Dirty oil dewatering process for refinery and oil field

A process and oil field technology, applied in the field of ultrasonic treatment new process, can solve the problems of difficult recycling of dirty oil, difficult to remove water and impurities in dirty oil, environmental pollution, etc., and achieve the goal of improving utilization value, processing capacity and high economic value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

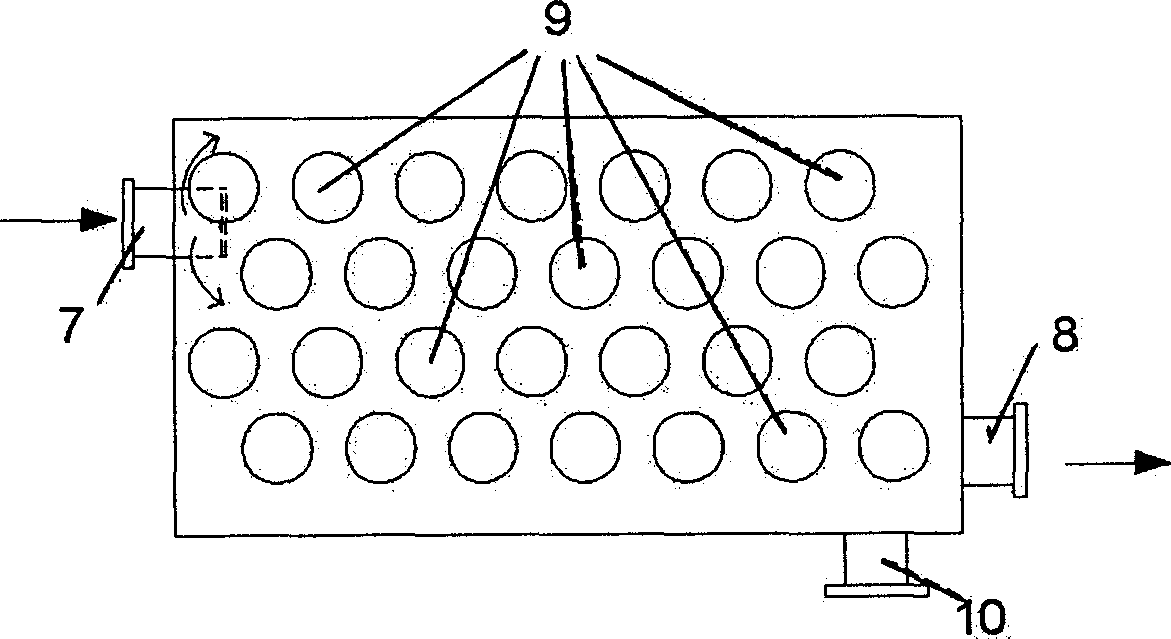

[0032] Ultrasonic frequency 28kHz. The heavy dirty oil with an initial water content of about 75% adopts the technology of the present invention (ultrasonic action part adopts figure 2 , image 3 processing device), after being subjected to an ultrasonic wave for 5 minutes, it is sent to a heat settling tank (temperature 80°C) for 4 hours, and the oil and water are separated rapidly, and the oil and water are divided into 3 layers. The average water content of the light oil layer after stripping is less than 1%, which can be directly used as distillate oil for refining or re-refining; the heavy oil slurry in the lower part of the oil layer has a water content of about 45%.

Embodiment 2

[0034] For the dirty oil (comprising the upper part light oil layer and the lower part heavy oil) after the dehydration of embodiment 1, carry out ultrasonic wave (frequency 28kHz) action again for 3 minutes after preheating, after the long-time thermal settlement (temperature 85 ℃) of heat settling tank, the oil layer The total moisture content is less than 28%. According to the recycling method of waste oil, it can be directly re-smelted or continue multiple cycles of dehydration to achieve the purpose of recycling.

Embodiment 3

[0036]Ultrasonic frequency 40kHz. The heavy dirty oil with an initial water content of about 75% adopts the technology of the present invention (ultrasonic action part adopts figure 2 , image 3 After 10 minutes of ultrasonic treatment, it is sent to a heat settling tank (at a temperature of 70°C) for 4 hours, and the oil and water are separated rapidly, and the sewage in the lower layer accounts for 51%. The volume is reduced by half.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com