Electrolytic plating assisting method for hot dip galvanizing of steel wire and electrolytic plating assistant

A technology of hot-dip galvanizing and plating flux, which is applied in hot-dip galvanizing process, coating, metal material coating process, etc. It can solve the problems of not being galvanized and the coating falling off, so as to prevent missing plating and maintain stability sex, enhanced protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

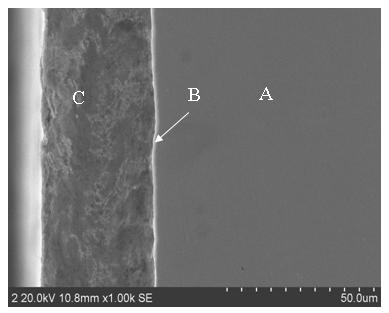

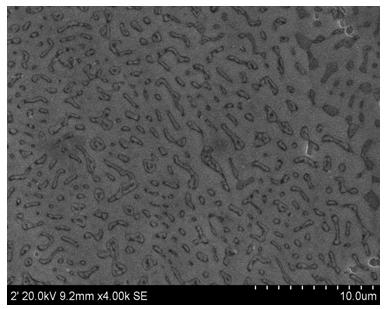

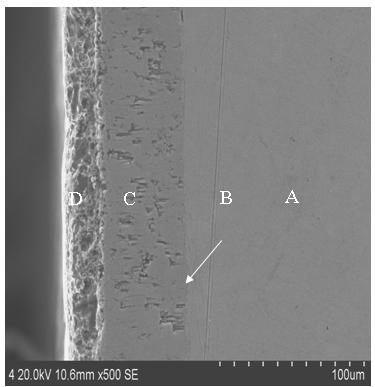

Image

Examples

Embodiment 1

[0061] The composition of electrolytic flux: zinc chloride (ZnCl 2 ) The concentration is 120g / L, potassium chloride (KCl) 75g / L, sodium chloride (NaCl) 75g / L, ammonium chloride (NH 4 Cl) 45g / L, boric acid (H 3 BO 3 ) 50g / L, acetic acid (CH 3 COOH) 35g / L, sodium fluoride (NaF) 12g / L, cerium chloride (CeCl 3 ) 25g / L, potassium fluorozirconate (K 2 ZrF 6 ) 25g / L, methanol (CH 3 OH) 25g / L, hydrogen peroxide (H 2 O 2 ) 10g / L, the rest is water.

[0062] The electrolytic assisting method for hot-dip galvanizing of steel wire includes alkaline washing and degreasing, pickling and derusting, weak acid activation, electrolytic assisting and drying processes, and the subsidiary process is the purification process of electrolytic booster. The specific steps and control parameters are as follows.

[0063] (1) Alkaline washing and degreasing: Use NaOH solution with a temperature of 70°C and a mass concentration of 12% to clean the surface of the steel wire, and the surface of the steel wire ca...

Embodiment 2

[0074] The composition of electrolytic flux: zinc chloride (ZnCl 2 ) The concentration is 220g / L, potassium chloride (KCl) 150g / L, ammonium chloride (NH 4 Cl) 90g / L, boric acid (H 3 BO 3 ) 100g / L, sodium fluoride (NaF) 1g / L, cerium chloride (CeCl 3 ) 2g / L, potassium fluorozirconate (K 2 ZrF 6 ) 20g / L, methanol (CH 3 OH) 50g / L, hydrogen peroxide (H 2 O 2 ) 20g / L, the rest is water.

[0075] The electrolytic assisting method for hot-dip galvanizing of steel wire includes alkaline washing and degreasing, pickling and derusting, weak acid activation, electrolytic assisting and drying processes, and the subsidiary process is the purification process of electrolytic booster. The specific steps and control parameters are as follows.

[0076] (1) Alkaline washing and degreasing: Use NaOH solution with a temperature of 80°C and a mass concentration of 5% to clean the surface of the steel wire. The surface of the steel wire can be evenly covered by a water film as the cleaning qualification....

Embodiment 3

[0087] The composition of electrolytic flux: zinc chloride (ZnCl 2 ) The concentration is 30g / L, sodium chloride (NaCl) 150g / L, ammonium chloride (NH 4 Cl) 2g / L, acetic acid (CH 3 COOH) 70g / L, sodium fluoride (NaF) 25g / L, cerium chloride (CeCl 3 ) 50g / L, potassium fluorozirconate (K 2 ZrF 6 ) 50g / L, hydrogen peroxide (H 2 O 2 ) 0.5g / L, the rest is water.

[0088] The electrolytic assisting method for hot-dip galvanizing of steel wire includes alkaline washing and degreasing, pickling and derusting, weak acid activation, electrolytic assisting and drying processes, and the subsidiary process is the purification process of electrolytic booster. The specific steps and control parameters are as follows.

[0089] (1) Alkaline washing and degreasing: Use NaOH solution with a temperature of 60°C and a mass concentration of 20% to clean the surface of the steel wire. The surface of the steel wire can be evenly covered by the water film as the cleaning qualification.

[0090] (2) Water washi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com