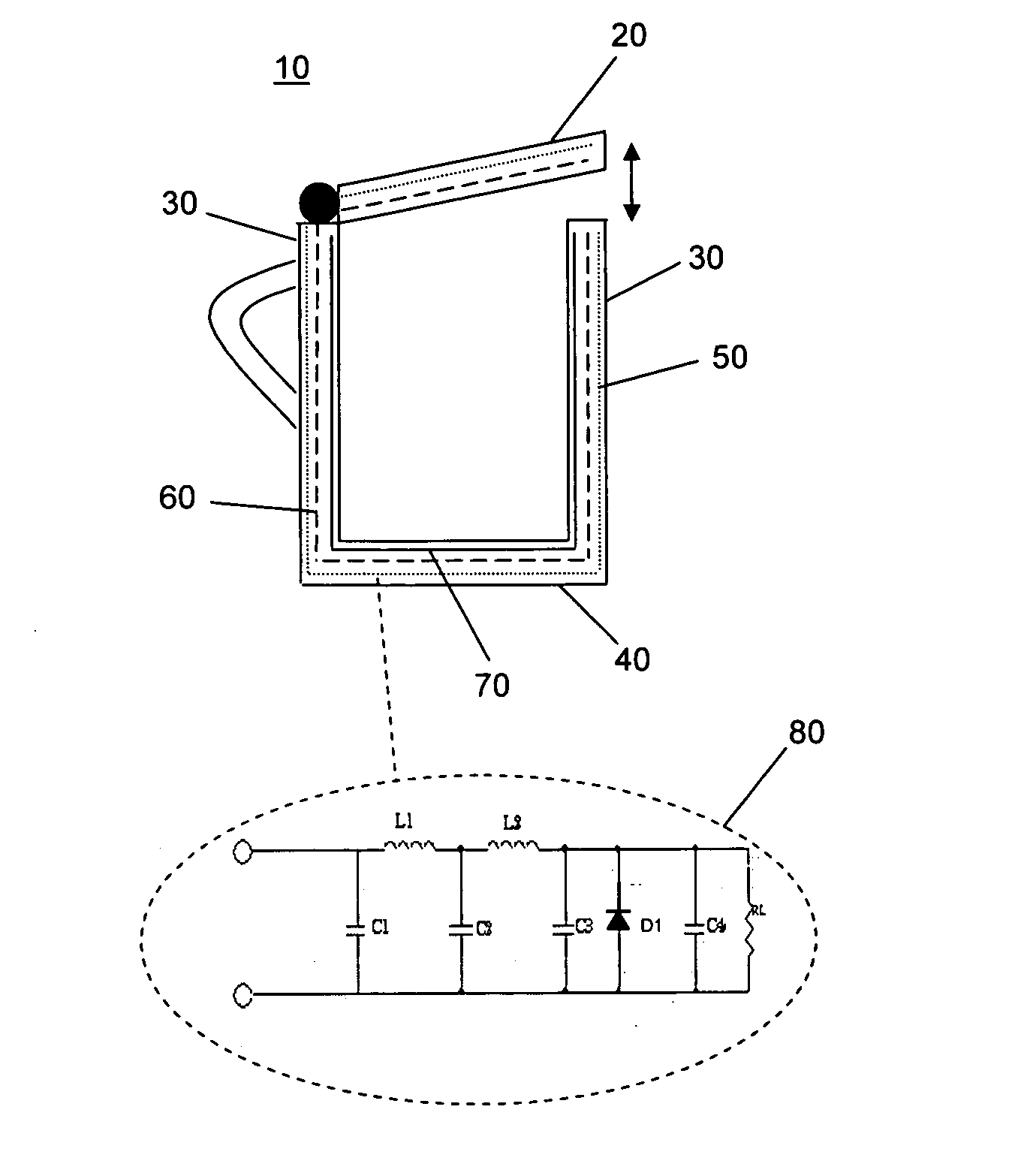

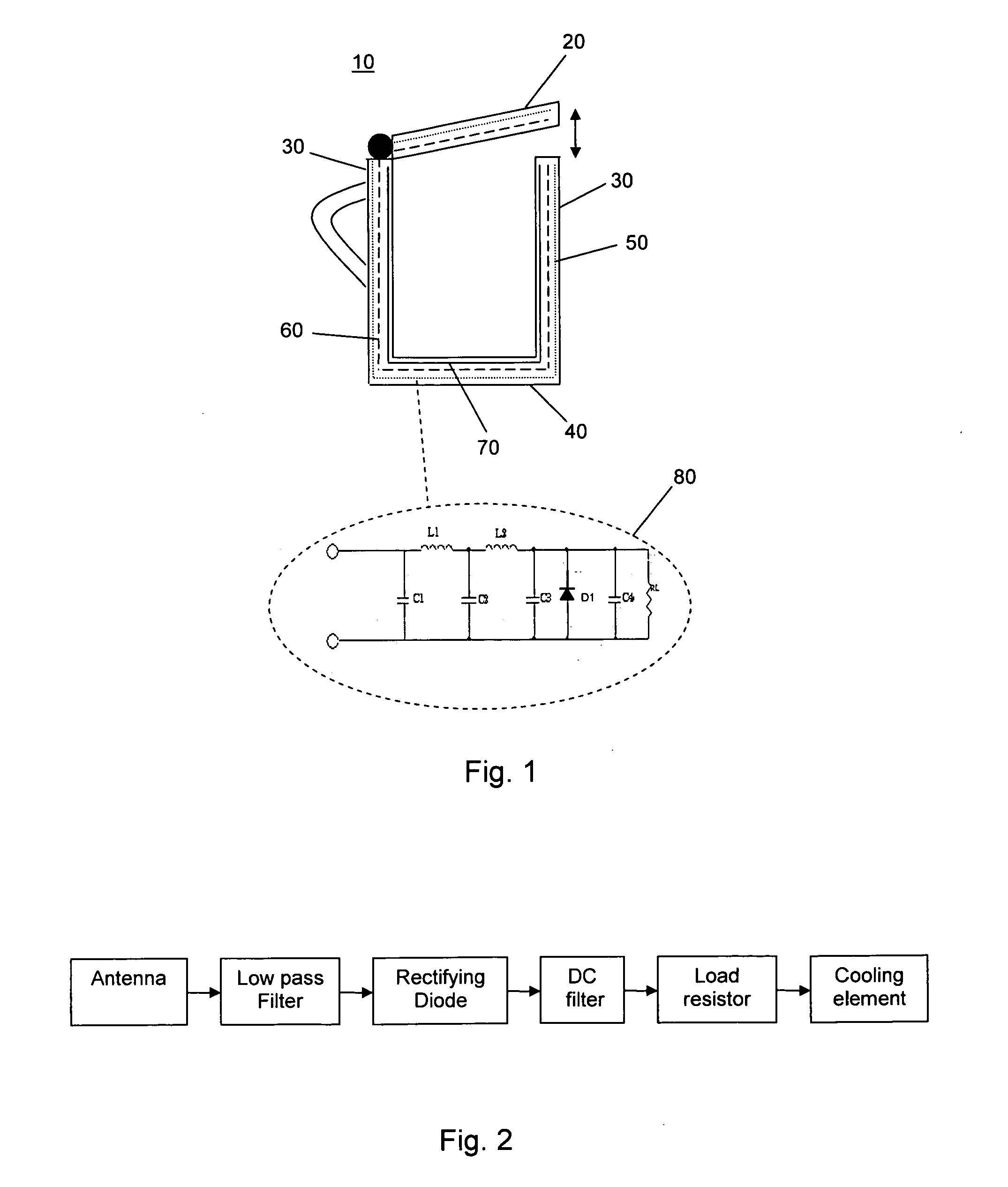

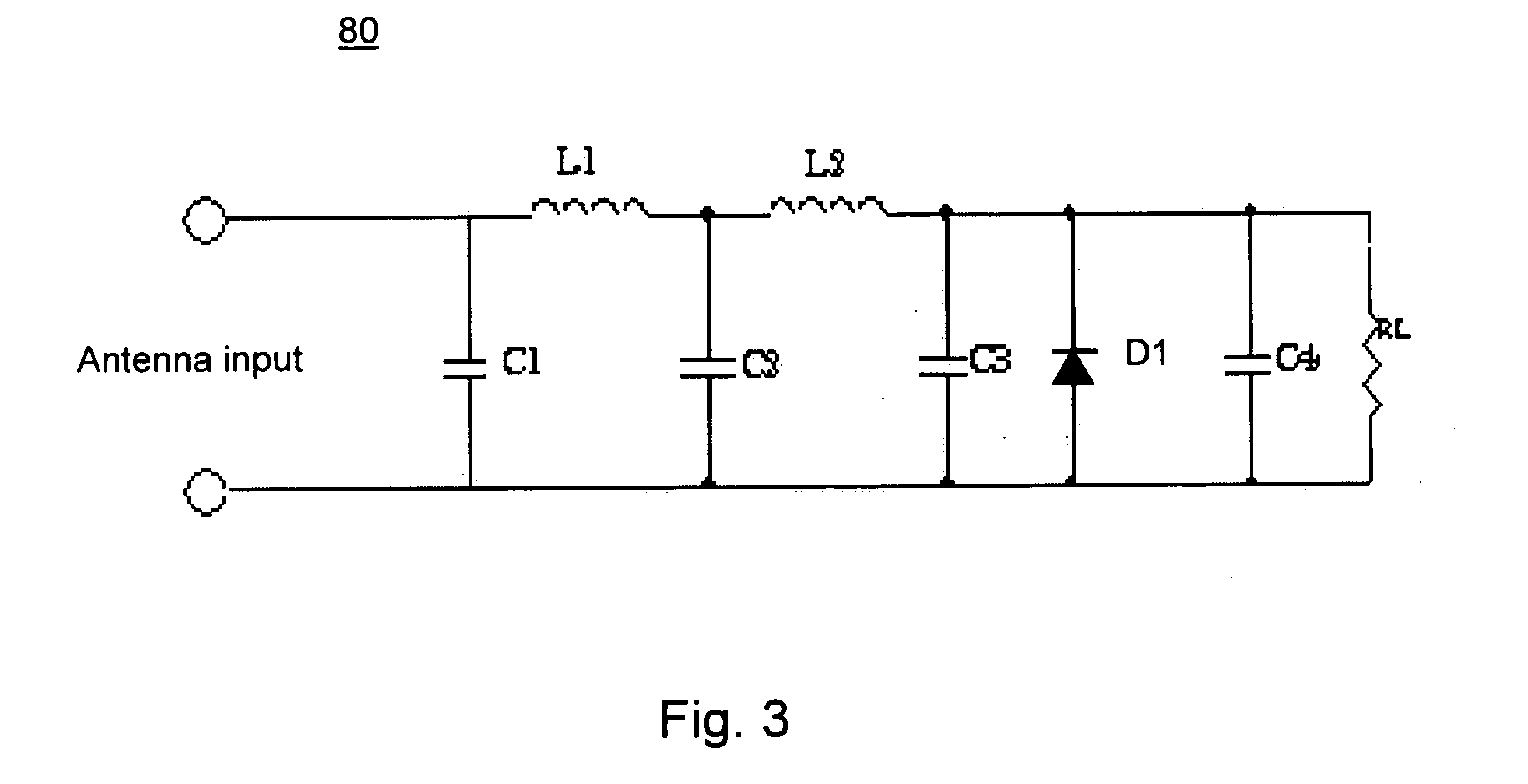

Container and method for cooling

InactiveUS20060207442A1Rapid and effective and controllable coolingMeat/fish preservationElectromagnetic wave systemMicrowave ovenEngineering

The present invention relates to a container and a method for cooling the container contents by microwave radiation. The container (10) includes a lid (20), at least one integrated electrical cooler (70), at least one integrated microwave receiving rectenna (50), and at least one integrated microwave shield (60) for shielding microwaves from reaching the interior of the container (10). The invention also relates to the method of cooling including the steps of sealing the container (10) through closing the container lid (20), and applying microwave radiation onto the outer surfaces of the container by utilizing a microwave oven. The container incident microwaves are received and converted into direct-current voltage through the rectenna (50), which powers the electrical cooler (70) for cooling the interior of the container (10) and its contents.

Owner:PETTERSSON JERRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com