Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9078 results about "Brake force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

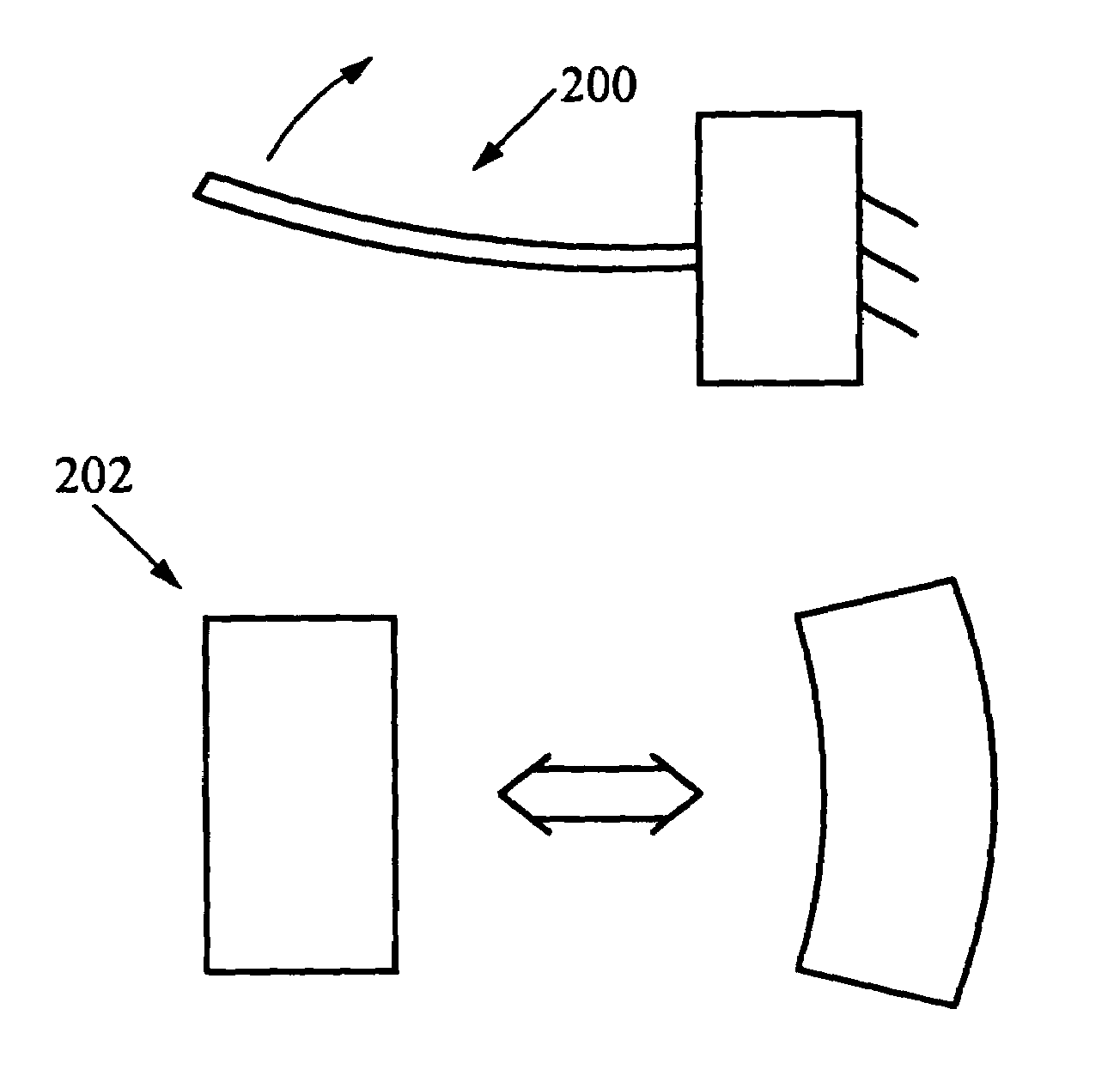

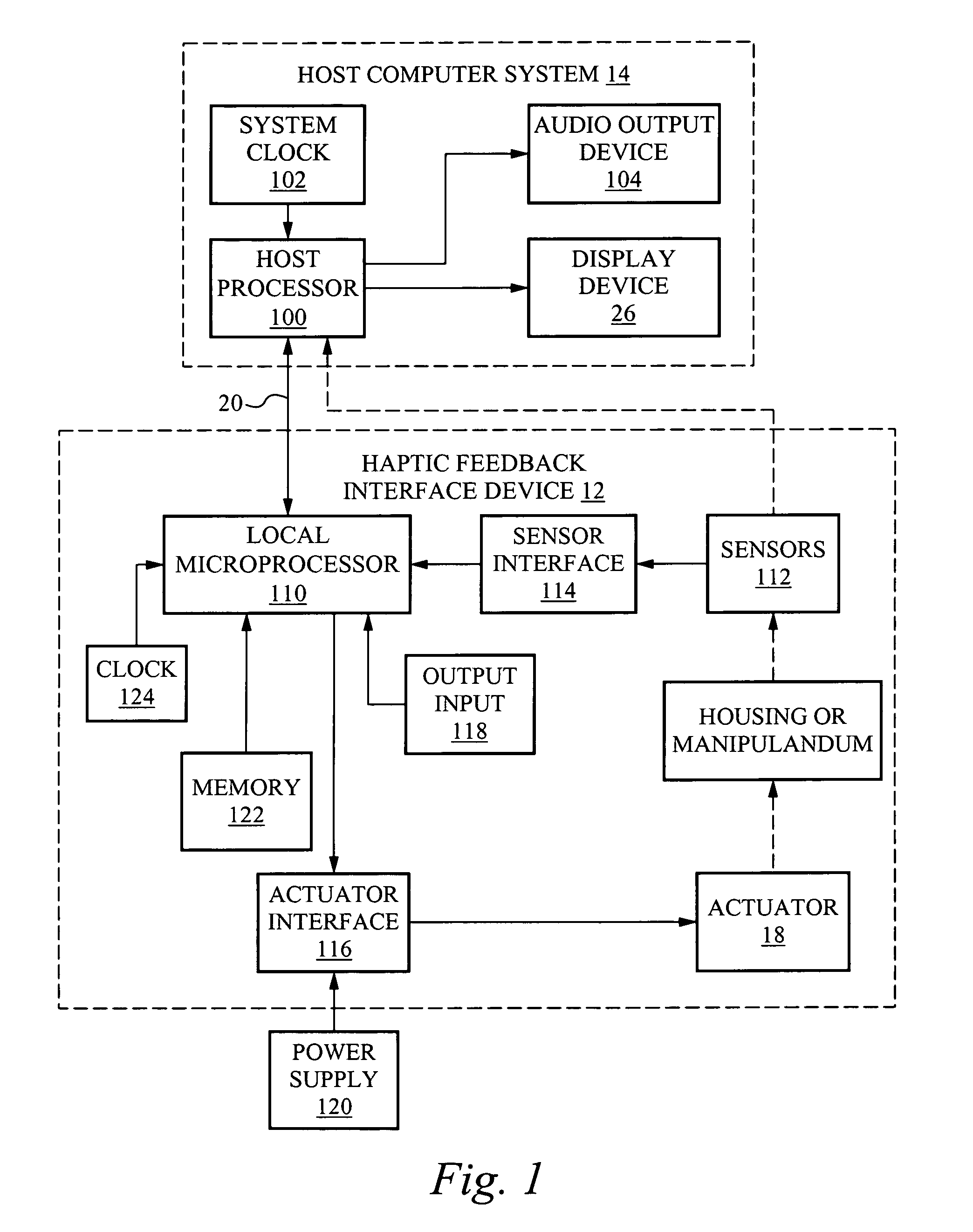

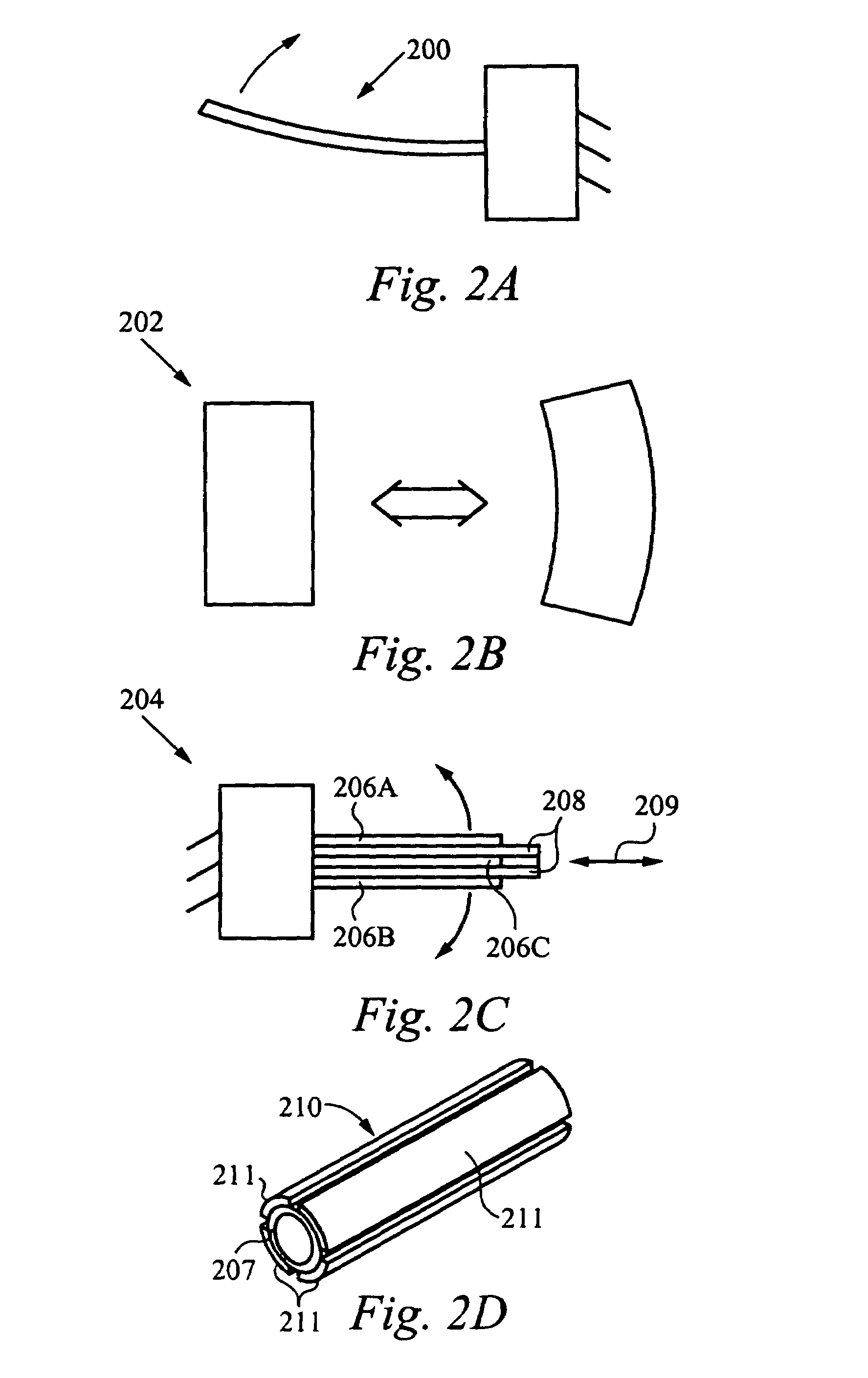

Haptic devices using electroactive polymers

ActiveUS7196688B2Low costEfficiently provideInput/output for user-computer interactionManual control with multiple controlled membersActive polymerHaptic sensing

Haptic feedback interface devices using electroactive polymer (EAP) actuators to provide haptic sensations and / or sensing capabilities. A haptic feedback interface device is in communication with a host computer and includes a sensor device that detects the manipulation of the interface device by the user and an electroactive polymer actuator responsive to input signals and operative to output a force to the user caused by motion of the actuator. The output force provides a haptic sensation to the user. Various embodiments of interface devices employing EAP actuators are described, including embodiments providing direct forces, inertial forces, and braking forces.

Owner:IMMERSION CORPORATION

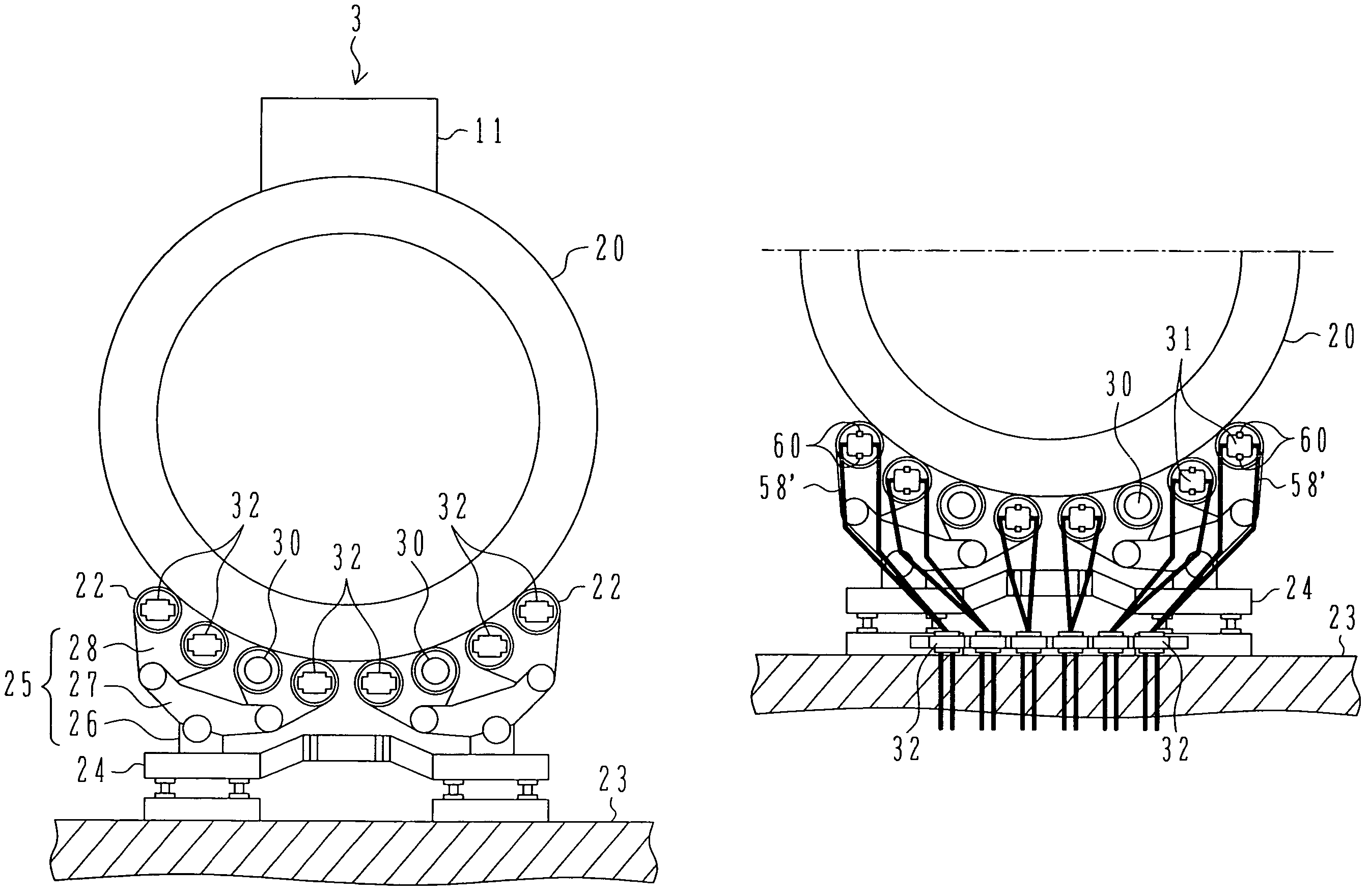

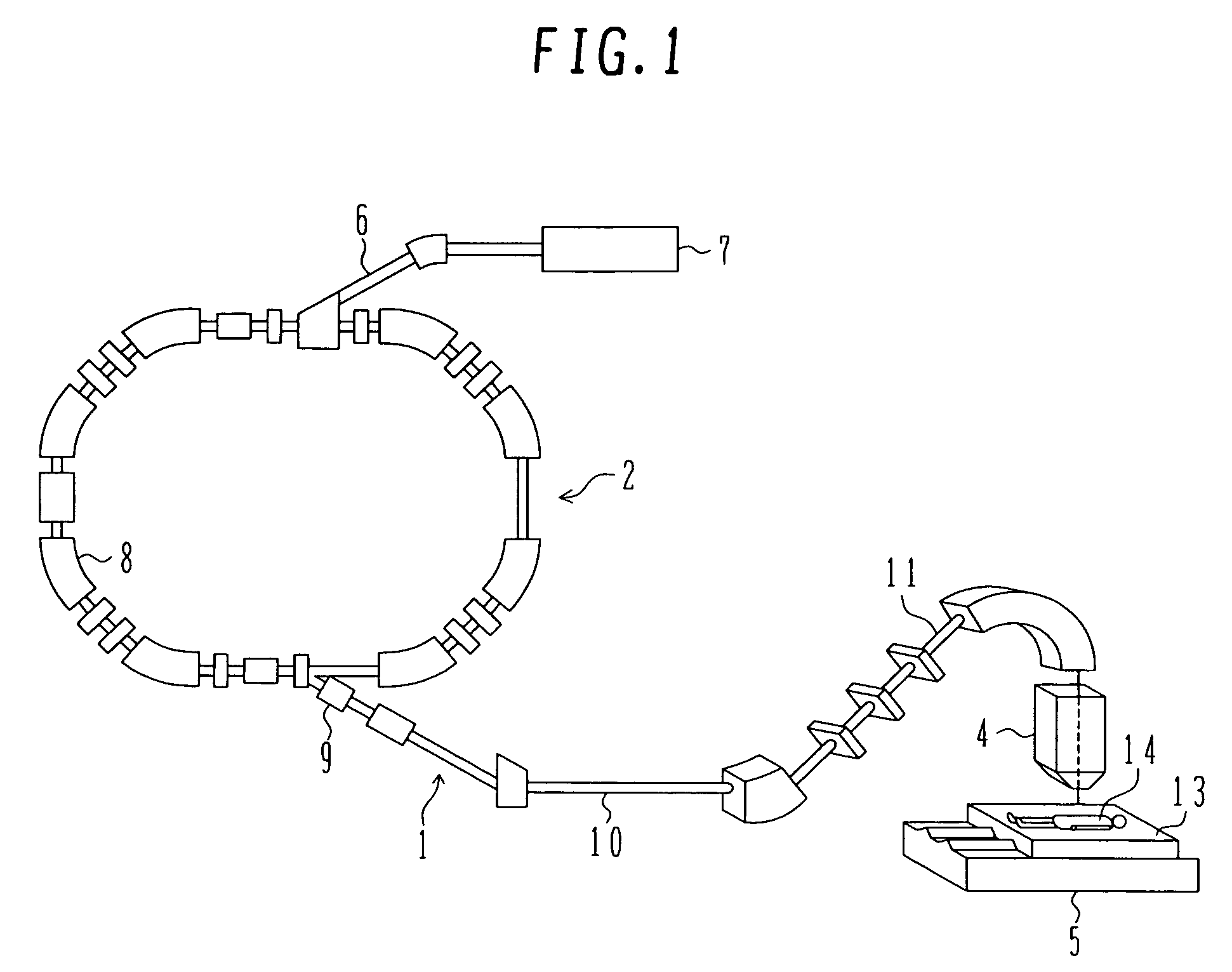

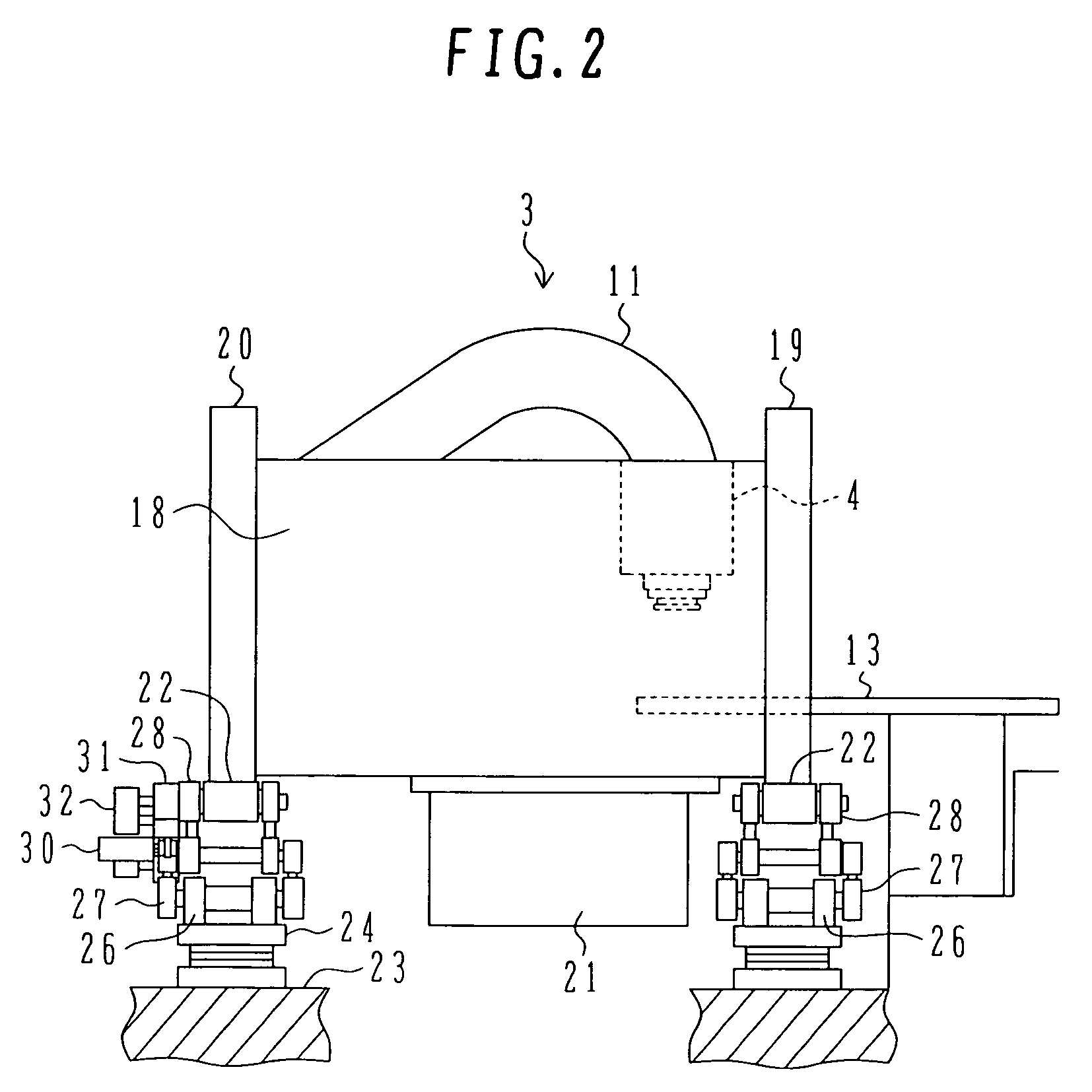

Rotating gantry of particle beam therapy system

ActiveUS7372053B2Improve rigidityVariation can be suppressedThermometer detailsFluid actuated brakesSolenoid valveParticle beam

A rotating gantry includes a link frame for supporting a plurality of rollers which rotatably support the rotating gantry, a brake for releasing a braking force applied to at least one of the rollers upon supply of air and applying the braking force to the one roller upon discharge of air, and a solenoid valve for sealing the supplied air in the brake when closed, and discharging the air from the brake when opened. The solenoid valve is supported by a solenoid valve support member mounted to the link frame such that the solenoid valve is positioned just near the brake. The rotating gantry can be more quickly braked and stopped while maintaining high irradiation accuracy.

Owner:HITACHI LTD +1

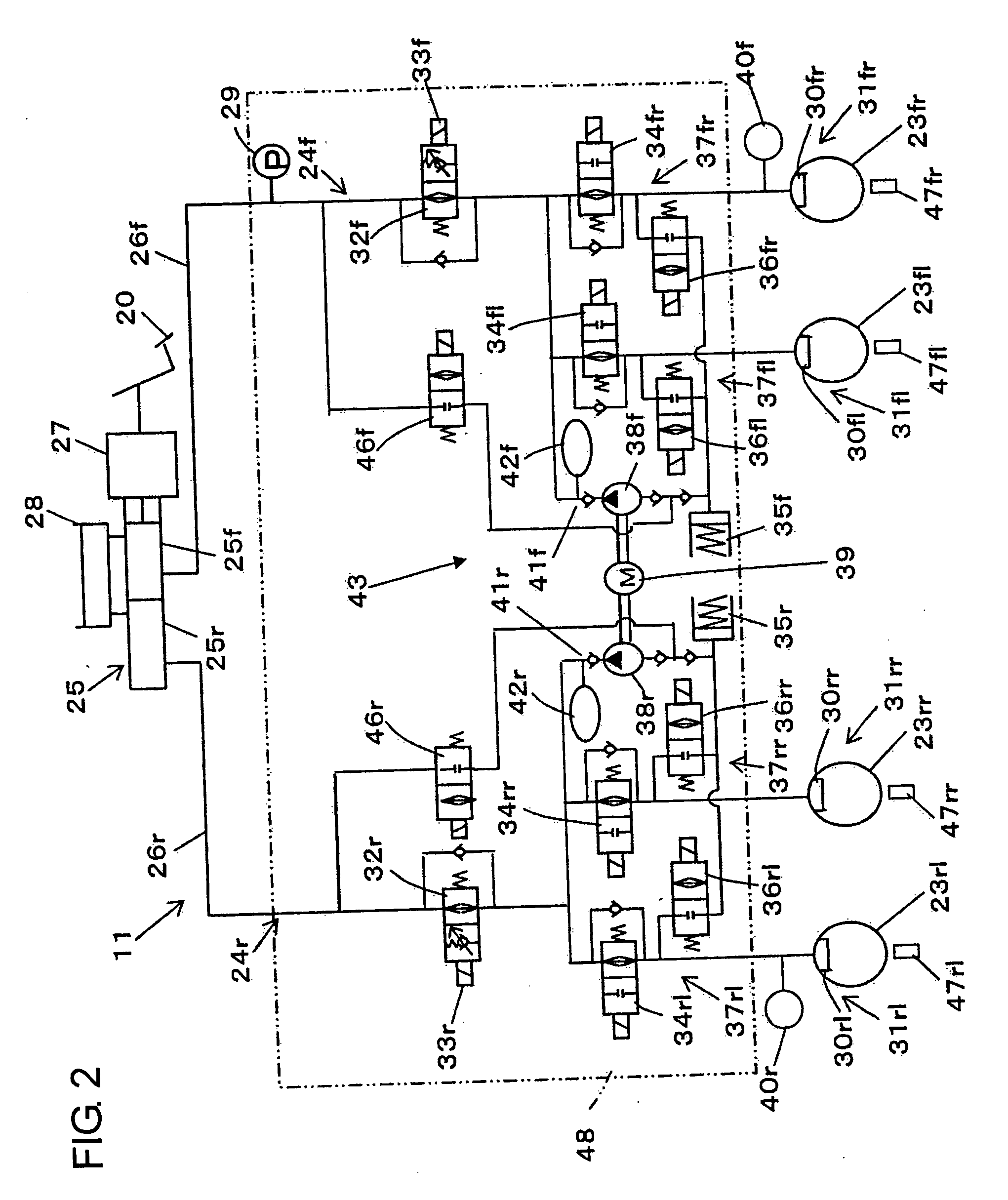

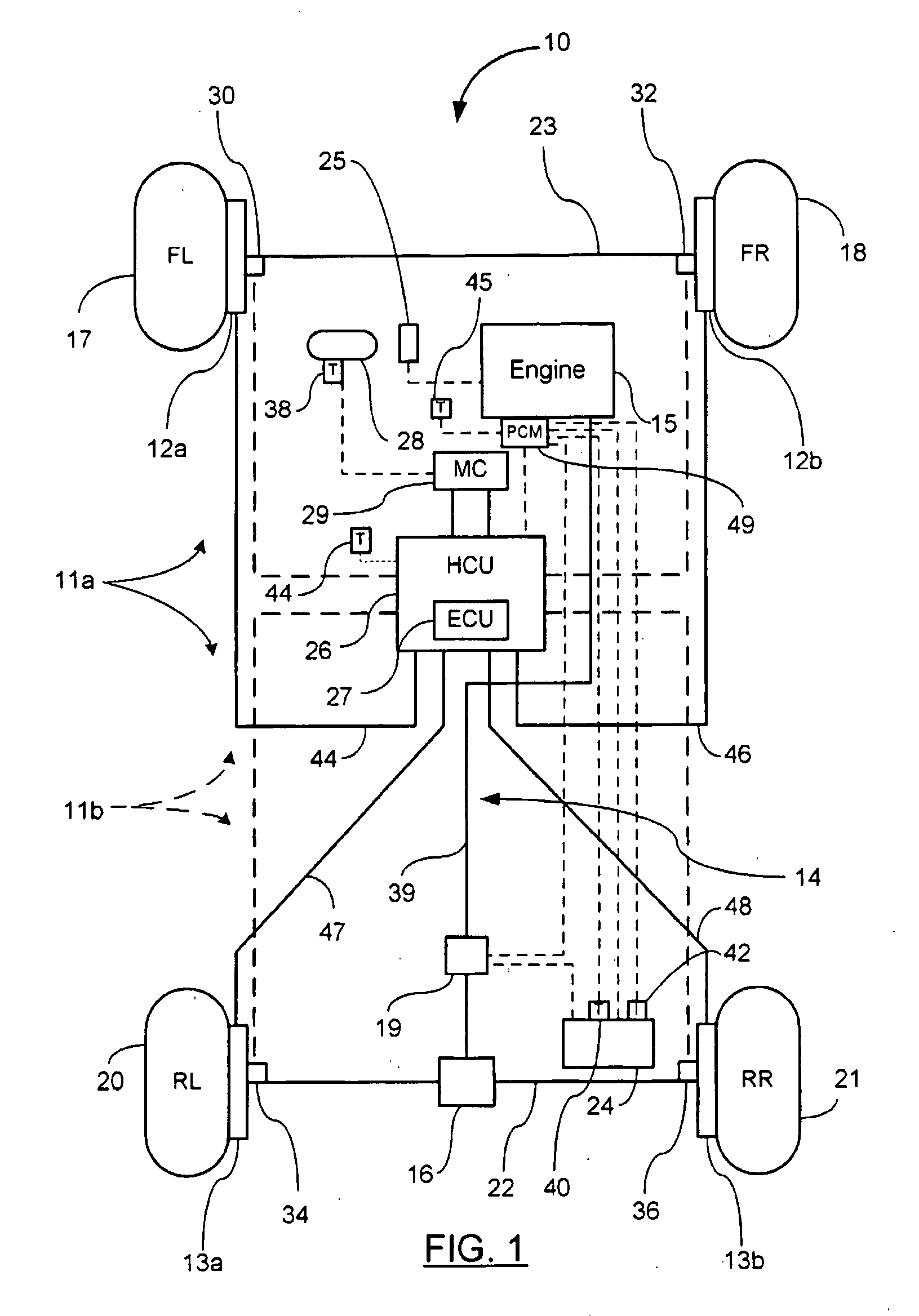

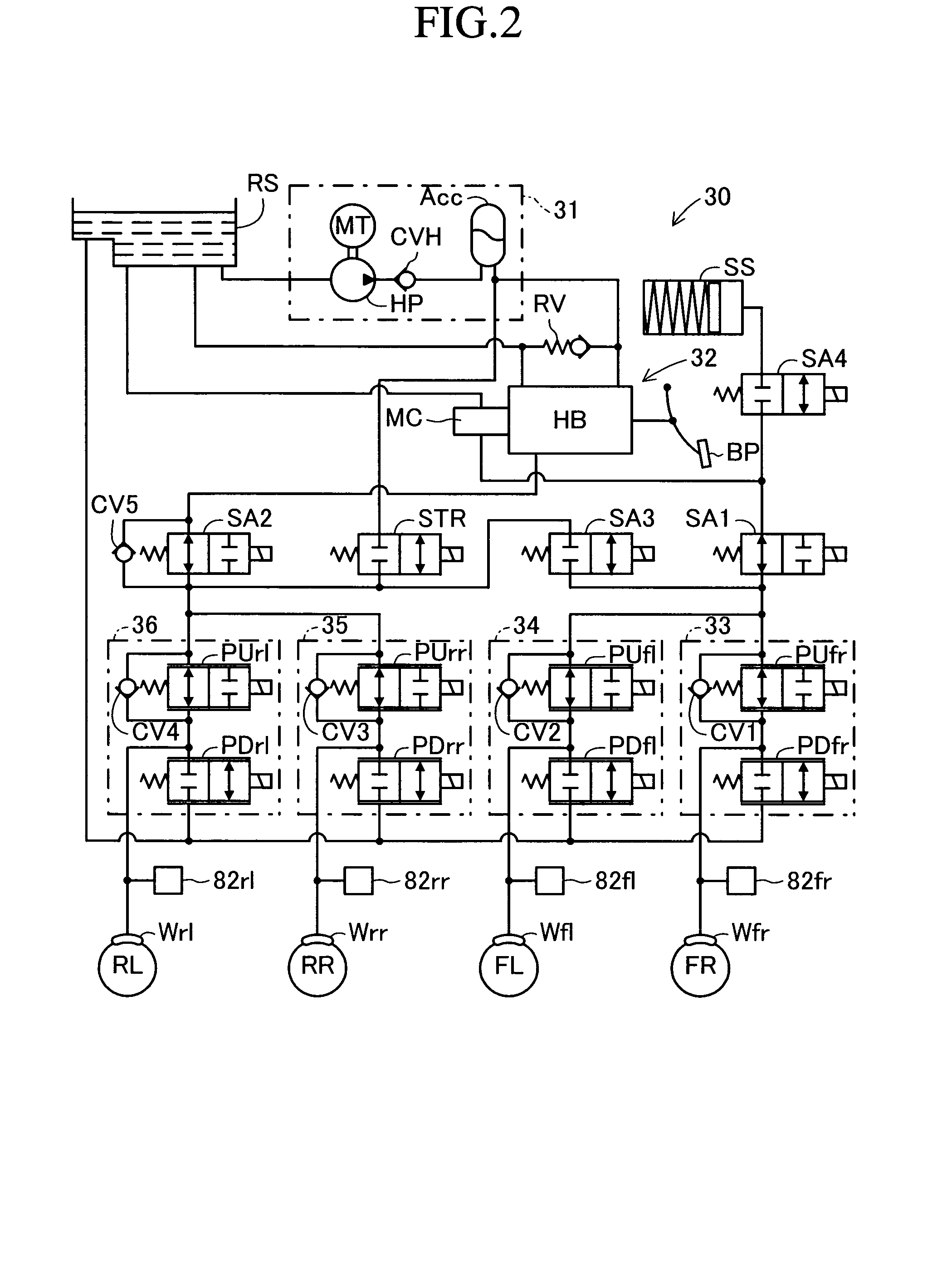

Vehicle brake device

InactiveUS20050269875A1Small dimensionLight weightPropulsion by batteries/cellsVehicular energy storageRegenerative brakeEngineering

A vehicle brake device is provided with a hydraulic brake device for boosting by a booster device a braking manipulation force generated upon a braking manipulation, for applying a base fluid pressure generated in dependence on the boosted brake manipulation force, to wheel cylinders of wheels so that a base hydraulic brake force is generated on the wheels, and for driving a pump to generate and apply a controlled fluid pressure to the wheel cylinders so that a controlled hydraulic brake force is generated on the wheels; braking manipulation state detecting means for detecting the braking manipulation state; a regenerative brake device for causing an electric motor to generate a regenerative brake force corresponding to the braking manipulation state on the wheels driven by the electric motor; variation detecting means for detecting the variation of an actual regenerative brake force actually generated by the regeneration braking device; and brake force compensating means for generating the controlled fluid pressure by driving the pump of the hydraulic brake device so that a controlled hydraulic brake force is generated on the wheels to compensate for the lack of the regenerative brake force due to the variation which is detected by the variation detecting means.

Owner:ADVICS CO LTD

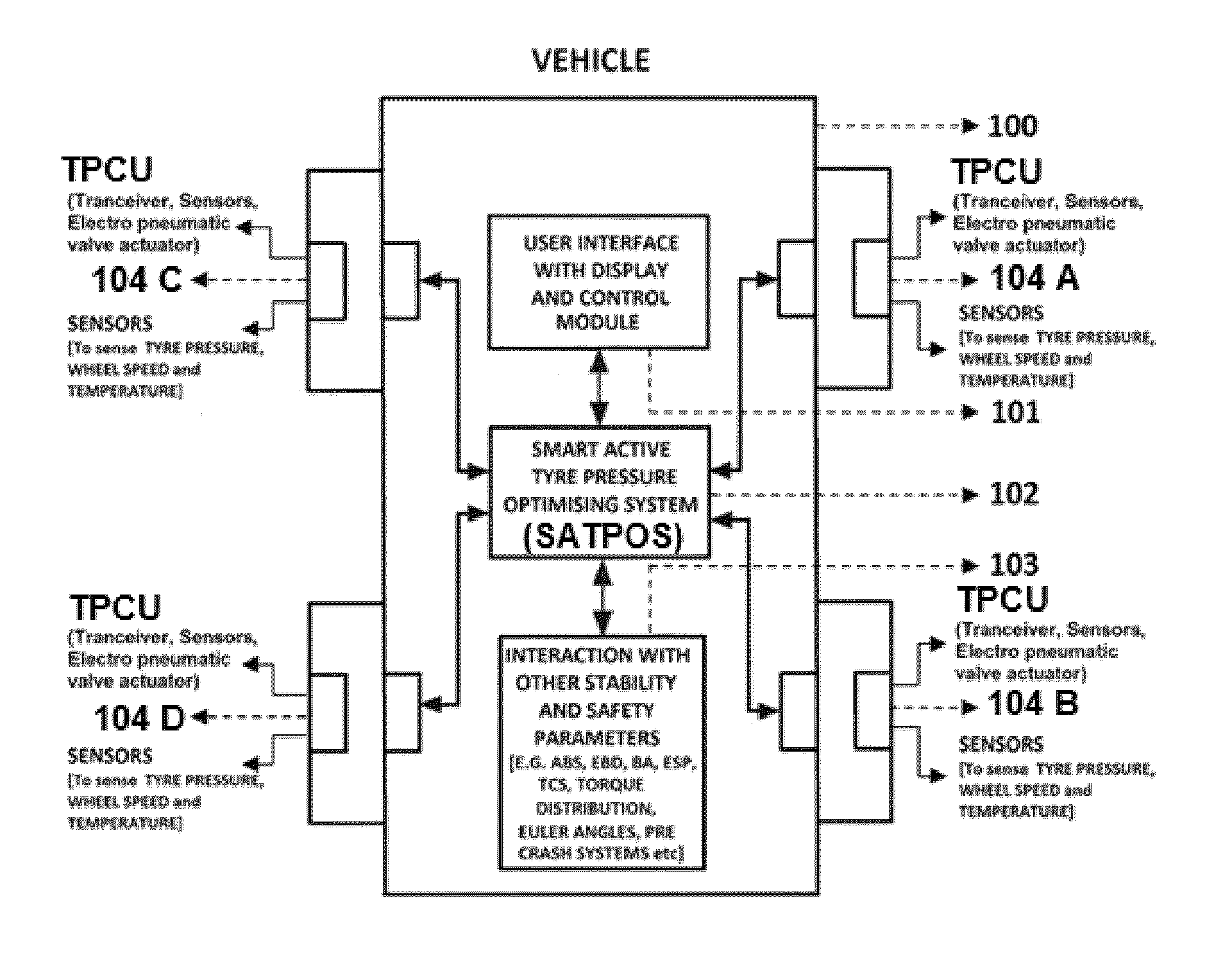

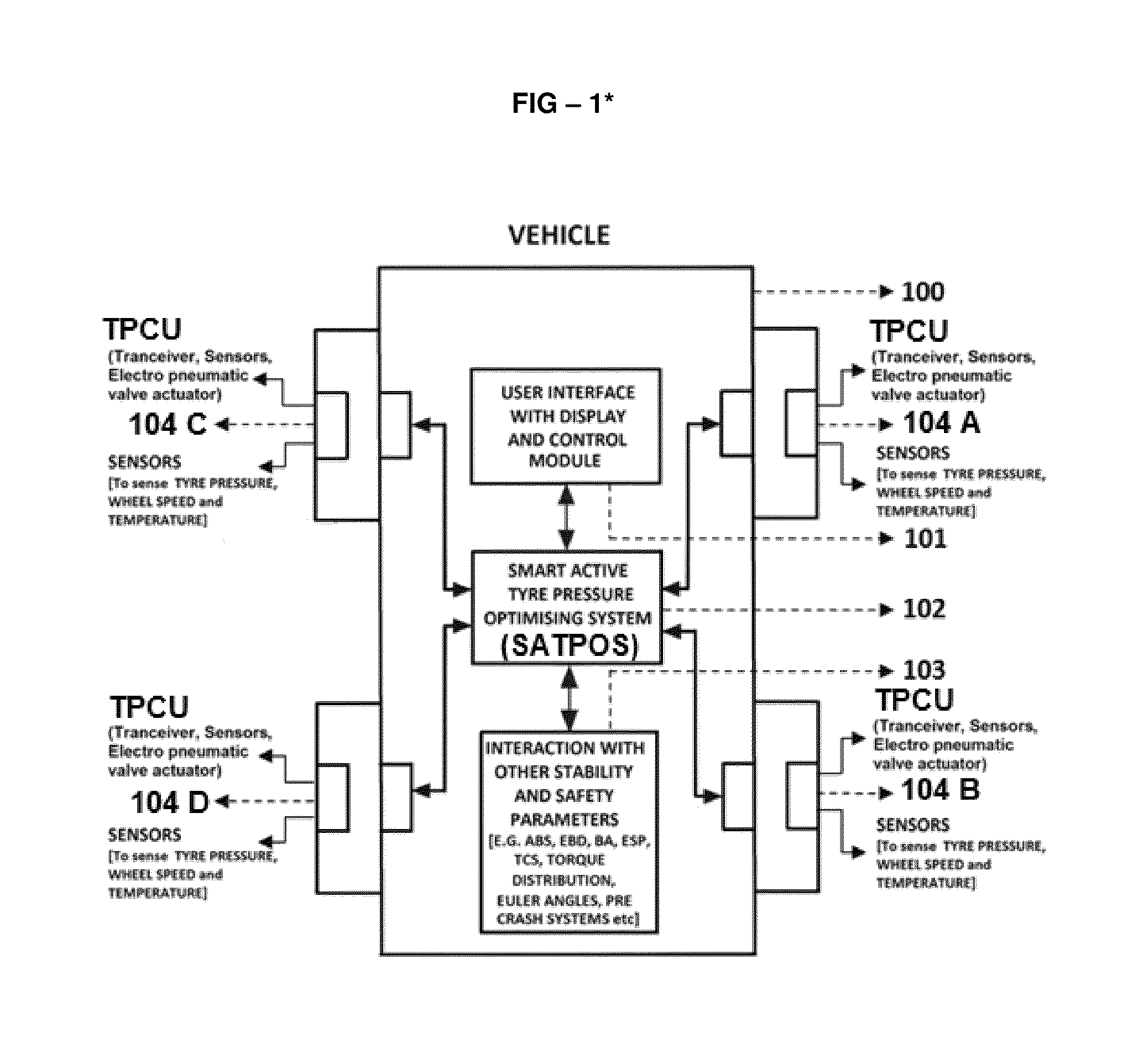

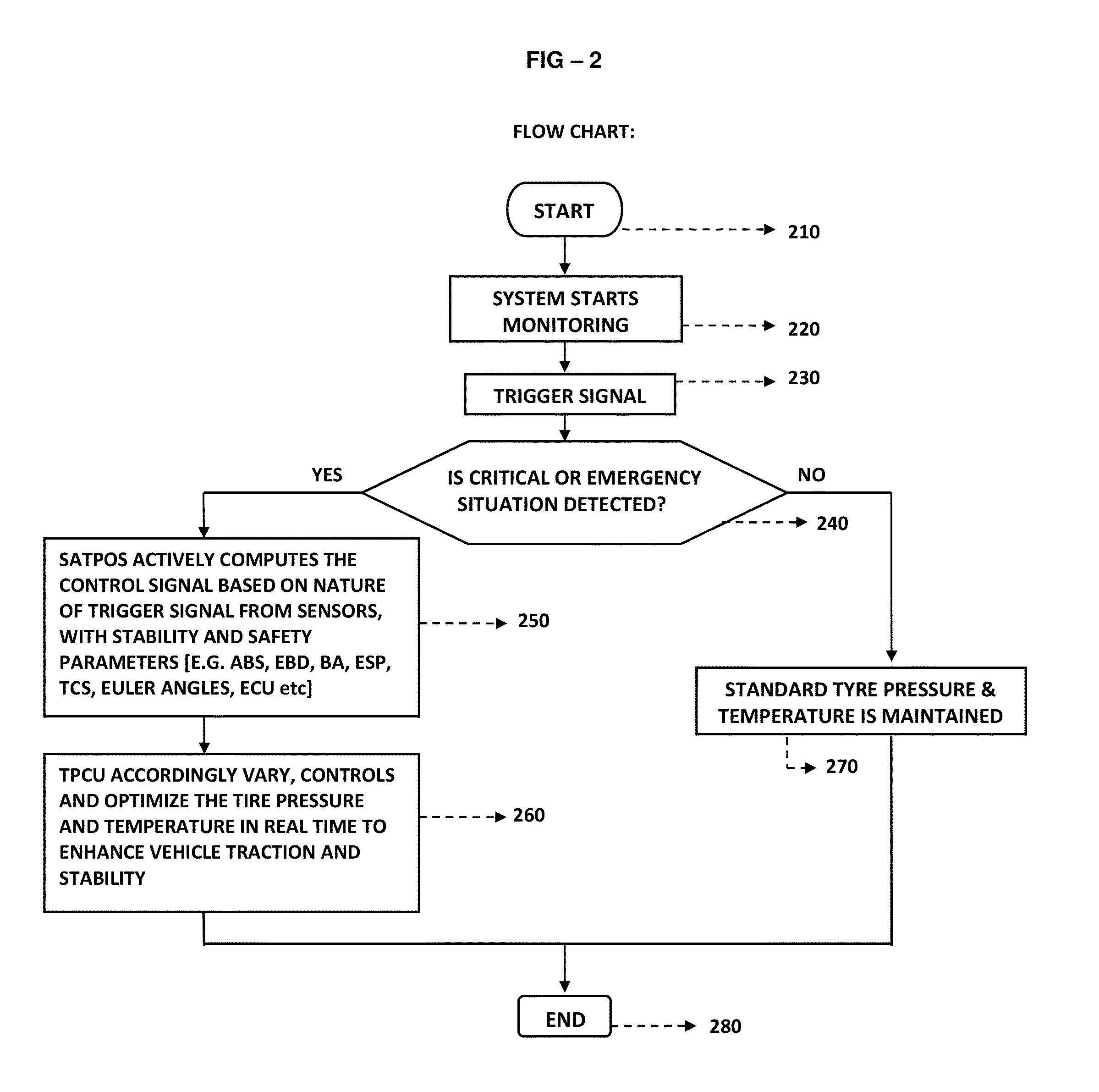

Smart active tyre pressure optimising system

ActiveUS20150005982A1Improve stabilityGreat tractionBraking element arrangementsInflated body pressure measurementSafe drivingMoisture

Smart Active Tyre Pressure Optimising System [TPOS]102 is a highly time sensitive design and technique that acts instantaneously in sensing and controlling the tire pressure particularly in imminent and inevitable critical driving situations to reduce emergency & high speed breaking distance, mitigate—loss of traction, hydroplaning, roll over, loss of stability, over & under steering, break failure, loss of control due to puncture by smartly sensing, perform context aware computing and directing the Tyre Pressure Control Units [TPCU]104 to instantaneously control the tyre pressure in right time with right pressure on right tyres thereby actively controlling the footprint and sidewall deformation rate to enhance traction & stability simultaneously sustaining drivability or steerability ultimately to avoid or reduce the impact of collusion and overcome or mitigate critical situations for protecting the vehicles, occupants, pedestrians and other objects around or on the way; also according to design, configurations and scenarios the system instantaneously optimises the tyre pressure on all tyres for further safe driving till next restoration else restores the pressure to optimum preset value utilising inbuilt reservoir or other external restoration systems immediately after the vehicle overcomes the critical situation to continue with safe and comfortable driving. In critical situations TPOS performs sensing, pre computing, current computing for controlling the tire pressure during critical situation, post computing to optimise tire pressure after overcoming accordingly. TPOS 102 utilise smart and adaptive closed loop processing algorithm with predetermined and tested lookup table to instantaneously check and compare the effects between predetermined and tested real world scenarios to the actual real world scenarios for actively sensing, computing and controlling the tire pressure accordingly to mitigate the critical situations. The controlling of tyre pressure is computed mainly based on parameters comprising of sensor system, vehicle safety and stability systems, nature of breaking & break force distribution, tires upper & lower cut-off pressure values, sensing reservoirs and tires internal & external pressure, temperature, moisture, humidity, wheel & tire specifications, vehicle & wheel speed, acceleration & deceleration, vehicle orientation & axial rotation, transverse motion & lateral acceleration, tires position or angle of attack, load & torque distribution, tire traction, steering position, cornering effects, change in Centre of gravity, over & under steering, hydroplaning, sensing road conditions, etc and to further enhance the efficiency, the system interoperates with vehicles existing safety and stability systems like ABS, EBD, ESC, TCS, Rollover mitigation systems, ECU, BA, Precrash systems, suspension & vertical dynamics, radar assisted auto breaking, cruise control system, aerodynamics & airbrakes etc. Other aspects of present invention are controlling the tire temperature according to environmental temperature, moisture and humidity thereby to enhance traction and vary tire pressure according to change in centre of gravity & load, driving modes—comfort, standard and sports modes.

Owner:MUTHUKUMAR PRASAD

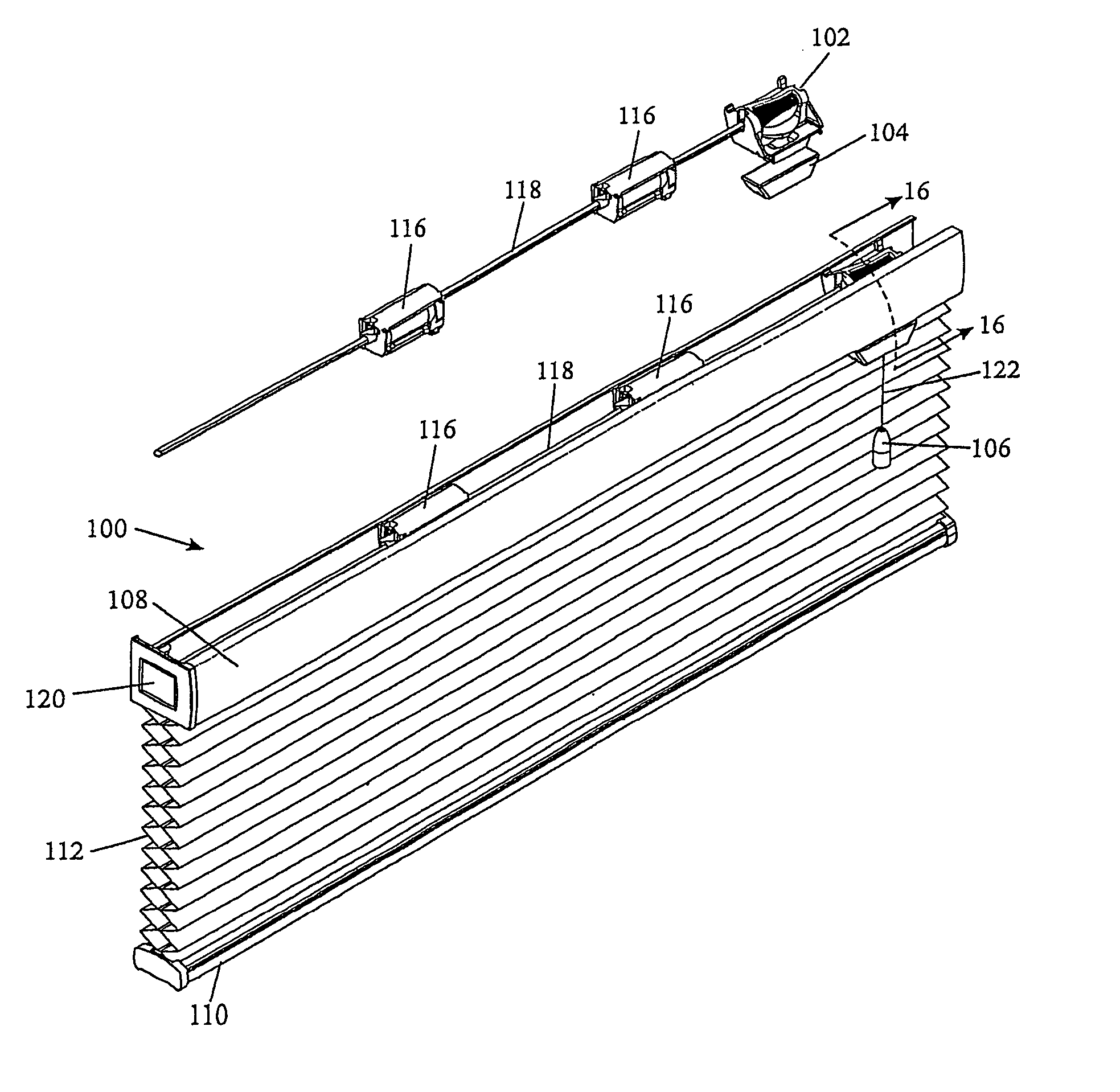

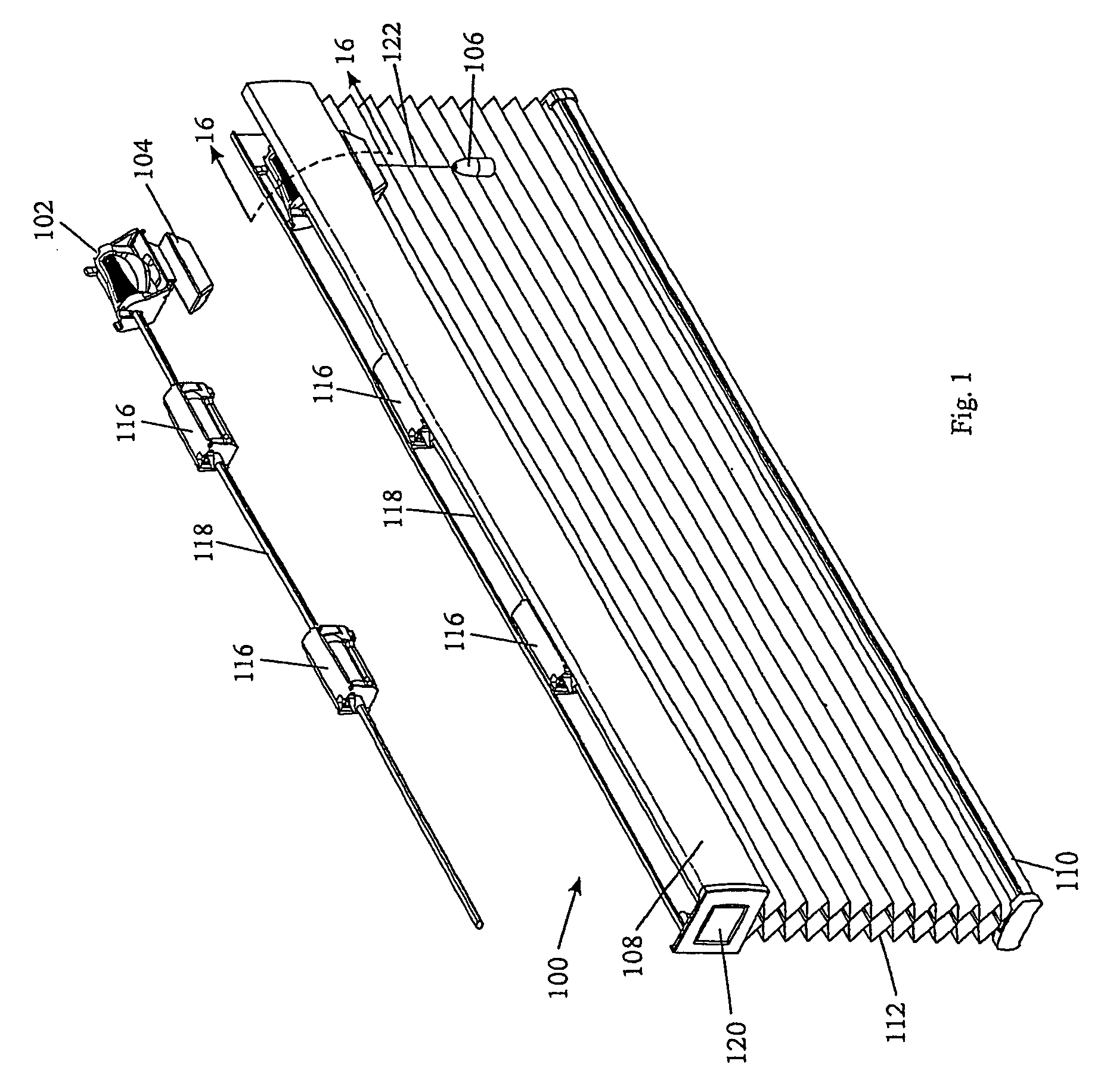

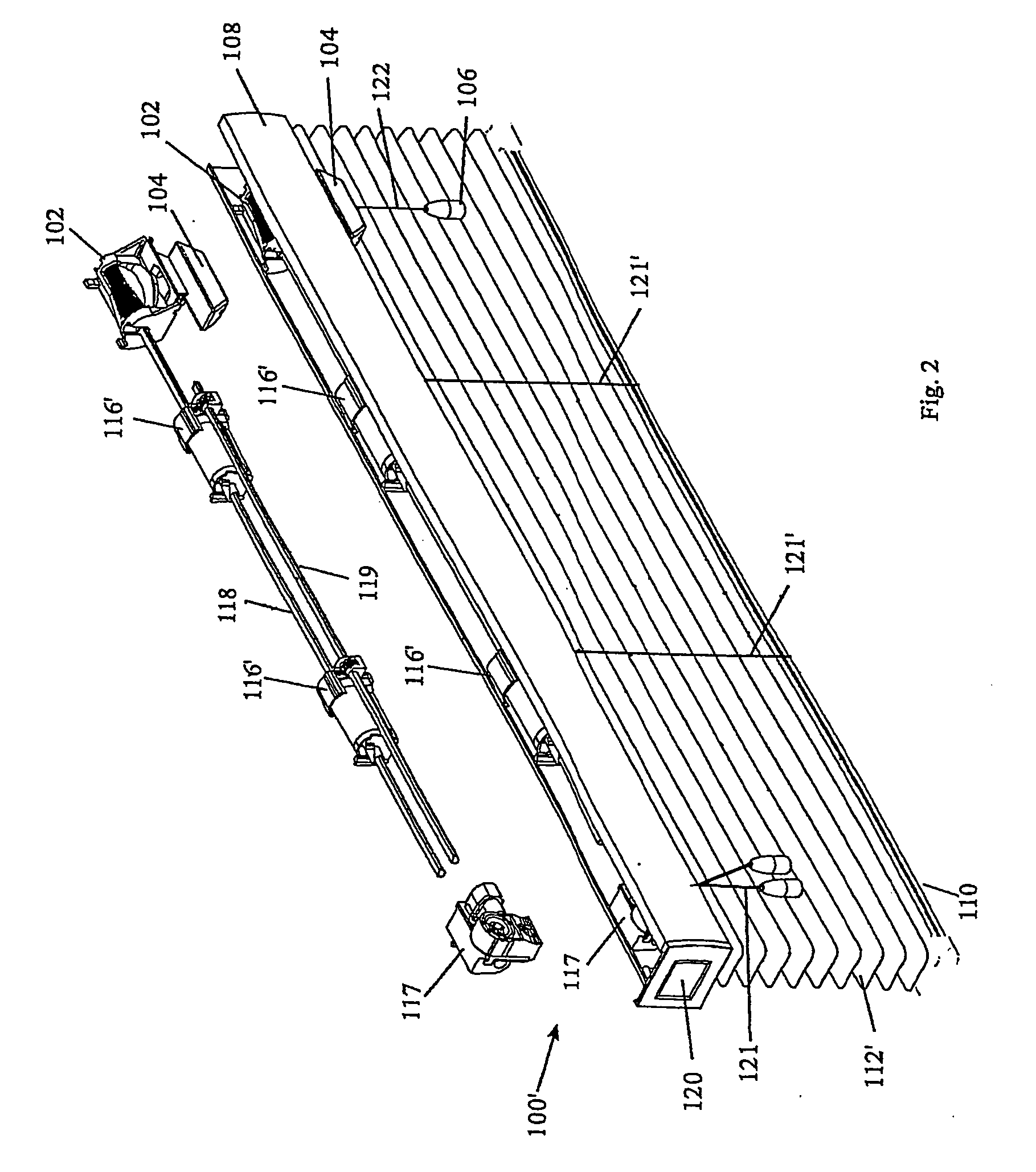

Drive for coverings for architectural openings

ActiveUS20060118248A1Many problemEliminate needExtensible doors/windowsCurtain accessoriesLinear motionEngineering

A cord drive mechanism to convert linear motion to circular motion for use in coverings for architectural openings. Various controls are used to provide a braking force on the cord. Some of the embodiments incorporate a capstan.

Owner:HUNTER DOUGLAS INC

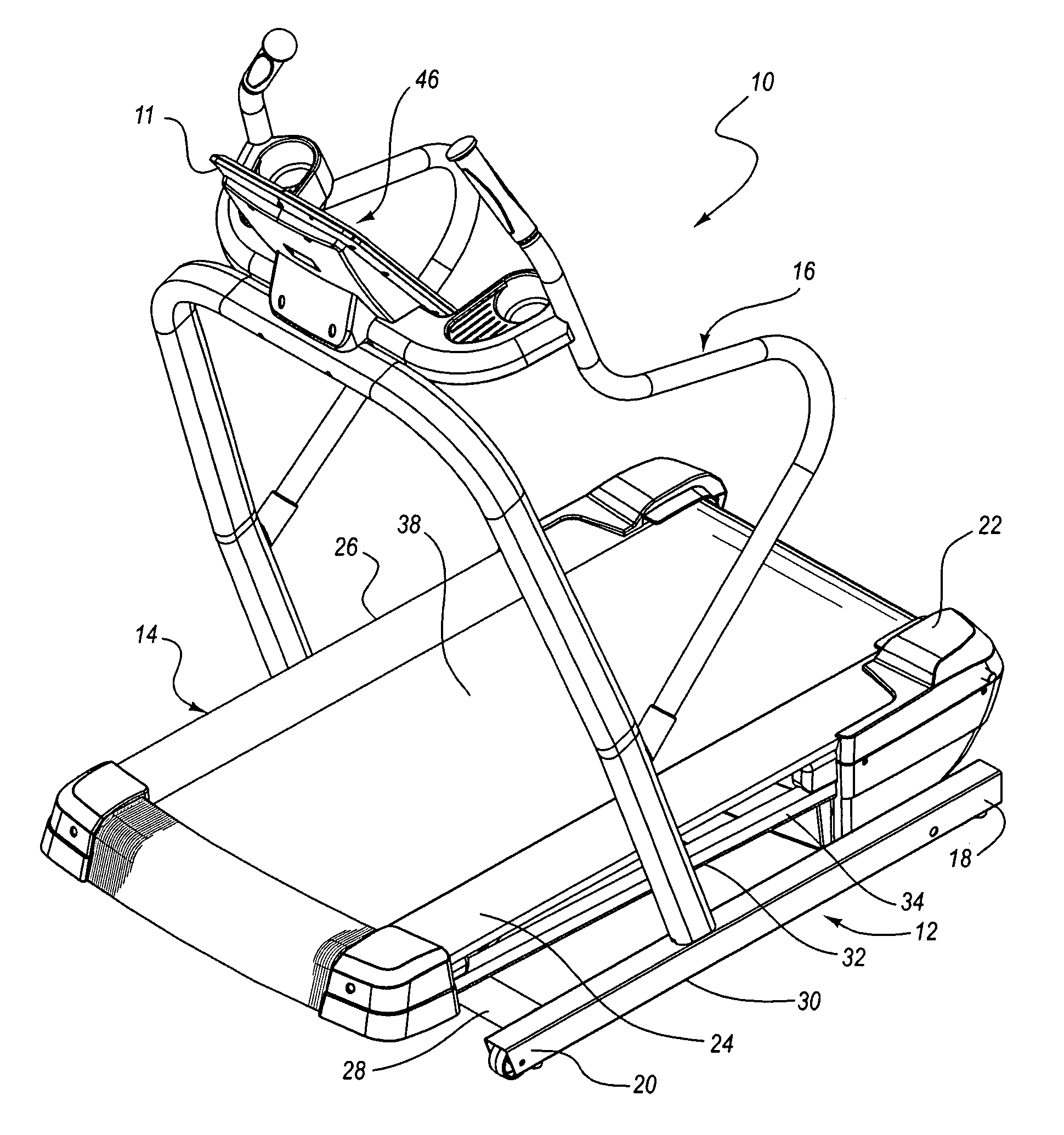

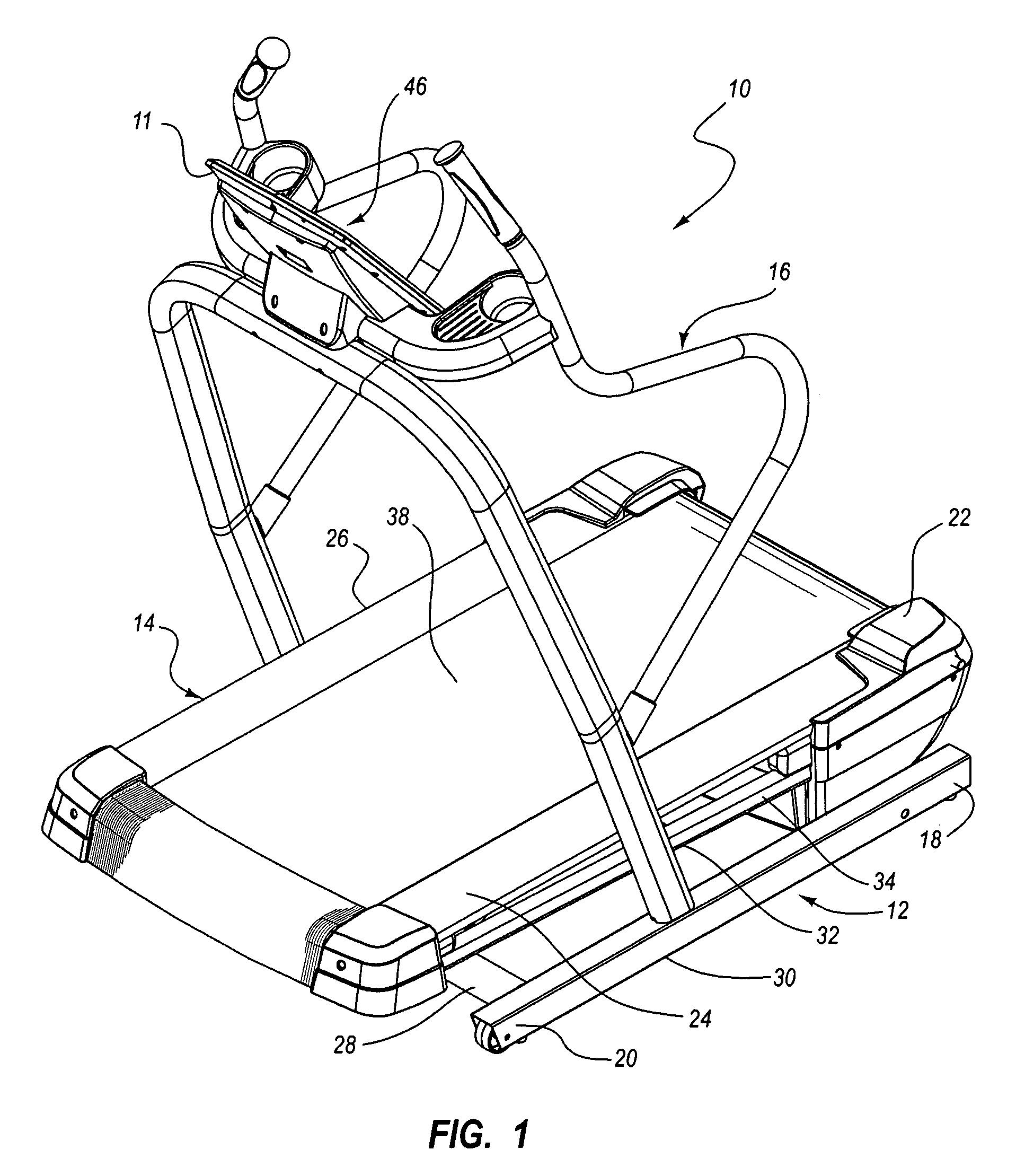

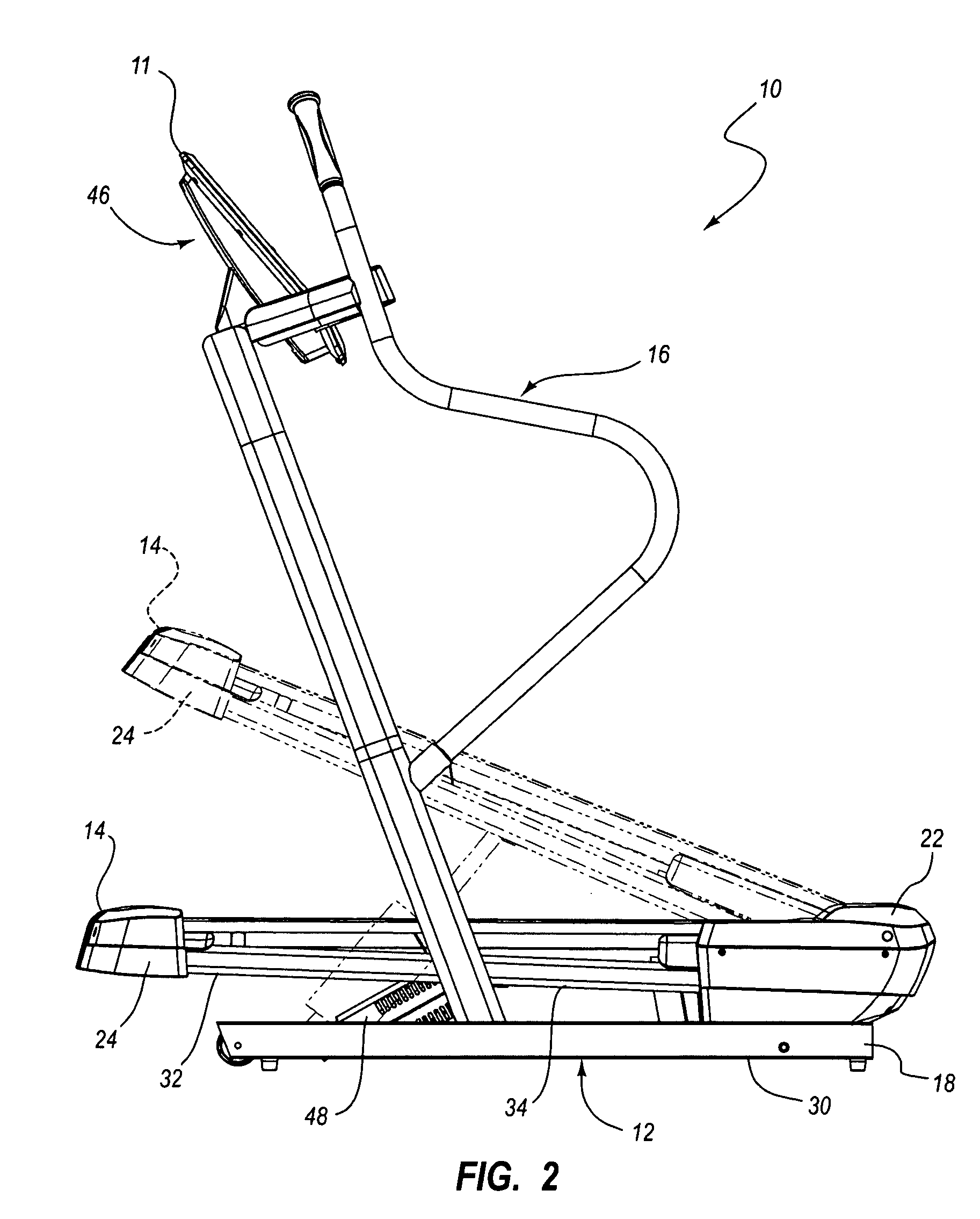

Inclining treadmill with magnetic braking system

InactiveUS7862483B2Increased leverageImprove tilt effectMuscle exercising devicesMovement coordination devicesMagnetic tension forceEngineering

A selectively inclining hiking exercise apparatus supports a user ambulating thereon. The selectively inclining hiking exercise apparatus includes a support base and a treadbase that selectively inclines with respect to the support base. The treadbase includes a motor for driving an endless belt upon which the user ambulates. The treadbase also includes a magnetic braking assembly for regulating the speed of the endless belt to prevent the endless belt from moving at a rate that is faster than the rate at which the treadbase motor is driving the endless belt. The magnetic braking assembly includes a magnet that selectively moves relative to the treadbase flywheel along a threaded lead screw to provide the braking force.

Owner:ICON HEALTH & FITNESS INC

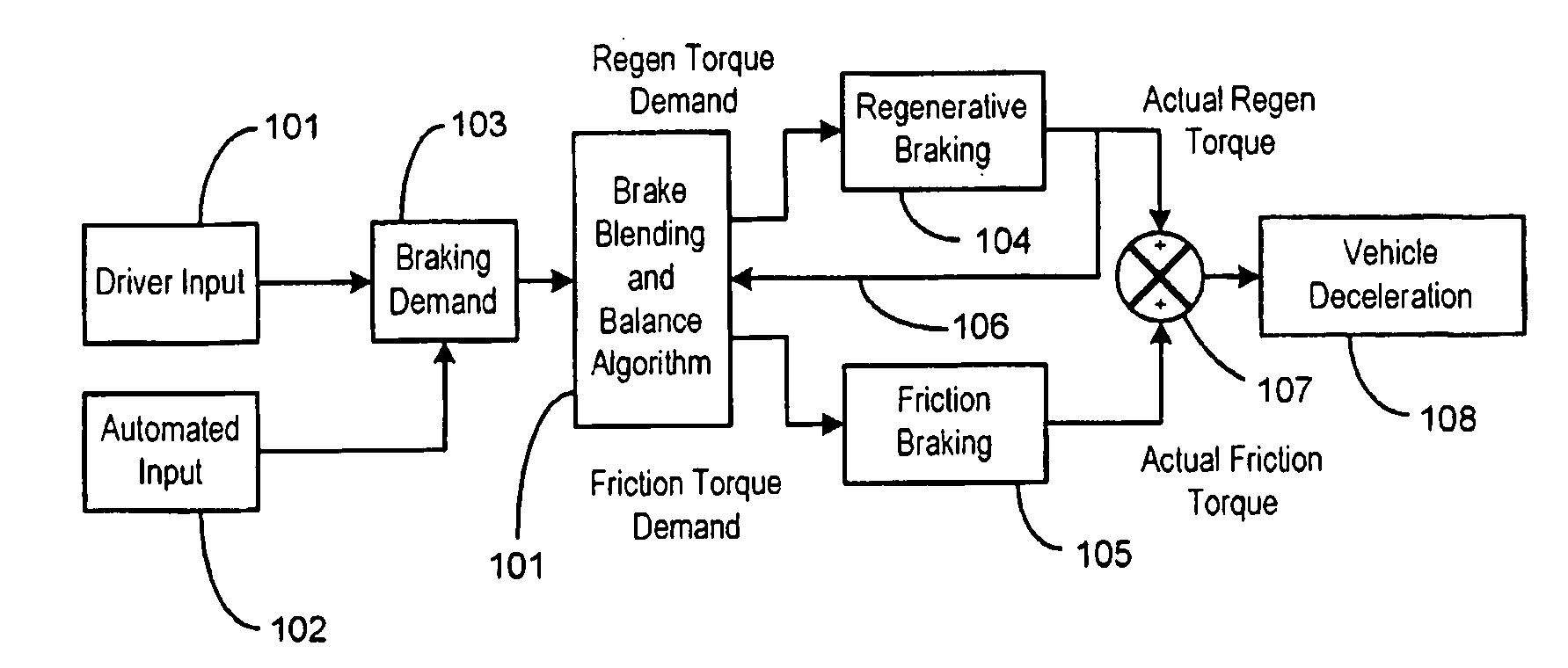

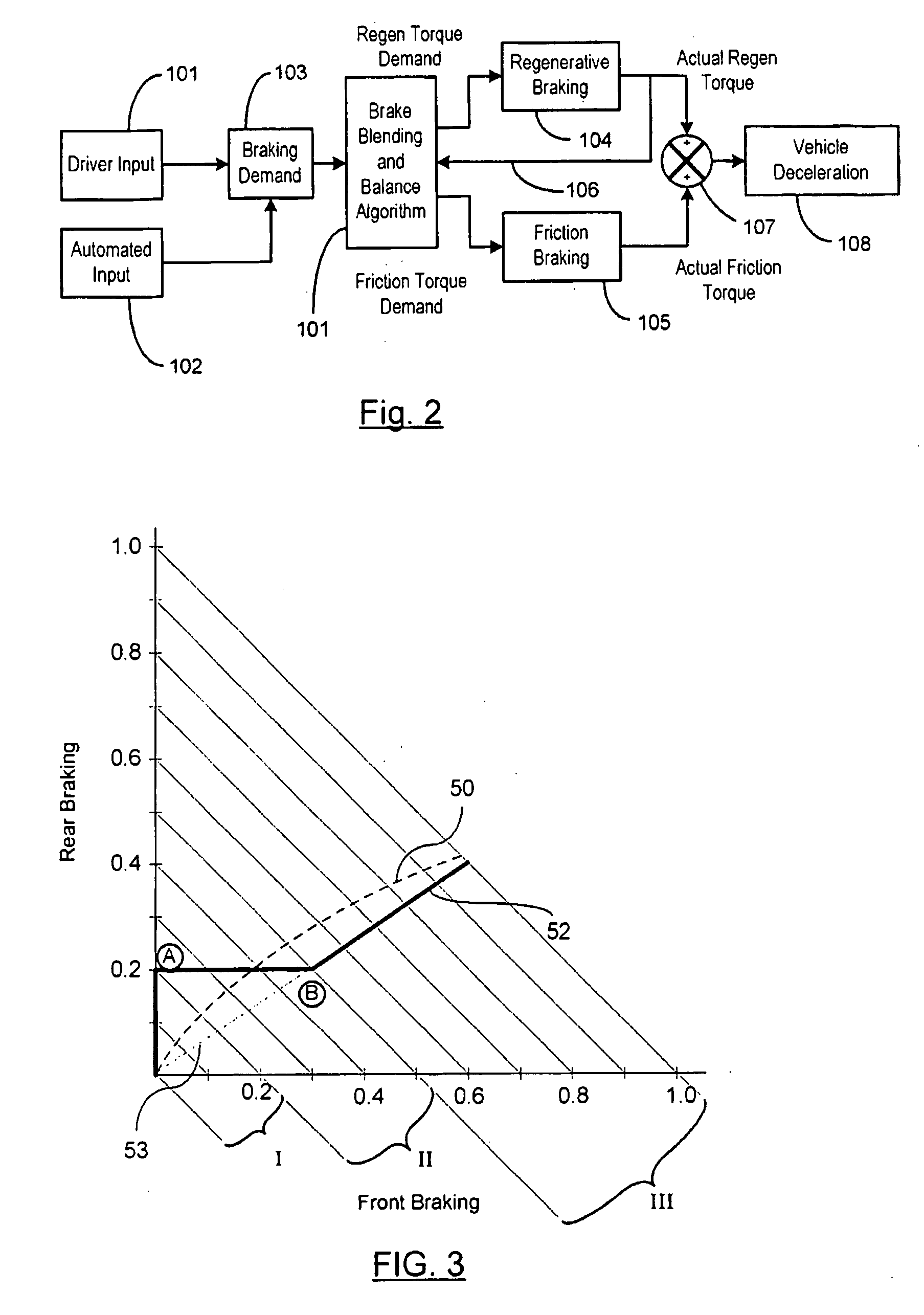

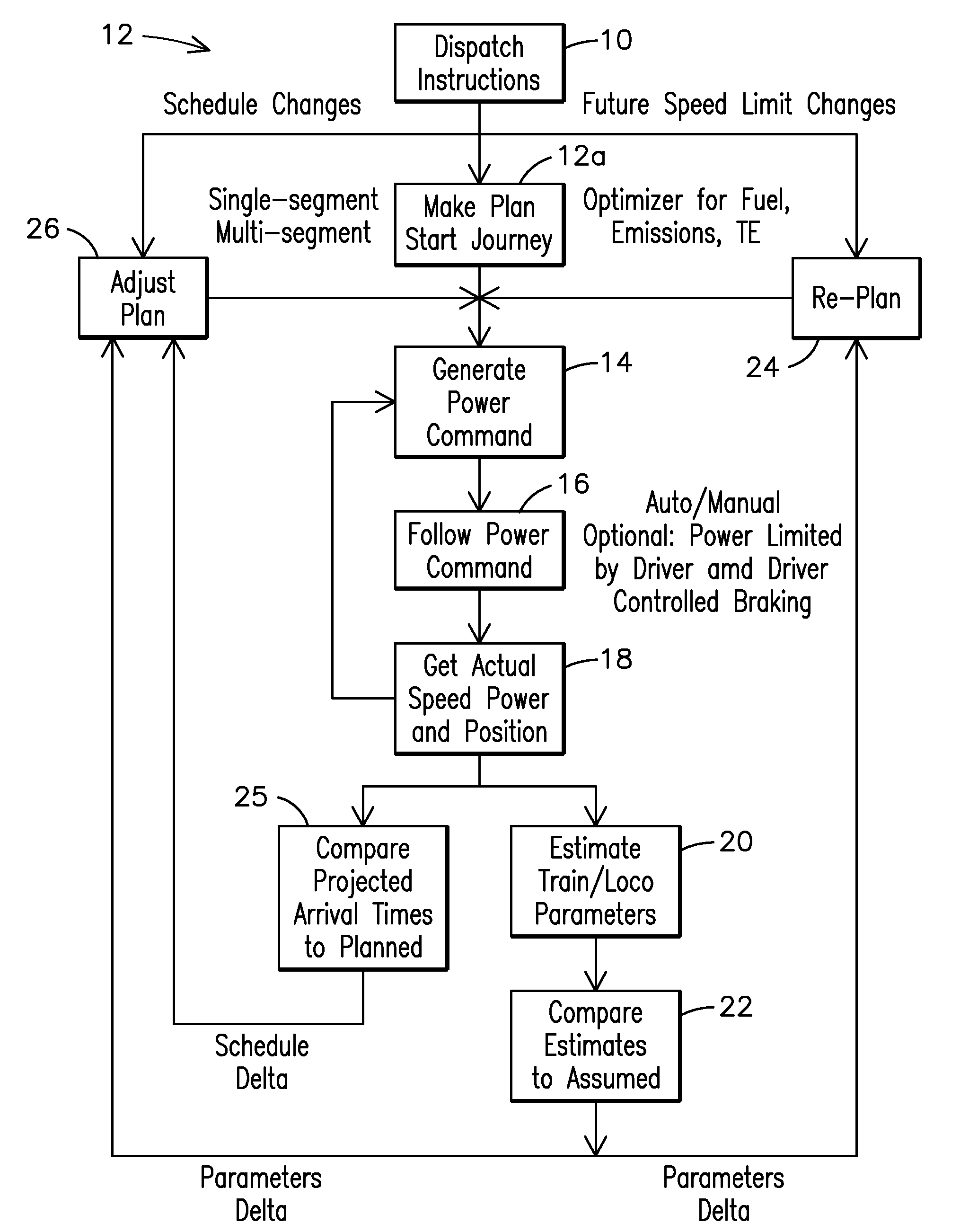

Vehicle System Having Regenerative Brake Control

ActiveUS20080100129A1Analogue computers for trafficBraking action transmissionRegenerative brakeKinetic energy

A method is provided for controlling the braking of a vehicle that has a first set of friction brakes for applying a first apply brake force to a first set of wheels and a second set of friction brakes for applying a second brake apply force to a second set of wheels. A powertrain assembly is coupled to the second set of wheels. The powertrain assembly includes a regenerative braking unit capable of recapturing kinetic energy from the second set of wheels. The vehicle is braked in a first phase of control using regenerative braking to brake the second set of wheels to achieve up to a first value of braking. The vehicle is braked in a second phase of control using the regenerative braking to maintain braking of the second set of wheels at the first value of braking force while selectively applying the first friction brakes to the first set of wheels up to a second value of braking.

Owner:KELSEY HAYES CO

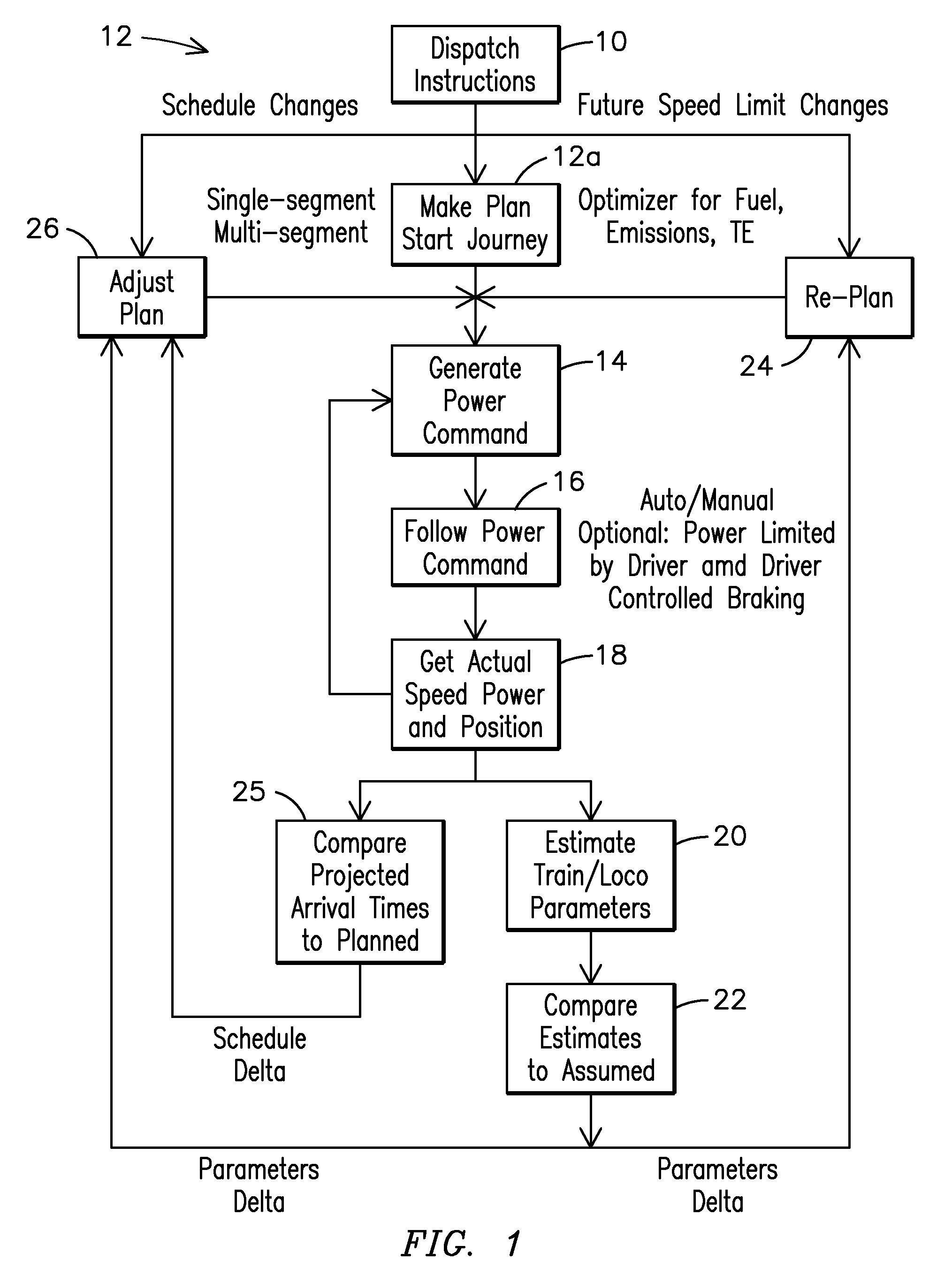

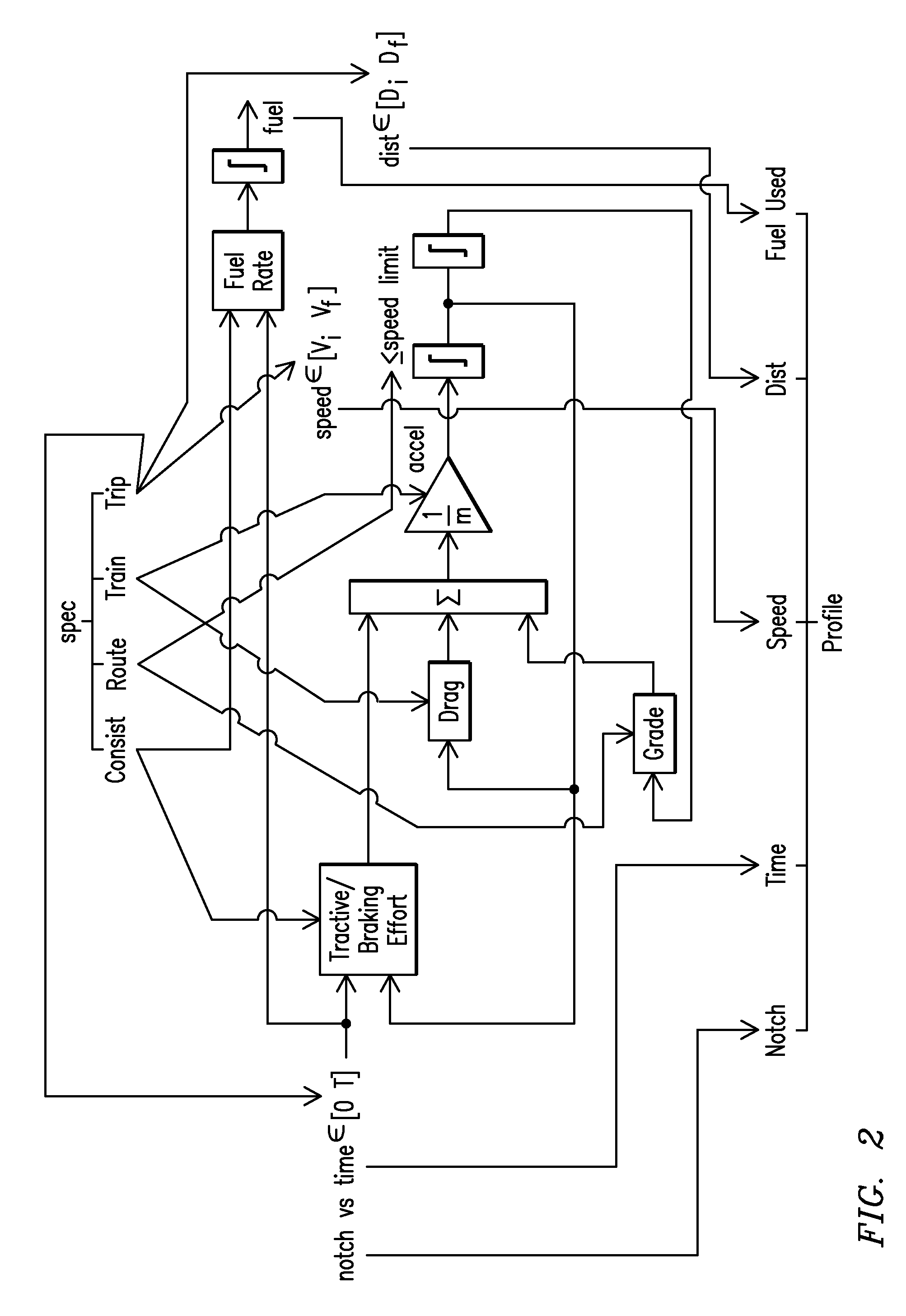

Trip optimizer method, system and computer software code for operating a railroad train to minimize wheel and track wear

ActiveUS20100023190A1Reduce the overall heightShorten speedDigital data processing detailsTrack side maintainanceWheel wearComputer software

A system for controlling a railroad train over a segment of track. The system comprises a first element for determining a location of the train on the segment of track; a second element for providing track characterization information for the segment of track; the track characterization information related to physical conditions of the segment of track; and a processor for controlling applied tractive forces and braking forces of the train responsive to the location of the train and the track characterization information to reduce at least one of wheel wear and / or track wear during operation of the train over the segment of track.

Owner:GE GLOBAL SOURCING LLC

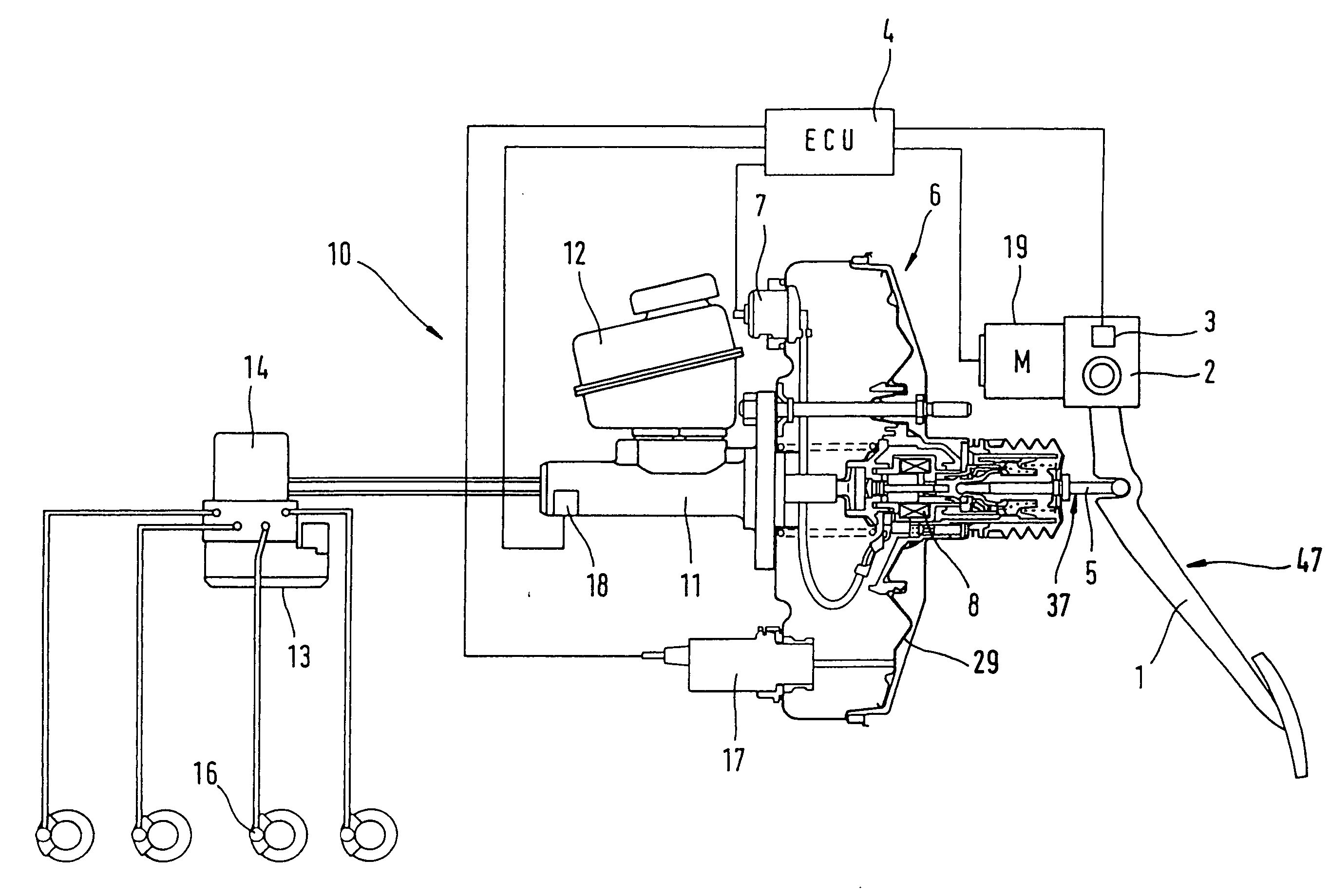

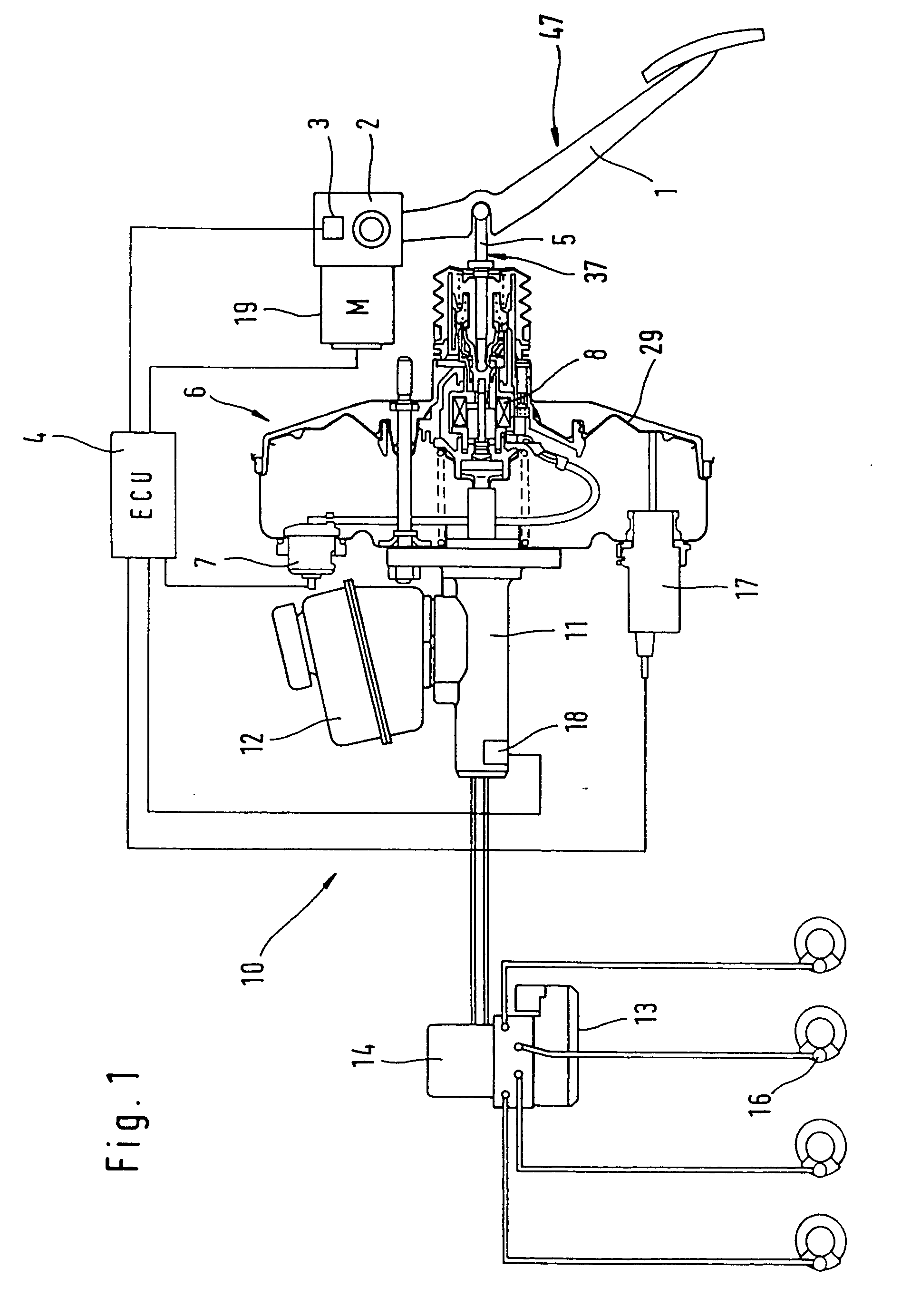

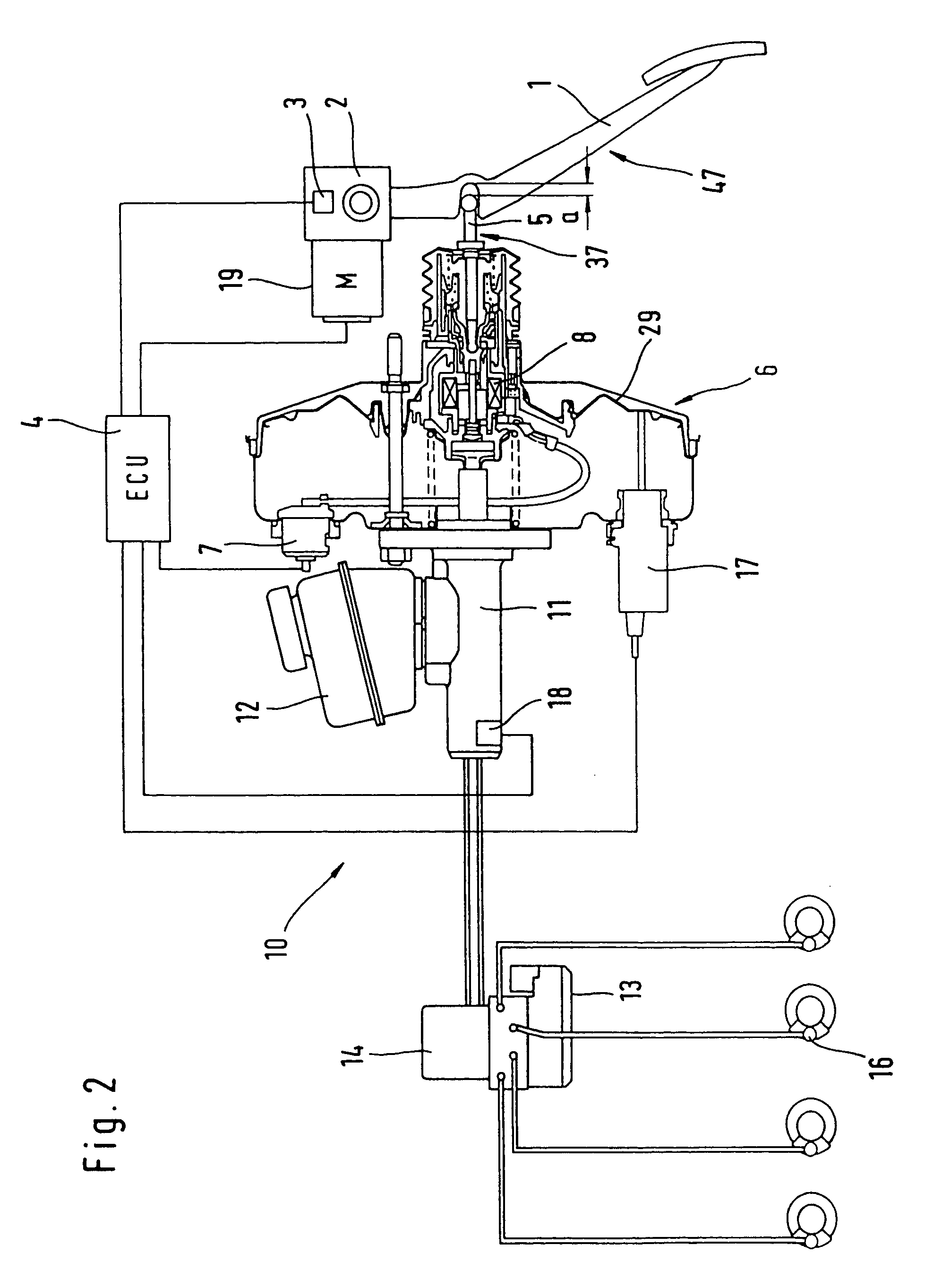

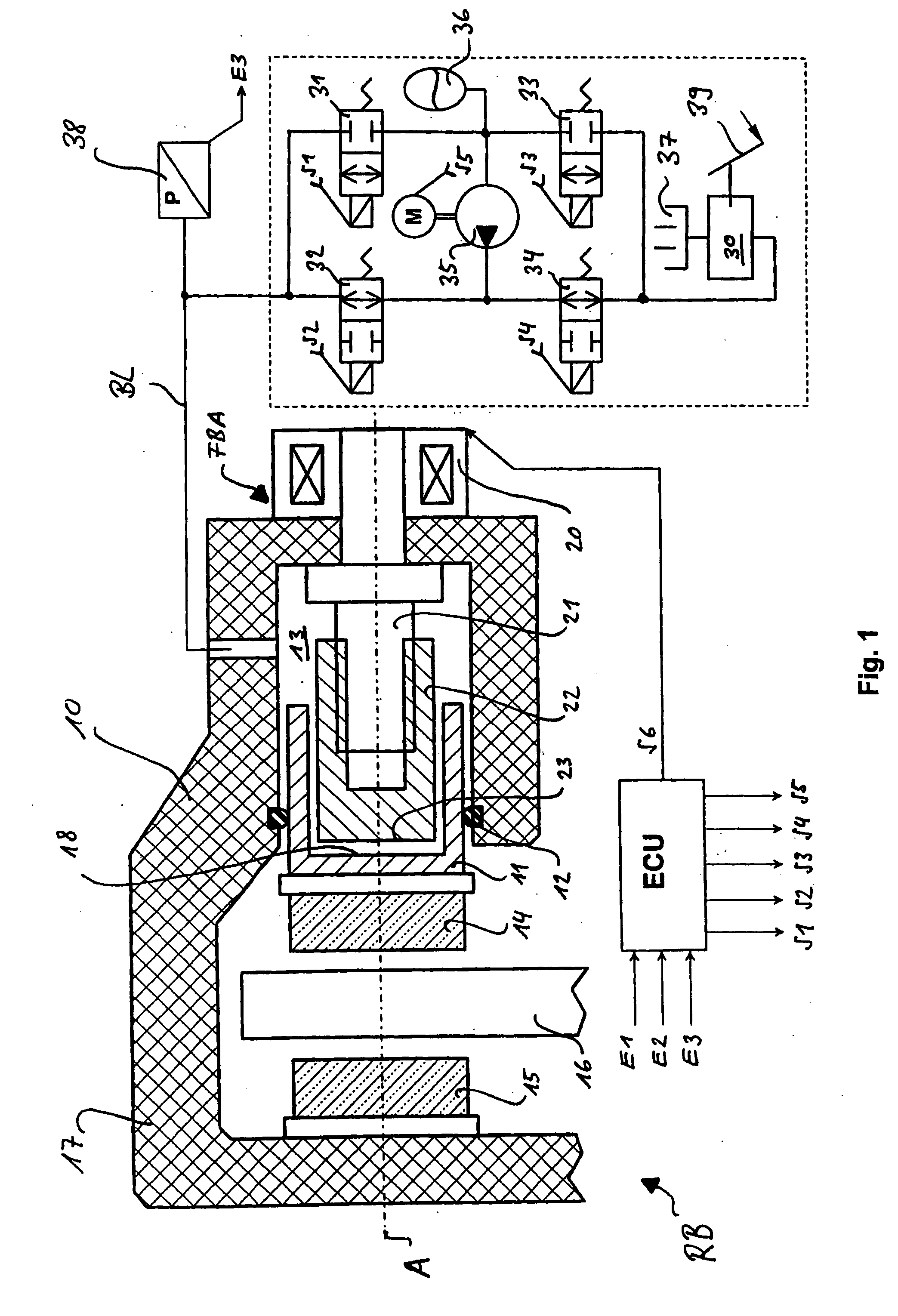

Brake by-wire actuator

InactiveUS20060163941A1High brake pressureReduce tractionBraking action transmissionFoot actuated initiationsMobile vehicleDistributor

The present invention relates to a brake-by-wire actuator for actuating the brake system of a motor vehicle, comprising a simulator which can be acted upon by a brake pedal, with a signal of an actuation sensor being sent to an electronic control unit which controls a pressure source in response to the signal of the actuation sensor, and wherein an output of the pressure source is connected to a distributor device for the brake force and actuates individual wheel brakes of the vehicle, also comprising means for enabling actuation of the brakes by muscular power within a fallback mode. In order to provide an improved fallback mode in a brake-by-wire actuator, according to the invention, a lost travel is provided between a first actuation component such as a brake pedal in particular or a component articulated at the brake pedal and an actuation component that is connected downstream in the flux of force, in particular an input member, in order to uncouple the first actuation component mechanically from the reactions of force of the motor vehicle brake system in the by-wire mode.

Owner:CONTINENTAL TEVES AG & CO OHG

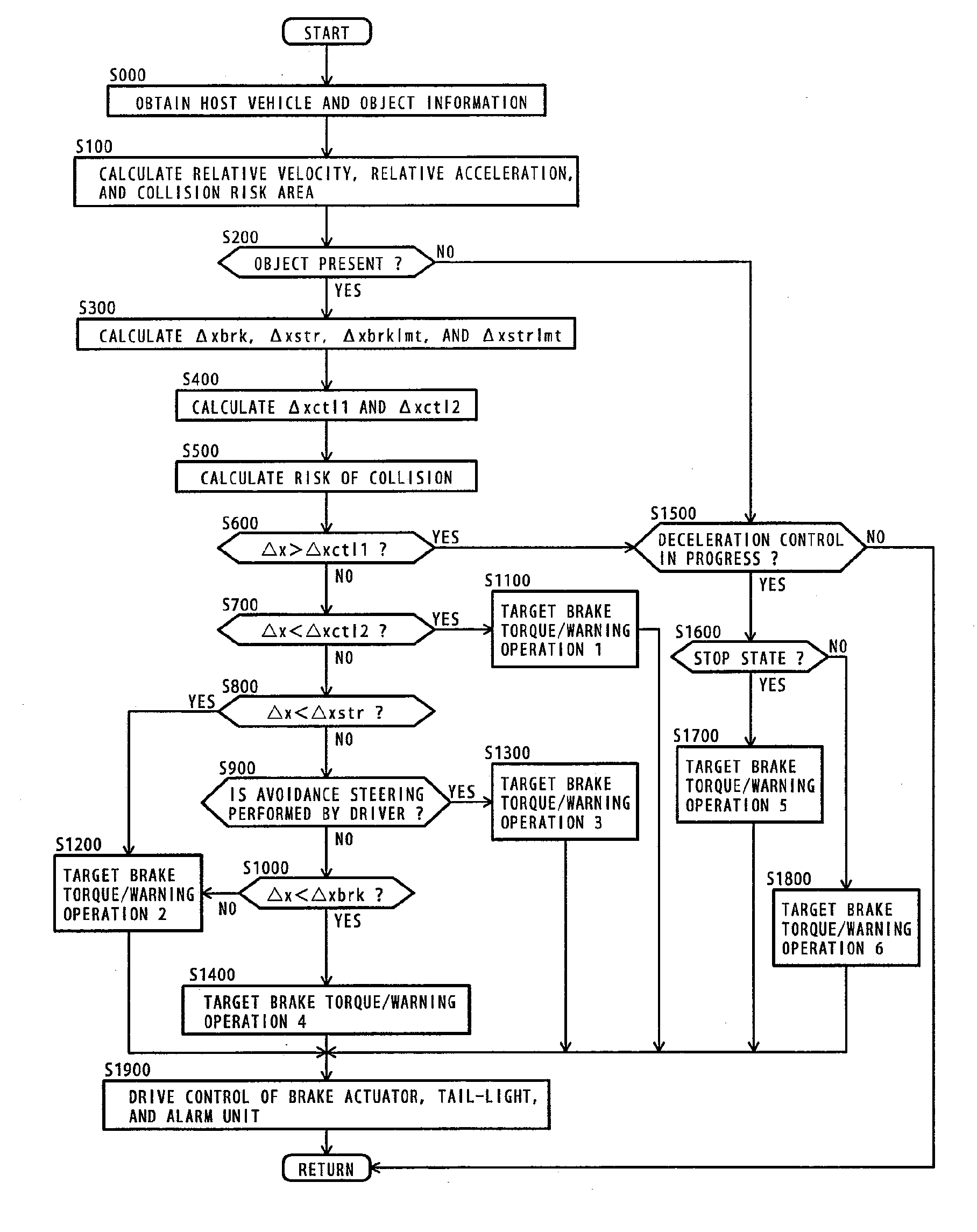

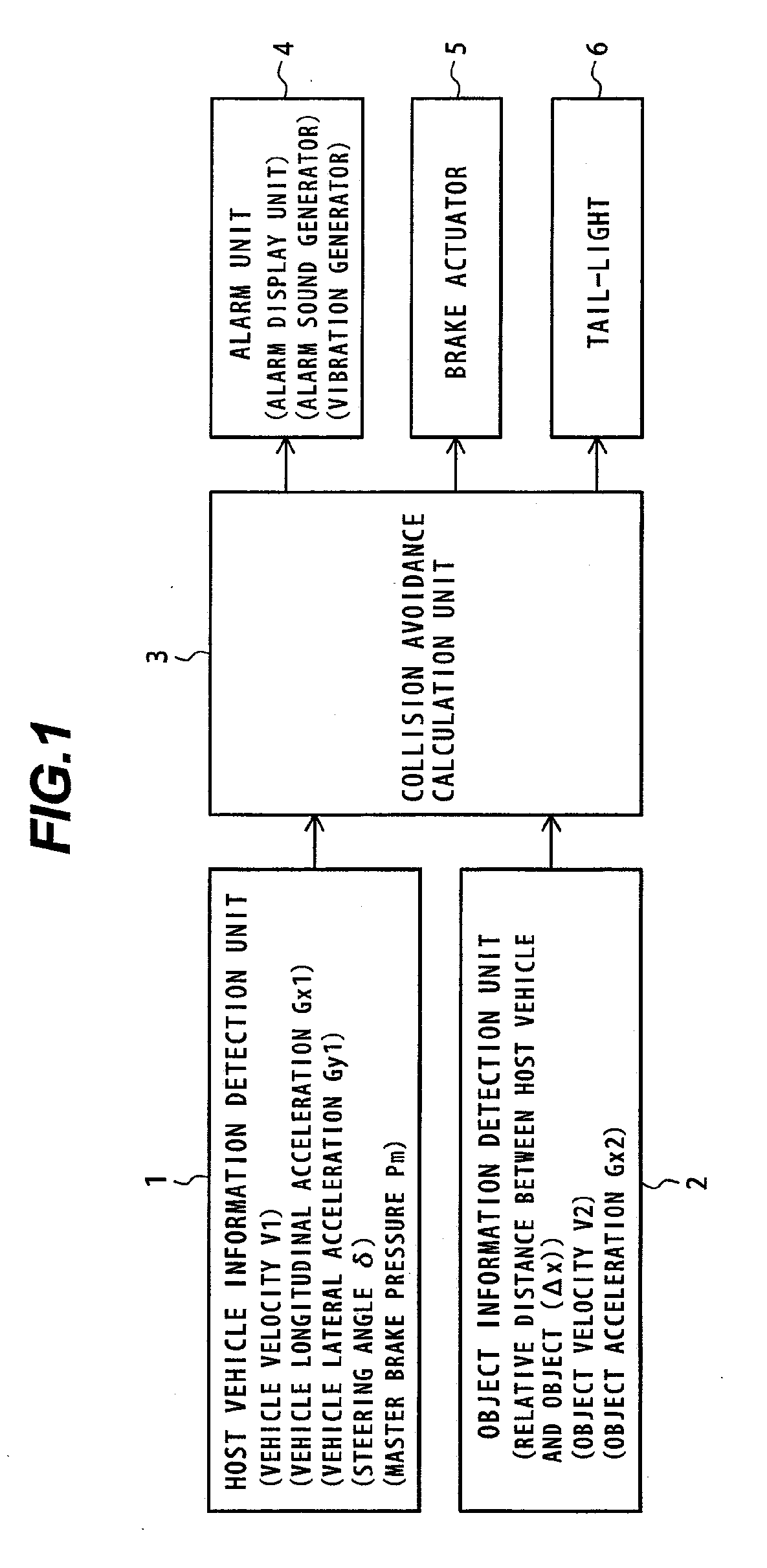

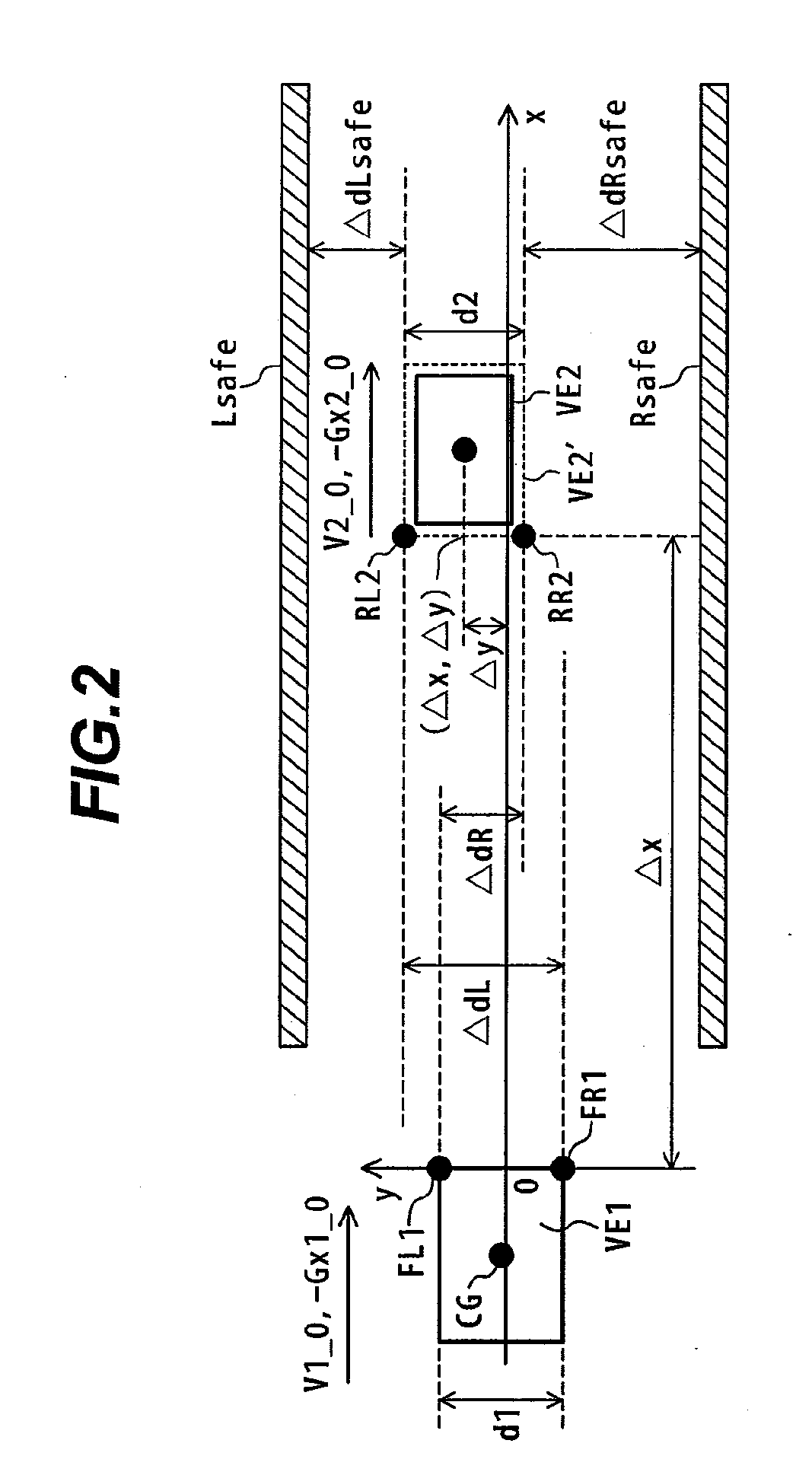

Forward Collision Avoidance Assistance System

InactiveUS20090143951A1Reduce driver 's uncomfortable feelingImprove drivabilityAnalogue computers for trafficPedestrian/occupant safety arrangementEngineeringActuator

An object of the present invention is to provide a forward collision avoidance assistance system that attains the reduction of driver's uncomfortable feeling and the improvement in drivability while ensuring the collision avoidance performance during operation for avoiding contact with an object.A collision avoidance calculation unit 3 determines a risk of collision between a host vehicle and an object detected in the host vehicle traveling direction based on information about the host vehicle detected by a host vehicle information detection unit 1 and information about the object detected by an object information detection unit 2, and calculates control information for object avoidance to be output to an actuator 5 based on a result of collision risk judgment. The collision avoidance calculation unit 3 uses a collision-avoidable limit distance Δxctl2 determined based on a physical limit that can avoid collision with the object, and a jerk-limited collision avoidable distance Δxctl1 determined based on the acceleration and jerk generated on the host vehicle by object avoidance movement, to control the brake force generated on the host vehicle by a brake actuator 5.

Owner:HITACHI LTD

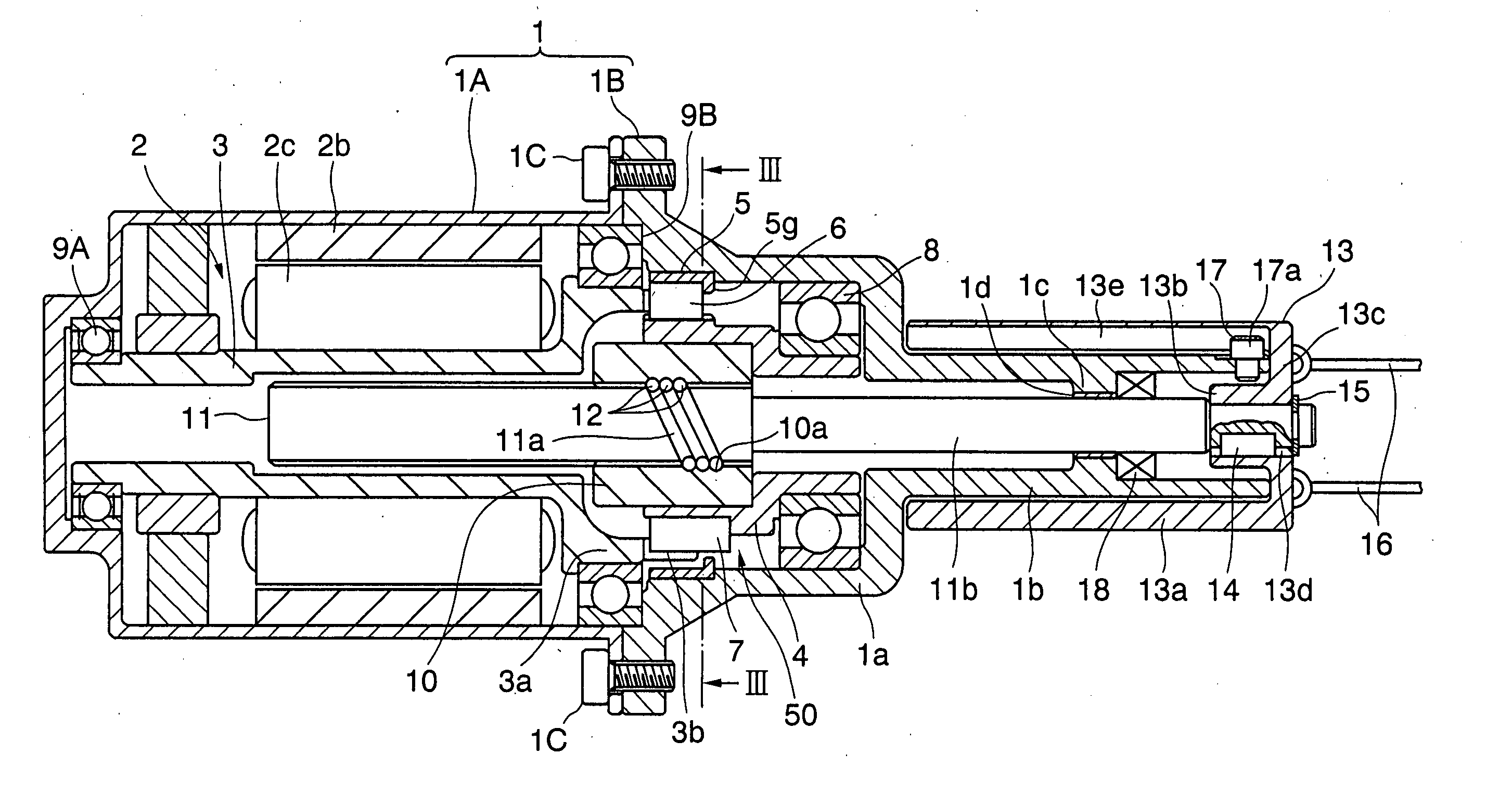

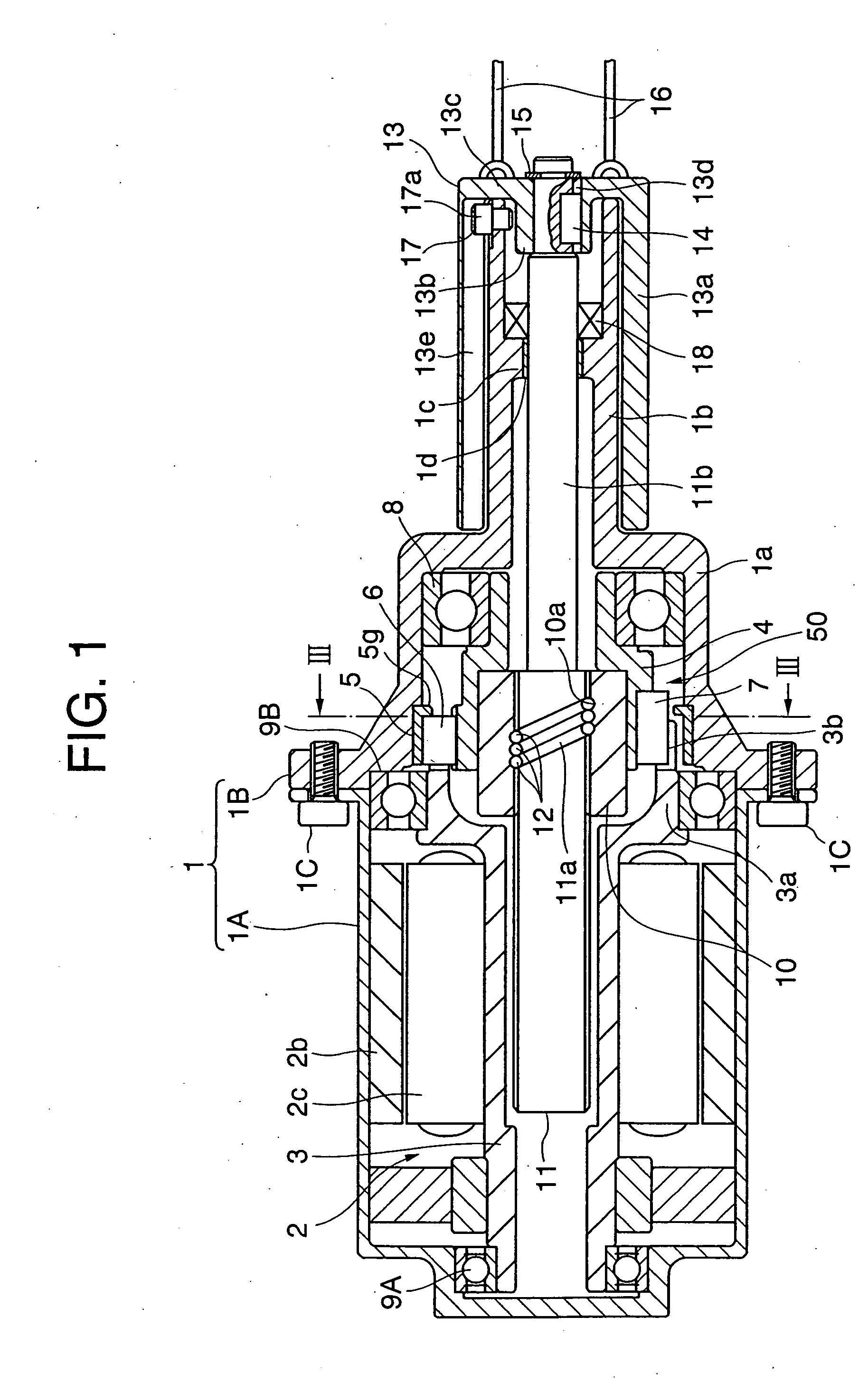

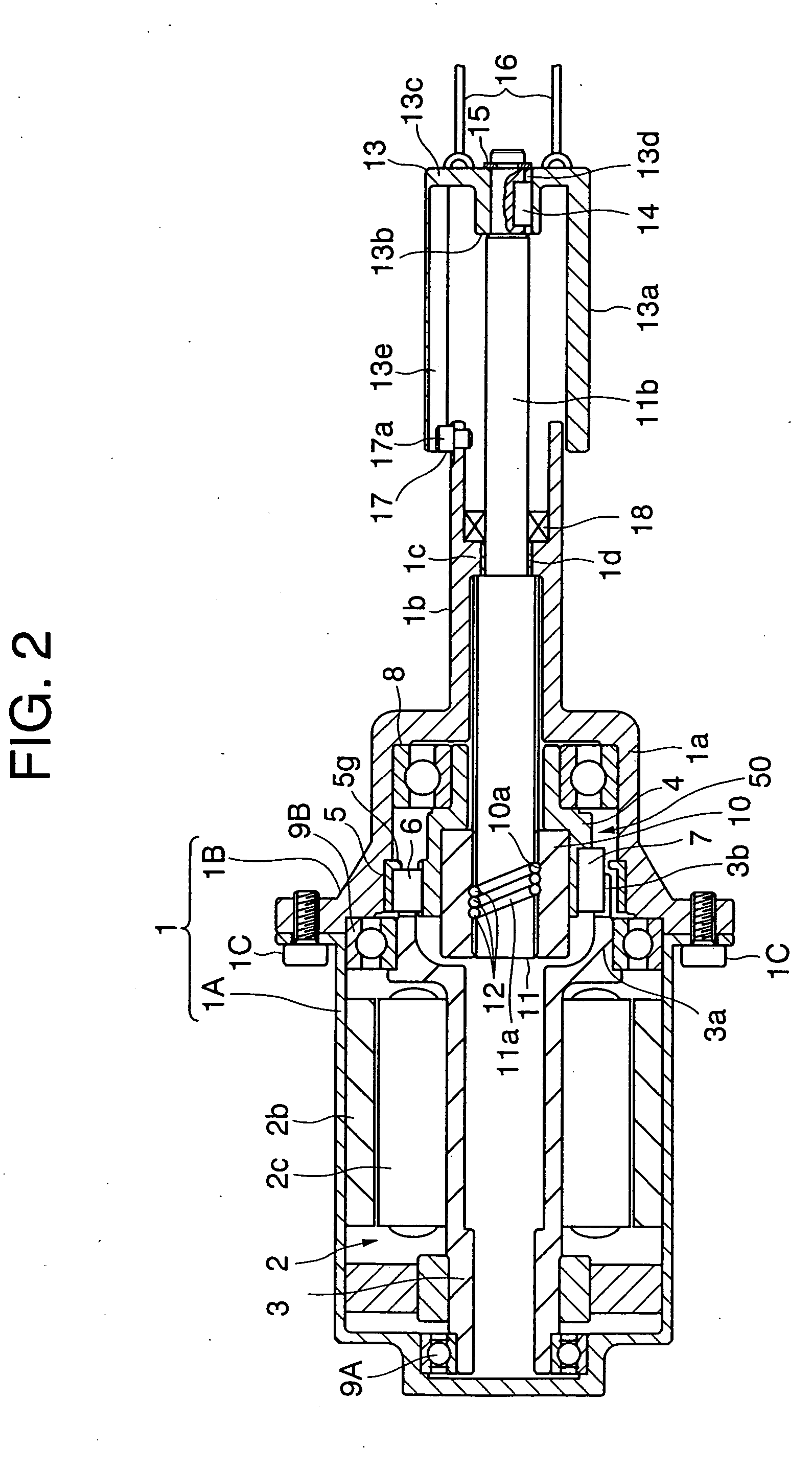

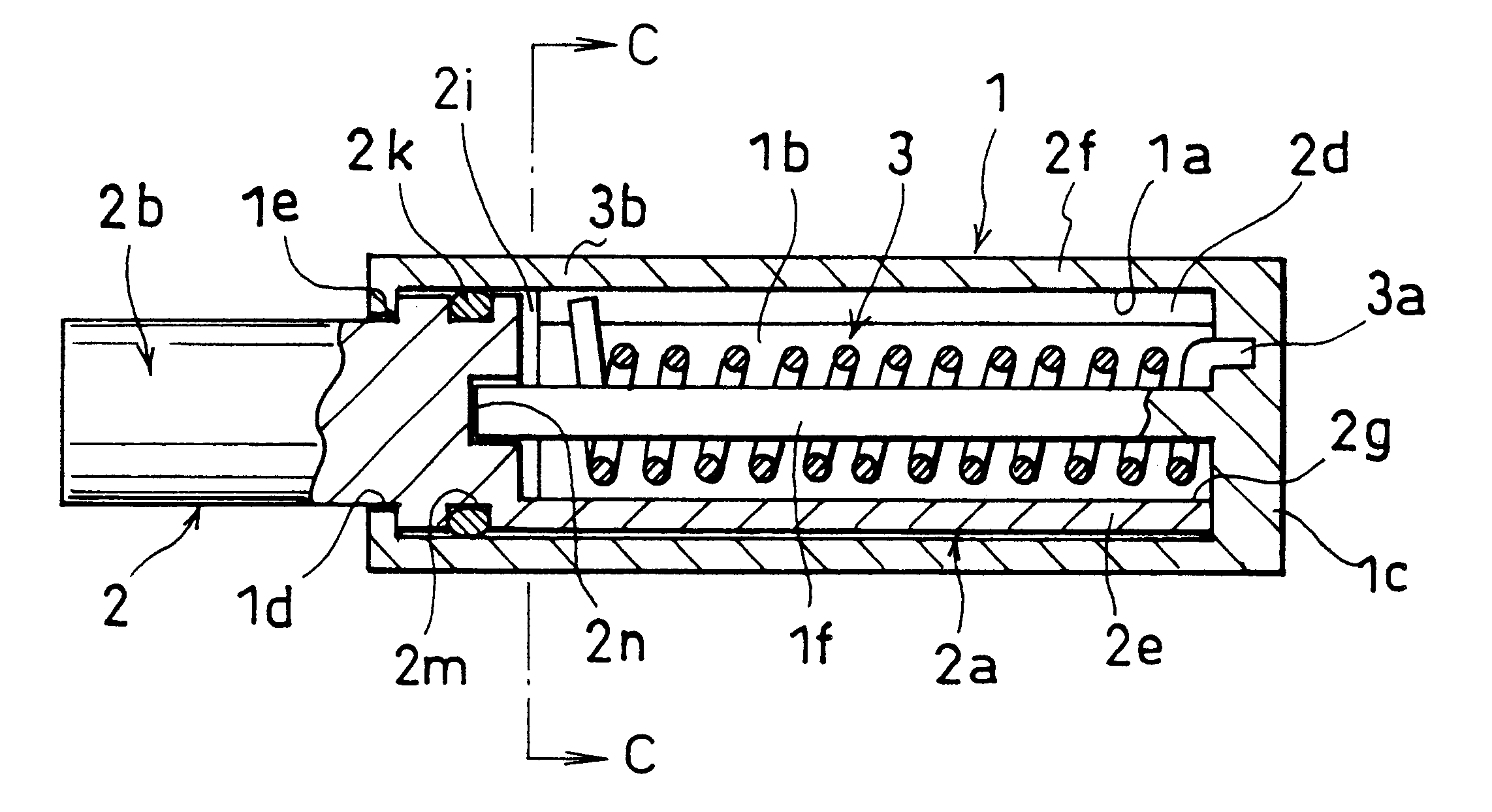

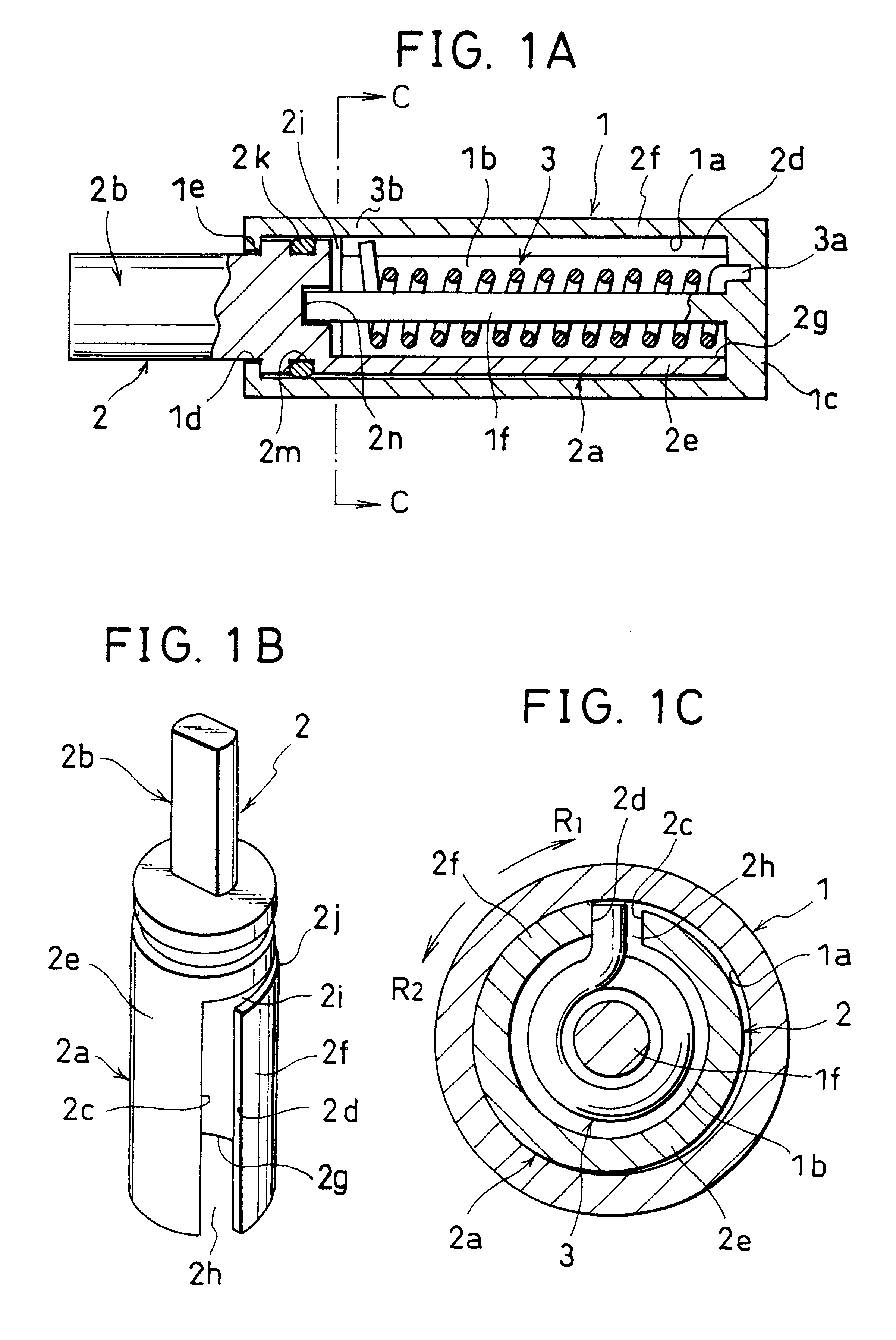

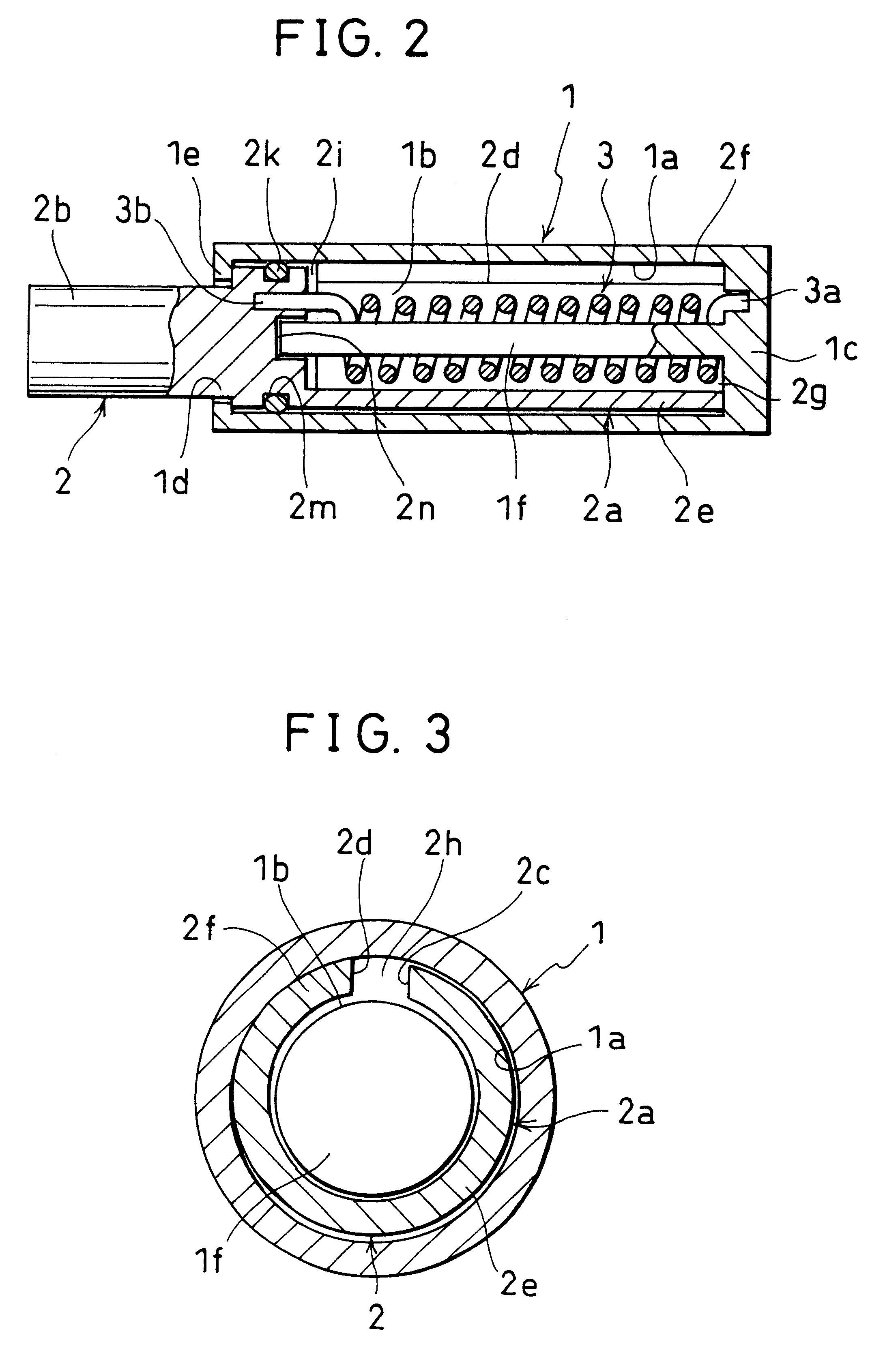

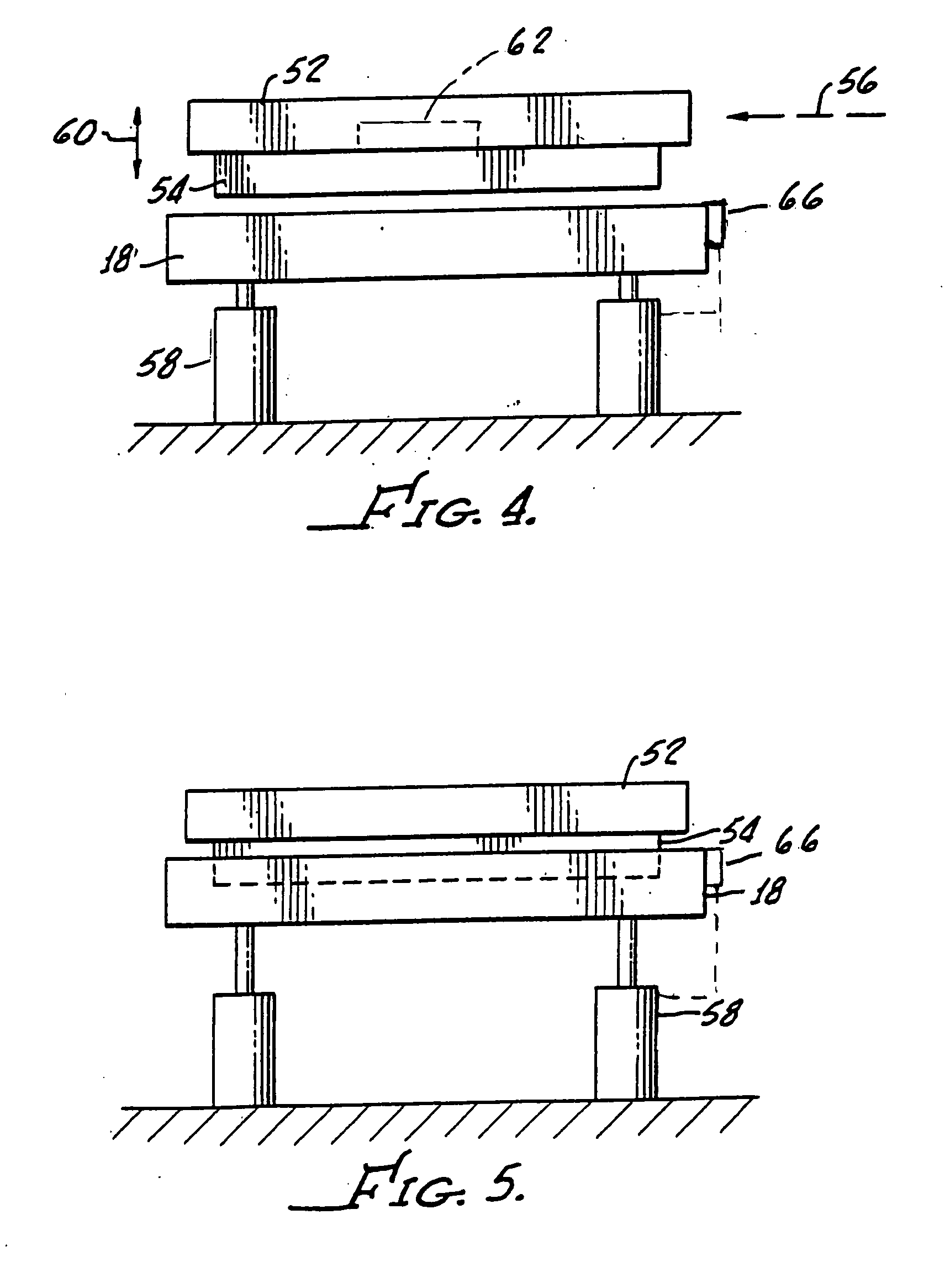

Linear actuator

ActiveUS20050155444A1Guarantee efficiencyGuaranteed normal transmissionToothed gearingsGearing controlEngineeringParking brake

A rotary shaft (3) and a rotation driven member (4) are so connected as to be capable of transmitting motive power when the rotary shaft (3) rotates relatively to the rotation driven member (4). A roller (6) gets displaced to a first position where a frictional force with an outer race (5) and the rotation driven member (4) decreases, thereby permitting transmission of a rotational force from the rotary shaft (3) to the rotation driven member (4). When the rotation driven member (4) rotates relatively to the rotary shaft (3), the roller (6) gets displaced to a second position where the frictional force with the outer race (5) and the rotation driven member (4) increases, thereby rotationally fixing the rotation driven member (4) with respect to the outer race (5). The power transmission from a brake apparatus (e.g., a parking brake apparatus) to an electric motor (2) can be hindered while permitting the power transmission to the brake apparatus from the electric motor (2) by using neither a worm exhibiting a relatively low transmission efficiency nor a worm wheel. In a state where the brake apparatus exhibits its braking force, the roller (6) receives the force from the brake apparatus and is thereby biased toward the second position, whereby a construction of a power transmission mechanism (50) can be simplified and costs can be reduced to such an extent.

Owner:NSK LTD

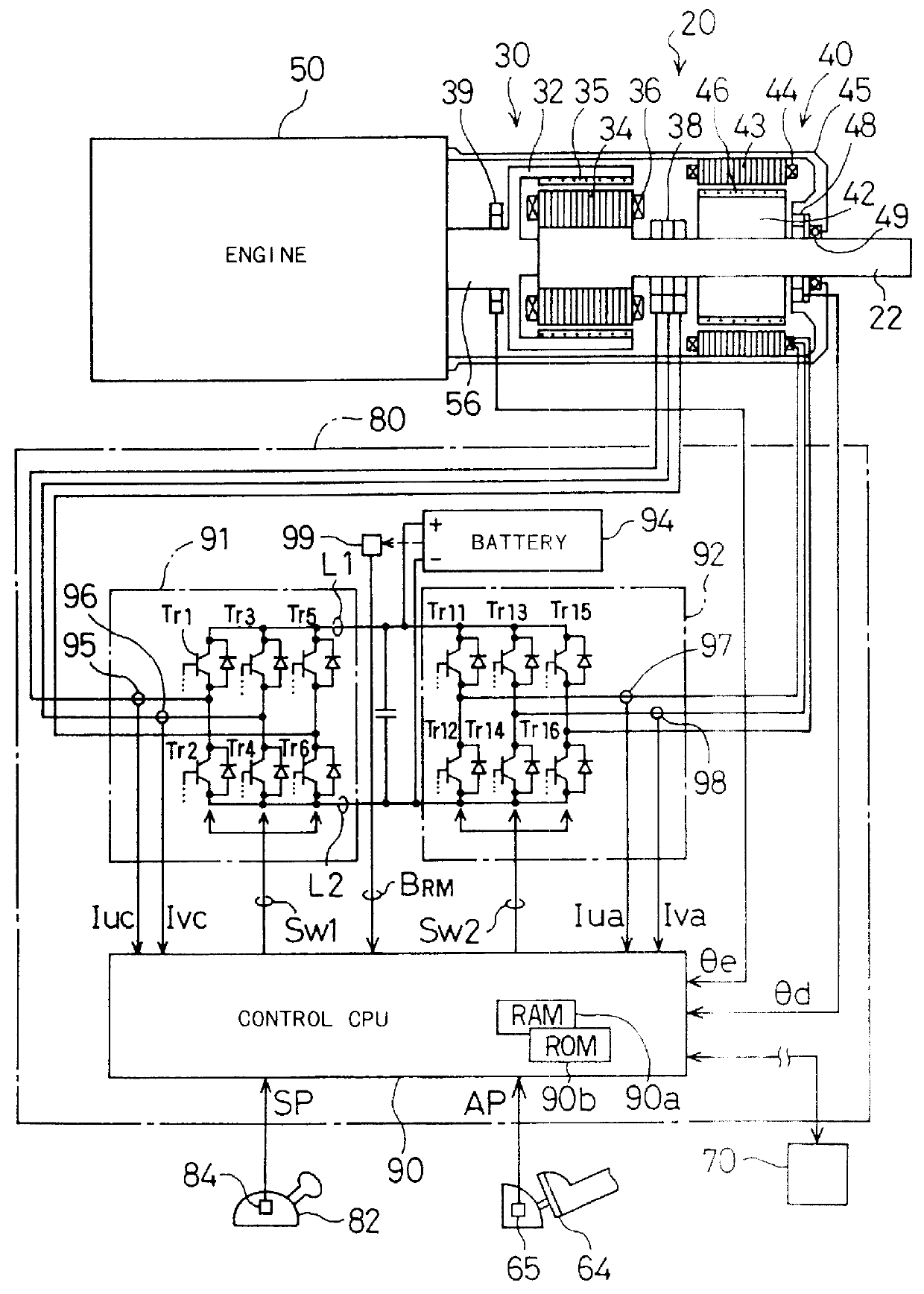

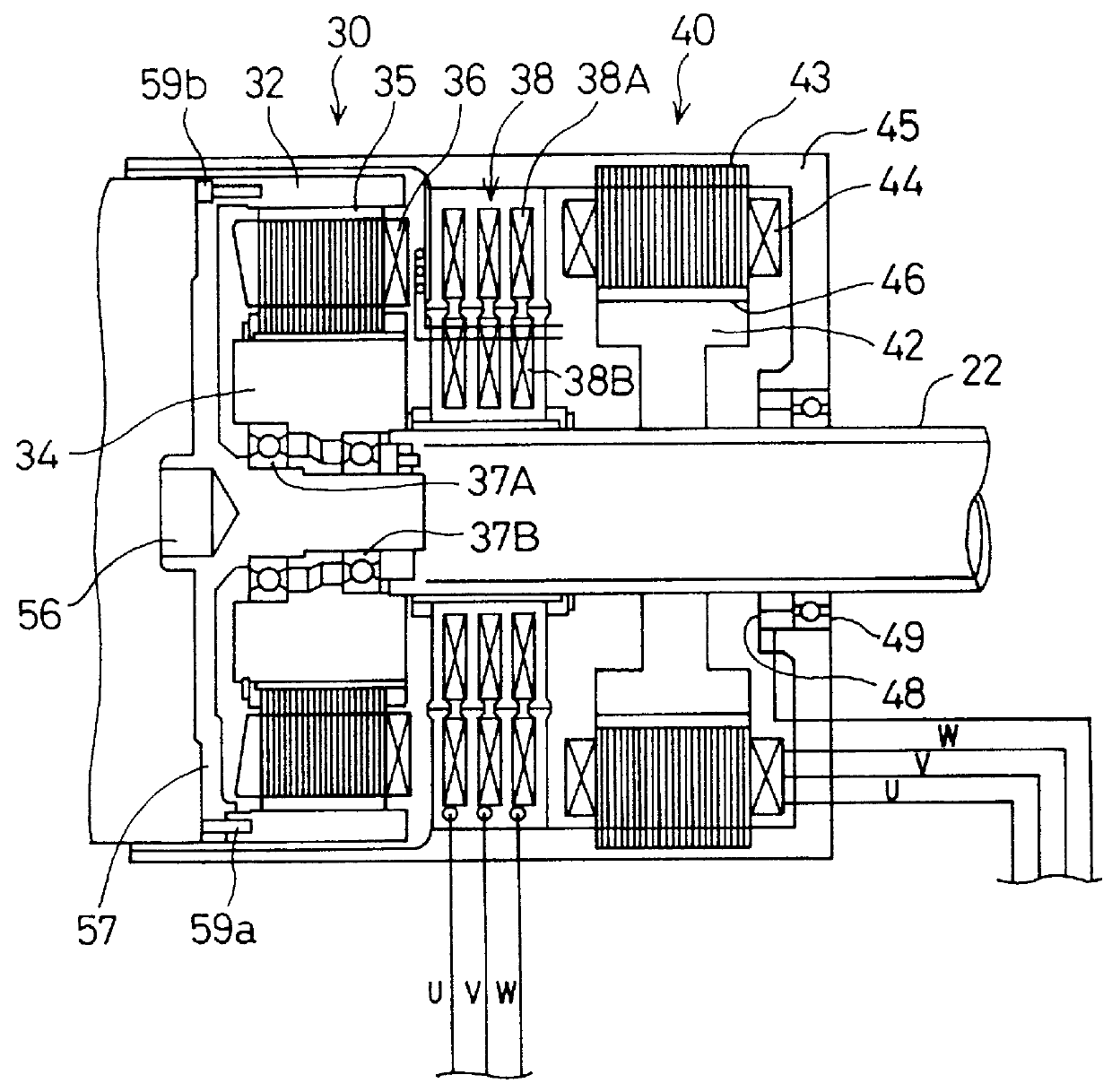

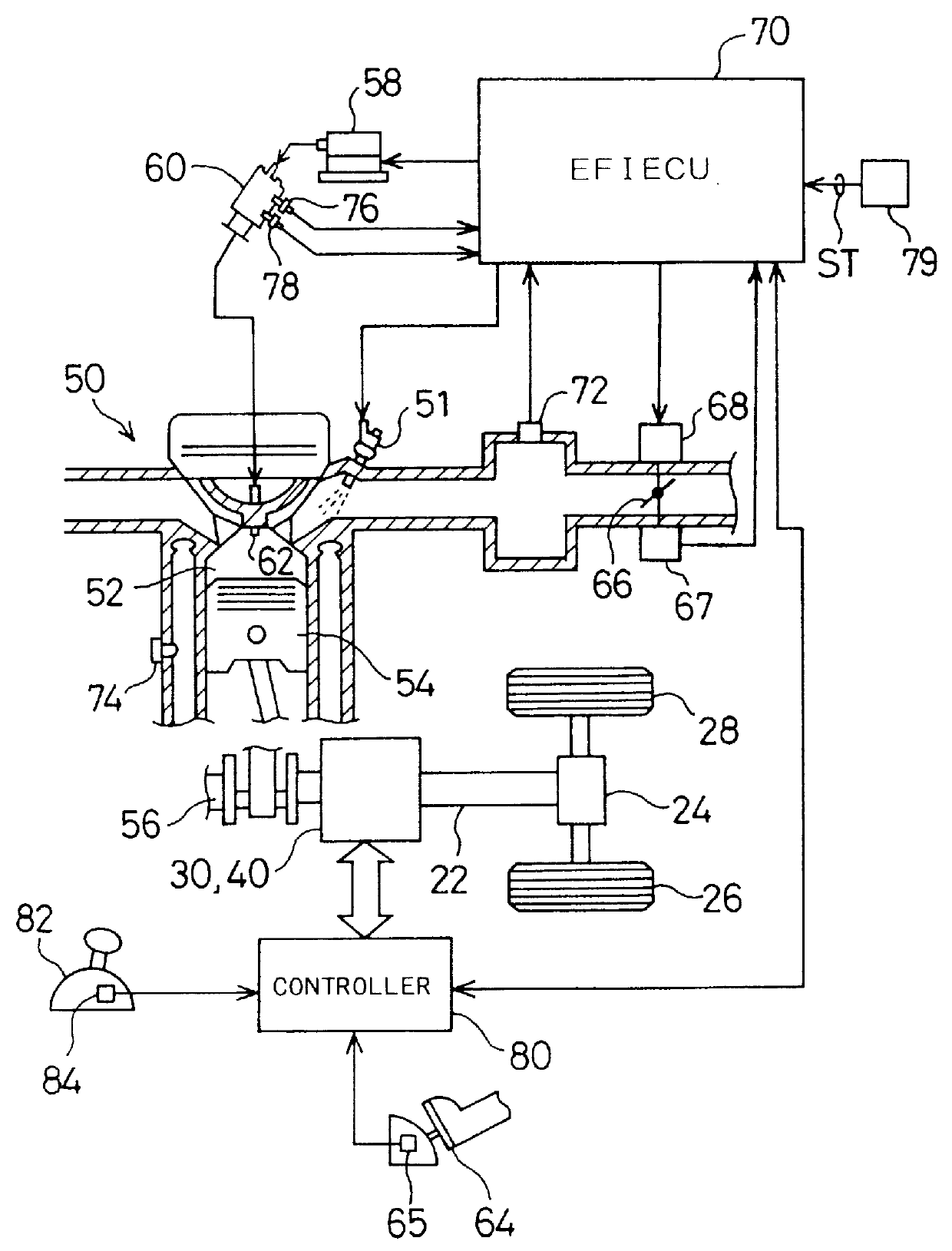

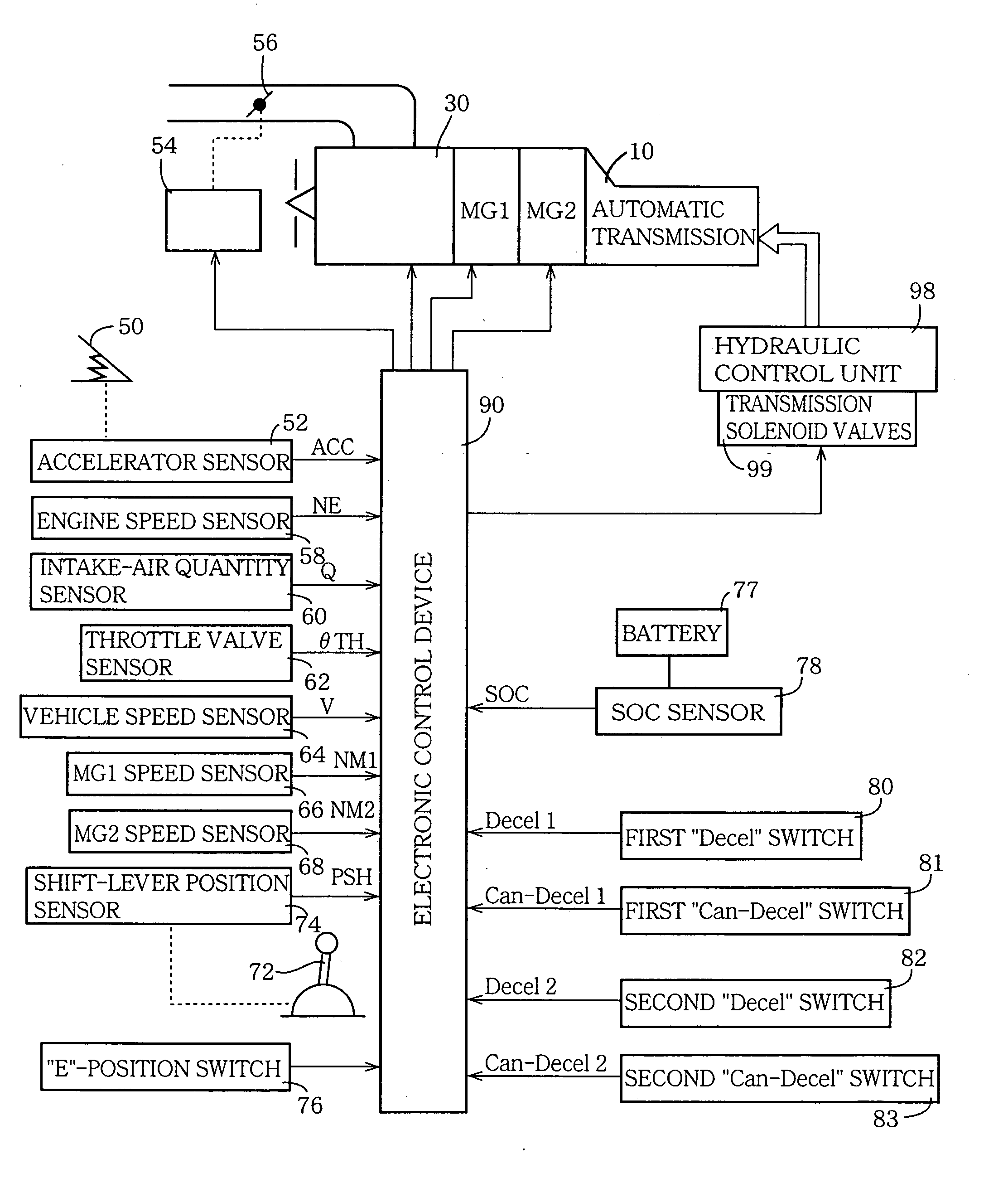

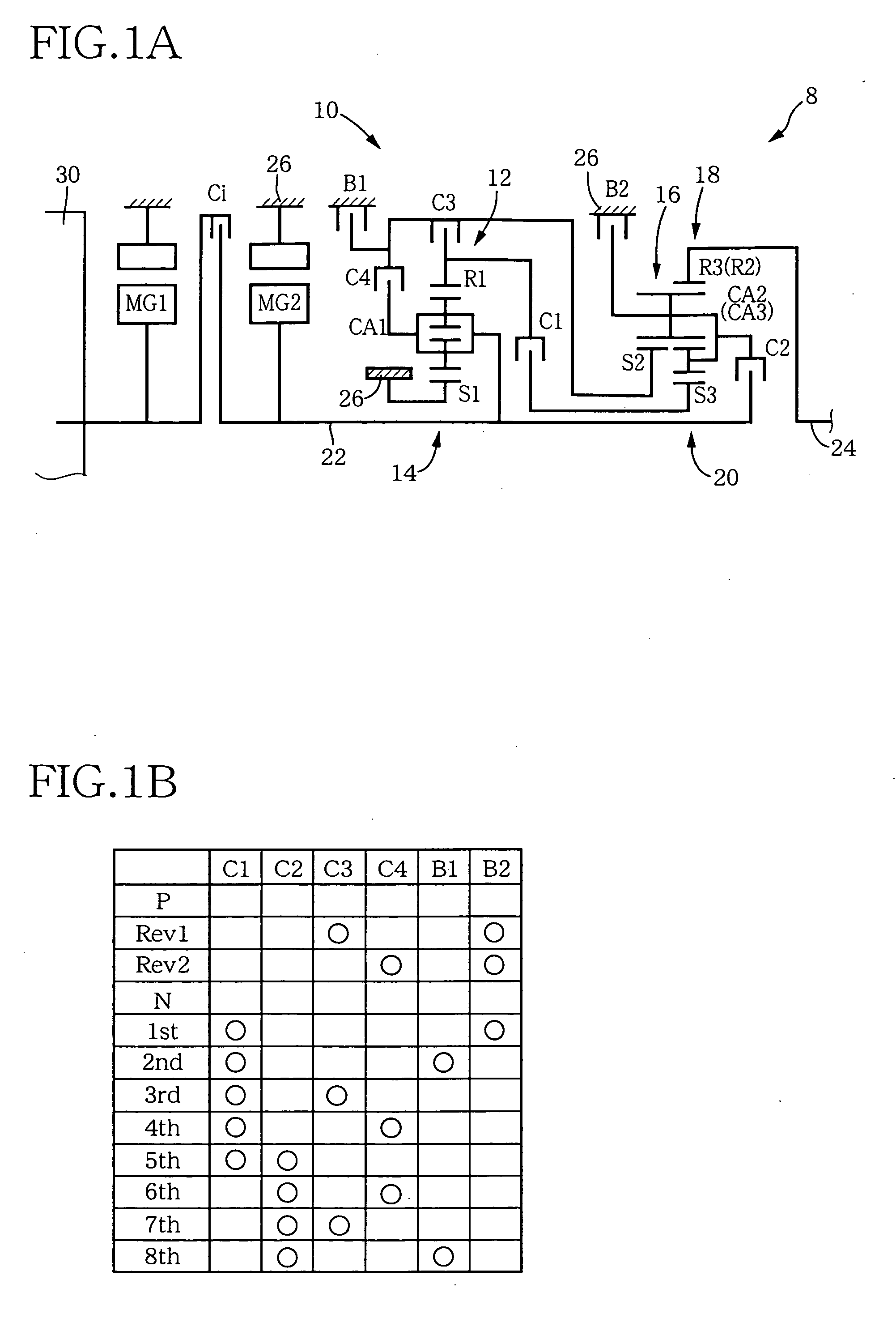

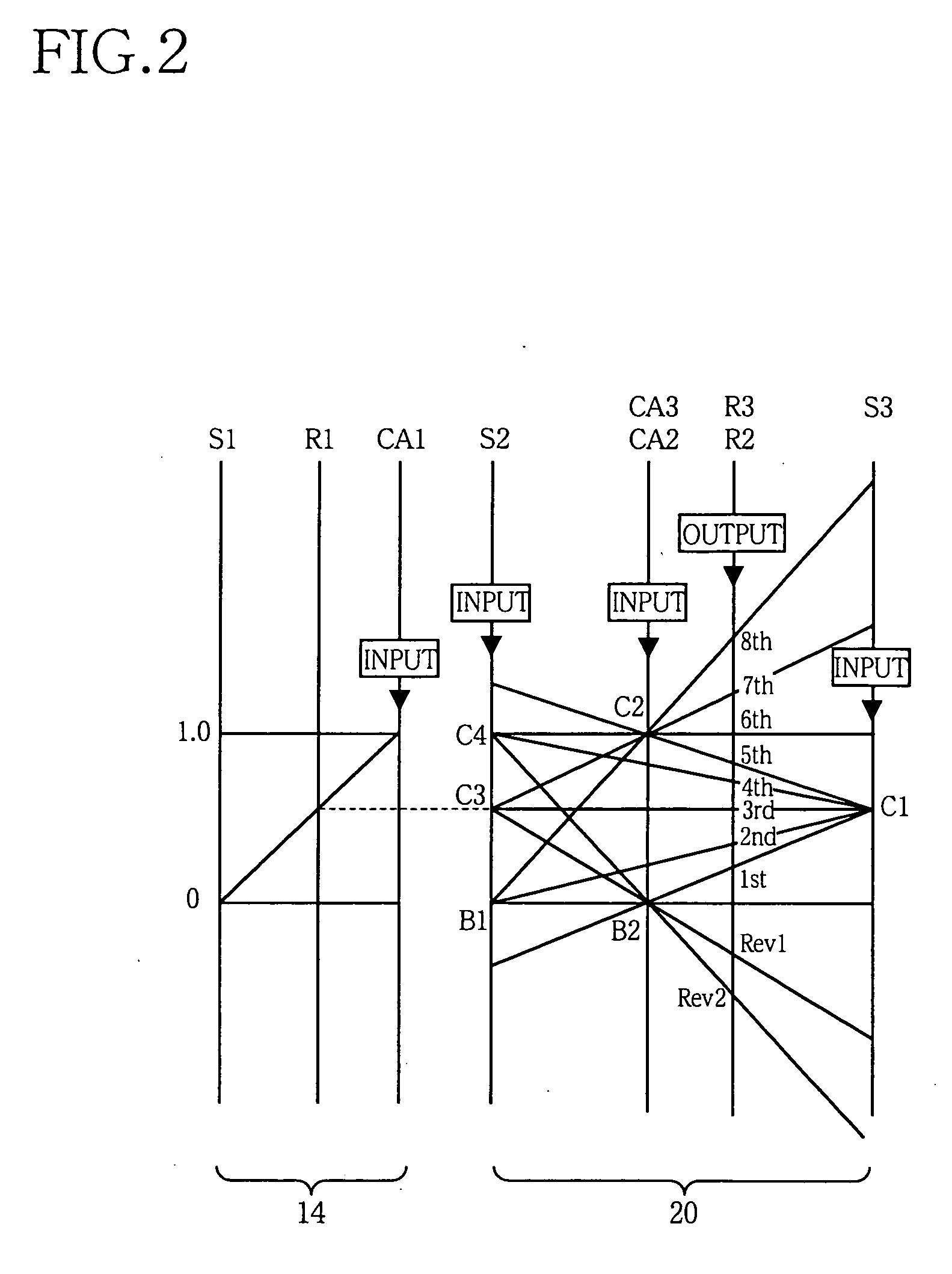

Power output apparatus, method of controlling power output apparatus, and driving system with power output apparatus incorporated therein

InactiveUS6087734AImprove energy efficiencyImprove efficiencyInternal combustion piston enginesElectric motor startersControl powerDrive shaft

A power output apparatus 20 includes a clutch motor, an assist motor, and a controller. The clutch motor and the assist motor are controlled by the controller to enable the power output from an engine to a crankshaft 56, and expressed as the product of its revolving speed and torque, to be converted to the power expressed as the product of a revolving speed and a torque of a drive shaft and to be output to the drive shaft. The engine can be driven at an arbitrary driving point defined by a revolving speed and a torque, as long as the energy or power output to the crankshaft is identical. A desired driving point that attains the highest possible efficiency with respect to each amount of output energy is determined in advance. In order to allow the engine to be driven at the desired driving point, the controller controls the clutch motor and the assist motor as well as the fuel injection and the throttle valve position. Such control procedures of the power output apparatus enhance the energy efficiency of the whole power output apparatus.

Owner:TOYOTA JIDOSHA KK

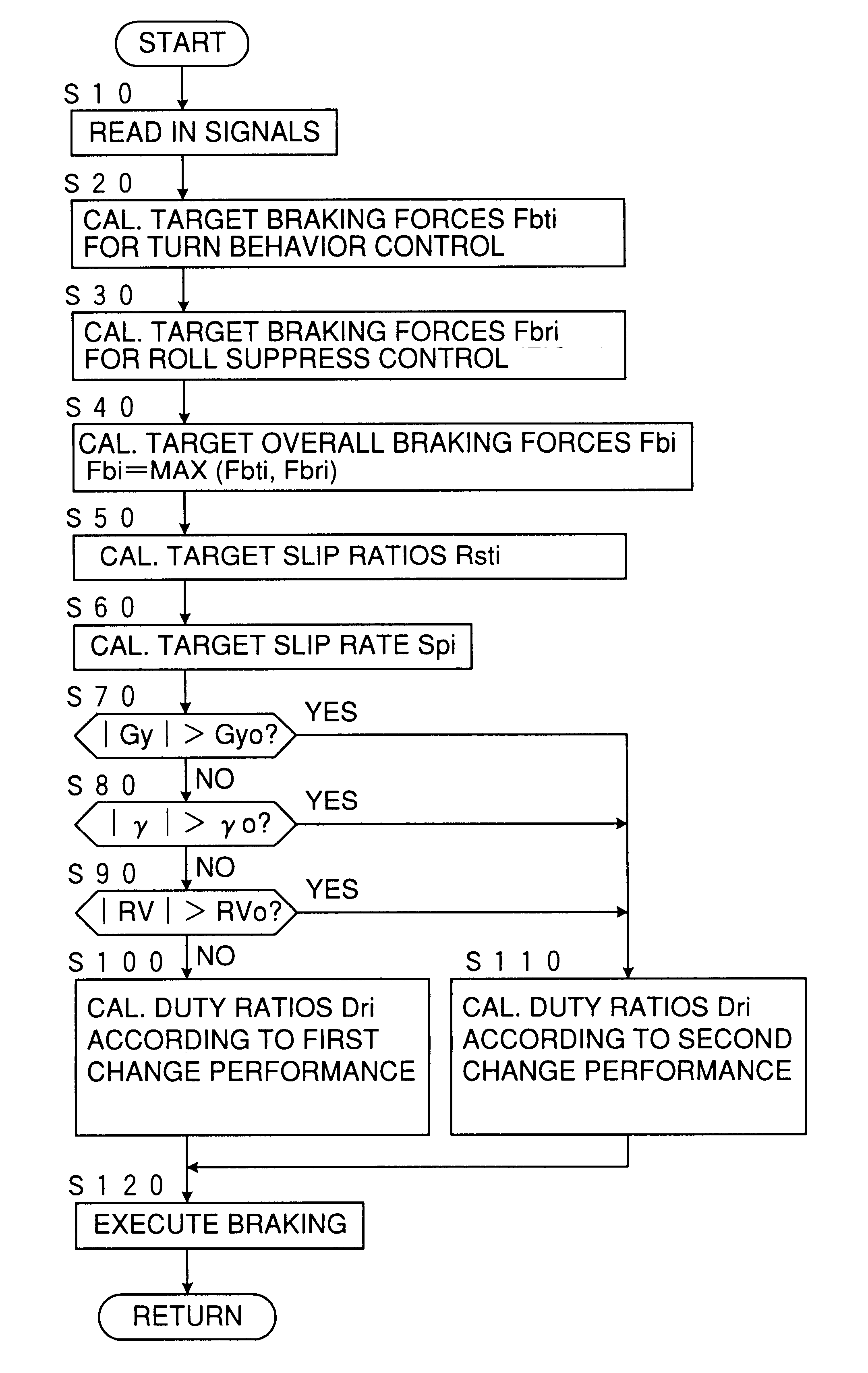

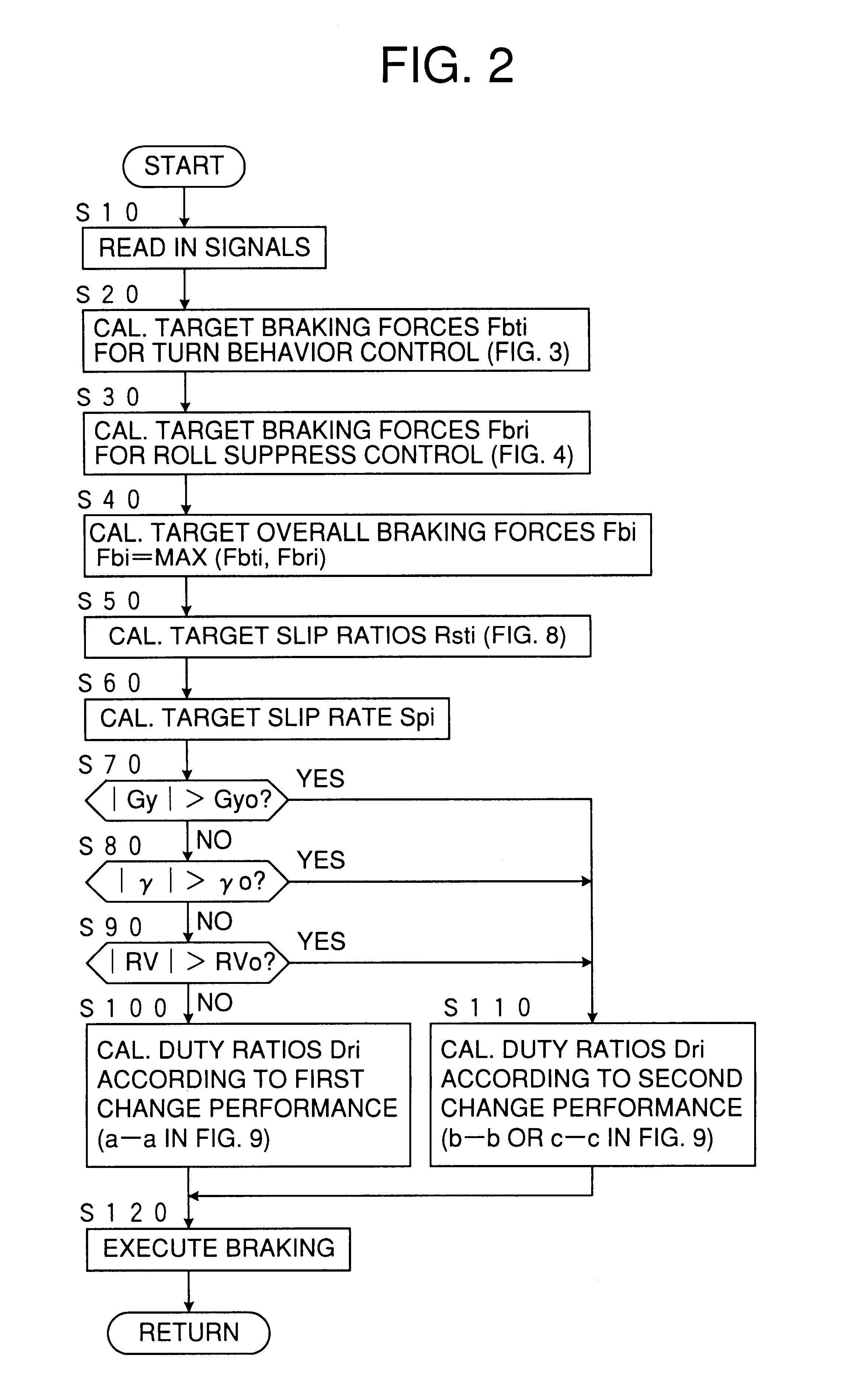

Device for controlling spin/driftout of vehicle compatibly with roll control

InactiveUS6278930B1Suppress a vehicle from excessively rollingHand manipulated computer devicesAnalogue computers for trafficInstabilityEngineering

A moving behavior control device for a vehicle calculates first target braking forces to be applied to the respective wheels for stabilizing the vehicle against a turn instability, second target braking forces to be applied to the respective wheels for stabilizing the vehicle against a roll instability, and target overall braking forces to be applied to the respective wheels by integrating the first and second target braking forces, and applies braking forces to the respective wheels according to the target overall braking forces, wherein the applied braking forces are decreased according to a first rate schedule by which the applied braking forces are decreased at a first rate according to an excess of the applied braking forces relative to the target overall braking forces when the vehicle is running at no probability of rolling beyond a predetermined threshold roll, and according to a second rate schedule by which the braking forces are lowered at a second rate smaller than the first rate according to the excess when the vehicle is running at such a probability.

Owner:TOYOTA JIDOSHA KK

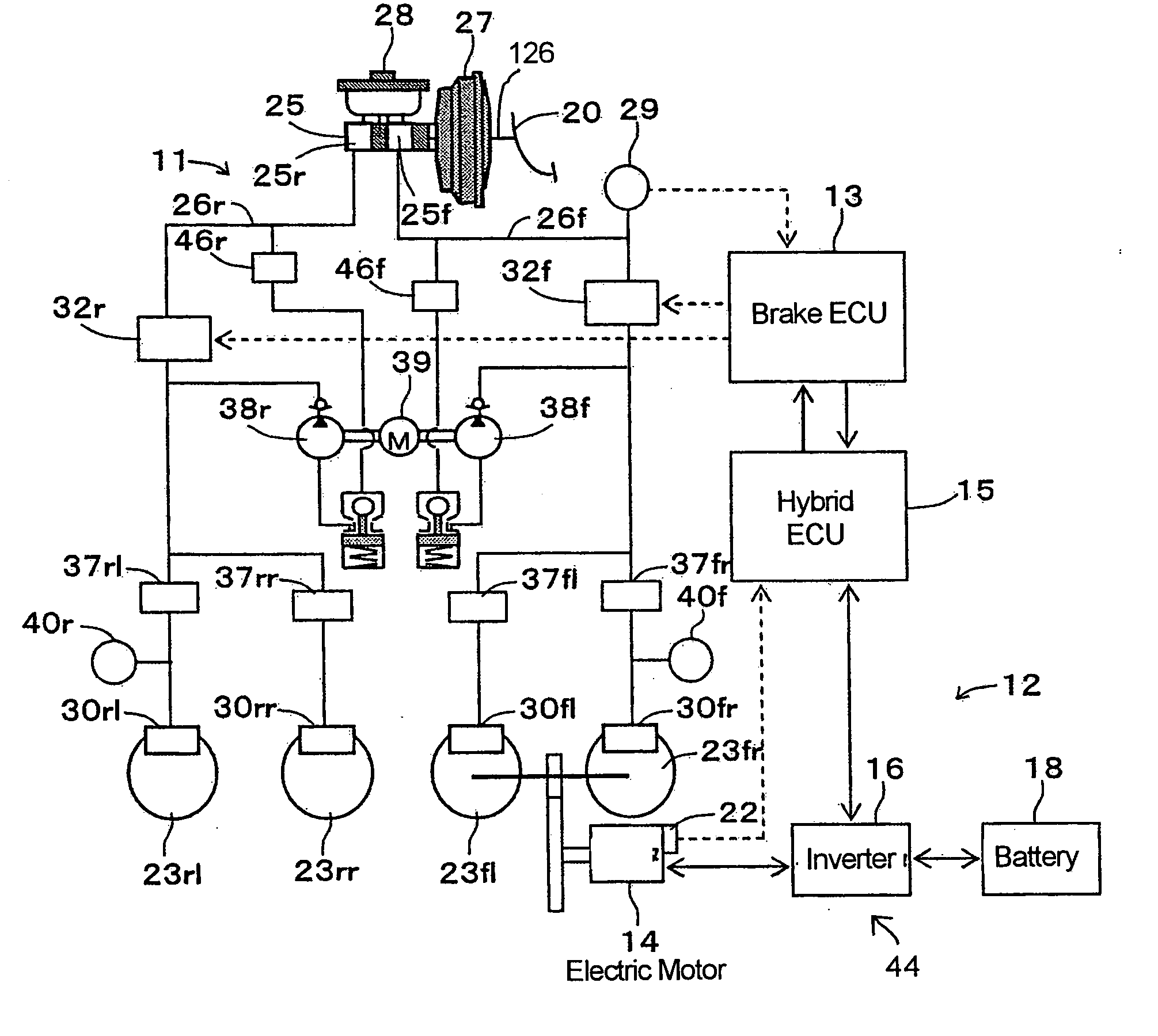

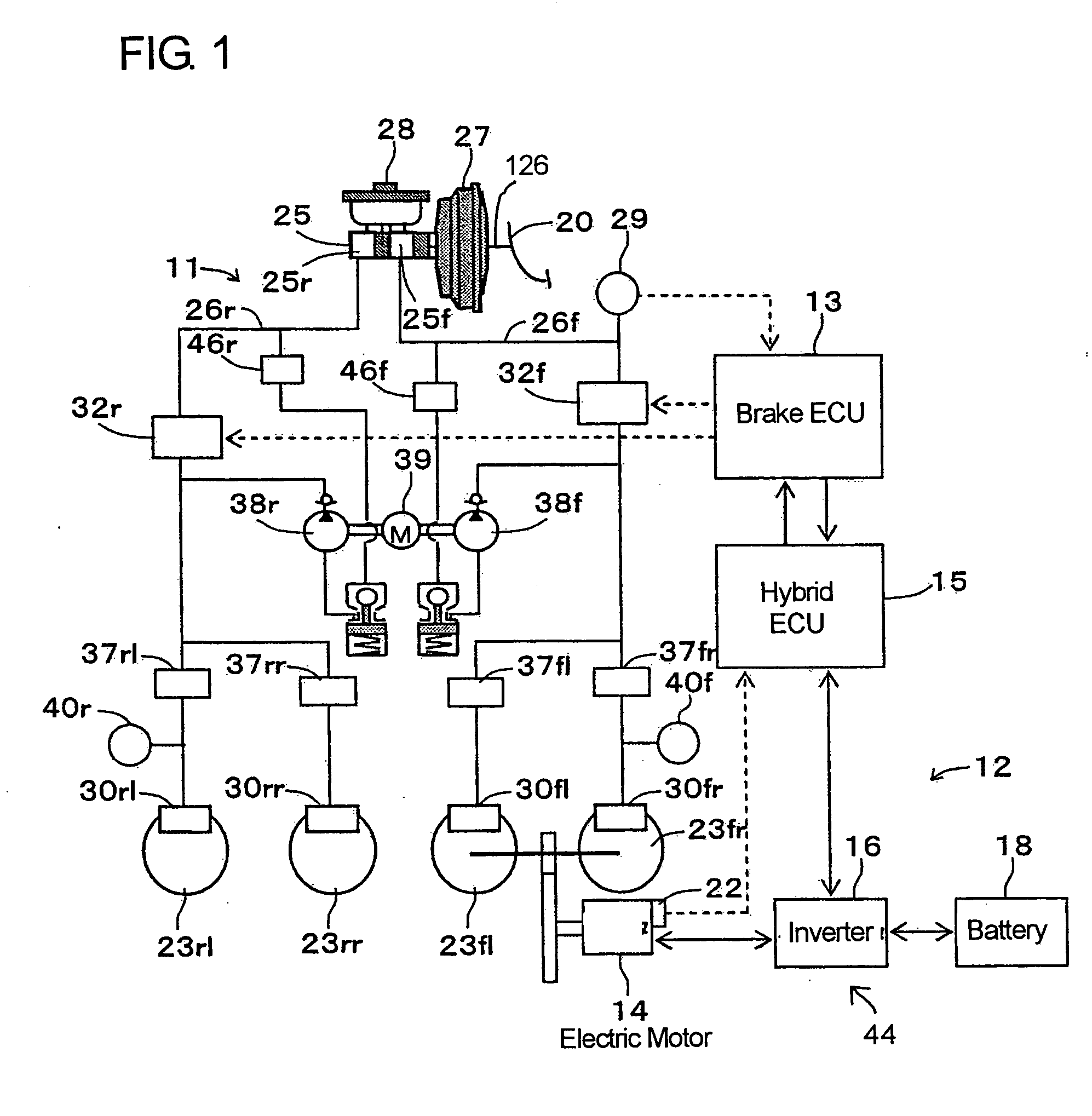

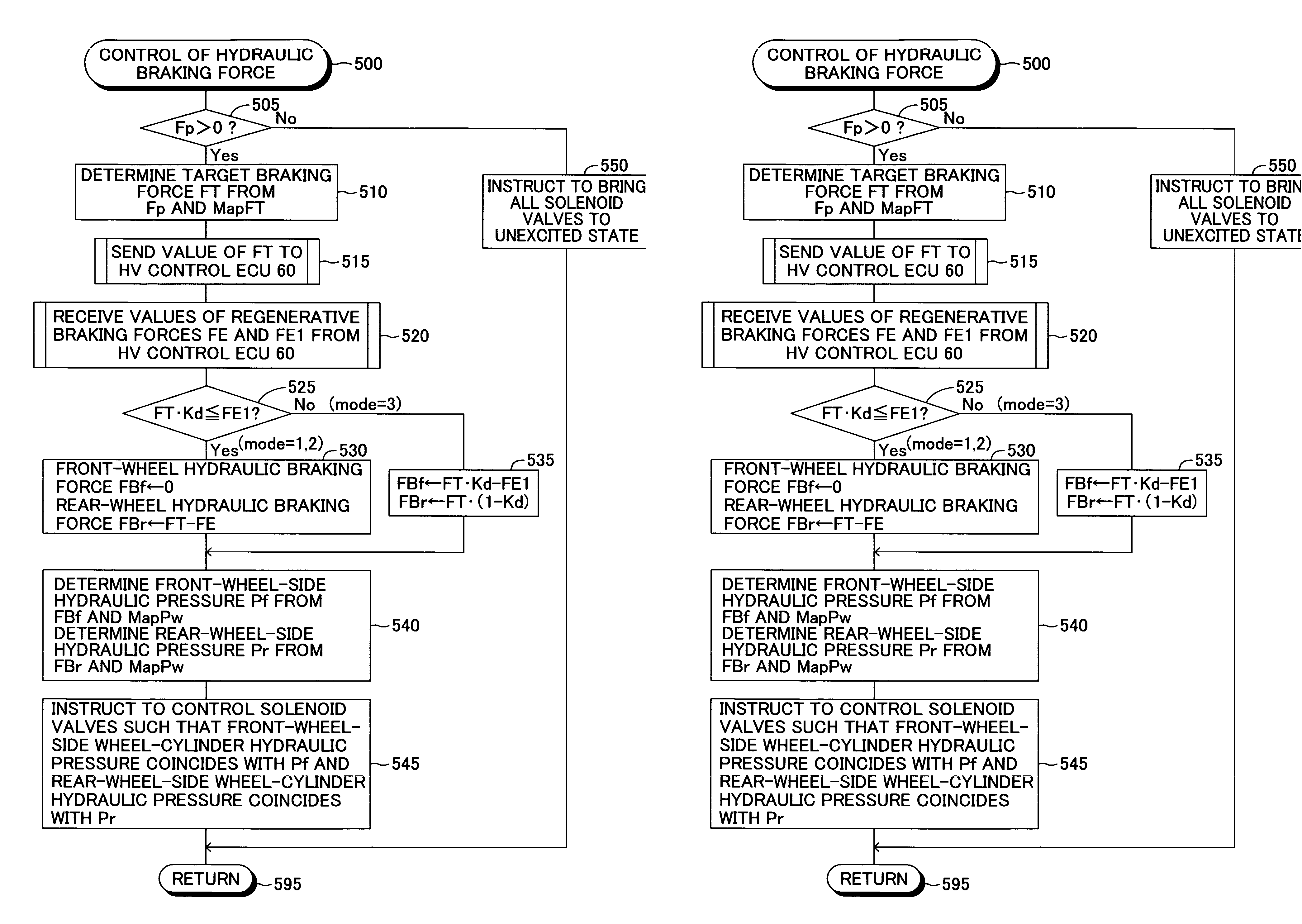

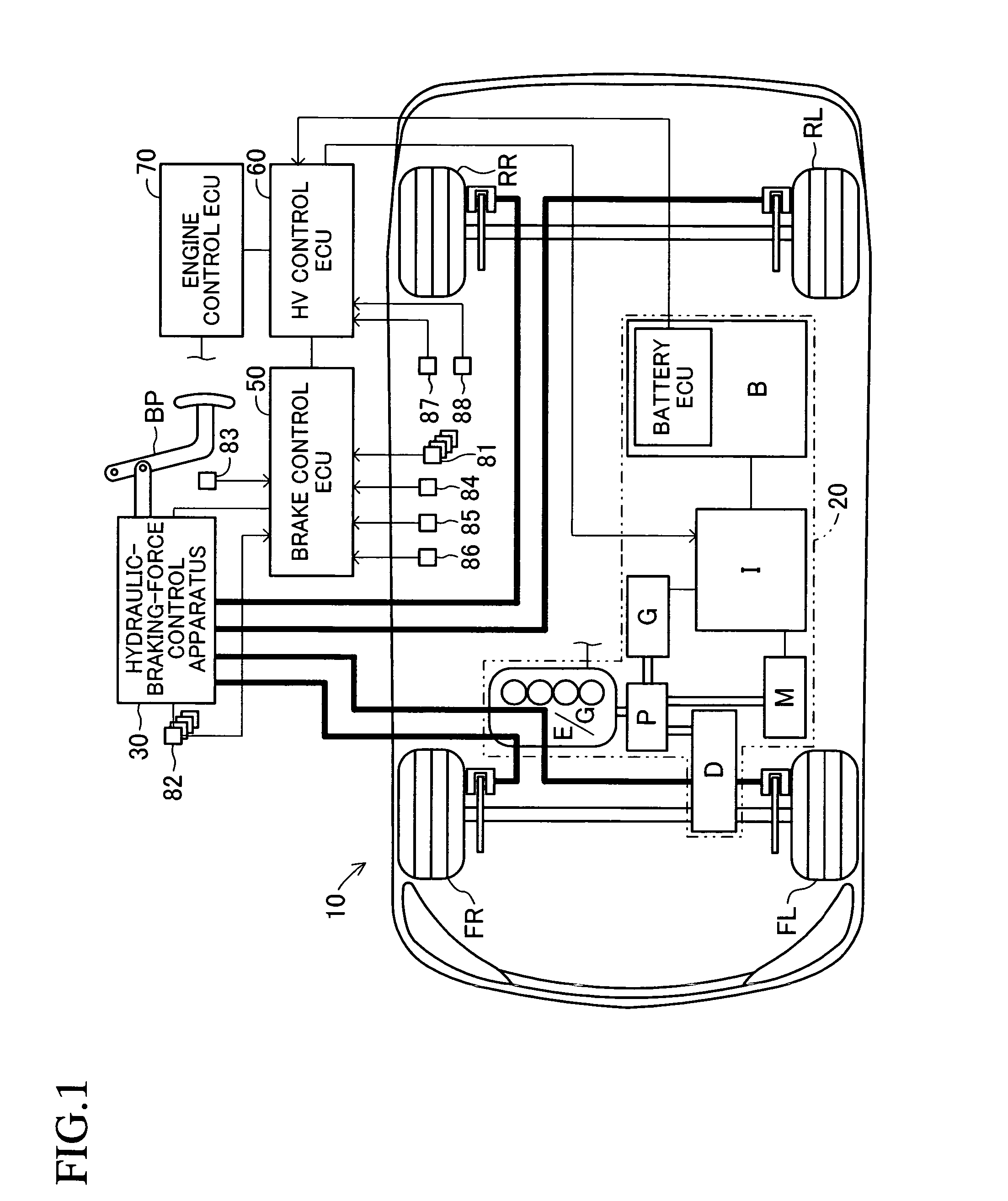

Brake control apparatus for vehicle

InactiveUS20070018499A1Suppress spinoutHighly efficient collection of electrical energyPlural diverse prime-mover propulsion mountingPropulsion by batteries/cellsDrive wheelRegenerative brake

A brake apparatus for a vehicle generally sets an upper limit value of regenerative braking force to the maximum value of the regenerative braking force which can be generated at the present. In the case of a front-wheel-drive vehicle, the total braking force, the sum of front-wheel braking force (front-wheel hydraulic braking force+regenerative braking force) and rear-wheel braking force (rear-wheel hydraulic braking force), is rendered coincident with a target braking force corresponding to a brake pedal depressing force, and the regenerative braking force is set to a largest possible value equal to or less than the upper limit value. As a result, the regenerative braking force can be larger than front-wheel-side target distribution braking force. The upper limit value is decreased from the maximum value by an amount corresponding to the degree of easiness of occurrence of a locking tendency at the driven wheels (front wheels).

Owner:ADVICS CO LTD

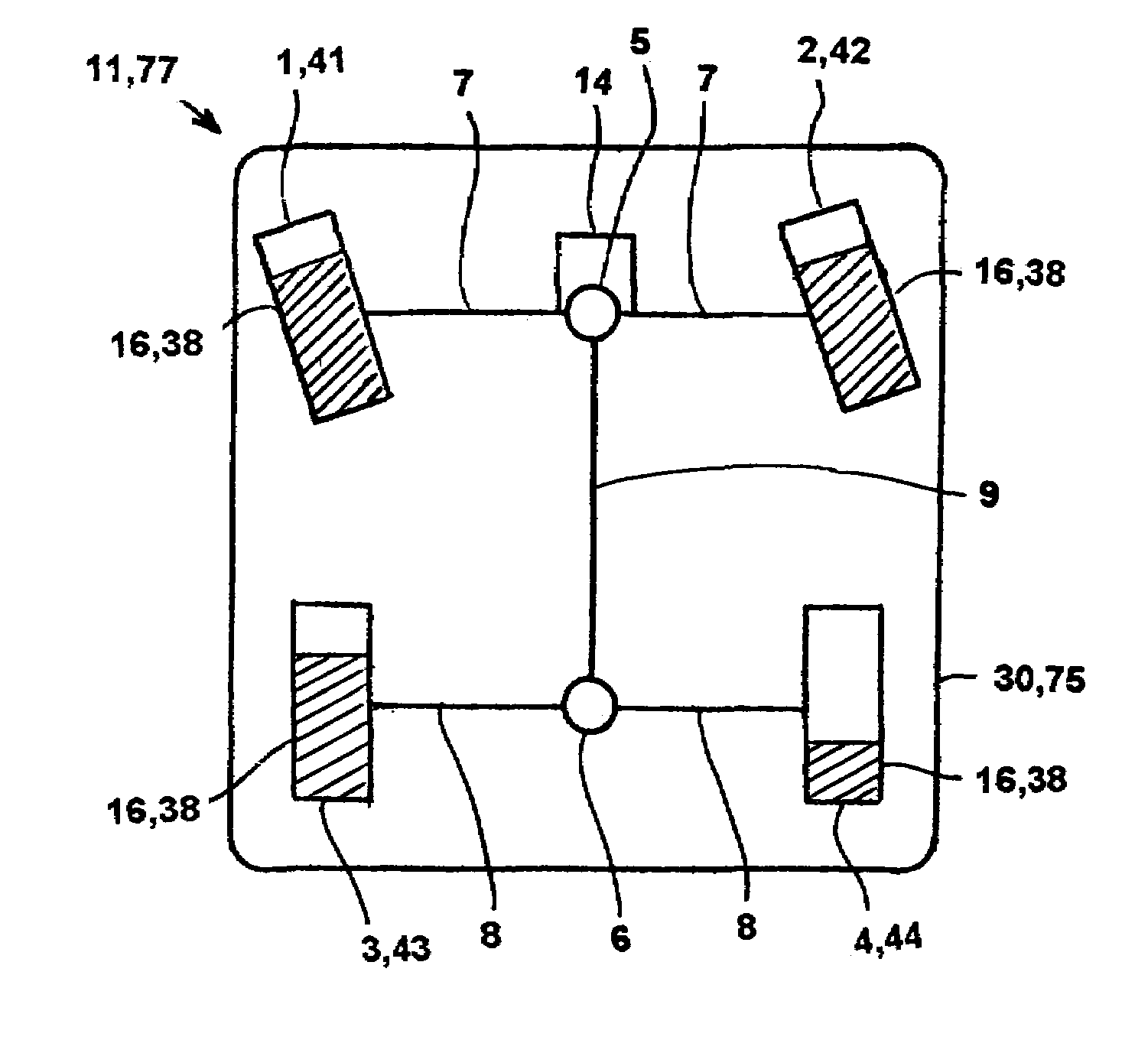

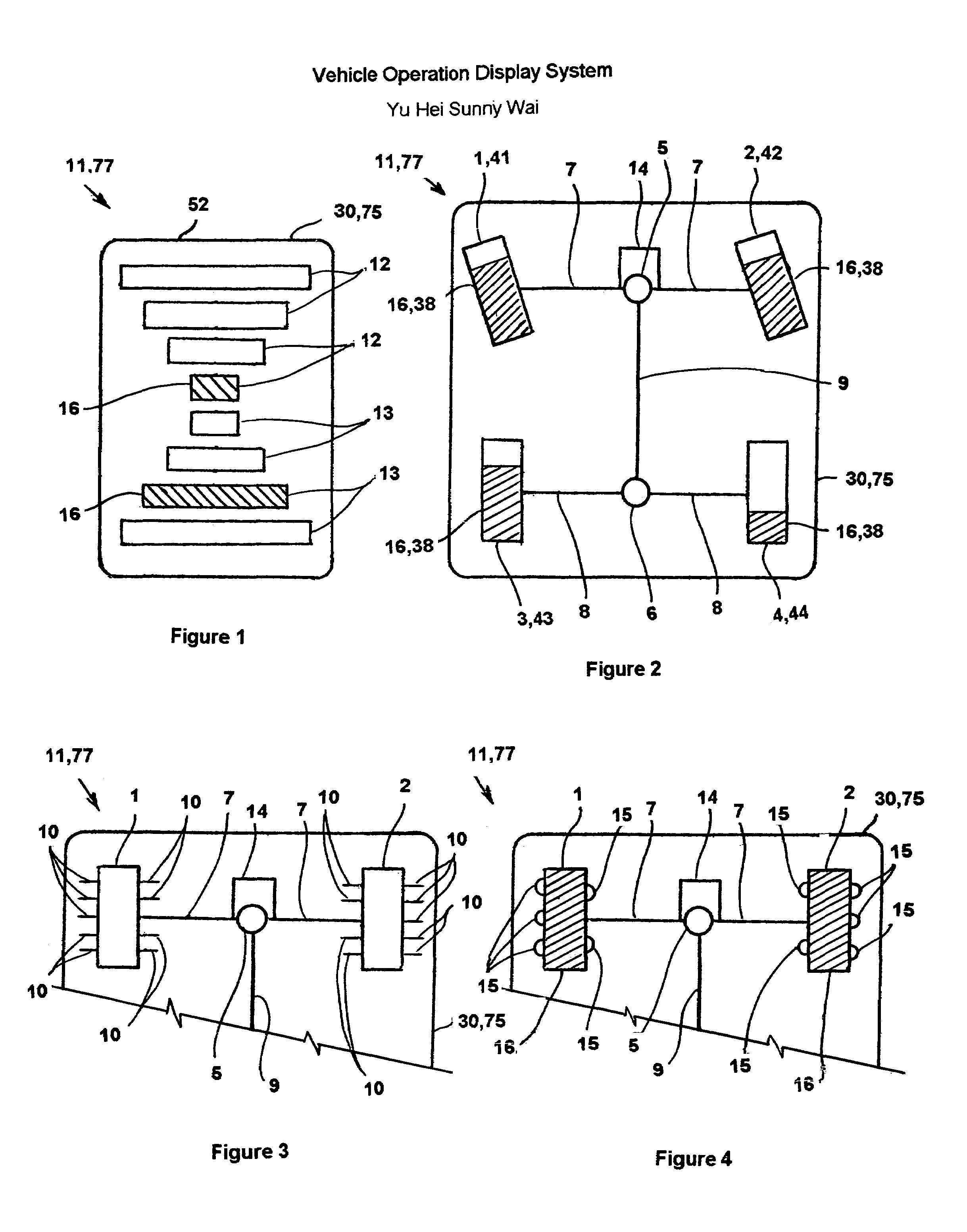

Vehicle operation display system

InactiveUS7145442B1Accurate visual displayRegistering/indicating working of vehiclesOptical signallingMobile vehicleMotorized vehicle

An apparatus, method, system and / or image editing process for presenting visual displays to the driver of a motor vehicle regarding the real time operating condition of the vehicle systems and components. These include the anti-lock braking system, the stability of the vehicle as to proximity to rolling over, the power consumed by vehicle components such as the heating system and lights and / or, for four-wheel drive vehicles, the torque and / or braking forces delivered to the wheels. The information is acquired from sensors and / or from signals generated by the vehicle and it processed by the vehicle CPU or, in another embodiment, by a display CPU, the information being presented in black and white or in color using an LED, LCD, vacuum fluorescent means, numerical display, gauge, meter or PDA.

Owner:VEHICLE OPERATION TECH

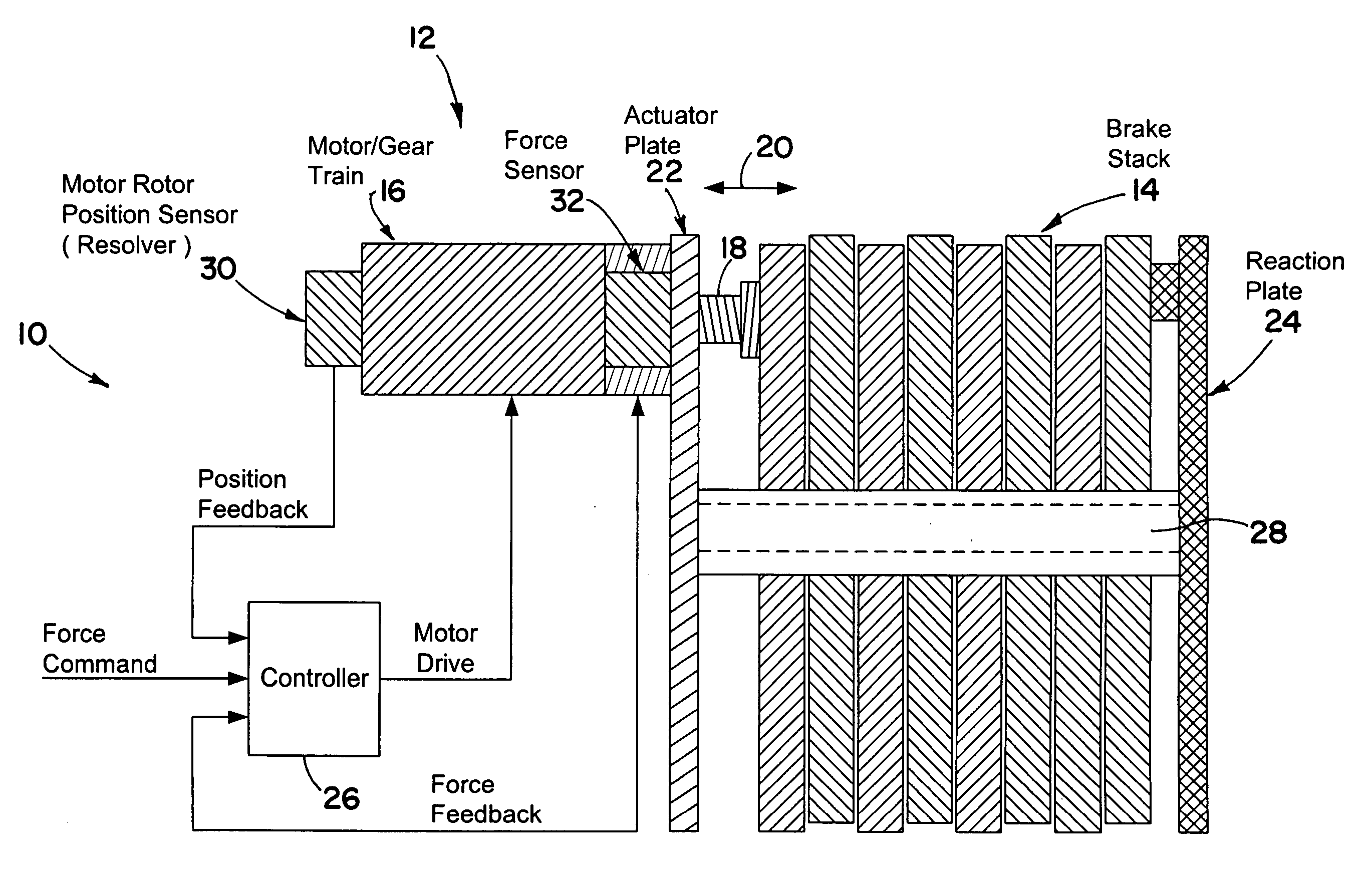

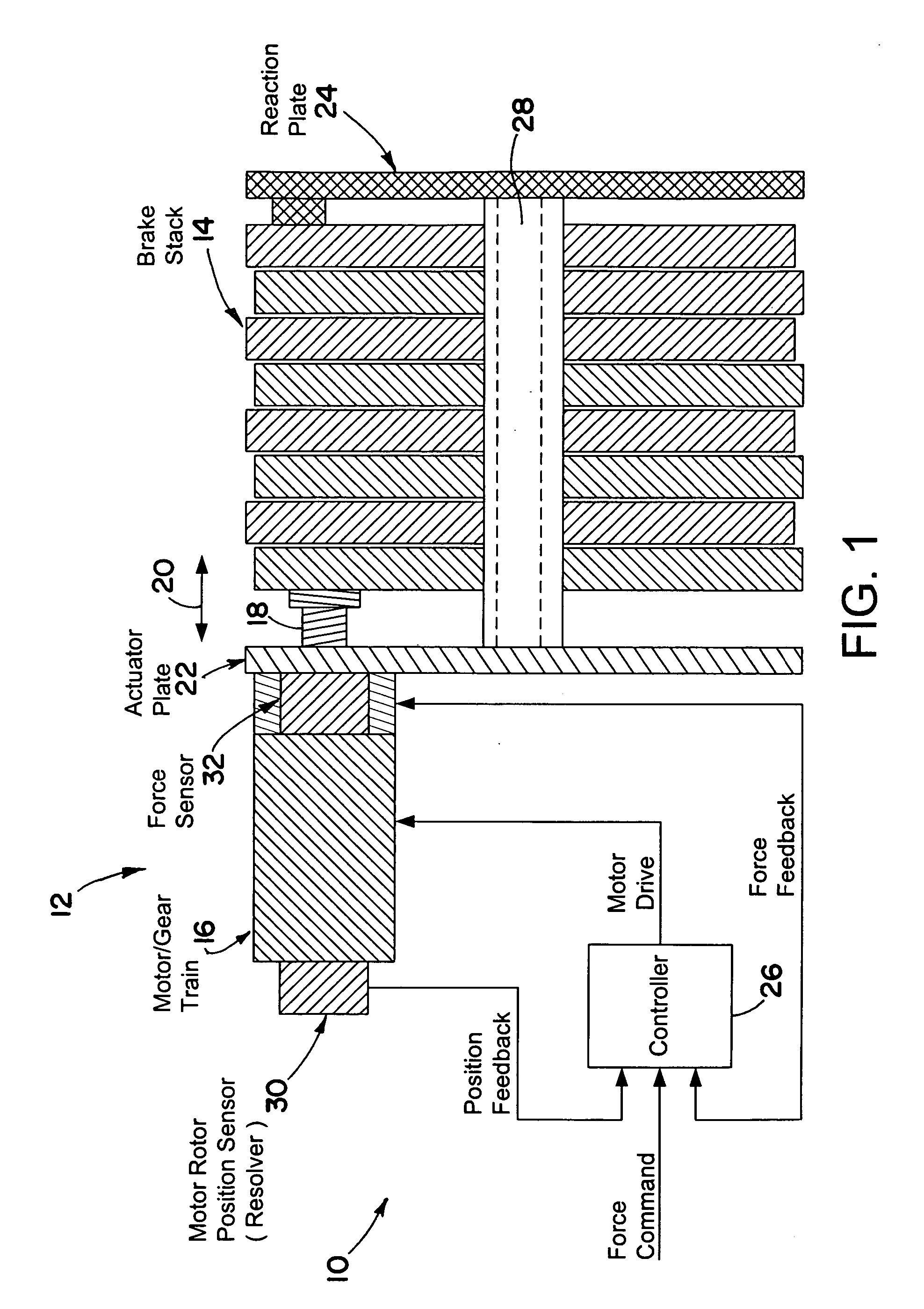

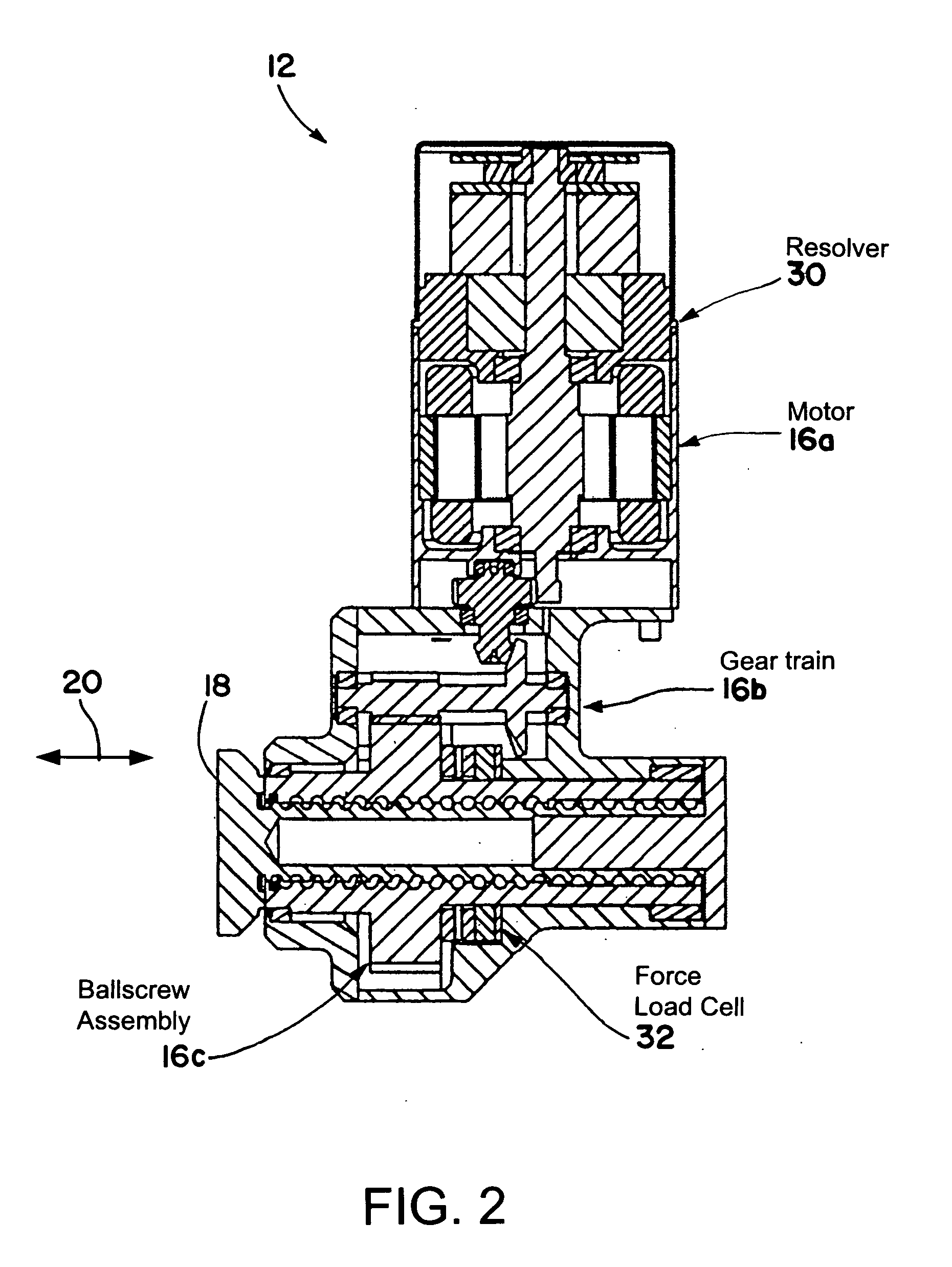

Electric brake position and force sensing and control

InactiveUS20050269872A1Braking action transmissionElectrodynamic brake systemsControl signalEngineering

A brake system including an electromechanical brake actuator having an actuator ram for exerting a brake force on a brake stack of a wheel to be braked in response to a control signal. In addition, the brake system includes a force sensor for sensing the brake force exerted on the brake stack by the actuator ram and outputting a force feedback signal based thereon; and a position sensor for sensing a position of the actuator ram and outputting a position feedback signal based thereon. Moreover, the brake system includes a controller for providing the control signal to the electromechanical brake actuator based on the force feedback signal and the position feedback signal.

Owner:THE BF GOODRICH CO

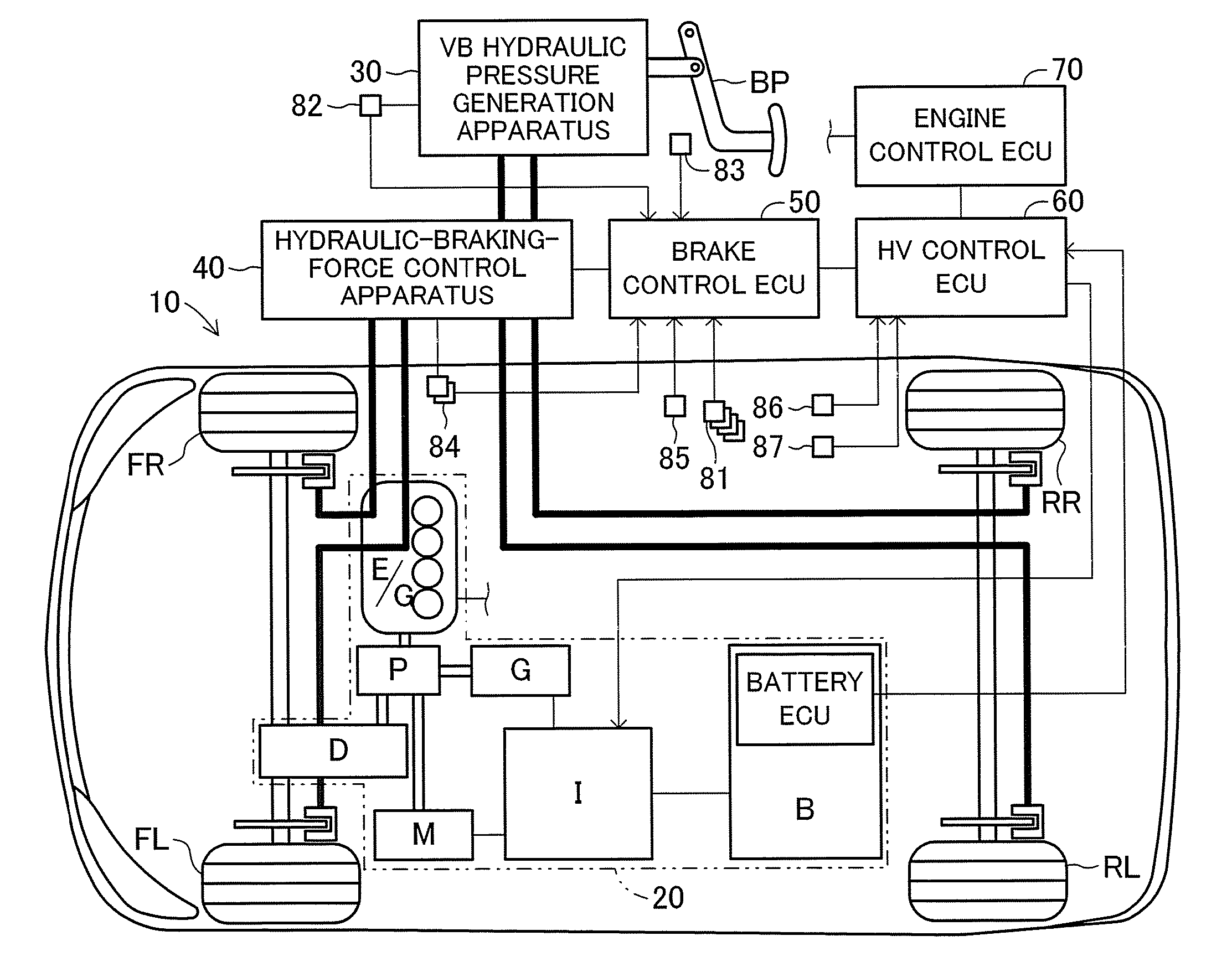

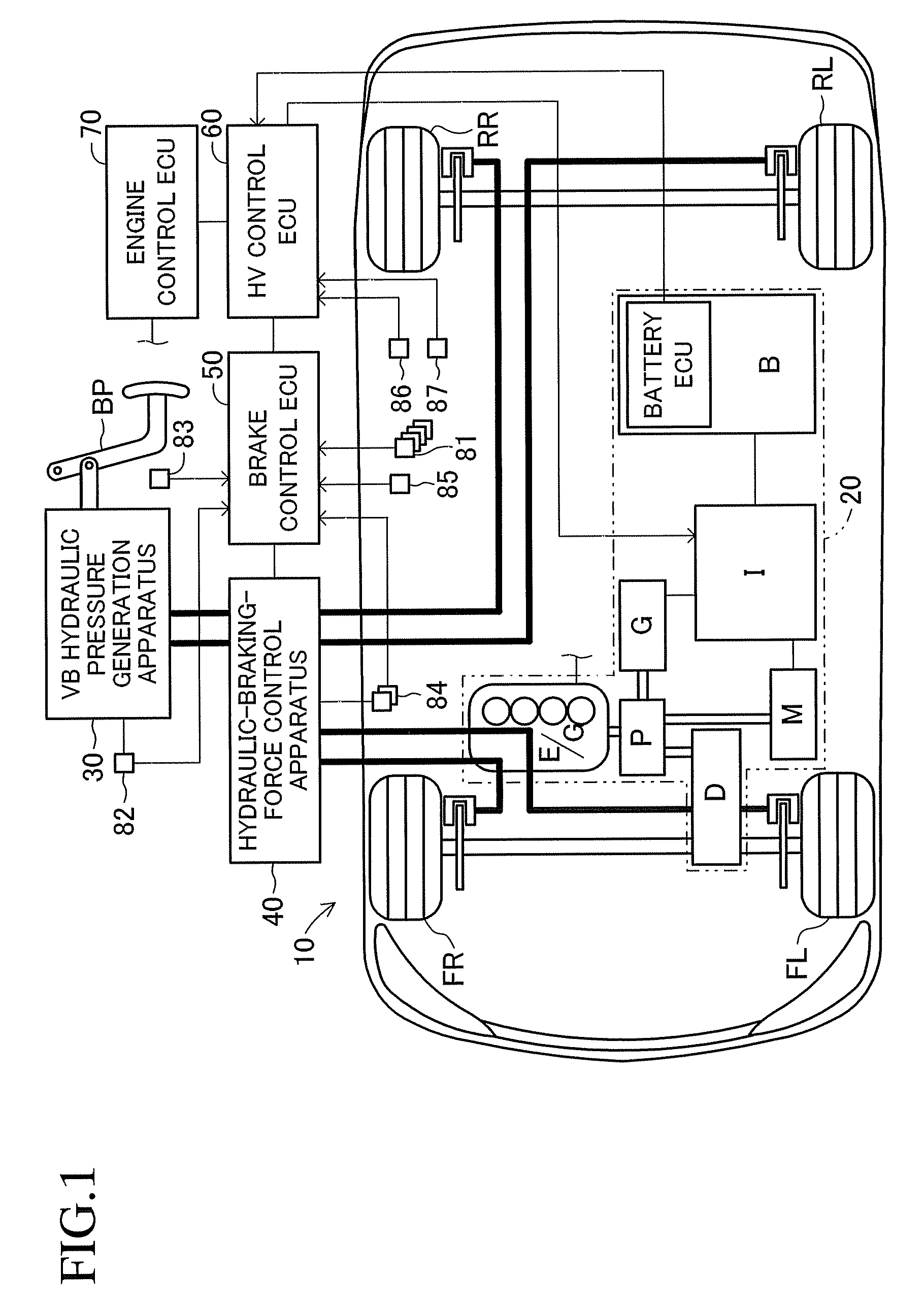

Brake control apparatus for vehicle

InactiveUS20060220453A1Improve energy efficiencyBraking element arrangementsBraking action transmissionRegenerative brakeDifferential pressure

A brake apparatus for a vehicle controls braking force acting on front wheels by hydraulic braking force (front-wheel-side vacuum-booster hydraulic pressure fraction+linear-valve differential pressure fraction), which is frictional braking force, and regenerative braking force, and controls braking force acting on rear wheels by hydraulic braking force (rear-wheel-side vacuum-booster hydraulic pressure fraction) only, to thereby perform regeneration-coordinative brake control. During performance of ABS control, the apparatus sets the limit regenerative braking force to a force under which locking of the front wheels does not occur in a case in which the force acts on the front wheels, which are wheels undergoing regenerative braking, and adjusts the regenerative braking force such that the regenerative braking force does not exceed the limit regenerative braking force.

Owner:ADVICS CO LTD

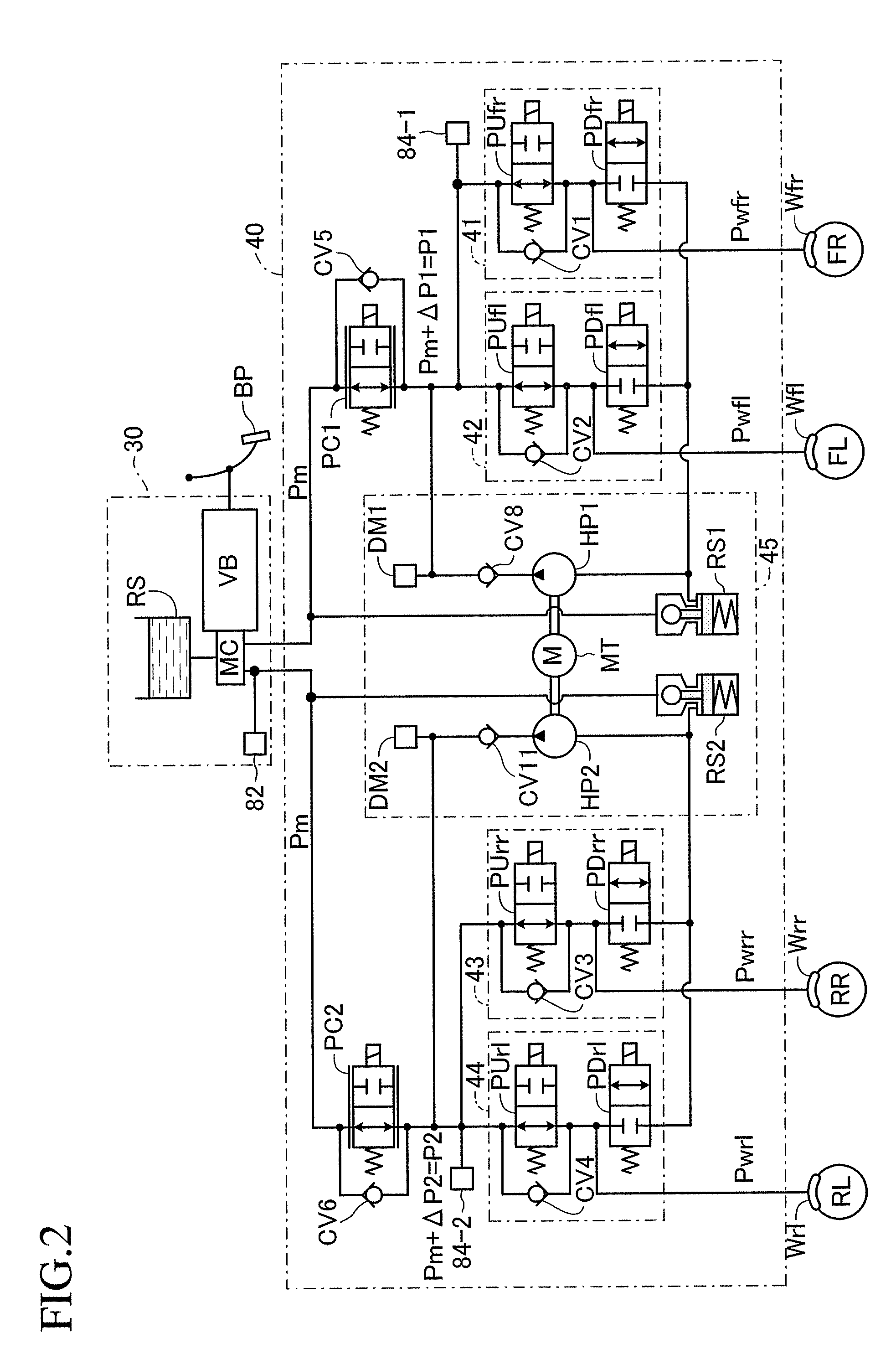

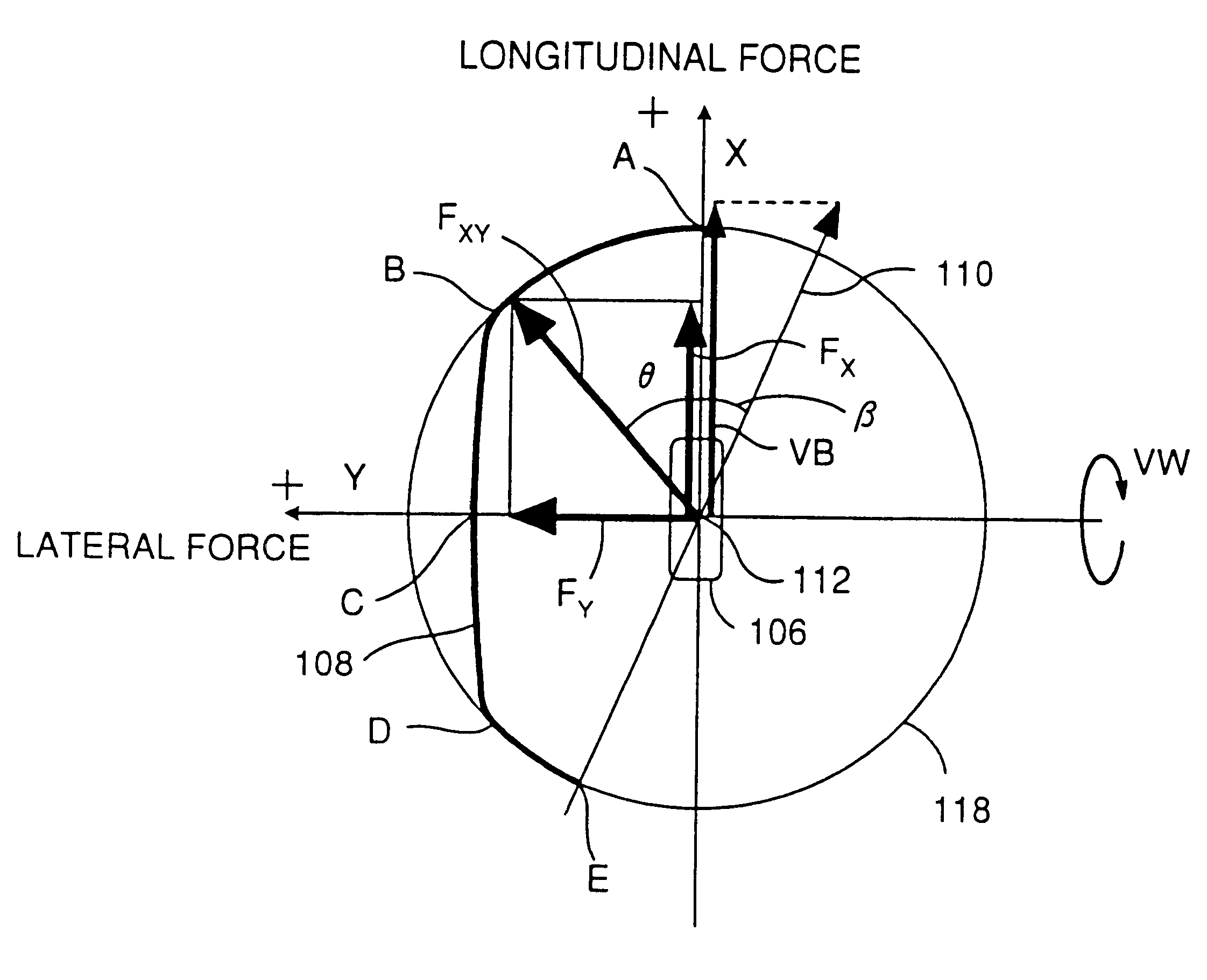

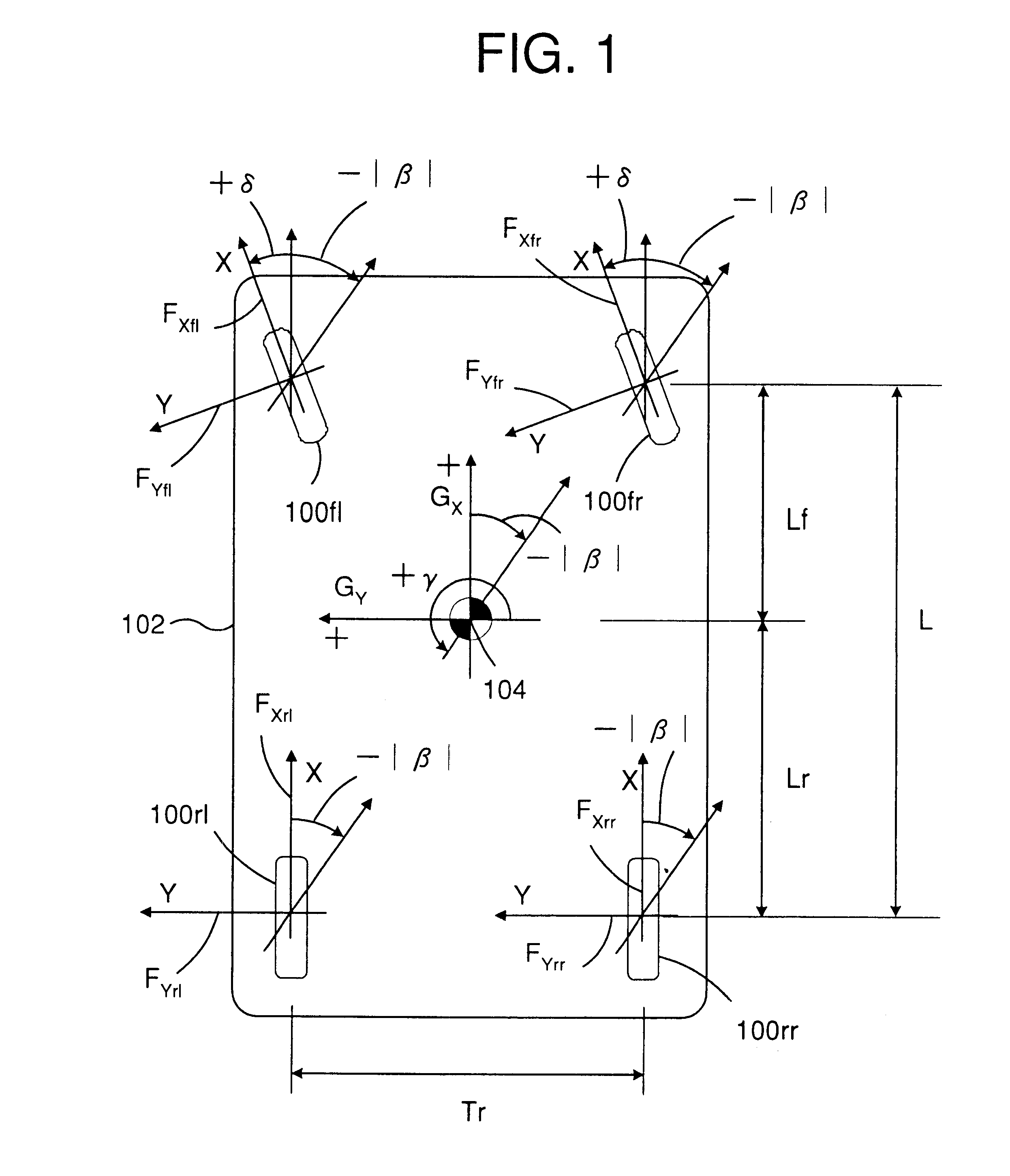

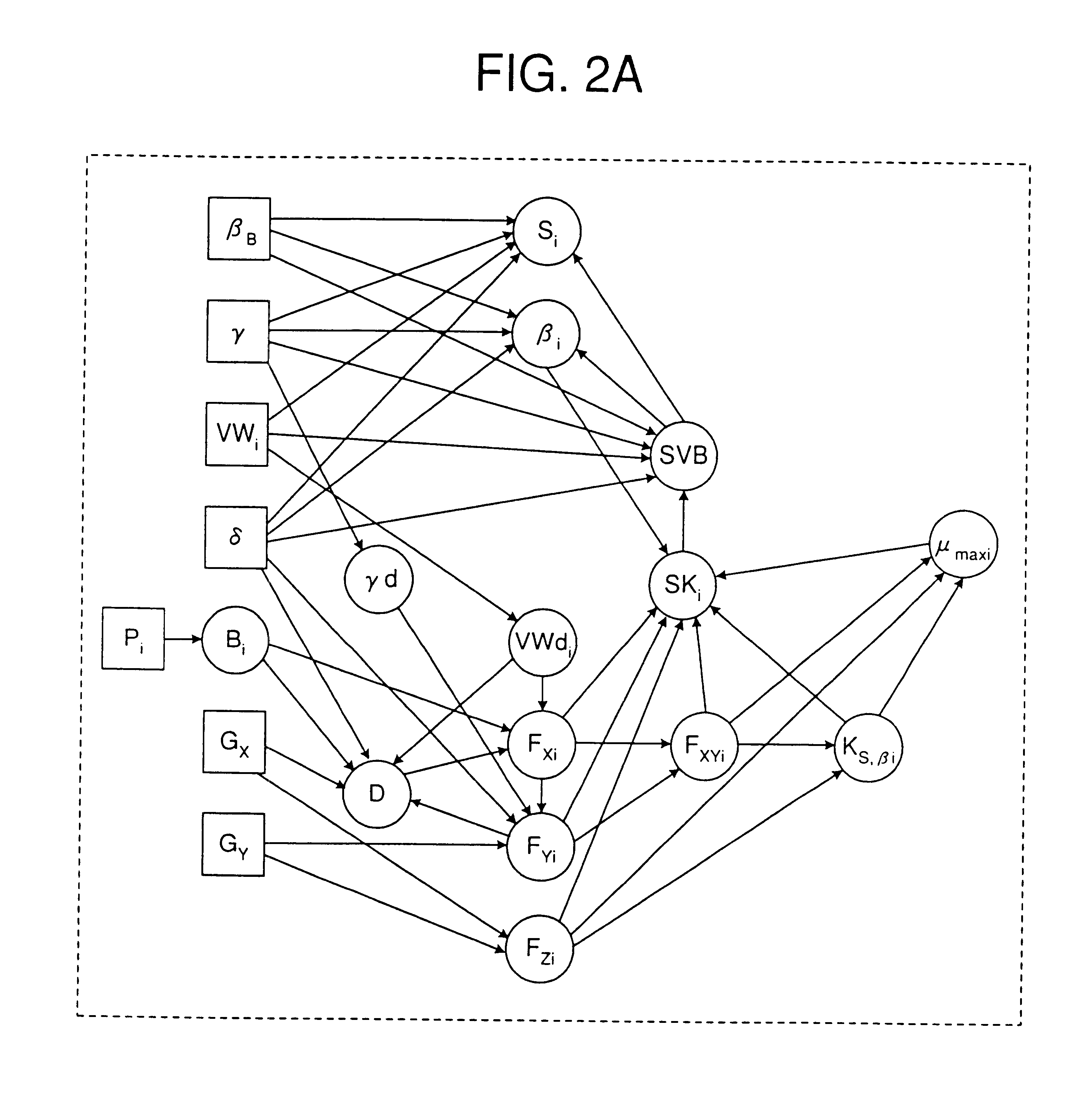

Vehicle motion control device and method

InactiveUS6659570B2Guaranteed uptimeKeep running stableDigital data processing detailsBrake control systemsVehicle behaviorMotion control

Vehicle motion control devices and methods systematically treat a conditions of each wheel to acquire and maintain the vehicle behavior stability together with anti wheel lock and wheel spin processing, braking forces distribution. Device for controlling a running behavior of a vehicle estimates a road reaction force on each wheel, calculates a yaw moment around a centroid of the vehicle body generated by the road reaction force on each wheel, and controls driving and braking forces on each wheel based upon the yaw moments so as to stabilize a running of the vehicle. Spin and Drift conditions are detected through presently generated yaw moments and critical yaw moments which can be generated by a road reaction force assumed to be maximized. Physical parameters of each wheels, required for detecting and controlling the behavior of the vehicle are estimated with a theoretical tire model.

Owner:TOYOTA JIDOSHA KK

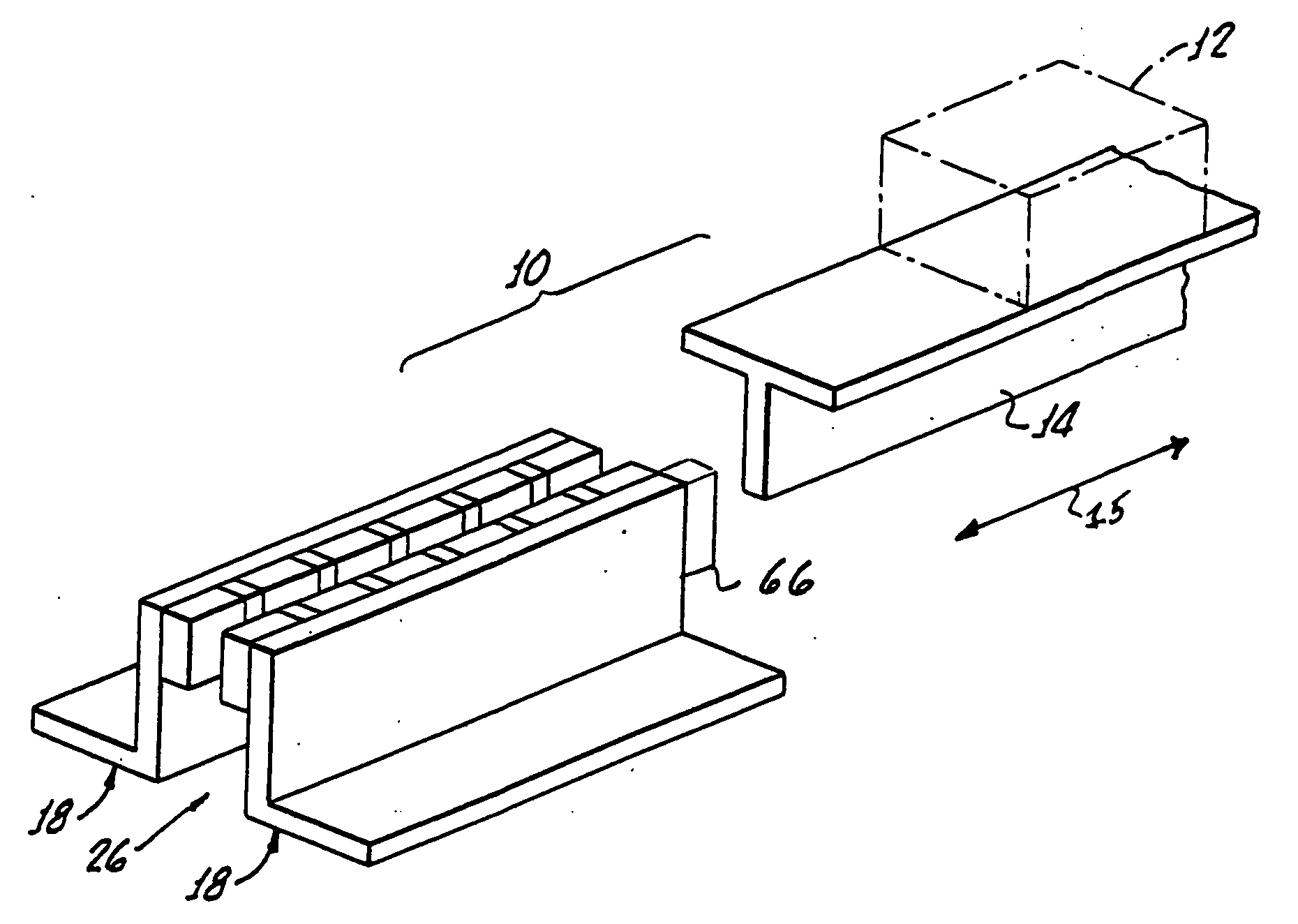

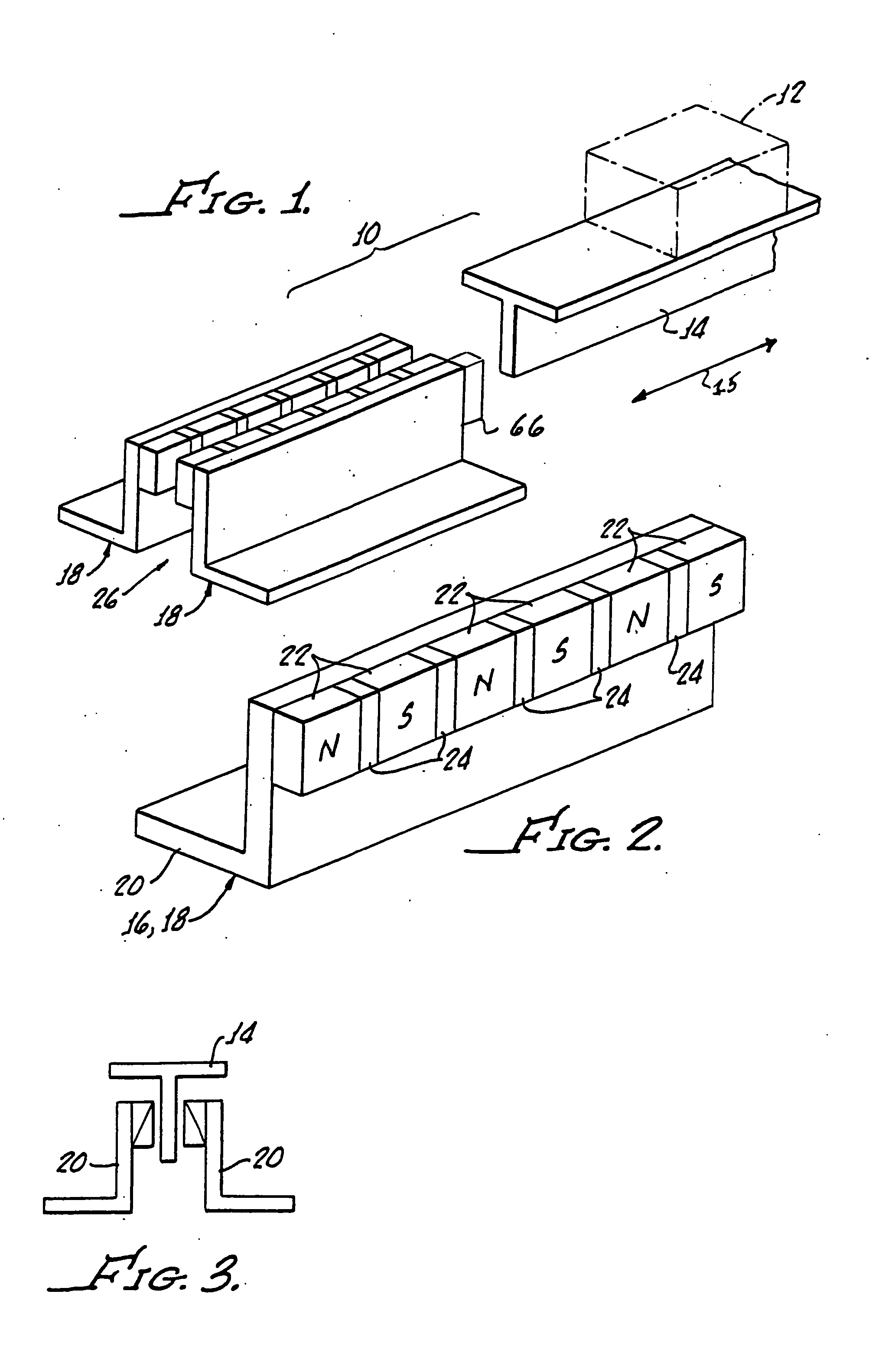

Exercise device with magnetic braking system

InactiveUS8876668B2Increased leverageImprove tilt effectMovement coordination devicesMuscle exercising devicesEngineeringBraking system

A selectively inclining hiking exercise apparatus supports a user ambulating thereon. The selectively inclining hiking exercise apparatus includes a support base and a treadbase that selectively inclines with respect to the support base. The treadbase includes a motor for driving an endless belt upon which the user ambulates. The treadbase also includes a magnetic braking assembly for regulating the speed of the endless belt to prevent the endless belt from moving at a rate that is faster than the rate at which the treadbase motor is driving the endless belt. The magnetic braking assembly includes a magnet that selectively moves relative to the treadbase flywheel along a threaded lead screw to provide the braking force.

Owner:IFIT INC

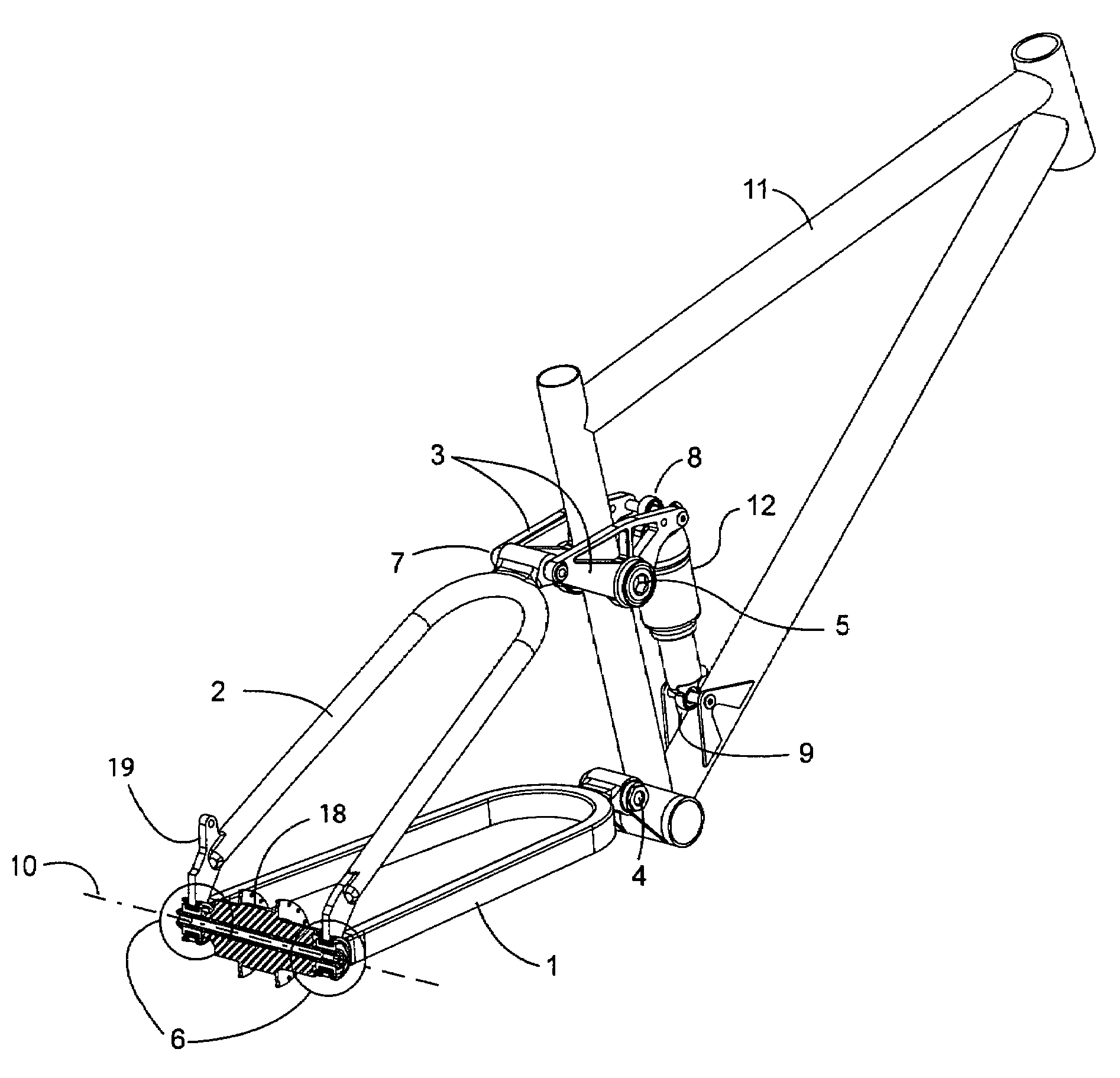

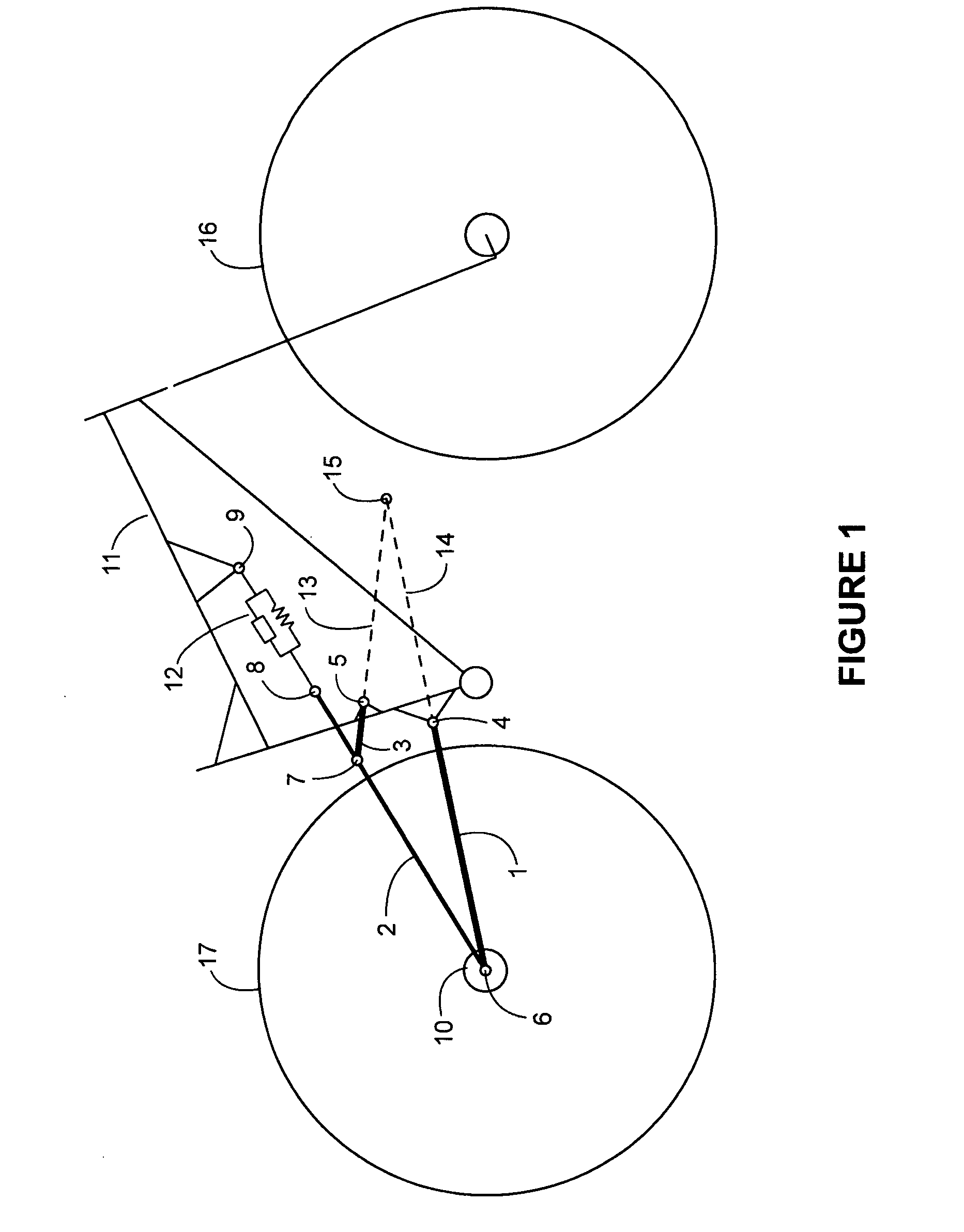

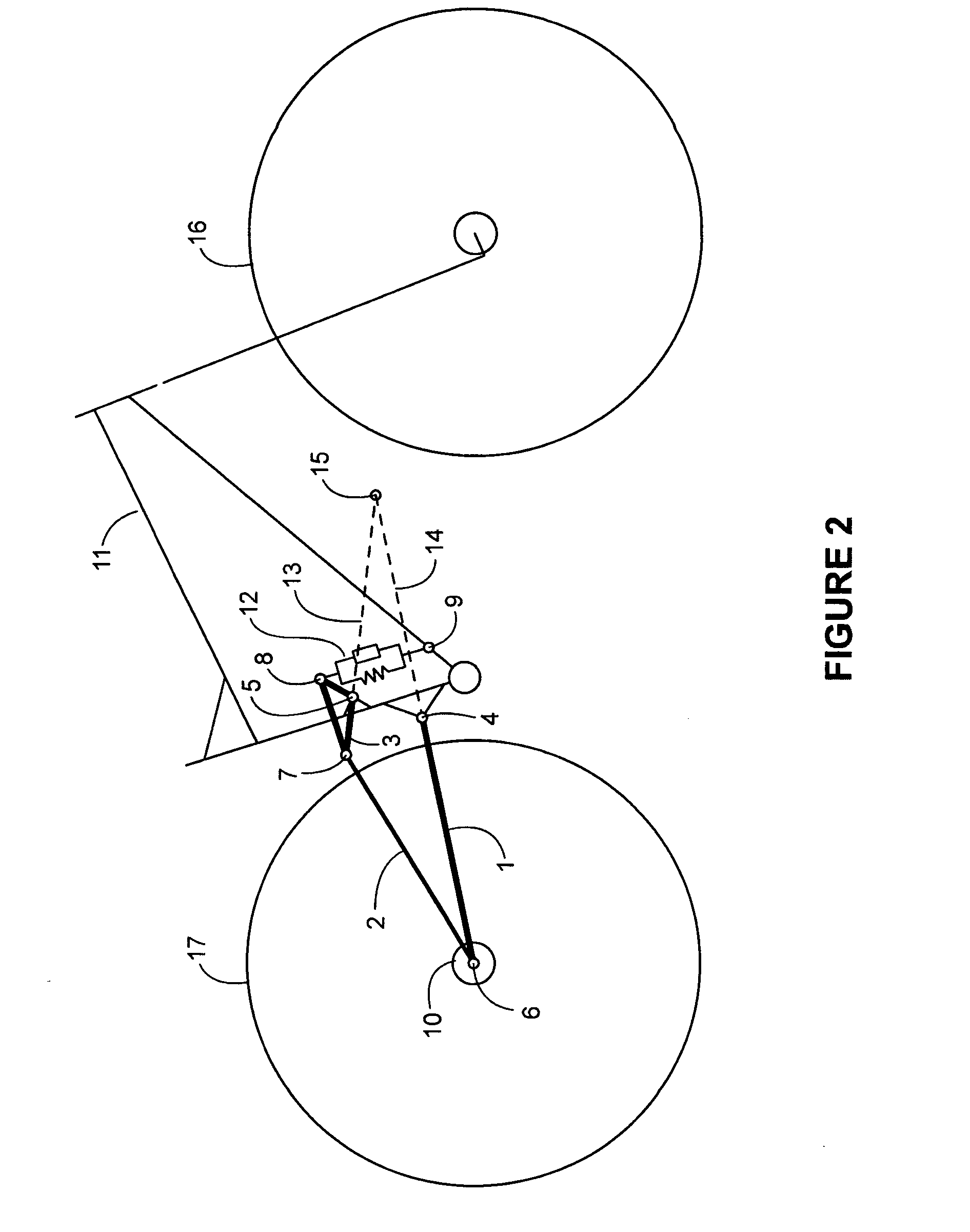

Vehicle suspension systems for seperated acceleration responses

InactiveUS20080067772A1Lower performance requirementsPassenger cyclesChildren cyclesEngineeringBrake force

Owner:SPLIT PIVOT

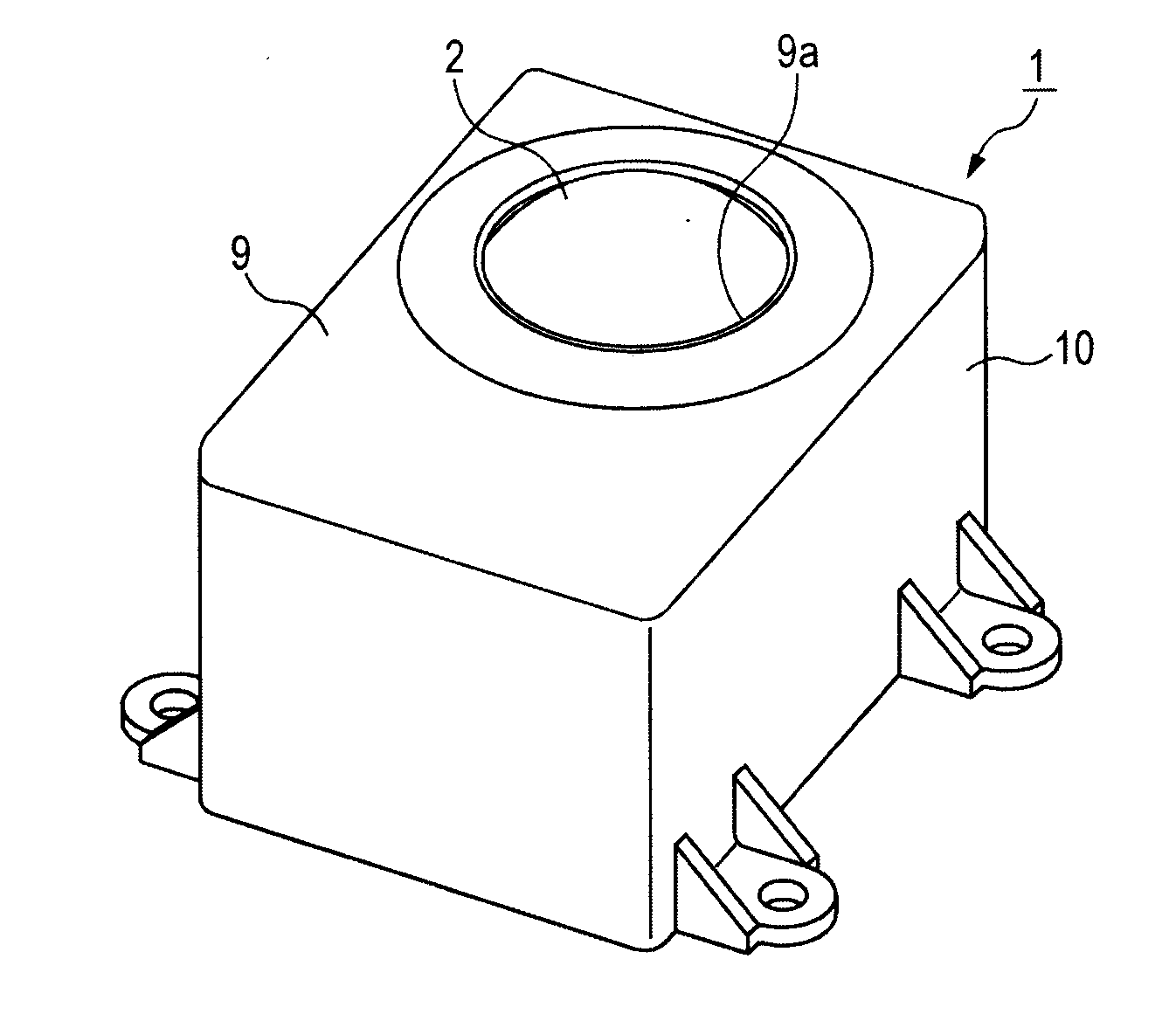

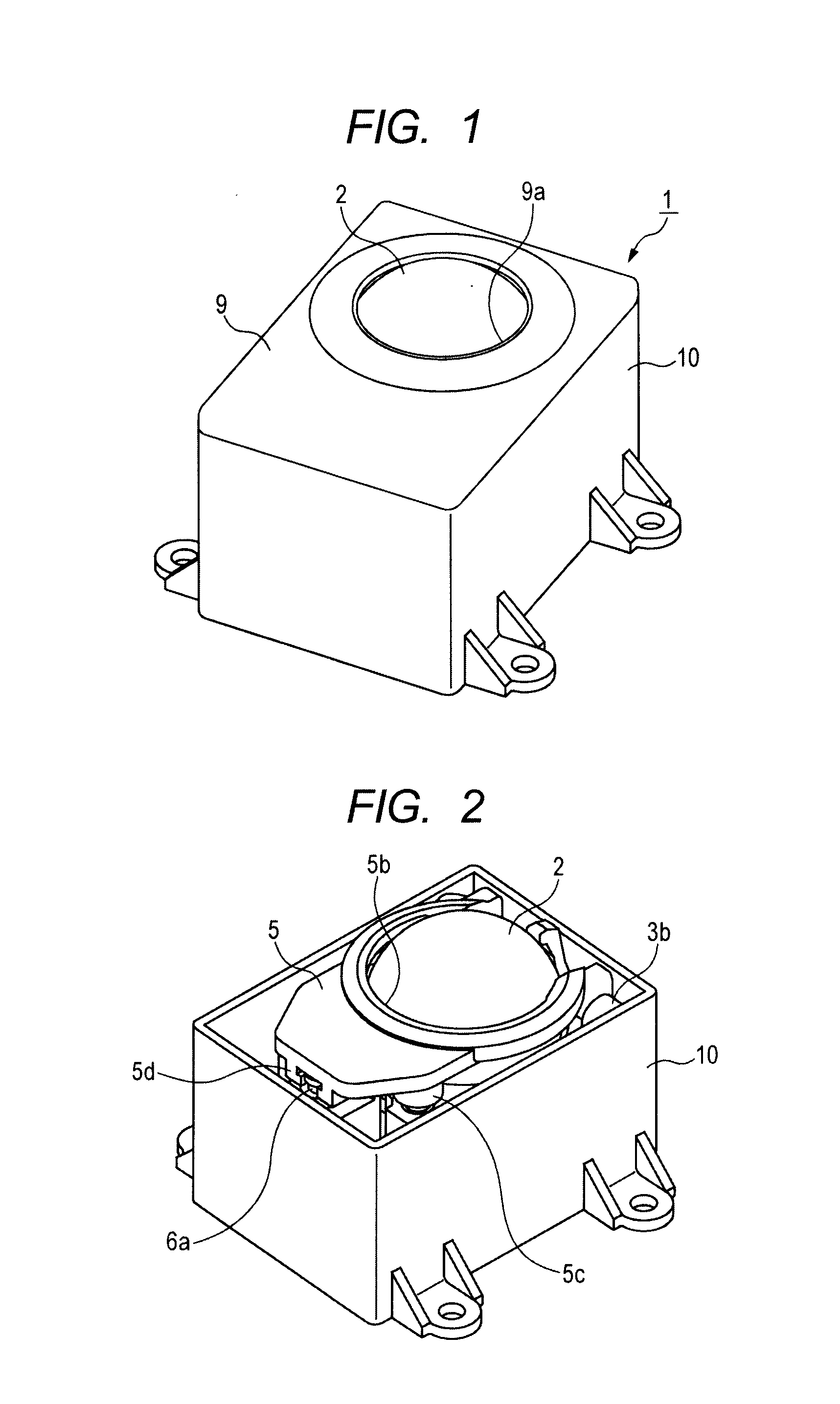

Rotary damper

InactiveUS6336252B1Enhanced level of machining precisionImprove the forceBuilding braking devicesWing fastenersFriction forceBase line

A rotary damper is adapted to exert braking force to an upswung door, a toilet lid or the like when the door is closed and dampen the impact produced by the closing door by a damping force far greater than the one obtained by a conventional rotary damper using viscous shearing resistance. The rotary damper can also make the door open by a force far smaller than a conventional rotary damper. A movable shaft is rotatably housed in a casing and has a cylindrical shaft section including an arcuate non-resilient section extending from a peripheral edge thereof to an axial base line close to the other free peripheral edge thereof and an eccentric resilient section extending from the axial base line to the other free peripheral edge thereof with its eccentricity increasing as a function of the distance from the base line relative to the radius of curvature of the inner peripheral surface so as resiliently abut the inner peripheral surface. The frictional force between the eccentric rest section and the inner peripheral surface increases when the movable shaft is driven to rotate to close the door to which it is fitted but falls remarkably when the movable shaft is driven to rotate in the opposite sense to open the door.

Owner:SUGATSUNE IND CO LTD

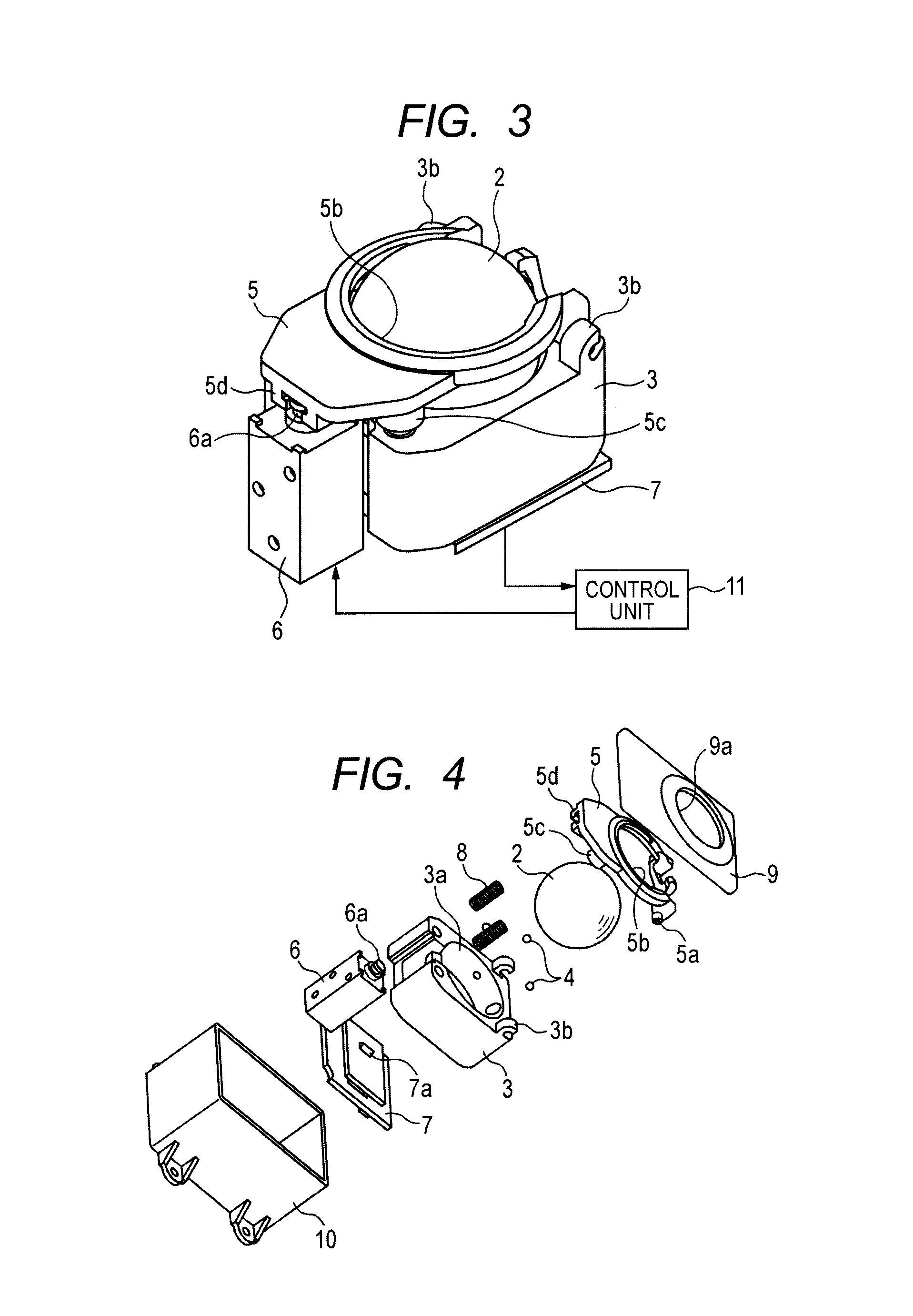

Operation feeling imparting type trackball device

InactiveUS20120038495A1Improve the quality of operationEasily realizing compact sizeElectronic switchingInput/output processes for data processingActuatorFriction force

A trackball device includes a friction plate rockably supported having opening in which a top portion of the sphere is exposed, as a brake unit applying braking force (friction force) to the sphere, and an actuator capable of driving the friction plate to a lower side. When the friction plate is driven by the actuator, the circumference portion of the opening of the friction plate is pressed to be in contact with the sphere from an upper side. A supporting member rotatably holding the sphere includes a plurality of supporting small spheres contacts the sphere at a point and a base member in which the supporting small spheres is arranged to be dispersed in the circumferential direction. The base member rockably supports the friction plate.

Owner:ALPS ALPINE CO LTD

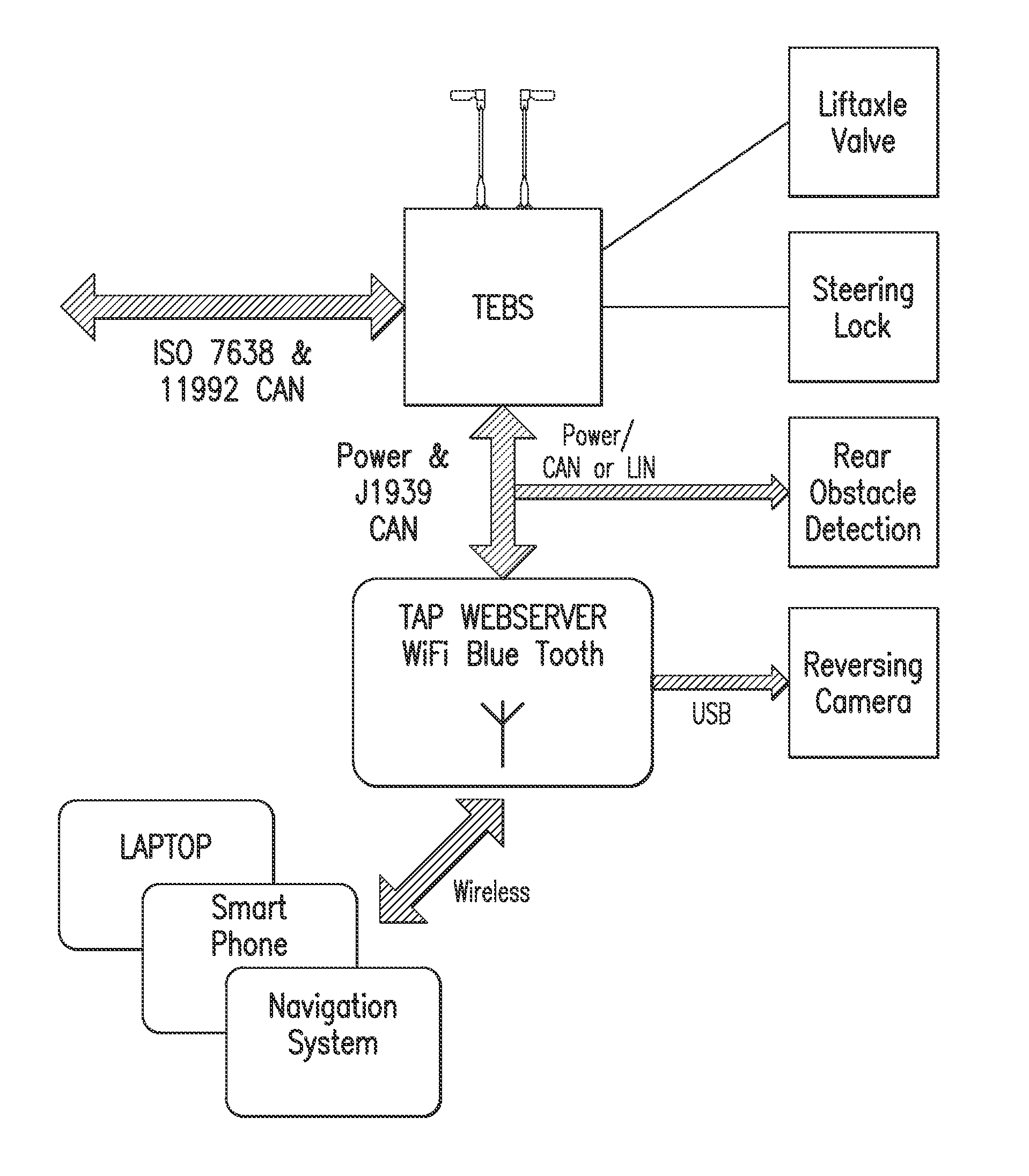

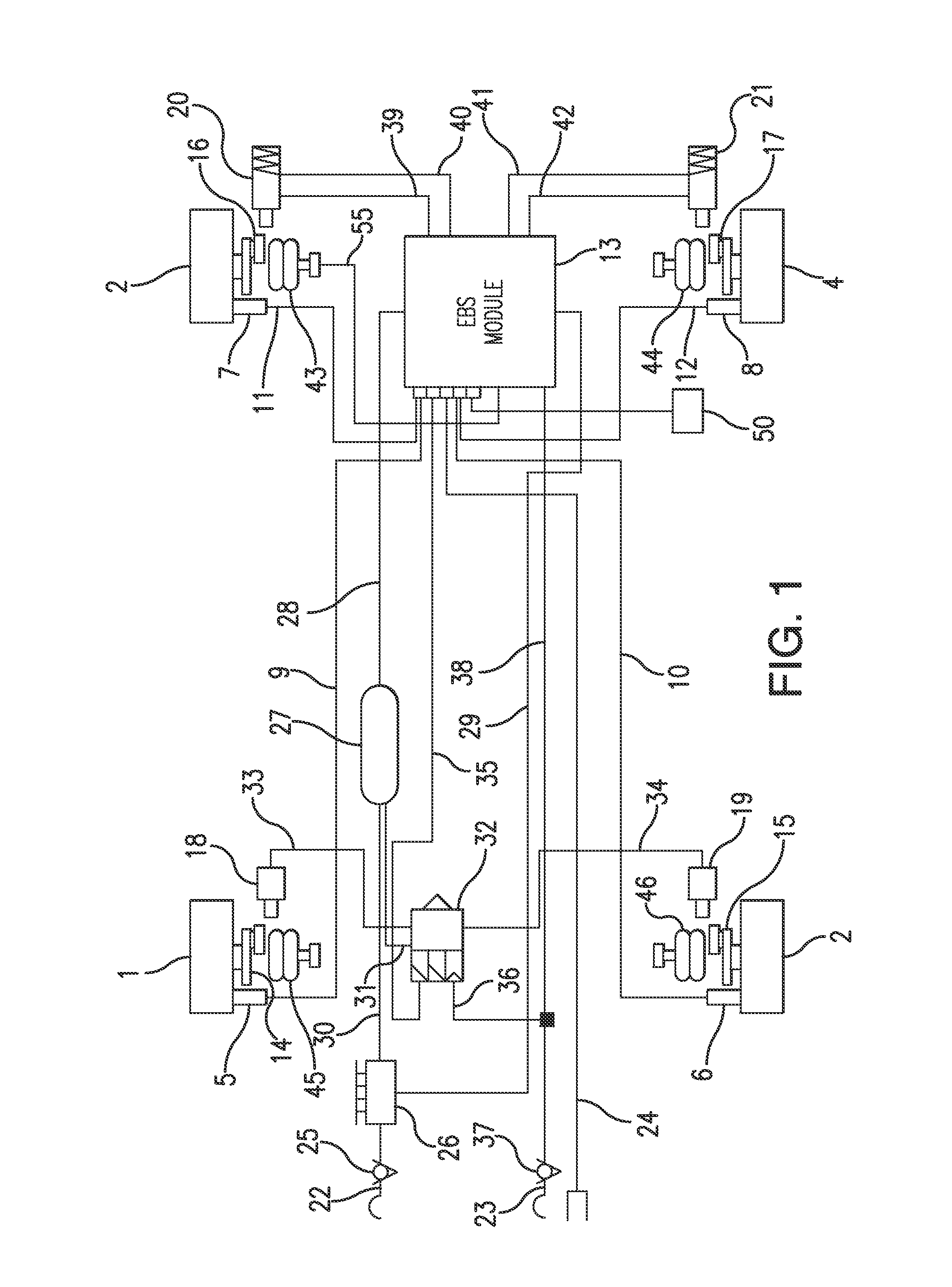

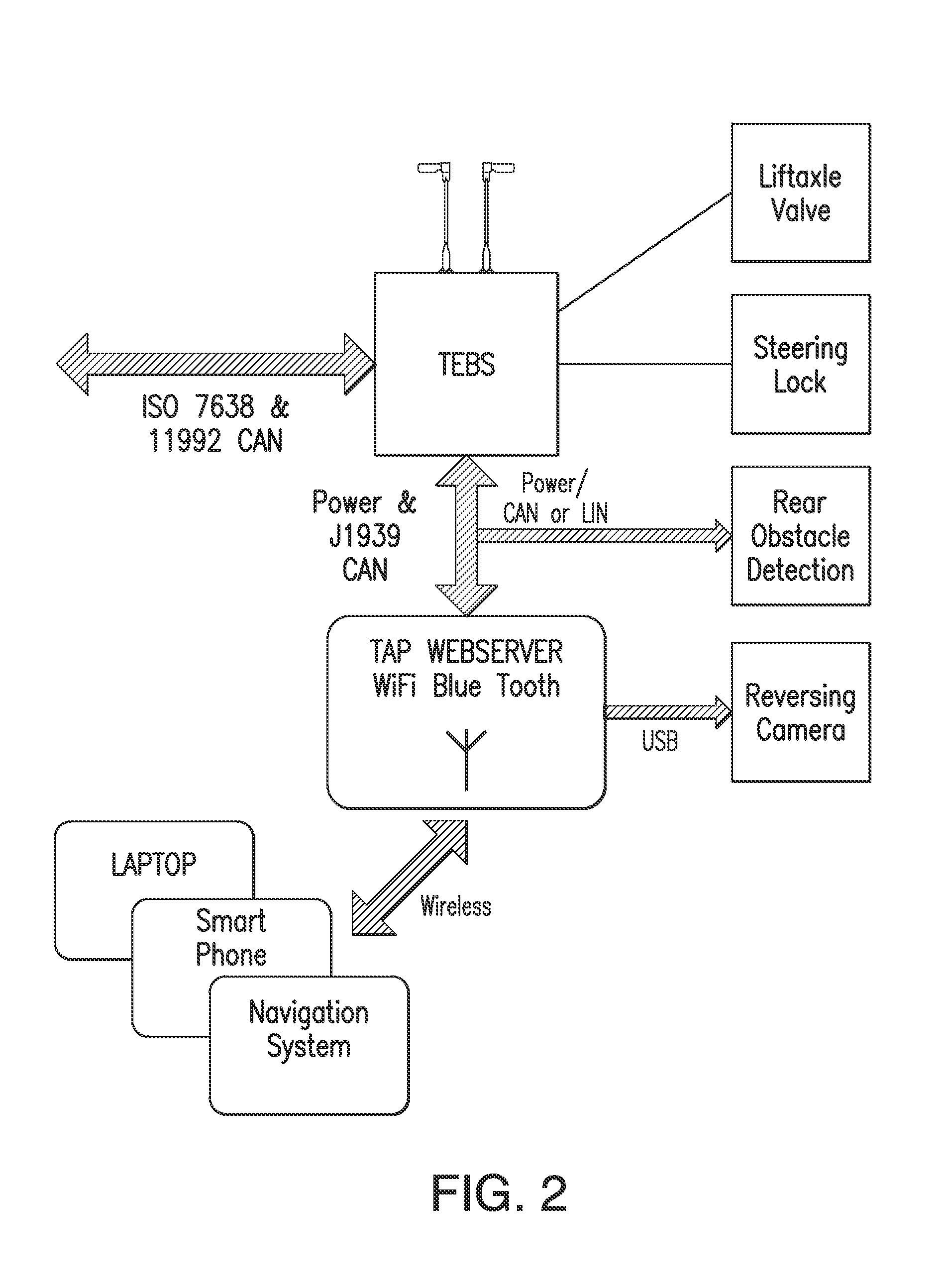

Trailer access point pairing

A trailer electronic braking system comprising a braking device capable of generating a braking force on a wheel on the trailer. The braking force is applied to the brake cylinders and is controllable by a braking ECU, which braking ECU is connected to a standards compliant communication bus on the trailer. The ECU is adapted to receive data inputs from sensors on the trailer. The system further includes an arrangement to interface to trailer electronics and a communications interface. In use, the arrangement transmits a request to the device for a driver to apply a predetermined condition to the trailer to enable control functions to be actuated from a remote device.

Owner:KNORR BREMSE SYST FOR COMML VEHICLES

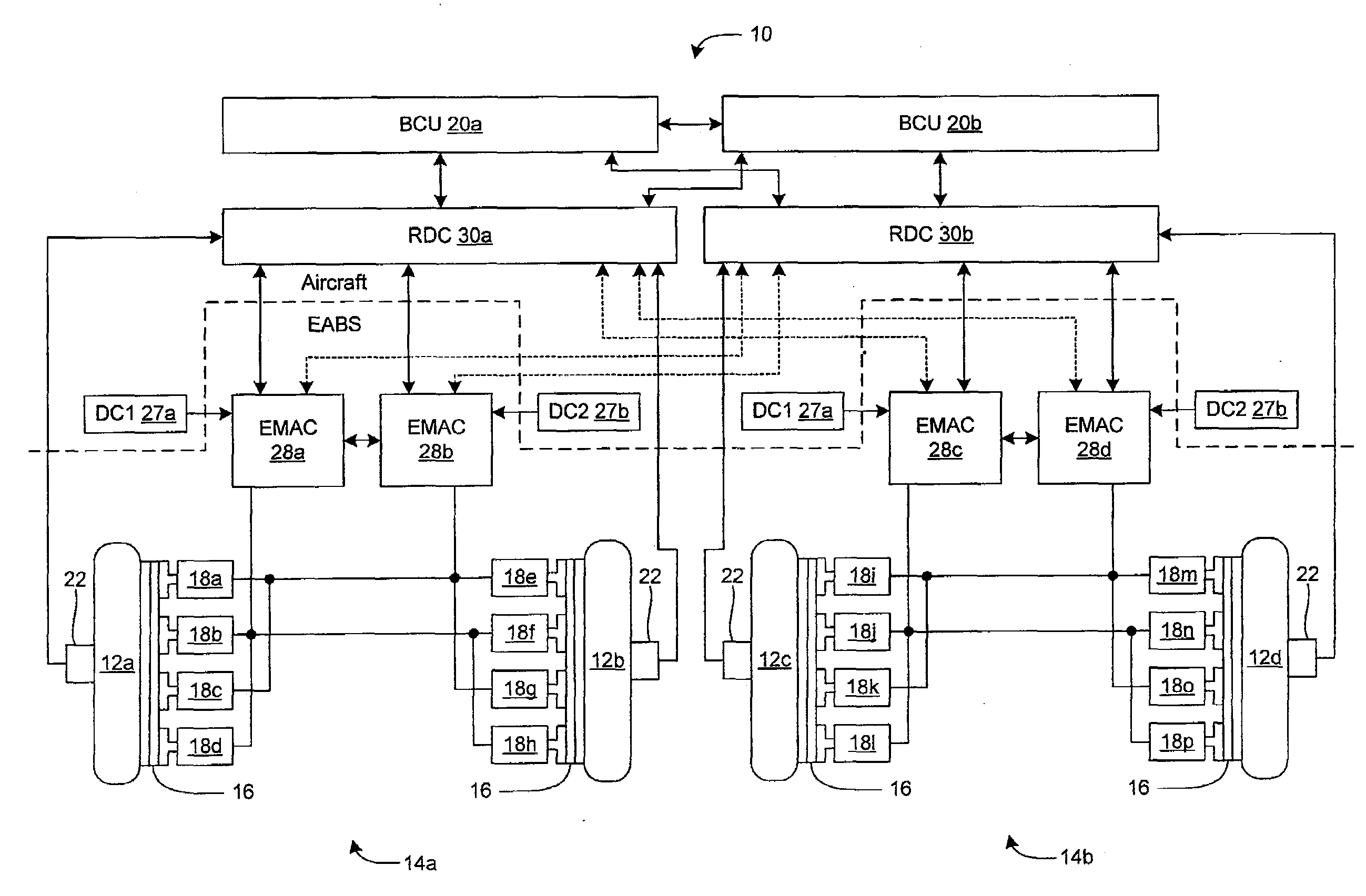

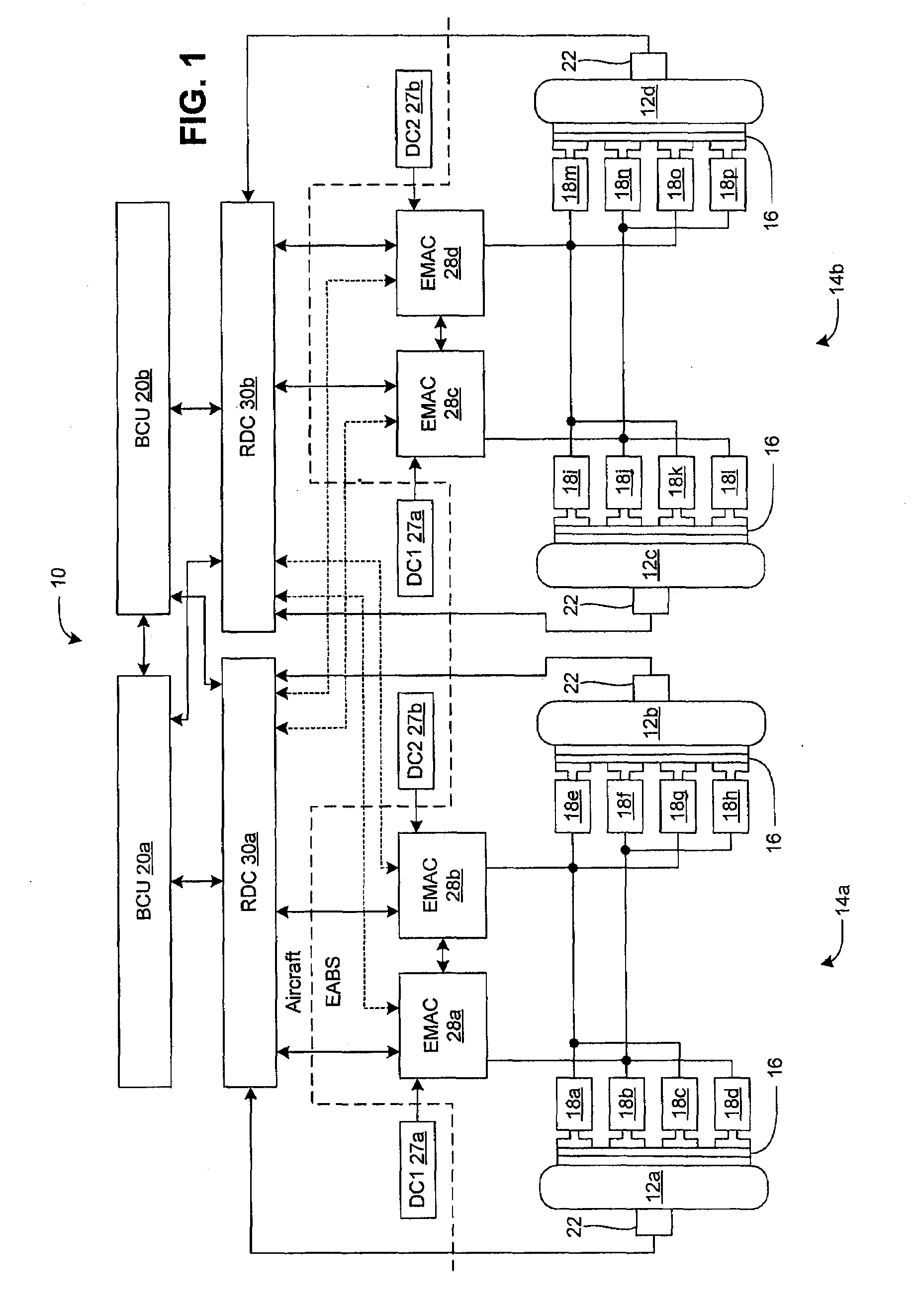

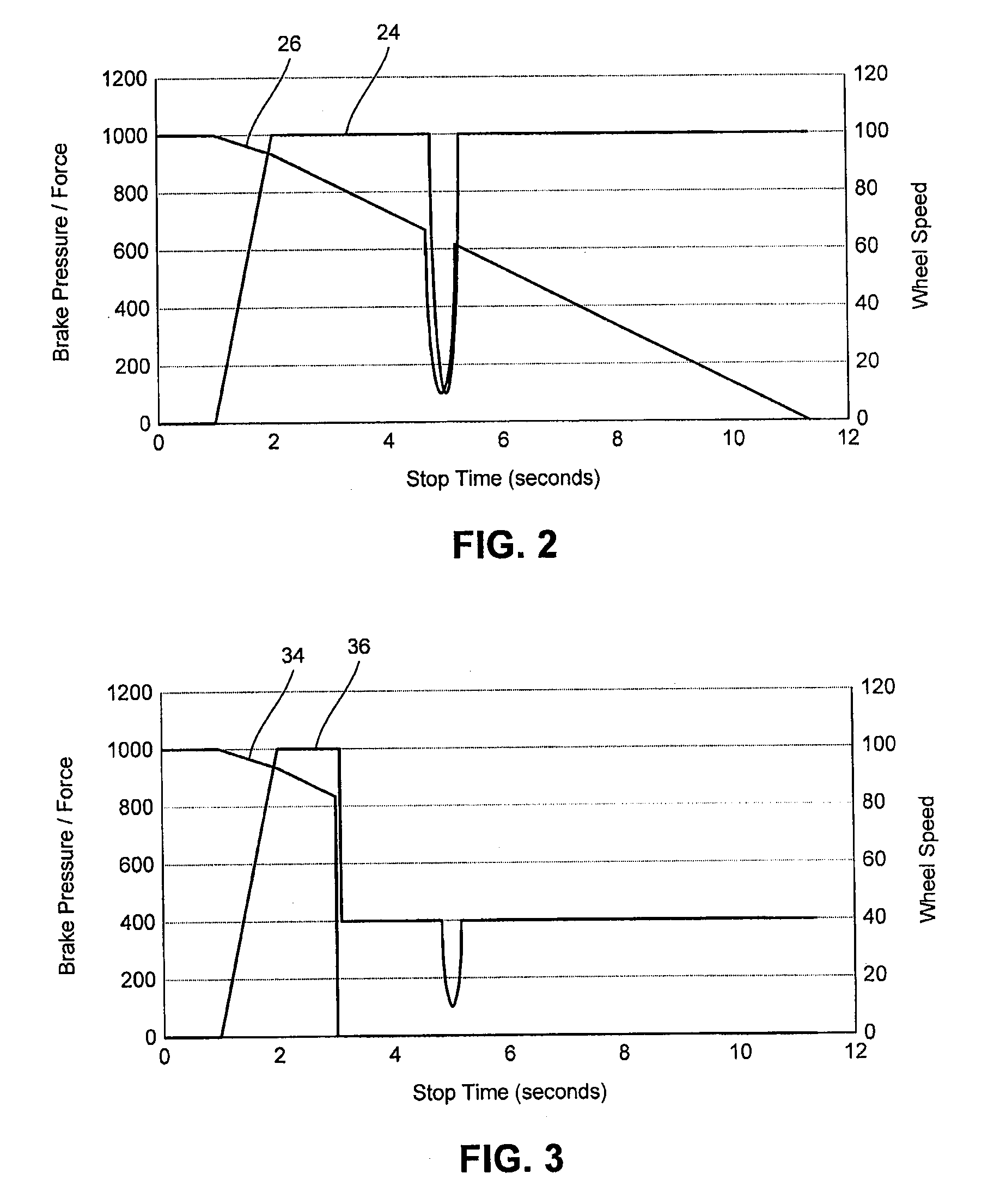

Aircraft brake control system and method

InactiveUS20090276133A1Broaden applicationBraking force can be appliedDigital data processing detailsBrake control systemsControl systemControl signal

A method includes receiving an input brake command that indicates a desired amount of braking for a vehicle. A brake control signal is then derived from the input brake command to facilitate applying a braking force to a wheel of the vehicle, and the braking force facilitates achieving the desired amount of braking for the vehicle. The method further comprises determining that data from a sensor associated with the wheel is unavailable, and then modifying the brake control signal in response to determining that the data is unavailable. The modification may be based on sensor data or controller output associated with a second wheel where data is available. Such modification facilitates the desired amount of braking for the vehicle.

Owner:THE BF GOODRICH CO

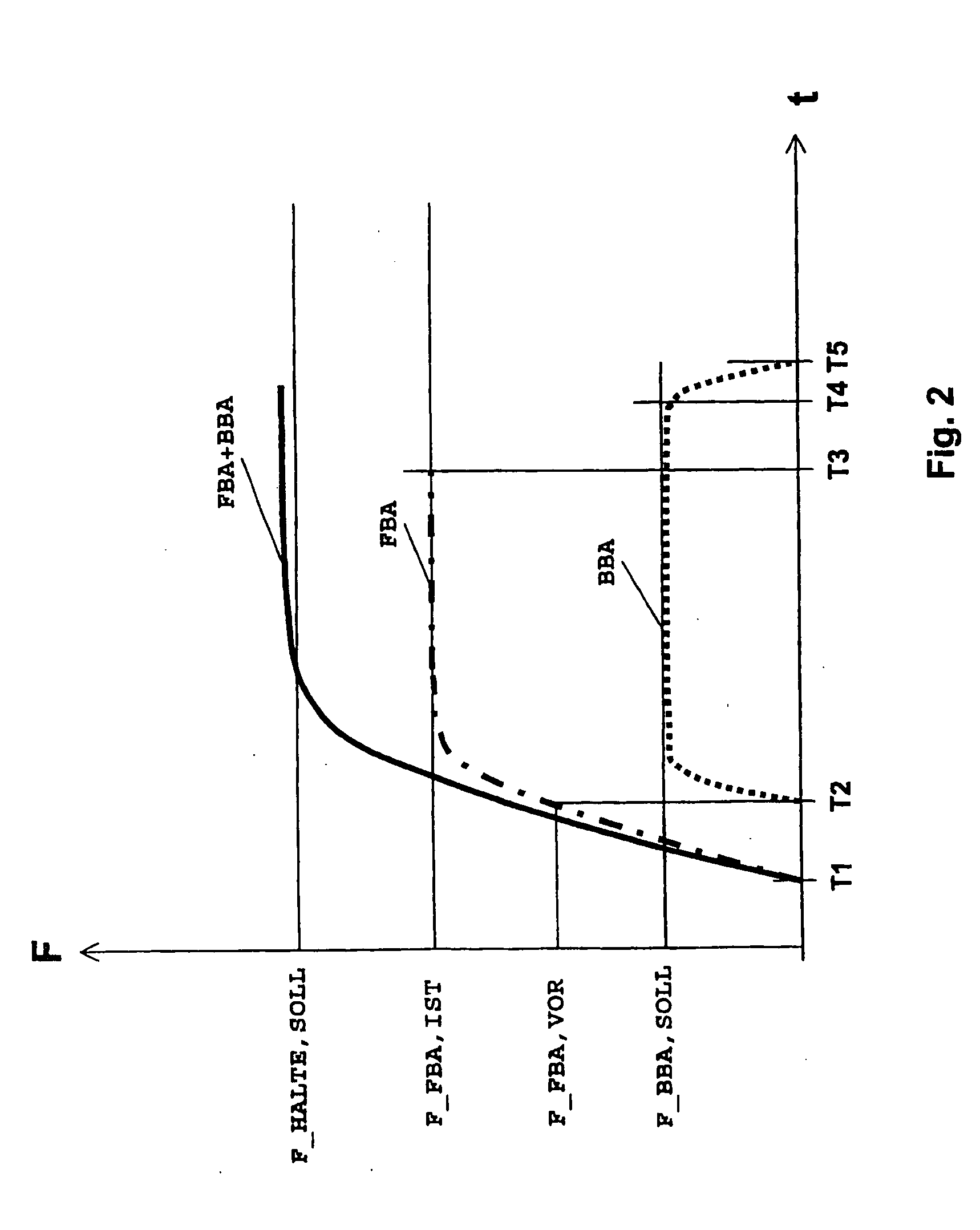

Method for operating the brake gear of a vehicle

InactiveUS20060267402A1Low powerLimited braking forceBraking action transmissionAnti-theft devicesAutomotive engineeringBrake force

A process for operating the brake arrangement of a vehicle is presented, which comprises an electrically controllable service brake system, which is set to generate brake forces independently of driver actuation, and which comprises an electrically controllable parking brake system, which is set to generate brake forces and maintain these forces. So that the parking brake system or its electromechanical actuating unit only needs to cope with relatively small load situations, it is proposed that, when, for certain operating conditions, the parking brake system has to maintain brake forces which are greater than the brake forces it is able to generate itself, the service brake system generates the additionally required brake forces.

Owner:LUCAS AUTOMOTIVE GMBH

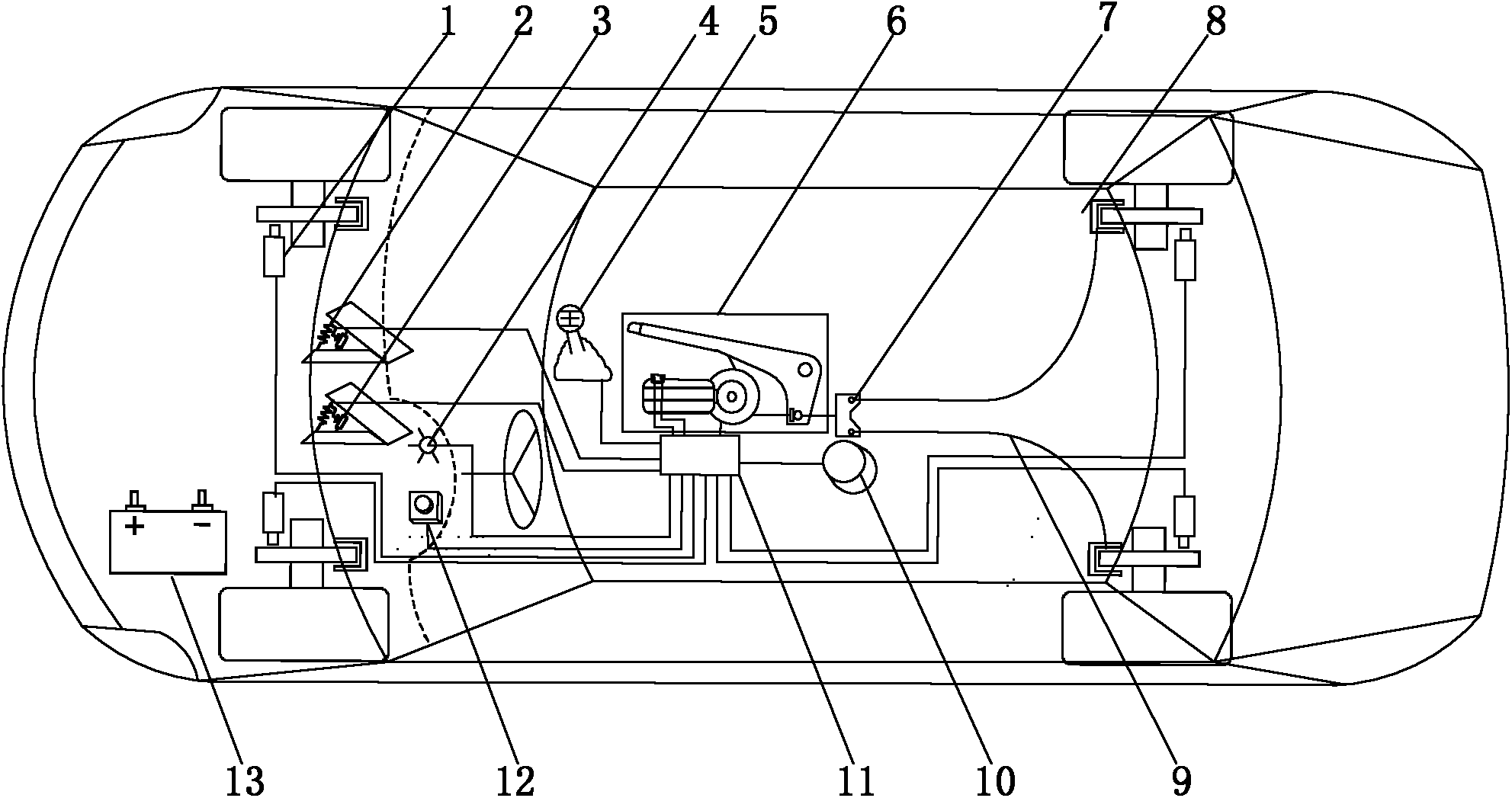

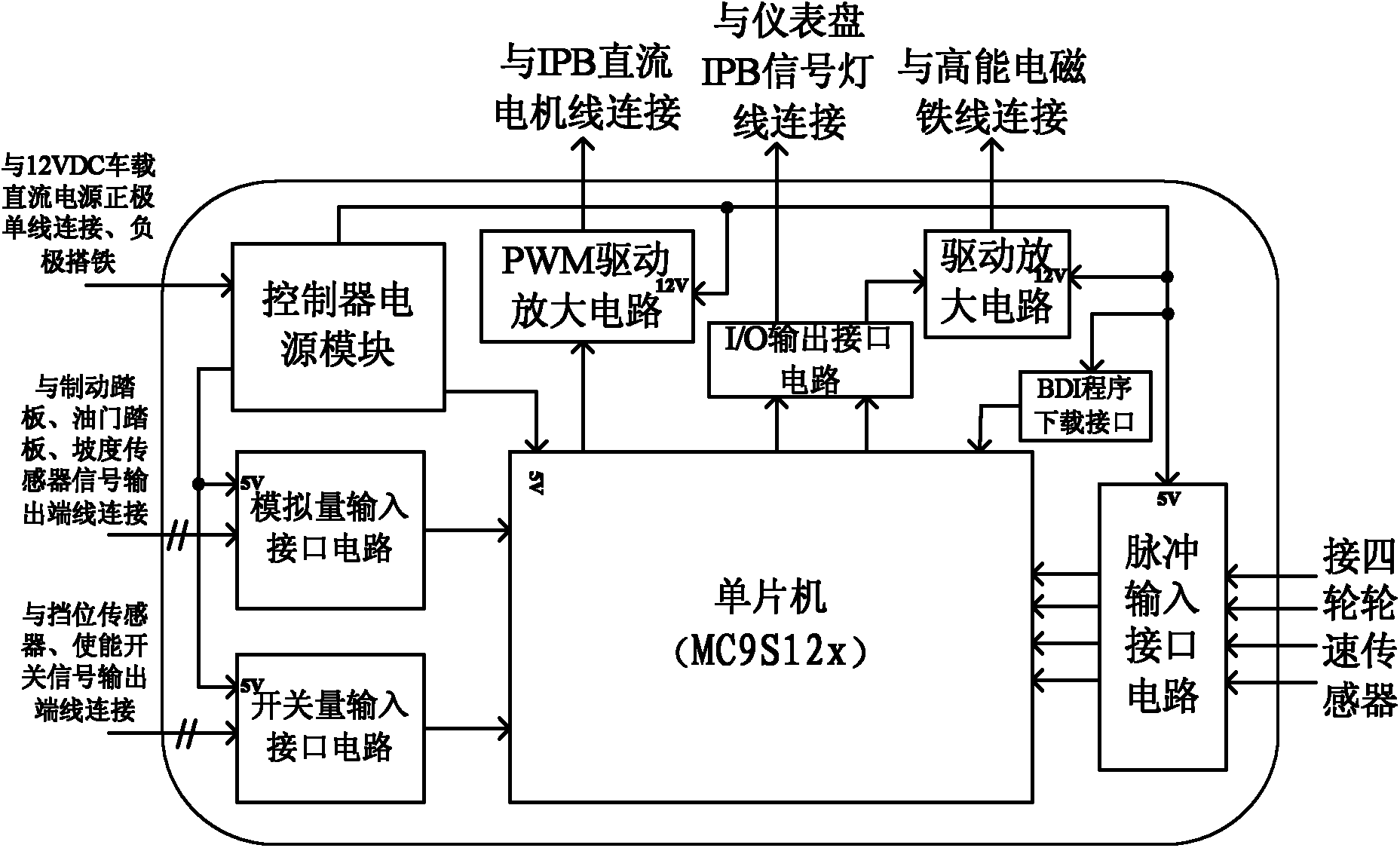

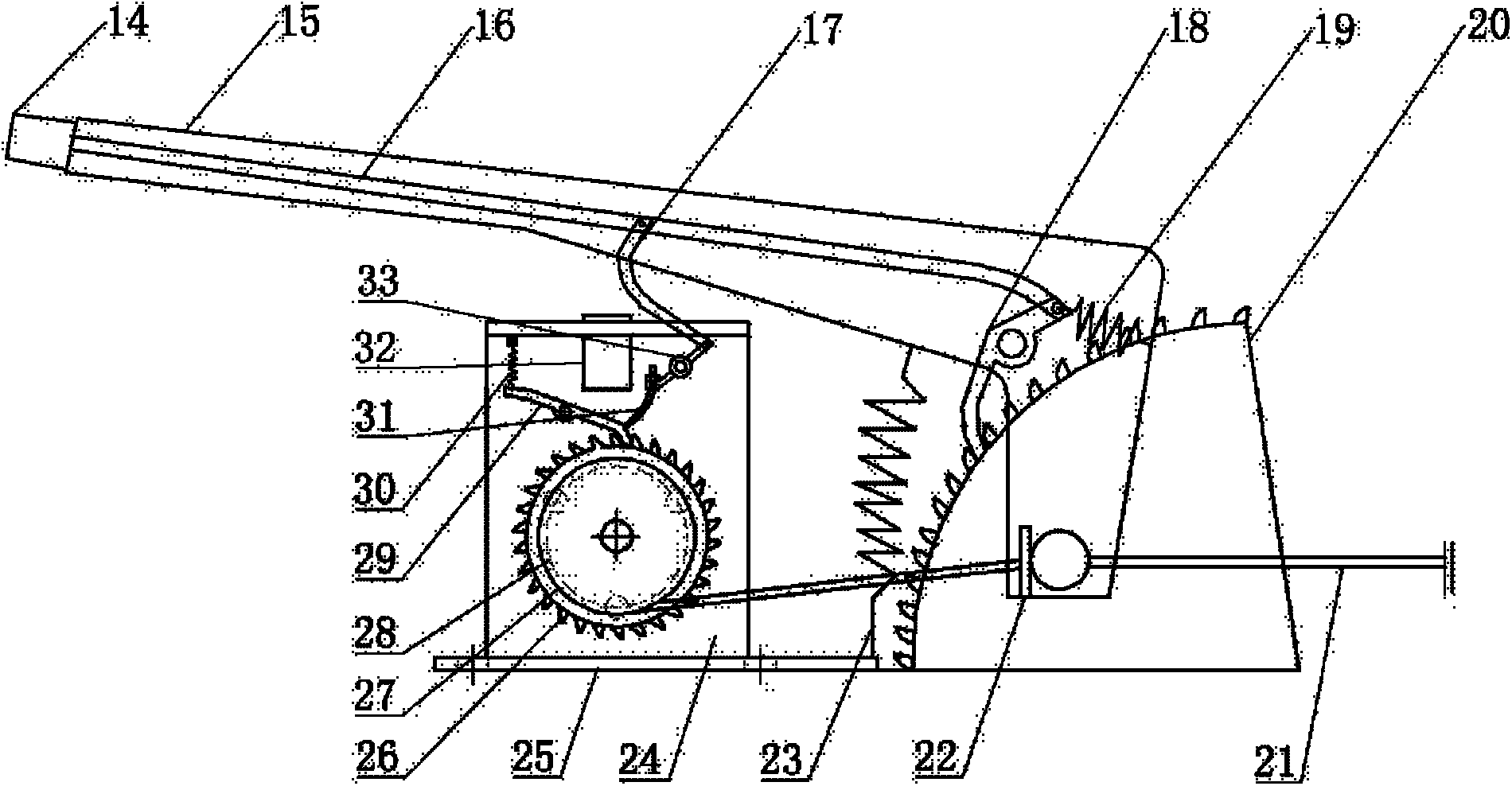

Intelligent parking braking and auxiliary starting control method

InactiveCN102431530ARealize intelligenceSafe and reliable parkingElectrodynamic brake systemsBraking systemsMicrocontrollerControl flow

The invention discloses an intelligent parking braking and auxiliary starting control method, which includes steps of firstly, initializing an intelligent parking braking controller and reading control parameters stored in a single-chip microcomputer, secondly, reading a vehicular speed signal V, a brake pedal travelling signal Db, an accelerator pedal travelling signal Da, a transmission gear signal Js, an ignition key door switch signal Key, an enable switch signal Button, a front wheel speed signal wf, a rear wheel speed signal wr and a gradient signal Sa, thirdly, invoking and performing an intelligent parking control procedure, an auxiliary starting control procedure, a parking brake automatic retracting control procedure, a long-term parking control procedure, an emergency braking control procedure or manual reset cutting-off control procedure according to the read signals and fulfilled response conditions, fourthly, converting the target torque of a motor according to the motor target braking force calculated from the control procedures, fifthly, calculating the target rotor current of the motor according to the obtained target torque of the motor, and sixthly, controlling the duty ratio of a motor PWM (pulse width modulation) driving control circuit according to the target rotor current of the motor.

Owner:JILIN UNIV

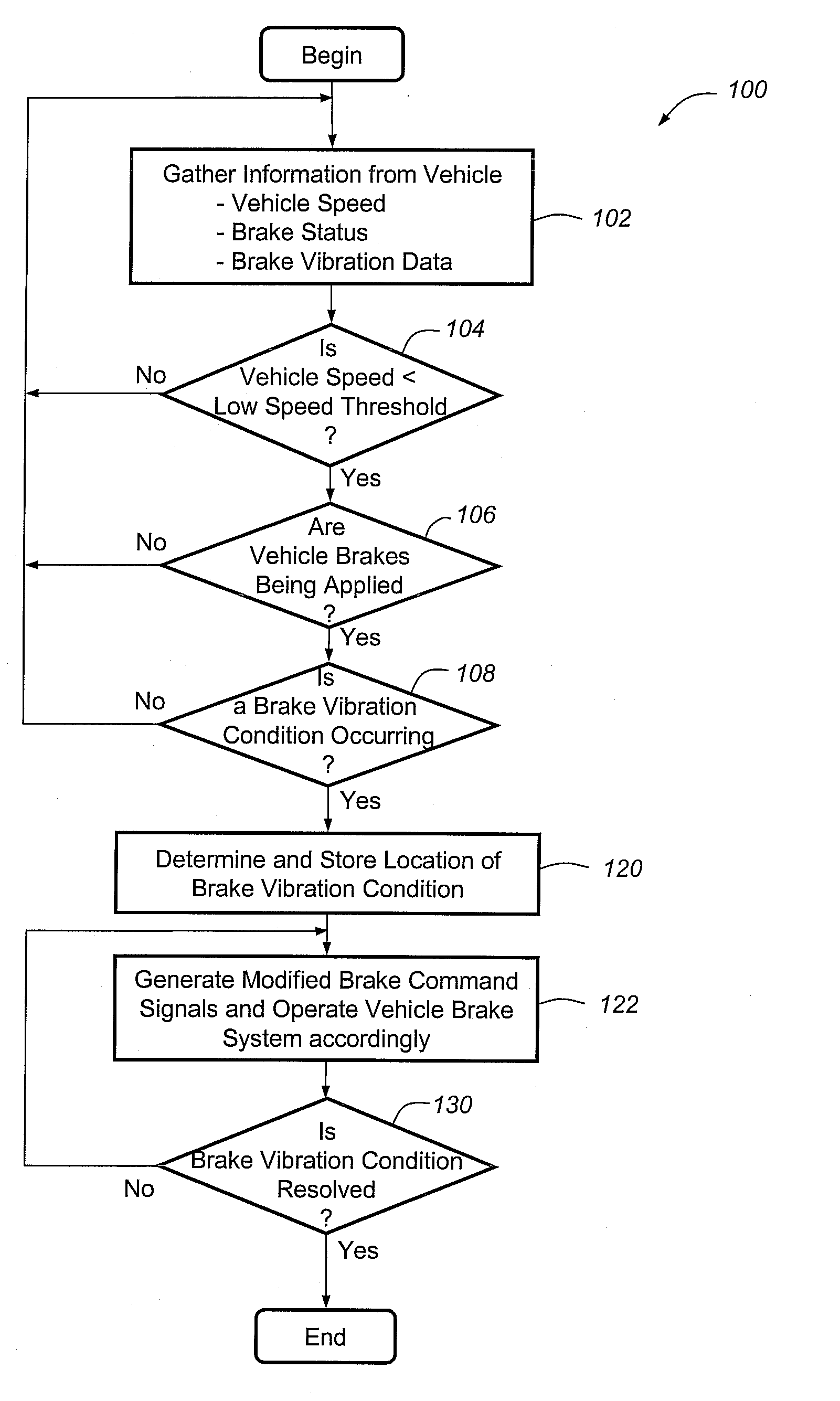

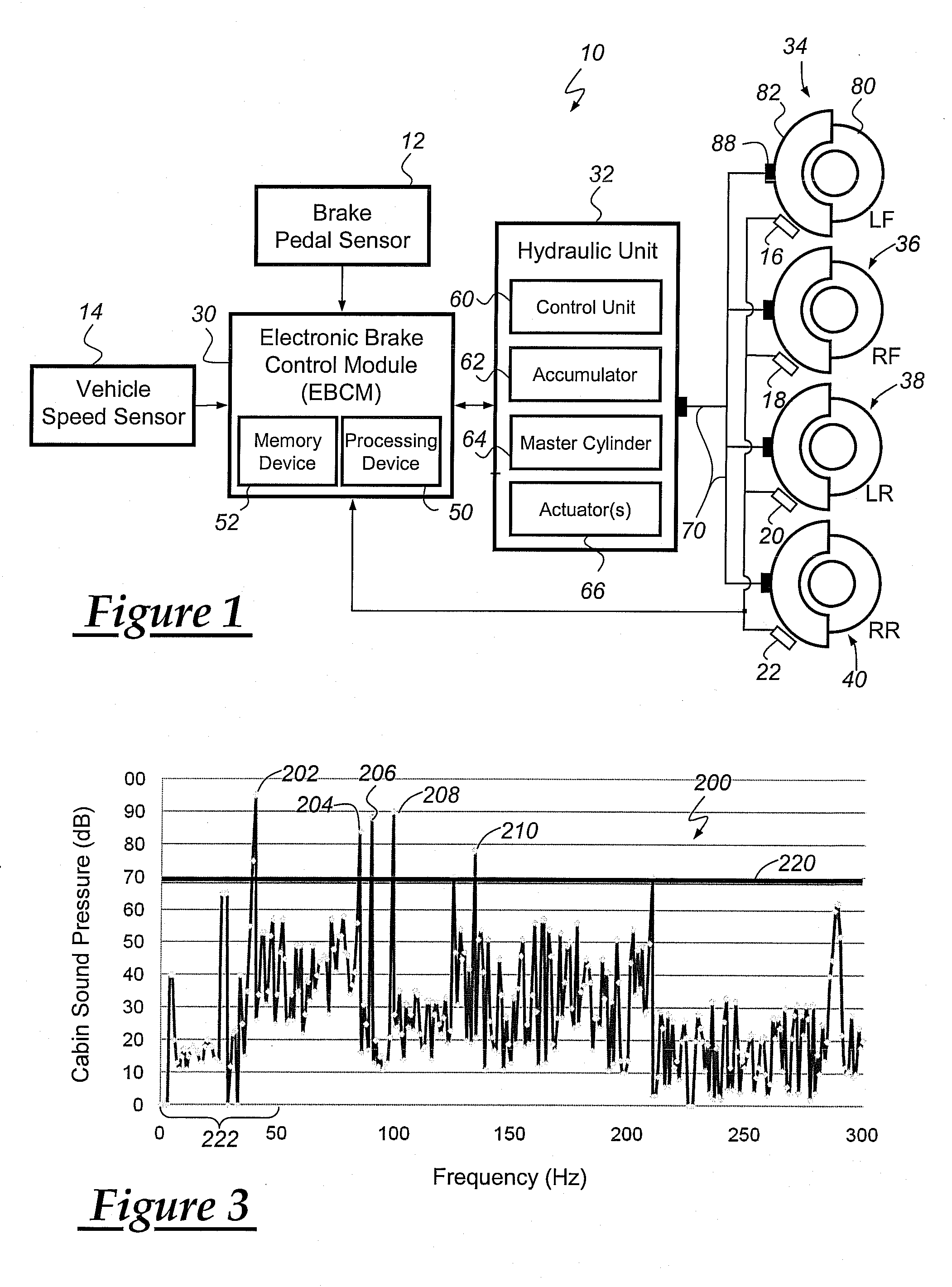

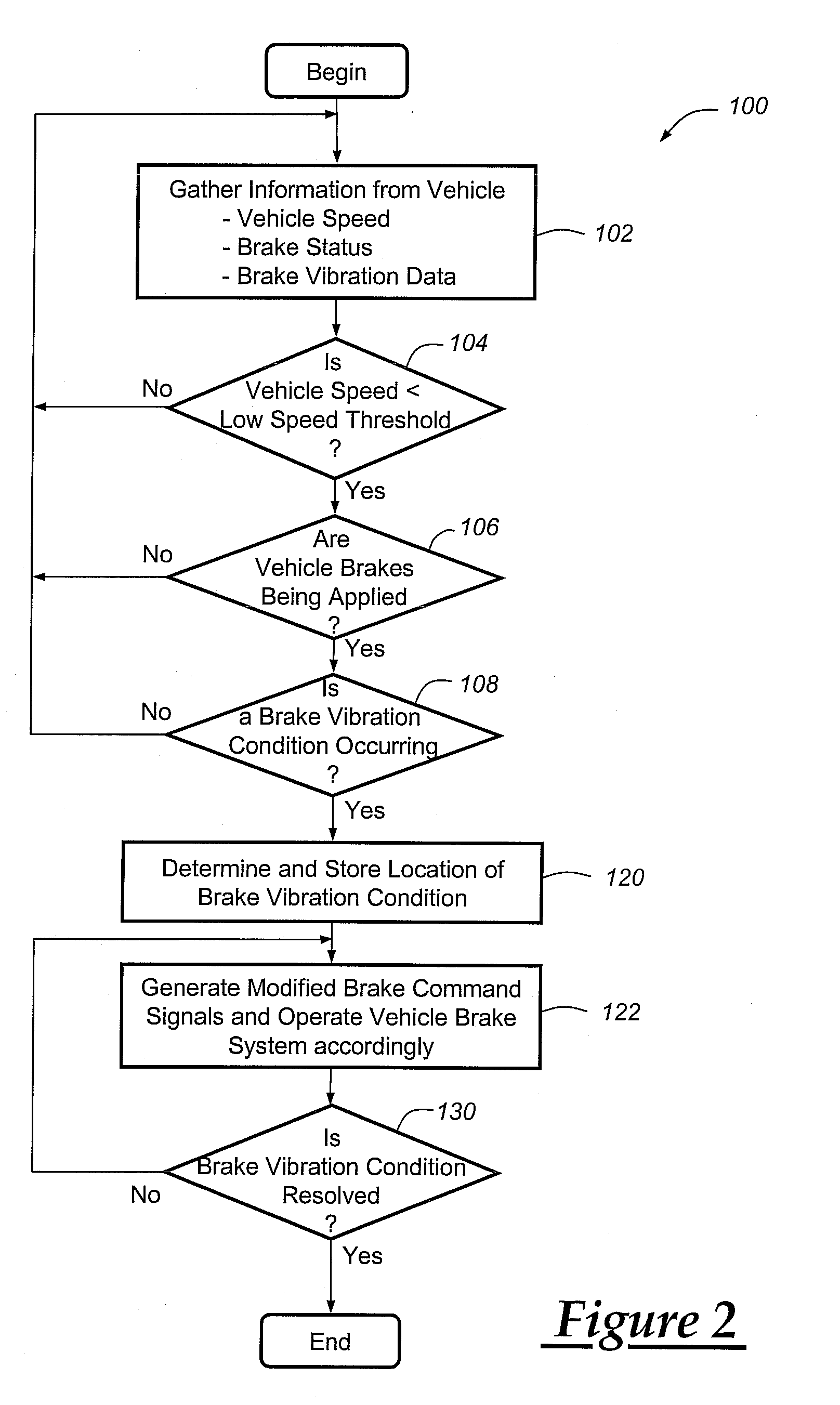

Method for operating a vehicle brake system

InactiveUS20100250081A1Reducing brake groan noiseReduce noiseVehicle testingNoise/vibration controlBrake torqueVehicle brake

A method for reducing or mitigating the effects of vibration in a vehicle brake system, particularly those that can lead to brake groan or other unwanted noise. According to an exemplary embodiment, when the vehicle brake system detects certain vibratory conditions, it makes slight braking adjustments (e.g., adjustments to fluid pressure, brake force, brake torque, etc.) that are aimed to address the brake groan. The vehicle brake system can then determine the effectiveness of the braking adjustments and, if need be, make additional braking adjustments. The method is particularly well suited for use with brake-by-wire systems, but can be used with a number of different vehicle braking systems.

Owner:GM GLOBAL TECH OPERATIONS LLC

Vehicle deceleration control apparatus

ActiveUS20060064225A1Driving comfortRetardation valueAnalogue computers for trafficPlural diverse prime-mover propulsion mountingValue setEmbedded system

A deceleration control apparatus for controlling a deceleration value of a vehicle, including a plurality of deceleration-value setting devices, a target-deceleration-value control portion operable to change a target deceleration value of the vehicle according to an operation of each of the deceleration-value setting devices, and a brake control portion operable to control a braking force to be applied to the vehicle, according to the target deceleration value changed by the target-deceleration-value control portion, wherein the target-deceleration-value control portion is operable to successively change the target deceleration value of the vehicle in response to successive operations of one and another of the plurality of deceleration-value setting devices such that the target deceleration value changed according to the operation of the above-indicated one deceleration-value setting device is subsequently changed according to the operation of the above-indicated another deceleration-value setting device.

Owner:TOYOTA JIDOSHA KK

Eddy current braking apparatus with adjustable braking force

InactiveUS20060278478A1Adjustable distanceGuaranteed uniform velocityDynamo-electric brakes/clutchesElectrodynamic brake systemsEngineeringLinearity

An eddy current brake includes a diamagnetic member, a first support wall and a second support wall with the first and second linear arrays of permanent magnets disposed on the walls facing one another. Apparatus is provided for moving at least one of the walls in order to control eddy current induced in the member in the passage of the member therepast to adjust the braking force between the magnets and the member. Apparatus is also provided for causing the velocity of the member to change the braking force between the magnets and the member.

Owner:MAGNETAR TECH

Anti-lock braking system based on an estimated gradient of friction torque, method of determining a starting point for anti-lock brake control, and wheel-behavior-quantity servo control means equipped with limit determination means

An anti-lock braking system includes a friction torque gradient estimating unit for estimating, from a small number of parameters, the gradient of friction torque with respect to a slip speed, and controls a braking force acting on wheels on the basis of the friction torque gradient estimated by the friction torque gradient estimating unit. The friction torque gradient estimating unit may employ several types of estimating methods; e.g., a method of estimating the gradient of friction torque from only time-series data concerning a wheel speed; a method of estimating the friction torque gradient from time-series data concerning wheel deceleration as well as from braking torque or time-series data concerning physical quantities associated with the braking torque; or a method of estimating the friction torque gradient from micro-gains which are obtained when brake pressure is excited in a very small amount at the resonance frequency of a vibration system comprising a vehicle, wheels, and a road surface and which represent the characteristics of the vibration system. Further, there is also disclosed a method of determining, from the thus-estimated friction torque gradient, the limit of the characteristics of friction torque developed between the wheels and the road surface.

Owner:TOYOTA CENT RES & DEV LAB INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com