Method for preparing NiCo2O4/graphene supercapacitor material with microwave method

A supercapacitor and graphene technology, which is applied in the manufacture of hybrid/electric double layer capacitors, etc., can solve the problems of unfavorable practical large-scale application, long reaction time, high production cost, etc., and achieve easy industrial implementation, excellent electrochemical performance, and feasibility sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Disperse 20 mg of graphite oxide in 40 mL of deionized water and ultrasonically form a uniform dispersion. Then add 1.00 mmol NiCl 2 . 6H 2 O and 2.00 mmol CoCl 2 . 6H 2 O, fully stirred for 1 h, then added 30 mmol of urea, and stirred for another 1 h. The mixture was transferred to a microwave reactor and heated to 100 °C under reflux for 15 min. The obtained product was separated by centrifugation, washed three times with deionized water and absolute ethanol, and finally vacuum-dried at 45 °C for 24 h. The dried material is used as a precursor and calcined at 300 °C for 2 h in the air atmosphere to obtain porous sheet-like NiCo 2 o 4 / Graphene supercapacitor material.

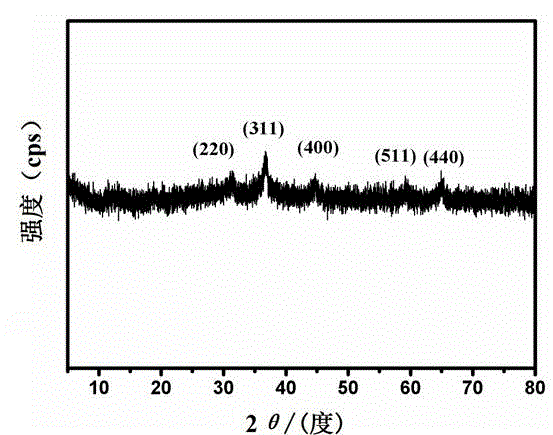

[0026] figure 1 It is the XRD pattern of the product, except that NiCo is observed in the figure 2 o 4 Except for the diffraction peak of , there are no other diffraction peaks, indicating that the target product has been synthesized and no by-products are produced.

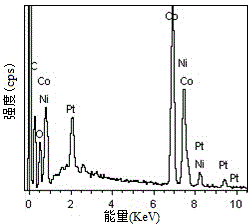

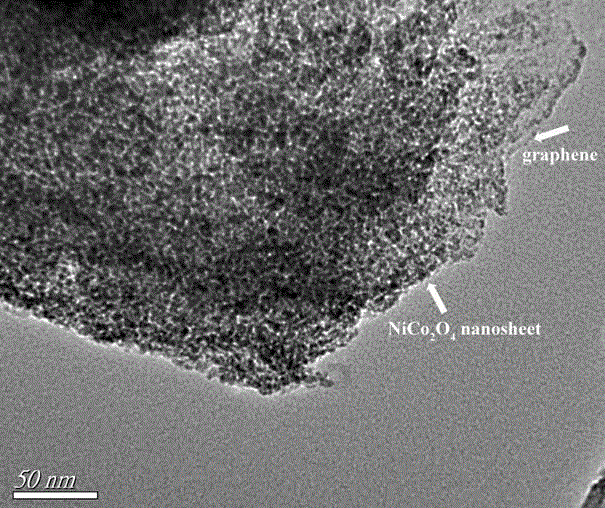

[0027] figure...

Embodiment 2

[0031] Disperse 20 mg of graphite oxide in 40 mL of deionized water and ultrasonically form a uniform dispersion. Then add 0.50 mmol NiCl 2 . 6H 2 O and 1.00 mmol CoCl 2 . 6H 2 O, fully stirred for 1 h, then added 30 mmol of urea, and stirred for another 1 h. The mixture was transferred to a microwave reactor and heated to 100 °C under reflux for 15 min. The obtained product was separated by centrifugation, washed three times with deionized water and absolute ethanol, and finally dried under vacuum at 45 °C for 24 h. The dried material is used as a precursor and calcined at 300 °C for 2 h in the air atmosphere to obtain porous sheet-like NiCo 2 o 4 / Graphene supercapacitor material.

Embodiment 3

[0033] Disperse 20 mg of graphite oxide in 40 mL of deionized water and ultrasonically form a uniform dispersion. Then add 0.75 mmol NiCl 2 . 6H 2 O and 1.50 mmol CoCl 2 . 6H 2O, fully stirred for 1 h, then added 30 mmol of urea, and stirred for another 1 h. The mixture was transferred to a microwave reactor and heated to 100 °C under reflux for 15 min. The obtained product was separated by centrifugation, washed three times with deionized water and absolute ethanol, and finally vacuum-dried at 45 °C for 24 h. The dried material is used as a precursor and calcined at 300 °C for 2 h in the air atmosphere to obtain porous sheet-like NiCo 2 o 4 / Graphene supercapacitor material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com