Convenient bean jelly and method for producing the same

A convenient jelly and convenient technology, applied in the field of food processing, can solve the problems of not being able to eat immediately, inconvenient to carry, etc., and achieve the effect of easy carrying, good promotion and application value, and easy purchase of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

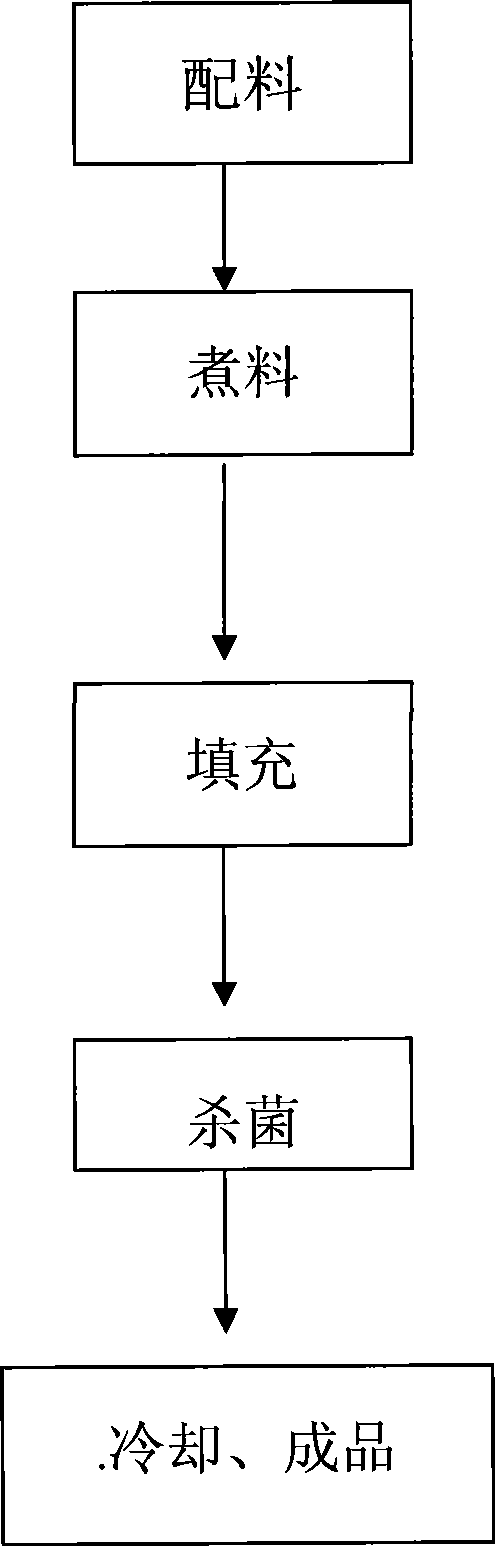

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 A kind of instant jelly

[0029] raw material:

[0030] Water 85Kg Konjac flour 0.21Kg

[0031] Corn starch 5Kg Salt 0.1Kg

[0032] Carrageenan 0.16Kg Citric acid 0.01Kg

[0033] Potassium chloride 0.1Kg Potassium sorbate 0.01Kg

[0034] Potassium dihydrogen phosphate 0.037Kg Edible essence 0.1Kg.

[0035] Mix the raw materials in the above ratio, stir and cook for 8-10 minutes, the temperature reaches 45-60°C, and let stand; then pour the slurry into the container, seal it with tin foil; sterilize at 80°C for 25 minutes; cool and pack the finished product.

Embodiment 2

[0036] Embodiment 2 A kind of instant jelly

[0037] raw material:

[0038] Water 95Kg Konjac Flour 0.6Kg

[0039] Corn starch 15Kg Salt 0.3Kg

[0040] Carrageenan 0.48Kg Citric acid 0.08Kg

[0041] Potassium chloride 0.33Kg Potassium sorbate 0.08Kg

[0042] Potassium dihydrogen phosphate 0.1Kg Edible essence 0.8Kg.

[0043] Mix the raw materials in the above proportions, stir and cook for 8-10 minutes, let the temperature reach 45-60°C, and let it stand; then pour the slurry into the container, seal it with tin foil; sterilize at 95°C for 20 minutes; cool and pack the finished product.

Embodiment 3

[0044] Embodiment 3 A kind of pineapple instant jelly

[0045] raw material:

[0046] Water 90Kg Salt 0.2Kg

[0047] Corn starch 10Kg Citric acid 0.06Kg

[0048] Carrageenan 0.35Kg Potassium sorbate 0.05Kg

[0049] Potassium chloride 0.2Kg food flavor 0.6Kg

[0050] Potassium dihydrogen phosphate 0.08Kg 0.3mm 3 Pineapple block 8Kg.

[0051] Konjac powder 0.4Kg

[0052] Mix the raw materials in the above ratio, stir and cook for 8-10 minutes, and let the temperature reach 45-60°C, and let it stand; then add pineapple pieces to the slurry and mix well, pour the slurry into the container, seal it with tin foil; sterilize at 95°C for 20 minutes ; Cooling and packaging the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com