Conical surface friction brake for industry and automobiles

A technology of friction brakes and conical surfaces, applied in the direction of brake types, drum brakes, brake parts, etc., can solve the problems of attenuation of braking performance, small braking torque, and high cost, and achieve increased braking pressure and improved stability , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

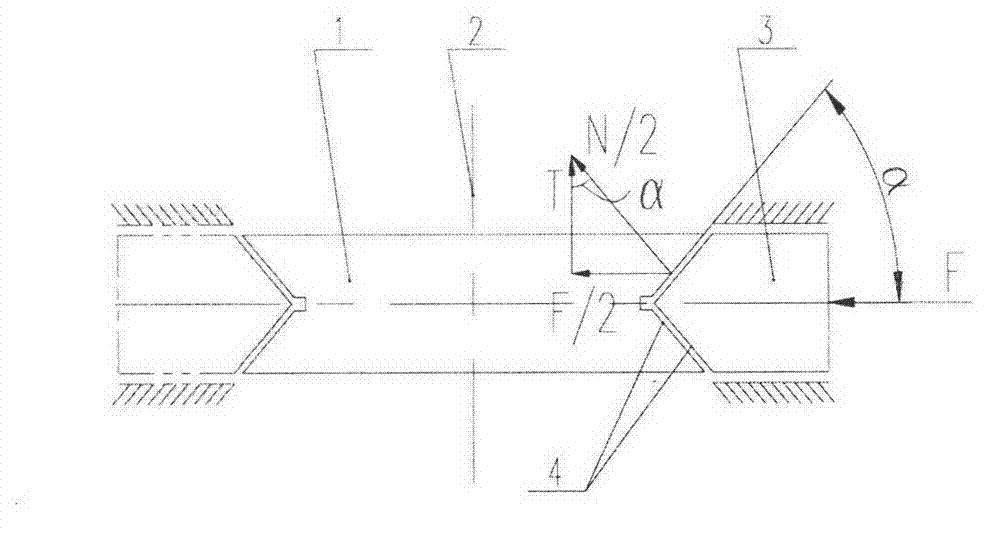

[0032] figure 1 It is the principle diagram of the conical surface friction braking of the present invention. The brake pressure bearing member 1 is circular, rotates around its center line 2 and has a conical surface 4 on it. The brake pressure applying member 3 has a conical surface 4 matching the brake pressure receiving member 1, and the braking force F can be applied to the brake pressure receiving member 1. The brake pressure applying member 3 can be arranged separately or symmetrically arranged along the circumference of the brake pressure receiving member 1, as shown by the double-dot chain line in the figure. When the angle between the braking force F and the cone surface is α, the pressure N=F / sinα generated on the two cone surfaces is 1 / sinα times the braking force F. The two conical surfaces generate a friction force of Nμ (μ is the sliding friction coefficient) under the action of the pressure N, thereby generating a braking torque relative to the center line 2 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com