Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

445 results about "Air brake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An air brake or, more formally, a compressed air brake system, is a type of friction brake for vehicles in which compressed air pressing on a piston is used to apply the pressure to the brake pad needed to stop the vehicle. Air brakes are used in large heavy vehicles, particularly those having multiple trailers which must be linked into the brake system, such as trucks, buses, trailers, and semi-trailers, in addition to their use in railroad trains. George Westinghouse first developed air brakes for use in railway service. He patented a safer air brake on March 5, 1872. Westinghouse made numerous alterations to improve his air pressured brake invention, which led to various forms of the automatic brake. In the early 20th century, after its advantages were proven in railway use, it was adopted by manufacturers of trucks and heavy road vehicles.

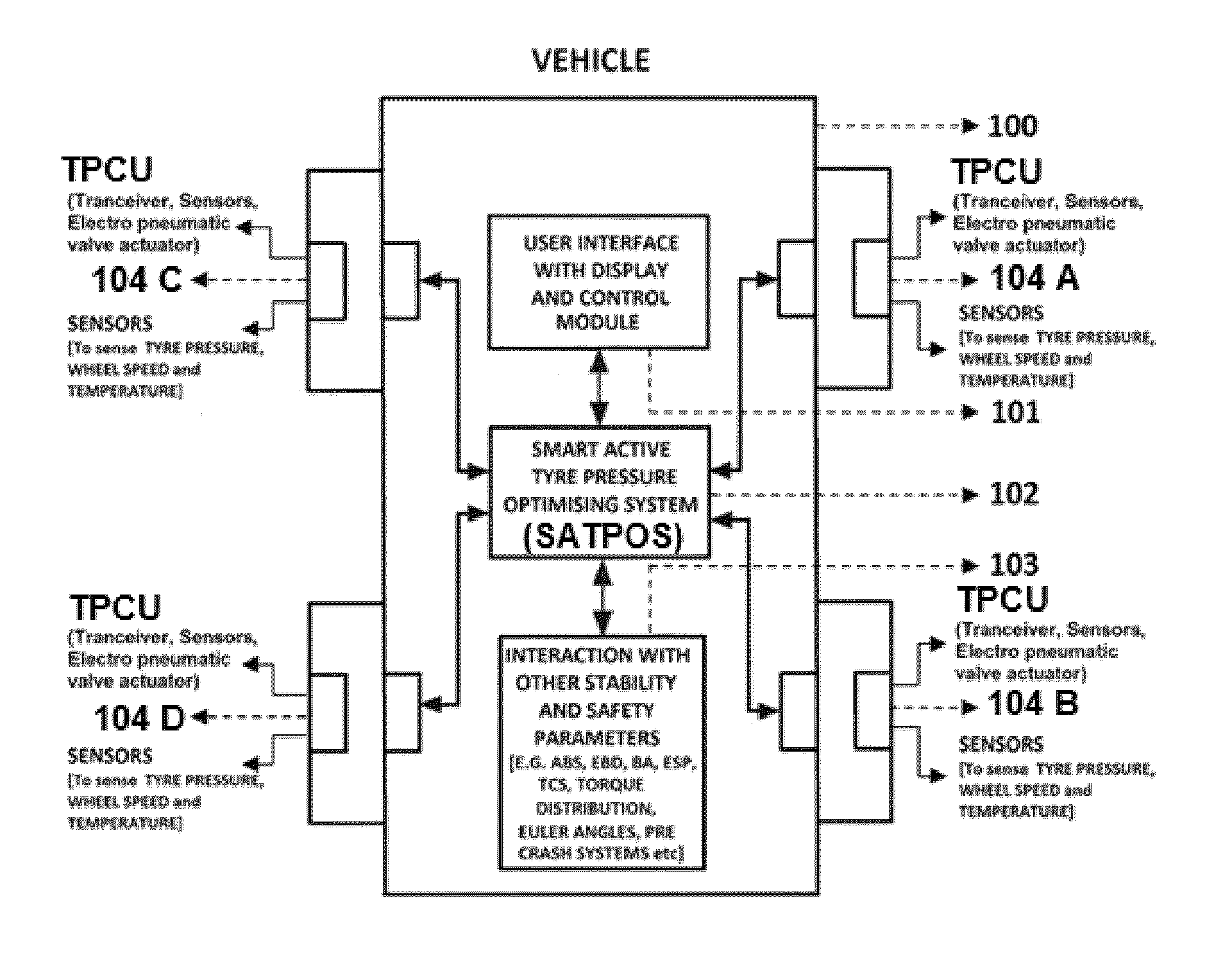

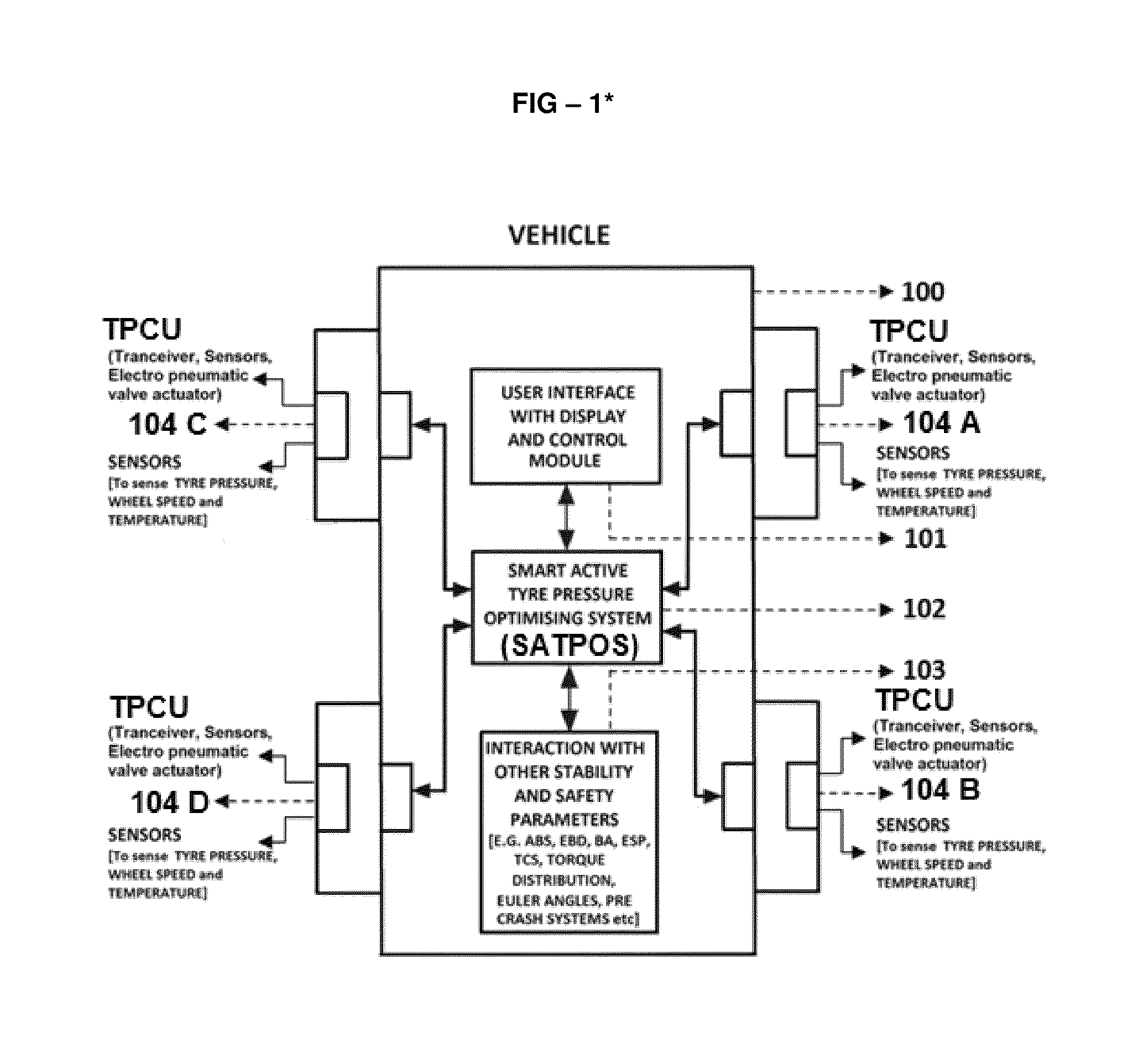

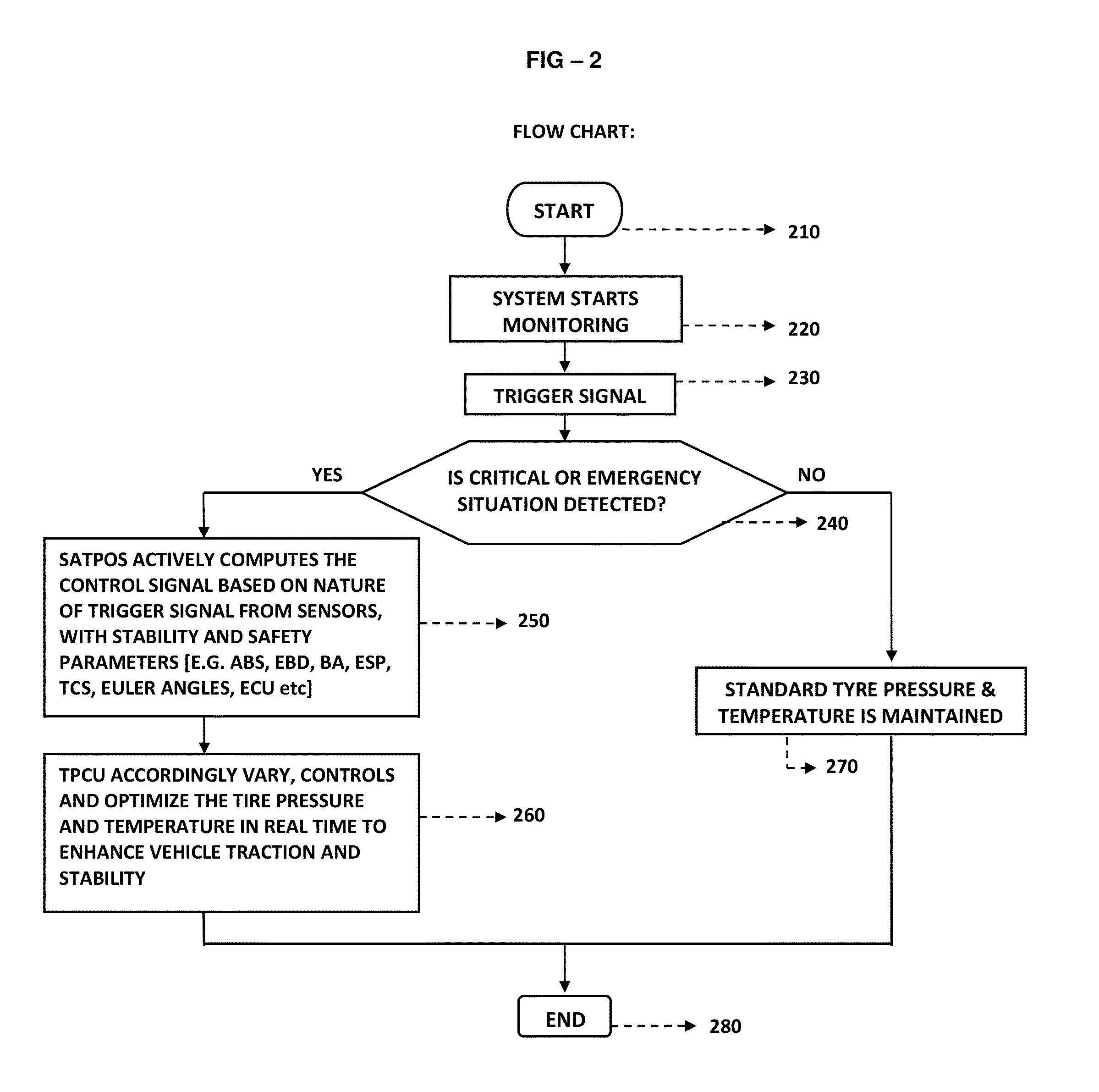

Smart active tyre pressure optimising system

ActiveUS20150005982A1Improve stabilityGreat tractionBraking element arrangementsInflated body pressure measurementSafe drivingMoisture

Smart Active Tyre Pressure Optimising System [TPOS]102 is a highly time sensitive design and technique that acts instantaneously in sensing and controlling the tire pressure particularly in imminent and inevitable critical driving situations to reduce emergency & high speed breaking distance, mitigate—loss of traction, hydroplaning, roll over, loss of stability, over & under steering, break failure, loss of control due to puncture by smartly sensing, perform context aware computing and directing the Tyre Pressure Control Units [TPCU]104 to instantaneously control the tyre pressure in right time with right pressure on right tyres thereby actively controlling the footprint and sidewall deformation rate to enhance traction & stability simultaneously sustaining drivability or steerability ultimately to avoid or reduce the impact of collusion and overcome or mitigate critical situations for protecting the vehicles, occupants, pedestrians and other objects around or on the way; also according to design, configurations and scenarios the system instantaneously optimises the tyre pressure on all tyres for further safe driving till next restoration else restores the pressure to optimum preset value utilising inbuilt reservoir or other external restoration systems immediately after the vehicle overcomes the critical situation to continue with safe and comfortable driving. In critical situations TPOS performs sensing, pre computing, current computing for controlling the tire pressure during critical situation, post computing to optimise tire pressure after overcoming accordingly. TPOS 102 utilise smart and adaptive closed loop processing algorithm with predetermined and tested lookup table to instantaneously check and compare the effects between predetermined and tested real world scenarios to the actual real world scenarios for actively sensing, computing and controlling the tire pressure accordingly to mitigate the critical situations. The controlling of tyre pressure is computed mainly based on parameters comprising of sensor system, vehicle safety and stability systems, nature of breaking & break force distribution, tires upper & lower cut-off pressure values, sensing reservoirs and tires internal & external pressure, temperature, moisture, humidity, wheel & tire specifications, vehicle & wheel speed, acceleration & deceleration, vehicle orientation & axial rotation, transverse motion & lateral acceleration, tires position or angle of attack, load & torque distribution, tire traction, steering position, cornering effects, change in Centre of gravity, over & under steering, hydroplaning, sensing road conditions, etc and to further enhance the efficiency, the system interoperates with vehicles existing safety and stability systems like ABS, EBD, ESC, TCS, Rollover mitigation systems, ECU, BA, Precrash systems, suspension & vertical dynamics, radar assisted auto breaking, cruise control system, aerodynamics & airbrakes etc. Other aspects of present invention are controlling the tire temperature according to environmental temperature, moisture and humidity thereby to enhance traction and vary tire pressure according to change in centre of gravity & load, driving modes—comfort, standard and sports modes.

Owner:MUTHUKUMAR PRASAD

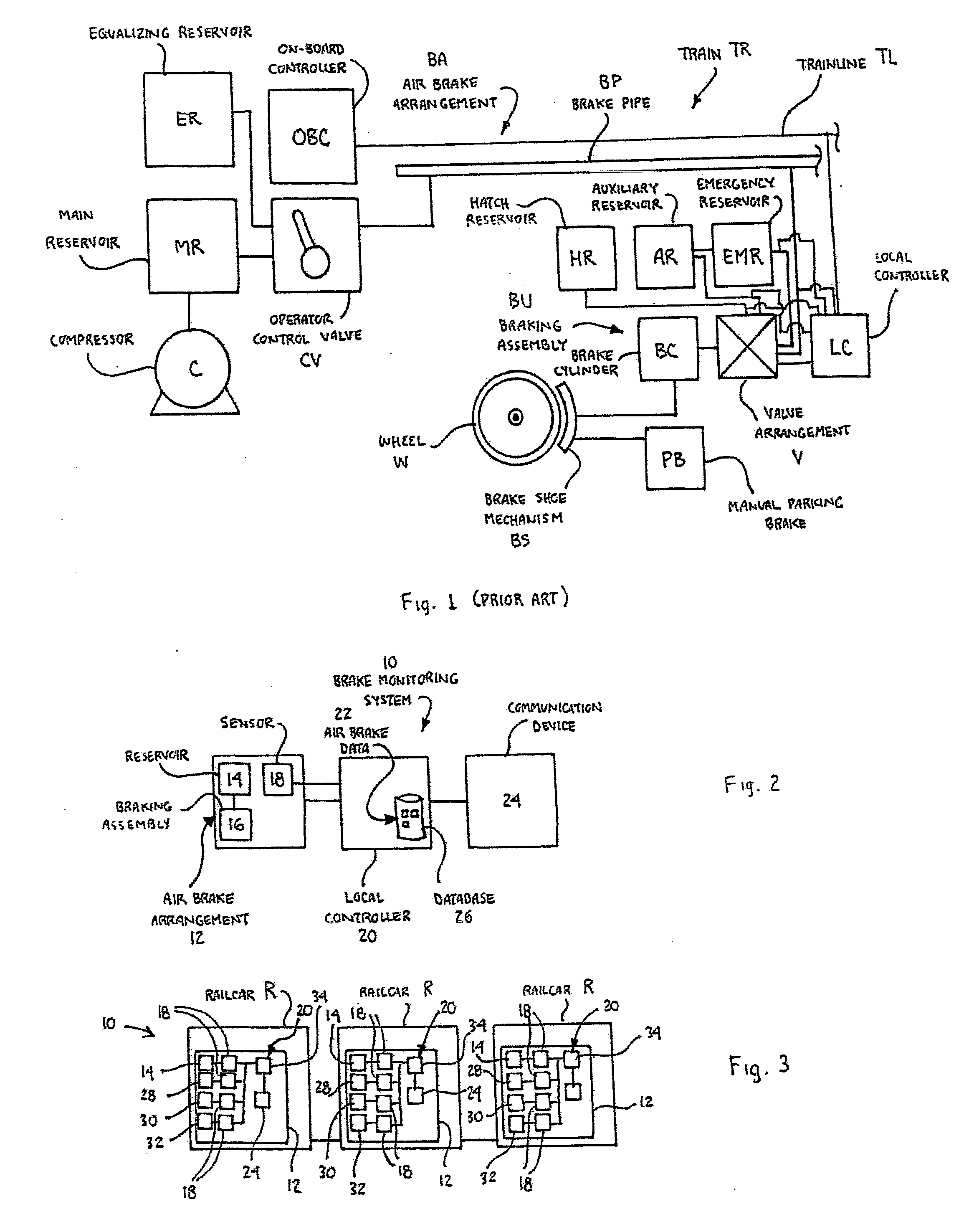

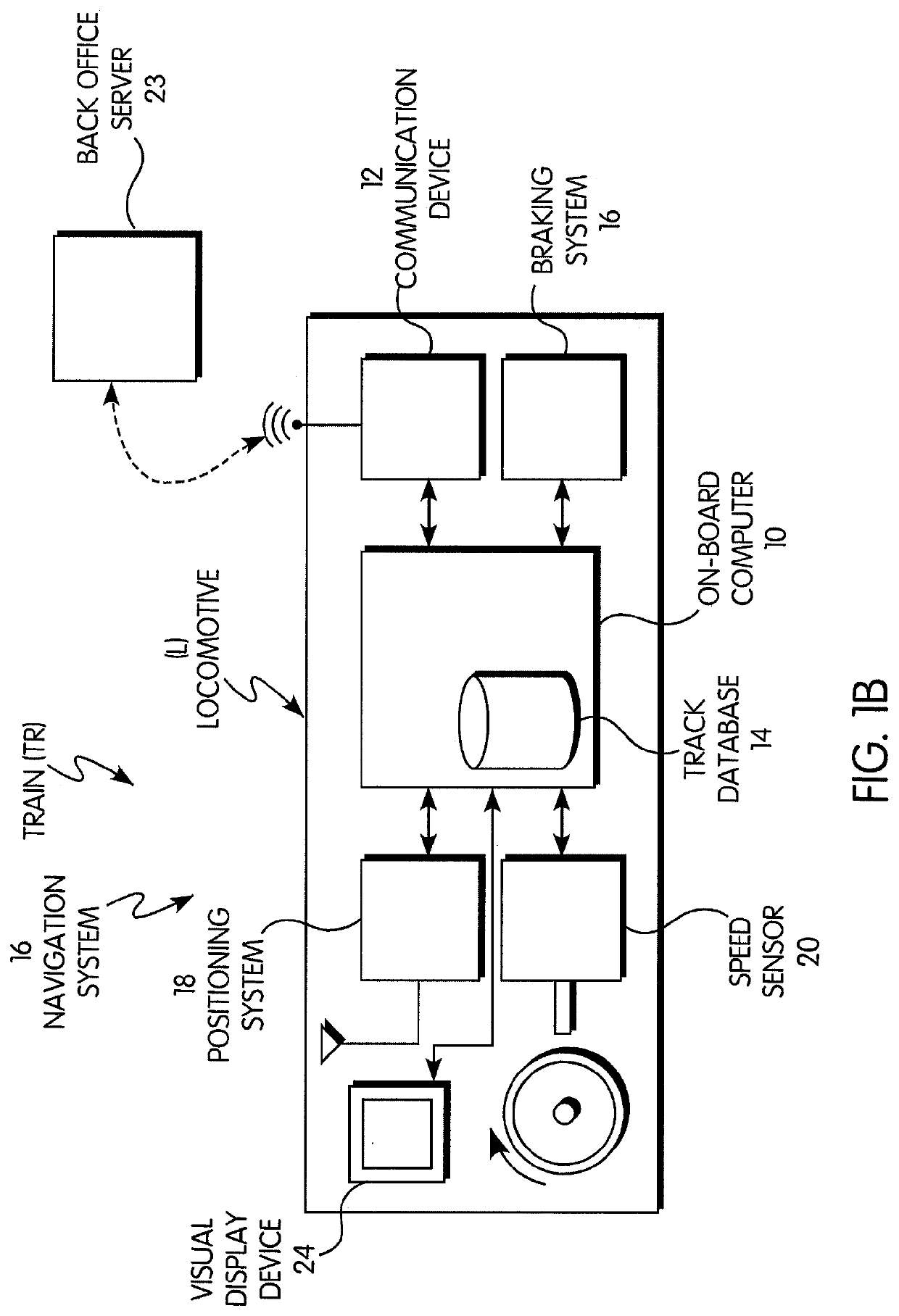

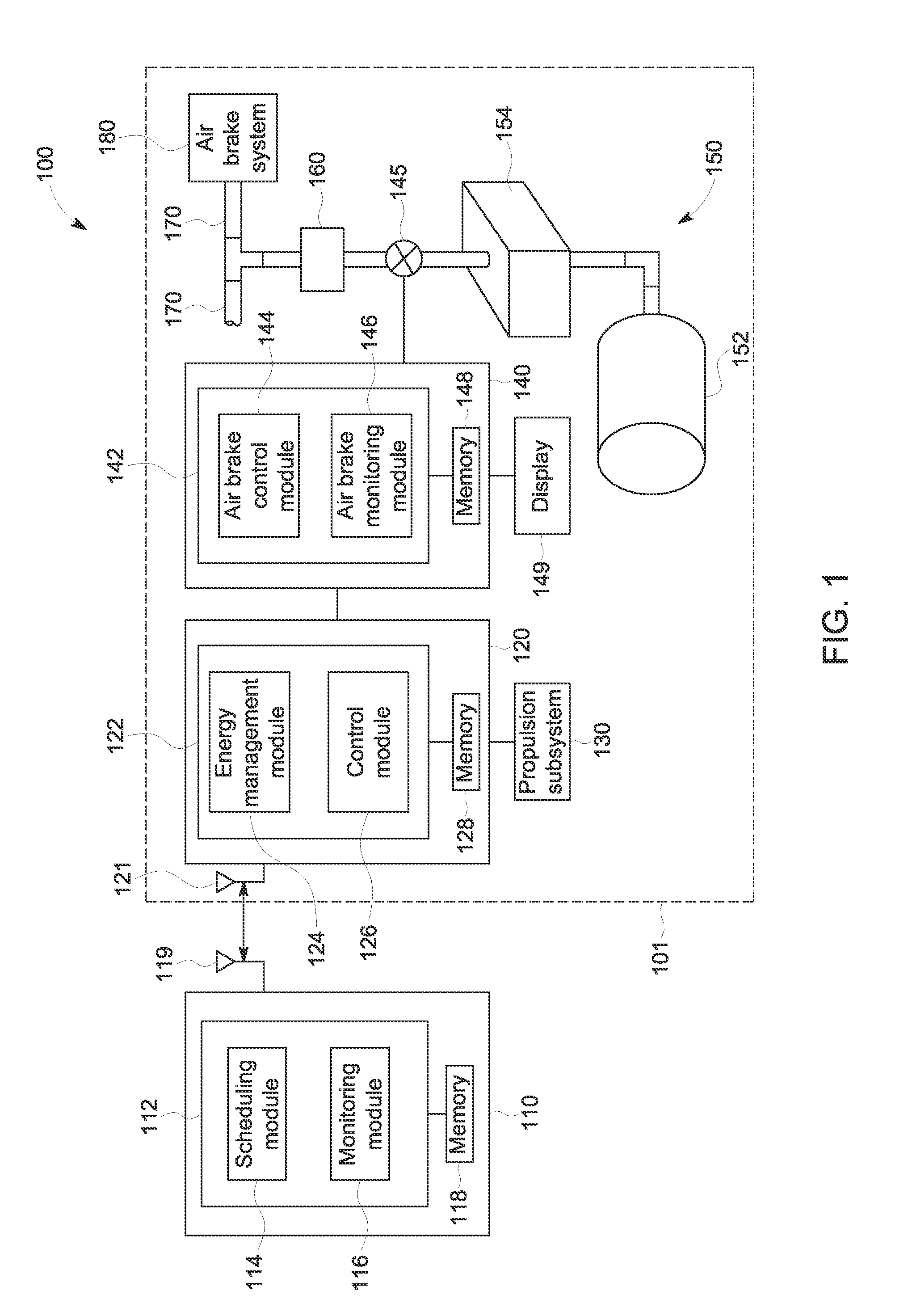

Brake Monitoring System for an Air Brake Arrangement

A brake monitoring system for an air brake arrangement including: at least one sensor to measure air pressure in at least one component of an air brake arrangement; at least one local controller to determine air brake data; and at least one communication device to transmit at least a portion of the air brake. An air brake arrangement and a computer-implemented method of determining air brake data in an air brake arrangement are also disclosed.

Owner:WABTEC HLDG CORP

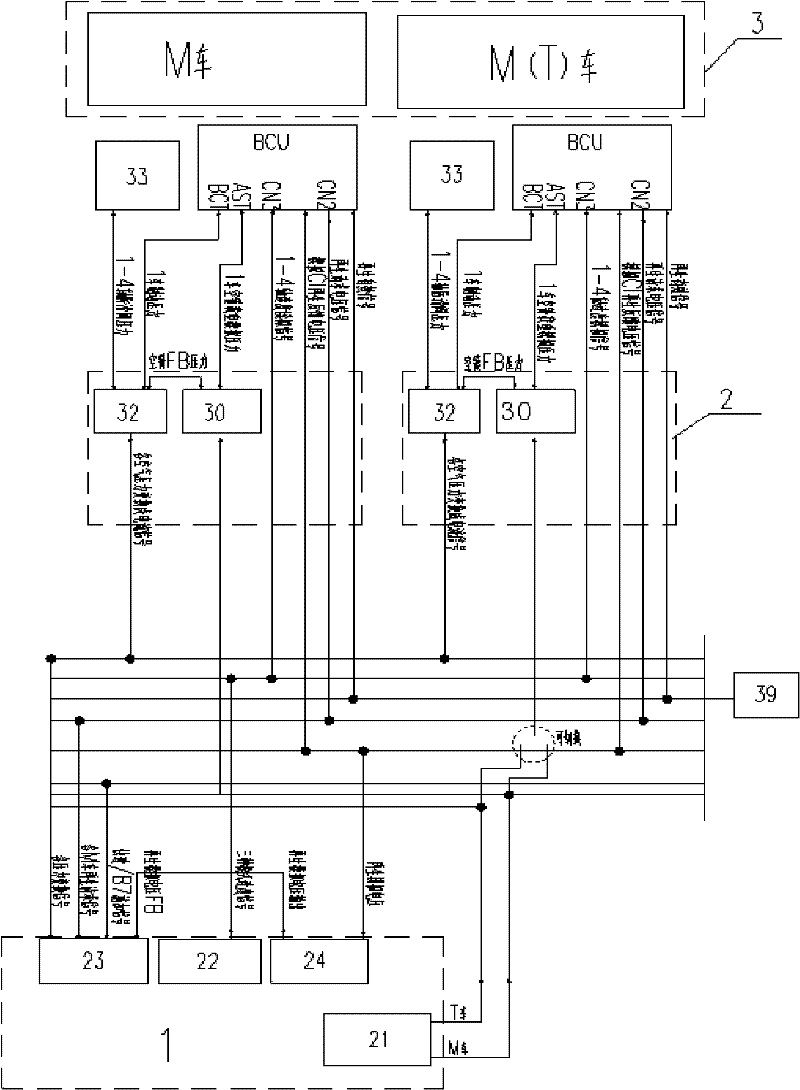

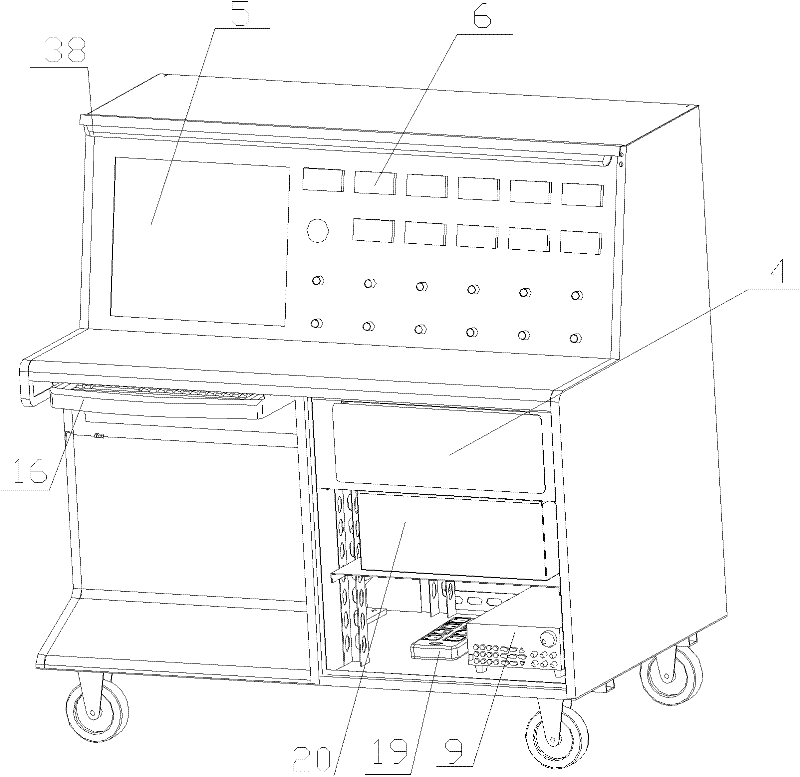

Method and system for testing brake of high-speed motor train unit

The invention relates to a method and a system for testing the brake of a high-speed motor train unit. The method comprises the following steps of: in a stationary state of a motor train unit, simulating various speed signals, train air spring load signals and regeneration brake analog signals by utilizing the testing system; after various analog signals are received by the motor train unit, applying a brake action by a train brake system, and outputting brake information; and acquiring and analyzing brake information data and judging whether the design requirements for various performance indexes of the brake system are met. According to the method and the system, in the stationary state of the motor train unit, various performance indexes of the motor train unit brake system can be comprehensively and effectively tested through simulating the train speed signals and the train air spring load signals, wherein the performance indexes comprise brake response time of the motor train unit, logic motions of an anti-slip system, regenerated brake feedback, air brake, sequential coordination control of regenerated brake, and the like, so that intensive study of complete train debugging key technologies of the motor train unit is realized so as to achieve the purpose of all-around high-precision analogue simulation of the test of the brake system.

Owner:CHINA RAILWAYS CORPORATION +1

Brake system of CRH (China railway high-speed) and brake method thereof

ActiveCN106080217AImprove maintainabilityImprove economyBraking action transmissionElectrodynamic brake systemsBraking systemArresting gear

The invention provides a brake system of CRH (China railway high-speed) and a brake method thereof. The brake system of the CRH comprises brake instruction equipment, a brake control unit, a basic brake device, a power brake device, and an air source device, wherein the brake instruction equipment is used for sending out a brake instruction; the brake control unit is used for receiving the brake instruction, and distributing the brake power; the basic brake device is used for executing the air brake; the power brake device is used for executing the non-friction brake; the air source device is used for providing compressed air for the brake system and other air utilization equipment. The brake method is used for the brake system of the CRH. The brake control method has the advantages that by favorably distributing the brake force, when the power brake of the CRH is sufficiently utilized, and the air brake distribution of the CRH and a trailer is also performed; by properly setting the numbers of basic brake devices of CRH and trailer in the brake system, the brake force which is applied to each set of basic brake device is uniform; the overhauling, maintenance and economy of basic brake are favorably realized.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

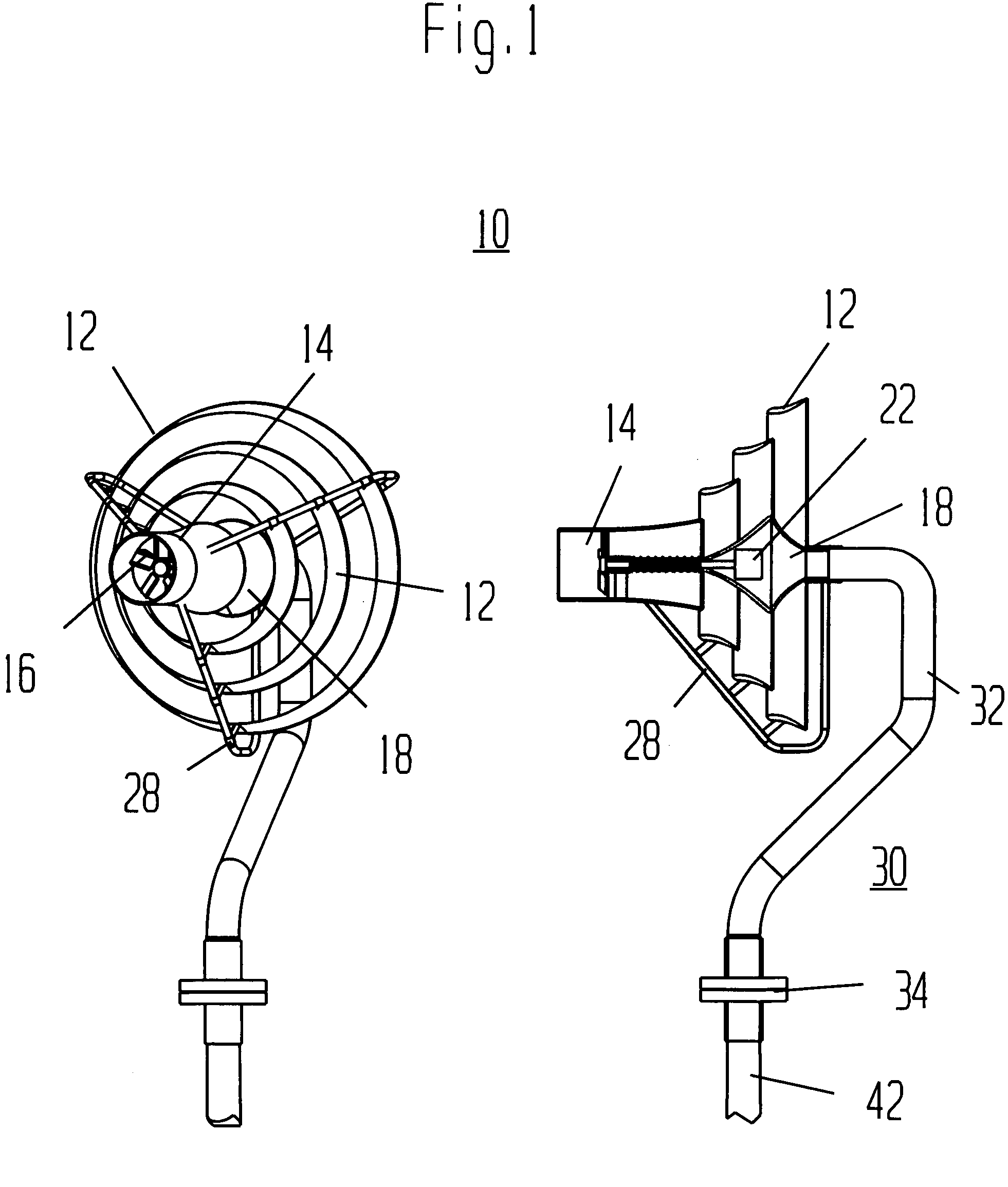

Habitat friendly, multiple impellor, wind energy extraction

ActiveUS20050207881A1Prevent speedingWind motor controlWind energy generationGuidance systemImpeller

A habitat friendly, pressure conversion, wind energy extraction system is disclosed for safely extracting usable energy from wind. The invention includes one or more shrouds or concentrator wings that convert the dynamic pressure of wind into relatively lower static pressure and thereby induces a vacuum that draws wind into a turbine centralized within the shrouds or concentrator wings. As such, the turbine impellor blades may be significantly smaller than the large diameter rotor blades of current popular designs and may be enclosed within the shrouds or concentrator wings that present themselves as highly visible objects and as such are easily avoided by birds in flight. The invention in particular includes a device and method of airflow regulation than minimizes or prevents the stalling, or the generation of a turbulent flow of wind over or between the shrouds or concentrator wings of the invention. This stalling has been shown to occur when airflow is quickly accelerated by force of vacuum and drawn out of the turbine shroud which then mixes with and disturbs the otherwise smooth flow of wind over or between the shrouds or concentrator wings. The system may also include an aerobrake that responds quickly to protect the impellor blades or associated mechanisms from overspeeding or exceeding other design limitations under gusting or violent wind conditions. The invention may also include several other novel features such as power converters for extending the impellor or impellors into the free flowing accelerated wind, an aerobrake to protect the impellor from overspeeding, and two novel forms of into-wind guidance systems. Other advantages and objects are as well disclosed that increase safety and wind energy extraction efficiency and allow the invention to be effectively installed within urban settings.

Owner:TOCHER ANGUS J

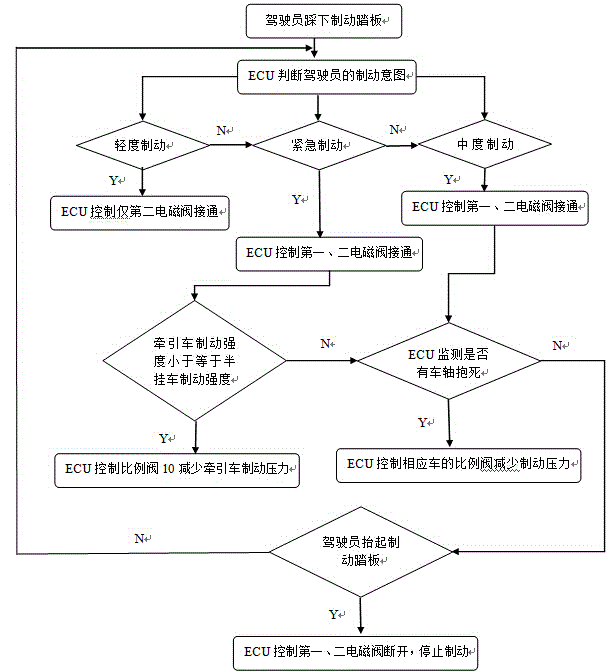

Brake control system and method for semi-trailer train

InactiveCN104875732APrevent dangerous working conditions such as "folding"Improved braking stabilityBraking systemsAir brakeSemi-trailer

The invention relates to the field of a semi-trailer train, in particular to a brake control system and method for the semi-trailer train. The brake control system for the semi-trailer train comprises an air braking system, a controller ECU (Electronic Control Unit) and a vehicle condition monitoring system; the air braking system comprises an energy supply module, a tractor braking module and a trailer braking module; the energy supply module comprises an air compressor, a standby air source, a pressure regulating valve and a three-loop protection valve; the tractor braking module comprises a tractor front-axis gas storage barrel, a tractor rear-axis air storage barrel; a brake proportional valve, a first two-position two-way electromagnetic valve, a tractor front-axis brake air chamber, a tractor rear-axis brake air chamber, a first air pressure sensor and a second air pressure sensor; the trailer braking module comprises a trailer air storage barrel, a second two-position two-way electromagnetic valve, an electrical control proportional valve, a trailer brake air chamber and a third air pressure sensor. According to the system, a braking pressure on a tractor and a trailer is regulated in real time; meanwhile, the problem of delay of trailer braking is solved; brake safety of the semi-trailer train is improved.

Owner:JIANGSU UNIV

Relay valve control method and device in hill starting process and air braking system

ActiveCN103213575AAchieve a normal startPrevent rollingBraking action transmissionRelay valveHigh pressure

The invention discloses a relay valve control method and device in a hill starting process and an air braking system. The method comprises the following steps of: acquiring a clutch pedal position signal and a speed signal; judging that a vehicle is in an anti-slip braking state when a clutch pedal is in the lowest position and the speed of the vehicle is zero, or judging that the vehicle is in an anti-slip braking releasing state when the clutch pedal is not in the lowest position and / or the speed of the vehicle is not zero; and when the vehicle is in the anti-slip braking state, instantly inputting high pressure control gas to a control gas inlet to a relay valve to realize the anti-slip braking of the vehicle, when the vehicle is in the anti-slip braking releasing state, stopping inputting high-pressure control gas to the control gas inlet to the relay valve to release the anti-slip braking of the vehicle, or when the vehicle is switched to the anti-slip braking releasing state from the anti-slip braking state, stopping inputting high-pressure control gas to the control gas inlet to the relay valve after delaying setting time so as to release the anti-slip braking of the vehicle. The control method provided by the invention is simple, and the performance demand on the control device is low.

Owner:ZHENGZHOU YUTONG BUS CO LTD

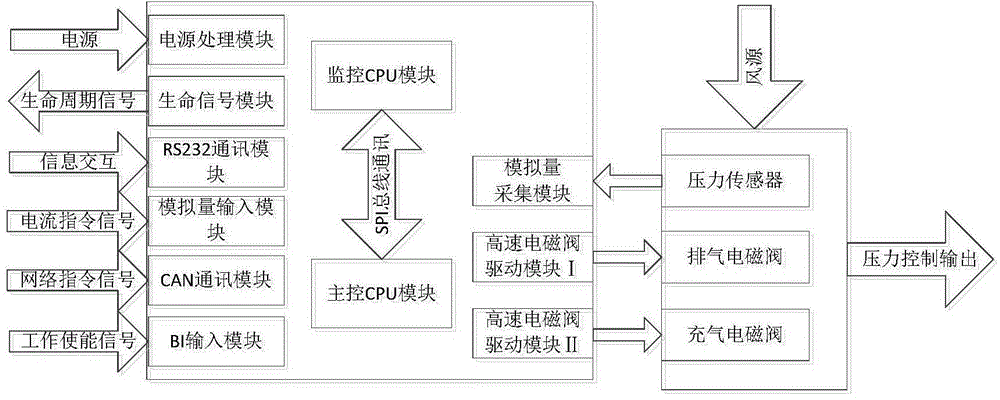

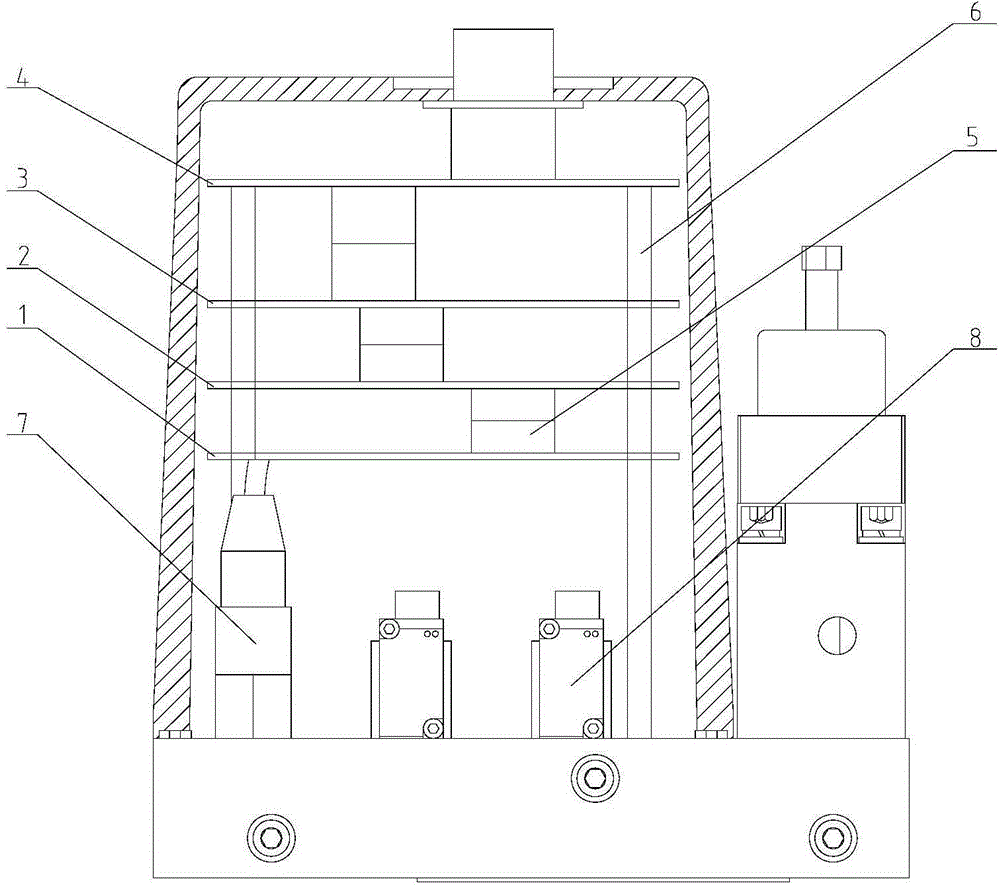

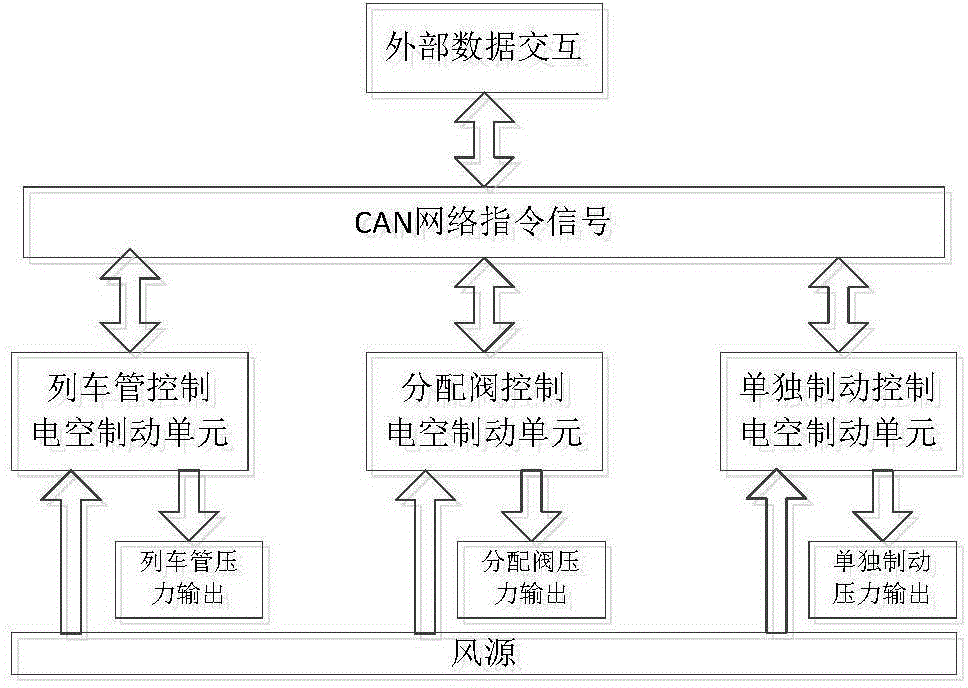

Microcontroller control electro-pneumatic brake unit for locomotive brake systems

ActiveCN104627201AImprove stabilityImprove module interchange rateRailway hydrostatic brakesRailway hydrodynamic brakesMicrocontrollerArea network

The invention relates to a microcontroller control electro-pneumatic brake unit for locomotive brake systems and aims to achieve conversion of electrical signals of a locomotive brake system and an air brake pressure signal. The microcontroller control electro-pneumatic brake unit comprises an air circuit portion and an electrical portion; the air circuit portion mainly comprises an intake electromagnetic valve, an exhaust electromagnetic valve and a pressure sensor. The electrical portion mainly comprises a life signal module, an RS232 communication module, an analog input module, a CAN (controlled area network) communication module, a BI (batch input) module, a master control CPU (central processing unit) module, a monitoring CPU module, a high-speed electromagnetic valve drive module, an analog acquiring module and a power processing module powering the modules above. The electro-pneumatic brake units in a brake control system can automatically control train tubes, distributor valves and independent brake pressures, separately, automatically in response to control commands of the electro-pneumatic brake units, the stability of the brake control system is improved, and fault rate is decreased.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST +1

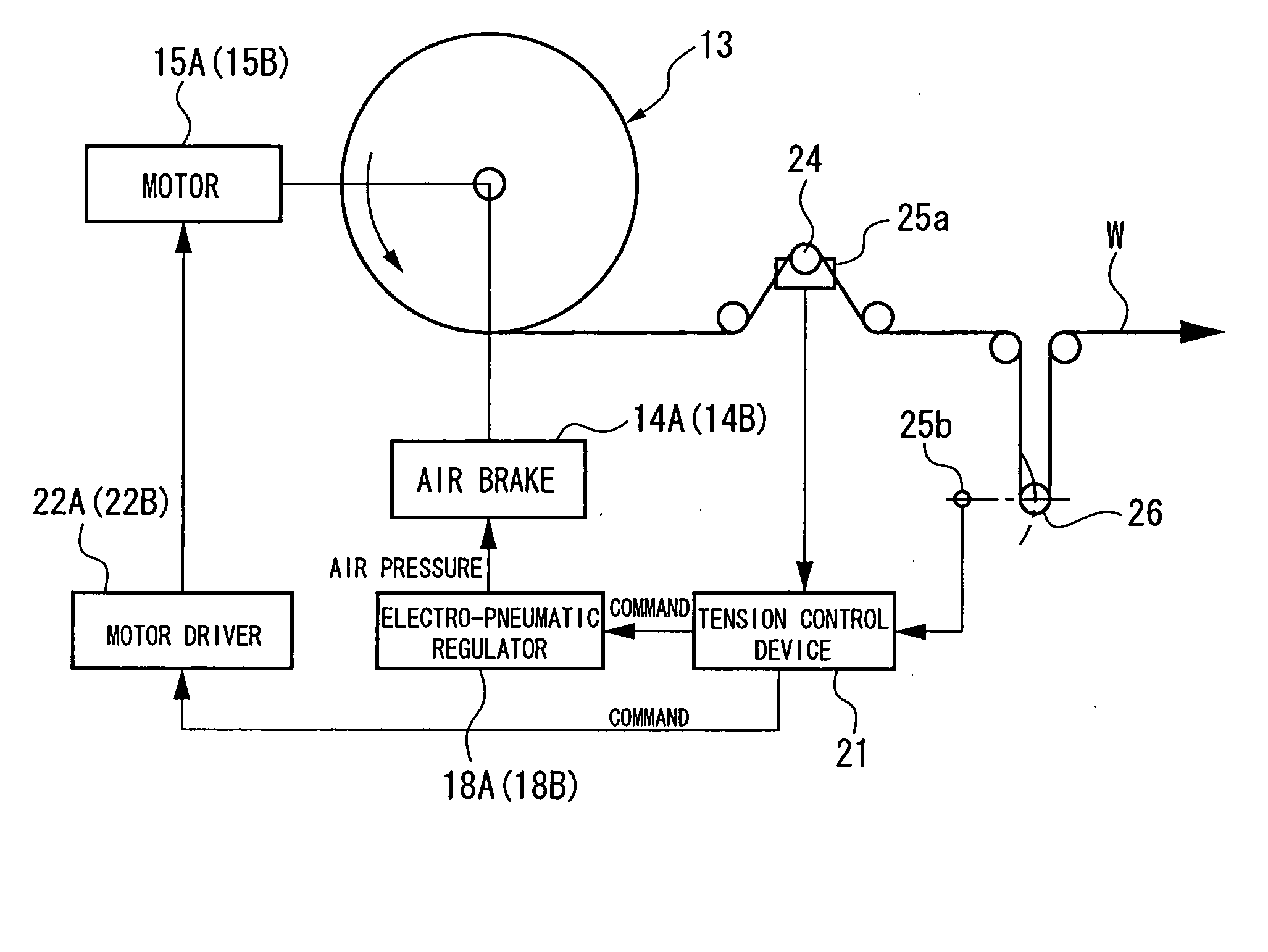

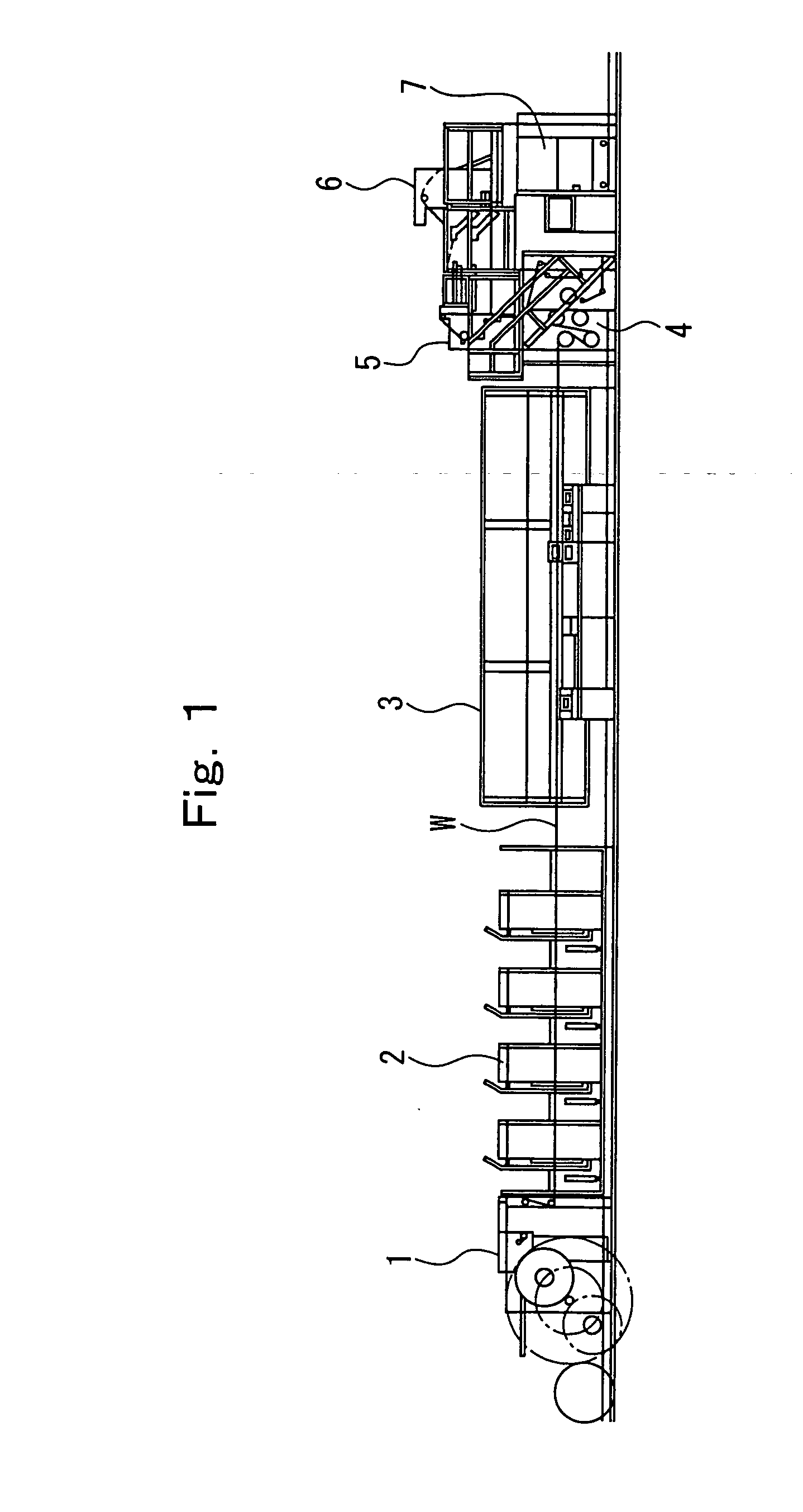

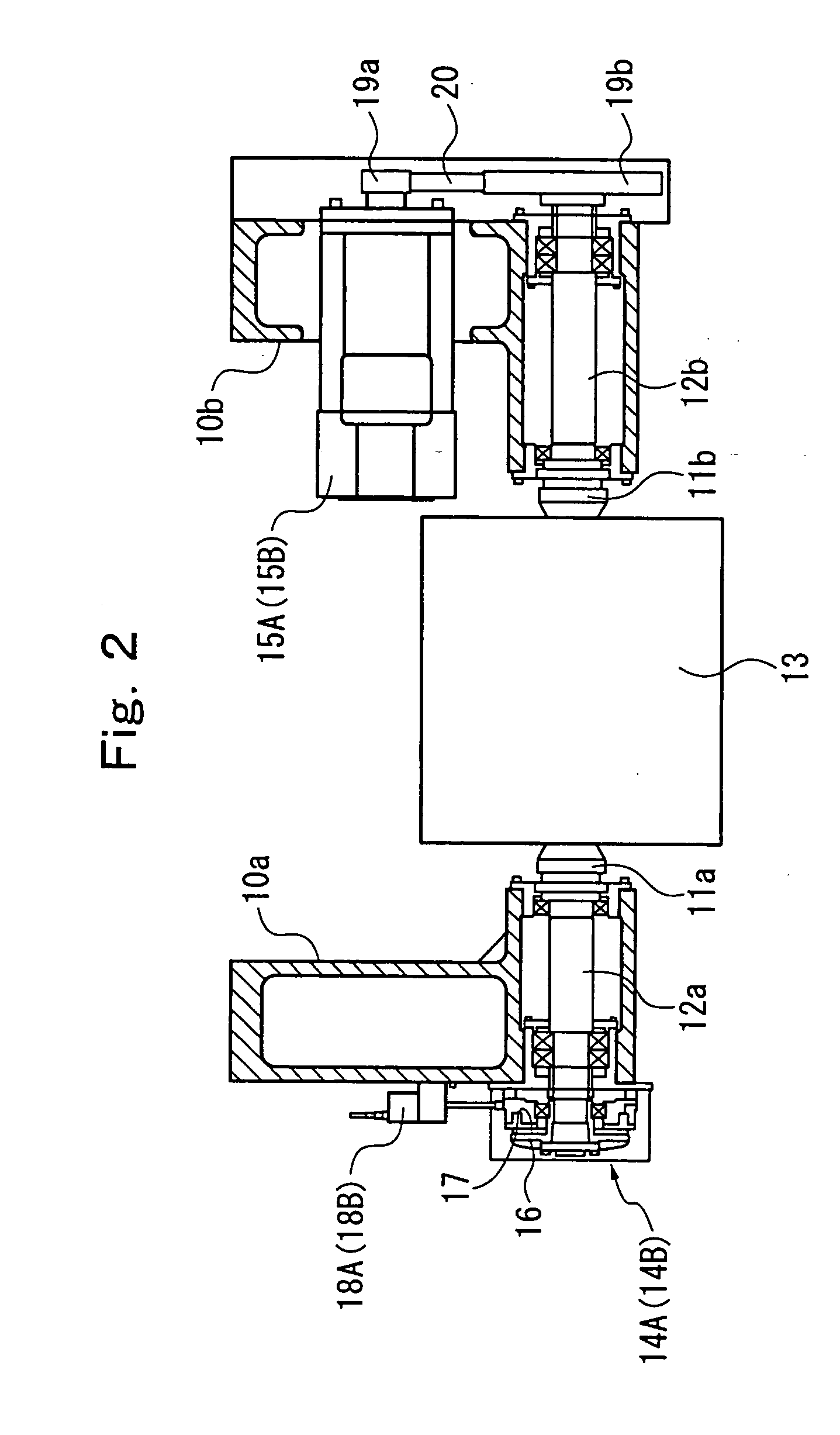

Braking force control method and device for strip-shaped material feeding device

InactiveUS20050242224A1Imposing burdenHigh accuracy braking force control satisfactorilyFilament handlingWebs handlingAir brakeControl theory

In a feeding device comprising turret arms having spindle shafts for supporting a web roll, an air brake for applying a braking force in a rotating direction to the spindle shafts, and an accelerating motor for applying a drive force in the rotating direction to the spindle shafts and a braking force in the rotating direction to the spindle shafts, a braking force control device has a tension control device which exercises control such that if a braking force required for the spindle shafts is lower than a constant value, only the braking force from the accelerating motor is supplied to the spindle shafts, and that if the braking force required for the spindle shafts is higher than the constant value, the braking force from the accelerating motor is supplied to the spindle shafts, and the braking force of the air brake is supplied to the spindle shafts.

Owner:KOMORI CORP

Vehicle emulator system

ActiveUS20200189635A1Reduce cost riskAccelerated trainingCosmonautic condition simulationsRailway traffic control systemsControl signalAir brake

A vehicle control signal generator includes emulation circuitry for emulating at least one operation of at least one vehicle control circuit. The emulation circuitry is programmed or configured to determine or receive user input and based at least partially on the user input, generate at least one control signal for controlling at least one of the following onboard vehicle subsystems: a propulsion system, a train line control system, an air brake system, a dynamic braking system, a head of train (HOT) system, an end of train telemetry (EOT) system, a 4-Aspect cab signaling system, a positive train control (PTC) system, an event recorder system, or any combination thereof.

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

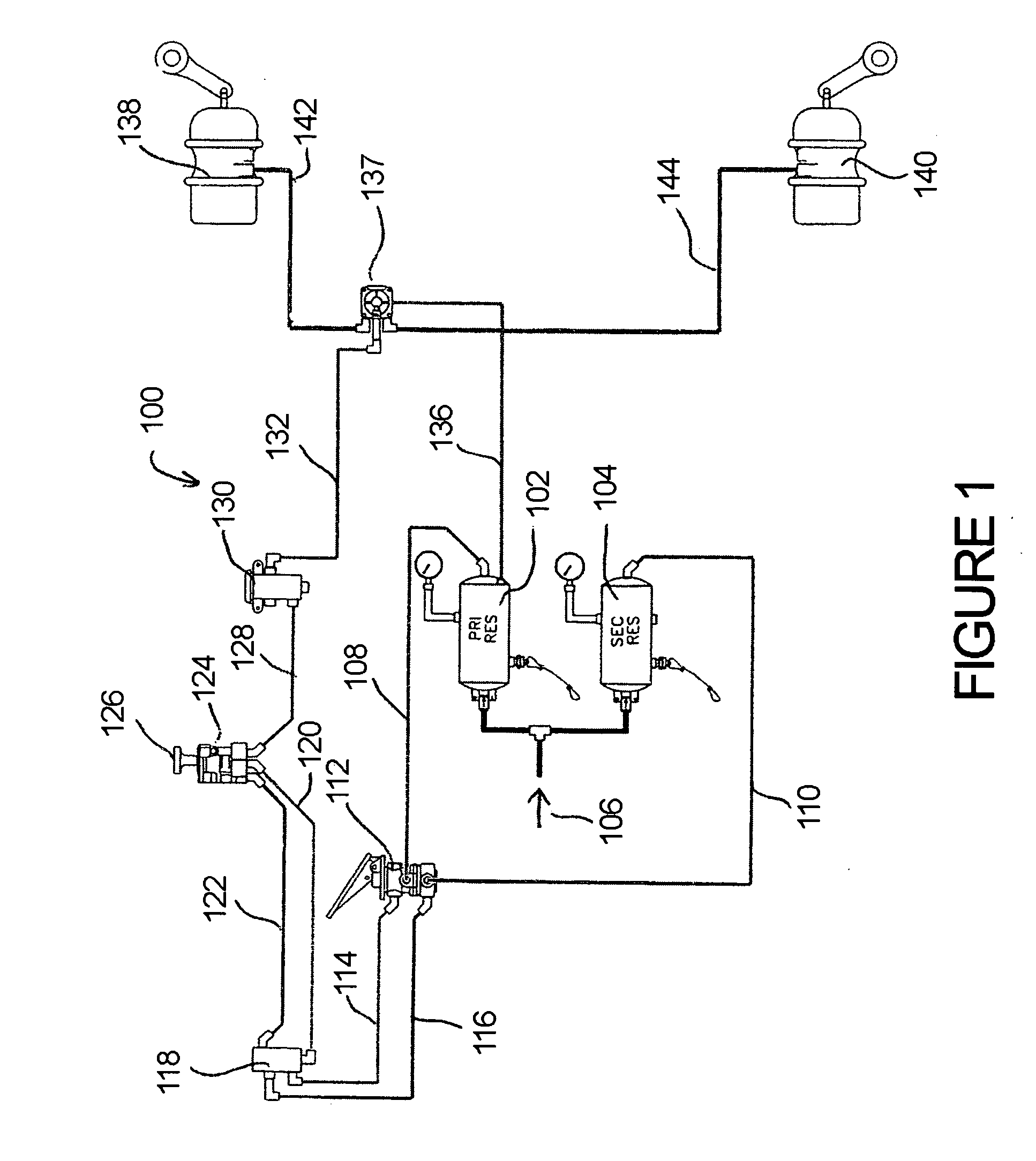

Modular electronic brake valve for air brakes vehicles

ActiveUS20060284480A1Avoid easy installationInstalled relatively quicklyServomotor componentsApplication and release valvesAir brakeEngineering

A vehicle brake system includes a source of fluid pressure adapted to supply a braking force to at least one brake actuator and a modular valve unit fluidly coupling the brake actuator to the source of fluid pressure. The modular valve unit includes a plurality of valve modules. Each of the plurality of valve modules includes a housing in which working elements of the valve module are contained and at least one port in the housing adapted to be an input port or an output port, the at least one port being adapted to cooperate with and be directly fluidly connected to at least one port of another of the plurality of valve modules, thereby obviating the need for tubing or piping. Each of the plurality of valve modules is self-contained and defines a stand-alone unit capable of operating independently of any other of the plurality of valve modules.

Owner:HALDEX BRAKE

Engineering maintenance vehicle traction force and brake force control method and system

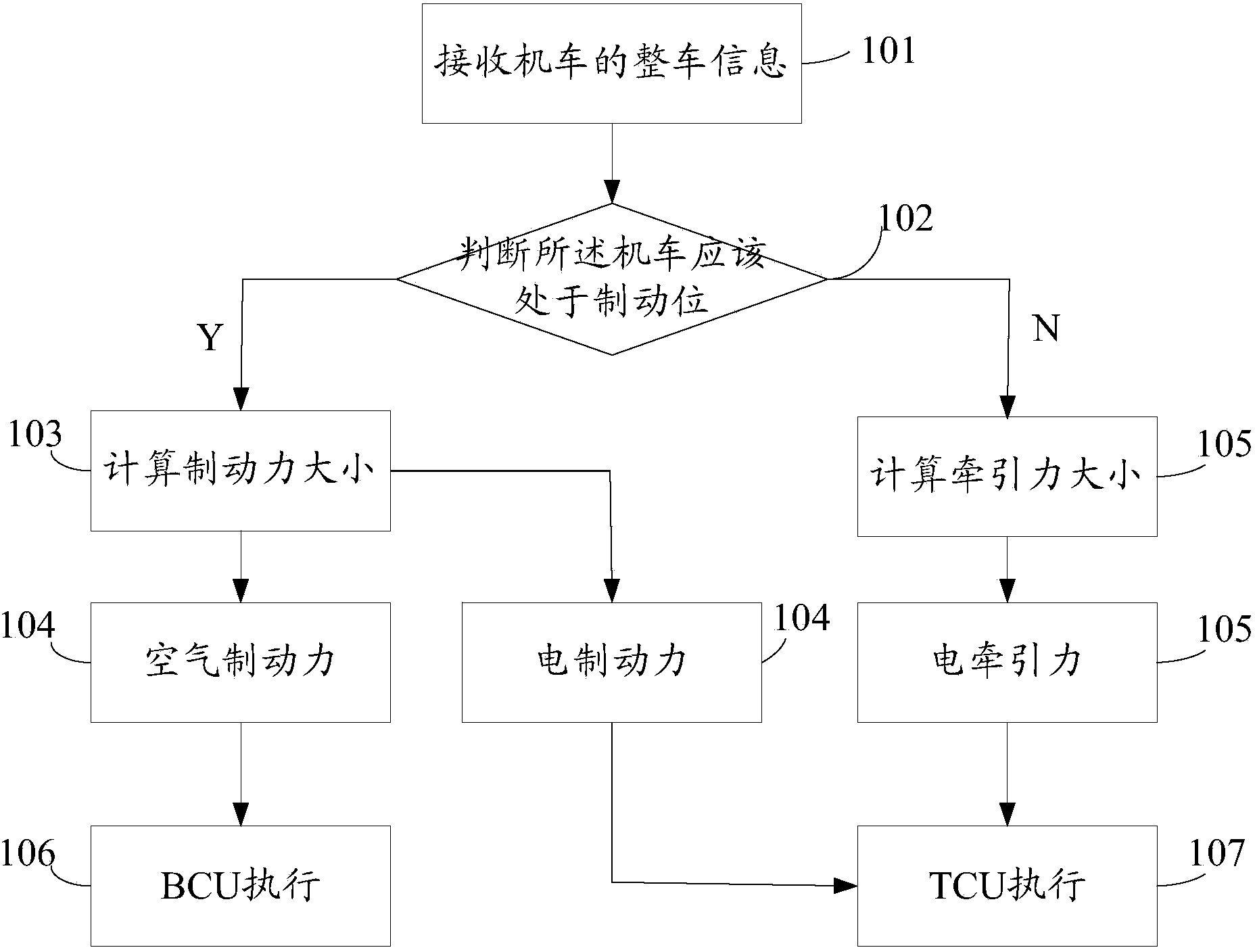

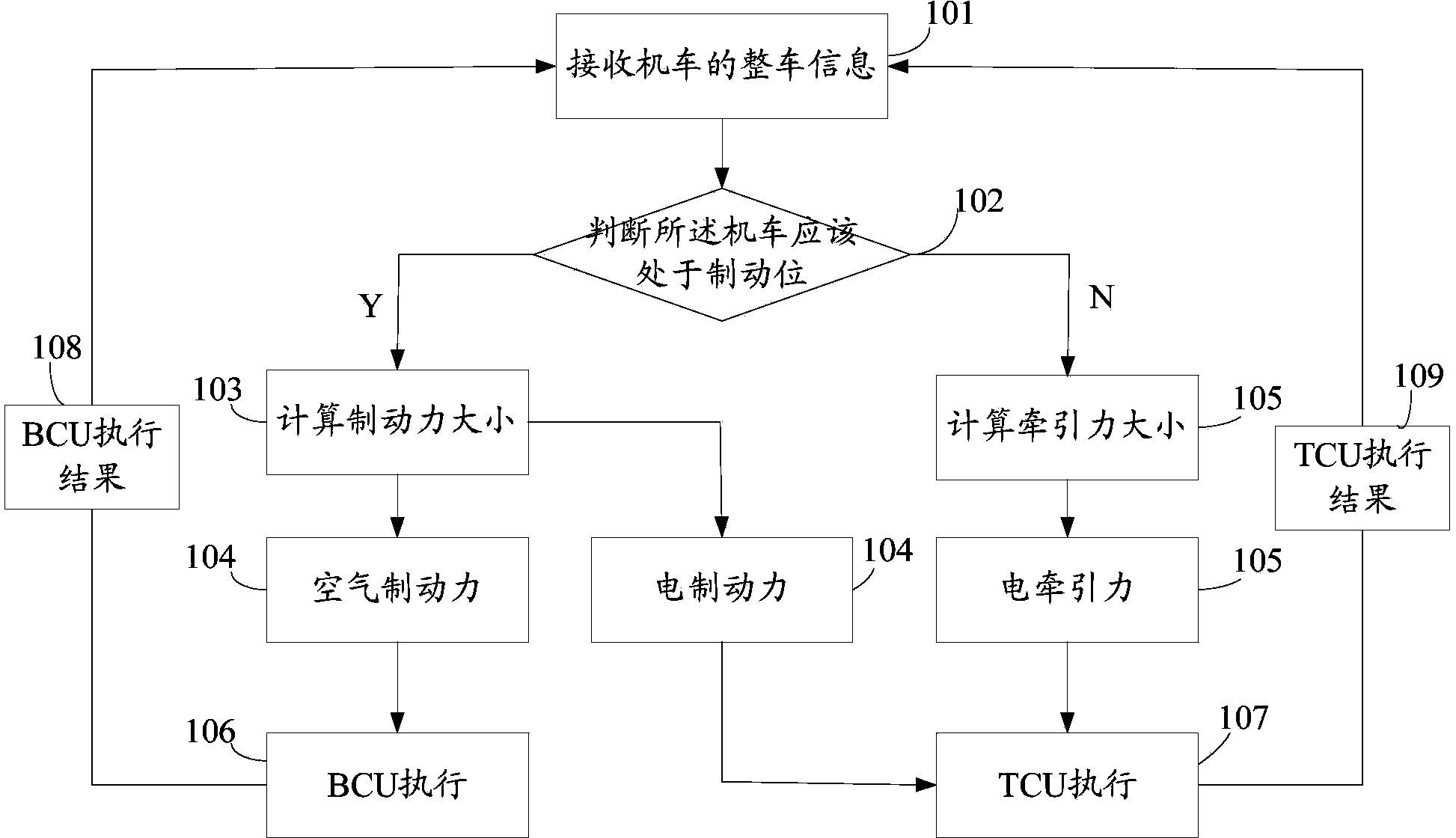

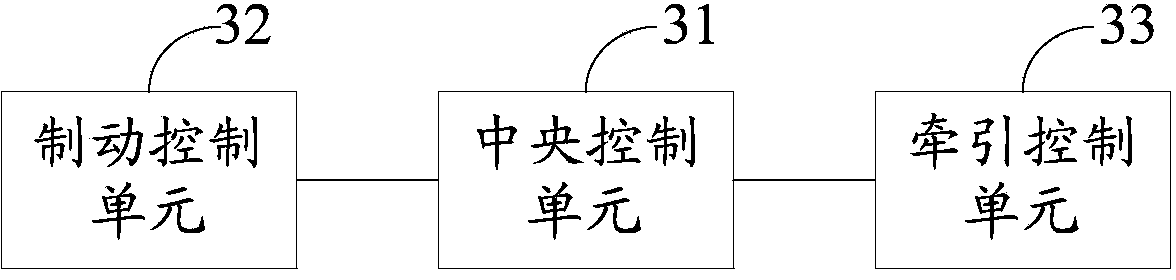

ActiveCN103625505AGuaranteed uptimeRun energy savingRailway braking systemsBraking systemsElectric forceTraction - action

The invention discloses an engineering maintenance vehicle traction force and brake force control method, which comprises the following steps that the whole vehicle information of a locomotive is received; whether the locomotive is expected to be in the brake position or not is judged according to the whole vehicle information; under the condition that the judging result shows that the locomotive is expected to be in the brake position, the dimension of the brake force is calculated; the brake force is divided into air brake force and electric brake force, the air brake force and the electric brake force are respectively delivered to a BCU (brake control unit) and a TCU (traction control unit) for executing the brake action; under the condition that the judging result shows that the locomotive is not expected to be in the brake position, the dimension of the traction force is calculated; the traction force is delivered to the TCU for executing the traction action. The engineering maintenance vehicle traction force and brake force control method has the advantages that through the integral consideration on the integral vehicle information, the dimension of the traction force or the brake force required to be exerted by an engineering maintenance vehicle is obtained, and in addition, the traction force or the brake force is allocated, so the execution action of the TCU and the BCU is more coordinated, the operation of the engineering maintenance vehicle is more stable, more energy can be saved, and the safety is higher.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

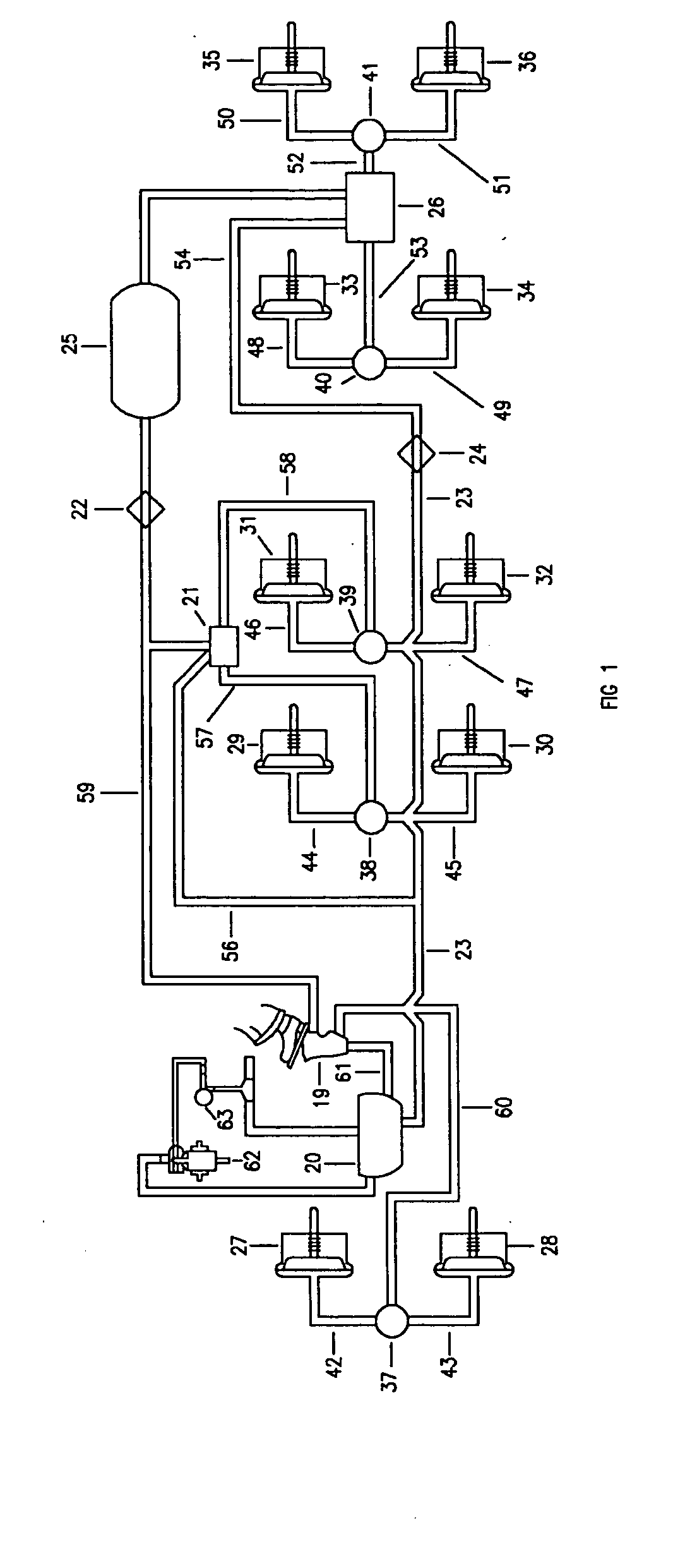

Pneumatic closed-looped antilock pressure modulating device for pneumatic brake systems

InactiveUS20050057088A1Effect deterioratesLong lastingApplication and release valvesBrake safety systemsShock waveDifferential pressure

This invention relates to a pneumatic closed-looped antilock pressure device in a pneumatic brake system for a truck tractors, semi-trailer and buses, and a differential pressure regulator for pneumatic brake system as it pertains to pneumatic brake systems for semi-trailers, buses, trucks, and trucks / semi-trailers, singular and in multiple combinations in automotive air brake installations; and more particularly to a pressure modulating device that employs a diaphragm, piston and elastomeric member with pneumatic antilock brake system functions, a means for modulating pneumatic signals, a means for oscillating pneumatic signals and a means relieve pressure internally, therewith sensing pneumatic shock wave signals, and dampening shock waves, and automatically adjusting brake actuation forces and the degree of angular rotation of the wheels in a closed-looped system without venting pressure to the atmosphere.

Owner:WASHINGTON WILLIAM E

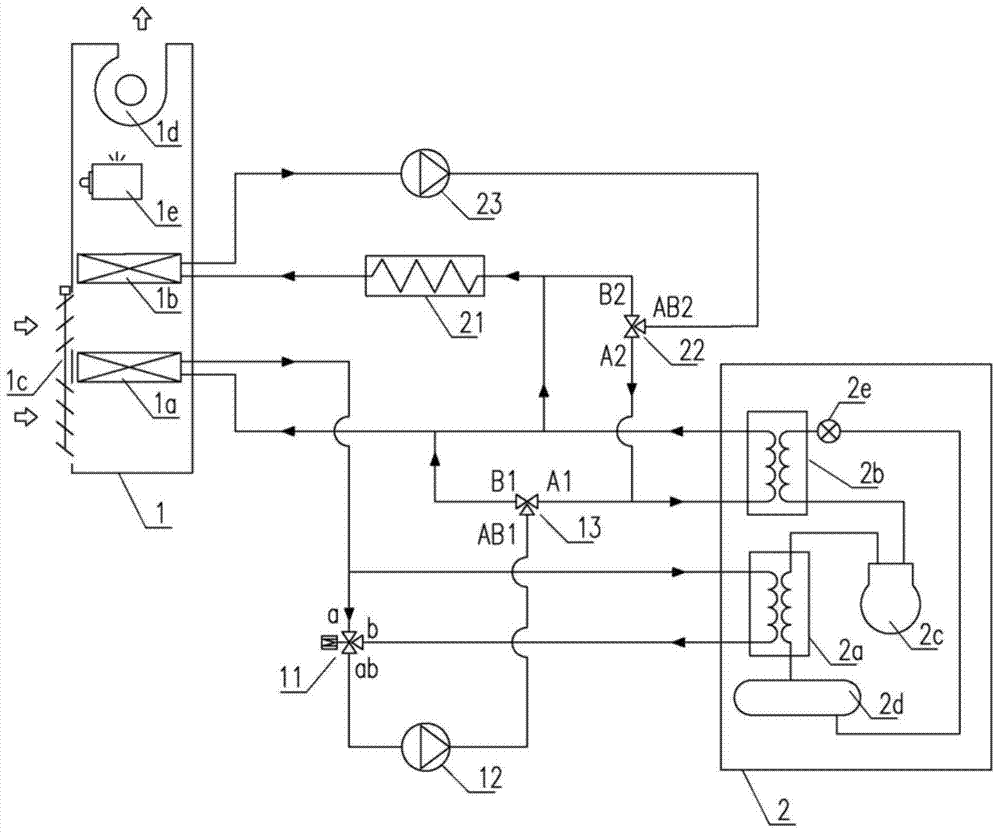

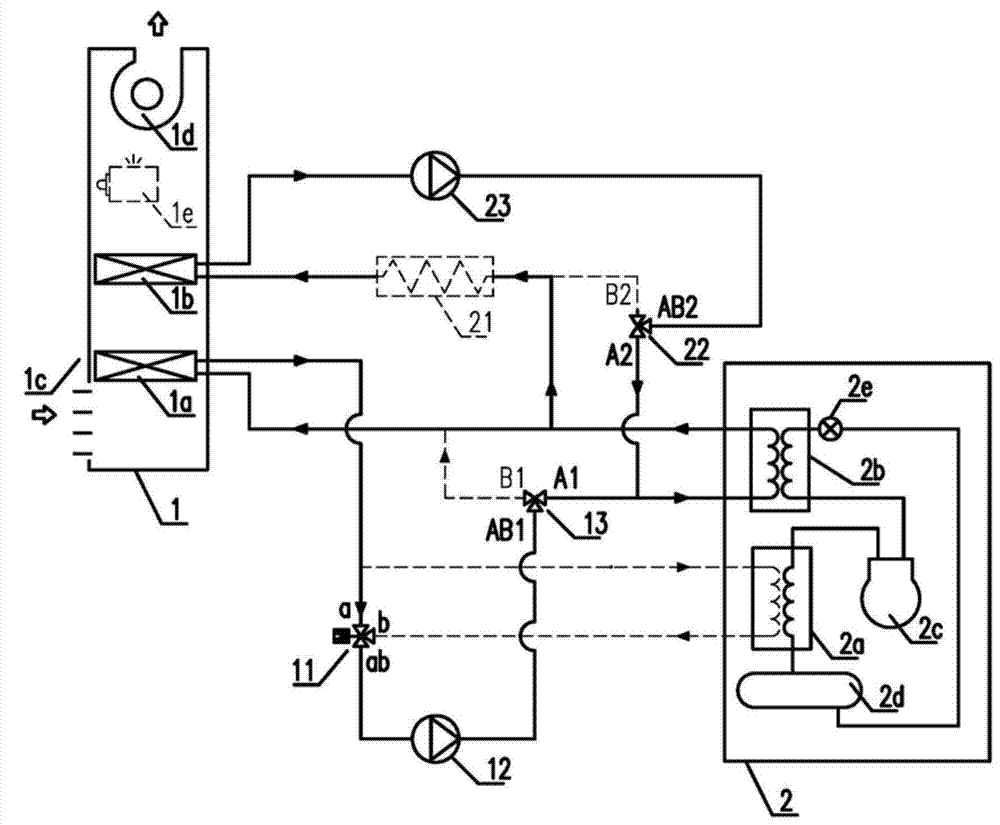

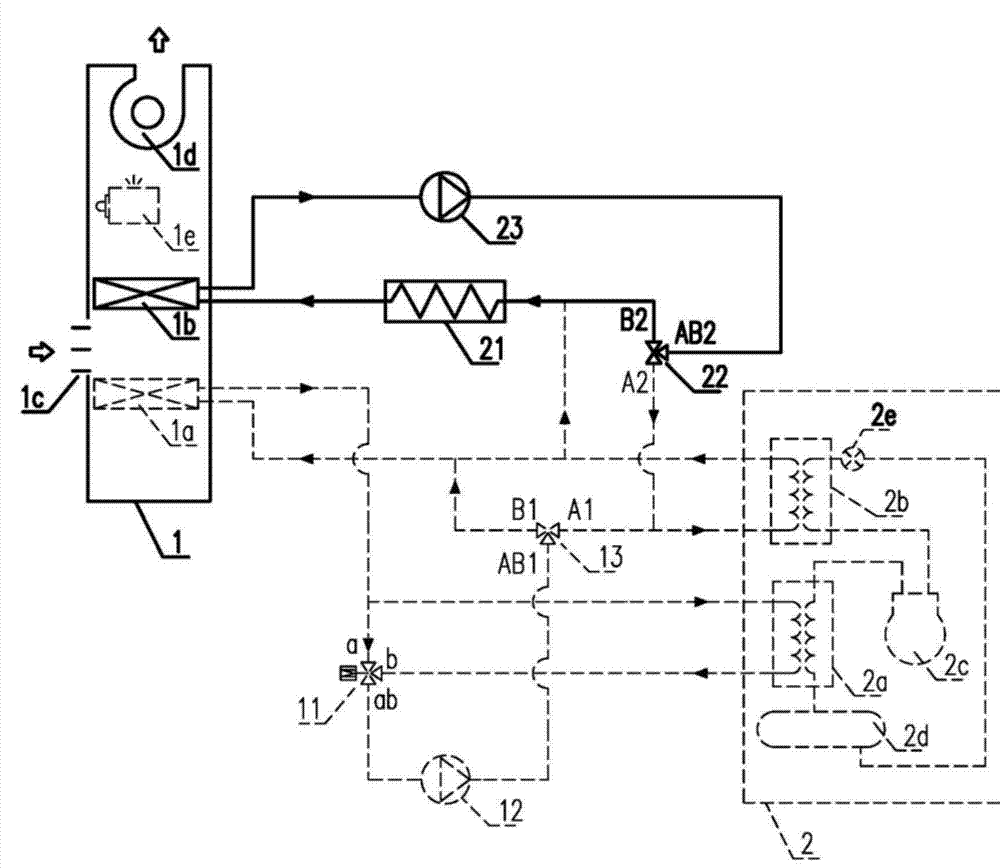

Environment room working condition adjusting system

ActiveCN104296276ARealize energy-saving operationAchieve uninterrupted supplyEnergy recovery in ventilation and heatingMechanical apparatusStable stateRoom temperature

The invention discloses an environment room working condition adjusting system which comprises an air conditioner cabinet, a cooling device, a secondary refrigerant freezing circulating pipeline and a secondary refrigerant thermocycling pipeline. The system can work at a temperature lowering state, a working condition stable state, a defrosting state, an after-defrosting recovery state and a temperature raising state. By switching control of the freezing circulating pipeline, the thermocycling pipeline and an air conditioner electric air brake, a proper cold source and a proper heat source can be provided for a freezing surface air cooler and a cold and heat surface air cooler of the air conditioner cabinet, and the stability of environment room temperature and humidity working conditions is guaranteed. Surface air cooler automatic defrosting under the low-temperature working conditions is achieved, environment room working condition stability during the defrosting process can be guaranteed, and long-time operation of the low-temperature working conditions is achieved. The cooling device of the system is provided with a heat recovery unit, waste heat recovery is used for controlling secondary refrigerant temperature, and energy-saving operation is achieved.

Owner:CHINA NAT ELECTRIC APP RES INST

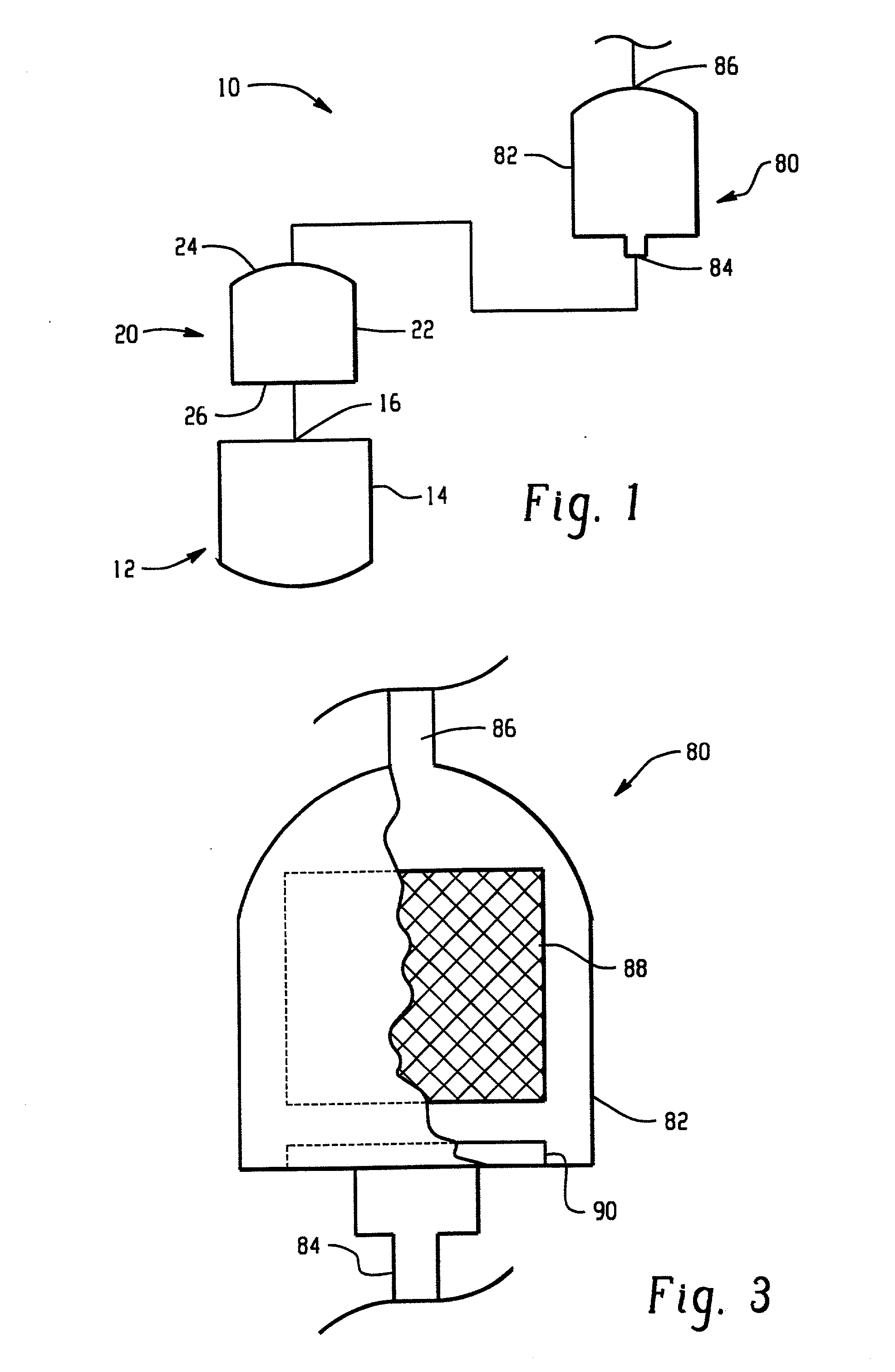

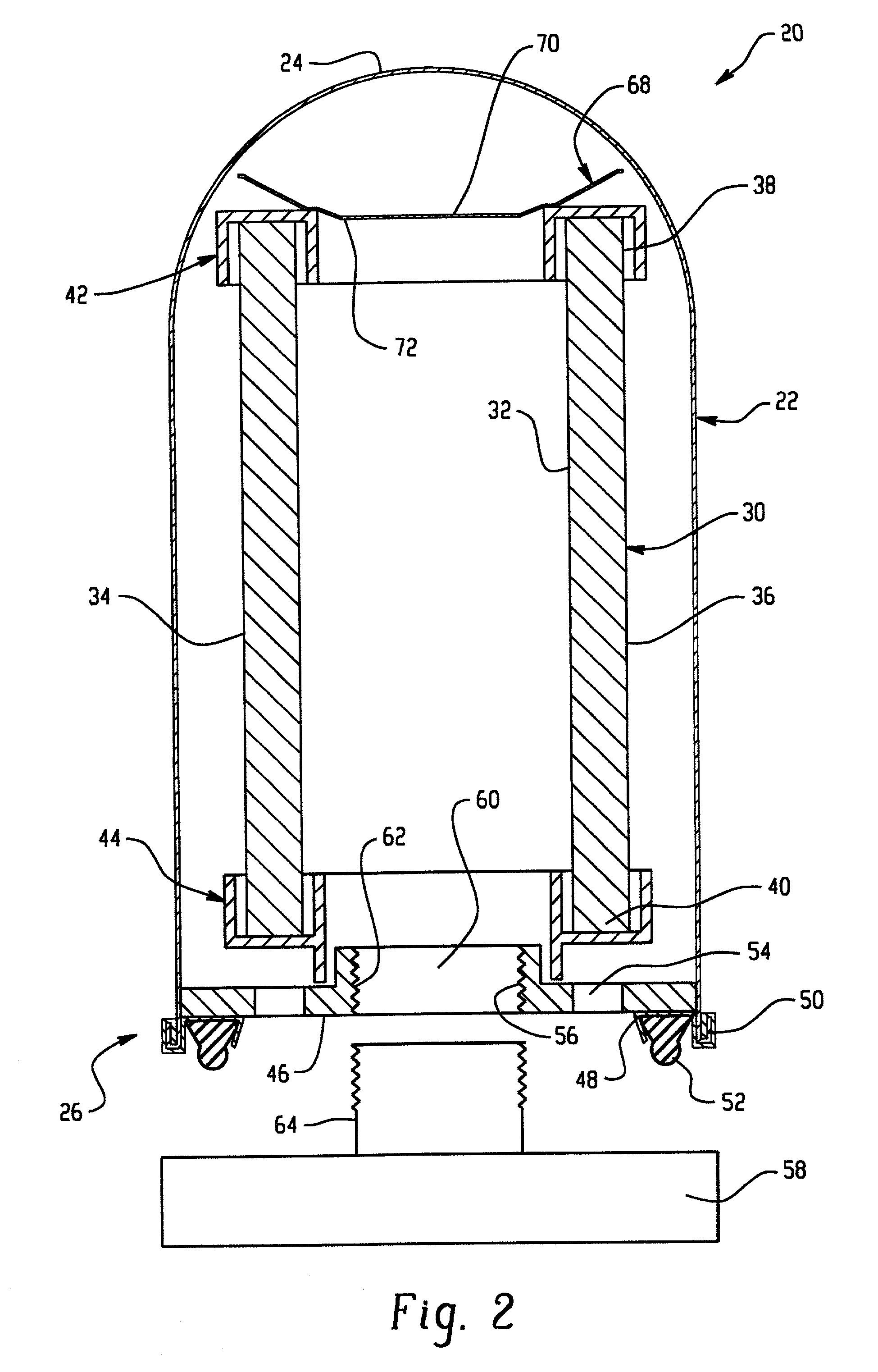

Self-contained adjustable air foil and method

An auxiliary air foil device for mounting on a vehicle is disclosed. The air foil device includes an enclosure comprising a base plate, a plurality of side walls, and an air foil panel. The air foil panel is pivotable between an open position and a closed position. In the closed position, the outside air flow will be substantially isolated from the volume within the enclosure. The open position provides access from outside of the enclosure to a volume within the enclosure. An actuator interconnects the underside of the air foil panel with the interior side of the base plate and allows for selective moving of the air foil panel between the open and closed positions. The actuator is pivotably connected to the base plate and the air foil panel, such that as the actuator changes length the rotational position of the air foil panel with respect to the base plate is also changed. In use, depending upon the application desired, the auxiliary air foil device of the present invention may be used as an air brake for the vehicle, as a means for increasing air flow into an engines air intake or cooling systems, as an adjustable spoiler, as a vacuum source for exhaust or other systems, or the like. The air foil device may be oriented with the pivoted edge of the air foil panel oriented towards either the front or rear end of the vehicle, and apertures in the base plate may be connected through the vehicle surface to optional air ducting means for delivering additional airflow or requiring it.

Owner:WEAVER DARRICK CHARLES

Locomotive air and electricity composite braking control system

ActiveCN104401352ADo not change operating habitsRealize dynamic brakingRailway hydrostatic brakesRailway hydrodynamic brakesAutomatic controlControl system

The invention discloses a locomotive air and electricity composite braking control system, which comprises an independent control valve IBV, an automatic control valve ABV, a braking control unit BCU, a central processing unit CPU, a locomotive braking unit LBU, a dynamic braking device DBU and a tread braking unit TBU; the output end of the independent control valve IBV and the output end of the automatic control valve ABV are respectively connected with the input end of the braking control unit BCU; the output end of the braking control unit BCU is connected with the input end of the central processing unit CPU; the output end of the central processing unit CPU is respectively connected with the dynamic braking device DBU and the braking control unit BCU; the output end of the braking control unit BCU is respectively connected with the locomotive braking unit LBU and the tread braking unit TBU. The locomotive air and electricity composite braking control system is safe, reliable, energy-saving and environmentally friendly; without changing the operation habit of a driver, dynamic braking can be realized by directly controlling an air braking handle; during braking, dynamic braking is stimulated preferentially, so that energy consumption is reduced to the maximum degree, and energy recovery is implemented.

Owner:CRRC ZIYANG CO LTD

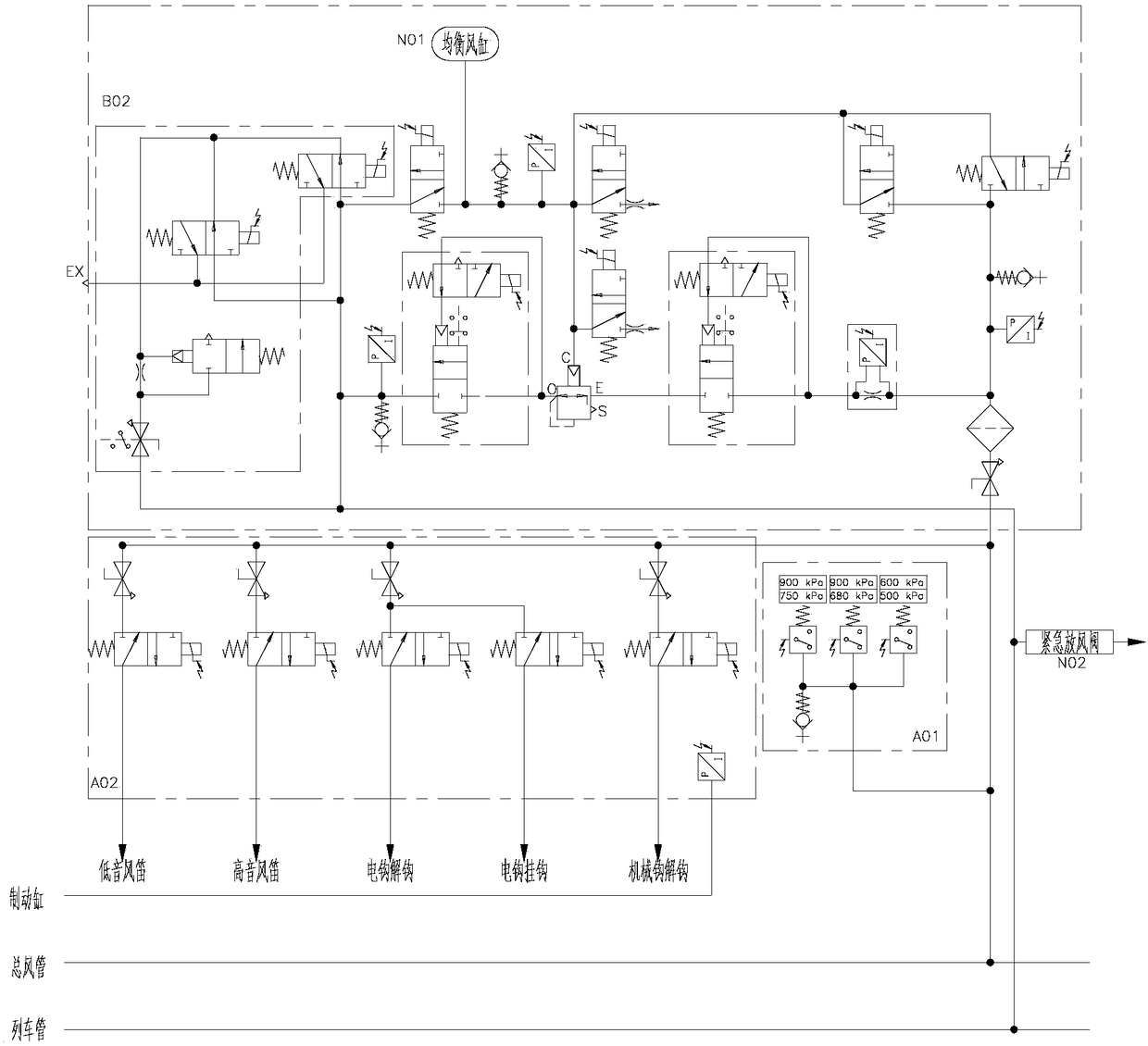

Control system and method for controlling centralized braking of train, and brake control system for motor train unit

ActiveCN109383554AFlexible groupingSave installation spaceBraking action transmissionRailway vehiclesControl systemControl signal

Embodiments of the invention provide a control system for controlling centralized braking of a train. The system comprises a pressure acquisition device and a train pipe control device, wherein the pressure acquisition device is used for acquiring a pressure of a main blast line; a pressure signal output end of the pressure acquisition device is connected with a pressure signal input end of the train pipe control device; a brake signal input end of the train pipe control device is connected with a brake signal output end of a brake controller; the train pipe control device is pneumatically connected with the main blast line and a train pipe through an air path end respectively. According to the scheme, the mounting space of a trailer and the cost are reduced. Moreover, because an automaticbrake control system is adopted to control pressure changes of the train pipe, a train can be linked with a passenger carriage adopting automatic air braking for operation, and the pressure changes of the train pipe and five-wire system control signals are controlled according to a brake request output by the brake controller and detection of a real-time pressure of the train pipe, thus realizingflexible formation.

Owner:CRRC TANGSHAN CO LTD

High speed train braking system and braking method thereof

The invention relates to a high speed train braking system and a braking method thereof. The braking method comprises the following steps of classifying fraction coefficient values into multiple sections according to a speed range and prestoring the classified fraction coefficient values into a BCU (Braking Control Unit); sending out a control instruction by virtue of the BCU; calculating air braking force required for train braking by virtue of the BCU; and finally generating a PBC (Pressure of Braking Control), and conveying hyperbaric air to a braking execution device, wherein the braking execution device is used for executing braking or parking. The BCU adopts a fraction coefficient which is not a constant average fraction coefficient, but is a sectional fraction coefficient value based on different speed ranges and braking levels, thereby being beneficial to the matching of a practical output braking force and a designed braking force; a condition that the practicable braking force is far greater than the designed braking force is avoided, so that the braking is smooth and steady; and meanwhile, the abrasion of a braking disc and a brake pad can be reduced, and the use economical efficiency of basic braking is improved.

Owner:CRRC QINGDAO SIFANG CO LTD

Air conditioner for idling stop vehicle

ActiveCN101863212AIncrease temperatureAir-treating devicesSpace heating and ventilation safety systemsEngineeringAir brake

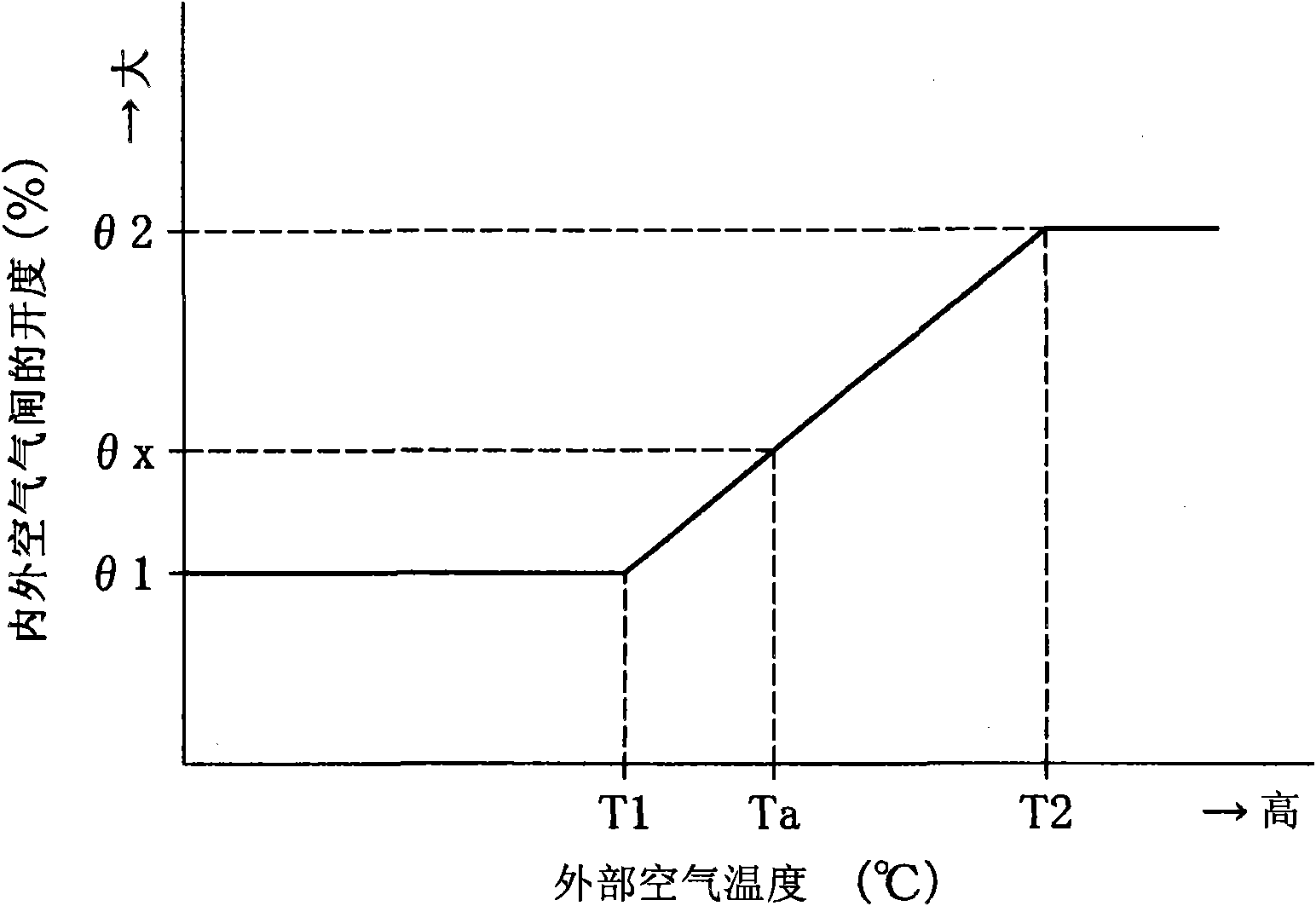

The present invention relates to an air conditioner for idling stop vehicle. When idling is stopped, the fan stage is set to Lo2 or lower. Furthermore an opening thetad of an inner-outer air brake can be changed according to the temperature Ta of outer air.

Owner:MITSUBISHI MOTORS CORP

Air brake controlling method electric automobile and controlling system thereof

ActiveCN1792690ARealize intermittent operationSave energyBraking action transmissionWorking pressureControl system

An air brake controlling method and system for electric car is disclosed. An air compressor starting / stopping control system is arranged in the air brake control system for making the air compressor work in preset pressure range. When the air compressor is stopped, the electromagnetic valve and pneumatic direction valve are used to unload the energy supply loop and discharge pollutant, ensuring that the air compressor is started in idle state.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

Brake interface module

A brake interface module for an electronic air brake (EAB) or a magnet valve that incorporates positive train control digital commands with additional fail-safe, discrete train control spare inputs into a single, fail safe output via redundant power supplies. The brake interface module comprises a positive train control circuitry including a first microcontroller and a second microcontroller operatively coupled to each other. The brake interface module also includes spare discrete inputs that utilize fail-safe principles and are continuously monitored by the second microcontroller to achieve fail-safe performance. Each power supply contains redundant, independent means of shutting down to facilitate self test.

Owner:WABTEC HLDG CORP

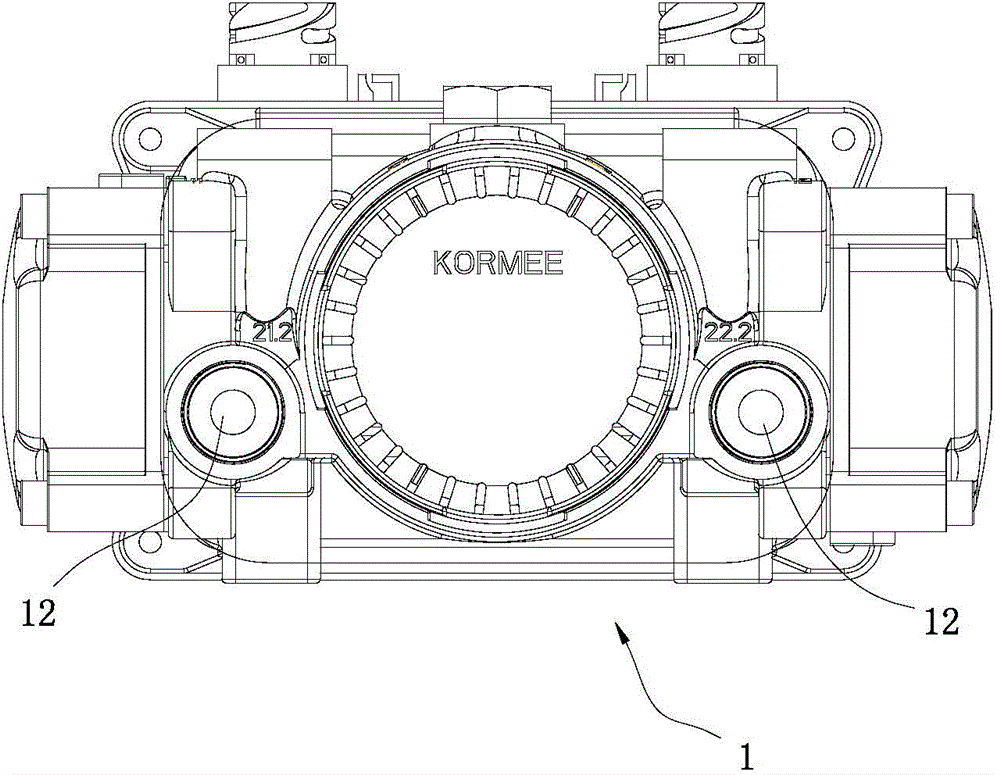

Electronic control relay valve assembly of anti-lock brake system

InactiveCN104309601APedal responsiveAccurate judgmentABS control systemsApplication and release valvesDriver/operatorSolenoid valve

The invention discloses an electronic control relay valve assembly of an ABS (anti-lock brake system). The electronic control relay valve assembly of the ABS comprises a valve body and a solenoid valve group; a pressure sensor used for detecting the pressure of brake air chambers is arranged in the valve body; the valve body comprises two main air inlets, four air outlets and an exhaust port; two air chambers are symmetrically distributed in the valve body; one of the two brake chambers is respectively communicated with one of the two main air inlets, two of the four air outlets and the exhaust port; a valve capable of controlling whether the main air inlet is communicated with the corresponding air outlets or not is arranged in each air chamber; a main control piston capable of abutting on the corresponding valve is arranged in each air chamber; the valves are controlled by the solenoid valve group connected with the valve body; the internal valve operation of the valve body is controlled through the solenoid valve group, and the pressurization working condition, the pressure-maintained working condition and the pressure-reduced working condition are realized through an internal logic operation method and threshold value control; the electronic control relay valve assembly is adapted to various working conditions; as an electronic control air brake vehicle is adopted, the reaction to stepping of a driver is more sensitive, and judgment on brake performance is more accurate; brake can be realized more rapidly, and the defects that the mechanical brake response time is slow, the brake comfort is poor and the like are eliminated.

Owner:GUANGZHOU KORMEE AUTOMOTIVE ELECTRONICS CONTROL TECH

Control valve having a variable nozzle cross-section for automatic compressed-air brakes

InactiveCN103189250AHigh speedIncrease the lengthBraking action transmissionAutomatic initiationsEngineeringControl valves

The invention relates to a control valve for indirectly acting compressed-air brakes of railway vehicles, containing a triple-pressure element (24) and a twin-pressure element (1), which comprises a control piston (2; 2'), on which from one side the pressure of the air of a main air line (L) acts and from the opposite side the pressure of the air of a valve spool chamber (S) acts and which interacts with an acceleration valve (6) via a tappet (5), which, in the open state, connects the main air line (L) via a check valve (12), and connects the valve spool chamber (S) via a valve (8; ; 8') or via a bore (9), to a channel (7), and further to a channel (13) for the additional ventilation at the start of braking via the triple-pressure element (24) and to a ventilation path (14) in the twin-pressure element (1) to the surroundings, wherein at least one throttle area (10) is arranged in the ventilation path (14), the effective cross-section of said throttle area being variable via actuation means in the twin-pressure element (1) from a closed or inactive state or from a minimum cross-section to a maximum cross-section.

Owner:KNORR BREMSE SYST FUR SCHIENENFAHRZEUGE GMBH

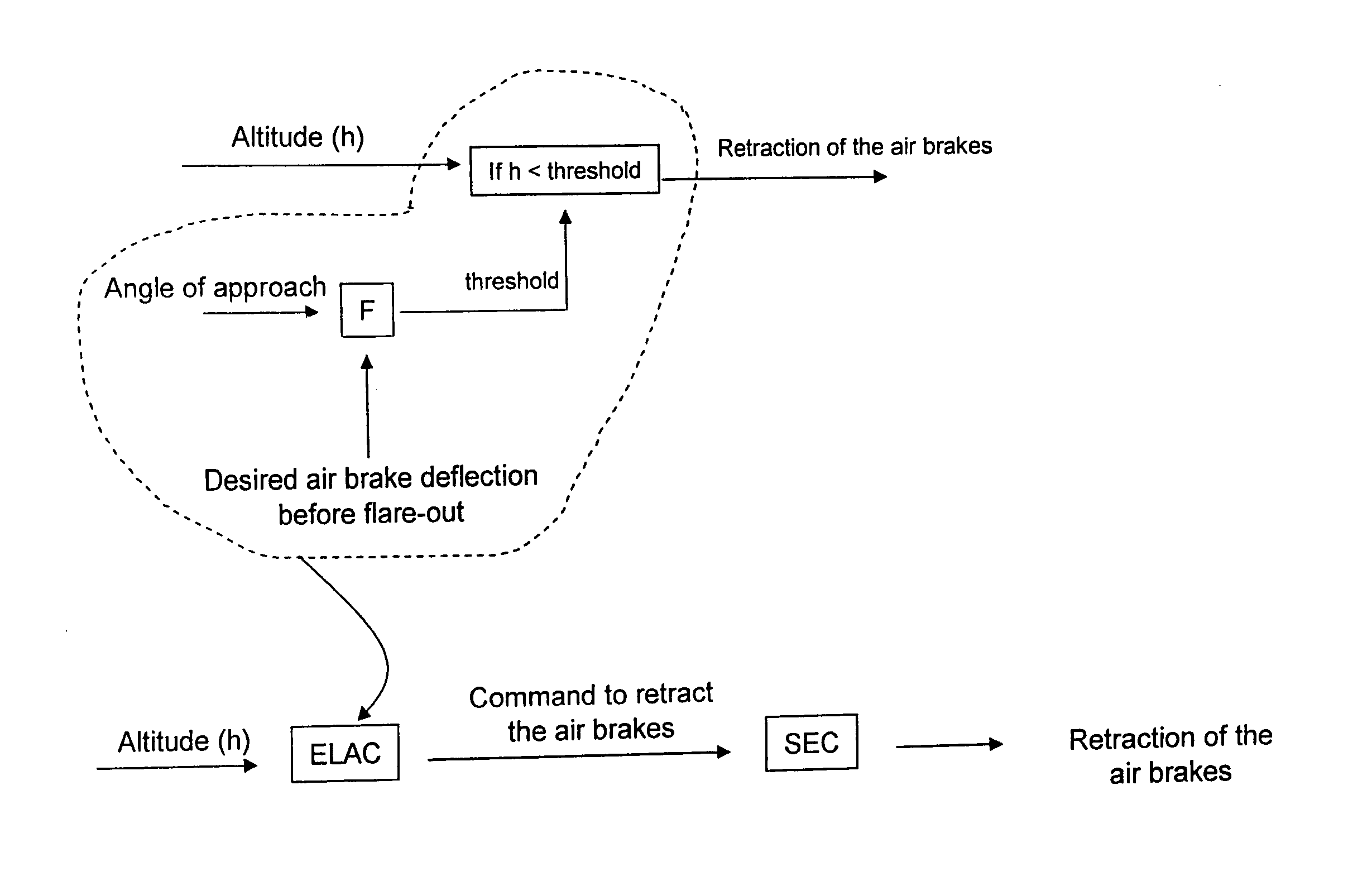

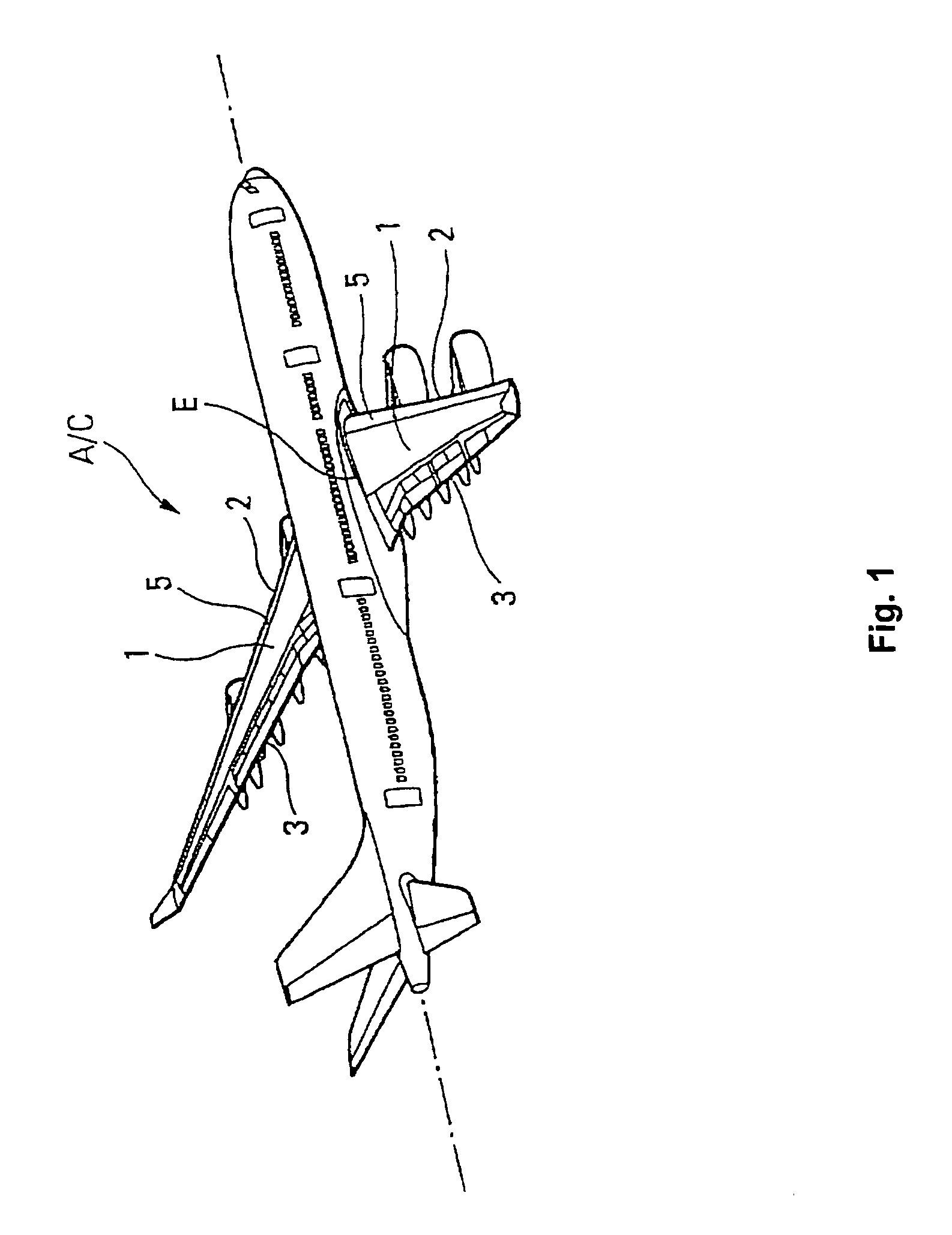

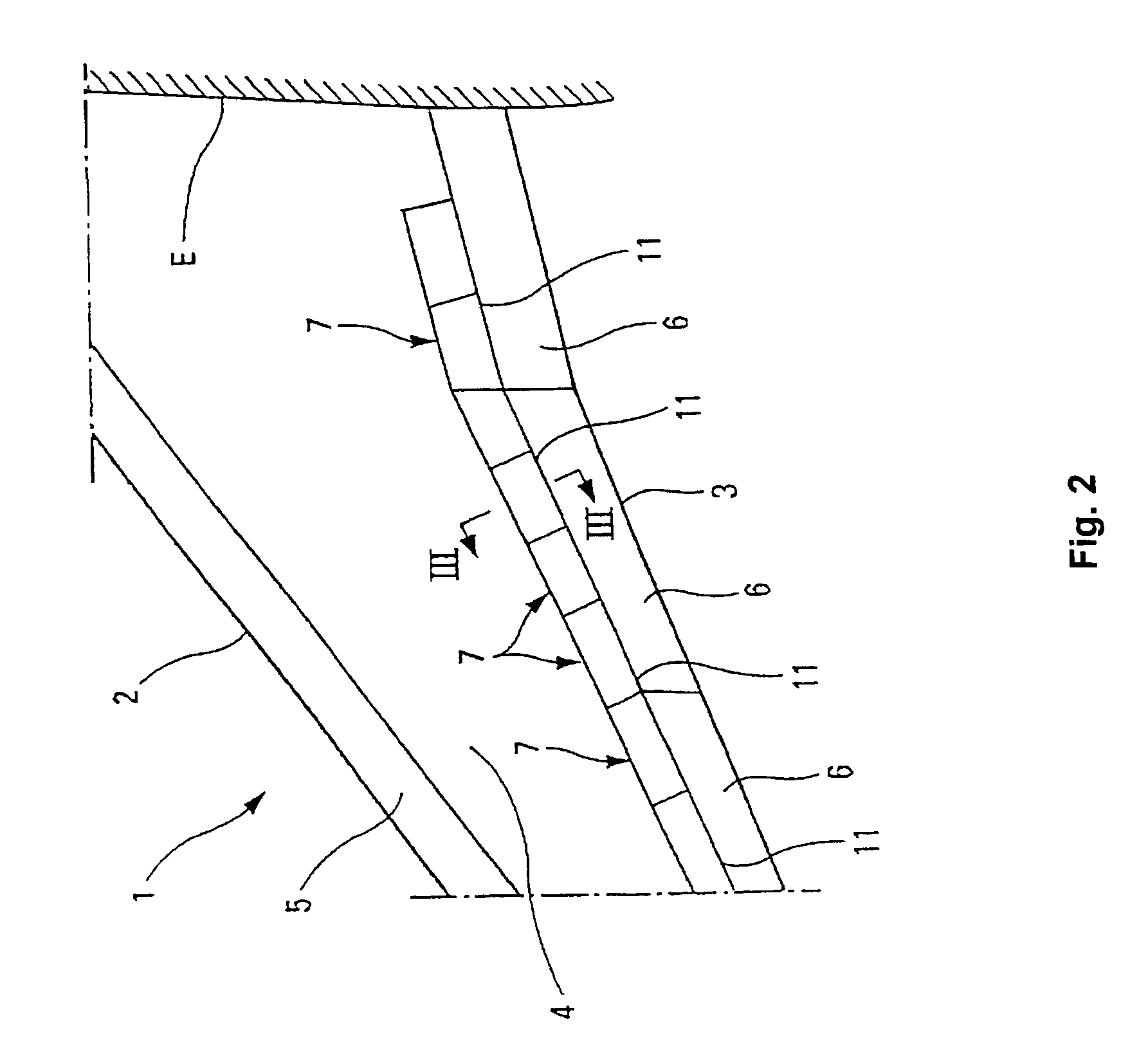

Procedure and device for improving the maneuverability of an aircraft during the approach to landing and flare-out phases

ActiveUS20090314897A1Improve mobilityConjoint controlsActuated automaticallyClassical mechanicsAir brake

The process improves the maneuverability of an aircraft during the approach to landing and then flare-out phases, the aircraft being equipped with air brakes. According to the process, the air brakes are put in a first deployed position during the approach phase, and as a function of a representative parameter of a given altitude and in case of a steep angle approach, they are actuated to transition to a second more retracted position than the first position so as to achieve a flare-out allowing to essentially maintain the same angle of incidence, corresponding in case of a steep angle approach to achieve a flare-out with habitual exterior piloting references during the flare-out phase.

Owner:AIRBUS OPERATIONS (SAS)

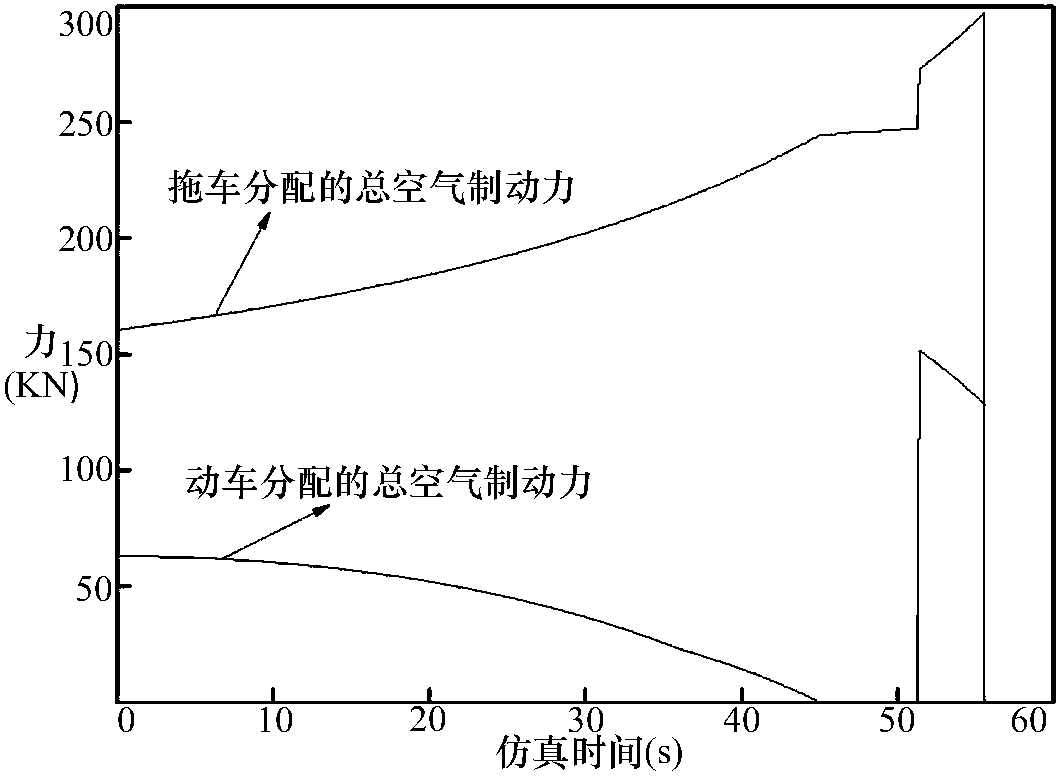

High-speed train braking force optimal distribution method

ActiveCN110091847AReduce slippageImprove braking effectBraking action transmissionRailway braking systemsDistribution methodMathematical model

The invention discloses a high-speed train braking force optimal distribution method which can be used for an electric-air braking force distribution strategy of a high-speed train; the method has thefollowing steps: firstly, building a mathematical model of a high-speed train braking process, and calculation of an object braking force, an electric braking force and an operation resistance is included; secondly, designing an objective function and constraint conditions for brake force optimal distribution, and proving the existence of an extreme value of the objective function; and then converting the established objective function and constraint conditions into a quadratic plan for solving. And finally, simulation shows that the distribution method not only can fully utilize different adhesion limits of each vehicle to effectively exert the available braking force of each vehicle, but also can reduce the slipping phenomenon of the bullet trains in a wet rail surface braking process,and is beneficial to improving the braking performance of the train and improving the braking efficiency.

Owner:HUNAN UNIV OF TECH

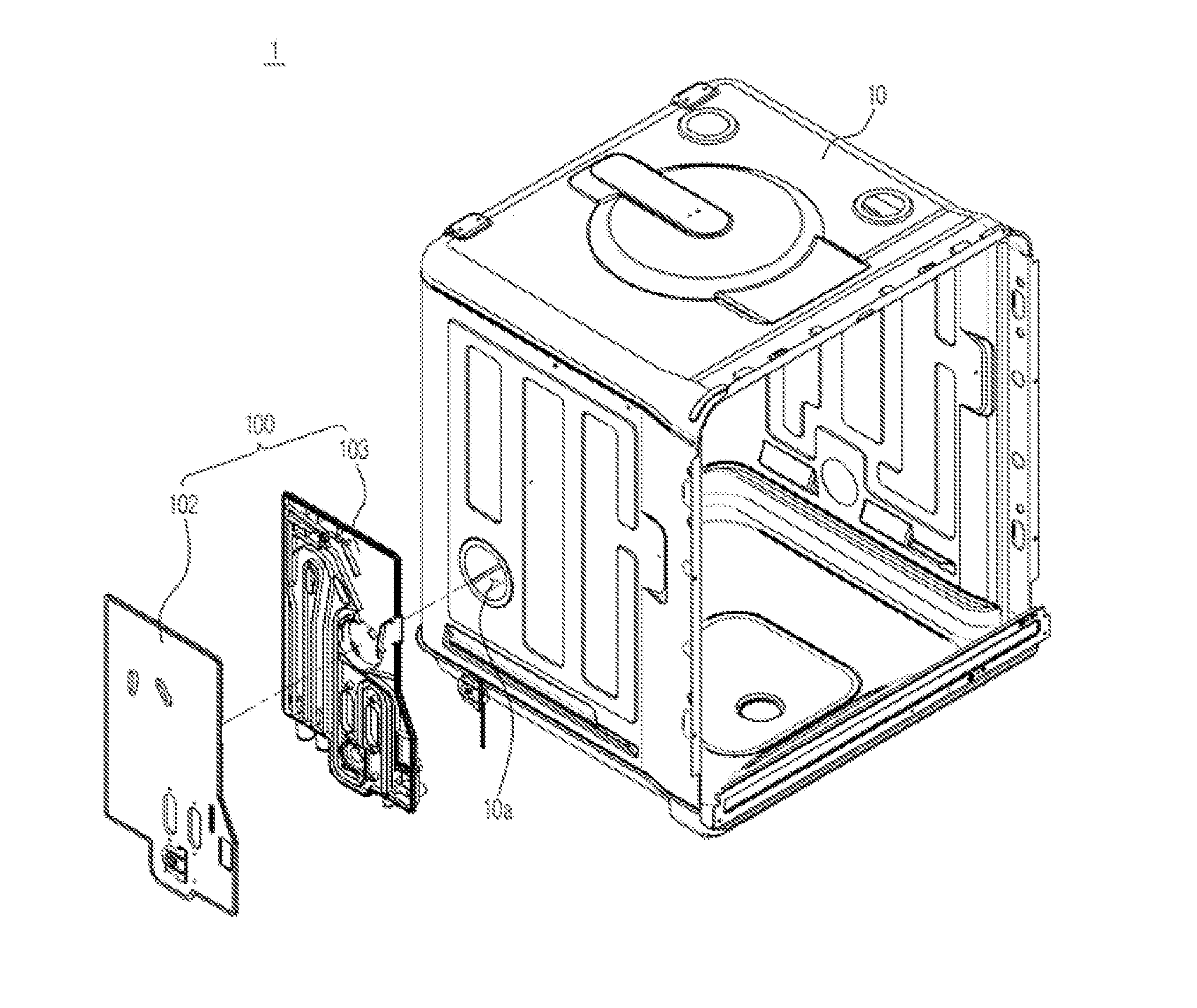

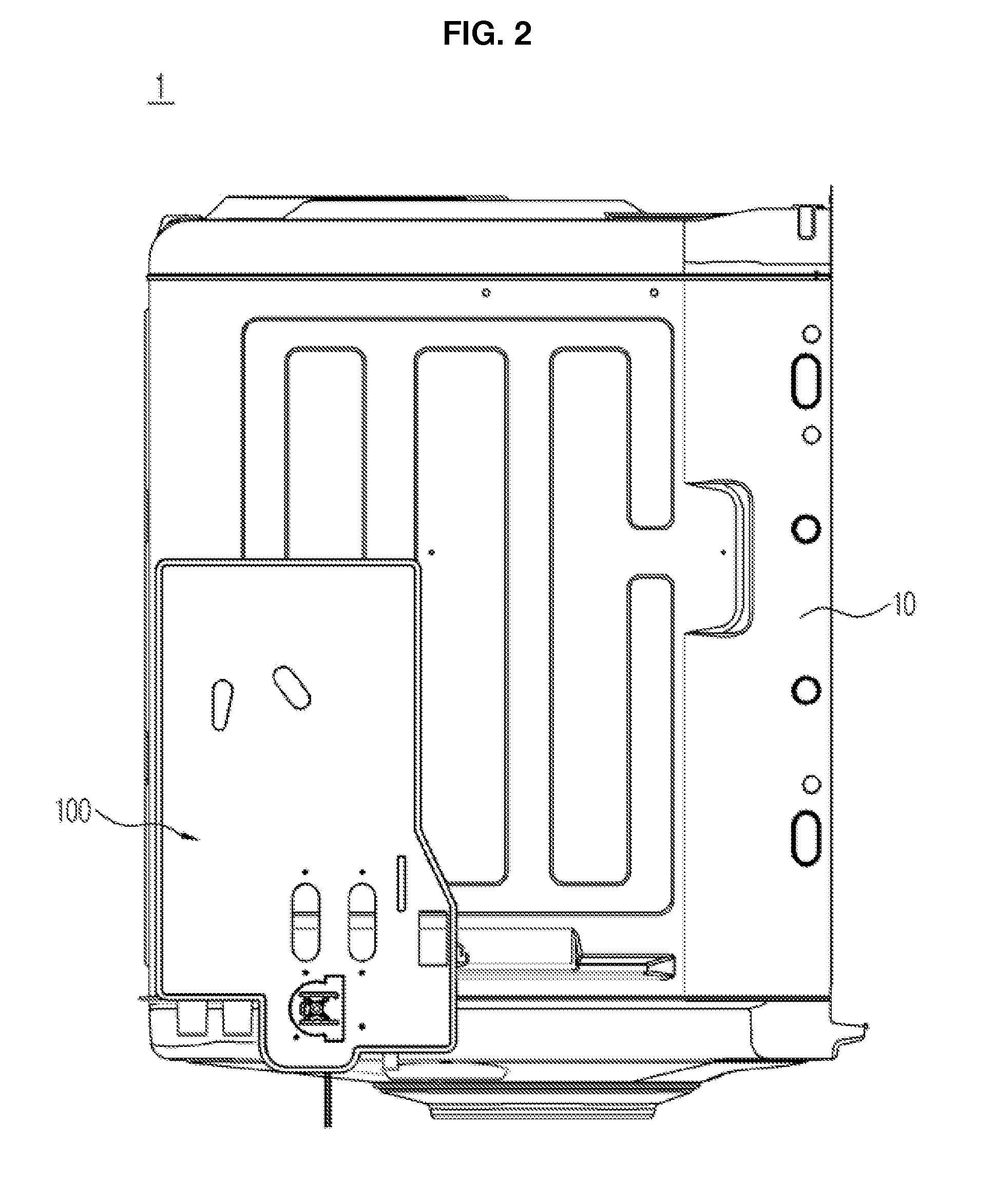

Dishwasher

ActiveUS20150068056A1OptimizationAvoid dischargeTableware washing/rinsing machine detailsAutomatic washing/rinsing machine detectionAir brakeEngineering

Disclosed herein is a dishwasher. The dishwasher includes a main body, a tub placed within the main body to receive dishes therein, and an air brake mounted to one lateral surface of the tub. The air brake includes a communication hole communicating with the tub to allow air to be introduced into the tub or to be discharged from the tub, a guide rib configured to guide air, introduced through the communication hole, upward of the air brake, and a vent formed in a lateral surface of the air brake to allow air to be discharged outward from the air brake or to allow outside air to be introduced into the air brake, the vent being located below the guide rib to prevent hot air from being discharged from the air brake.

Owner:SAMSUNG ELECTRONICS CO LTD

Spin-on filtering oil removal cartridge

InactiveUS20020189458A1Save valuable spaceSmall sizeCombination devicesDispersed particle filtrationEngineeringFilter element

A serviceable filtering oil removal cartridge for use in a compressed air assembly of a vehicle air brake system includes a housing having a first end and a second end. A filtering element is disposed within the housing for agglomerating and removing oil from compressed air entering the oil removal cartridge. A load plate is disposed within the housing for supporting the filtering element. The load plate includes a connecting portion dimensioned to allow the oil removal cartridge to be removed and installed as a single unit. The connecting portion is preferably a threaded annulus.

Owner:BENDIX COMML VEHICLE SYST LLC

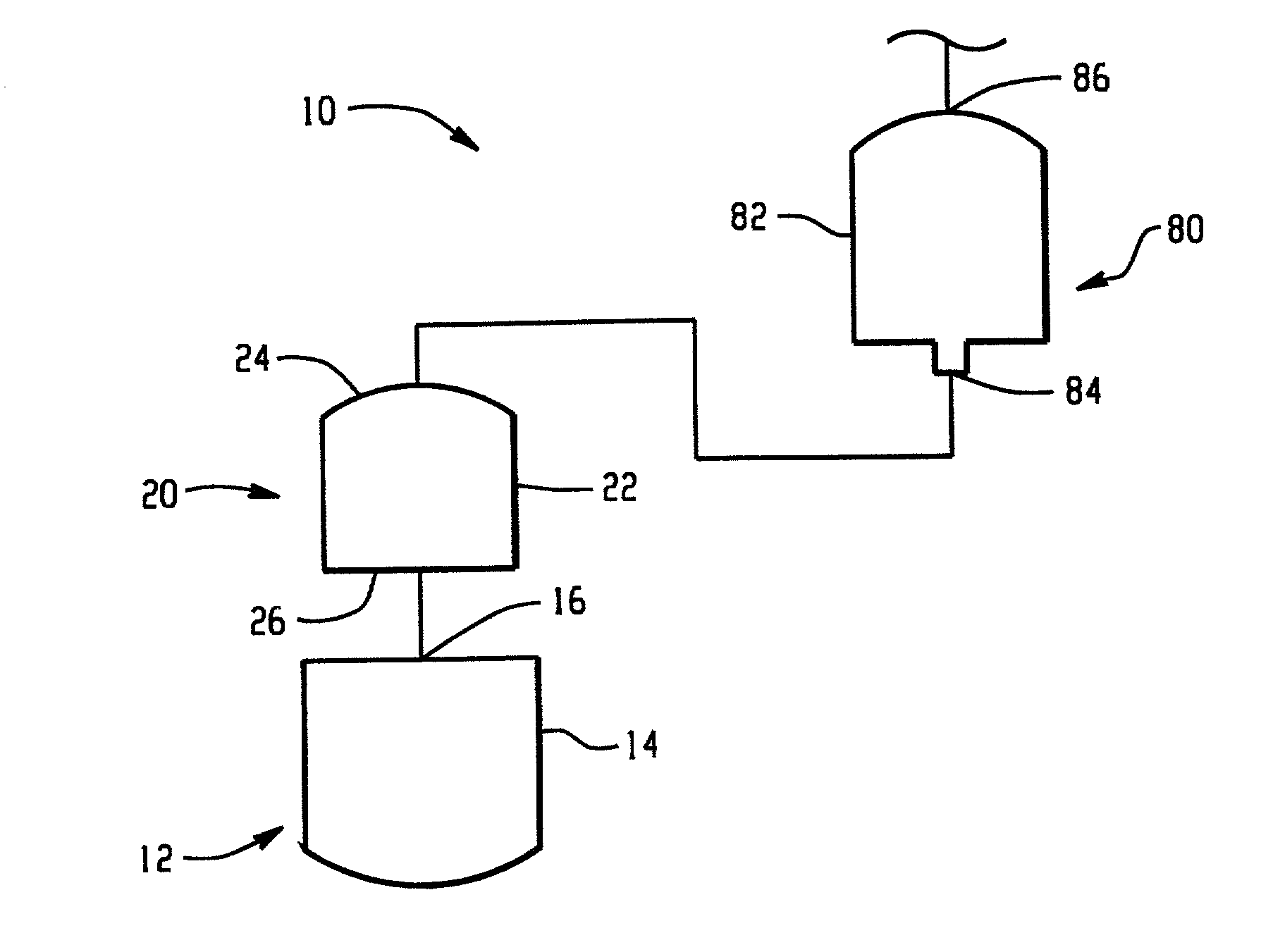

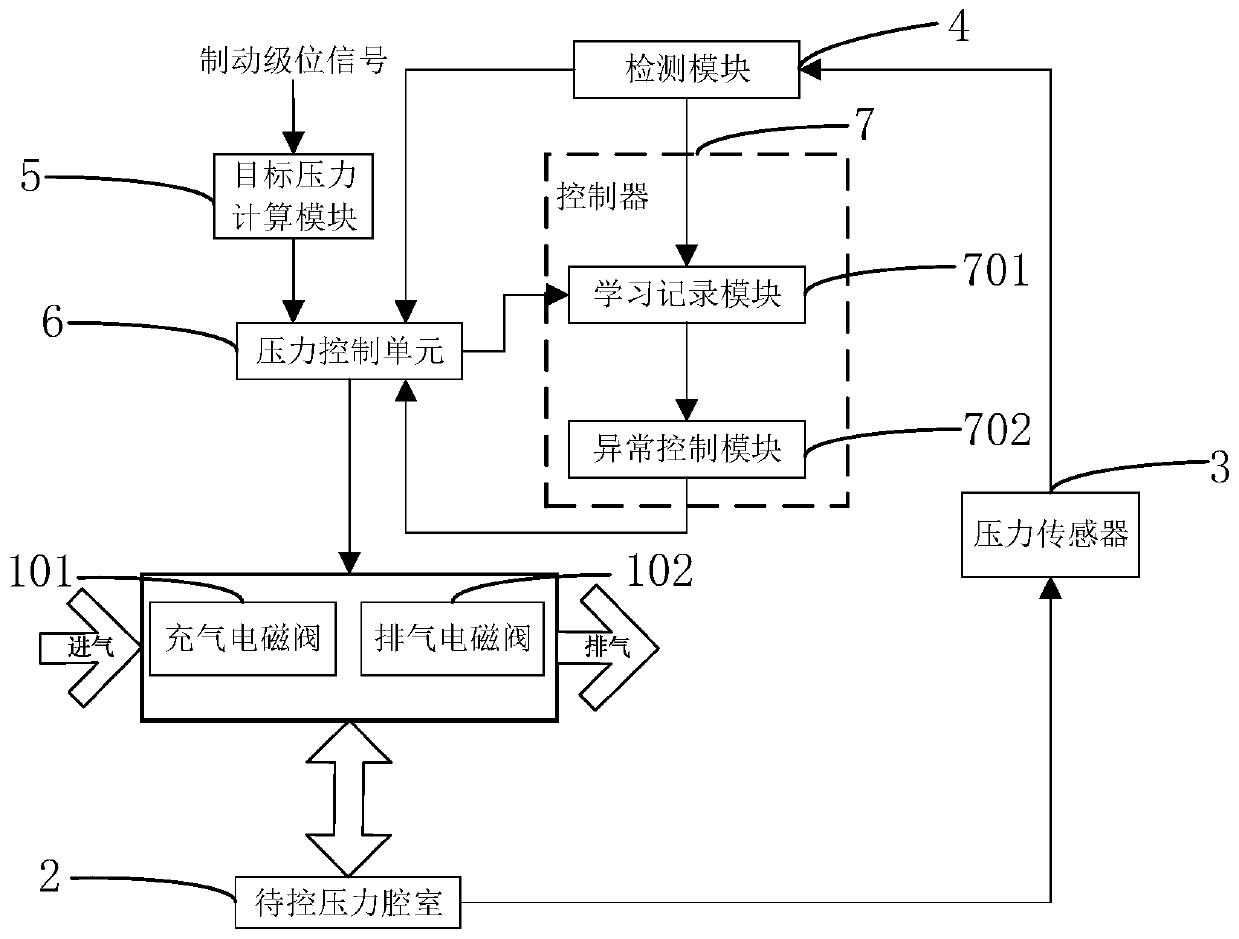

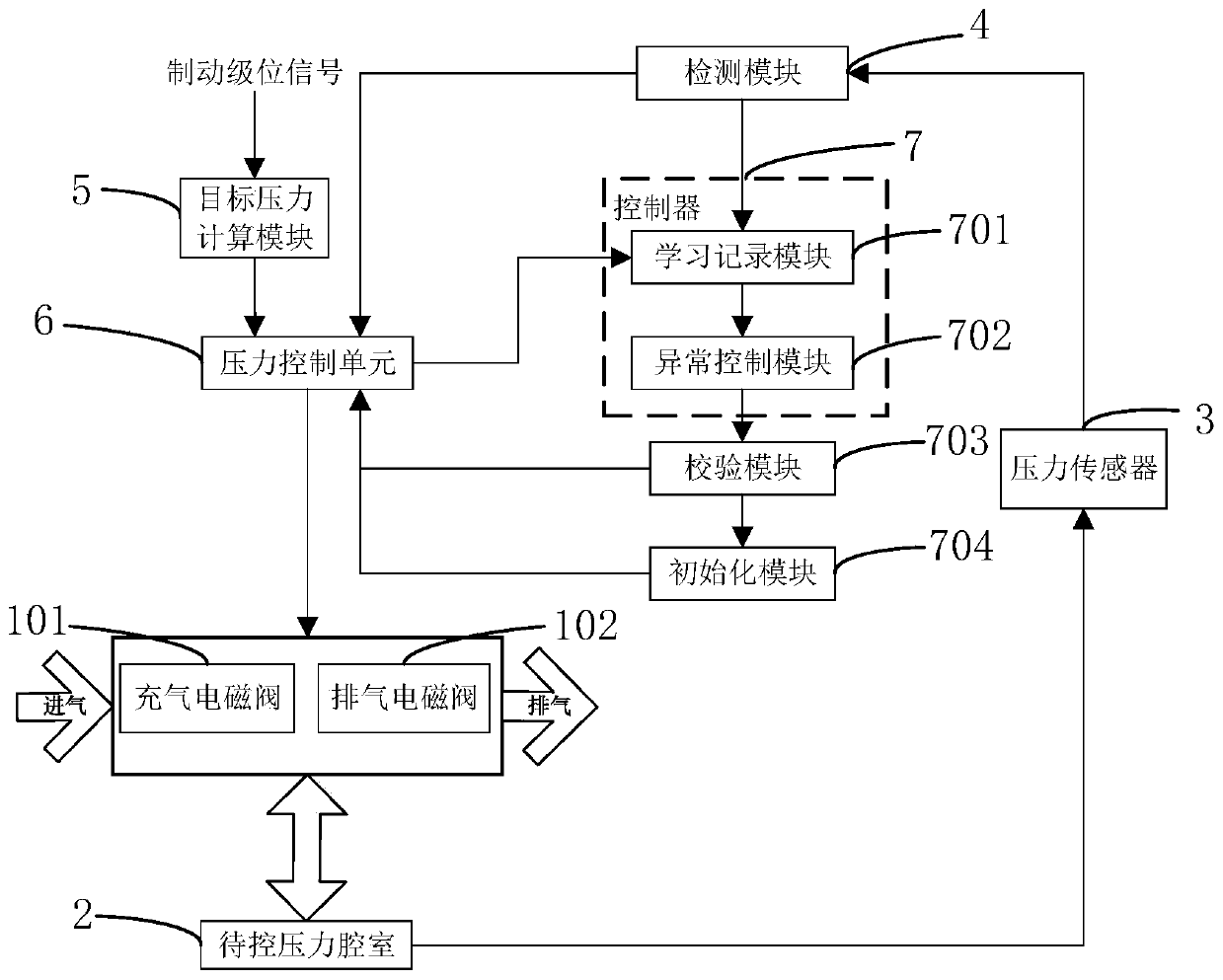

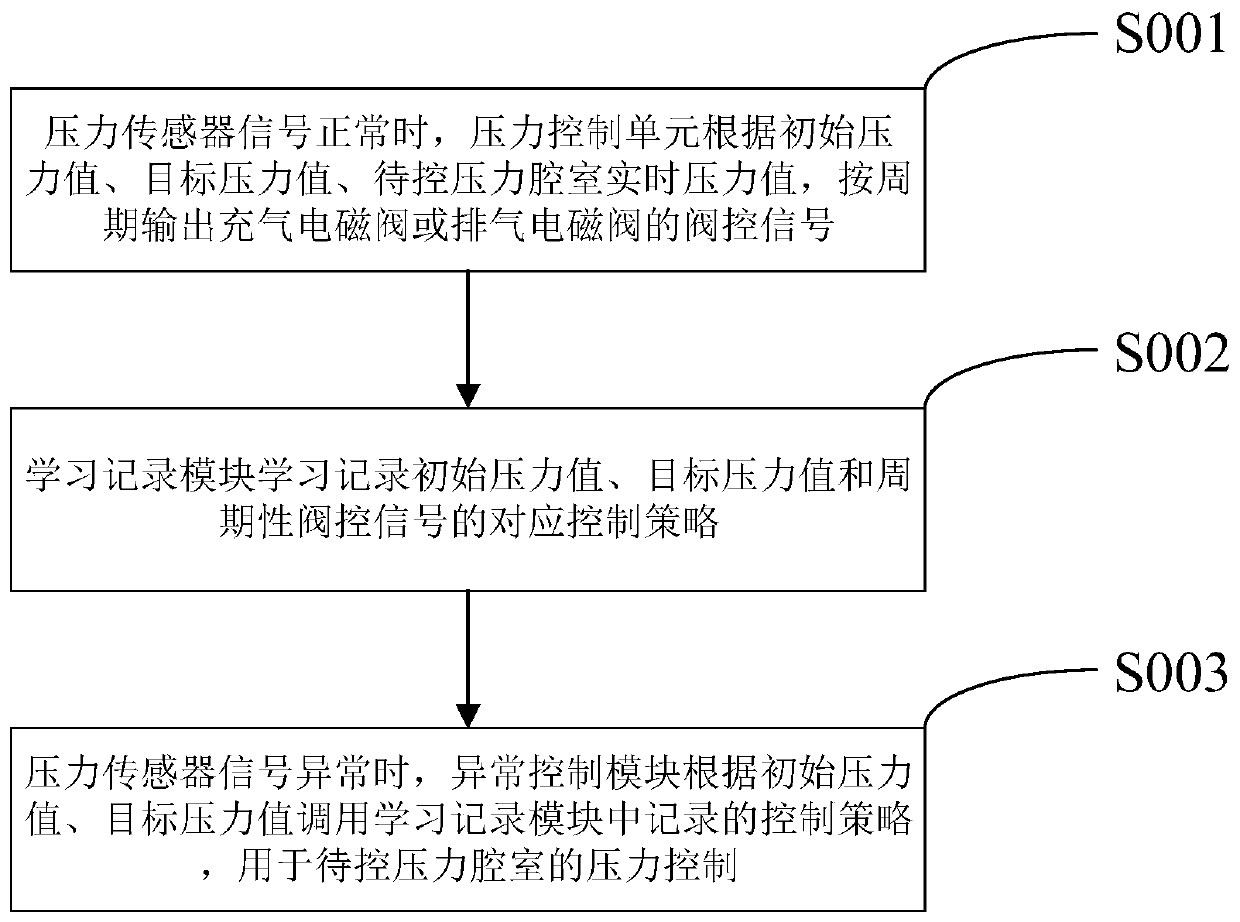

Air brake pressure control system and brake control method

ActiveCN110395242AEasy to controlControl module for precise controlBrake safety systemsElectricityControl system

The invention discloses an air brake pressure control system and a brake control method. The system comprises an air inflation electromagnetic valve, an exhaust electromagnetic valve, a pressure sensor, a detection module, a pressure control unit and a controller, wherein controller comprises a learning record module and an abnormal control module. According to the brake control method, a synchronous learning and a recording control strategy of the learning record module is utilized, when signals of the pressure sensor are abnormal, the abnormal control module calls the control strategy of thelearning record module, and the air inflation electromagnetic valve or the exhaust electromagnetic valve is controlled to gradually reach the target pressure according to the corresponding control strategy. Compared with a certain fixed state that a control electromagnetic valve is in the normal power or normal power loss, the pressure of a pressure chamber to be controlled is more accurate.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST +1

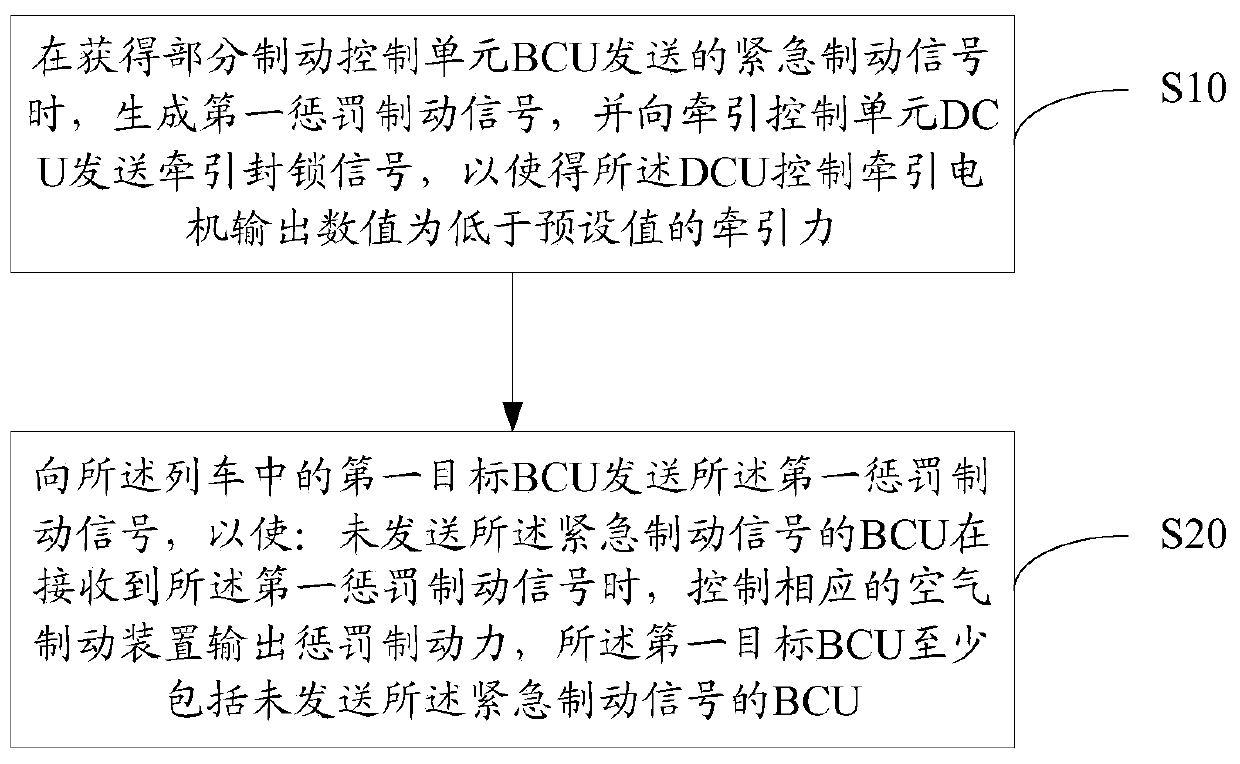

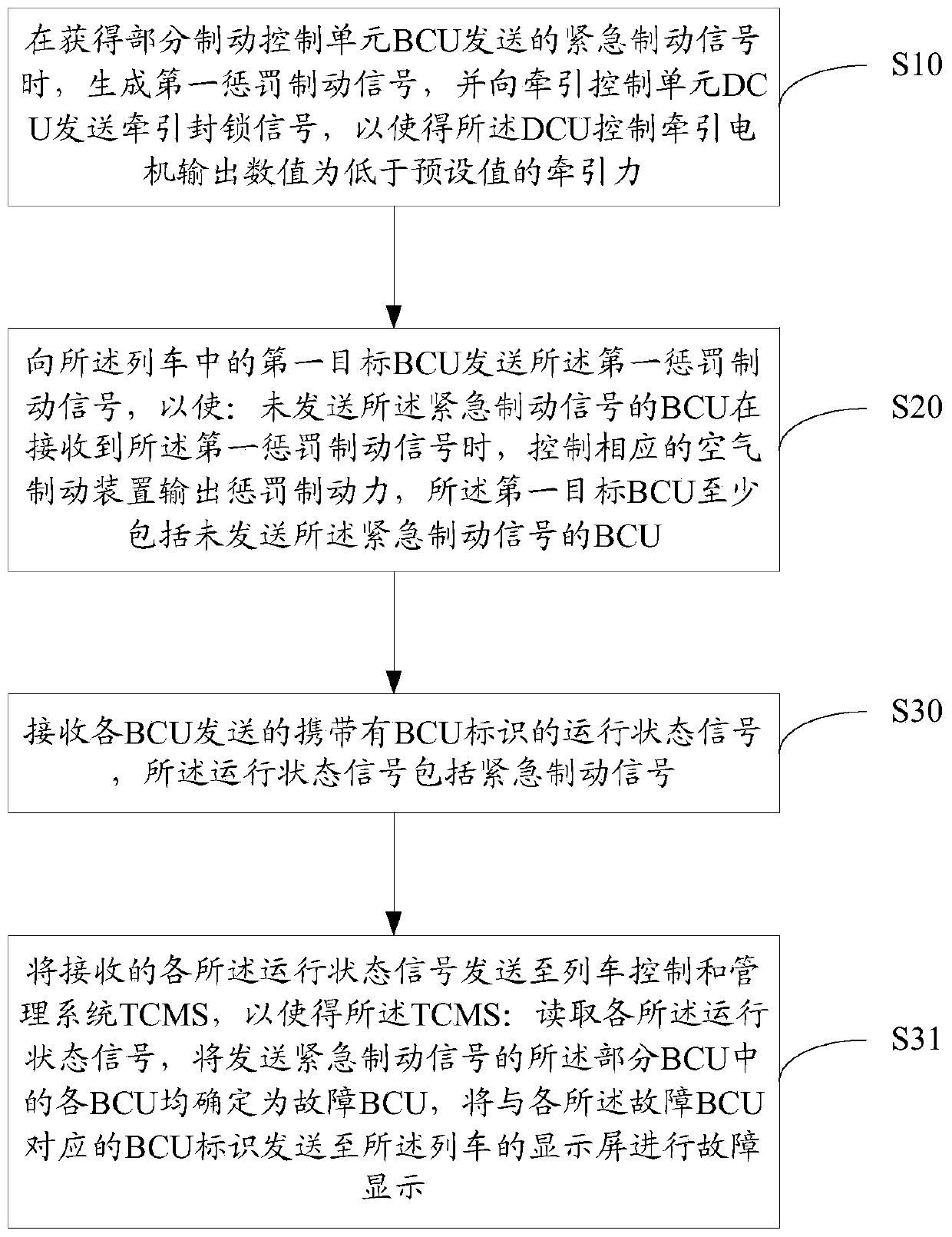

Train brake control method and equipment

ActiveCN110949448AShorten speedLarge braking forceSignalling indicators on vehicleAir brakeElectric machinery

The invention discloses a train brake control method and equipment. The method comprises the following steps: when emergency brake signals sent by a part of brake control units BCU are acquired, generating a first punishment brake signal, sending a traction blocking signal to a traction control unit DCU so as to enable the DCU to control the traction motor to output traction force with the numerical value lower than a preset value; sending a first punishment braking signal to a first target BCU in the train; when the BCU which does not send the emergency brake signal receives the first punishment brake signal, controlling the corresponding air braking device to output punishment braking force, wherein the first target BCU at least comprises a BCU which does not send an emergency braking signal, The braking force of the whole train in a non-traction running state can be increased, and the deceleration of the train is increased, so that the high friction force and high loss of the wheelsof the vehicle subjected to accidental emergency braking can be quickly dispersed to the wheels of other vehicles, the high friction force and high loss of the local wheels of the train are reduced,and the wheel scratching risk is reduced.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Brake monitoring systems and methods

ActiveUS20140136068A1Analogue computers for trafficComputations using stochastic pulse trainsMonitoring systemBraking system

An air brake monitoring system includes an air brake control module and an air brake monitoring module. The air brake control module is configured to control variation of an amount of pressure in a brake pipe of the vehicle to actuate brakes of a braking system of the vehicle. The air brake monitoring module is configured to obtain a reference replenishment volume corresponding to a volume of air used to recharge the braking system after application of the brakes of the braking system when the braking system when a first amount of brakes are operational, to obtain an actual replenishment volume corresponding to an actual volume of air used to recharge the braking system of the vehicle after a braking activity performed by the vehicle, and to generate a signal based on a comparison of the actual replenishment volume to the reference replenishment volume.

Owner:GE GLOBAL SOURCING LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com