Acrylic acid-epoxy ester hybrid resin and coatings thereof

A hybrid resin and epoxy resin technology, applied in the field of epoxy ester resin, can solve the problems of relatively high solvent solubility, poor moisture and heat resistance, poor corrosion resistance, etc., to avoid the risk of paint peeling, and to achieve good chemical resistance. Performance, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

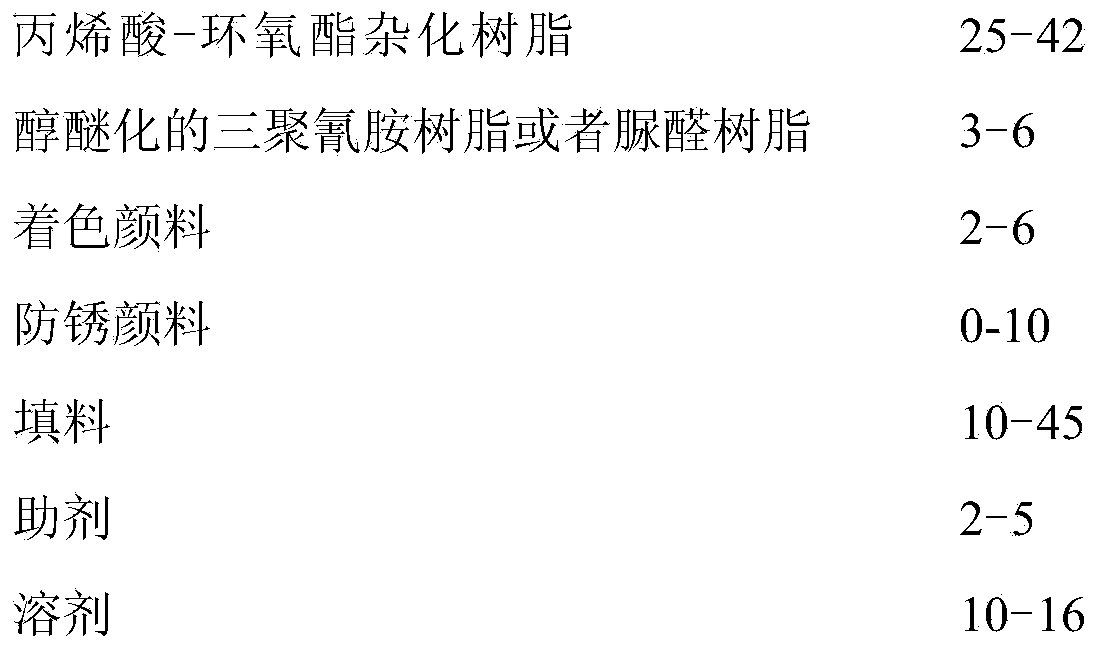

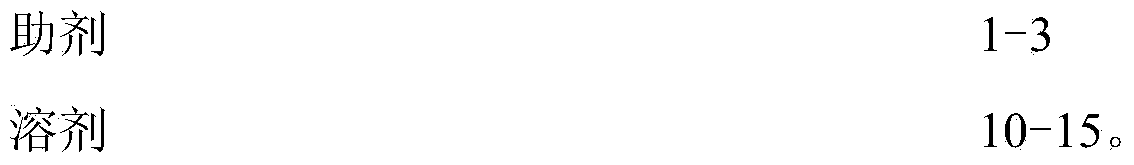

[0053] Embodiment 1 prepares acrylic acid-epoxy ester hybrid resin

[0054] Step 1: Preparation of epoxy ester: As shown in the formula in Table 1, put epoxy resin E-12, soybean oil acid, linolenic acid and zinc oxide into the reaction kettle, add 80kg of refluxing xylene, heat up to 150°C-160°C and then click When the motor is normal, start stirring. When the temperature is 180°C-200°C, keep warm for 4 hours and start to detect the acid value and viscosity. When the acid value is about 6mgKOH / g, it is the end of the reaction. While cooling, dilute with xylene until the solid content is (50±1)%, and at the same time control the viscosity to be around 120s (coat four cups, 25°C), filter and discharge for later use;

[0055] Step 2: Preparation of acrylic acid-epoxy hybrid resin: formula as shown in Table 1, 1000kg epoxy ester, take 16kg AIBN and mix evenly with the acrylic monomer in the formula, then take 250kg of mixed monomer and put it into the reaction kettle to make a pri...

Embodiment 2

[0056] Embodiment 2 prepares acrylic acid-epoxy ester hybrid resin

[0057] Step 1: Preparation of epoxy ester: as shown in the formula in Table 2, put epoxy resin E-12, soybean oil acid, oleic acid, linolenic acid and zinc oxide into the reaction kettle, add 84kg of reflux xylene, and heat up to 180°C-200°C Keep warm at ℃ for 4 hours and start to detect the acid value and viscosity. When the acid value is about 7mgKOH / g, it is the end of the reaction. Put the material into the dilution kettle, and dilute it with xylene while cooling until the solid content is (50±1)%. Adjust the viscosity for about 150s and set aside;

[0058] Step 2: Preparation of acrylic acid-epoxy hybrid resin: According to the formula in Table 2, put 2000kg of epoxy ester into the reaction kettle and raise the temperature. Take 18kg of BPO and acrylic acid monomer and mix evenly, then take 200kg of mixed monomer and put it into the reactor as a primer, raise the temperature to 98°C and start to keep war...

Embodiment 3

[0063] Embodiment 3 prepares acrylic acid-epoxy ester hybrid resin

[0064] Step 1: Preparation of epoxy ester: as shown in the formula in Table 3, put epoxy resin E-12, dehydrated ricinoleic acid, linolenic acid and lead oxide into the reaction kettle, add 60kg of reflux xylene, heat up to 180°C-200°C and keep warm Start to check the acid value and viscosity after 4 hours, when the acid value is about 5mgKOH / g, it is the end of the reaction, put the material into the diluting kettle, dilute with xylene while cooling until the solid content is (50±1)%, adjust the viscosity About 110s, spare;

[0065] Step 2: Preparation of acrylic acid-epoxy ester hybrid resin: as shown in Table 3, mix 1500 kg of epoxy ester, 12 kg of tert-butyl benzoyl peroxide and acrylic acid monomer, and then put kg of mixed monomer into the reactor Make a base in the middle, raise the temperature to 130°C and start keeping warm, control the holding temperature at 130°C-135°C for 30 minutes, drop the rema...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com