Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2071 results about "Chloride potassium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium is a mineral that is found in many foods and is needed for several functions of your body, especially the beating of your heart. Potassium chloride is used to prevent or to treat low blood levels of potassium (hypokalemia).

Pullulan capsules

The invention is a hard capsule comprising pullulan in an amount of 85% to 90% by weight, potassium chloride in an amount of 1.0% to 1.5% by weight, carrageenan in an amount of 0.1% to 0.4% by weight, one or more surfactants in an amount of 0.1% to 0.2% by weight and water in an amount of 10% to 15% by weight. Additionally the invention is related to new uses of pullulan containing containers.

Owner:WARNER-LAMBERT CO

Reduced sodium salty taste composition, process for its preparation and food systems containing such composition

A reduced sodium salty taste composition for reduction of sodium chloride in food contains sodium chloride, at least one of a food acid and a salt of a food acid, at least one of an amino acids and a salt of an amino acid, and can additionally contain potassium chloride, yeast extract, sweeteners, and flavors. A food containing the reduced sodium salty taste composition and a process for making the reduced sodium salty taste composition are disclosed.

Owner:MCCORMICK & CO INC

Recovery of common salt and marine chemicals from brine

InactiveUS6776972B2High purityLow costGeneral water supply conservationSeawater treatmentSaline waterEvaporation

A new process for recovery of common salt, potassium chloride, concentrated magnesium chloride with enriched bromide, and high purity magnesia from brine in an integrated manner, said process comprises preparation of calcium chloride by reaction of hydrochloric acid generated in the process with limestone, desulfatation of brine with calcium chloride, production of sodium chloride of superior quality in solar pans, solar evaporation of bittern thereby producing carnallite and end bittern, processing carnallite through established processes to produce potassium chloride, recovering end bittern containing highly concentrated magnesium chloride and enriched bromide and calcination of a part of the end bittern after solidification to produce high purity magnesia and hydrochloric acid utilizable in the process.

Owner:COUNCIL OF SCI & IND RES

Low Sodium Salt Composition

The present invention relates to a low sodium salt composition and the methods used to make it. In particular, the invention relates to the combined processing of sodium and potassium chloride to produce a low sodium salt composition. The low sodium salt composition includes sodium chloride and a modified chloride salt composition. The modified chloride salt composition includes a homogenous amalgamation of chloride salts, food grade acidulant, and carrier.

Owner:S & P INGREDIENT DEV

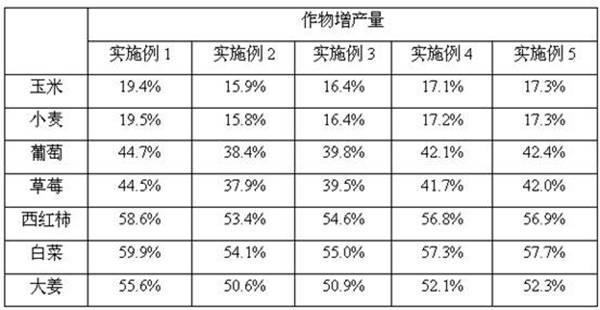

Polypeptide-ammonium polyphosphate trace element liquid chelated fertilizer and preparation method thereof

The invention discloses a polypeptide-ammonium polyphosphate trace element liquid chelated fertilizer and a preparation method of the liquid chelated fertilizer. The polypeptide-ammonium polyphosphate trace element liquid chelated fertilizer comprises the components by weight percent: 5-25% of urea, 5-15% of ammonium polyphosphate, 5-25% of potassium nitrate, 0.2-3% of potassium silicate, 0.8-5% of potassium chloride, 0.008-0.1% of polyaspartic acid, 0.8-5% of ammonium sulfate, 0.8-5% of ethylene diamine tetraacetic acid (EDTA) calcium, 0.2-3% of EDTA magnesium, 0.02-1.5% of EDTA boron, 0.005-0.1% of EDTA zinc, 0.005-0.1% of EDTA iron, 0.005-0.05% of EDTA copper, 0.005-0.05% of EDTA manganese, 0.001-0.01% of nickel sulfate, 0.001-0.01% of ammonium molybdate, 0.0008-0.01% of cobaltous sulfate, 0.008-0.1% of polyacrylamide and the balance of water. The polypeptide-ammonium polyphosphate trace element liquid chelated fertilizer disclosed by the invention is simple in technology, scientific in proportion, balanced in fertilization, low in cost and good in effect.

Owner:张朝晖

Health table salt

The invented healthy edible salt is prepared by mixing with sodium chloride, various amino acid, peptide substance, vitamin B family, polysaccharide, or chitin, antioxidant, nucleic acid seasoning, potassium chloride, calcium salt, magnesium salt, selenium salt, and potassium iodide. It can effectively prevent various diseases, also can prevent osteoporosis, cancer, diabetes, dysinsulinosis, lithiasis, coronary heart disease, senile dementia, bark farus etc. it also possesses the functions of antisenility, antifatigue, antidepression, improving immune power, promoting growth etc.

Owner:岳静 +1

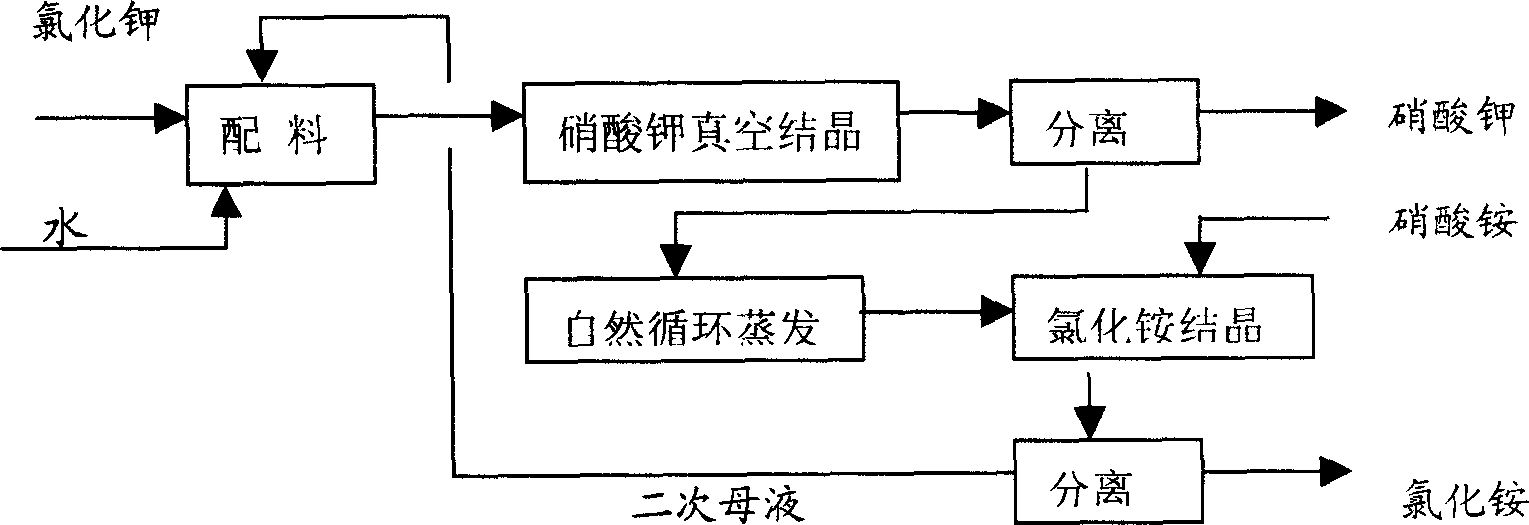

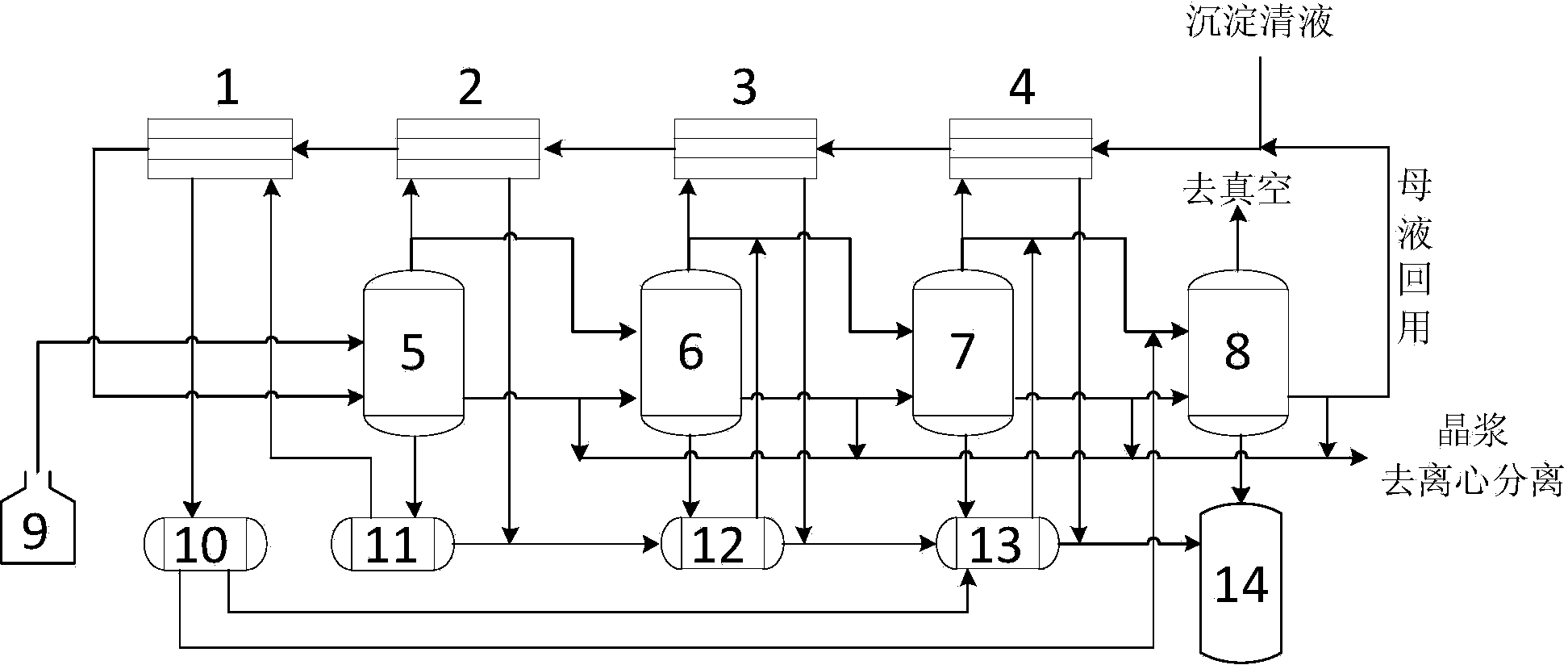

Process for preparing potassium nitrate by double decomposition method

ActiveCN1827526ALess process equipmentEasy to manufactureAlkali metal nitrate preparationCyclic processAmmonium nitrate

The invention provides a metathesis method for preparation of potassium nitrate. After raw potassium chloride, ammonium nitrate and craft water finish their preparation at a certain ratio, they are input into vacuum cooling crystallizer. Then potassium nitrate is separated by crystallization and grows up. The crystallized liquid thickens by the thickening apparatus and continuously separates potassium nitrate as aim products by centrifugal machine. After the separated mother liquid exchanges heat with the reacting liquid, it is input into natural circulation evaporator to concentrate, adopting backward feed and dual effect concentration with constant pressure in the first chamber and negative pressure in the second chamber. Through cooling crystallization, thickening by the thickening apparatus, the concentrated liquid continuously separates ammonium chloride as by-products. The gained secondary mother liquid returns to preparation groove. Repeating this cyclic process, we could sequentially get solid potassium nitrate and ammonium chloride.The invention has improved production stability and product quality a lot and reduced raw material consumption and energy consumption, with simple and serial flow process. The invention has realized the mass production.

Owner:EAST CHINA ENG SCI & TECH

Efficient composite modifying-refining agent for hypoeutectic cast aluminium-silicon alloy and treatment process

InactiveCN1936044ASimplify the melt handling processImprove performanceStrontium carbonateSilicon alloy

The invention relates to a high efficiency compounded refiner for hypoeutectic aluminum-silicon alloy and the method of application. It contains 10-30wt% NaCl, 10-15wt% KCl, 10-20wt% sodium fluoride, 1-30wt% potassium fluoborate, and 1-20wt% potassium fluotitanate, 1-20wt% strontium carbonate, 1-15wt% cerium fluoride, 5-20wt% granular lanthanum abundant mixed rare earths and 1-5% heachloroethane. After taking the process of heating, dehydrating, mixing according to the ratio to equal, pressing to molding, it could be sealed to use. The technology includes the following steps: after the magnesium alloy melting in crucible, heating to 720-740 degree centigrade and removing the slag, standing for 3-5 minutes, pressing the refiner into alloy liquid to take refining process for 5-10 minutes, standing for 5-10 minutes after process to gain hypoeutectic aluminum-silicon alloy melt. The invention simplifies melt process technology, lowers cost and improves the capability of alloy.

Owner:重庆工学院

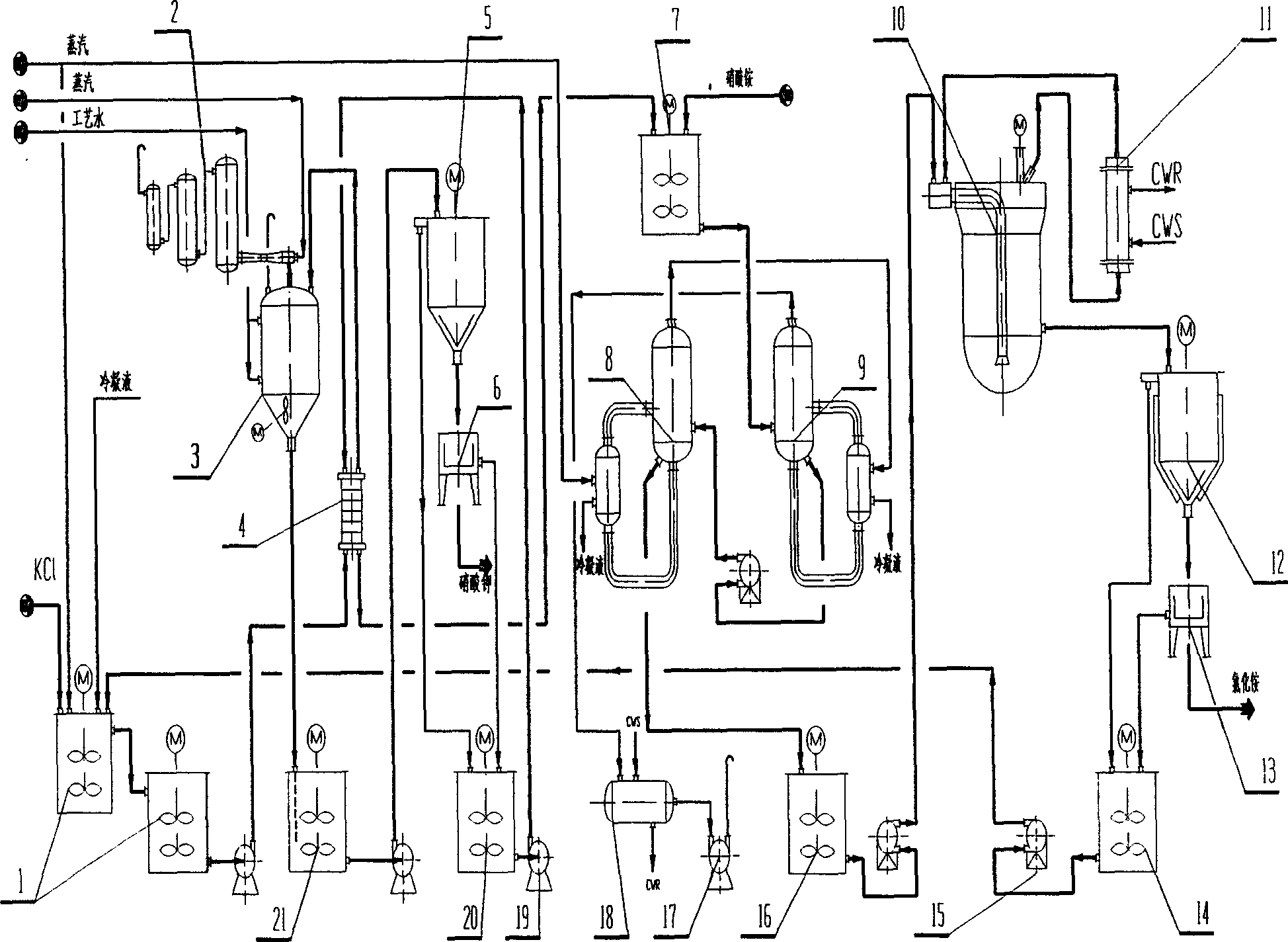

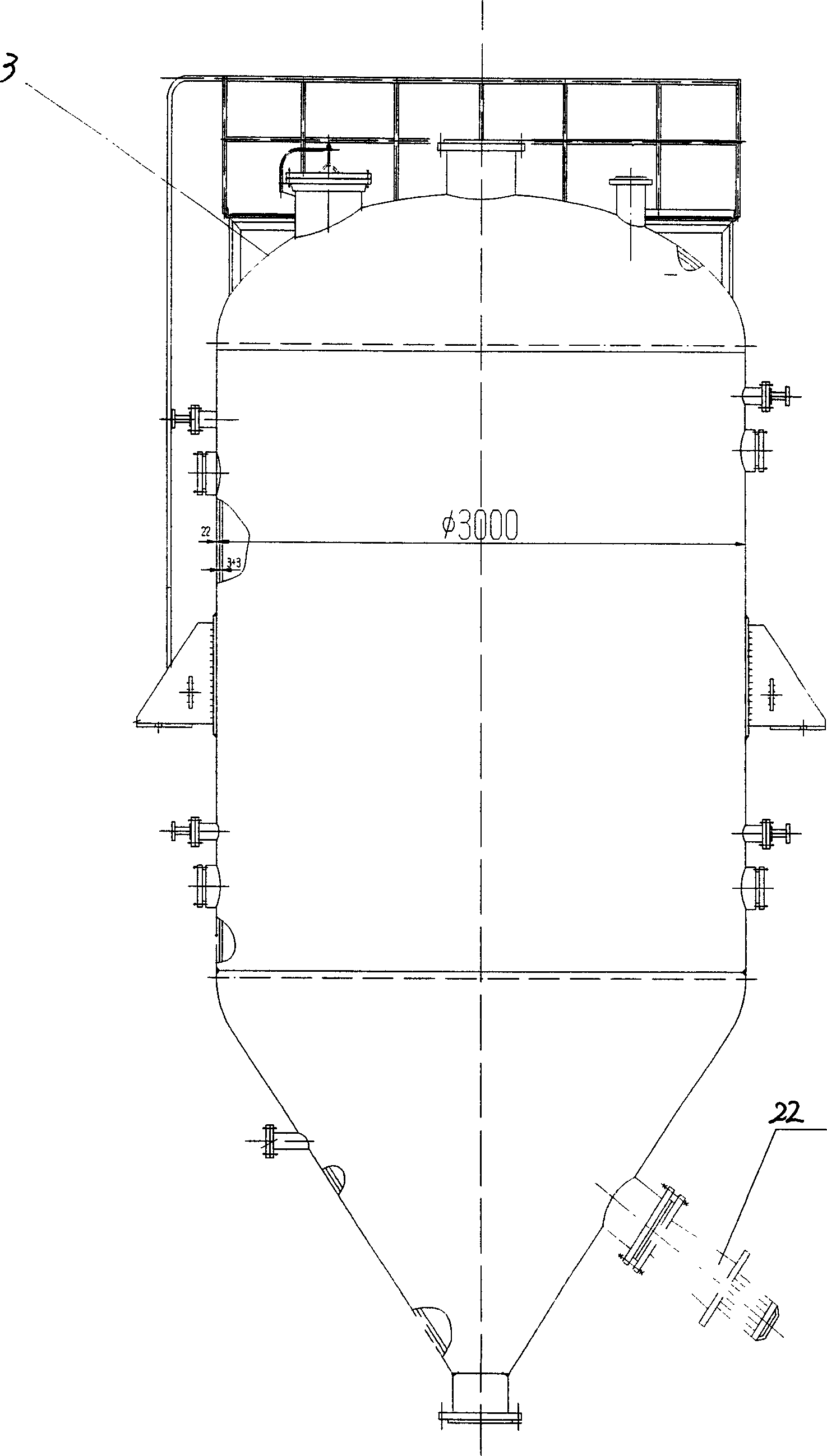

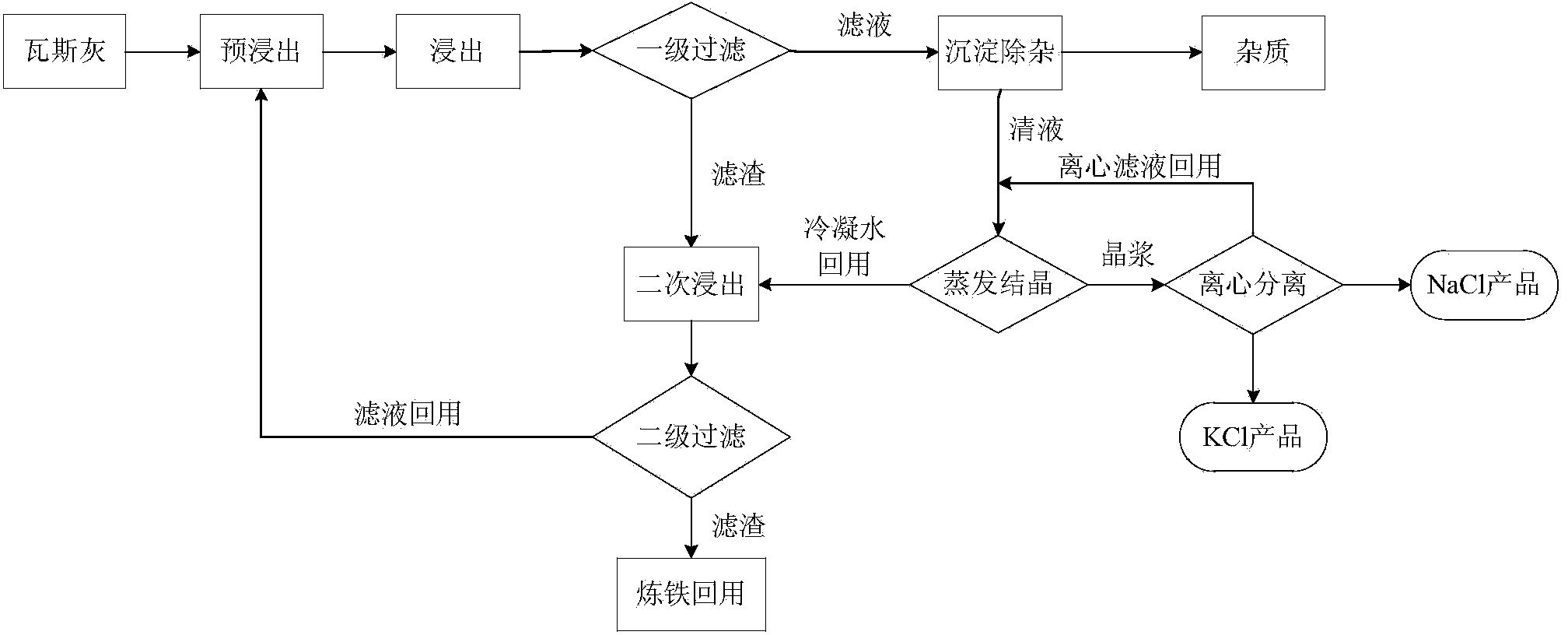

Method for producing potassium chloride by using blast furnace dust of iron and steel enterprises

ActiveCN103435073AHarm reductionQuality improvementAlkali metal chloridesProcess engineeringEnvironmental engineering

The invention discloses a method for producing potassium chloride by using blast furnace dust of iron and steel enterprises. The method comprises the following steps: mixing the blast furnace dust with running water according to a certain ratio in a pre-leaching process; at the end of the mixing, stirring and leaching the mixed solution in a leaching process; filtering the mixed solution in a primary filtering procedure; removing impurities out of primary filtrate in a precipitating and impurity removing procedure; leaching the primary filter residue for the second time in a secondary leaching procedure; adding a precipitator to the primary filtrate in the precipitating procedure for precipitate and removing impurities; standing still for layering or filtering after completely precipitating; carry out multi-effect crystallization on clear liquid in an evaporation crystallization process to produce potassium chloride and sodium chloride products; filtering the mixed solution to secondary filtering equipment after the secondary leaching procedure reaches the filter condition; and recycling secondary filter residue for making iron, and returning the secondary filtrate to the pre-leaching process to be used again. By adopting the method, the high potassium feature in the blast furnace dust is fully utilized, waste materials are changed into valuable resources, the damage of emission of waste to the environment is reduced, and a high-quality potassium chloride product is also produced.

Owner:UNIV OF SCI & TECH BEIJING

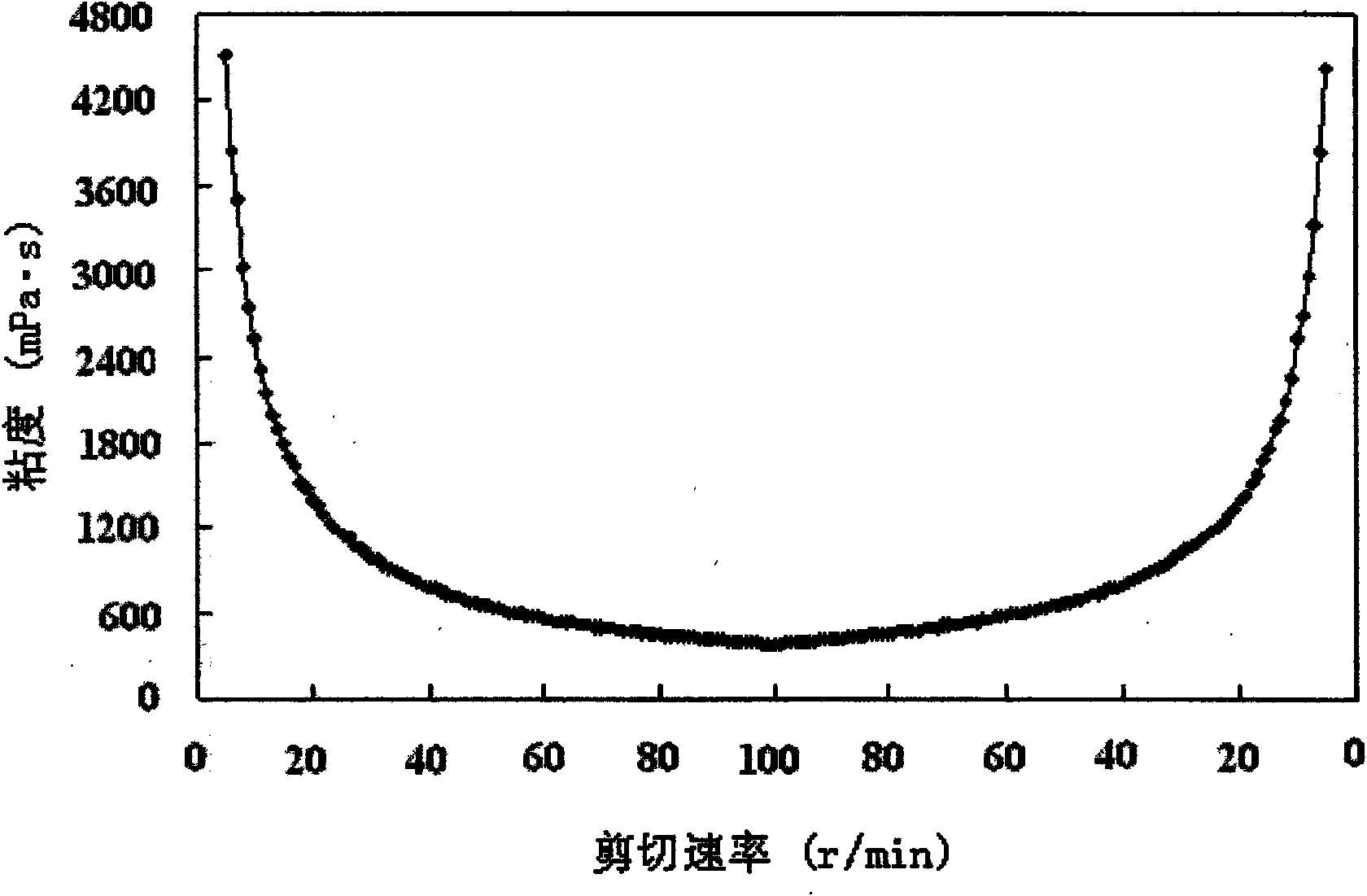

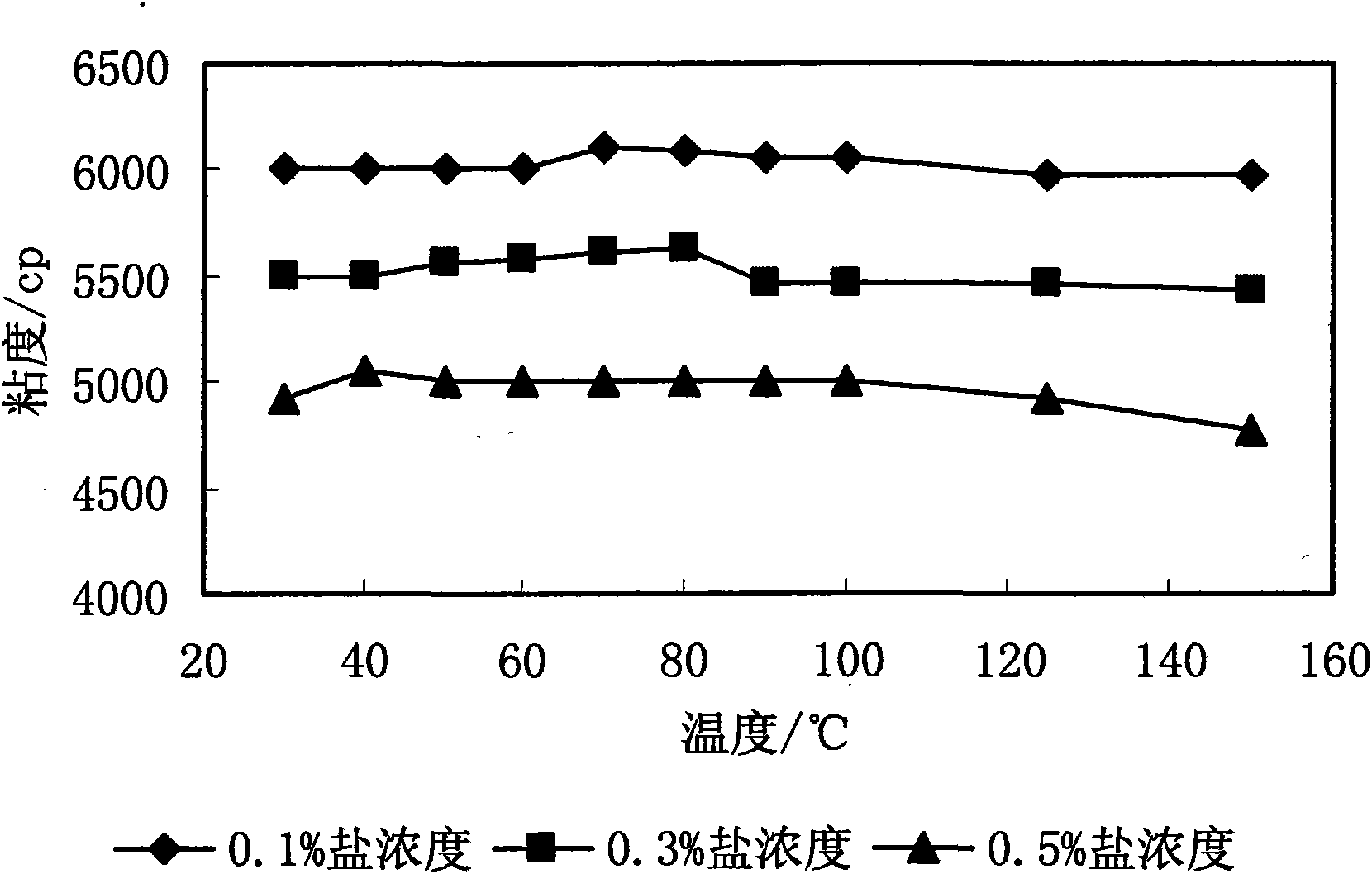

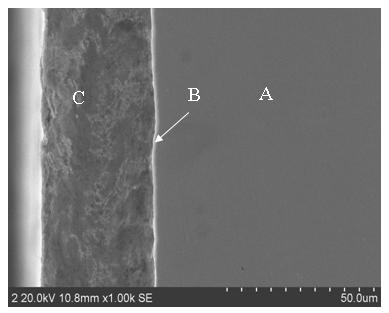

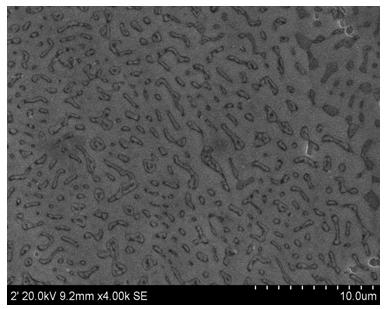

Sphingomonas sp. TP-5 and method and application of same for producing welan gum

InactiveCN101619300AImprove stabilityUnique shear thinningBacteriaMicroorganism based processesBiotechnologyInorganic salts

The invention relates to Sphingomonas sp. TP-5 and a method and an application of the same for producing welan gum. A strain of the invention is prepared by separating and acclimating sugar-contained wastewater in a molasses plant, has a systematic name of Sphingomonas sp. and a preservation number of CGMCCNo.3097, not only can grow in nutrient media of beef broth, LB and nutrient agar, but also can grow in a sugar-contained inorganic-salt culture medium. The TP-5 strain can be fermented in the sterile culture medium containing sugar, inorganic salt and water at a temperature condition of 28-37 DEG C; ymotic fluid is extracted to obtain the welan gum achieving a temperature-resistant limit value of 150 DEG C; and potassium chloride in different concentrations is added so that a welan gum solution remarkably improves the viscosity, enhances the temperature stability, does not vary the viscosity with temperature and presents stronger temperature tolerance, thereby being applied to seawater drilling mud and a high salinity reservoir viscous water flooding system.

Owner:NANKAI UNIV

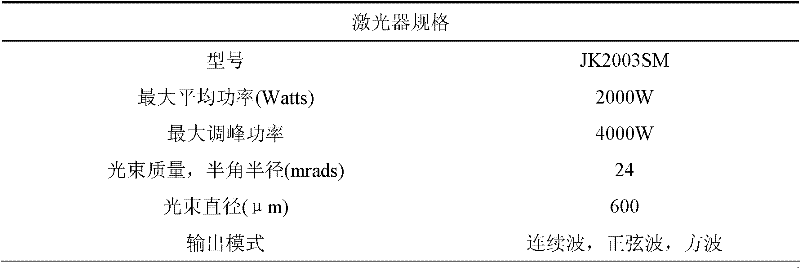

Active agent for laser welding and method for laser welding by utilizing same

InactiveCN102179645AStrong penetrating powerIncrease profitWelding/cutting media/materialsSoldering mediaAluminium chlorideLithium chloride

The invention discloses an active agent and a method for carrying out surface treatment on materials to be welded of aluminium and aluminium alloys so as to improve the energy utilization rate of the aluminium and the aluminium alloys, deepen the fusion depth of welding seams and further obtain higher welding quality. The active agent for laser welding consists of a chloride and a fluoride, wherein the mass ratio of the chloride to the fluoride is (1-2): (1-4); the chloride is at least one of lithium chloride, sodium chloride, potassium chloride, zinc chloride, magnesium chloride, aluminium chloride, calcium chloride or tin chloride; and the fluoride is at least one of lithium fluoride, sodium fluoride, magnesium fluoride or calcium fluoride. When the surface treatment is carried out, firstly the fluoride and the chloride are mixed fully and uniformly, water is added to form a supersaturated solution, then the supersaturated solution is coated on the surface of a welded test piece as a coating agent, then drying is carried out, and finally laser welding is carried out under the condition of gas protection.

Owner:TIANJIN UNIV

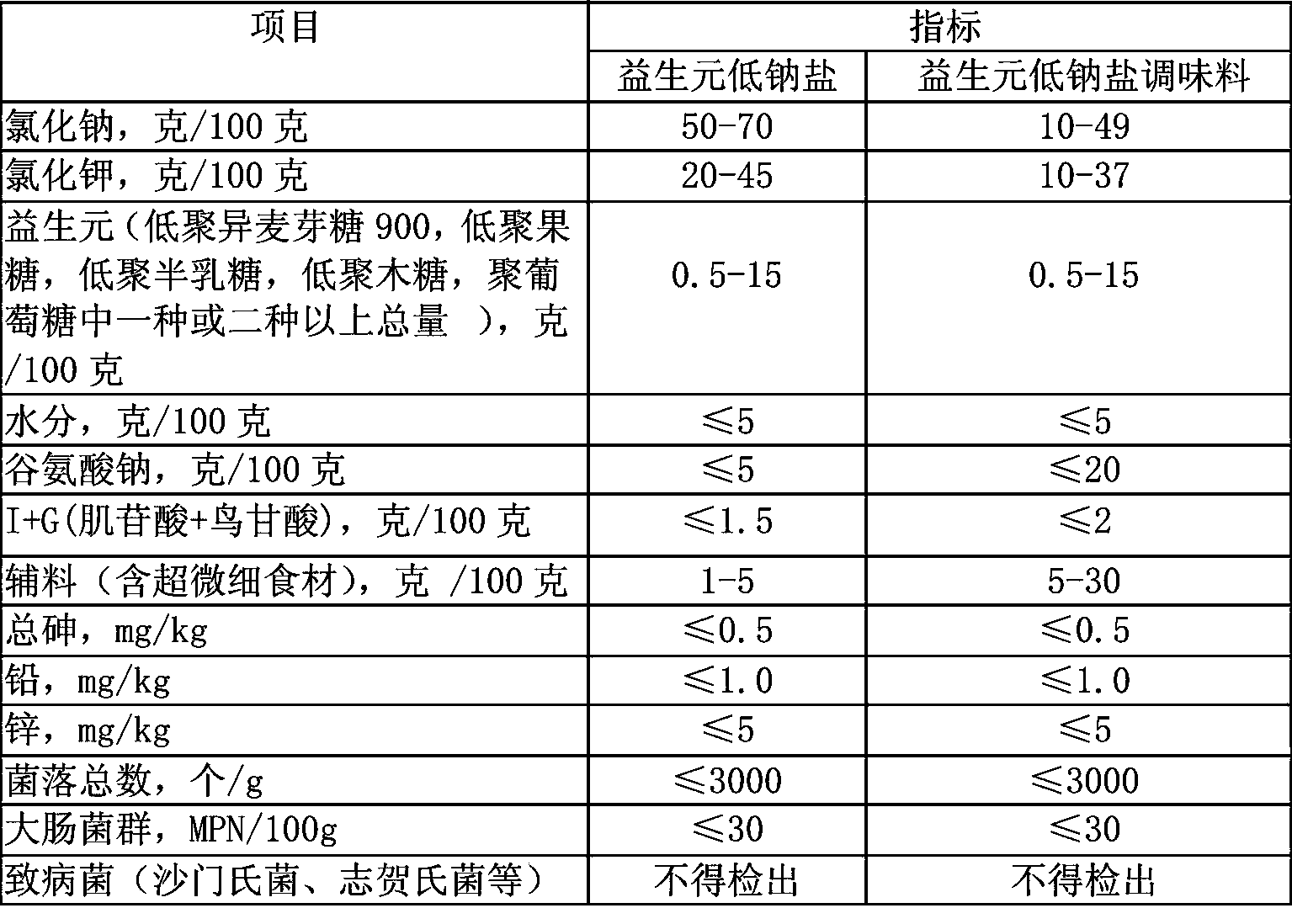

Prebiotic low-sodium salt and prebiotic low-sodium salt composite seasoning, and preparation method thereof

InactiveCN103876104APromote growth and reproductionPrevent sub-health diseasesSugar food ingredientsFood ingredient functionsBiotechnologyHigh sodium

The invention relates to a health-care seasoning, particularly a prebiotic low-sodium salt and a prebiotic low-sodium salt composite seasoning, and a preparation method thereof. The prebiotic low-sodium salt comprises 50-70% of sodium chloride, 20-45% of potassium chloride, 0.5-15% of prebiotic and 1-5% of ultrafine food powder and other auxiliary materials. Unless otherwise specified, the percents in the invention are mass percents. The prebiotic low-sodium salt seasoning comprises 10-49% of sodium chloride, 10-37% of potassium chloride, 0.5-15% of prebiotic and 5-30% of ultrafine food powder and other auxiliary materials. The prebiotic low-sodium salt and prebiotic low-sodium salt seasoning overcome the defects of high sodium chloride content, unbalanced sodium and potassium ions and high tendency to causing hypertension and kidney diseases of the human body; the water-soluble dietary fiber-oligosaccharide prebiotic, which is beneficial to the human health, is added to well promote growth and reproduction of the probiotic in the intestinal tract, thereby preventing constipation and subhealth diseases caused by accumulation of toxins in the intestinal tract.

Owner:SICHUAN YISHENGYUAN TECH CO LTD

Low-mercury catalyst used for synthesizing vinyl chloride

InactiveCN102962082APlay a fixedActivePhysical/chemical process catalystsPreparation by halogen halide additionPtru catalystCopper chloride

The invention discloses a low-mercury catalyst used for synthesizing vinyl chloride. The low-mercury catalyst takes mercuric chloride as a main active component, one or more of precious metals such as Au, Pd, Pt, Ru, Rh, Os and Ir salts or complexes thereof as active regulators, and one or more of potassium chloride, ferric chloride, zinc chloride and copper chloride as cocatalysts. By adding trace amount of precious metal salt into the mercuric chloride, the low-mercury catalyst forms a stable composite metal compound, plays a role in fixing and activating mercuric chloride, and still maintains very high catalytic activity and stability when the load capacity of the mercuric chloride is reduced to 0.1-2%.

Owner:DALIAN RES & DESIGN INST OF CHEM IND

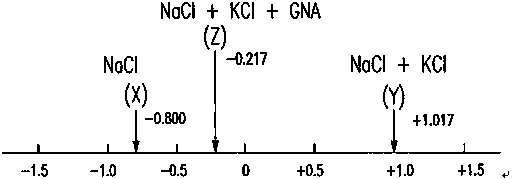

Salt replacing composition, process for its preparation and food systems containing such composition

A salt replacing composition for replacing sodium chloride in food contains a major amount of potassium chloride, in combination with ammonium chloride, sucrose, one or more of disodium inosinate and disodium guanylate, an organic acid, and a salt of glutamic acid. A reduced sodium chloride composition contains the salt replacing composition and sodium chloride. A food containing the salt replacing composition and a process for making the salt replacing composition.

Owner:MCCORMICK & CO INC

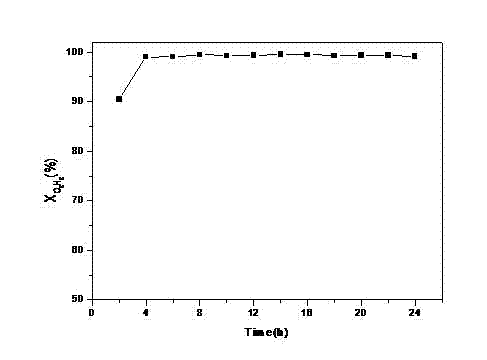

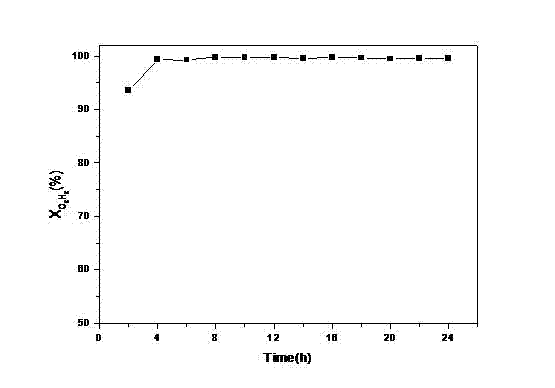

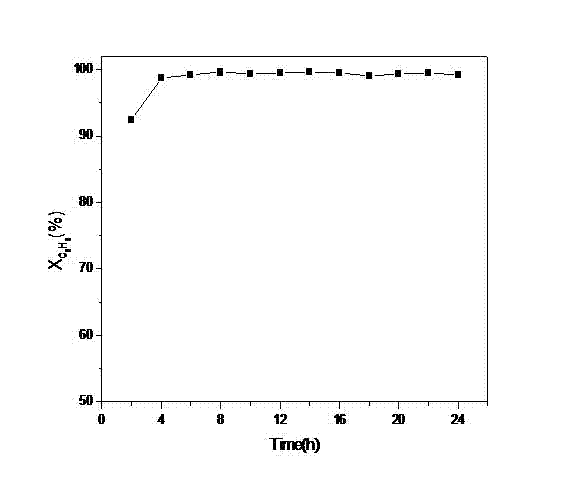

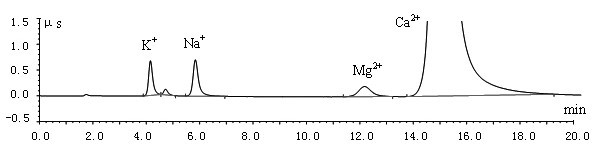

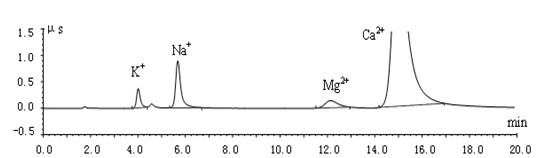

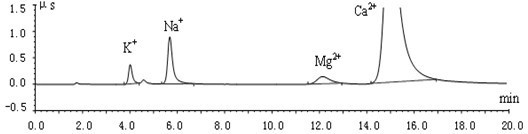

Method for determining content of potassium, sodium, calcium and magnesium in cigarette paper simultaneously

The invention discloses a method for determining content of potassium, sodium, calcium and magnesium in cigarette paper simultaneously, which includes the following steps: cutting 100+ / -0.1 mg of a cigarette paper sample, using 100mL of 0.02mol / L hydrochloric acid as an extracting agent, ultrasonic-extracting for 18-22min to obtain extract liquor, selecting 5.0mL of the extract liquor to a 25mL volumetric flask, bringing to the volume with 0.02mol / L hydrochloric acid to obtain diluent, and filtering the diluent through a 0.45 mu m filtering film to obtain sample liquid to be detected; selecting sodium chloride, potassium chloride, hexahydrate magnesium chloride and anhydrous calcium chloride, using pure water as solvent, preparing mixed standard solution through gradual diluting, and adding 0.02mol / L hydrochloric acid to prepare series standard working solution; detecting and analyzing the series working solution and the sample liquid to be detected respectively through an ion chromatographic instrument; and drawing a standard curve and calculating results. The method is fast and simple to operate, high in sensitivity, low in detection limit, good in recovery rate, and suitable for batch analyzing of important inorganic elements in the cigarette paper.

Owner:CHINA TOBACCO HEBEI INDUSTRIAL CO LTD

Agricultural composite manure and preparing method thereof

InactiveCN1583681AReduce use costReduce pollutionAmmonium salt fertilisersUrea compound fertilisersDicarbonateSodium phosphates

An agricultural nutritive composite fertilizer able to increase the resistance of agricultural crops to diseases is prepared from ammonium molybdate, borax, sodium phosphate, urea, potassium sulfate (or chloride), complex copper, complex zinc, potassium dicarbonate and auxiliary.

Owner:陈天骏

A kind of sodium-free refining agent for aluminum and aluminum alloy and production method thereof

The invention discloses a sodium-free refining agent for aluminum and aluminum alloy, which consists of the following ingredients in percentage by weight: 15 to 25 percent of potassium aluminium fluoride, 5 to 15 percent of calcium fluoride, 10 to 25 percent of potassium carbonate, 10 to 25 percent of potassium sulfate, 5 to 15 percent of barium sulfate, 15 to 30 percent of potassium chloride and3 to 5 percent of anhydrous aluminium chloride. The invention also discloses a production method of the sodium-free refining agent. Because the sodium-free refining agent does not contain sodium salts, compared with sodium-containing refining agents, the sodium-free refining agent effectively solves the problem of antimony modification and phosphor modification influence caused by more or less sodium salt contained in the existing refining agent and overcomes the defects of alloy casting performance influence, melt flowability reduction and sodium brittleness possibly caused by the sodium element in aluminum-magnesium system alloy with the magnesium content being higher than 2 percent. A better use effect can be obtained in the antimony modification and phosphor modification alloys and high-magnesium-aluminum alloy. The invention belongs to the qualitative improvement on the prior art.

Owner:HEBEI SITONG NEW METAL MATERIAL CO LTD

Soybean dedicated biological organic green fertilizer and preparation method thereof

ActiveCN104045425AIncrease profitSufficient nutritionFertilizer mixturesRapeseedAmmonium Hydrogen Carbonate

The invention discloses a soybean dedicated biological organic green fertilizer which is characterized by being prepared from the following raw materials in parts by weight: 100-120 parts of human and animal excreta, 50-60 parts of corn straw, 35-50 parts of rapeseed cake meal, 25-30 parts of urea, 21-25 parts of ammonium hydrogen carbonate, 35-40 parts of diammonium phosphate, 10-13 parts of a limestone powder, 1-2 parts of zinc oxide, 29-35 parts of animal urine, 17-23 parts of potassium chloride, 24-28 parts of peanut cake meal, 5-7 parts of brown sugar, 5-7 parts of an EM agent, 8-10 parts of a soil improvement agent, and a proper amount of water. The organic fertilizers are fermented and then are mixed with the general chemical fertilizers, and the melting urea is utilized to coating the surface, so that a slow release effect is played, subsequent nutrients for soybean are allowed to be sufficient, the utilization rate of the fertilizer is improved, the fertilization cost is substantially reduced, the yield of the soybean is improved, and economic benefits are also correspondingly improved; and the soybean dedicated biological organic green fertilizer is green and environmentally friendly, and is convenient to popularize and apply.

Owner:广西三合生态农业发展有限公司

Compound polyethylene glycol electrolyte powder and preparation method thereof

The invention relates to compound polyethylene glycol electrolyte powder and a preparation method thereof, in particular to a powder compound containing polyethylene glycol and electrolyte. The powder compound comprises, by weight, 6000 parts of polyethylene glycol, 118-176 parts of sodium chloride, 60-90 parts of potassium chloride, 137-205 parts of sodium bicarbonate, 461-692 parts of anhydrous sodium sulfate, 19-29 parts of powder essence, and / or 5-7.6 parts of aspartame. The compound polyethylene glycol electrolyte powder has fine micromeritic properties and taste.

Owner:SHENZHEN WANHE PHARMA

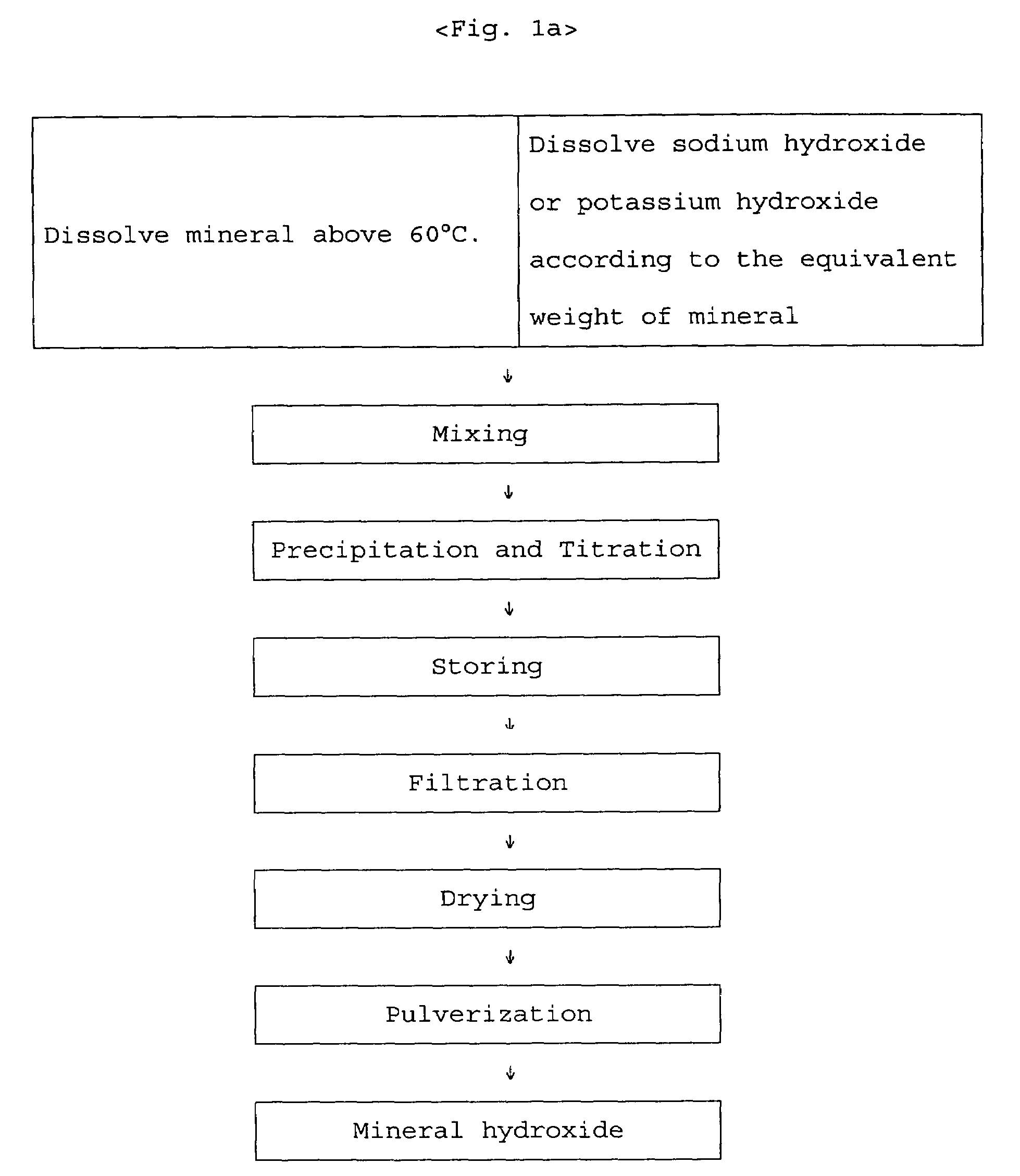

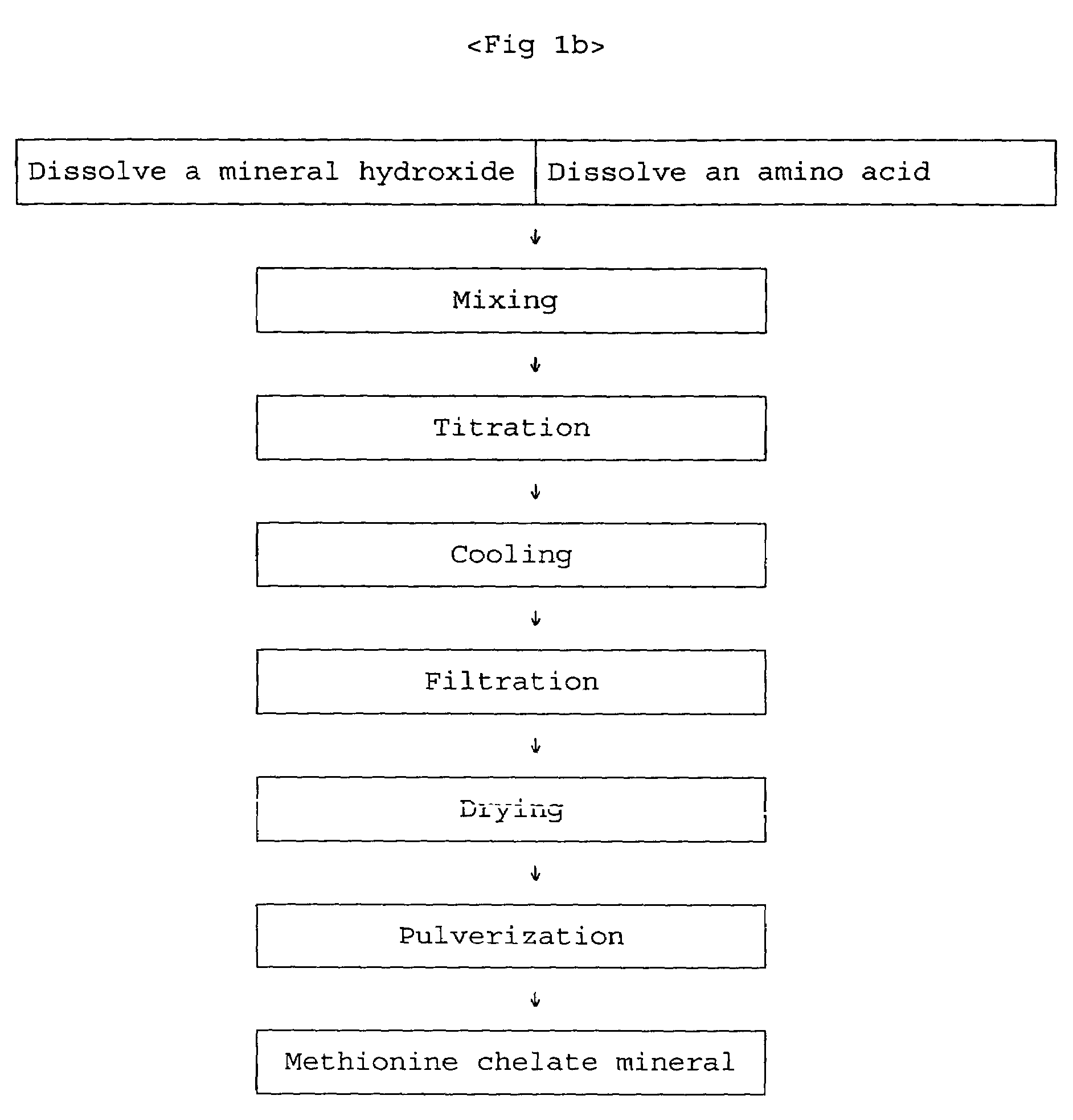

Method for preparation of organic chelate

InactiveUS7087775B2Copper organic compoundsIron organic compoundsIntestinal structureHigh absorption

A method for the preparation of organic chelates utilized as ingredients of animal feedstuffs. The organic chelates are passed to the intestines of livestock without decomposition in the stomach, and thereby have a high absorption rate. The present invention provides a preparation method of perfect chelate minerals having a high yield and containing copper, zinc, iron, manganese, or cobalt. The organic chelate mineral is prepared by precipitating metal sulfates or chlorides with sodium hydroxide or potassium hydroxide in a solution of two equivalents of an amino acid completely dissolved at above 70° C., collecting metal hydroxide by removing sodium sulfate, potassium sulfate, sodium chloride or potassium chloride through filtering, dissolving the metal hydroxide by adding the equivalent weights of hydrochloric acid, and then neutralizing the hydrochloric acid added for dissolving metal hydroxide.

Owner:LEE SANG BUM +1

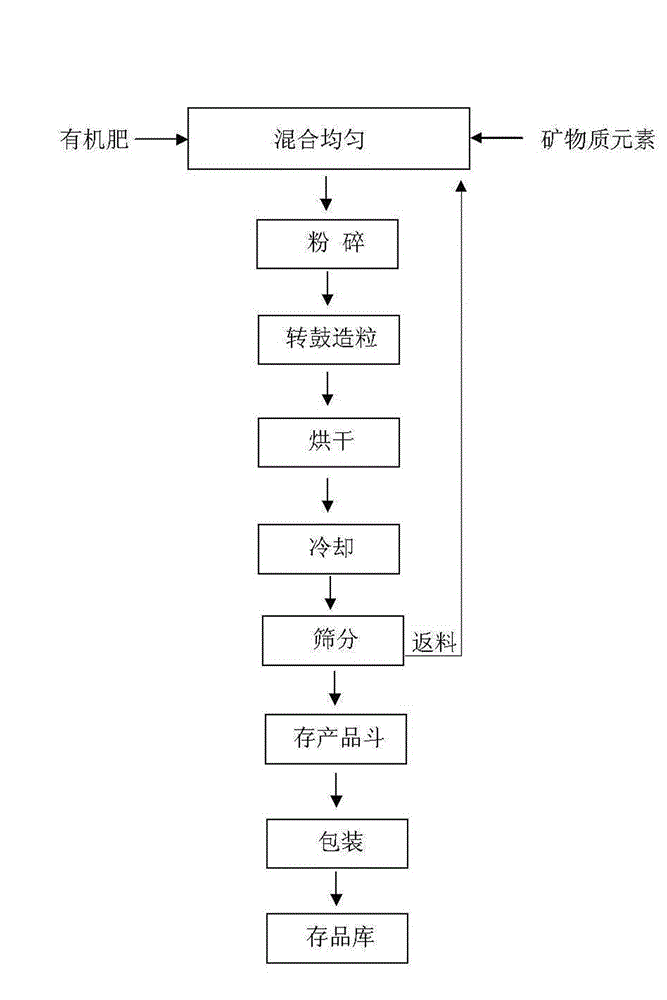

Total nutrient organic-inorganic compound fertilizer

InactiveCN102875236AReduce or eliminate compactionIncrease profitFertilizer mixturesPhosphateInorganic compound

The invention provides a total nutrient organic-inorganic compound fertilizer, which comprises the following components in percentage by weight: 10-15 percent of bean cake, 10-15 percent of cotton cake, 20-25 percent of poultry excrement, 5-10 percent of humic acid, 0.1-0.2 percent of sporotrichum thermophile, 15-33 percent of urea, 8-25 percent of monoammonium phosphate, 8-25 percent of potassium sulfate or potassium chloride, 0.6-1 percent of calcium powder, 0.5-1.5 percent of magnesium oxide, 0.1-0.3 percent of copper sulfate, 0.3-0.5 percent of ferrous sulfate, 0.2-0.5 percent of zinc sulfate, 0.2-0.5 percent of manganese sulfate, 0.2-0.3 percent of boric acid and 0.000006-0.00002 percent of ammonium molybdate. The total nutrient organic-inorganic compound fertilizer contains macroelements, secondary elements, microelements, organic matters and microorganisms, the utilization rate of the fertilizer can be increased, the soil organisms can be activated, and soil hardening is relieved or eliminated.

Owner:何建国

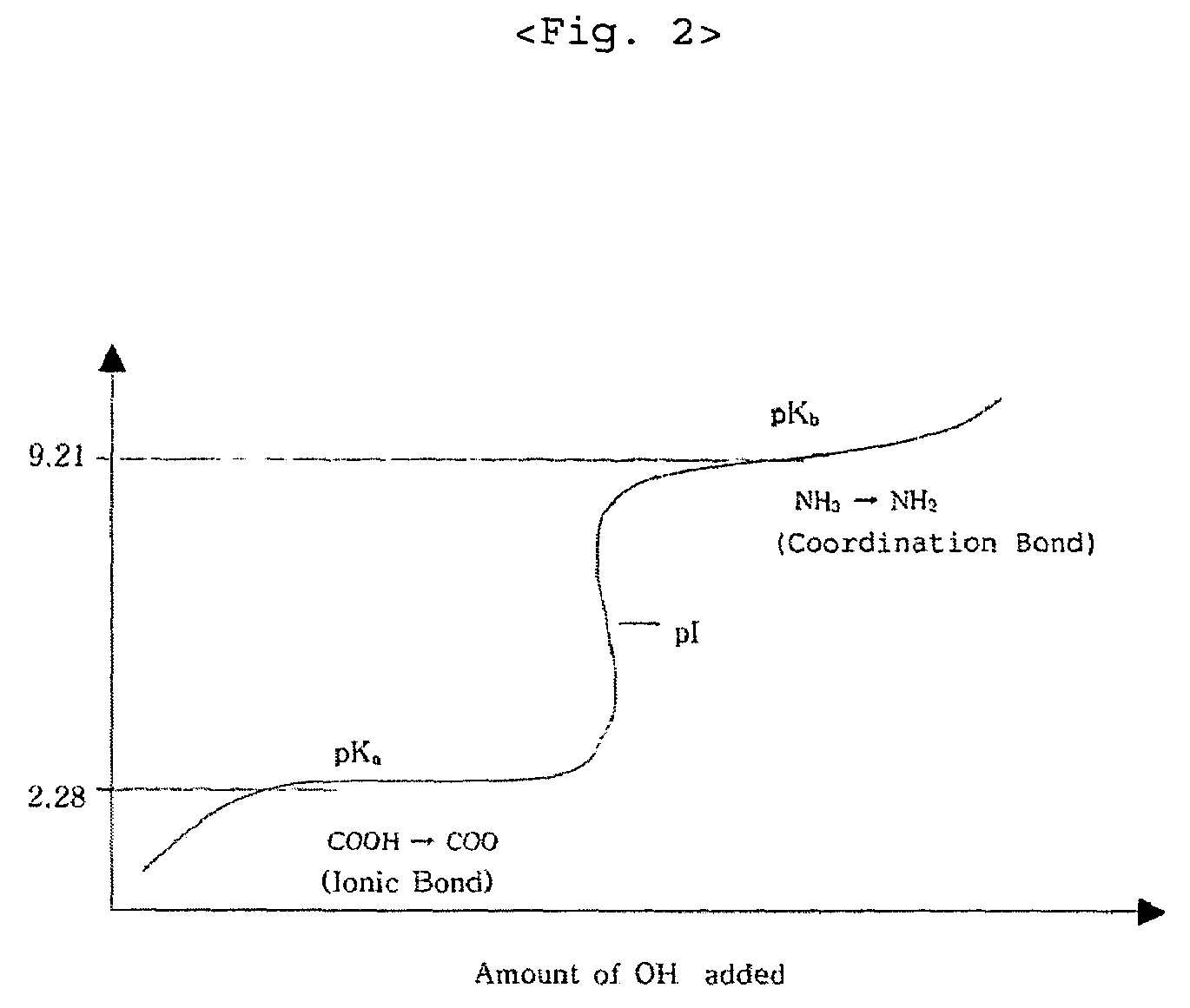

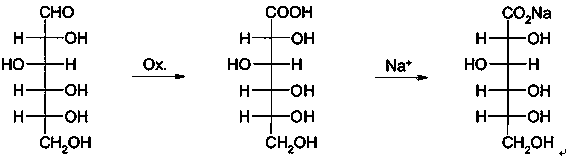

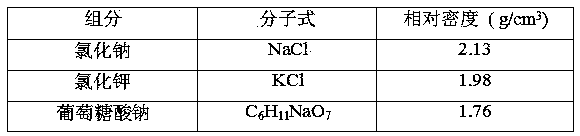

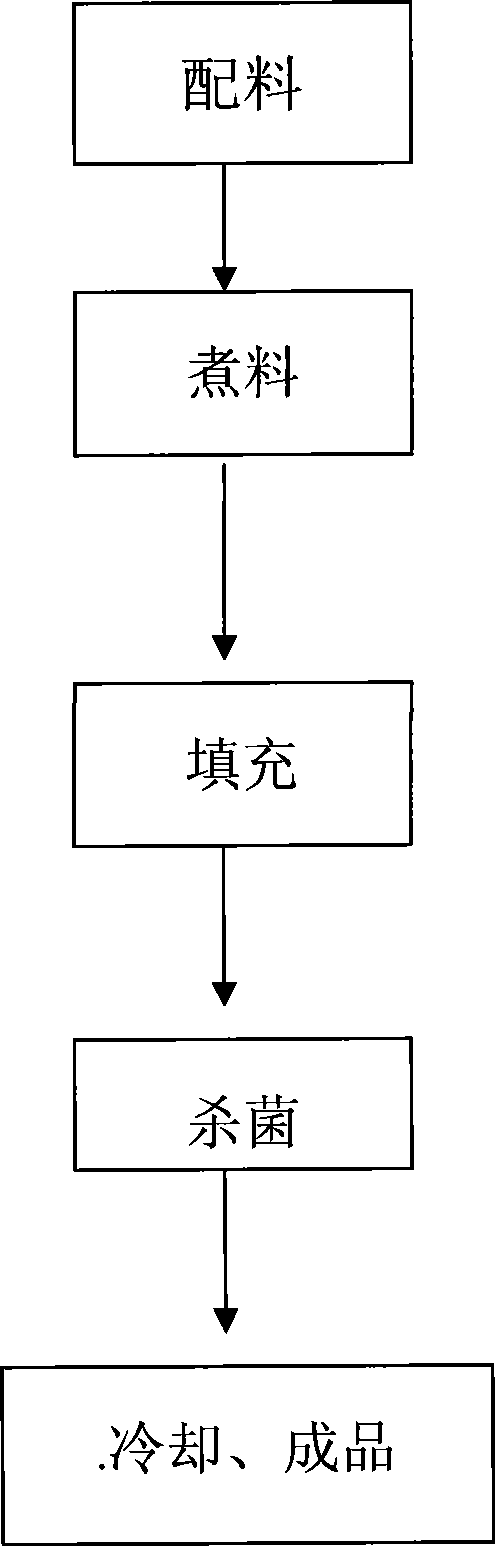

Novel low-sodium salt containing sodium gluconate and preparation method thereof

ActiveCN103404834AReasonable compositionMask bitternessFood preparationSpray driedChloride potassium

The invention discloses a novel low-sodium salt containing sodium gluconate and a preparation method thereof. The novel low-sodium salt is specifically prepared from the following ingredients in percentage by weight: 15-25% of sodium gluconate, 40-70% of sodium chloride, 15-25% of potassium chloride and 0.5-2% of maltodextrin. The preparation method comprises the steps of mixing sodium chloride, potassium chloride and sodium gluconate according to the ratio, dissolving a mixture into deionized water, heating and stirring until the mixture is completely dissolved, adding 1.5% of maltodextrin into a solution, stirring for certain time, and then, immediately carrying out spray drying. The finally prepared low-sodium salt product is powdery, and the moisture granularity is within a specific range. The sodium content of the product is at least 25% lower than that of the traditional edible salt; and compared with the ordinary low-sodium salt, due to the innovation of the preparation manners for the product, the product has the advantages that the homogeneity is improved, and the taste is pure and is not bitter on the premise that the salinity is guaranteed.

Owner:SHANDONG XIWANG SUGAR

Color function seasoning low-sodium liquid salt and preparing method thereof

InactiveCN104000166AReduce intakePrevent morbidityNatural extract food ingredientsFood ingredient functionsSalt contentPlant Sources

The invention relates to a color function seasoning low-sodium liquid salt formula and a preparing method of color function seasoning low-sodium liquid salt. Low-sodium liquid salt mother liquor is used as main raw materials of the low-sodium liquid salt. The low-sodium liquid salt mother liquor comprises (according to the mass percent in the mother liquor salt content total quantity) 60%-80% of sodium chloride, 15%-30% of potassium chloride and 5%-15% of magnesium chloride. The low-sodium liquid salt further comprises a plant source function component with the adding quantity (according to the mass added into 100 mL of low-sodium liquid salt mother liquor) is 0.5%-10%. Optimization technologies such as mixing, homogenization, sterilization and filling are carried out, and color function seasoning low-sodium liquid salt products with function component activity being maintained to the maximum degree are prepared. A controllable-quantity liquid packaging container is used, the salt can be easily and evenly blended into food, the problem that solid salt is dissolved slowly, so that excessive adding or uneven dispersing may happen is solved, and accordingly eating is convenient and flexible. Compared with traditional solid salt production, during a production process of the liquid salt, a large amount of equipment needed for salt drying can be reduced, energy loss is lowered, and waste water discharging is lowered.

Owner:CHINA AGRI UNIV

Convenient bean jelly and method for producing the same

The invention relates to the technical field of food processing, in particular to convenient bean jelly and a method for preparing the same. The convenient bean jelly is prepared from the following raw materials by weight percentage and by the following steps: corn flour taken as a major ingredient is added and mixed with carrageenin, potassium chloride, monopotassium phosphate, konjaku flour, common salt, citric acid, potassium sorbate, and flavor composition; the mixture is boiled for 8 to 10 minutes till the temperature reaches between 45 and 60 DEG C; pulpy liquid is filled in a container and the container is sealed with a thin film or tinfoil; the container is sterilized for 25 minutes at a temperature between 80 and 95 DEG C; and then the container is cooled to obtain the finished product. The convenient bean jelly can be eaten directly after the package is opened, carried conveniently and stored for a plurality of months. The production process of the convenient jelly has the advantages of readily available raw materials, low production cost, high production ratio, simple process and so on. Therefore, the convenient jelly and the method have good popularized and use value.

Owner:上海美吉食品有限公司

Nuisanceless powder injection refining flux

The invention relates to a nuisanceless powder injection refining flux belonging to a flux for casting. Aiming at the problem that a hexachloroethane powder injection refining flux inevitably generates toxic chlorine gas and fluorine gas which are harmful to the health of an operator, etch equipment and tools and cause serious pollution to the environment to generate public hazards. The nuisanceless powder injection refining flux is characterized by comprising the following components in percent by weight: 15-25 percent of Na2SiF6, 5-15 percent of Na2SO4, 5-15 percent of Na2NO3, 5-15 percent of CaF2, 15-25 percent of KCl and the balance of NaCl added to 100 percent. The NaCl and the KCl are combined to achieve favorable spread performance, coverage and separability; the Na2SiF6 produces non-toxic and volatile SiF4 and AlF3 and SiO2 with good slagging performance; a large quantity of hydrogen and other impurities can be taken out in the floating process of a fusant; the CaF2 promotes slag bodies to flow, and the Na2NO3 enables the fusant to raise the temperature partially, and a small quantity of molten aluminum or aluminum alloy doped in slag is dropped back to the fusant. On trial, the nuisanceless powder injection refining flux shows a favorable refining effect and has the beneficial effect of no toxicity or public hazards.

Owner:镇江市丹徒区振华熔剂厂

Composition with efficacies of whitening, moisturizing, repairing and caring skin, as well as preparation method and applications of composition

InactiveCN107411982AIncrease brightnessFirming and Lifting ContourCosmetic preparationsToilet preparationsArginineCuticle

The invention relates to a composition with the efficacies of whitening, moisturizing, repairing and caring the skin, as well as a preparation method and applications of the composition. The skin care composition is prepared from the following raw materials: water, sodium hyaluronate, sodium dihydrogen phosphate dihydrate, potassium chloride, sodium hydroxide, calcium chloride, glutamine, benzalkonium chloride, magnesium sulfate, aminobutyric acid, sodium ascorbate, alanine, arginine, lysine hydrochloride, valine, histidine, leucine, taurine, coenzyme A, alcohol, polysorbate 80, thiamine, disodium diphosphate, recombinant human epidermal cell growth factors and the like. The skin care composition disclosed by the invention can permeate the muscle bottom for replenishing water for the skin from the deep layer, so that the skin is full of elasticity, the color of the skin is brightened, the fine wrinkles are reduced, the skin is clean and watery, the balance of water and oil is regulated, the pores are shrunk, meanwhile, the brightness of the face can be increased, the injured epidermal layer is effectively repaired, the activity of tyrosinase is inhibited, the generation of skin melanin is reduced, so that the skin is healthy, natural and white.

Owner:刘毅

Electrolytic plating assisting method for hot dip galvanizing of steel wire and electrolytic plating assistant

InactiveCN101948990AEasy to dryImprove protectionHot-dipping/immersion processesElectrolysisEthylic acid

The invention relates to electrolytic plating assistant for hot dip galvanizing of a steel wire. Electrolytic plating assistant comprises the following components: 30-220 g / L of zinc chloride, 0-150 g / L of potassium chloride, 0-150 g / L of sodium chloride, 2-90 g / L of ammonium chloride, 0-100 g / L of boric acid, 0-70 g / L of acetic acid, 1-25 g / L of sodium fluoride, 2-50 g / L of cerium chloride, 0-50 g / L of potassium fluozirconate, 0-50 g / L of methanol, 0.5-20 g / L of hydrogen peroxide and the balance of water. The electrolytic plating assisting method comprises the following steps: washing with alkali, removing oil, washing with water, washing with acid to remove rust, washing with water, activating with weak acid, electrolyzing to assist plating, drying, and purifying the electrolytic plating assistant. The method can reduce the generation of AlCl3, prevent skip plating and reduce the generation of smoke dust. The electrolytic plating assistant has the characteristic of relatively high melting point, and thus, can increase the drying temperature and shorten the drying time. The dried plating assistant has the characteristics of low brittleness, high compatibility with electrogalvanizing, and low tendency to shedding.

Owner:NORTHEASTERN UNIV

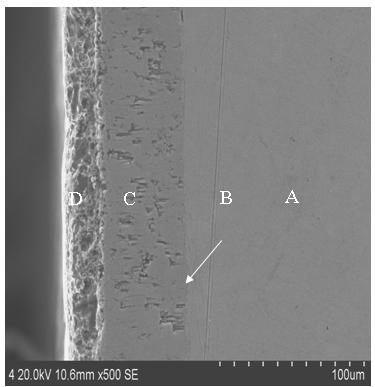

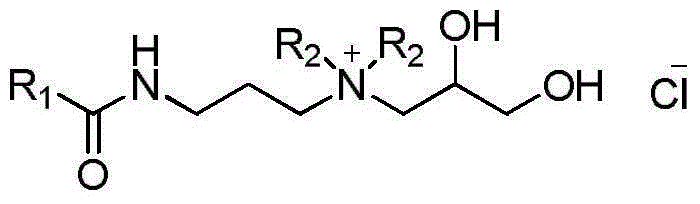

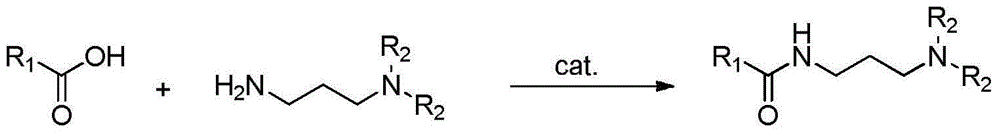

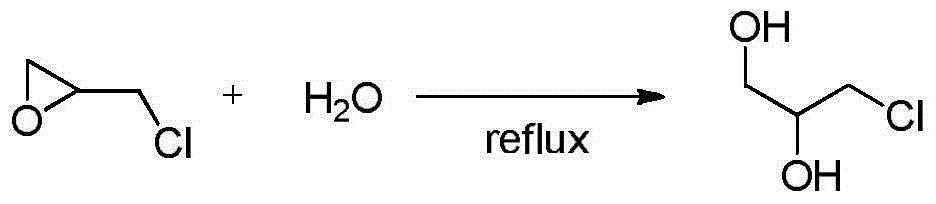

Cationic viscoelastic surfactant and preparation and application thereof

InactiveCN105080424AExcellent high temperature resistance and shear resistanceGood suspension effectOrganic compound preparationTransportation and packagingFracturing fluid3-MCPD

The invention discloses a cationic viscoelastic surfactant and preparation and application thereof. The preparation method of the cationic viscoelastic surfactant comprises the following steps: firstly, mixing long-chain fatty acid with dimethylaminopropylamine according to a certain proportion, adding a catalyst solution to obtain a required amide product intermediate A by a series of reaction; allowing reflux condensation reaction of epoxy chloropropane and water at a certain proportion to be carried out in oil bath of 100 DEG C to obtain colourless and transparent 3-chloro-1,2-propylene glycol aqueous solution, namely an intermediate B; heating the intermediate A in oil bath for melting, and dropwise adding an aqueous solution B to obtain the required viscoelastic surfactant by a series of reaction; the surfactant can be mixed with a potassium chloride solution according to a certain proportion to obtain clean fracturing fluid which is low in cost and excellent in performance, besides, the clean fracturing fluid has excellent high-temperature resistance, shearing resistance, and excellent solid-carrying performance, is automatic and thorough in gel breaking, causes little damage to the reservoir stratum and has the characteristic of wide application range.

Owner:SOUTHWEST PETROLEUM UNIV

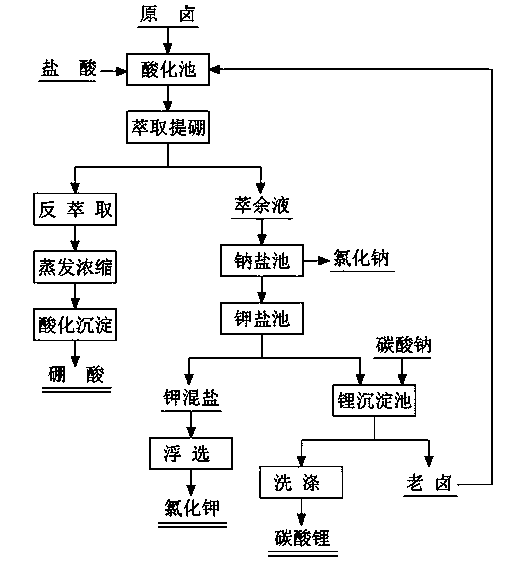

Method for comprehensively utilizing potassium, boron and lithium in carbonate type salt lake brine

ActiveCN103508462AGood for concentration and enrichmentSolve the difficulty of comprehensive utilization of lithiumBoron-oxygen compoundsAlkali metal chloridesChloride potassiumLithium carbonate

The invention provides a method for comprehensively utilizing potassium, boron and lithium in carbonate type salt lake brine. The brine type is converted from the carbonate type into the chloride type through introducing the acidification technology, so that the brine composition is simplified, and further the technical problem of combined extraction of potassium, boron and lithium from the carbonate type salt lake brine is solved. According to the method, the acidification technology is adopted to regulate the pH value of the brine, and the solvent extraction method is adopted to extract boric acid from the acidified brine; raffinate enters a sodium salt pond, then is subjected to solarization and evaporation to separate out sodium salt, and gets into a potassium salt pond to separate out potassium mixed salt; the potassium mixed salt is purified to prepare potassium chloride by adopting the flotation method; the precipitation method is adopted to extract lithium carbonate from the potassium separated mother liquor with enrichment of lithium; old brine subjected to lithium extraction is returned to the acidification pond for recycling.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

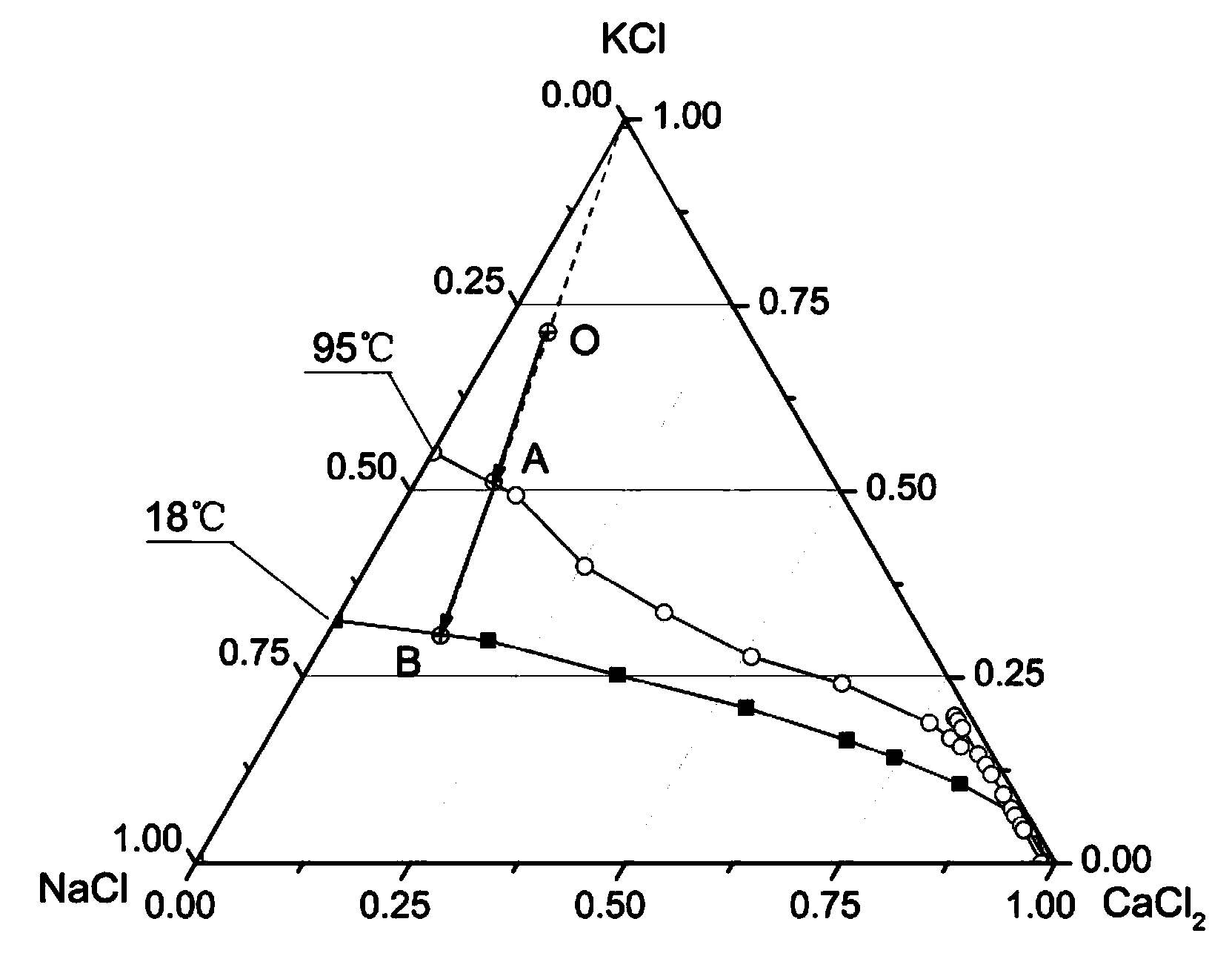

Process for producing potassium chloride by using potassic salt ores

InactiveCN102963912AQuality improvementCoarse granularityAlkali metal chloridesChloride potassiumRaw material

The invention discloses a process for producing potassium chloride by using potassic salt ores, which comprises the following steps: firstly, crushing potassic salt ores into particles with a size of 2-5 mm; then, adding the particles into a decomposition crystallizer through an electromagnetic oscillator, and simultaneously adding fresh water and circulated saturated fluid KCl-NaCl-MgCl2-H2O quanternary-system brine into the decomposition crystallizer, wherein in the process of adding, the circulated brine and raw ores are simultaneously fed into a reaction area of the decomposition crystallizer, and the fresh water is added at the junction of the reaction area and a crystallization area of the decomposition crystallizer; driving a bottom flow of the decomposition crystallizer into a flotation machine to carry out flotation, wherein the flotation is implemented sequentially through primary rougher flotation, primary scavenging and primary or secondary fine flotation; and carrying out washing, centrifugal dehydration and drying on concentrates subjected to fine flotation so as to obtain a potassium chloride product. The process disclosed by the invention is simple in production process and easy to operate, and has no restriction on the content of each component of the raw material potassic salt ores. Produced potassium chloride products are good in quality, large in particle size, and can be easily filtered and subjected to centrifugal dehydration, the energy consumption is reduced in the process of drying, and a phenomenon of blocking is uneasily caused, thereby bringing convenience to users.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com