Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

290results about How to "Large braking torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

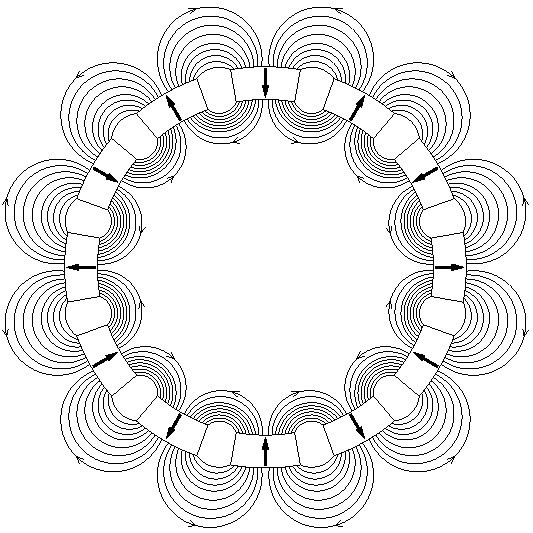

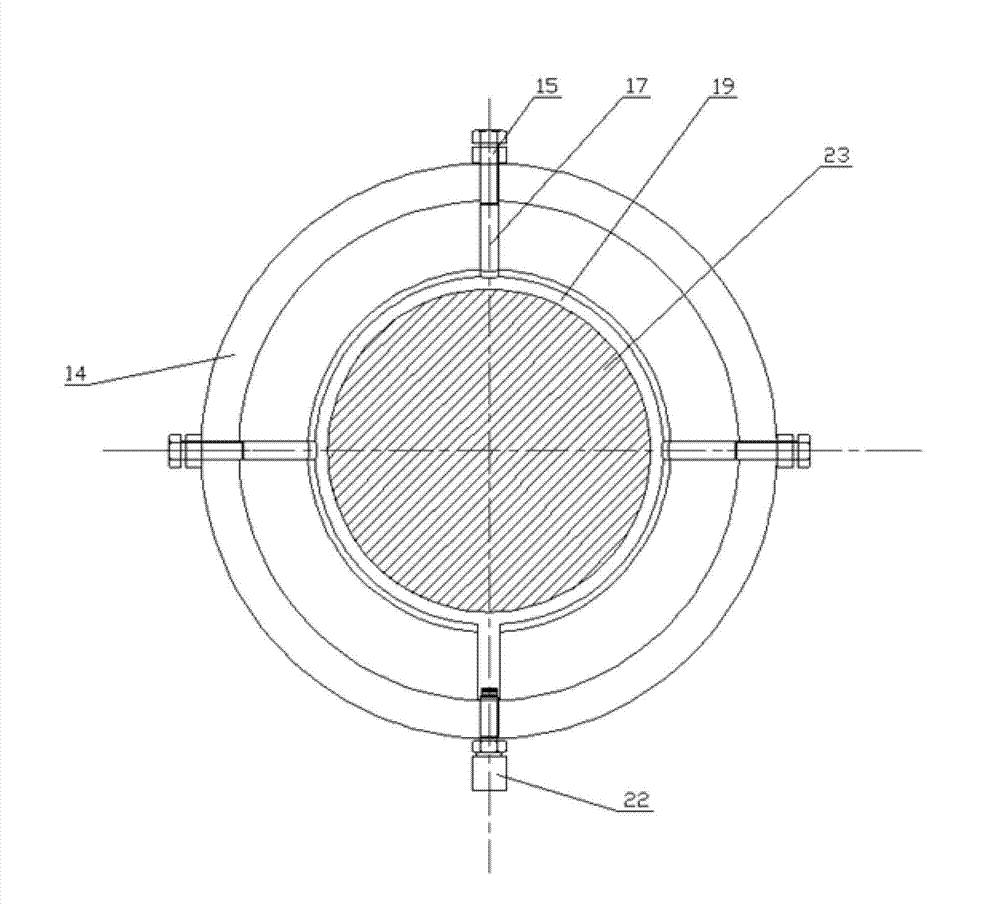

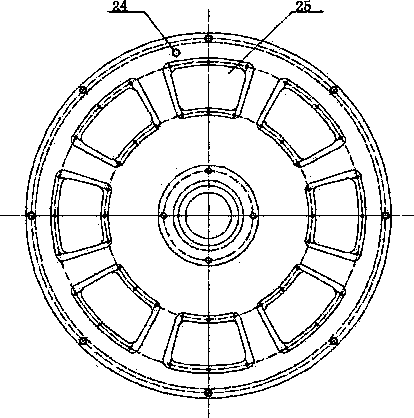

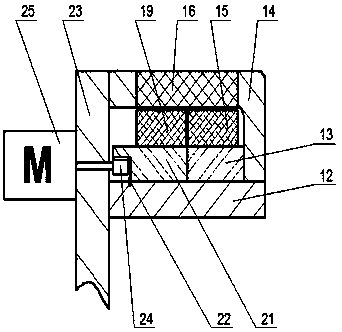

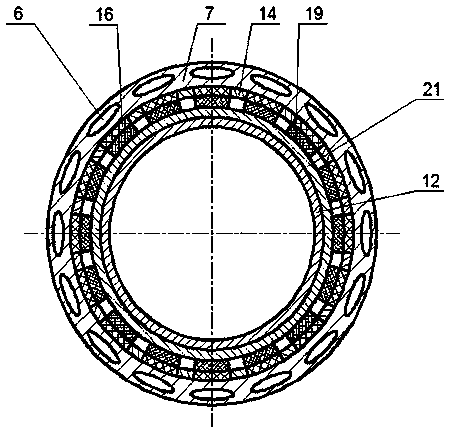

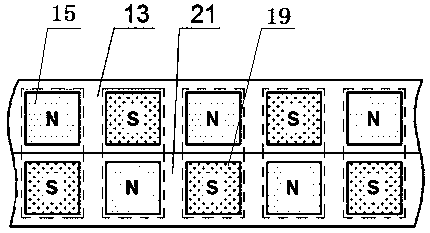

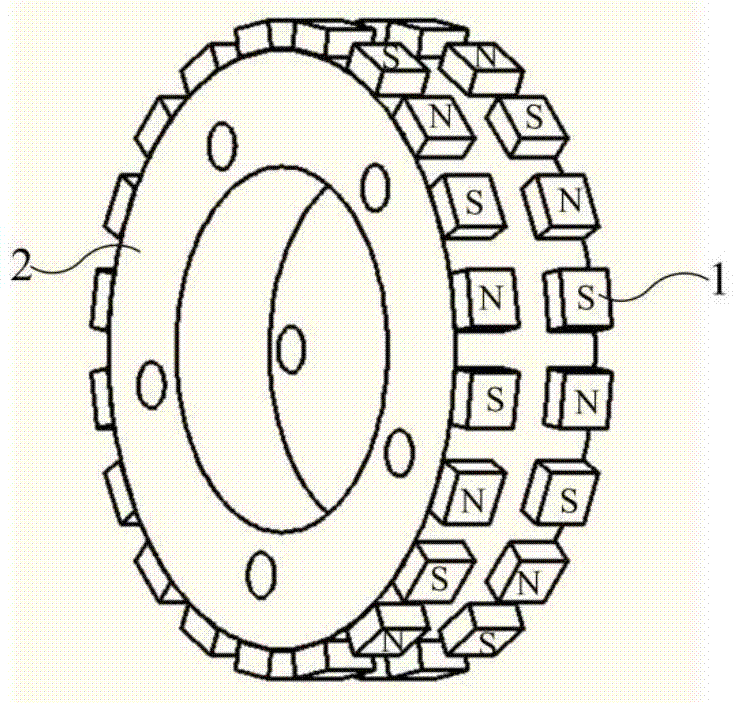

Permanent-magnet eddy current retarder based on Halbach array

InactiveCN102497085AImprove utilization efficiencyIncrease the magnetic field strength of the working air gapPermanent-magnet clutches/brakesOptical axisCoupling

Rotors are installed on a transmission shaft; the transmission shaft is installed in a central hole of a fixing plate; two ends of a bidirectional screw shaft are installed inside holes above the central hole of the fixing plate; two ends of each of three linear optical shafts are fixed into holes in front of, behind and below the central hole of the fixing plate; each of the two rotors consists of a Halbach-array permanent-magnet ring and a retaining rack; an outer cylindrical surface of the permanent-magnet ring is fixed inside a center hole of the retaining rack; a radial clearance is formed between an inner cylindrical surface of the permanent-magnet ring and an outer cylindrical surface of each rotor; four installing holes are uniformly distributed on the retaining rack; an upper installing hole is matched with the bidirectional screw shaft through a screw nut; the other three installing holes are matched with the linear optical shafts through linear bearings; and a servo motor is connected whit the bidirectional screw shaft through a shaft coupler. In the radial-array permanent-magnet eddy current retarder, the utilization ratio of a magnet is high, the brake moment is large, the response is quick, the heat dissipating conditions are good and the stepless regulation of the brake moment is realized.

Owner:ZHEJIANG UNIV

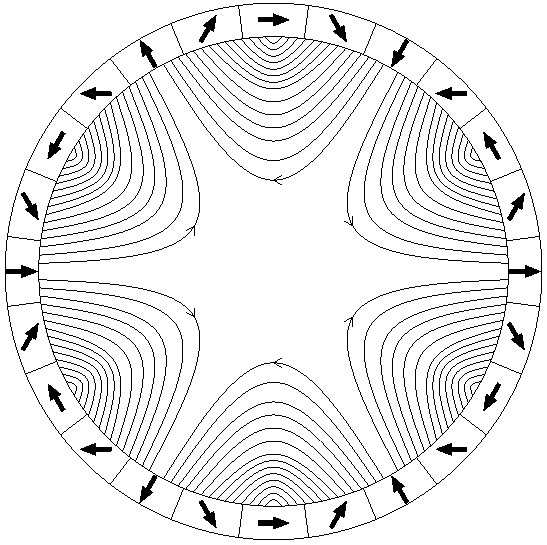

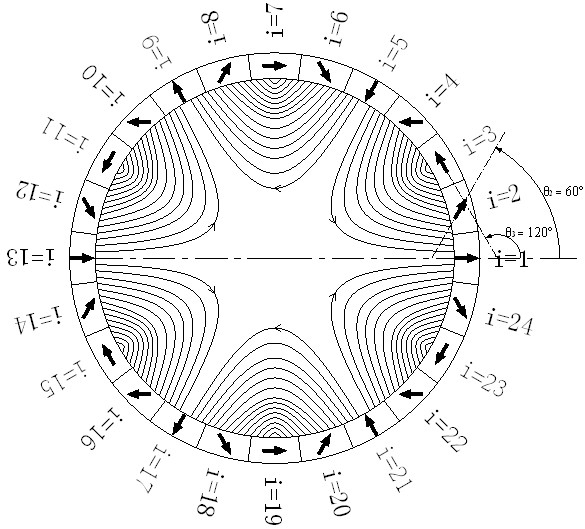

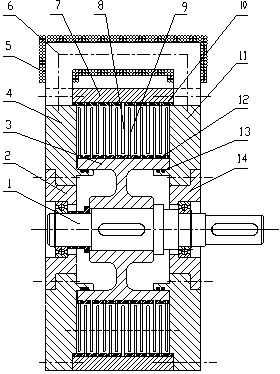

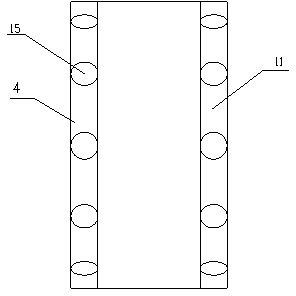

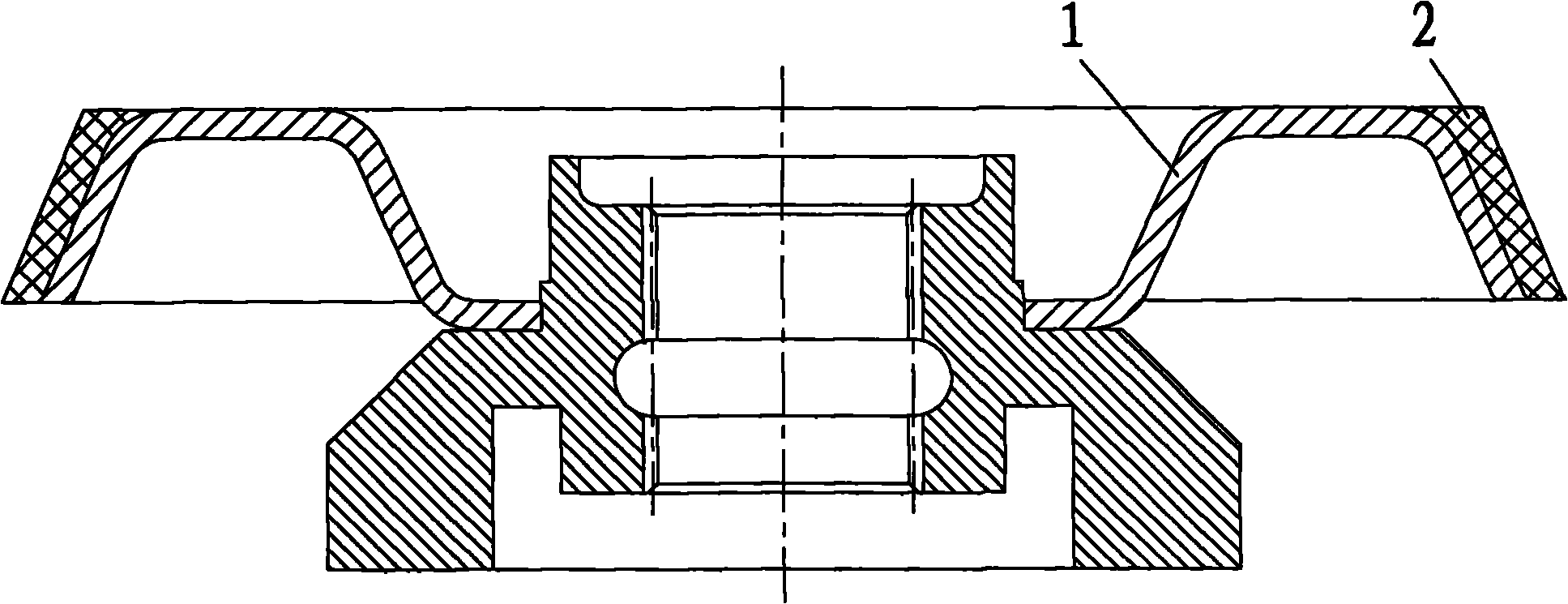

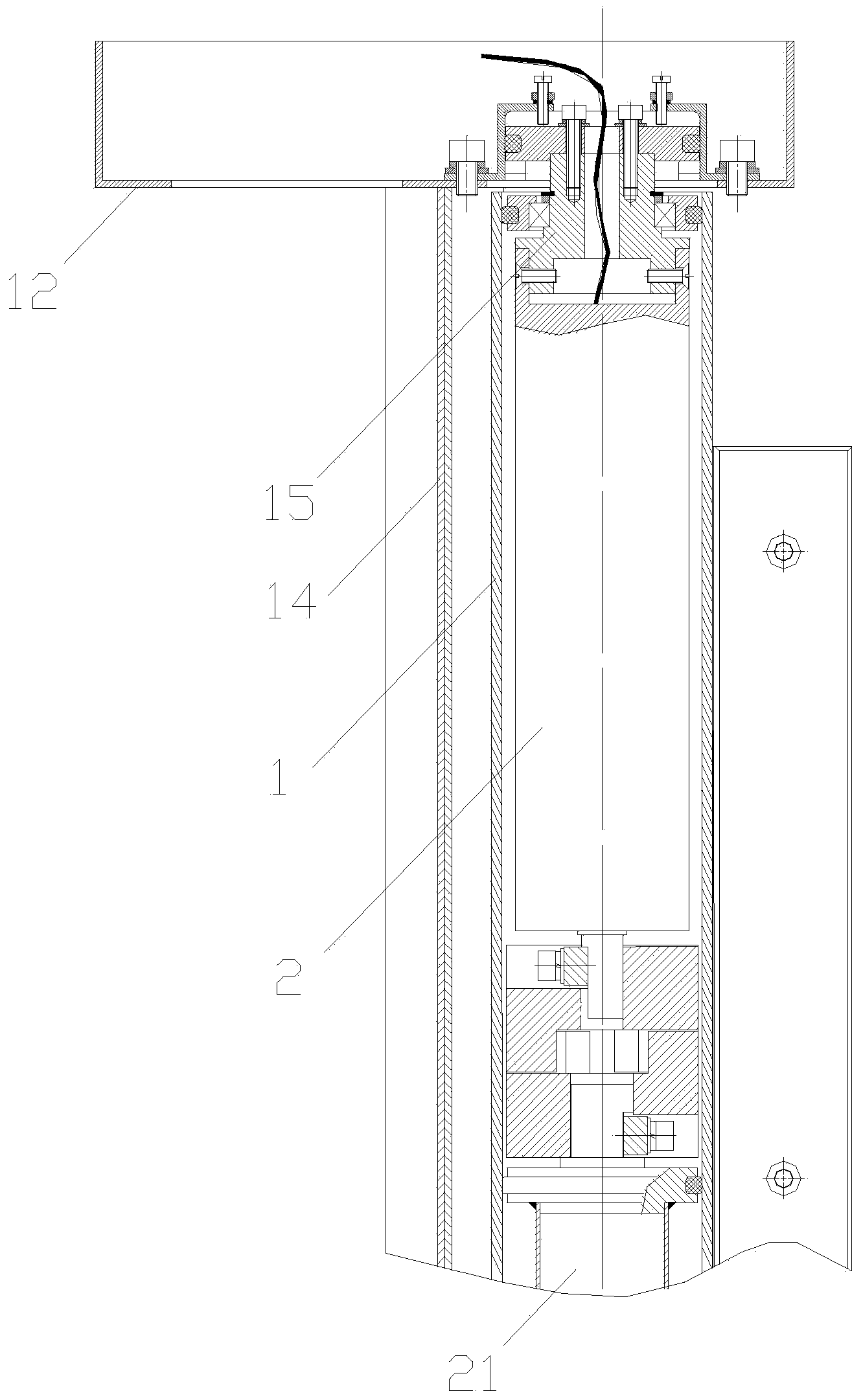

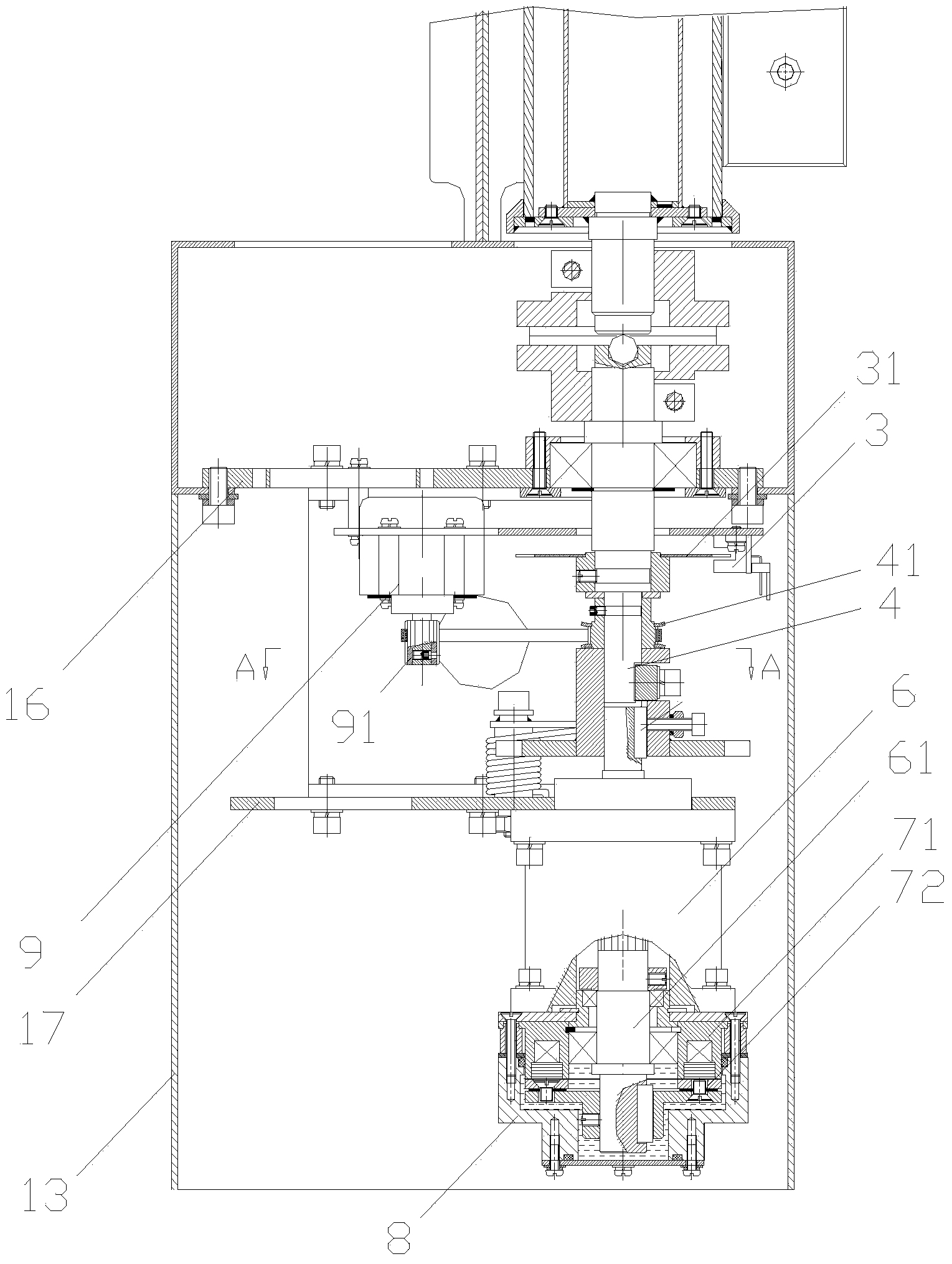

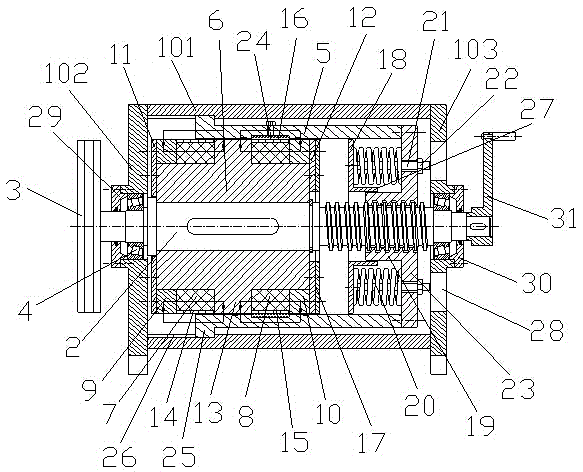

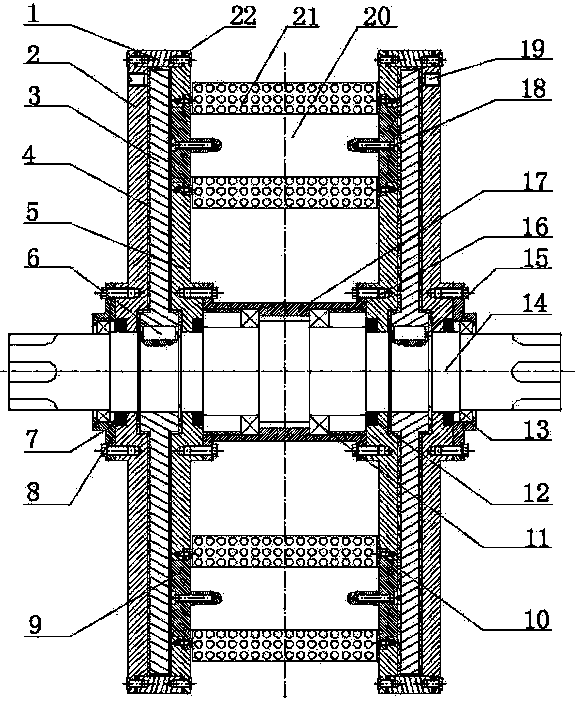

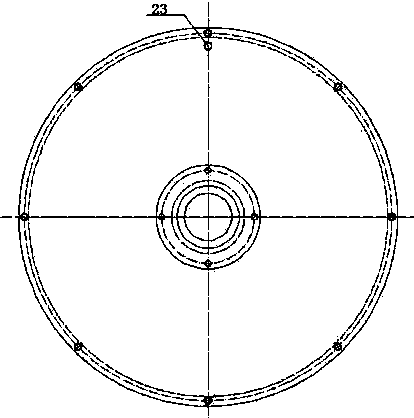

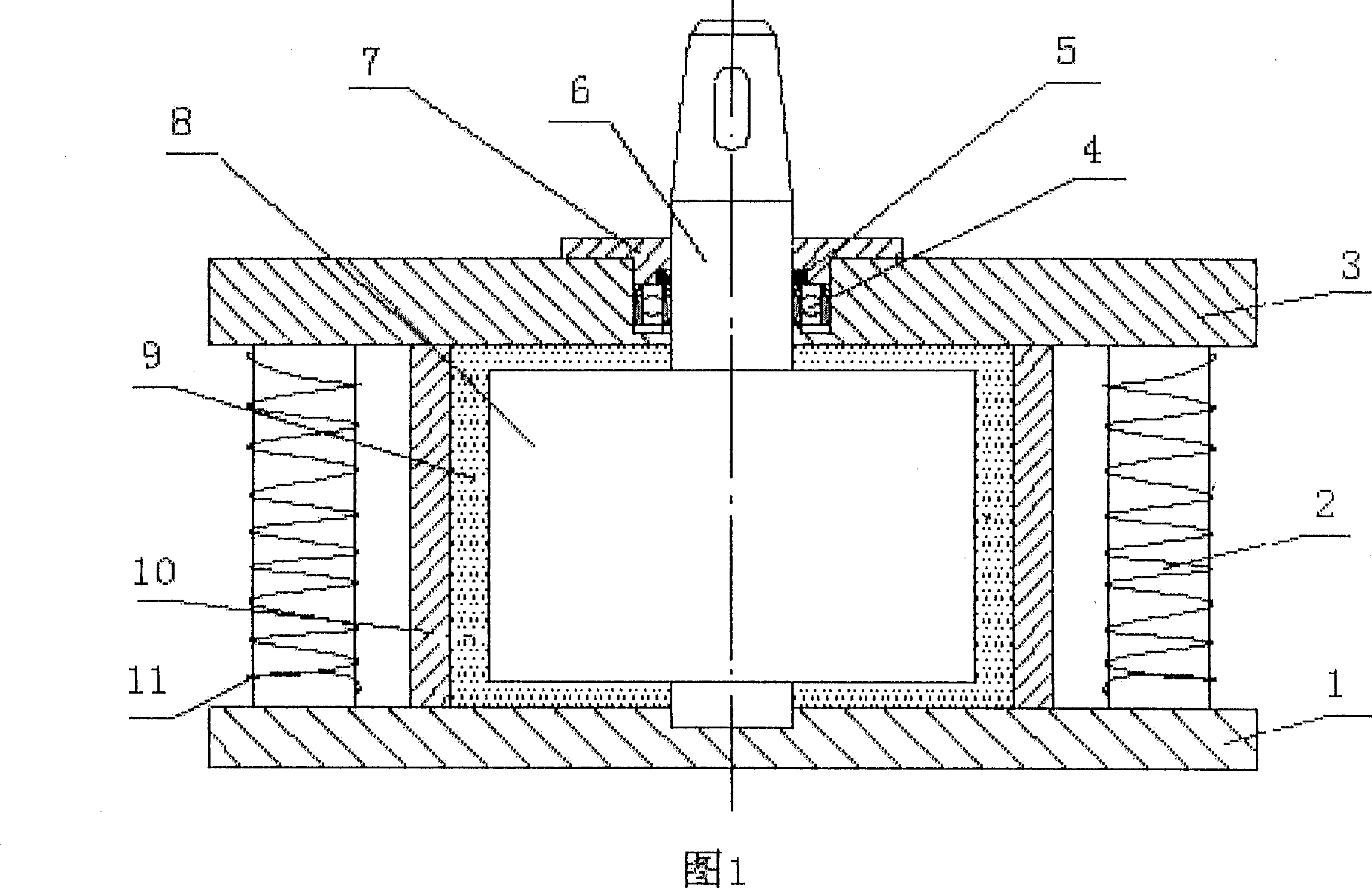

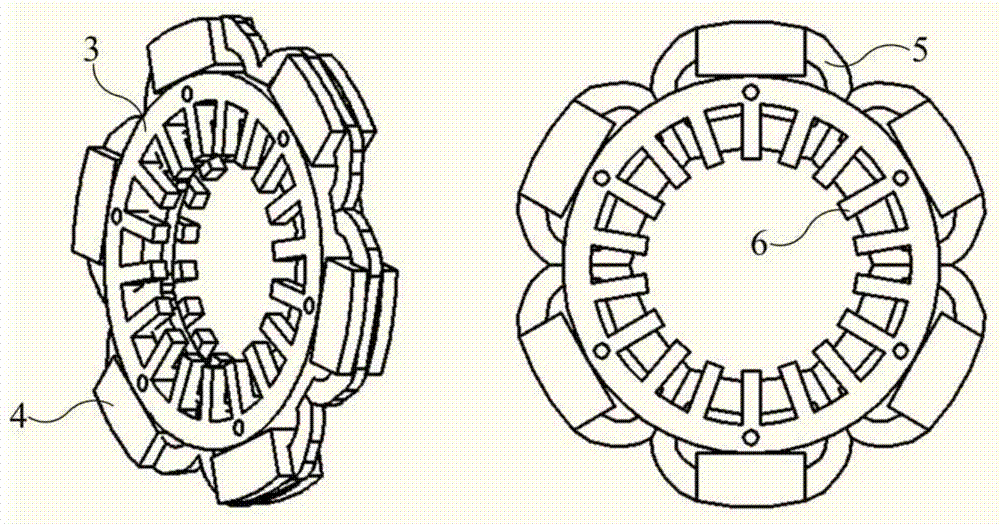

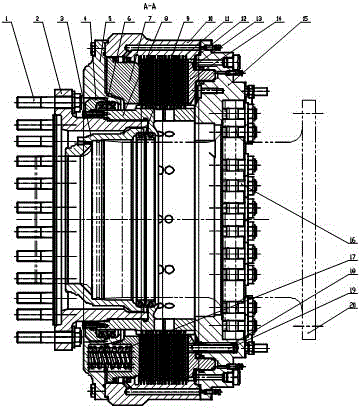

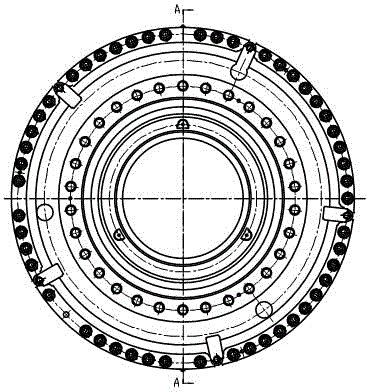

Multiple-disc type magnetorheological brake

InactiveCN102146968AGood heat dissipationImprove cooling effectLiquid resistance brakesMagnetic currentBrake torque

The invention relates to a multiple-disc type magnetorheological brake which mainly comprises a transmission shaft, a wheel hub, a drive friction plate group, a driven friction plate group, inner and outer magnetic isolation rings, an exciting coil with a U-shaped iron core, magnetic-conducting side plates and a magnetic isolation casing. A sealing ring is used for sealing magnetorheological fluid between the drive friction plate group and the driven friction plate group; the drive friction plate group and the driven friction plate group are respectively sleeved on the magnetic isolation rings and the wheel hub through splines; the drive friction plate group is separated from the driven friction plate group by the inner magnetic isolation ring and the outer magnetic isolation ring; the exciting coil with the U-shaped iron core is directly spliced in iron core jacks of the magnetic conducting side plates; and the braking torque can be changed through changing the current intensity of the coil. When the braking torque is not enough, the quantity of friction plates can be increased or the quantity of the exciting coil with the U-shaped iron core can be increased to adapt to the big torque braking. The multiple-disc type magnetorheological brake has the advantages that the structure is compact, the braking torque is big, the assembly and the disassembly are convenient, the coil is easily used for radiating the heat, and the number of turns wounded by the coil is more.

Owner:CHINA UNIV OF MINING & TECH

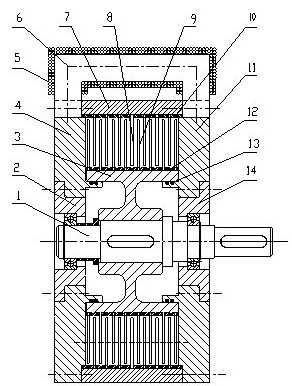

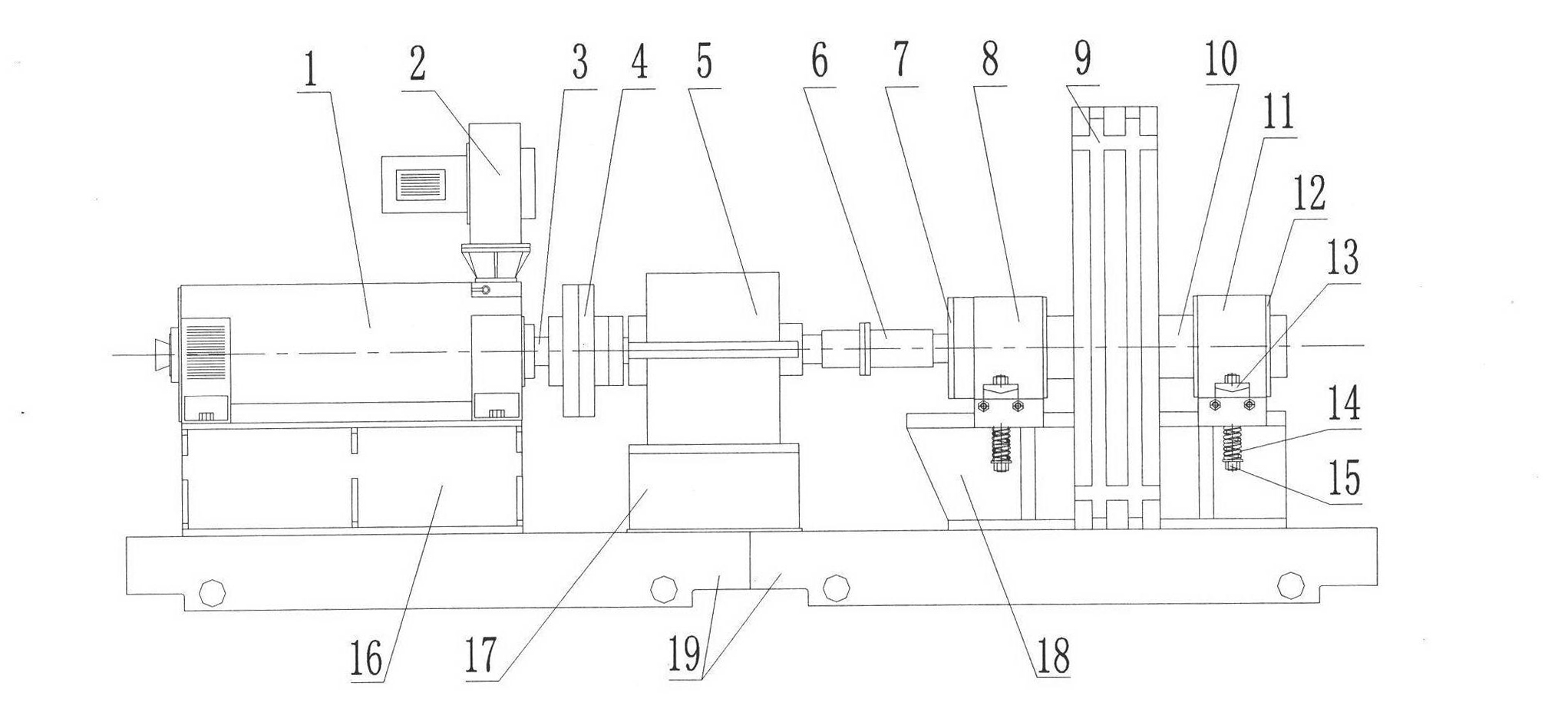

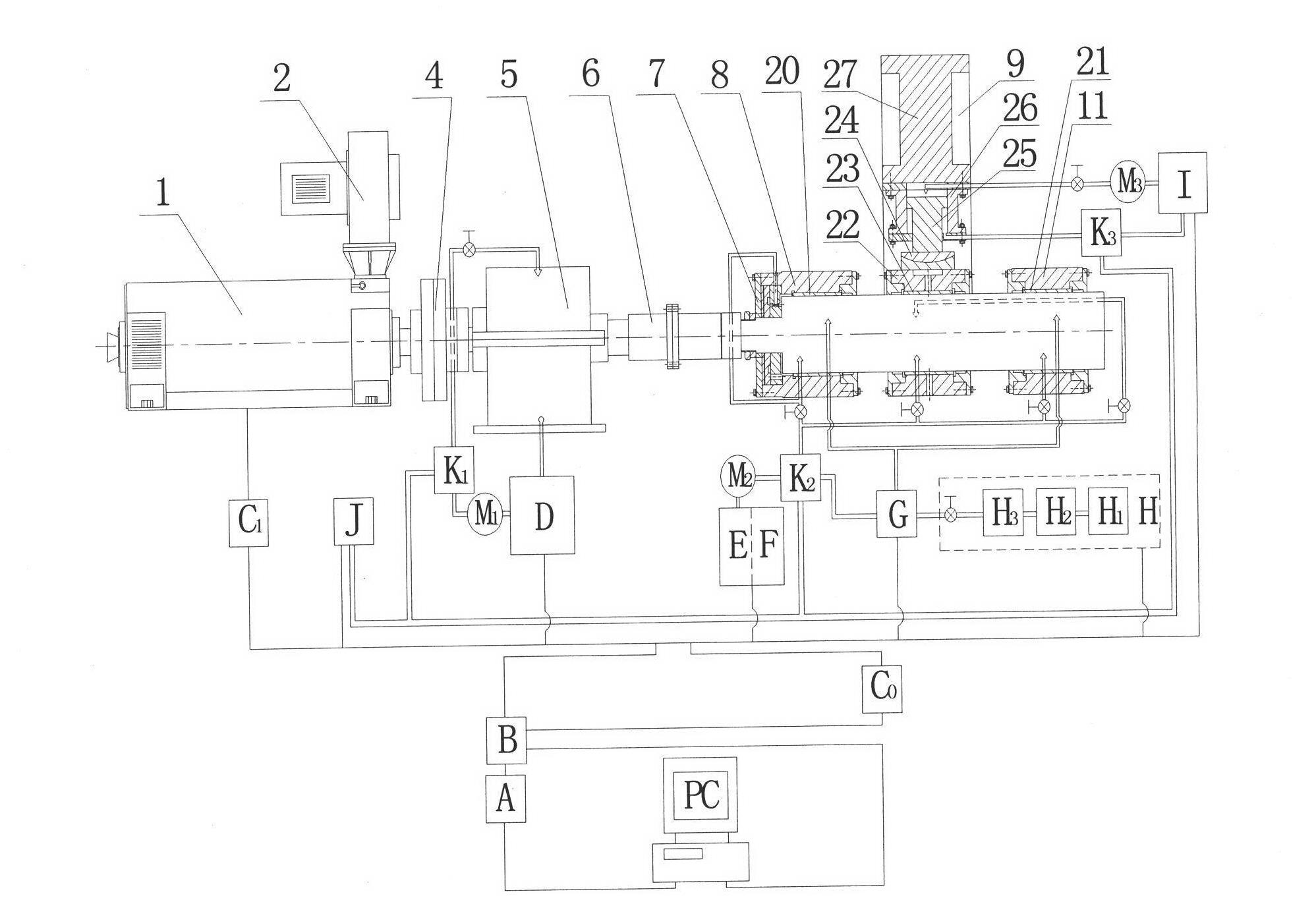

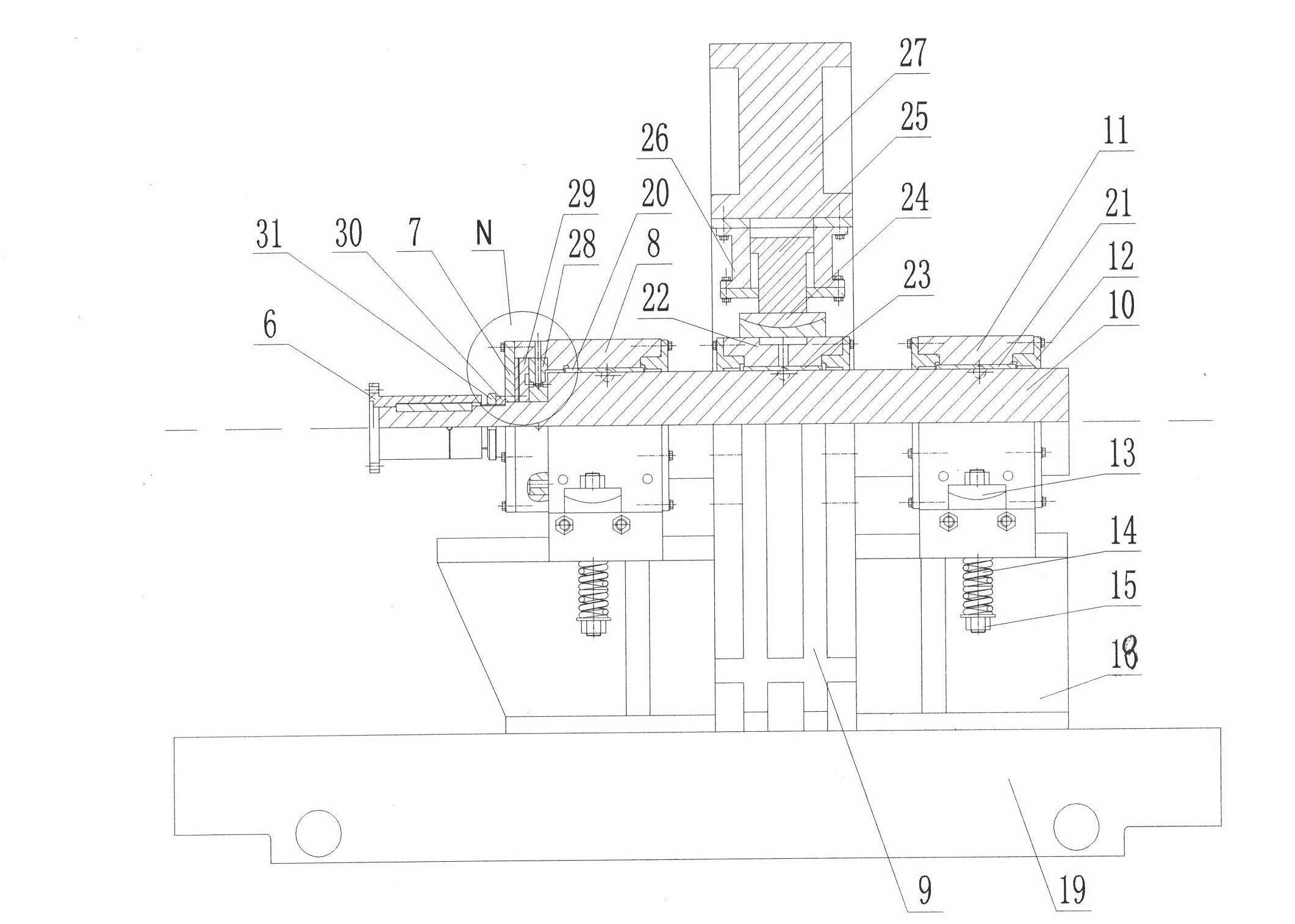

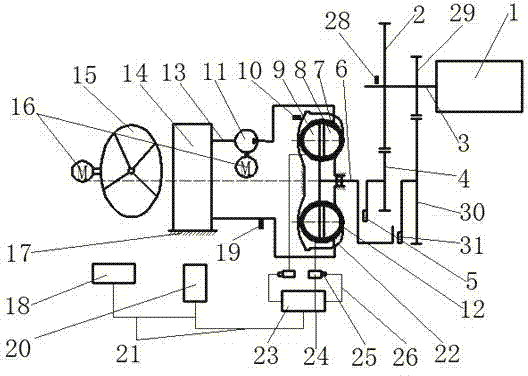

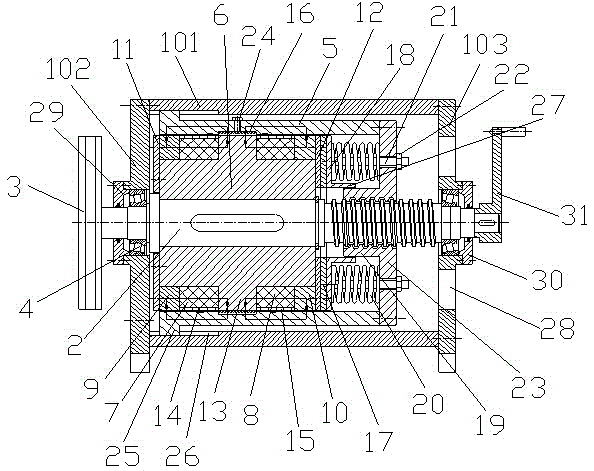

Rolling mill oil film bearing comprehensive test bench

The invention discloses a comprehensive test-bed for an oil film bearing of a rolling mill, belonging to the technical field of testing equipment of oil film bearings of rolling mills. The comprehensive test-bed is characterized by comprising a mechanical system, a motor driving system, a hydraulic loading system, a lubricating system, an air pressure control system, an electric control system and a computer data acquisition system which are combined to form an integral and uniform operation; flow sensors, temperature sensors, pressure sensors and displacement sensors mounted on the bearing and all pipelines are connected to the computer data acquisition system through a PLC (Programmable Logic Controller); and the electric control system is connected with and controls the motor driving system, the hydraulic loading system, the lubricating system and the air pressure control system. The invention realizes integration of an electromechanical hydropneumatic integral system by setting rotation speed of a motor shaft and the dynamically controlling rolling conditions of the hydraulic load and testing performance of the oil film bearing of the rolling mill by the data acquisition system. The system has the advantages of compact structure and convenience for operation, and is suitable for the fields of various teaching and scientific research.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

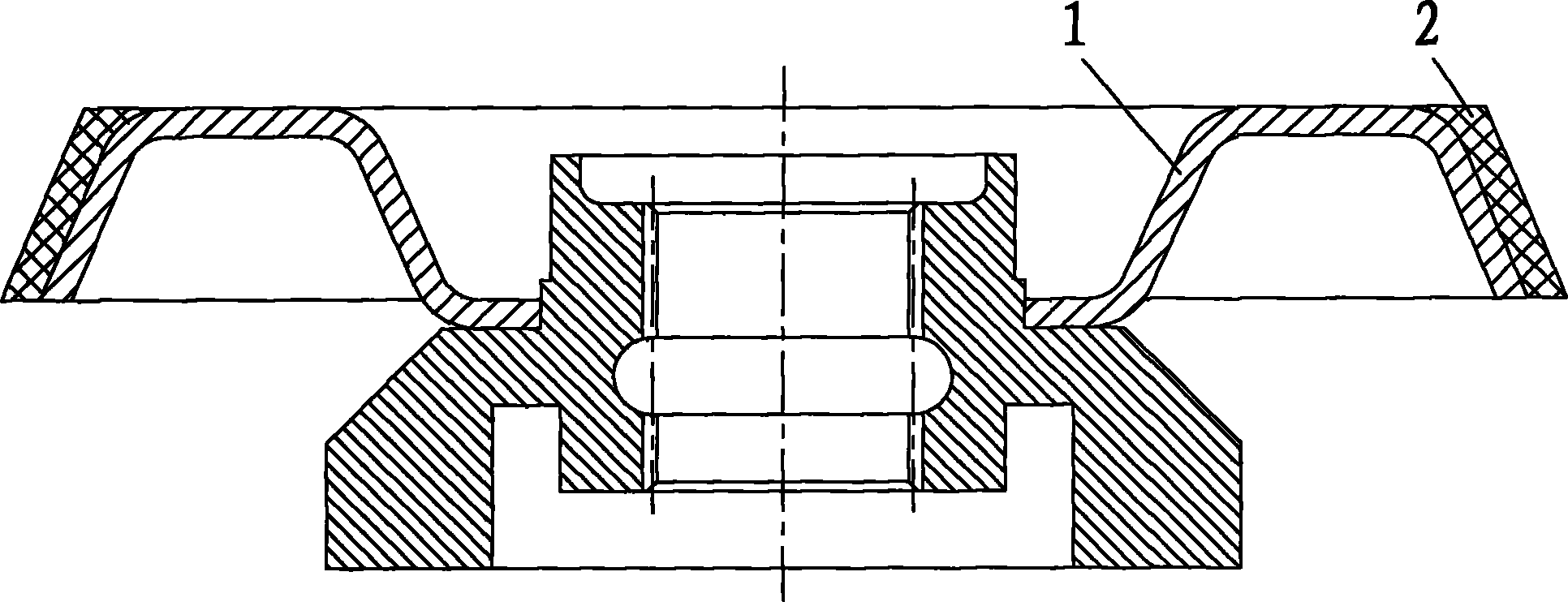

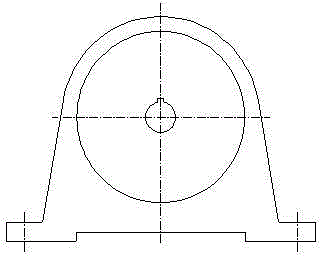

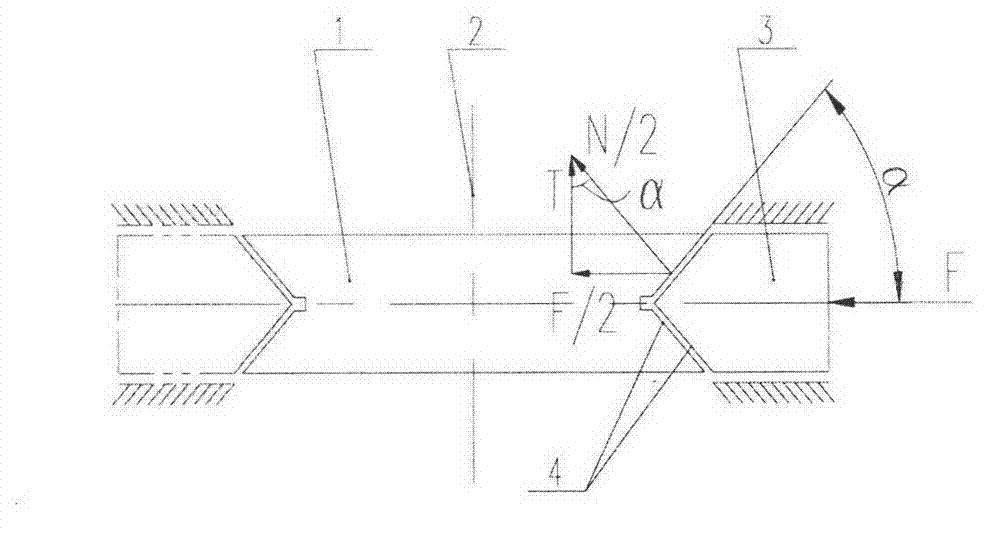

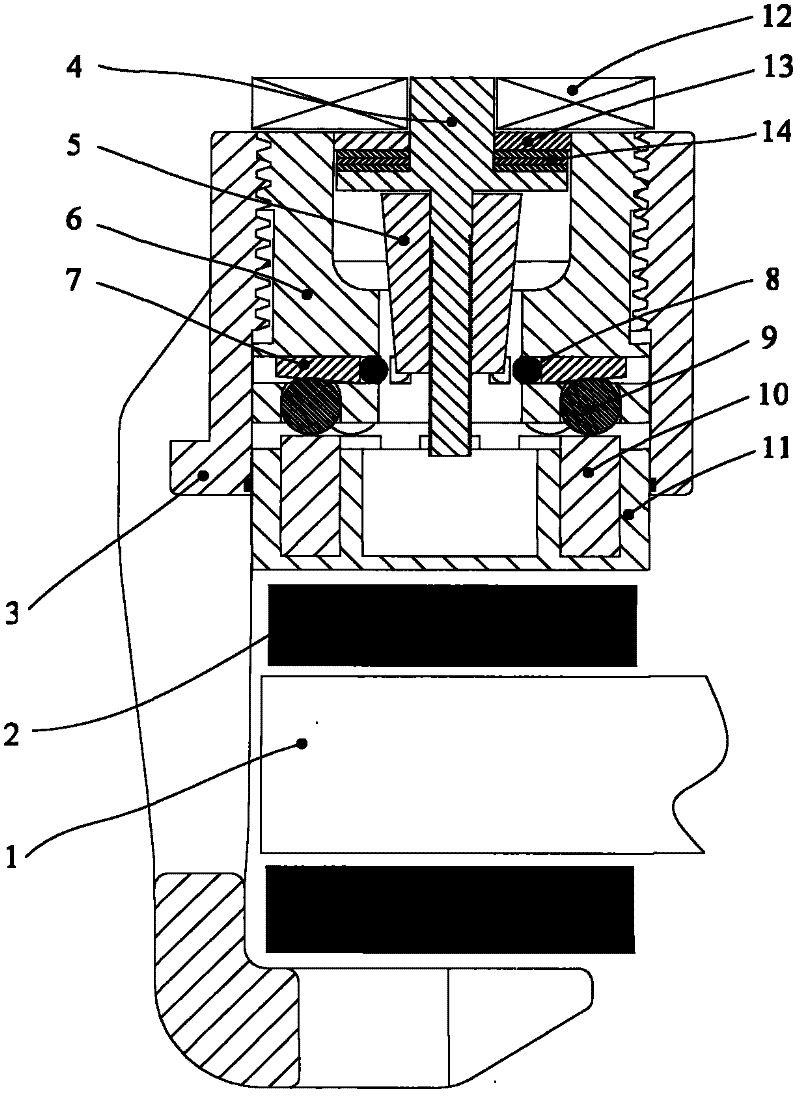

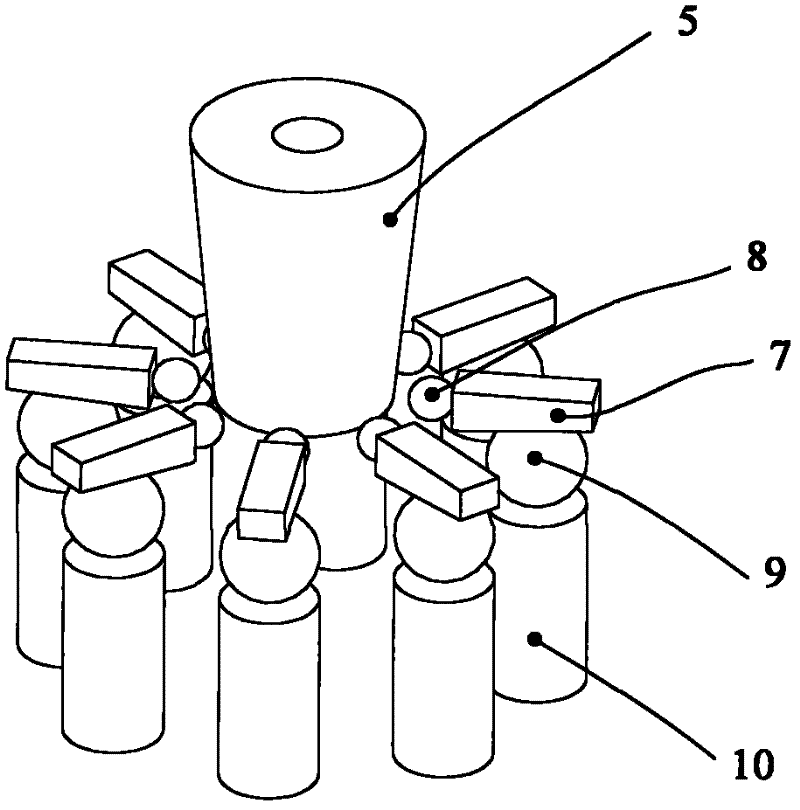

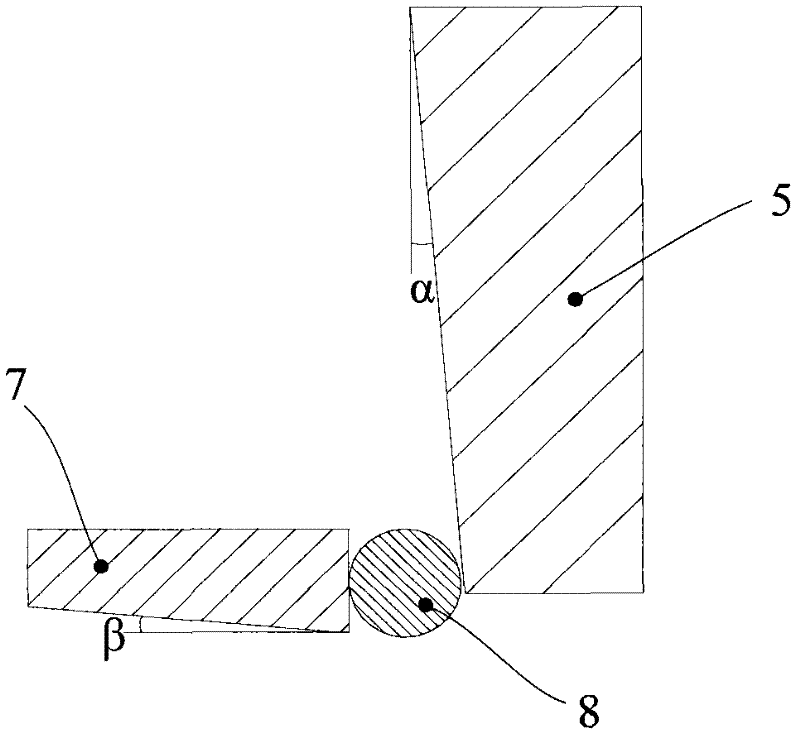

Floating tong type bipushing rod pneumatic disk brake based on rectangular torsional spring single dicrection clutch

ActiveCN1948778ALarge braking torqueConstant braking force ratioAxially engaging brakesBrake actuating mechanismsCalipersDisc brake

The invention comprises a pressure arm unit, a rotation shaft unit, a return spring, a push pedal, an internal friction plate, a brake, an external friction plate, a support and a caliper body arranged in order from right to left. Because of using the rectangular section torsional spring function, in a specific environment the invention can realize a one-way transmission of the torque and also can realize an overload protection effectively. The reasonable design of the pressure arm unit can supply the stable brake moment.

Owner:WUHAN YOUFIN AUTOPARTS

Radial extrusion type magnetorheological fluid brake

InactiveCN103089863AIncrease shear stressImprove reliabilityLiquid resistance brakesDrive shaftMagnetorheological fluid

The invention discloses a radial extrusion type magnetorheological fluid brake, and belongs to the field of hydraulic resistance brakes. On the basis of an existing device, a right guiding magnetic brake outer shell, a pressurization device, a coil fixing ring, pressurization channels, a right magnet exciting coil and a separation magnet ring are added to the brake, wherein the right guiding magnetic brake outer shell is arranged on the right of a left guiding magnetic brake outer shell, a gap is reserved between the right guiding magnetic brake outer shell and the left guiding magnetic brake outer shell, and the pressurization device is arranged on the outer circumference of the right guiding magnetic brake outer shell; a magnetorheological fluid gap is formed between a driving shaft and the right guiding magnetic brake outer shell, the other magnetorheological fluid gap is formed between the driving shaft and the left guiding magnetic brake outer shell, and a left magnet exciting coil, the right magnet exciting coil and the separation magnet ring are arranged in the gap formed between the right guiding magnetic brake outer shell and the left guiding magnetic brake outer shell; and the left magnet exciting coil and the right magnet exciting coil are fixed through the coil fixing ring, the pressurization channels are respectively arranged on the right guiding magnetic brake outer shell, the coil fixing ring and the separation magnet ring. The radial extrusion type magnetorheological fluid brake is simple in assembling and compact in structure, provides large braking torque, meanwhile enhances device reliability, and reduces energy consumption.

Owner:CHINA UNIV OF MINING & TECH

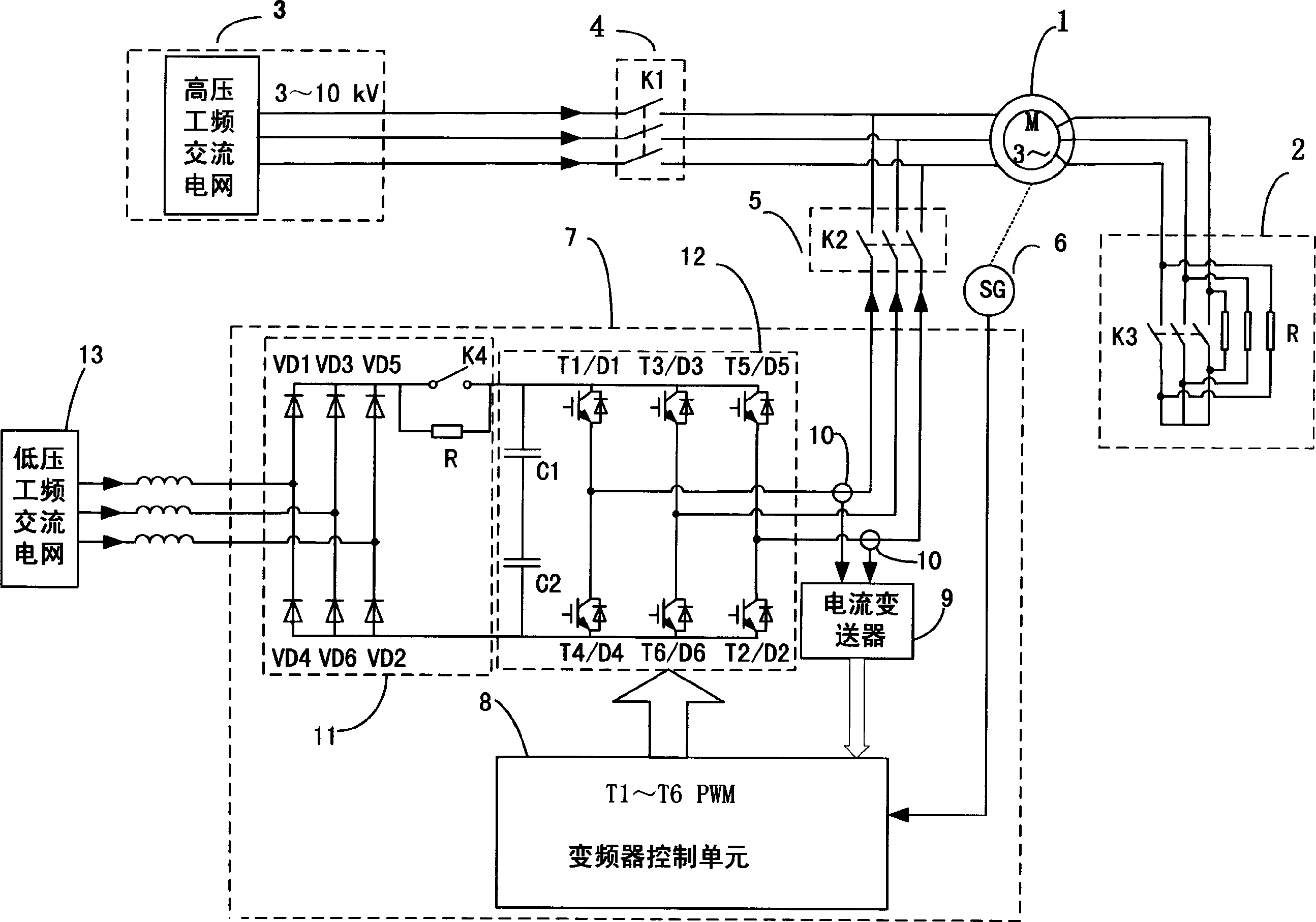

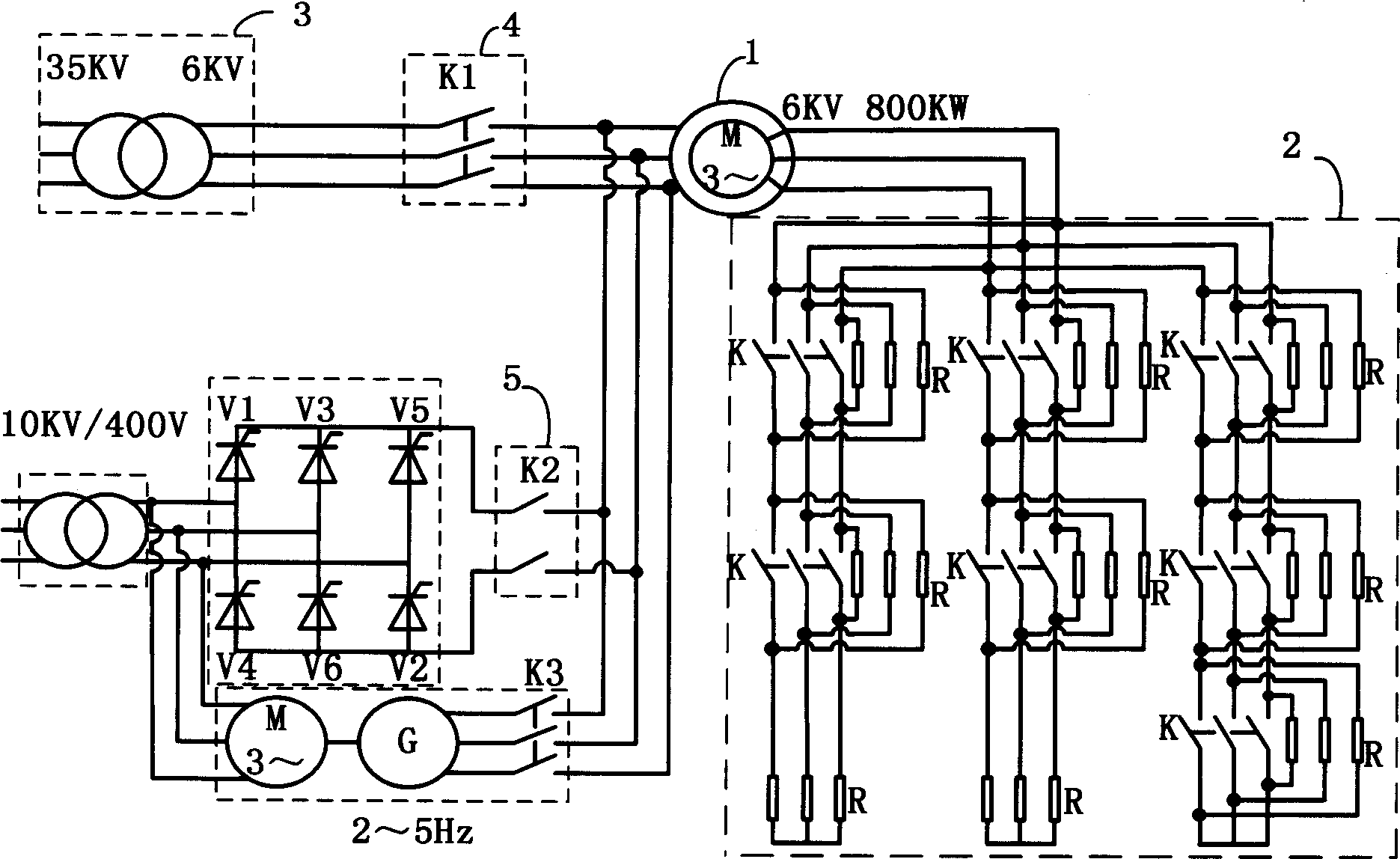

Low-voltage low-frequency transformer of high-voltage wound asynchronous motor for drining mine hoister

InactiveCN1641994ASolve the problem of frequency conversion speed regulationIncrease total daily outputElectronic commutation motor controlAC motor controlLow voltageTransformer

The invention relates to a low voltage low frequency transducer that is used to drive mine winder high voltage winding asynchronous motor. It comprises rectification circuit, inverter circuit, and frequency transducer control unit. The control system of the invention is in the transducer and the output voltage is especial PWM low DC voltage and low voltage low frequency PWM AC. It adopts discontinuity switching operation mode and only connects to the high voltage winding asynchronous motor to drive the motor directly by high voltage switch when the motor is in retarding braking stage and retarding crawling stage. The invention has the advantage of great DC dynamic brake moment and low frequency crawling dynamic moment, as well as low cost.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Friction brake disk of double-speed electric-block and preparation method thereof

ActiveCN101870438AIncrease coefficient of frictionIncreased shear strengthOther chemical processesFriction liningMetal fiberLow noise

The invention relates to a friction brake disk of a carbon-base double-speed electric-block and a preparation method thereof, aiming to provide the brake disk which has large brake moment, high shear strength, high temperature resistance, wear resistance, environmental protection and low noise. The preparation method has the advantages of simple technology, convenient manufacture and low cost. The invention has the technical scheme that the friction brake disk of the double-speed electric-block comprises an iron-base frame and a friction material layer which is attached to the brake surface of the iron-base frame, wherein the friction material layer comprises modified phenol-formaldehyde resin, aramid fiber, short carbon fiber, SACF mineral fiber, precipitated baryte, modified bauxite, metal sulfides, hydrogenated nitrile-butadiene rubber, metal fiber, nano calcium carbonate, stearic acid, vulcanization accelerator, medium-carbon frictional property modifier and melamine-cashew nut shell oil. The preparation method comprises the following steps: (1) weighing raw materials; (2) synthetically kneading the raw materials; (3) compression molding; (4) thermocuring; and (5) machining.

Owner:杭州汉乐科新材料科技有限公司

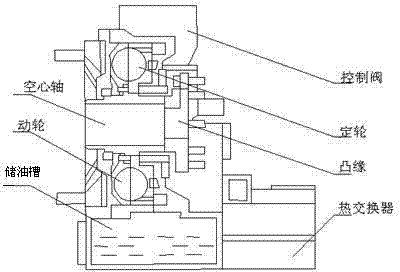

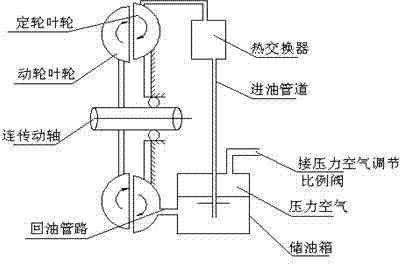

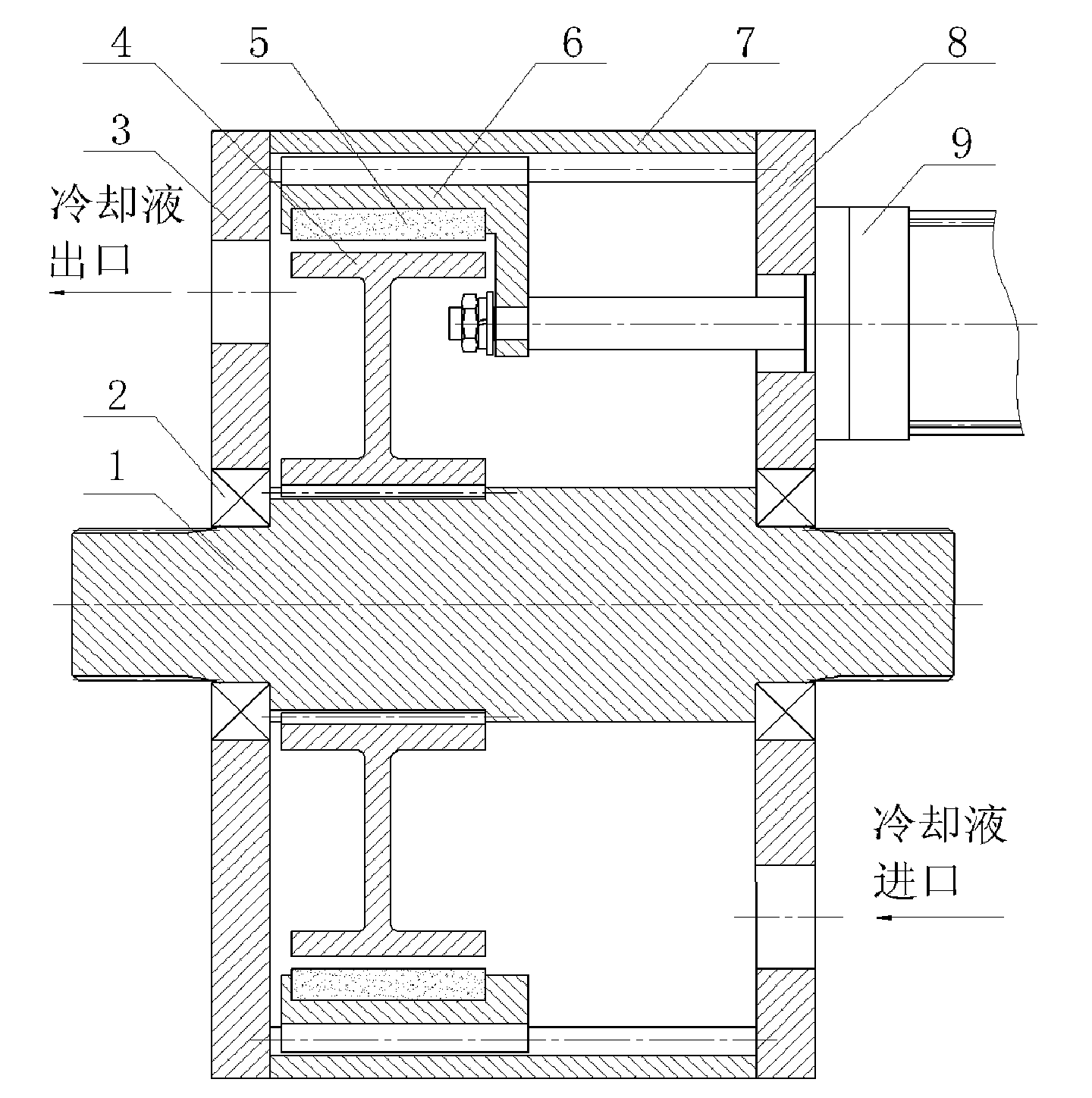

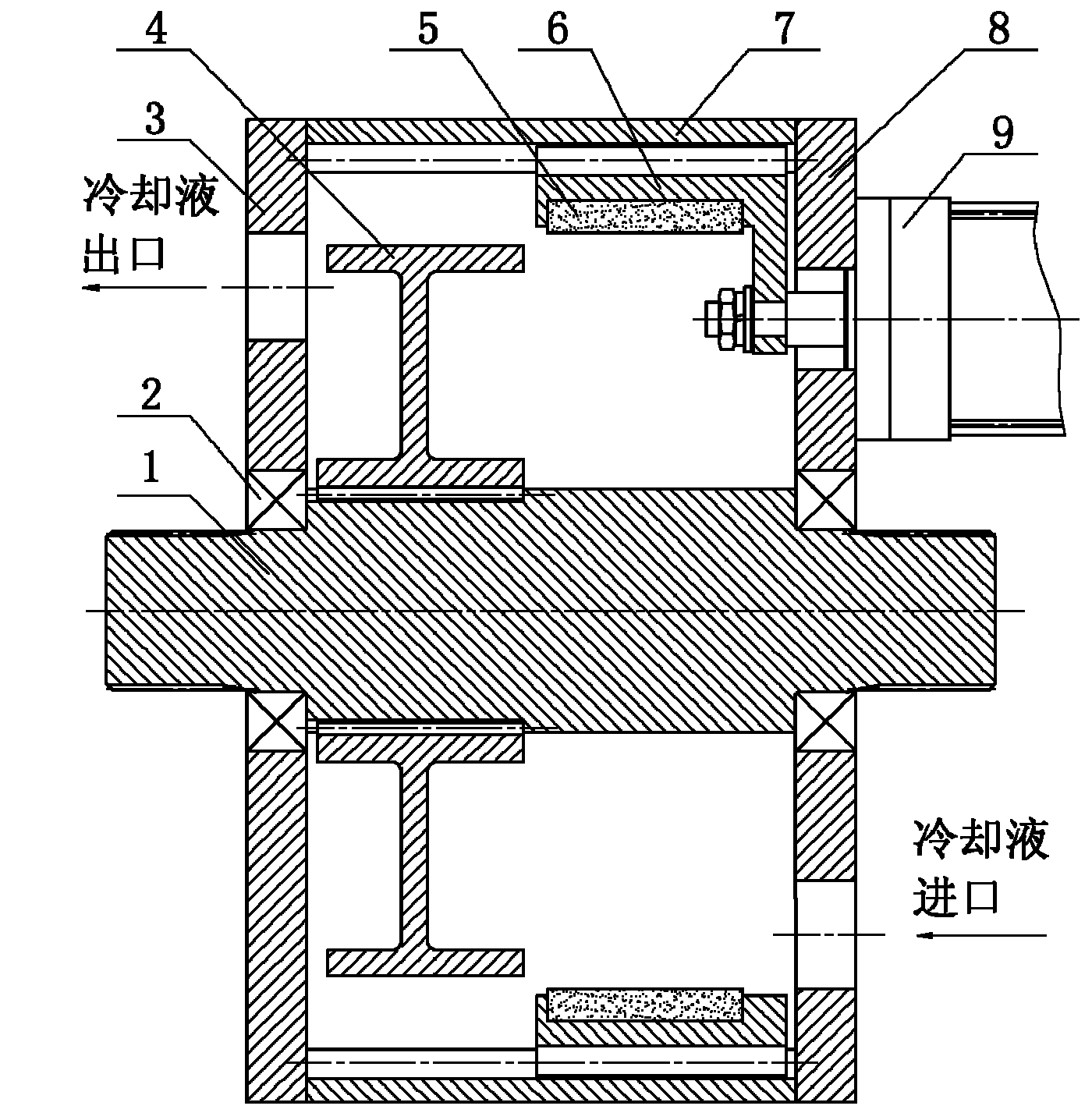

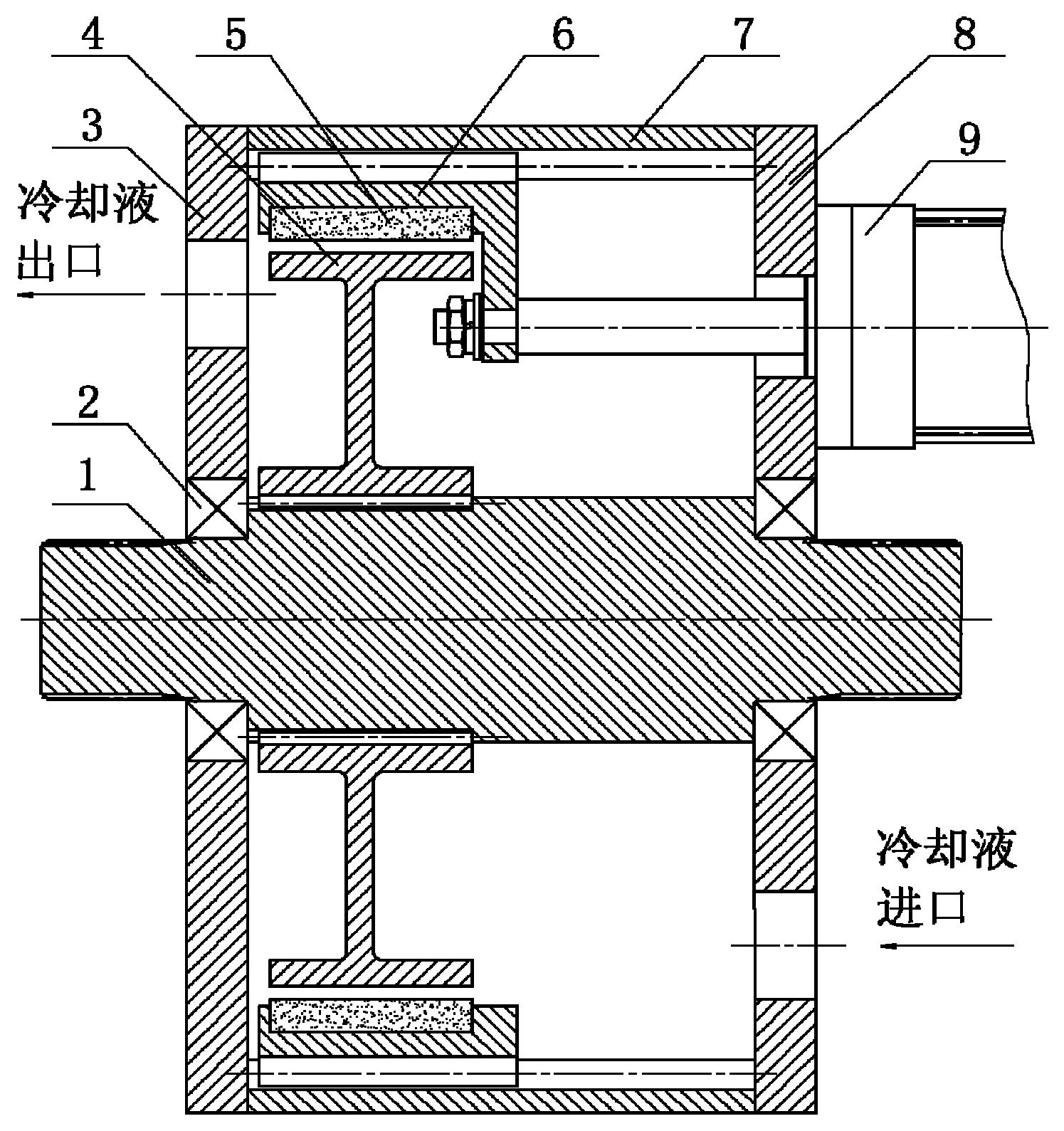

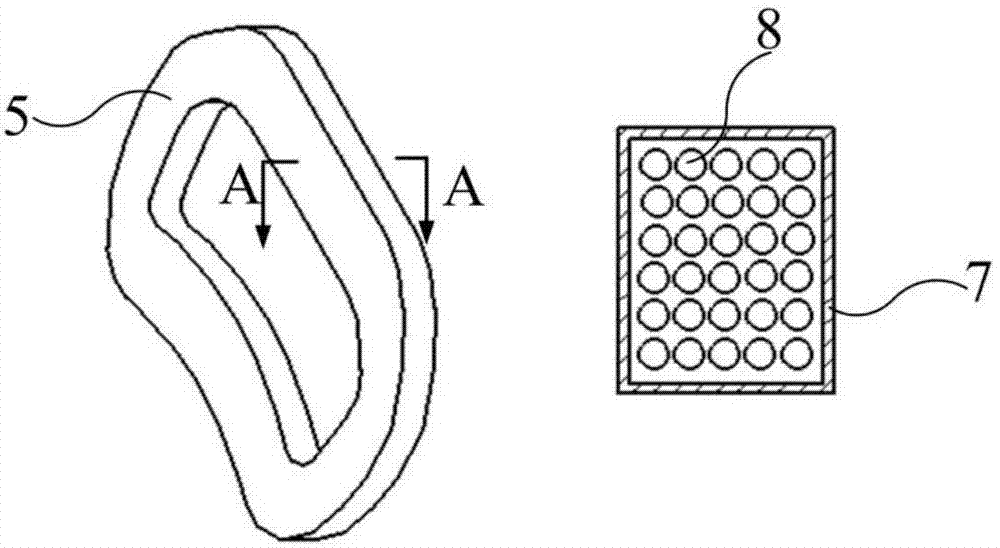

Independent type hydraulic retarder based on magnetorheological fluid and control method thereof

ActiveCN102927167ASave powerSolve the problem that the braking torque is not large and the braking effect is not goodLiquid resistance brakesNon-rotating vibration suppressionBrake torqueDrive wheel

The invention discloses an independent type automobile hydraulic retarder based on a magnetorheological fluid and a control method thereof. A working cavity is sealed, the magnetorheological fluid is filled in the working cavity, a driving wheel, a fixed wheel, a coil and a cooling water jacket are accommodated in the working cavity, the moving wheel and the fixed wheel are coaxially opposed with clearance, the coil is winded around the outer edges of the moving wheel and the fixed wheel, the coil is fixed at the outer edge of the moving wheel, a clearance exists between the coil and the outer edge of the fixed wheel, the coil is connected with a vehicle power supply outside the working cavity, an output end of a moving wheel shaft extends out of the working cavity and is connected with a speed changer through a driving gear pair, the cooling water jacket is fixedly sleeved on the fixed wheel outer ring, the cooling water jacket is connected with a water pump and a radiator outside the working cavity, according to vehicle information of a vehicle controller, an electronic control unit calculates the current which is input into the coil, establishes magnetic field in the working cavity and generates a braking torque which acts on the moving wheel shaft, the electronic control unit controls the water pump to work so that the cooling water can circularly flows among a cooling water pipeline, the cooling water jacket and the radiator, and the temperature of the magnetorheological fluid can be decreased.

Owner:JIANGSU UNIV

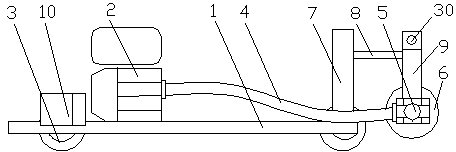

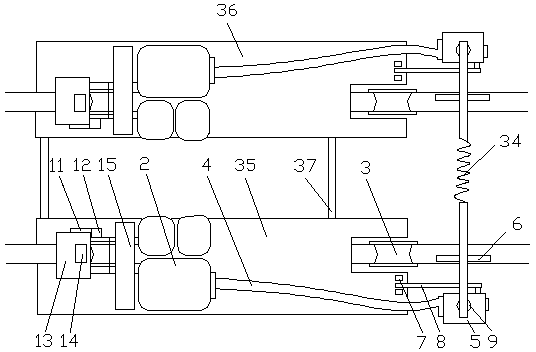

Automatic steel rail duplex rust removing machine

ActiveCN104631234AHard and wear-resistant working surfaceEasy to attachTrack superstructureRailway track constructionCouplingEngineering

The invention discloses an automatic steel rail duplex rust removing machine. The automatic steel rail duplex rust removing machine comprises a rack, engines and wheels connected to the lower portion of the rack, and is characterized in that the two engines are adopted and distributed on steel rails on the two sides respectively, the automatic steel rail duplex rust removing machine further comprises two soft shafts and two steering gears, one ends of the soft shafts are connected with rotating shafts of the engines through couplers, the other ends of the soft shafts are connected with input shafts of the steering gears, output shafts of the steering gears are connected with blade grinding wheels, the rack is fixedly connected with two connecting pieces, vertical adjusting pieces are arranged above the steering gears and elastically connected with the steering gears, connecting rods of the connecting pieces are connected with the vertical adjusting pieces, a transverse spring pull rod is connected between the vertical adjusting pieces of the steel rails on the two sides, and the rack is connected with a drive component. The kinetic energy of the engines is directly transmitted to the blade grinding wheels through the soft shafts, a duplex structure is adopted, synchronous automatic constant-speed rust removing can be carried out on pedal faces of the two steel rails at the same time, and the rust removing quality and efficiency are greatly improved.

Owner:德阳路安恒轨道技术开发有限公司

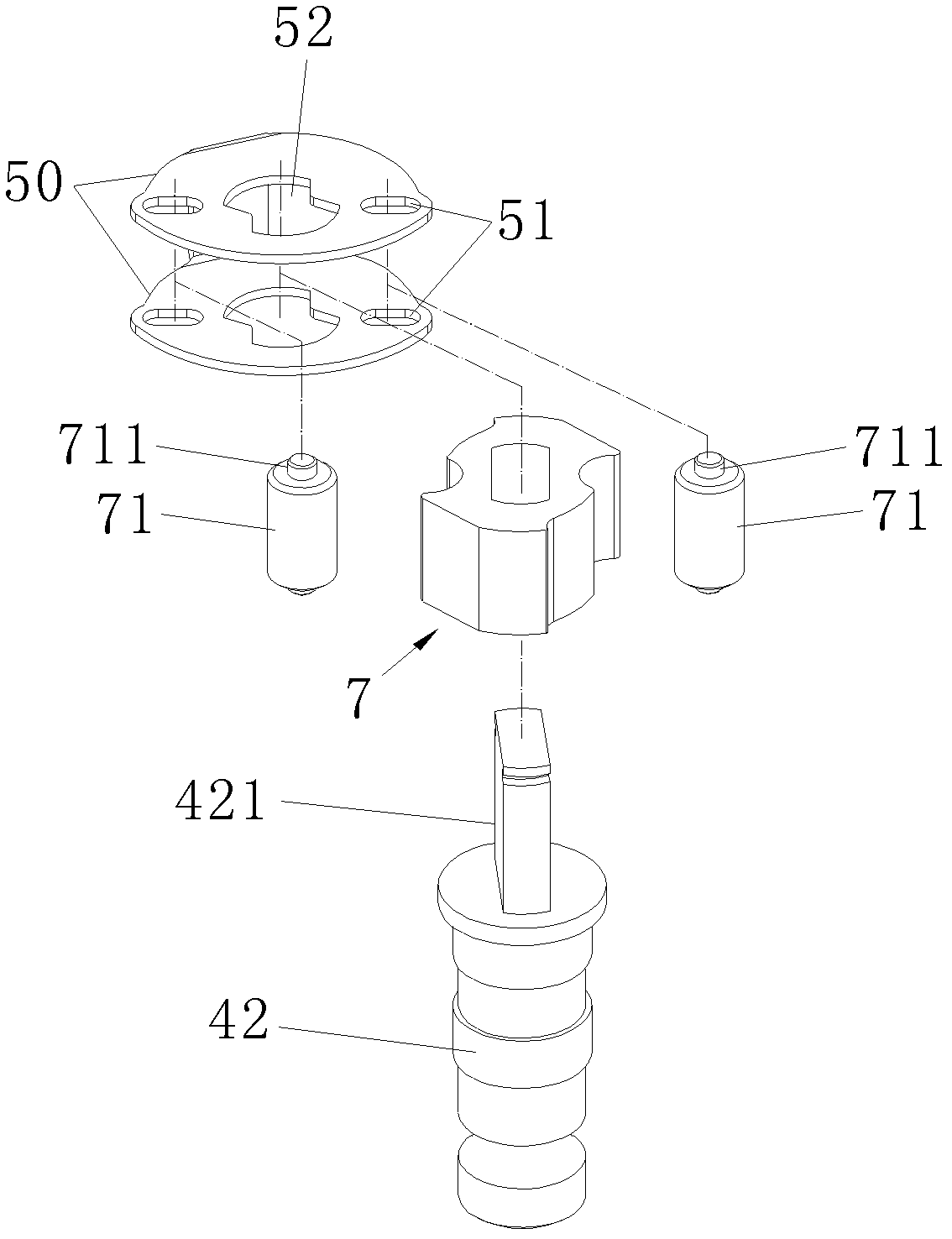

Revolving door mechanism for automatic entrance guard device

The invention provides a revolving door mechanism for an automatic entrance guard device, which adopts the technical scheme that the revolving door mechanism for the automatic entrance guard device comprises a door spindle, a motor and a torque force transmission rod fixedly connected with the motor, the revolving door mechanism for the automatic entrance guard device is characterized in that the lower end of the torque force transmission rod is connected with a small shaft and a positioning plate coaxially fixed with the small shaft, a positioning notch is formed in the circumference of the lower end of the torque force transmission rod, and a positioning wheel is controlled by a torsion spring and matched with the positioning notch for accurate positioning during door spindle opening or closing; the upper and the lower gear shafts of a transmission are connected with the small shaft and an electromagnetic brake respectively, and the rotational speed of the lower gear shaft is faster than that of the upper gear shaft; the invention adopts the technical effects that the stopping accuracy of a revolving door is excellent, the repeatability of repeatedly opening or closing is better, a common friction brake type electromagnetic brake is adopted for replacing a castellated jaw clutch electromagnetic brake, and the mechanism noise is small.

Owner:SHANGHAI HUAMING INTELLIGENT TERMINAL EQUIP

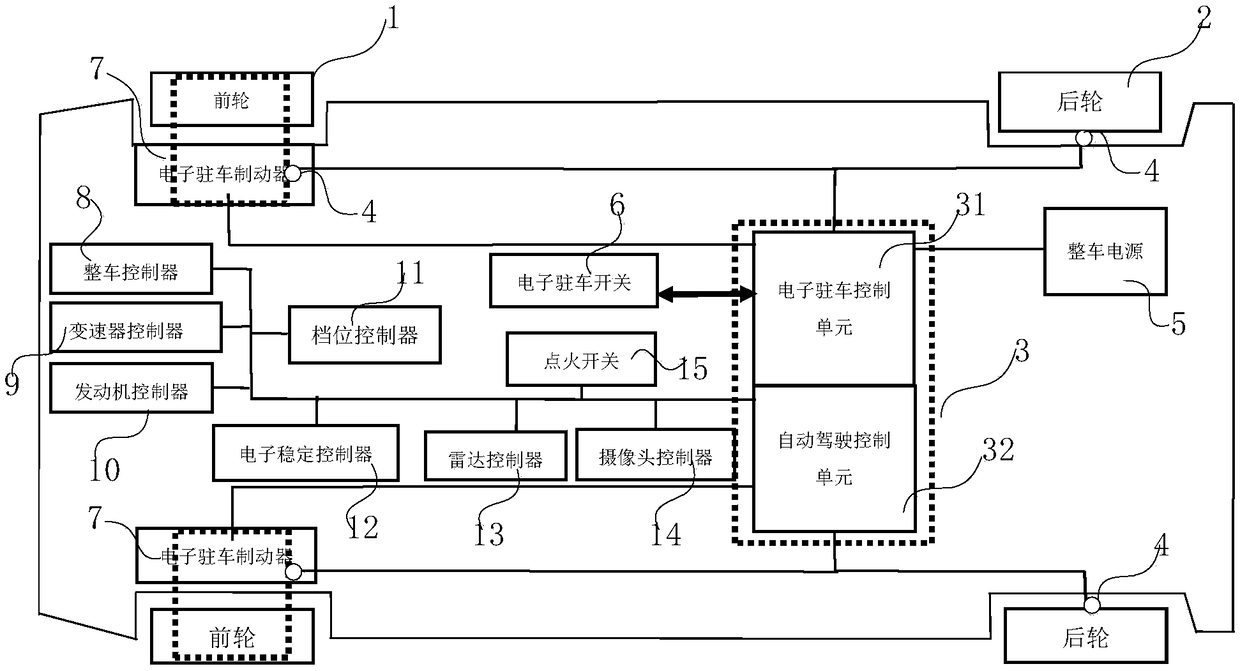

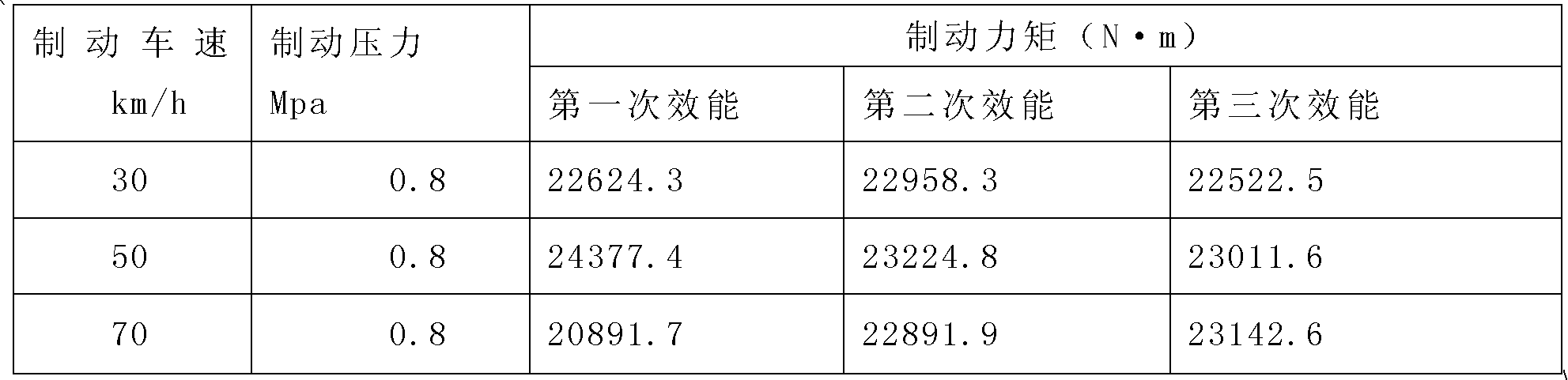

Electronic parking system and electronic parking redundant brake control method

PendingCN109229081AReduce in quantityLarge braking torqueBraking action transmissionHand actuated initiationsWheel speed sensorSignal on

The invention provides an electronic parking system and an electronic parking redundancy brake control method, which comprises the following steps: a controller is integrated with an electronic parking control unit and an automatic driving control unit which work independently; Two electronic parking brakes respectively arranged on two front wheels of the whole vehicle; Four wheel speed sensors ontwo front wheels and two rear wheels of the vehicle; the electronic parking control unit is connected with an electronic parking switch through a communication line, and the electronic parking brakeand the wheel speed sensor are connected with each other. The automatic driving control unit is connected with the radar controller and the camera controller signals on the whole vehicle. In autopilotmode, the autopilot control unit operates and the electronic parking control unit, electronic parking brake and wheel speed sensor are used as redundant backup braking systems. The electronic parkingcontrol system fully meets the requirement of automatic driving redundant braking backup, and can realize redundant braking in automatic driving mode.

Owner:苏州齐思智行汽车系统有限公司

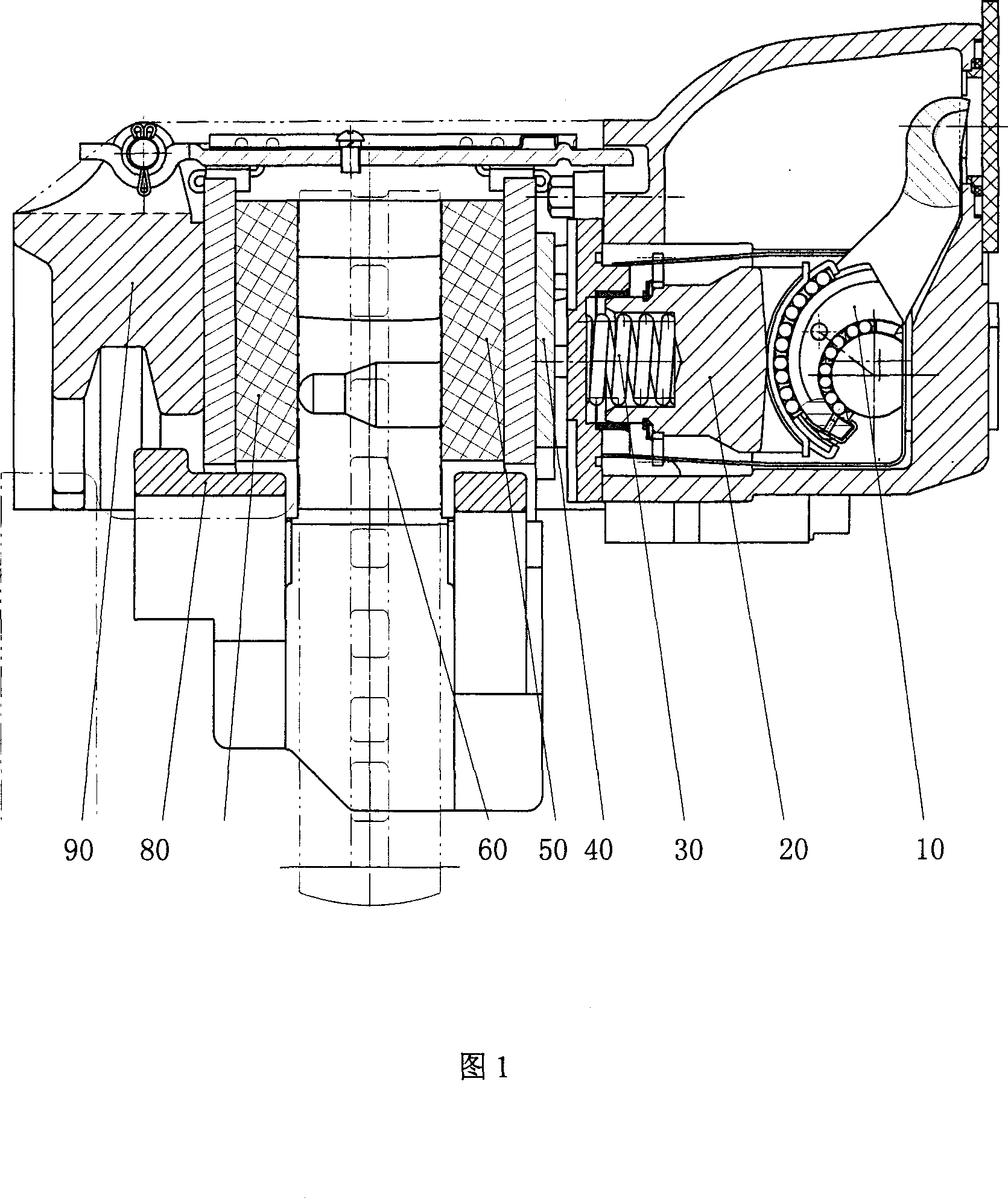

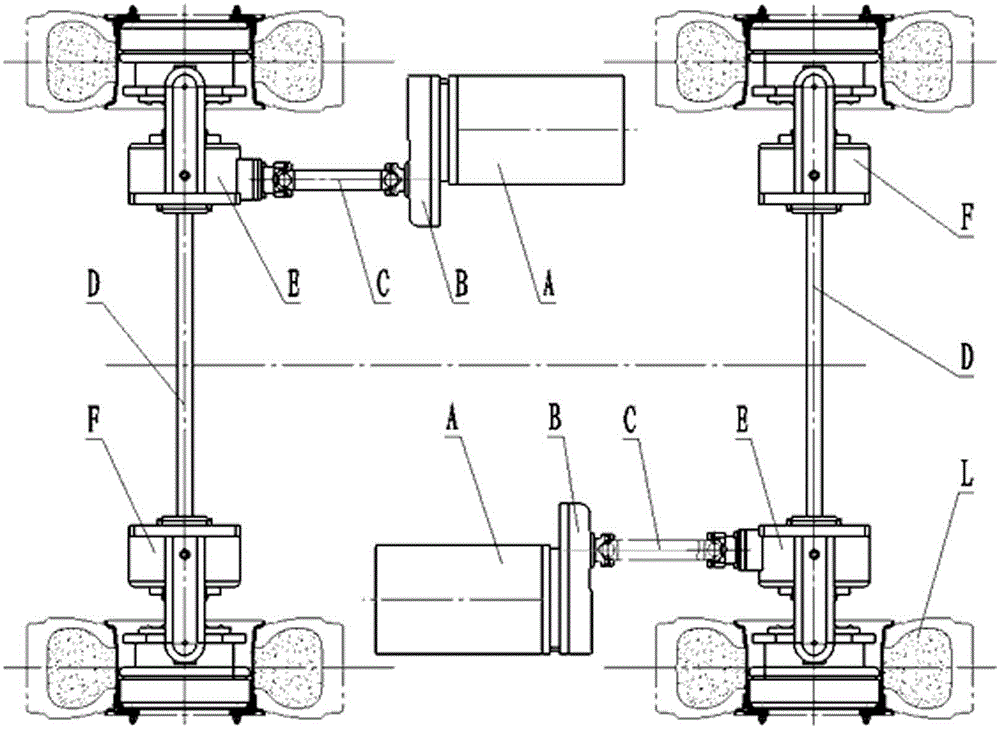

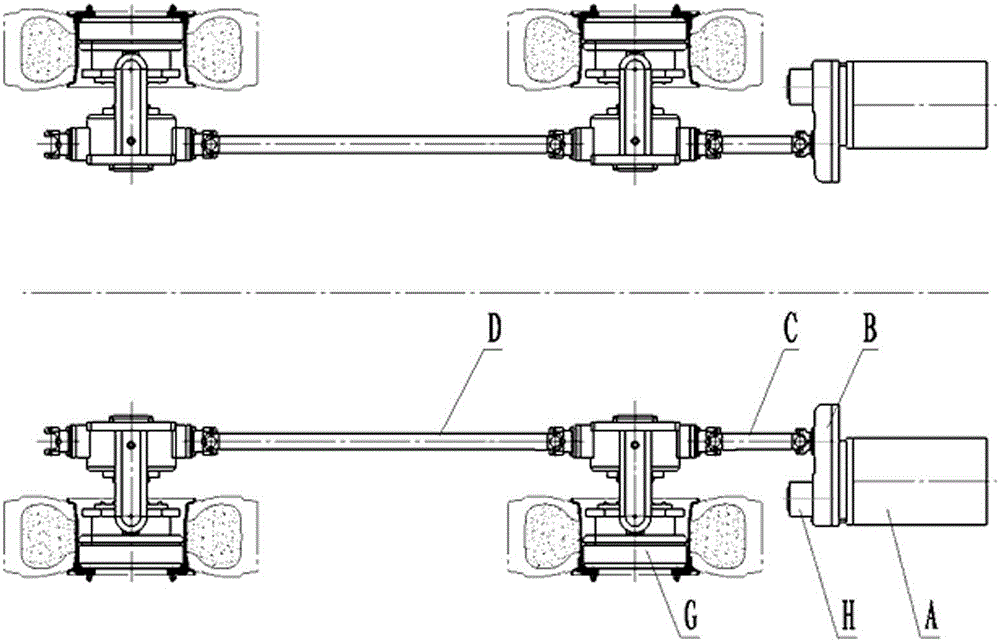

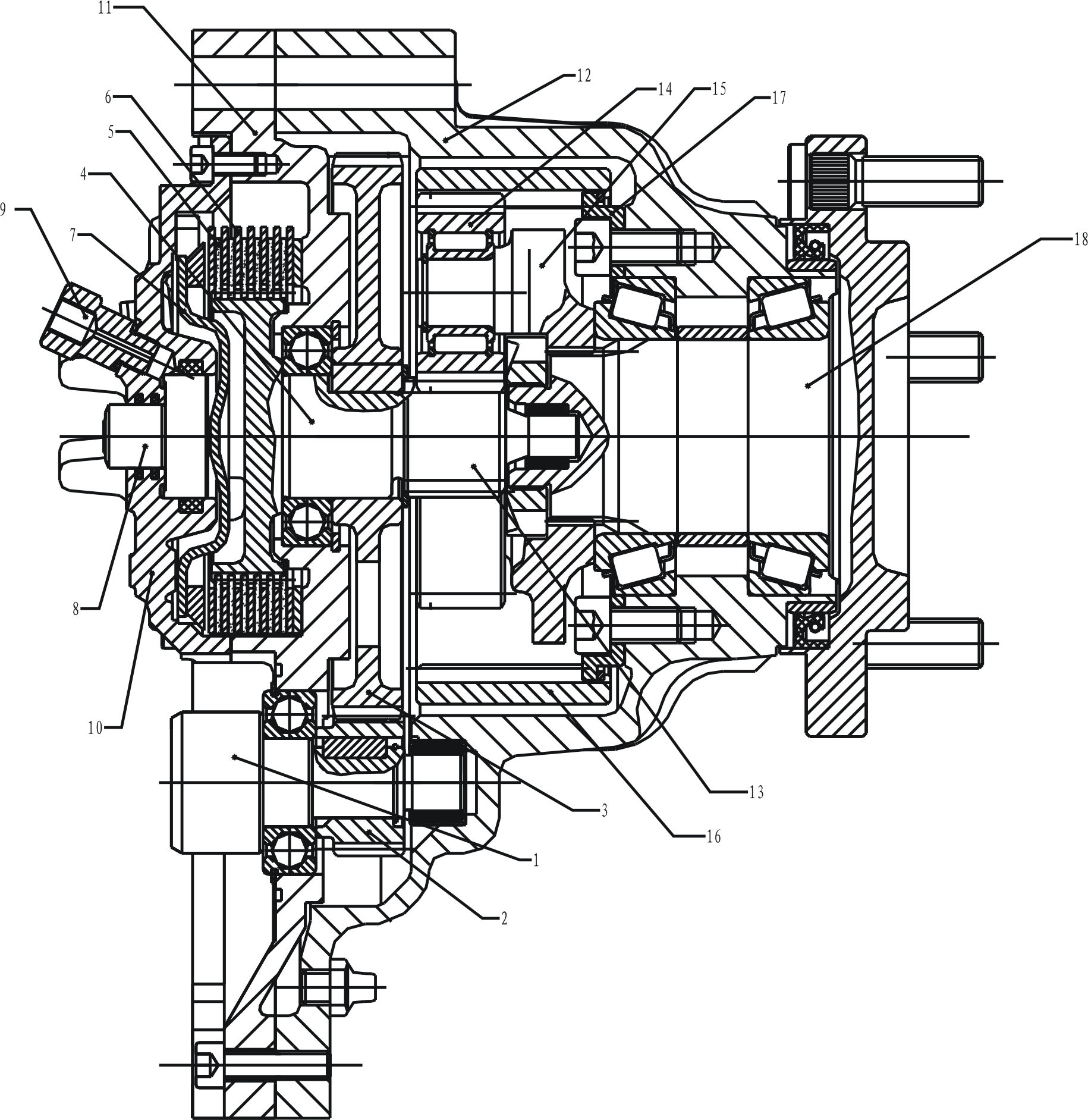

Heavy shuttle car hub driving system integrating differential respective drive and wet-type brake

ActiveCN105197020APower balance without overloadImprove power utilizationElectric motor propulsion transmissionManufacturing technologyDifferential function

The invention belongs to the technical field of design and manufacturing of underground coal mine subsidiary transport equipment parts, and provides a heavy shuttle car hub driving system integrating differential respective drive and wet-type brake. The problem that the existing shuttle car brake system is poor in steering differential function, large in brake impact and the like is solved. A drive front axle and a drive rear axle of a shuttle car are respectively controlled by two driving systems which are connected with each other in parallel; each driving system comprises a motor, a single-reduction gearbox, a hub reduction gear I and a hub reduction gear II; each hub reduction gear I and the corresponding hub reduction gear II are symmetrically mounted at two ends of a transverse transmission shaft of a corresponding shuttle car drive axle, and are positioned on the inner side of a corresponding walking rubber wheel of the shuttle car; the hub reduction gears I are connected with an outputting end of the single-reduction gearbox through transmission shafts; and the single-reduction gearbox is driven by the motors. By the two driving systems which are connected with each other in parallel, problems of abrasion of tires, eccentric load of the hub reduction gears and the like are solved, and motor power utilization rate is improved.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Permanent magnet change length magnetorheological fluid and friction composite soft landing device

InactiveCN105288876AAvoid the downside of being unavailableDoes not consume energyBuilding rescueMagnetic currentDrive shaft

The invention discloses a permanent magnet change length magnetorheological fluid and friction composite soft landing device. The permanent magnet change length magnetorheological fluid and friction composite soft landing device comprises a shell, a transmission shaft and a coiling block. The shell comprises a horizontal outer cylinder. A left side cover and a right side cover are arranged at the two ends of the outer cylinder respectively. The transmission shaft is arranged in the outer cylinder, and the axis of the transmission shaft coincides with the axis of the outer cylinder. The left end and the right end of the transmission shaft stretch out of the left side cover and the right side cover respectively and are fixedly connected with the left side cover and the right side cover through bearings. The coiling block is arranged at the left end of the transmission shaft in a sleeving manner and fixedly connected with the transmission shaft, and an escape rope is wound on the coiling block. A magnetorheological brake part and a friction brake part are arranged in the shell. The permanent magnet change length magnetorheological fluid and friction composite soft landing device is simple in structure, energy does not need to be additionally added, the landing distance can be controlled, and safety and the comfort level are high.

Owner:CHONGQING UNIV OF TECH

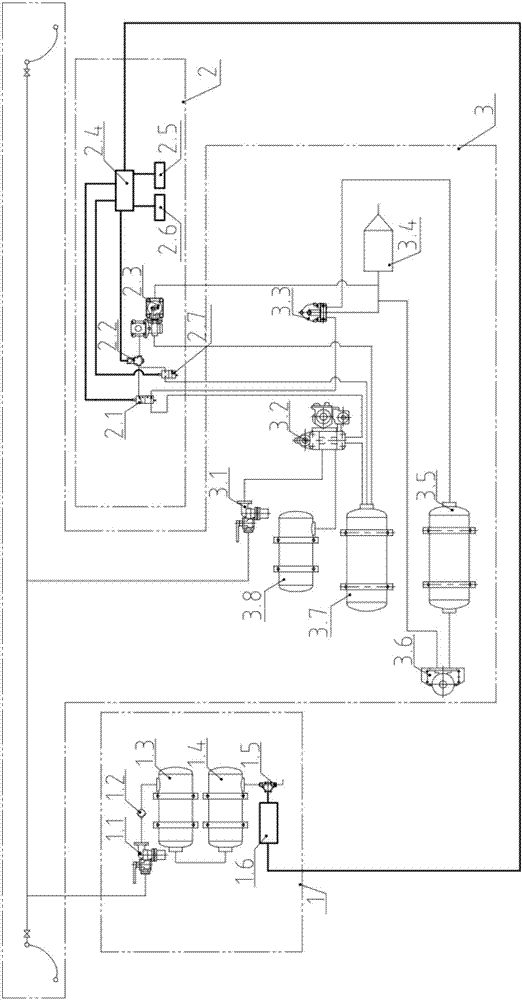

Pneumatic-electric braking system for goods train

InactiveCN107298111AImprove adaptabilitySimple structureRailway hydrostatic brakesRailway hydrodynamic brakesElectronic control unitElectricity

The invention relates to a pneumatic-electric braking system for a goods train. An air brake system is additionally provided with a pneumatic power generating module and an electric control dynamic adjustment module, wherein the air brake system is suitable for conventional goods trains and is composed of a train pipe, a 120# distribution valve, a braking cylinder, an auxiliary air cylinder, an acceleration relief air cylinder and a mechanical empty and heavy vehicle adjusting assembly, and the mechanical empty and heavy vehicle adjusting assembly is composed of a mechanical proportional valve, a weight measuring mechanism and a pressure reduction air cylinder; the pneumatic power generating module is composed of an air storage cylinder assembly, a pneumatic power generator and a storage battery unit, and the storage battery unit comprises a storage battery and a management system; the electric control dynamic adjustment module is composed of a brake electronic control unit, a switching electromagnetic valve, a proportional electromagnetic valve, a relay valve and sensors; and the pneumatic power generating module is used for supplying power to the electric control dynamic adjustment module, and pneumatic-electric braking is finally achieved. Compared with the prior art, the pneumatic-electric braking system for the goods train can meet the requirement for precise control over braking under no-load or heavy-load conditions and has the advantages of skid resistance and high sensitivity.

Owner:TONGJI UNIV

Improved drum brake structure

ActiveCN102305252AReduced service lifeExtended service lifeBrake actuating mechanismsMechanically actuated drum brakesEngineeringCam

The invention discloses an improved drum brake structure which comprises a shell, a pair of brake shoes arranged in the shell, a resetting element and a brake arm assembly, wherein the resetting element is connected with the pair of brake shoes; one end of each brake shoe is rotatably positioned in the shell, and a gap between the other ends of the brake shoes is provided with a brake wheel driven to rotate by the brake arm assembly; a pin roller is respectively abutted and connected between the brake wheel and the end surfaces of the brake shoes on two sides; locating plates are arranged on the two axial end surfaces of the brake wheel, and the pin roller is rotatably positioned between the two locating plates; the edge of the brake wheel is provided with a limiting edge face which is matched with the end surface of the brake shoes to be abutted with the pin roller; and a rolling meshing structure is arranged between the limiting edge face and the pin roller. According to the improved structure provided by the invention, the phenomenon that the original drum brake adopts the working mode of directly driving the brake shoes to expand by a cam is changed, and the shortages of poor brake effect and long vehicle brake sliding distance of the existing drum brake can be effectively improved.

Owner:CHANGXING HUAYI ELECTROMECHANICAL

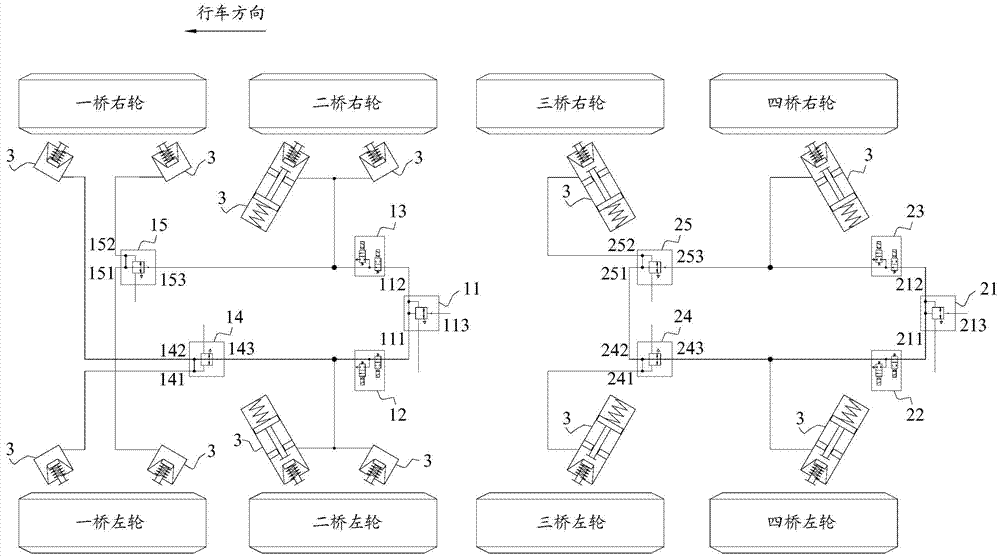

Service braking system of four-axle chassis and crane with same

ActiveCN103481882APrinciple improvementImprove handling stabilityBraking action transmissionRelay valveControl system

The invention discloses a service braking control system of a four-axle chassis. The service braking control system is characterized in that a brake valve is communicated with a control port of a first relay valve of a first brake circuit, brake chambers are used for controlling a second axle, the brake chambers arranged on the left and right sides of a first axle are respectively controlled and communicated by a second relay valve and a third relay valve, and a control port of the second relay valve and a control port of the third relay valve are respectively communicated with an air outlet of an anti-lock magnetic valve of the second axle; a braking valve is communicated with a control port of a fourth relay valve of a second brake circuit, brake chambers are used for controlling a fourth axle, and the brake chambers arranged on the left and right sides of a third axle are respectively controlled and communicated by a fifth relay valve and a sixth relay valve; a control port of the fifth relay valve and a control port of the sixth relay valve are respectively communicated with the air outlet of an anti-lock magnetic valve of a fourth axle, and an abnormal anti-lock phenomenon of the second axle and the fourth axle is fully avoided through system optimization configuration. The invention also provides a crane with the service braking system.

Owner:XUZHOU HEAVY MASCH CO LTD

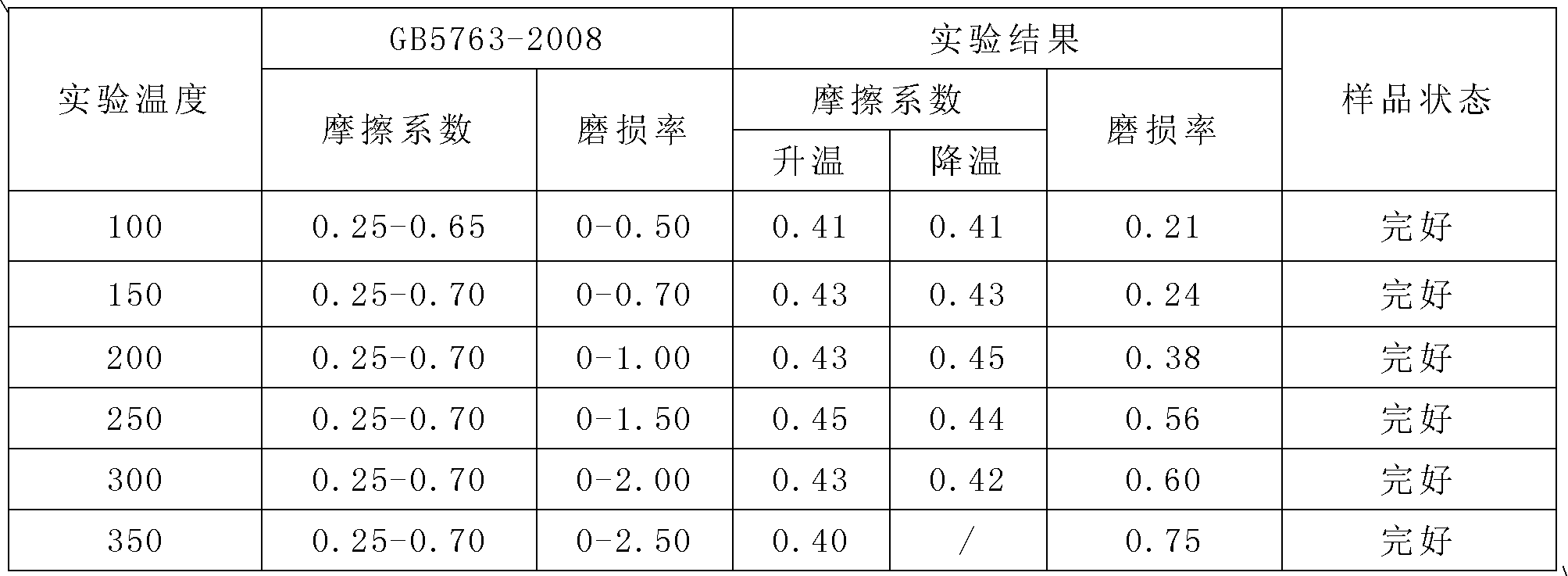

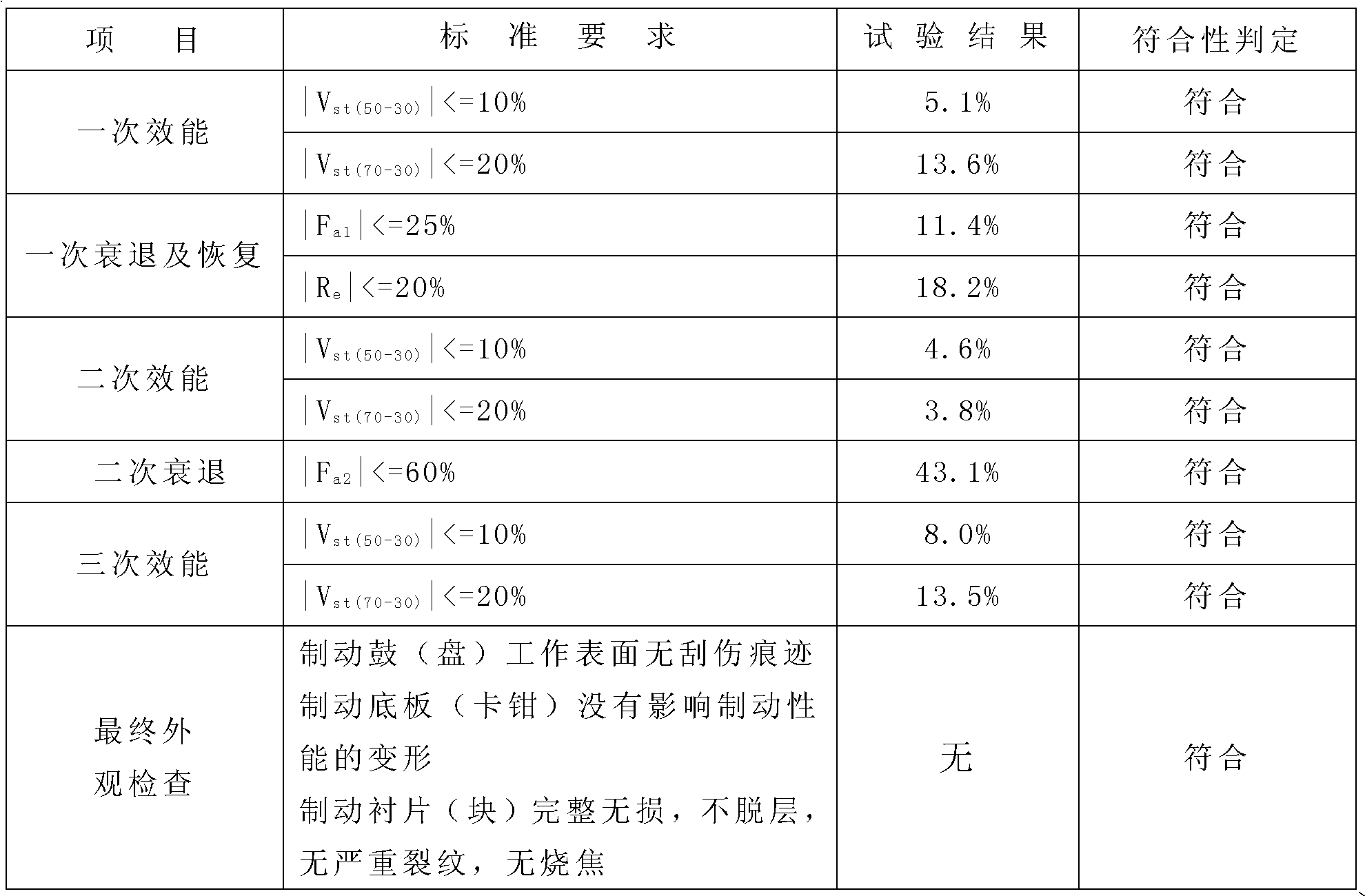

Semimetal ceramic matrix air disc brake pad and production method thereof

InactiveCN101813151ALarge braking torqueNo significant declineBraking discsFriction liningTruckDisc brake

The invention discloses a semimetal ceramic matrix air disc brake pad of an air disc braking system for heavy-duty freight cars and a production method thereof, wherein the production flow is as follows: sequentially weighing and putting 10 nonmetal assorted fibre, 35-40 metal fibre, 20 or 25 of friction performance regulator, 15-25 of vitrified bond, 5-10 of elastic toughening agent and 10 of filler into a high-speed mixer to mix uniformly, then carrying out pressing and thermocuring treatment according to a dry once-through molding technique of the traditional resin matrix friction materials, finally machining, ceramic processing, inspecting and packaging. The semimetal ceramic matrix air disc brake pad manufactured according to the technique has large braking torque, comfortable emergency braking, small heat fading and simple production technology, is environmental friendly, is particularly suitable for air disc brakes of the heavy-duty freight cars, and has wide market prospect.

Owner:HUNAN BOYUN AUTOMOBILE BRAKE MATERIALS +1

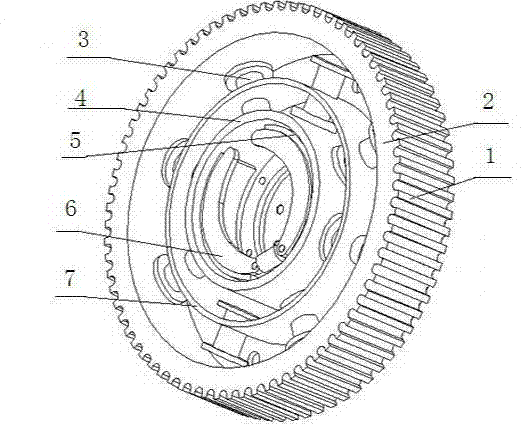

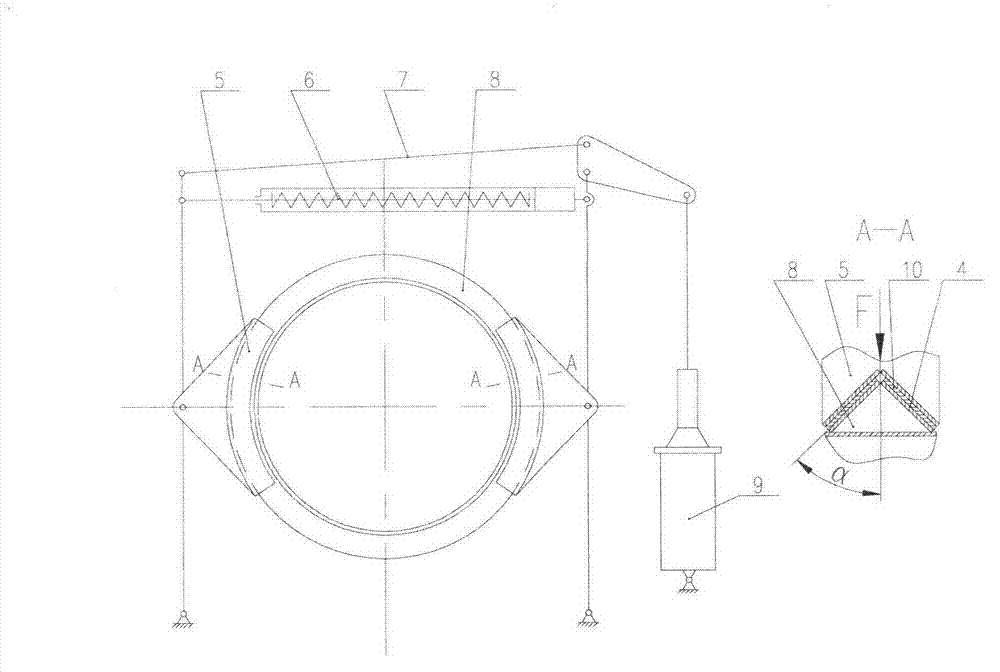

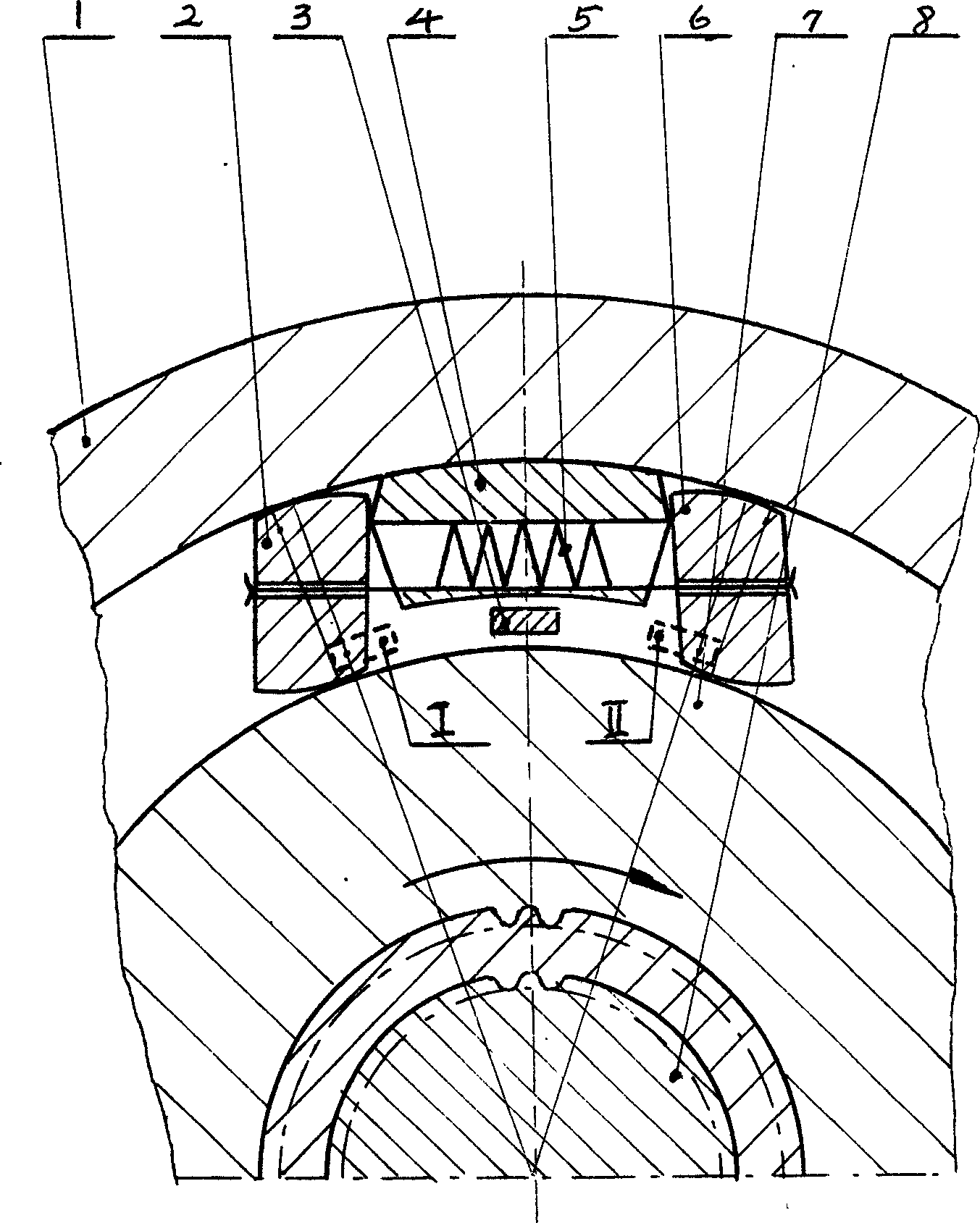

Brake integrating rotary barrel type eddy current retarder and drum brake

ActiveCN103089857AReduce generationIncreased braking safetyElectrodynamic brake systemsDrum brakesEddy currentElectromagnetic brake

The invention discloses a brake integrating a rotary barrel type eddy current retarder and a drum brake, wherein the brake is used for braking and speed reduction of an automobile. A retarder outer rotor, a brake drum and a coil support are coaxial, and the coil support is located between the retarder outer rotor and the brake drum. A plurality of magnet exciting coils provided with iron cores are fixed on the coil support and are evenly distributed along the circumferential direction of the outer circle of the brake drum, the axial leads of the magnet exciting coils are located in the radial direction of the brake drum, and first gas intervals are formed between the magnet exciting coils and the retarder outer rotor, and second gas intervals are formed between the magnet exciting coils and the brake drum. Two adjacent magnet exciting coils provided with the iron cores, facing to the same gas interval, are opposite in polarity. When the automobile speed is low, a brake shoe enables a friction liner to be pressed towards the brake drum to achieve friction braking; when the automobile runs at a normal automobile speed, the magnet exciting coils are powered on to produce electromagnetic braking torque to reduce the automobile speed, and then the automobile is braked through friction. When the automobile speed is high, electromagnetic braking and friction braking act in a combined mode. Braking thermal failure is avoided, and safety performance of automobile braking is improved.

Owner:BAOHUA SEMI TRAILER FITTINGS CO LTD ZHENJIANG CITY

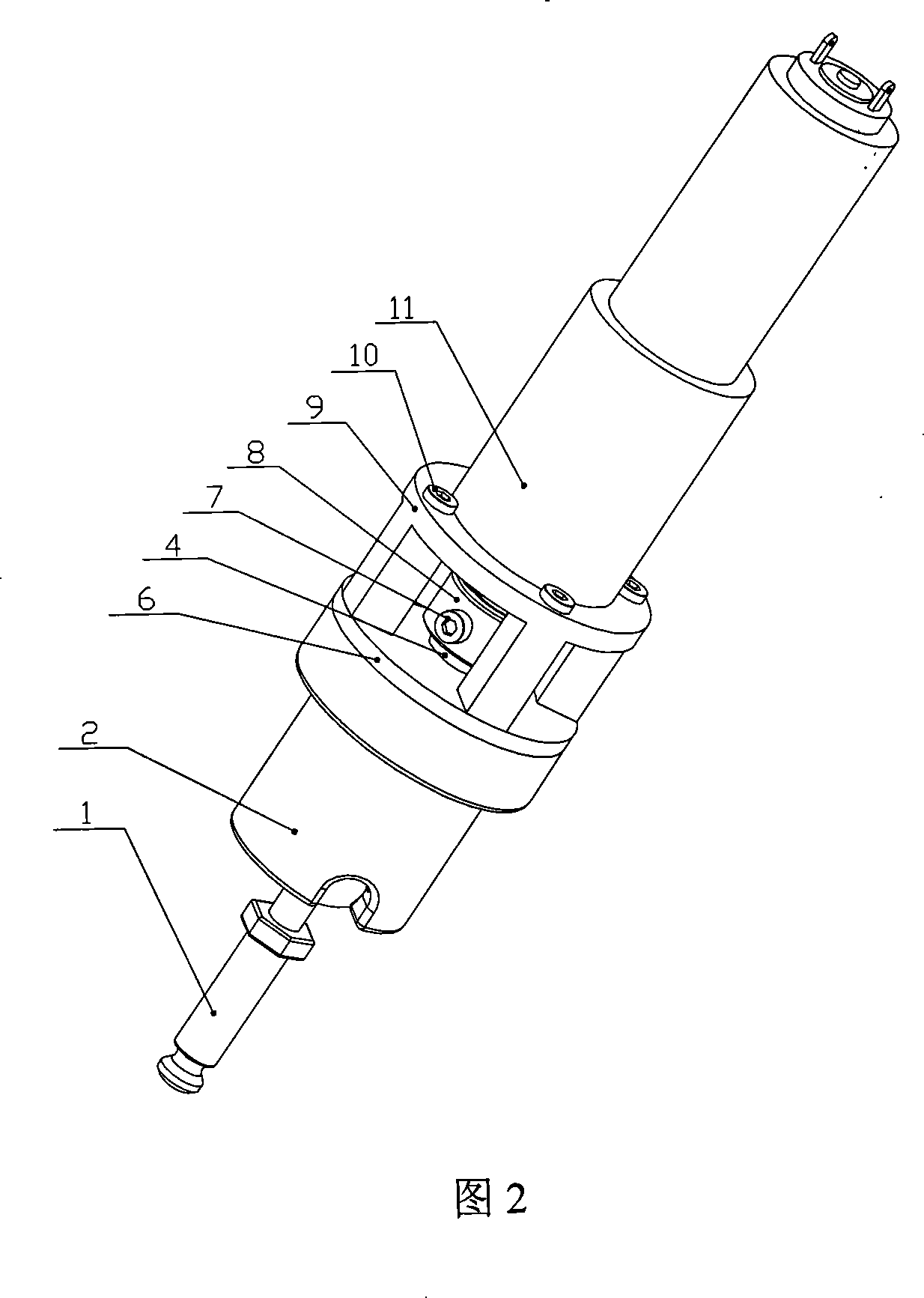

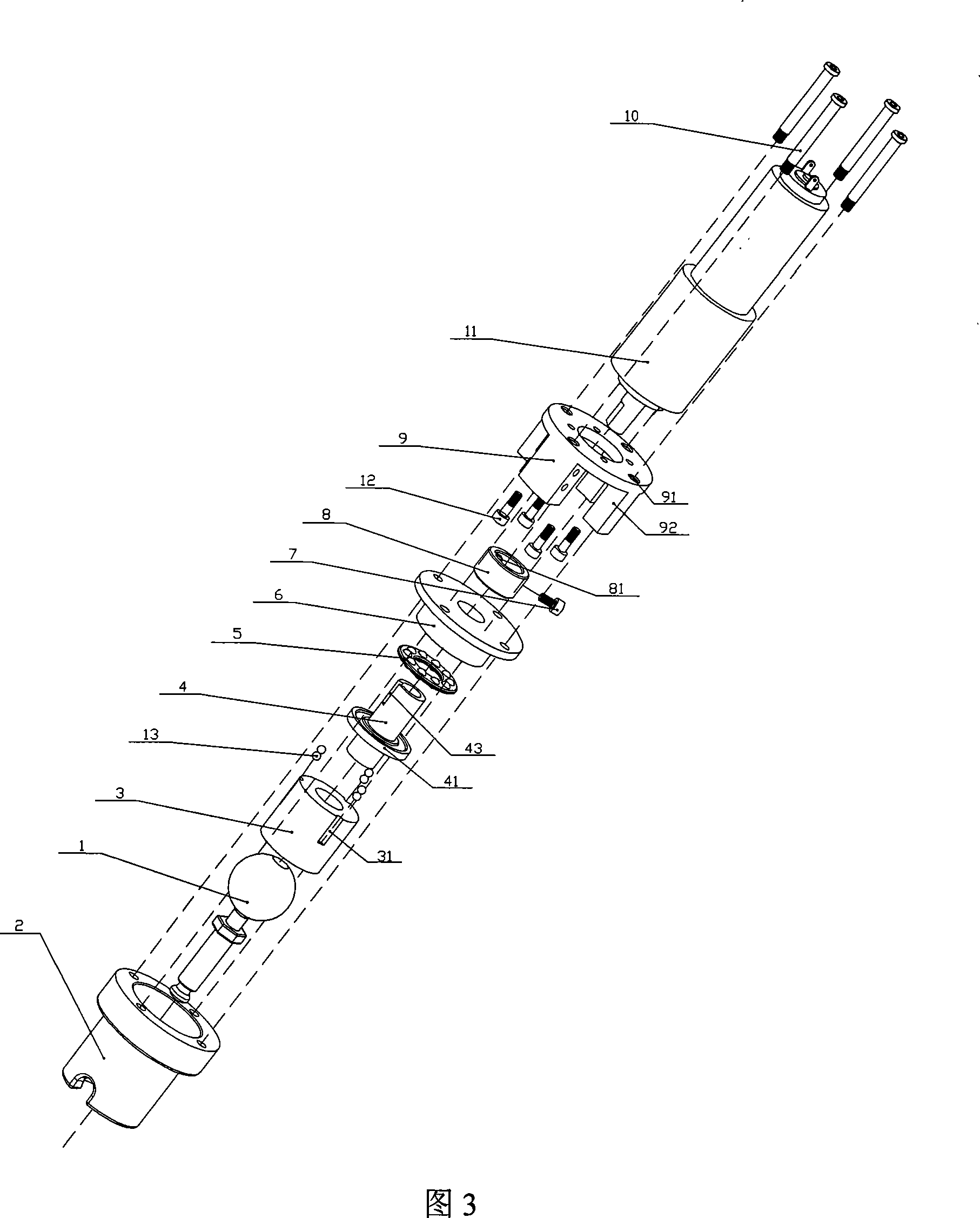

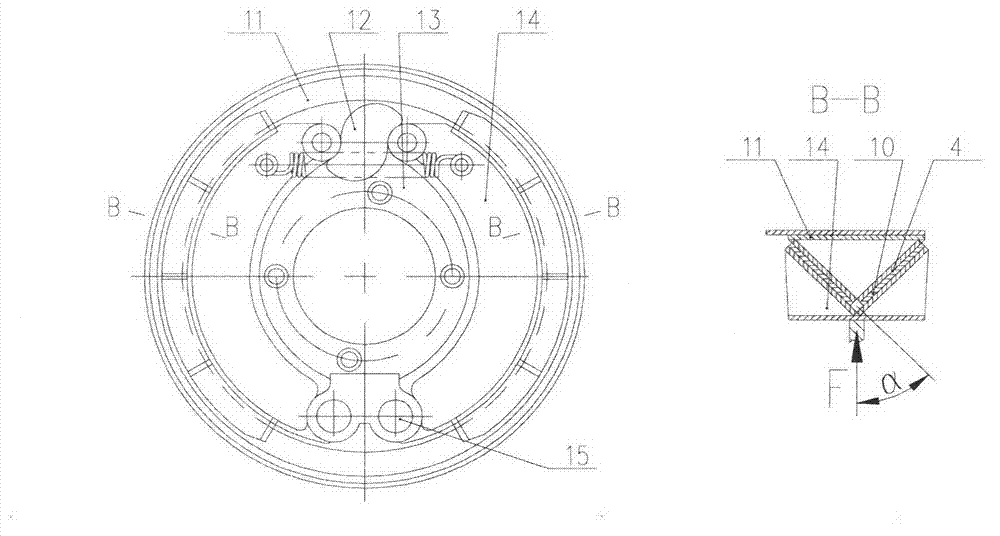

Spherical hinge type joint electric locking device

InactiveCN101214662AIncrease flexibilitySimple structureJointsPivotal connectionsBrake torqueSpherical joint

The present invention relates to an electric locking device of a spherical hinge type joint, which comprises a ball rod, a spherical joint seat, a ball-thrusting tile, a threaded shaft, a ball support ring, an antithrust end closure, a key ring, a motor seat, a direct current speed-down motor, etc. The ball rod is installed on the bottom of the spherical joint seat, the ball-thrusting tile is intalled in the spherical joint seat and press the ball head of the ball rod, a ball is installed in a cylindrical hole formed by the semicircular groove of the ball-thrusting tile and the semicircular groove of the spherical joint seat, the threaded shaft is suitably installed in the ball-thrusting tile via a triangular external thread, the ball support ring is installed on the threaded shaft, the antithrust end closure fastens the threaded shaft and the ball support ring on the spherical joint seat, the key ring is fastened in the key slot of the threaded shaft, the direct current speed-down motor is installed on the motor seat by motor-fixing bolts, the motor seat is tightly connected with the spherical joint seat by trip bolts, and then key ring bolts are installed on the key ring. Widely applicable to mechanical arms and robots, the device has the advantages of good flexibility, simple structure, reliable unlocking and locking and great brake torque.

Owner:BEIHANG UNIV

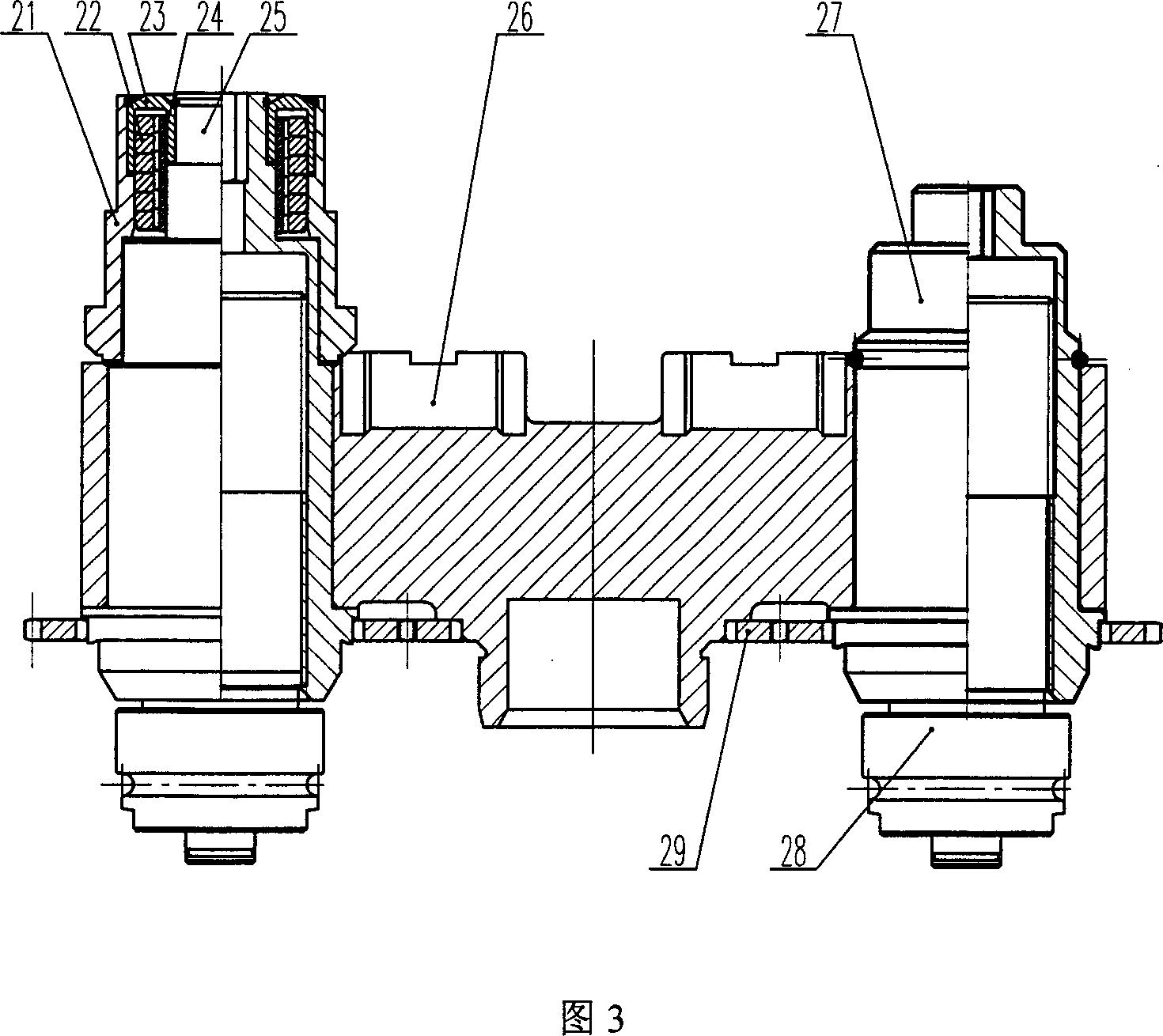

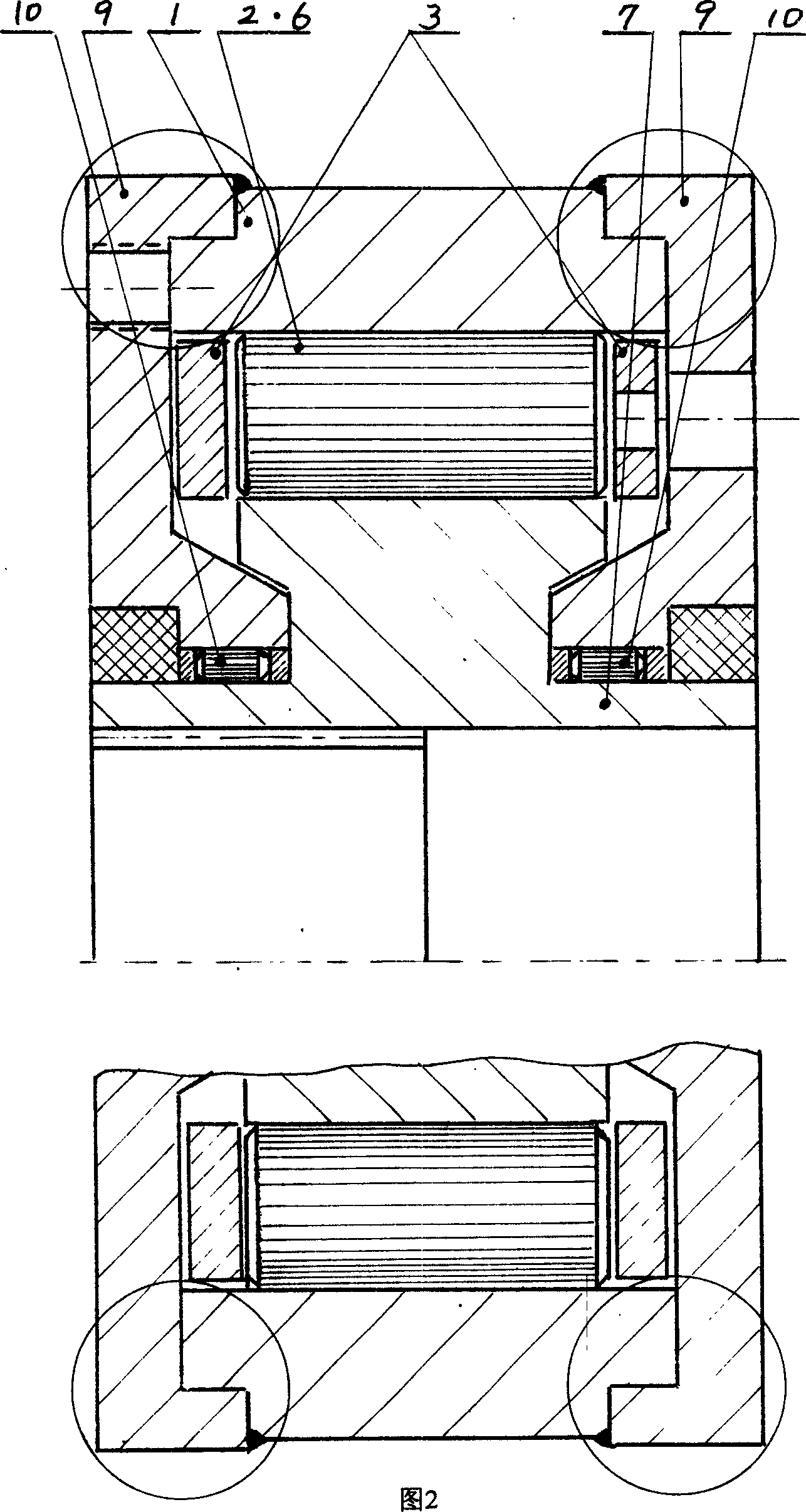

Eddy current retarder device based on magnetorheological effect

InactiveCN103807329ALarge braking torqueSmall magnetic resistanceLiquid resistance brakesElectrodynamic brake systemsMagnetic currentElectricity

The invention relates to an eddy current retarder device based on the magnetorheological effect. The eddy current retarder device comprises rotor discs, a stator assembly, a transmission shaft and magnetorheological fluid. The stator assembly comprises a bearing sleeve, stator shells and the like and is located in the middle, the two rotor discs are placed in the stator shells on the two sides of the stator assembly respectively, and gaps between the shells and the rotor discs are filled with the magnetorheological fluid. Eight excitation devices are respectively fixed to the inner side shell of the stator shells on the two sides. Through the structure, air gaps between rotors and a stator are replaced by the magnetorheological fluid with high magnetic permeability and low electrical conductivity, and therefore magnetic circuit magnetic resistance is reduced; meanwhile, under the magnetic field effect, the magnetorheological fluid is converted from Newtonian fluid with low viscosity into Bingham fluid with high shear yield stress. In the brake process, the brake torque generated by eddy currents and the brake torque generated by the magnetorheological fluid act at the same time. The eddy current retarder device with the structure has the advantages of being capable of saving energy and electricity, small in coil heating amount, large in brake torque, and good in brake torque controllability and low-speed performance.

Owner:FUZHOU UNIV

A vehicle wheel-side composite braking device integrating permanent magnet braking and friction braking

ActiveCN109058328BImproved resistance to heat fadingReduce wearBraking discsBrake actuating mechanismsClassical mechanicsMagnetic poles

Owner:合肥九州龙腾科技成果转化有限公司

Rotor cooling type automobile permanent magnet liquid cooling retarder

InactiveCN102185462AImprove cooling effectImprove securityElectrodynamic brake systemsElectric machinesDrive shaftCooling fluid

The invention provides a rotor cooling type automobile permanent magnet liquid cooling retarder, belonging to the technical field of baking. The rotor cooling type automobile permanent magnet liquid cooling retarder comprises a stator, a rotor and a cylinder, wherein the stator comprises a left end cover, a stator hub, a permanent magnet, a magnet retainer and a right end cover; the permanent magnet is uniformly fixed on the magnet retainer, the magnet retainer is connected with the stator hub and slides axially, the rotor is connected with the transmission shaft and rotates along with the transmission shaft; the cylinder is fixed on the right end cover and is connected with the magnet retainer to control the magnet retainer to slide axially; the transmission shaft is connected with the stator and drives the rotor to rotate in the retarder; the stator and the transmission shaft can form an enclosed space and cooling liquid flows in the retarder, so the rotor can be directly cooled. in the invention, liquid cooling is carried out on the rotor in the retarder, thus generating a good heat dissipation effect; the permanent magnet is fixed at the radial inner side of the magnet retainer without rotating, thus having high security; the control on brake moment is simple, reliable and gradable; and the retarder provided by the invention has simple structure and high functional reliability and is easy to manufacture.

Owner:BEIJING UNIV OF TECH

Auxiliary braking device for magnetic rheological body petroleum drilling rig

ActiveCN1945047ALarge amount of liquidLarge heat capacityLiquid resistance brakesPetroleumConductive materials

The auxiliary braking device with magnetic rheological body for petroleum rig includes one cylinder of non-magnetic conductive material and two end caps of magnetic conductive material to form one sealed cylindrical cavity, two magnetic conductive columns with wound exciting coil outside the cylinder and between the two end caps, one shaft of non-magnetic conductive material with fixed magnetic conductive blades set between the two end caps, and magnetic rheological body filled in the sealed cylindrical cavity. The present invention can provide great braking moment at all rig winch speeds, and has stepless regulation of braking moment, fast response, low cost and long service life.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

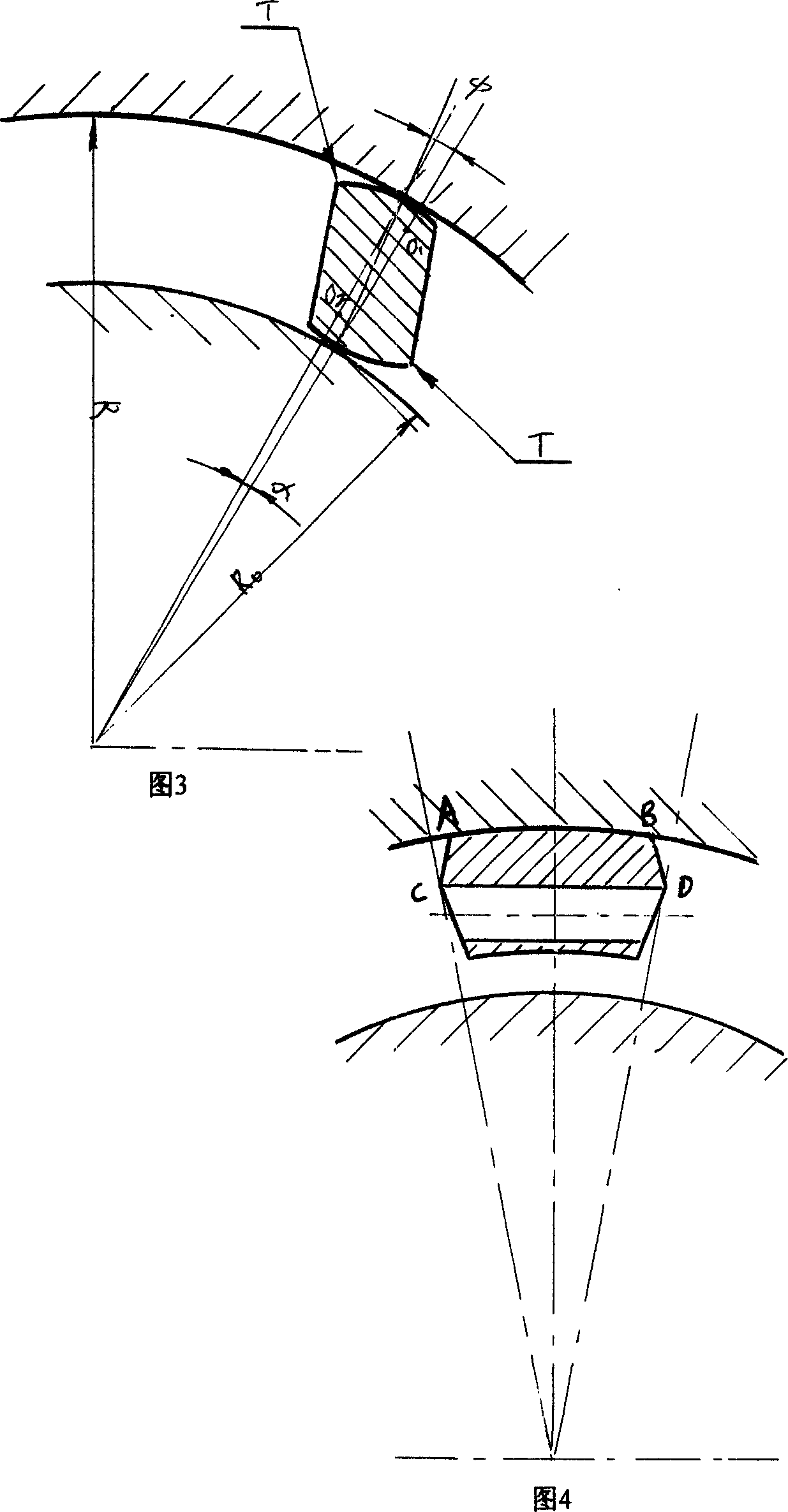

Conical surface friction brake for industry and automobiles

ActiveCN102808873ALarge braking torqueSuper boostBraking membersDrum brakesBrake torqueFriction torque

The invention relates to a friction brake for industry and automobiles, which is structurally characterized in that a brake friction pair consists of a brake pressure stressing piece and a stressed piece, wherein the friction surfaces of the brake pressure stressing piece and the stressed piece adopt conical surfaces, and another mode relative to the existing drum brake that the cylindrical surface and the disk brake adopt the end surfaces to produce friction torque is adopted, and the conical surface friction brake belongs to the technical field of mechanical devices and transportation. As the conical surface friction brake has the characteristics of the realization of being automatically reinforcing and changing the included angles between the brake acting force and the conical surfaces, so as to adjust the size of the torque, and the like, the friction brake can improve the interchangeability of the brake parts, widen the friction material selecting range, save the energy sources, and increase the brake torque, as a result, the friction brake has wide application prospect in the industry and the automobile brakes.

Owner:四川劲兴制动科技有限公司

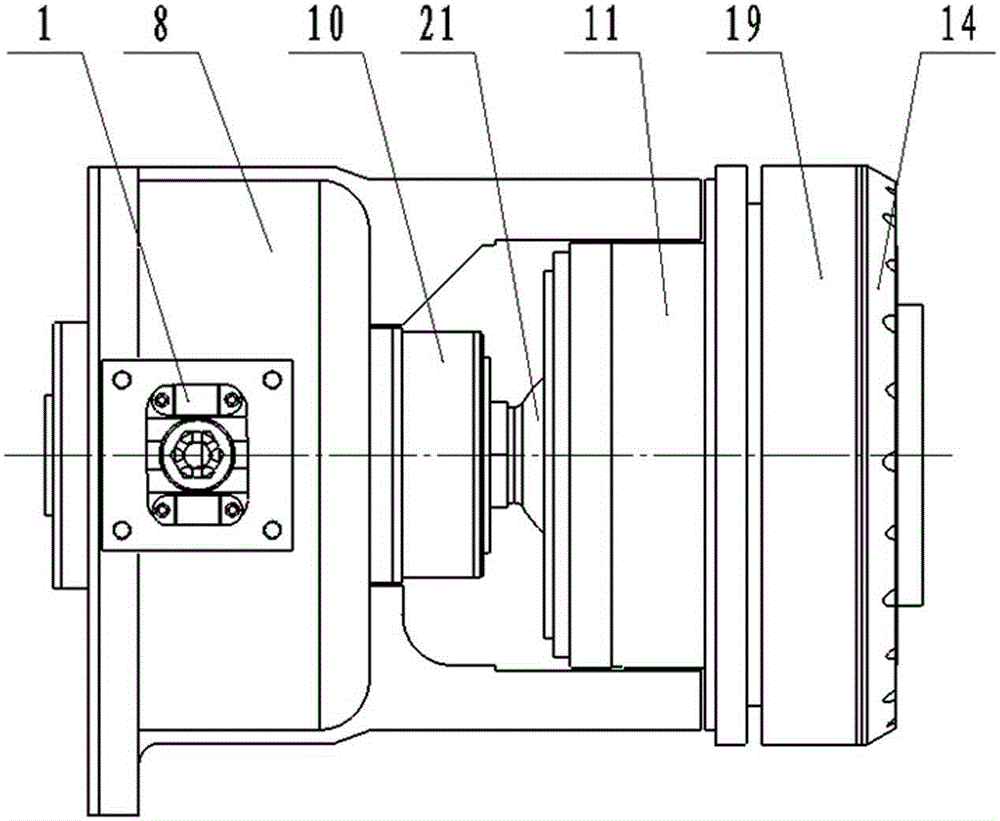

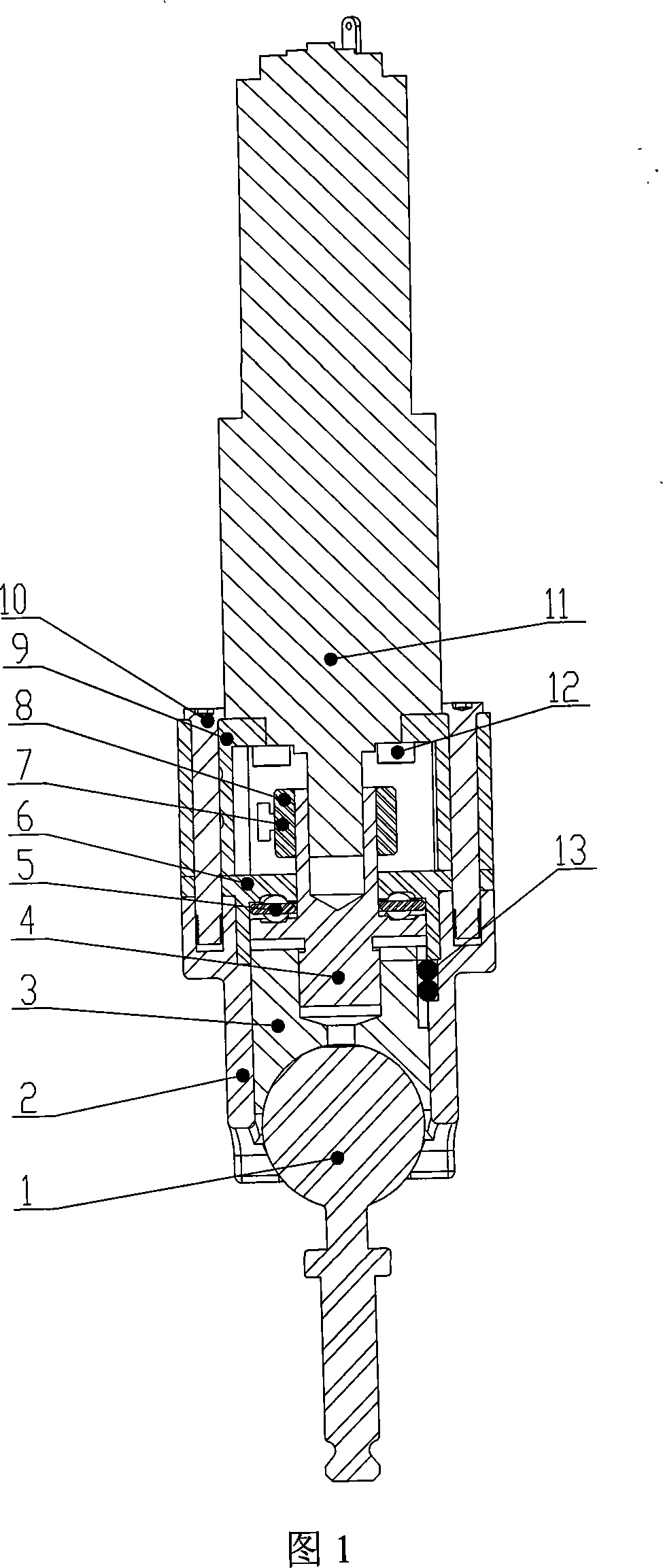

Drive axle of electronic forklift

ActiveCN102529579ACompact and reasonable structure designImprove transmission efficiencyBraking element arrangementsToothed gearingsEngineeringPlanetary system

The invention belongs to the field of drive axle assemblies of forklifts, and particularly relates to a drive axle of an electronic forklift. The drive axle of the electronic forklift comprises an axle housing assembly, a primary speed reducer arranged in the axle housing assembly, a secondary speed reducer arranged in the axle housing assembly, a hub and a brake, wherein the axle housing assembly comprises an axle housing and an axle cover; one end of the axle housing is opened and connected with the axle cover; a hub mounting hole position is arranged at the other end of the axle housing and used for mounting the hub; the primary speed reducer is driven by a cylindrical helical gear pair; the secondary speed reducer is driven by a cylindrical gear planetary system; and the brake is arranged on the outer side of the axle cover and is used for braking an axle shaft. The electronic forklift wheel edge drive axle power transmission direction is axially parallel to the hub (namely the wheel), the structure design is reasonable and compact, and the transmission efficiency is high.

Owner:湖北星星电驱动有限公司

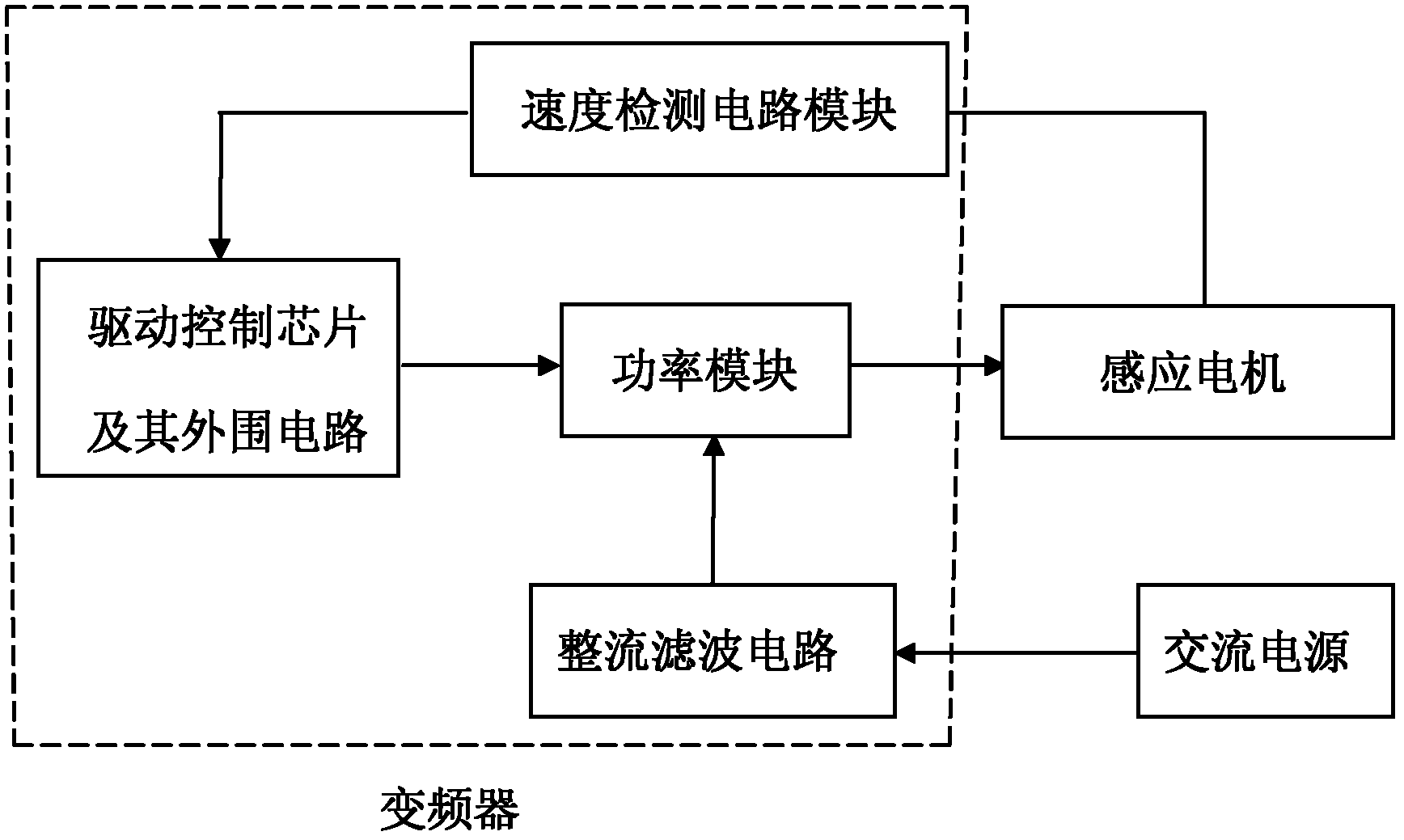

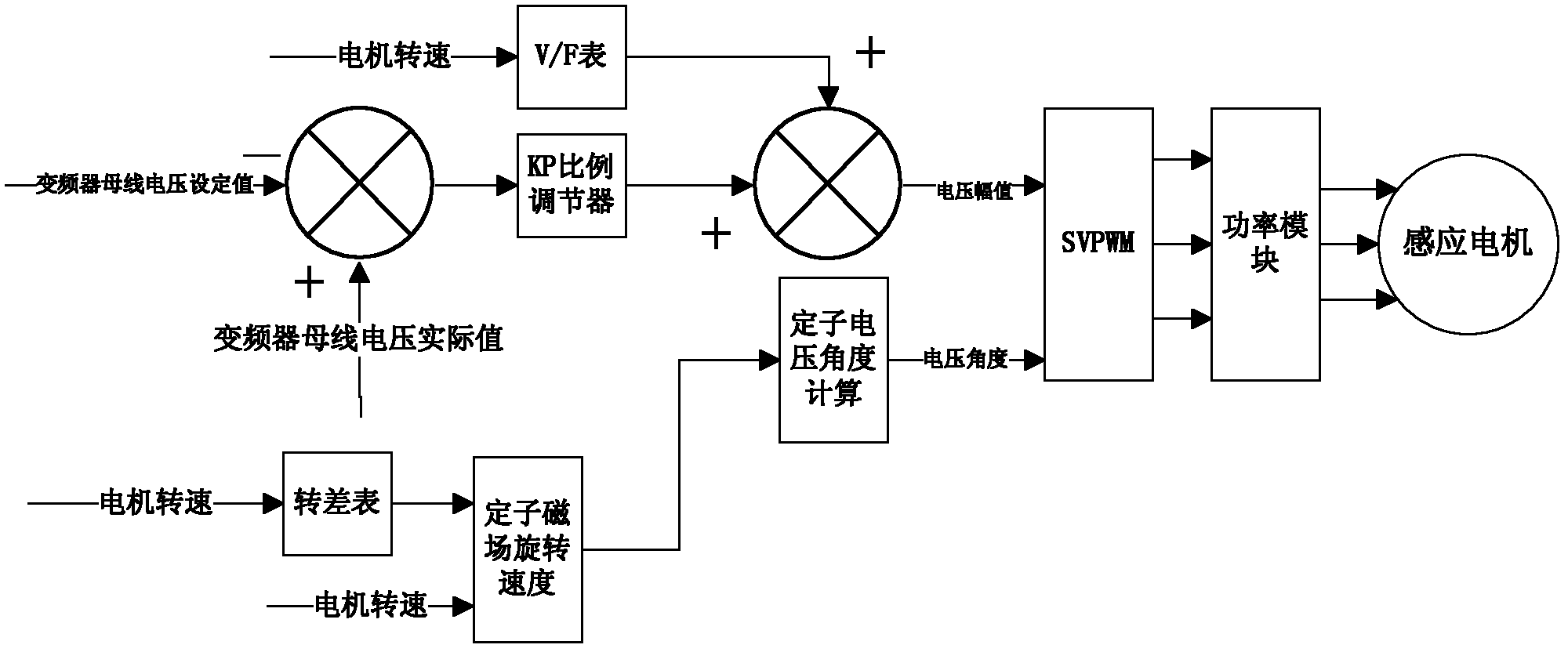

Brake control method for induction motor

ActiveCN102355175AGuaranteed braking performanceReduce bus voltageMotor/generator/converter stoppersDynamo-electric converter controlElectricityFrequency changer

The invention relates to a brake control method for a motor, in particular to the brake control method for an induction motor. The method is applied to a system consisting of an alternating current power supply, a frequency converter, the induction motor and a load. The control method comprises the following steps of: (1) determining voltage amplitude and a voltage angle during the braking of theinduction motor; and (2) controlling the output voltage of the frequency converter based on the determined voltage amplitude and the determined voltage angle, and automatically tracking the maximum braking torque of the induction motor on the premise of ensuring that the bus voltage of the frequency converter is constant or tends to be constant to ensure the braking performance of the induction motor. The braking of the induction motor under normal power supply and power failure conditions is met by adopting the same algorithm at the same time, so the algorithm is simplified.

Owner:WUXI ECOVI TECH

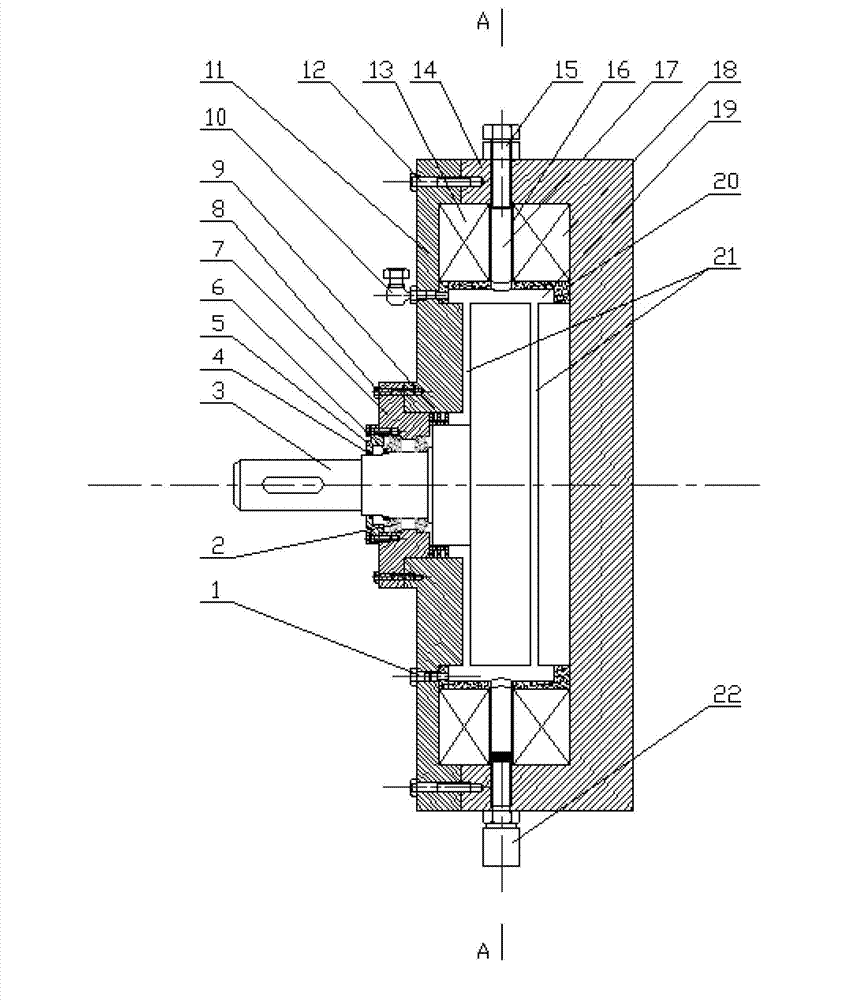

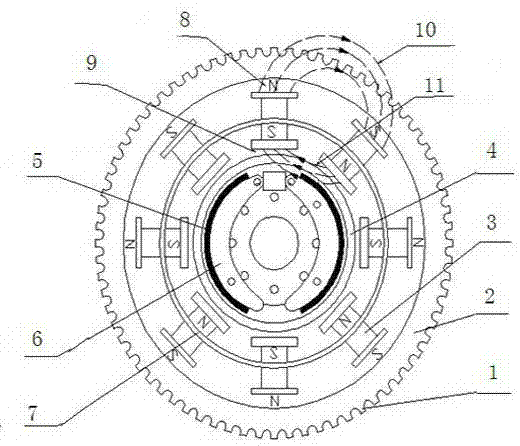

Electromechanical brake and automobile

ActiveCN102410324ALarge braking torqueReduce torqueBrake actuating mechanismsActuatorsElectric machineCalipers

The invention provides an electromechanical brake which comprises a braking disc (1), a friction plate (2), a braking caliper body (3) and a power mechanism, wherein the power mechanism can push the friction plate (2) to move forwards so as to clamp the braking disc (1); the power mechanism comprises a motor (12) and a moving mechanism which is connected with the output end of the motor (12); the moving mechanism can be used for converting the rotation movement of the motor into linear movement; the moving mechanism is arranged in the braking caliper body (3), wherein the power mechanism also comprises a torque increasing mechanism for amplifying output torque of the motor (12); the input end of the torque increasing mechanism is connected with the output end of the moving mechanism; and the output end of the torque increasing mechanism can come into contact with the friction plate (2). Accordingly, the invention provides an automobile which comprises the brake. The electromechanical brake provided by the invention has the advantages of small volume, simple structure, low cost, long service life and the like compared with the prior art.

Owner:CHERY AUTOMOBILE CO LTD

Self-excitation retarding device and control method thereof

ActiveCN104753310ACompact structureReduce volumeAssociation with control/drive circuitsMagnetic circuit stationary partsLow speedControl theory

The invention relates to a self-excitation retarding device and a control method thereof. The self-excitation retarding device comprises a stator assembly, a rotor assembly and a control assembly, the rotor assembly comprises an eddy current brake rotor and a power generator rotor, the stator assembly comprises a stator support, an eddy current brake stator iron core, a coil winding assembly and a power generator stator iron core, and the control assembly comprises a first solid state relay, a rectifier, a second solid state relay and a third solid state relay. The stators of a retarding and braking portion and a power generating portion are integrated highly, so that the self-excitation retarding device is compact in structure, and both size and mass are reduced to some extent; a power generator stranded wire and an eddy current brake stranded wire are directly connected, so that alternating current output by the power generator stranded wire can be directly fed into the eddy current brake stranded wire, and the self-excitation retarding device can output large braking moment when an automobile travels at a low speed.

Owner:山东大侨发展股份有限公司

Block duoble-directional overrunning clutch parking brake and manufacturing method thereof

InactiveCN1584357AIncrease the number ofSmall form factorBraking element arrangementsBraking membersMarine engineeringHardness

A parking brake is based on a roller external planetary bi-directional overrun brake. An external ring replaces external planetary block and heel. Wedges replace rollers. A fork controls wedges between the external and internal rings to go forward or backward or to stop. The both sides of the external ring are machined to be projected outwards at the portions engaged with the front and rear caps, of which the corresponding portions are machined to be recess for assembling with tight fit and being welded with low carbon steel electrodes with little annealed areas and hardness of HRC60 at its inner surface.

Owner:金仁成

Wet type multi-disc brake

InactiveCN104675887AStable working performanceIncrease working areaAxially engaging brakesBraking elementsBrake torqueDisc brake

The invention discloses a wet type multi-disc brake integrating functions of speed lowering, braking and parking. The wet type multi-disc brake which is mainly applicable to the harsh-condition and inconvenient-to-maintain brake systems of various machines is characterized in that parts are mounted by using a shell as a base, the brake is fixed by the connection of a stud and an axle, and a drive wheel is connected with a hub through a connecting bolt to synchronously rotate with car wheels; each friction plate working cavity is a sealed cavity which can effectively deal with external harsh work conditions, circulation cooling oil is fed into the sealed cavity, temperature rise can be lowered effectively, consumption is reduced, stable work performance is achieved, slight abrasion is achieved, and adjustment is generally not needed during use; each friction plate is annular and large in working area, the multi-disc structure is used, and large brake torque can be obtained under small gasket pressure; the brake torque can be adjusted by changing the number of friction pairs, and friction pair standardization can be achieved easily; good radiating and cooling effect, low working temperature and long service life are achieved, and the service life of the wet type multi-disc brake is generally 3-5 times of that of a dry type brake.

Owner:JIAOZUO JINGU BRAKE INC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com