Method for preparing silver nanometer wire with controllable wire diameter by cation control microwave method

A silver nanowire and cation technology, applied in the field of nano silver wire material preparation, can solve the problems of thick wire diameter and low aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

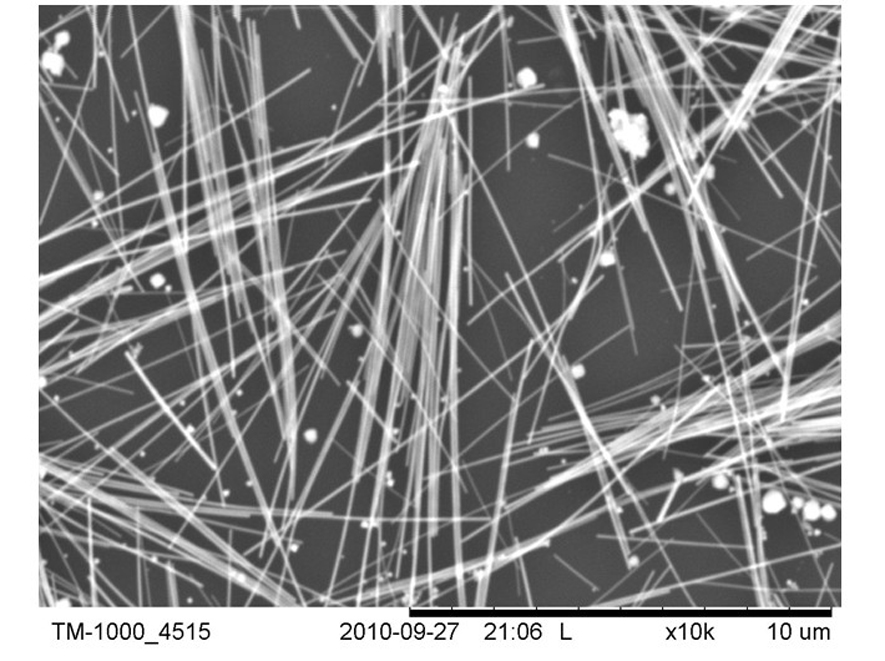

[0045] Follow the preparation process. Mix 0.4g of silver nitrate and 0.8g of PVP into a beaker filled with 30g of ethylene glycol according to a mass ratio of 1:2, and stir ultrasonically for 5-10 minutes to obtain a uniform transparent solution; add 0.04g of sodium chloride and continue ultrasonically stirring 2 to 3 minutes; at this time, it is a milky white suspension, which is the precursor for preparing silver nanowires. The prepared suspension was put into a microwave oven, and the reaction conditions were: 2.45GHz, 320W, 5min. After the reaction, the solution was centrifuged at 4000r / min for 8min. The obtained solid was dispersed with 50 ml of water, washed ultrasonically, centrifuged again, and the product was dried at room temperature. The scanning electron microscope test sample is to stick the sample on the aluminum base sample stage, figure 1 The SEM photos of the silver nanowires obtained according to Example 1 are given. from figure 1 It can be seen from th...

Embodiment 2

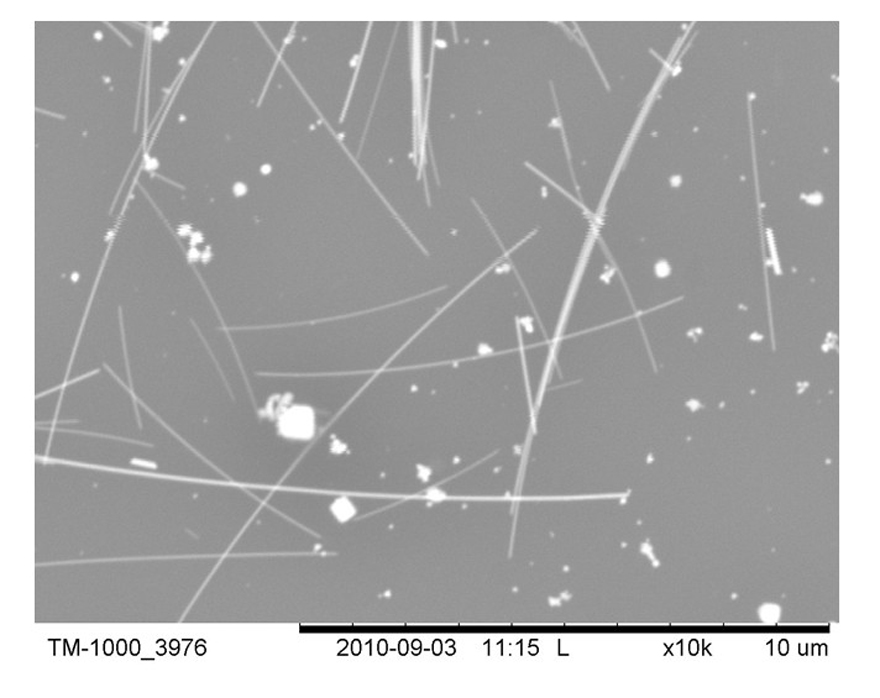

[0047]Follow the preparation process. According to the mass ratio of 1:1.5, mix 0.35g of silver nitrate powder and 0.525g of PVP into a beaker filled with 20g of ethylene glycol, and ultrasonically stir for 5 to 10 minutes to obtain a uniform transparent solution; add 0.035g of manganese chloride, Continue ultrasonic stirring for 2 to 3 minutes to prepare the precursor of silver nanowires. The prepared suspension was put into a microwave oven, and the reaction conditions were: 2.45GHz, 320W, 4.5min. After the reaction, the solution was centrifuged at 4000r / min for 8min. The obtained solid is dispersed with 50ml of ethanol and processed by ultrasonic washing, centrifuged again, and the product is dried at normal temperature. The scanning electron microscope test sample is to stick the sample on the aluminum base sample stage, figure 2 Provided according to the SEM photo of the silver nanowire that embodiment 2 obtains, from figure 2 It can be seen that the average diameter...

Embodiment 3

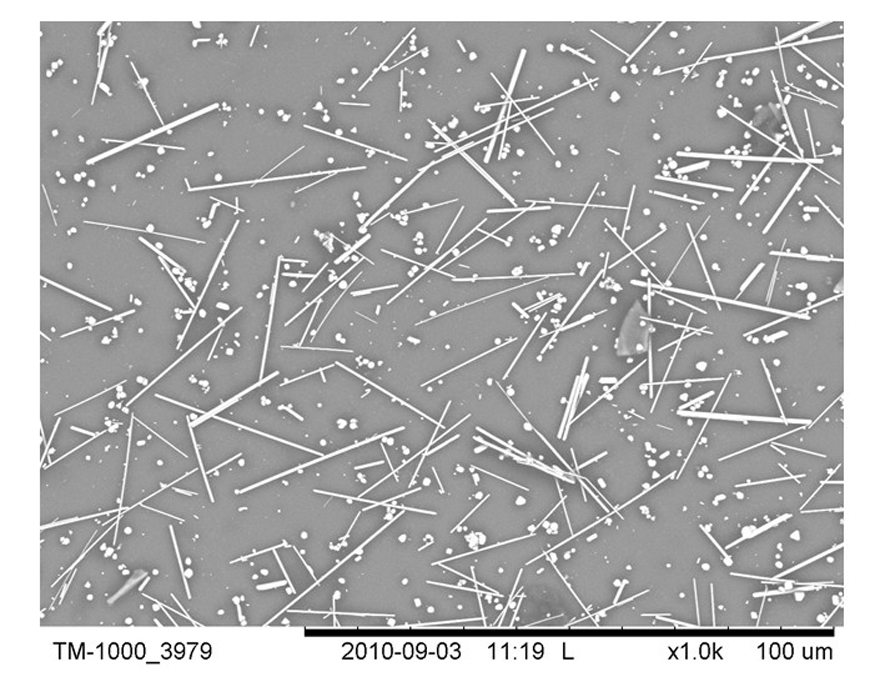

[0049] Follow the preparation process. According to the mass ratio of 1:1.38, mix 0.34g silver nitrate and 0.55g PVP into a beaker filled with 25g ethylene glycol, and stir ultrasonically for 5-10 minutes to obtain a uniform transparent solution; add 0.02g sodium sulfide and continue ultrasonic stirring for 2 ~3 minutes, it is the precursor for preparing silver nanowires. The prepared suspension was put into a microwave oven, and the reaction conditions were: 2.45GHz, 320W, 4min. After the reaction, the solution was centrifuged at 4000r / min for 8min. The obtained solid was dispersed with 50ml of ethanol (or water), washed ultrasonically, centrifuged again, and dried at room temperature. The scanning electron microscope test sample is to stick the sample on the aluminum base sample stage, image 3 The SEM photograph of the silver nanoparticle that obtains according to embodiment 3 is provided, from image 3 It can be seen that the average diameter of silver nanowires is 350...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com