Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90results about How to "Good reversing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

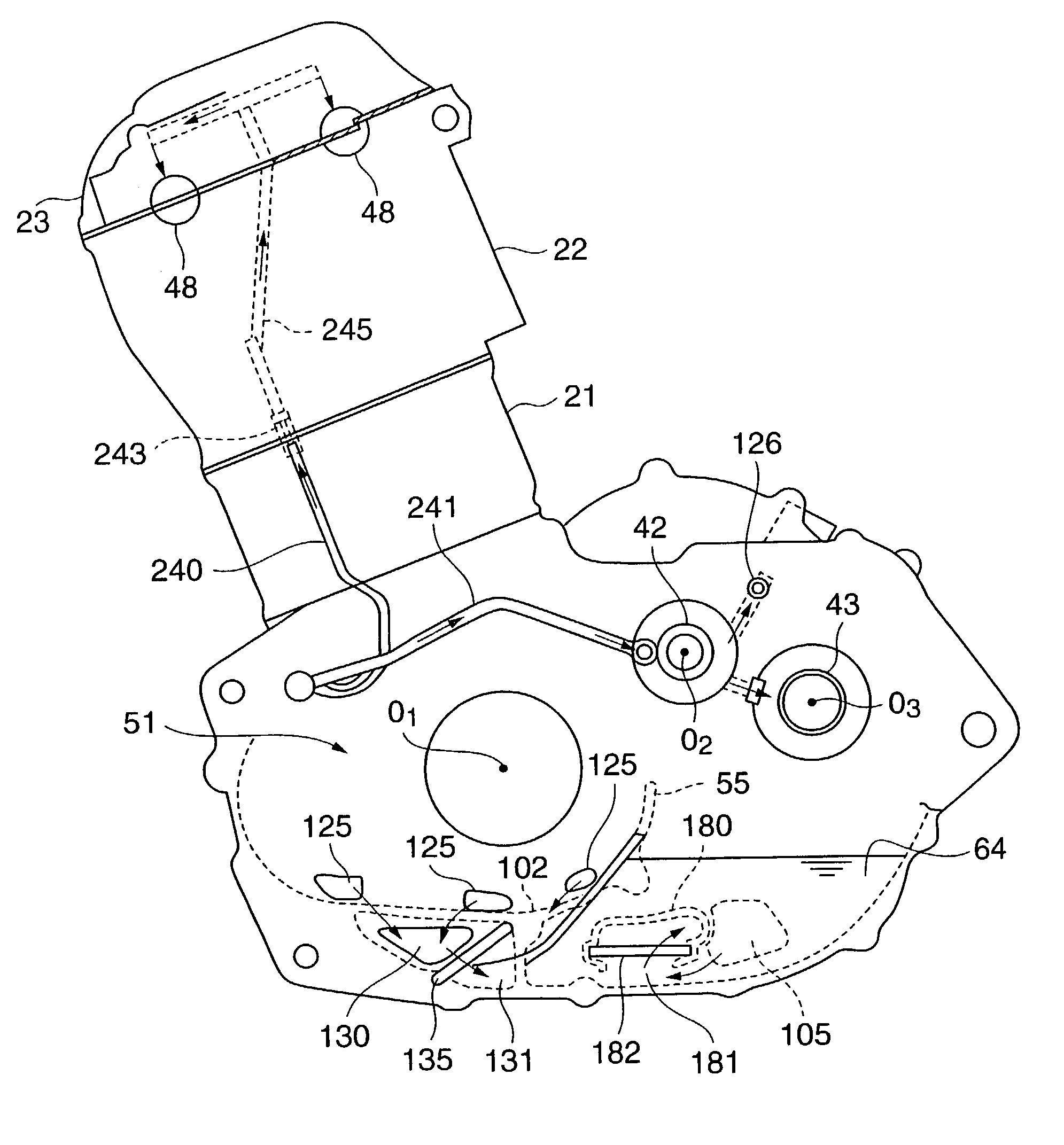

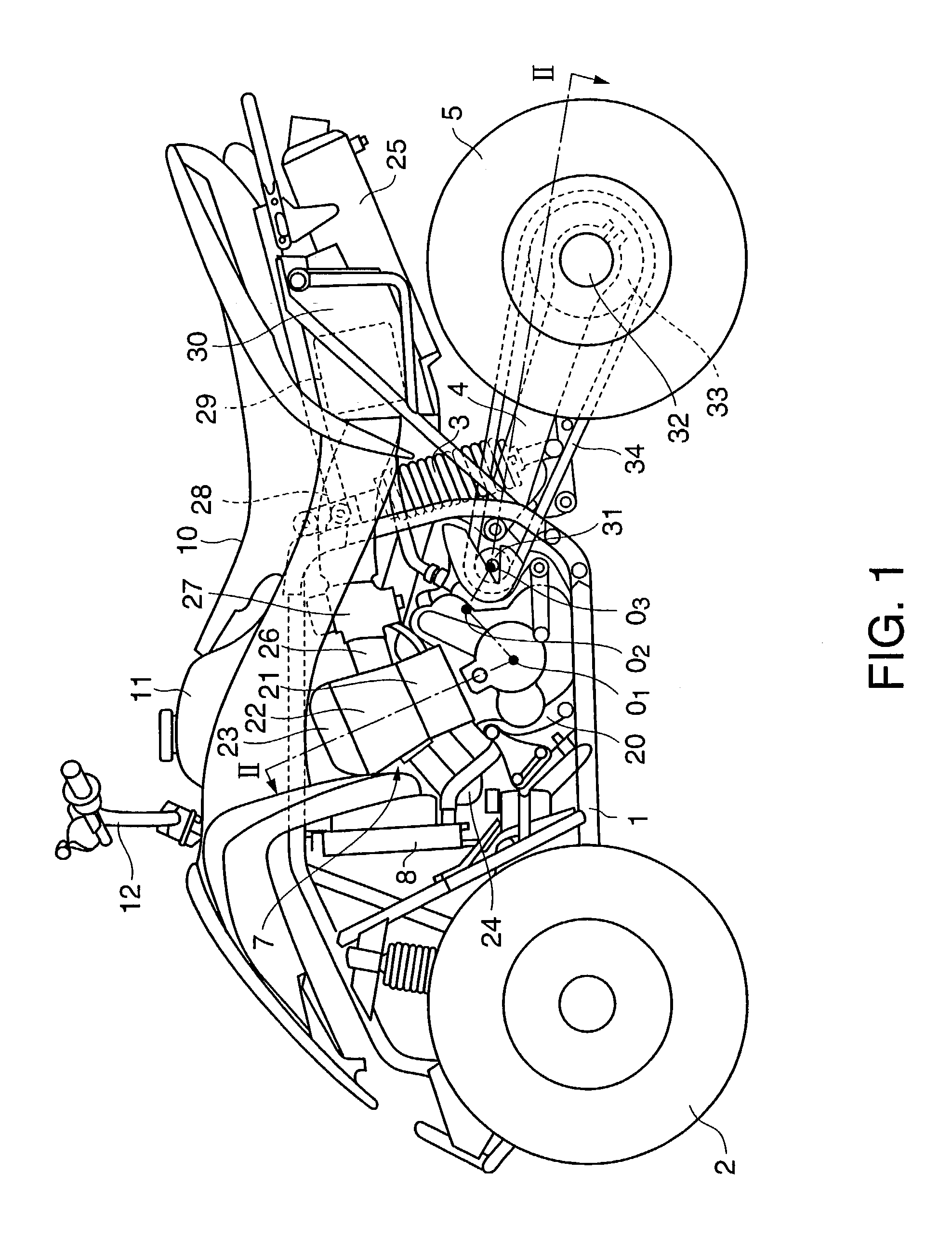

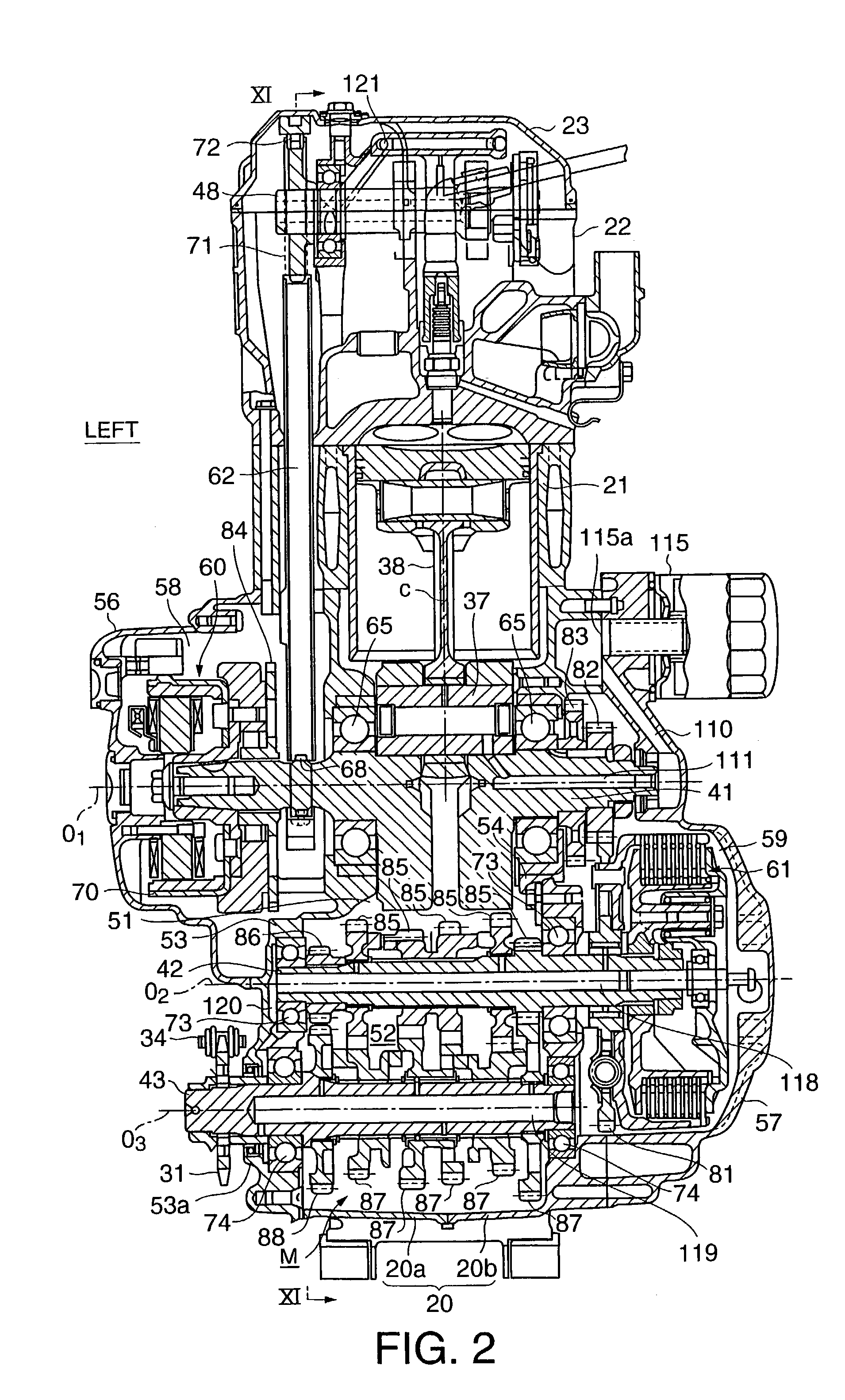

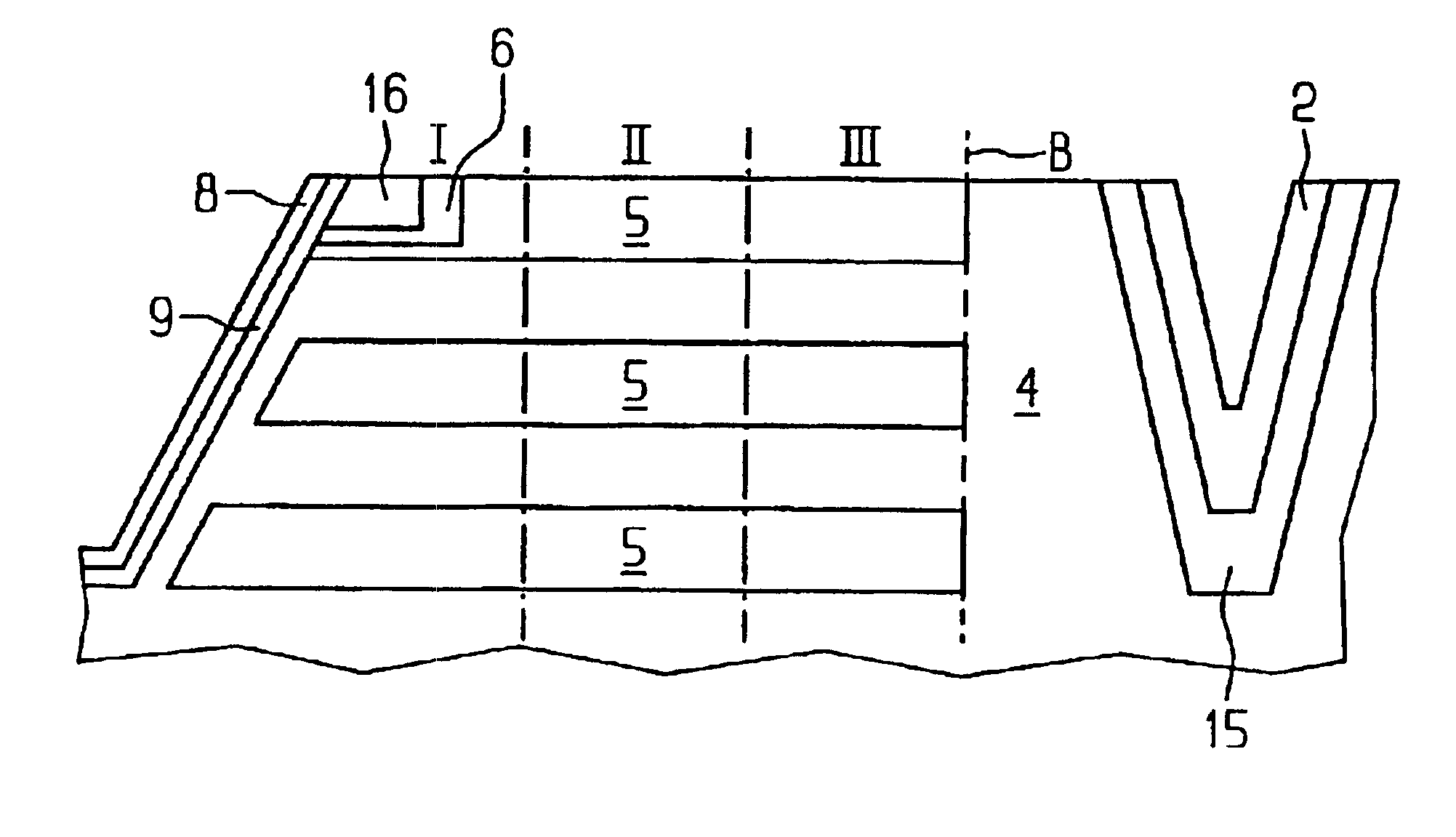

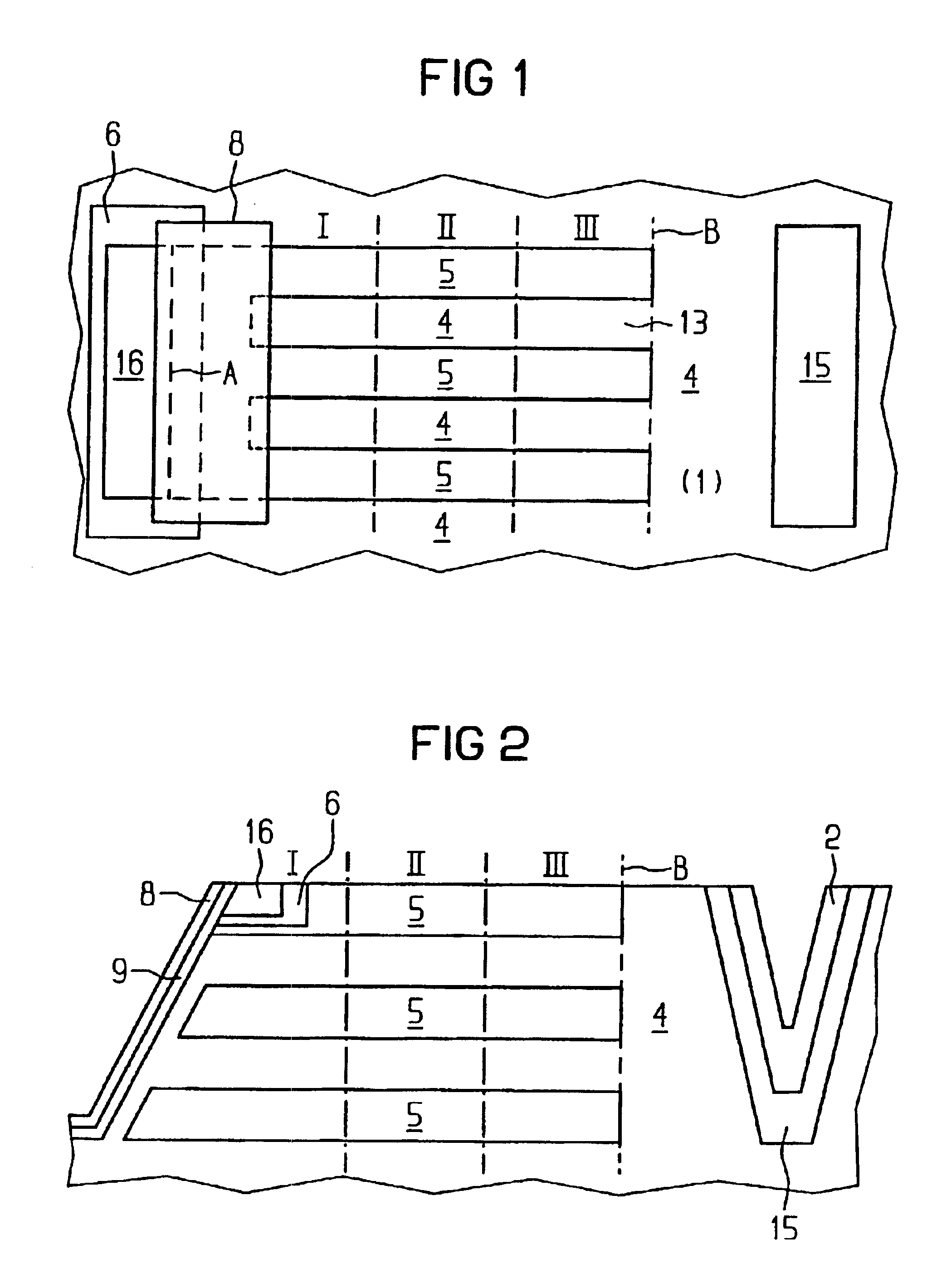

Dry-sump lubrication type four-stroke cycle engine

InactiveUS7040454B2Easy to usePrecision lubricationLubrication of auxillariesLubricant conduit arrangementsAir pumpFour-stroke engine

The interior of a crankcase is divided into a front crank chamber and a rear transmission chamber by a partition wall of a given height. A lower part of the transmission case is used as an oil reservoir chamber for reserving lubricating oil. Opposite ends of the crankcase are covered with covers to form a generator chamber and a clutch chamber. The crank chamber is connected to the generator chamber by a drain passage to drain oil collected in the crank chamber into the generator chamber. A scavenging pump placed in the clutch chamber sucks the oil collected in the generator chamber through an oil passage extending across the crankcase under the crank chamber and discharges the oil into an air space in the clutch chamber.

Owner:KAWASAKI HEAVY IND LTD

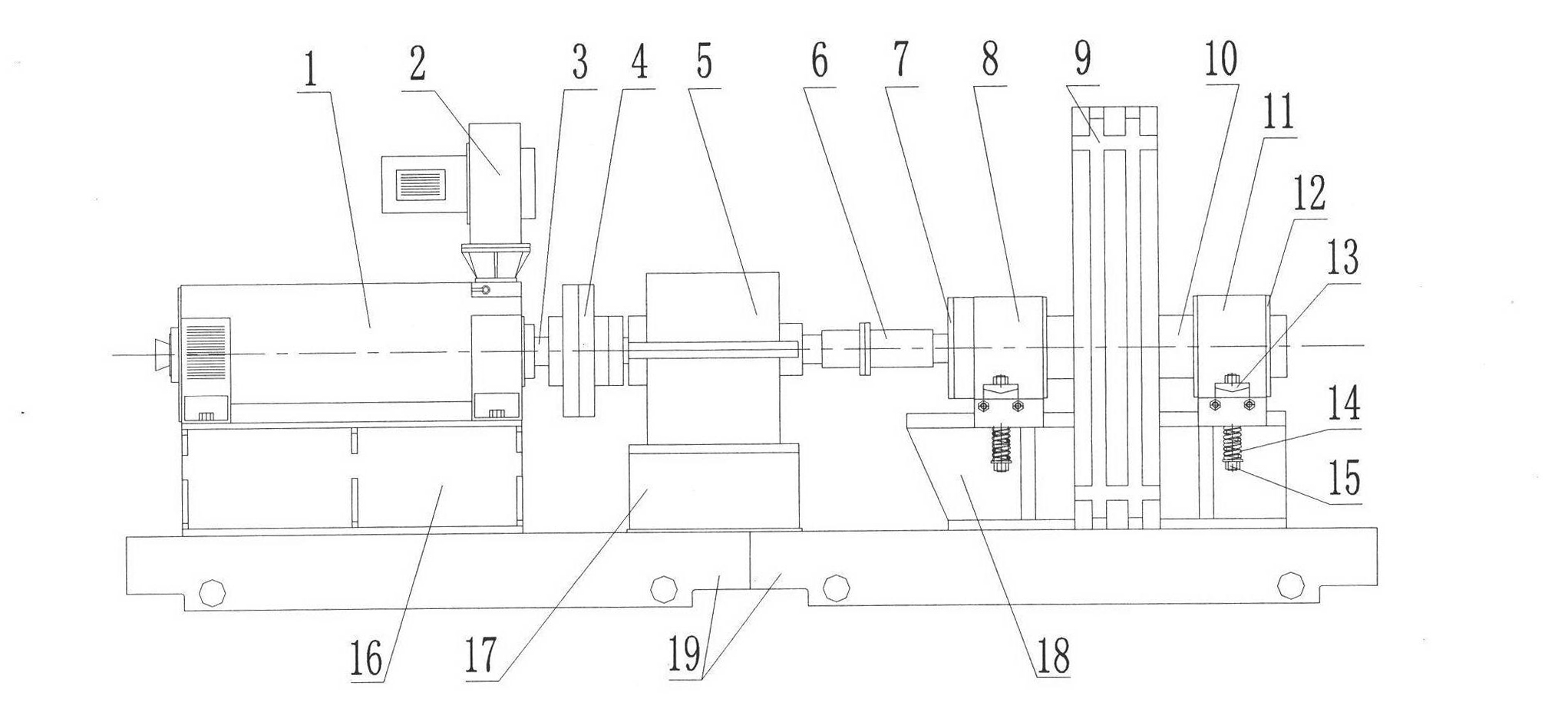

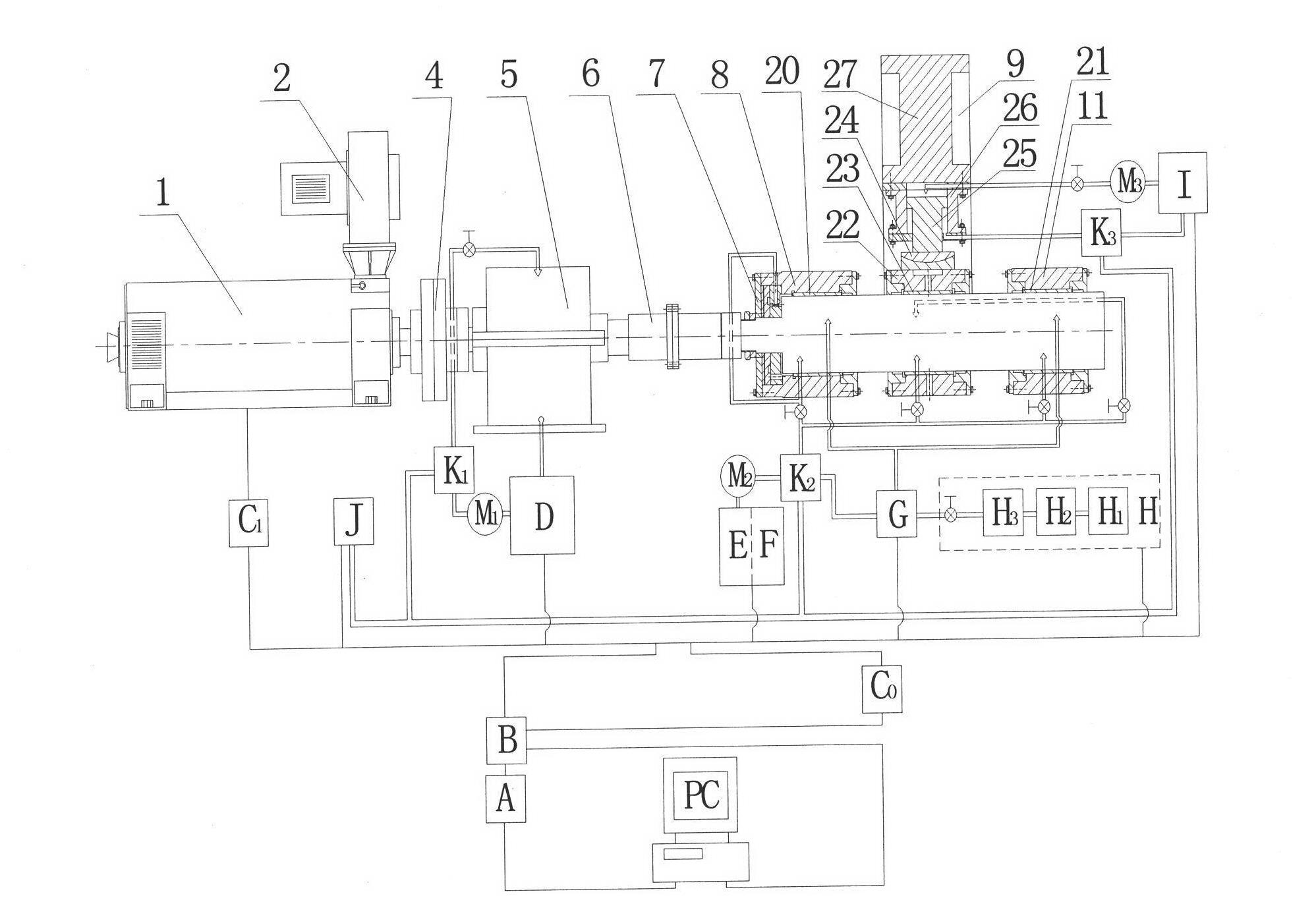

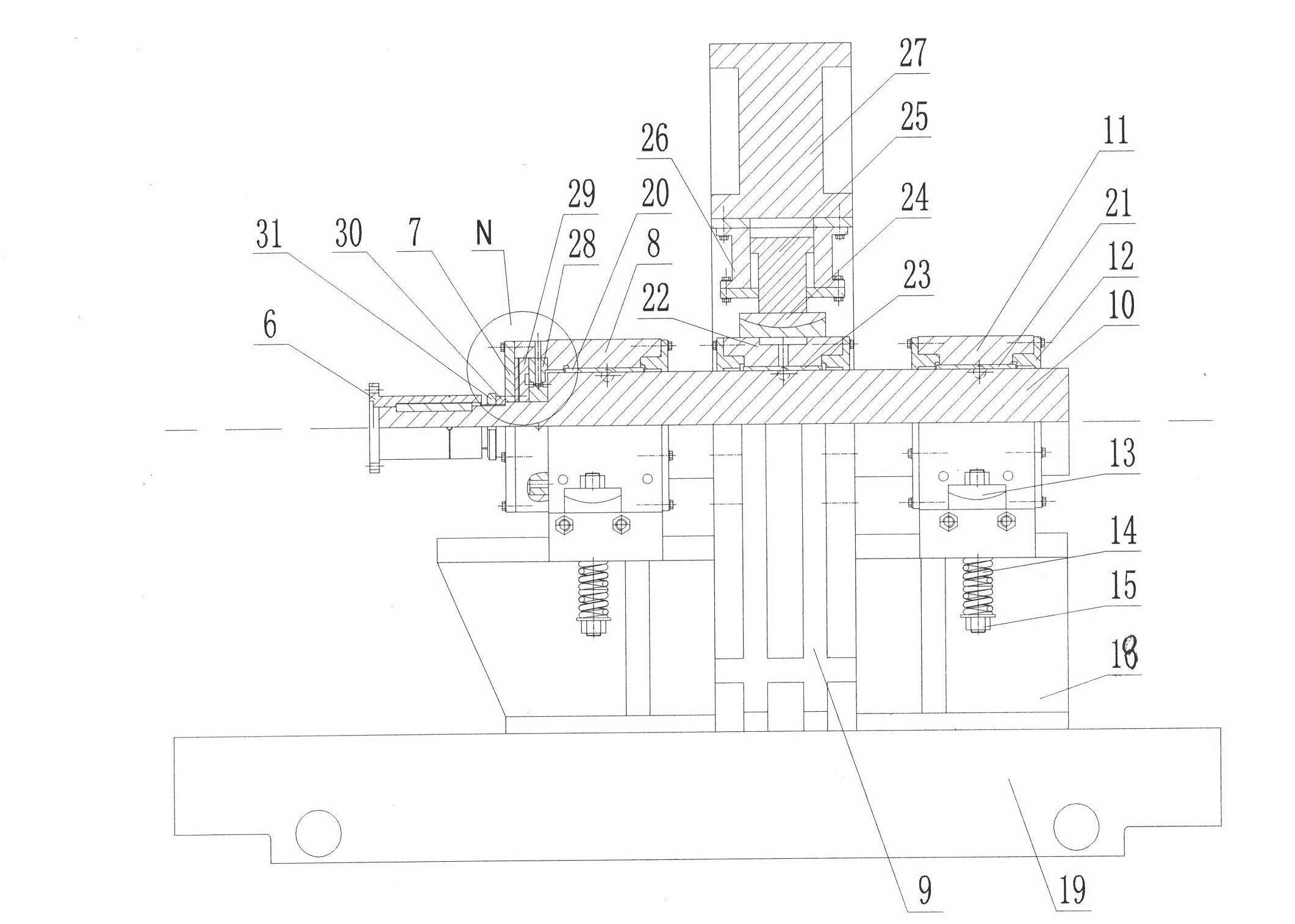

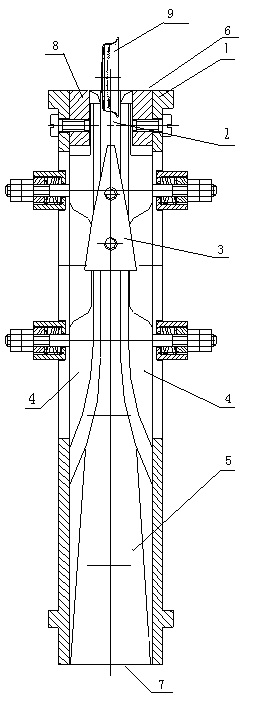

Rolling mill oil film bearing comprehensive test bench

The invention discloses a comprehensive test-bed for an oil film bearing of a rolling mill, belonging to the technical field of testing equipment of oil film bearings of rolling mills. The comprehensive test-bed is characterized by comprising a mechanical system, a motor driving system, a hydraulic loading system, a lubricating system, an air pressure control system, an electric control system and a computer data acquisition system which are combined to form an integral and uniform operation; flow sensors, temperature sensors, pressure sensors and displacement sensors mounted on the bearing and all pipelines are connected to the computer data acquisition system through a PLC (Programmable Logic Controller); and the electric control system is connected with and controls the motor driving system, the hydraulic loading system, the lubricating system and the air pressure control system. The invention realizes integration of an electromechanical hydropneumatic integral system by setting rotation speed of a motor shaft and the dynamically controlling rolling conditions of the hydraulic load and testing performance of the oil film bearing of the rolling mill by the data acquisition system. The system has the advantages of compact structure and convenience for operation, and is suitable for the fields of various teaching and scientific research.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

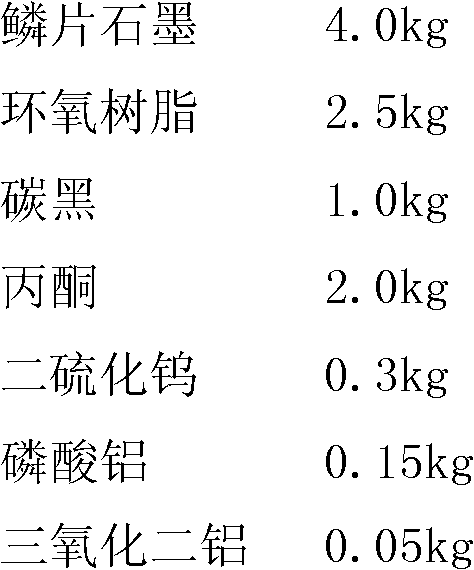

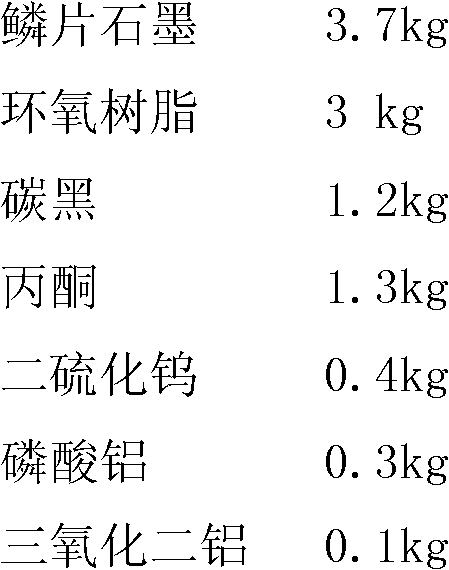

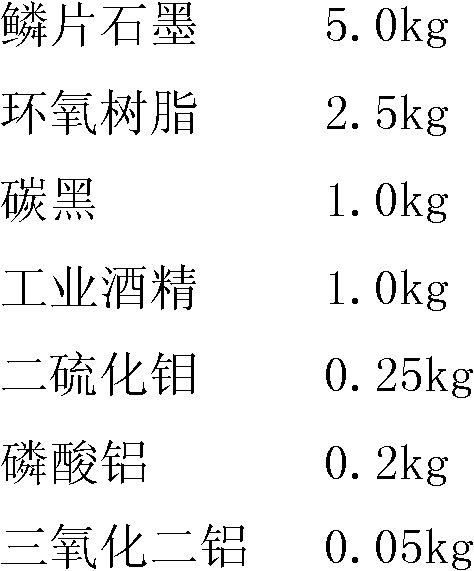

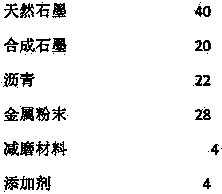

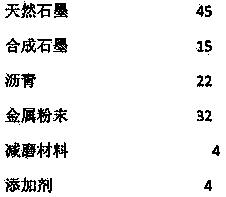

Electric brush for electric tool motor and preparation method thereof

ActiveCN103259150ALow resistivityImprove wear resistanceRotary current collectorBrushes manufactureElectric machineryEngineering

The invention discloses an electric brush for an electric tool motor and a preparation method thereof. Electric brush mixture is roasted and then compressed to form the electric brush. The electric brush mixture comprises, part by weight, 30-60 parts of natural graphite, 25-40 parts of binder, 10-15 parts of amorphous carbon, 10-25 parts of solvent and 4-8 parts of additive. According to the electric brush for the electric tool motor and the preparation method thereof, preparation technologies are simple, operation is easy, the electric brush is low in resistivity, good in abrasion resistance, good in reversing performance, strong in anti-interference capability and long in service life, various requirements of the electric tool motor for the electric brush can be met better, and application ranges are wide.

Owner:SUZHOU DONEKA NEW MATERIALS CORP LTD

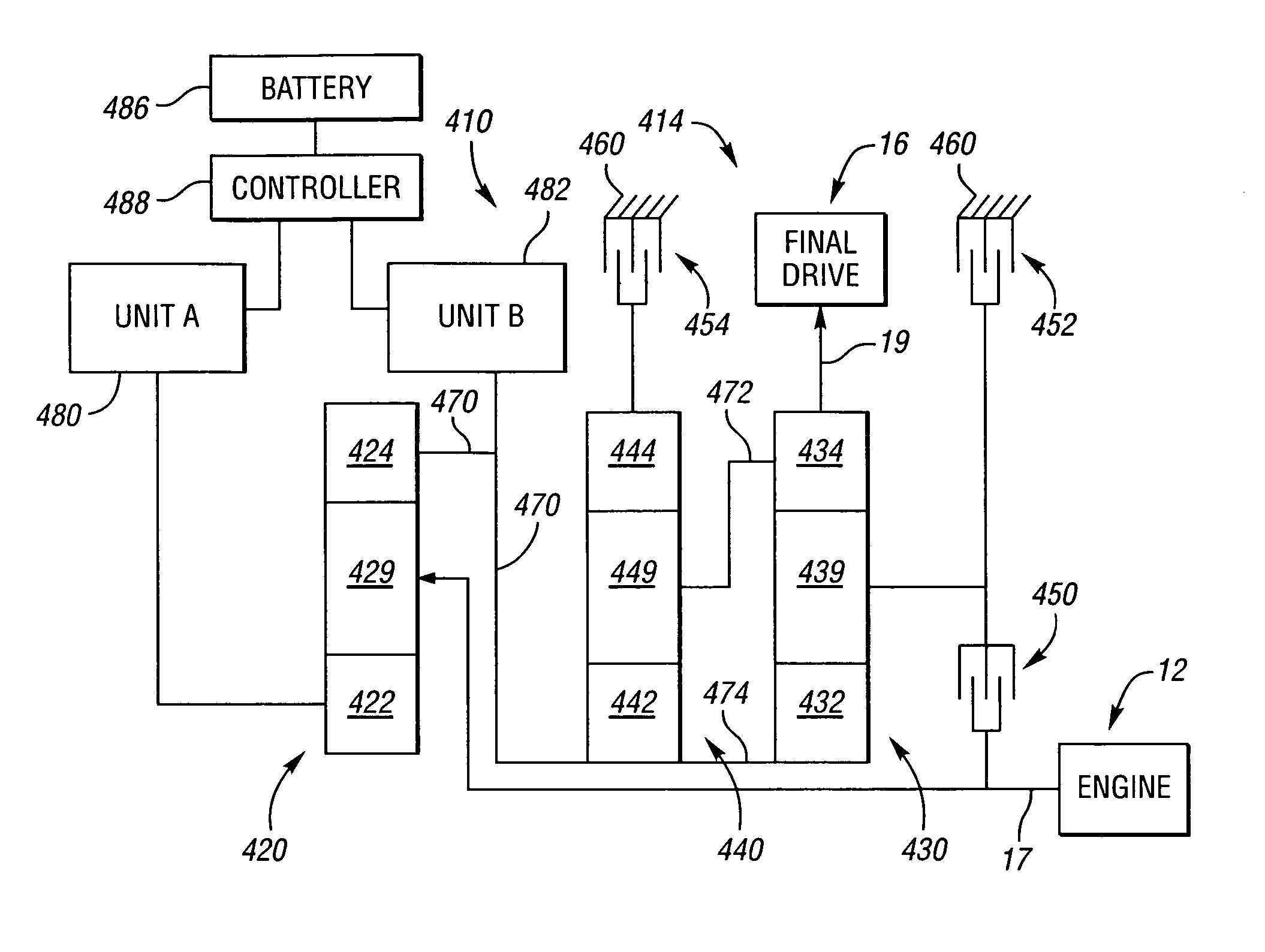

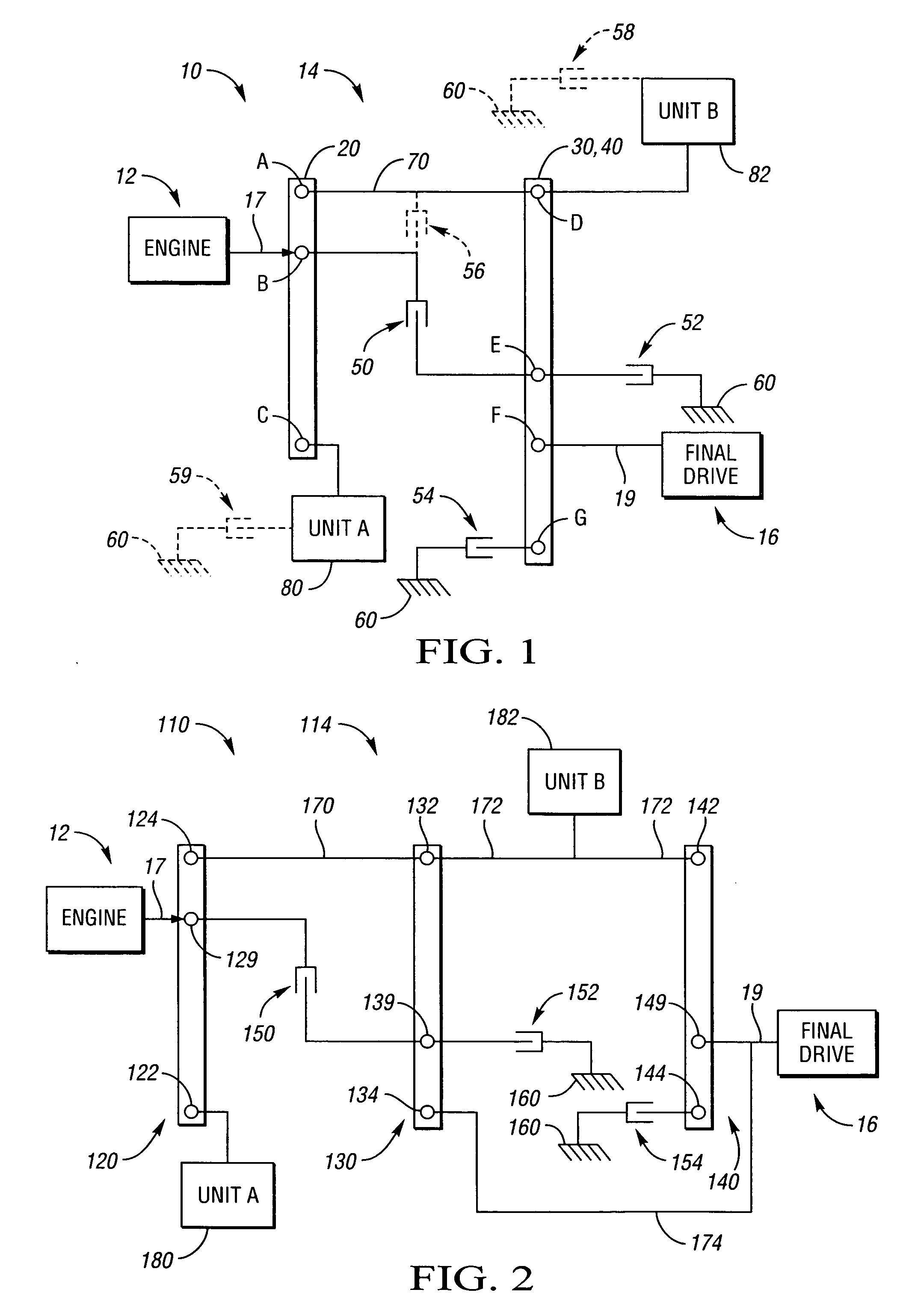

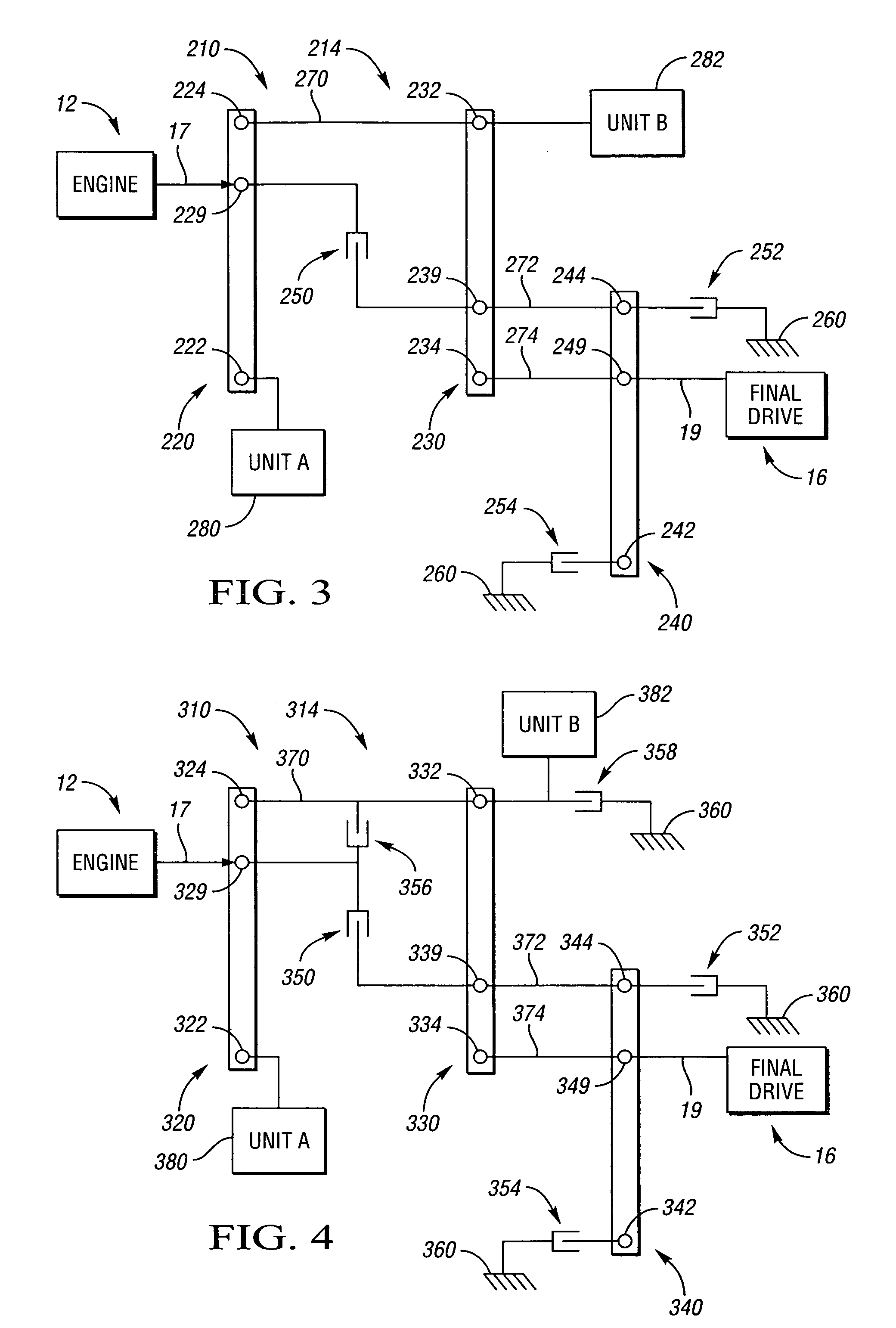

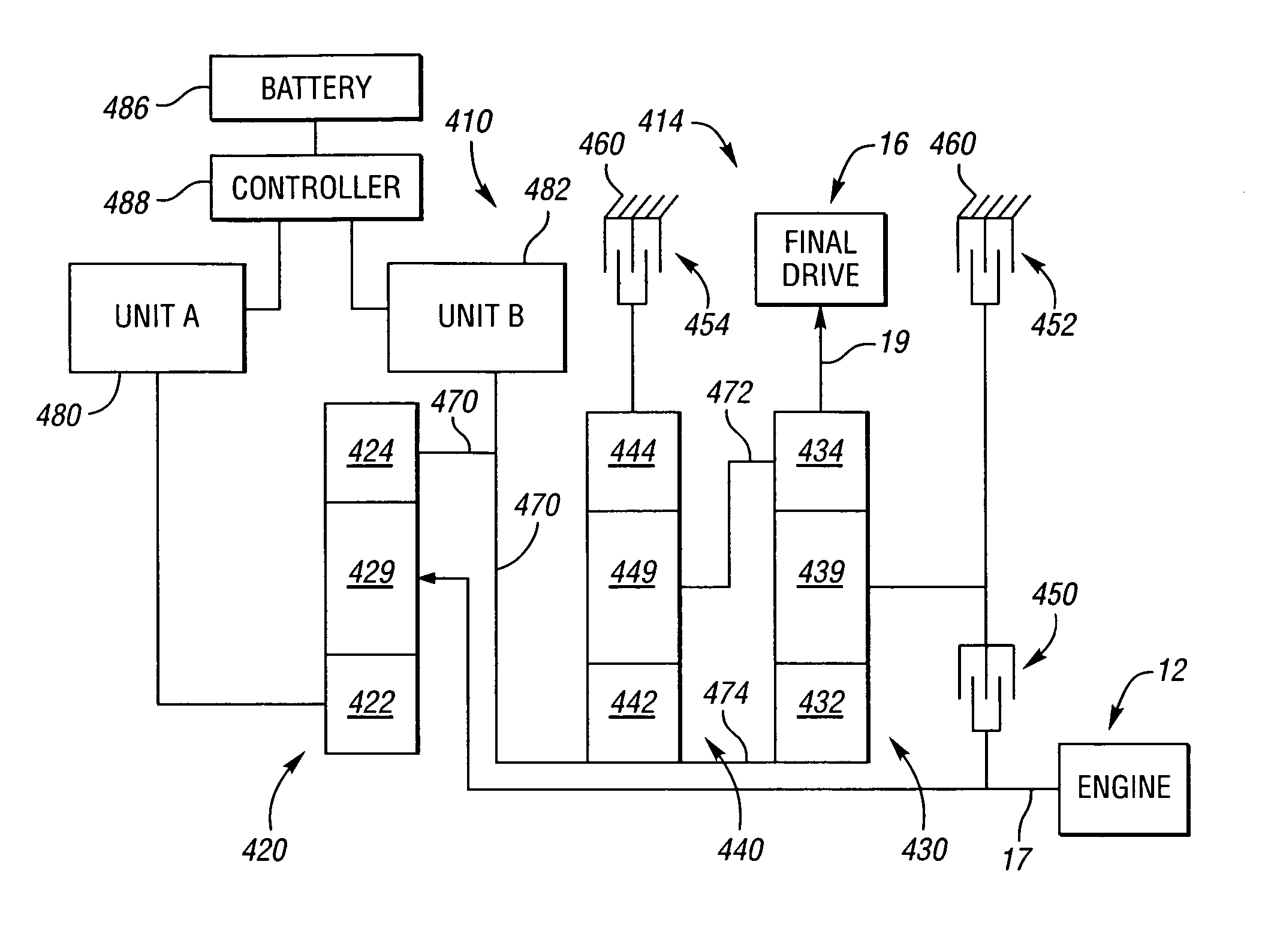

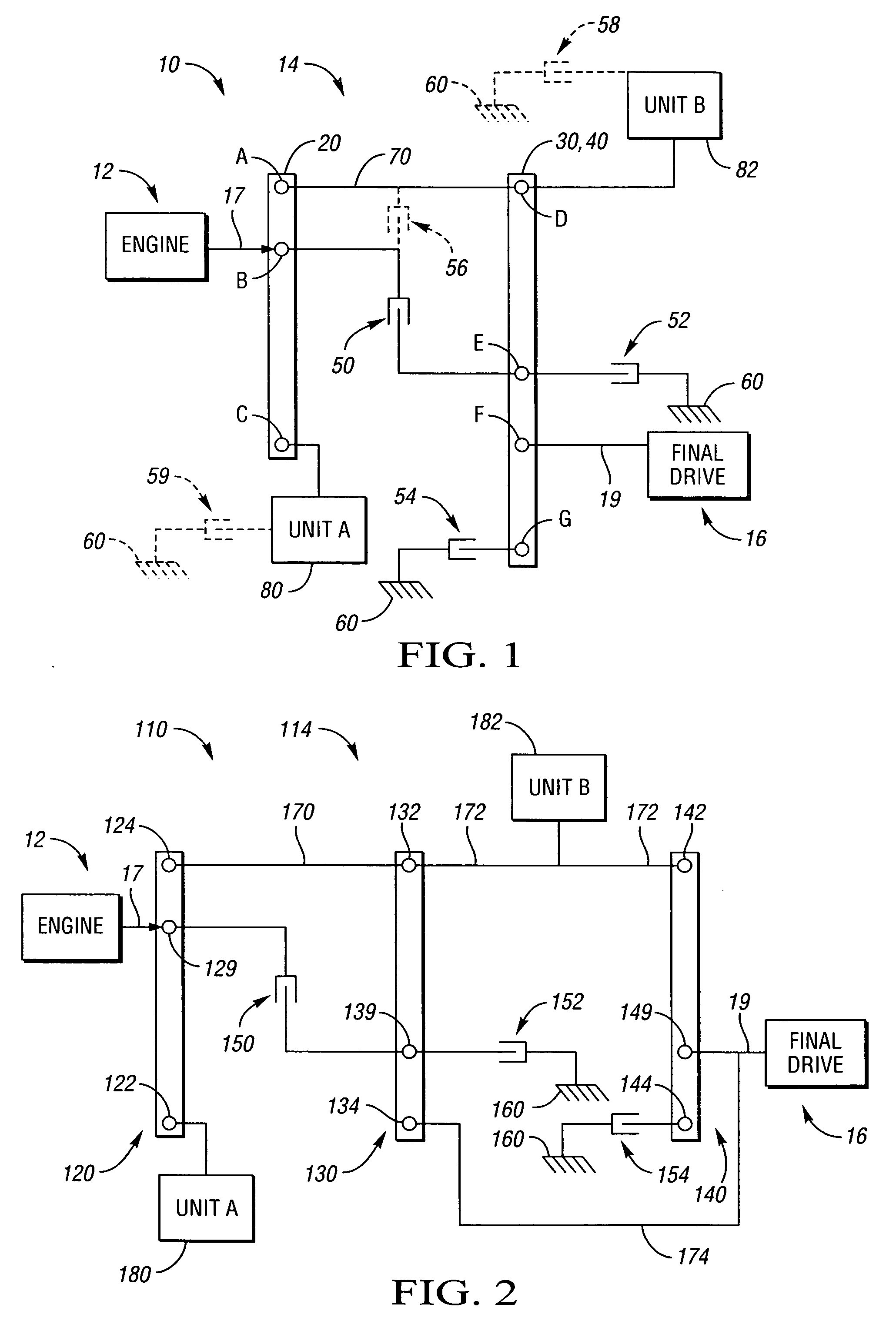

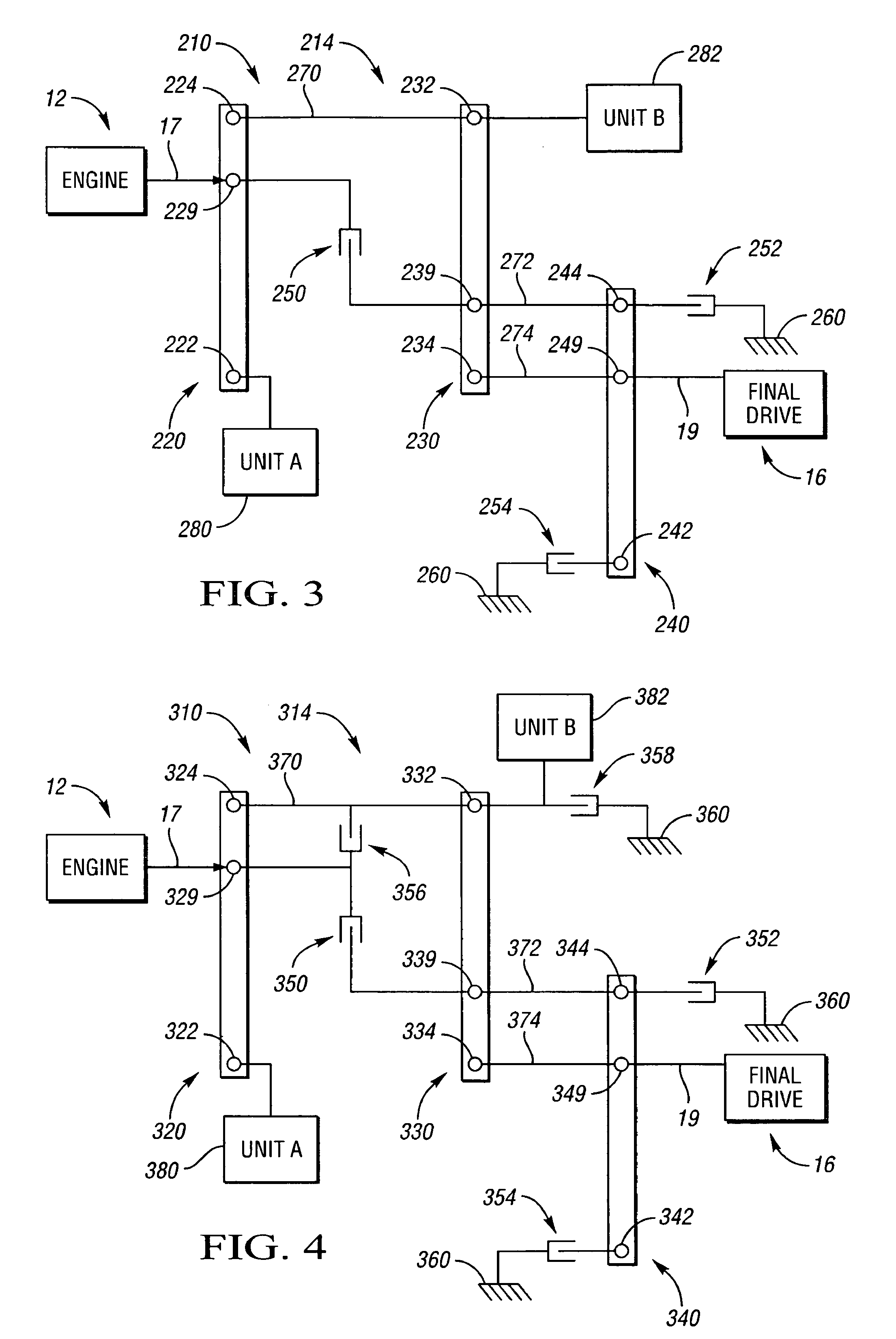

Dual mode EVT with input split reverse mode

InactiveUS20070021258A1Sufficient performanceHigh output torqueHybrid vehiclesToothed gearingsDesign standardDual mode

Owner:GM GLOBAL TECH OPERATIONS LLC

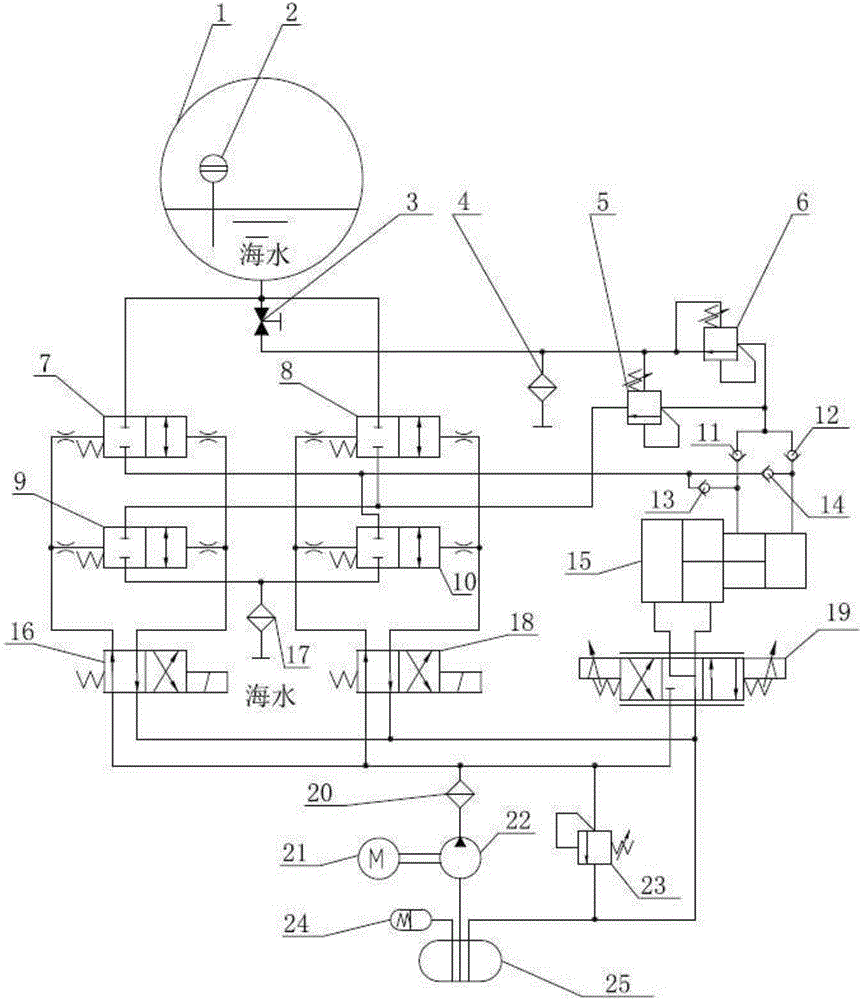

Hydraulic system used for adjusting buoyancy of full-ocean-depth submersible

ActiveCN106516057AImprove reliabilityReduce or even eliminate pressure spikesUnderwater vesselsUnderwater equipmentEngineeringControl valves

The invention relates to a hydraulic system used for adjusting the buoyancy of a full-ocean-depth submersible. The hydraulic system comprises a hydraulic power source, a seawater hydraulic power source, a water ballast space and a water ballast space control valve set. The hydraulic power source drives the seawater hydraulic power source to work, and water injection or water drainage of the interior of the water ballast space is controlled through switching of the water ballast space control valve set, and thus adjusting of the buoyancy of the full-ocean-depth submersible is achieved. The hydraulic system is simple in structure and convenient to use; and a pressure cylinder of the hydraulic system is driven by oil pressure and outputs aqueous media, compared with traditional axial plunger type seawater pumps, the machining cost of the hydraulic system is low, and the flow is larger, the service life is long, the reliability is good and the volume efficiency is high with the same volume. The submersible buoyancy adjusting working condition of the hydraulic system has quite low requirements for pumping flow pulsation, the hydraulic system is better agree with the submersible buoyancy adjusting working condition than the axial plunger pumps, and the outlet pressure of the pressure cylinder can meet the full-ocean-depth application requirements by adjusting the pressure ratio of the pressure cylinder.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

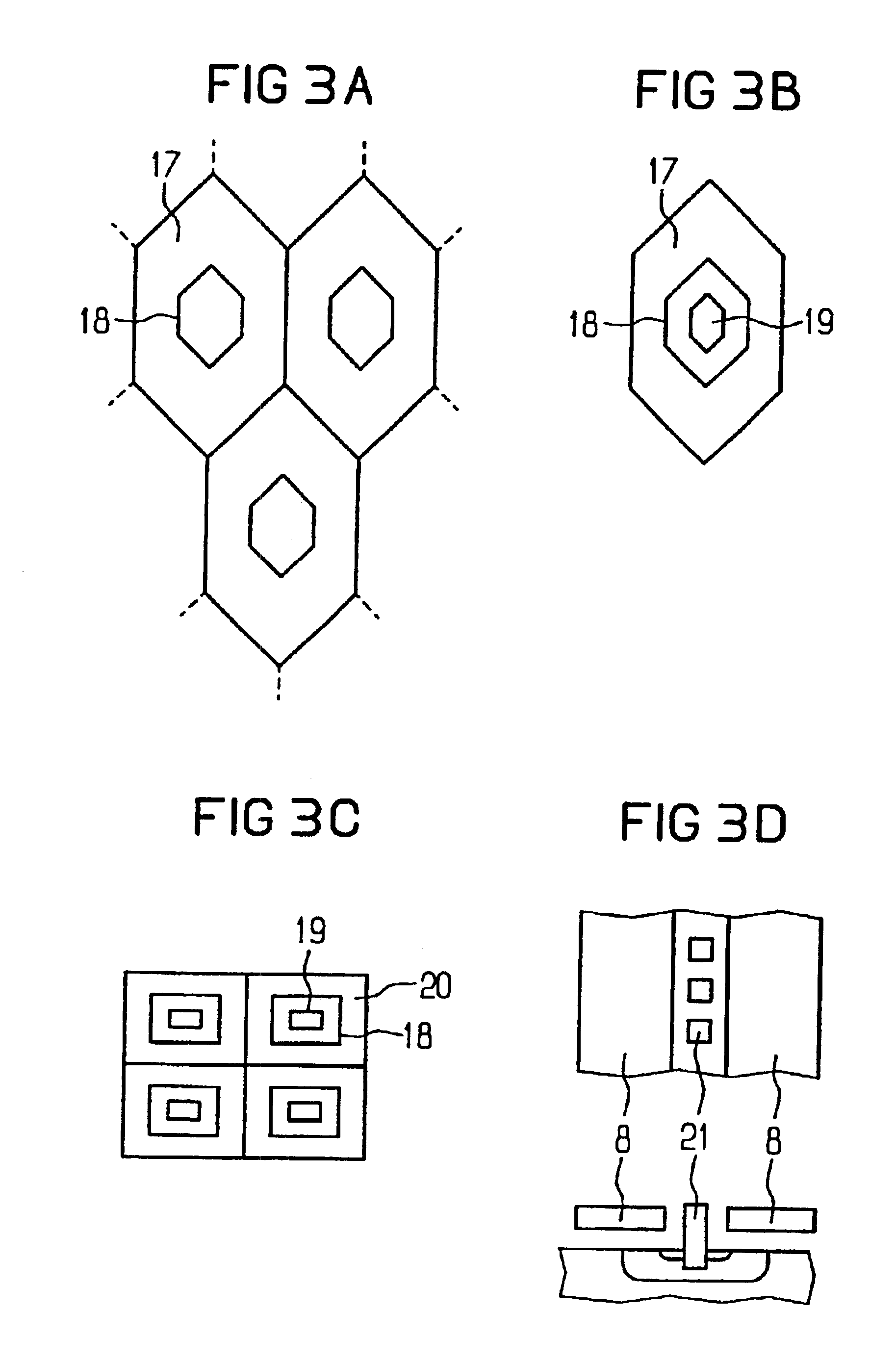

High-voltage semiconductor component

InactiveUS6894329B2Improve sturdinessIncrease load capacityTransistorSemiconductor/solid-state device manufacturingHigh pressureP–n junction

A semiconductor component has a semiconductor body comprising blocking pn junction, a source zone of a first conductivity type connected to a first electrode and bordering on a zone forming the blocking pn junction of a second conductivity type complementary to the first conductivity type, and a drain zone of the first conductivity type connected to a second electrode. The side of the zone of the second conductivity type facing the drain zone forms a first surface, and in the region between the first surface and a second surface located between the first surface and the drain zone, comprises areas of the first and second conductivity type nested in one another. The second surface coincides with the surface of the drain zone facing the source zone, such that the regions of the first and second conductivity type nested inside each other reach the drain zone.

Owner:INFINEON TECH AUSTRIA AG

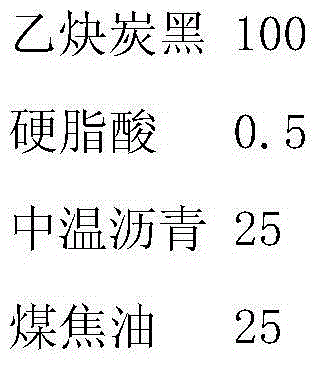

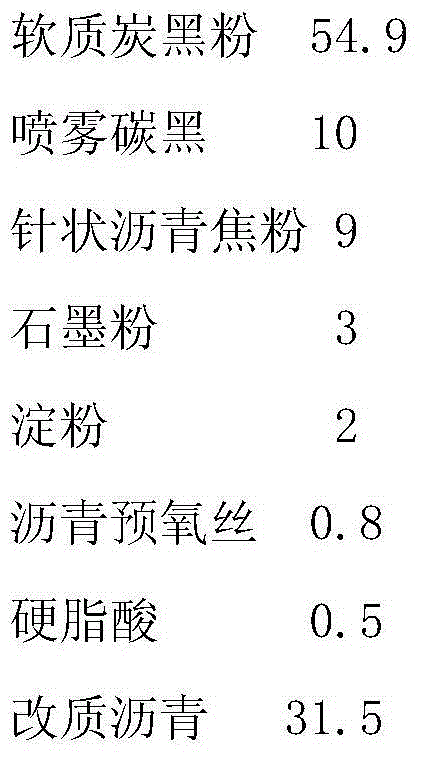

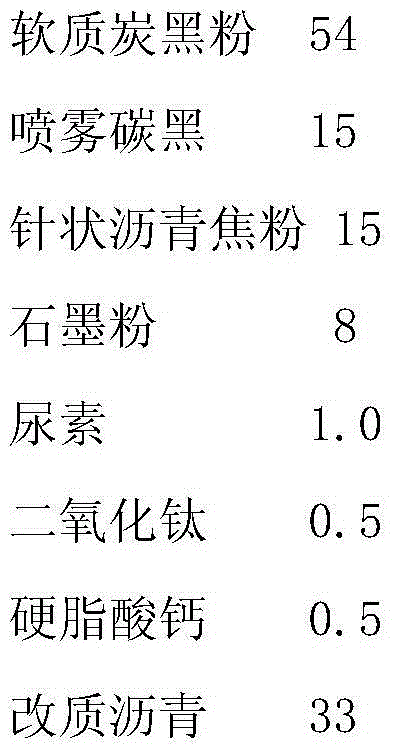

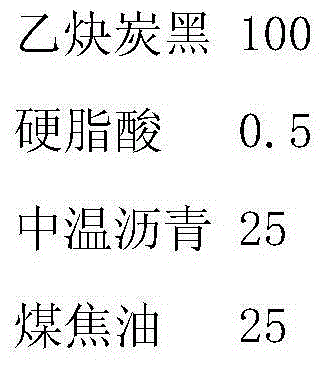

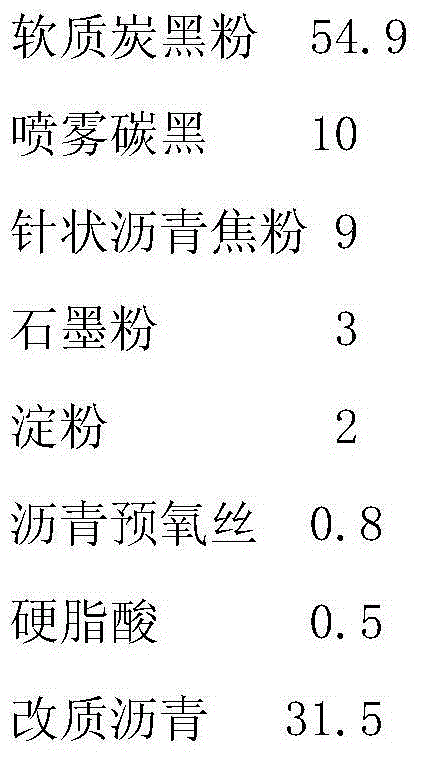

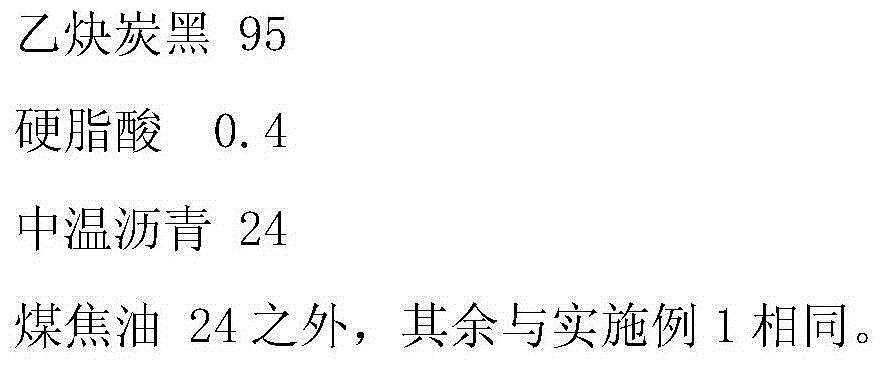

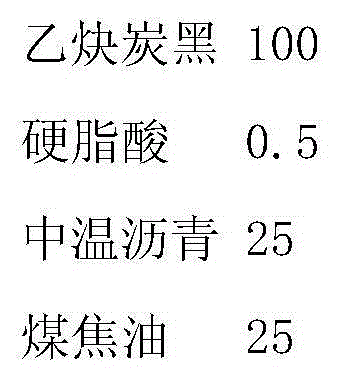

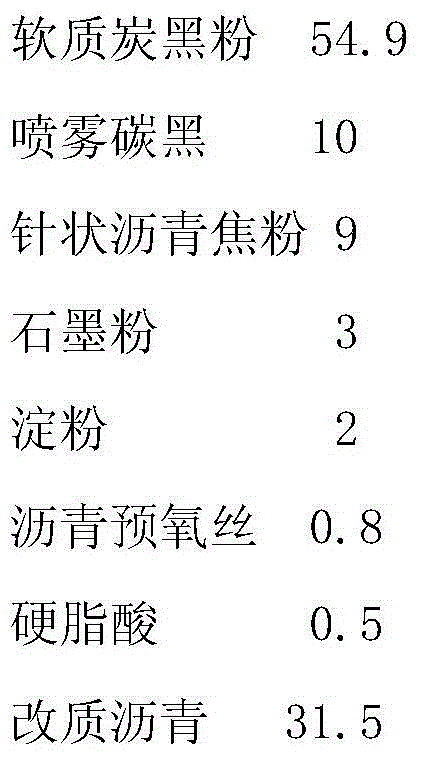

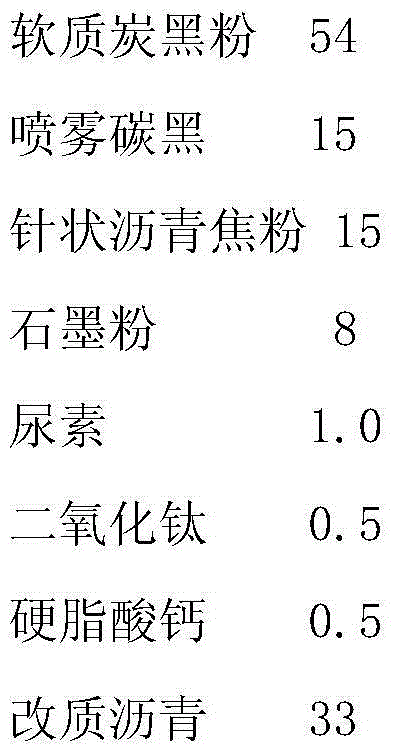

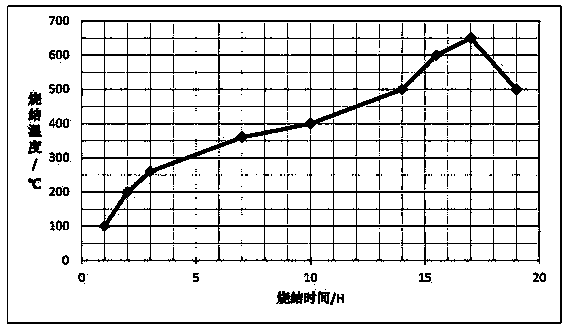

Manufacturing method of carbon brush used for locomotive traction motor

ActiveCN106033862AImprove wear resistanceGood orientationBrushes manufactureDiesel locomotiveMixed materials

The invention discloses a manufacturing method of a carbon brush used for a locomotive traction motor. The method comprises the following steps of under a heating condition, carrying out mixed extrusion processing on a soft carbon black powder, spray carbon black, a pitch coke powder, a graphite powder, a pore-forming agent, a directional auxiliary agent, modified pitch and a lubricant so as to acquire a mixed material; carrying out grinding processing on the mixed material so as to acquire a first mixed powder; mixing the first mixed powder and carrying out flaking processing so as to acquire a sheet-shaped material; carrying out smashing and grinding processing on the sheet-shaped material so as to acquire a second mixed powder; blending the second mixed powder and then pressing the power into a carbon-brush pressed shape, and then successively carrying out roasting and graphitization processing so as to obtain the carbon brush. Breaking strength of the carbon brush manufactured through the above method is high, commutation performance is good and an allowable passing current density is large. The carbon brush is suitable for a diesel locomotive traction motor and is also suitable for an electric locomotive traction motor.

Owner:SUZHOU DONEKA NEW MATERIALS CORP LTD

Dual mode EVT with input split reverse mode

InactiveUS7963874B2Sufficient performanceHigh output torqueHybrid vehiclesToothed gearingsDual modeEngineering

Owner:GM GLOBAL TECH OPERATIONS LLC

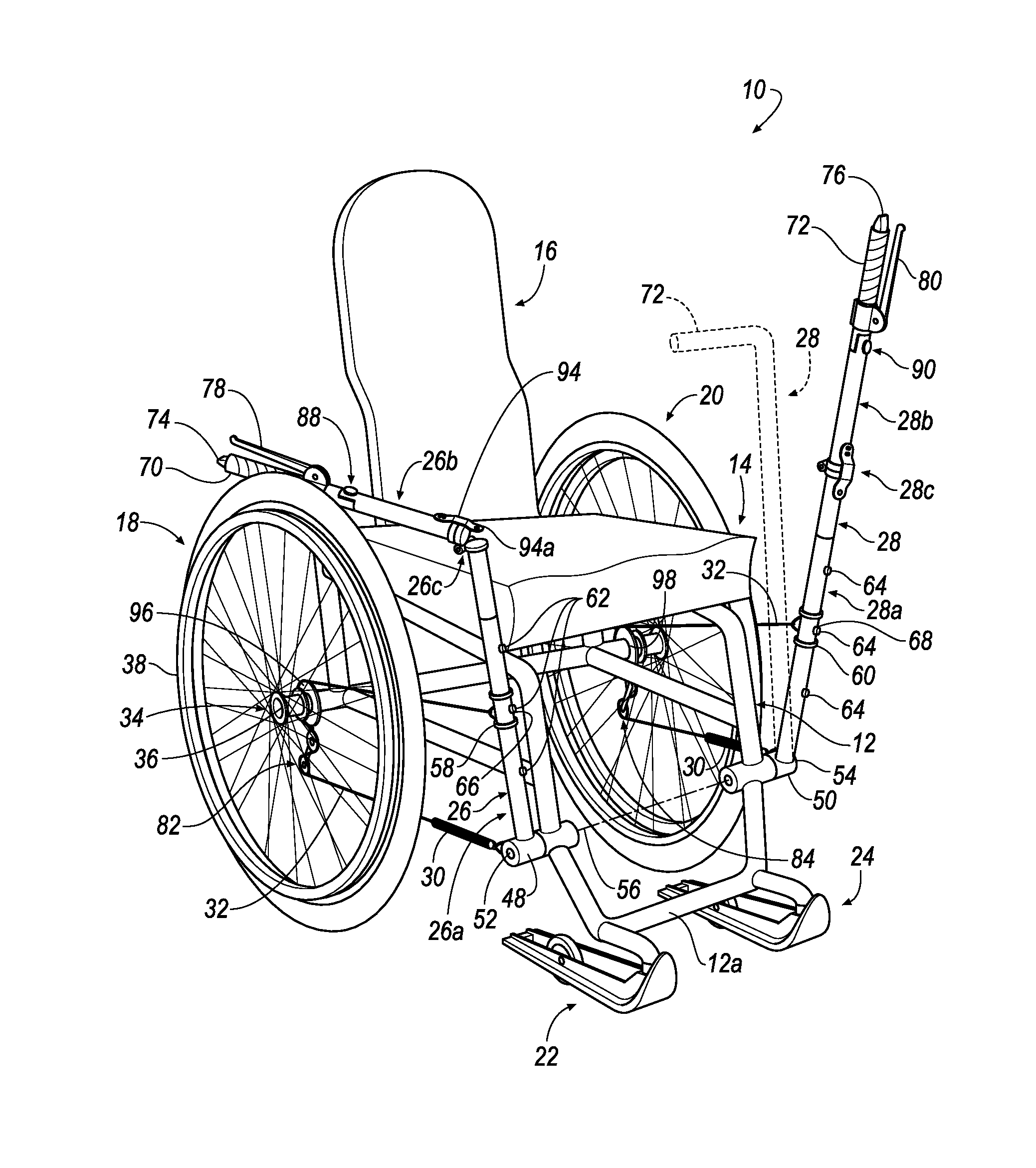

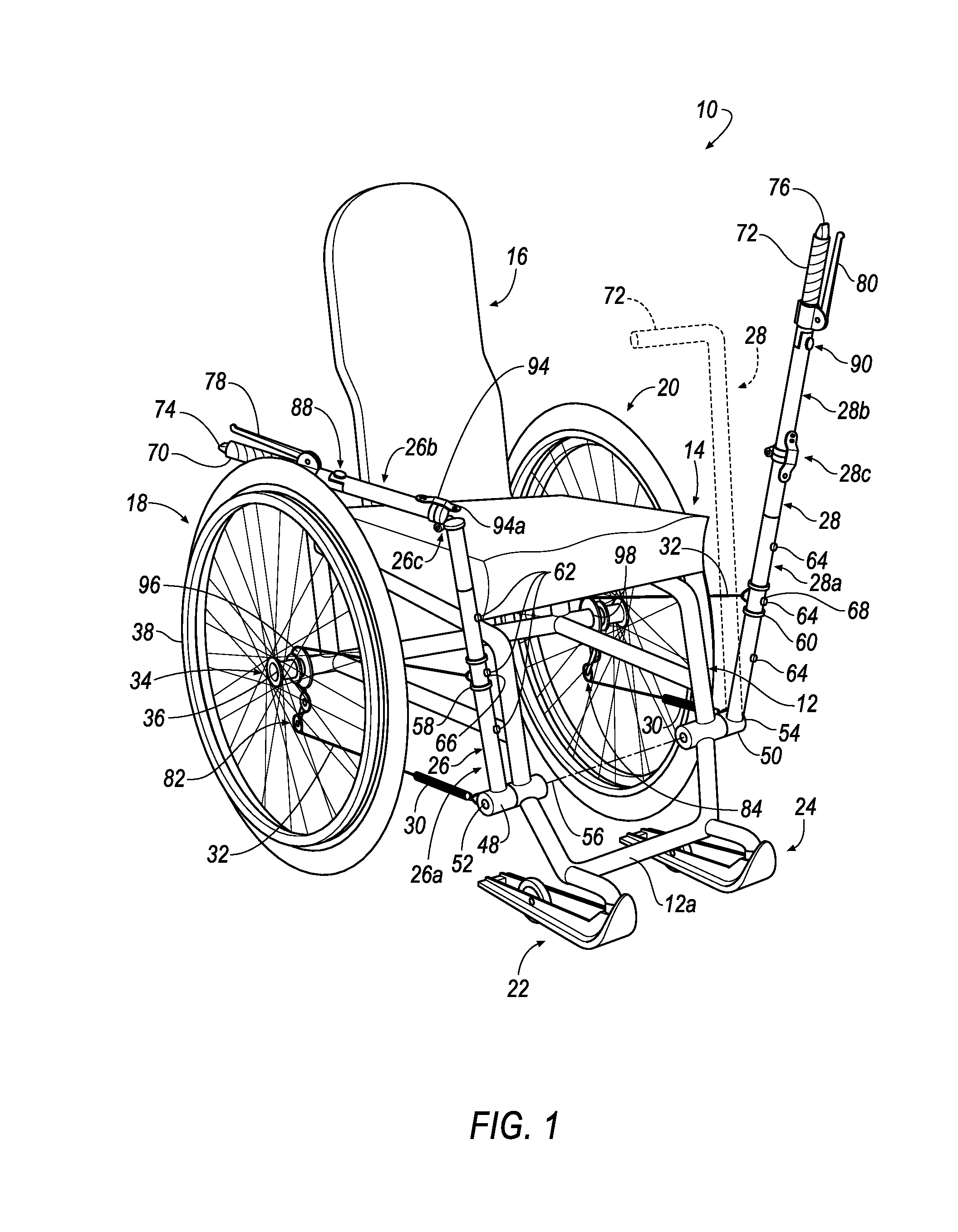

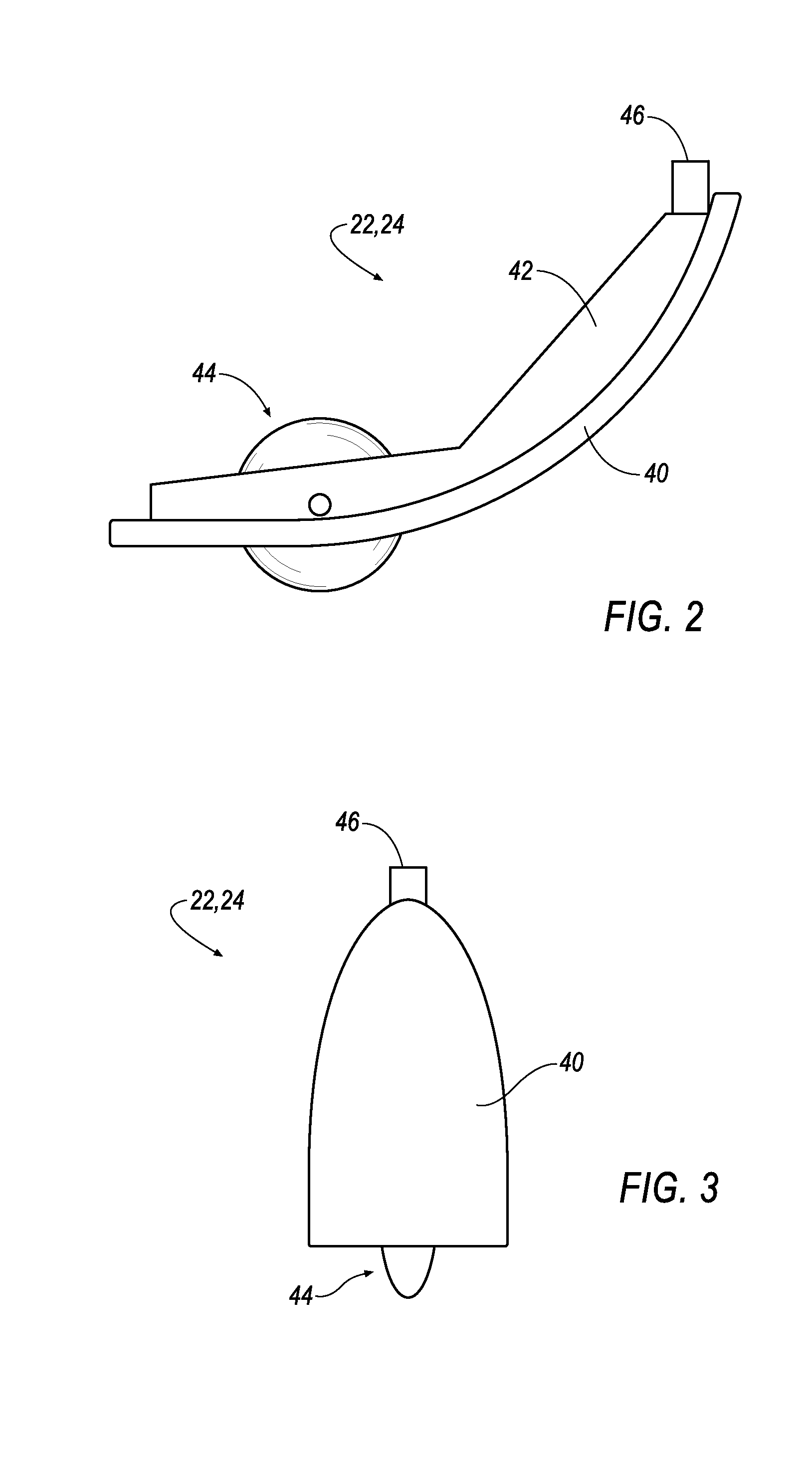

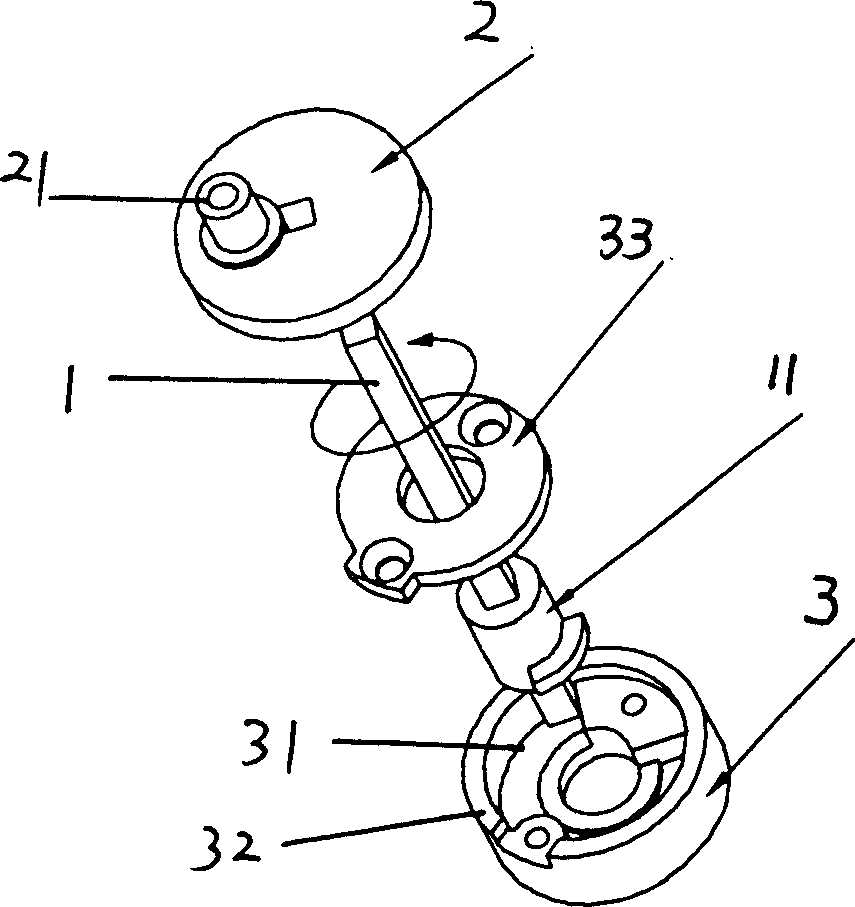

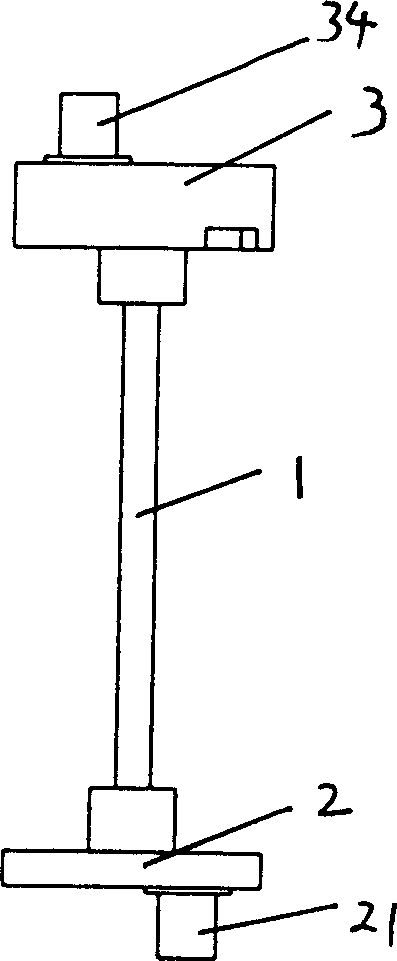

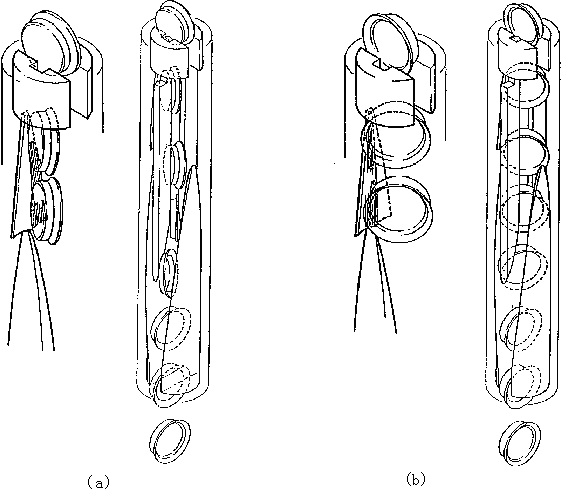

Human powered wheelchair with jackdrive™ propulsion system

ActiveUS9398988B1Quantity maximizationStrengthen operable muscleCyclesWheelchairs/patient conveyanceDrive wheelEngineering

A human powered wheelchair includes a frame, a seat mounted to the frame for supporting an operator having a torso, two independently driven wheels disposed at the rear of the wheelchair, and a JACKDRIVE™ propulsion system. The JACKDRIVE™ propulsion system includes two independent drive levers adapted to be grasped by the operator and to be pushed forward in a bench press movement away from the torso of the operator, a biasing member for exerting a biasing force to move each lever toward the torso of the operator, a driving chain connected to each lever, and a unidirectional driving mechanism operatively coupled to the driving chain and each driven wheel for directly translating the bench press movement of each lever into unidirectional motion of each driven wheel so as to propel the wheelchair in a forward direction.

Owner:DEMIRZA ENTERPRISES LLC

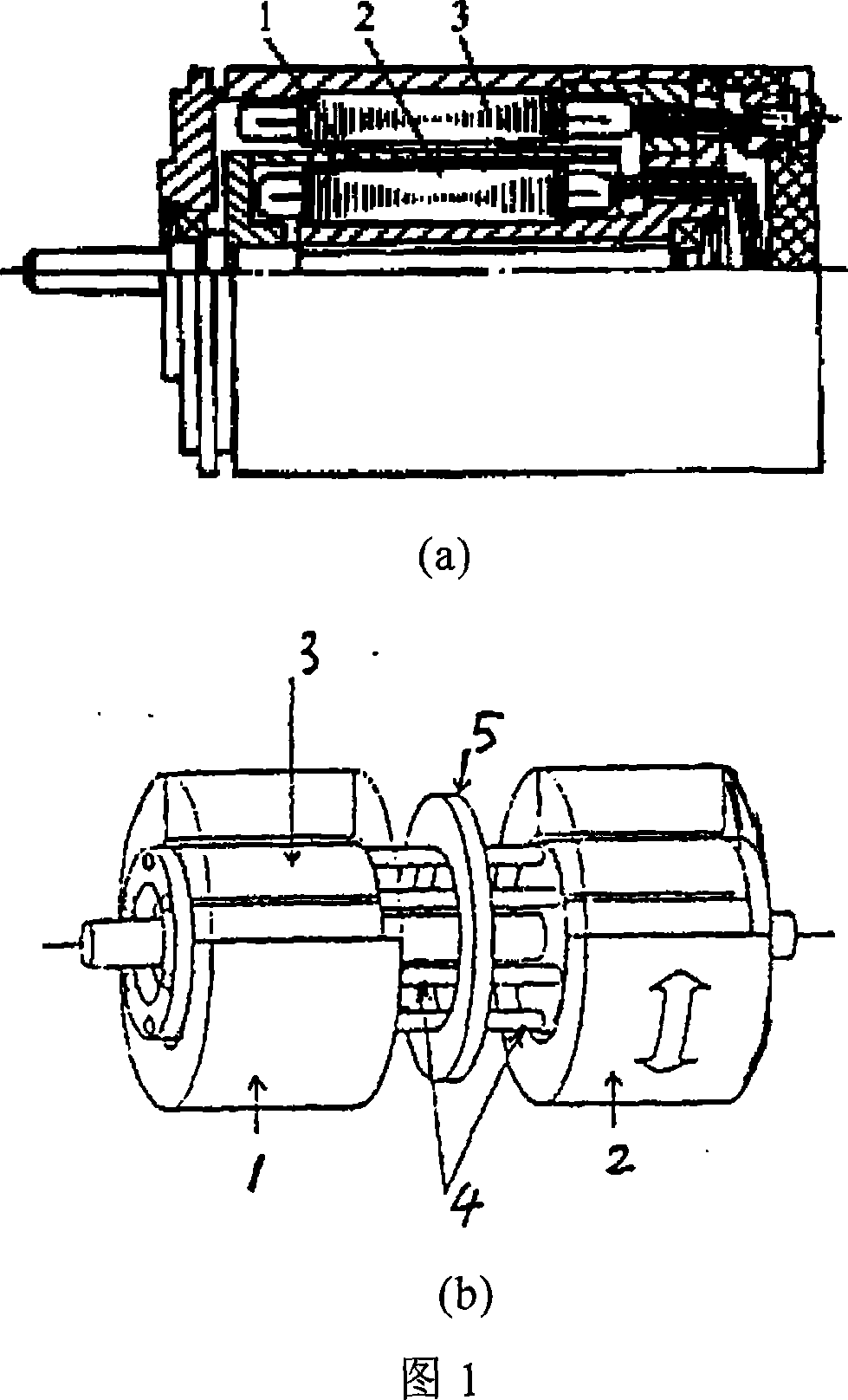

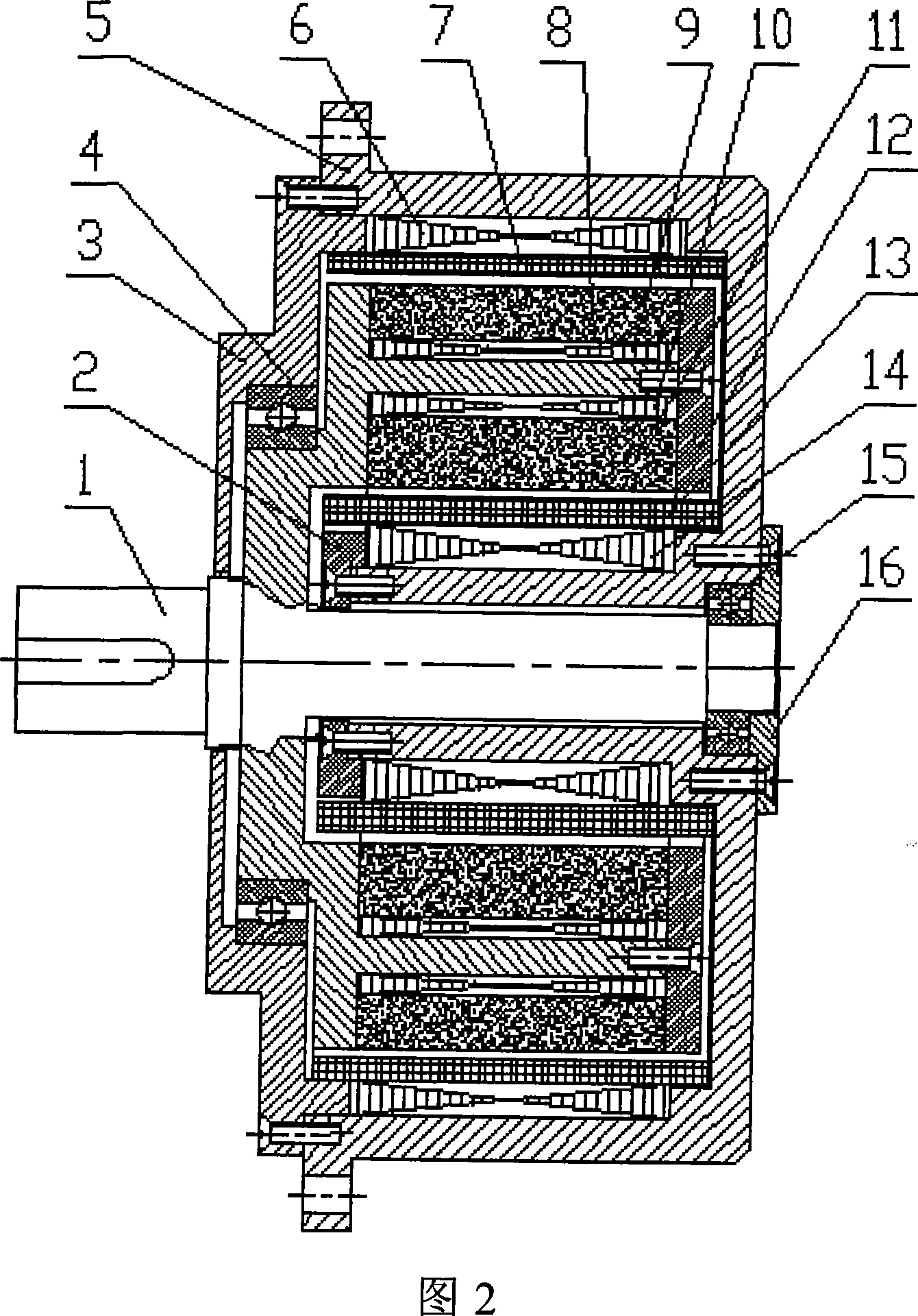

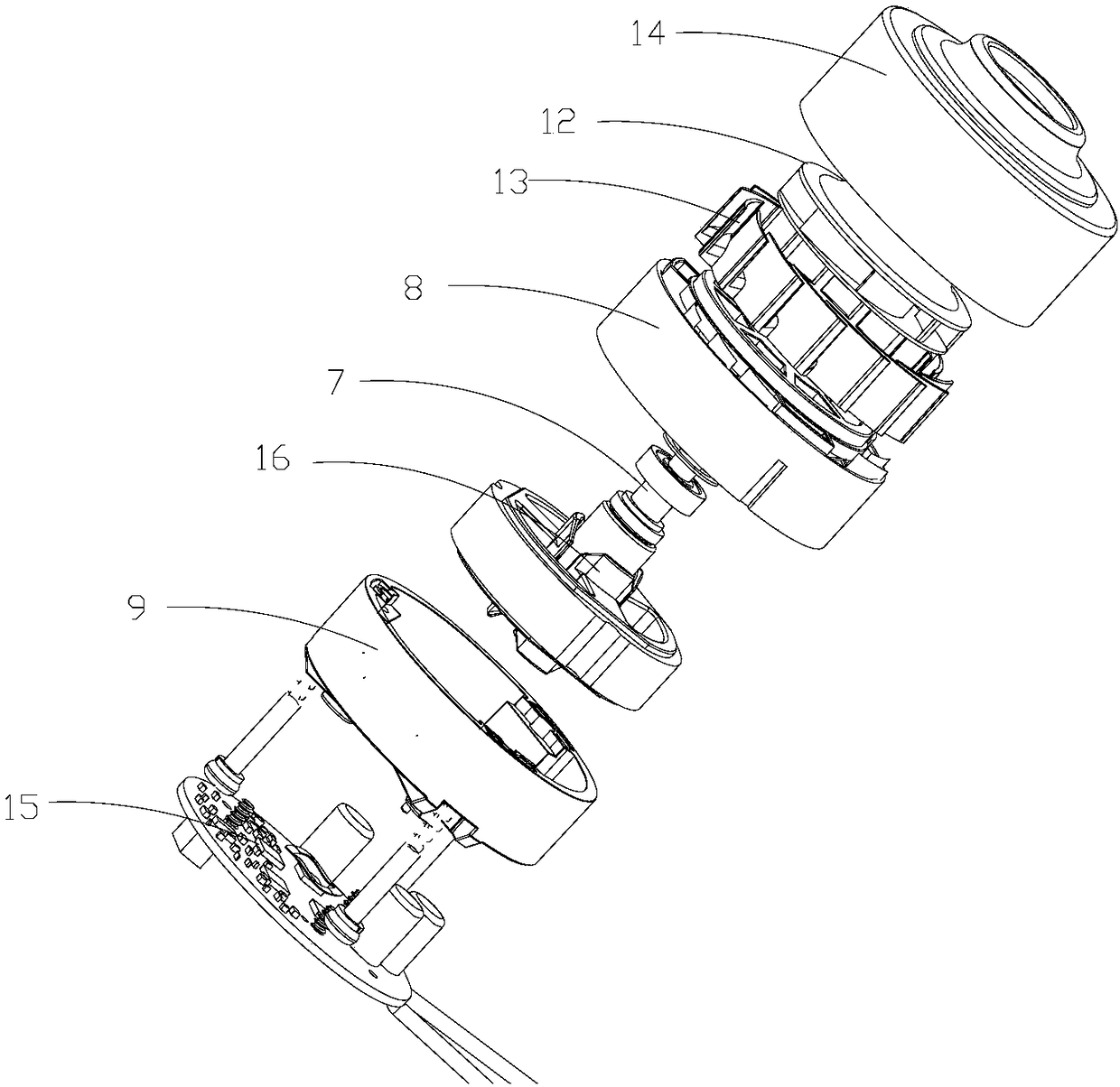

Torque motor for satellite antenna pointing mechanism

InactiveCN101159400AReduce volumeReduce weightMagnetic circuit rotating partsMagnetic circuit stationary partsSatelliteEnergy loss

A torque motor for a satellite antenna direction mechanism utilized in a facility, mainly comprise a cup-shaped rotating shaft, a left limit ring, a left end cover, a left bearing, a housing, an iron core of an outside stator, an outside hollow cup-shaped stator, an outside Halbach magnet body, an iron core of an outside rotor, an iron core of an inside rotor, an inside Halbach magnet body, a right limit ring, an stator of an inside hollow cup-shaped stator, an iron core of an inside stator, a right bearing and a right end cover, wherein the outside Halbach magnet body, the iron core of an outside rotor, the iron core of an inside rotor and the inside Halbach magnet body are connected with the cup-shaped rotating shaft, which are rotating parts of the motor, and others are static parts of the motor. The invention utilizes the outside Halbach magnet structure and the inside Halbach magnet structure, which can largely reduce the thickness of the iron core and increase the air gap flux density and the sinusoidal degree of the air gap, therefore reducing the volume, weight, switch disturbing moment and energy loss of the motor, and accomplishing the outout torque of the torque motor significantly.

Owner:BEIHANG UNIV

Graphene/nano carbon fiber reinforced copper-base graphite motor carbon brush and preparation method thereof

ActiveCN109524866APracticalStrong copper-based graphite motor carbon brush has better practicabilityRotary current collectorBrushes manufactureFiberDispersity

The invention discloses a graphene / nano carbon fiber reinforced copper-base graphite motor carbon brush. The carbon brush is prepared by mixing, pressing and then sintering an aggregate and a powder according to a certain ratio, wherein the weight ratio of the aggregate to the powder is (65-75): (30-35); the aggregate is a mixture of electrolytic copper powder and tin powder which have a weight ratio of (70-75):(25-30); and the powder is a mixture of graphene powder, isostatic pressing formed graphite powder, carbon black and nano carbon fiber which have a weight ratio of 30:20:40:10. The graphene / nano carbon fiber reinforced copper-base graphite motor carbon brush of the invention has good commutation and self-lubricating performance, prolongs the service life of an AC-DC motor, has low commutator abrasion, is simple in preparation process, low in equipment requirement, easy to operate. A prepared carbon brush reinforced body has good dispersity and good practicability.

Owner:周国力

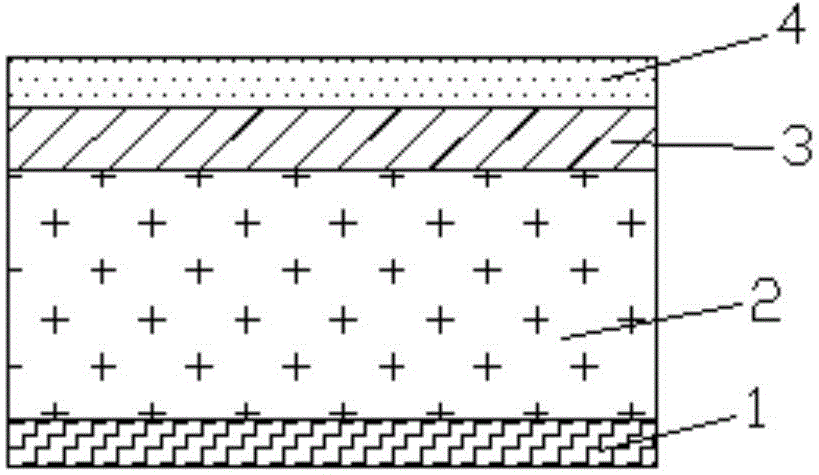

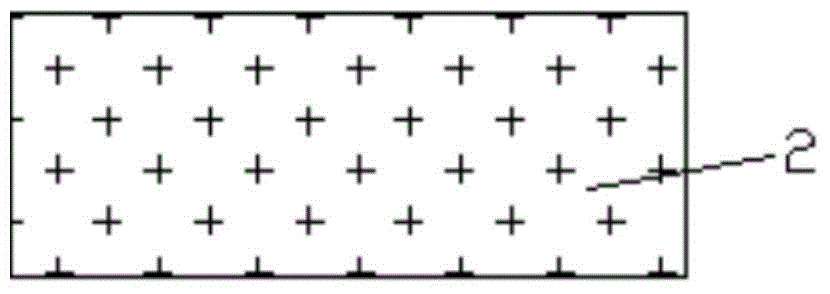

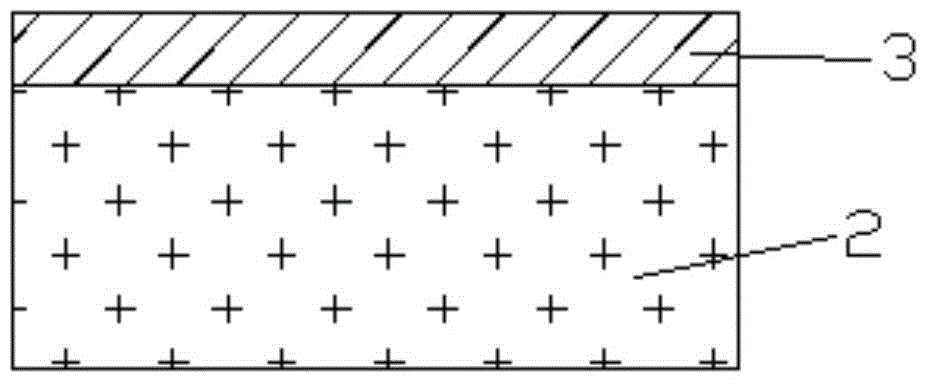

Diamond schottky diode and manufacturing method thereof

InactiveCN104617159AReduce leakage currentImprove reverse performanceSemiconductor/solid-state device manufacturingSemiconductor devicesVoltageOptoelectronics

The invention discloses a diamond schottky diode and a manufacturing method thereof. The diamond schottky diode comprises an ohmic electrode, a P-type highly-doped diamond substrate, a drift layer and a schottky electrode which are laminated in sequence, wherein the schottky electrode is of a single hafnium layer structure or a composite layer structure comprising a plurality of single metal layers with a single hafnium layer as a bottom layer. According to the diamond schottky diode manufactured by the method, the withstand voltage is improved, the reverse leakage current is reduced, and the reverse performance of the diamond schottky diode is improved.

Owner:王宏兴

Material for preparing locomotive traction motor carbon brush

ActiveCN106032328AImprove wear resistanceImprove orientationCeramicwareDiesel locomotiveCarbon black

The invention discloses a material for preparing a locomotive traction motor carbon brush. The material comprises soft carbon black powder, sprayed carbon black, pitch coke powder, graphite powder, a pore forming agent, a directional auxiliary agent, modified asphalt and a lubricant. According to the present invention, the carbon brush prepared from the material has characteristics of high rupture strength, good direction change performance and high passing current density, and is used for the diesel locomotive traction motor and the electric locomotive traction motor.

Owner:SUZHOU DONEKA NEW MATERIALS CORP LTD

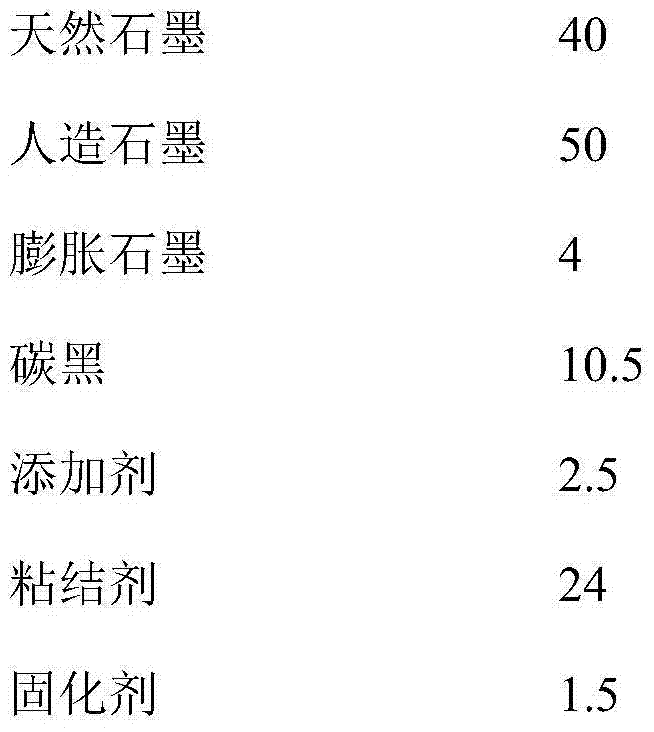

Electric brush for treadmill motor and manufacturing method of same

ActiveCN104779503AImprove wear resistanceReduce noiseRotary current collectorBrushes manufactureElectrical resistance and conductanceInterference resistance

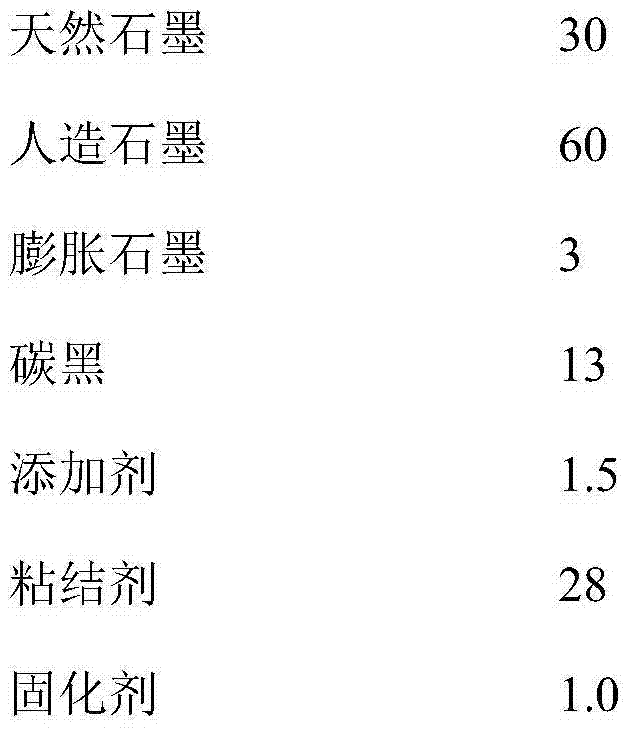

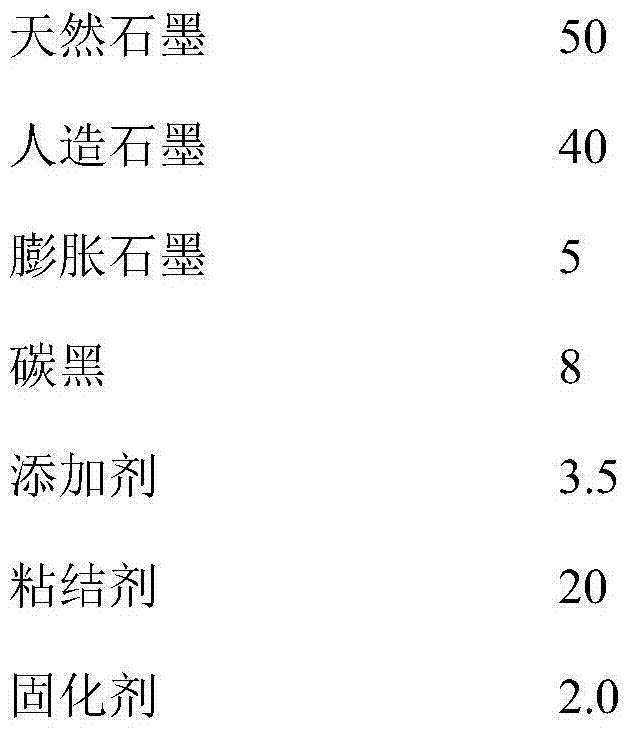

The present invention discloses an electric brush for a treadmill motor and a manufacturing method of same. The materials of the electric brush for the motor belong to the field of material science, comprising natural graphite, synthetic graphite, expanded graphite, carbon black, an additive, an adhesive and a curing agent. The electric brush for the treadmill motor disclosed by the present invention is low in noise caused during operation, low in resistance, good in direction switching, powerful in interference resistance and long in service life. More importantly, the electric brush is high in abrasion resistance, low in noise and spark grade, sparkless in empty load, and good in product stability.

Owner:SUZHOU DONSUN CARBONWARE CO LTD

Method for manufacturing high reliability glass passivated miniature surface-mounted diode

InactiveCN107393821AReduce surface electric fieldGood reversing performanceSemiconductor/solid-state device manufacturingSemiconductor devicesThermal expansionBoron trioxide

The invention provides a method for manufacturing high reliability glass passivated miniature surface-mounted diode. The method comprises diode core preparation, electrode welding and processing and package. A forward sand blasting cutting mode is used by chip separation to form a positive oblique angle, the surface electric field of a device is greatly reduced, and the stability of a chip surface is improved. In a chip corrosion process, acid corrosion is used to remove a chip mesa damage layer, a corrosion process is used to remove heavy metal ions adhered to the chip surface, a process of neutralizing alkali metal ions in a thermal passivation mode and growing a silicon dioxide passivation protection layer at the chip surface is used, the chip surface is cleaned to the maximum, the influence of interface charge is reduced, thus the device has good reverse performance, and the reliability of the product is improved. Passivation glass powder with the main components of zinc oxide, diboron trioxide and silicon dioxide is subjected to high temperature molding to realize the passivation and packaging effect of a chip mesa, the thermal expansion coefficients of an electrode and chip are same with that of a glass passivation layer, the ability of resistance to temperature shock of the product is improved, a special solder is used to sinter the electrode and an axial product, and a surface-mounted package structure is realized.

Owner:CHINA ZHENHUA GRP YONGGUANG ELECTRONICS CO LTD STATE OWNED NO 873 FACTORY

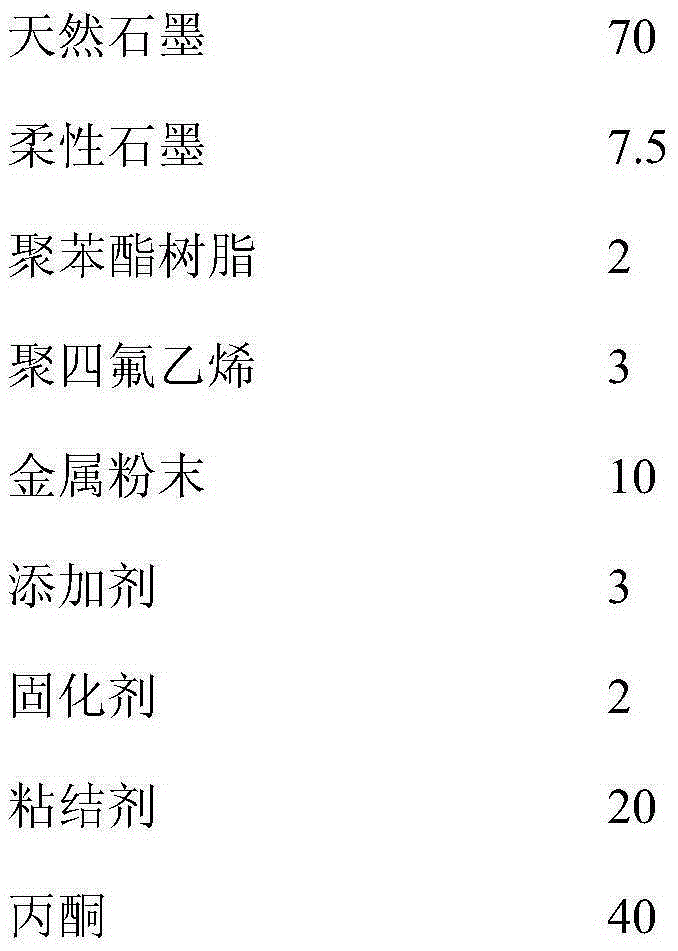

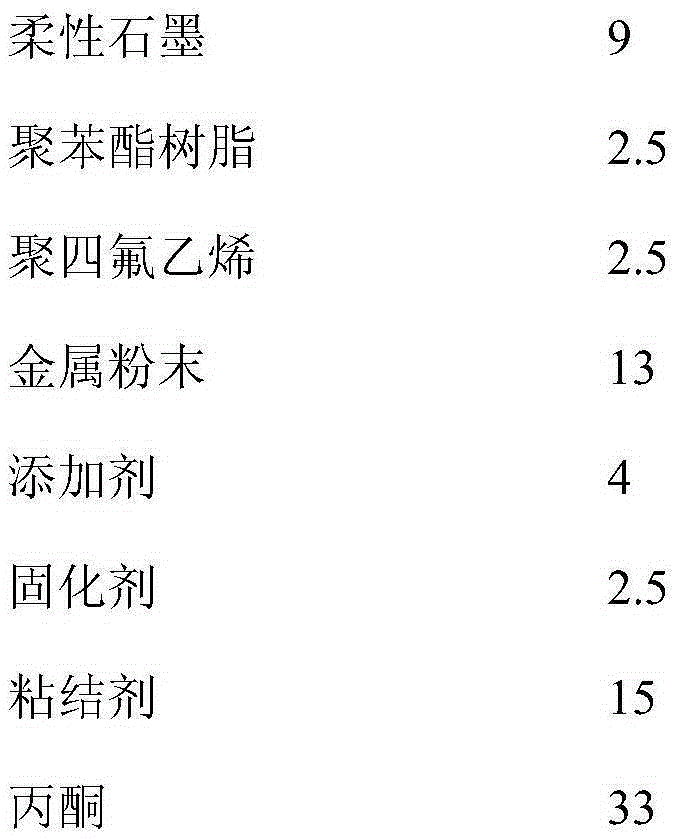

Electric brush for treadmill motor

InactiveCN106654782AReasonable compositionFormulation ScienceRotary current collectorBrushes manufactureLow noiseGraphite

The invention provides an electric brush for a treadmill motor. An electric brush preparation method comprises steps that matrix powder materials and a binder solution are mixed uniformly to prepare an electric brush raw material mixture; the electric brush raw material mixture is dried and crushed to acquire electric brush raw material powder; the electric brush raw material powder is added to a pressing die to carry out pressing processing to acquire an electric brush blank; thermal curing processing on the electric brush blank is carried out to acquire a half-finished electric brush product; finished product processing on the half-finished electric brush product is carried out to acquire a finished electric brush; the matrix powder materials comprise graphite, polyphenyl ester resin, polytetrafluoroethylene and metal powder. The electric brush has advantages of proper electrical resistivity, good wear-resisting performance, good commutation performance and low spark grade and further has more important advantages of high efficiency, low noise and good product stability.

Owner:SUZHOU DONSUN CARBONWARE CO LTD

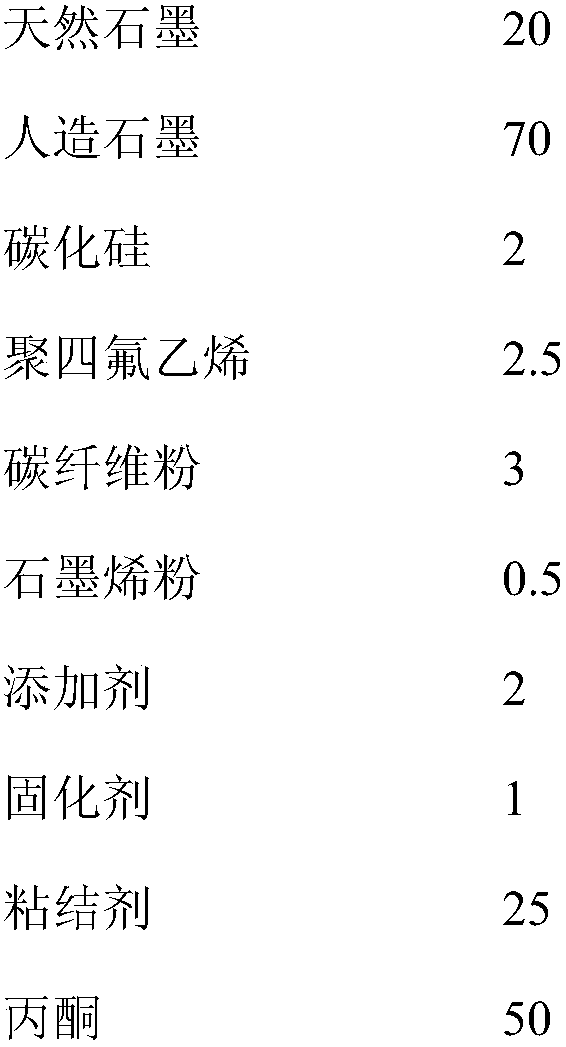

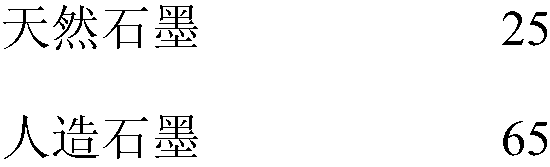

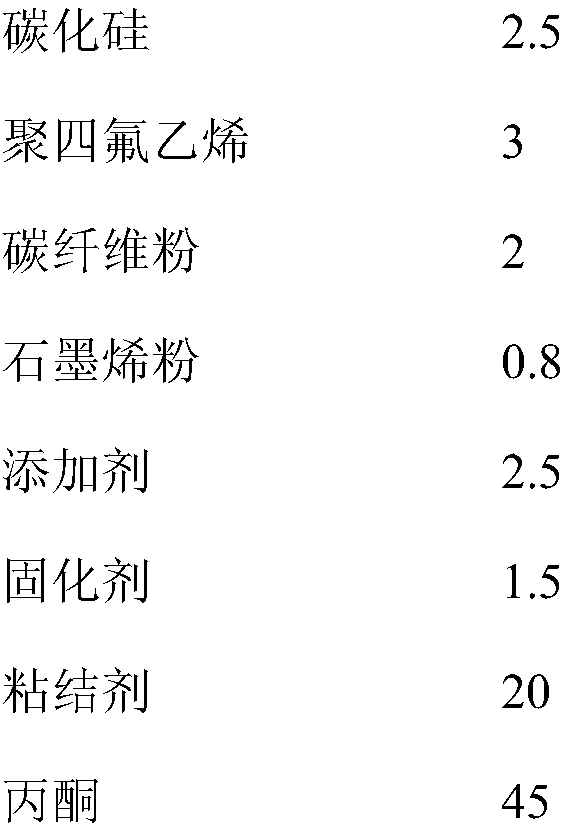

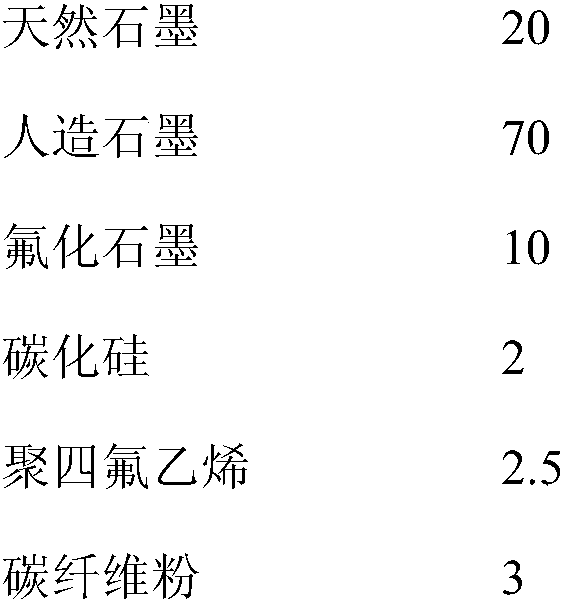

Material used for preparing brush for motor of dust collector

InactiveCN107666099AImprove the lubrication effectReduce coefficient of frictionRotary current collectorFiberGraphite

The invention discloses a material used for preparing a brush for a motor of a dust collector. The brush comprises a matrix powder material and a binder, the matrix powder material comprises graphite,silicon carbide, polytetrafluoroethylene, carbon fiber powder, graphene powder, additives and curing agents, and the ratio of the parts by weight of the matrix powder material to the binder is 5-8:1-2. According to the brush for the motor of the dust collector, prepared by employing the material, the resistivity is low, the wear resistance is good, the spark grade is low, and the product stability is good; and the motor of the brush is high in degree of vacuum so that the usage requirements of high efficiency and high lifetime of the high-efficiency type dust collector motor can be met.

Owner:SUZHOU DONSUN CARBONWARE CO LTD

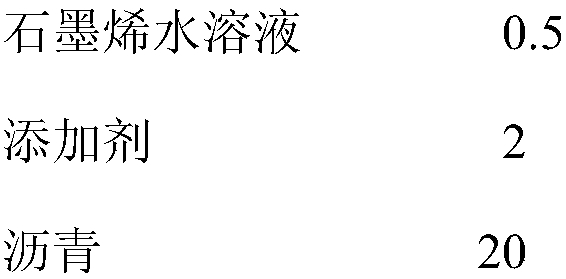

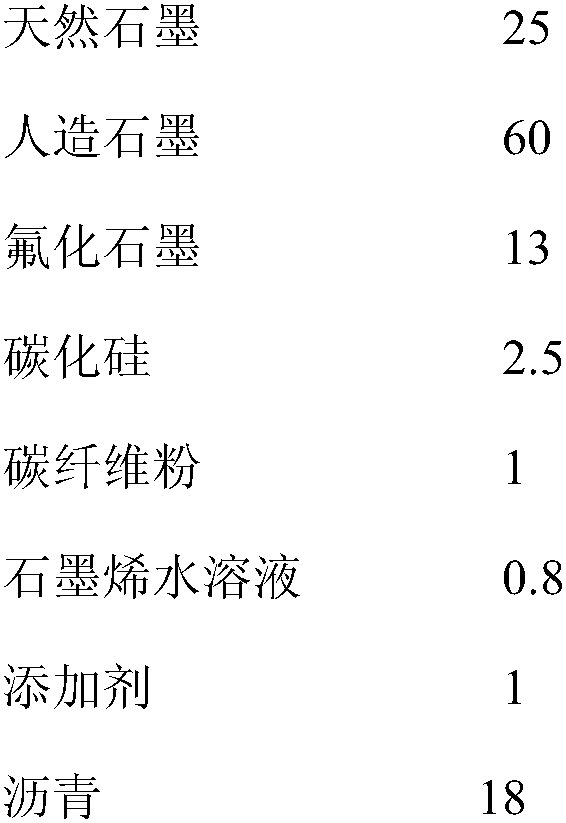

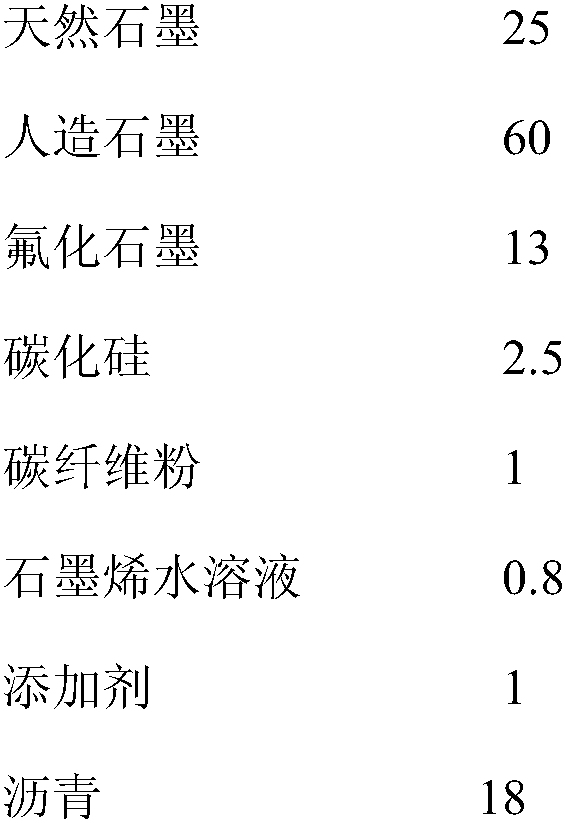

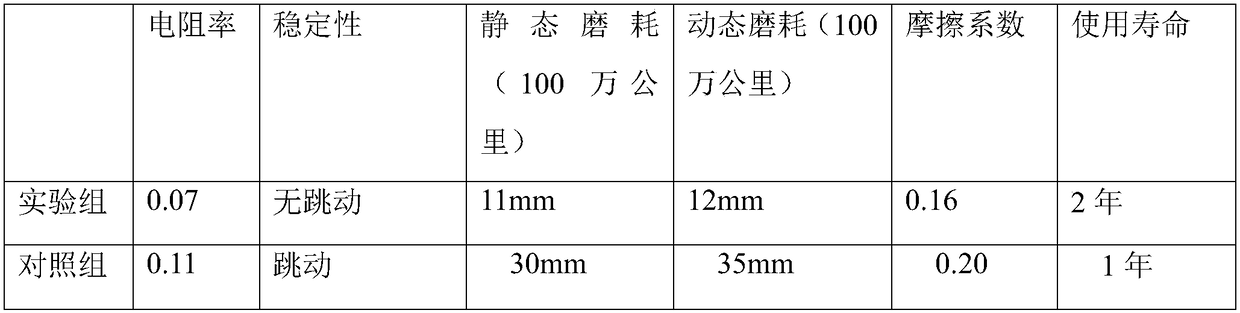

Preparation method of brush for electric tool motor

InactiveCN107785763AModerate resistivityImprove wear resistanceRotary current collectorBrushes manufactureAngle grinderElectric machine

The invention discloses a preparation method of a brush for an electric tool motor, relating to the field of materials. The method comprises the steps of: mixing base powder comprising an aqueous solution of graphene with a pitch binder uniformly under the heating condition to obtain a brush raw material mixture; crushing, screening and mixing the brush raw material mixture to obtain brush raw material mixture powder; adding the brush raw material mixture powder into a pressing mold and pressing to obtain a brush blank; roasting the brush blank to obtain an initial brush product; and processing the initial brush product to obtain a finished brush product. The brush for the electric tool has moderate resistivity, low brush running spark grade, good commutation performance, good product stability, excellent abrasion resistance and electromagnetic interference resistance, and is especially suitable for medium and low power angle grinder motors.

Owner:SUZHOU DONSUN CARBONWARE CO LTD

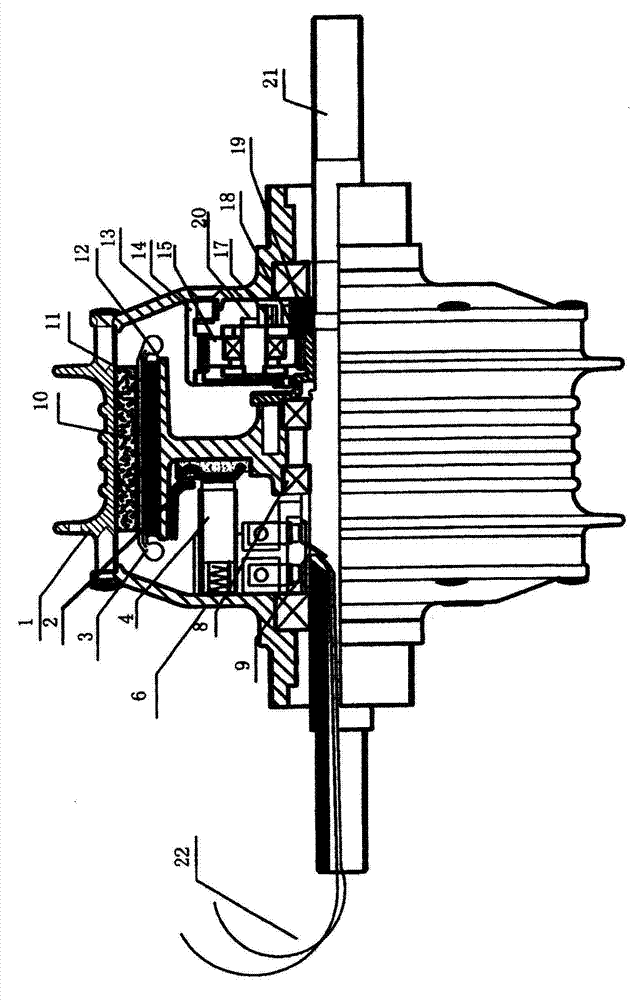

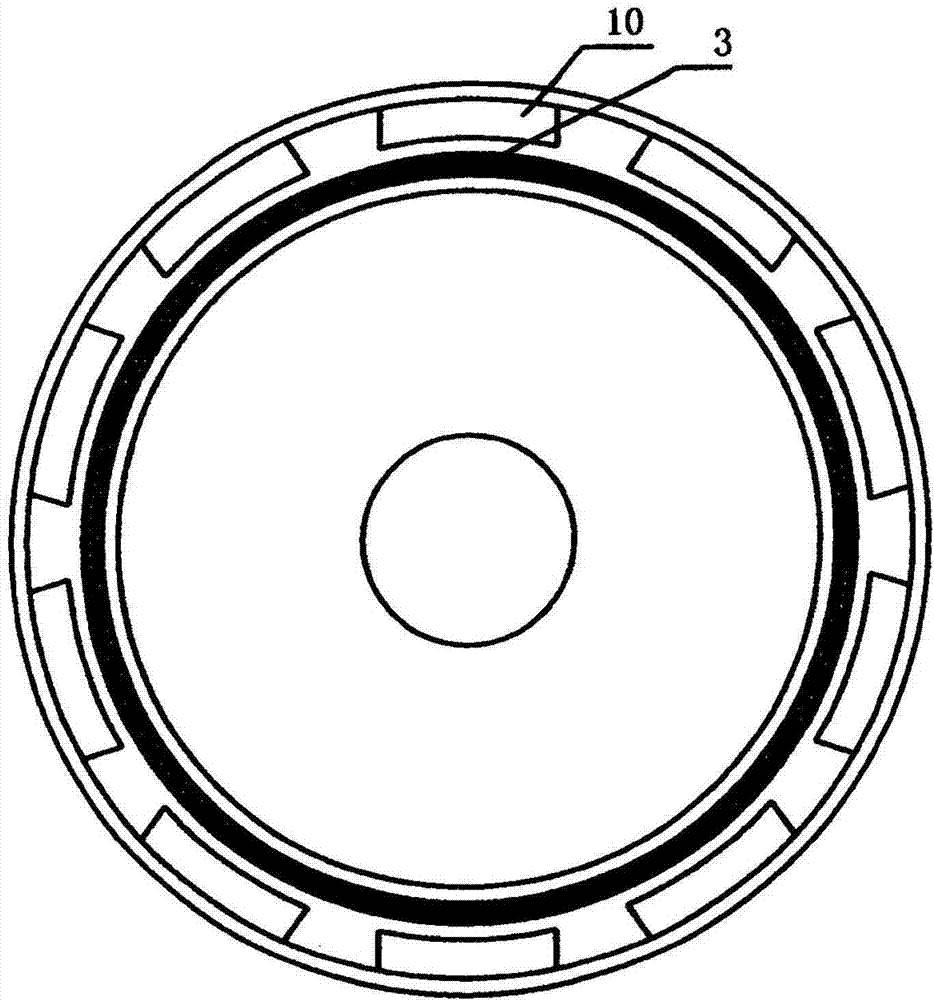

Full-rotor hub motor

InactiveCN104753271AReduce volumeReduce weightWheel based transmissionMotor depositionGear wheelEngineering

A full-rotor hub motor comprises a motor shaft. A wheel hub casing is fixed on the motor shaft via a bearing, and serves as an external rotor of the motor. An internal rotor and a planetary deceleration mechanism are included, a sun gear of the planetary deceleration mechanism is fixedly connected with the internal rotor, an external gear is fixedly connected with the external rotor, a planetary gear carrier is fixedly connected the motor shaft via a clutch, the sun gear and the external gear rotate in opposite directions, and the internal rotor connected to the sun gear and the external rotor connected to the external gear rotate in opposite directions. The motor does not include a stator, when the motor is powered on, the internal rotor rotates in the direction, opposite to the moving direction of a wheel, at a high speed, the external gear is fixed on the hub casing, and thus, the hub casing drives the wheel to move forwards.

Owner:河南超微电动汽车有限公司

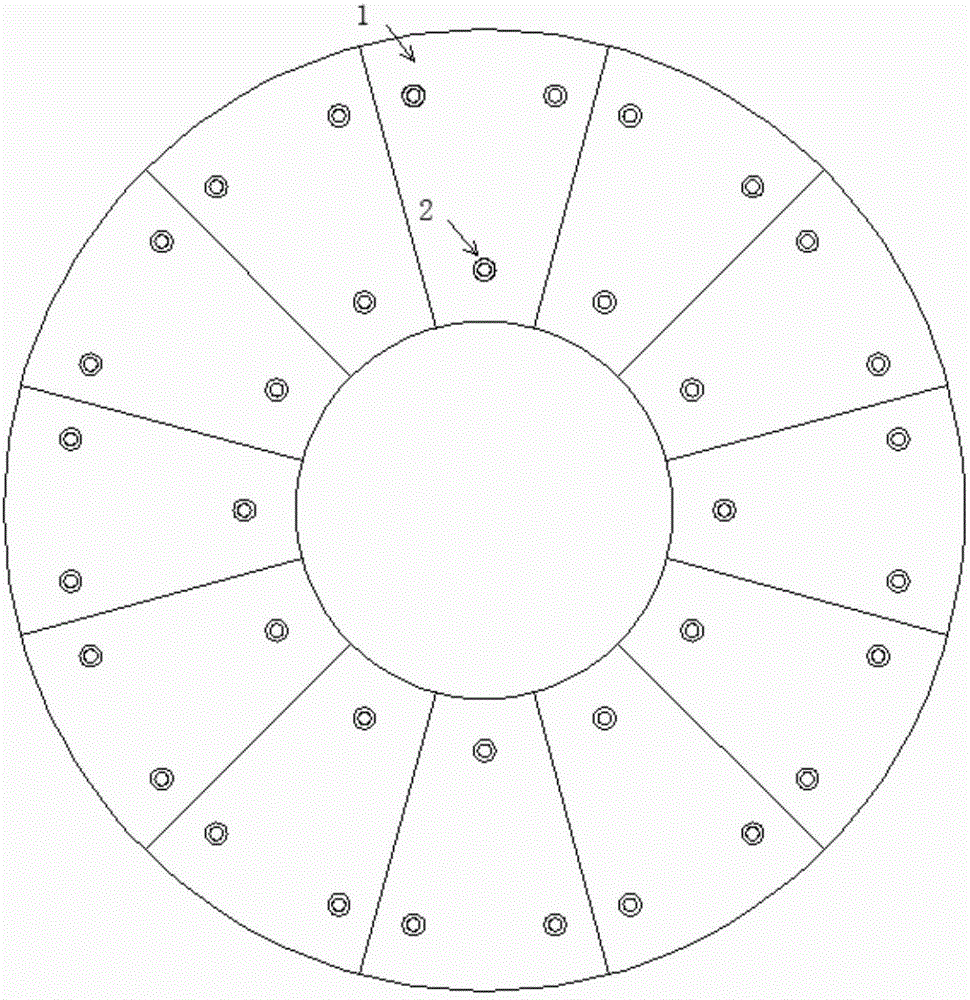

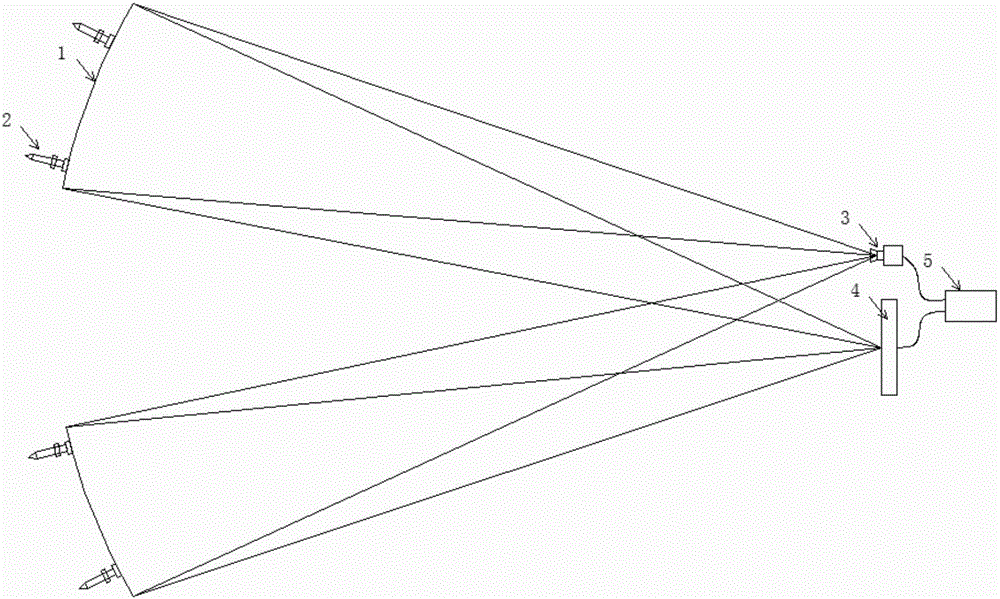

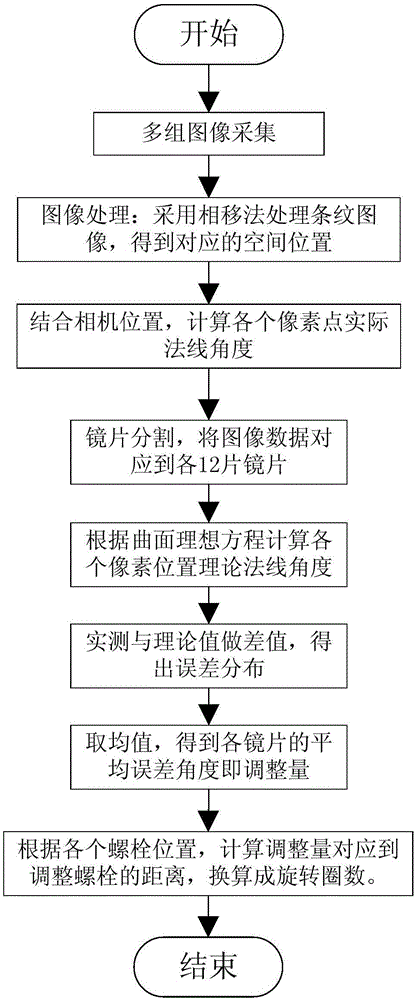

Automatic detection and performance analysis optimization device and system for optical system

ActiveCN106706271AImprove efficiencyImprove regulation efficiencyTesting optical propertiesImaging processingComputer science

The invention discloses an automatic detection and performance analysis optimization device for an optical system. The device obtains the number of error points at the level of pixels in a mode of continuously changing images through image display equipment, cooperating with an image collector for collection and carrying out the processing of images, carries out the adjustment of a focusing system, the performance analysis, focusing light spot fitting and the evaluation of hot spot analysis, and finally obtains the optical system which accords with the expectation. The device and method improve the efficiency, and reduce the cost and risk. Because the image processing and analysis speed is high, the adjustment parameters of the whole optical system can be obtained in several seconds, and are used for guiding the manual or automatic adjustment equipment to carry out the adjustment, thereby greatly improving the adjustment efficiency, and reducing the adjustment cost and risks. Meanwhile, the device achieves the optical performance analysis and detection which accords with the reality. The device achieves the reverse performance optimization and improves the utilization efficiency.

Owner:大连鉴影光学科技有限公司

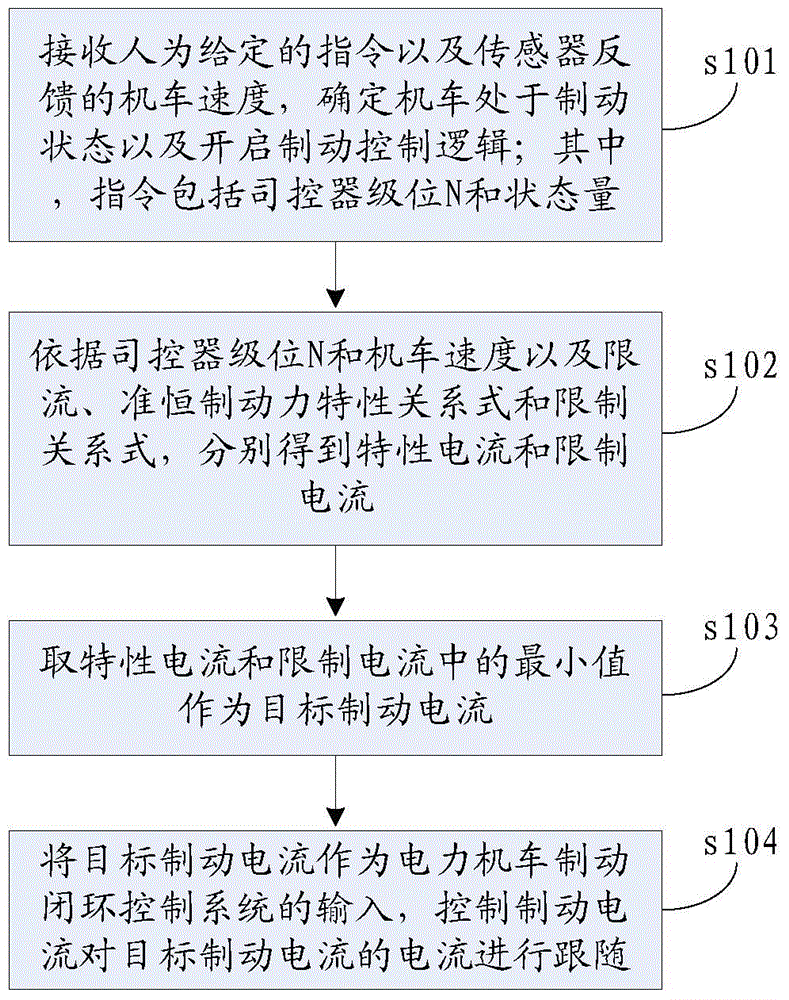

Electric locomotive braking control method and system

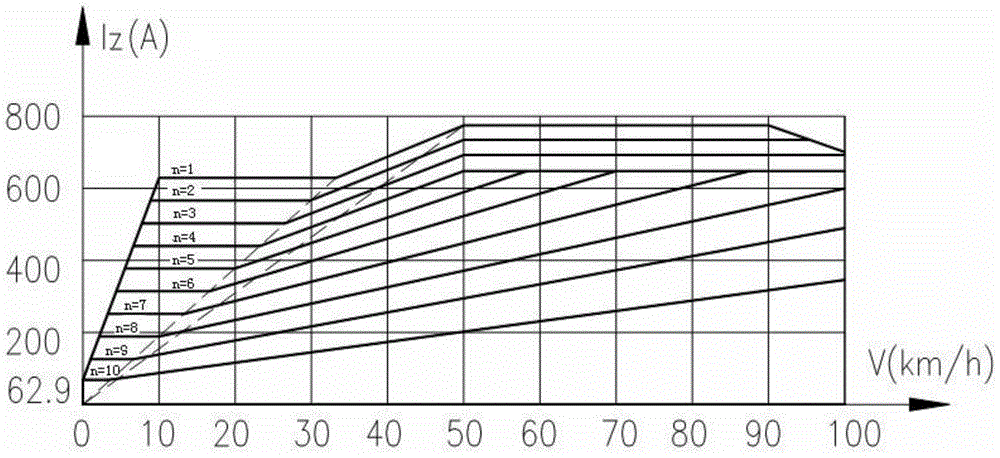

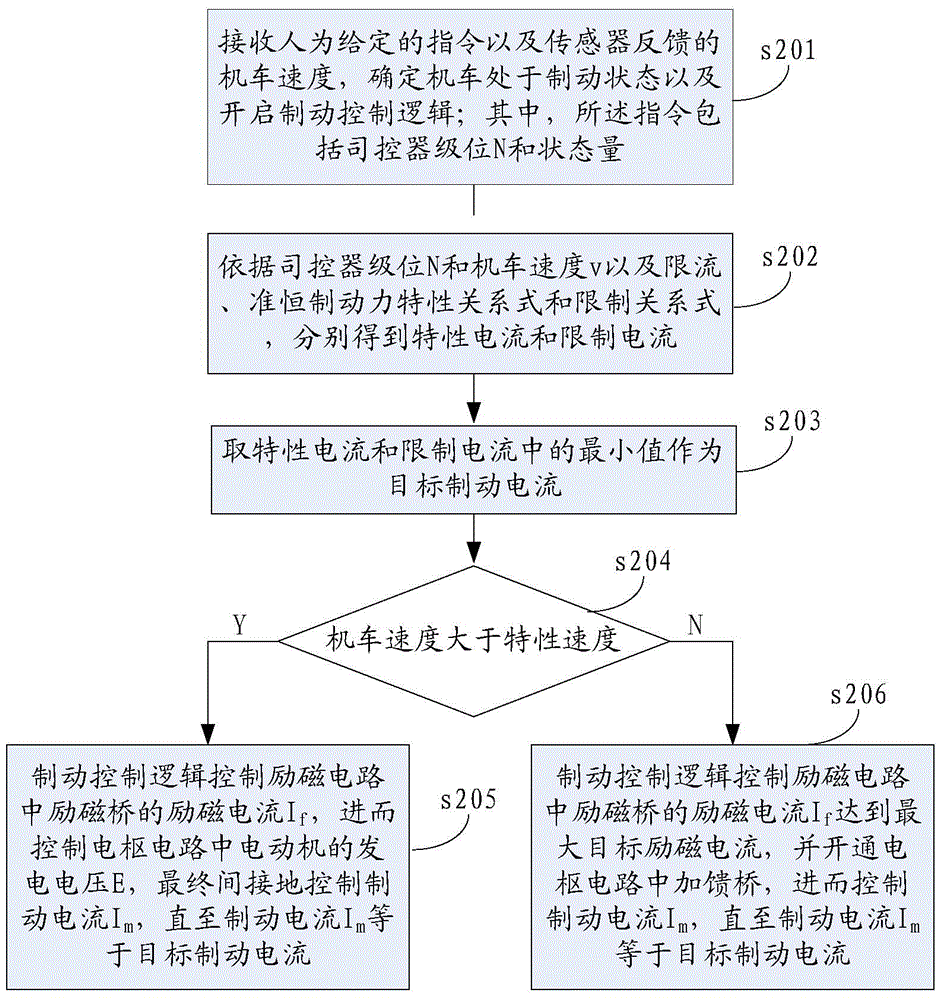

ActiveCN104590038ASteady braking forceSmooth changeElectrodynamic brake systemsClosed loopElectric power

The invention discloses an electric locomotive braking control method. The method includes the steps of receiving a manually-given instruction and the locomotive speed v fed back by a sensor, determining that a locomotive is in the braked state, and starting the braking control logic, wherein the instruction includes the motorman controller level N and the state amount; obtaining the characteristic current I1 and the limiting current I2 according to the motorman controller level N, the locomotive speed v and the characteristic relational expression and the limiting relational expression of the current-limiting and quasi-constant braking force, and selecting the minimum value in the characteristic current I1 and the limiting current I2 to serve as the target braking current IZ; using the target braking current IZ as the input of an electric locomotive braking closed-loop control system, and controlling the braking current Im to follow the current of the target braking current IZ. The invention further discloses an electric locomotive braking control system. By means of the method and the system, under the periodic locomotive speed sudden change working condition of the electric locomotive, the braking electricity generation voltage and the braking current changes are smoother, the influences of electric impact on an electric motor are effectively eliminated, and meanwhile the reversing performance is optimized and the reverser working environment is improved.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

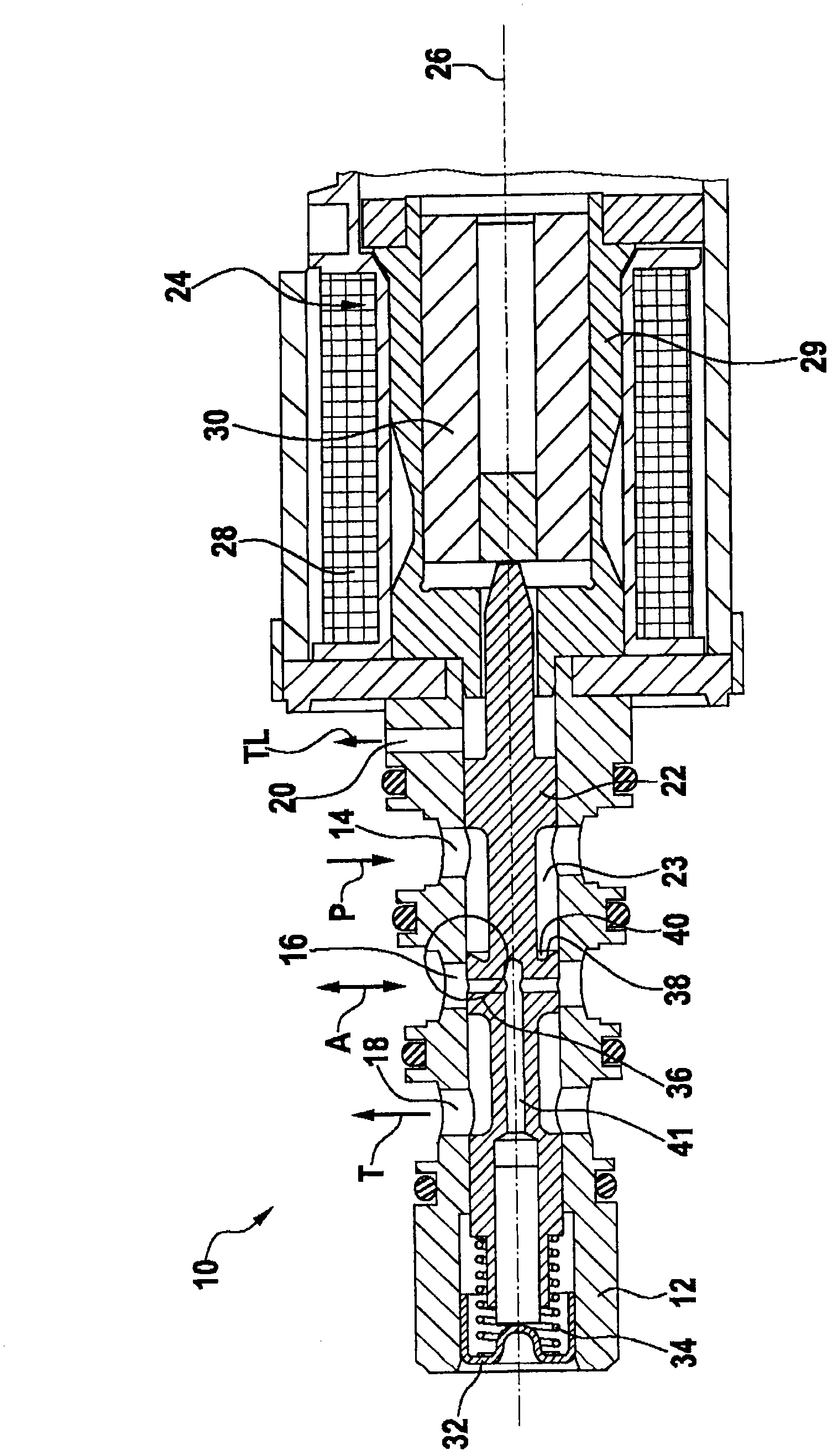

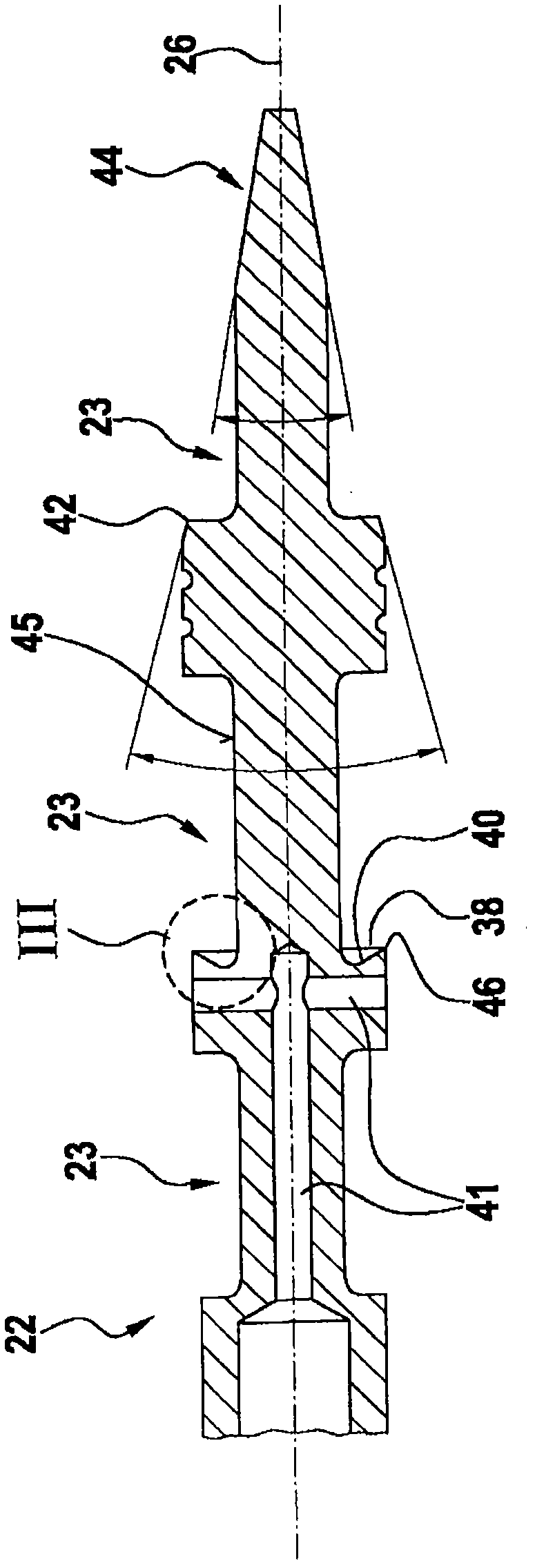

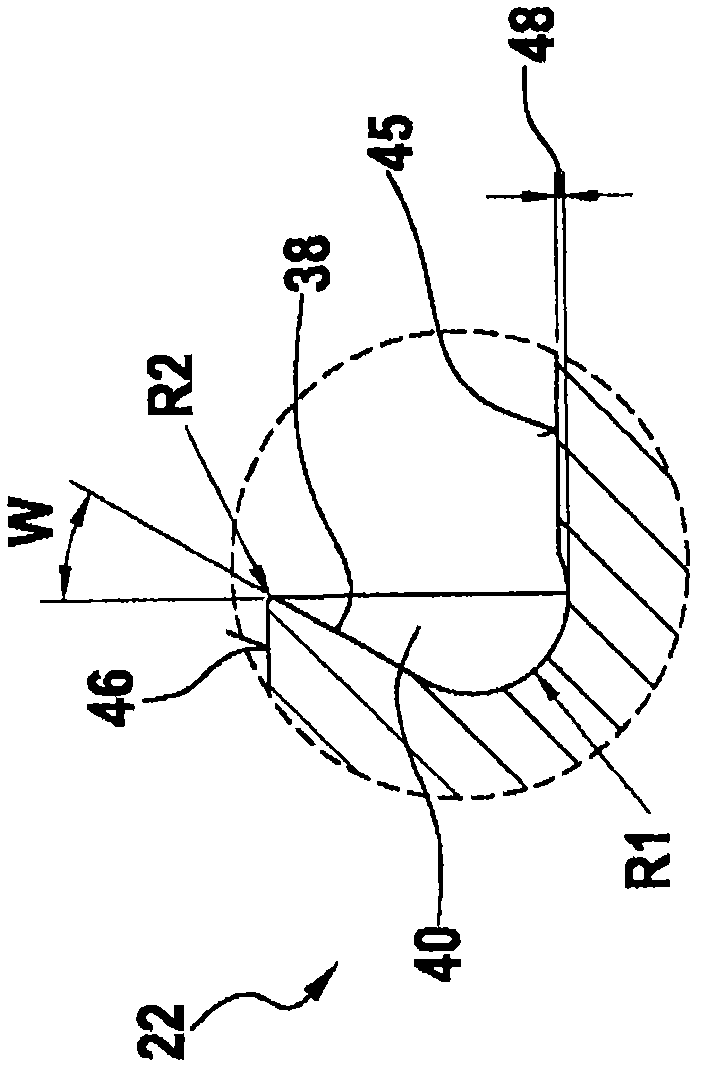

Pressure regulating valve, particularly for controlling a clutch in a motor vehicle automatic transmission

ActiveCN102537416AHigh trafficAxial force component is smallOperating means/releasing devices for valvesGearing controlAutomatic transmissionEngineering

A pressure regulating valve (10) for controlling a clutch in a motor vehicle automatic transmission, having a housing (12) having a first transverse opening (14) which acts as a fluid inlet, and a second transverse opening (16) which acts at least temporarily as a fluid outlet, the two transverse openings (14, 16) being spaced axially from one another, and having a valve slide (22) guided in the housing (12), the valve slide including an axially extending recess (23) in its circumferential surface, the recess fluidically connecting the two transverse openings (14, 16) to one another in a first axial position of the valve slide (22) and separating them from one another in a second axial position, in the circumferential surface of the valve slide (22) the recess (23) having a face (38) having an undercut (40) at its end closest to the second transverse opening (16).

Owner:ROBERT BOSCH GMBH

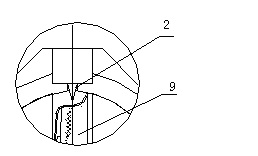

Crown cap reversing device

ActiveCN102674220AReduce volumeSimple structureFlanged caps applicationSlide plateIndustrial engineering

The invention provides a crown cap reversing device, and belongs to the field of packaging machinery. The crown cap reversing device comprises a barrel and two reversing plates, a guide opening, a guide sliding plate and two lower guide plates are sequentially arranged from a cap inlet to a cap outlet of the barrel, the guide opening consists of two cylinders and a guide key, the upper end of the guide sliding plate is connected with a bead of the guide key, the guide sliding plate is a camber with a protruded middle and two spread wings, each lower guide plate is of a cambered structure with a protruded middle and two spread wings, the length of each lower guide plate is 3-5 times of that of the guide sliding plate, one of the two lower guide plates is connected with the lower end of the guide sliding plate, and the two reversing plates are symmetrically arranged, used for assisting in reversing rotation, respectively fixedly connected with the barrel and positioned between the two lower guide plates. The crown cap reversing device is small in size, simple in structure, fine in reversing effect and high in yield.

Owner:安徽格太信控科技有限公司

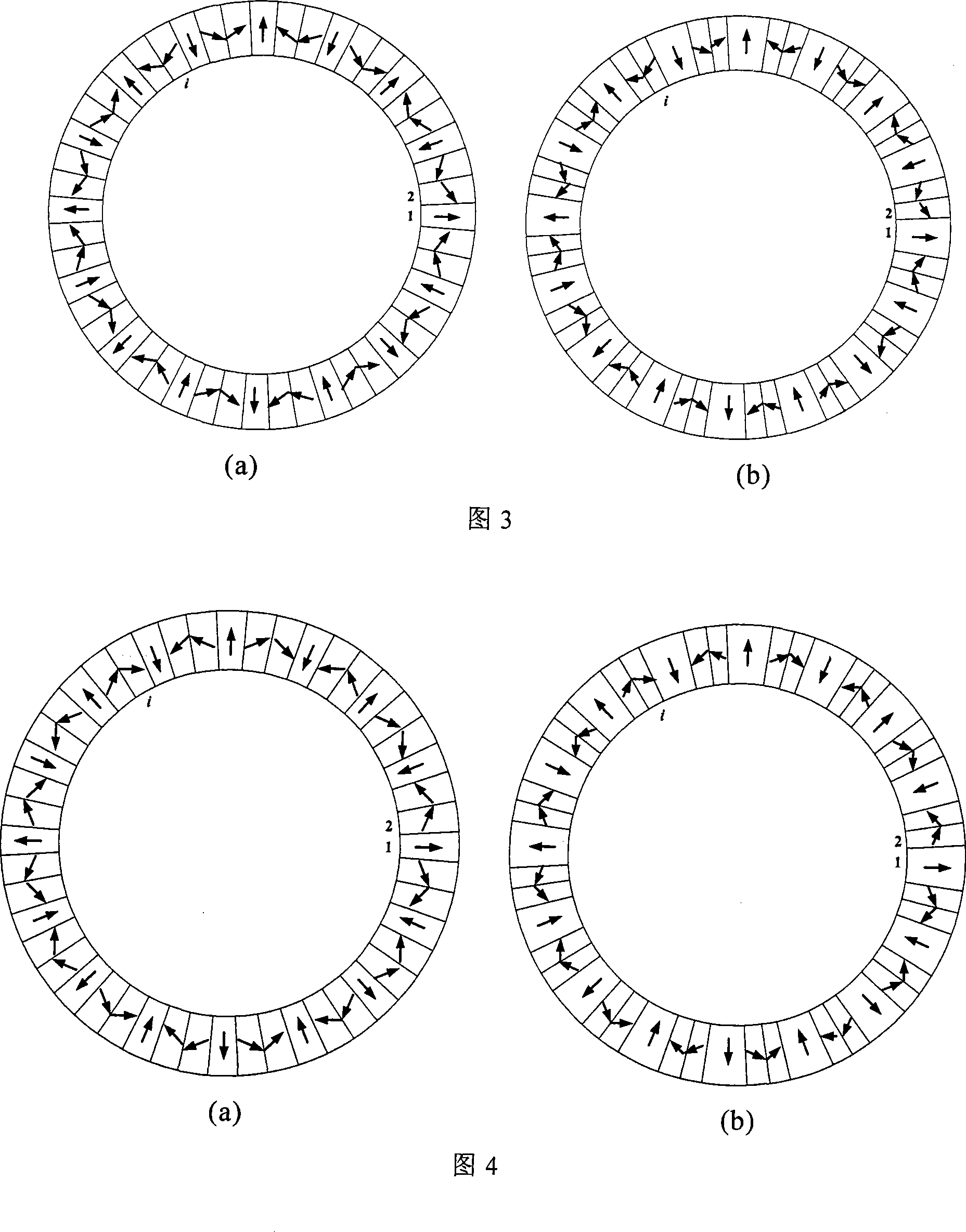

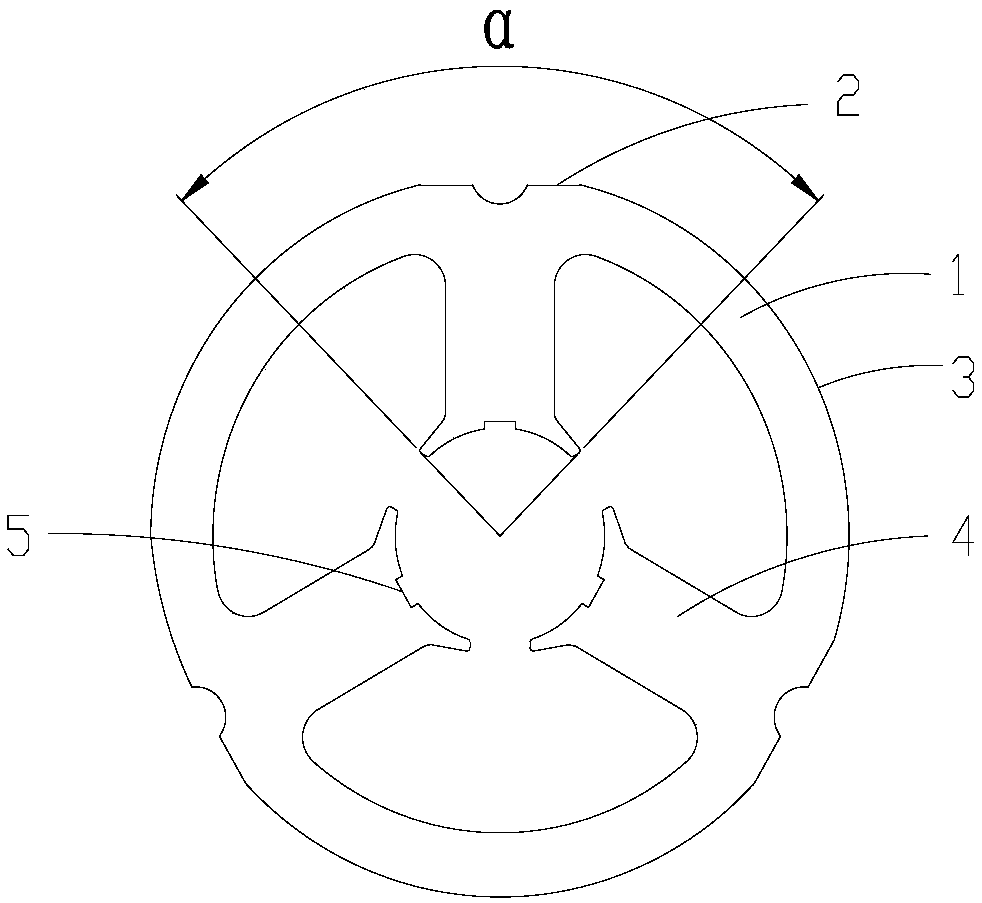

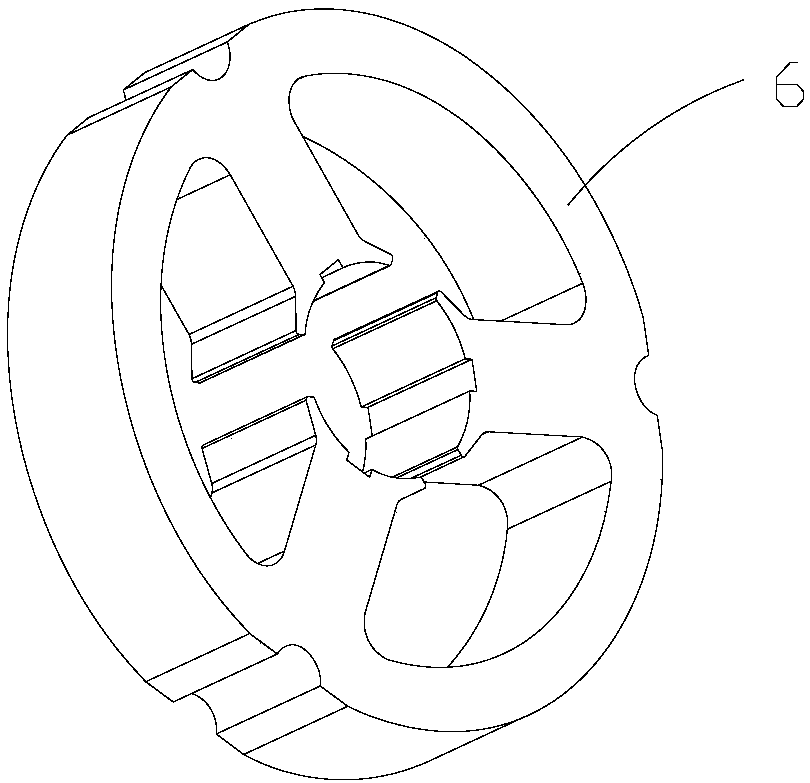

Stator iron core of brushless motor and brushless motor

PendingCN108134458AGood reversing performancePrecise positioningMagnetic circuit stationary partsBrushless motorsImpeller

Provided in the invention is a stator iron core of a brushless motor. The stator iron core comprises an annular yoke portion and a plurality of teeth extending on the yoke portion towards an axis. A straight-edge positioning edge is arranged on the outer ring of the yoke portion; an arc edge is adjacent to the positioning edge on the yoke portion; and the angular range of a pole shoe is from 80 degrees to 89.5 degrees. Besides, the invention also provides a motor being composed of a stator iron core, a rotor passing through the center of the stator iron core, a first bracket for fixing end portions of the stator iron core and the rotor, a circuit board fixedly connected to the first bracket, a second bracket connected fixedly and cooperatively with the first bracket. The contours of the innermost sides of the inner walls of the first bracket and the second bracket are consistent with the external contour of the stator and outer straight edges and outer positioning edges are formed. Inaddition, the motor also includes an iron core bracket coating the stator iron core, a moving impeller fixedly connected with the rotor, and an annular fixed impeller coating the moving impeller; thefixed impeller is fixedly connected to the inside of a cover case fixedly connected with the second bracket; and a circuit board is fixedly connected to the first bracket. The stator iron core that can be installed and located conveniently has the good commutation performance within a limited size and a smaller size.

Owner:SUZHOU CLEAN BLOOM ELECTRIC CO LTD

Carbon brush used for locomotive traction motor

ActiveCN106033858AImprove wear resistanceGood orientationRotary current collectorBrushes manufactureDiesel locomotiveMixed materials

The invention discloses a carbon brush used for a locomotive traction motor. The carbon brush is made of a soft carbon black powder, spray carbon black, a pitch coke powder, a graphite powder, a pore-forming agent, a directional auxiliary agent, modified pitch and a lubricant. The carbon brush is characterized by under a heating condition, carrying out mixed extrusion processing on the soft carbon black powder, the spray carbon black, the pitch coke powder, the graphite powder, the pore-forming agent, the directional auxiliary agent, the modified pitch and the lubricant so as to acquire a mixed material; carrying out grinding processing on the mixed material so as to acquire a first mixed powder; mixing the first mixed powder and carrying out flaking processing so as to acquire a sheet-shaped material; carrying out smashing and grinding processing on the sheet-shaped material so as to acquire a second mixed powder; blending the second mixed powder and then pressing the power into a carbon-brush pressed shape, and then successively carrying out roasting and graphitization processing. Breaking strength of the carbon brush is high, commutation performance is good and an allowable passing current density is large. The carbon brush is suitable for a diesel locomotive traction motor and is also suitable for an electric locomotive traction motor.

Owner:湖北东南佳新材料有限公司

Brush material for manufacturing electric tool motor

InactiveCN107785746AModerate resistivityImprove wear resistanceRotary current collectorDynamoelectric machine connectorsFiberAngle grinder

The invention discloses a brush material for manufacturing an electric tool motor, relating to the field of materials. The brush comprises base powder and asphalt; in particular, the base powder comprises an aqueous solution of graphene; and the base powder further comprises graphite, silicon carbide and carbon fiber powder. The brush for the electric tool has moderate resistivity, low brush running spark grade, good commutation performance, good product stability, excellent abrasion resistance and electromagnetic interference resistance, and is especially suitable for medium and low power angle grinder motors.

Owner:SUZHOU DONSUN CARBONWARE CO LTD

A ground brush and a preparation method thereof

ActiveCN109004481AReasonable compositionFormulation ScienceRotary current collectorBrushes manufactureElectric machineGraphite

The invention discloses a ground brush and a preparation method thereof, belonging to the technical field of brushes. The grounding brush of the invention is prepared from graphite powder, copper powder, tin powder, zinc carbonate, antiwear agent and ishing oil. The invention also provides a preparation method of a grounding brush. The method comprises the following steps of: putting raw materialsinto a cold mixer for mixing, passing through a 40-mesh sieve, placing a lower part of the sieve in a mold, and pressing under 4t / cm3 to obtain a bulk density of 5.65 g / cm3; and then, pressing the lower part of the sieve in a mold to obtain a bulk density of 5.65 g / cm3. 5.75 g / cm3 of brush blank, placing the brush blank in a mesh belt furnace, and heating at 248 DEG C + / 15 DEG C, 300 DEG C + / 15 DEG C, 4000 DEG C + / 15 DEG C, 500 DEG C + / 15 DEG C, 600 DEG C + / 15 DEG C, 700 DEG C + / 15 DEG C, 780 DEG C + / 15 DEG C for 1h-1.5h. The grounding brush of the invention has low resistivity, good abrasionresistance, no lead, long service life, high abrasion resistance, and is suitable for electric machines.

Owner:美尔森哈碳电碳(哈尔滨)有限公司

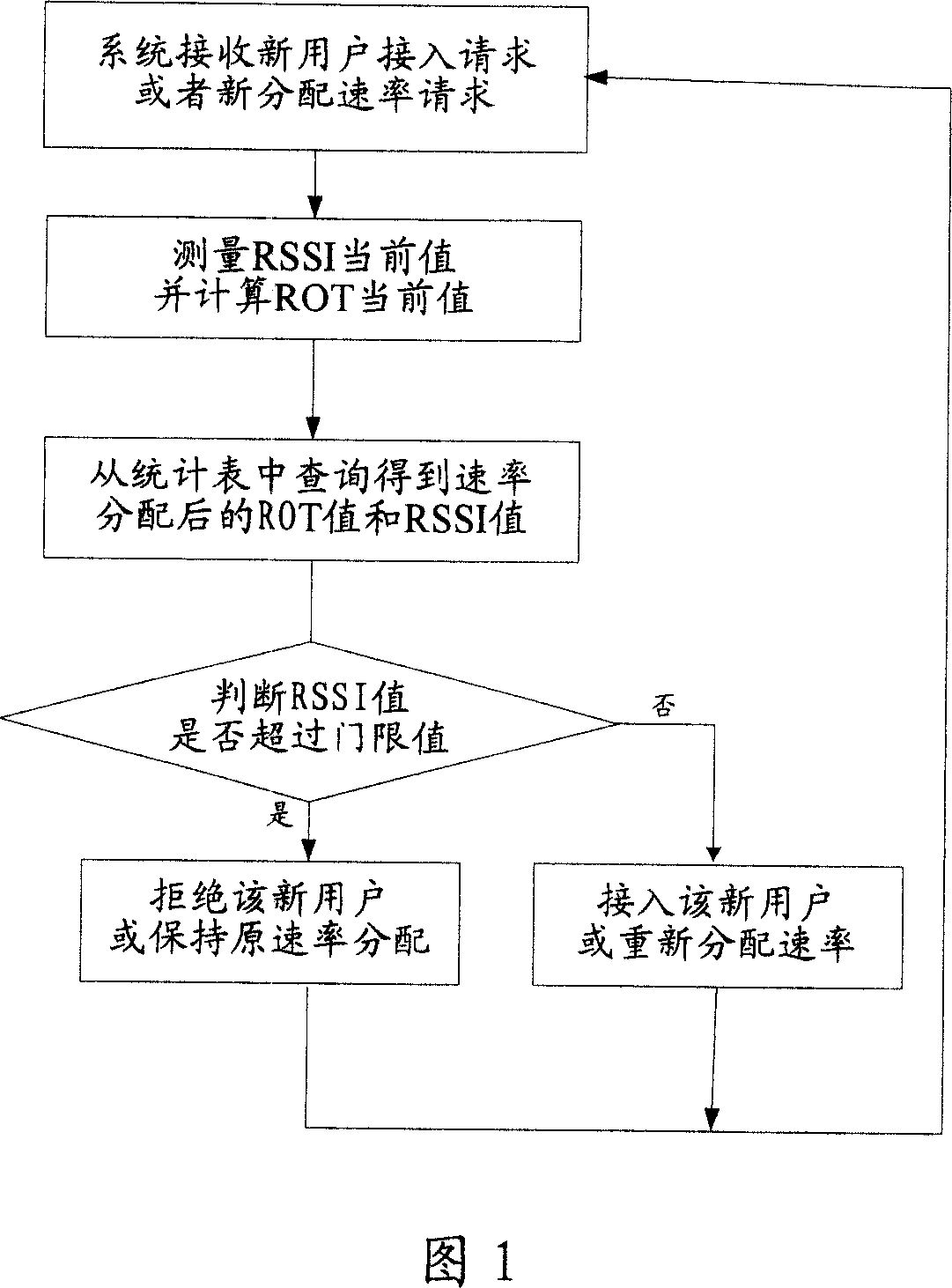

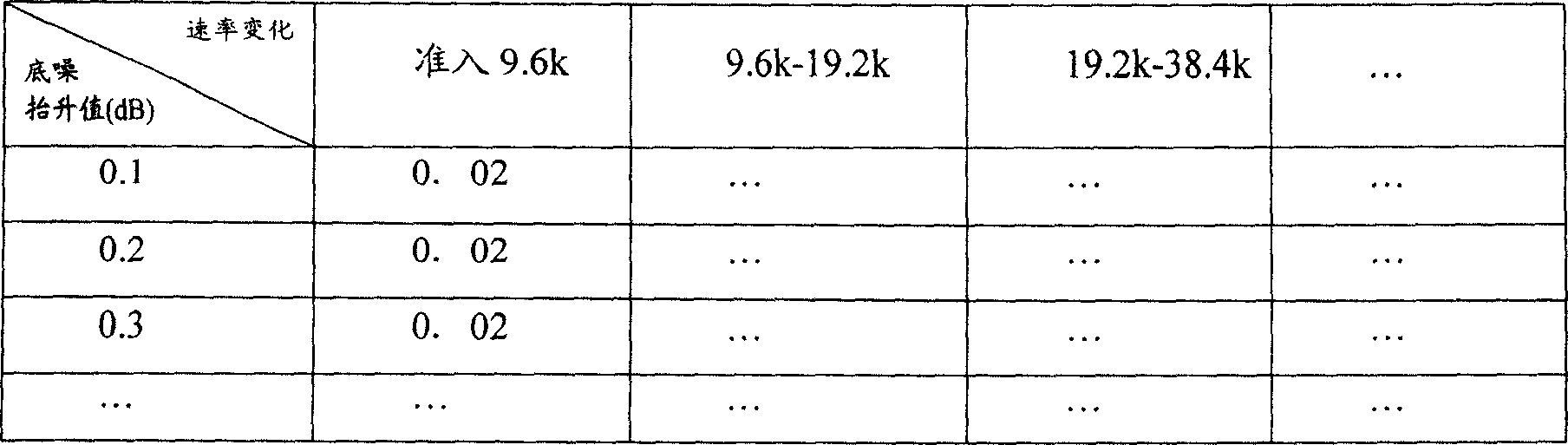

Reverse load control method

InactiveCN100365957CImprove reverse coverageIncrease capacityRadio/inductive link selection arrangementsRadio transmission for post communicationCode division multiple accessPrediction system

This invention relates to a method for controlling reverse load of a CDMA system including the following steps: when a system distributes new rate, it measures the current value of a reverse signal strength and computes the current value of the basic noise to make sure to carry out the distributed risen value of the basic noise and reverse signal strength value base on the current value of the basic noise to judge the reverse signal strength value and execute the new rate distribution when it does not exceed the preset threshold, otherwise, the original rate is kept and the method also includes that a test system carries out the variable value of the current value of the basic noise after distributing the new rate and records the new value in the statistic list.

Owner:HUAWEI TECH CO LTD

Electric brush

ActiveCN111244713AImprove the lubrication effectIncrease coefficient of frictionRotary current collectorBrushes manufactureCompression moldingDC - Direct current

The invention discloses an electric brush. The electric brush comprises a metal electric brush limiting box and an electric brush material fixed in the metal electric brush limiting box, wherein the electric brush material is prepared by mixing carbon matrix powder with metal powder, an antifriction material and the like, performing compression molding by using a mechanical press or a hydraulic press, and performing machining treatment after sintering. The electric brush prepared by the method is especially suitable for a low-voltage direct-current high-efficiency dust collector and can also be used for alternating-current direct-current motors for kitchen appliances, such as wall breaking machines, juicers or other fields. The electric brush prepared through the method is high in motor efficiency, good in electric brush commutation performance, low in noise, long in service life, low in spark grade and good in product stability in the operation process of the motor, and is an energy-saving electric brush for a direct-current motor.

Owner:SUZHOU DONSUN CARBONWARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com