Method for drying leaf-silk in a grading way and equipment thereof

A stage-by-stage drying technology, which is applied to the stage-by-stage drying of leaf shreds, and realizes the above-mentioned step-by-stage drying leaf shreds processing method in the field of equipment, which can solve the problem of not being able to realize rapid dehydration of high-humidity leaf shreds, reduce the temperature of the drying process, and reduce the temperature of leaf shreds. Improve the efficiency of rapid dehydration and drying, strengthen the airflow drying process, and facilitate rapid dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

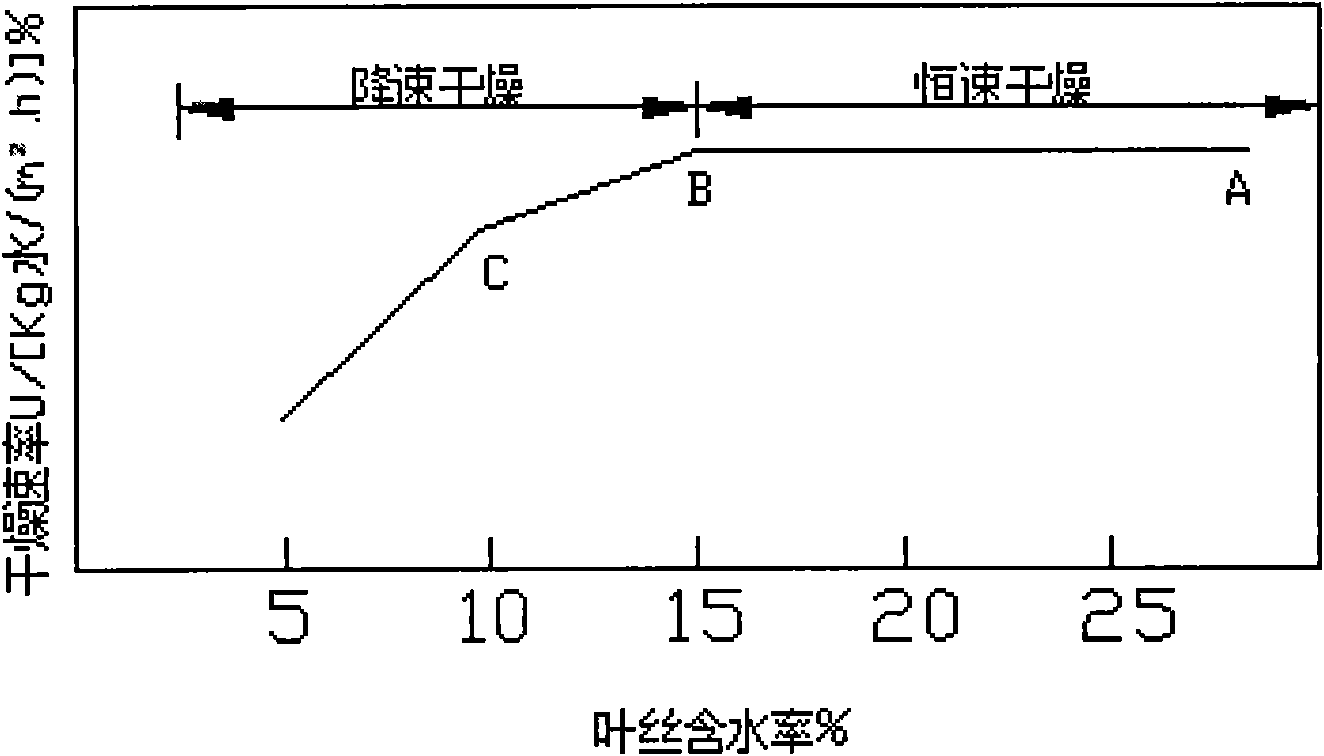

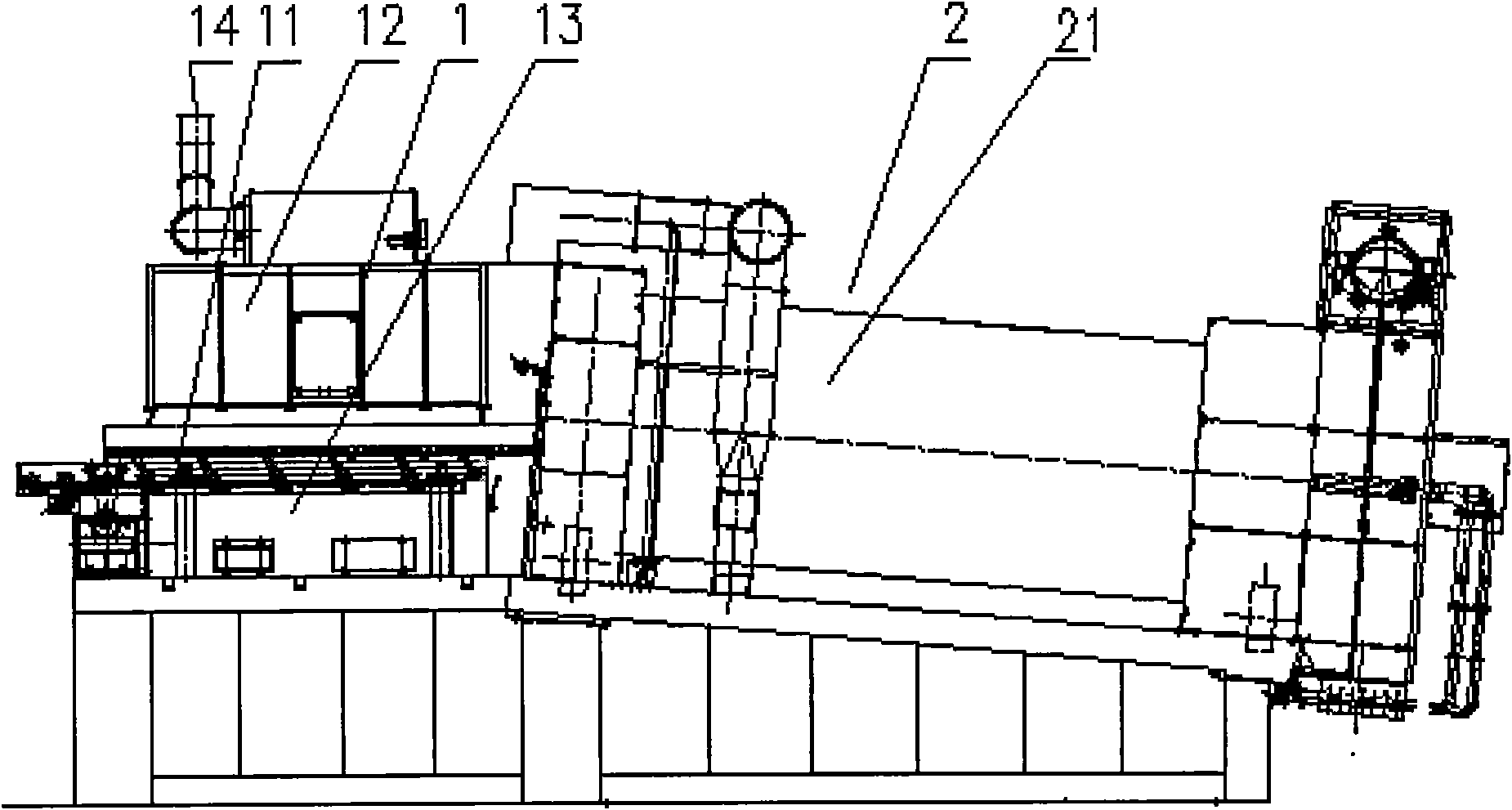

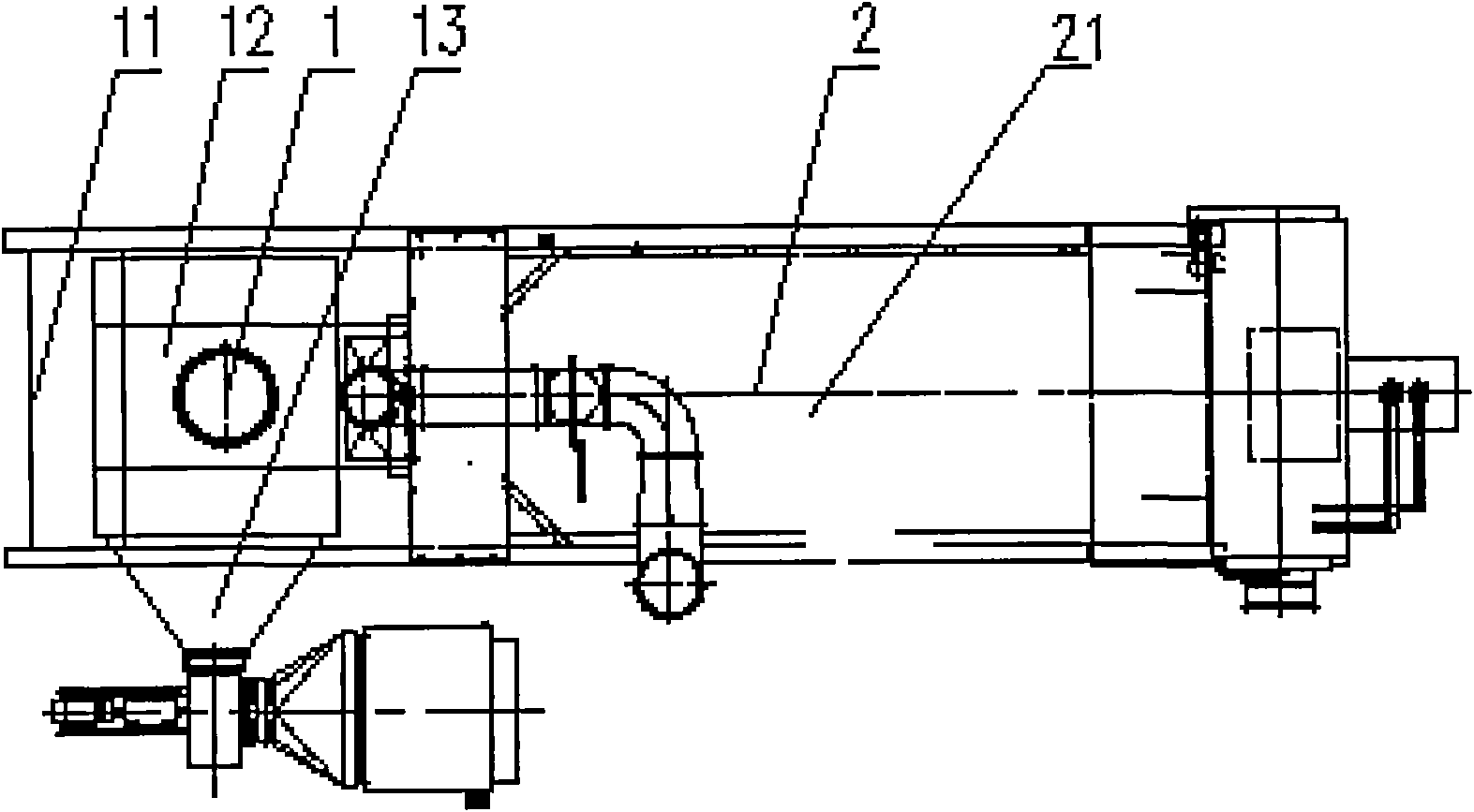

[0025] Such as figure 1 As shown, leaf shred drying is composed of two stages: constant-rate drying stage AB and decreasing-rate drying stage BC. The critical point B of the constant-rate drying stage AB and the decelerating-rate drying stage BC is not only related to the properties of leaf shreds, but also varies significantly with different drying conditions. When the leaf shreds are evenly dispersed in the hot air and dried, compared with the same direction movement of the leaf shreds and the airflow in the similar stacking drying of the drum drying and the tower tube air drying, the moisture of the leaf shreds corresponding to this critical point will be significantly reduced to about 15%. Therefore, the first stage of drying adopts fluidized drying, which is beneficial to reduce the value of the critical moisture content of the leaf silk, and achieve the purpose of rapid dehydration under the premise of keeping the leaf silk at a low temperature.

[0026] The invention f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com